Patents

Literature

147results about How to "Good barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

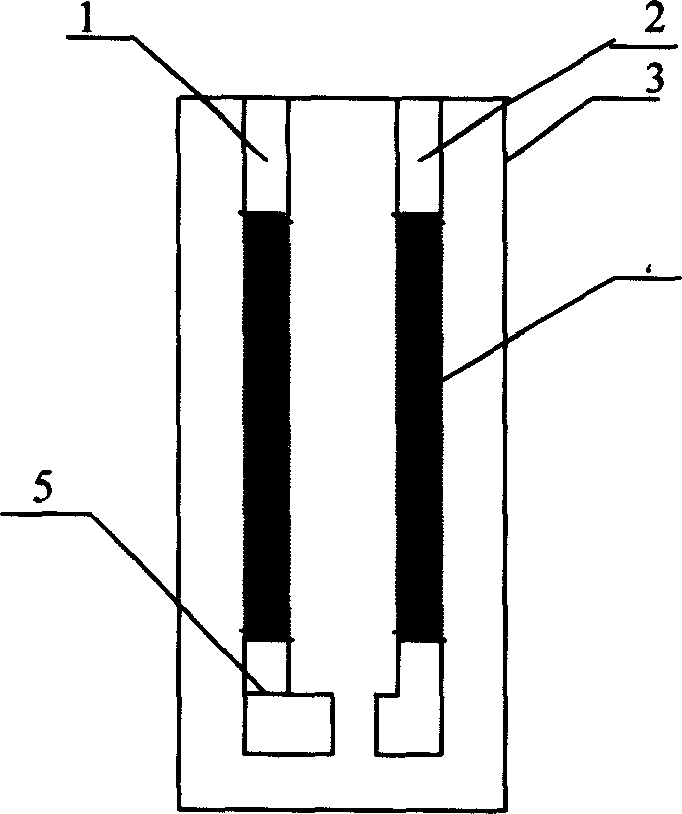

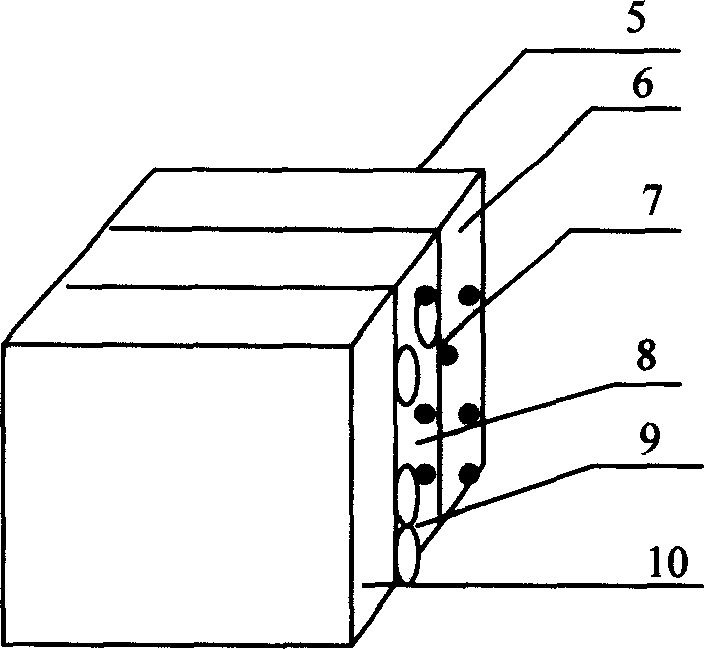

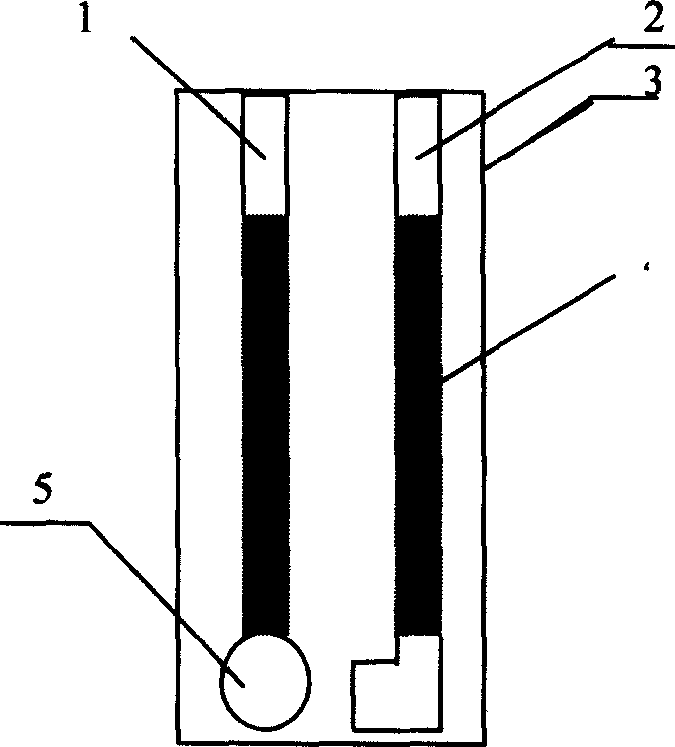

Biological enzyme electrode for biosensor, and its prepn. method

ActiveCN1563969AGood barrierOvercoming interference currentMaterial analysis by electric/magnetic meansEnzyme electrodeFerrocene

On substrate of electrode made from organic insulating material, conducting material is printed through spraying method so as to form working electrode and basal body, and a layer of polycarbonate insulator is coated on surfaces of intermediate part between them. Lower part of basal body of working electrode is coated a conversion zone formed through integrated application including techniques of high polymer built up film or ferrocene covering, embedding enzyme, nano technique, and diffusing astriction so as to fabricate biologic enzyme electrode. The invention raises each performance of biologic sensor and practicability integrally.

Owner:NANKAI UNIV

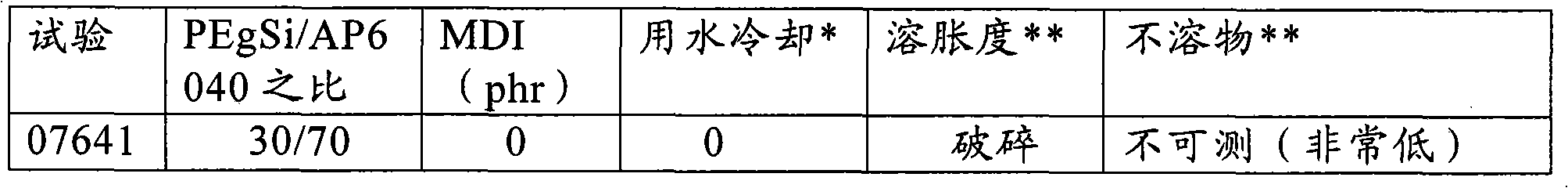

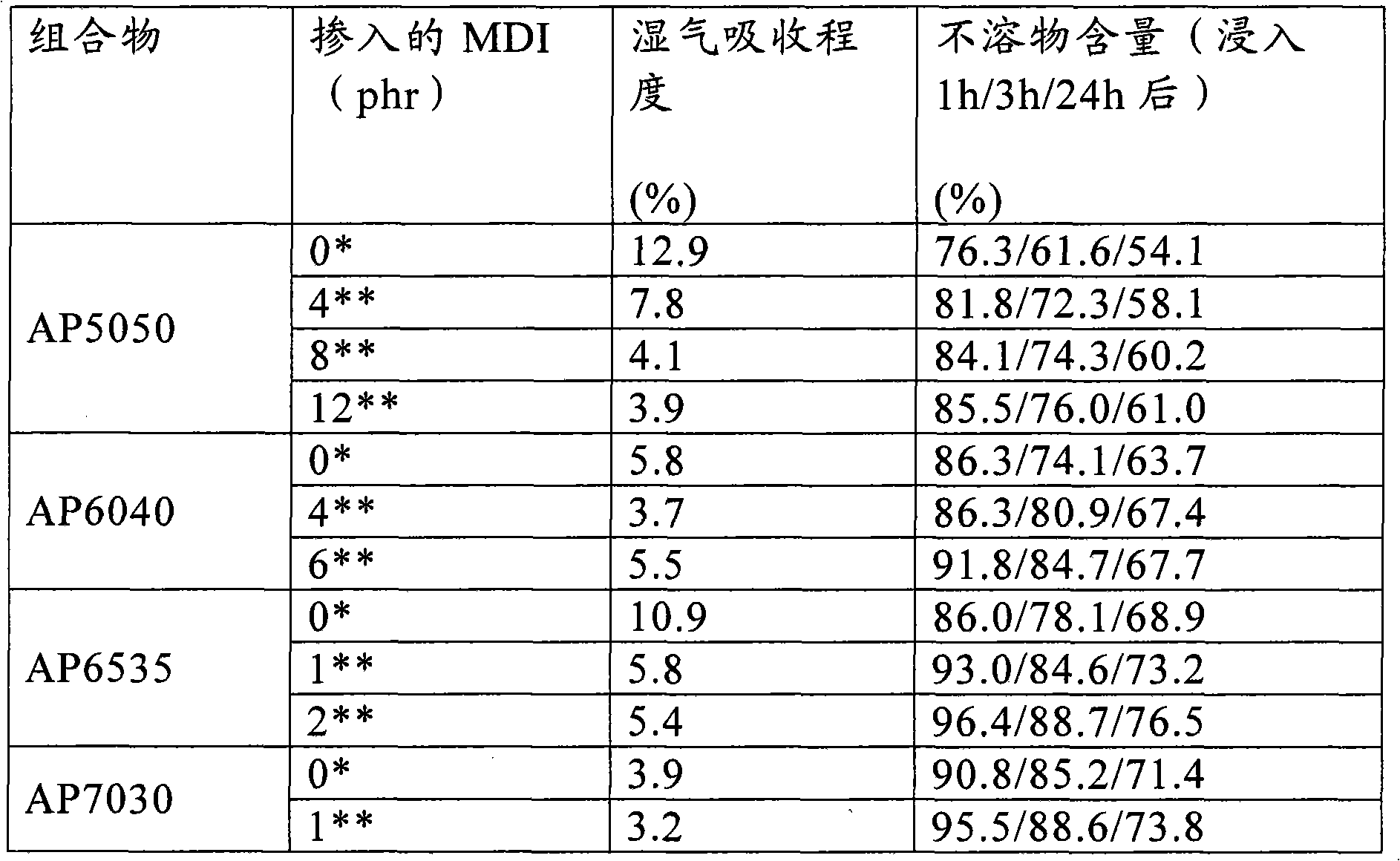

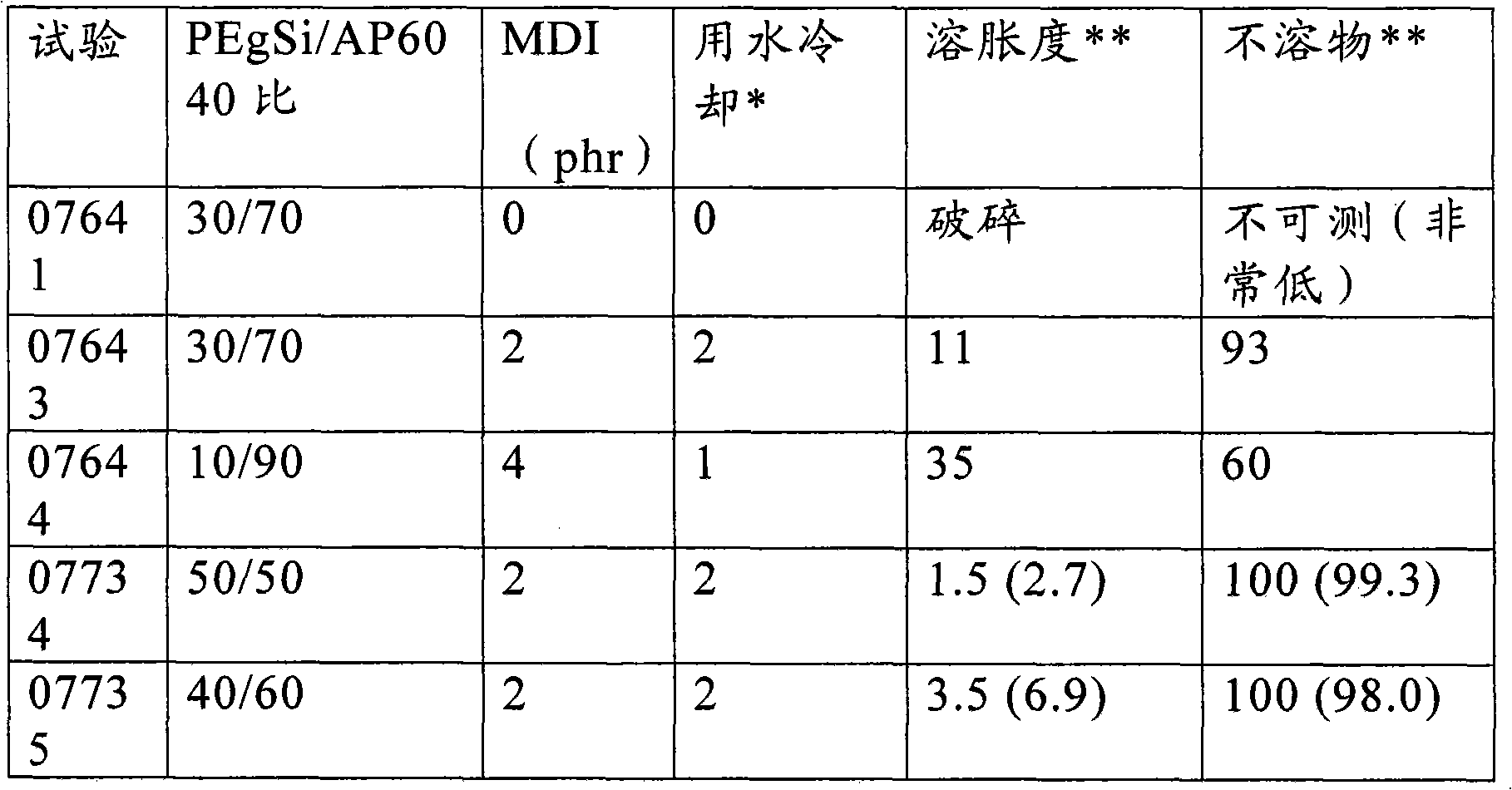

Method for preparing thermoplastic compositions based on plasticized starch and resulting compositions

InactiveCN101932647AFull mixabilitySatisfactory physical and chemical stabilityPlasticizerSubject matter

The subject matter of the present invention is a starch-based composition comprising: (a) at least 51% by weight of a plasticized amylaceous composition comprising starch and a plasticizer for said starch, obtained by thermomechanically mixing granular starch and a plasticizer for said starch, (b) at most 49% by weight of at least one non-amylaceous polymer, and (c) a bonding agent having a molecular mass of less than 5000, comprising at least two functions, at least one which is capable of reacting with the plasticizer and at least another of which is capable of reacting with the starch and / or the non-amylaceous polymer, these amounts being expressed with respect to solids and relative to the sum of (a) and (b), a method for preparing such a composition and a thermoplastic composition obtained by heating such a composition.

Owner:ROQUETTE FRERES SA

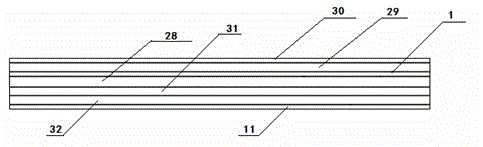

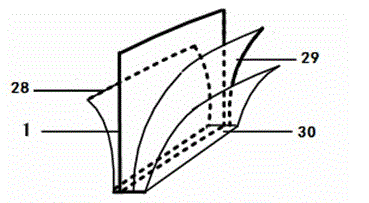

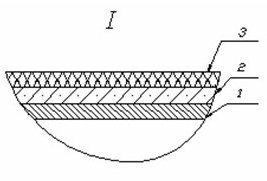

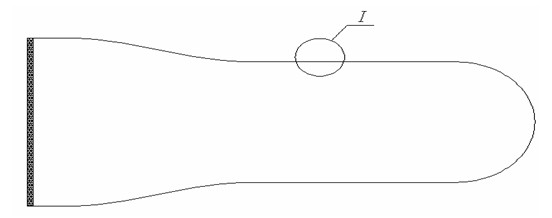

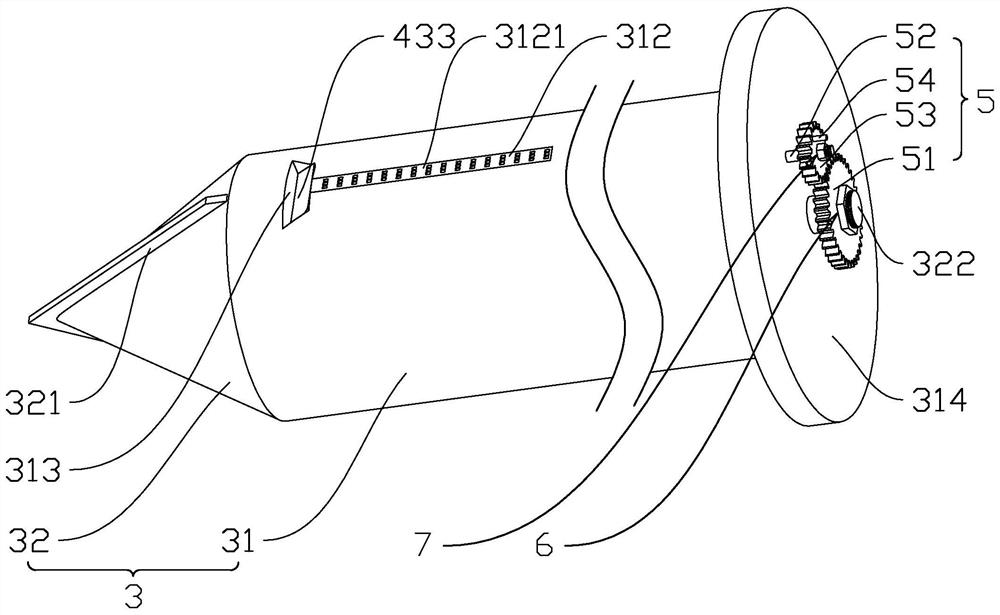

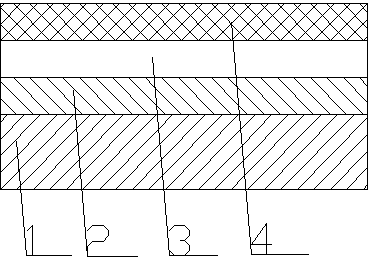

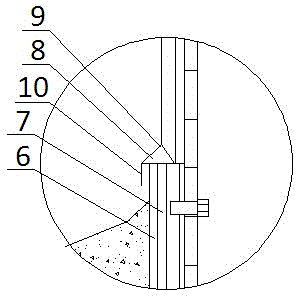

Perfumed aluminum-free composite inner liner paper for multi-coating cigarettes as well as preparation method and device of perfumed aluminum-free composite inner liner paper

The invention relates to a perfumed aluminum-free composite inner liner paper for multi-coating cigarettes as well as a preparation method and a device of the perfumed aluminum-free composite inner liner paper. The perfumed aluminum-free composite inner liner paper comprises two layers of raw paper, a blocking layer, two functional coatings, a perfuming coating and a surface layer, wherein the two sides of one layer of raw paper are respectively coated with the blocking layer and one functional coating, and the surface layer is attached on the functional coating; one side of the other layer of raw paper is sequentially coated with the other functional coating and the perfuming coating; the perfuming coating is combined with the blocking layer; the coating compound device comprises a double-sided coating part, a single-sided coating part and a compounding part. According to the perfumed aluminum-free composite inner liner paper for the multi-coating cigarettes as well as the preparation method and the device of the perfumed aluminum-free composite inner liner paper, the limitation of the original single-layer raw paper coating and single-physical-form functional blocking layer material is broken through; the perfumed aluminum-free composite inner liner paper has a damp-proof function, and is high in safety and barrier property as well as good in an anti-mould effect; therefore, a technical support is provided for the development of the novel and environment-friendly perfumed aluminum-free composite inner liner paper for the cigarettes.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

