Double-layer plastic film composite tape and manufacturing method thereof

A technology of plastic film and plastic film, which is applied in the field of communication materials, can solve the problems of poor corrosion resistance, short service life, and inability to fully guarantee the bonding strength of plastic film, metal foil, and tape, etc., to achieve improved mechanical properties and good Good effect of blocking effect and self-adhesive performance of vertical lap joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

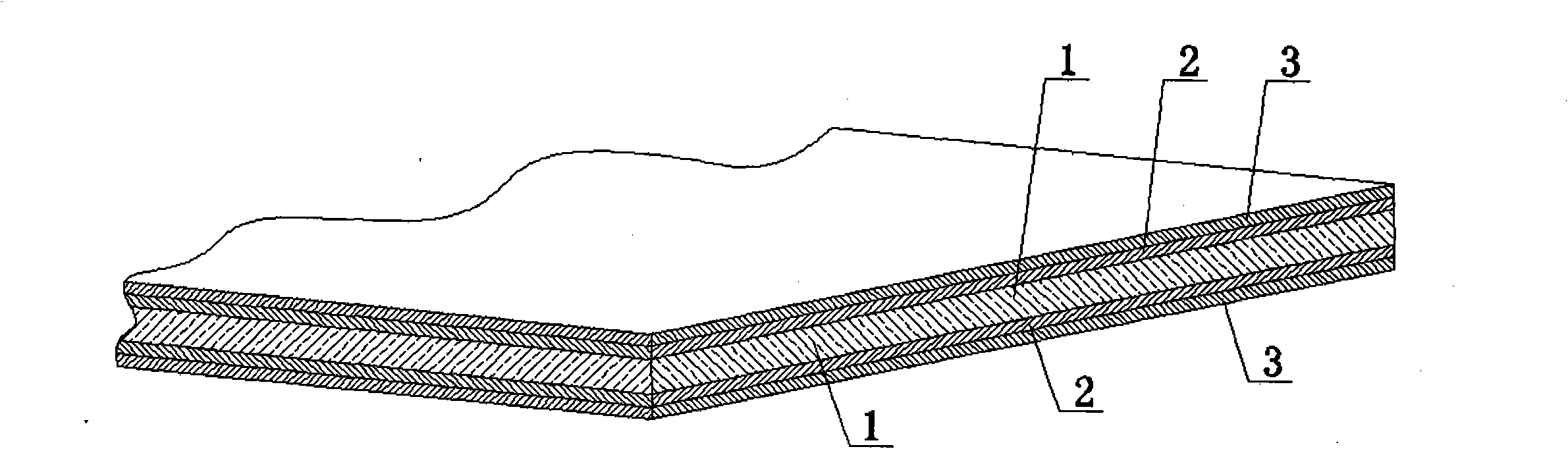

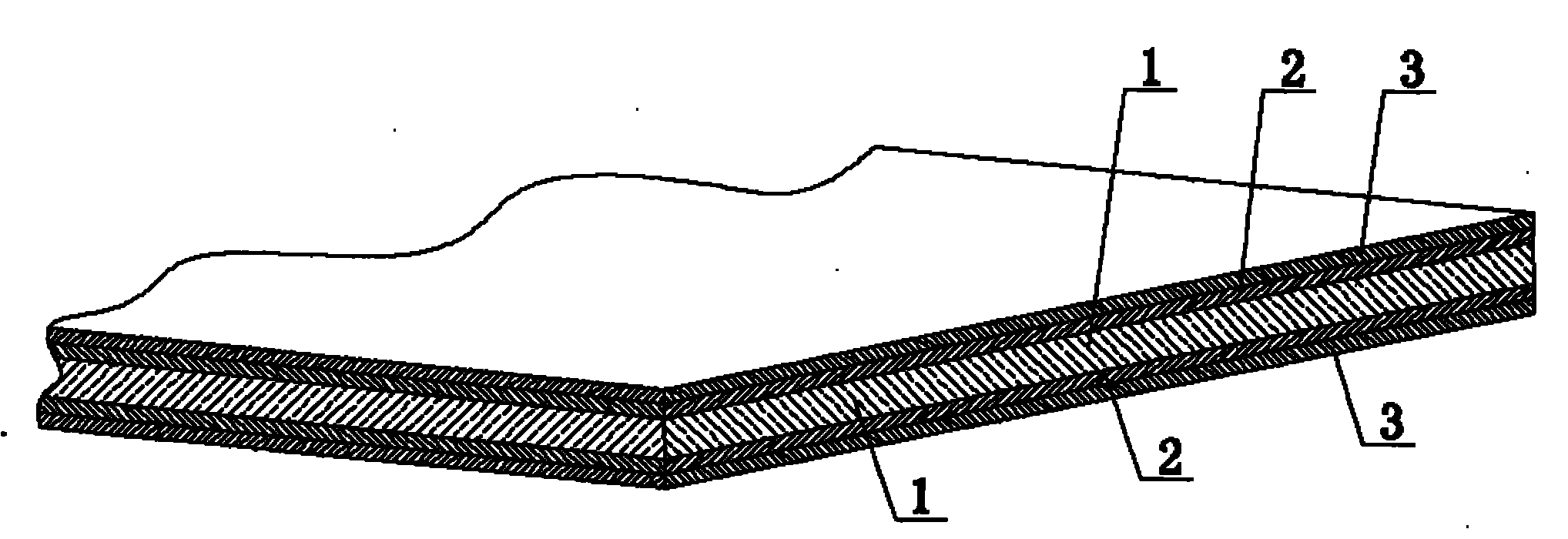

[0019] Embodiment 1: as figure 1 Shown, a kind of double-layer plastic film composite tape, it comprises strip-shaped metal foil 1, the inner layer plastic film 2 of 0.025mm thickness and the outer layer plastic film 3 of 0.025mm thickness are composited on the outer surface of metal foil. The inner plastic film 2 and the outer plastic film 3 all adopt polyethylene plastic film.

Embodiment 2

[0020] Embodiment 2: a kind of preparation method of double-layer plastic film composite tape, it comprises the following steps successively: (1) strip-shaped metal foil is preheated through preheating zone and hot drum heating zone before compounding, and metal foil surface temperature reaches 120°C; (2) Extrude and compound the inner plastic film on the two surfaces of the strip-shaped metal foil through two horizontal rubber rollers; (3) After compounding, the heating zone is cured to make the surface temperature of the inner plastic film reach 60° C.; (4) Extrude and compound the outer layer of plastic film to the two surfaces of the inner layer of plastic film through two horizontal rubber rollers.

Embodiment 3

[0021] Embodiment 3: a kind of preparation method of double-layer plastic film compound tape, it comprises the following steps successively: (1) strip-shaped metal foil is passed through the preheating of heating zone before compounding and hot drum heating zone, makes metal foil surface temperature reach 130°C; (2) Extrude and compound the inner plastic film on the two surfaces of the strip-shaped metal foil through two horizontal rubber rollers; (3) After compounding, the heating zone is cured to make the surface temperature of the inner plastic film reach 65° C.; (4) extrude and compound the outer layer of plastic film to the two surfaces of the inner layer of plastic film through two horizontal rubber rollers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com