Low-cost long-cycle graphite negative electrode material, preparation method and application thereof

A graphite negative electrode and graphite micropowder technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of difficult to meet the requirements of high-end power battery materials, low compaction density, large specific surface area, etc., and achieve high Coulombic efficiency for the first time , high carbonization residual carbon, and the effect of reducing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

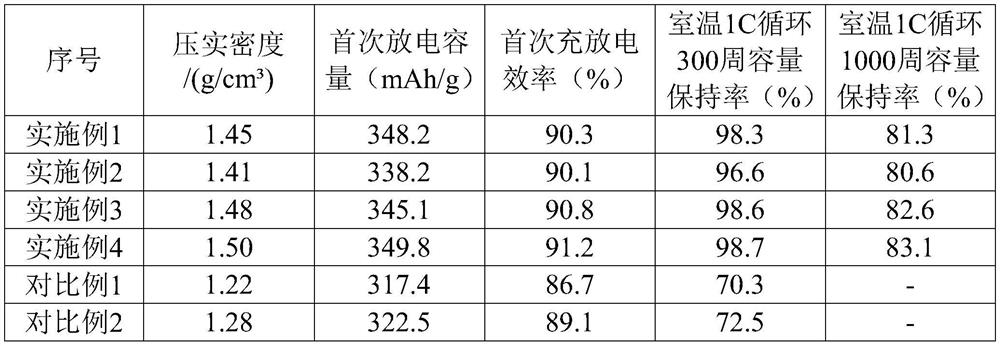

Examples

preparation example Construction

[0034] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0035] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0037] (1) After crushing the tailings of high-purity graphite products in the impact mill, they are shaped and classified to obtain the average particle size D 50 16μm graphite powder. Pitch (softening point 70°C) and graphite fine powder were added to the mixer at a mass ratio of 16:100, the speed was adjusted to 240r / min, and mixed for 1.5 hours to obtain the precursor powder.

[0038] (2) Fill the precursor powder into the rubber mold of the molding machine, and use high-frequency electromagnetic vibration to make the precursor compact. After compaction, vacuumize, discharge the air between the precursor particles, and put it into a container filled with water. In a high-pressure container, pressurize to 120MPa, heat to 140°C, keep the pressure for 3 hours, cool to room temperature and press into a block.

[0039] (3) Carbonize the block in step (2) in a nitrogen atmosphere, raise the temperature to 1200°C at a rate of 25°C / min and keep it warm for 2 hours. During the pro...

Embodiment 2

[0041] (1) After crushing the tailings of the resistance material products in the impact mill, they are shaped and classified to obtain the average particle size D 50 17μm graphite powder. Pitch (softening point 80°C) and graphite fine powder were added to the mixer at a mass ratio of 12:100, the speed was adjusted to 200r / min, and mixed for 2.5 hours to obtain the precursor powder.

[0042] (2) Fill the precursor powder into the rubber mold of the extrusion molding machine, and use high-frequency electromagnetic vibration to make the precursor compact. After compaction, vacuumize to discharge the air between the precursor particles. In a high-pressure container, pressurize to 90MPa, heat to 170°C, keep the pressure for 2 hours, cool to room temperature and press into a block.

[0043](3) Carbonize the block in step (2) in a nitrogen atmosphere, raise the temperature to 1100°C at a rate of 20°C / min and keep it warm for 3 hours. During the process, nitrogen gas is continuously...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com