Anti-haze window screen fiber based on conductive macromolecules, and preparation method and application thereof

A conductive polymer and anti-smog technology, which is applied in the field of window screen fibers, can solve problems such as easy failure and quality degradation of window screens, and achieve excellent blocking effect, high elongation rate, and good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

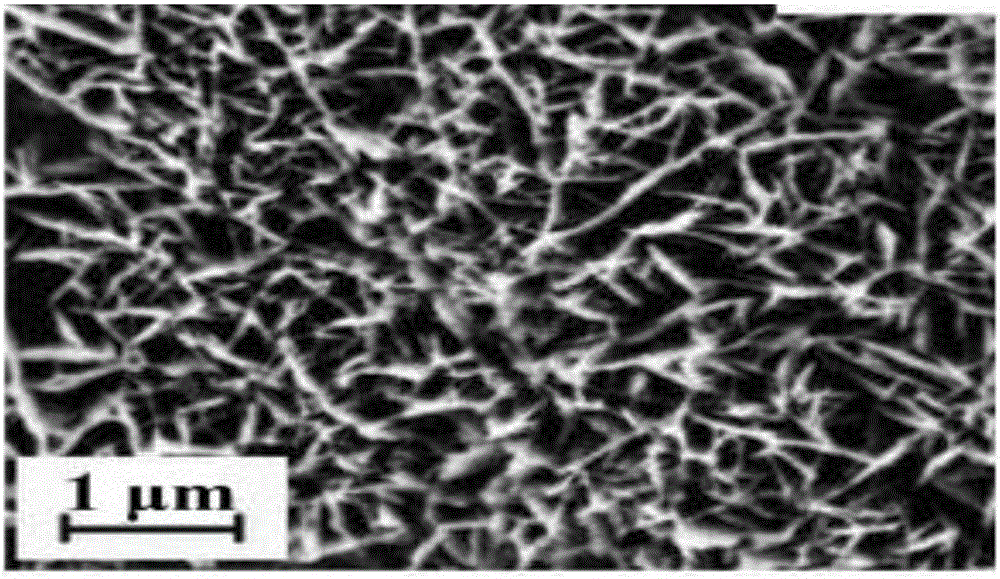

[0049] (1) Preparation of conductive polymer surface treatment agent based on conductive polymer PEDOT-PSS.

[0050]

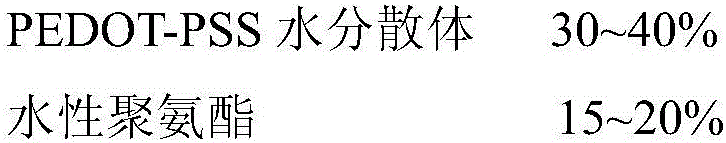

[0051] In percent by weight, the raw material consists of:

[0052]

[0053] Add 100mL of deionized water and 1.30g of PSS-Na (sodium polystyrene sulfonate) into a three-neck round bottom flask, stir rapidly at room temperature to fully disperse it. Add 0.26g of EDOT (3,4-ethylenedioxythiophene) dropwise with a micro-injection pump. After the dropwise addition, stir rapidly for about 5 minutes. Then add 0.60g (NH 4 ) 2 S 2 o 8 , add 0.05g of ferric sulfate under rapid stirring, continue to stir for 5min, adjust the pH of the reaction solution with 10% dilute hydrochloric acid to keep it at about 2, and the reaction solution gradually turns blue ink. After continuing to react for 20 h, a dark blue PEDOT-PSS aqueous dispersion was obtained as a raw material for the next step.

[0054] Add a certain amount of PEDOT-PSS aqueous dispersion into the cont...

Embodiment 2~7

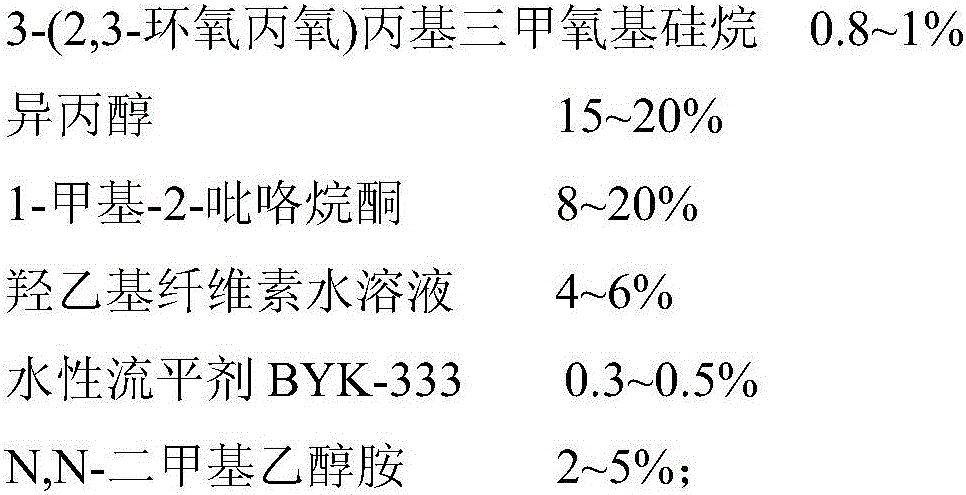

[0066] The proportions of each component were changed, and the rest of the method was the same as in Example 1. The influence of the anti-smog effect of window screen fibers made of conductive polymer surface treatment agents of different proportions was investigated. The specific proportions are shown in Table 2.

[0067] Table 2

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com