Patents

Literature

35results about How to "Make sure to fill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

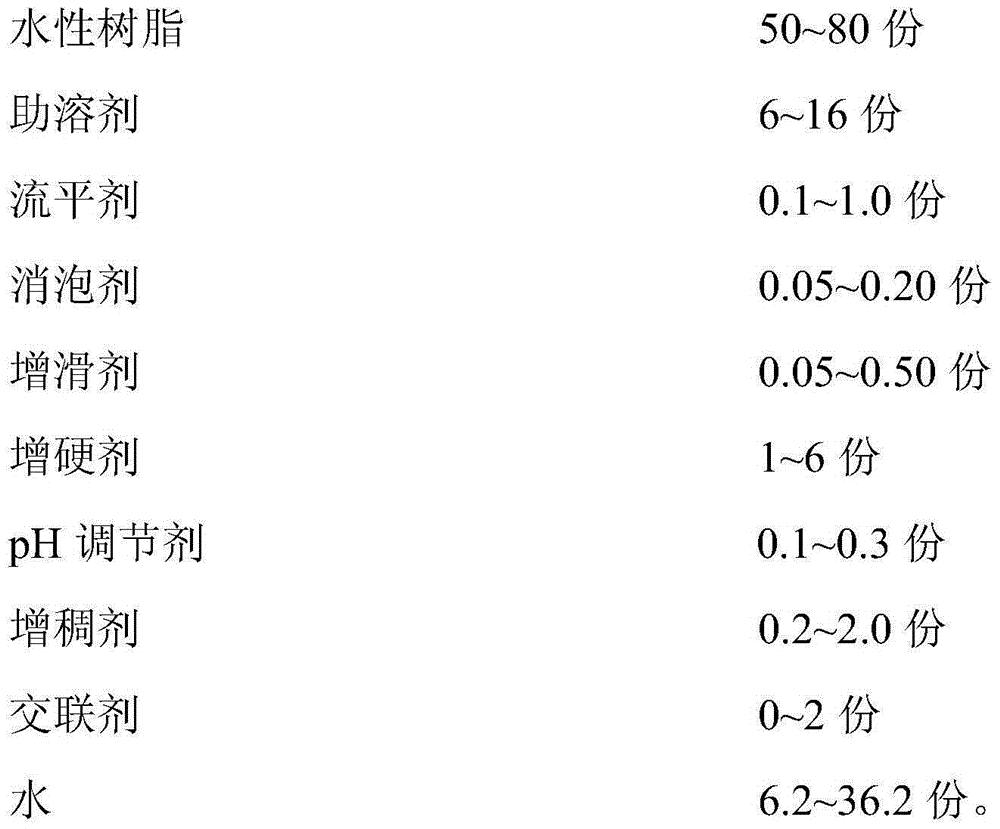

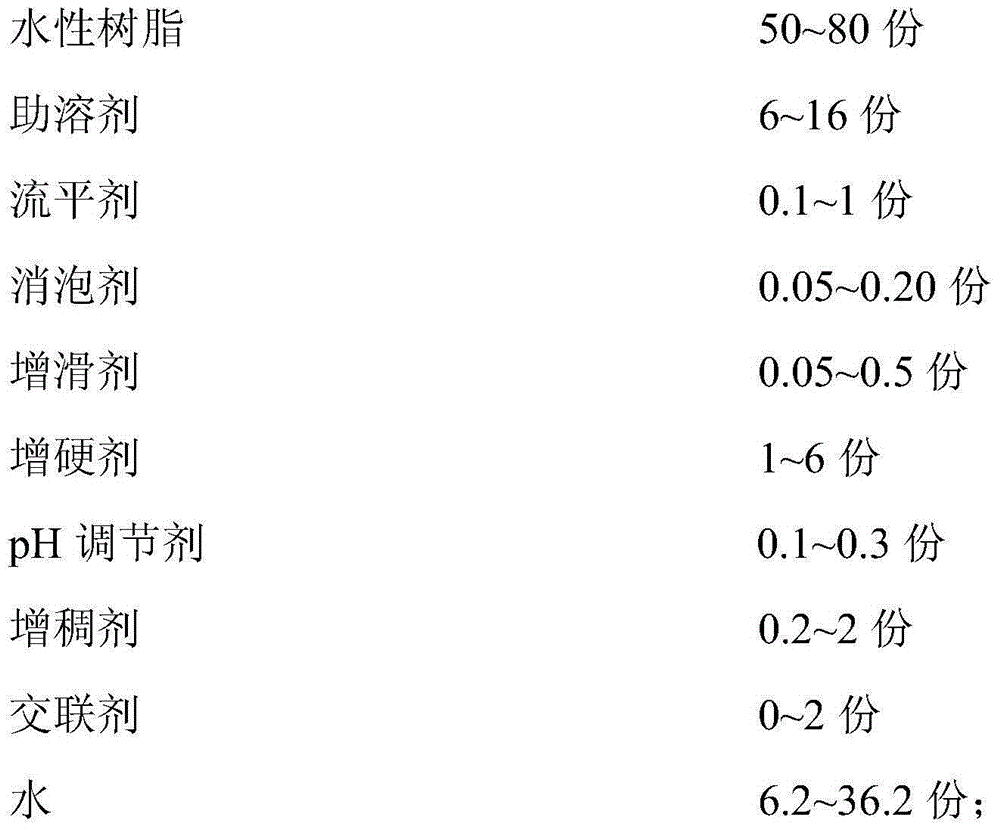

High-strength directly aluminizing water-based base coat and preparation method and application of high-strength directly aluminizing water-based base coat

ActiveCN103866607AGood sealingGood flexibilityNon-fibrous pulp additionPaper/cardboardWater basedWater vapor

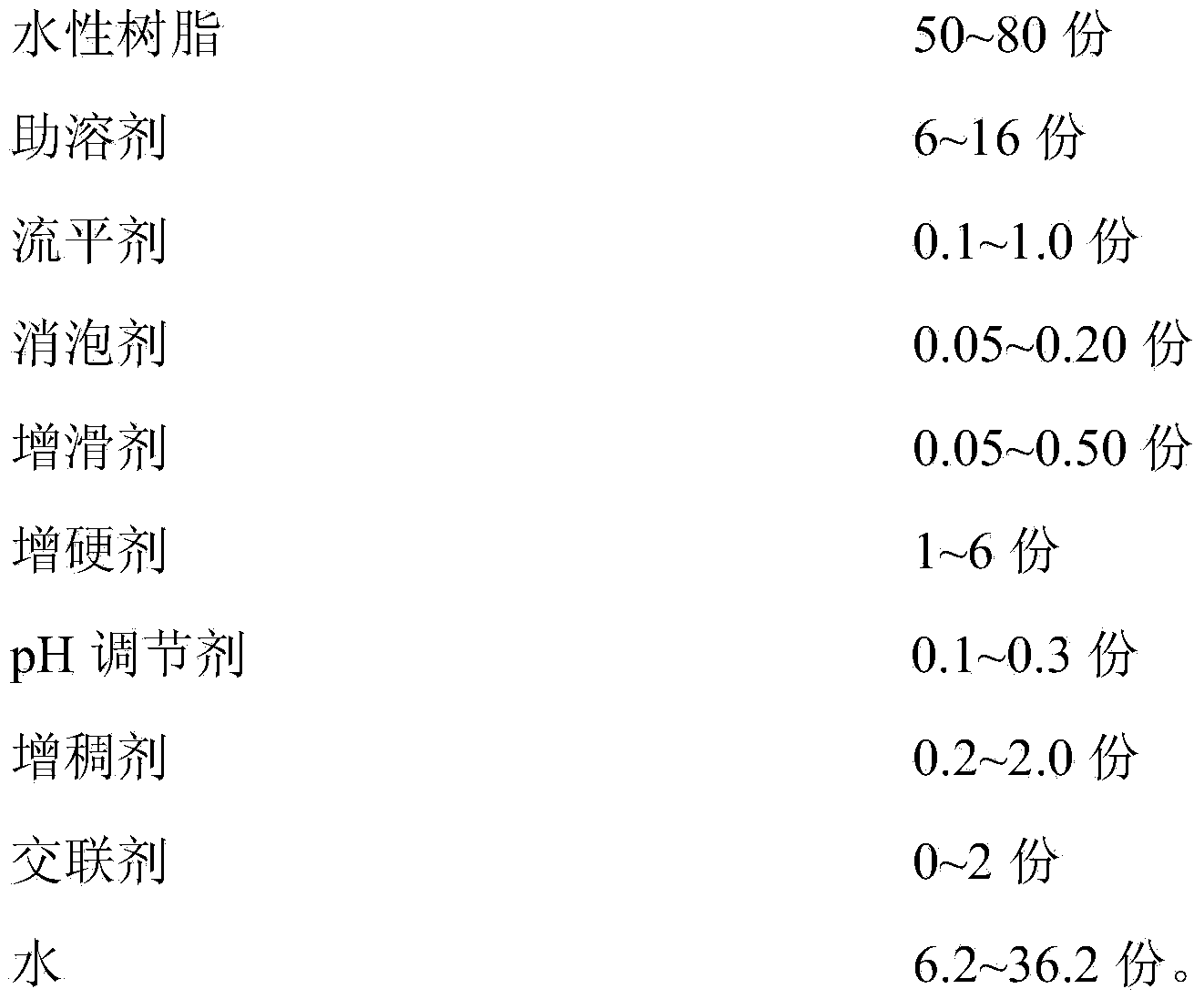

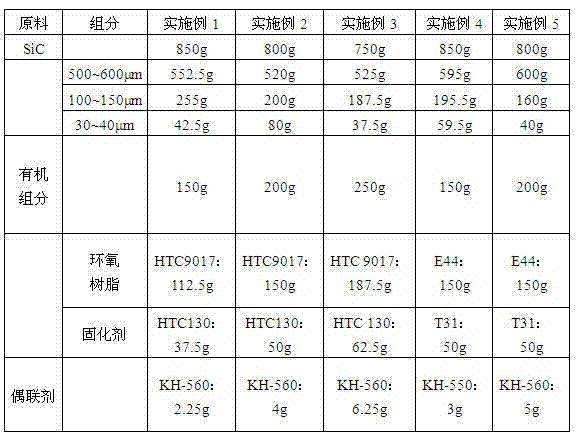

The invention discloses high-strength directly aluminizing water-based base coat and a preparation method and application of the high-strength directly aluminizing water-based base coat. The directly aluminizing water-based base coat comprises the following components in parts by mass: 50-80 parts of water-based resin, 6-16 parts of cosolvents, 0.1-1 part of flatting agents, 0.05-0.20 part of antifoaming agents, 0.05-0.5 part of slipping agents, 1-6 parts of hardening agents, 0.1-0.3 part of pH regulator, 0.2-2 parts of thickening agents, 0-2 parts of crosslinking agents and 6.2-36.2 parts of water. With good closure, the direct aluminizing water-based base coat disclosed by the invention guarantees the filling of micropores in the paper surface as well as the separation of water vapor; due to the characteristic of flexibility, the bending resistance of paper is realized; the viscosity resistance ensures that the film rolls are not bonded with each other after base coating on the aluminizing body paper; moreover, by adjusting the leveling property of the selected resin system and the coating, the base coat has high aluminizing metal texture.

Owner:GUANGZHOU HUMAN CHEM

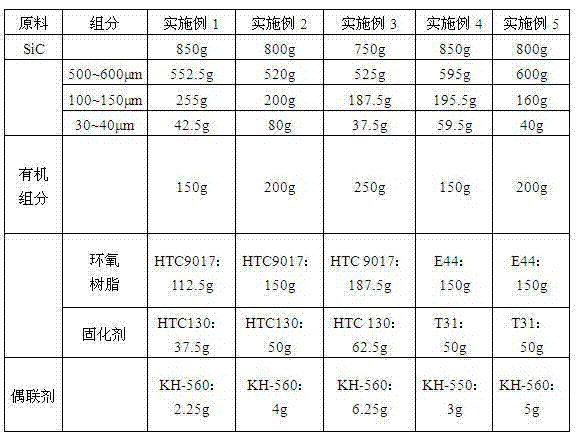

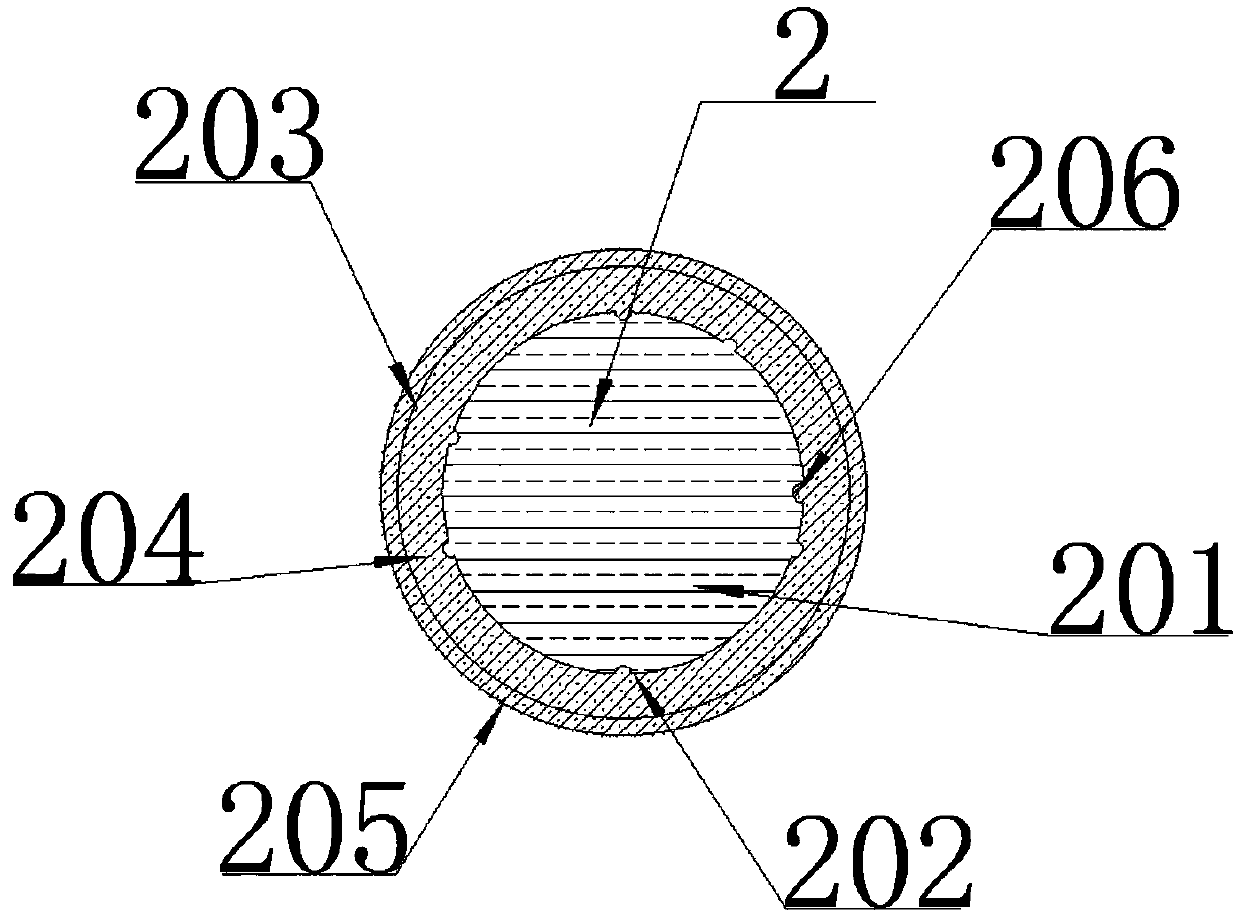

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677AImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

