Patents

Literature

789results about How to "Wrinkle free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

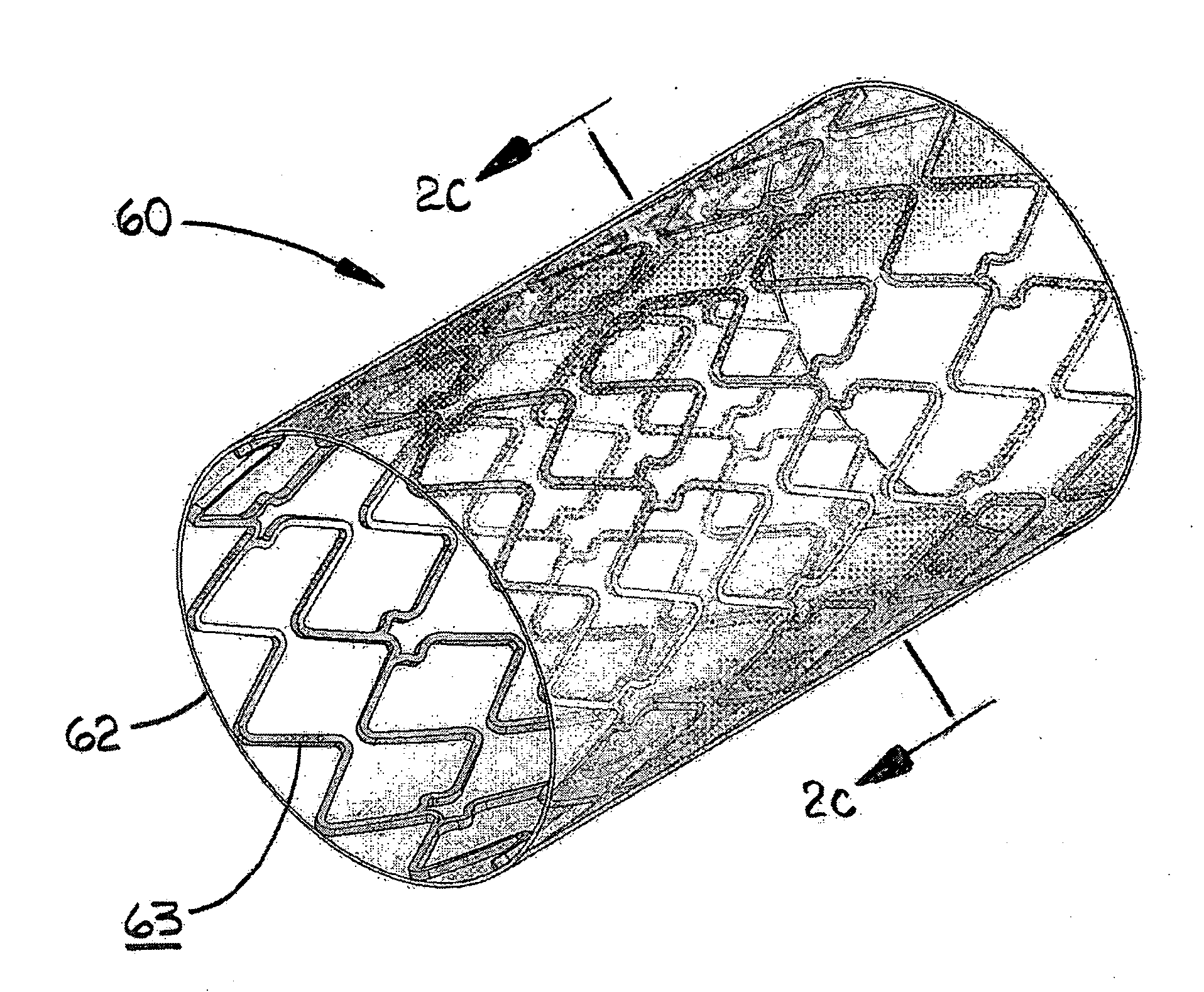

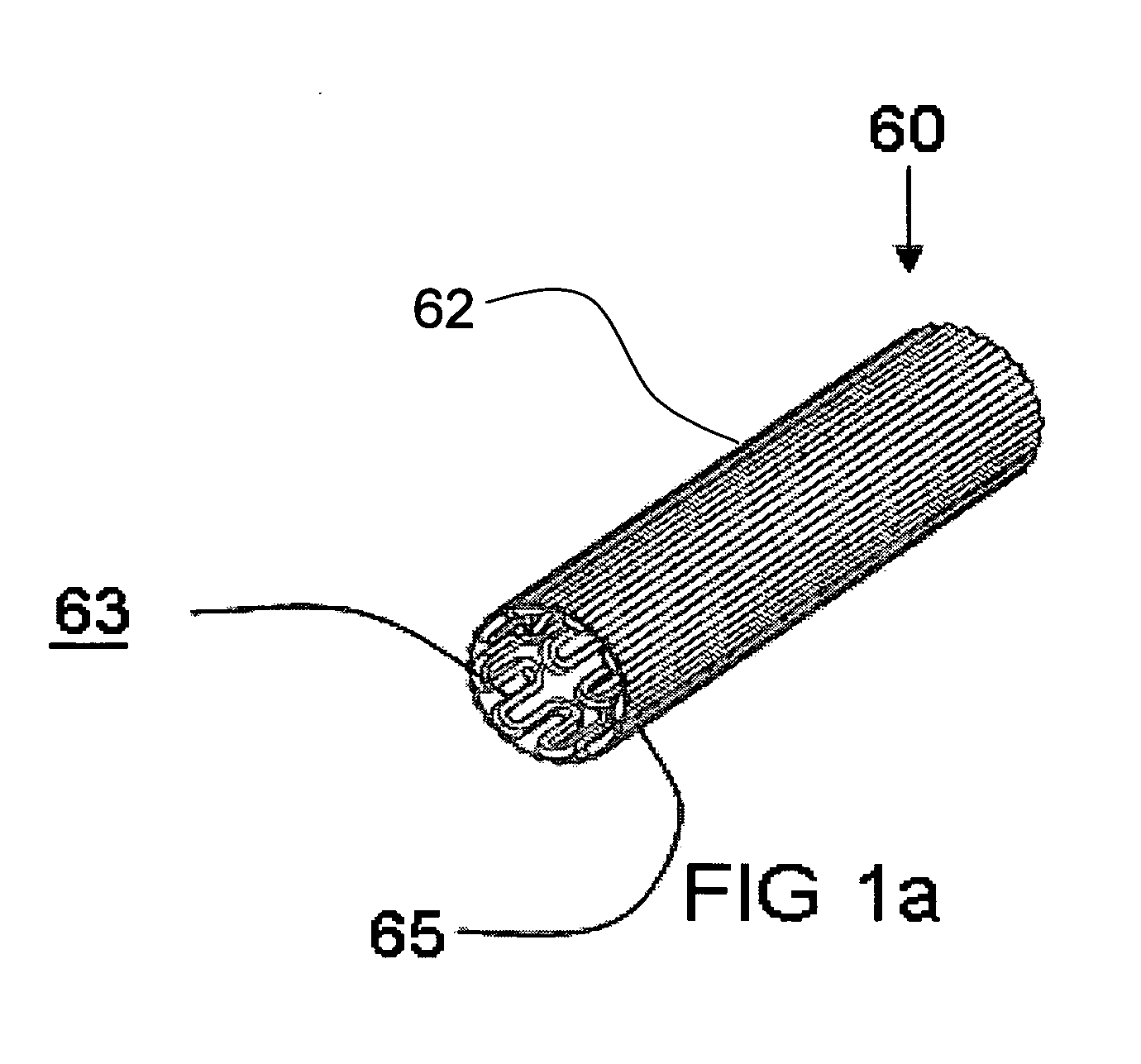

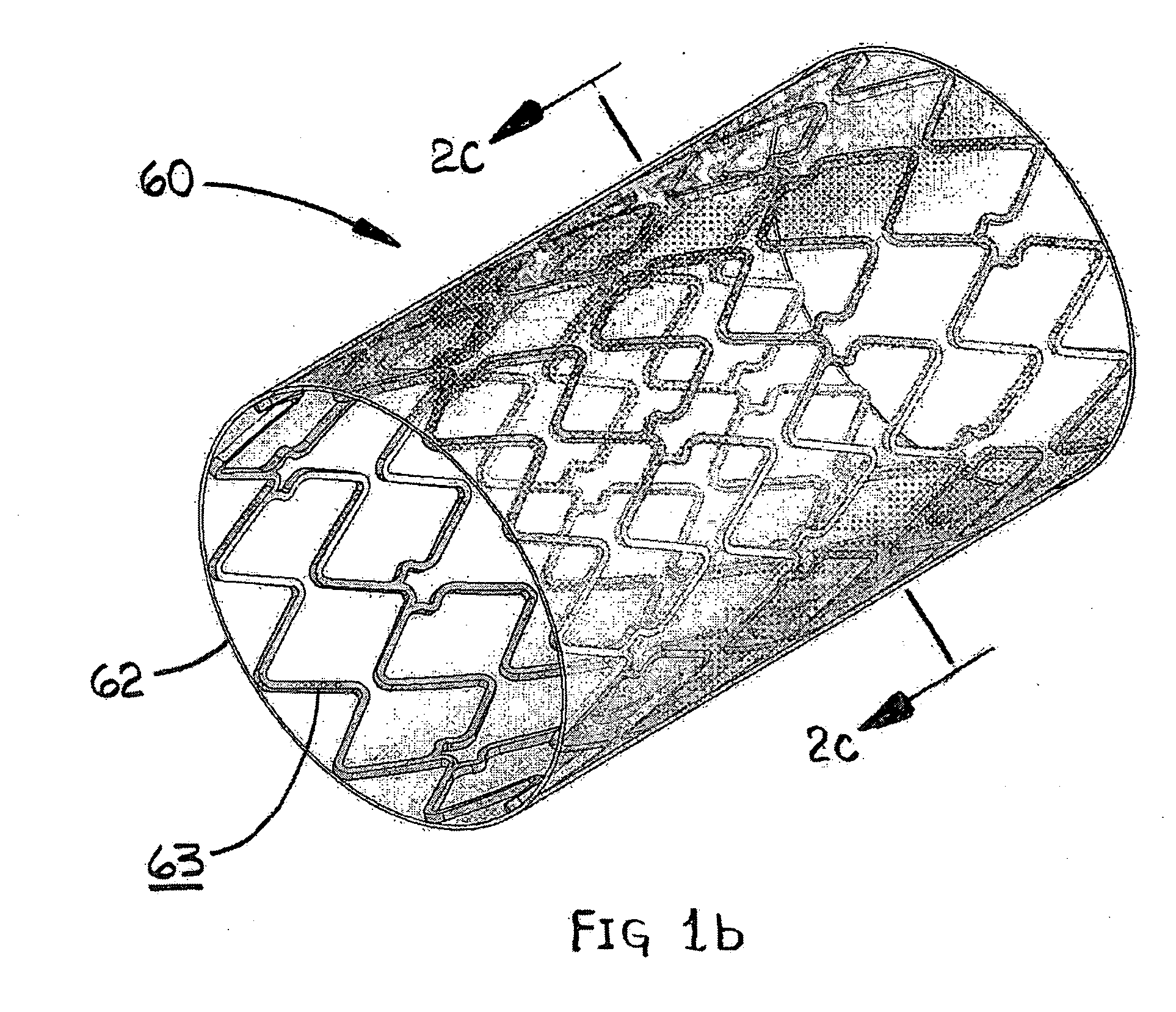

Expandable stent with wrinkle-free elastomeric cover

An improved stent-graft device is provided that delivers a smooth flow surface over a range of operative expanded diameters by applying a unique cover material to the stent through a technique that allows the cover to become wrinkle-free prior to reaching fully deployed diameter. The unique cover material then allows the device to continue to expand to a fully deployed diameter while maintaining a smooth and coherent flow surface throughout this additional expansion. Employed with a self-expanding device, when the device is unconstrained from a compacted diameter it will self-expand up to a fully deployed diameter with the graft being substantially wrinkle-free over diameters ranging from about 30-50% to 100% of the fully deployed diameter. Preferably, the graft component comprises an elastomeric material, such as silicone, polyurethane, or a copolymer of PAVE-TFE.

Owner:WL GORE & ASSOC INC

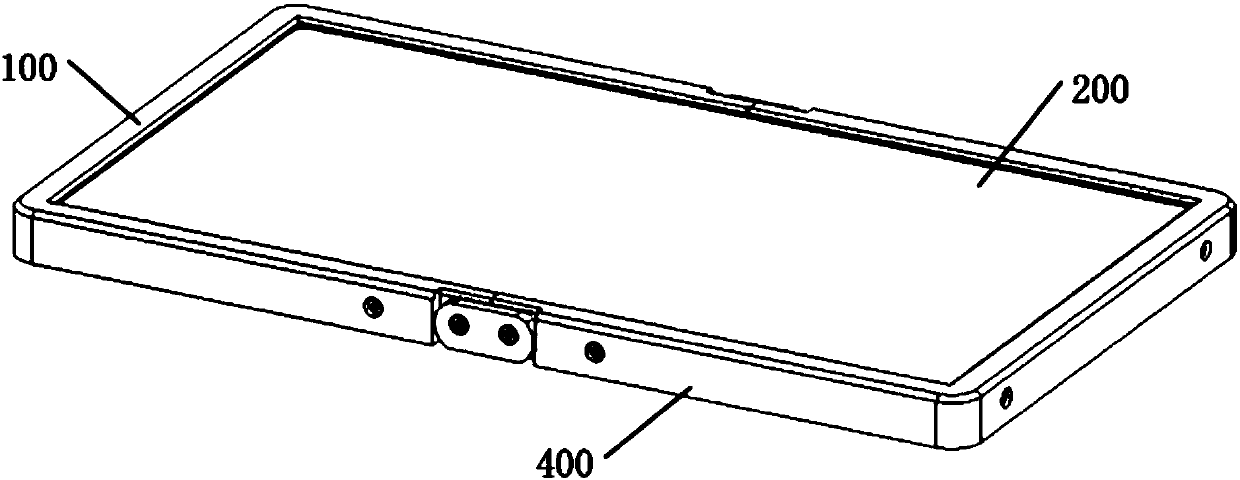

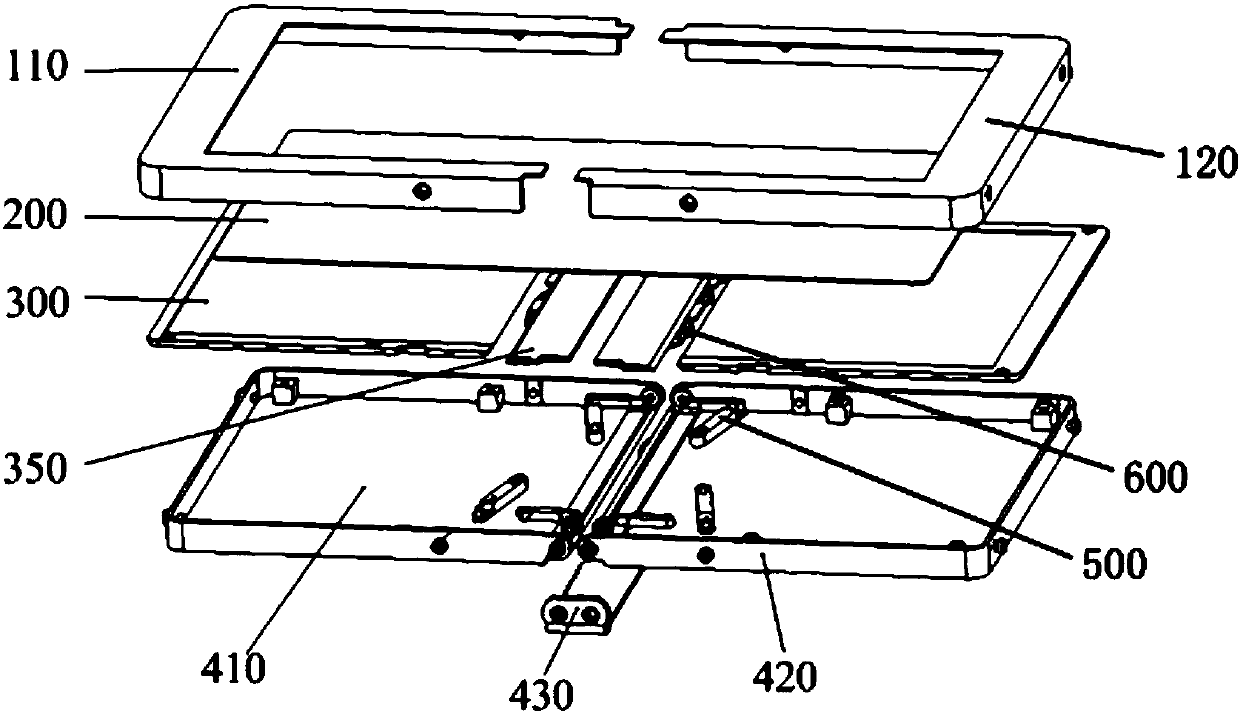

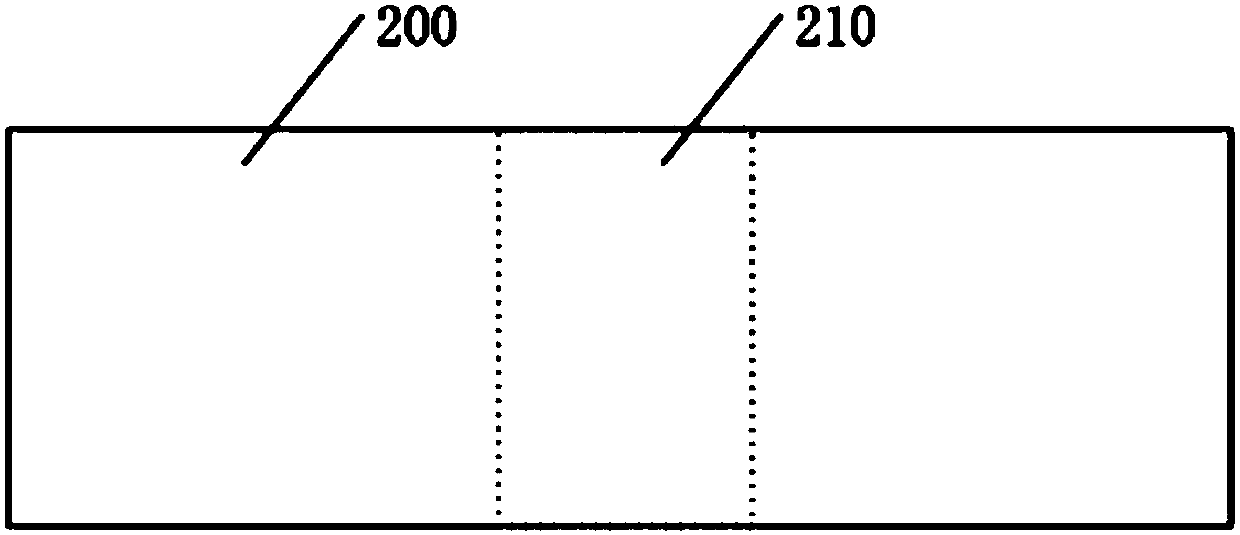

Foldable display device

The invention provides a foldable display device which comprises a shell, a middle frame, a display panel and a surface frame. The shell comprises a shell bending device, the middle frame is mounted to the shell, the middle frame comprises a middle frame bending device opposite to the shell bending device, the display panel is mounted to the middle frame and comprises a panel bending area oppositeto the middle frame bending device, the surface frame is mounted to the shell, and the display panel is clamped into an opening. When the display panel is bent, the middle frame bending device and the shell form a cavity, and the panel bending area is bent and then placed into the cavity.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

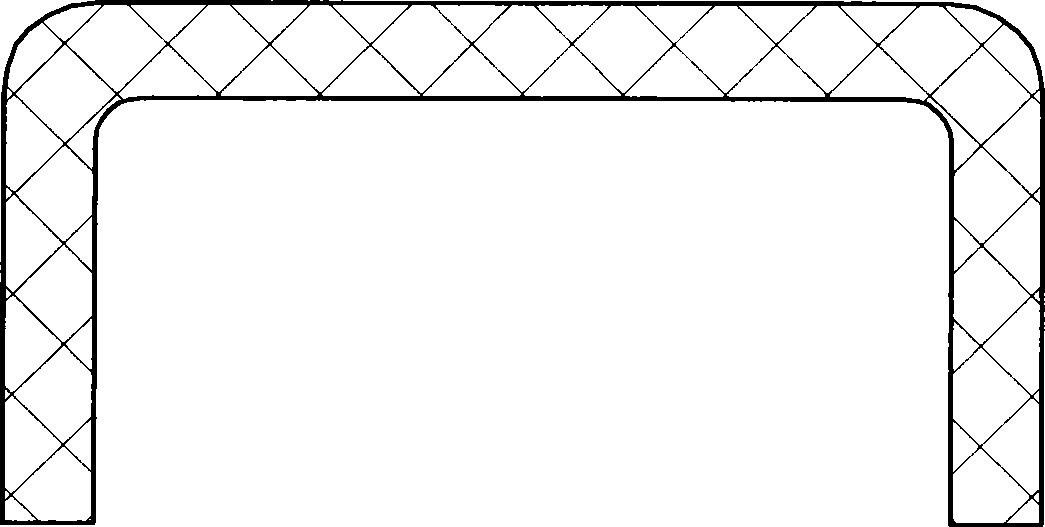

Curing formation method for non-flat plate composite product and shaping mould

The invention discloses a curing forming method and a forming die used for a non-slab composite material part. The method comprises the steps as follows: composite material part blank is arranged on a rigid die body which has the same shape with the processing shape and gluing and layer-paving are carried out according to the required dimension; after the layer-paving is finished, the composite material part blank is arranged on the rigid die body; furthermore, surfaces with plane are provided with elastic soft layers; corner pure rubber layers which are connected with elastic soft layer joint seams are arranged at corner profile so as to form a soft die surface; subsequently, vacuum bag auxiliary material is arranged on the soft die surface so as to prepare the vacuum bag curing forming composite material part. By the flexible soft die consisting of rubber-fabrics, the method arranges the composite material part blank on the surface of the soft die after the layer-paving is finished; the method for preparing the vacuum bag curing forming part solves the surface quality problems in the prior art that the non-die surface of the bag-pressing forming composite material part is crapy, accidented and has no gloss and the like, and improves the working efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

