Patents

Literature

180results about "Noise reducing fuel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

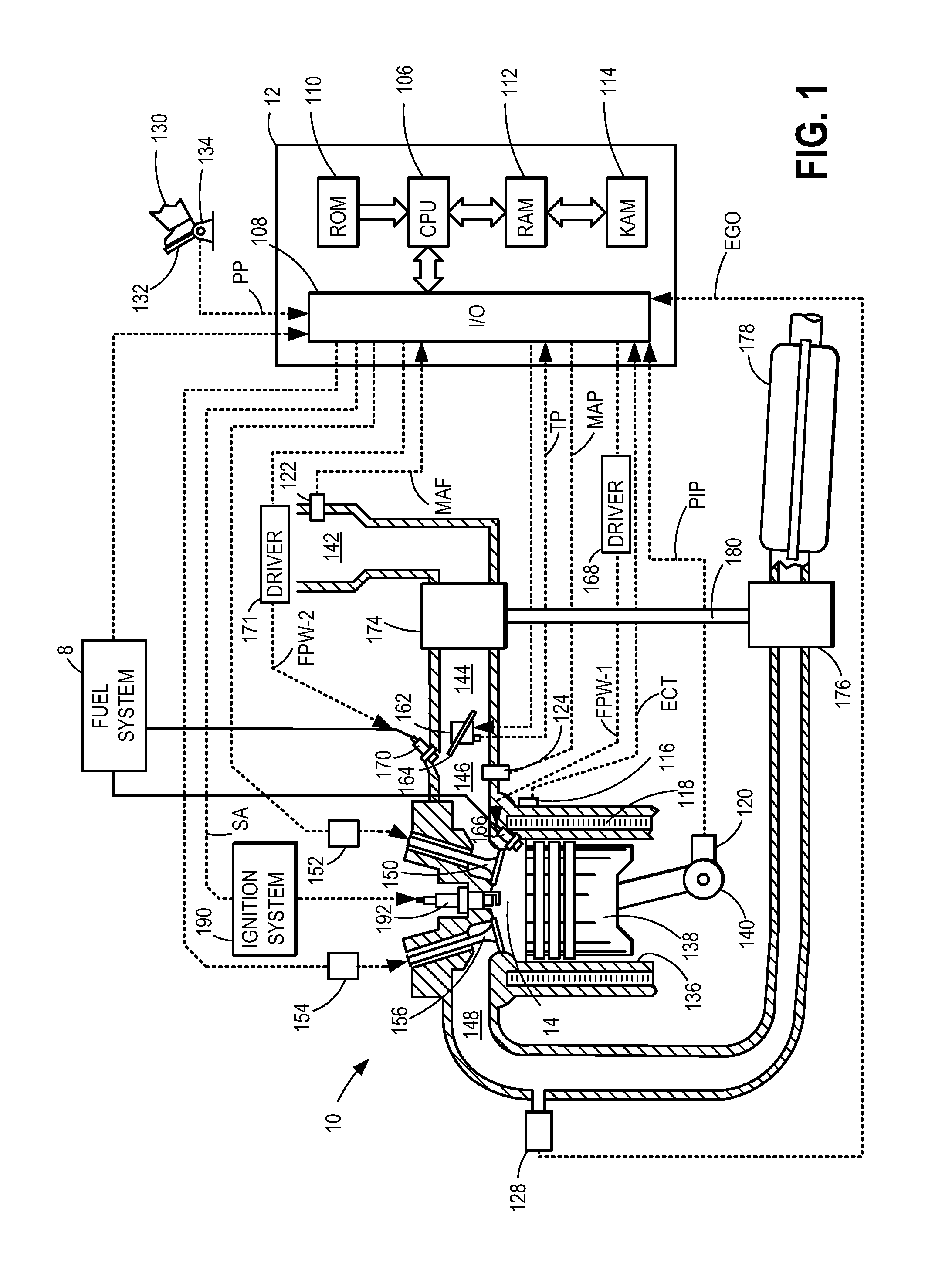

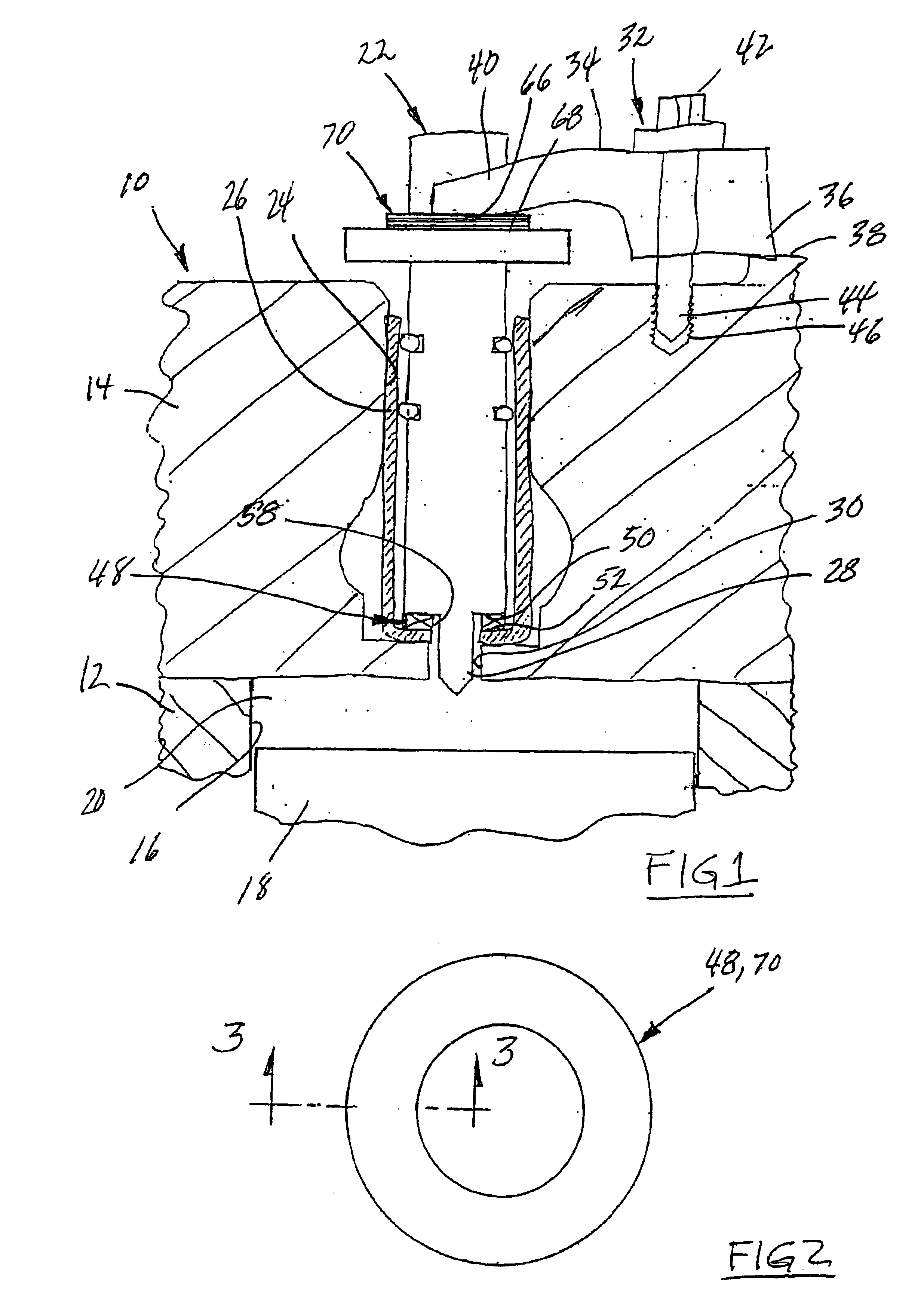

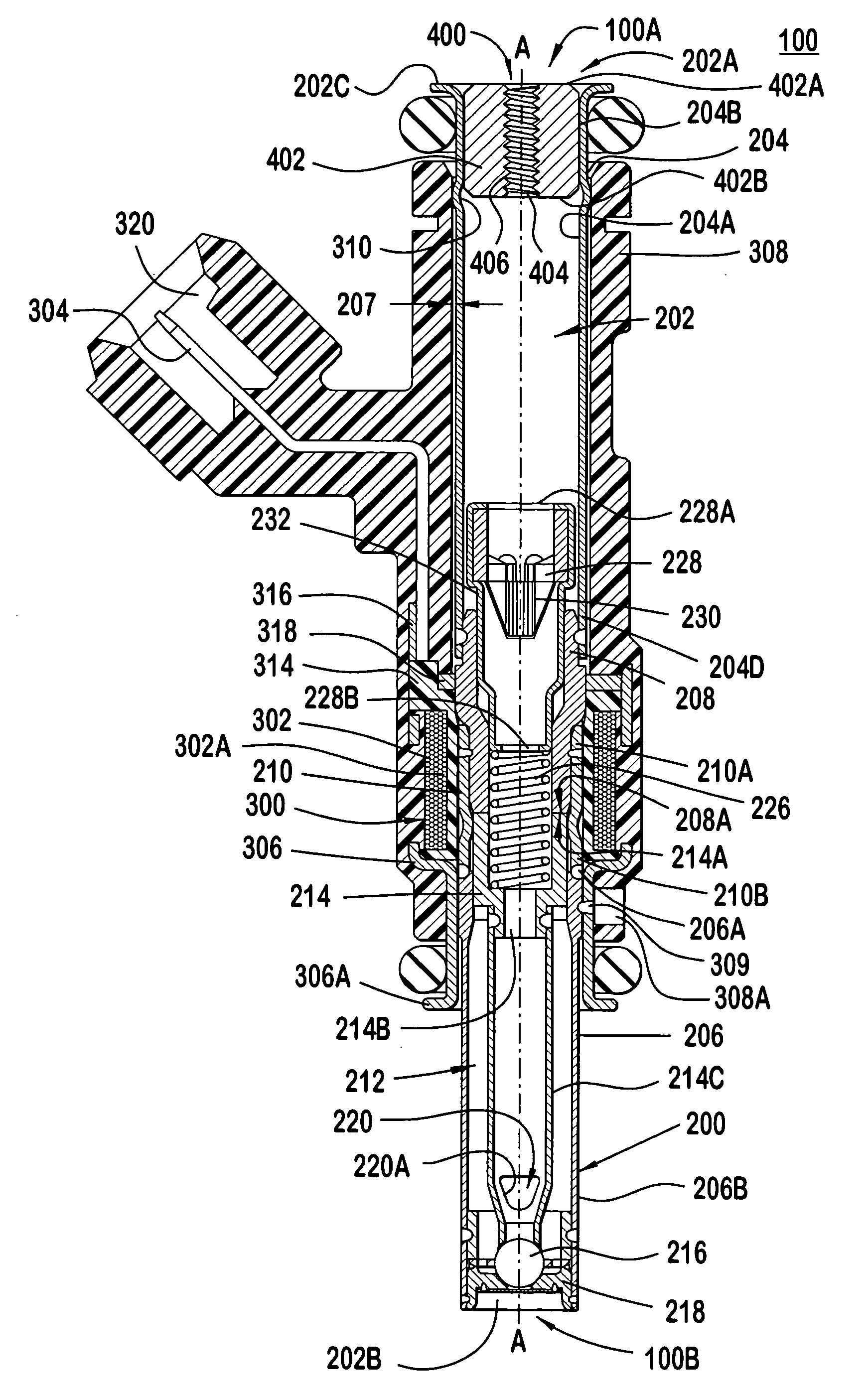