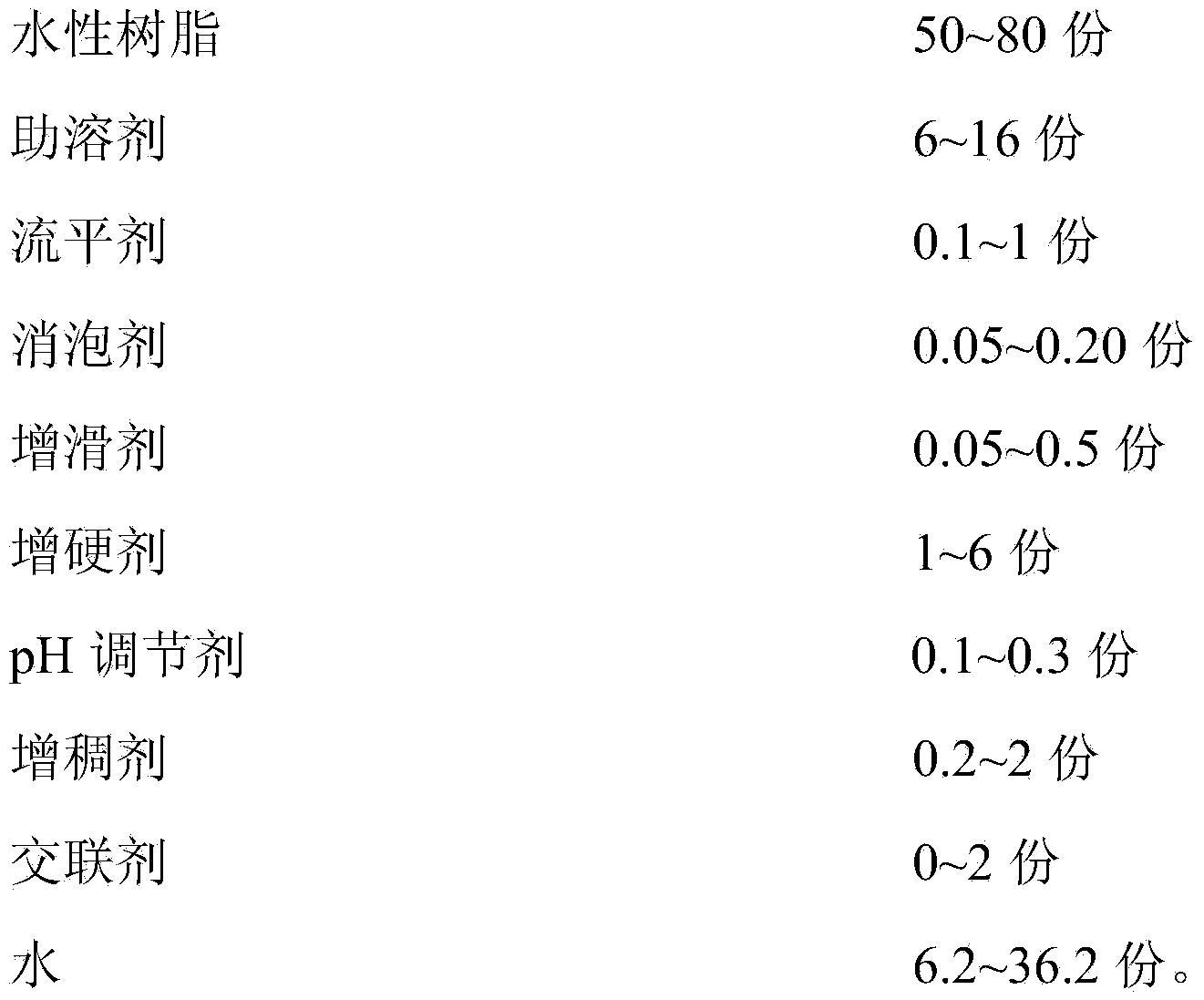

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

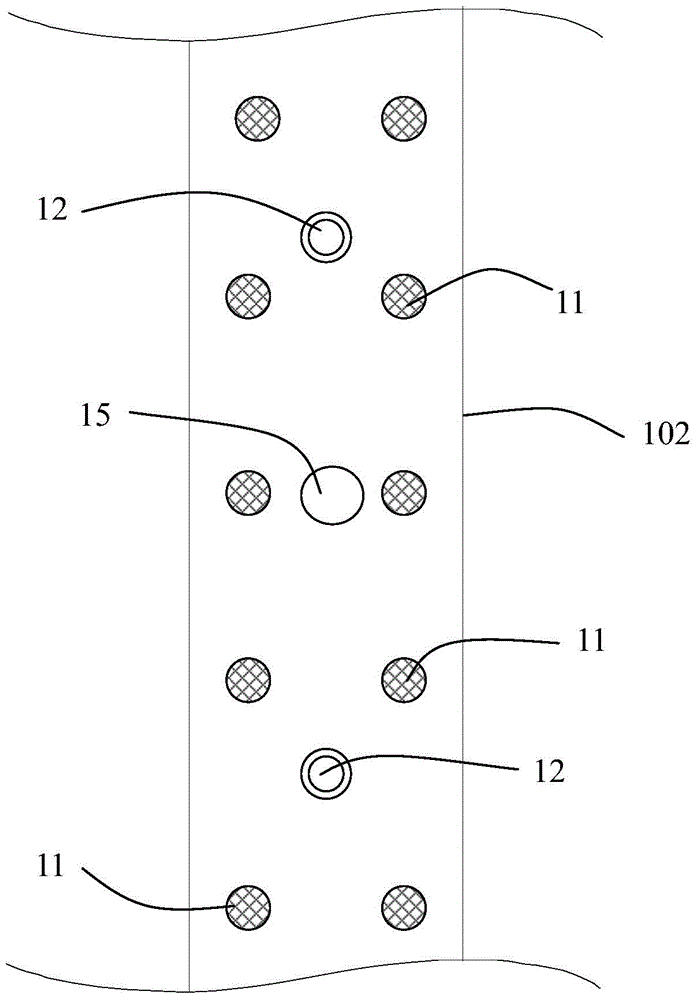

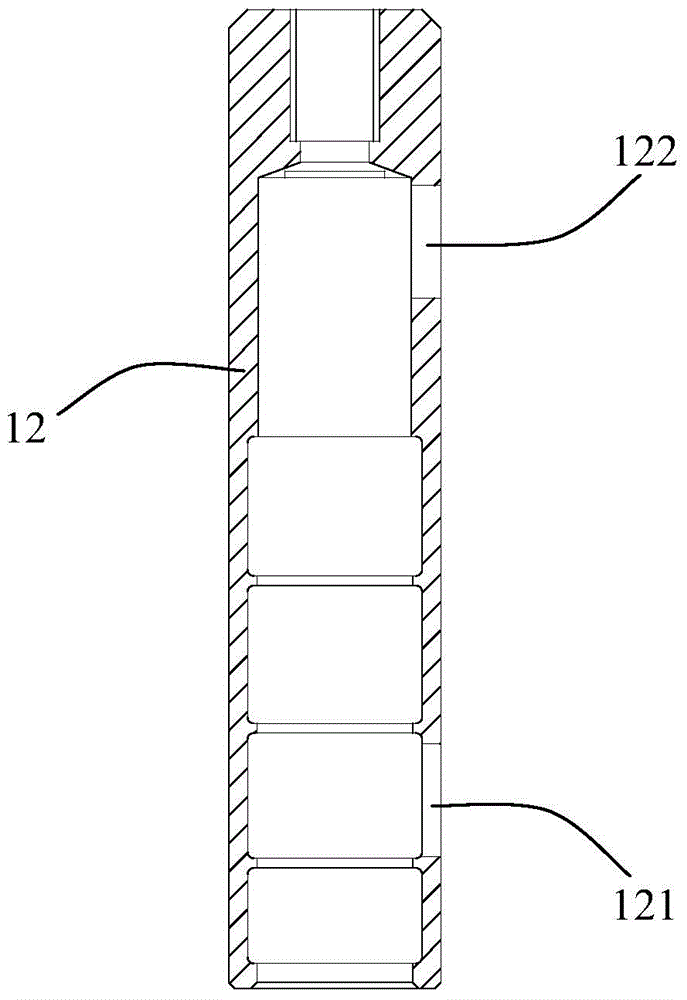

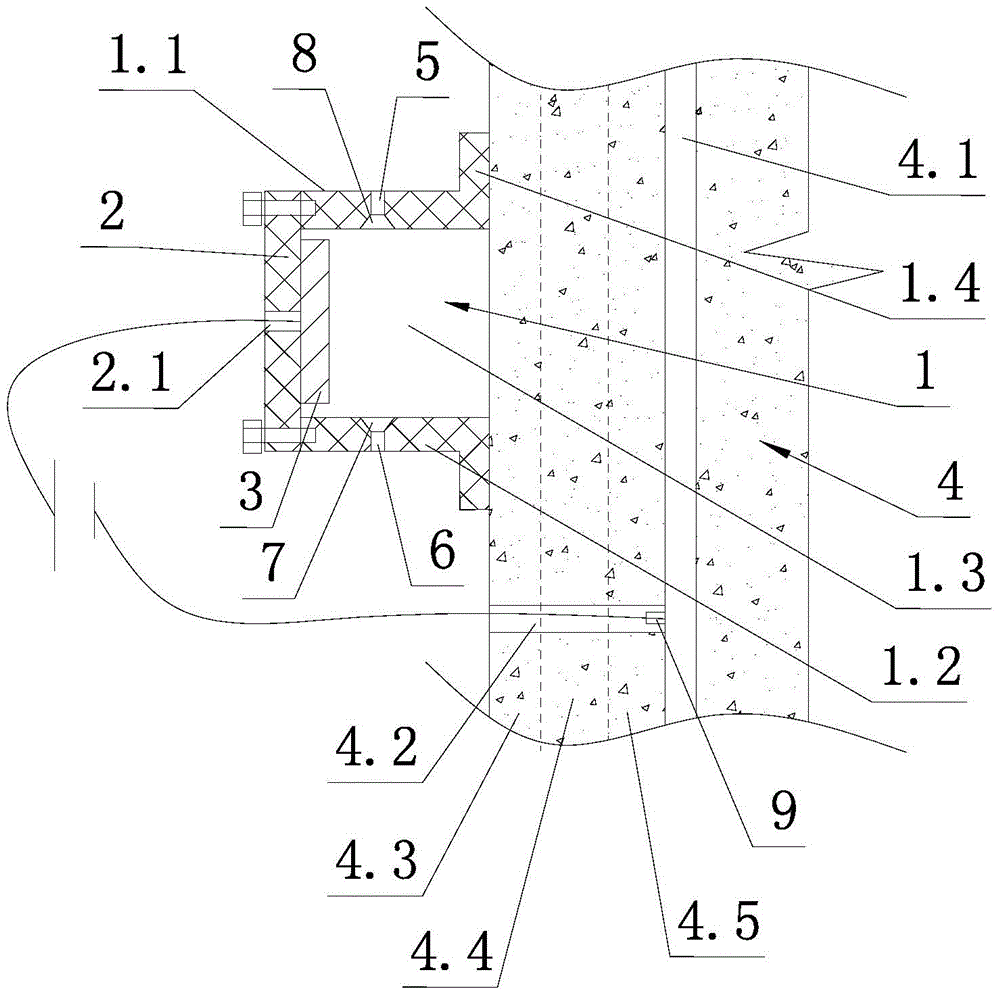

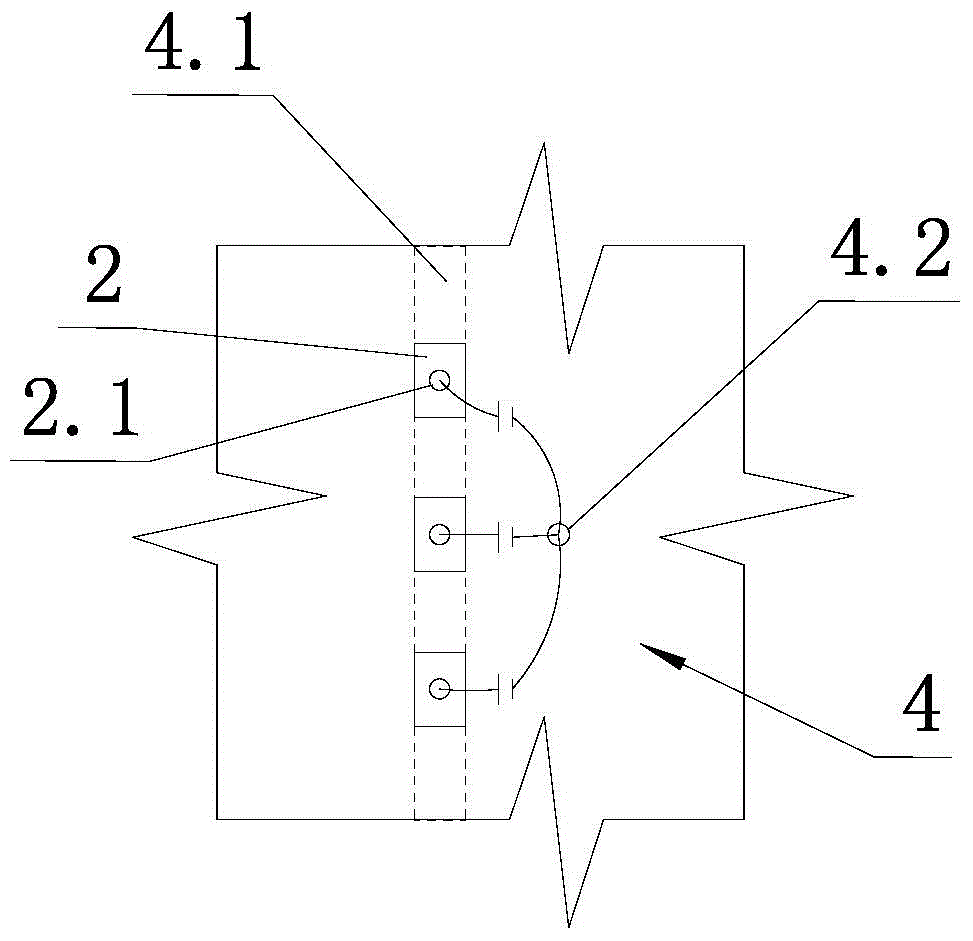

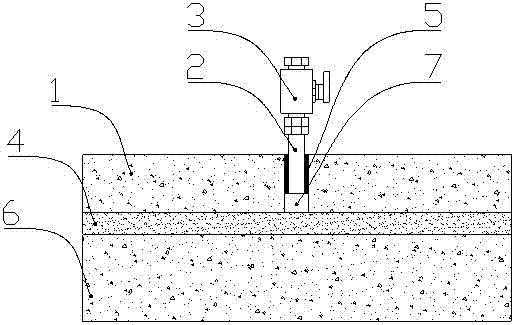

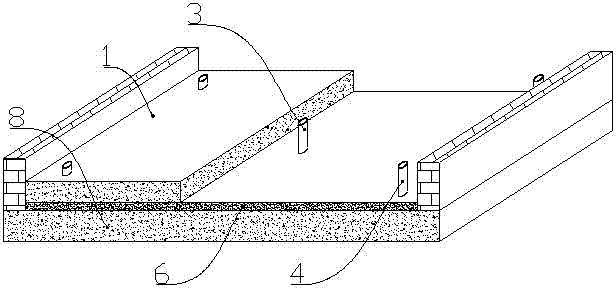

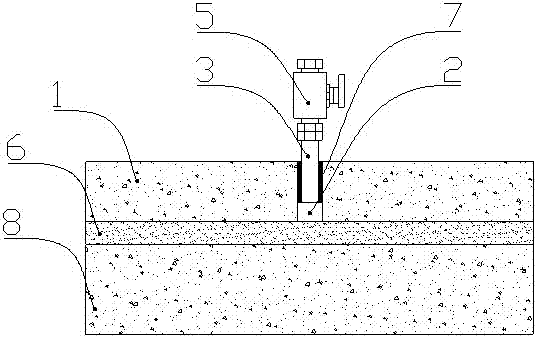

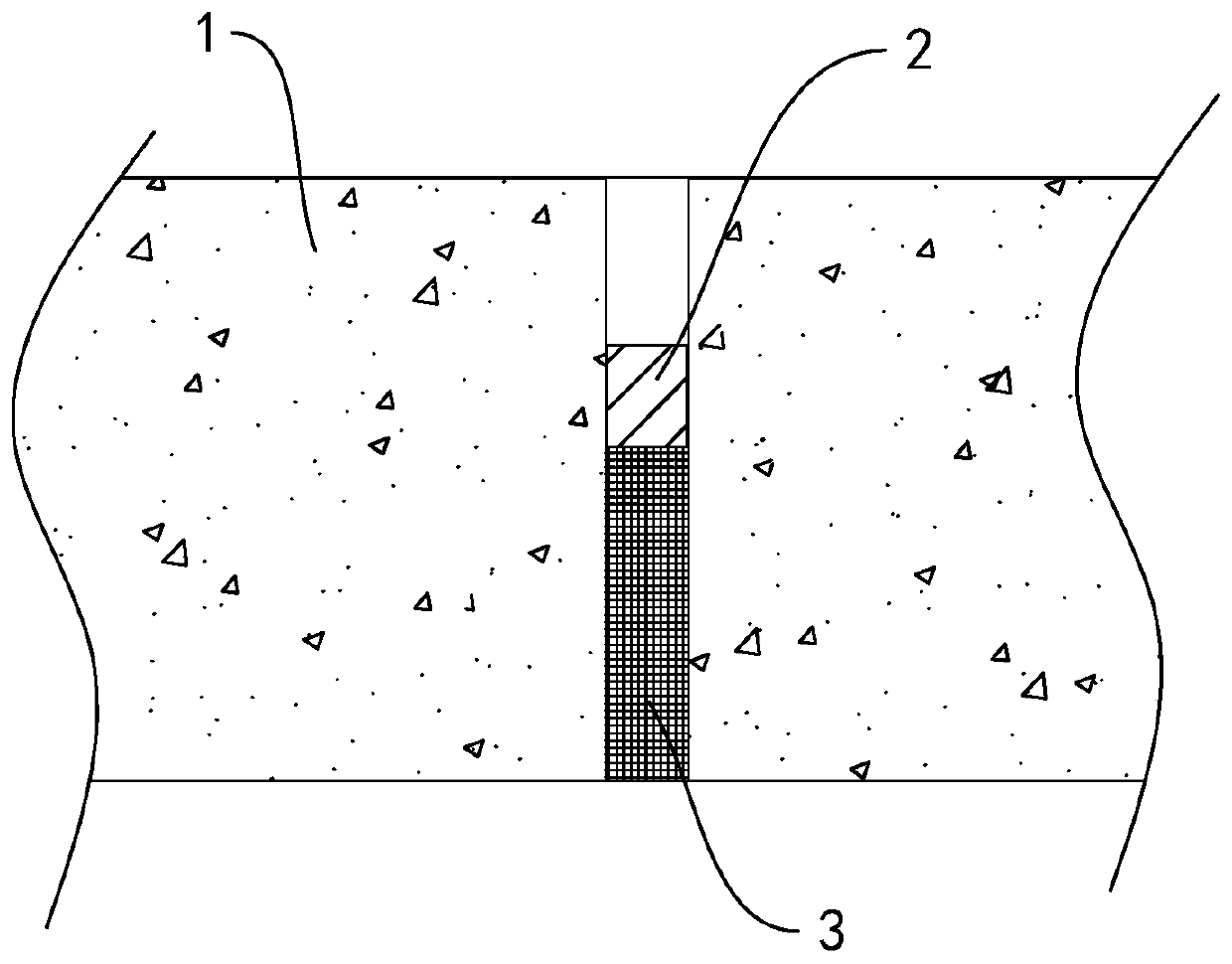

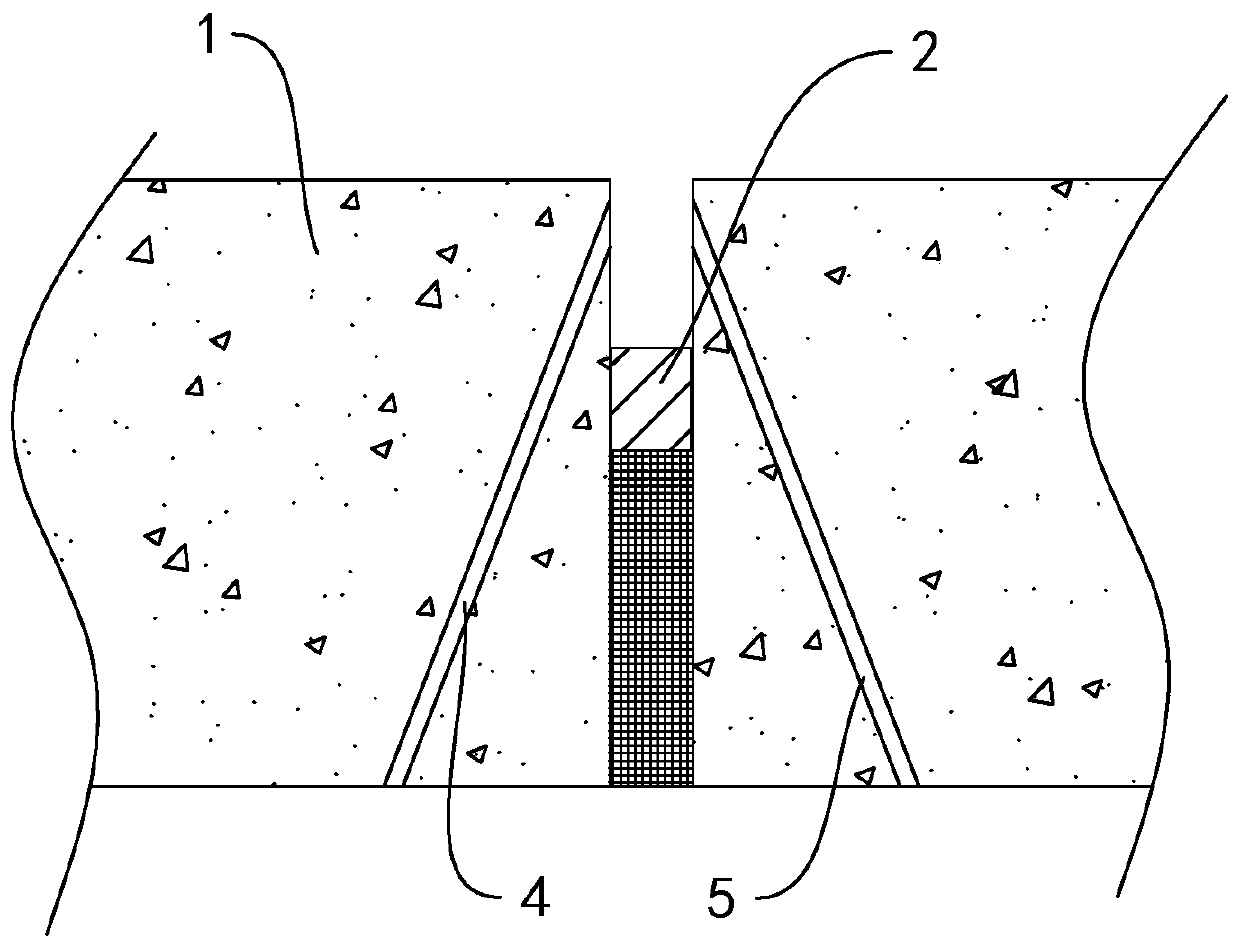

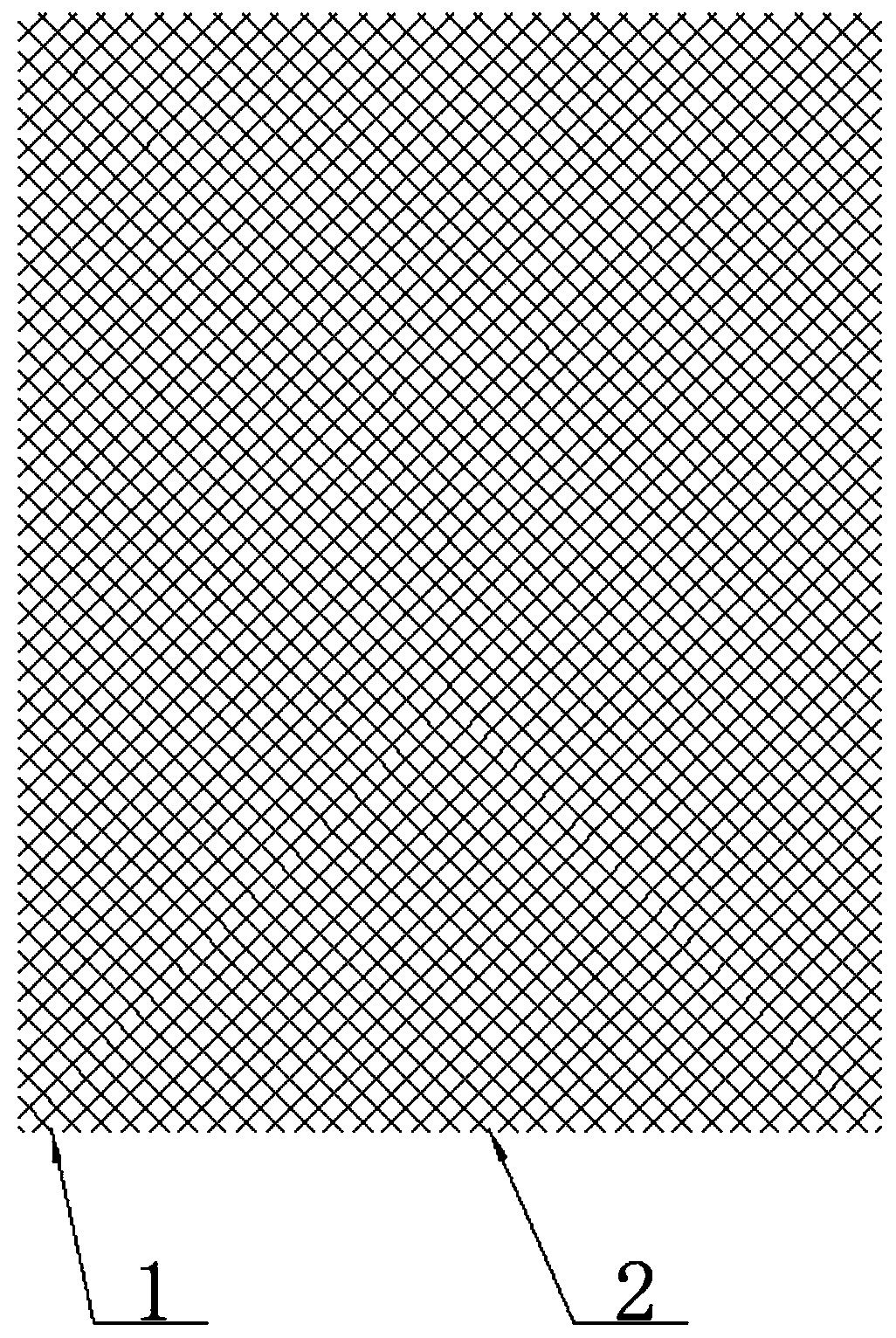

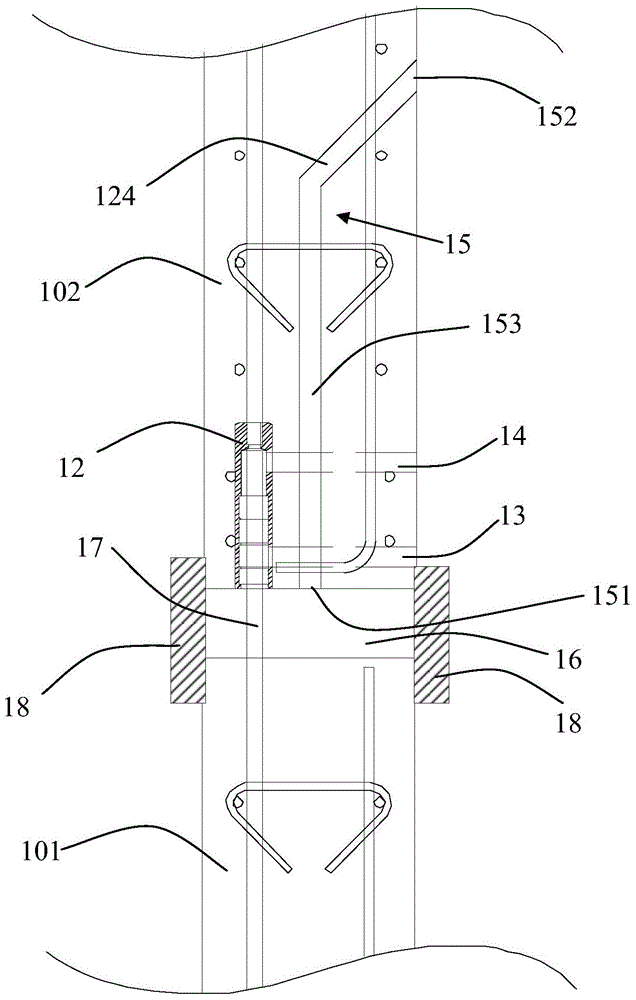

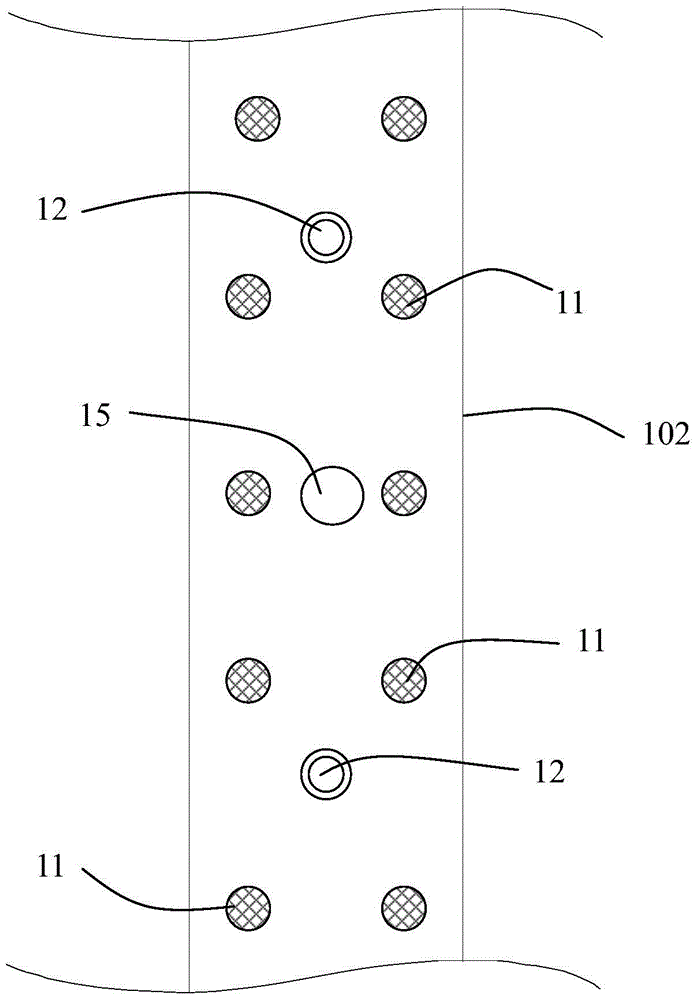

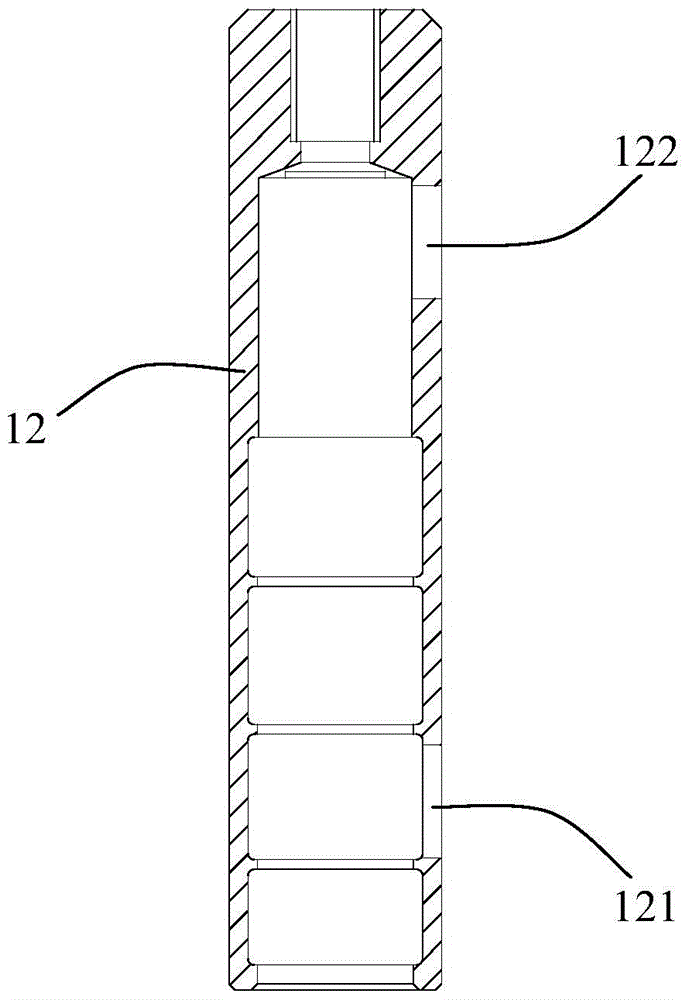

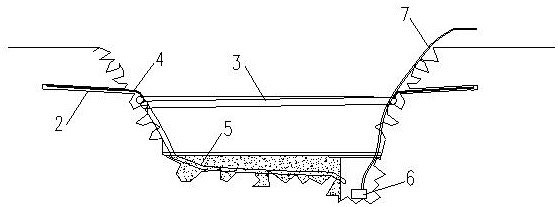

Detection method and detection structure for grouting density of prefabricated part

ActiveCN104865352AMake sure to fillNo bubblesBuilding reinforcementsMaterial analysisSlurryComputer science

The invention discloses a detection method and a detection structure for grouting density of prefabricated parts. The detection method comprises the following steps: providing at least one first prefabricated part and a second prefabricated part, preserving a grouting construction gap between the first prefabricated part and the second prefabricated part, and forming opposite grouting interfaces between the first prefabricated part and the second prefabricated part; arranging prefabrication testing points on the grouting interfaces of the first prefabricated part or / and the second prefabricated part, and connecting the prefabrication testing points with a signal receiver; grouting size into the grouting construction gap; when the size in the grouting construction gap triggers the prefabrication testing points, transmitting signals to the signal receivers from the prefabrication testing points; based on the signals transmitted from the prefabrication testing points, judging the grouting density degree of the grouting construction gap. As the prefabrication testing points are arranged on the grouting interfaces, the density degree of size grouting in the grouting construction gap can be detected, the size can be completely filled without bubble, and the grouting connection quality between the prefabricated parts can be ensured.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

