Organic UV blocker-supported silica aerogel composite

A technology of silica and hydrophobic silica, which is applied in the direction of cosmetics, aerosol delivery, cosmetic preparations, etc., can solve problems such as the inability to reduce skin irritation, and achieve excellent ultraviolet blocking effect and excellent blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0075] Preparation Example 1: Preparation of Silica Airgel Composite

[0076] (1) Preparation of surface-modified hydrophobic silica airgel

[0077] The surface of powder-type hydrophobic silica airgel (RAGEL-P, average particle diameter 50 μm) manufactured by REM Tech. was modified to be hydrophilic using the following method.

[0078] Hydrophobic silica airgel (20 g) was added to a mixed solvent of distilled water (100 g) and ethanol (50 g) and mixed. The mixture was poured into a SUS plate and introduced into a furnace, followed by heating at 350 °C for 2 hours to modify the surface of the hydrophobic silica airgel to be hydrophilic.

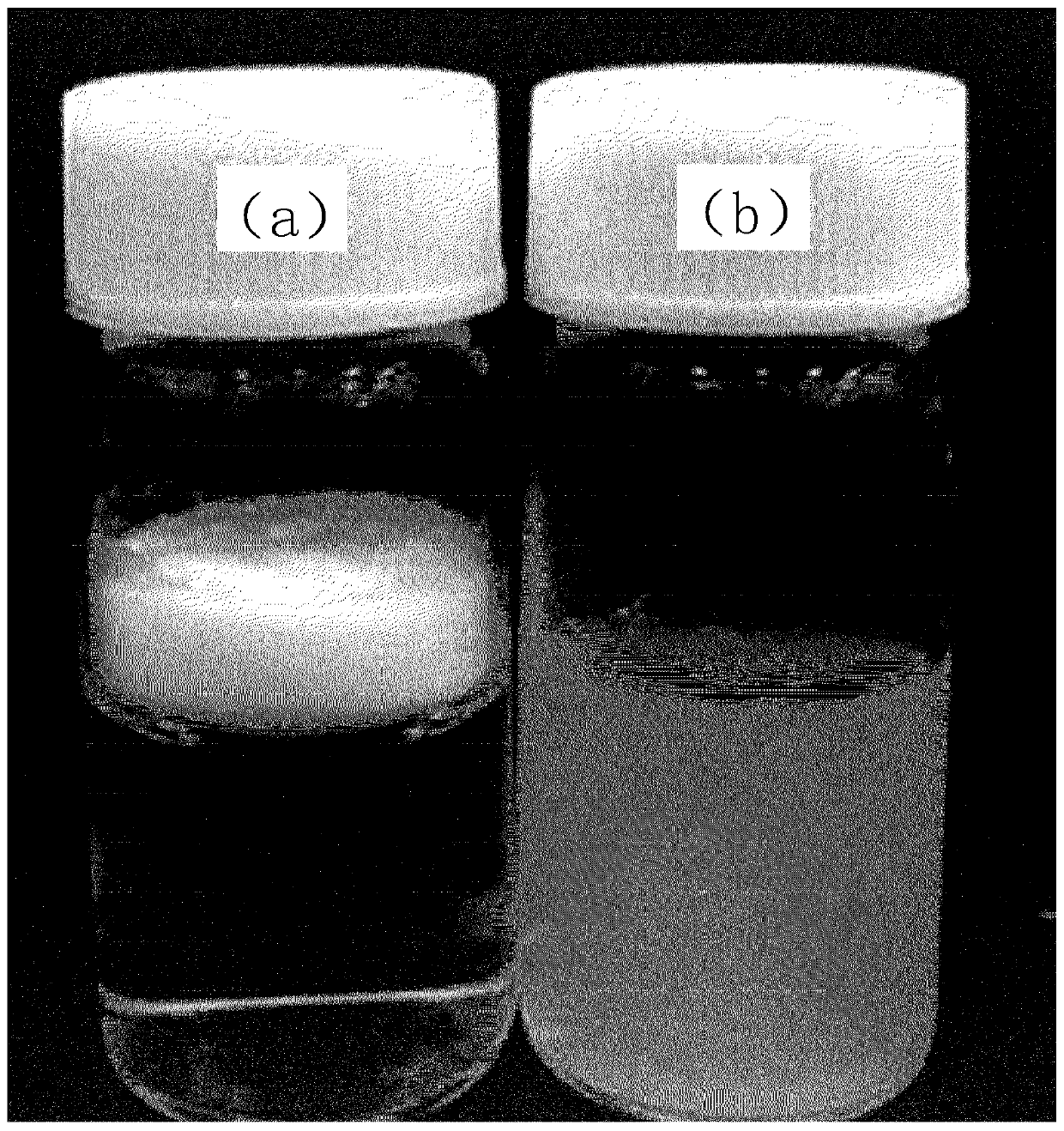

[0079] figure 1 It is a photograph comparing (a) dispersing airgel in distilled water before surface modification and (b) dispersing airgel in distilled water after surface modification. It can be confirmed that the hydrophobic silica airgel after surface modification is uniformly dispersed in water, while the hydrophobic silica airgel bef...