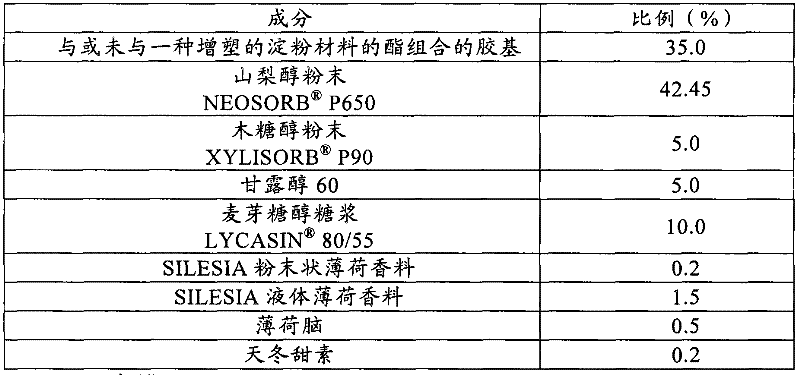

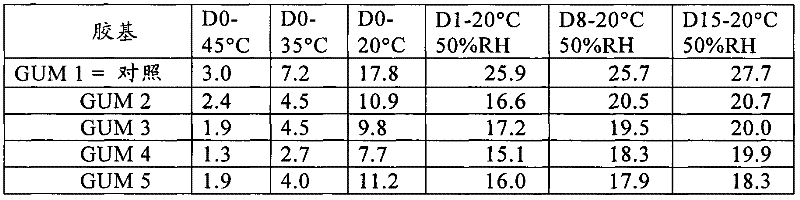

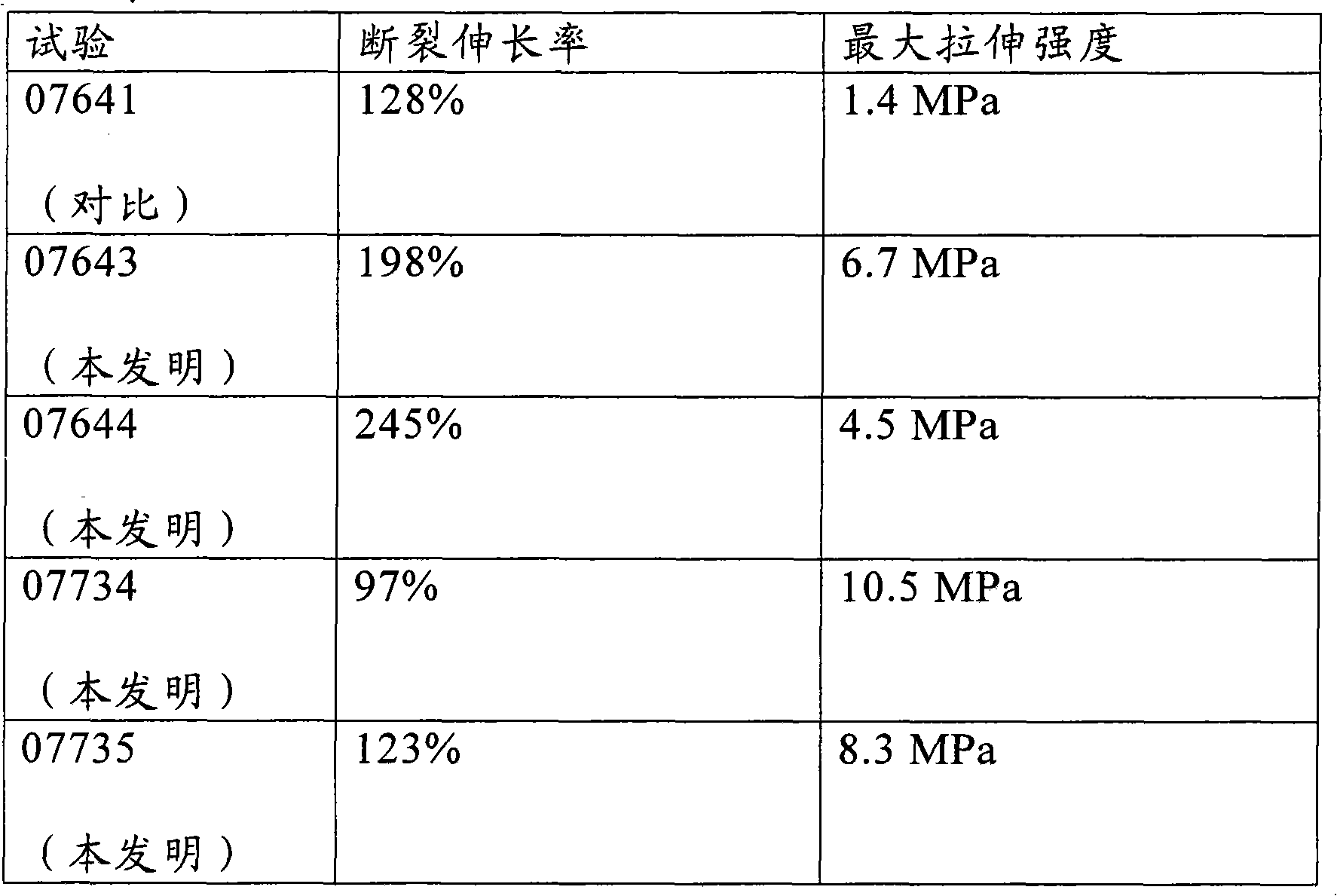

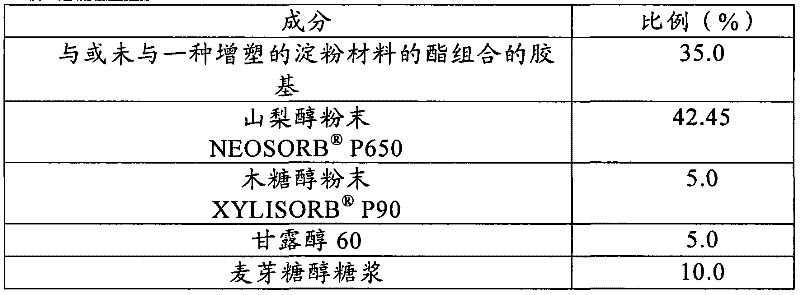

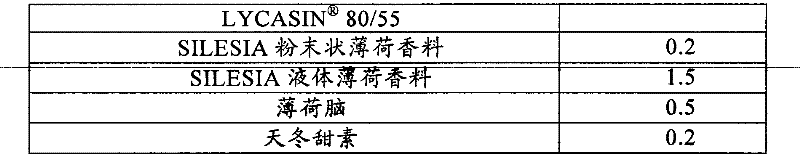

Elastomeric compositions based on esters of a starchy material and method for preparing such compositions

InactiveCN102186916AImprove mechanical propertiesImprove flexibilityChewing gumElastomerPolymer science

The subject matter of the present invention is an elastomeric composition, characterized in that it contains: - at least 5% and at most 70% by weight of an ester of a starchy material, which has a degree of ester substitution (DS) of between 1.0 and 3.0, preferably between 1.2 and 3.0, - at least 5% and at most 40% by weight of a plasticizer of this ester of starchy material, said plasticizer preferably being other than water, and - at least 25% by weight and at most 90% by weight of an elastomeric non-starch polymer.

Owner:ROQUETTE FRERES SA

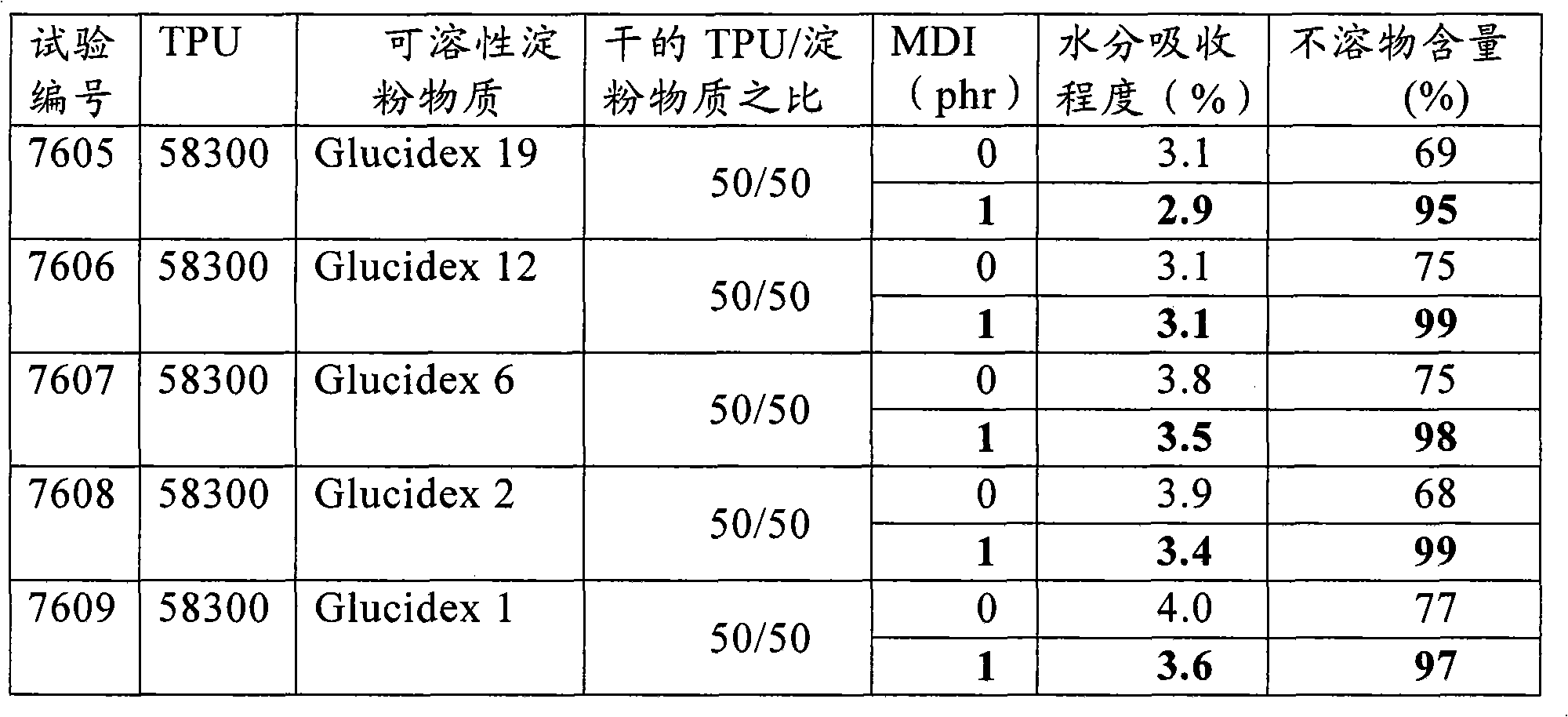

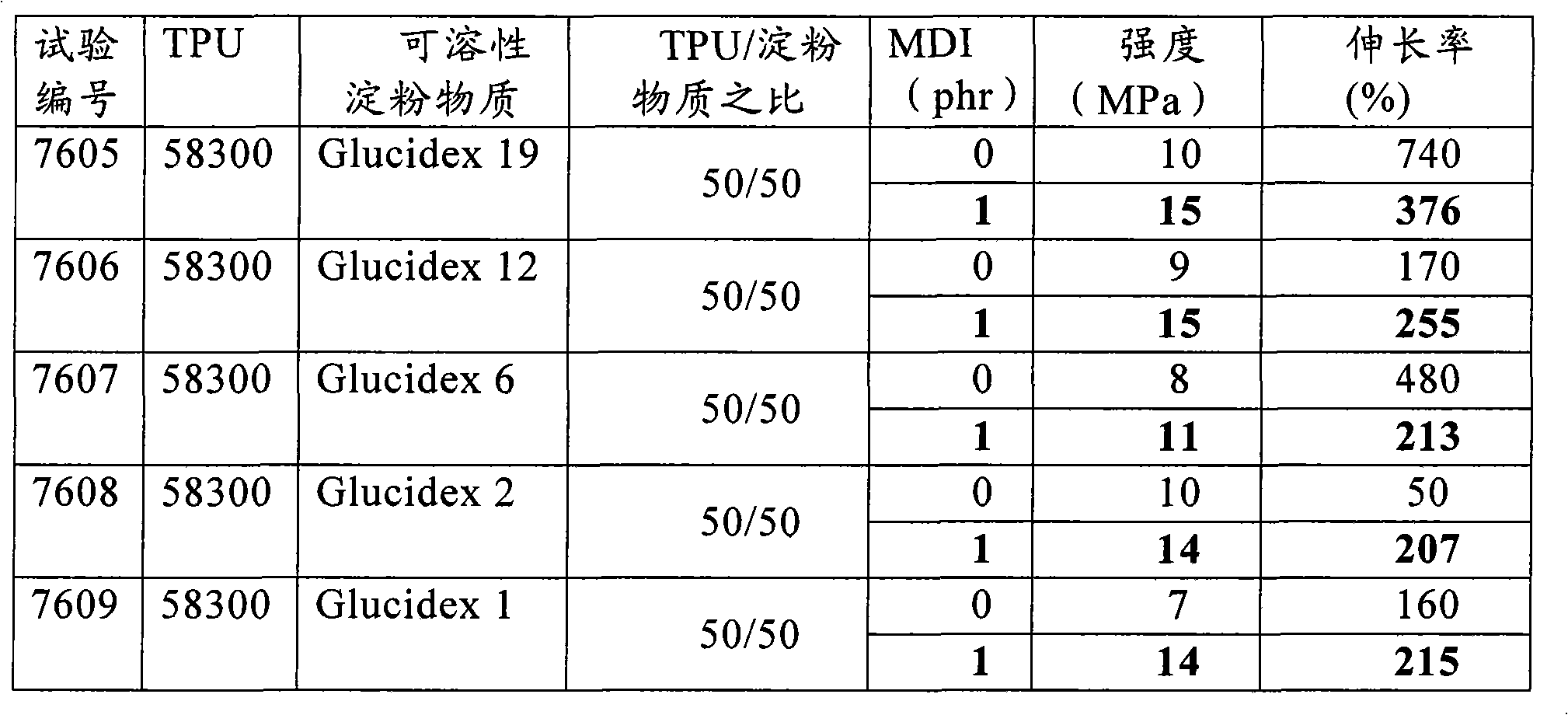

Thermoplastic compositions based on soluble starch and method for preparing such compositions

InactiveCN101932648AFull mixabilitySatisfactory physical and chemical stabilityHydrogenSubject matter

The subject matter of the present invention is a novel starch-based composition comprising: (a) at least 45% by weight of at least one soluble starch, (b) at most 55% by weight of at least one non-biodegradable, non-amylaceous polymer, and (c) a bonding agent carrying at least two functional groups capable of reacting with molecules carrying functions comprising an active hydrogen, these amounts being expressed with respect to solids and relative to the sum of (a) and (b). The present invention also relates to a method for preparing such a starch-based composition and to a thermoplastic composition prepared by heating such a composition.

Owner:ROQUETTE FRERES SA

Pure oil lipstick product with repairing function and preparation method thereof

InactiveCN109939017ASafe, Reliable and AccessibleEffective careCosmetic preparationsToilet preparationsAntioxidantCrack lips

The invention provides a pure oil lipstick product with a repairing function and a preparation method thereof. The pure oil lipstick product with the repairing function contains active ingredients including eramide, sodium hyaluronate, phytosterol oleate and stearyl glycyrrhetinate; specifically, the pure oil lipstick product is prepared from, by weight, 30-35% of solid oil and fat, 30-40% of natural liquid oil and fat, 1.66-9.5% of other active ingredients, 0.1-5% of an antioxidant and synthetic liquid oil and fat. The pure oil lipstick product is mild, has high safety and good stability, caneffectively nurse the lips, prevent the lips from drying and cracking and promote rapid healing of the dry and cracked lip part and has a moisturizing and nourishing effect. The invention further provides the preparation method of the pure oil lipstick product. The method creatively solves the problem that ceramide is easily precipitated in skin care product systems, is easy and convenient to operate and easy in popularization and production and has a good application prospect.

Owner:广东三好科技有限公司

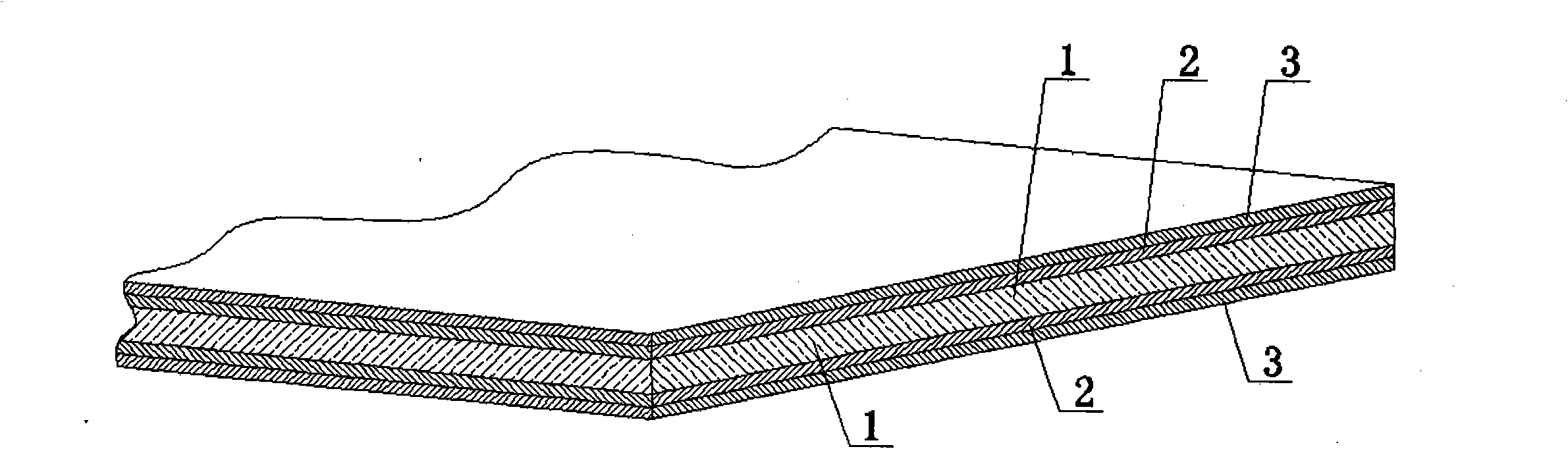

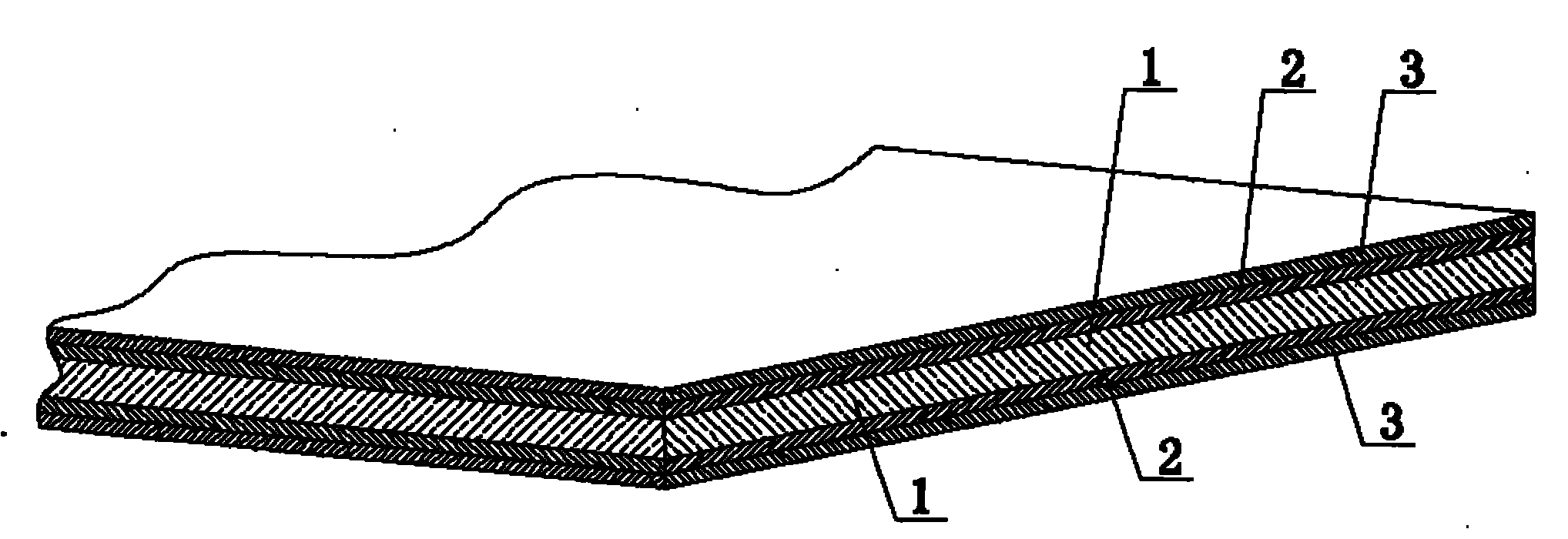

Condom and preparation method thereof

The invention provides a condom, comprising a barrel provided with an open end and a closed end, wherein the barrel is composed of three elastic adhesive films which are integral and are an inner layer adhesive film, a middle layer adhesive film and an outer layer adhesive film from inside to outside respectively, and the middle layer adhesive film is a water-soluble polyurethane adhesive film or a polyisoprene adhesive film. The invention also provides a preparation method of the condom. The condom provided by the invention is improved in barrel structure and material, thus the comprehensive performances of the adhesive films are effectively improved and the condom provided by the invention has high barrier property; and meanwhile, the preparation process is simple.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