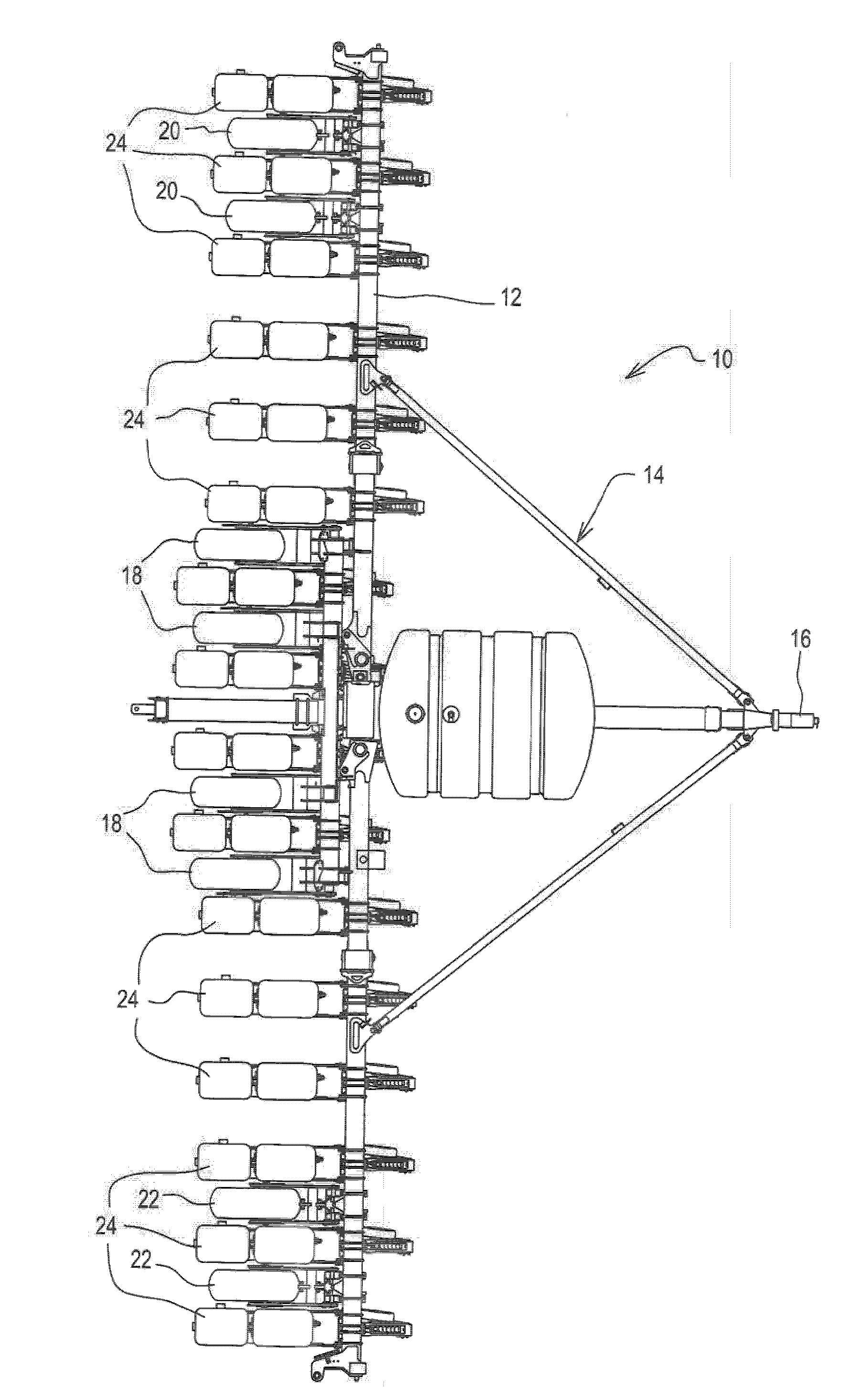

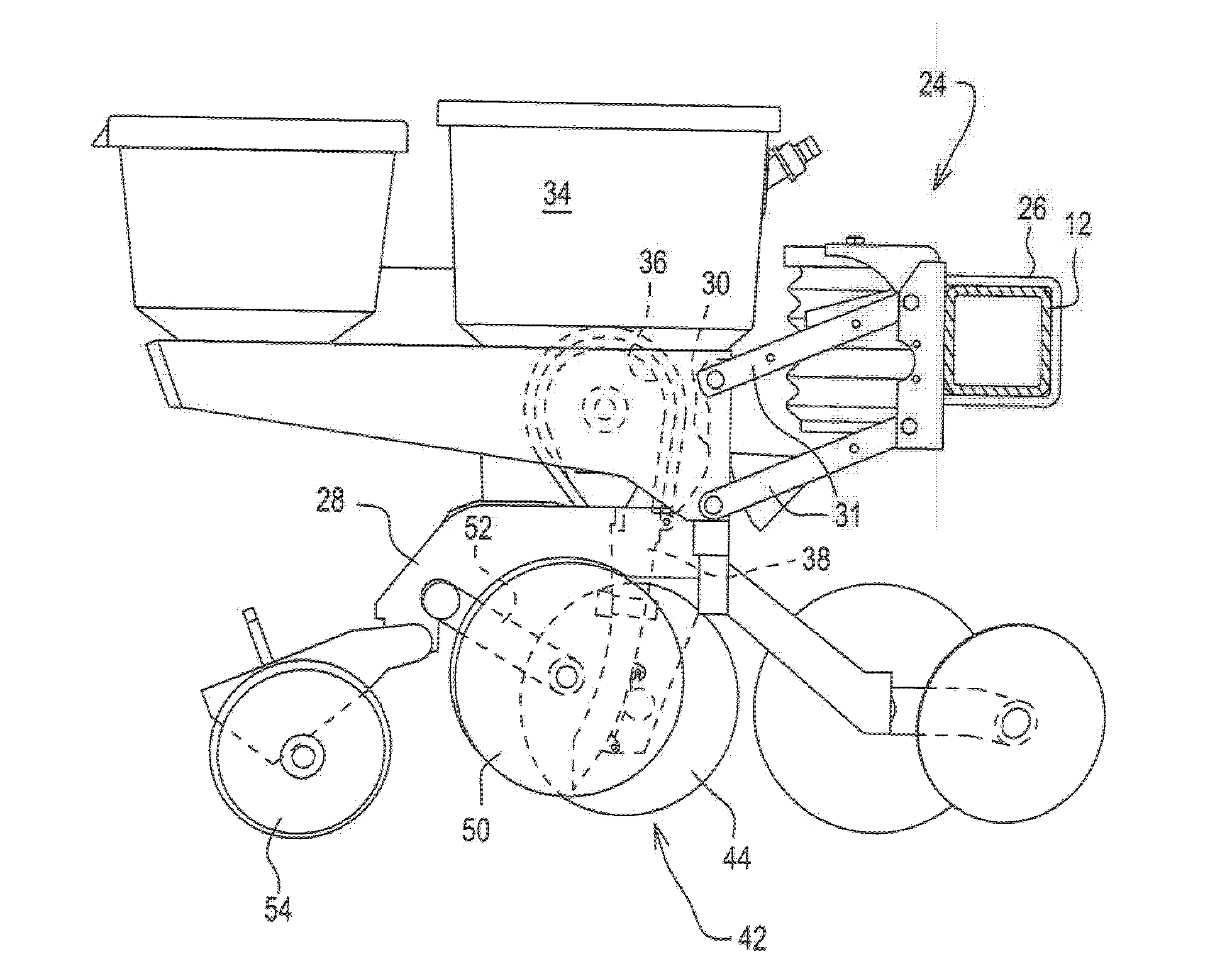

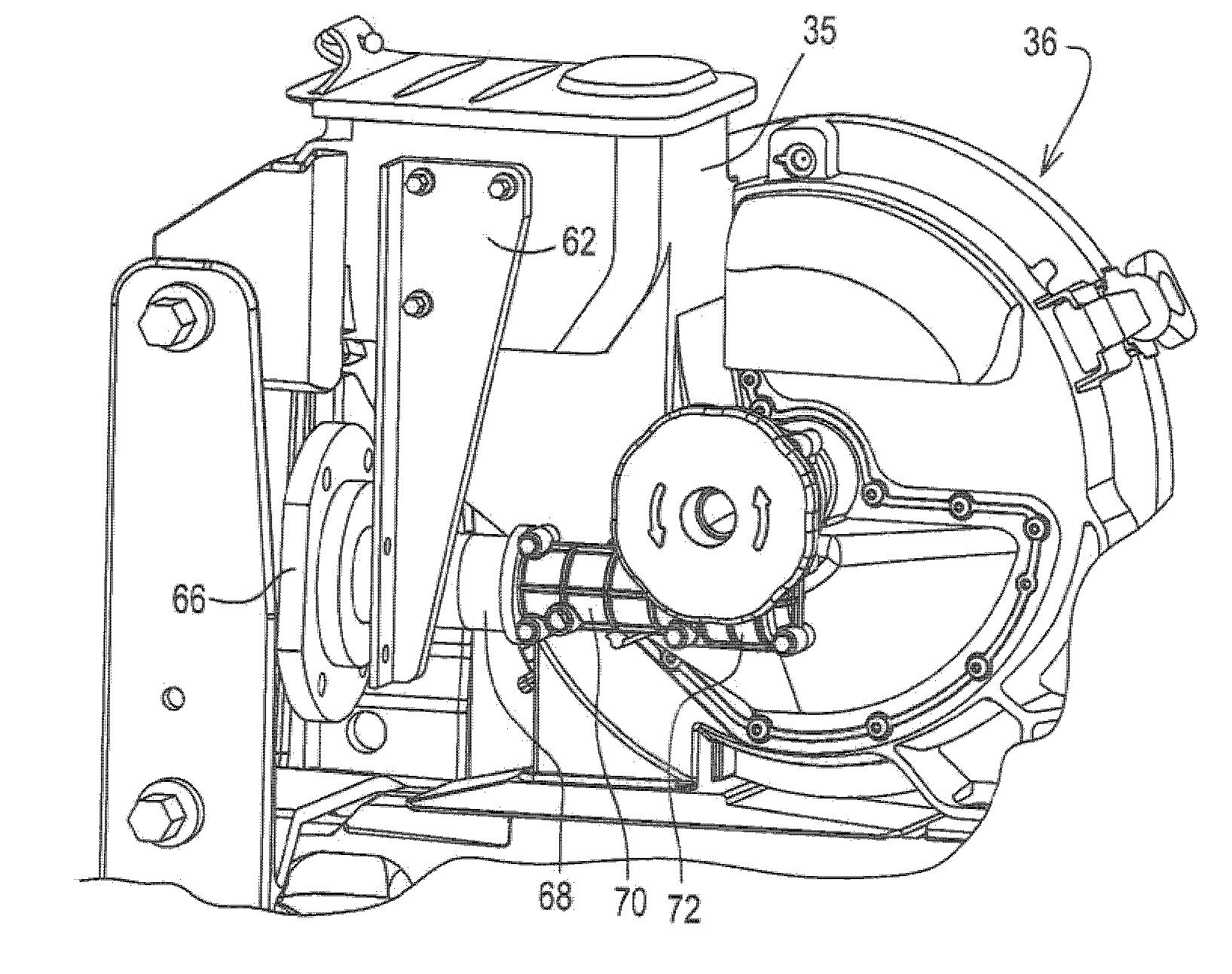

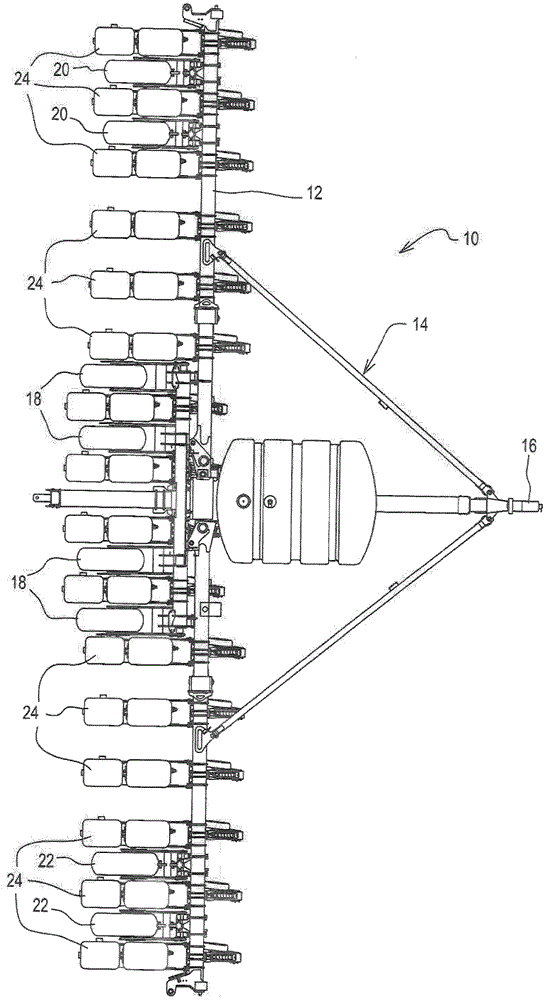

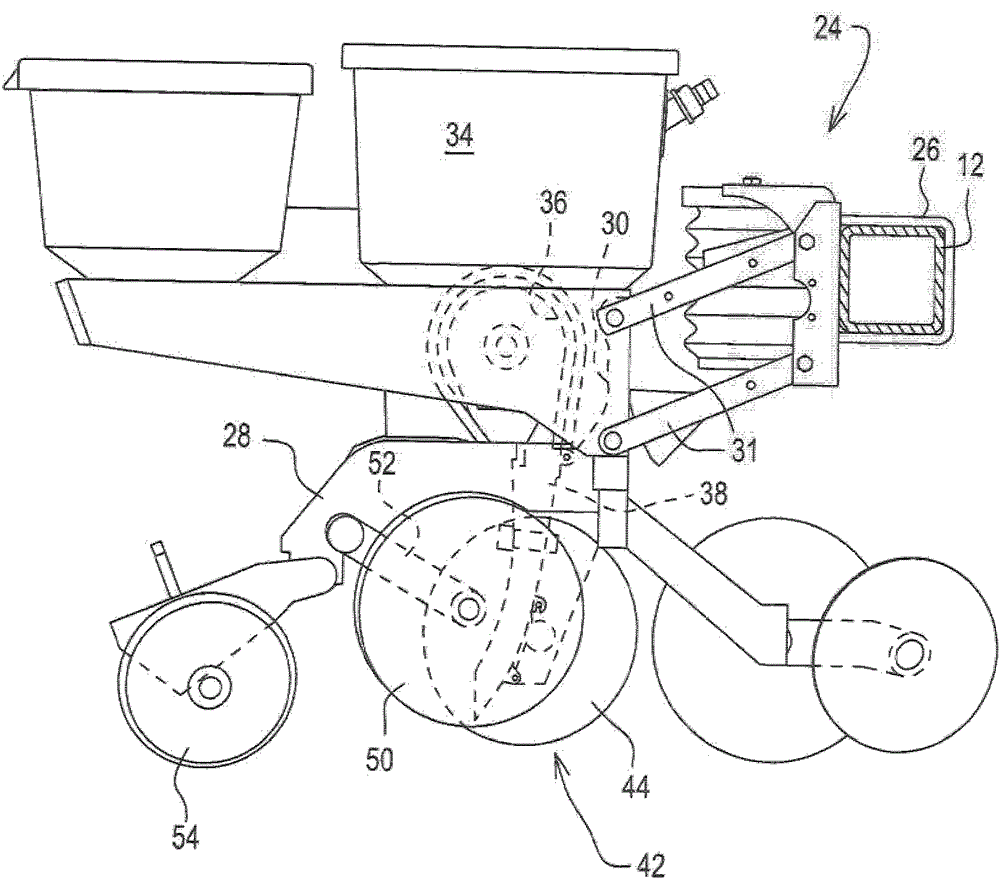

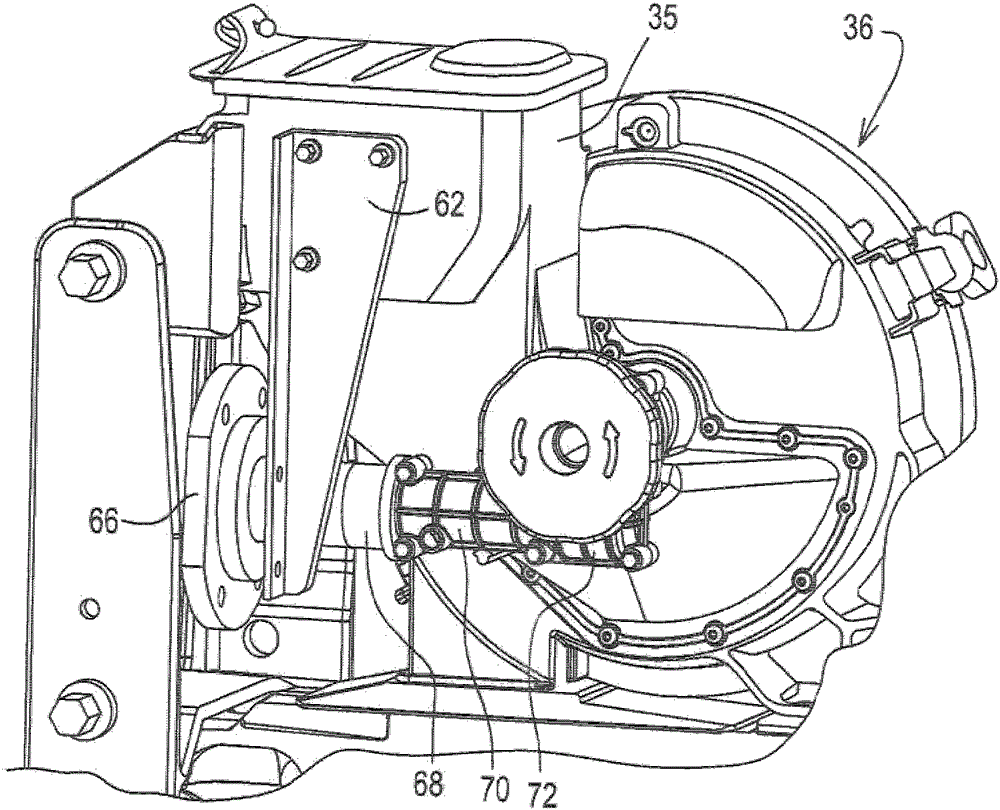

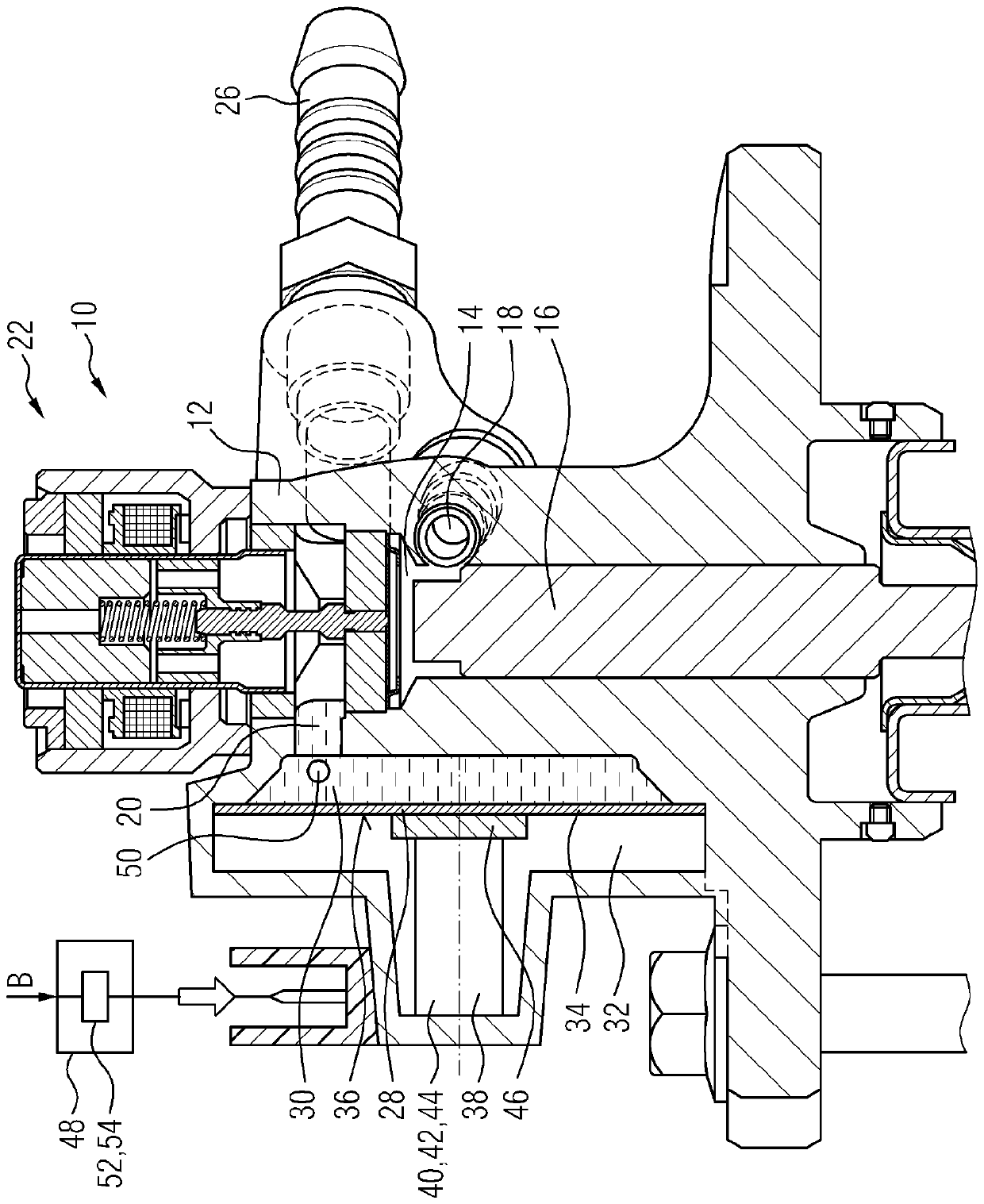

Planter and method of operating a planter with individual meter control

ActiveCN102754545AMake sure to fillSeed depositing seeder partsBroadcast seedersMotor drivePlanting seed

A planter is described which utilizes individual seed meter motor drives at each row unit. motor controllers control each seed meter drive motor. Each individual row seed meter can be individually started, stopped and operated at a unique rate. Prior to planting, the meters can be operated to fill the meters and ensure that the meters are primed and ready to start dropping seed as soon as the planter begins operation to plant seed. When a seed delivery system is used with each meter to move seed from the meter to the soil, the delivery system is also primed with seed before operation of the planter.

Owner:DEERE & CO

Chloride ion concentration detection device of reinforced concrete structure and nondestructive testing method thereof

The invention discloses a chloride ion concentration detection device of a reinforced concrete structure and a nondestructive testing method thereof. The device comprises detection single units (1) and a direct current power supply, wherein a stainless steel plate (3) is arranged in each detection single unit; a cover plate (2) of each detection single unit, a water-proof protective housing (1) and the surface of the reinforced concrete structure (4) form a closed cavity; electrolyte solution is injected into the cavity; the stainless steel plate (3) is also positioned in the cavity; a negative electrode of the direct current power supply is connected with reinforcement (4.1) of the reinforced concrete structure (4), and a positive electrode of the direct current power supply is connected with the stainless steel plate (3) of each detection single unit through a wire; the key point of the method is that the chlorine ion concentrations at different time points correspond to the chlorine ion concentrations of different depths of the reinforced concrete structure (4). According to the device and the method, the chlorine ion concentrations of different depths of the reinforced concrete structure (4) can be effectively detected, the detection process is convenient, and structural damage is not caused.

Owner:浙大宁波理工学院

Construction technology for reconstructing durable waterproof layer by using minimally invasive method

InactiveCN107448008AImprove adhesionSolve the leakBuilding repairsProtective foundationSurface layerEngineering