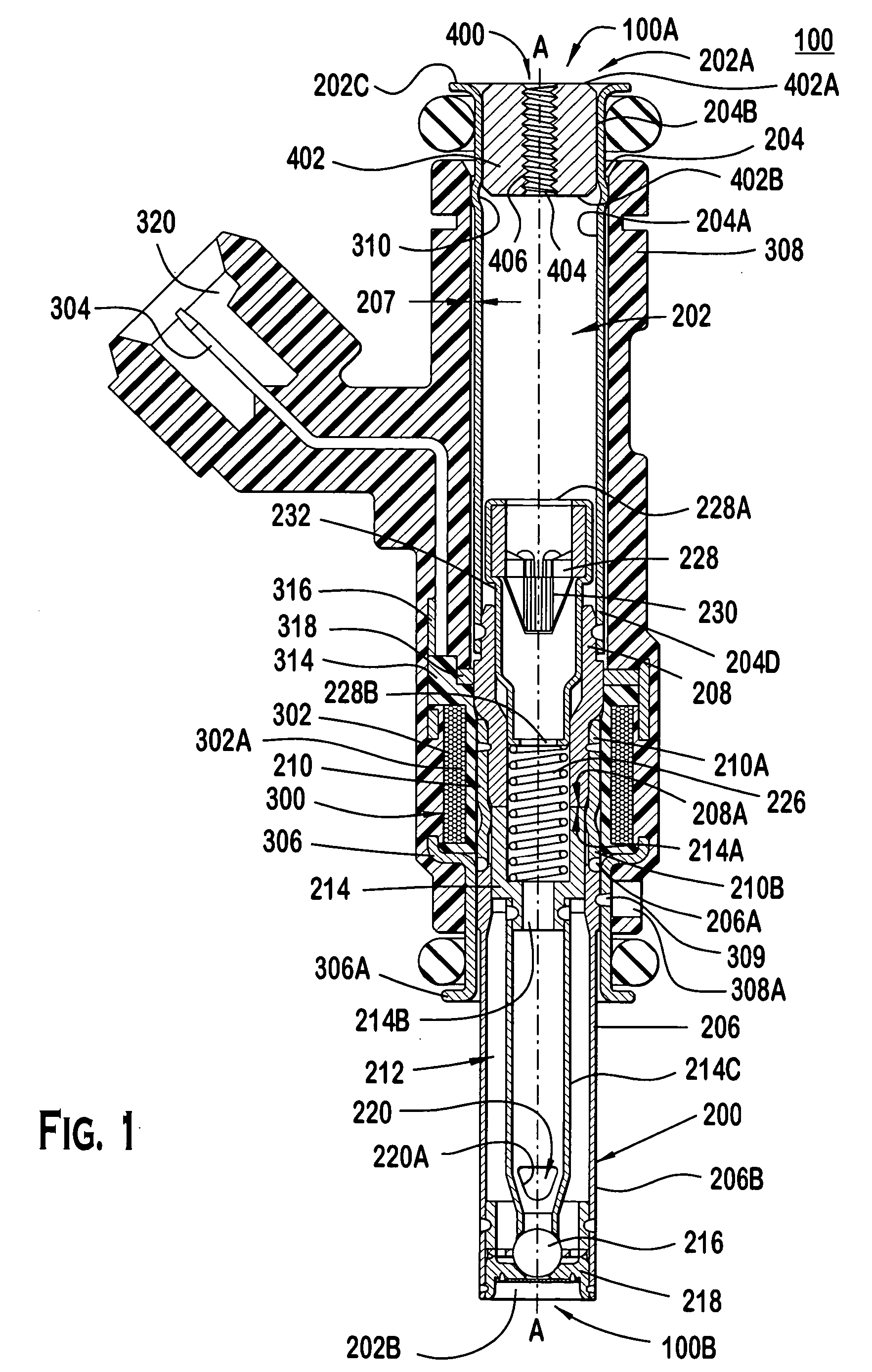

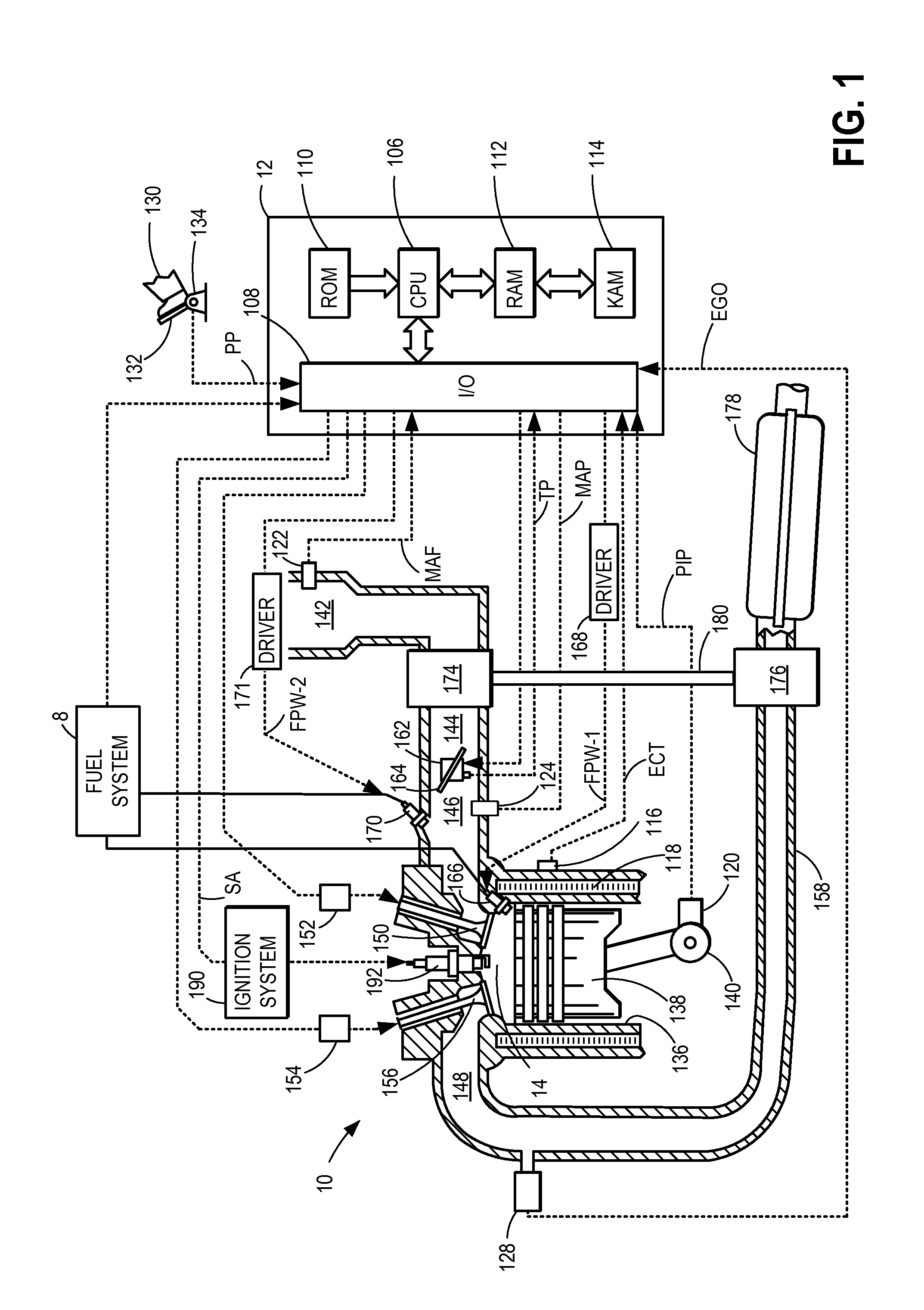

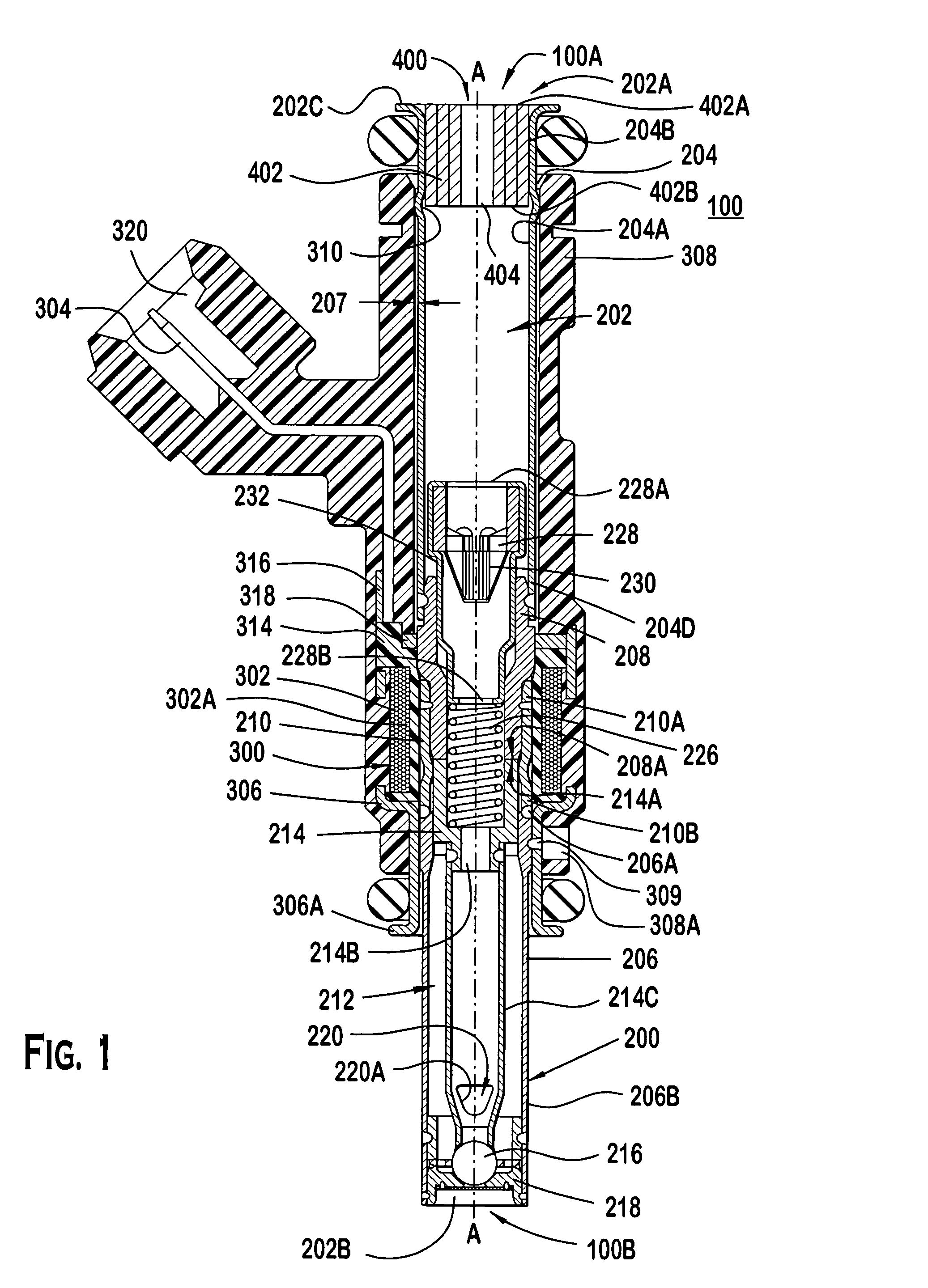

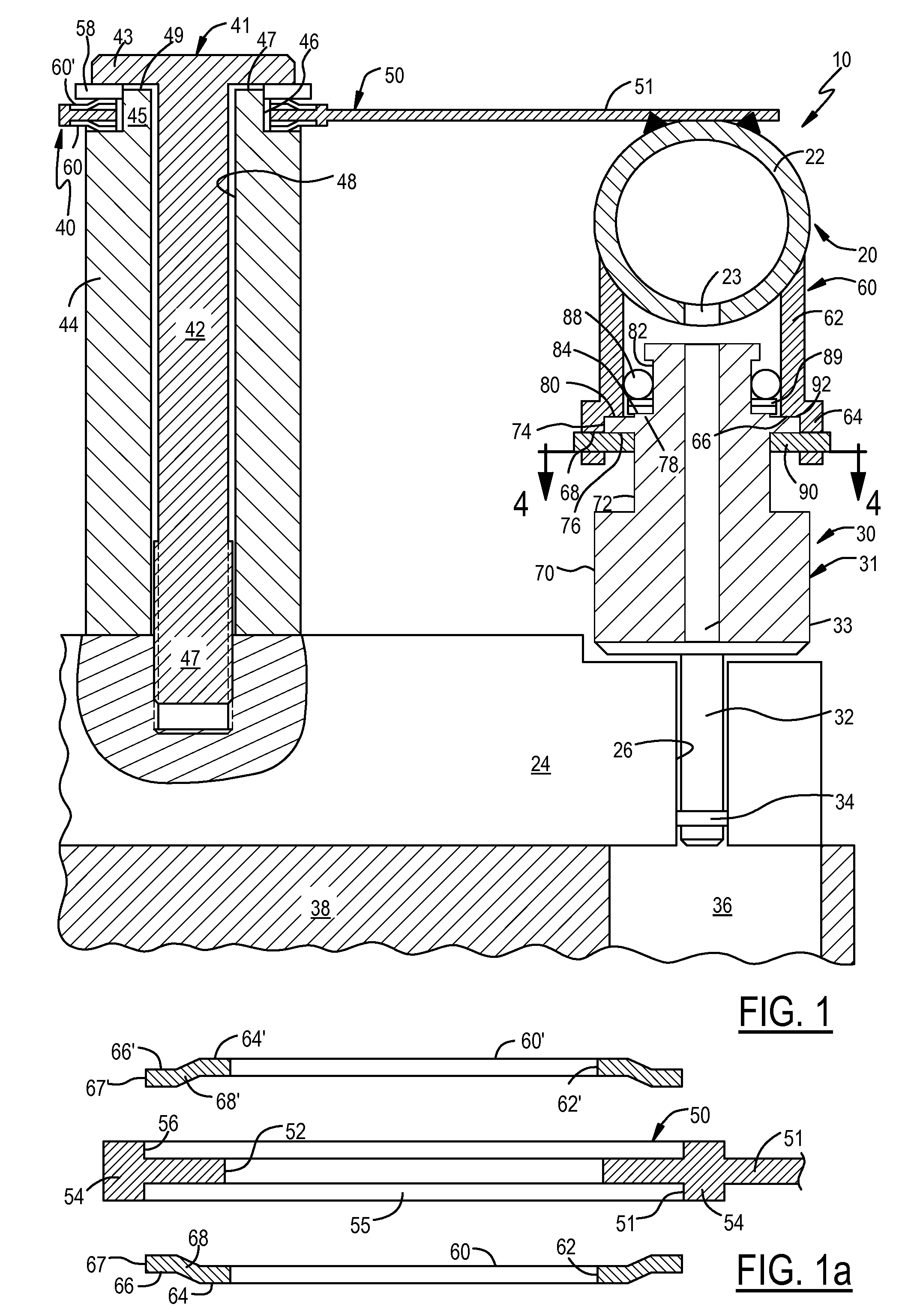

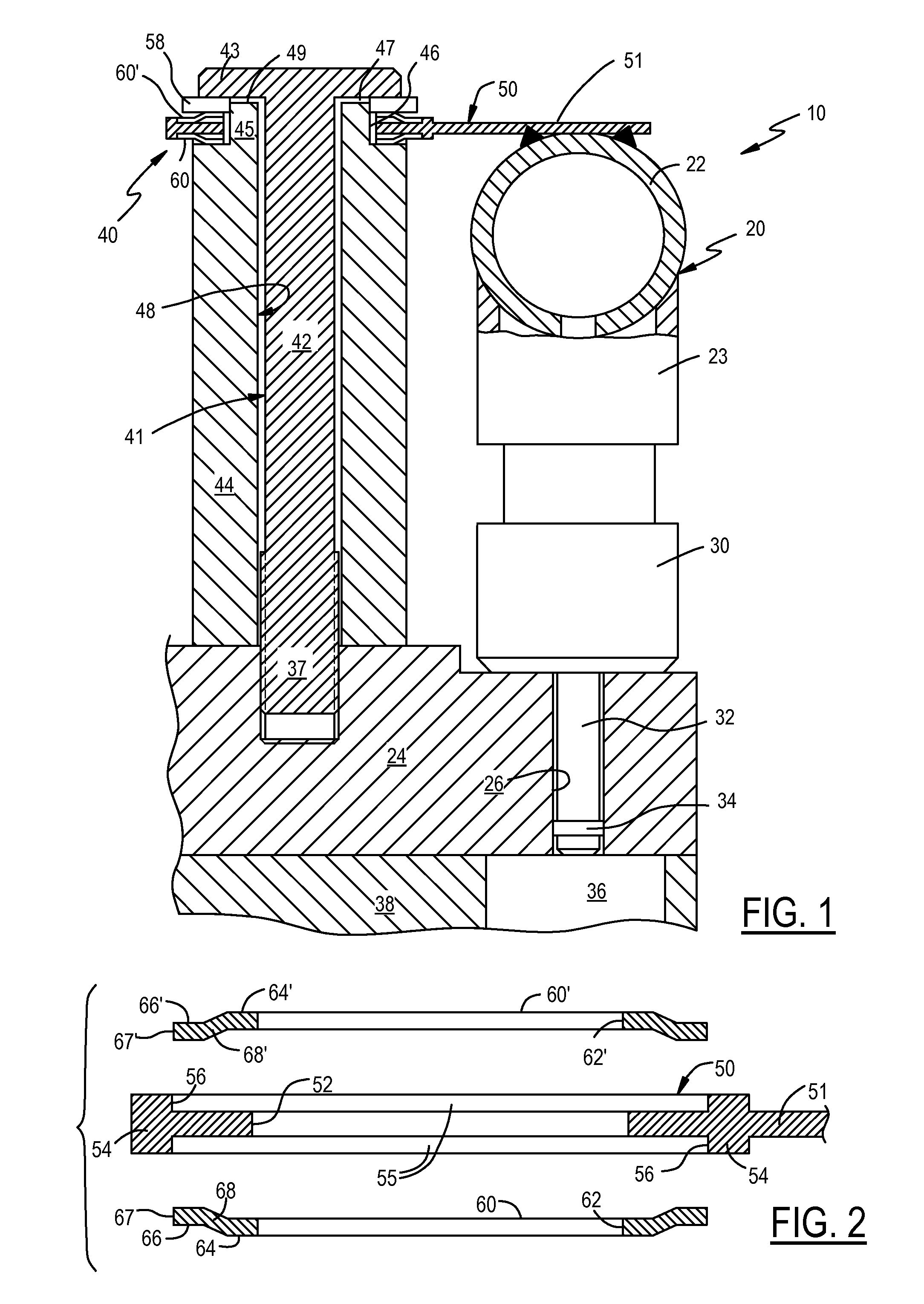

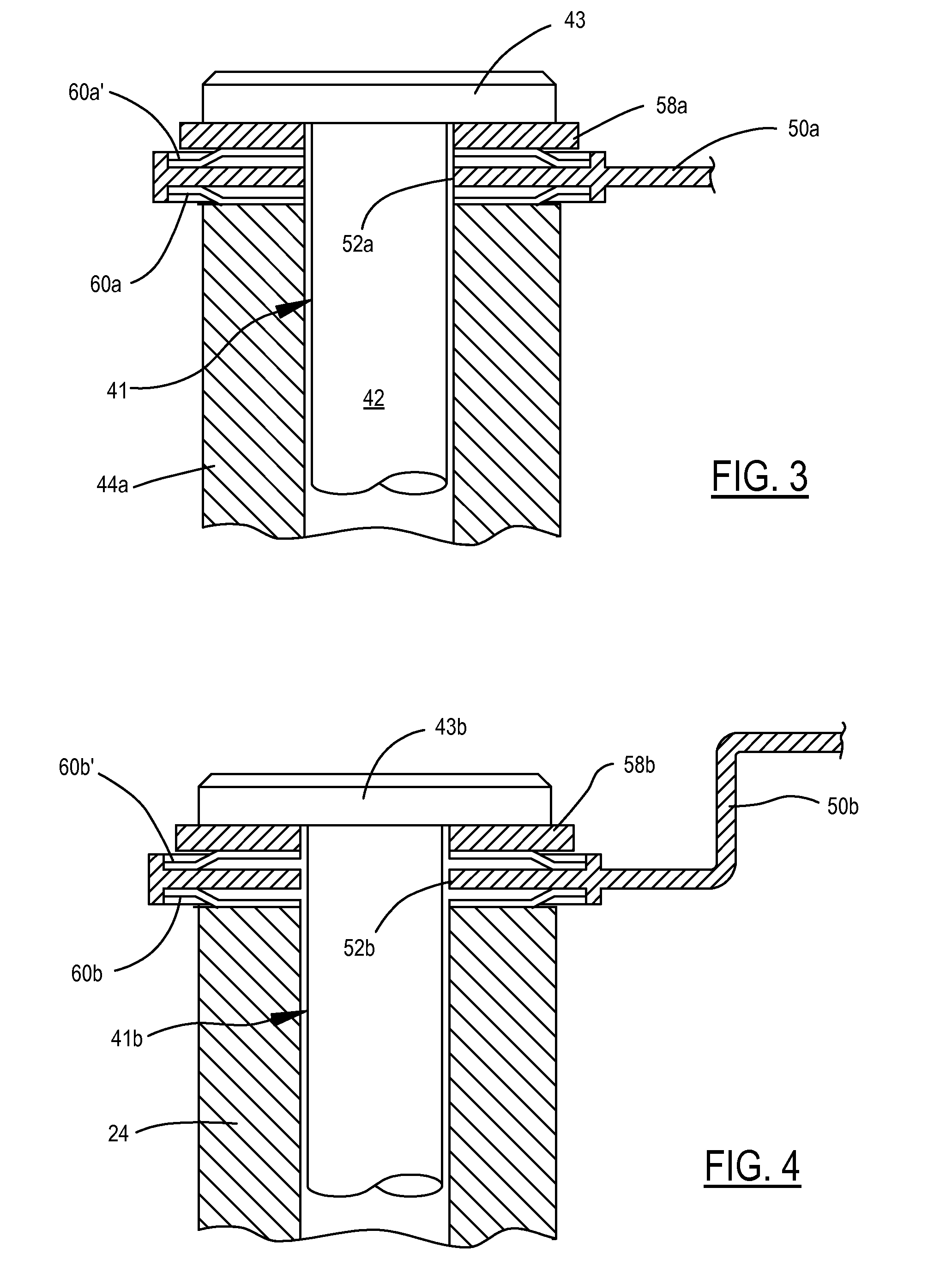

Method and apparatus for attenuating fuel pump noise in a direct injection internal combustion chamber

ActiveUS7406946B1Dampen fuel pressure pulsationDampen fuel pressure fluctuationNoise reducing fuel injectionLow-pressure fuel injectionCombustion chamberEngineering