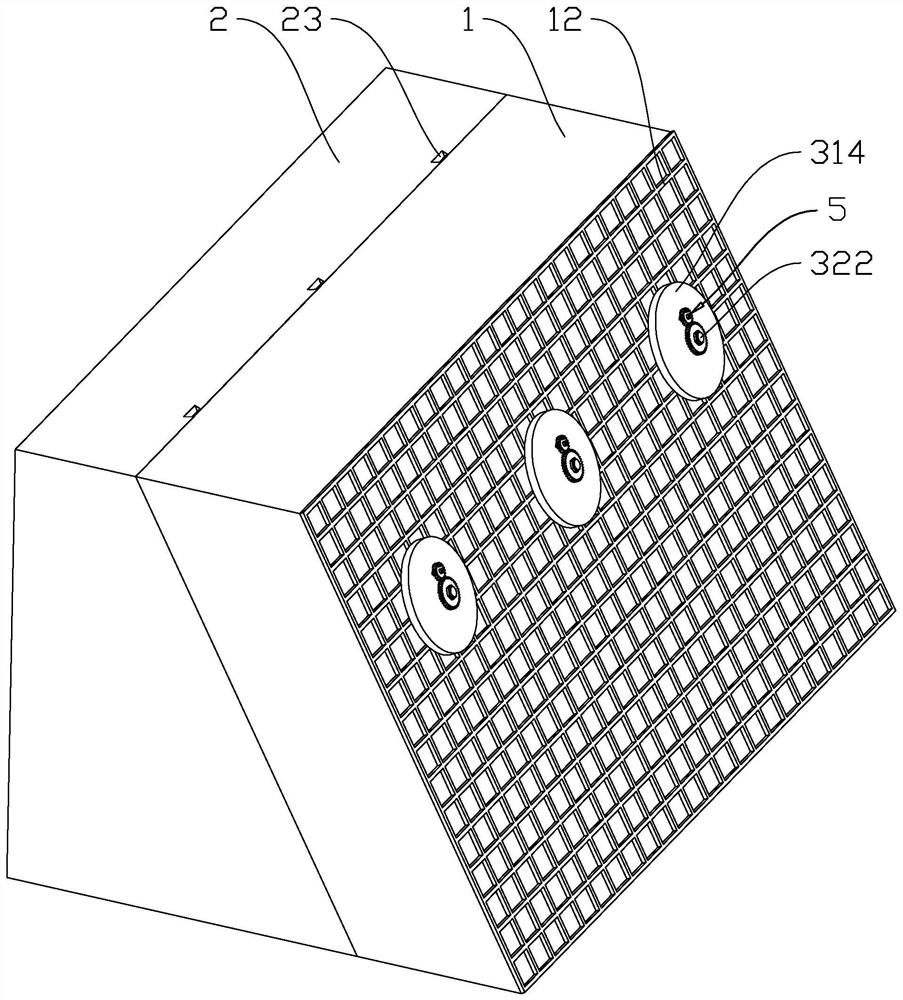

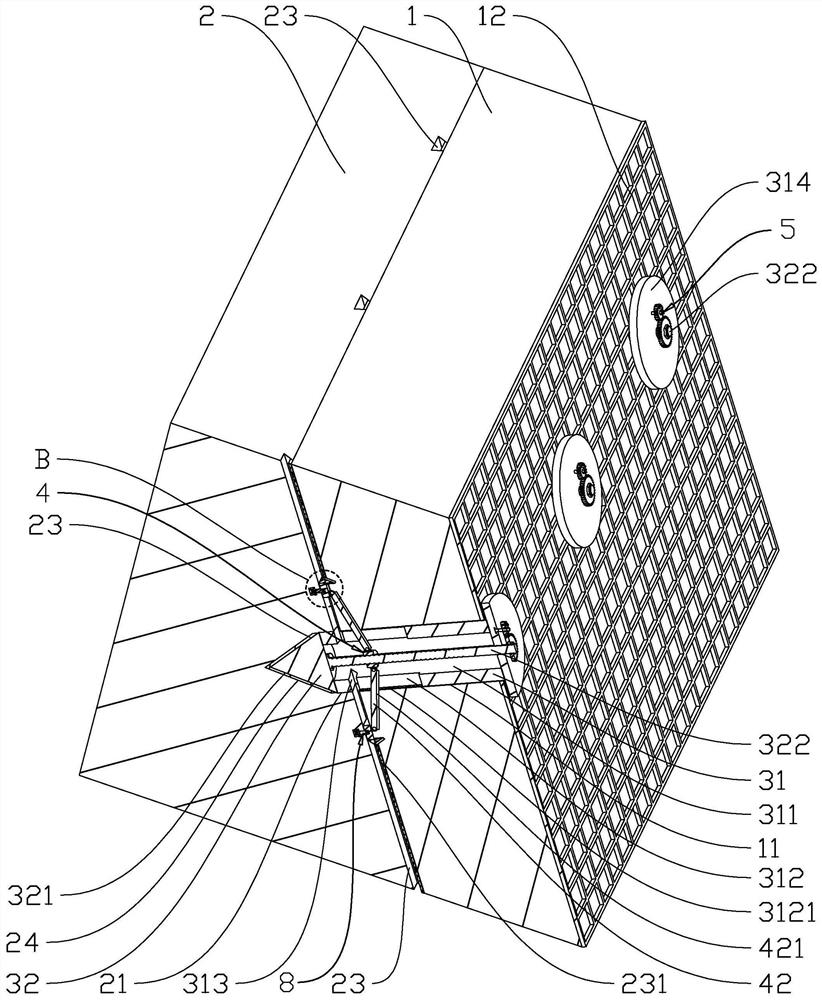

Novel process for highway slope protection

ActiveCN111910659AImprove stabilityImprove slope protection effectHops/wine cultivationTurf growingAgricultural engineeringScrew thread

The invention relates to a novel process for highway slope protection. The process comprises the following steps of (1) forming a first mounting hole in an unstable area slope surface, forming a second mounting hole and a third mounting hole in a stable area slope surface, and enabling the second mounting hole to correspond to and communicate with the first mounting hole; (2) arranging a supporting assembly between a stable area and a non-stable area, wherein the supporting assembly comprises a pile column arranged in the first mounting hole and connected with the second mounting hole in an inserted manner and a drill bit fixed to the end of the pile column; (3) forming a columnar through hole in the pile column, rotatably mounting a threaded rod on the drill bit, and arranging a reinforcing assembly connected with the stable area slope surface on the threaded rod; and (4) laying a planting net on the unstable area slope surface, wherein the pile column penetrates through the plantingnet and is fixed with the planting net. In the application, the threaded rod in the pile column is connected with the stable area slope surface through the reinforcing assembly, so that the stabilityof the pile column in the using process is enhanced, the pile column can still play a good slope protection role in areas with soft soil, and the probability of water and soil loss is reduced.

Owner:安徽祺泰建设集团有限公司

Method for preparing thermoplastic compositions based on plasticized starch and resulting compositions

The subject matter of the present invention is a method for preparing a starch-based thermoplastic composition, comprising the following steps: (a) selecting at least one granular starch and at least one organic plasticizer for this starch, (b) preparing a plasticized composition by thermomechanically mixing this starch and this plasticizer, (c) optionally incorporating at least one functional substance carrying functions comprising an active hydrogen, (d) incorporating at least one bonding agent carrying at least two functional groups capable of reacting with molecules carrying functions comprising an active hydrogen, and optionally (e) heating the mixture to a temperature sufficient to cause the bonding agent to react with the plasticizer and with the starch and / or the functional substance, it being possible for steps (d) and (e) to be carried out simultaneously, and also a starch-based thermoplastic composition that can be obtained by means of this method.

Owner:ROQUETTE FRERES SA

Thermoplastic or elastomeric compositions based on esters of a starchy material and method for preparing such compositions

InactiveCN102186917AImprove mechanical propertiesImprove flexibilityChewing gumElastomerSubject matter

The subject matter of the present invention is a thermoplastic or elastomeric composition, characterized in that: a) it exhibits a degree of biodegradability of less than 50%, preferably less than 30%, and b) it contains at least 0.5% and at most 99.95% by weight of an ester of a starchy material, which has a degree of ester substitution (DS) of between 1.6 and 3, and at least 0.05% by weight and at most 99.5% by weight of a polymer other than starch.

Owner:ROQUETTE FRERES SA

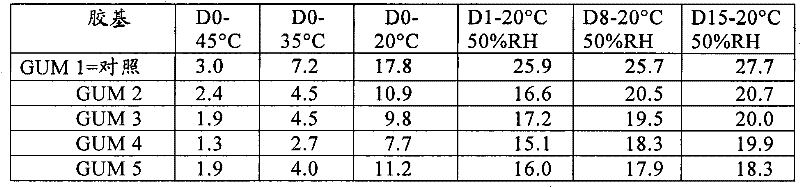

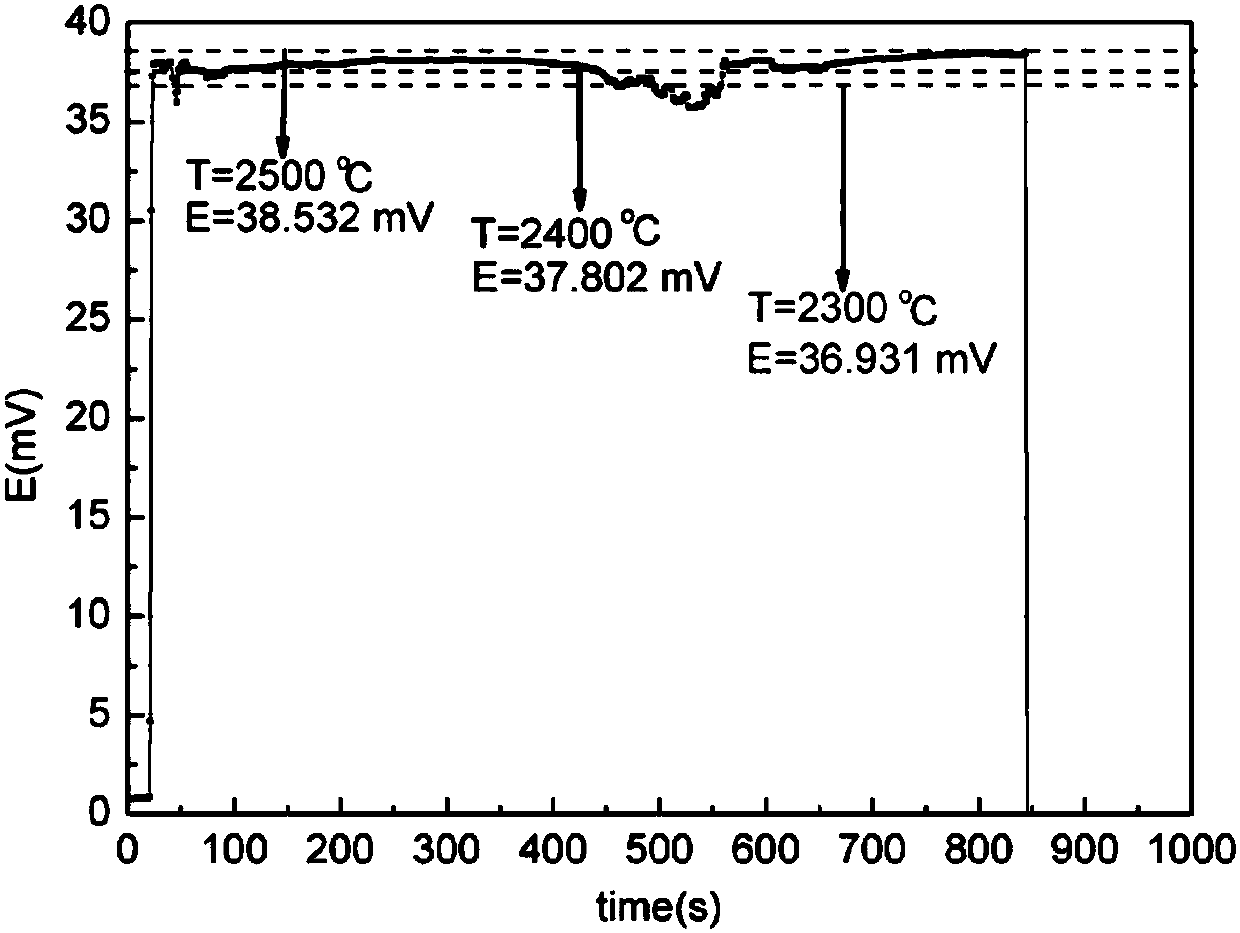

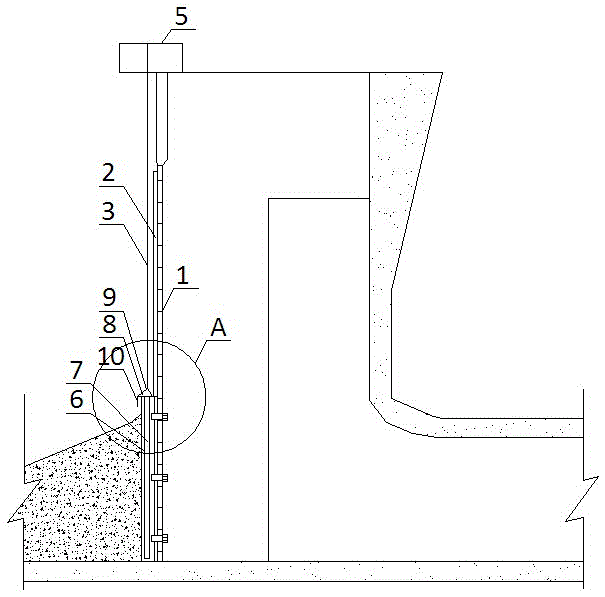

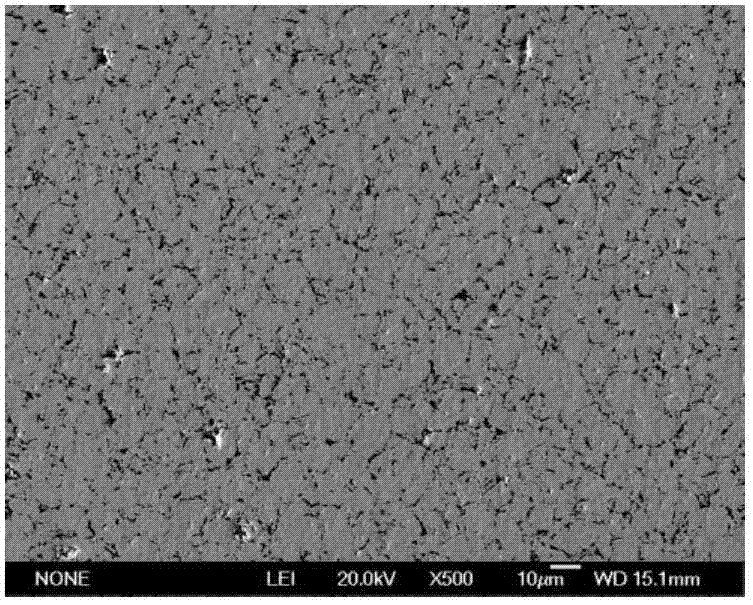

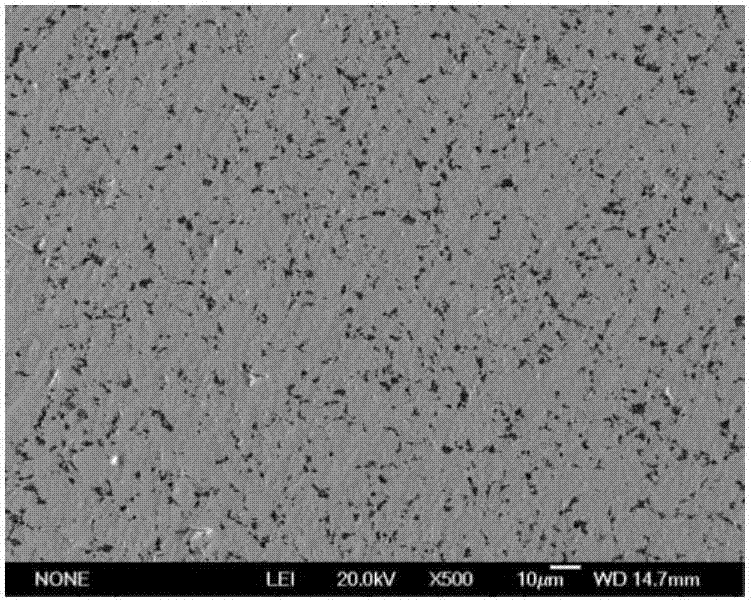

Densification method for high-temperature antioxidant coating of tungsten-rhenium thermocouple

ActiveCN108034939AReduce microcracksReduce porosityMolten spray coatingChemical vapor deposition coatingRheniumPorosity

The invention belongs to the technical field of temperature measurement, and particularly relates to a densification method for an antioxidant coating of a tungsten-rhenium thermocouple. According tothe densification method, the antioxidant coating of the tungsten-rhenium thermocouple is attached to the surface of a substrate of the tungsten-rhenium thermocouple, and comprises a transition layerand an oxygen barrier layer located on the surface of the transition layer, and the thermal expansion coefficient of the material of the transition layer is between the material of the substrate of the tungsten-rhenium thermocouple and the material selected by the oxygen barrier layer; isostatic pressing and heat treatment are carried out on the antioxidant coating of the tungsten-rhenium thermocouple, so that the antioxidant coating is more compact, micro-cracks are less, and the porosity is lower; meanwhile, the thermal stress is released, so that the thickness of the antioxidant coating ofthe tungsten-rhenium thermocouple is reduced by more than 40%; and the oxygen-resistant ablation resistance of the coating in an aerobic environment above 2000 DEG C is remarkably enhanced, so that the problem of long-time contact type temperature measurement in an ultra-high-temperature aerobic environment above 2000 DEG C is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

High-barrier HDPE (high-density polyethylene) membrane production process

ActiveCN104004212APrevent membrane yellowingGood barrierCoatingsBulk chemical productionTemperature resistanceChemistry

The invention discloses a high-barrier HDPE (high-density polyethylene) membrane production process which comprises the steps: blending of a bottom coating solution, unreeling, corona treatment, bottom coating, drying, surface coating, surface coating drying, and reeling. By adopting the manner, the high-barrier HDPE membrane production process disclosed by the invention has the advantages of good barrier property, simple production process, high chemical stability, long service life, good temperature resistance, and high membrane strength; a release member is effectively prevented from yellowing, and the problem of catalyst poisoning during production is solved.