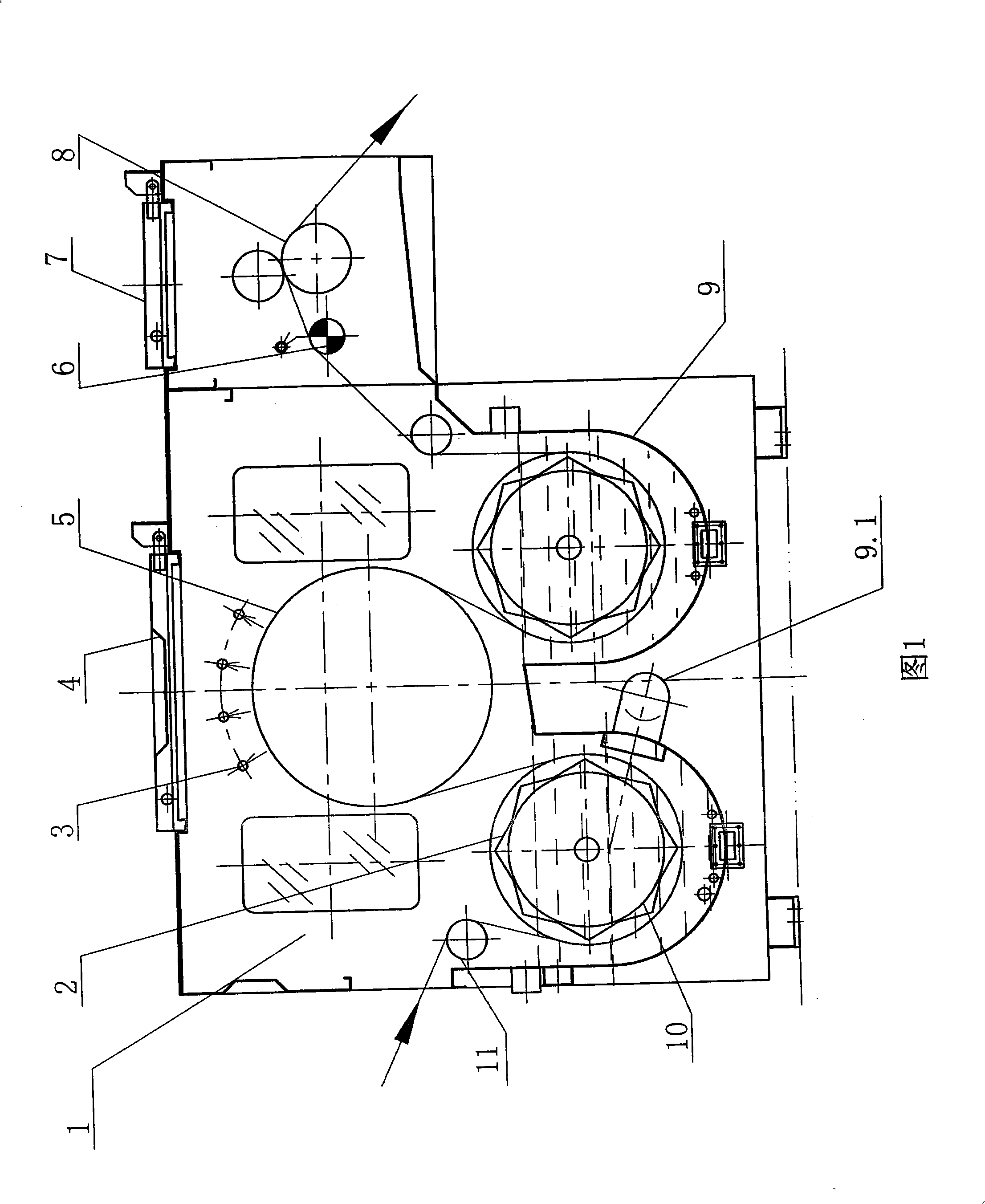

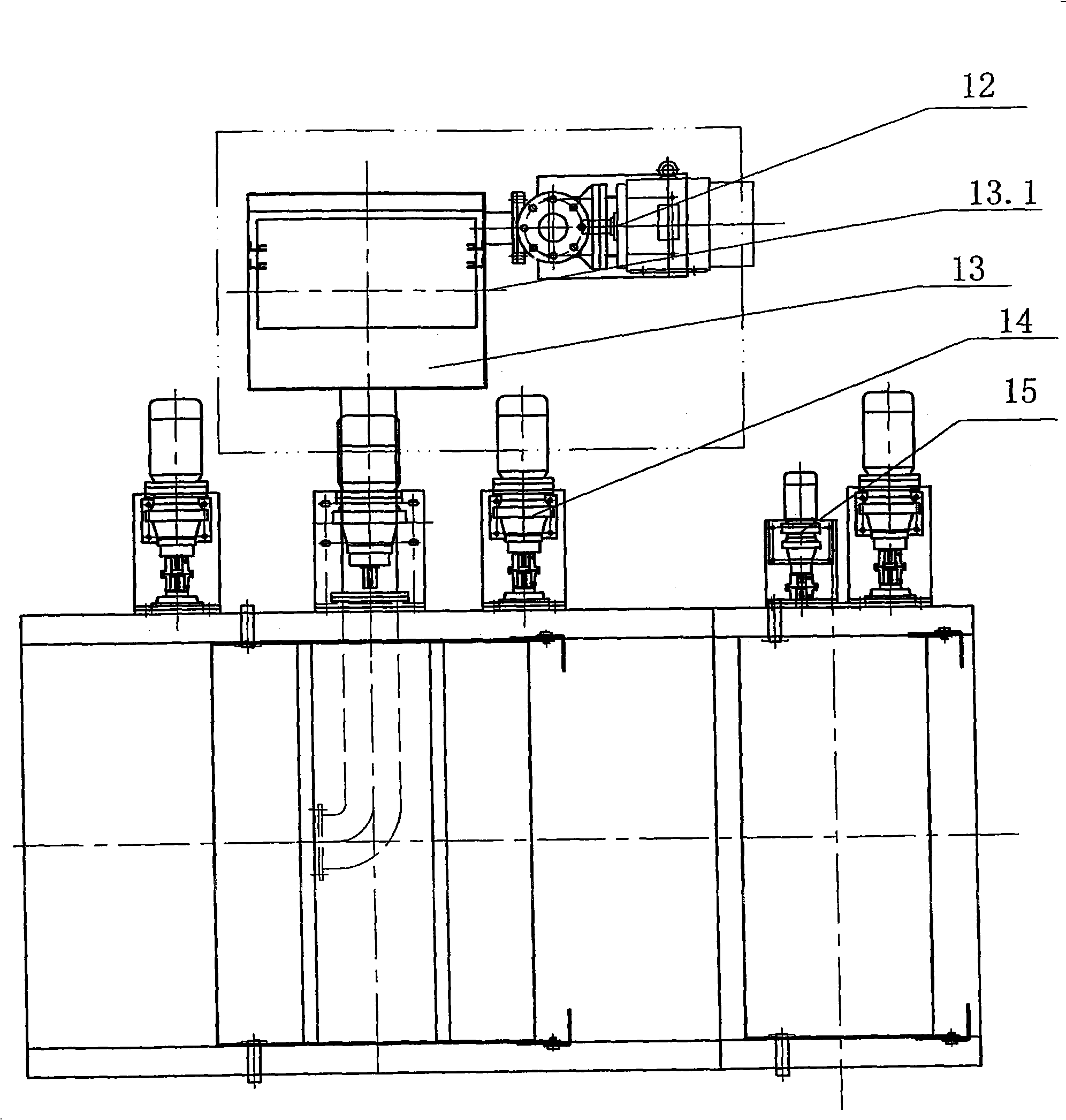

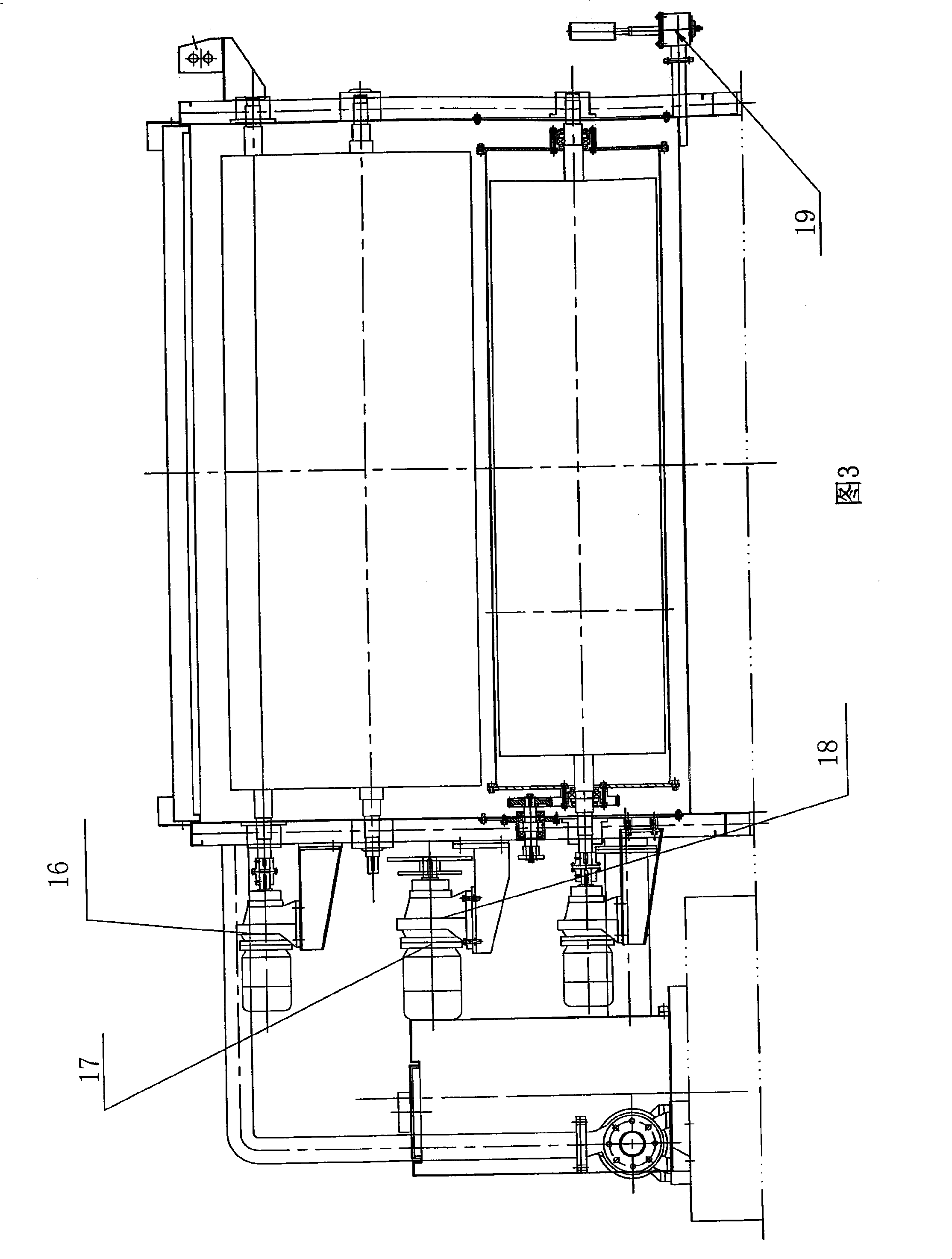

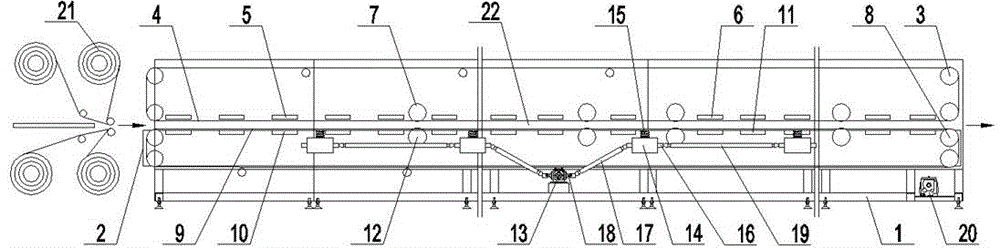

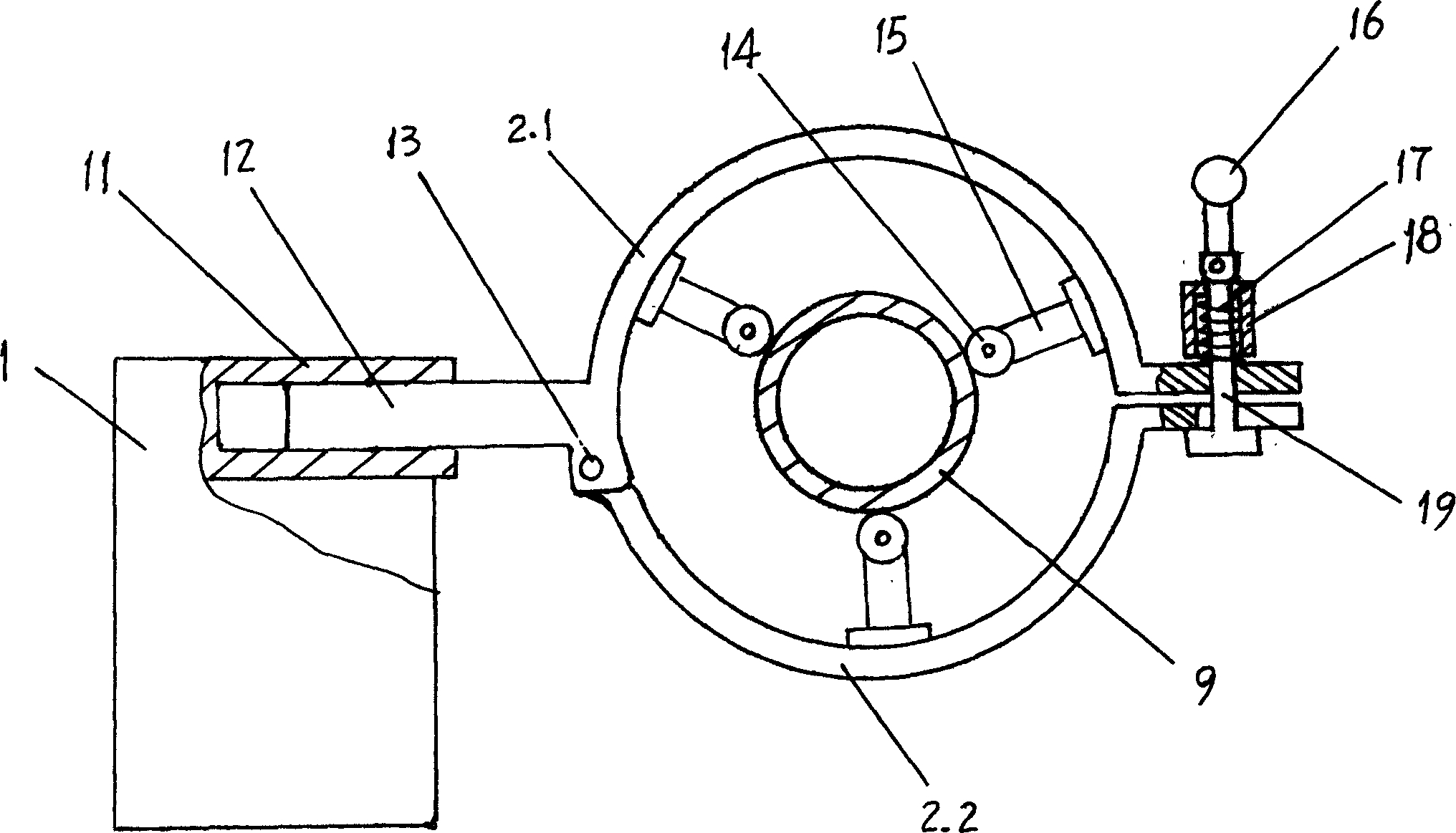

Novel double oscillation tumbling barrel scouring machine

InactiveCN101328681AFully washable exchange effectAchieve energy savingTextile treatment machine arrangementsDry-cleaning apparatus for textilesEngineeringWater washing

The invention relates to a novel dual-oscillation revolving drum washing machine, which is suitable for the water scrubbing, bleaching and open-width processing technique of knitted and woven fabrics. The novel dual-oscillation revolving drum washing machine comprises a box body (1), wherein, flumes (9) are vertically arranged on the lower part inside the box body, and the number of the flumes (9) is two, with one on the left and one on the right; an external wire roll (2) is respectively arranged inside the two flumes (9); a plum-blossom roll (10) is respectively arranged inside the two external wire rolls (2); a reticulated revolving drum (5) is vertically arranged on the middle of the upper part inside the box body (1); and the upper side of the reticulated revolving drum (5) is provided with a spray device (3). By adoption of the novel dual-oscillation revolving drum washing machine, the amount of water, steam and an auxiliary agent is small; the water scrubbing effect is good; and the quality of the textile fabrics after water scrubbing is good.

Owner:张琦

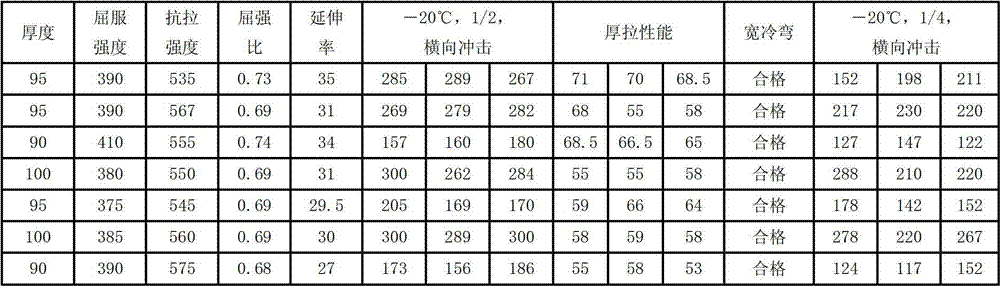

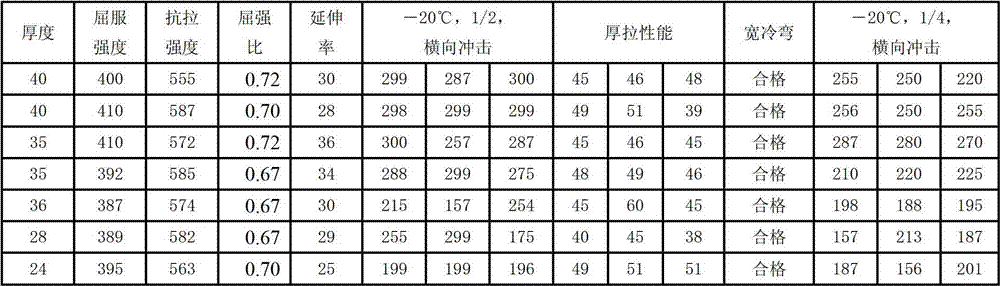

High-performance ocean platform steel and its production method

The invention provides high-performance ocean platform steel and its production method. When the thickness of a steel plate is 8-40mm, the steel plate is composed of the following chemical components, by weight, 0.11-0.13% of C, 0.20-0.50% of Si, 1.45-1.55% of Mn, 0.012% or less of P, 0.003% or less of S, 0.035-0.045% of V, 0.025-0.030% of Nb, 0.050% or less of Ti, 0.020-0.050% of Al, and the balance Fe and inevitable impurities; and when thickness of a steel plate is 40-100mm, the steel plate is composed of the following chemical components, by weight, 0.10-0.12% of C, 0.20-0.50% of Si, 1.50-1.60% of Mn, 0.012% or less of P, 0.003% or less of S, 0.070-0.075% of V, 0.030-0.040% of Nb, 0.050% or less of Ti, 0.020-0.050% of Al, and the balance Fe and inevitable impurities. The production method of the steel plate of the invention comprises the steps of electric furnace smelting, LF furnace refining, VD vacuum treatment, continuous casting (or die casting), heating, control rolling, cooling, stacking, and normalizing to prepare the steel plate. Through a reasonable component design and process optimization, the steel plate of the invention has excellent mechanical performances, welding performances and processing performances, and has strong market competitiveness.