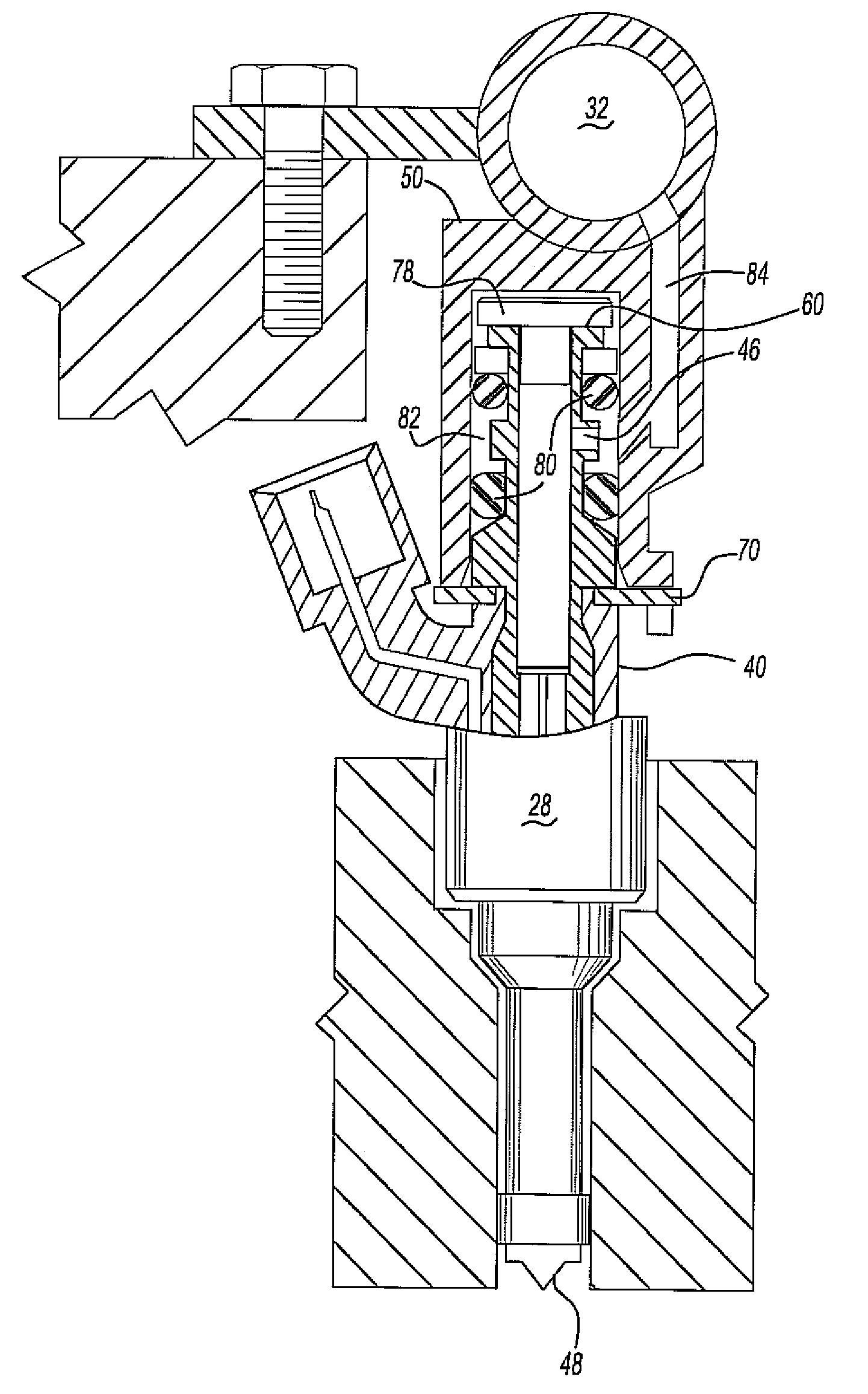

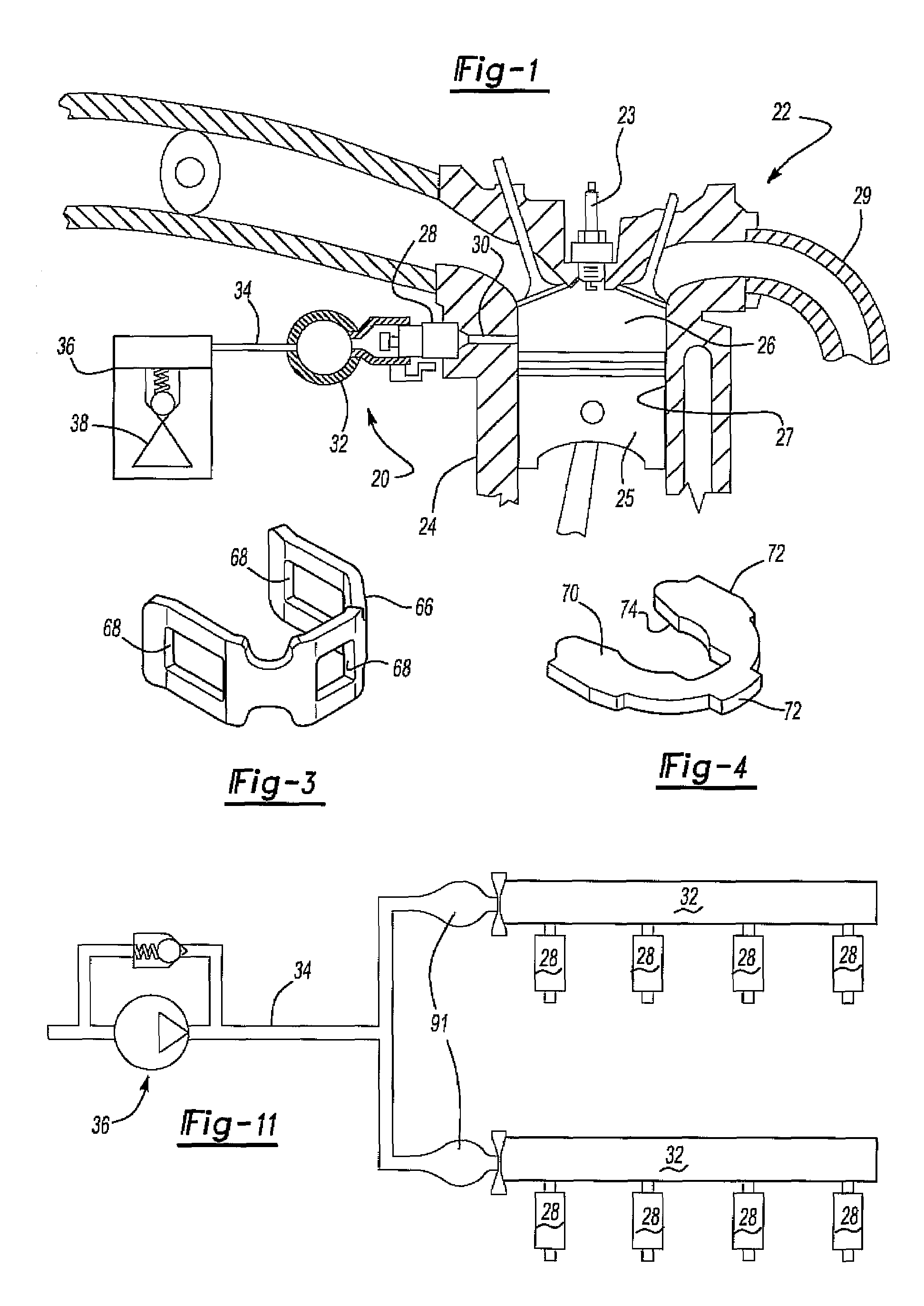

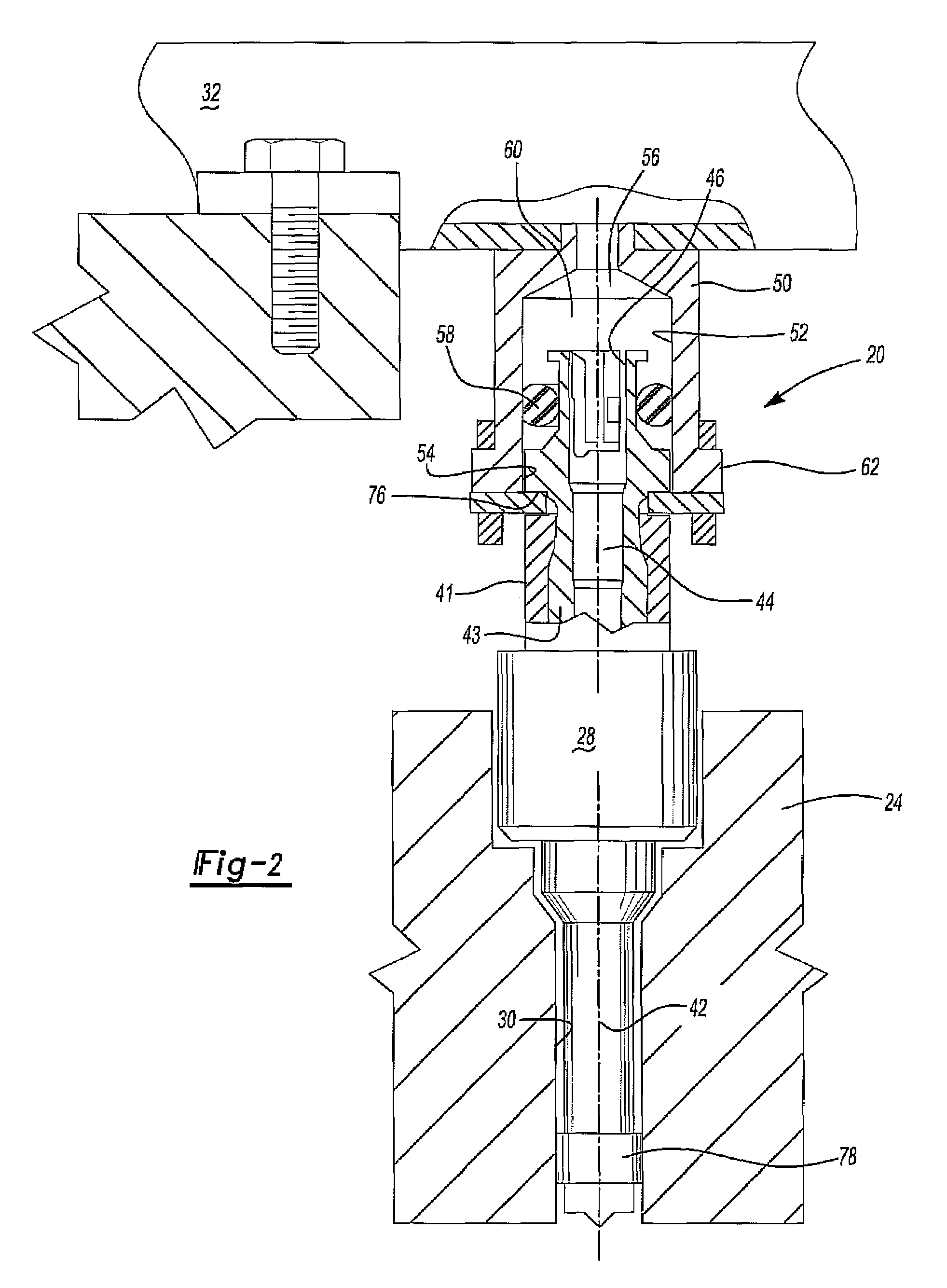

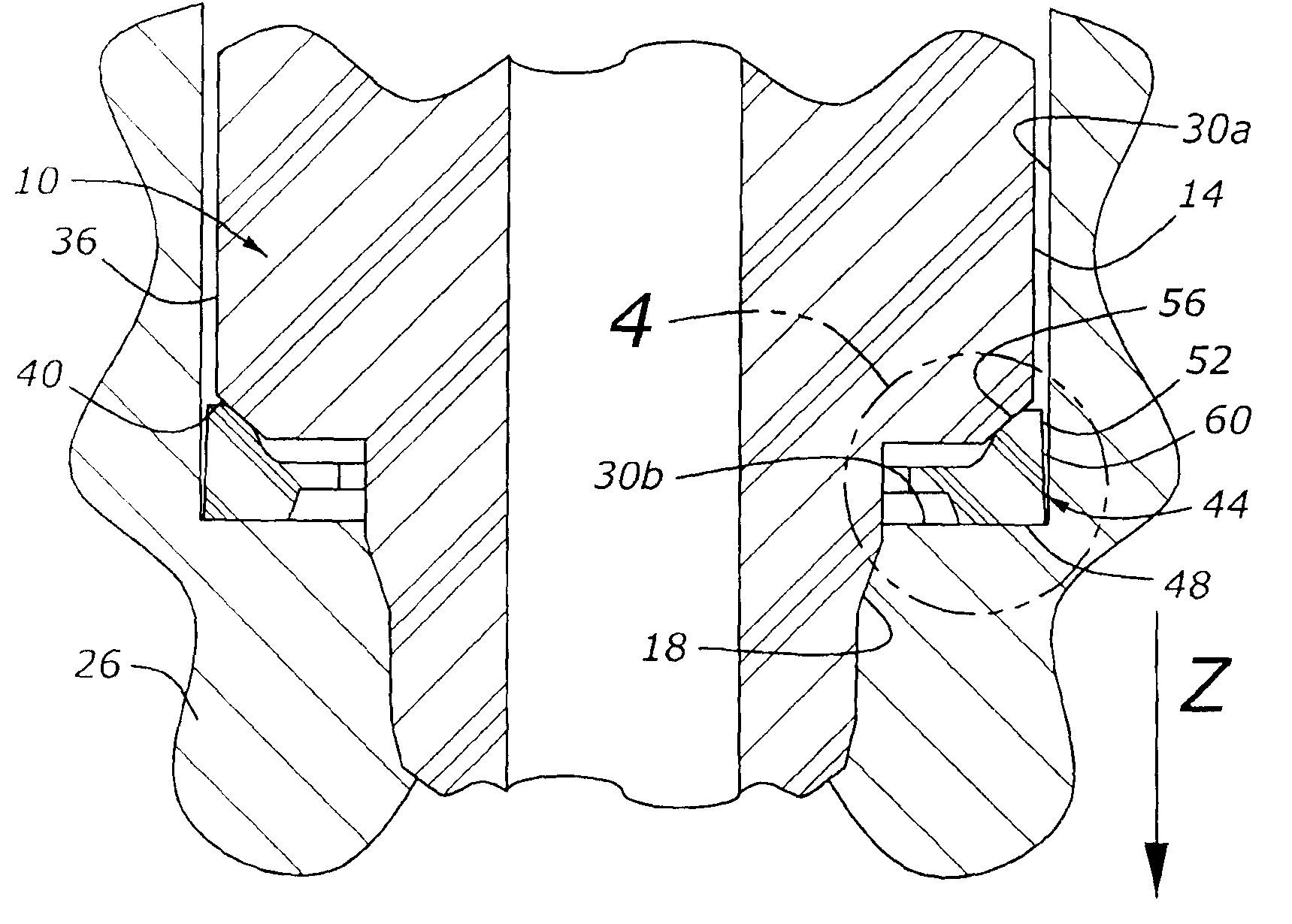

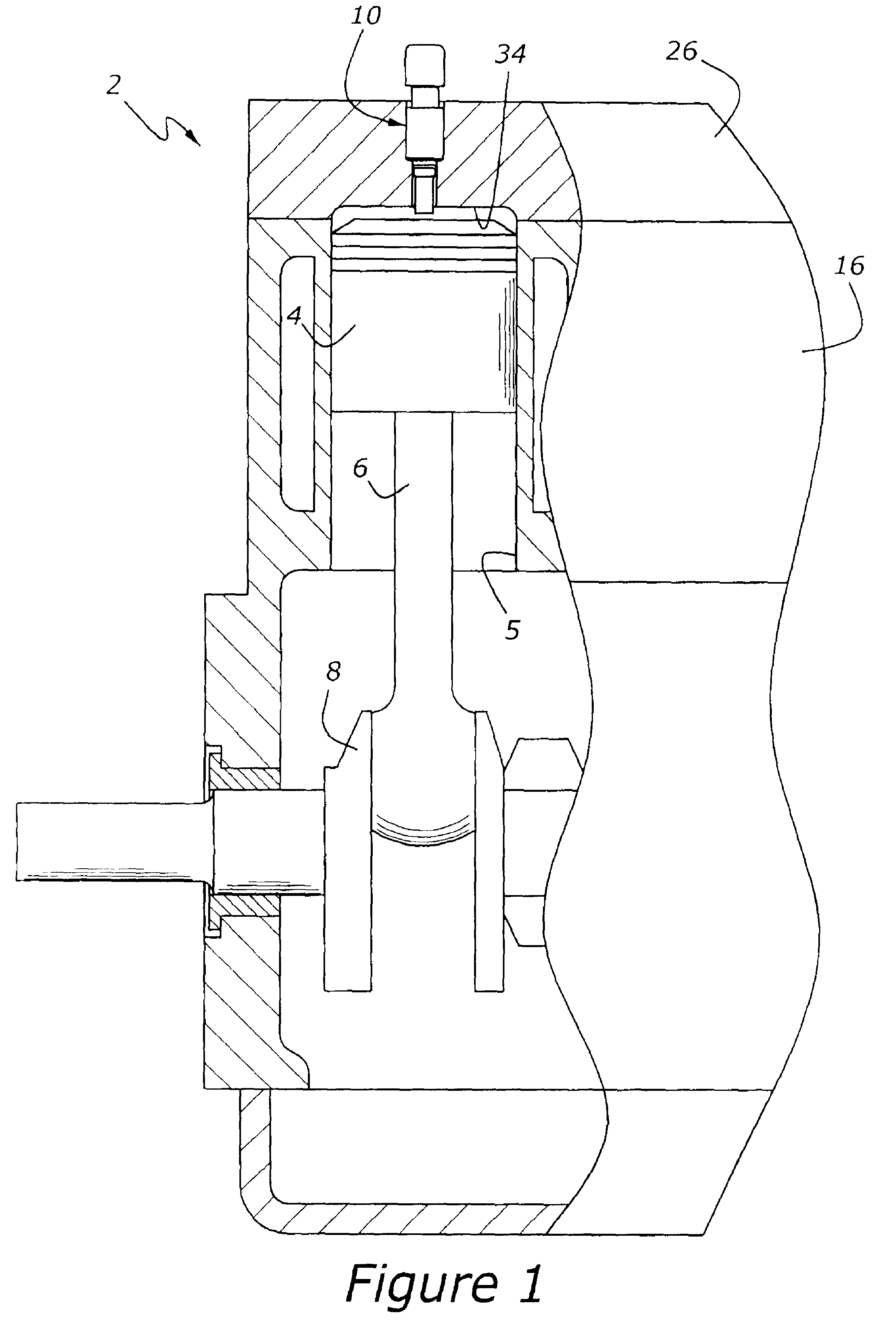

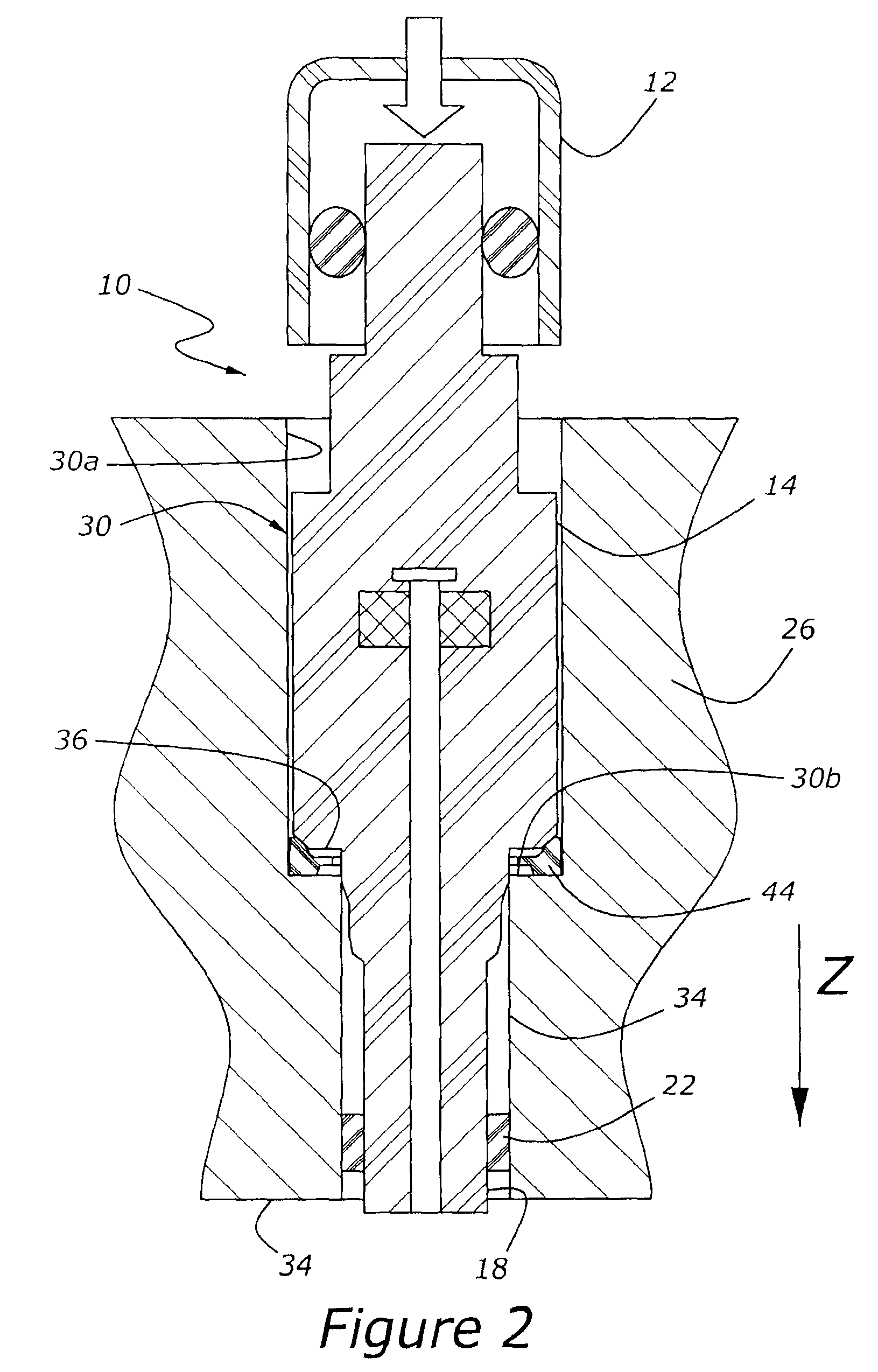

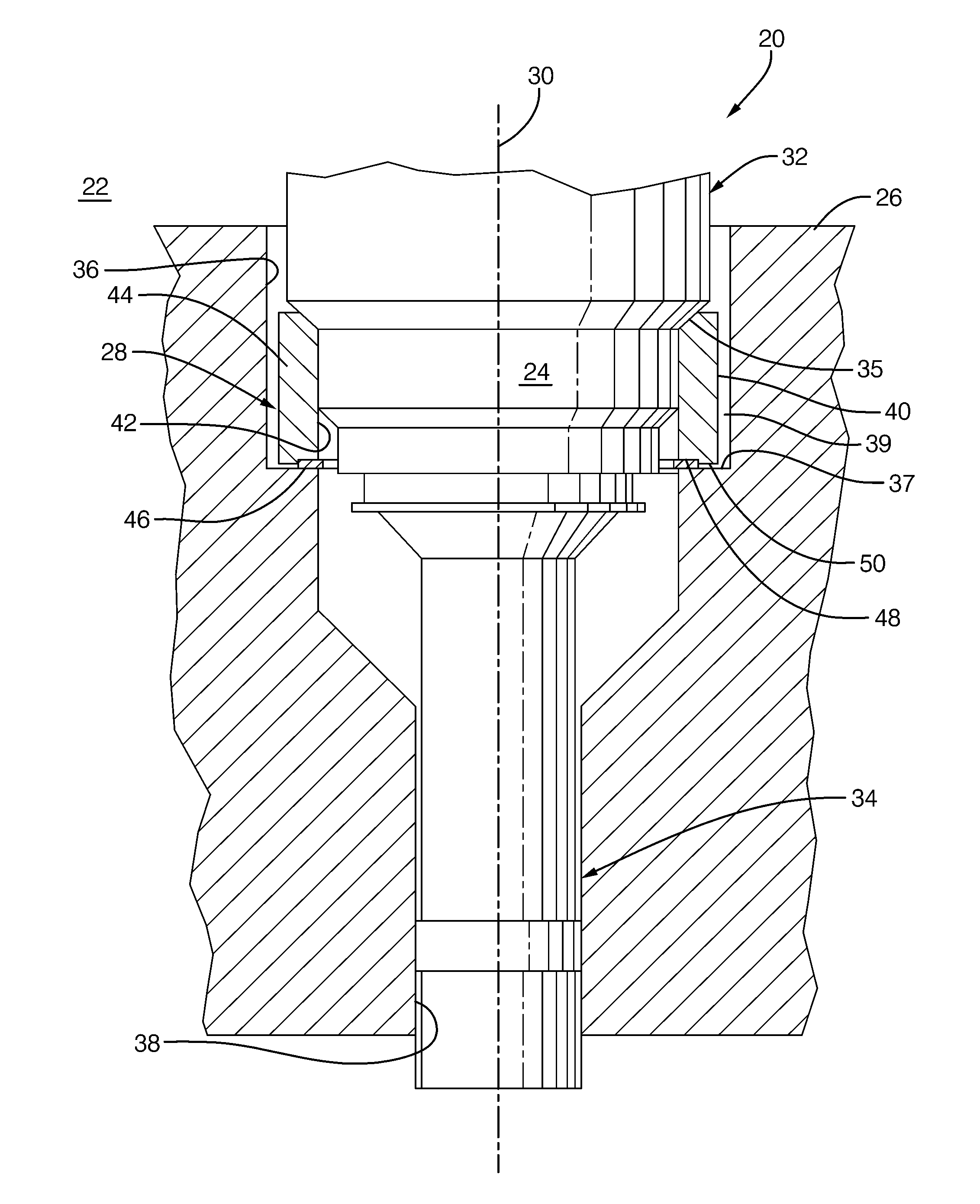

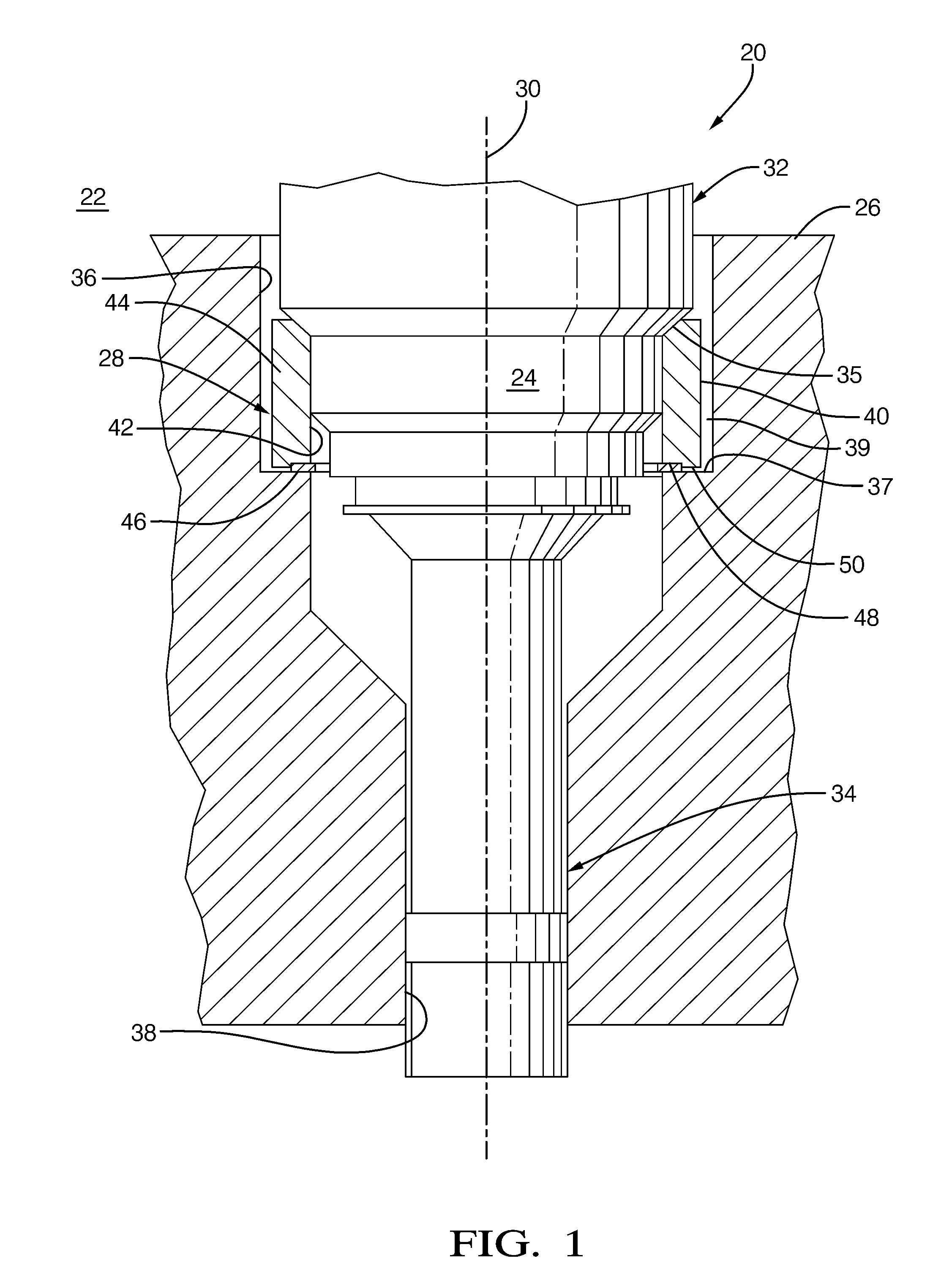