Owner:UPASS MATERIAL TECH JIANGSU

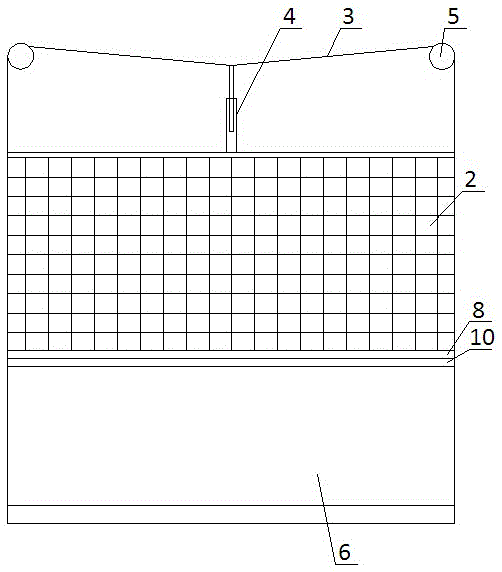

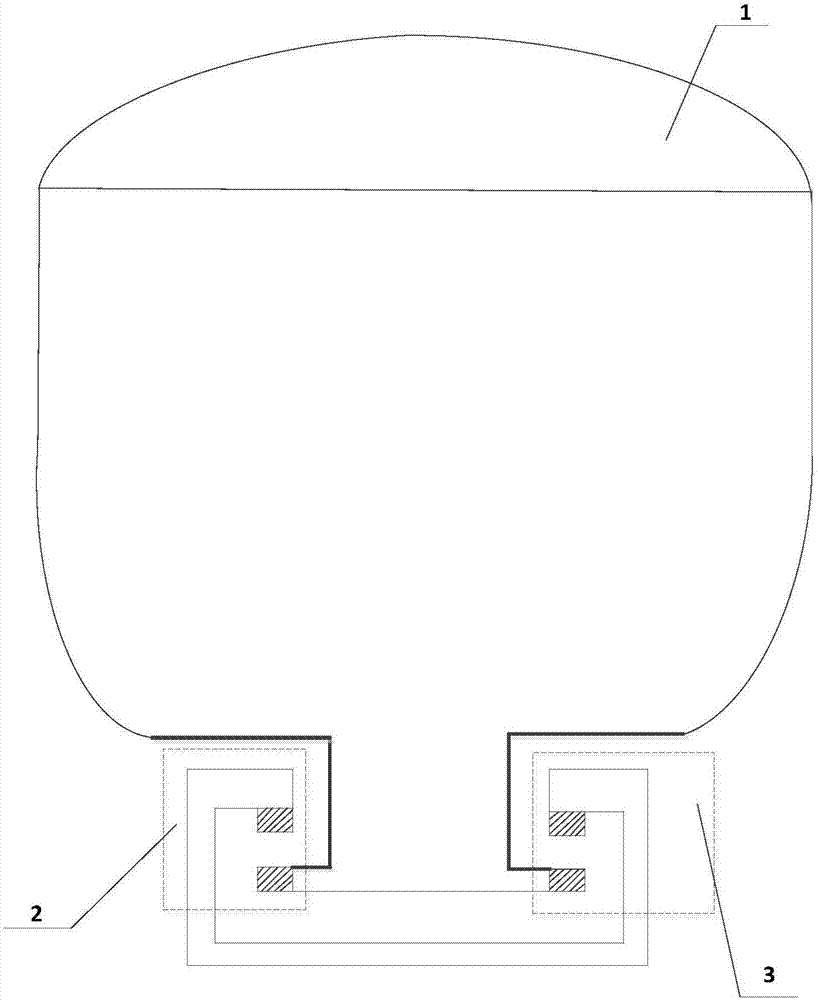

Stopping device for water getting in hydropower station

InactiveCN105568939AIncrease heightImprove the blocking effectWater-power plantsHydro energy generationPower stationArchitectural engineering

The invention discloses a stopping device for water getting in a hydropower station. The stopping device comprises a trash rack, a stopping plate, a geogrid, a steel rope, a cylinder and two fixed pulleys, wherein the stopping plate comprises an outer baffle and an inner baffle, the outer baffle is fixed to the lower portion of the trash rack, and the inner baffle is movably mounted in the outer baffle. The two fixed pulleys are symmetrically fixed above the trash rack, and the two ends of the steel rope wind across the two fixed pulleys correspondingly and then are symmetrically fixed to the two sides of the upper portion of the inner baffle; a piston rod of the cylinder is fixedly connected to the middle of the steel rope, and the cylinder controls the inner baffle to go up and down through the steel rope; the geogrid is fixed to the upper portion of the trash rack and located between the inner baffle and the trash rack. According to the stopping device, the height of the stopping plate can be adjusted in real time according to the water level at a water getting opening, and therefore the best silt stopping effect is achieved.

Owner:SICHUAN QUANFENG NEW MATERIALS & TECH CO LTD

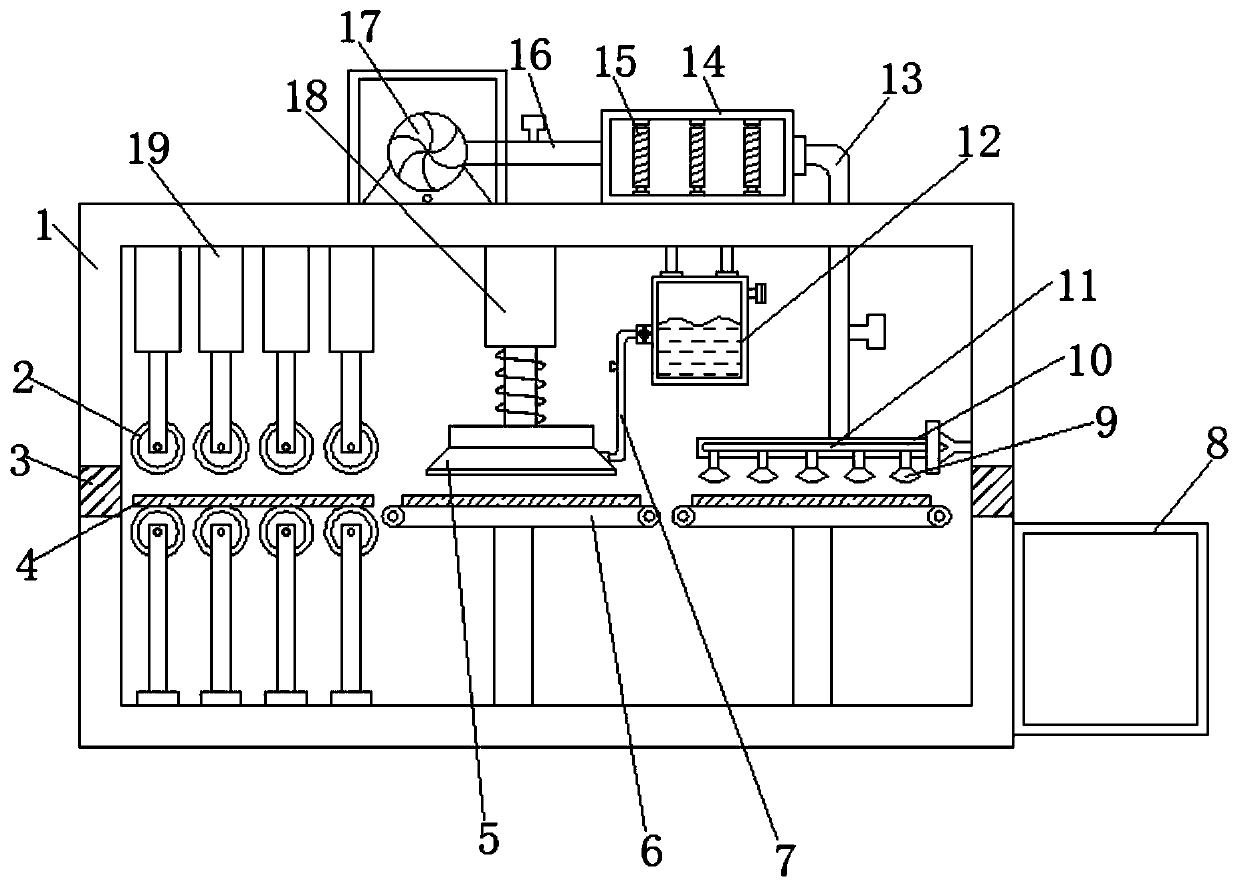

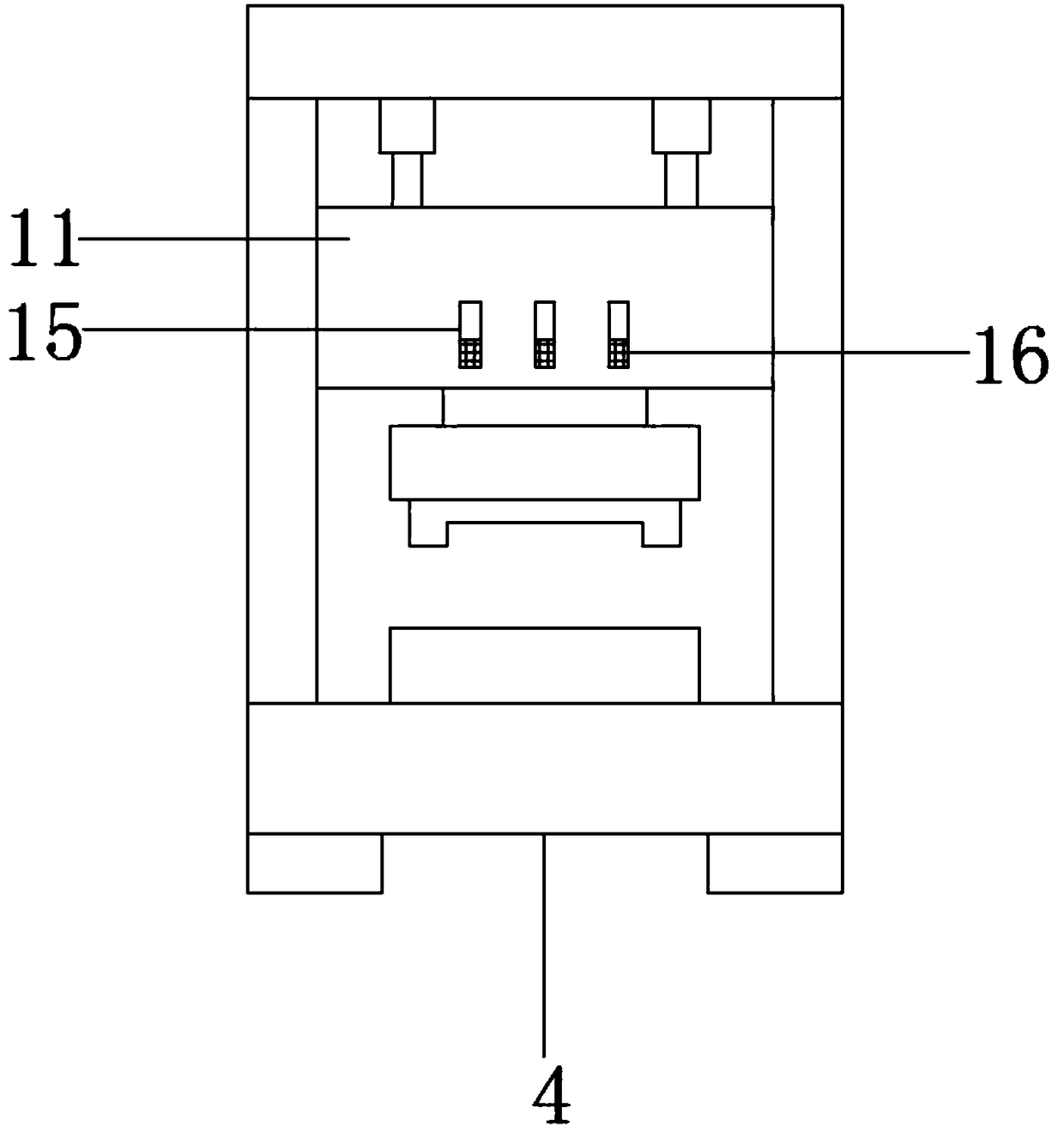

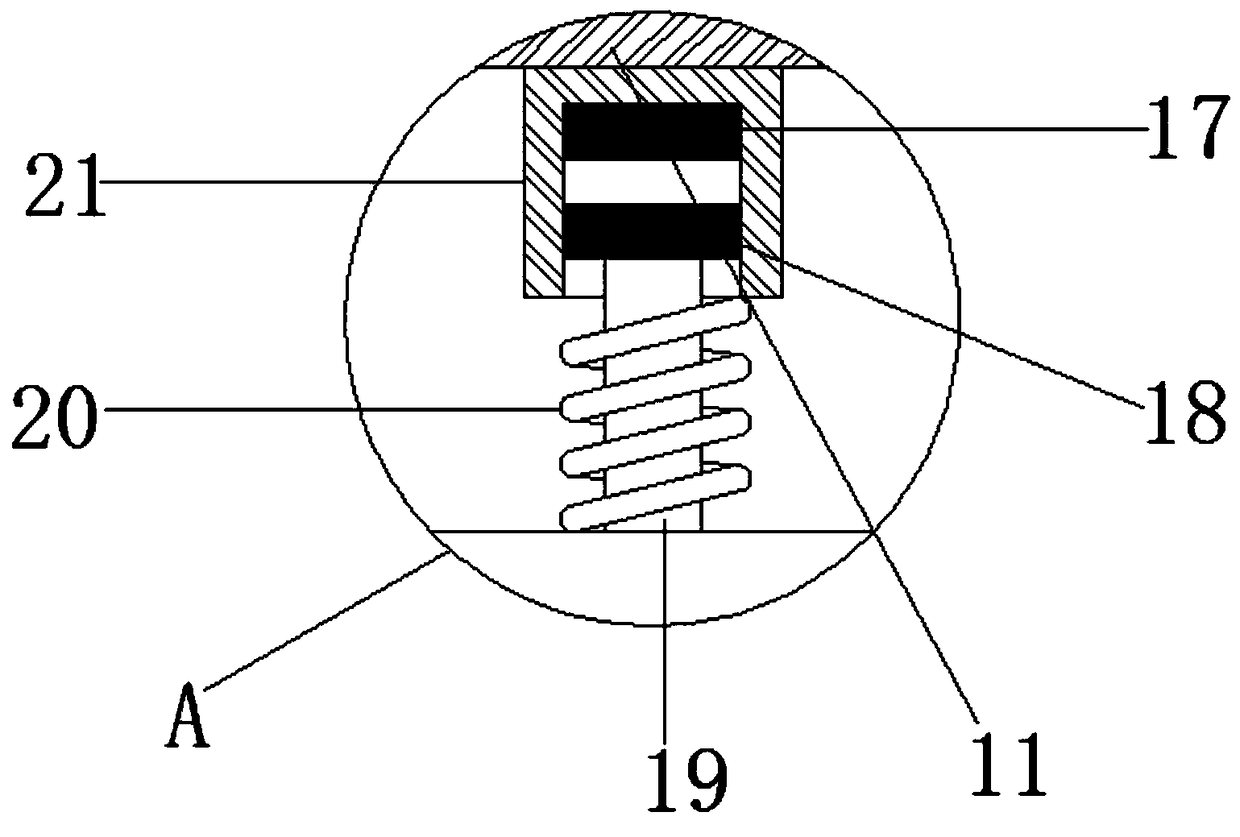

Packaging bag printing device

InactiveCN110893717AGuaranteed stabilityImprove buffering effectRotary pressesPrinting press partsCold airEngineering

The invention discloses a packaging bag printing device. The device comprises a box body; a second electric push rod is arranged on the inner wall of the bottom of the box body; the outer wall of oneside of the second electric push rod is rotationally connected with a transmission roller; a supporting rod is arranged on the inner wall of the bottom of the box body; a driven roller is rotatably connected to the outer wall of one side of the supporting rod; a packaging bag body is placed on the outer wall of the top of the driven roller; through grooves are formed in the outer walls of the twosides of the box body respectively; a first electric push rod is arranged on the inner wall of the top of the box body; and a printing head is arranged on the outer wall of one end of the first electric push rod. After the packaging bag body is printed, an air blower and a resistance wire can be started, cold air generated by the air blower is blown out of an air outlet hopper after being heated by the resistance wire, the packaging bag body can be effectively dried, the printing efficiency is improved, a good blocking effect can be achieved when the packaging bag body is dried by a protectionshell, and the stability of the packaging bag body is guaranteed.

Owner:株洲蓝海包装有限公司

Preparation method for producing deep-drawn cold-formed medicinal aluminum foil with cast-rolling billet in short process

PendingCN111549261AHigh bursting strengthGood barrierMetal rolling arrangementsTemperature treatmentDeep drawing

The invention discloses a preparation method for producing deep-drawn cold-formed medicinal aluminum foil with a cast-rolling billet in a short process. The method sequentially includes the steps of smelting, cast rolling, cold rolling, homogeneous high-temperature treatment, intermediate rolling, slitting shear trimming, intermediate annealing, finish rolling, foil rolling, coil combining, finished product rolling, parting-off, and furnace loading for annealing. Raw materials of the deep-drawn cold-formed medicinal aluminum foil include an aluminum alloy and an Al-Fe intermediate alloy with amass content of 20% or a Fe-containing additive with a mass content of 75%, and elements in the aluminum alloy include 0.025-0.10% of Si, 1.25-1.65% of Fe, 0.001-0.10% of Cu, less than 0.05% of Mn, less than 0.05% of Mg, less than 0.05% of Cr, less than 0.05% of Zn, 0.01-0.04% of Ti and the balance A. By means of the recorded preparation method, final product detection shows that the end face layer offset after parting-off is less than or equal to 0.5 mm, the width of the corrugated edge is 3 mm, and the peak value is 1 mm; the surface cleanliness dyne value is greater than or equal to 65 dyn; as for mechanical properties, the tensile strength is 80-115 MPa, the elongation rate is 23%, and the yield ratio is 42%; and the Erichsen value is 5.0 mm, the deep drawing height is 2.0 mm, the surface hardness value is 22 HV, the bursting strength is 400-800 Ka, and the surface swabbing reaches level A.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Beverage cup loading machine

ActiveCN106214002AShorten working timeReduce splashBeverage vesselsEngineeringMechanical engineering

The invention relates to a beverage cup loading machine which comprises a water conveying device and a transition container. The water conveying device is used for allowing the transition container obtain a beverage from the water conveying device. The transition container is provided with a liquid circulating opening. The liquid circulating opening is used for being controlled to be opened or closed so as to discharge liquid and transferring the beverage in the transition container into a water cup. By means of the beverage cup loading machine, the beverage cup loading speed can be increased, and the beverage can not be easily splashed out when poured.

Owner:李永刚

Overflow water drainage integral type sluice weir

The invention discloses an overflow water drainage integral type sluice weir which comprises a weir body, wherein the weir body is enclosed by two side walls and a base plate; an overflow water blocking wall is arranged on the base plate; and a water drainage hole is arranged in the overflow water blocking wall. The overflow water drainage integral type sluice weir disclosed by the invention realizes the functions of waterflood overflow and water drainage by an overflow water blocking wall structure; a water drainage pipe is controlled by a sluice valve and is convenient for operation; a power eliminating pool is arranged in the front of a power eliminating ridge so as to improve the energy eliminating effect; and an integral type waterflow adjusting structure is provided for items of water conservancy, municipal administration and the like. The overflow water drainage integral type sluice weir has higher applicability on a small and medium waterflow structure; meanwhile, a spillway is not viewed during waterflood overflow, the water surface keeps relatively complete and static, the breast wall has a favorable blocking effect on water floating sundries and is convenient for cleaning; and the relative hiding of the power eliminating pool has a favorable inhibiting effect on waterflood overflow noise.