The invention discloses a construction technology for reconstructing a durable waterproof layer by using a minimally invasive method. Firstly, defects of a construction surface are treated; 2-8 grouting holes are formed per square meter of the construction surface, and hollow needles connected with feed valves are embedded in the grouting holes in a connection mode; secondly, epoxy acrylate is injected in the grouting holes to serve as a back-surface filling agent to reinforce a back-surface layer, and an AHA turbine sealant is injected in the grouting holes; after the AHA turbine sealant overflows from the hollow needles in every two adjacent grouting holes, the feed valve on the previous hollow needle is closed, and then the AHA turbine sealant is injected again in the hollow needles where the AHA turbine sealant overflows until all the feed valves are in a closed state; after the AHA turbine sealant is cured for 24 hours, the hollow needles are removed, and the grouting holes are blocked off. The construction technology has the following advantages that the process is simple, labor is saved, energy conservation and environmental protection are achieved, and resources are saved.

Owner:韩旭 +1

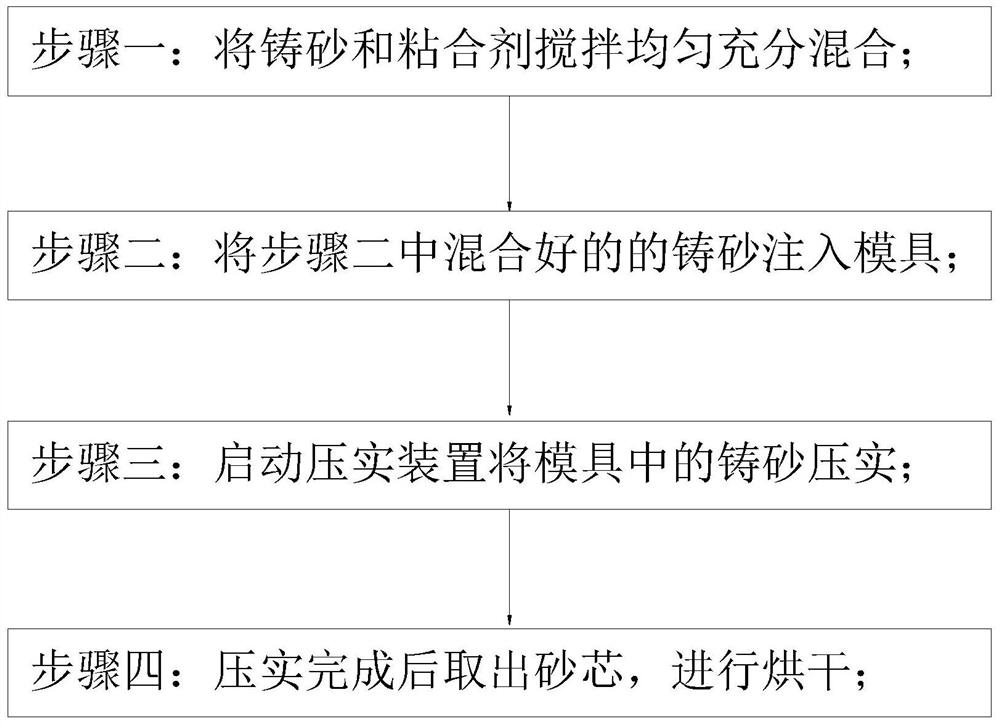

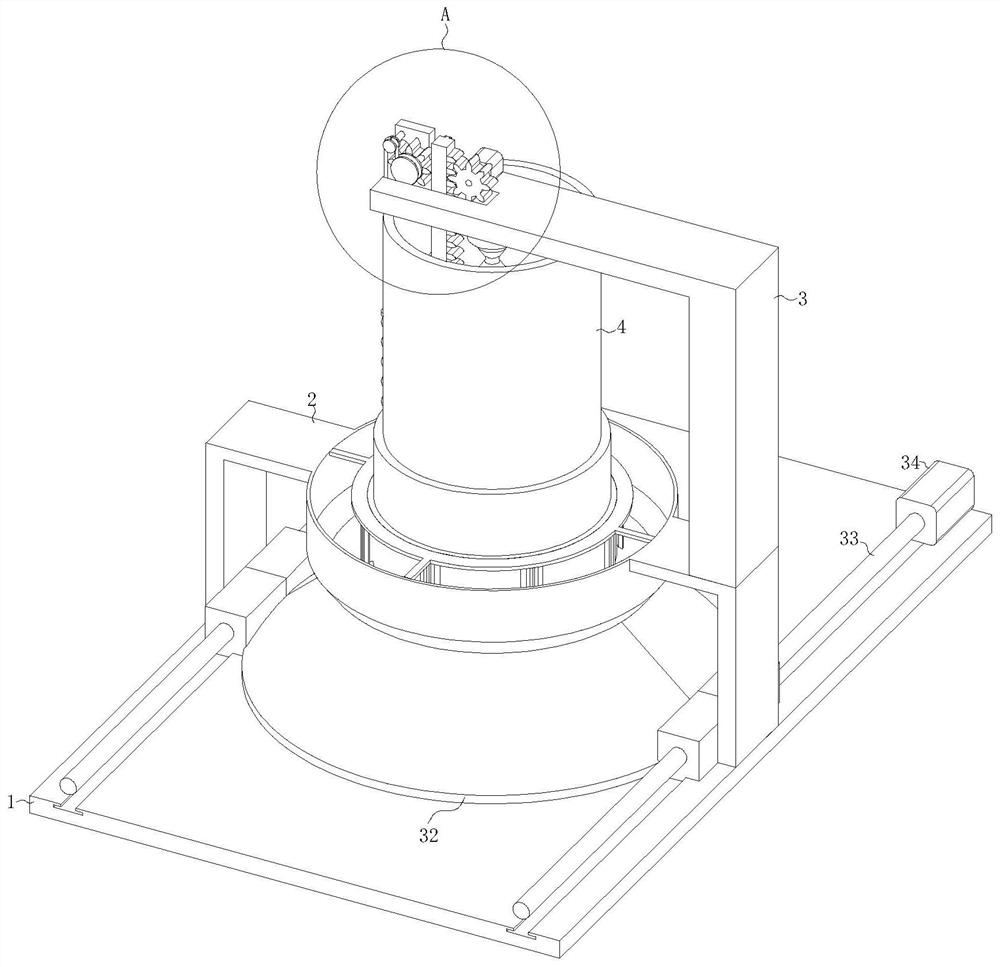

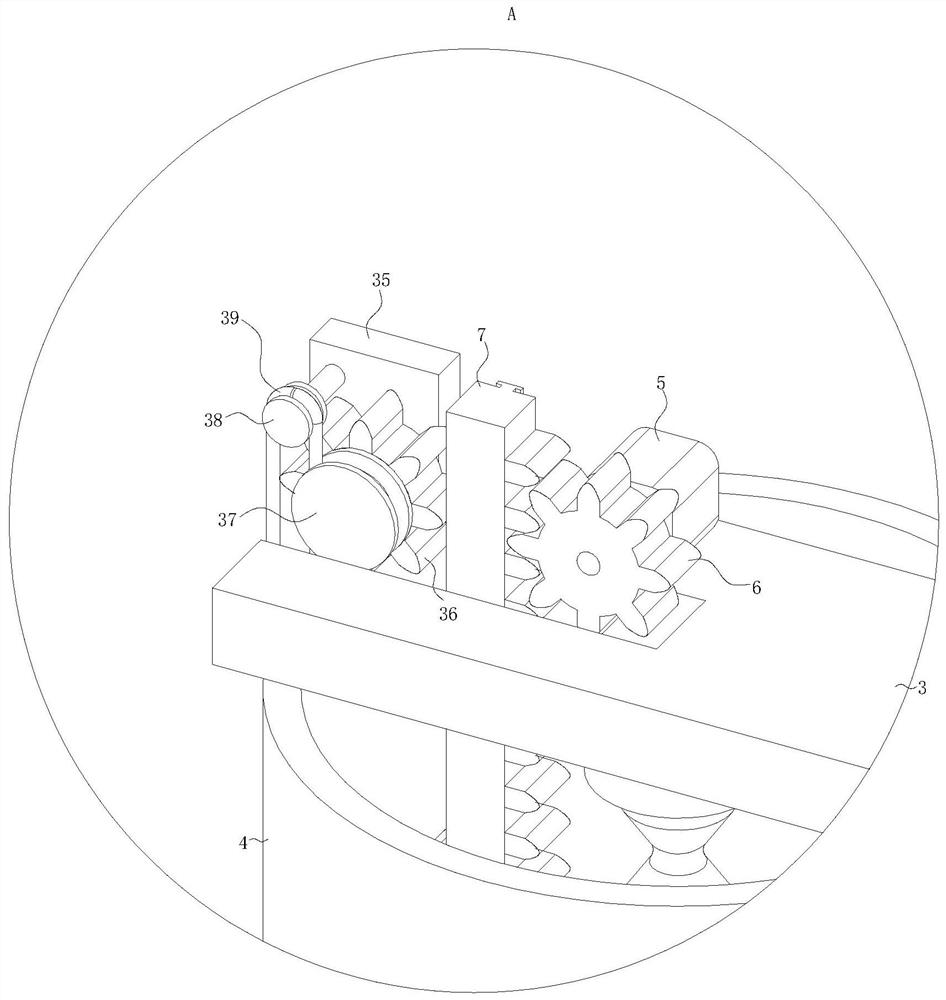

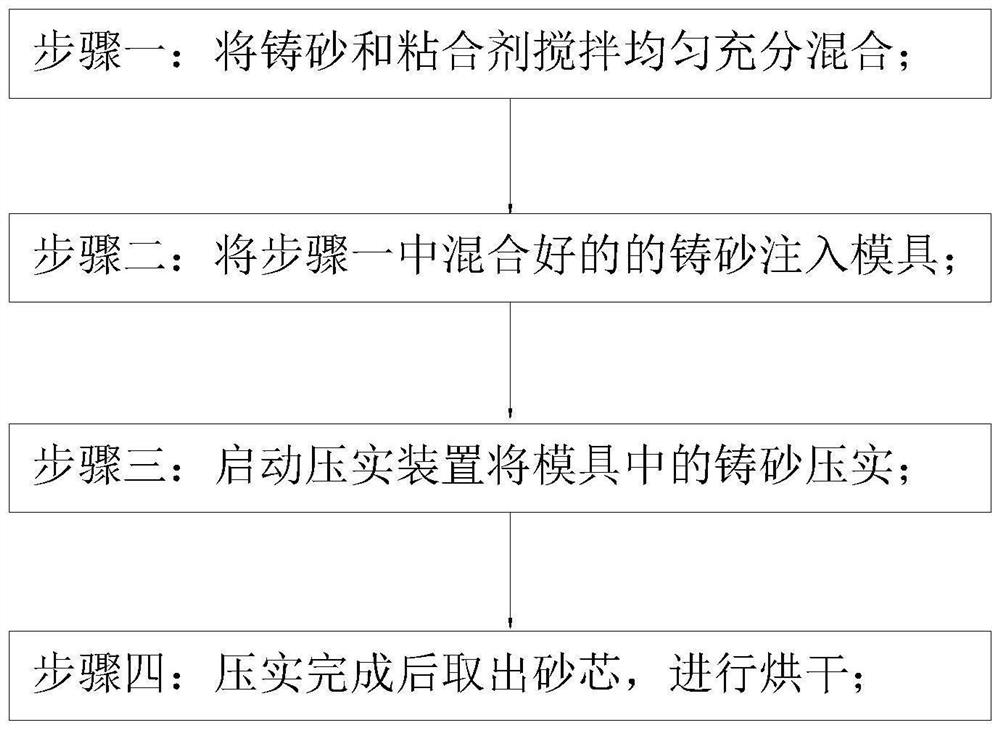

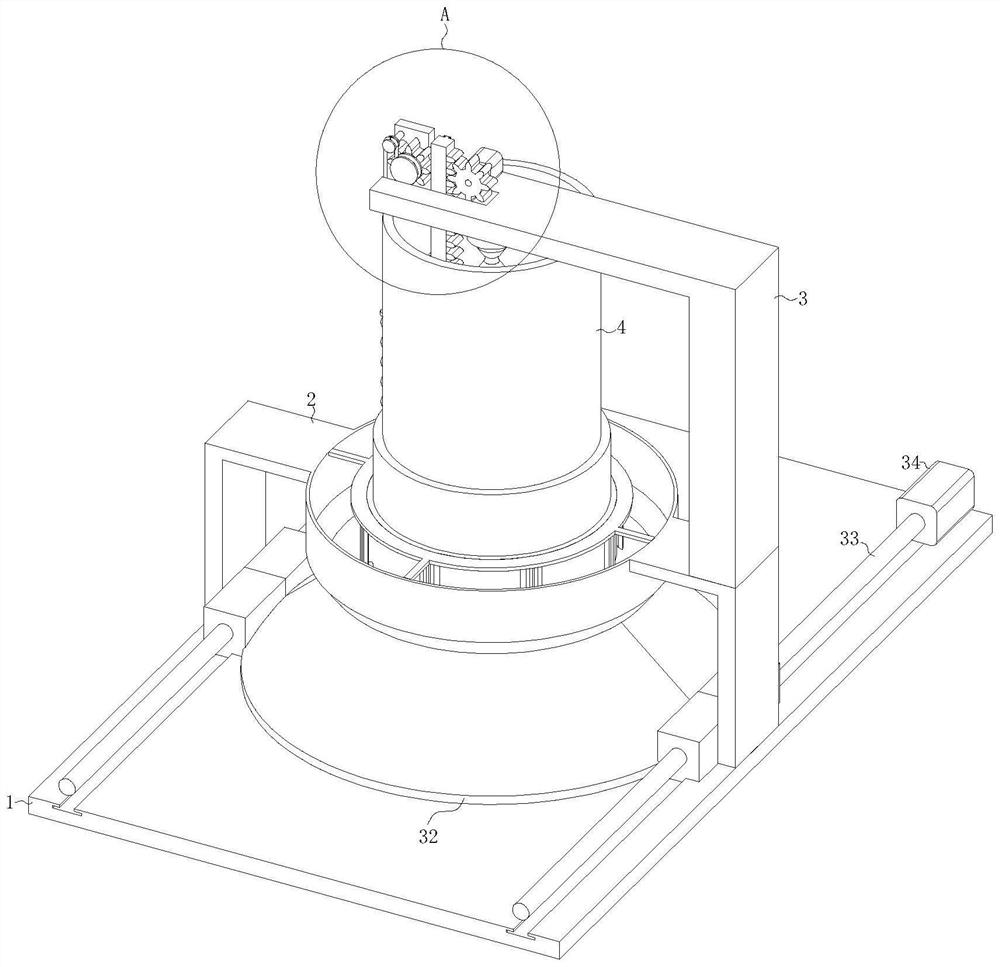

Sand mold casting core-making process

ActiveCN112792299AInject evenlyImpactfulFoundry mouldsMoulding machinesThreaded pipeGeotechnical engineering

The invention discloses a sand mold casting core-making process in the technical field of sand core manufacturing, and the process comprises the following specific steps: step 1, uniformly stirring and fully mixing casting sand and an adhesive; step 2, injecting the casting sand mixed in the step 2 into a mold; step 3, starting a compaction device to compact the casting sand in the mold; and step 4, after compaction is completed, taking out a sand core and drying the sand core. A rotating disc is arranged, a bidirectional rack moves up and down to drive the rotating disc to move synchronously, and the rotating disc rotates along an inner threaded pipe while moving up and down, so that a compaction hammer is driven to move up and down and rotate at the same time, the compaction hammer rotates when rising, the falling casting sand is thrown to all positions in the mold, and the thrown casting sand has certain impact force, and the role of compaction is achieved; and the compaction hammer rotates when descending to twist and compact the casting sand falling into the mold, so that on the one hand, the casting sand is compacted, and on the other hand, the periphery of the casting sand is extruded, and it is ensured that the casting sand can fill the corners of the mold.

