3D four-layer glued channel down jacket fabric

A down jacket fabric, 3D technology, applied in the direction of clothing, clothing, clothing features, etc., can solve the problems of waste of human resources, poor comfort, difficult to take care of, etc., to improve comfort, good high temperature resistance and water resistance, and save labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

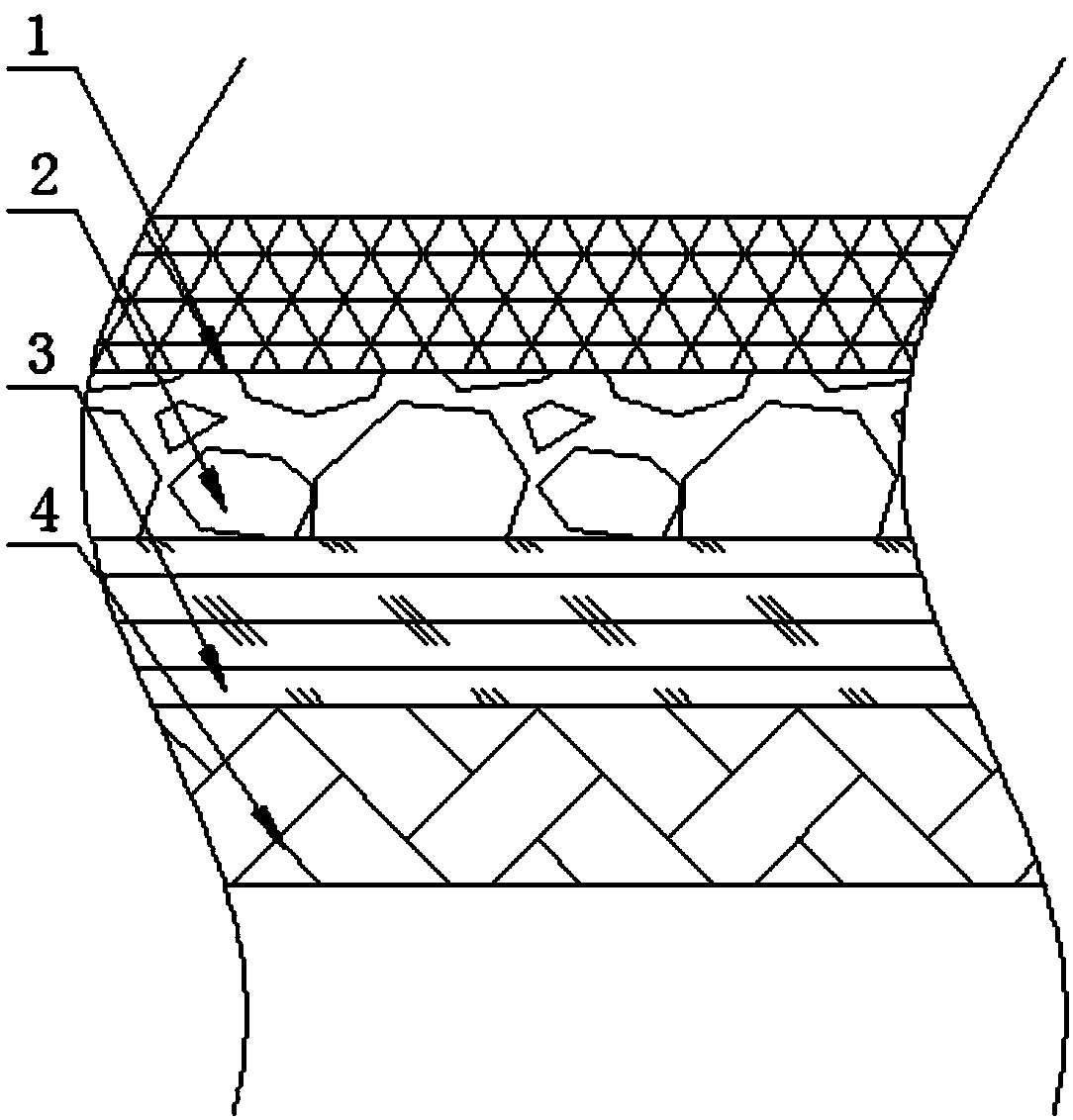

[0030] A 3D four-layer glued channel down jacket fabric, comprising a first chemical fiber fabric layer 1, a first TPU film layer 2, a second TPU film layer 3 and a second chemical fiber fabric layer 4, one side of the first chemical fiber fabric layer 1 and the first One side of the TPU film layer 2 is glued and connected, the other side of the first TPU film layer 2 is glued and connected with one side of the second TPU film layer 3, and the other side of the second TPU film layer 3 is glued and connected with one side of the second chemical fiber fabric layer 4. A TPU film layer 2 and a second TPU film layer 3 are members of the same material;

[0031] Wherein, the first chemical fiber fabric layer 1 and the second chemical fiber fabric layer 4 are one or at least two layers of knitted fabric layer, woven fabric layer, polyester fabric layer or nylon fabric layer, the first chemical fiber fabric layer 1 and the second chemical fiber fabric layer The thickness of chemical fi...

Embodiment 2

[0047]A 3D four-layer glued channel down jacket fabric, comprising a first chemical fiber fabric layer 1, a first TPU film layer 2, a second TPU film layer 3 and a second chemical fiber fabric layer 4, one side of the first chemical fiber fabric layer 1 and the first One side of the TPU film layer 2 is glued and connected, the other side of the first TPU film layer 2 is glued and connected with one side of the second TPU film layer 3, and the other side of the second TPU film layer 3 is glued and connected with one side of the second chemical fiber fabric layer 4. A TPU film layer 2 and a second TPU film layer 3 are members of the same material;

[0048] Wherein, the first chemical fiber fabric layer 1 and the second chemical fiber fabric layer 4 are one or at least two layers of knitted fabric layer, woven fabric layer, polyester fabric layer or nylon fabric layer, the first chemical fiber fabric layer 1 and the second chemical fiber fabric layer The thickness of chemical fib...

Embodiment 3

[0064] A 3D four-layer glued channel down jacket fabric, comprising a first chemical fiber fabric layer 1, a first TPU film layer 2, a second TPU film layer 3 and a second chemical fiber fabric layer 4, one side of the first chemical fiber fabric layer 1 and the first One side of the TPU film layer 2 is glued and connected, the other side of the first TPU film layer 2 is glued and connected with one side of the second TPU film layer 3, and the other side of the second TPU film layer 3 is glued and connected with one side of the second chemical fiber fabric layer 4. A TPU film layer 2 and a second TPU film layer 3 are members of the same material;

[0065] Wherein, the first chemical fiber fabric layer 1 and the second chemical fiber fabric layer 4 are one or at least two layers of knitted fabric layer, woven fabric layer, polyester fabric layer or nylon fabric layer, the first chemical fiber fabric layer 1 and the second chemical fiber fabric layer The thickness of chemical fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com