Owner:WUYANG IRON & STEEL +1

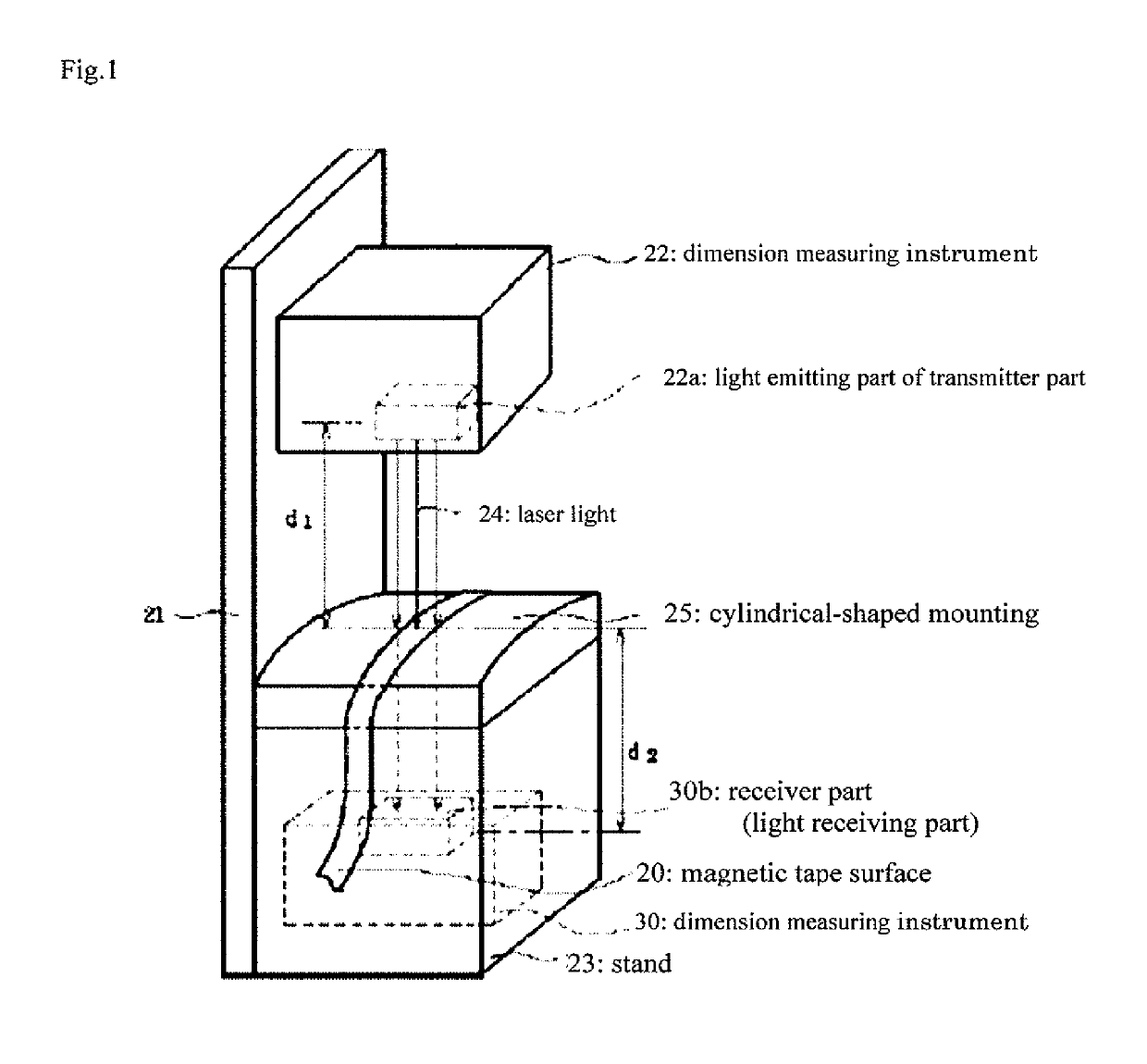

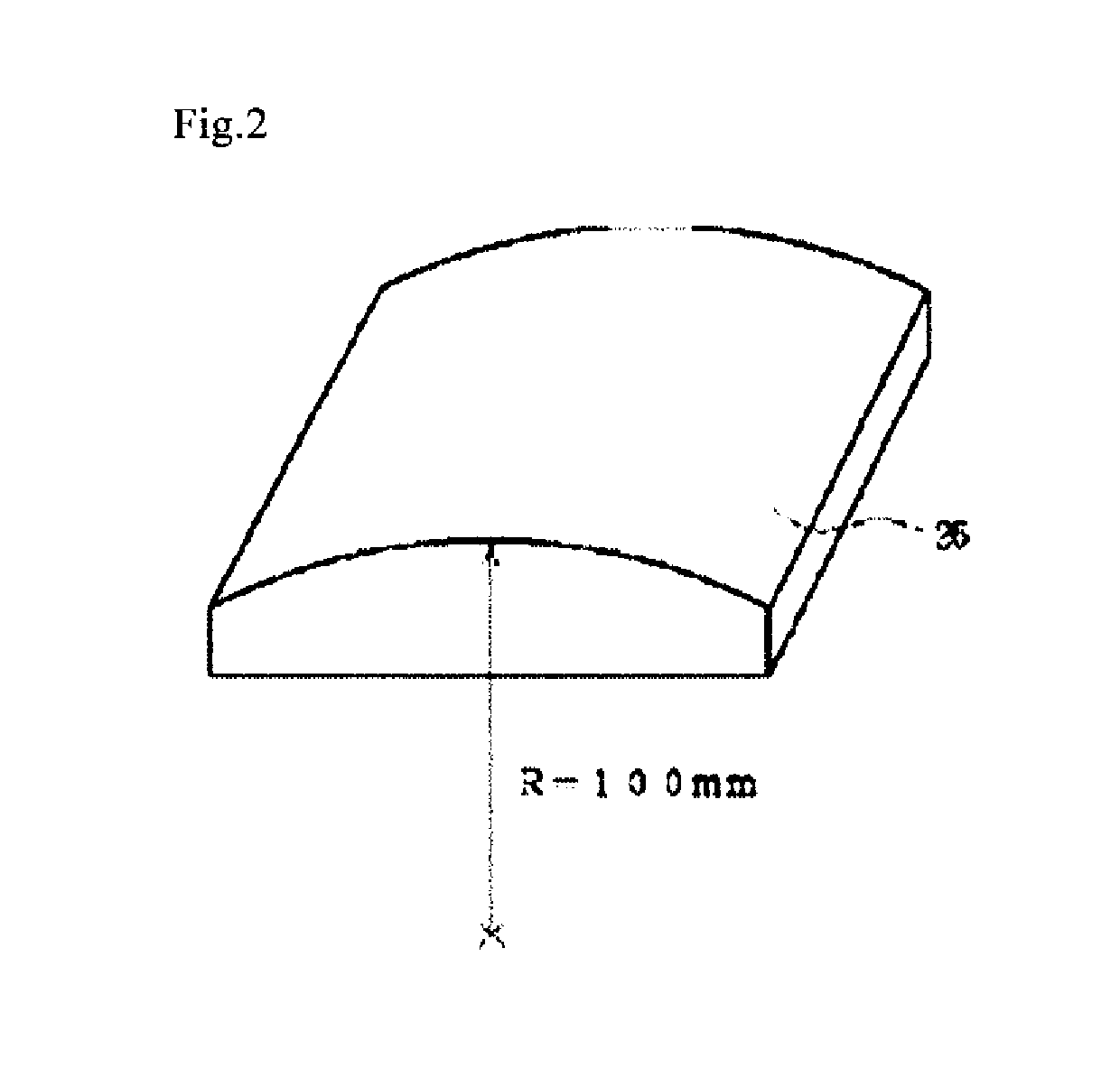

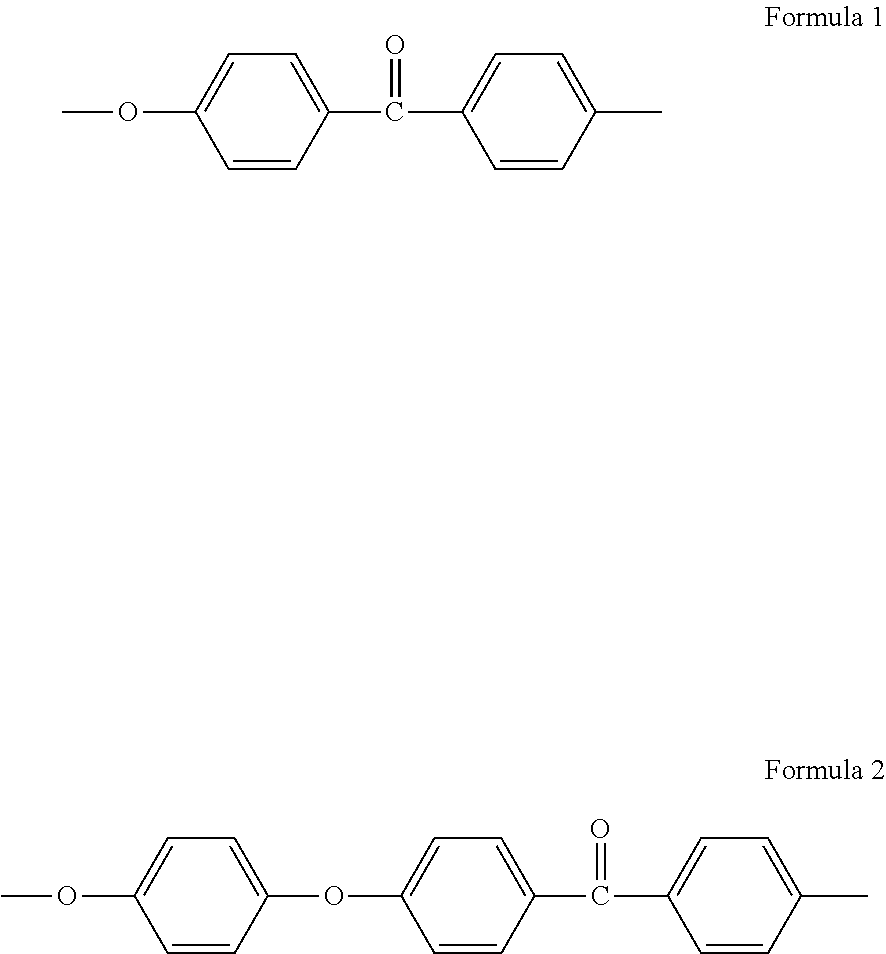

Resin film

ActiveUS20190180781A1High-density recordingAdjustmentDisposition/mounting of recording headsBase layers for recording layersYoung's modulusEngineering

To provide a resin film, of which dimensional stability required of an ultra-high density recording medium can be controlled easily by drive tension, and which has processability at high temperature in a processing step of the resin film into a magnetic recording medium. A resin film having a Young's modulus in the film longitudinal direction of 1 GPa or more and a film thickness of 1 μm or more, wherein the product of the Young's modulus in the longitudinal direction and the thickness is 5 GPa·μm or more and 20 GPa·μm or less and wherein a dimensional change in the film longitudinal direction is −2% or more and +2% or less when the film is heated at a rate of 5° C. / min under a load of 2 kg / mm2 applied in the longitudinal direction and the temperature has reached 110° C., the resin film satisfying at least either of the following (1) or (2): (1) the Young's modulus in the film longitudinal direction is 6 GPa or less and the film thickness is 4.5 μm or less; and (2) the Young's modulus in the film longitudinal direction is 4 GPa or less and the film thickness is 6 μm or less.

Owner:TOYOBO CO LTD

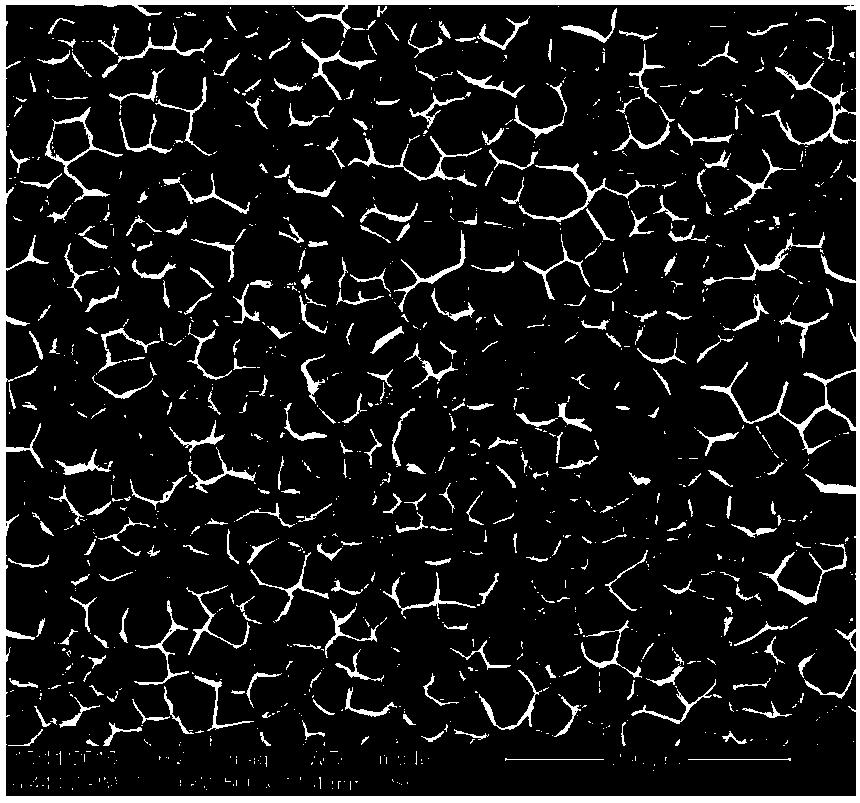

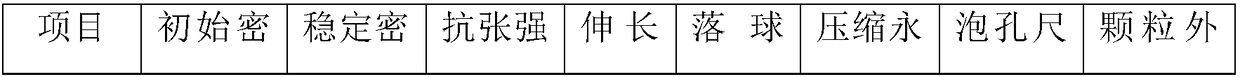

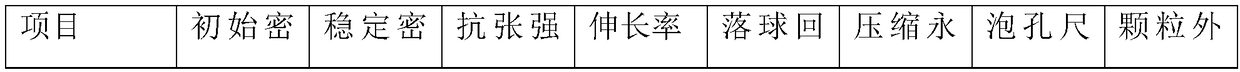

Thermoplastic polyurethane foaming particle and preparation method thereof

ActiveCN108239385AProduction environmental protectionSimple preparation processThermoplastic polyurethaneAlloy

The invention relates to a thermoplastic polyurethane foaming particle and a preparation method thereof. The thermoplastic polyurethane foaming particle comprises the following components in percentage by mass: (A) 65-90% of a thermoplastic polyurethane elastomer; (B) 2-30% of a thermoplastic resin polymer; and (C) 0-15% of a compatilizer. The preparation method comprises the following steps: adding blending alloy particles of the thermoplastic polyurethane elastomer, the thermoplastic resin polymer and the compatilizer into an autoclave, adding carbon dioxide into the autoclave, enabling carbon dioxide in the autoclave to be in a supercritical state, relieving pressure of the autoclave so as to obtain non-foaming particles containing carbon dioxide; heating and foaming the non-foaming particles containing carbon dioxide in hot air, thereby obtaining the foaming particles. The thermoplastic polyurethane foaming particle prepared by the method is stable in dimension, basically non-shrinkable, bright and full in surface, uniform in foam diameter, controllable in foam size of 10-100 microns and excellent in resilience.

Owner:WANHUA CHEM GRP CO LTD

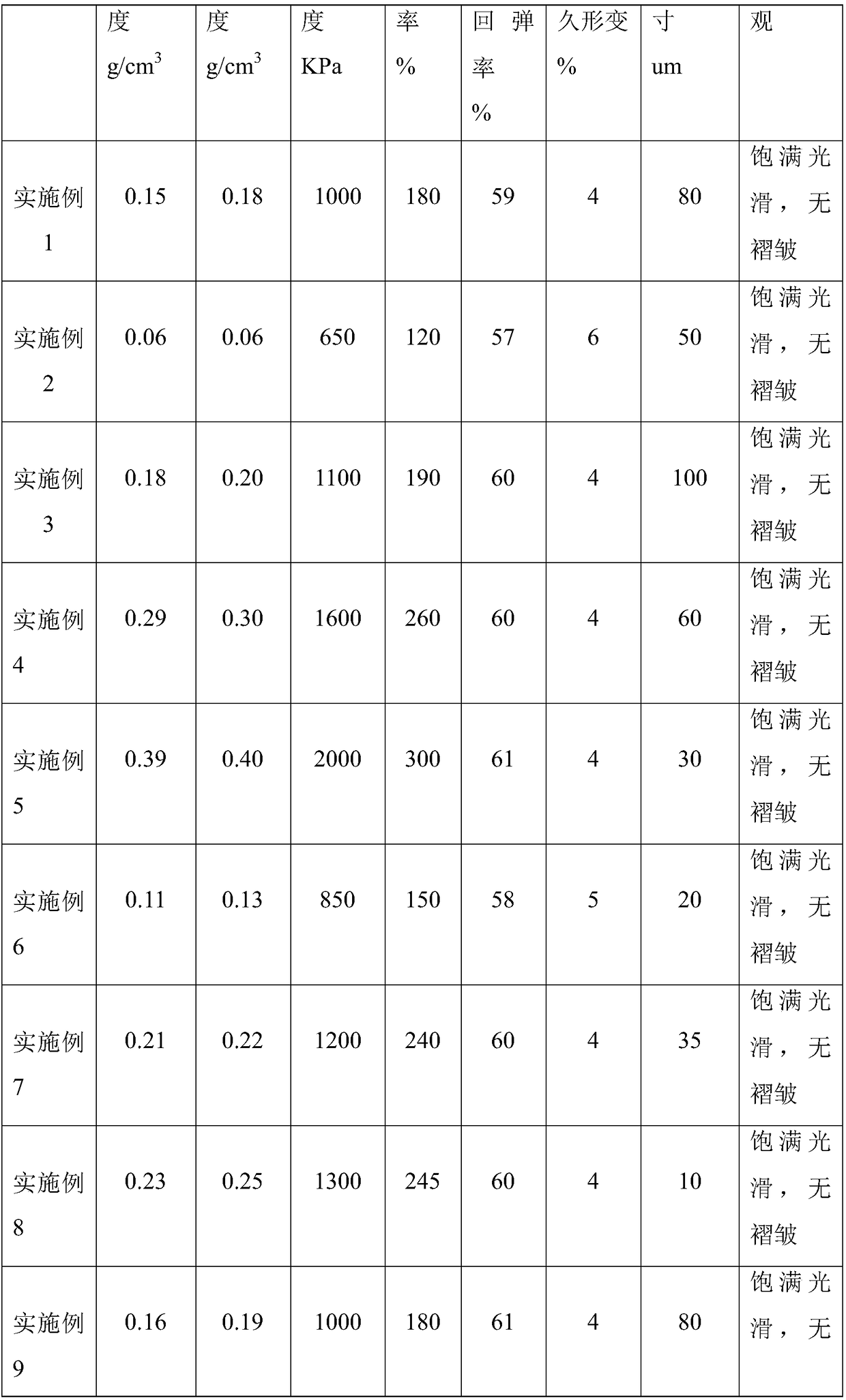

Vacuum thermal baffle packaging film and preparation method thereof

ActiveCN101844642AGood hot tack propertiesGood aging resistanceFlexible coversWrappersWrinklePolyethylene glycol

The invention discloses a vacuum thermal baffle packaging film and a preparation method thereof. The vacuum thermal baffle packaging film comprises a biaxially oriented nylon layer, a polyethylene glycol terephthalate layer, an aluminum foil layer, a biaxially oriented nylon layer and a composite polyethylene layer sequentially from inside to outside. Compared with the prior art, the vacuum thermal baffle packaging film has the characteristics of smooth appearance of bag bodies (+ / -5 percent of limit deviation), no phenomena of wrinkles, crystal points, PE coke buttons and the like, high barrier properties of packaging bags and good vacuumizing effect, peel strength, temperature tolerance and anti-aging effect.

