Supersonic flame spraying equipment and spraying method thereof

A technology of supersonic flame and spraying equipment, applied in the direction of spraying device, etc., can solve the problems of easy generation of powder, lack of height adjustment function, loss, etc., to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

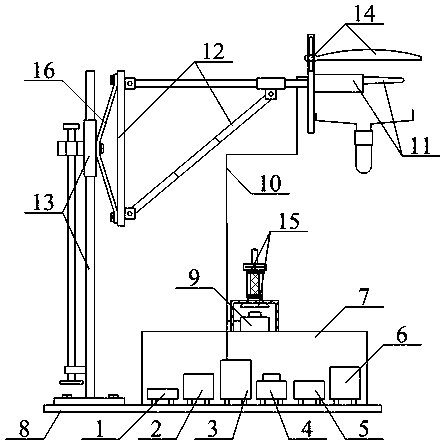

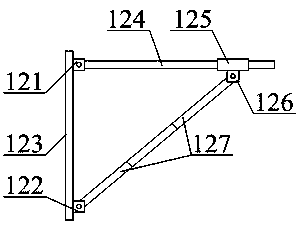

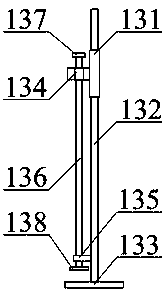

[0051] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a supersonic flame spraying equipment includes an air compressor 1, a heat exchanger 2, a main control cabinet 3, a booster pump 4, an oil tank 5, an oxygen bus 6, a casing 7, a base 8, and a powder feeder 9. Extension tube 10, supersonic flame spray gun 11, angle-adjustable support frame 12, height-position movable adjustment rod 13, anti-splash residual spray powder collection cover 14, anti-powder pollution adsorption and export core 15 and V-shaped connecting frame 16, The air compressor 1, the heat exchanger 2, the main control cabinet 3, the booster pump 4, the oil tank 5 and the oxygen bus bar 6 are bolted to the inner bottom of the casing 7 from left to right; Bolts at the bottom of the shell 7 are installed on the upper right side of the base 8; the bolts of the powder feeder 9 are installed at the upper middle posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com