Method for manufacturing silicon carbide high-temperature ion implantation mask with selectivity cut-off layer

A technology of high-temperature ion implantation and manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc. Good control and other issues to avoid contamination on the surface of the device, simplify the surface cleaning process, and achieve the effect of good blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

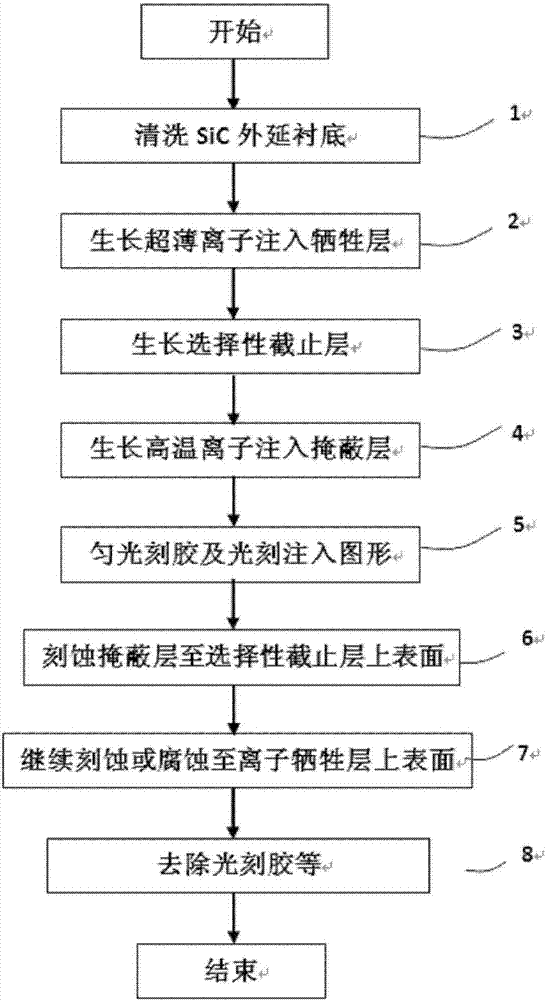

[0043] In order to understand the present invention in depth, the present invention will be described in detail below in conjunction with specific embodiments, a method for forming a silicon carbide high-temperature ion implantation mask with a selective cut-off layer on a silicon carbide (SiC) epitaxial substrate:

[0044] Step 1: Clean the silicon carbide substrate with standard RCA (3#, 1# each for 10 minutes), and clean it with N 2 Blow dry chips.

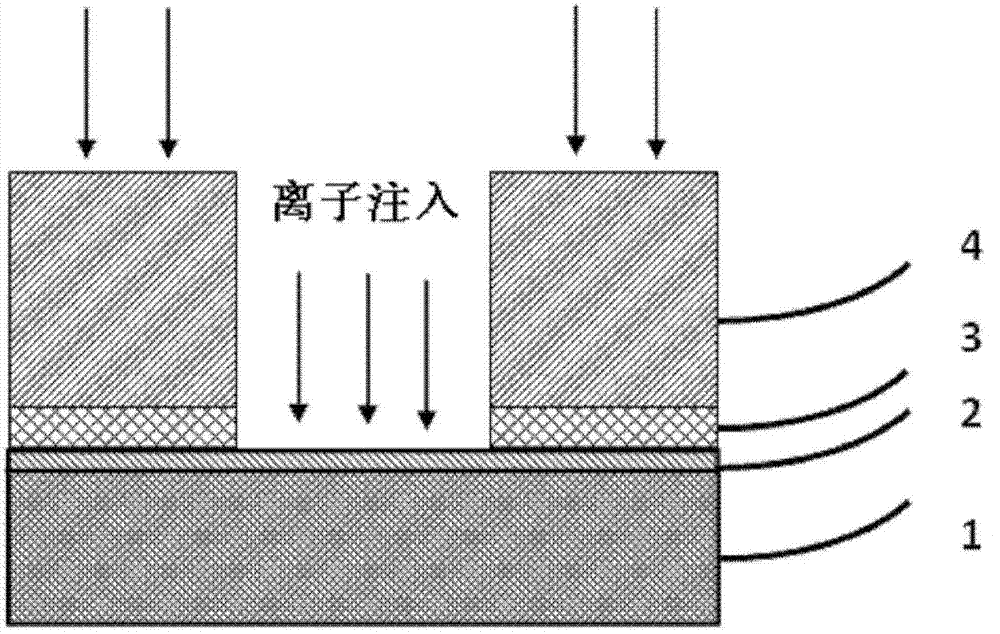

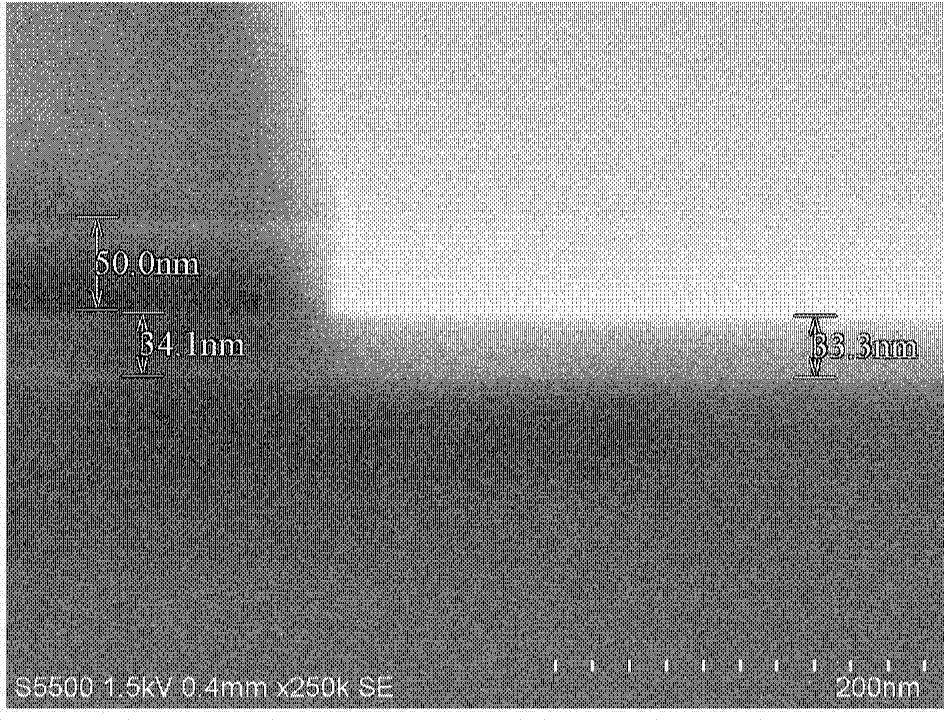

[0045] Step 2: On the clean silicon carbide substrate obtained in the previous step, grow a 20-30nm ion-implanted sacrificial layer film at 1150° C. for 90 minutes by using wet oxygen (hydrogen-oxygen ignition) method.

[0046] Step 3: growing a 500 angstrom amorphous silicon layer at 550° C. as a selective cut-off layer on the ion-implanted sacrificial layer film obtained in the previous step by LPCVD.

[0047] Step 4: On the basis of the previous step, use the PECVD growth method to grow 2μm SiO on the amorphous silicon laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com