Owner:山东金宇重型机械有限公司

Method for changing volume of crack and its application

ActiveCN107642348AMake sure to fillDelayed decline rateFluid removalHorizontal stressINCREASED EFFECT

The invention relates to a method for changing the volume of a crack and its application. The method includes the following steps that 1, the characteristic parameter of a reservoir is evaluated, wherein the characteristic parameter includes a brittleness index, a natural fracture development degree and a horizontal stress difference coefficient; 2, the type and use amount of an adopted propping agent is determined through simulation software; 3, liquid of the propping agent determined in the step 2 is used for fracturing transformation of the reservoir. The provided method for changing the volume of the crack is reasonable and simple in design, calculation and operation are easy to conduct, the changed volume of the crack can be effectively improved, the filling degree of cracks differentin scales, the yield-increasing effect is improved to the greatest extent after pressing, and the decline rate of yield is delayed.

Owner:CHINA PETROLEUM & CHEM CORP +1

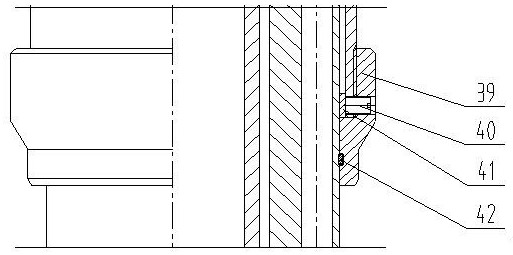

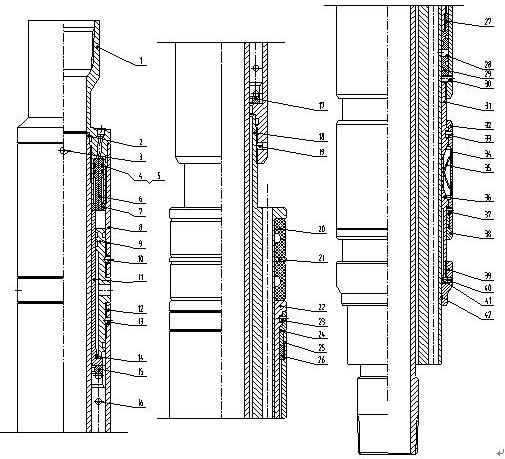

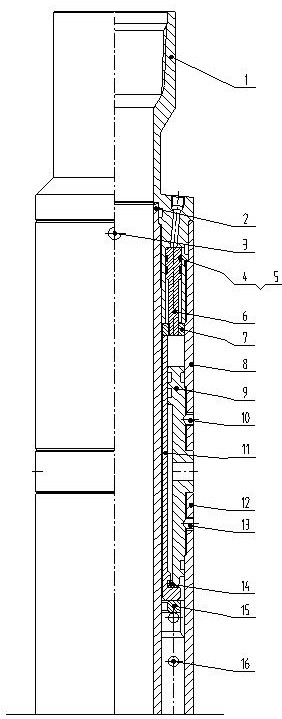

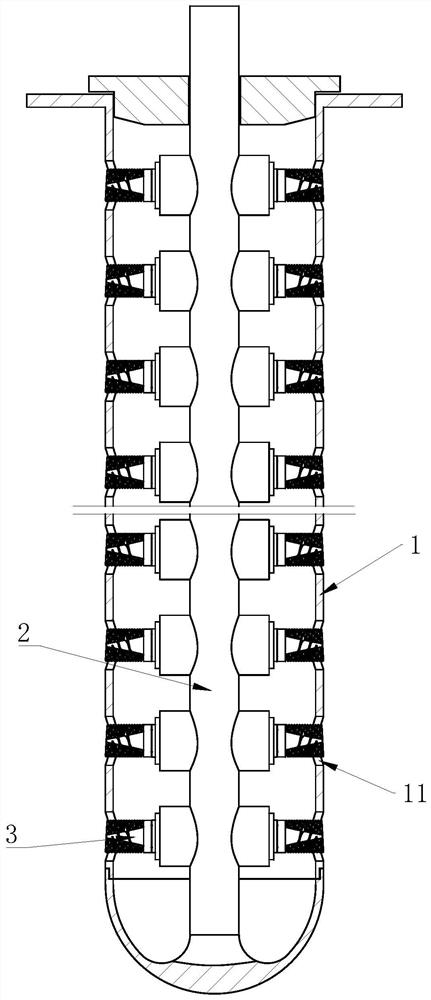

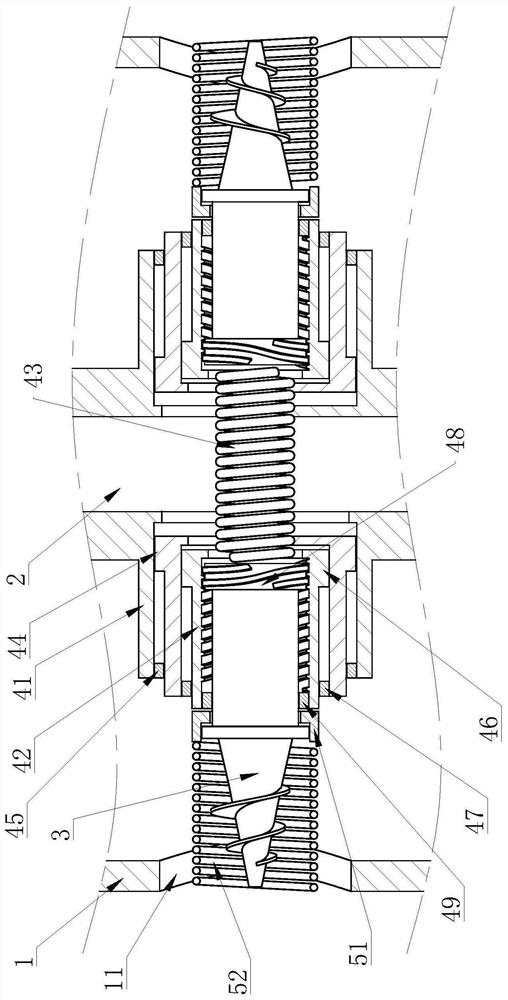

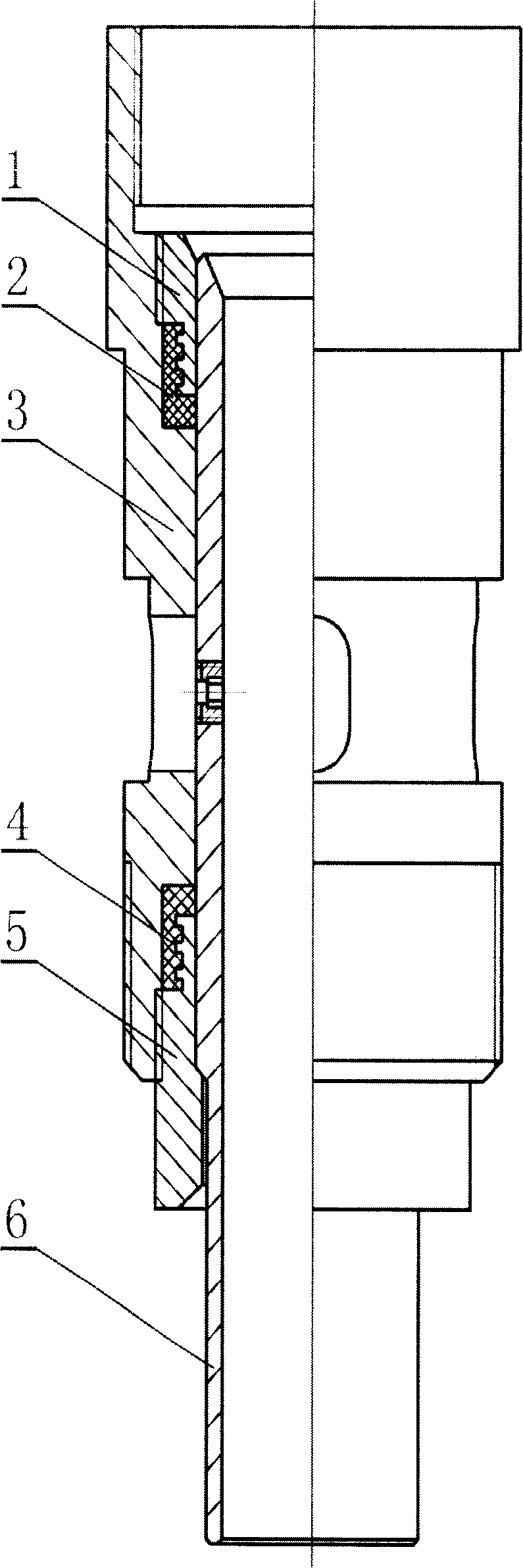

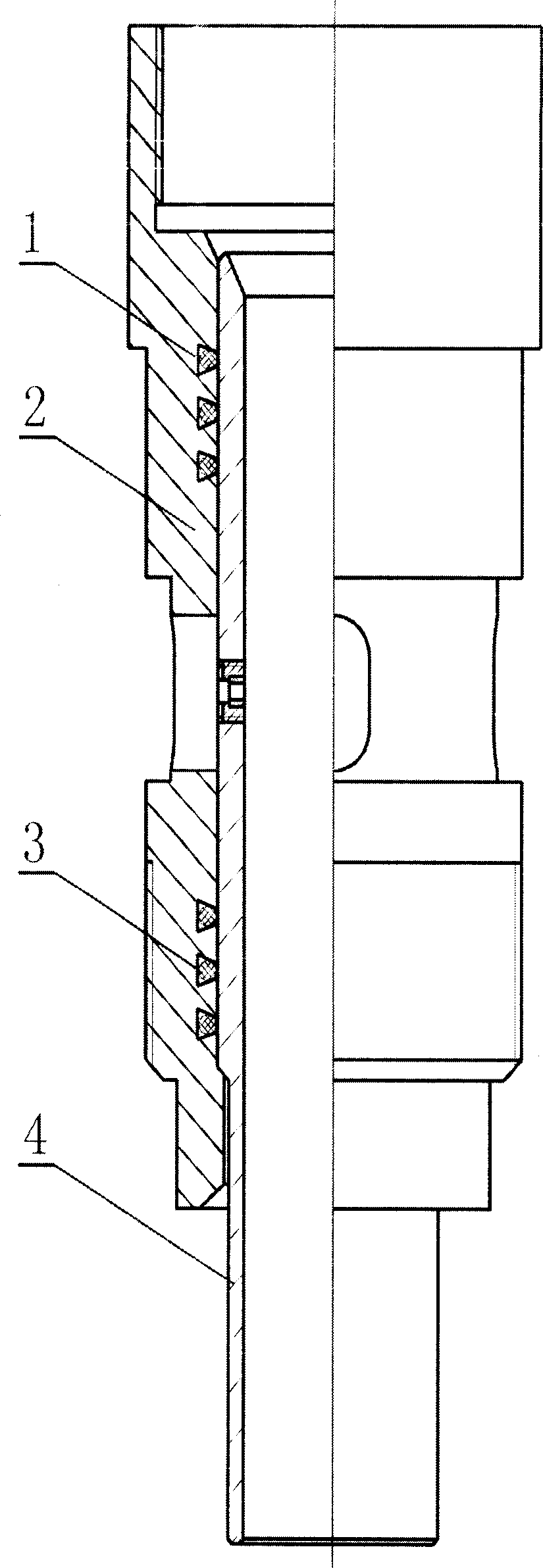

Oil jacket safety packer with anchoring function and method thereof

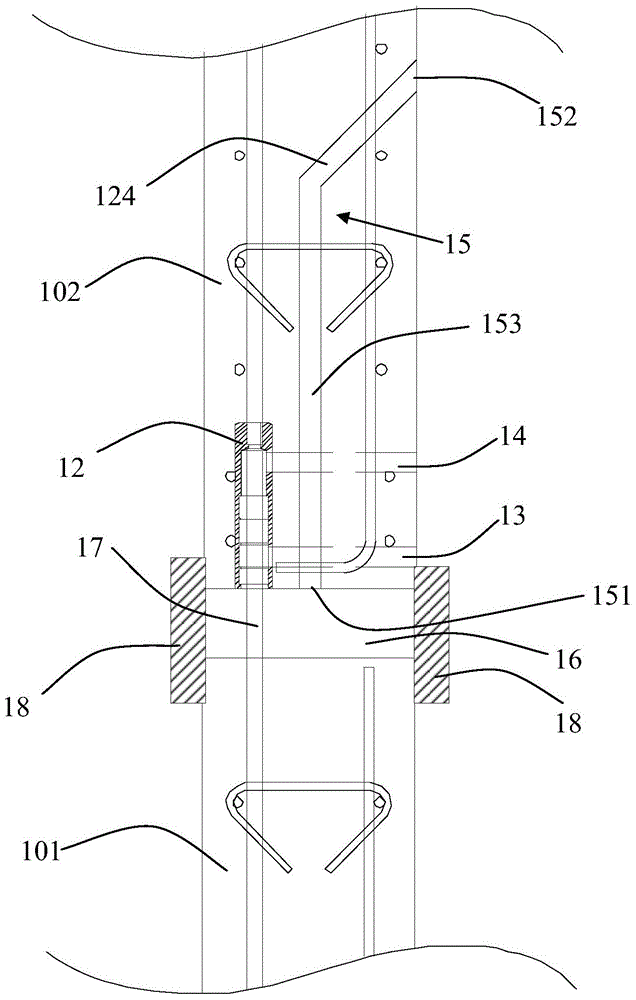

ActiveCN112696170AReduce variable volumeShorten the timeFlushingSealing/packingStructural engineeringPetroleum engineering

The invention discloses an oil jacket safety packer with an anchoring function and a method thereof. The oil jacket safety packer comprises a large-displacement well washing control device and a packer setting anchoring and unsetting device, the large-displacement well washing control device is mounted outside a central pipe in a sleeving mode, and the upper end of the large-displacement well washing control device is connected with a first hydraulic control pipeline; and the packer setting anchoring and unsetting device is arranged outside the central pipe in a sleeving mode, and the upper end of the packer setting anchoring and unsetting device is connected with a second hydraulic control pipeline. According to the oil jacket safety packer, setting anchoring can be continuously provided when a setting hydraulic control pipeline has no pressure, and opening and closing of a large-displacement well washing channel can be realized through a well washing hydraulic control pipeline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Construction process of rebuilding durable waterproof layer through space displacement method

The invention discloses a construction process of rebuilding a durable waterproof layer through a space displacement method. The construction process includes the steps that a construction surface defect is processed; five grouting holes are drilled in the construction surface, a hollow grouting needle head connected with a feed valve is buried in the grouting hole in the center, and hollow overflow needle heads are connected into the grouting holes in the four corners in a buried mode; epoxy acrylate is injected into the grouting hole through the hollow grouting needle head and serves as back face filler to enhance the back face layer, and then an AHA turbo sealant is injected into the corresponding grouting hole; after slurry overflows from the hollow overflow needle heads, the feed valve is switched off; after the AHA turbo sealant is cured for 24 h, the hollow needle heads are removed, and the grouting holes are blocked. The construction process has the advantages of being simple, saving manpower and energy, protecting environment and saving resources.

Owner:韩旭 +1

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677BImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

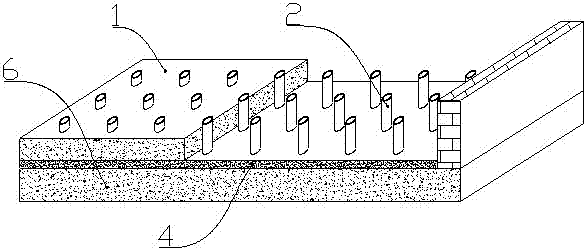

Method for reinforcing soil around pile

ActiveCN113802552AEnsure compactionTake it out smoothlyBulkheads/pilesArchitectural engineeringStructural engineering

The invention provides a method for reinforcing soil around a pile, and belongs to the technical field of civil engineering. The method for reinforcing soil around the pile comprises the following steps: 1, forming a base hole with the hole diameter larger than that of a cast-in-place pile in a compacted foundation; 2, transversely forming a plurality of embedding holes in the hole wall of the base hole; and 3, sinking a cylindrical pouring formwork in the base hole, forming a reinforcing interlayer between the pouring formwork and the hole wall of the base hole, pouring concrete into the reinforcing interlayer, taking out the pouring formwork out after the concrete is solidified, and forming a pile periphery reinforcing body with a transverse embedded pile matched with the embedding hole on the inner side of the base hole. The method has the advantages that the soil around the pile needing to be reinforced can be reinforced, and the like.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

A kind of high-strength direct-plating aluminum water-based primer and its preparation method and application

ActiveCN103866607BGood sealingGood flexibilityNon-fibrous pulp additionPaper/cardboardWater basedWater vapor

The invention discloses high-strength directly aluminizing water-based base coat and a preparation method and application of the high-strength directly aluminizing water-based base coat. The directly aluminizing water-based base coat comprises the following components in parts by mass: 50-80 parts of water-based resin, 6-16 parts of cosolvents, 0.1-1 part of flatting agents, 0.05-0.20 part of antifoaming agents, 0.05-0.5 part of slipping agents, 1-6 parts of hardening agents, 0.1-0.3 part of pH regulator, 0.2-2 parts of thickening agents, 0-2 parts of crosslinking agents and 6.2-36.2 parts of water. With good closure, the direct aluminizing water-based base coat disclosed by the invention guarantees the filling of micropores in the paper surface as well as the separation of water vapor; due to the characteristic of flexibility, the bending resistance of paper is realized; the viscosity resistance ensures that the film rolls are not bonded with each other after base coating on the aluminizing body paper; moreover, by adjusting the leveling property of the selected resin system and the coating, the base coat has high aluminizing metal texture.