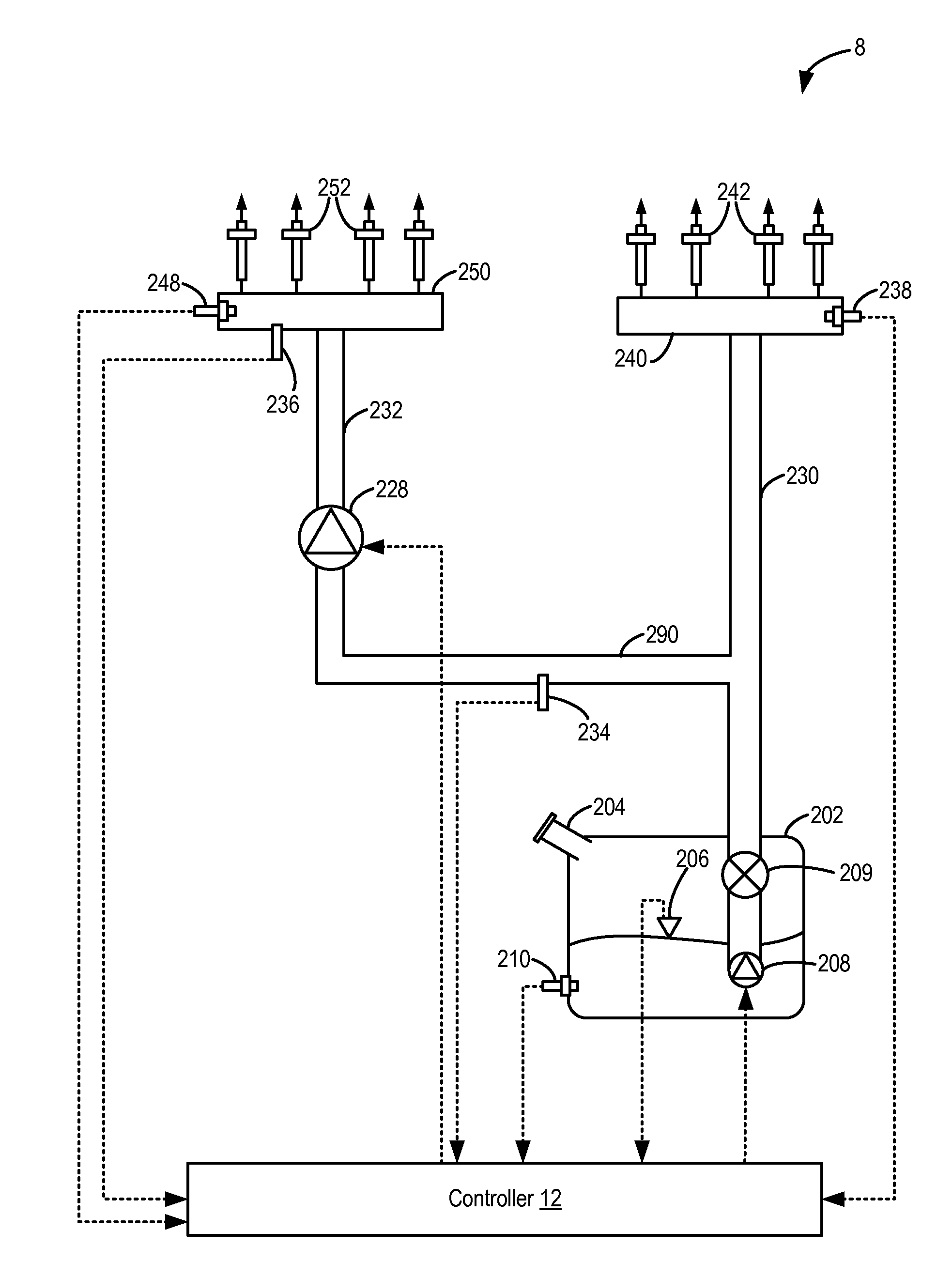

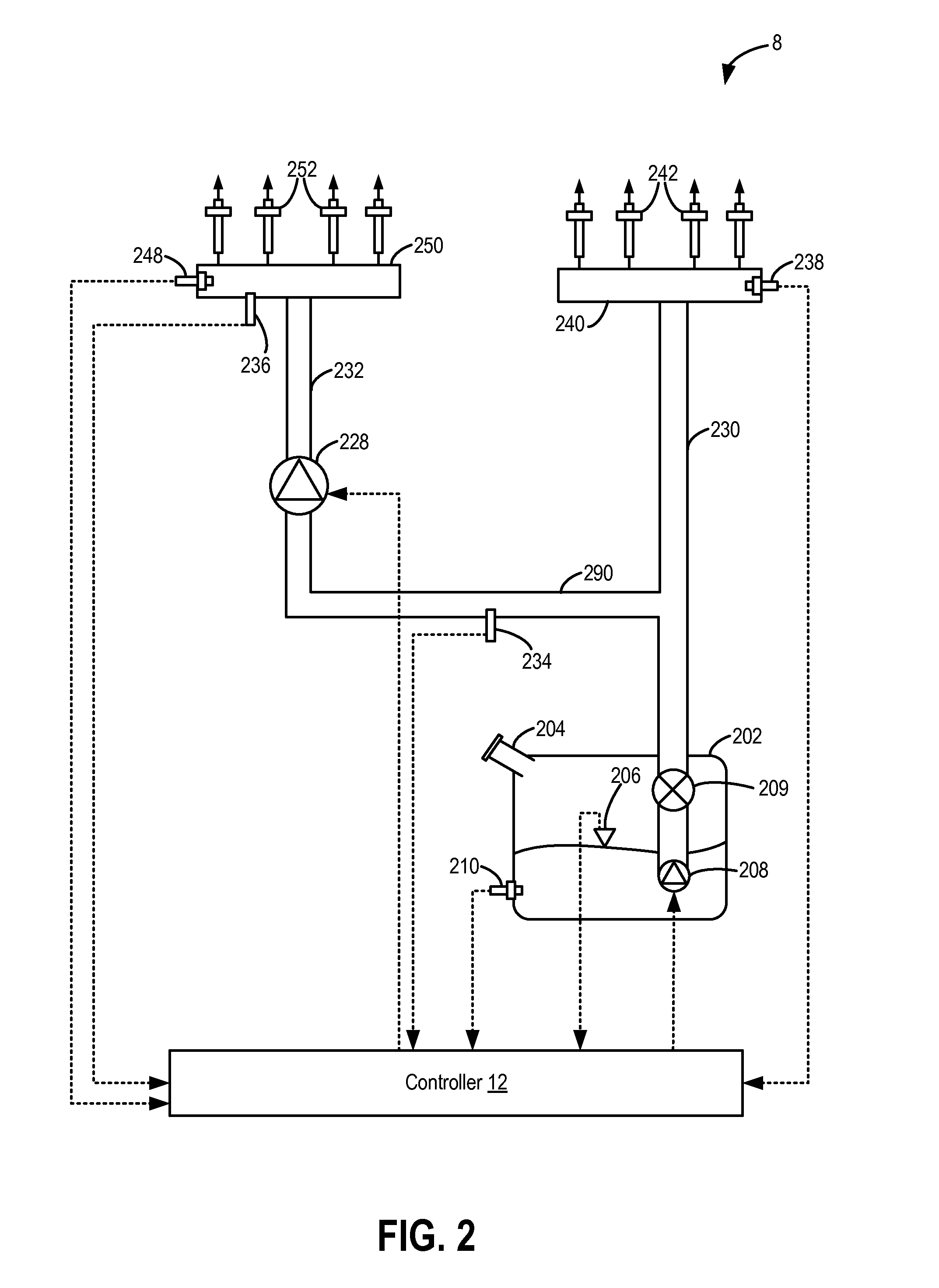

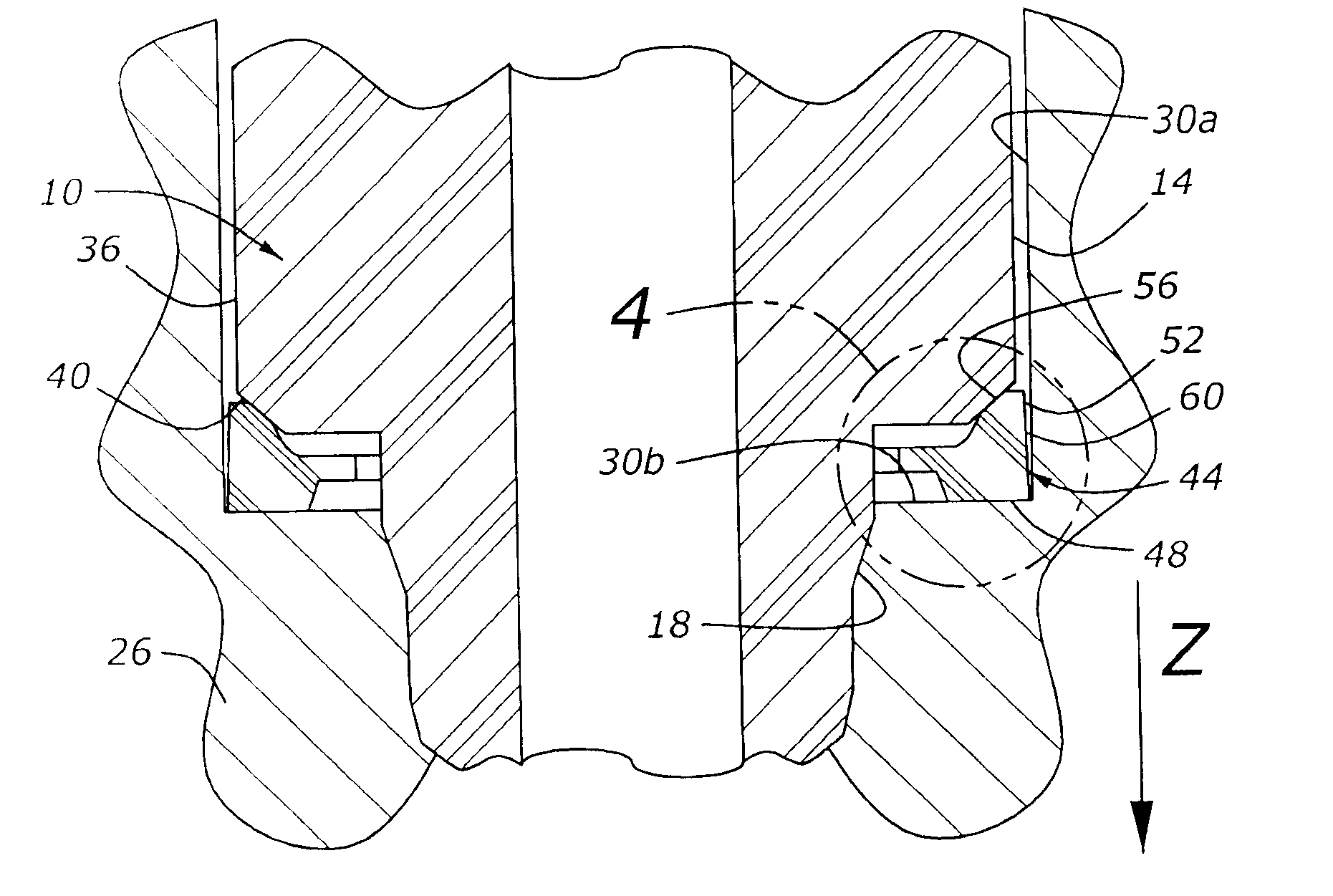

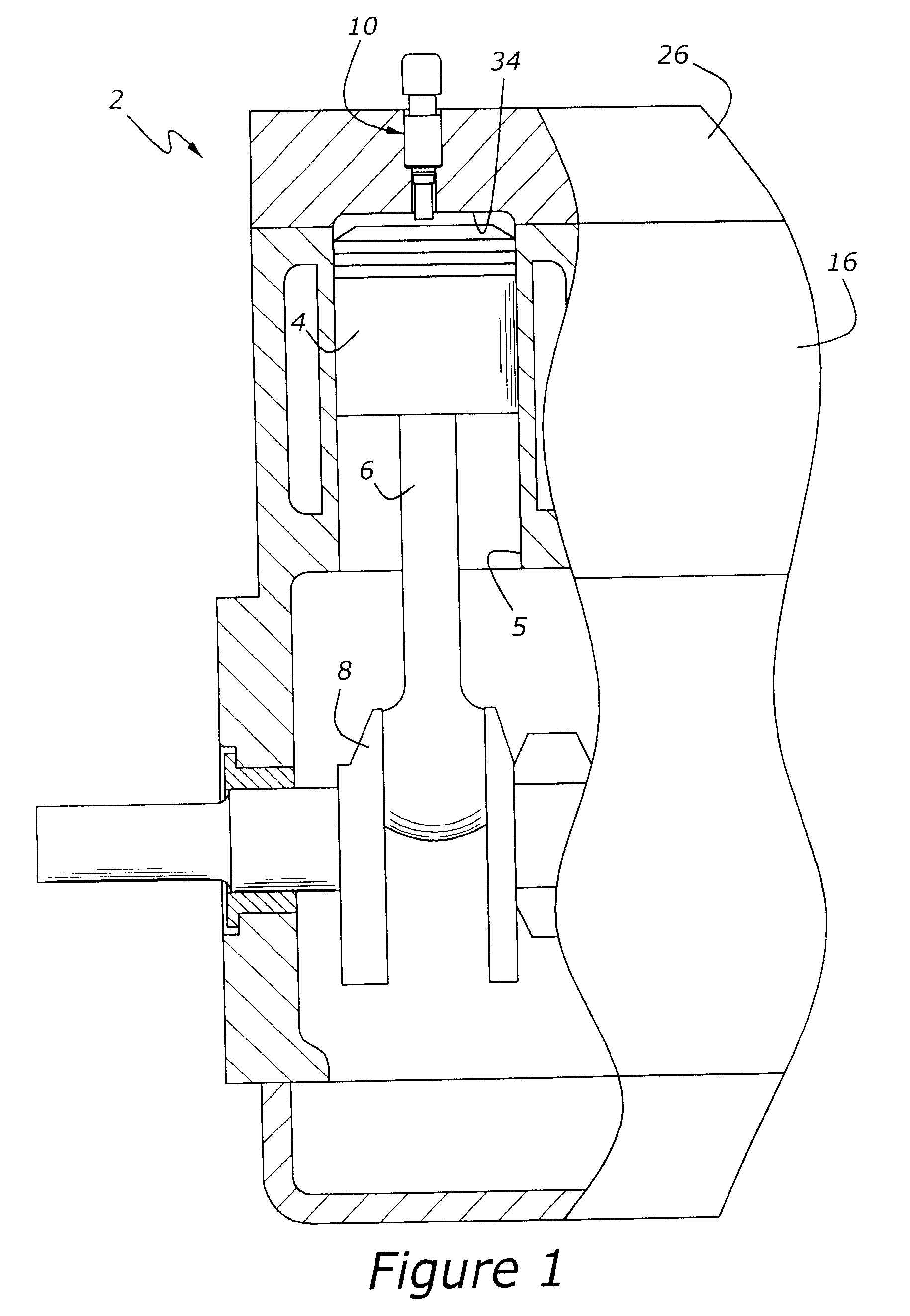

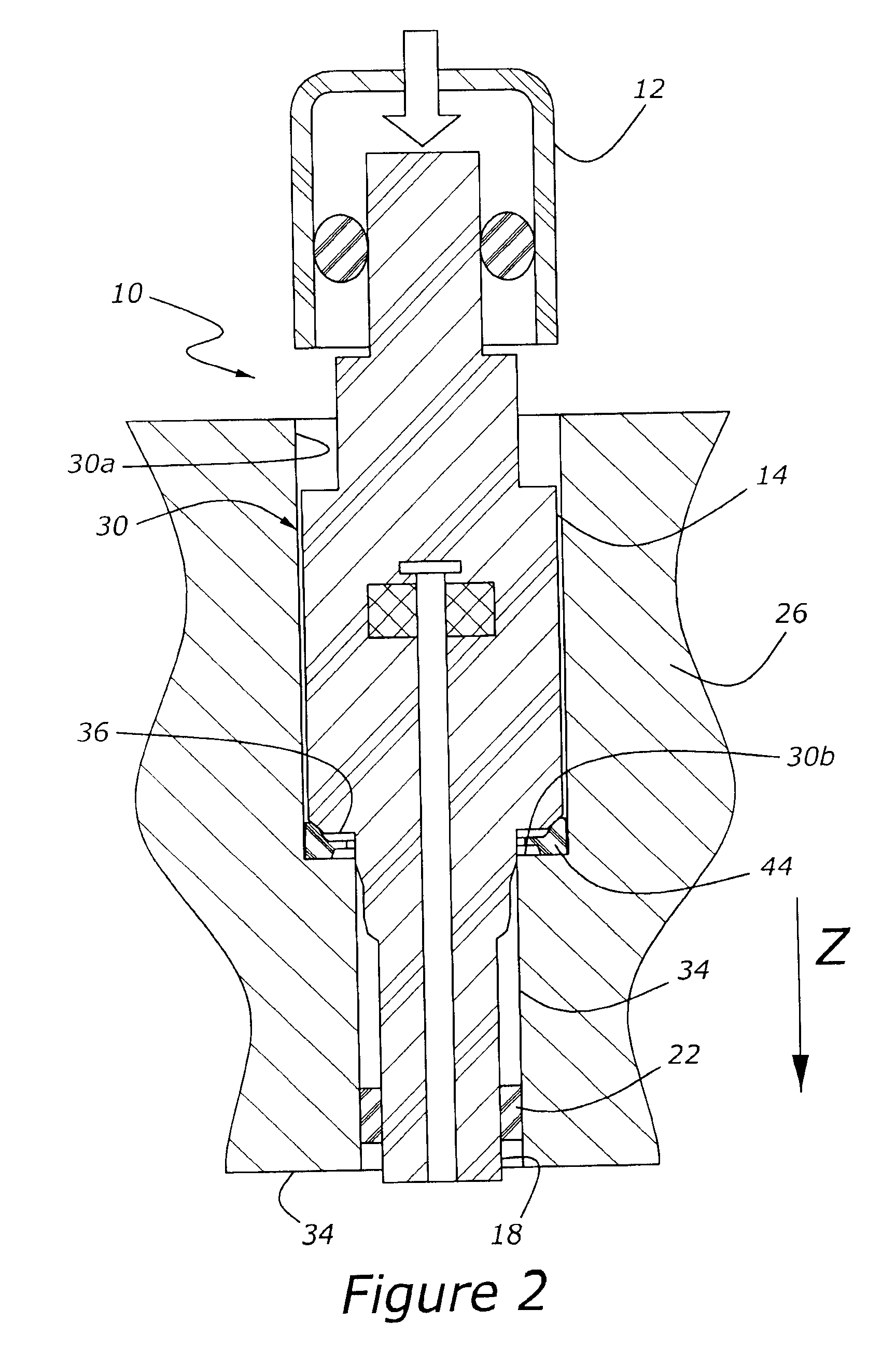

A method and apparatus for attenuating fuel pump noise in a direct injection internal combustion engine. In one proposal, the direct