High-pressure fuel pump

A high-pressure pump and fuel technology, applied in fuel injection pumps, fuel injection devices, liquid fuel engines, etc., can solve problems such as inability to ensure correct dosage, damage, and unexpected noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

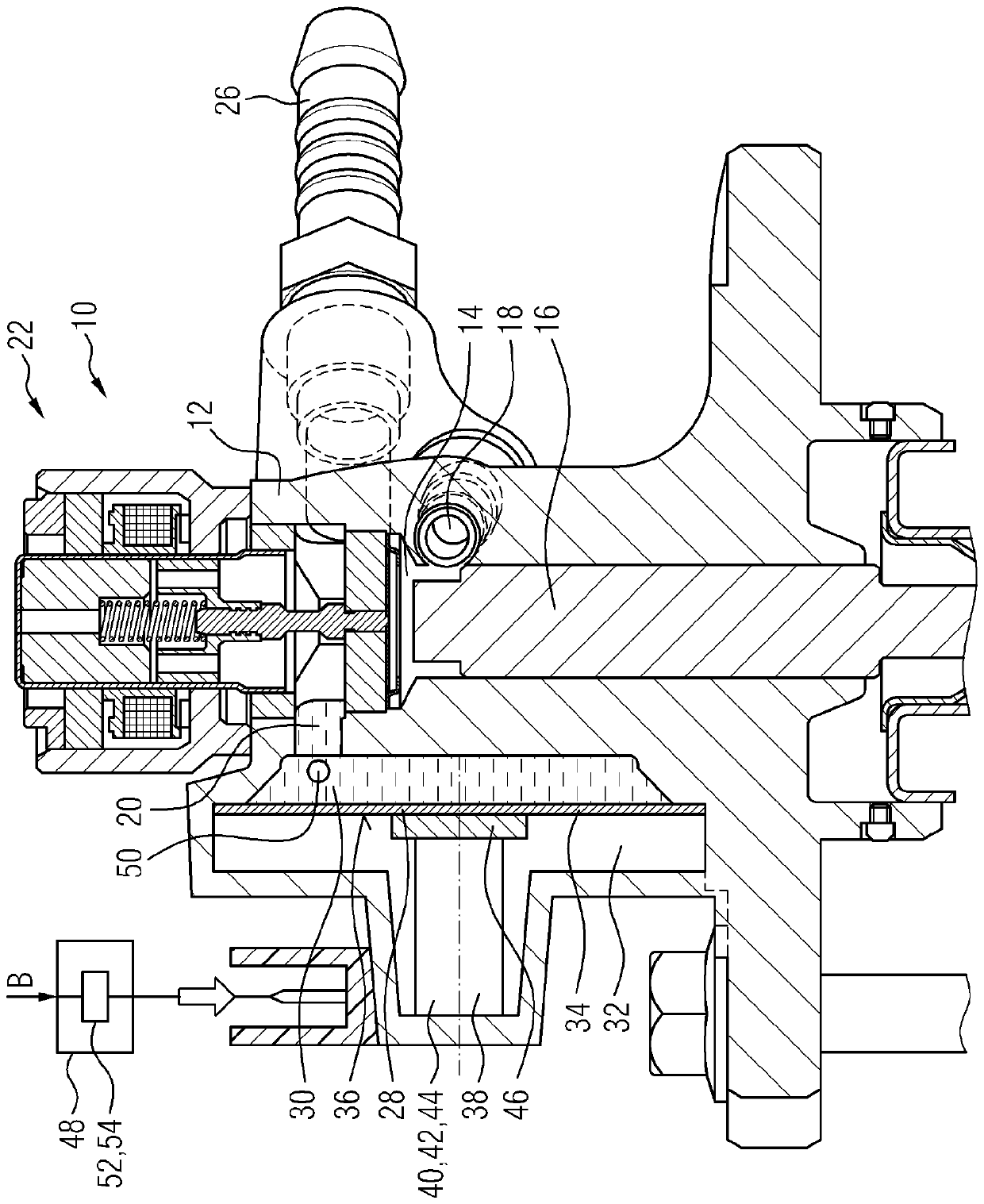

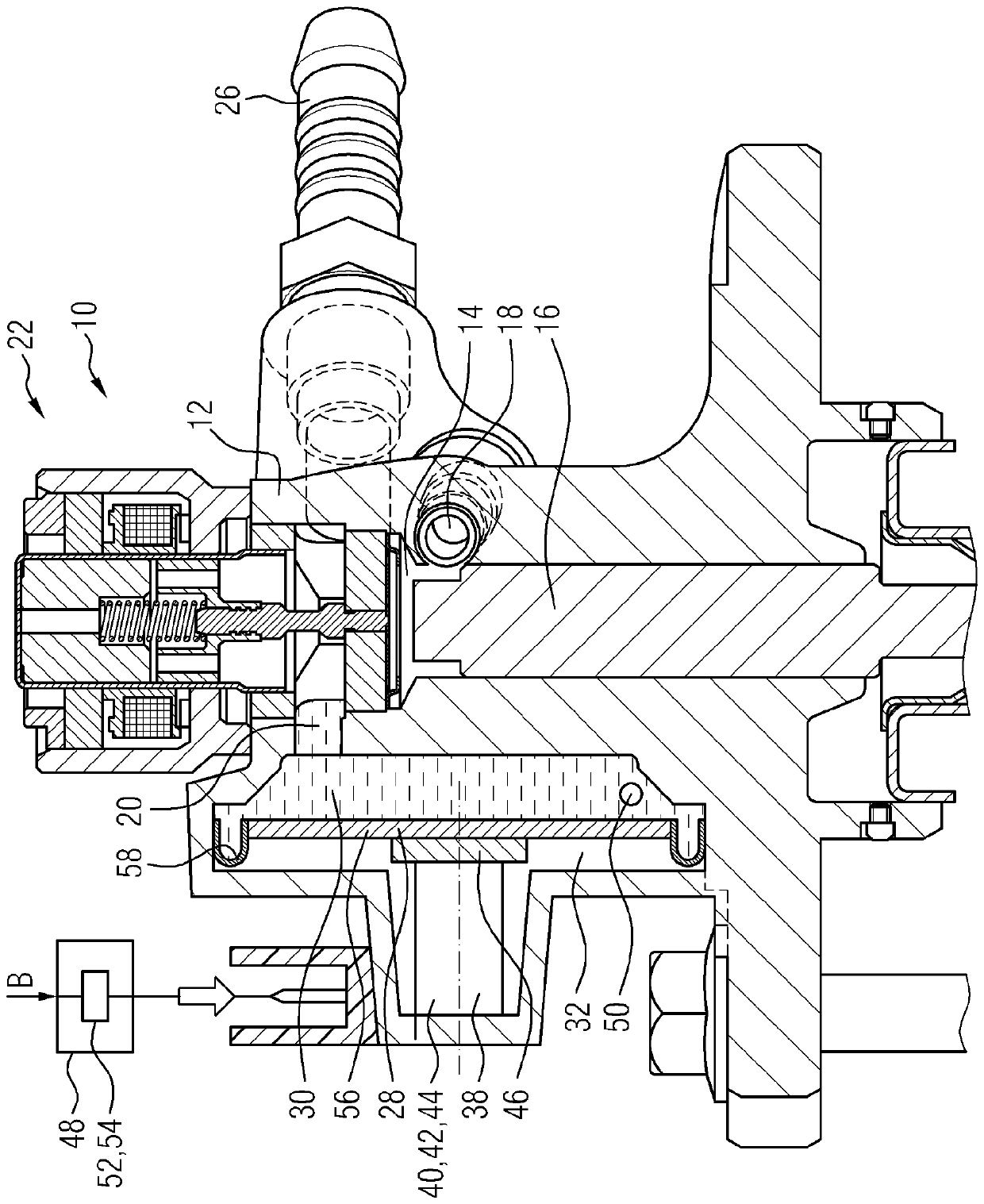

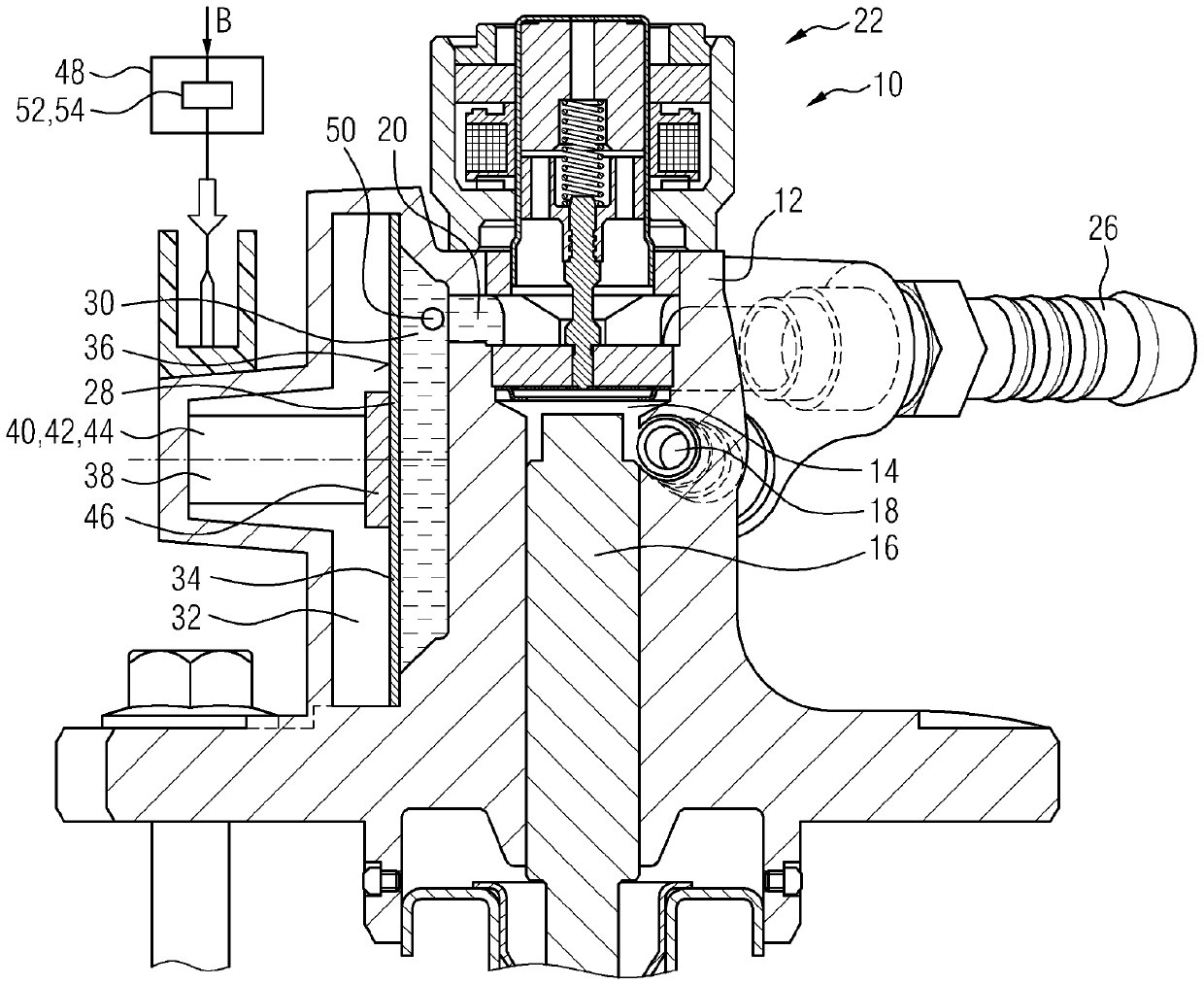

[0031] figure 1 A longitudinal section through a first embodiment of a high-pressure fuel pump 10 is shown with a housing 12 in which a pressure chamber 14 is formed. A pump piston 16 is guided in the housing 12 , which cyclically increases and decreases the volume of the pressure chamber 14 by means of a translational movement. In this case, the fuel arranged in the pressure chamber 14 is subjected to high pressure. The high-pressure fuel is then conducted further to downstream elements via the high-pressure connection 18 on the high-pressure fuel pump 10 .

[0032] Fuel is delivered from the low-pressure region 20 of the high-pressure fuel pump 10 to the pressure chamber 14 . In the closed state, the valve device 22 separates the pressure chamber 14 from the low-pressure region 20 . The low-pressure area 20 is delimited by the housing 12 of the high-pressure fuel pump 10 , the valve arrangement 22 and the supply line 26 , via which fuel is delivered to the high-pressure f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com