Cryogenic treatment method of tungsten-titanium alloy

A tungsten-titanium alloy, cryogenic treatment technology, applied in the field of cryogenic treatment of metal materials, can solve problems such as difficulty in rolling and forging, and achieve the effects of reducing grain growth, good mechanical properties, and low cooling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

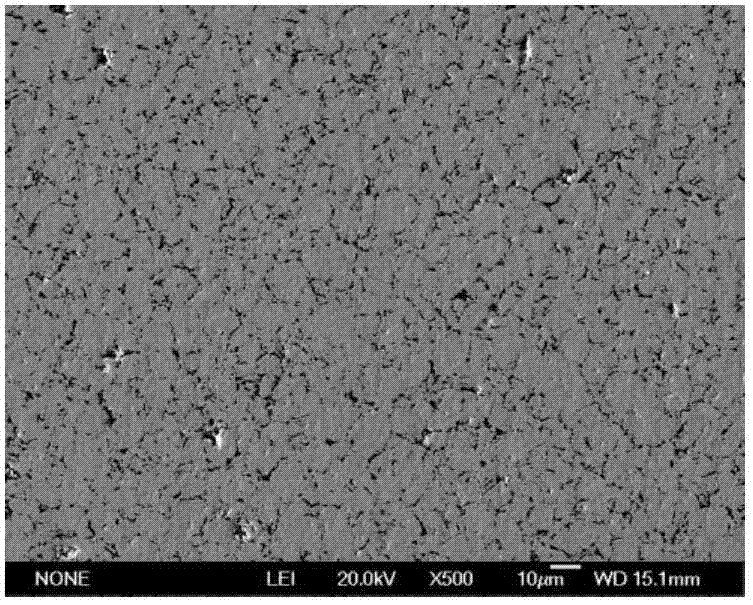

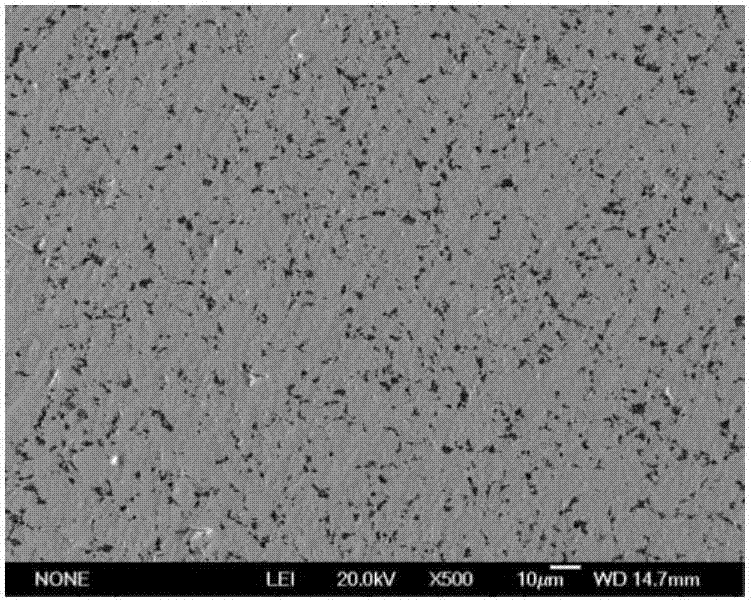

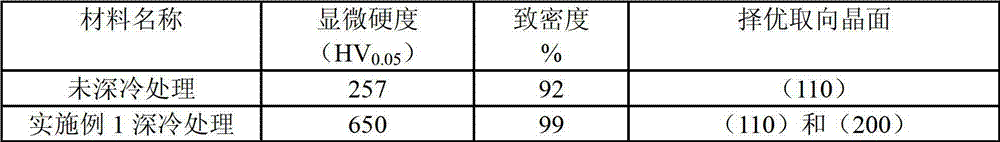

Embodiment 1

[0024] Step 1: Grind the tungsten-titanium alloy with fine sandpaper to remove scale and wire cutting marks, then rinse the surface residue with running water, and then use ultrasonic waves and alcohol to further clean the residue and moisture on the surface of the tungsten-titanium alloy;

[0025] Step 2, place the tungsten-titanium alloy cleaned in step 1 on the sample rack of the cryogenic treatment equipment, open the valve of the self-pressurized low-temperature fluid delivery device equipped with liquid nitrogen, and use the gas spray method to treat the alloy. The parameters are: the cooling rate is 15°C / min, the holding temperature is -196°C, and the holding time is 2h. After processing, cut off the power, turn off the cold source, take out the tungsten-titanium alloy and put it in a water bath at 25°C at a rate of 220°C / s. warm up.

[0026] Then, the above step 1 and step 2 are repeated, and the cryogenically treated tungsten-titanium alloy is subjected to a second cr...

Embodiment 2

[0028] Step 1: Grind the tungsten-titanium alloy with fine sandpaper to remove scale and wire cutting marks, then rinse the surface residue with running water, and then use ultrasonic waves and alcohol to further clean the residue and moisture on the surface of the tungsten-titanium alloy;

[0029] Step 2, place the tungsten-titanium alloy cleaned in step 1 on the sample rack of the cryogenic treatment equipment, open the valve of the self-pressurized low-temperature fluid delivery device equipped with liquid nitrogen, and use the gas spray method to treat the alloy. The parameters are: the cooling rate is 8°C / min, the holding temperature is -150°C, and the holding time is 4h. After treatment, cut off the power, turn off the cold source, take out the tungsten-titanium alloy and put it in a water bath at 15°C at a rate of 180°C / s. warm up.

[0030] Then, the above step 1 and step 2 are repeated, and the cryogenically treated tungsten-titanium alloy is subjected to a second cryo...

Embodiment 3

[0032] Step 1: Grind the tungsten-titanium alloy with fine sandpaper to remove scale and wire cutting marks, then rinse the surface residue with running water, and then use ultrasonic waves and alcohol to further clean the residue and moisture on the surface of the tungsten-titanium alloy;

[0033] Step 2, place the tungsten-titanium alloy cleaned in step 1 on the sample rack of the cryogenic treatment equipment, open the valve of the self-pressurized low-temperature fluid delivery device equipped with liquid nitrogen, and use the gas spray method to treat the alloy. The parameters are: the cooling rate is 13°C / min, the holding temperature is -175°C, and the holding time is 24h. After the treatment, the power is cut off, the cold source is turned off, and the tungsten-titanium alloy is taken out of the cryogenic treatment equipment with a clamp and placed in a water bath at 20°C. Rapid temperature recovery at a rate of 200°C / s, that is, a cryogenically treated tungsten-titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com