Feedback type oscillating jet stream refrigerating machine

An oscillating jet and feedback technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of reduced pressure resistance and complex structure of the machine, and achieve improved refrigeration efficiency, high operating efficiency, and low refrigeration temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] A typical implementation of the feedback type oscillating jet refrigerator of the present invention is as follows:

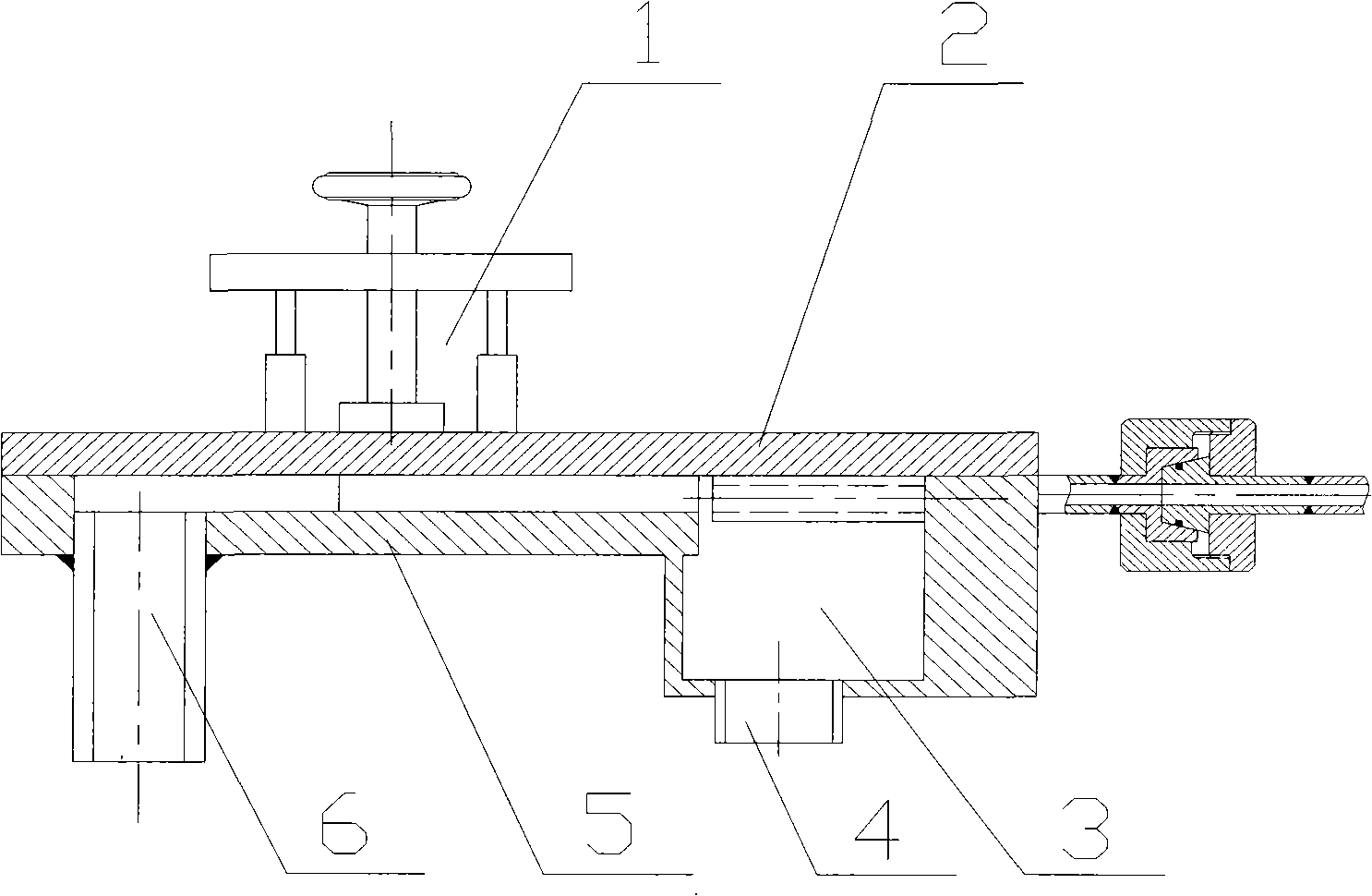