experiment example 1

[0084] Experimental example 1: Measurement of loading amount of organic ultraviolet blocking agent

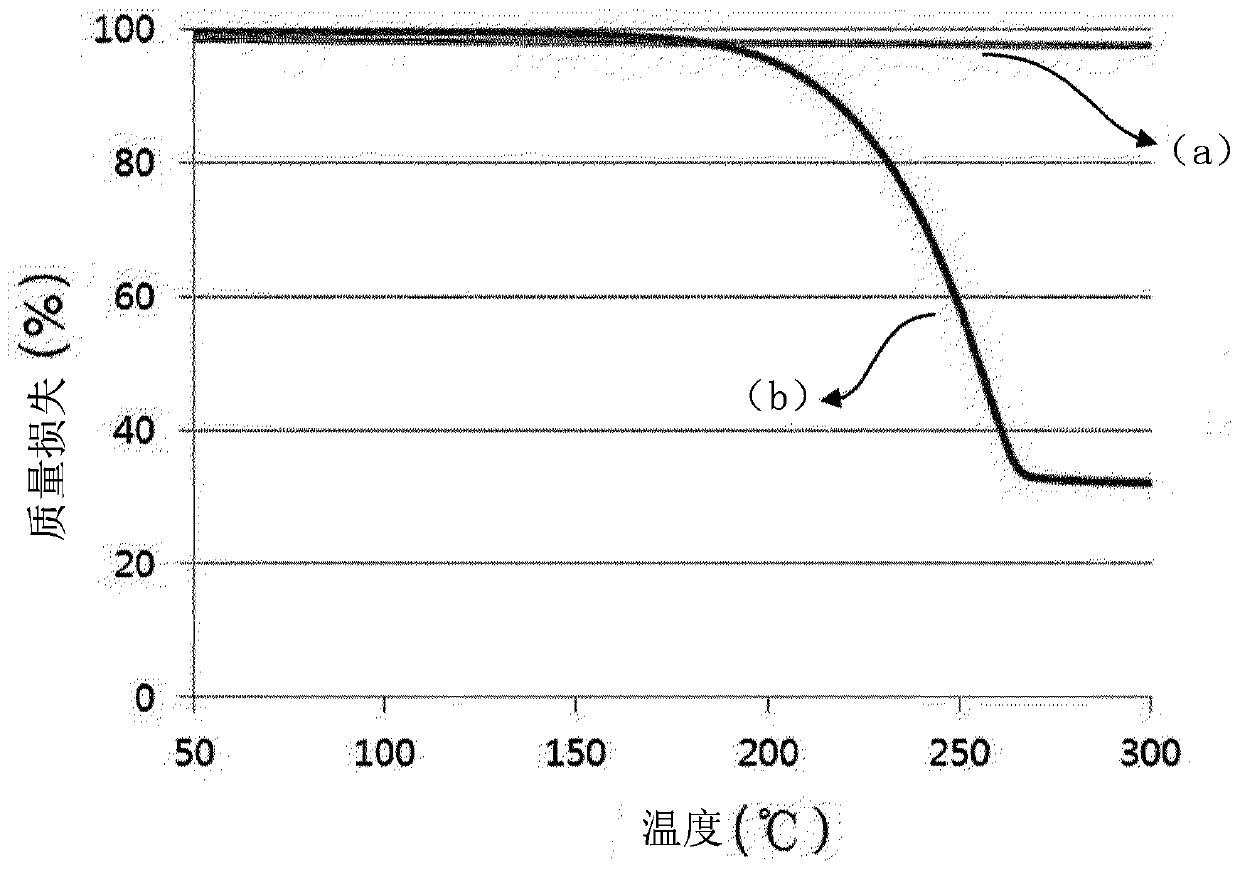

[0085] In order to determine the loading amount of the organic UV blocking agent in the silica airgel composite prepared in Preparation Example 1, a thermogravimetric analysis (TGA) was carried out using a thermal analyzer (Mettler-Toledo TGA / DSC 1), and the results Such as figure 2 shown.

[0086] refer to figure 2 , it can be confirmed that the silica airgel (a) before loading the organic ultraviolet blocking agent has no weight change, but the silica airgel composite (b) carrying the organic ultraviolet blocking agent has 66% mass loss. From this, it can be confirmed that the silica airgel composite of Preparation Example 1 carried the organic ultraviolet blocking agent therein, and the content was 66% by weight of the total weight of the composite.

preparation example 2

[0087] Preparation Example 2: Preparation of Cosmetic Composition for UV-blocking

[0088] (1) Preparation of Examples 1 to 3

[0089] The compositions (unit: weight %) in Table 1 below were used to prepare the ultraviolet blocking cosmetic compositions of Examples 1 to 3.