Owner:HUANGSHAN NOVEL

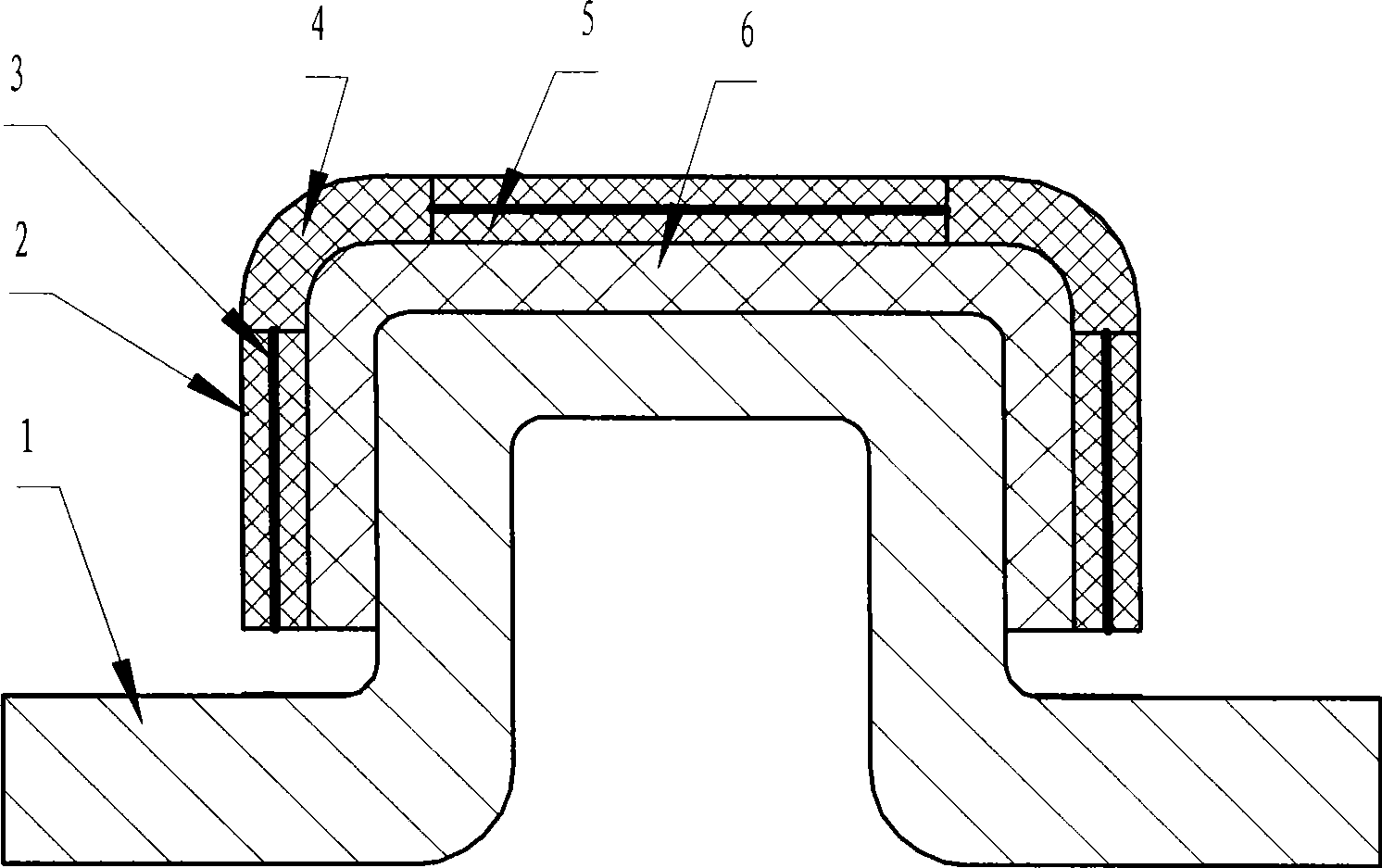

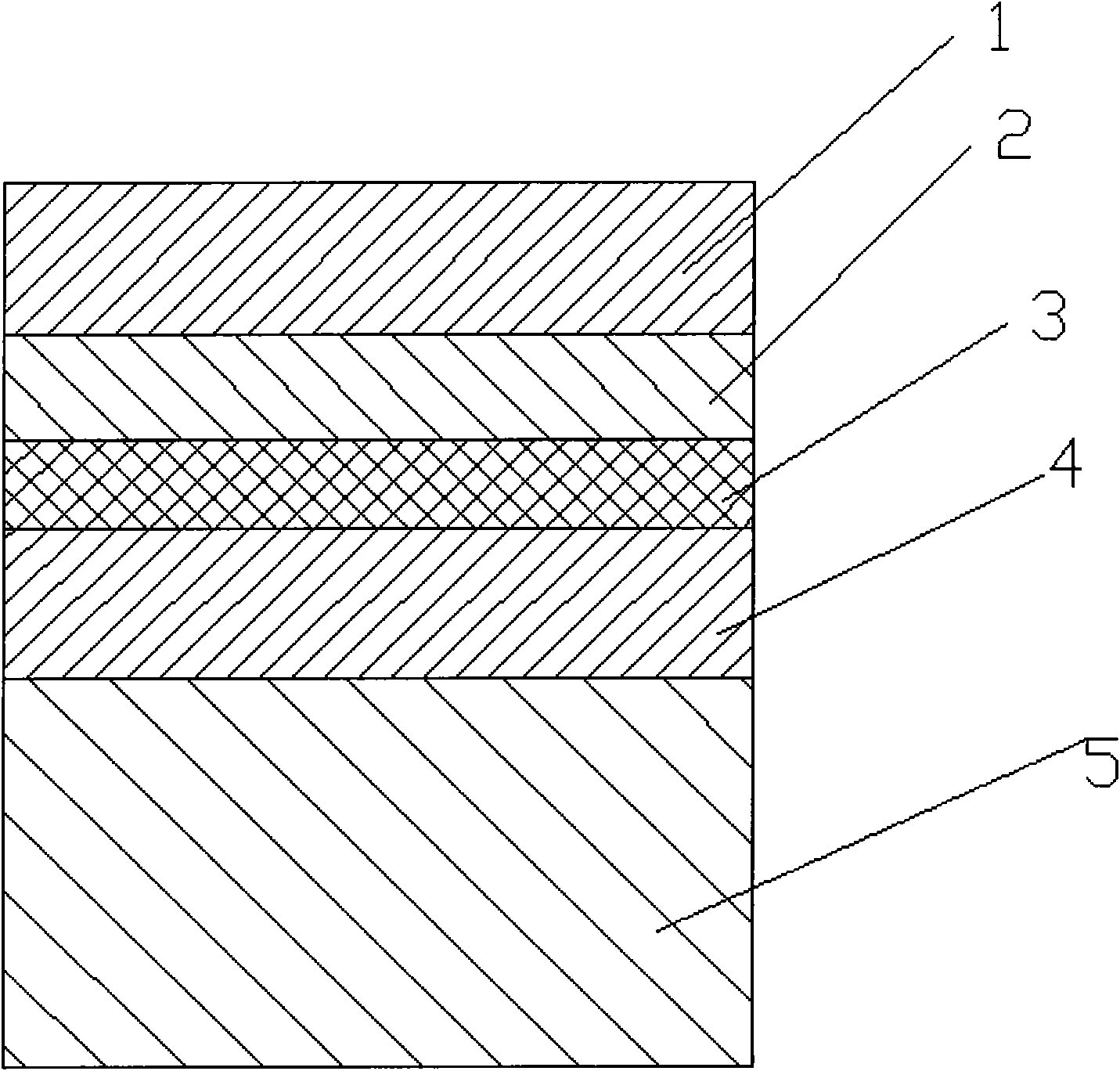

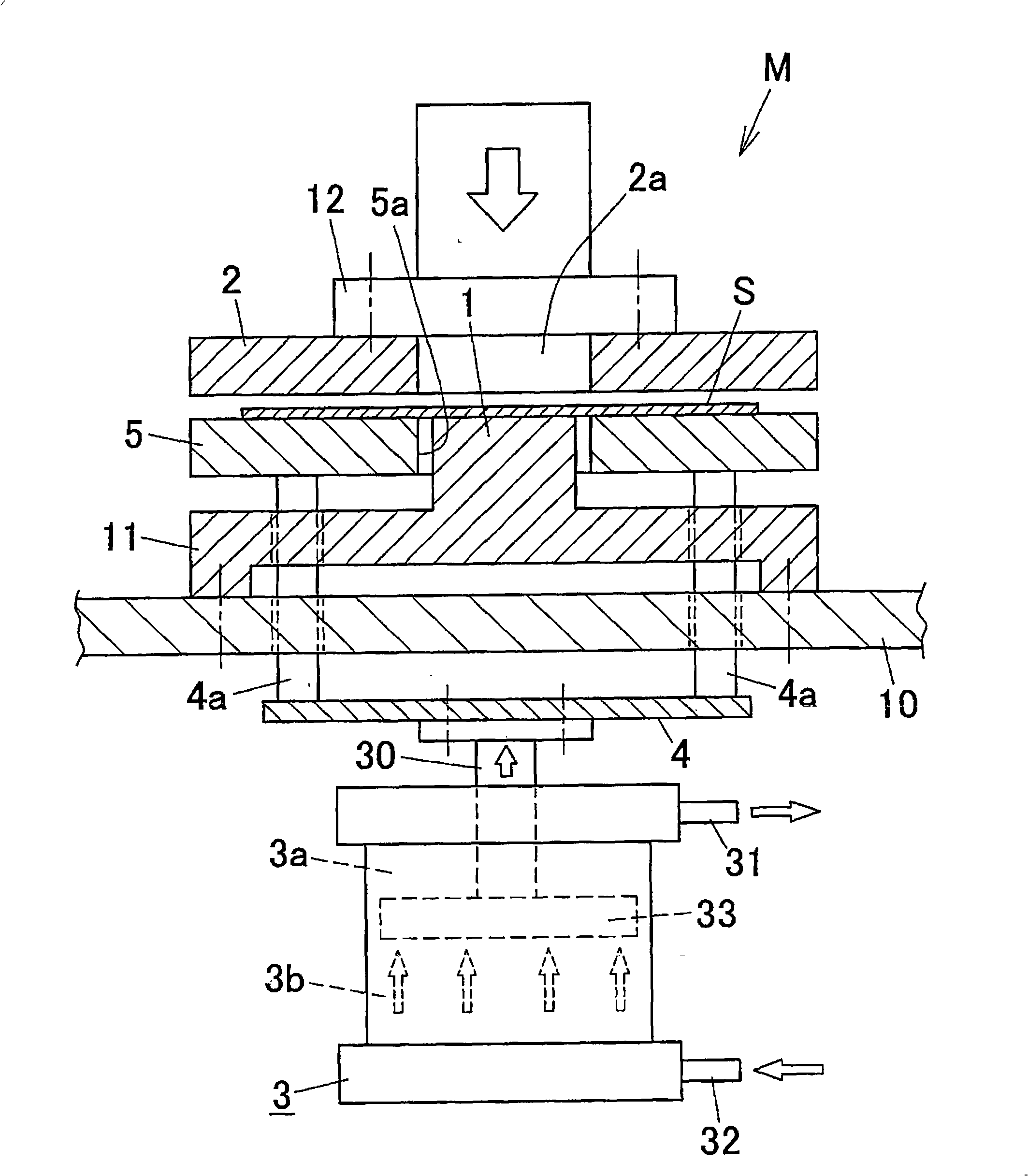

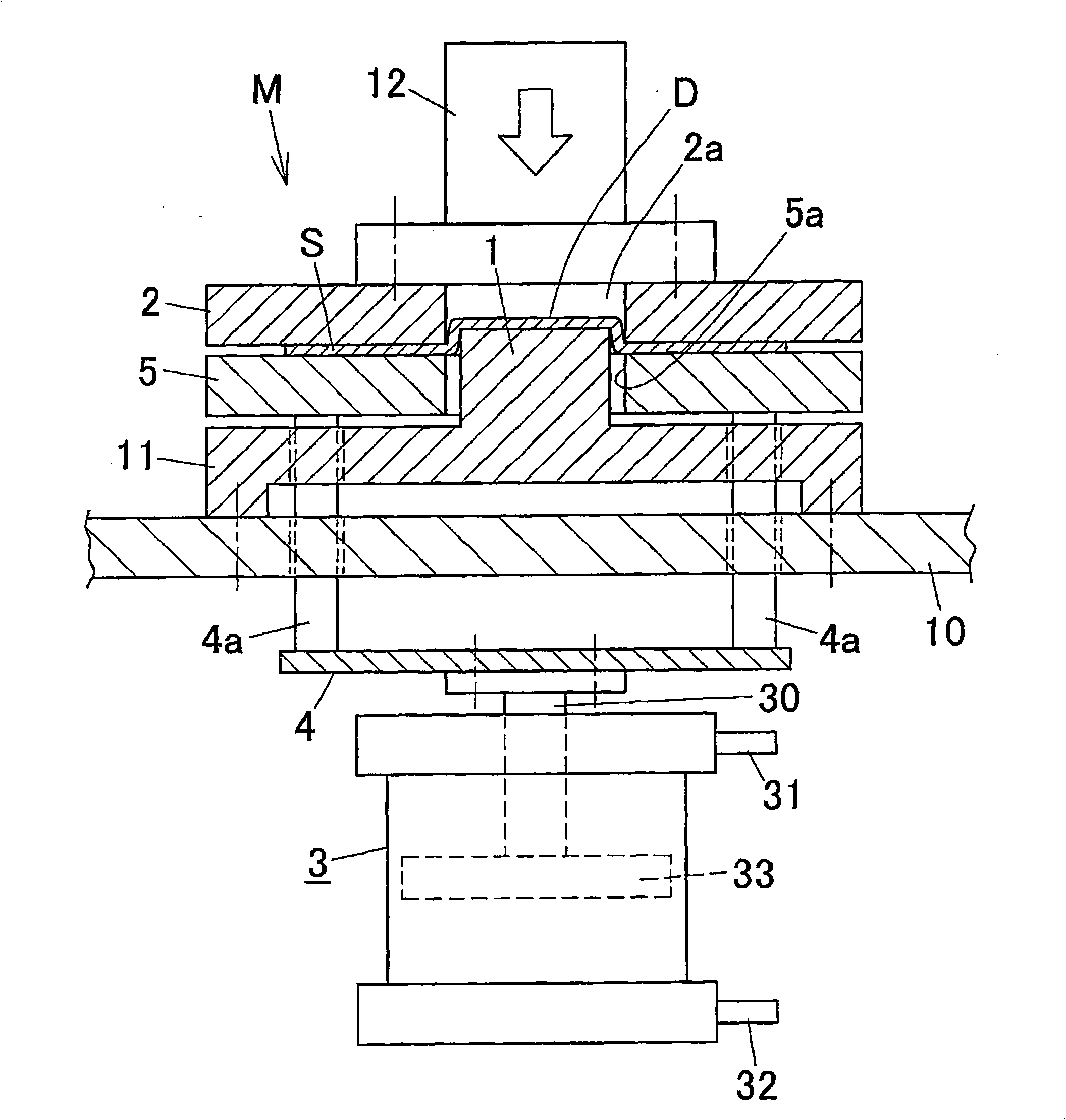

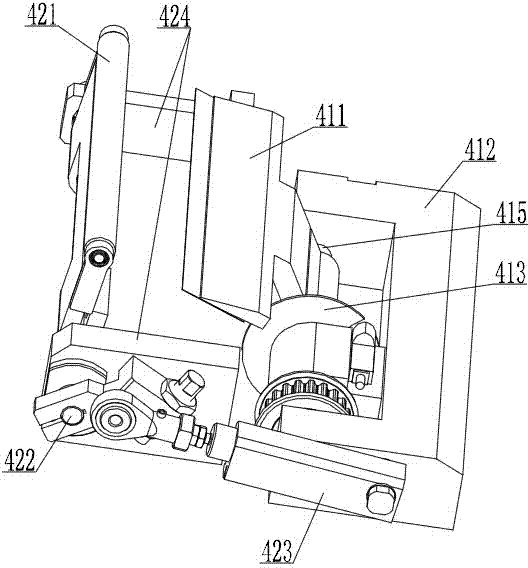

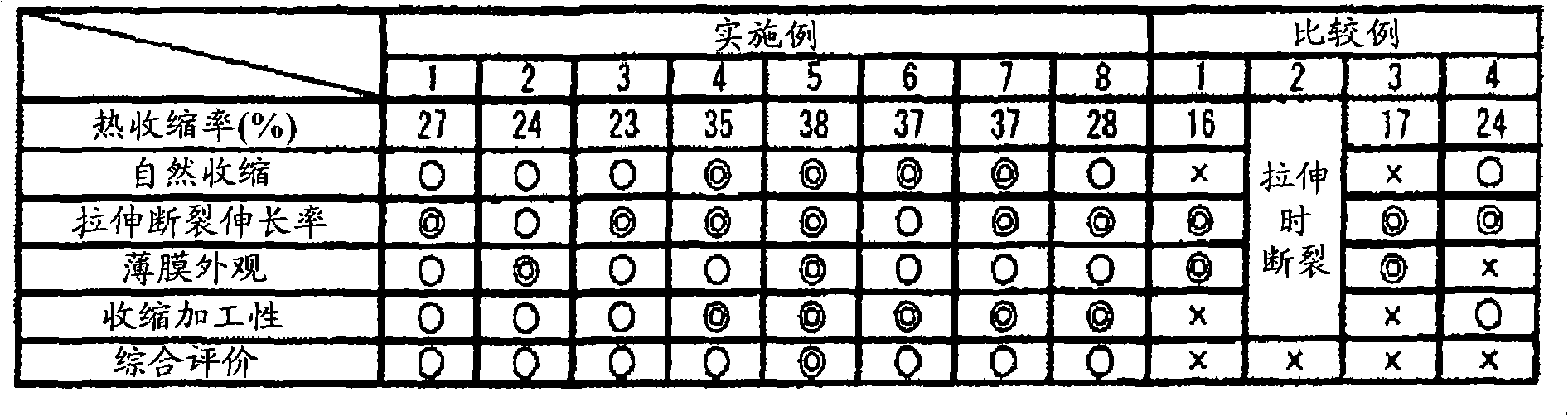

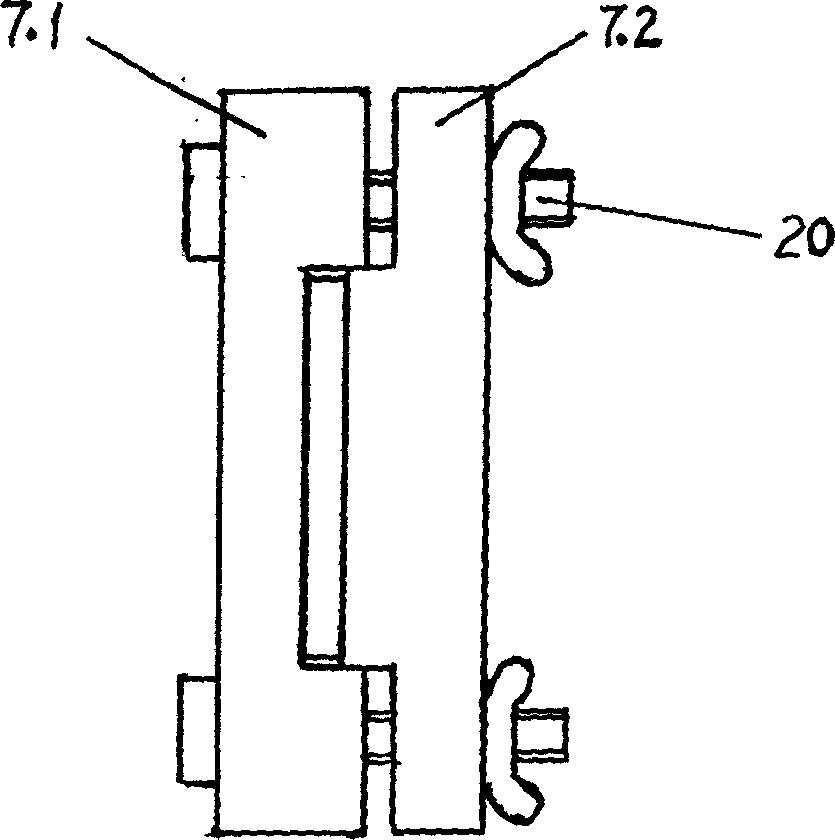

Forming method and forming device for battery shell

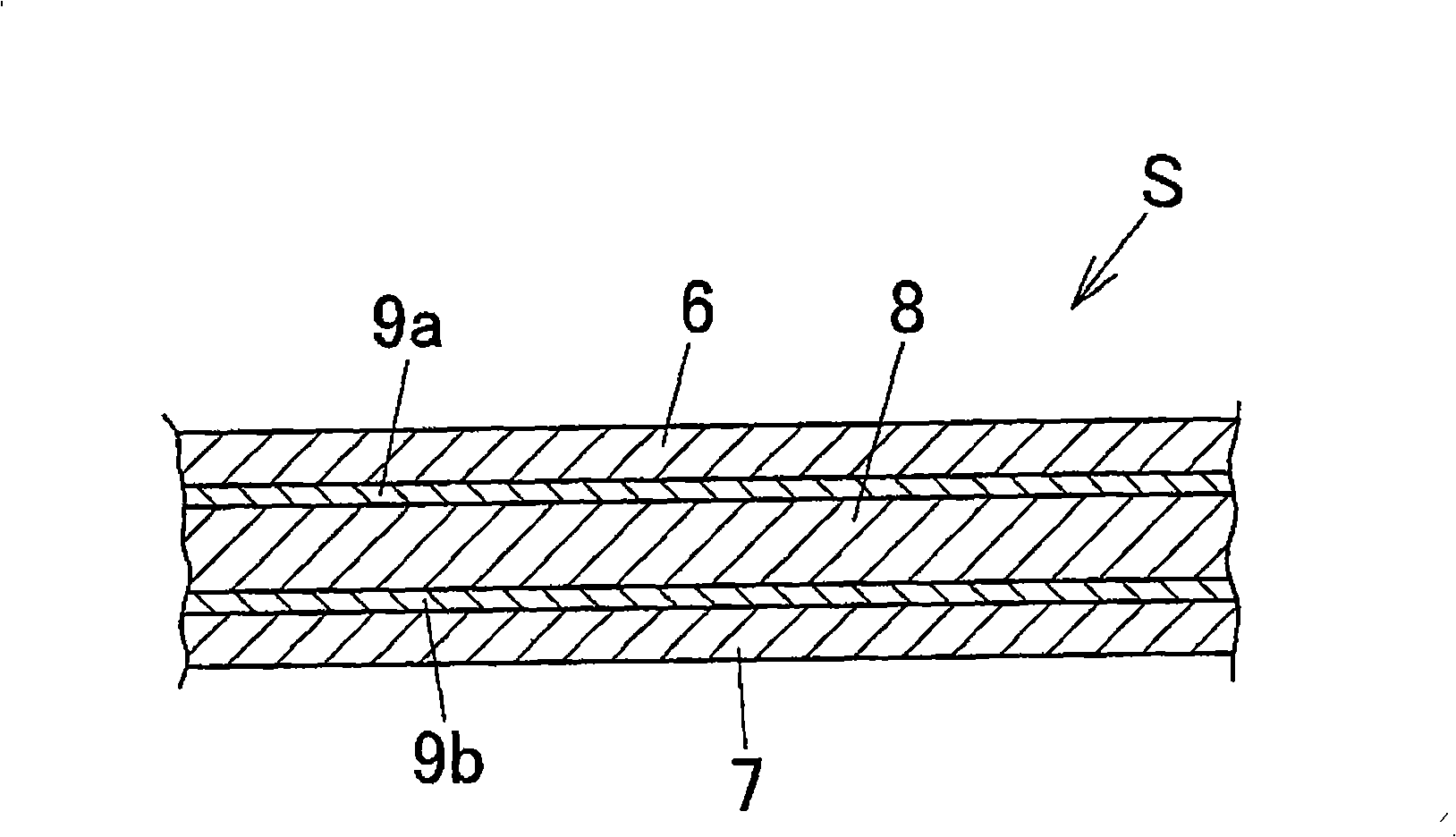

ActiveCN101259498AImprove yieldReduce sizeLamination ancillary operationsSynthetic resin layered productsResistElectrical battery

The invention provides a forming method of battery shell which is charactered in that: a forming sheet (S), which includes a resin film layer as an outside layer, a resin film layer as an inner layer and an aluminium foil layer between two film layers, is punch formed to required shape by a punch forming mould composed of a die (2), a former block (1) and a crease-resist pressure pad component (5). According with the forming method, in a deep pulling / processing process that punch forming is realized by the forming sheet with special lamination structure used as forming material, the crease-resist pressure pad pressure generated by the crease-resist pressure pad can be adjusted suitably according with forming shape size, deepness also likes. Consequently, more deep process can be processed easily and suitable range of forming shape is enlarged, and a deep pulling process without crease is processed.

Owner:株式会社力森诺科包装

Extruded and foamed thermoplastic polyurethane elastomer particle and preparation method thereof

ActiveCN108239386AProduction environmental protectionSimple preparation processThermoplastic elastomerThermoplastic polyurethane

The invention relates to an extruded and foamed thermoplastic polyurethane elastomer particle and a preparation method thereof. The particle contains the following components in percentage by mass: (A) 65%-90% of a thermoplastic polyurethane elastomer, (B) 2%-30% of a thermoplastic resin polymer, (C) 0.5%-15% of a compatilizer and (D) 0.1%-5% of a foaming nucleating agent. The preparation method of a TPU formed particle comprises the following steps: uniformly mixing the thermoplastic polyurethane elastomer, the thermoplastic resin polymer, the compatilizer and the foaming nucleating agent, putting the mixture into melt extrusion equipment, and carrying out granulation, so as to obtain a blending alloy particle; and putting the blending alloy particle into foaming extrusion equipment, carrying out melting plastification so as to obtain a melt, dissolving supercritical carbon dioxide into the melt, foaming by virtue of a mouth mold, and carrying out underwater dicing, so as to obtain the formed particle. The prepared thermoplastic polyurethane foamed particle is stable in size and basically does not shrink, the surface is bright and plumy, and the diameters of foamed holes are uniform.

Owner:WANHUA CHEM GRP CO LTD

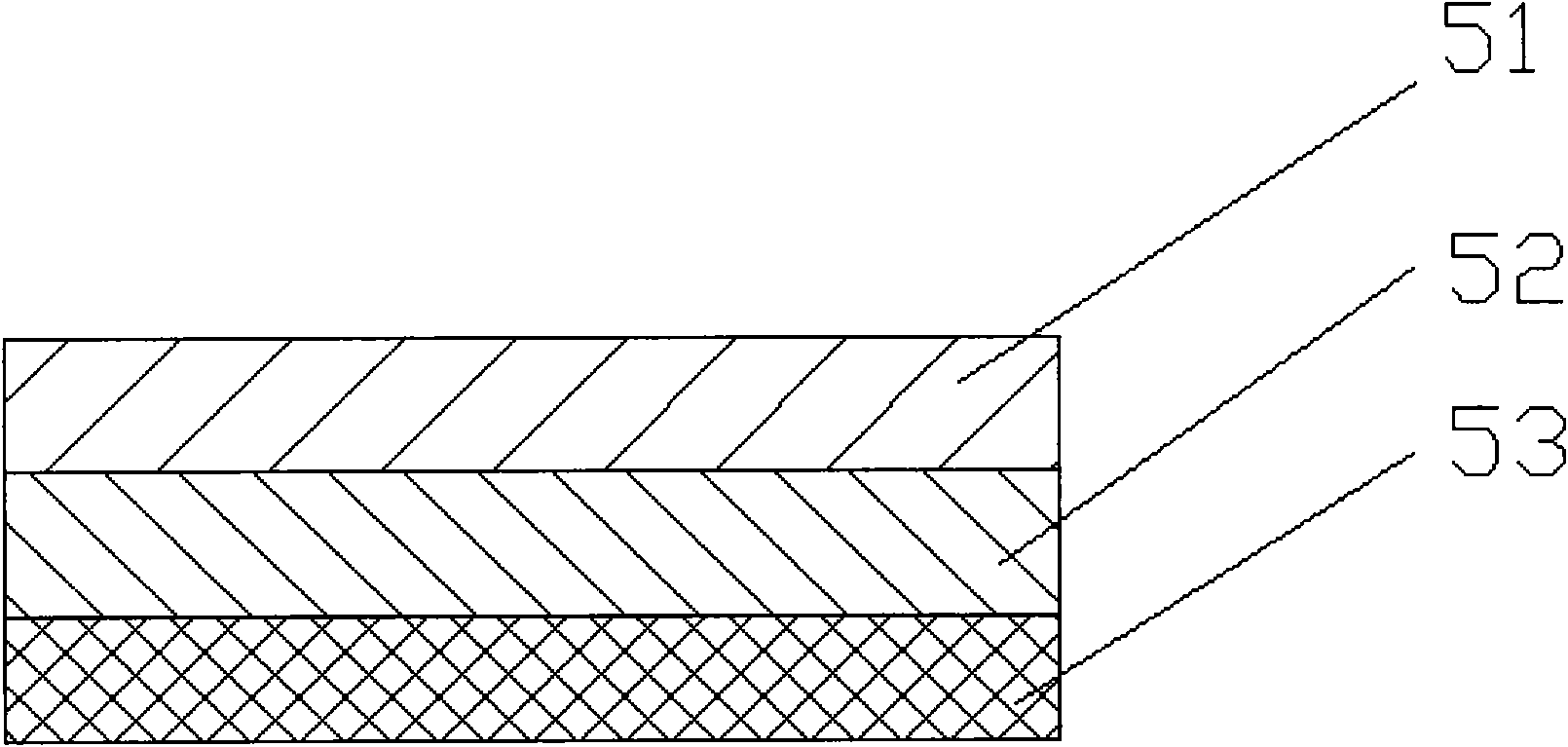

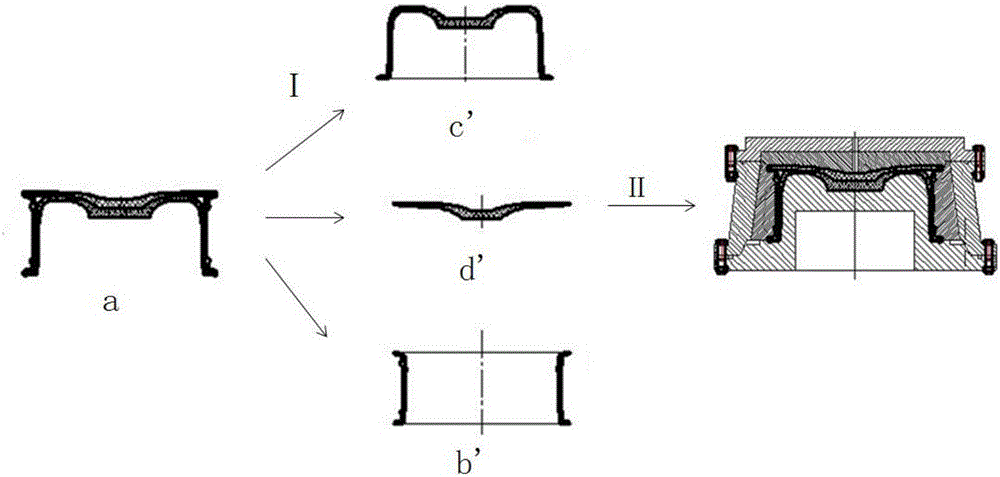

High-viscosity self-adhesive protection film and preparation method thereof

InactiveCN105500859AIncrease stickinessWrinkle freeSynthetic resin layered productsFlat articlesWrinkleLow-density polyethylene

The invention discloses a high-viscosity self-adhesive protection film and a preparation method thereof. The high-viscosity self-adhesive protection film successively comprises a self-adhesive layer, a middle layer and an anti-stick back layer from top to bottom, and the anti-stick back layer is an anti-stick back layer added with an anti-stick master batch. In the high-viscosity self-adhesive protection film, the viscosity of the self-adhesive layer is high, and the anti-sticking back layer effectively prevents the self-adhesive layer from being bonded with the back layer when reeling is performed and facilitates unreeling, wherein the self-adhesive layer is prepared from modified SEBS and linear low-density polyethylene. The middle layer is prepared from linear low-density polyethylene and low-density polyethylene. The anti-stick back layer is prepared by selecting linear low-density polyethylene, low-density polyethylene and the anti-stick master batch. The added anti-stick master batch prevents the self-adhesive layer from being bonded with the back layer when reeling is performed, facilitates unreeling, and also guarantees that the self-adhesive film does not deform. The high-viscosity self-adhesive protection film does not need additional gluing and is easy to unreel, and during production, the film does not adhere to a roller and does not generate wrinkles or foams.

