Gluing device and gluing method

A glue sticking device and glue sticking technology, which is applied in the direction of electrode manufacturing, etc., can solve the problems of easy wrinkling of stickers, inconvenient adjustment of cutting length, bubbles, etc., and achieve the effect of accurate sticking position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

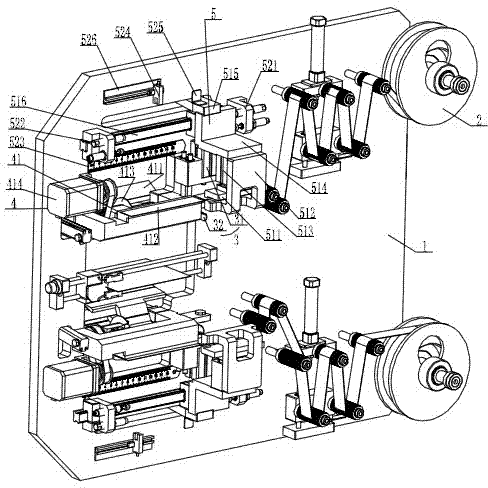

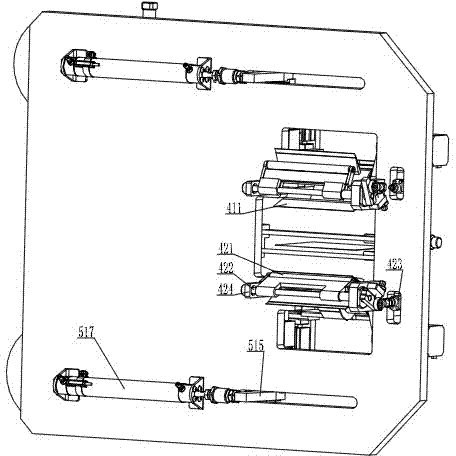

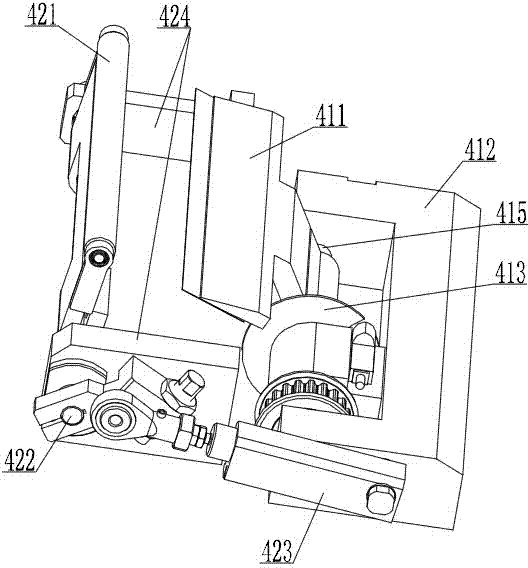

[0029] refer to Figure 1 to Figure 3 .

[0030] The gluing device includes a substrate 1 for fixing the gluing system, a correction drive system (not shown in the figure) for realizing the overall deviation correction of the gluing device, an unwinding mechanism 2 for fixing the tape material roll, a cutting mechanism 3 for cutting the tape, and a gluing device. Mechanism 4, the gluing mechanism 4 includes a gluing roller wheel 421 and a movable gluing plate 411 arranged opposite to the gluing roller wheel 421, and the movable gluing plate 411 transfers the adhesive tape toward the direction of the pole piece. Glue-applying roller 421 caters to the movable glue-applying plate 411 to roll the adhesive tape on the pole piece smoothly.

[0031] In a preferred embodiment, the gluing device further includes a glue opening m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com