Owner:曾皋波

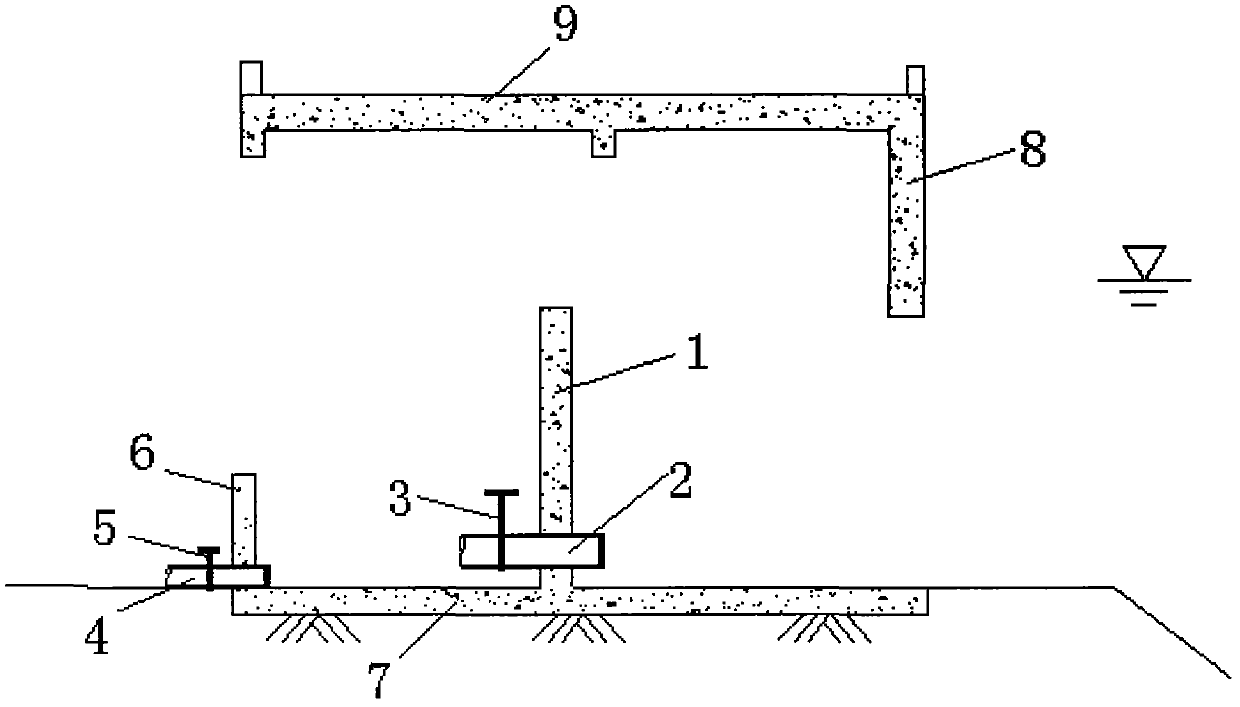

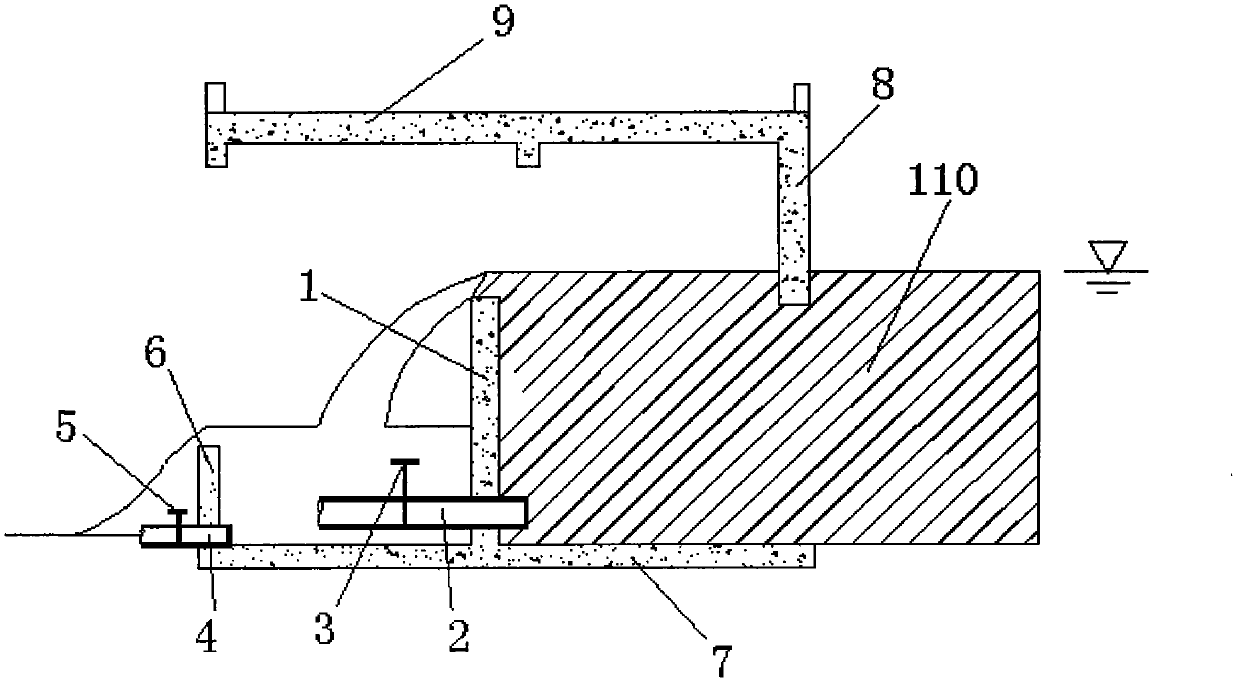

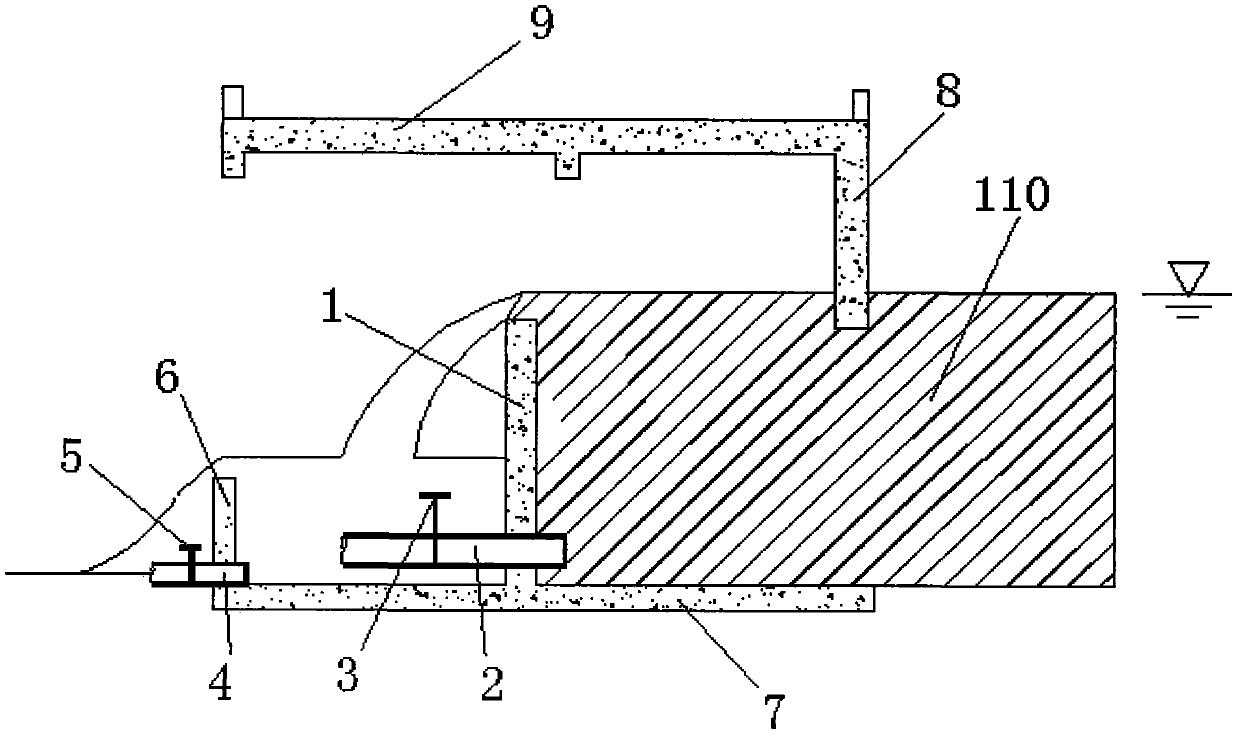

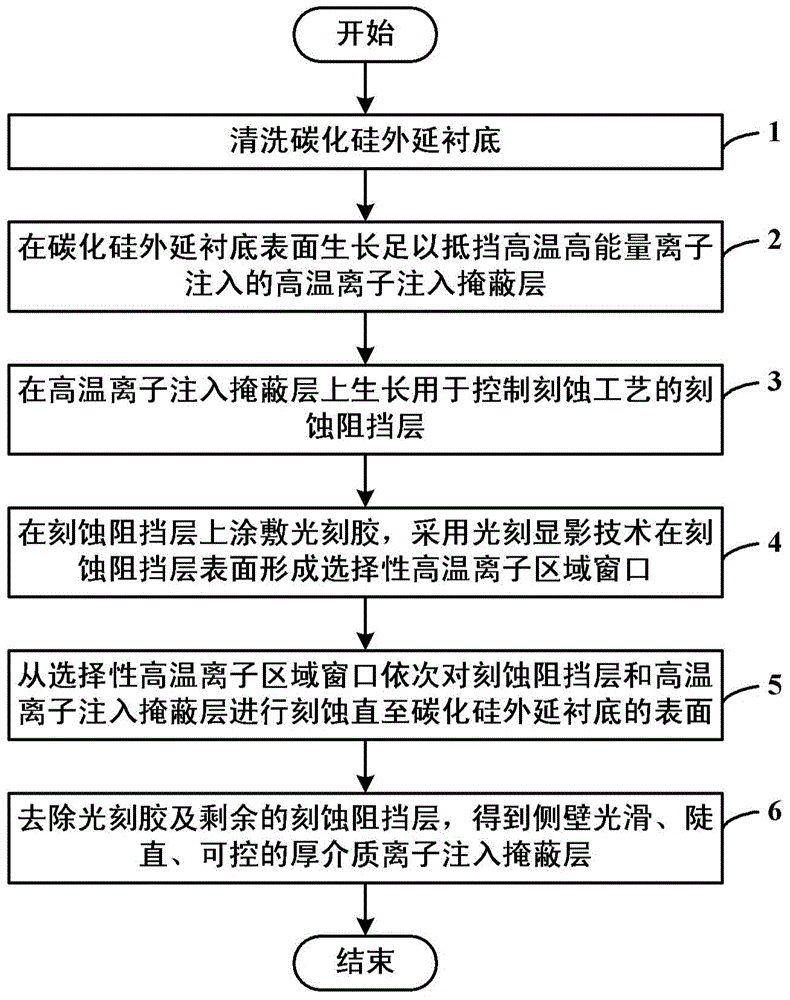

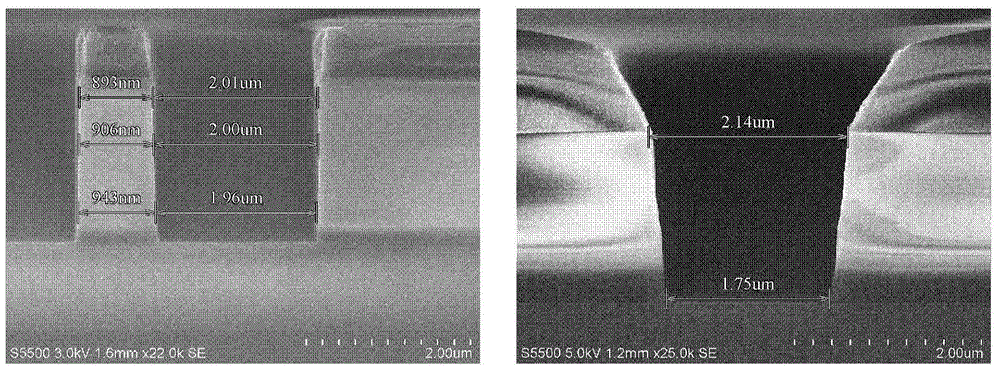

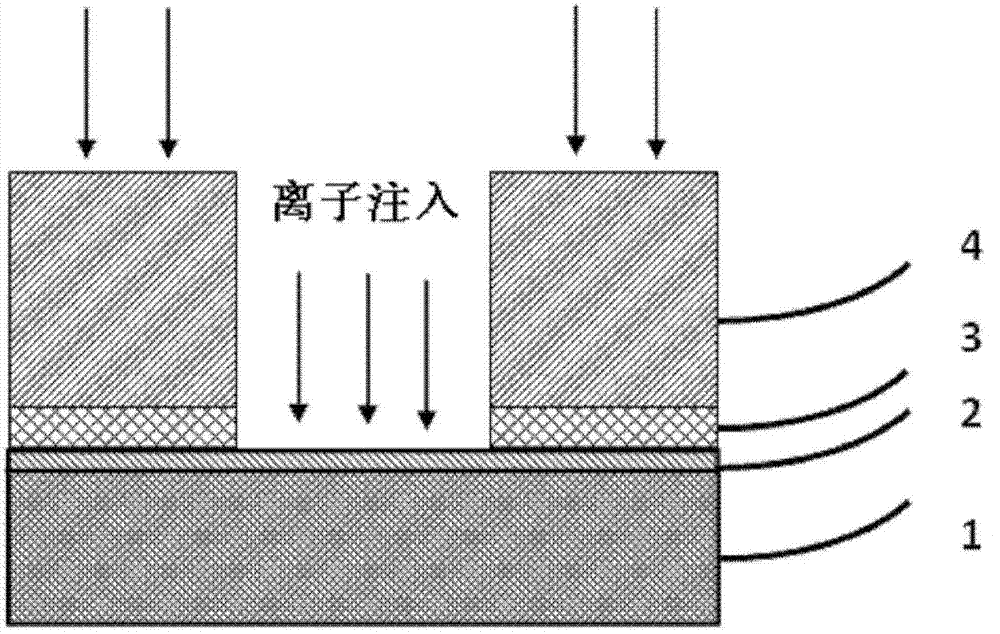

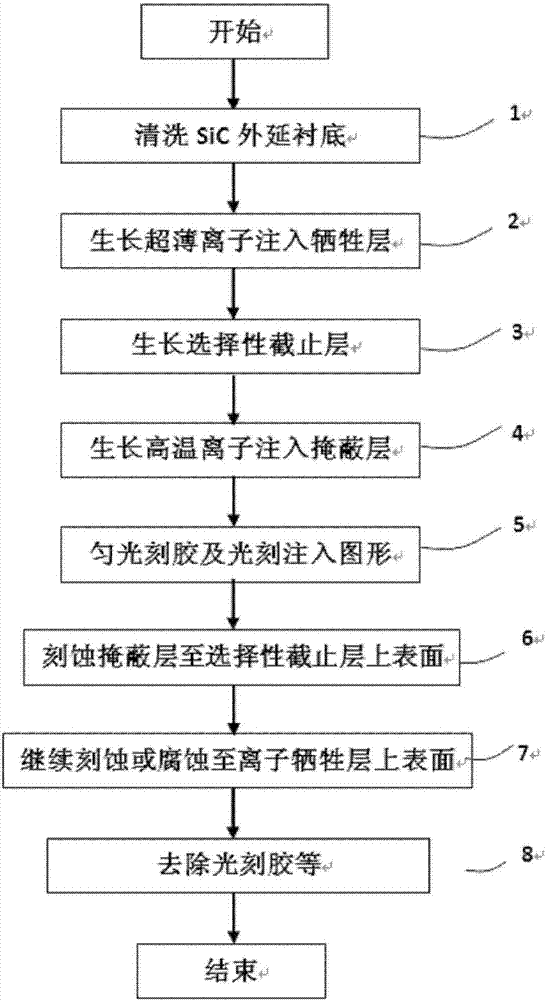

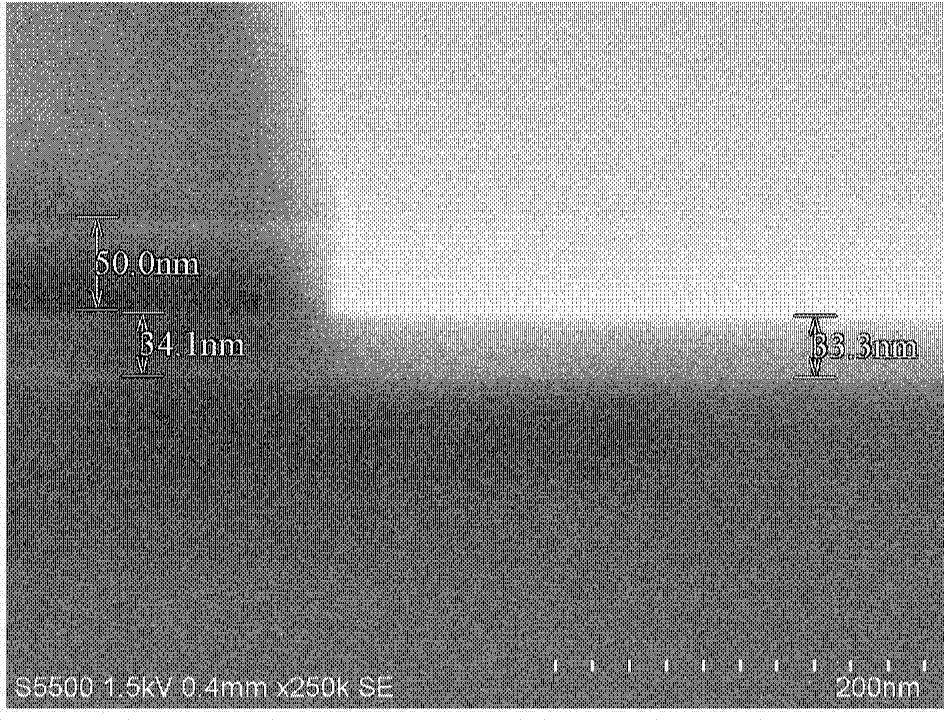

Method for accurately controlling steepness when silicon carbide high-temperature ions are injected into mask

ActiveCN103560078ASatisfy injection requirementsPerformance is not affectedSemiconductor/solid-state device manufacturingHigh energyOptoelectronics

The invention discloses a method for accurately controlling steepness when silicon carbide high-temperature ions are injected into a mask. The method comprises the steps that a silicon carbide epitaxial substrate is cleaned; a high-temperature ion injection masking layer capable of sufficiently resisting against the injected high-temperature and high-energy ions grows on the surface of the silicon carbide epitaxial substrate; an etching resisting layer used for controlling an etching process grows on the high-temperature ion injection masking layer; photoresist coats the etching resisting layer, and a selective high-temperature ion area window is formed in the surface of the etching resisting layer by adopting a photoetching developing technology, etching is sequentially carried out on the etching resisting layer and the high-temperature ion injection masking layer from the selective high-temperature ion area window to the surface of the silicon carbide epitaxial substrate; the photoresist and the unnecessary etching resisting layer are removed to obtain the steep and controllable thick-medium ion injection masking layer with the smooth lateral wall. By means of the method, angle control over an etching surface is carried out accurately, the steep thick-medium ion injection masking layer with the smooth lateral wall is obtained, and good uniformity and strong controllability of the selective ion injection area are guaranteed.