Owner:POLI FILM PROTECTIVE FILM SUZHOU

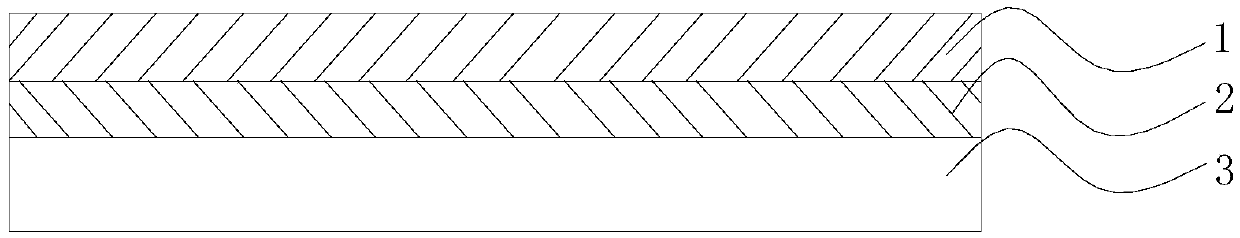

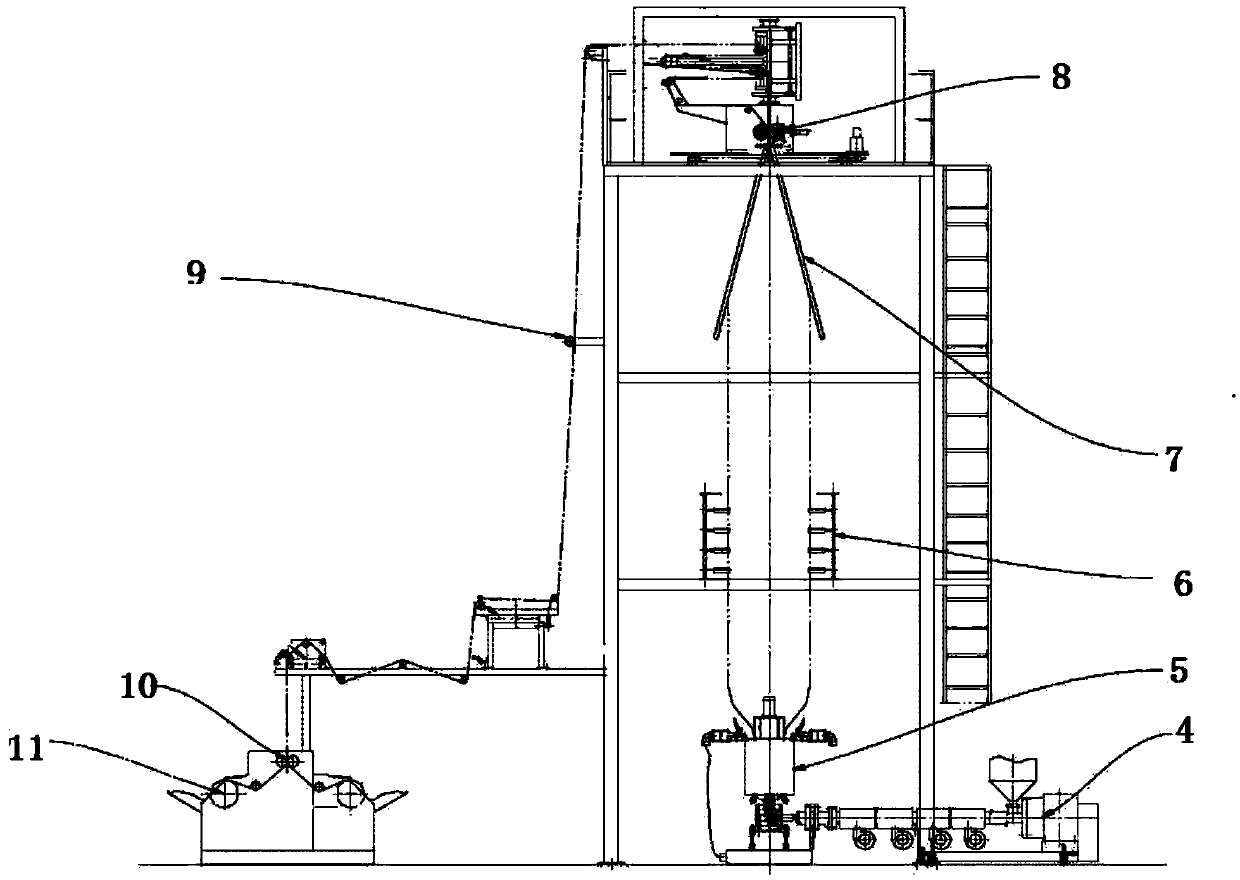

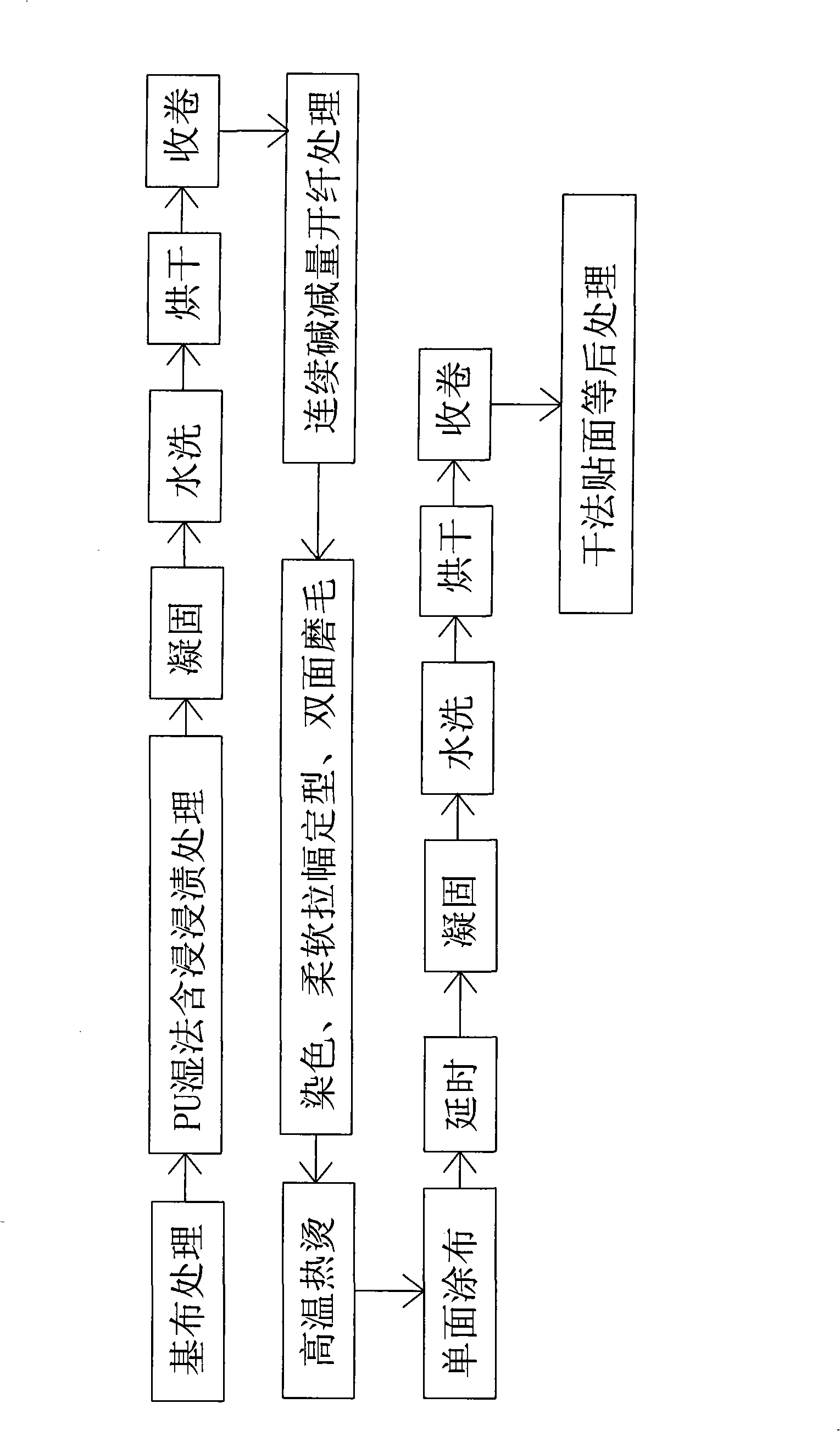

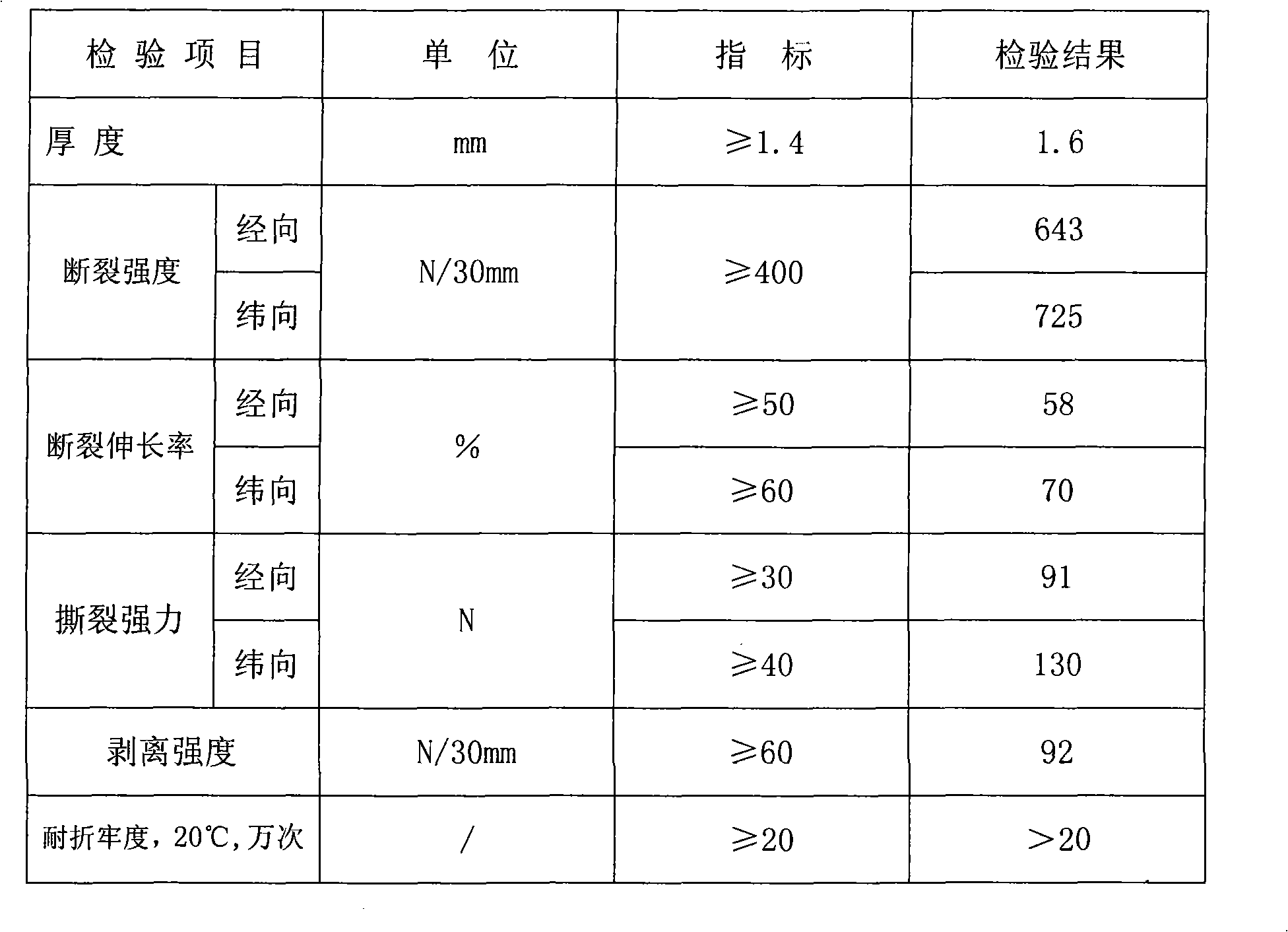

Method for processing island ultra-thin fiber high-density needling non-woven fabrics emulation leather

InactiveCN101260619AUniform thicknessHigh tear strengthFibre treatmentHeating/cooling textile fabricsHigh concentrationTime delays

The invention relates to a method for machining an island superfine fiber high density pinprick non-woven fabrics artificial leather, which is applied to the artificial leather manufacture and comprises the following processes: (1) the foundation process; (2) the PU wet method dipping process; (3) the continuous alkali abatement fiber opening process; (4) the pigmentation, the flexible tentering and shaping, the peached finish on two sides by a roughing-up machine; (5) the post treatments such as the dry method facing. The method is characterized in that the following processes are performed between the (4) process and the (5) process which are as follows: (6) the rolling blanching at a high temperature of 80 to 120 DEG C; (7) the high concentration polyurethane DMF solution with a weight ratio of PU: DMF of 100:50-93 is coated on the single side of the fabrics; (8) the time delay of 30 to 80 seconds; (9) a low temperature of 10 to 15 DEG C high concentration of 15 to 25 percent of DMF solution coagulating basin is coagulated, washed by water, dried and wrapped up. The method has the advantages that the manufactured finished leather has even thickness, excellent anti-tear strength and good ventilation property, the shortcoming that the cross breaks of the fibril synthetic leather is concave is overcome; the single spreading effectively avoids the foaming phenomenon on the coating surface; the section color is constant, etc.