injection fuel nozzle is suspended from a fuel rail in a fashion that avoids direct metal-to-metal contact between the injector and the engine block. The direct injection nozzle may also be connected to the fuel rail by a pair of spaced-apart seals which equalize the longitudinal pressure on the nozzle during operation. Enlarged diameter fuel reservoirs and / or a restricted orifice may be provided fluidly in series between the fuel pump and the direct injection nozzle in order to attenuate noise resulting from fuel pump pulsation.

Owner:HITACHI LTD

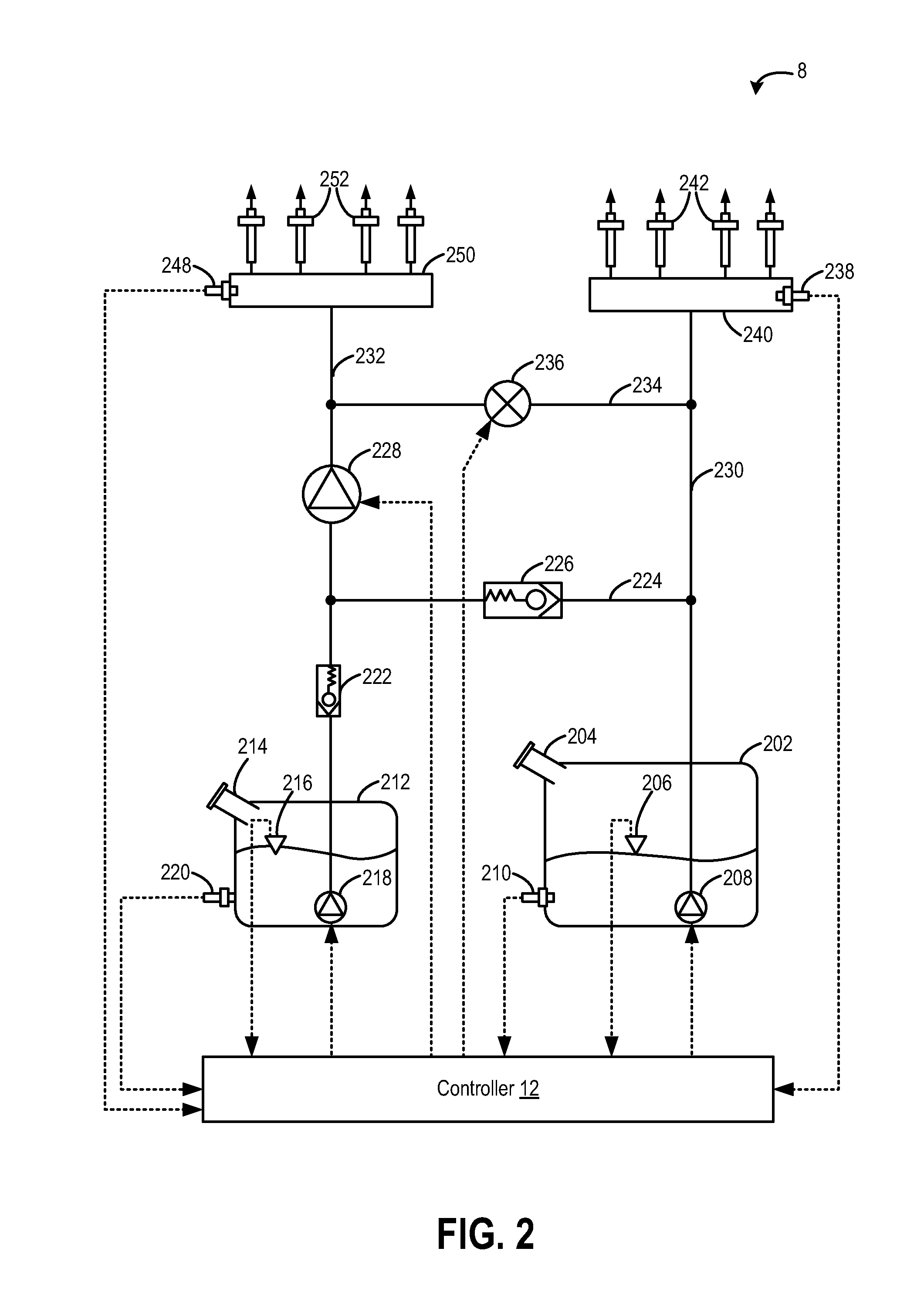

Direct injection fuel pump