Owner:江苏中科汉韵半导体有限公司

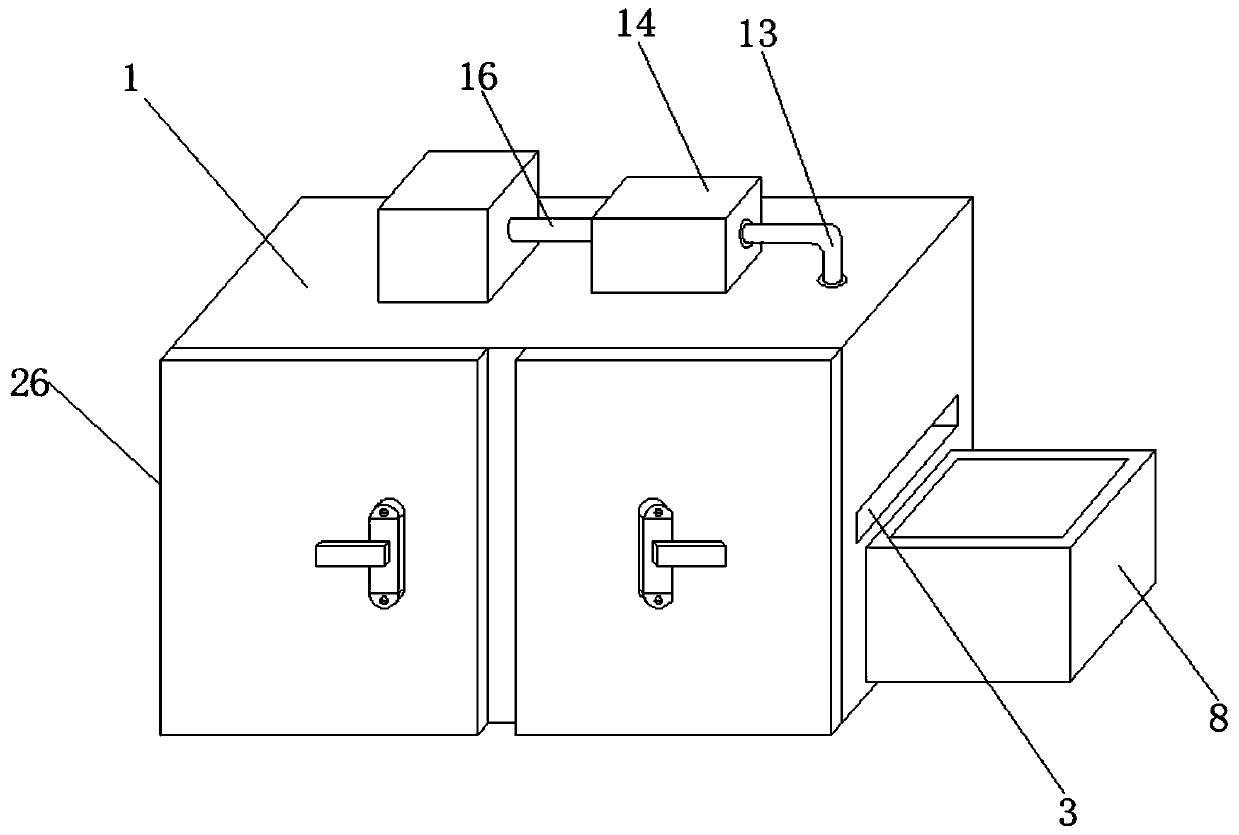

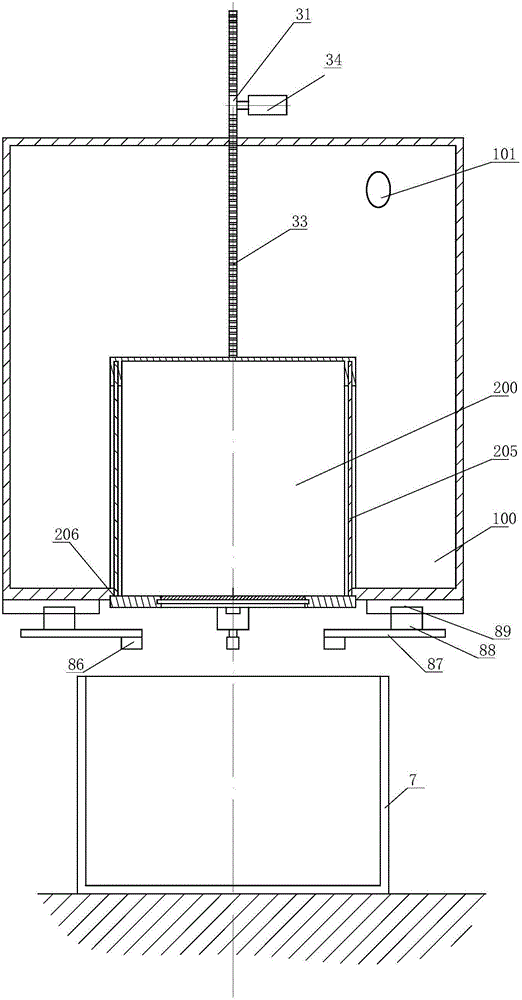

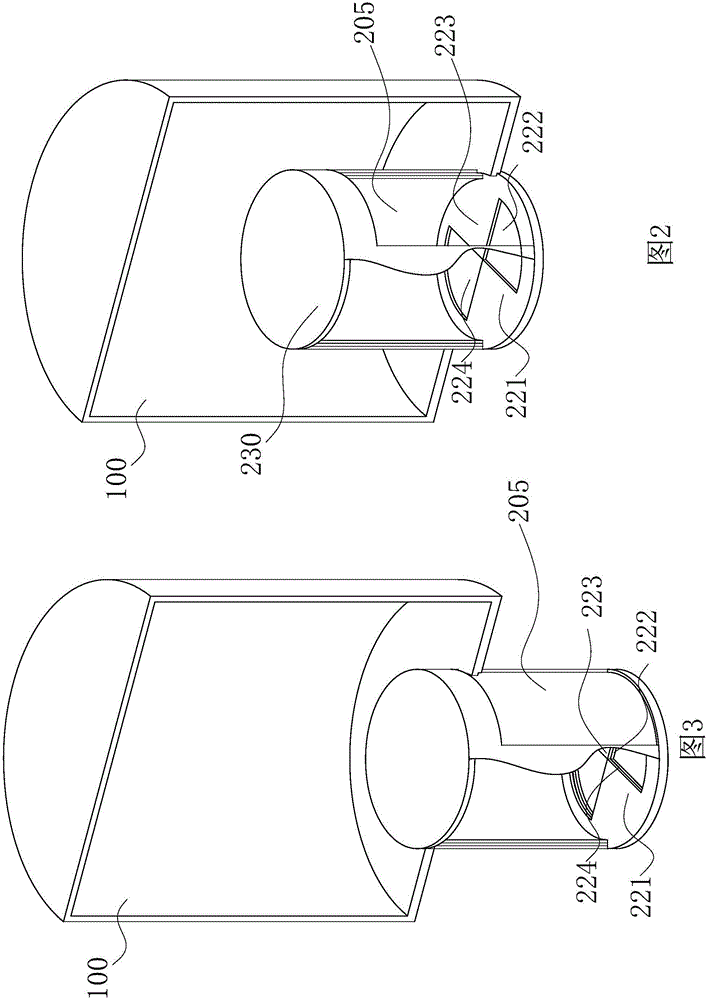

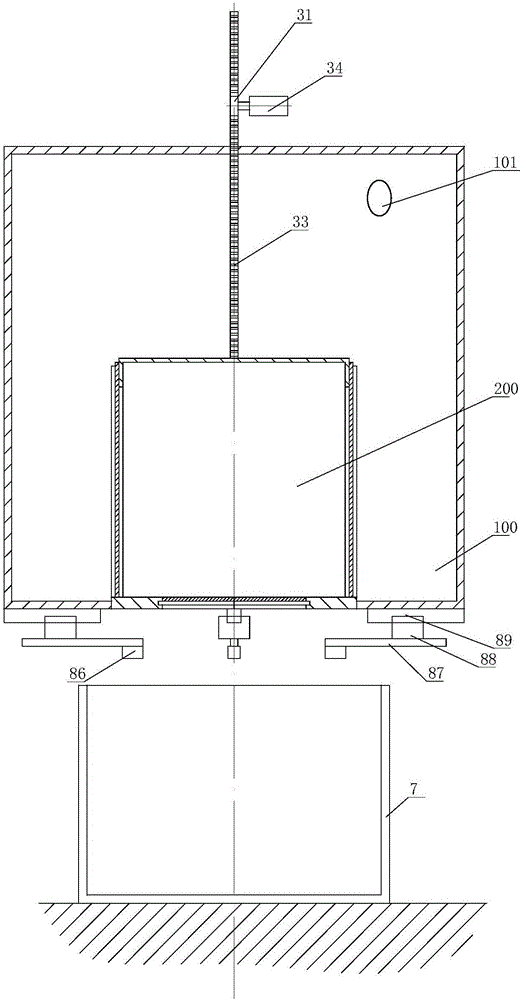

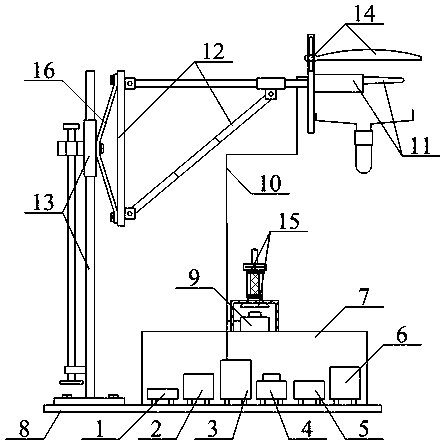

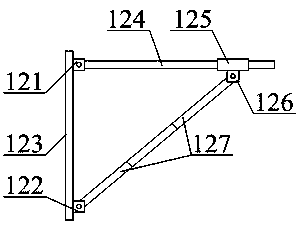

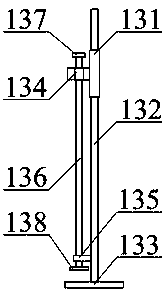

Supersonic flame spraying equipment and spraying method thereof

PendingCN109365187AEnsure safetyConvenient for spraying workSpraying apparatusSpray methodEngineering

The invention provides supersonic flame spraying equipment and a spraying method thereof. The supersonic flame spraying equipment comprises an air compressor, a heat exchanger, a main control cabinet,a pressurizing pump, an oil tank, an oxygen bus bar, a machine shell, a base, a powder feeder, an extension pipe, a supersonic fame spraying gun, an angle-adjustable supporting frame, a height position movable adjustment rod, a spattering-preventive collection cover for remaining sprayed powder, a powder pollution-preventive adsorption exporting core and a V-shaped connecting frame. According tothe supersonic flame spraying equipment, a first lining seat, a second lining seat, a joining lining seat, an angle motion bar, a sliding pipe, a third lining seat and a telescopic adjustment rod arearranged; adjustment of the telescopic adjustment rod through extension and contraction is benefited; the sliding pipe slides on the outer wall of the angle motion bar, and at this moment, the angle motion bar moves inside the first lining seat, the inclination angle of the angle motion bar is changed, and the spraying angle of the supersonic flame spraying gun is changed; and finally, extension and contraction work of the telescopic adjustment rod is stopped so that the spraying work can be guaranteed to proceed smoothly.

Owner:ZHENGZHOU LIJIA THERMAL SPRAYING MACHINERY CO LTD

Double-layer plastic film composite tape and manufacturing method thereof

ActiveCN101987522AGood adhesionImprove mechanical propertiesLaminationLamination apparatusMetal foilIsolation layer

The invention discloses a double-layer plastic film composite tape. The tape comprises a strip metal foil, wherein an inner plastic film and an outer plastic film are adhered to the strip metal foil through two-step composition on the outer surface of the metal foil. The outer plastic film of the composite tape can be easily peeled from the inner plastic film, and the inner plastic film and the outer plastic film do not destroy each other. In the process of manufacturing a cable, longitudinal wrapping lap self-adhesion performance is high, and the composite tape has excellent effect of blocking damp invasion, so a cable core is protected. The double-layer plastic film composite tape has higher corrosion resistance because plastic layers are coated on two sides of a metal tube shielding tape, and an isolation layer with chemical corrosion resistance is arranged between the metal component layer and corrosive water and gas. The manufacturing method is simple, the process technology is mature and reliable, and the manufactured composite tape has a flat, smooth and uniform surface.

Owner:烟台万泰通信科技有限公司

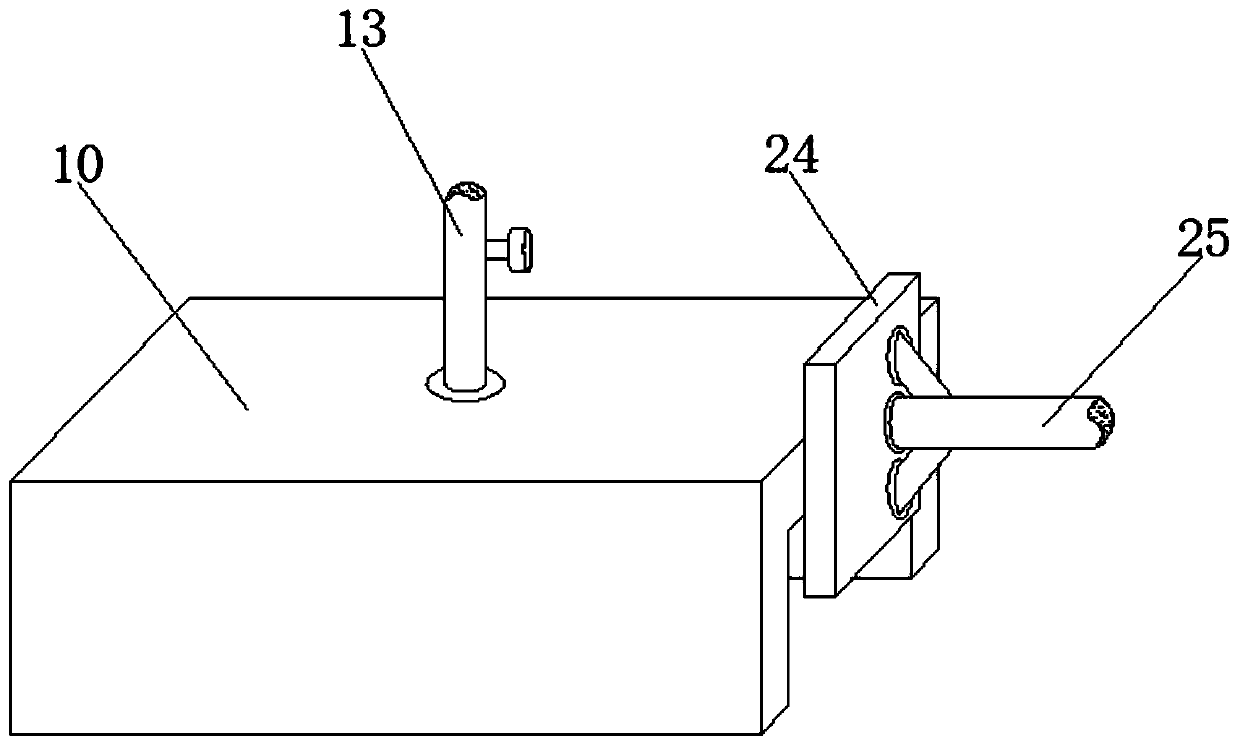

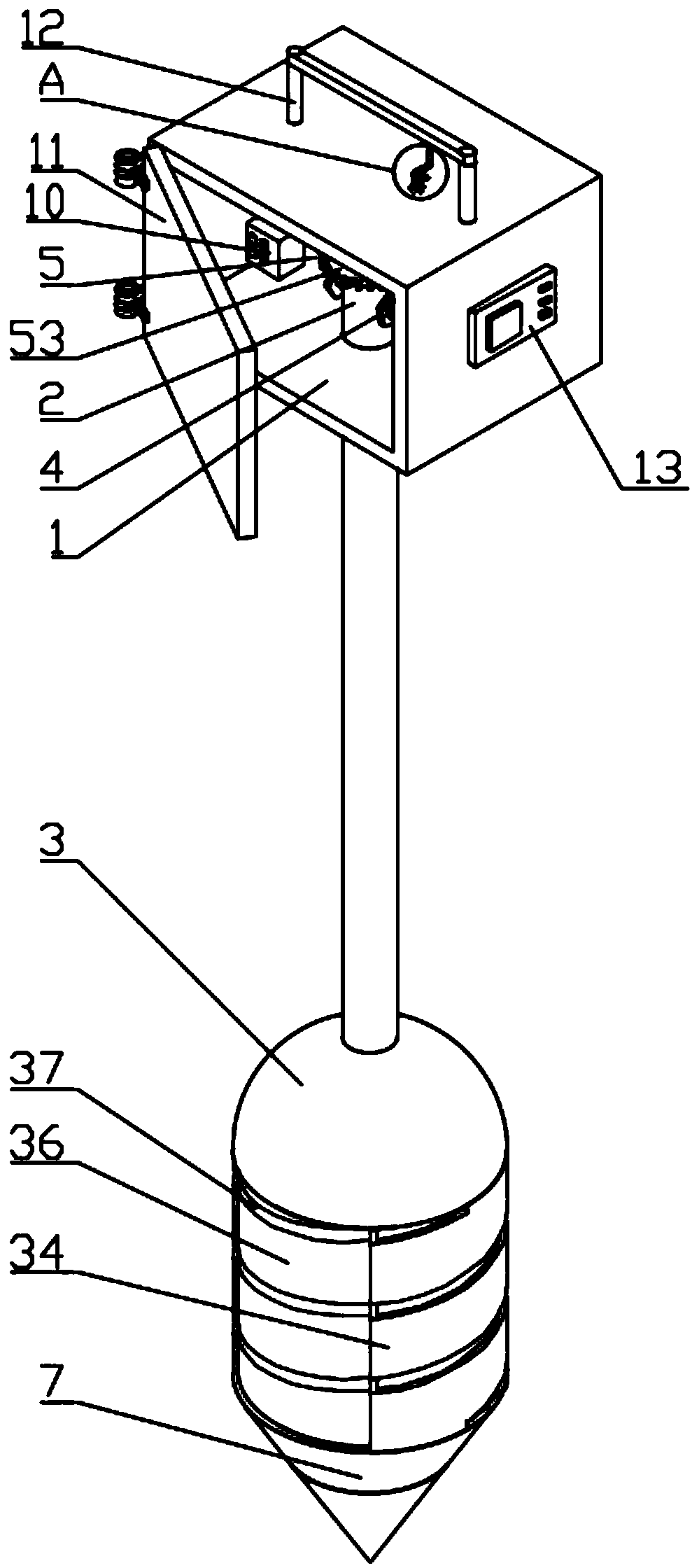

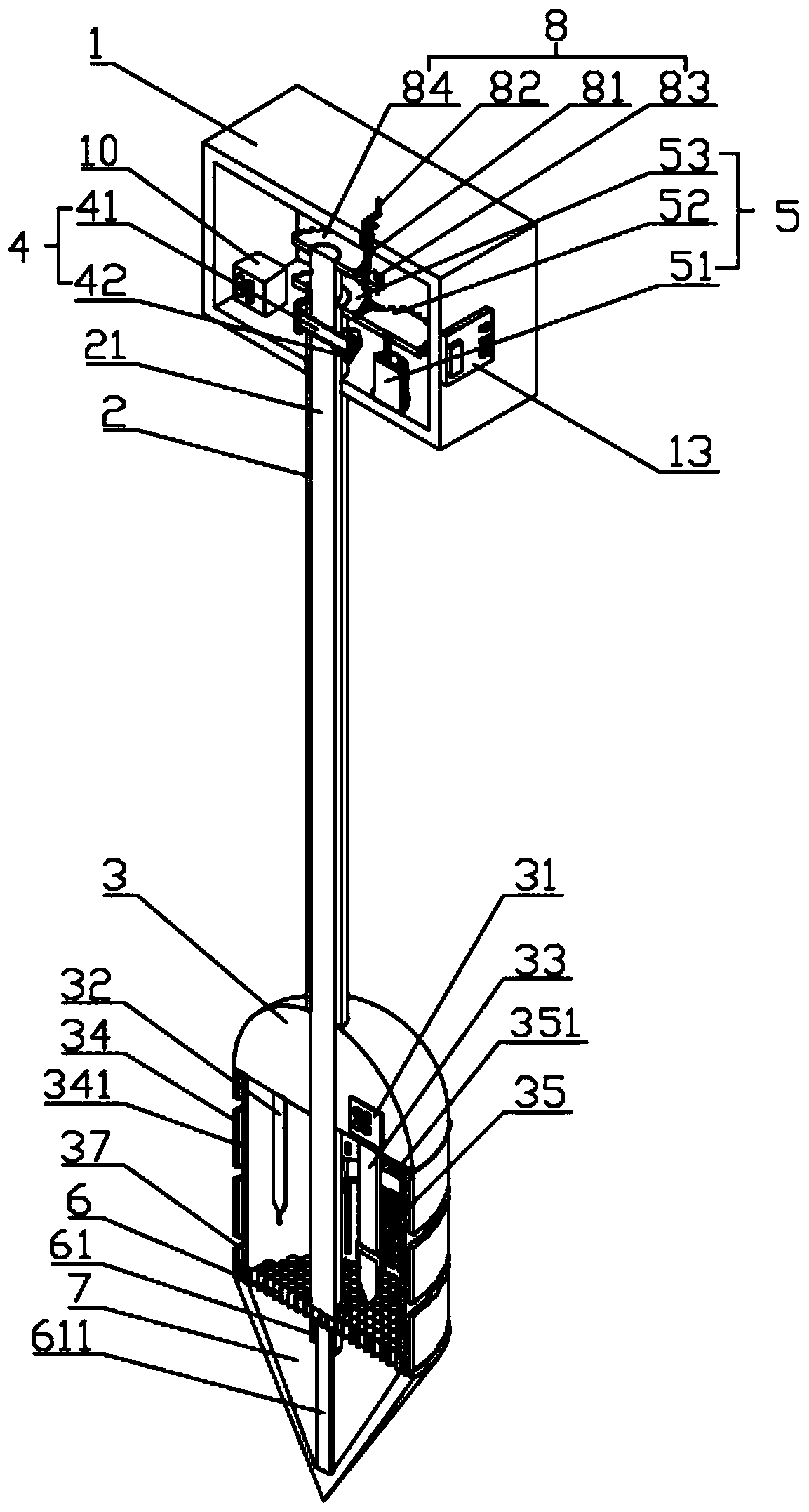

Soil sampling and detecting device

InactiveCN110823627AImprove protectionAvoid collision damageWithdrawing sample devicesEarth material testingSoil scienceEnvironmental engineering

The invention relates to a soil sampling and detecting device. The soil sampling and detecting device comprises a detection box, a casing pipe penetrates the bottom portion of the detection box, a rotating rod is arranged in the casing pipe, a fixing component is arranged on the rotating rod, a base is fixed at the lower end of the casing pipe, a driving component is arranged in the detection box;, the rotating rod penetrates the base and is rotationally connected with the base, an arc-shaped soil drilling plate, a soil salinity detector and an acidity and alkalinity testing sensor are fixed on the bottom surface of the base, a protective plate is movably arranged in the arc-shaped soil drilling plate, a fixing rod is fixed to the protective plate, the end, away from the protective plate,of the fixing rod is fixed to the side wall of the rotating rod, a drill bit is installed at the bottom of the protective plate and the bottom of the arc-shaped soil drilling plate, and the drill bit,the protective plate and the arc-shaped soil drilling plate form a closed space used for protecting the soil salinity detector and the acidity and alkalinity testing sensor. According to the soil detection device in the scheme, the soil salinity detector and the acidity and alkalinity testing sensor are well protected in the soil drilling process, and the phenomenon that the soil salinity detector and the acidity and alkalinity testing sensor are collided and damaged is avoided.