Owner:NANPING JINYUE ARTIFICIAL LEATHER

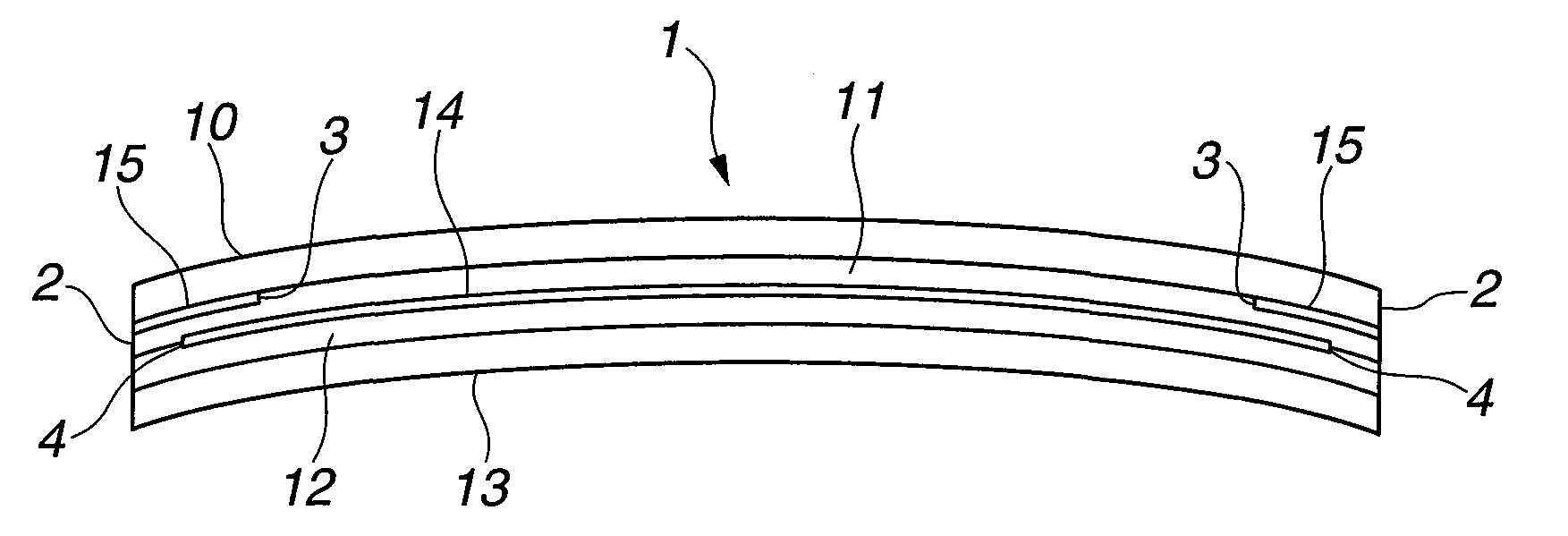

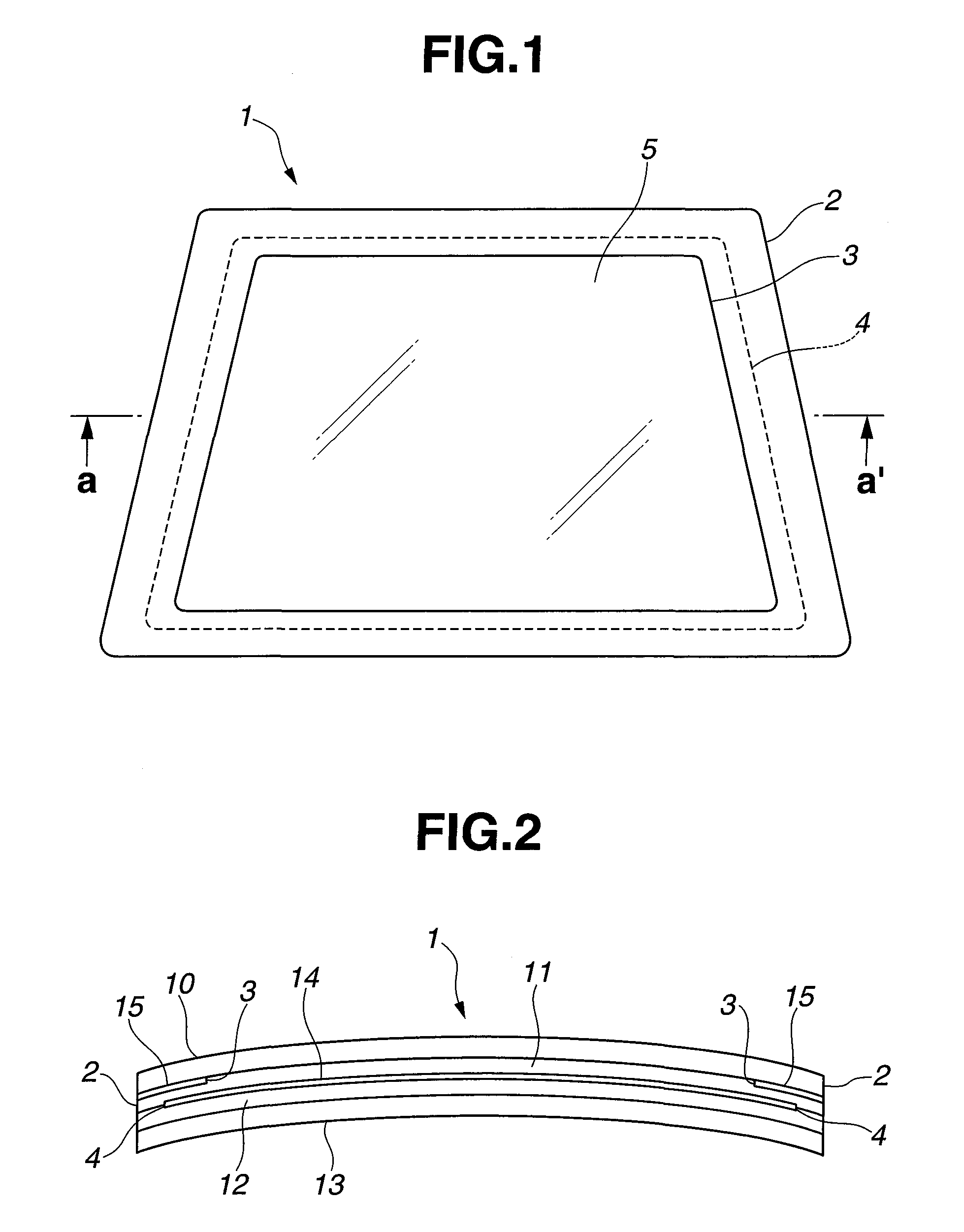

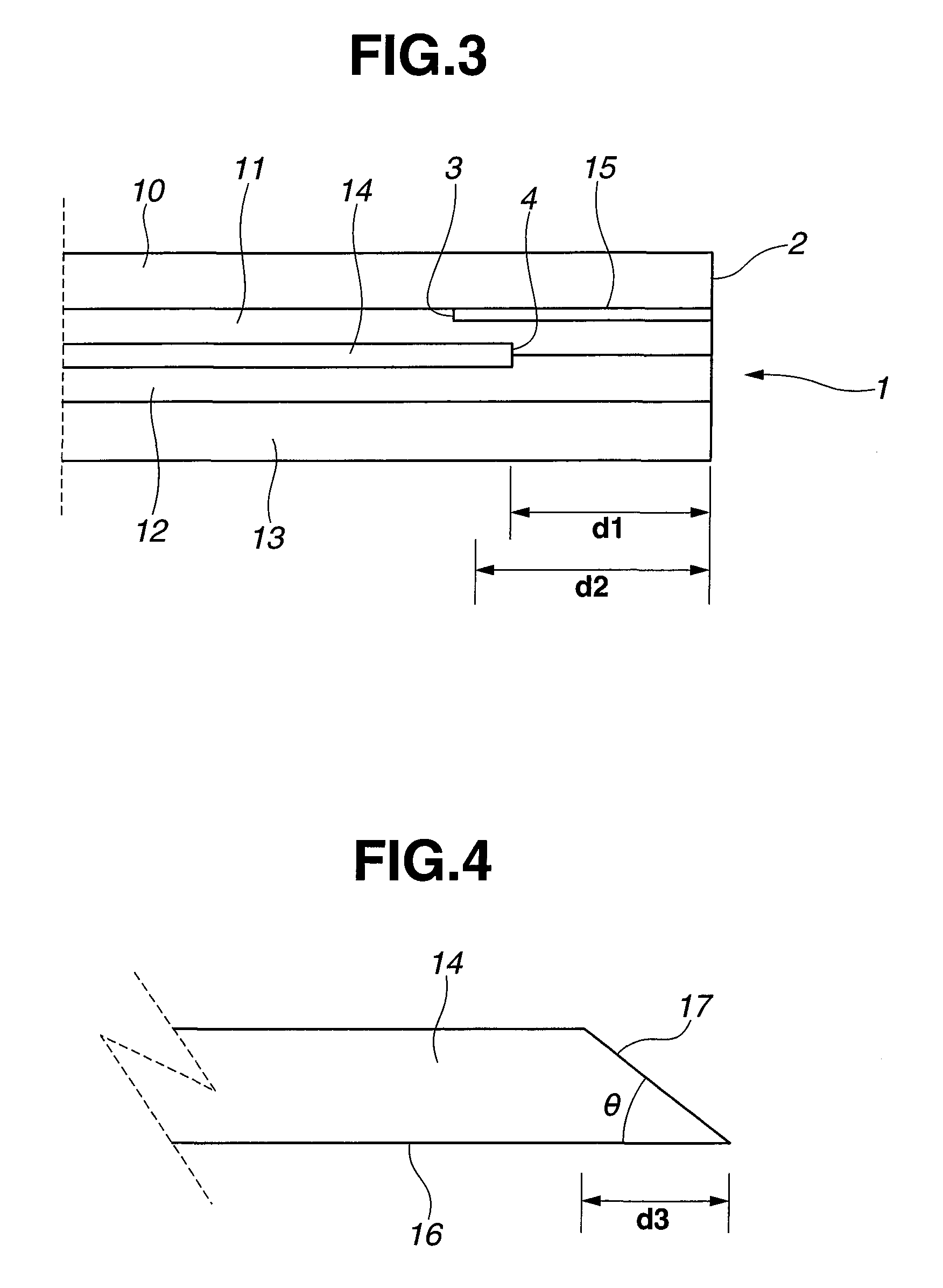

Laminated Glass With Inserted Plastic Film

According to the present invention, there is provided a plastic film-inserted laminated glass comprising an outdoor side glass plate, an interlayer, a plastic film, another interlayer and an indoor side glass plate which are laminated in this order, which is characterized in that the glass plates have a curved shape formed by bending, the plastic film includes an infrared reflecting film formed thereon and at least at one side of the laminated glass, an edge of the plastic film is placed apart from corresponding edges of the glass plates by a distance ranging from 5 mm to 200 m in a direction toward a central portion of the glass plates.

Owner:CENT GLASS CO LTD

Lemon slice flower tea composition and preparation method for same

InactiveCN103815095AReduce heatClear fire and moisten throatTea substituesDiabetes mellitusDrug product

The invention relates to a composition, which is prepared from the following raw materials in parts by weight: 1 to 20 parts of lemon slices and 1 to 2 parts of stevia. Any single component or combination from lilies, honeysuckle flowers, globe amaranth and peony flowers can be added into the composition. In addition, the invention also relates to the use of the composition for the preparation of a healthcare product or a medicament or a product for prevention and treatment of hypertension, digestion aiding, obesity reduction, prevention and treatment of diabetes, freckle removal, wrinkle removal or skincare and throat clearing and nourishing.

Owner:常小勇 +1

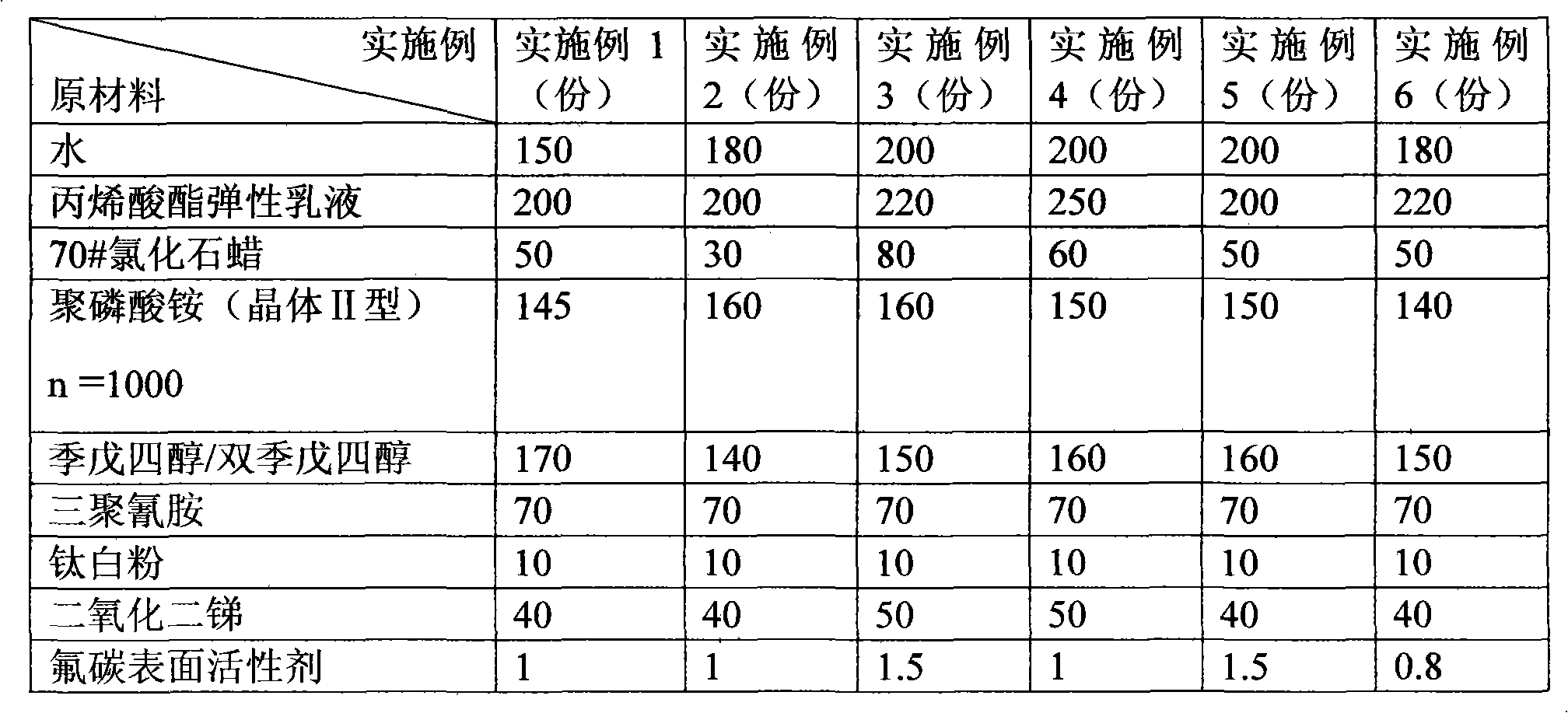

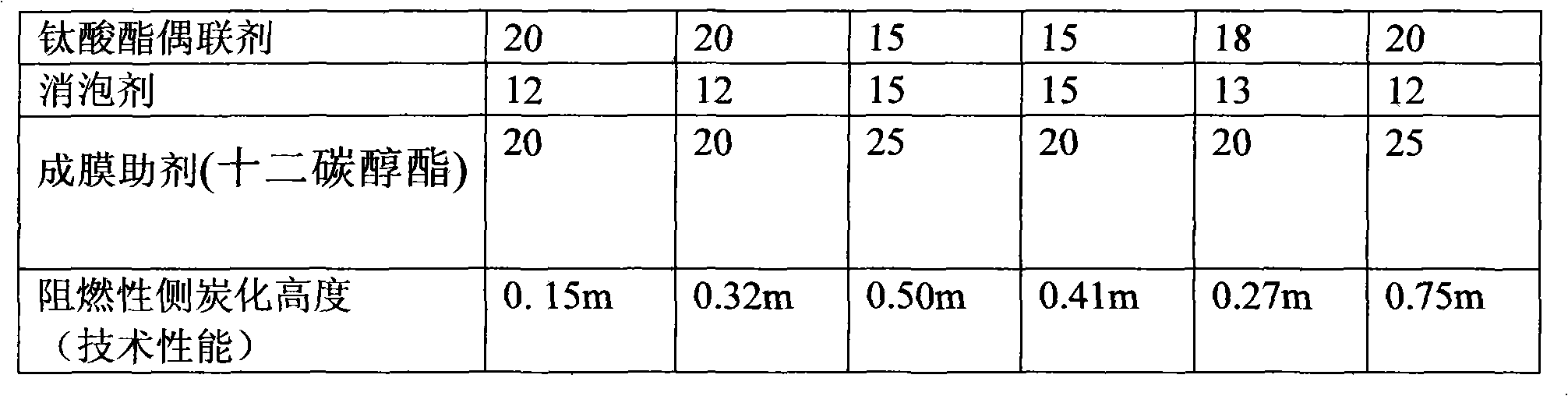

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

InactiveCN101597454AGood film forming effectGood water resistanceFireproof paintsSolventAmmonium polyphosphate

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

Multi-effect ceramide face cream

InactiveCN105326678AWith whiteningMoisturizingCosmetic preparationsToilet preparationsWrinkle skinPotassium

The invention discloses multi-effect ceramide face cream. The multi-effect ceramide face cream is prepared from a component A and a components B, wherein the component A is prepared from, by weight, 60%-80% of water, 5%-10% of mineral oil, 2%-6% of glycerin, 1%-6% of butanediol, 1%-3% of cetyl alcohol, 1%-3% of sorbitan stearate, 1%-3% of polydimethylsiloxane, 1%-2% of beewax, 0.2%-0.5% of PEG-40 stearate and 0.2%-0.5% of cetyl palmitate, and the component B is prepared from, by weight, 0.1%-0.3% of phenoxyethanol, 0.1%-0.3% of laureth-9, 0.1%-0.2% of xanthan gum, 0.05%-0.12% of propyl hydroxybenzoate, 0.05%-0.12% of methylparaben, 0.05%-0.12% of Carbomer, 0.05%-0.12% of potassium acrylates / C10-30 alkyl acrylate crosspolymer, 0.02%-0.12% of sodium hydroxide, 0.00005%-0.00015% of phenylethyl resorcinol, 0.005%-0.012% of ceramide 2 and the like. The multi-effect ceramide face cream has the effects of whitening, moisturizing, wrinkle removing, aging resisting and allergy resisting.

Owner:蝶柔化妆品(浙江)有限公司

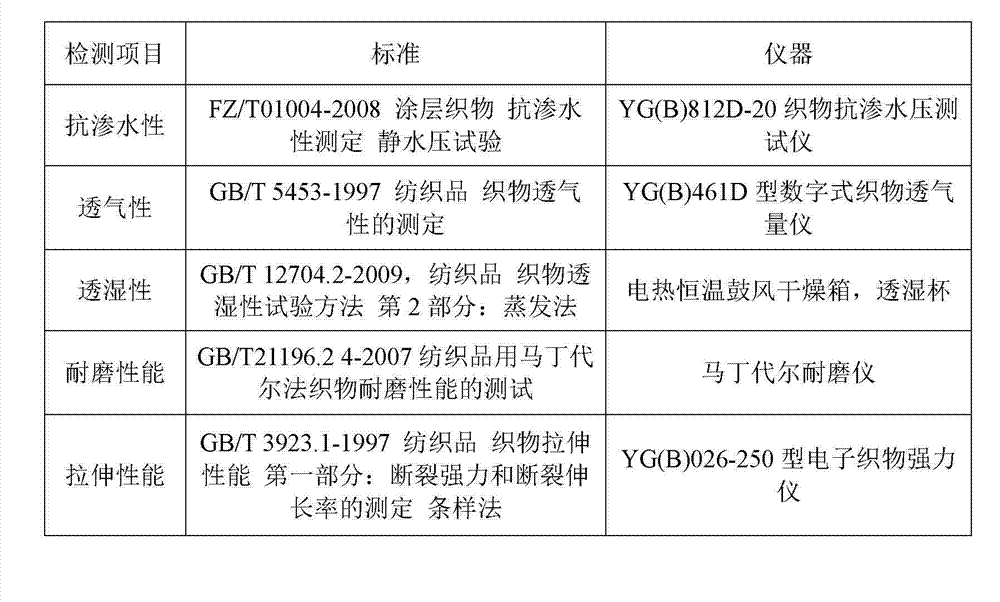

Method for producing textile coated with coating adhesive

InactiveCN102965907AImprove thermal stabilityGood weather resistancePhysical treatmentAdhesiveWater resistant

The invention relates to a method for producing textile coated with coating adhesive, comprising the following steps of: sheering double-stop end vinyl silicone oil, hydrogen-containing silicone oil, oily polyurethane resin, silane coupling agent, pentaerythritol triacrylate and nano-stage white carbon black by a high-shear homomixer at high efficiency under room temperature to prepare coating adhesive; and hot pressing a base cloth by a hot-press roller of a planishing mill, coating the coating adhesive onto the base cloth, putting the base cloth provided with the coating adhesive on a bundle transferring frame of a 200 KeV low-energy electron accelcrator through a driving roller to be cured in a radiation way to obtain the textile coated with the coating adhesive. The water permeability resistance of the textile is 17084-36483 Pa, the mean air permeability of the textile is 10.97-25.1L / M<2>.s, the moisture permeability rate of the textile is 5799-7832 g / m<2>.24h, the coating layer starts to be broken after being ground at 116-140 circles, the radial breaking strength of the textile reaches 802.7N, and the latitudinal breaking strength of the textile reaches 456.7N. The textile produced by the method can increase the humidity management, is free from wrinkle, easy to iron and press, good in tensile property and recovery property, elastic, flexible, smooth, comfortable in hand feel, nontoxic, sunshine-resistant, wind-resistant, water-resistant, and suitable for the clothes, the outdoors, the fashion fabric and the like.

Owner:JIHUA 3509 TEXTILE

Production method of permanent ultraviolet protecting, moisture absorbing and sweat removing fabric

ActiveCN104799458AReduce surface tensionImprove permeabilitySingeingHeating/cooling textile fabricsChemistryPolyester

The invention discloses a production method of a permanent ultraviolet protecting, moisture absorbing and sweat removing fabric. The method comprises the steps of blending and weaving; singeing; desizing-scouring-bleaching; mercerizing; sizing; dyeing; softening and tentering; pre-shrinking and arranging. The fabric manufactured by the production process is outstanding in permanent ultraviolet resisting function; the UPF is not less than 150; micro pores of CTATEX super-comfortable polyester fibers can be opened fully by the desizing-scouring-bleaching and mercerizing, holes in the fibers are smooth, the moisture absorbing and breathing performances of the fabric can be improved under the absorbing effect of hole cores, and the water drops can be absorbed within 3 seconds according to the test; the fuzzing and pilling resistance of the fabric is more than 4 grades; the advantages of wearing resistance, non-ironing, wrinkle preventing and quick drying of the polyester fibers are remained to the maximum; the fabric is particularly suitable for wearing when working and living outdoor in a hot season.

Owner:SWOTO PROTECTION & TECH CO LTD +1

Gluing device and gluing method

ActiveCN103579577ANo bubblesWrinkle freeElectrode manufacturing processesElectrical and Electronics engineering

The invention discloses a gluing device. The gluing device comprises a gluing mechanism. The gluing mechanism comprises gluing rollers and movable gluing plates opposite to the gluing rollers. The movable gluing plates are used for transferring a glue tape towards a pole piece. The gluing rollers cooperate with the movable gluing plates and evenly rolling-paste the glue tape on the pole piece. The invention also discloses a gluing method utilizing the gluing device. The gluing rollers are used for gluing and can evenly rolling-paste the glue tape on the pole piece along with pole piece feeding without bubble and fold production.

Owner:SHENZHEN YINGHE TECH

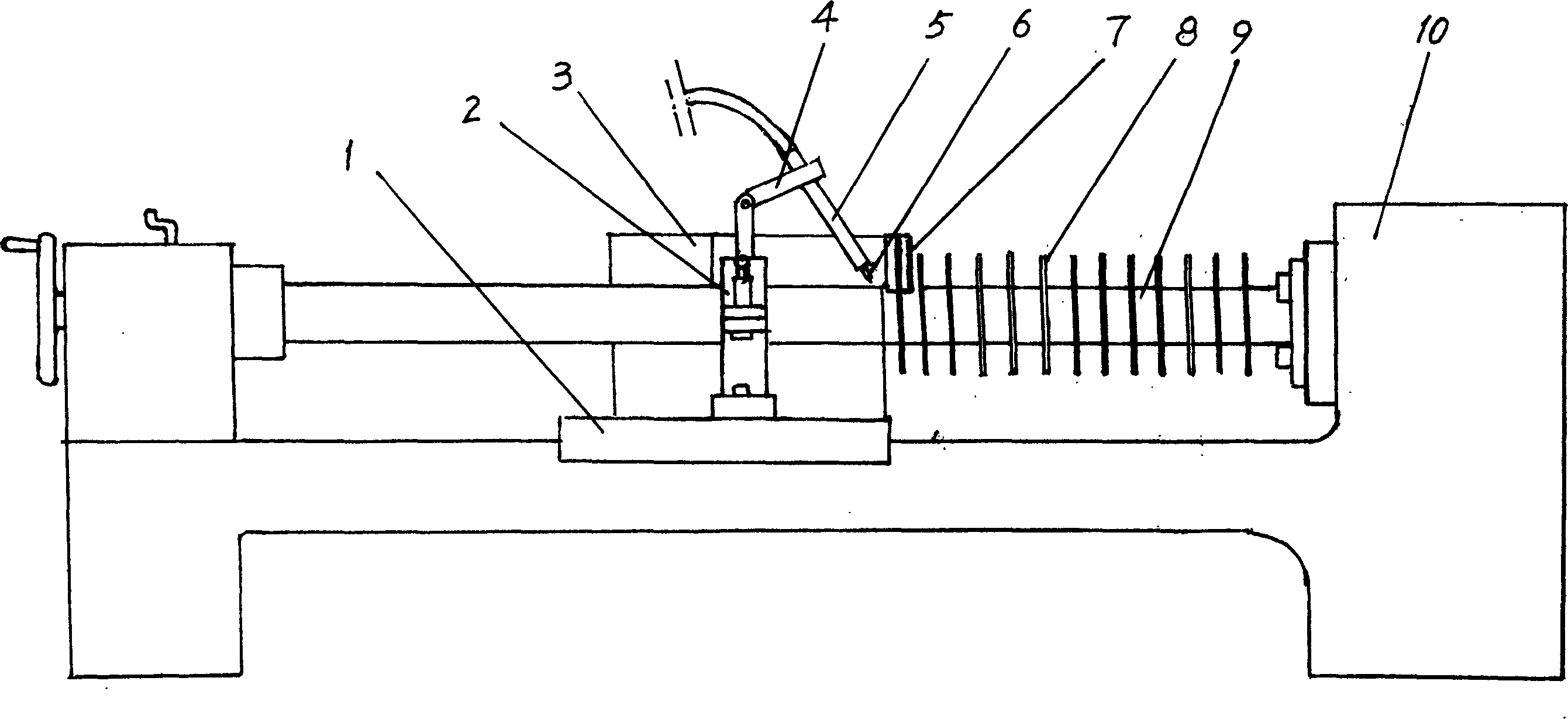

Simple bending method of large-diameter thin-walled aluminum tube

The invention discloses a simple bending method of a large-diameter thin-walled aluminum tube. The simple bending method includes the steps of firstly, filling core material, namely mixture of melted rosin and fine sand, into the large-diameter thin-walled aluminum tube; secondly, cooling the large-diameter thin-walled aluminum tube after the core material is filled in; thirdly, performing stretch bending to the cooled large-diameter thin-walled aluminum tube to form a bent tube by a stretch bender; fourthly, removing the core material filled in the bent tube; and fifthly, washing the bent tube. Simple bending of the large-diameter thin-walled aluminum tube is achieved by the method, and the bent tube formed by the method is high in precision and small in section distortion and overcomes the defects of wrinkle, crushing, cracking and the like compared with that in a bending forming process without filling. Compared with a numerical-control bent tube process, the method is simple in bent condition, simple to operate and short in processing period, reduces costs of using a special numerical-control tube bender and manufacturing a bent tube mould and avoids a large amount of process exploration and repeated mould repairing.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Method for making anti-aging moisturizer

InactiveCN101700212AMaintain integrityAnti agingCosmetic preparationsToilet preparationsSkin whiteningMoisturizer

The invention belongs to the field of articles for daily use, in particular relates to a method for making anti-aging moisturizer. Main components include tea polyphenol, SOD, kojic acid palmitate, vitamin A, bighead atractylodes rhizome, chinaroot greenbrier rhizome, bletilla, radix angelicae and radix ampelopsis; in certain ratio, the main components are subject to smashing, mixing, decocting, filtering, filtering residue, reverse osmosis concentration, heating dissolution and stirring in sequence, thus obtaining the product. The product made by adopting the invention can eliminate wrinkle and stain, stop losing of moisture, keep the skin to be moist and has the functions of skin whitening, removing beverage, removing wrinkle, moisturizing and anti-aging.