Owner:GUANGZHOU HUMAN CHEM

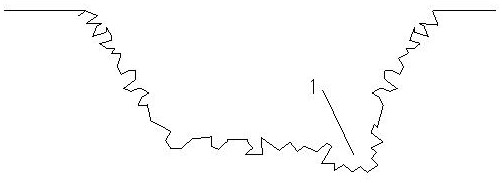

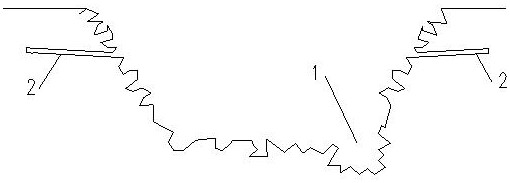

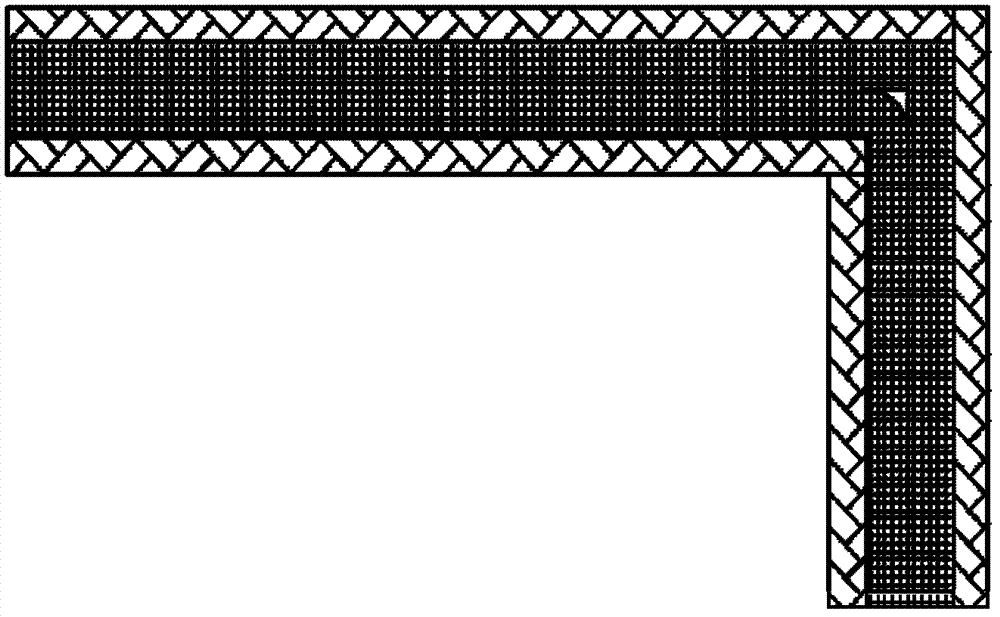

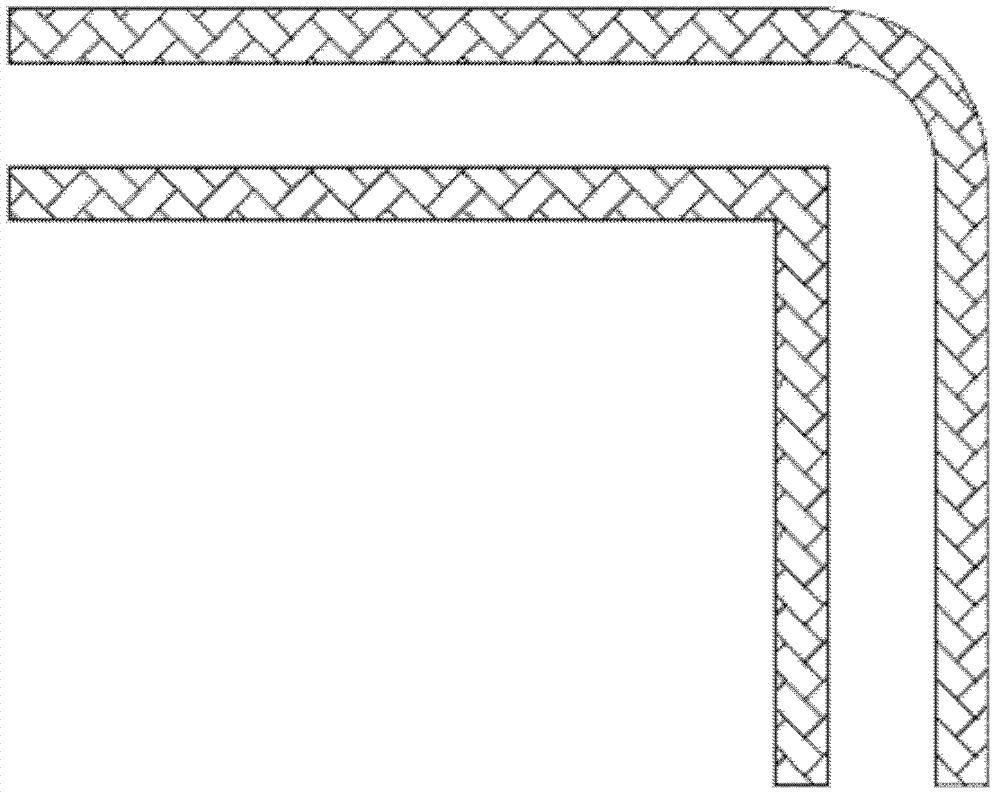

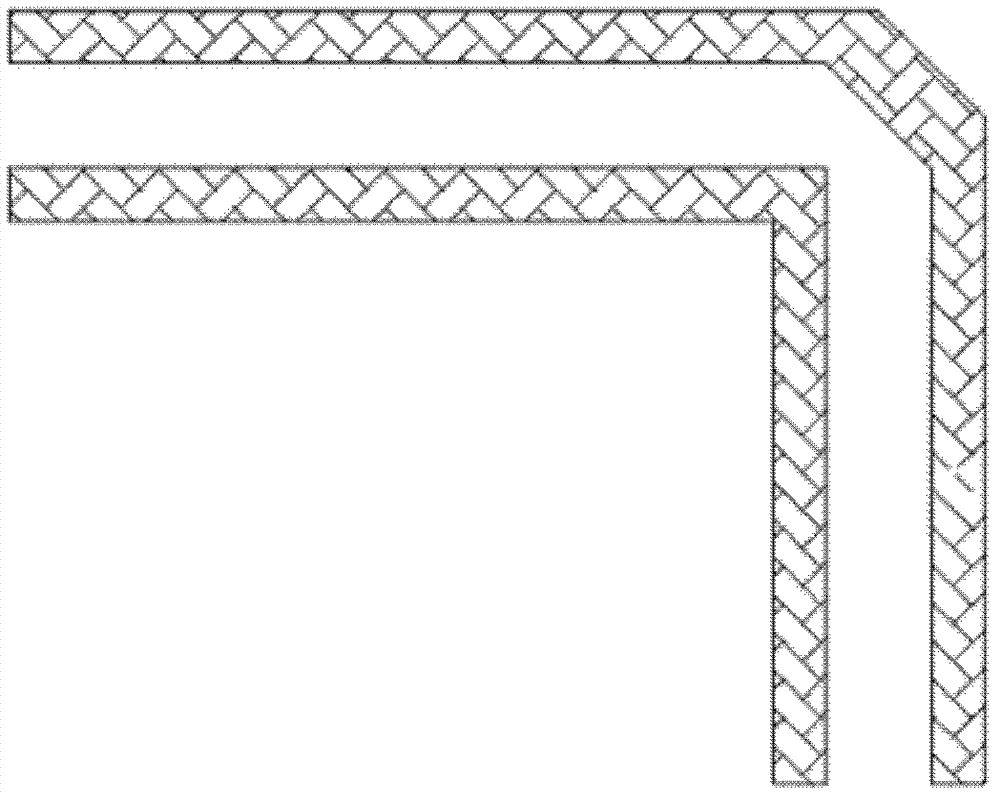

Novel trench isolation groove for filling trench

ActiveCN102627252AChange corner shapeAvoid unfilledSolid-state devicesFluid speed measurementIonEtching

The invention discloses a novel trench isolation groove for filling a trench and belongs to a micro electro mechanical system (MEMS) and a micro processing technology. According to the trench isolation groove provided by the invention, the distance between any point on the inner wall surface and the outer wall surface is respectively not greater than d, wherein the d is the width of the trench isolation groove. The trench isolation groove meeting the technical characteristics has diversified forms. The invention provides a plurality of specific embodiments. The corner shape of the trench isolation groove is directly changed, and thus the phenomenon that a small unfilled part at the corner of a rectangular groove appears is avoided and the groove corner can be ensured to be completely filled. Although etching ions rebound from the bottom surface to cause secondary etching on the side wall, the corner of the rectangular trench is of a circular arc and the like; and the distance between the inner wall surface and the outer wall surface is smaller than or equal to 2mu m and is equal to the distance between the two sides of the rectangular groove, so that no clearance in filling is ensured.

Owner:XI AN ZHISENSOR TECH CO LTD

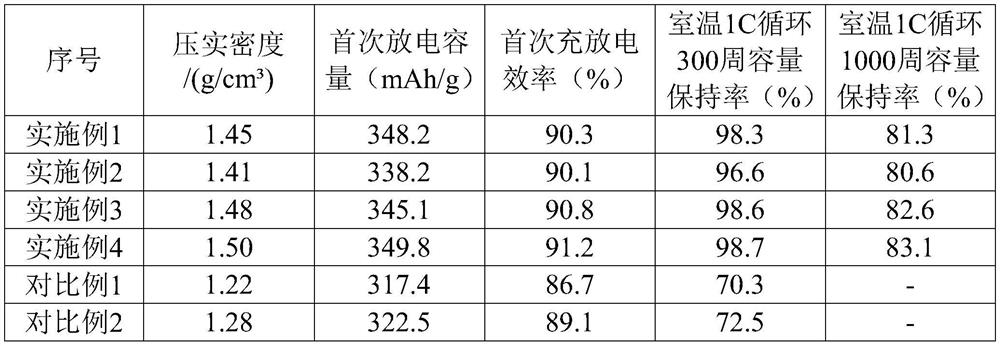

Low-cost long-cycle graphite negative electrode material, preparation method and application thereof

ActiveCN113526956AMake sure to fillPrevent volatilizationSecondary cellsNegative electrodesCarbon coatingElectrical battery

The invention provides a low-cost long-cycle graphite negative electrode material, a preparation method and application thereof. In the preparation method, the temperature of a forming press is controlled to be 40-100 DEG C higher than the melting point of asphalt, so that the asphalt is kept in a liquid state, the asphalt can be completely ensured to be filled into pores in graphite micro powder at high temperature and high pressure while an asphalt coating layer is formed on the surface of the graphite micro powder; in a high-pressure carbonization process, volatilization of low-molecular-weight aromatic compounds and straight-chain small-molecular aliphatic hydrocarbons in asphalt can be inhibited; and a pressurization process is also beneficial to the proceeding of polymerization reaction, so that the carbonization residual carbon of the asphalt is high, the internal pores of the graphite micro powder can be quickly densified, the compaction density of the negative electrode material is improved, a uniform and compact carbon coating layer can be formed on the surface of the graphite micro powder, the specific surface area of the negative electrode material is reduced, and the first efficiency and the cycle performance of the battery are improved.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

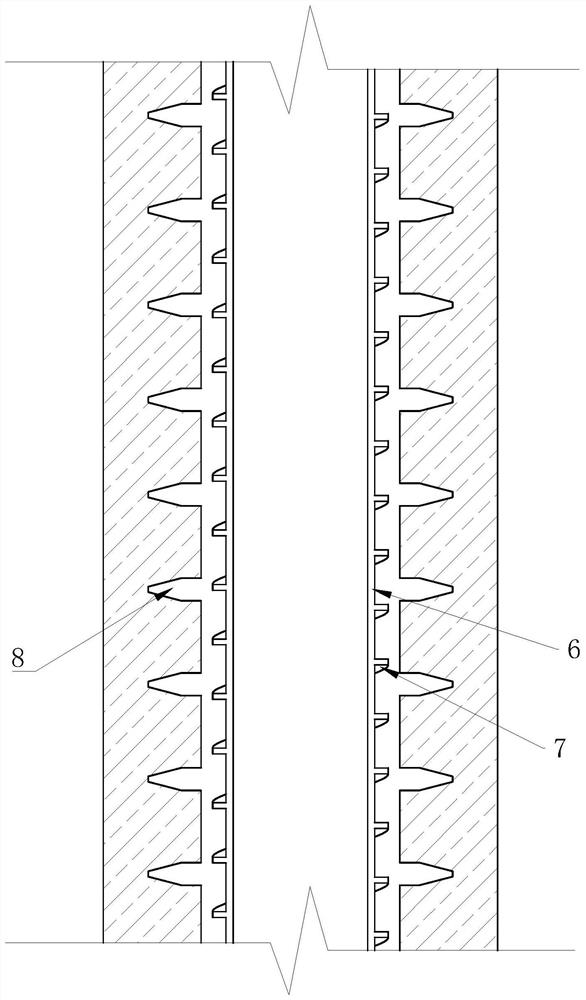

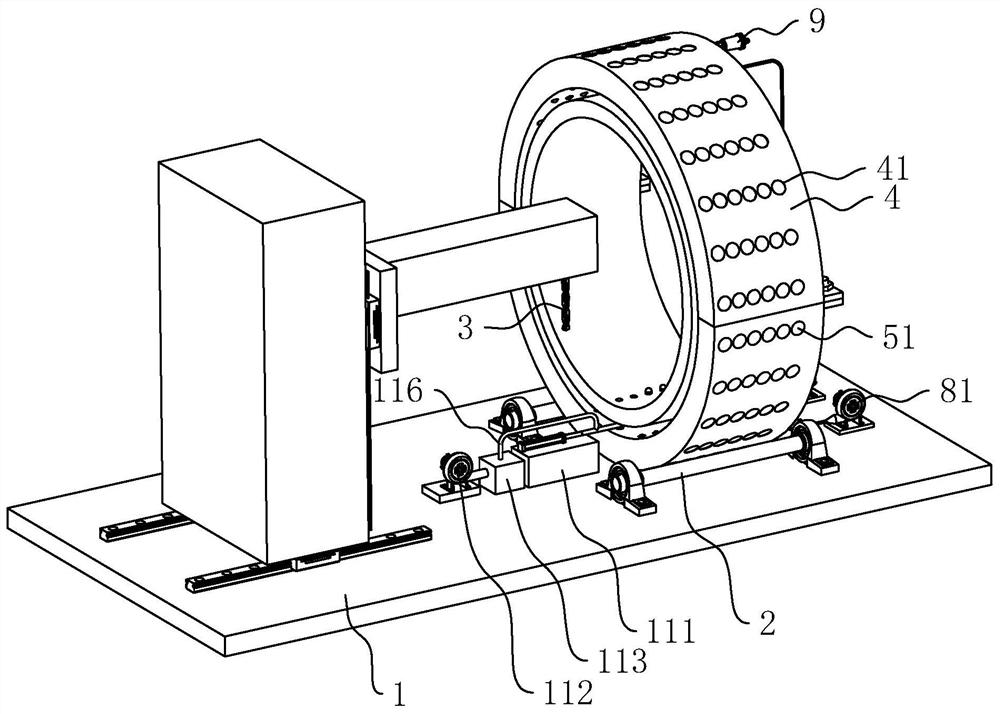

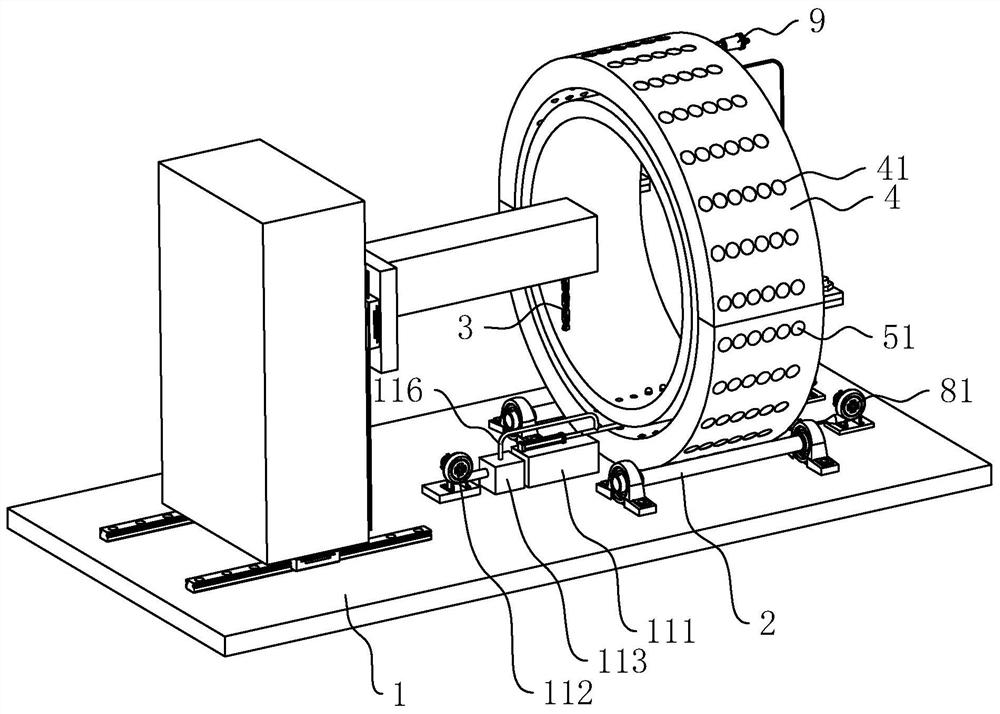

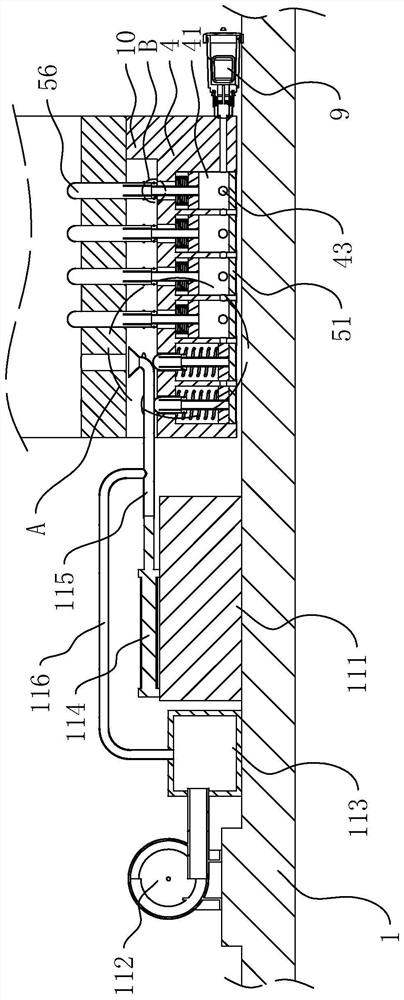

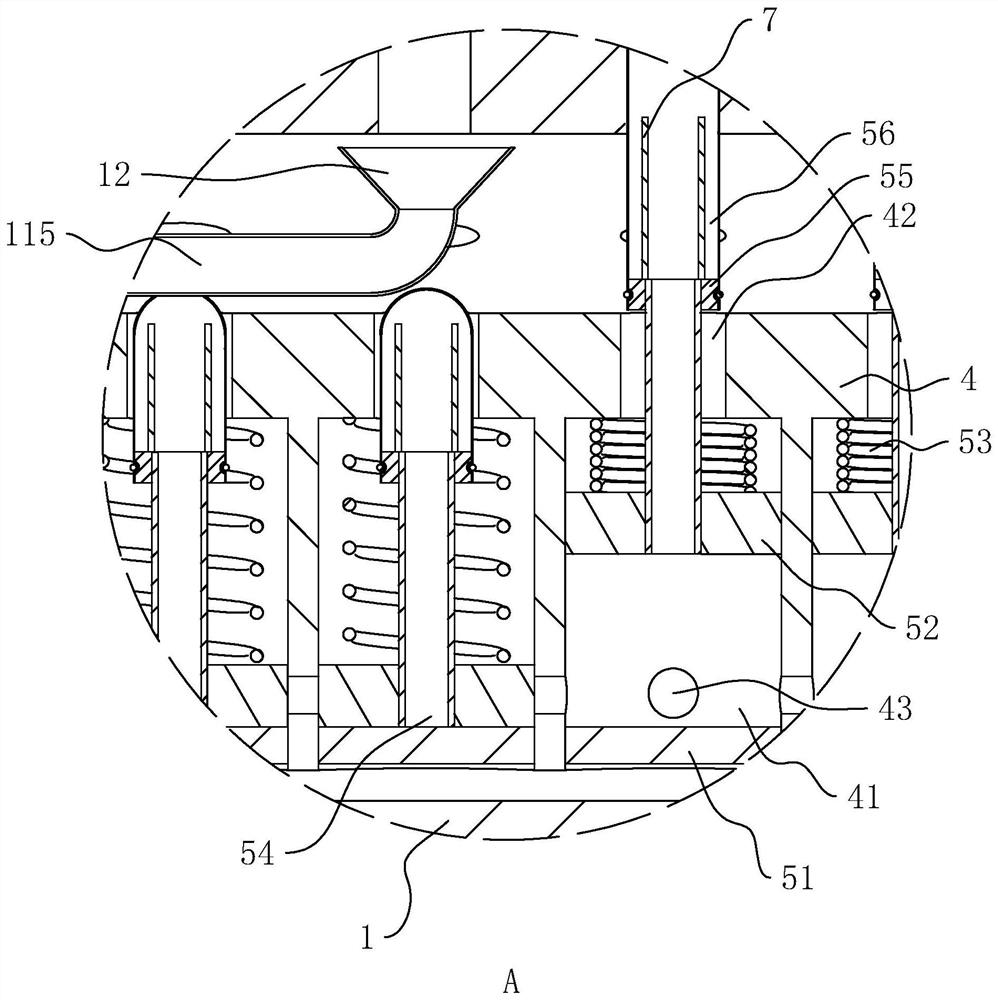

Drilling-and-backfilling type circular mould drilling equipment

ActiveCN113695622AReduce drop inReduce the possibility of collapseWork clamping meansPositioning apparatusControl systemClassical mechanics

The invention relates to the field of circular mould drilling equipment, in particular to drilling-and-backfilling type circular mould drilling equipment. The equipment comprises two semicircular clamping rings which are detachably connected, a circular mould is clamped between the two clamping rings, the clamping rings are placed on a circular mould roller carrier, a plurality of containing holes are formed in the outer side walls of the clamping rings, filling assemblies are arranged in the containing holes, the filling assemblies correspond to material holes in the circular mold one to one, each filling assembly comprises an electromagnet arranged at the opening end of the corresponding containing hole, the electromagnets are electrically connected to a control system, a magnetic block used for repelling the electromagnet is arranged in each containing hole in a sliding manner, a reset compression spring is further shored between each magnetic block and the closed end of the corresponding containing hole, and an air guide pipe is arranged on each magnetic block; and the air guide pipes penetrate through the inner walls of the clamping rings in a sliding manner and are provided with sleeve bases, the sleeve bases are sleeved with balloons, one ends of the air guide pipes are communicated with the corresponding containing holes, and the other ends of the air guide pipes are communicated with the corresponding balloons. The equipment has the advantage that the possibility that workers need to clean drilling cuttings in feeding holes of the circular mould subsequently is reduced.