Owner:CHENGDU FUYANG TECH DEV

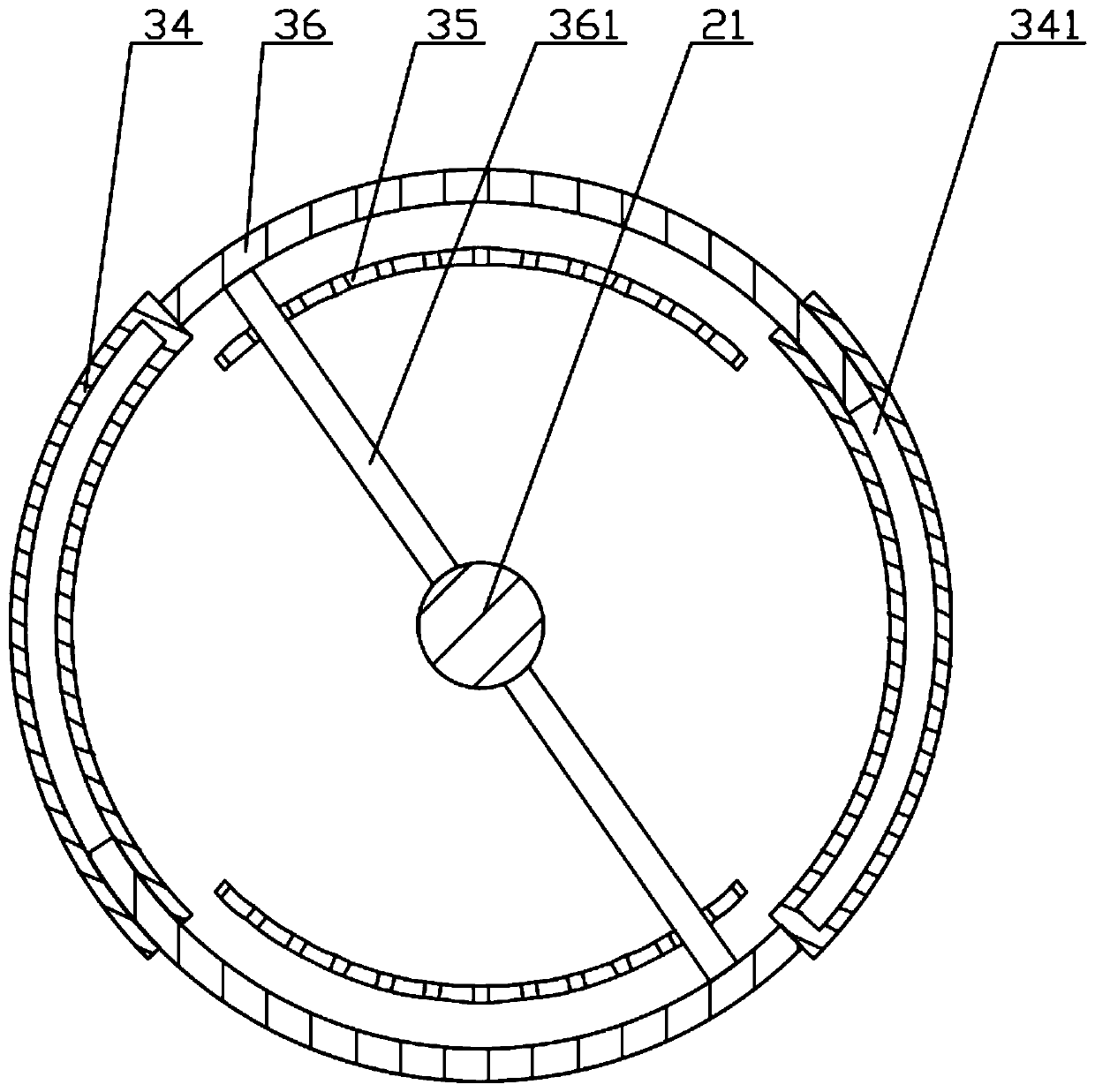

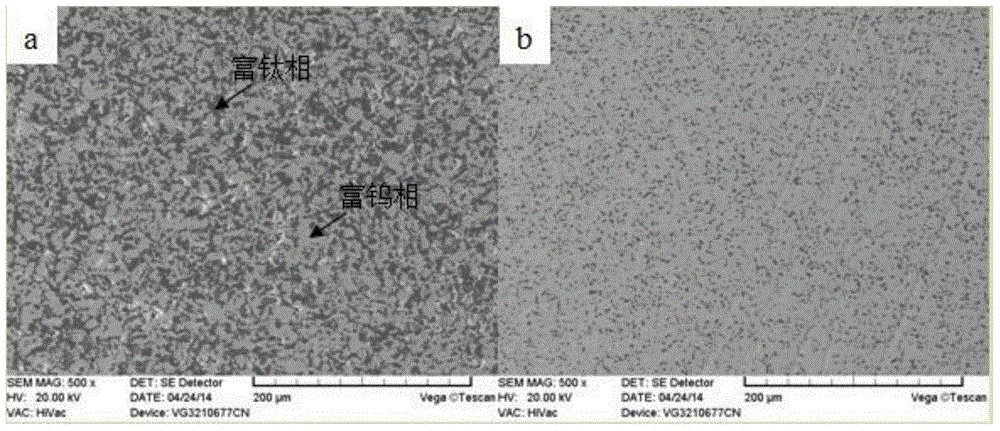

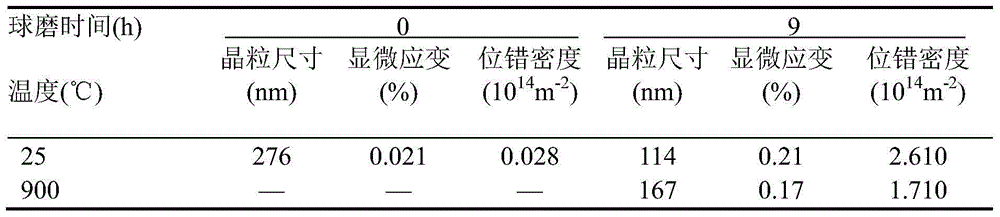

Preparation method of aplitic tungsten-titanium alloy

InactiveCN104611599APromote sinteringImprove defectsVacuum evaporation coatingSputtering coatingHigh energyTitanium alloy

The invention discloses a preparation method of aplitic tungsten-titanium alloy. The preparation method comprises the following steps: after performing high-energy ball milling on tungsten powder, adding titanium hydride powder, and performing uniform mixing; then performing compression so as to form a green body, and after performing vacuum low-temperature sintering, performing thermal extrusion and quenching so as to obtain the aplitic tungsten-titanium alloy. Through the use of the preparation method disclosed by the invention, the defects of the loss of the ball milling effect and the grain growth, which are caused by the high-temperature sintering, are overcome, the obtained tungsten-titanium alloy is fine in crystal grains, high in density and fine and uniform in rich titanium phases, the occupied area is small, and a new method of the aplitic tungsten-titanium alloy is provided.

Owner:XIAN UNIV OF TECH

Train automatic-parking executing system

InactiveCN107962978AReduce resistanceReduce energy consumptionRailway stationRailway auxillary equipmentMotor driveControl theory

The invention discloses a train automatic-parking executing system which comprises a servo motor, a driving beam, a driven beam, a turnout control relay, a trolley, a turnout structure with magnetic levitation plates and a turnout controller. The turnout structure with the magnetic levitation plates is arranged on the driven beam. The servo motor is mounted under the driving beam and connected with the trolley, the turnout control relay and the turnout controller. The driving beam and the driven beam are mechanically connected. The servo motor drives the trolley to drive the driven beam, underthe action of the driven beam, the turnout structure with the magnetic levitation plates, the driven beam and the driving beam are moved to a set rail as a whole, and thus a train runs to the set rail. An existing magnetic levitation rail structure is improved, levitating magnets are arranged in groove structures, airflow resistance is reduced, energy consumption of the magnetically levitated train is lowered, the safety guarantee capacity of magnetic levitation traffic is enhanced, and riding of magnetic levitation traffic is more quiet and comfortable.

Owner:成都天府轨谷科技有限公司

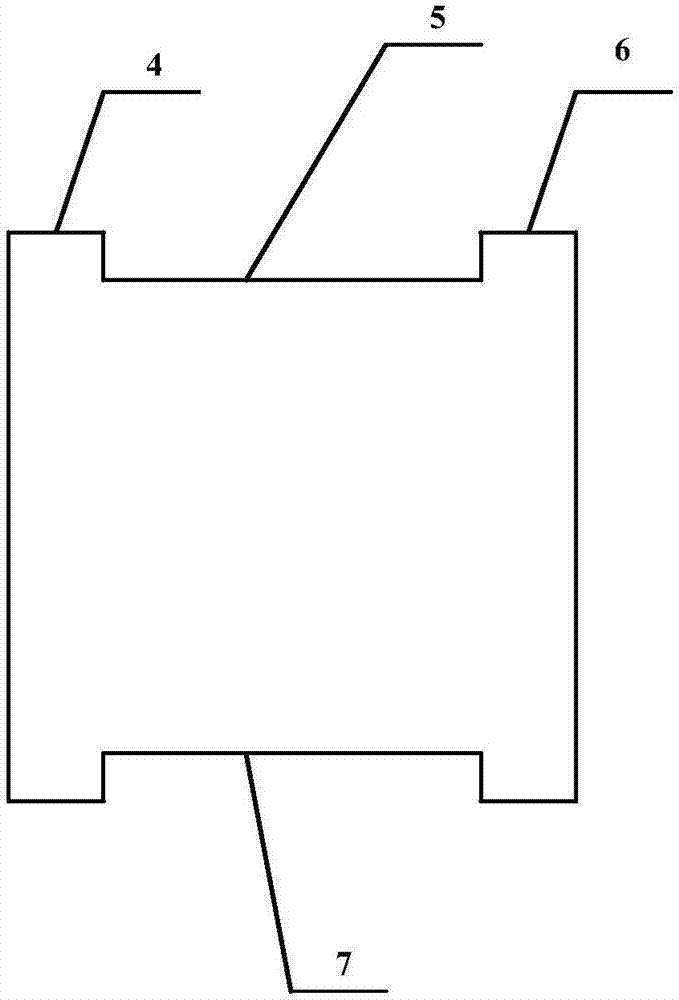

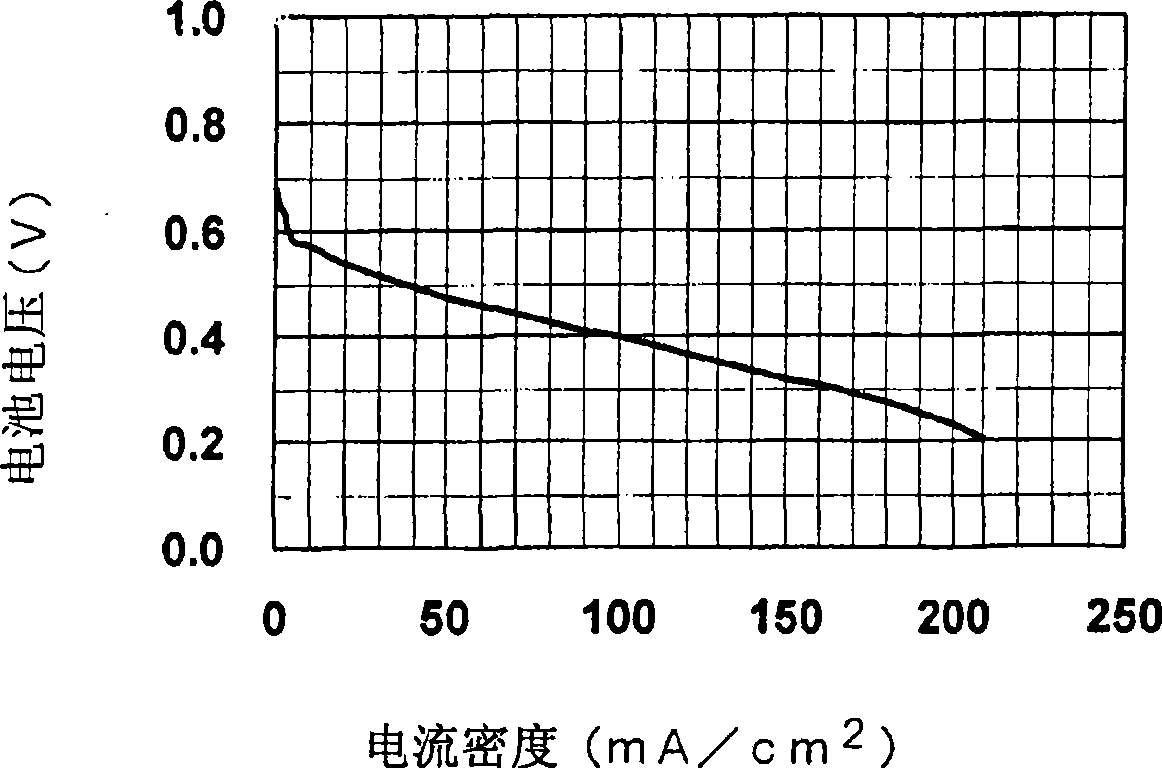

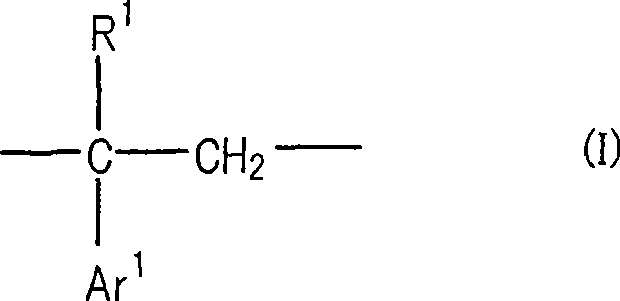

Polyelectrolyte film, film-electrode assembly, and solid-polymer-type fuel cell

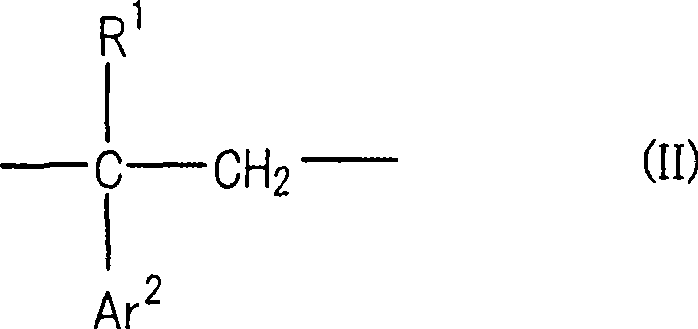

InactiveCN101385173AImprove ionic conductivityGood formabilityNon-metal conductorsSolid electrolyte fuel cellsPolymer scienceCopolymer

The invention relates to polymer electrolyte membrane, and membrane electrode assembly employing the membrane and solid polymer type fuel cell. A polymer electrolyte membrane comprising as a main ingredient a block copolymer which comprises, as its constituents, a polymer block (A) having as a main unit an aromatic vinyl compound unit and a polymer block (B) forming a flexible phase, and has ion-conducting groups on the polymer block (A), said aromatic vinyl compound unit being such that the hydrogen atom bonded to the alpha-carbon atom is replaced with an alkyl group or an aryl group optionally having substituent(s), and at least one of hydrogen atoms directly bonded to the aromatic ring is replaced with an alkyl group; and a membrane electrode assembly and a polymer electrolyte fuel cell both of which uses it. The polymer block (A) can further have a restraining phase, and / or can be cross-linked. The electrolyte membrane is mild to the environment, has a high ion conductivity and good bonding properties to electrodes, is excellent in moldability, and is not easily influenced by methanol; and displays excellent performance in polymer electrolyte fuel cells, particularly direct methanol fuel cells.

Owner:KURARAY CO LTD

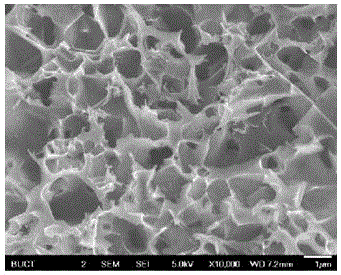

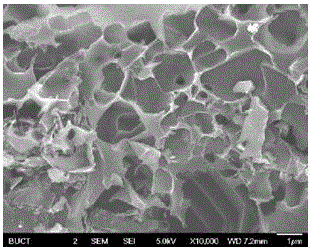

Method for preparing porous carbon by utilizing rose stems

InactiveCN105731454AEasy to storeReduce concentrationOther chemical processesPotassium hydroxideChromium adsorption

The invention relates to a method for preparing porous carbon by utilizing rose stems. According to the porous carbon, rose stems are taken as raw materials, and the method comprises the following specific steps: segmenting, cleaning, drying, pre-carbonizing, uniformly mixing with potassium hydroxide according to a mass ratio of 1:(1-3), carbonizing and activating at the temperature of 600-750 DEG C, cooling to room temperature, performing hydrochloric acid washing and deionized water washing; and finally, drying again, thereby obtaining the porous carbon. The porous carbon prepared by the method has high adsorption capacity on chromium ions and PM2.5, the maximum chromium adsorption amount can be 344.83mg / g, and the PM2.5 concentration after blocking can be reduced to 0.0588mg / m<3>.