Owner:HANGZHOU LIUYI TECH

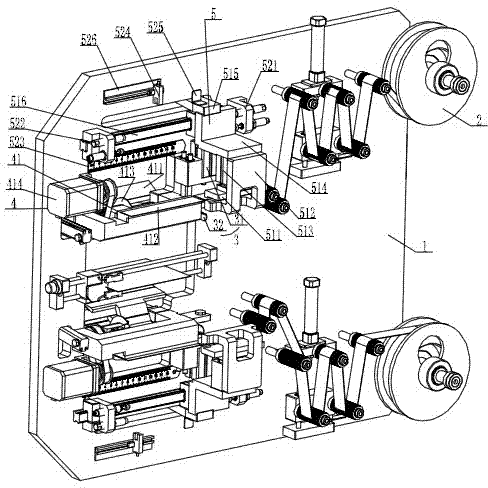

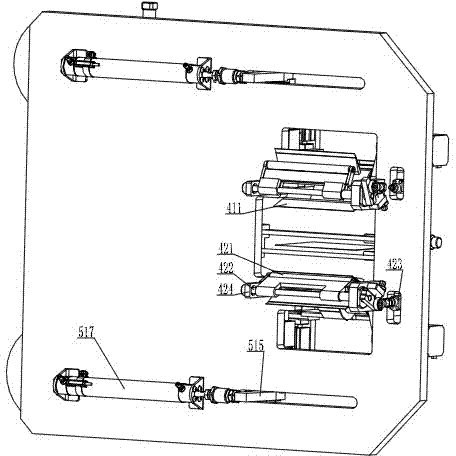

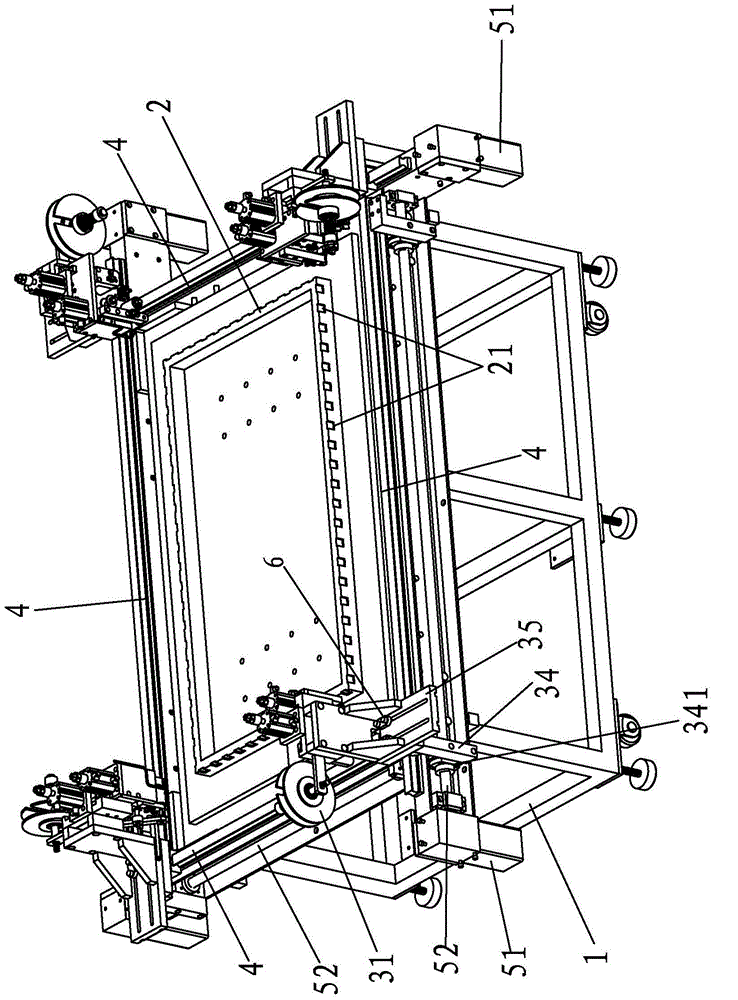

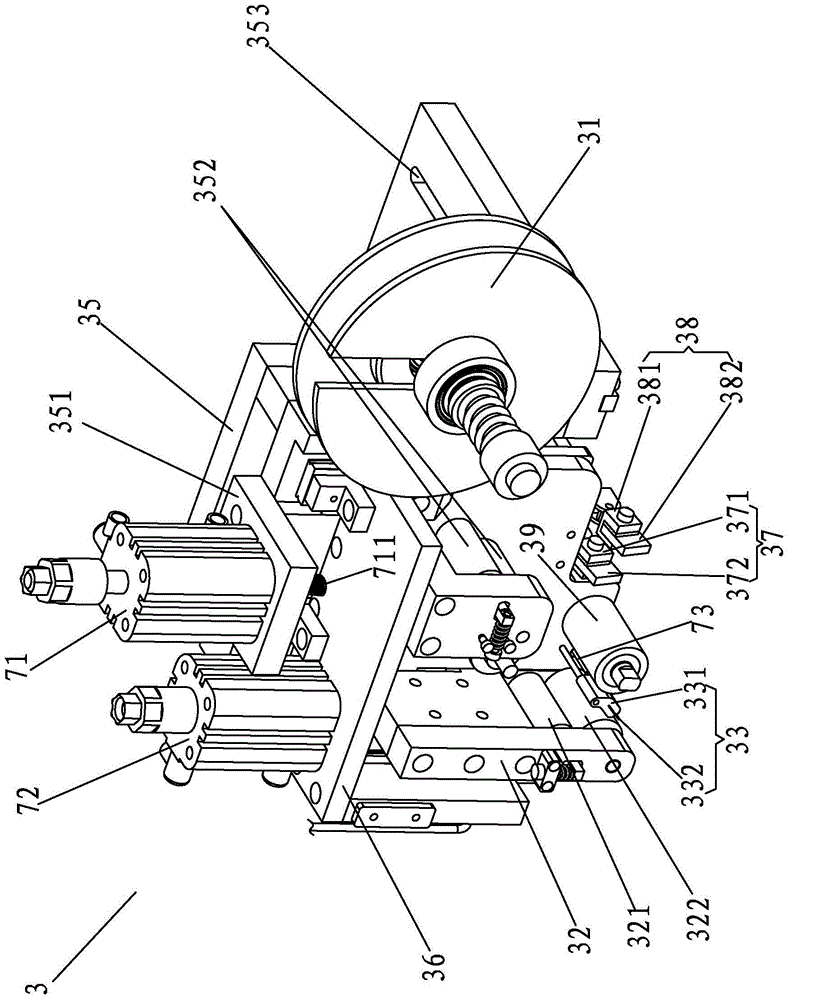

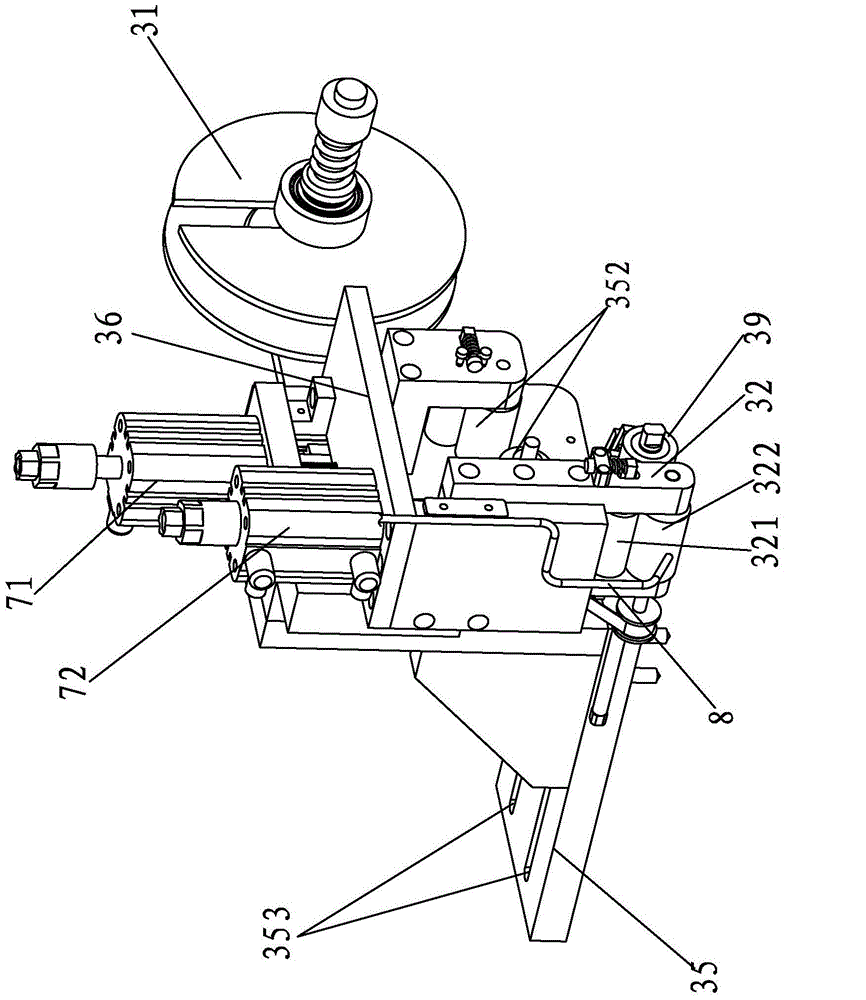

Automatic laminator

ActiveCN103978759AThe operation steps are the sameImprove efficiencyLamination ancillary operationsLaminationMechanical engineeringEngineering

The invention discloses an automatic laminator. A frame is included, and the frame is provided with a fixed table and a laminator; the laminator comprises a laminator head and a movement driving mechanism; the laminator head comprises a mounting seat and a take-up reel, a front pressure head for sticking an easy tear film on the right side of a front frame, a film cutting tool bit for cutting the easy tear film, a rectangular pressure head for folding the easy tear film extending out of the right side of the front frame downwards, and a side pressure head for pressing the easy tear film folded to the side face of the front frame on the side face of the front frame, wherein the tape reel, the front pressure head, the film cutting tool bit, the rectangular pressure head and the side pressure head are arranged on the mounting seat and at the same side; and the film cutting tool bit is behind the front pressure head, and the rectangular pressure head is between the side pressure head and the film cutting tool bit. Compared with the prior art, the automatic laminator of the invention realizes mechanical automatic lamination operation to substitute traditional manual operation, and has the advantages of high efficiency, time and labor saving, no bubble or wrinkle, and good lamination effect.

Owner:FUJIAN RICHES ELECTRONICS SCI & TECH

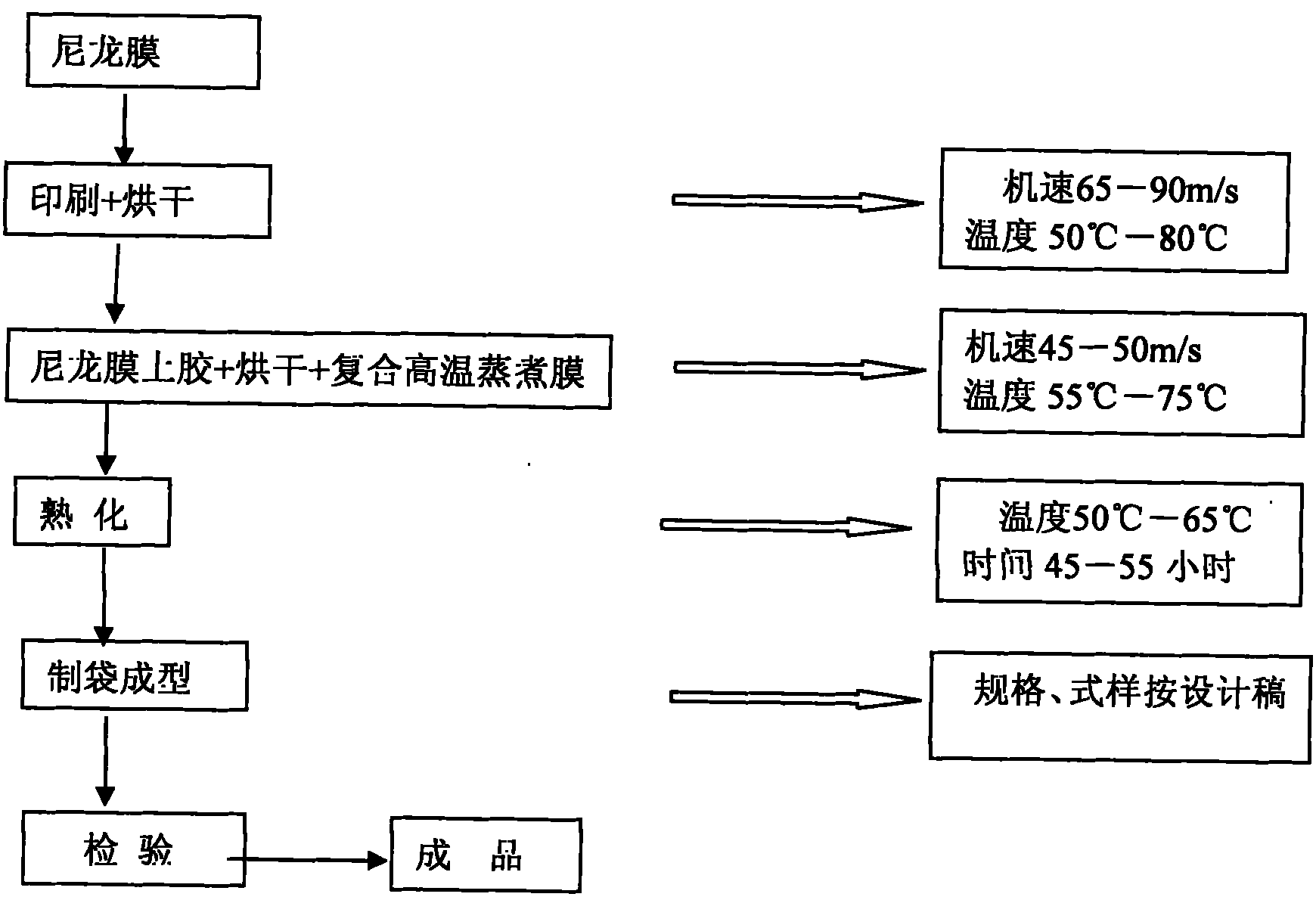

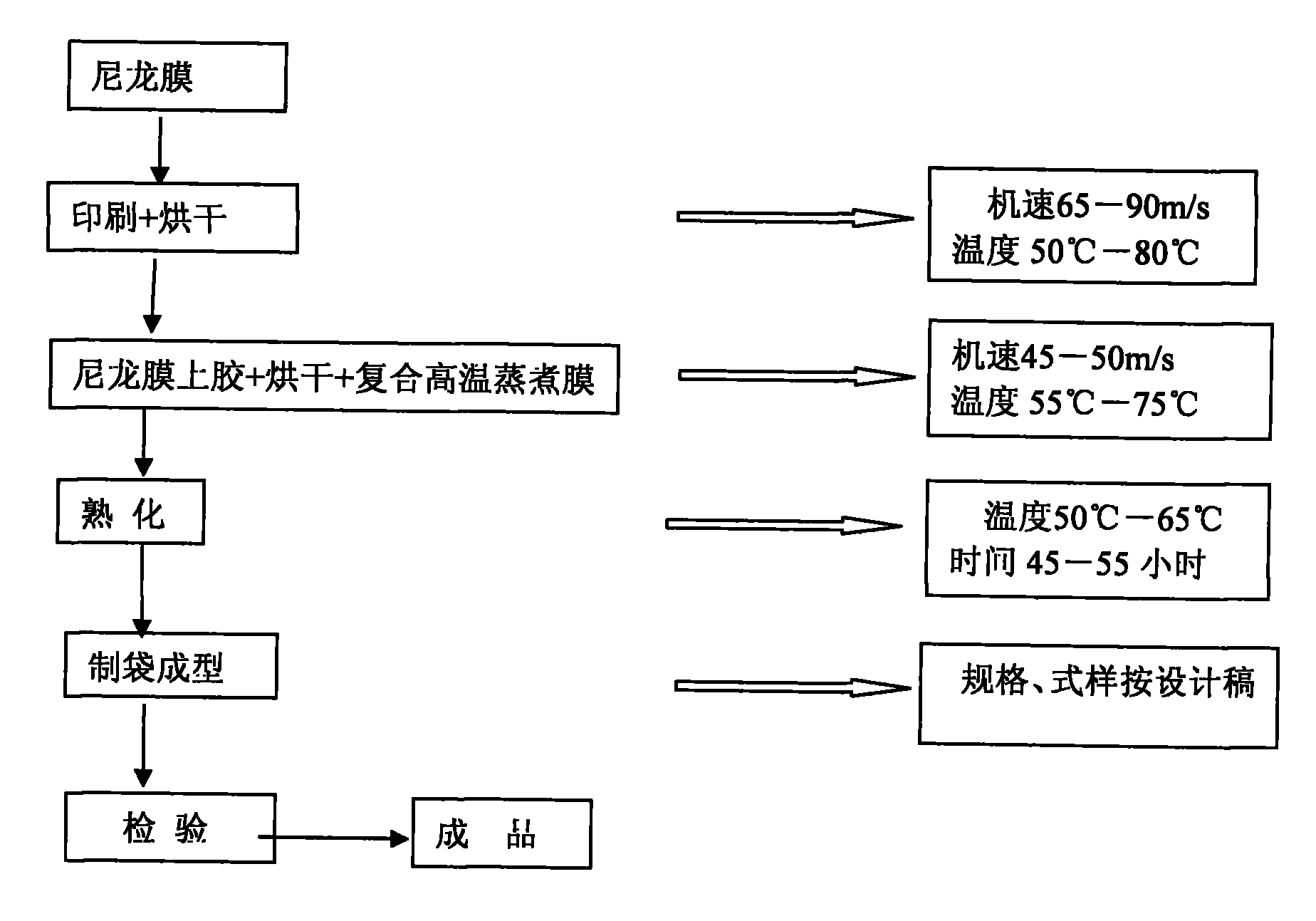

Manufacturing method of vacuum cooking and packaging bag for food

InactiveCN101837855AIncrease air flowImprove toughness and strengthLamination ancillary operationsBagsCompound aEngineering

The invention relates to a manufacturing method of a vacuum cooking and packaging bag for food, which comprises the following steps: selecting and proportioning raw materials and controlling the process flow; compounding a BOPA with an RCPP; firstly, delivering the printed BOPA into a compounding process; and proportioning a polyurethane glue and a solvent by weight; stirring uniformly and gluing on the BOPA; and manufacturing and forming a bag by heating in a drying tunnel, aging at constant temperature and heat sealing. After the food is packaged in vacuum, the vacuum package can resist high-temperature cooking and sterilizing at 135 DEG C for 30 minutes, and the packaging bag can not loose or leak air, can ensure the quality of the food and prolong the preservation and quality guarantee period of the food.

Owner:赵秀雄

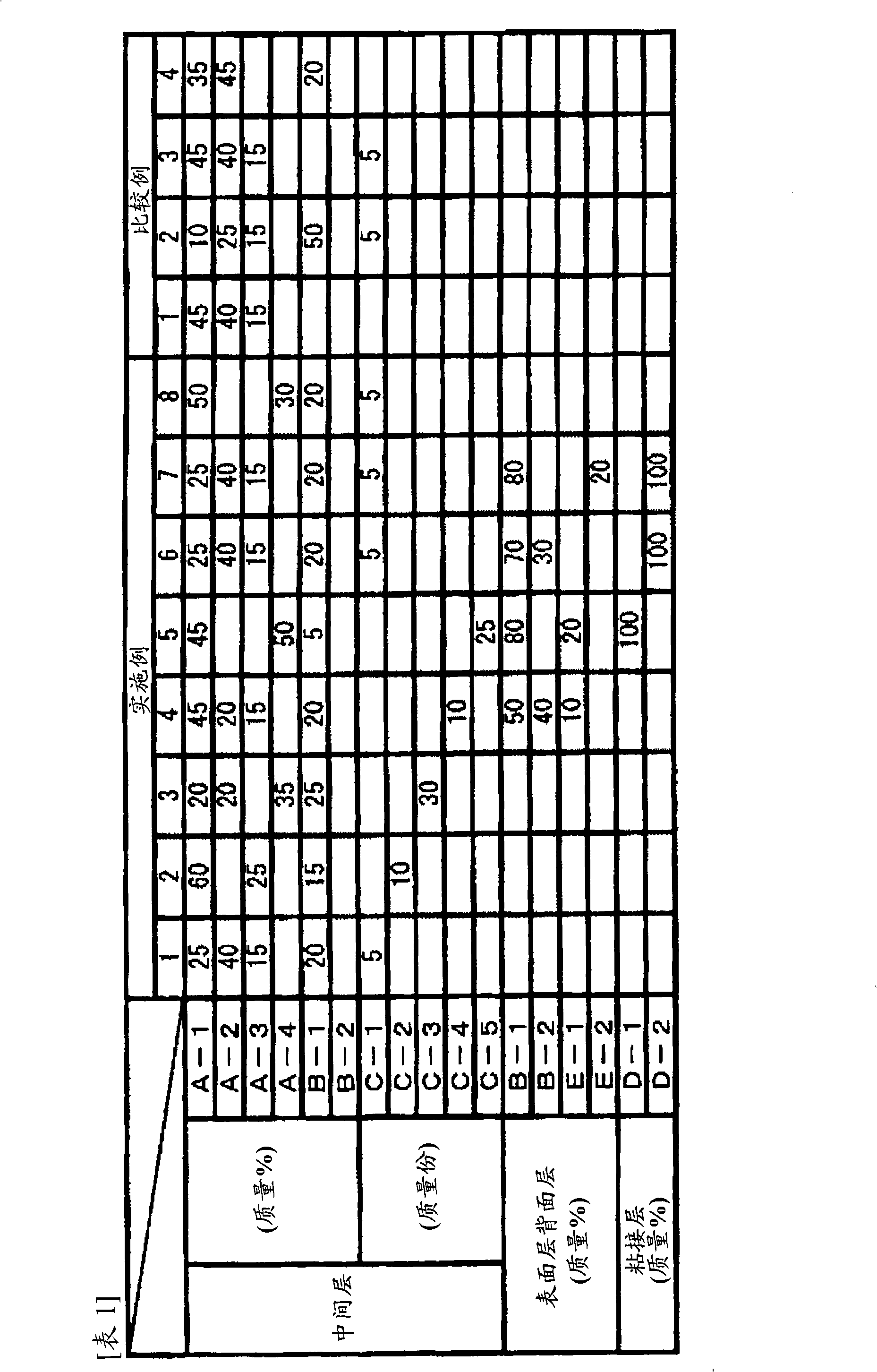

Thermally shrinkable polyolefin film, molded article using the film, thermally shrinkable label, and container

ActiveCN101316708AImprove featuresEasy to processStampsSynthetic resin layered productsPolyolefinPolyresin

Disclosed is a thermally shrinkable polyolefin film which comprises a mixed resin mainly composed of a polyolefin resin (A), a polylactic acid resin (B) and a resin (C) capable of improving the compatibility between the resin (A) and the resin (B) or has at least one layer comprising the mixed resin, wherein the ratio of the resin (A) to the resin (B) ((A) / (B)) is 99 / 1 to 70 / 30 by mass. The film has a thermal shrinkage ratio in at least one direction of 20% or higher as determined after immersing the film in hot water of 80 DEG C for 10 seconds, has a natural shrinkage ratio of less than 10% as determined after storing the film for 7 days under environment of 40 DEG C and 50% RH, is excellent in thermal shrinking properties and shrinkage finishing, and is reduced in natural shrinking. Also disclosed is a thermally shrinkable polyolefin label. Further disclosed is a container having the label thereon.

