Novel trench isolation groove for filling trench

A trench isolation, a new type of technology, applied in the direction of measuring devices, instruments, fluid velocity measurement, etc., can solve the problem of incomplete filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

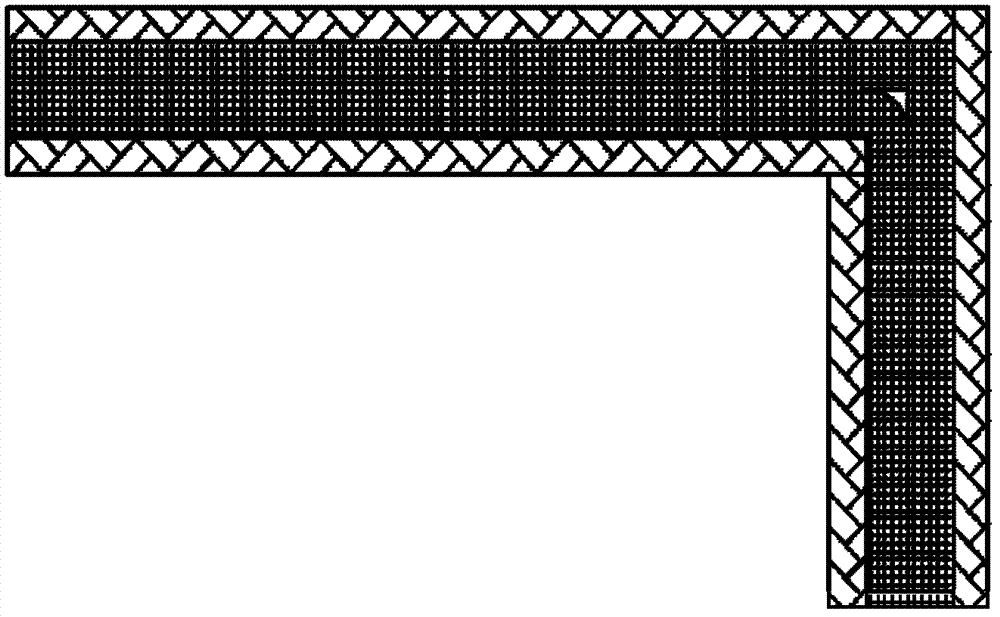

Image

Examples

Embodiment 1

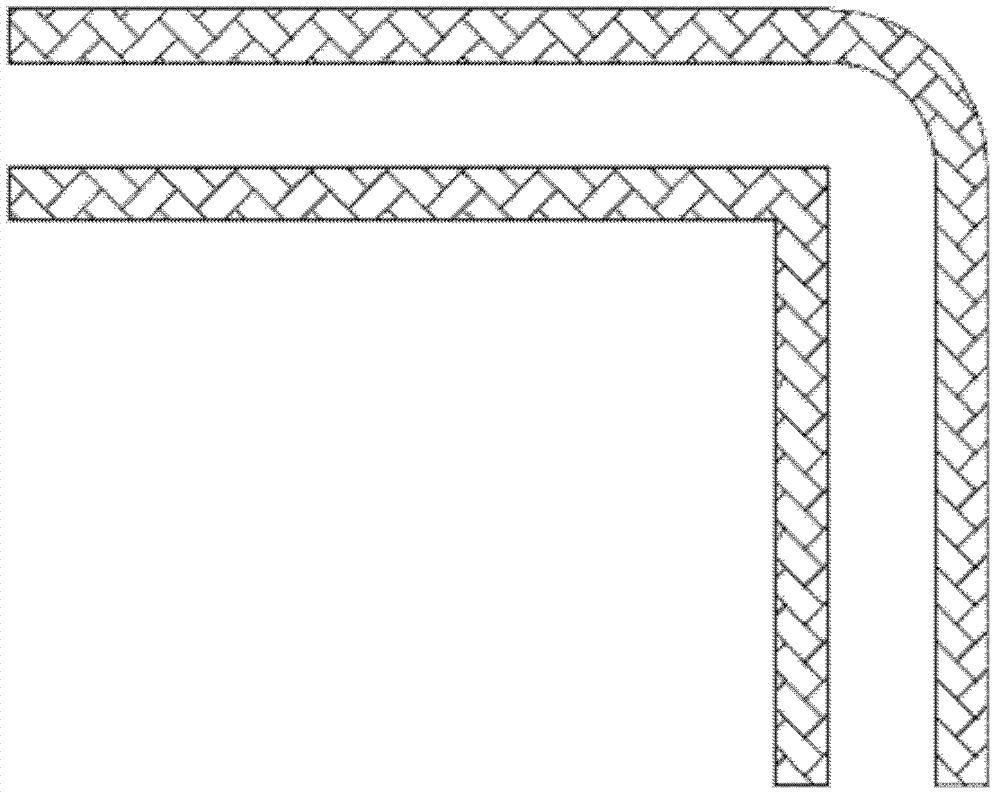

[0024] refer to figure 2 , the trench isolation groove in this embodiment, the inner wall of the groove is a right-angled corner, the corner of the outer wall is rounded, and the rounded corner is formed with the right-angled corner of the inner wall as the center and a radius of 2 μm. arc line.