Owner:BEIJING UNIV OF CHEM TECH

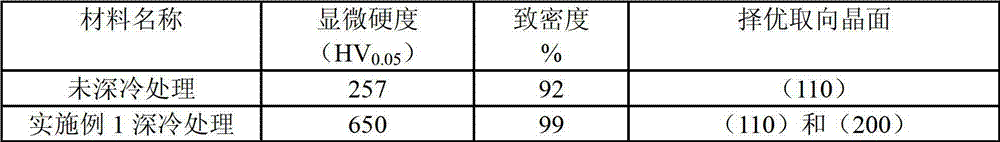

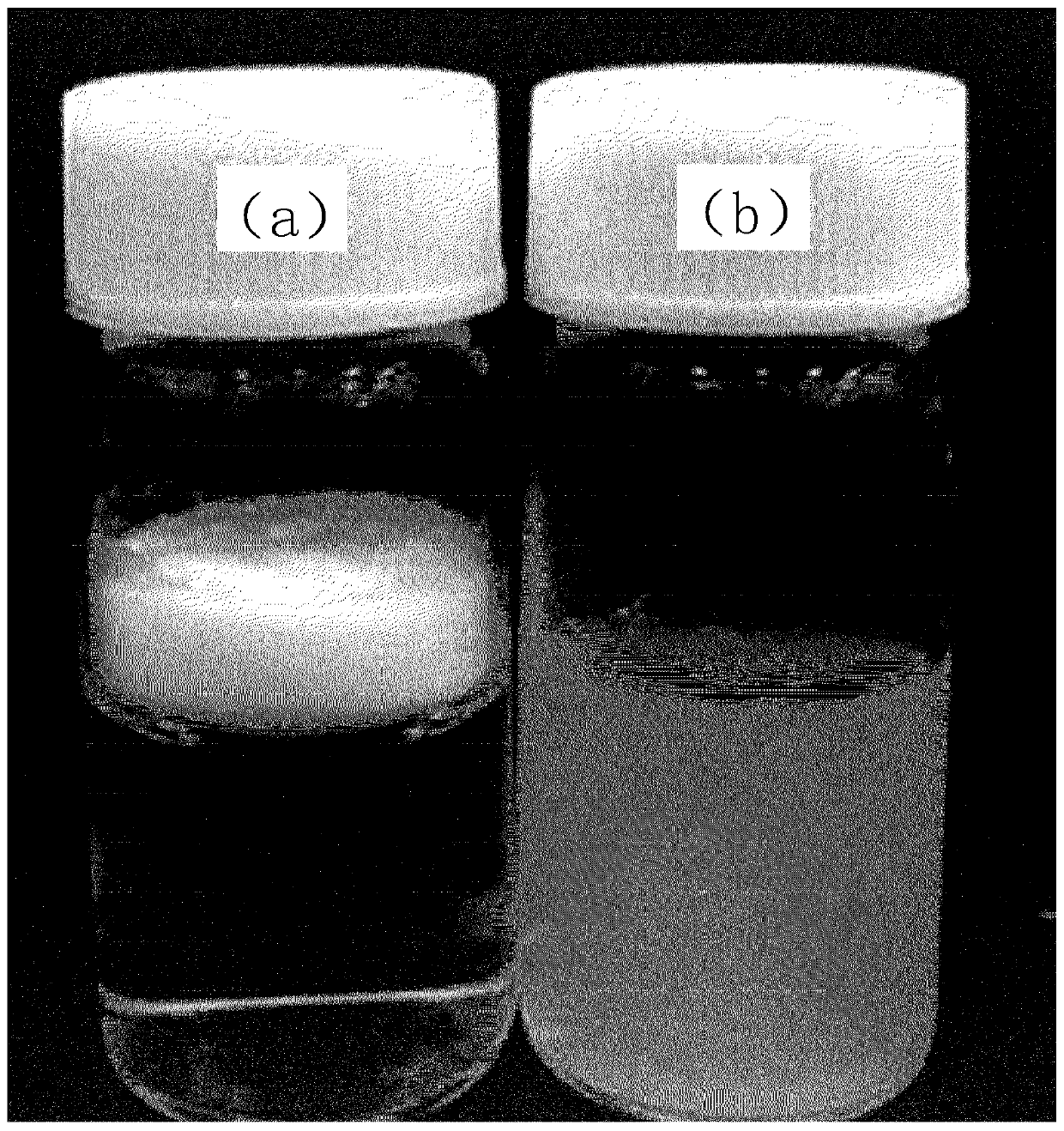

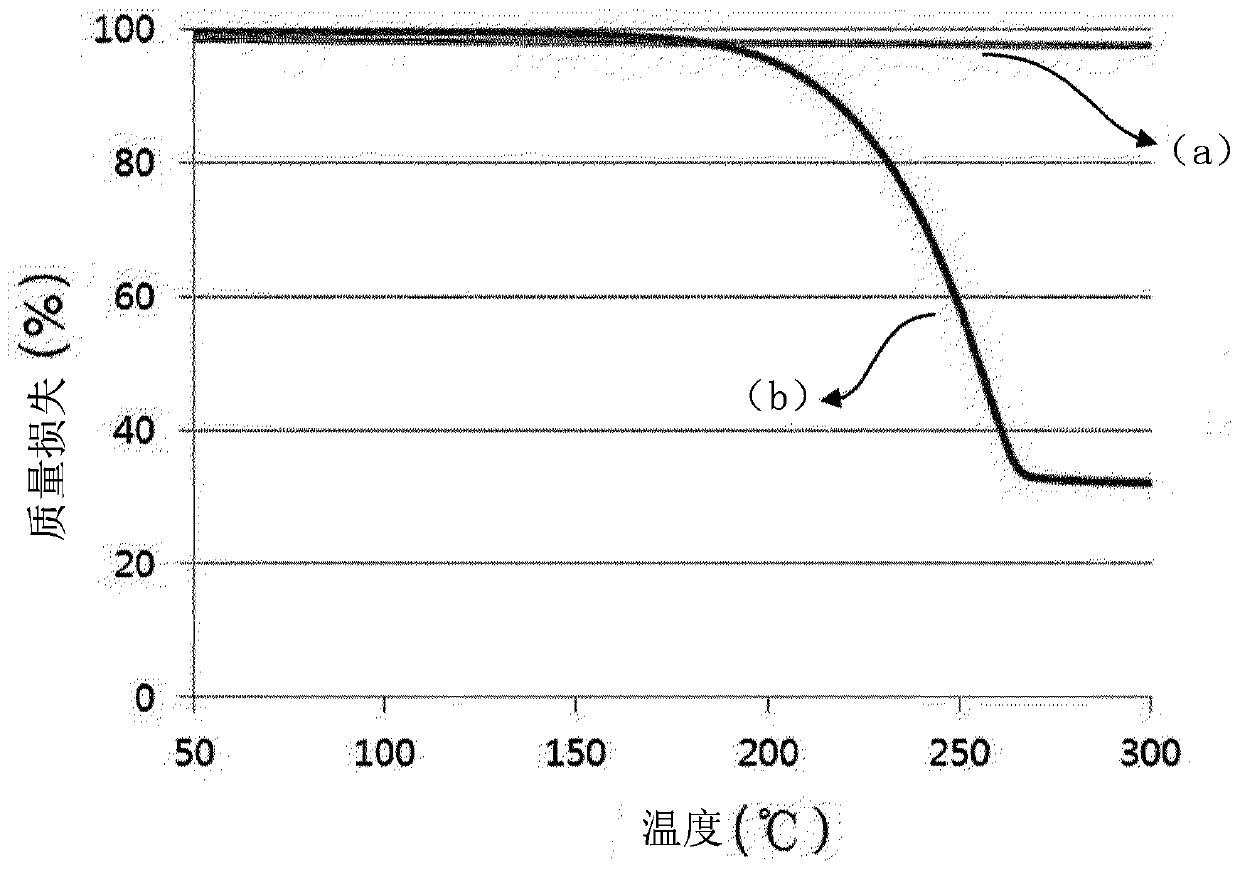

Cryogenic treatment method of tungsten-titanium alloy

The invention discloses a cryogenic treatment method of a tungsten-titanium alloy. The method comprises the following steps of: placing the cleaned tungsten-titanium alloy on a specimen holder of cryogenic treatment equipment; opening a valve of a self-pressurized cryogenic fluid conveying device filled with a cryogenic medium; treating the alloy by using a gas spraying method; after the treatment is finished, cutting off a power supply and closing a cryogenic source; and taking out the tungsten-titanium alloy to be put into a water bath of 15 to 25 DEG C to quickly realize the temperature raise at the rising rate of 180 to 200 DEG C / s, thereby obtaining the tungsten-titanium alloy of the cryogenic treatment. The tungsten-titanium alloy obtained by using the cryogenic treatment method has the definite crystal orientation and the good mechanical property, so that a film with a good blocking effect is achieved.

Owner:成都金钨硬质合金有限公司

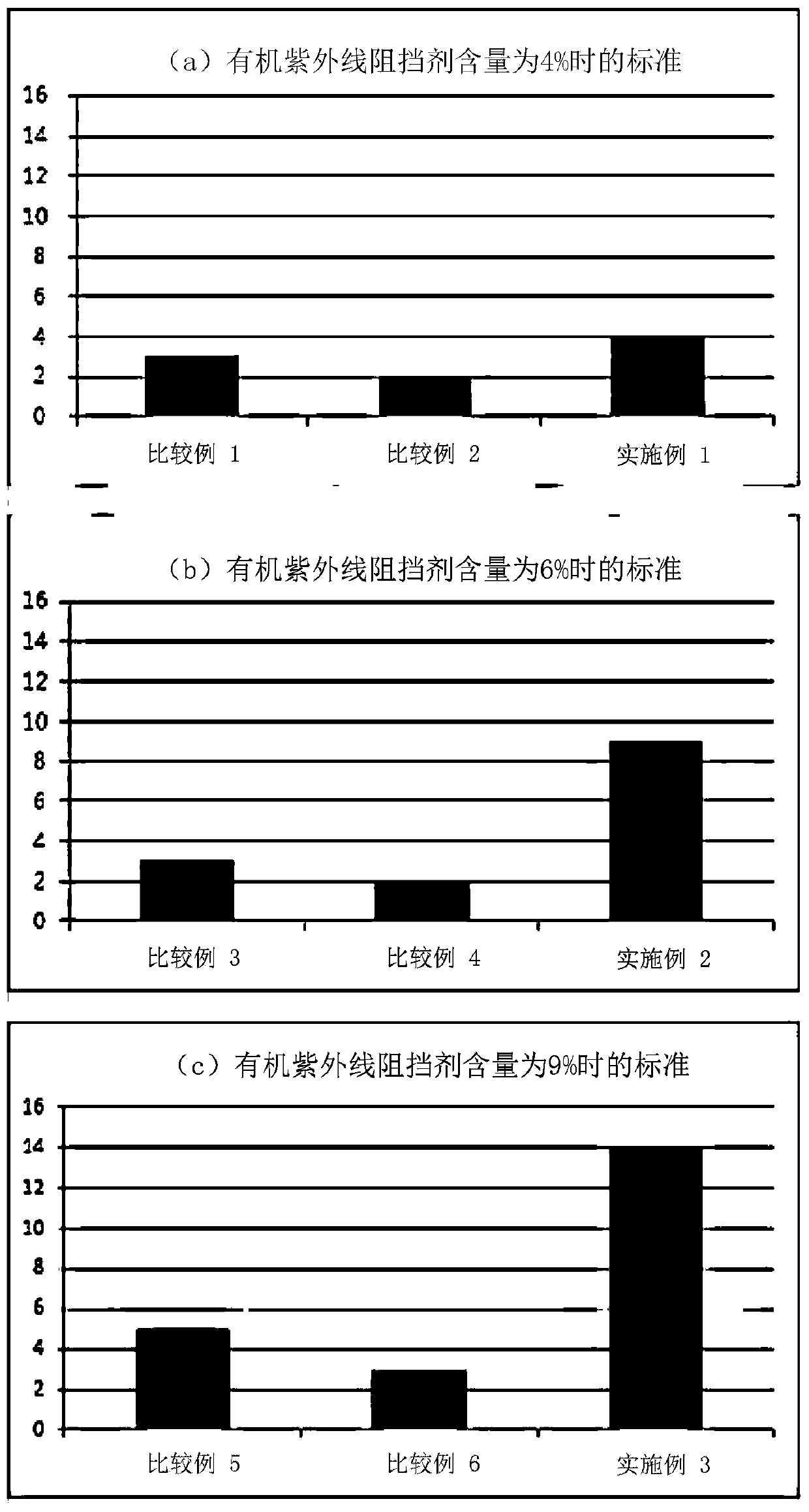

Organic UV blocker-supported silica aerogel composite

InactiveCN109789057AGood barrierCosmetic preparationsToilet preparationsHydrophobic silicaMaterials science

Owner:阿斯汀株式会社

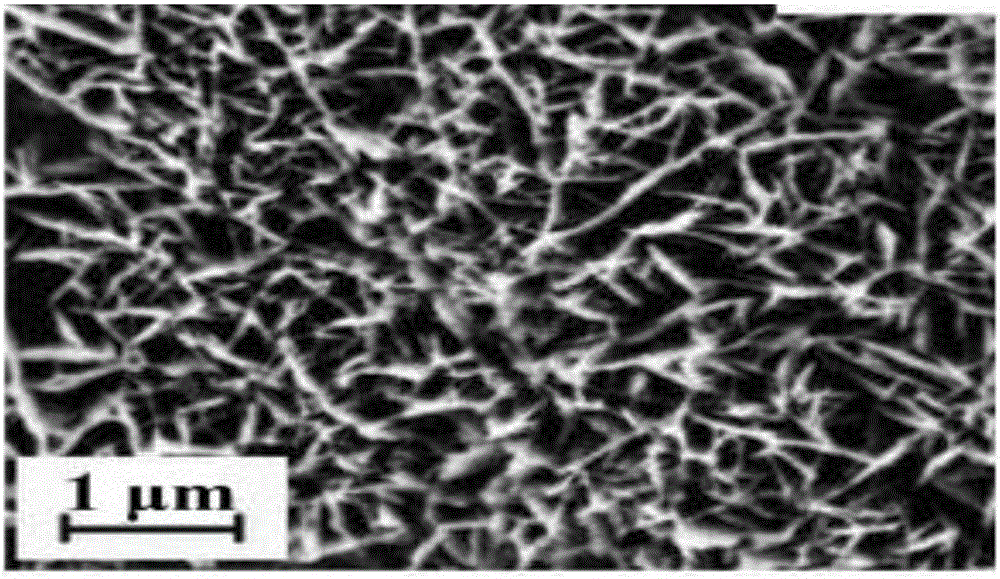

Anti-haze window screen fiber based on conductive macromolecules, and preparation method and application thereof

The invention discloses an anti-haze window screen fiber based on conductive macromolecules, and a preparation method and an application thereof. The anti-haze window screen fiber comprises a fiber and a conductive macromolecule surface treatment agent layer attached on the surface of the fiber; a conductive macromolecule surface treatment agent is composed of a PEDOT-PSS aqueous dispersion body, waterborne polyurethane, 3-(2,3-epoxypropoxy)propyl trimethoxy silane, isopropanol, 1-methyl-2-pyrrolidone, a hydroxyethyl cellulose aqueous solution, a waterborne flatting agent BYK-333 and N,N-dimethylethanolamine. The invention also discloses the preparation method and application of the anti-haze window screen fiber. A screen window is prepared by the anti-haze window screen fiber based on the conductive macromolecules, and in the premise of not affecting a ventilation effect, the blocking rate of PM2.5 is enhanced; and the preparation method is simple, and the product has high repeatable use rate.

Owner:JIANGSU HUACHANG YARNS & FABRICS CO LTD

Method for manufacturing silicon carbide high-temperature ion implantation mask with selectivity cut-off layer

ActiveCN103578942AGood barrierSatisfy injection requirementsSemiconductor/solid-state device manufacturingMOSFETHigh energy

The invention discloses a method for manufacturing a silicon carbide high-temperature ion implantation mask with a selectivity cut-off layer. The method includes the steps of cleaning a silicon carbide substrate, adopting a heat oxidation method to grow an ion implantation sacrificial layer mask on the silicon carbide substrate, adopting an LPCVD method to grow the selectivity cut-off layer used for controlling the etching process on the obtained ion implantation sacrificial layer mask, adopting an epitaxy or growing method to form an insulating medium masking layer on the selectivity cut-off layer, evenly coating the insulating medium masking layer with photoresist, carrying out photoetching to develop a selectivity ion implementation area window, carrying out dry-method etching or corrosion on the insulating medium masking layer from the selectivity ion implementation area window to the surface of the selectivity cut-off layer, continuously carrying out etching or corrosion to the surface of an ion implantation sacrificial layer, removing the photoresist, and obtaining the ultra-thin ion implementation sacrificial layer mask. The method for manufacturing the silicon carbide high-temperature ion implantation mask is suitable for a silicon carbide SBD, a JBS diode, an MOSFET device and other silicon carbide devices requiring high-temperature high-energy ion implantation.

Owner:江苏中科汉韵半导体有限公司

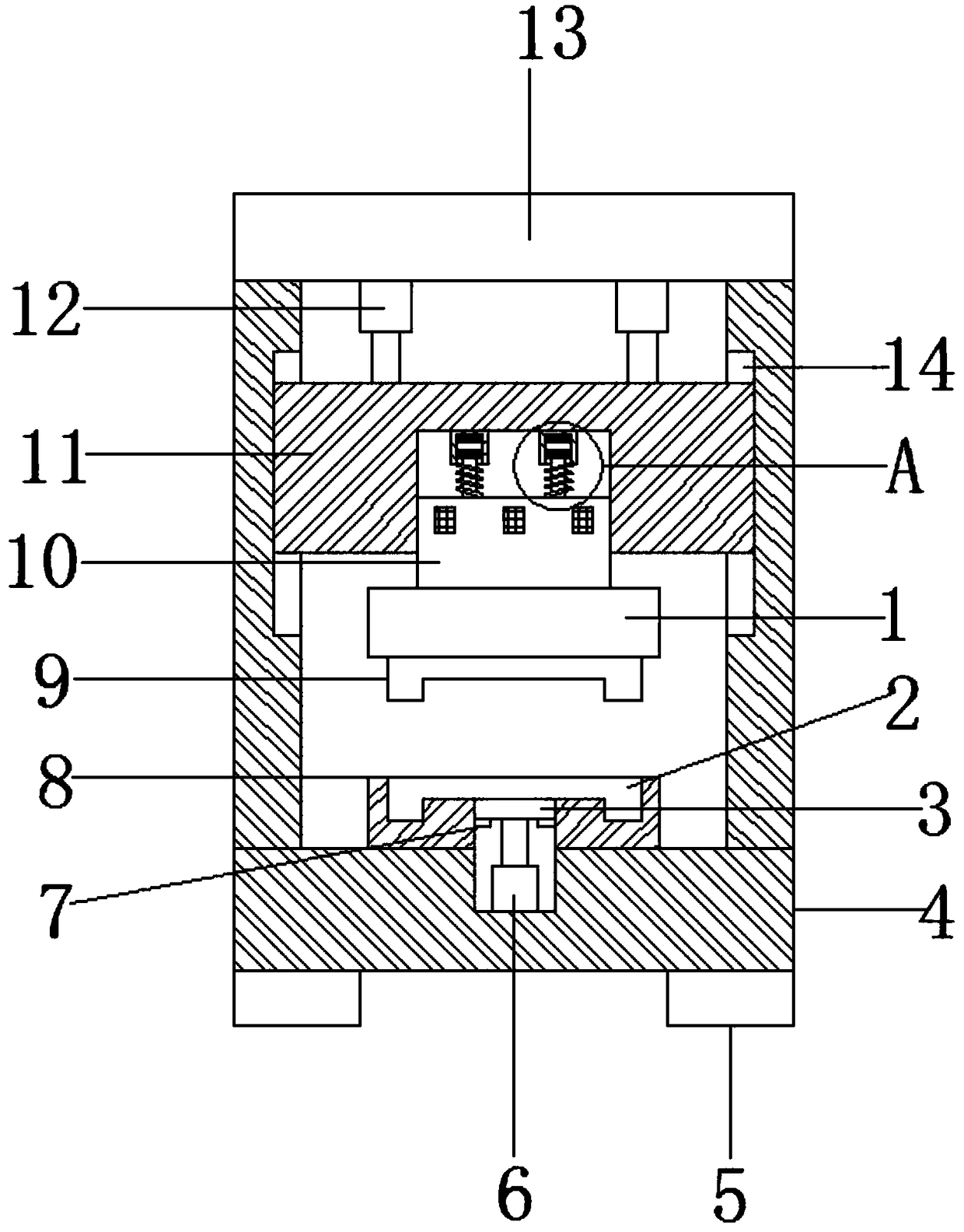

Movable disposable molding die with side wall

The invention discloses a movable disposable molding die with a side wall, which comprises a base. Support pads are welded at four corners of the bottom outer wall of the base, and a lower pressing plate is fixed on the top outer wall of the base through screws. A stamping groove is arranged on the top outer wall of the lower pressing plate. Vertically arranged support plates are welded on both sides of the top outer wall of the base, and top plates with same horizontal are welded on the top outer walls of the two support plates. Sliding slots are arranged at opposite sides of the outer wall of the two support plates, and the inner walls of the two support plates are slidingly connected with a same moving block. A groove is arranged at the bottom outer wall of the moving block, and the inner wall of the groove is slidingly connected with a slide block. An upper pressing plate is fixed at the bottom outer wall of the slide block through a screw. The movable disposable molding die with side wall plays a double buffer function, avoids the damage of the die caused by overpressure, improves the service life of the die, is convenient to carry out the material collection, saves the material collection time, and improves the production efficiency.

Owner:十堰市雄振汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com