Owner:MITSUBISHI CHEM CORP

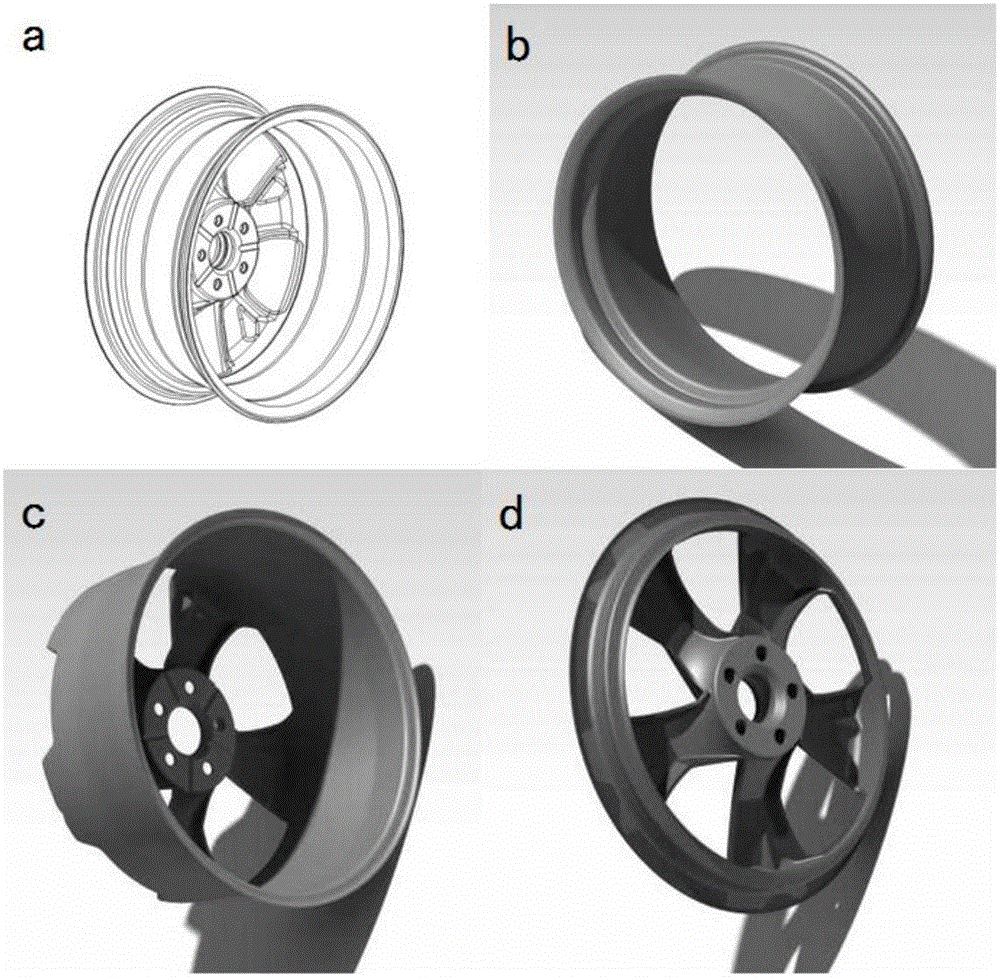

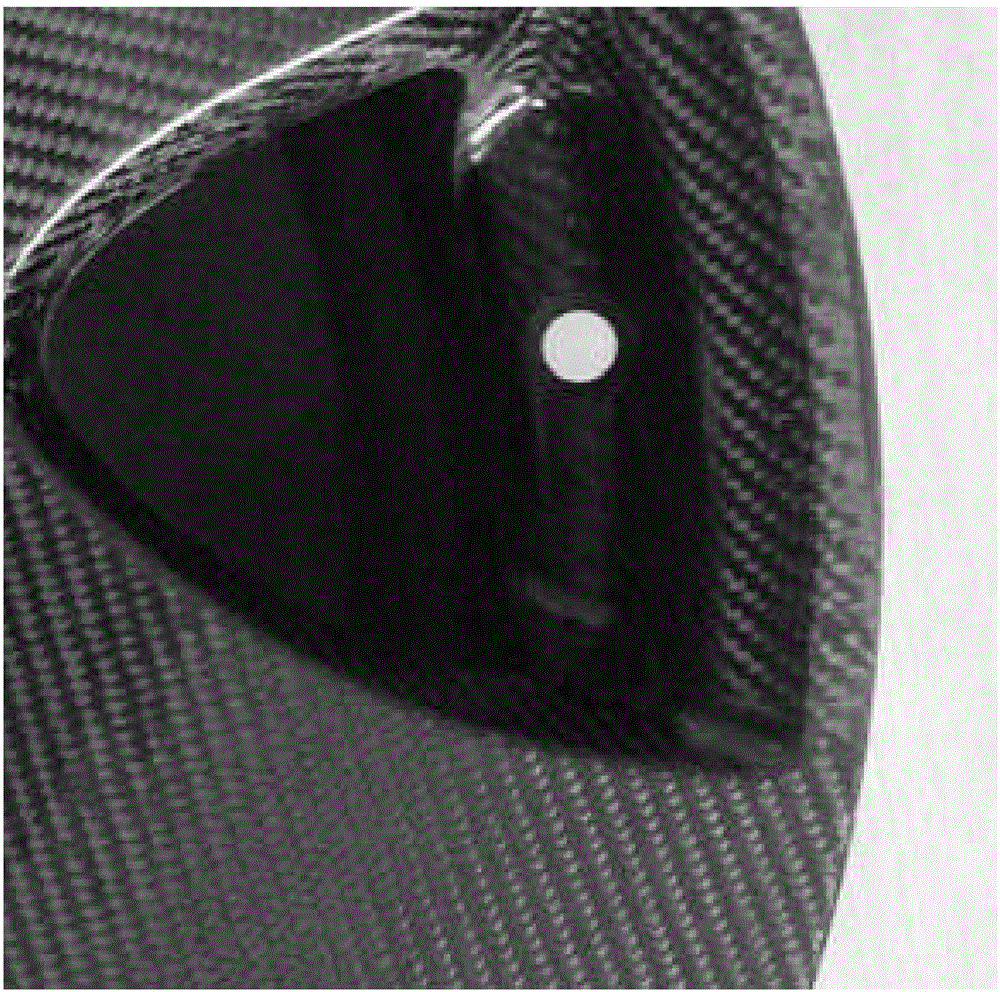

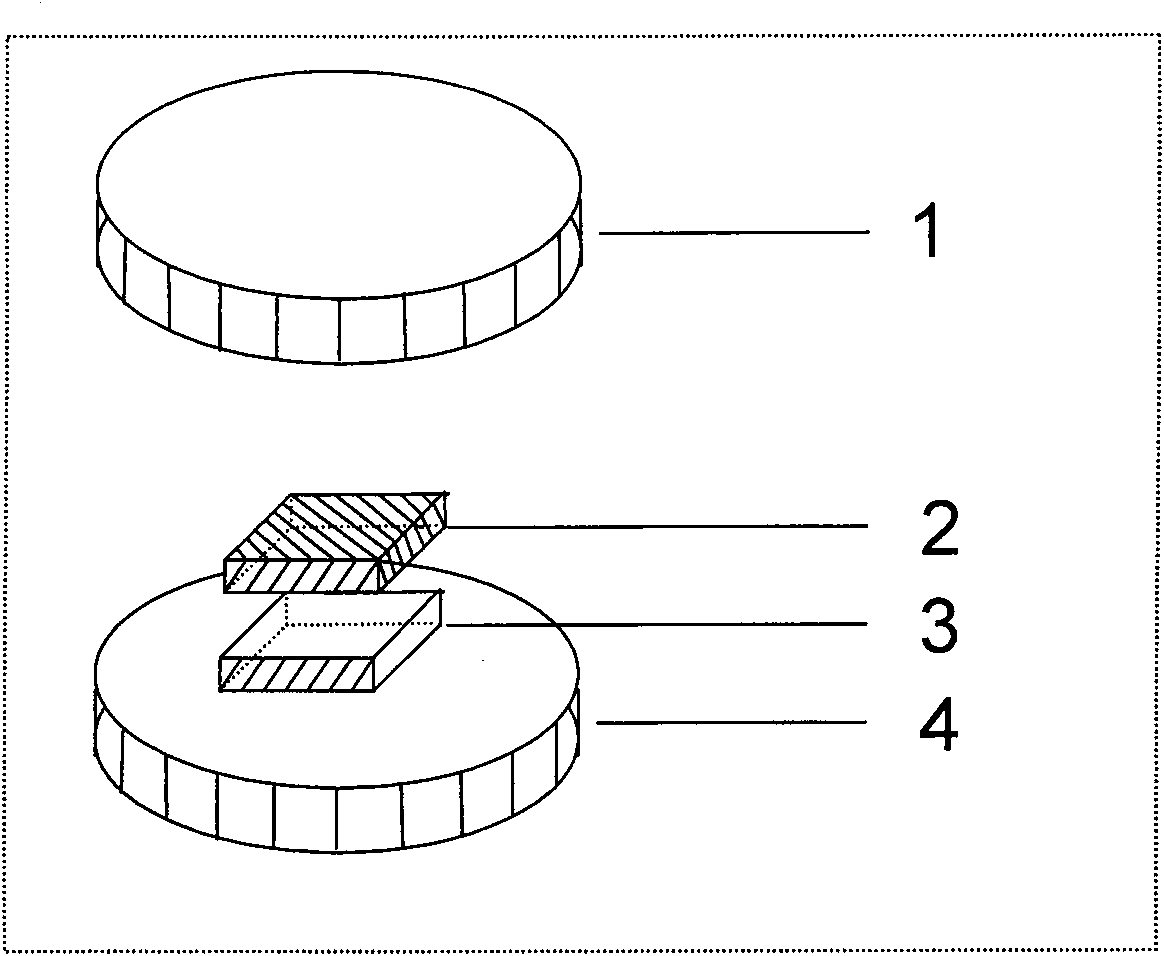

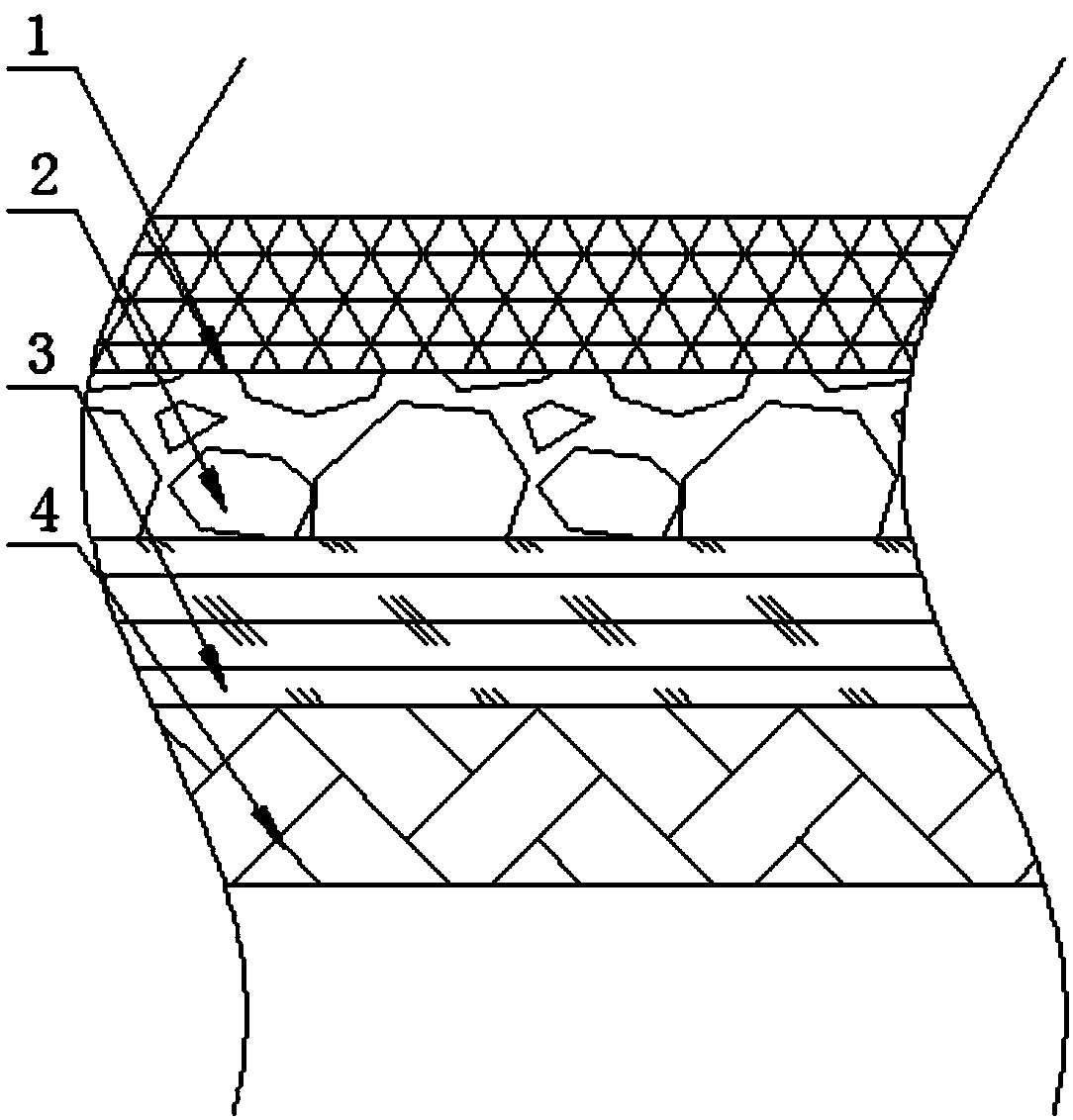

Manufacturing method for composite hub

The invention relates to a manufacturing method for a composite hub. The manufacturing method comprises the following steps that a reinforced fiber perform is manufactured in advance; a sealed die cavity is filled with the reinforced fiber perform, and then is vacuumized; a resin system is injected in the die cavity with compressed air; and the composite hub is obtained after curing. The resin system is injected in a die with the compressed air, and pressure is maintained for a certain time after injection is completed, so that the acceptable volume content of a reinforced material is increased, the purpose that the volume content of the reinforced material is controllable is achieved, and the mechanical strength of the hub is controlled and improved. The composite hub, manufacturing according to the manufacturing method, is extremely low in void ratio and high in fiber content, fibers are uniformly distributed in a composite material structure, without folds, and since the perform is manufactured in a blocked manner, a complex product is split into simple components, the production efficiency is high, and the quality is controllable and stable.

Owner:HARBIN FRP INST

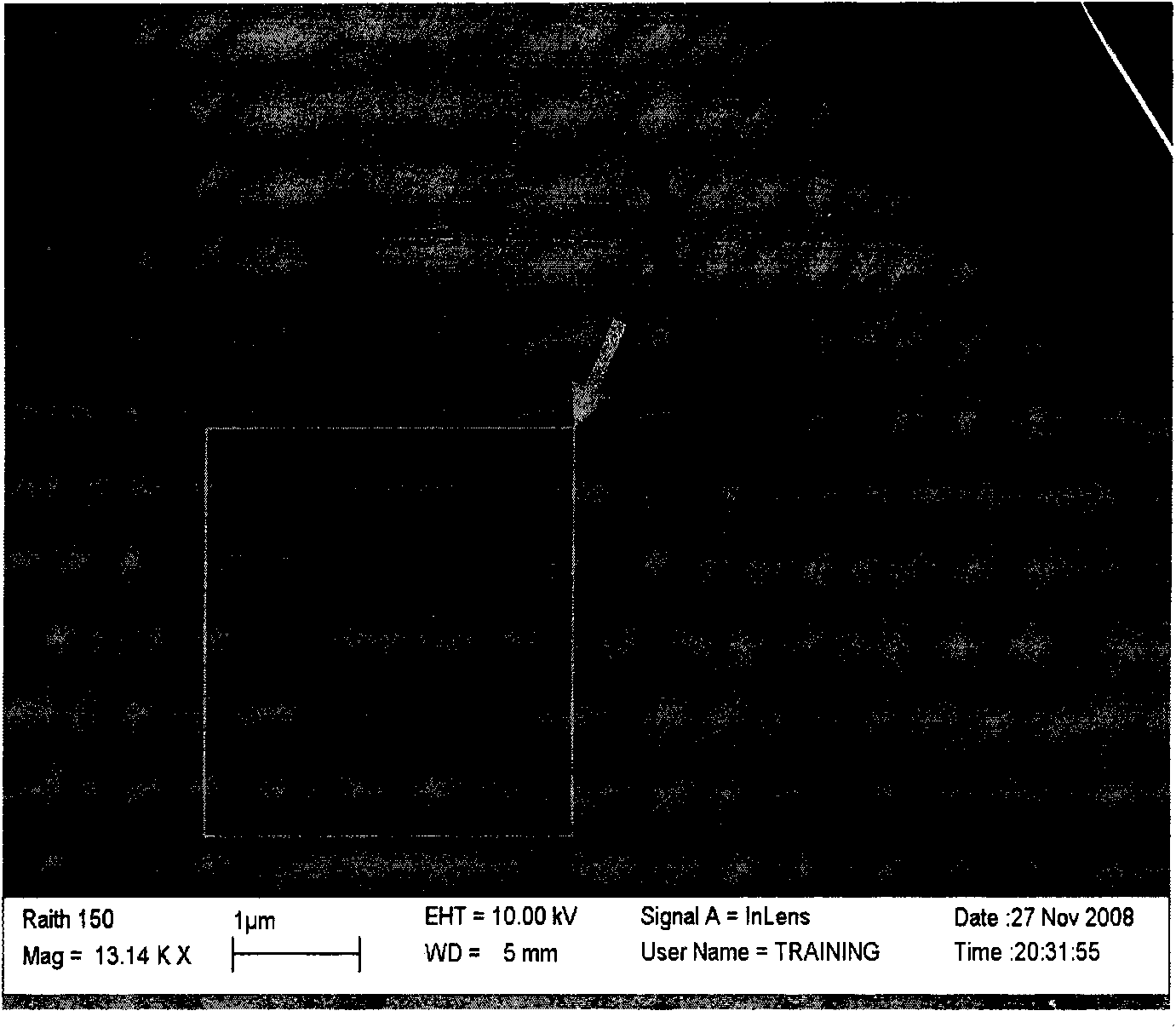

Method for preparing single-layer graphene film on SiO2 substrate directly

InactiveCN101768012ASimple stepsEasy to implementHighly oriented pyrolytic graphiteSingle layer graphene

The invention relates to a method for preparing two-dimensional nanomaterial single-layer graphene film on SiO2 substrate directly, comprising (1) preparing substrate and conducting purification treatment; (2) processing block-shaped highly-oriented pyrolytic graphite or natural flake-shaped graphite; (3) preparing the single-layer graphene film sample through mechanical compression method: adjusting pressure within 10kg-20kg, keeping pressure within 5-10min, then releasing the pressure, removing the block-shaped graphite, and taking out the silicon substrate to obtain the single-layer graphene film sample. The method for preparing the single-layer graphene film uses fewer devices, has low cost and high successful rate, and is easy to implement. The raw material is directly contacted with the substrate, accordingly, the pollution to the sample caused by the introduction of other auxiliary media can be avoided. The obtained graphene sample is of a complete sheet shape due to effect of pressure, without folds.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for finishing cotton-nylon elastic woven fabrics

InactiveCN101845735AImprove color vibrancyWrinkle freeTextile storage in superimposed formFibre treatmentEngineeringAmmonia

The invention provides a method for finishing cotton-nylon elastic woven fabrics, and the process flow comprises singeing, desizing, mercerizing, dry setting and preshrinking, which is characterized in that a step of cold batching yarding is added between the steps of singeing and desizing, and the steps of liquefying ammonia and pre-tendering are added between the steps of mercerizing and dry setting, therefore the whole process flow is as follows: singeing, cold batching yarding, desizing, mercerizing, liquefying ammonia, pre-tendering, dry forming and preshrinking. The invention has scientific and easily-operated process, compared with conventional cotton-nylon elastic woven fabrics, the cotton-nylon elastic woven fabrics obtained by the invention has better gloss, greatly improved fabric color brightness, no fold and turned edge on surface fabric, uniform fabric width, good tendering and setting effects, favorable elasticity up to 20-30% and the first-rate product rate above 99%, can further perfect the stability of product quality and satisfies high quality requirement on top grade fabrics.

Owner:LUTAI TEXTILE

Combined type flat plate compounding machine

InactiveCN104476898AWrinkle freeMeet production needsLaminationLamination apparatusReducerEngineering

The invention discloses a combined type flat plate compounding machine. The combined type flat plate compounding machine comprises a rack and a supporting frame, wherein a plurality of upper heating plates are arranged at the front end of the rack at the inner side of the lower end of an upper conveyor belt, a plurality of upper cooling plates are arranged at the rear end of the rack at the inner side of the lower end of the upper conveyor belt; a plurality of lower heating plates which are matched with the upper heating plates are arranged at the front end of the supporting frame at the inner side of the upper end of a lower conveyor belt; a plurality of lower cooling plates which are matched with the upper cooling plates are arranged at the rear end of the supporting frame at the inner side of the upper end of the lower conveyor belt; a gap regulating mechanism comprises a speed reducer arranged at the lower end of the rack and a plurality of gearboxes arranged at the two sides of the speed reducer, wherein the lower end of a regulating screw is connected to the gearboxes, the upper end of the regulating screw is connected to the supporting frame, rotary shafts of the two gearboxes close to the two sides of the speed reducer are respectively connected to motor shafts at the two ends of the speed reducer by virtue of a first universal shaft, and the rotary shafts of the two gearboxes adjacent to the two sides of the speed reducer are connected with each other by virtue of a second universal shaft.

Owner:JIANGSU HONGYE MACHINERY

3D four-layer glued channel down jacket fabric

PendingCN109130347ADurableConvenient careGarment special featuresSynthetic resin layered productsFiberEngineering

The invention discloses a 3D four-layer glued channel down jacket fabric. The 3D four-layer glued channel down jacket fabric comprises a first chemical fiber fabric layer, a first TPU film, a second TPU film and a second chemical fiber fabric layer, wherein one surface of the first chemical fiber fabric layer is glued and connected with one surface of the first TPU film, the other surface of the first TPU film is glued and connected with one surface of the second TPU film, the other surface of the second TPU film is glued and connected with one surface of the second chemical fiber fabric layer, and the first chemical fiber fabric layer and the second chemical fiber fabric layer are one or at least two of a knitted fabric layer, a woven fabric layer, a Dacron fabric layer and a nylon fabriclayer. The 3D four-layer glued channel down jacket fabric has the characteristics of being solid and durable, easy to take care, anti-wrinkle and non-ironing; the 3D four-layer glued channel down jacket fabric has an effect of expelling parasites, and has preferable fragrance, so that the comfortable sensation of a user is improved; alphabets, logos, patterns and the like can be represented perfectly on channels, so that the fabric is more fashionable and popular, and the manpower is saved.

Owner:SUZHOU XINGFENGQIANG TEXTILE TECH CO LTD

Welding method for heat radiating fin of heat exchanger and equipment thereof

InactiveCN1544193AGood welding effectImprove heat conduction and heat transfer performanceArc welding apparatusTubular elementsSteel tubeArc welding

The invention is a method of welding cooling fins of a transducer, and its character: the end head of the stainless steel band is welt upright on the steel pine wall, then the steel pipes rotates at uniform speed to apply stretching prestress on the stainless steel band, the steel band is driven by the rotating steel pipe to be wound upright on the steel pipe, at the time of winding, the Wu electrode of an argon-arc welding gun aligns with the horizontal point of tangency between the stainless steel band and the steel pipe and at the time of welding, outputs current to stabilize the arc to weld the roots of the cooling fins. Its advantages: it can continuously weld 1.0 -1.5mm thick, 10-15mm wide steel bands upright on to a stainless steel pipe with a 40-60 mm diameter, and it has good welding effect and enhances heat conducting and transferring performances and prolongs service life of the transducer.

Owner:温振武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com