Large-capacity motor outgoing line connecting method and connector

A connection method and lead wire technology are applied in the field of large-capacity motor lead wire connection methods and joints, which can solve the problems of motor failure and shutdown, contact pressure reduction, wire core fuse, etc., to ensure stable operation, enhance cohesion, and avoid oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

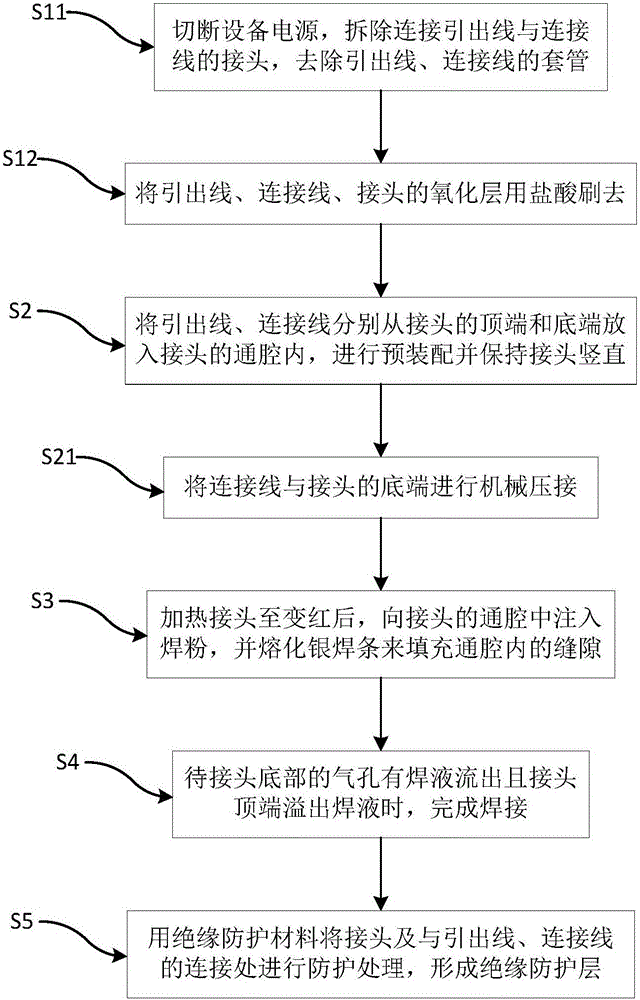

[0055] Such as figure 1 As shown, a large-capacity motor lead wire connection method described in this embodiment includes the following steps:

[0056] Step S11, cut off the power supply of the device, remove the connectors connecting the lead wires and the connecting wires, and remove the sleeves of the lead wires and the connecting wires. After the large-capacity motor has been used for a period of time, the contact resistance is too large, causing an overheating fault. First cut off the power supply of the equipment, disassemble the overheated connection, that is, disassemble the connection of the lead wire and the connecting wire, and remove the lead wire and the connecting wire. Remove a certain length from the pipe, and the removed length is determined according to the length of the lead-out line. If the length of the lead-out line is sufficient, the end of the lead-out line can be sawed off directly.

[0057] Step S12, brushing off the oxide layers of the lead wires, ...