[0090] [Table 1]

[0091]

[0092] The water phase ingredients of A were mixed and heated at 80° C., and the thickener of B was introduced therein to prepare the water phase part. The oil phase ingredients of C were mixed and heated at 80°C to prepare an oil phase part. The oil phase part was added to the water phase part, and the resultant was stirred at 3000 rpm for 5 minutes using a homogenizer to prepare an oil-in-water type ultraviolet blocking cosmetic composition.

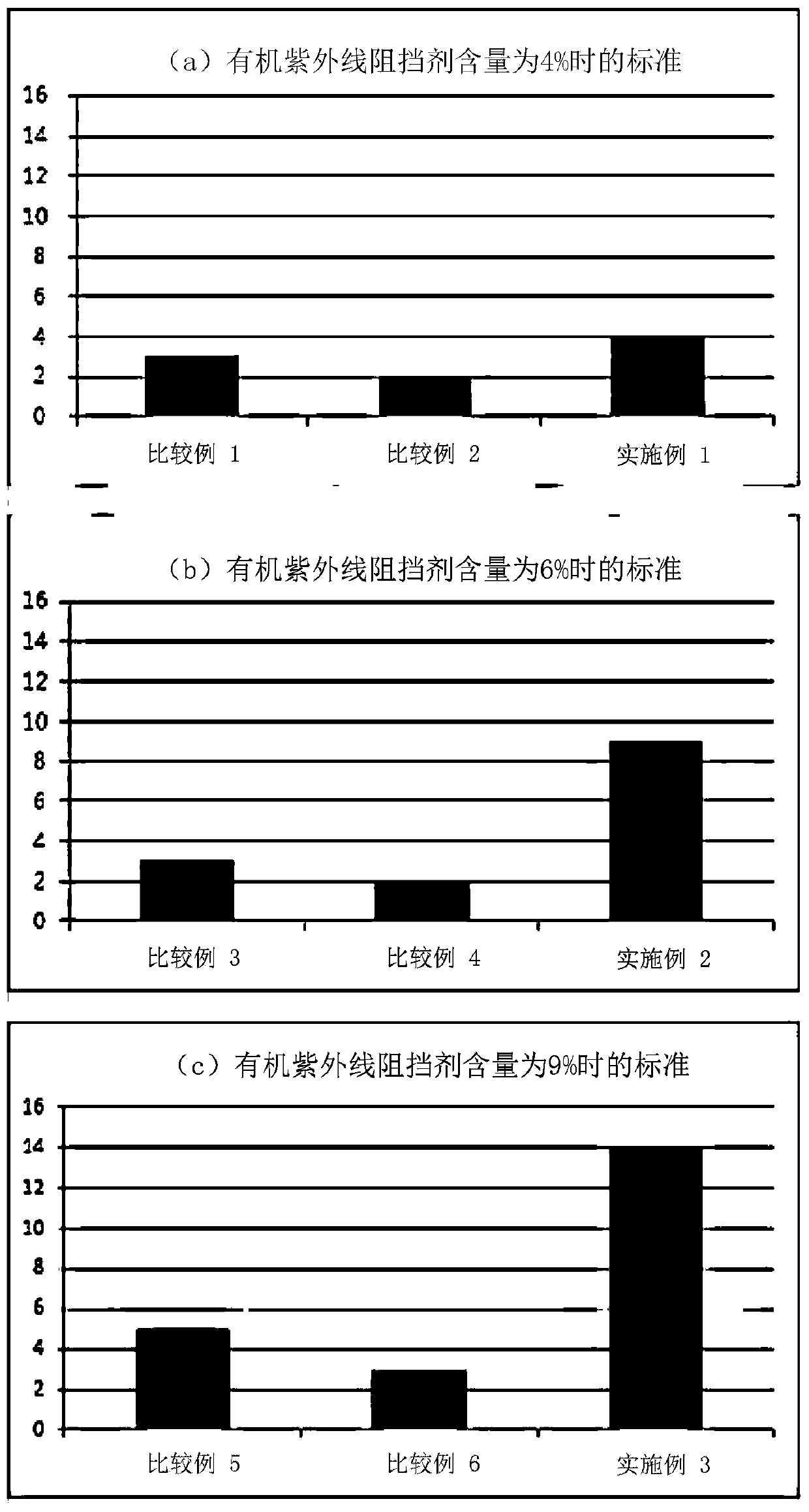

[0093] (2) Preparation of Comparative Examples 1 to 6

[0094] The composition (unit: weight %) of the following Tables 2 and 3 while only changing the type of ultraviolet blocking agent, the preparation method of Examples 1 to 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com