Owner:常州朱美拉模具技术有限公司

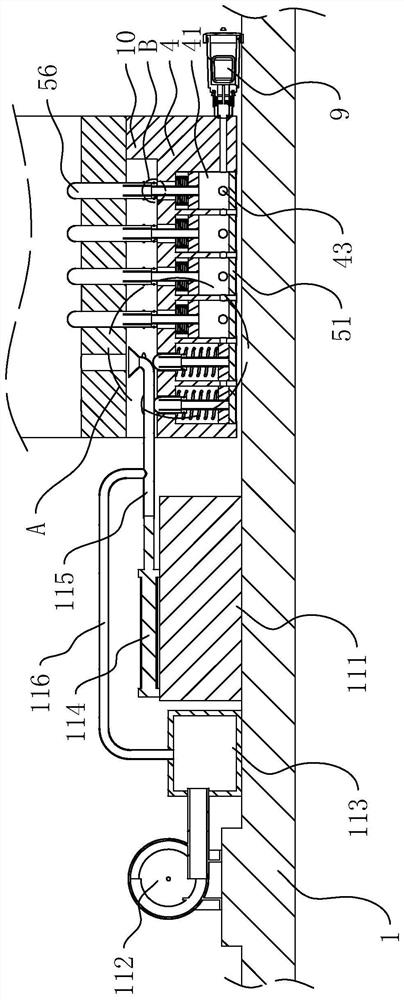

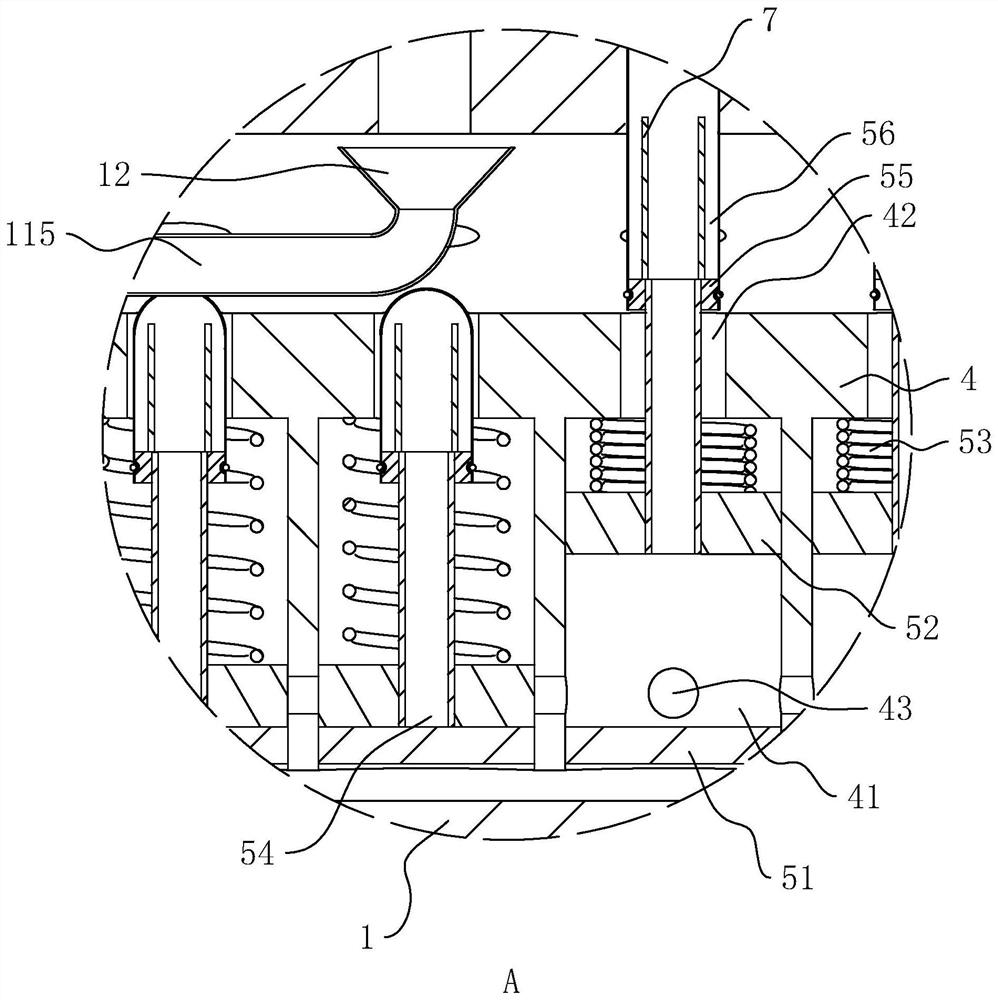

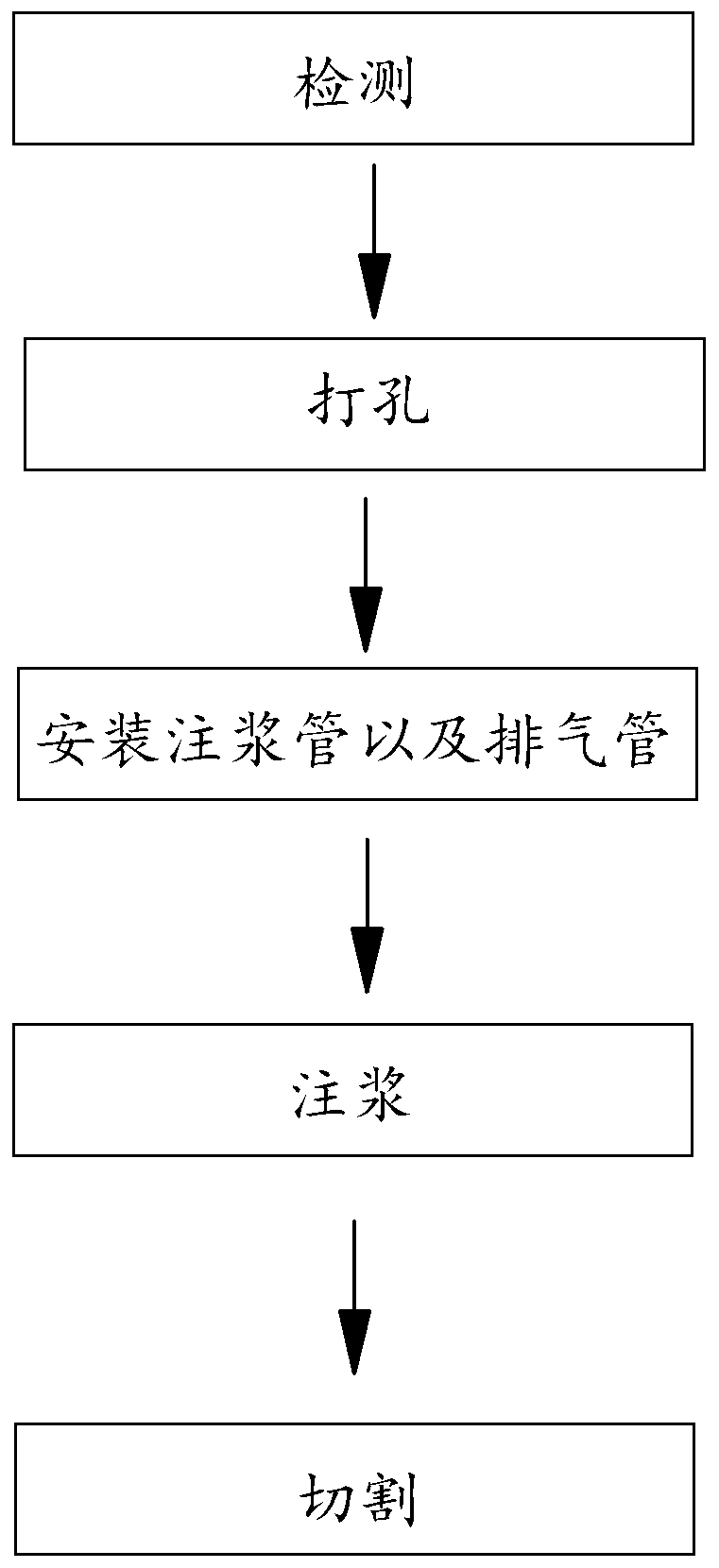

Construction technology of grouting back of expansion joint

ActiveCN110878698APrevent leakageMake sure to fillUnderground chambersTunnel liningReinforced concreteWater leak

The invention relates to a construction technology of grouting the back of an expansion joint. The construction technology specially comprises the following steps of first step, performing detection:detecting the armoring situation of the inner part of a tunnel shield concrete reinforced pipe, and marking the positions of inner reinforcing bars on the surface of the tunnel shield concrete reinforced pipe; second step, performing drilling: performing drilling to obtain a grouting hole and an exhaust hole in the 12'o clock positions of the tunnel shield concrete reinforced pipe; third step, mounting a grouting pipe and an exhaust pipe; and fourth step, performing grouting: injecting cement grout into the expansion joint, after the cement grout is drained from the exhaust pipe, sealing the exhaust pipe, controlling the grouting pressure to be 0.3MPa-0.5MPa, when grout in a grout bin of a grouting machine does not fall down within 15 minutes, stopping grouting, finally, separating the grouting machine from an unidirectional check grouting pipe, and completing the grouting. The construction technology has the advantages that grouting can be performed on the back of a water stopping pipe in the expansion joint, so that the expansion joint without a water leakage condition can be subjected to waterproof prevention, and the expansion joint cannot cause the situation of water seeping within a short term.

Owner:北京金河水务建设集团有限公司

Self-lubricating bearing copper mesh and manufacturing method thereof

PendingCN109253166AGood lubrication effectLong-lasting and reliable workBearing componentsLubricationCopper wire

The invention relates to a self-lubricating bearing copper mesh and a manufacturing method thereof. The self-lubricating bearing copper mesh is formed by carrying out warp and weft cross weaving on aplurality of copper wires, wherein the copper wire comprises a copper wire body, the outer surface of the copper wire body is pressed by external force to form a concavo-convex attached surface, and the attached surface is covered with a wear-resistant lubricating graphite layer. According to the present invention, the graphite layer can be firmly wrapped on the copper wire body due to the presence of the attached surface, the graphite layer forms graphite powder during the rotational friction due to the presence of the graphite layer, and the graphite powder lubricates the rotational friction, such that the lubrication effect is good.

Owner:江苏新风网业有限公司

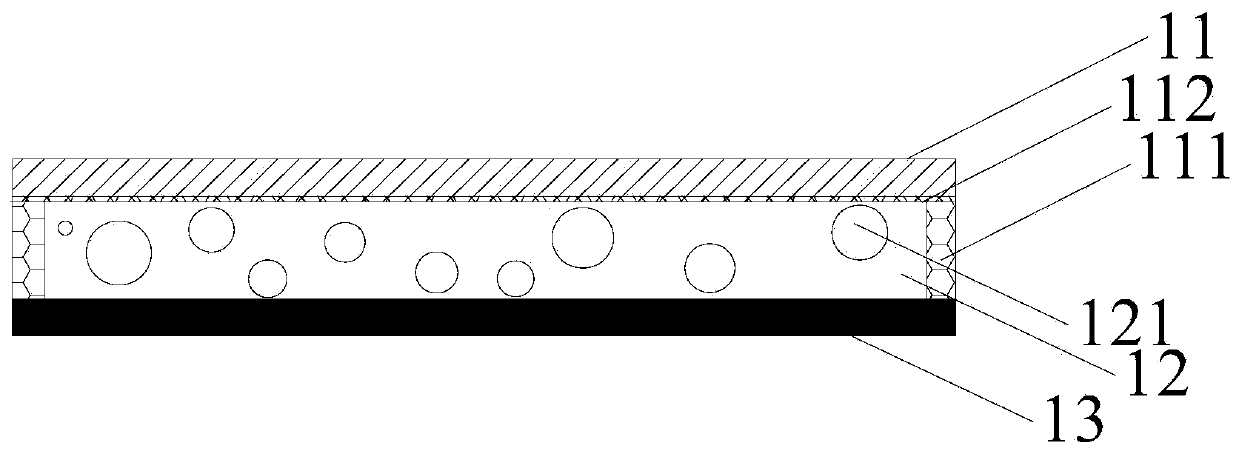

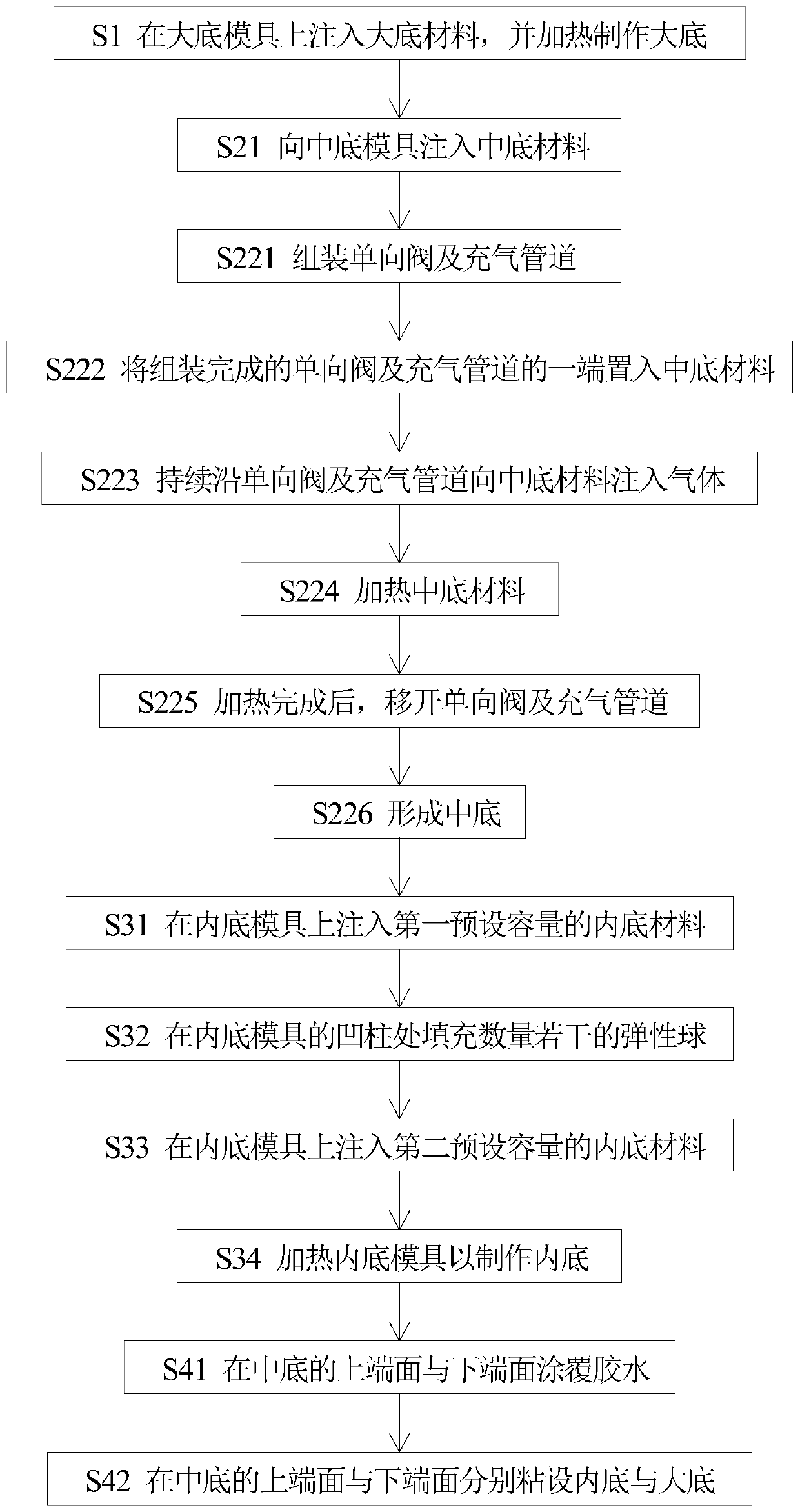

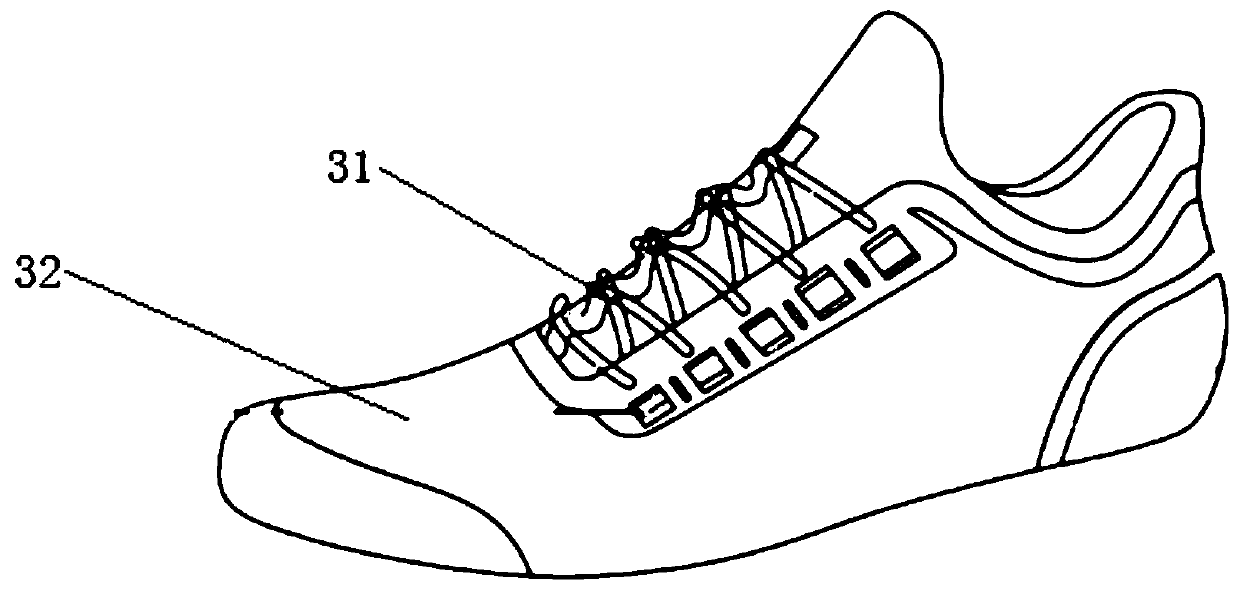

High-elasticity damping shoe soles, manufacturing method of shoe soles and sports shoes

InactiveCN110731575AGuaranteed stabilityHigh elastic experienceSolesDomestic footwearShoe industryStructural engineering

The invention relates to the technical field of shoe industry production, in particular to high-elasticity damping shoe soles, a manufacturing method of the shoe soles and a pair of sports shoes. Eachhigh-elasticity damping shoe sole comprises an insole, a midsole and an outsole which are stacked from top to bottom, wherein each insole is consistent with the outer edge of each outsole and is larger than the outer edge of each midsole; the outer edge of the lower end surface of each insole is provided with an elastic column and is arranged to prop against the outer edge of the upper end surface of each outsole; and each elastic column is arranged around the outer edge of each midsole, and the height of each elastic column is equal to the thickness of each midsole. The high-elasticity damping shoe soles solve the problem that the material and the composition structure of existing sports shoe soles difficultly meet the high-elasticity performance requirement of a user.

Owner:惠州市思凯鞋业有限公司

A Method and Its Application of Reforming Fracture Volume

Owner:CHINA PETROLEUM & CHEM CORP +1

A sand casting core making process

ActiveCN112792299BImpactfulMake sure to fillFoundry mouldsMoulding machinesManufacturing technologyAdhesive

The invention discloses a sand casting core-making process in the technical field of sand core manufacturing. The specific steps of the process are as follows: Step 1: Stir and mix the casting sand and binder evenly and thoroughly; Casting sand is injected into the mold. Step 3: Start the compaction device to compact the casting sand in the mold. Step 4: After the compaction is completed, take out the sand core and dry it; by setting the rotating disc, the two-way rack drives the rotating disc when it moves up and down Synchronous movement, the rotating disc will rotate along the inner threaded pipe while moving up and down, so as to drive the compaction hammer to rotate while moving up and down. The casting sand has a certain impact force and plays the role of compaction. When the compaction hammer is lowered, it rotates and twists and compacts the casting sand falling into the mold. On the one hand, the casting sand is compacted, and on the other hand, the casting sand is Squeeze all around to ensure that the casting sand can fill the corners of the mold.

Owner:山东金宇重型机械有限公司

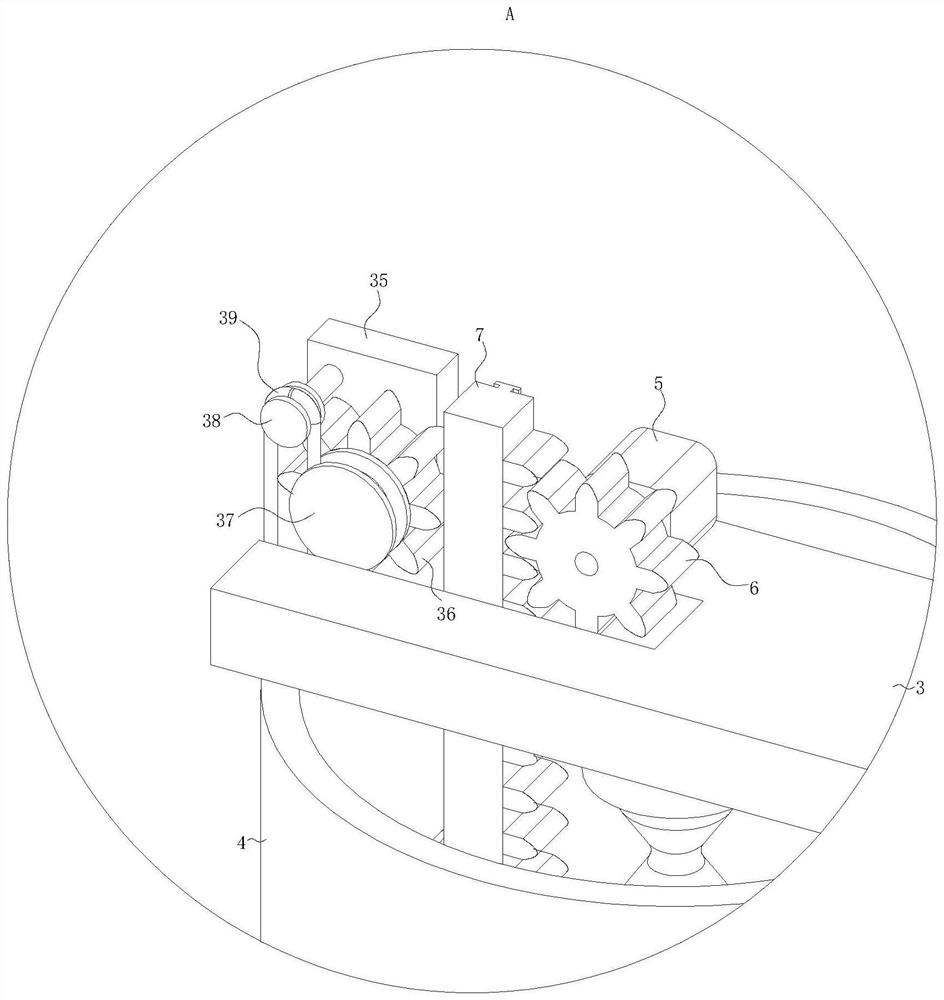

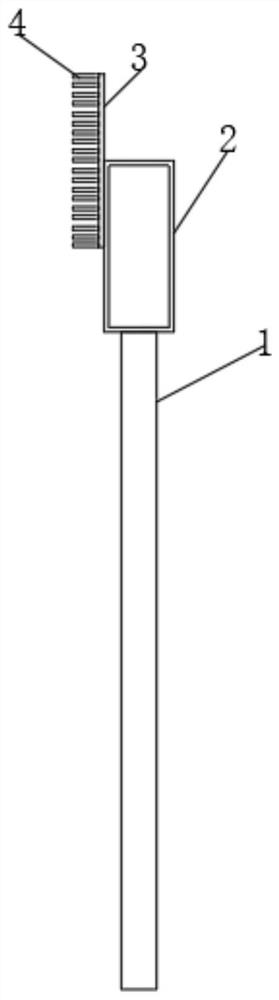

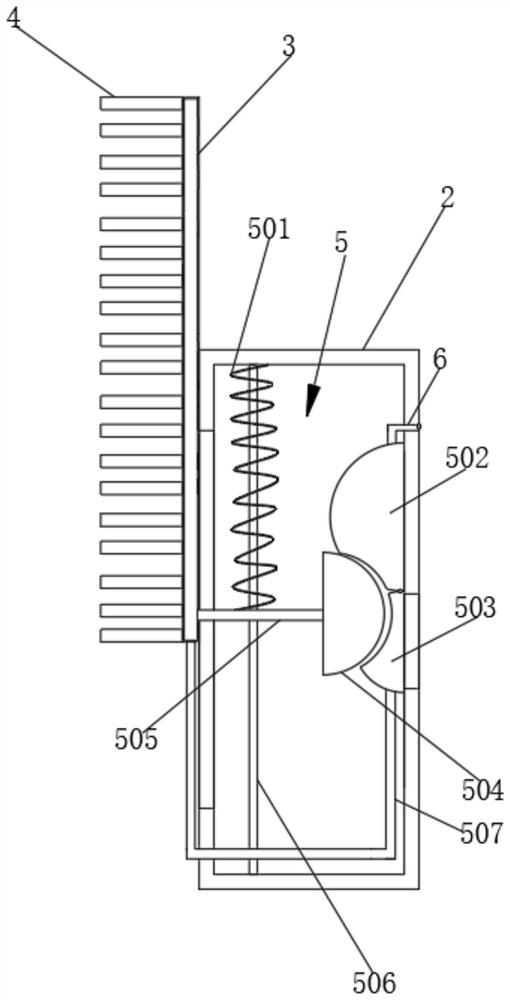

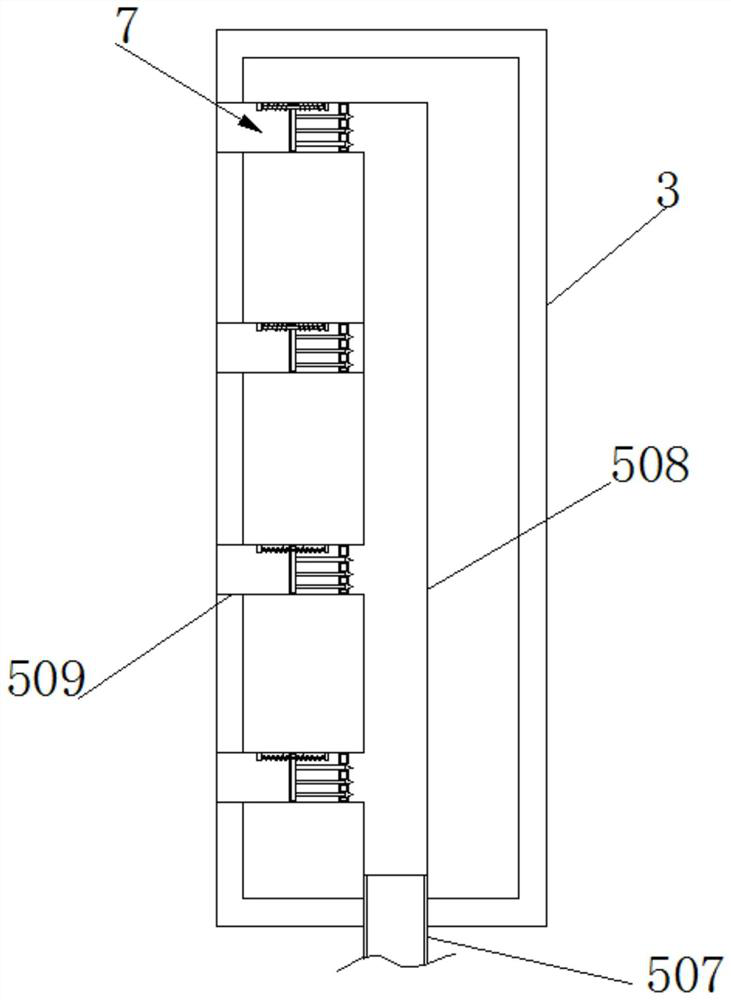

Toothbrush with automatic toothpaste squeezing function

The invention relates to the technical field of toothbrushes, and discloses a toothbrush with an automatic toothpaste squeezing function. The toothbrush comprises a toothbrush handle, an operation box is connected to the top of the toothbrush handle, a movable plate is arranged on one side of the operation box, bristles are adhered to one side of the movable plate, and a squeezing mechanism is arranged in the operation box. By arranging the movable plate and the squeezing mechanism, the movable plate can move during tooth brushing, the movable plate repeatedly squeezes toothpaste in the small air bag during moving, the toothpaste in the small air bag is squeezed onto the movable plate through the discharging pipe, the vertical cavity and the transverse cavity, and the situation that the toothpaste falls off during tooth brushing is avoided; and the toothpaste directly appears on the movable plate by utilizing the tooth brushing action, so the additional action is not required to be applied, and the use is convenient.