[0025] Of course, as a development of this embodiment, the inner wall of the groove is a right-angled corner, the corner of the outer wall is rounded, and the rounded corner is an arc formed by taking the right-angled corner of the inner wall as the center of the circle and having a radius of less than 2 μm. Line, and tangent to the outer wall, is also an implementation that satisfies the technical features of the present invention.

Embodiment 2

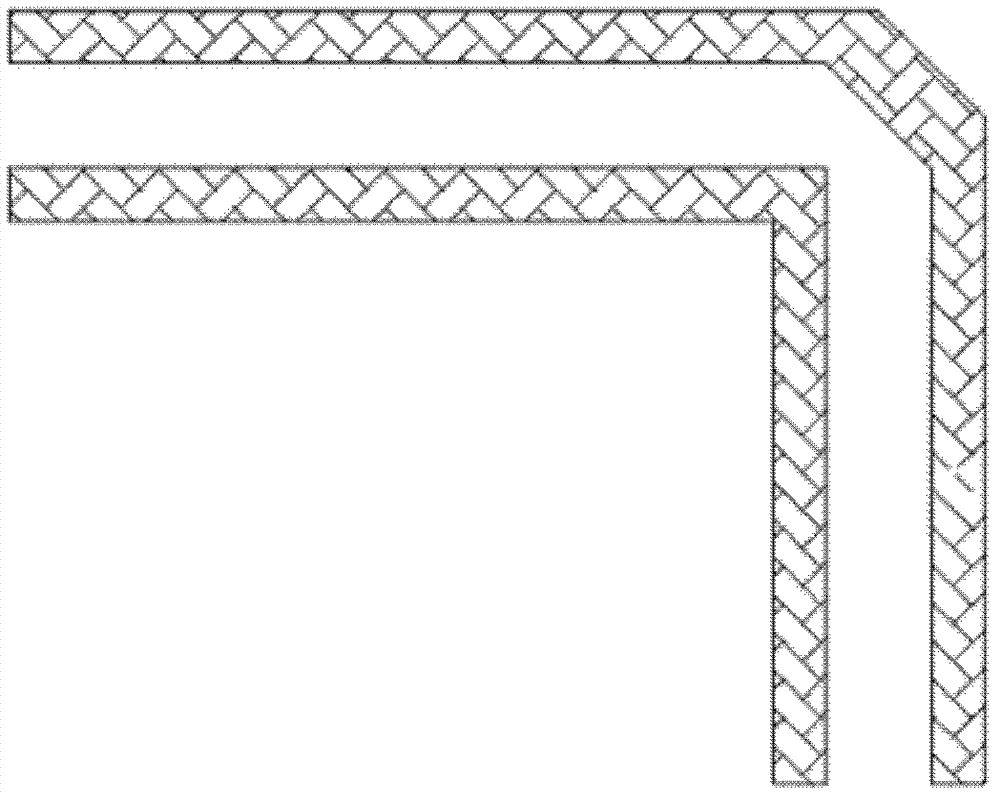

[0027] refer to image 3 : the channel isolation groove in the present embodiment, the inner wall of the groove is a right-angled corner, and the outer wall corner is a half-side chamfer, that is, the outer wall corner is a slash that is 45° with the two sides of the outer wall; The vertical distance between the line and the right-angled corner of the inner wall is 2 μm.

[0028] Of course, as a development of this embodiment, the inner wall of the groove is a right-angled corner, and the vertical distance between the oblique line of the outer wall corner and the right-angled corner of the inner wall is less than 2 μm, which is also an implementation that satisfies the technical features of the present invention.

Embodiment 3

[0030] refer to Figure 4 : In the trench isolation groove in the present embodiment, the inner wall surface and the outer wall surface corners of the groove are half chamfered, and the two chamfered lines are parallel lines with a distance of 2 μm, and the chamfered lines and the two sides of the outer wall surface are all 45° angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com