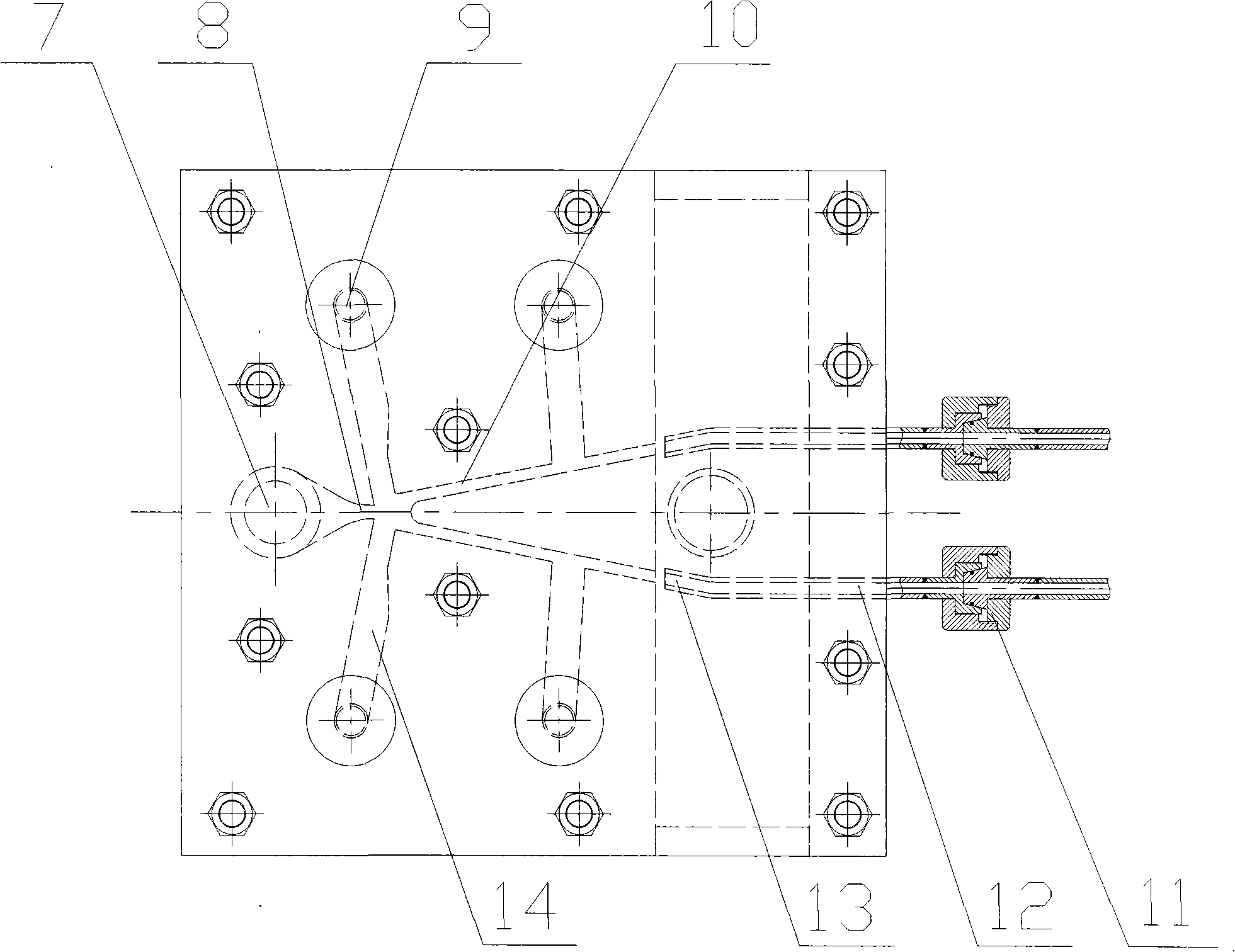

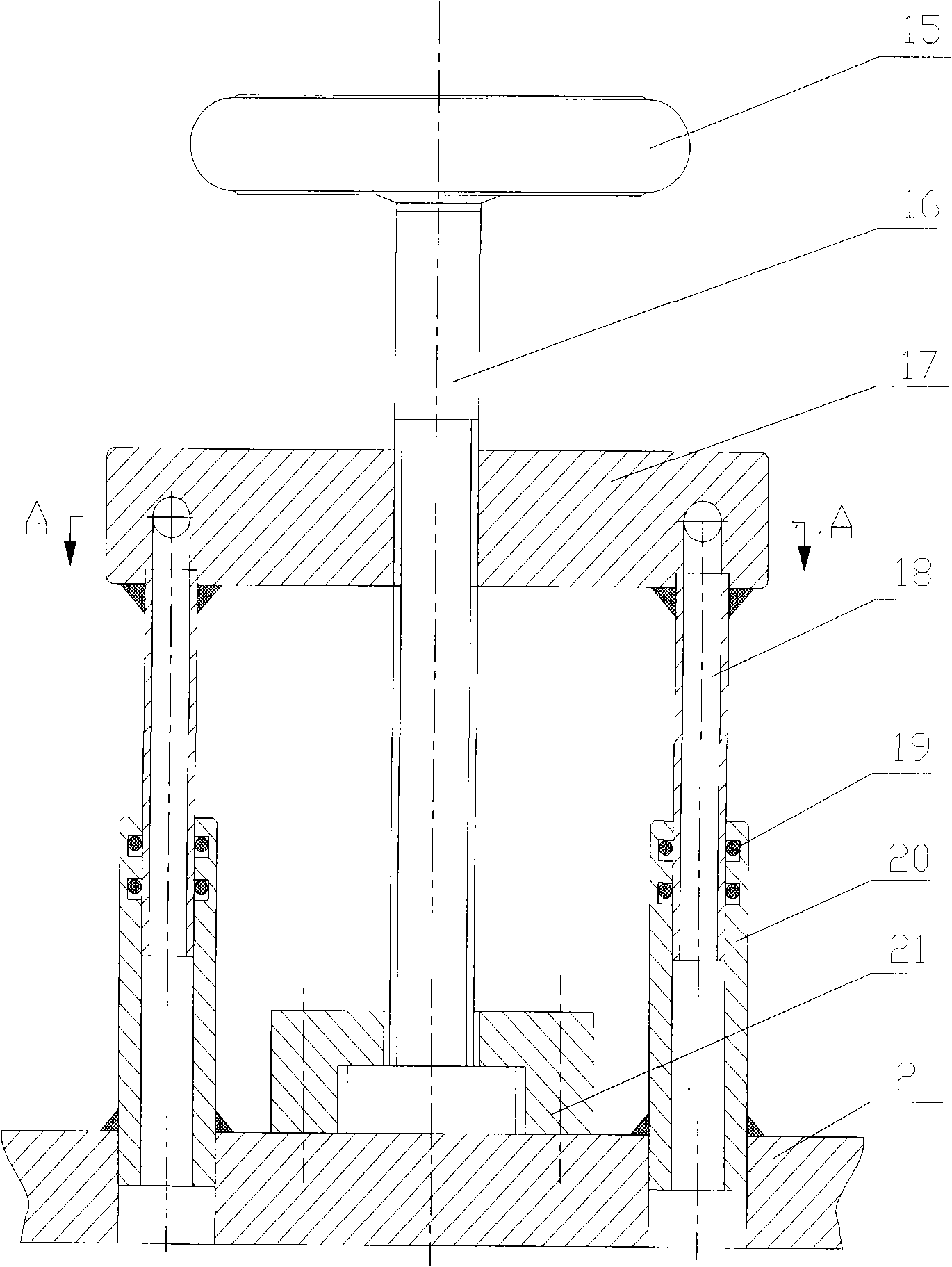

[0034]The feedback type oscillating jet refrigerator is mainly composed of the adjusting mechanism 1, the upper cover 2, the outlet cavity 3, the cold air outlet 4, the body 5, the inlet pipe 6, the inlet cavity 7, the jet nozzle flow channel 8, the upper cover opening 9, and the branch flow The channel 10, the pipe joint 11, the receiving tube 12, the receiving tube inlet 13 and the compression wave feedback channel 14 are composed. It is characterized in that the whole machine is completely static and adopts the structure of the feedback type oscillating jet generator and the receiving tube 12. The length of the middle section of the compression wave feedback channel 14 is changed by the adjustment mechanism 1, thereby changing the wall switching frequency of the jet. The compression wave feedback channel 14 is processed into two sections on the body, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com