Embodiment 2

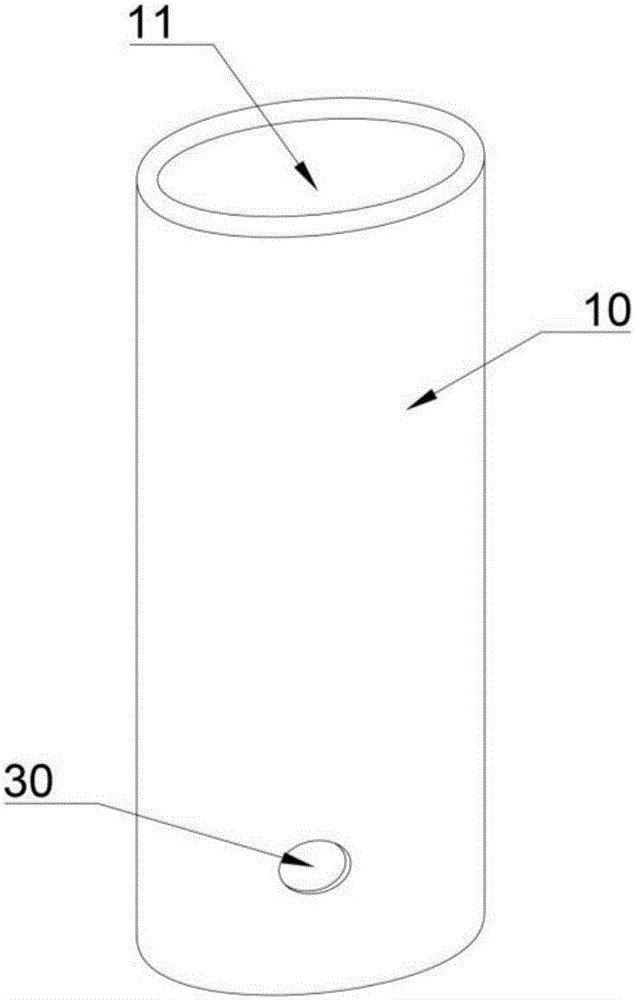

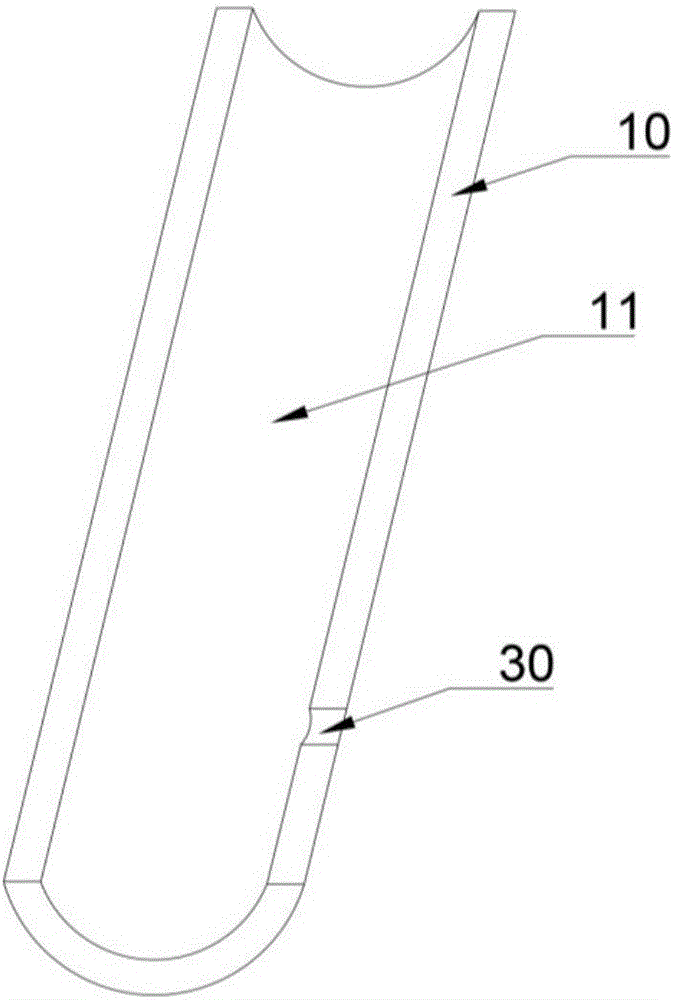

[0065] Such as figure 2 , image 3 As shown, a joint described in this embodiment is a cylindrical structure with a through cavity 11 inside, including a body 10 and a through cavity 11. The top and bottom ends of the body 10 are used to connect the lead wire and the connection wire respectively. The through cavity 11 is arranged coaxially with the body 10 , and the body 10 is provided with an air hole 30 communicating with the outside world and the through cavity 11 , and the air hole 30 is set near the bottom of the body 10 .

[0066] Specifically, the joint is a copper joint, the body 10 is cylindrical, and the through cavity 11 is also cylindrical. The through cavity 11 is coaxially arranged with the main body 10. The diameter of the through cavity 11 is slightly larger than the diameter of the lead wire and the connection wire, which is convenient for installation. The bottom of the connector is provided with an air hole 30 near the bottom end, the air hole 30 communica...

Embodiment 3

[0070] Such as Figure 4 , Figure 5 As shown, this embodiment is a further limitation of the first embodiment above. The bottom end of the joint is provided with an outwardly extending boss 20, and the boss 20 is provided with a boss through cavity 21, and the boss through cavity 21 The cross-section is greater than or equal to the cross-section of the cavity 11, and the outer wall of the boss 20 is provided with a crimping opening 22. The boss 20 is an axial or radial extension of the body 10, the body 10 is cylindrical, the through cavity 11 is cylindrical, the boss 20 is cylindrical, the cross section of the boss 20 is larger than the cross section of the body 10, and the boss 20 is arranged coaxially with the body 10, the cross section of the through cavity 21 of the boss is equal to the cross section of the through cavity 11, and the boss 20 can be mechanically connected with the connecting wire.

[0071] The top port of the through cavity 11 is funnel-shaped, which fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com