Owner:刘义军

A detection method and detection structure of grouting compactness of prefabricated components

ActiveCN104865352BMake sure to fillNo bubblesBuilding reinforcementsMaterial analysisSlurryComputer science

The invention discloses a detection method and a detection structure for grouting density of prefabricated parts. The detection method comprises the following steps: providing at least one first prefabricated part and a second prefabricated part, preserving a grouting construction gap between the first prefabricated part and the second prefabricated part, and forming opposite grouting interfaces between the first prefabricated part and the second prefabricated part; arranging prefabrication testing points on the grouting interfaces of the first prefabricated part or / and the second prefabricated part, and connecting the prefabrication testing points with a signal receiver; grouting size into the grouting construction gap; when the size in the grouting construction gap triggers the prefabrication testing points, transmitting signals to the signal receivers from the prefabrication testing points; based on the signals transmitted from the prefabrication testing points, judging the grouting density degree of the grouting construction gap. As the prefabrication testing points are arranged on the grouting interfaces, the density degree of size grouting in the grouting construction gap can be detected, the size can be completely filled without bubble, and the grouting connection quality between the prefabricated parts can be ensured.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Seeding machine and method of operating a planting machine using separate seed metering controls

ActiveCN102754545BMake sure to fillSeed depositing seeder partsBroadcast seedersSeederControl system

A seeding machine (10) is described. The seeding machine (10) is adapted to be moved over soil in a planting operation to plant seed, the machine (10) comprising: a row unit (24) having a trench opener (42), seed meter (36, 136), and a motor (66, 140) to drive the seed meter (36, 136); and a control system (80) including a seed sensor (100, 102) associated with the seed meter (36, 136). In order to minimize waste of seed during planting operation it is proposed to provide the machine (10) with a control system (80) which is adapted to operate the motor (66, 140) prior to operation of the seeding machine (10) to plant seed, to drive the seed meter (36, 136) in a priming operation to fill the seed meter (36, 136) with seed and to stop the motor (66, 140) in response to seed being detected by the associated seed sensor (100, 102) whereby when beginning a planting operation moving the seeding machine (10) over a field, seed is immediately discharged from the seed meter (36, 136).

Owner:DEERE & CO

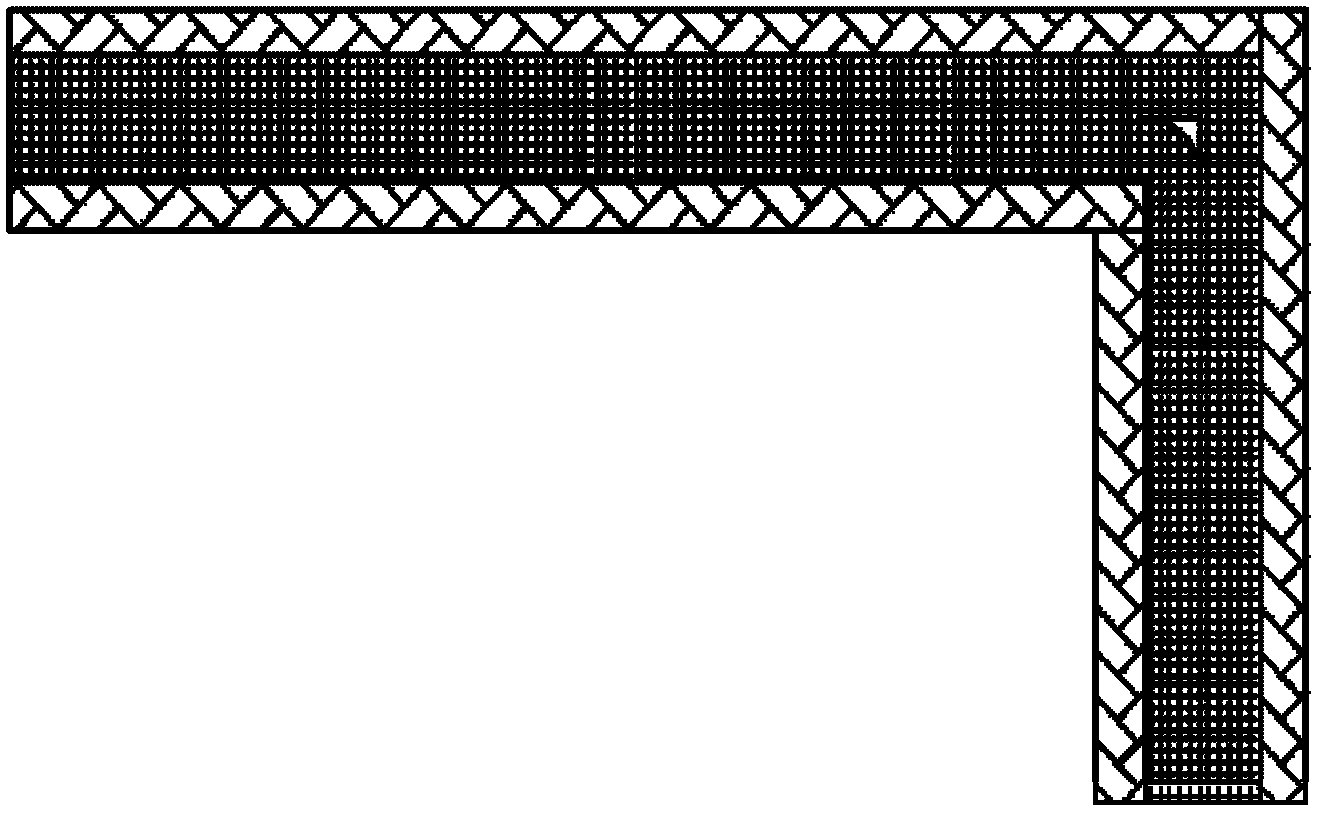

Construction method for pit well of strong weathered rock foundation rich in low-pressure-bearing fissure water

InactiveCN113136884AHigh strengthImprove flatnessProtective foundationExcavationsTube drainageStructural engineering

The invention relates to a construction method for a pit well of a strong weathered rock foundation rich in low-pressure-bearing fissure water. The construction method comprises the following steps that (1) a water collecting pit is chiseled in the bottom of the pit well; a flow guide hole is drilled in the side wall of the pit well; a flow guide pipe is plugged into the flow guide hole; a circle of collecting pipes are horizontally arranged on the peripheral side wall of the pit well and are in communication with the flow guide pipes; a drainage pipe is connected to the lowest part of the collecting pipe and extends to the water collecting pit; a water pump is arranged at the bottom of the water collecting pit; pit bottom concrete is poured; a side template supporting cushion block is anchored on the side wall of the pit well; and side formworks corresponding to the side walls of the pit well are installed on the inner sides of the side formwork supporting cushion blocks, scaffold pipes are arranged on the inner sides of the side formworks to outwards support the side formworks, concrete is poured between the side formworks and a rock stratum, the collecting pipe, the drainage pipe and a water pump drainage pipe are poured into the concrete, and the surface of the concrete is cleaned after vibrating and compacting. The constructed pit well is high in strength and good in flatness; and waterproof construction is facilitated, after the water content of the concrete meets the requirement, the bottom plate can be constructed for waterproofing.

Owner:CHINA 22MCC GROUP CORP

Hollow water distributor sealing device

The invention relates to a hollow water distributor sealing device used in oil field water filling technique, which is mounted on common hollow water distributor or track hollow water distributor, wherein the invention is mainly formed by upper sealing element, sealing element, lower sealing element and core; the upper sealing element is inside the sealing element; the lower sealing element is on the sealing element; upper sealing element is above the through hole of sealing element, while the lower one is under the through hole; the core is not mounted with sealing element; when picking up core, the sealing elements do not move in the well, to avoid unreliable sealing problem. The invention can save cost and increase the water filling time.

Owner:陈飞

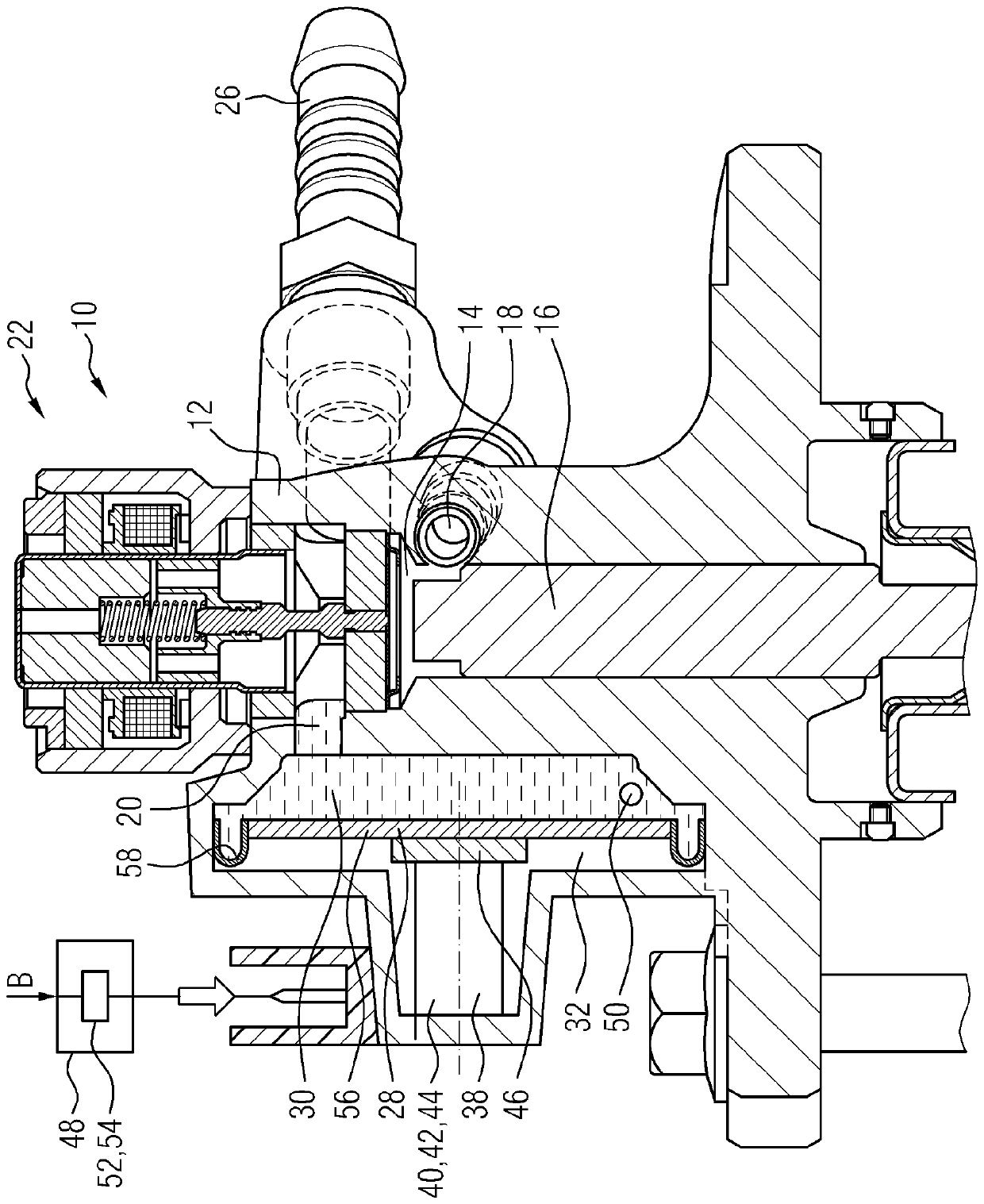

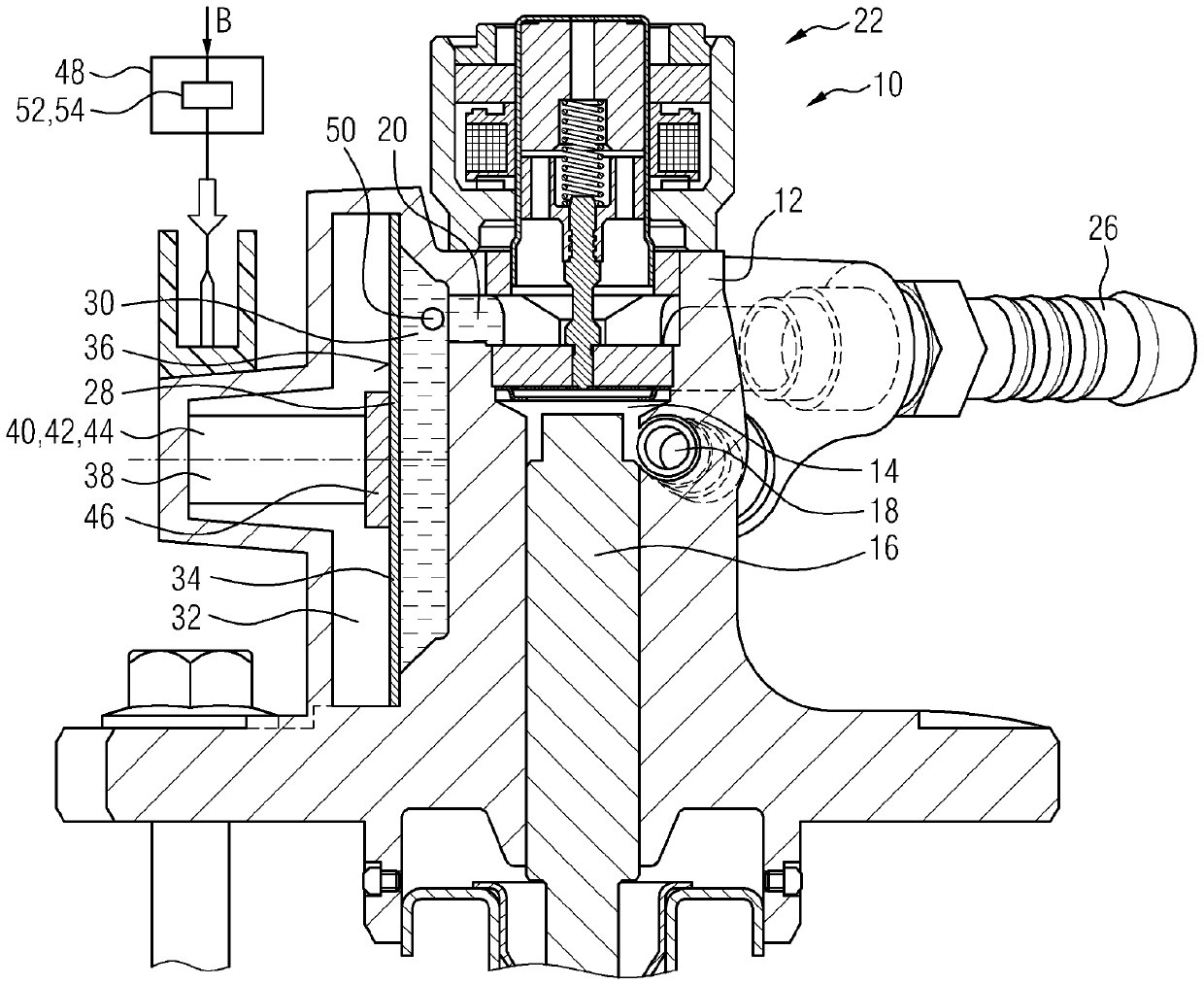

High-pressure fuel pump

InactiveCN110005559AVolume adjustmentVolume changePositive displacement pump componentsNoise reducing fuel injectionHigh pressureLow-pressure area

The invention relates to a high-pressure fuel pump (10) with a low-pressure area (20). In order to change the volume (30), the low-pressure area is defined by a sealing element (28), which can be offset from a still position. An adjustable adjusting element (38) interacts with the sealing element (28) so as to adjust the volume (30) of the low-pressure area (20) according to the needs.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Drill and backfill ring die drilling equipment

ActiveCN113695622BReduce drop inReduce the possibility of collapseWork clamping meansPositioning apparatusControl systemEngineering

The invention relates to the field of ring die drilling equipment, in particular to a drill and backfill type ring die drilling equipment, which comprises two semicircular and detachably connected clamping rings, the ring die is clamped between the two clamping rings In between, the clamping ring is placed on the roller frame of the ring die, the outer side wall of the clamping ring is provided with a plurality of accommodating holes, the accommodating holes are provided with filling components, the filling components and the material holes on the ring die are set in one-to-one correspondence, and the filling components It includes an electromagnet arranged at the open end of the accommodating hole, the electromagnet is electrically connected to the control system, a magnetic block for repulsing the electromagnet slides in the accommodating hole, and a reset pressure is supported between the magnetic block and the closed end of the accommodating hole. The magnetic block is provided with an air guide tube, the air guide tube slides through the inner wall of the clamp ring and is provided with a sleeve seat, a balloon is sleeved on the sleeve seat, one end of the air guide tube communicates with the corresponding accommodating hole, and the other end is connected with the corresponding balloon Connected. The present application has the advantage of reducing the possibility that the worker needs to clean up the drill chips in the feed hole of the ring die subsequently.

Owner:常州朱美拉模具技术有限公司

Novel trench isolation groove for filling trench

ActiveCN102627252BChange corner shapeAvoid unfilledSolid-state devicesFluid speed measurementEtchingEngineering

The invention discloses a novel trench isolation groove for filling a trench and belongs to a micro electro mechanical system (MEMS) and a micro processing technology. According to the trench isolation groove provided by the invention, the distance between any point on the inner wall surface and the outer wall surface is respectively not greater than d, wherein the d is the width of the trench isolation groove. The trench isolation groove meeting the technical characteristics has diversified forms. The invention provides a plurality of specific embodiments. The corner shape of the trench isolation groove is directly changed, and thus the phenomenon that a small unfilled part at the corner of a rectangular groove appears is avoided and the groove corner can be ensured to be completely filled. Although etching ions rebound from the bottom surface to cause secondary etching on the side wall, the corner of the rectangular trench is of a circular arc and the like; and the distance between the inner wall surface and the outer wall surface is smaller than or equal to 2mu m and is equal to the distance between the two sides of the rectangular groove, so that no clearance in filling is ensured.

Owner:XI AN ZHISENSOR TECH CO LTD

Repairing process for coating damage of three-layer polyolefin coating exposed base material

ActiveCN110743758AConsistent structurePatch ConsistentPretreated surfacesCoatingsAdhesive cementPolymer science

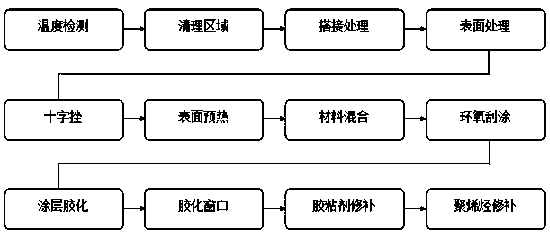

The invention relates to a repairing process for coating damage of a three-layer polyolefin coating exposed base material. The repairing process comprises the following steps: step 1, controlling temperature and humidity; step 2, primarily cleaning a damaged region; step 3, carrying out lap joint treatment; step 4, treating the base material; step 5, carrying out cross filing treatment; step 6, preheating the surface; step 7, selecting a liquid-state double-component repairing material which is recommended by the same manufacturer as a mother coating bottom layer material; step 8, carrying outblade coating on a bottom layer coating; step 9, gelling a coating; step 10, gelling a window; step 11, repairing by an adhesive; and step 12, repairing polyolefin. The process is used for carrying out corresponding repairing construction and detection, and the quality of the repaired coating can meet related quality requirements of the corresponding coating. Meanwhile, the process greatly avoidsa phenomenon that a coating pipe is peeled and remade as the coating pipe is damaged to the base material; and meanwhile, the construction cost is reduced and resources are saved.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com