ActiveUS20140224209A1Reduce degradation rateImprove fuel pump lubricationElectrical controlWear reducing fuel injectionLubricationFuel pump

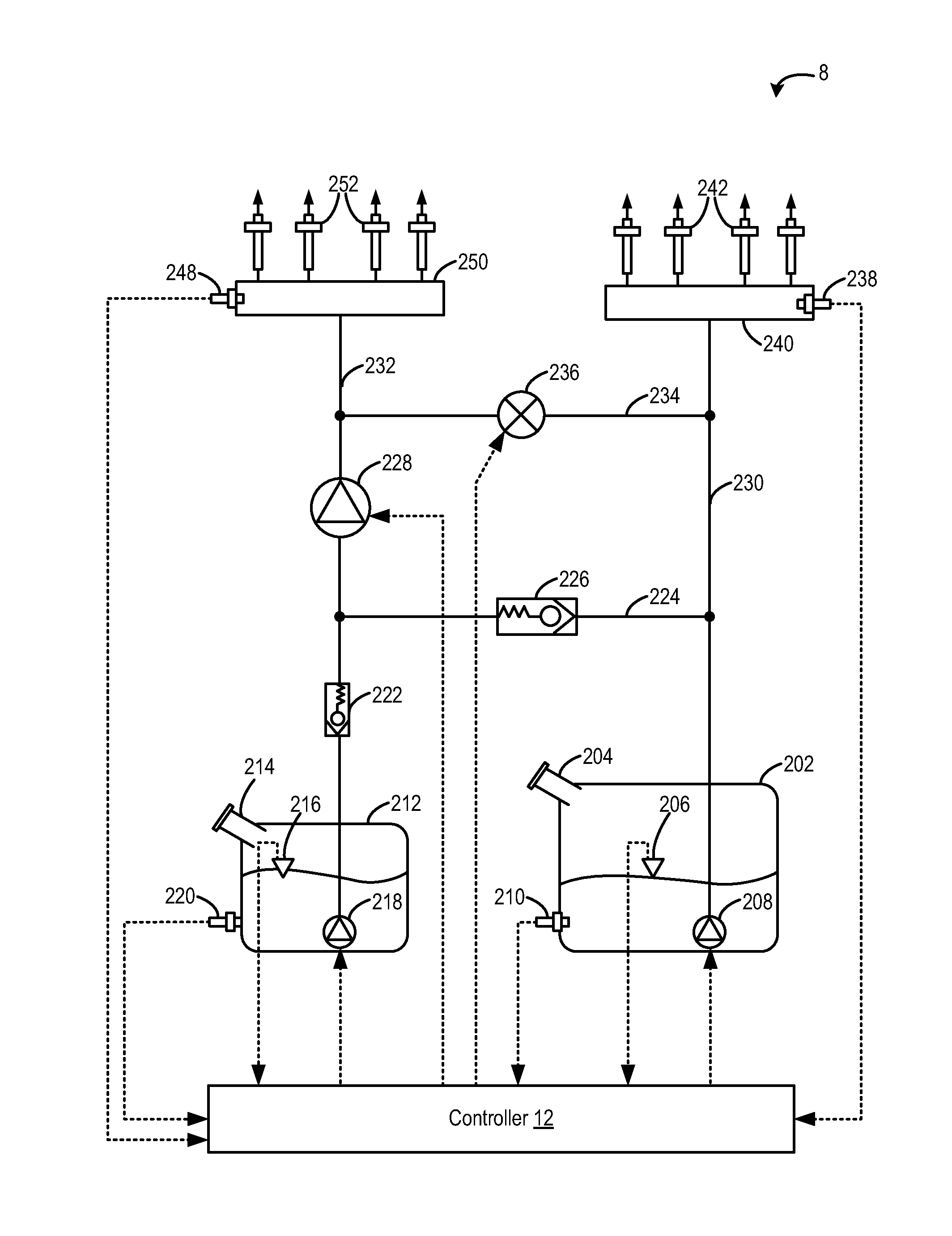

Methods and systems are provided for a direct injection fuel pump. The methods and system control pressure within a compression chamber so as to improve fuel pump lubrication.

Owner:FORD GLOBAL TECH LLC

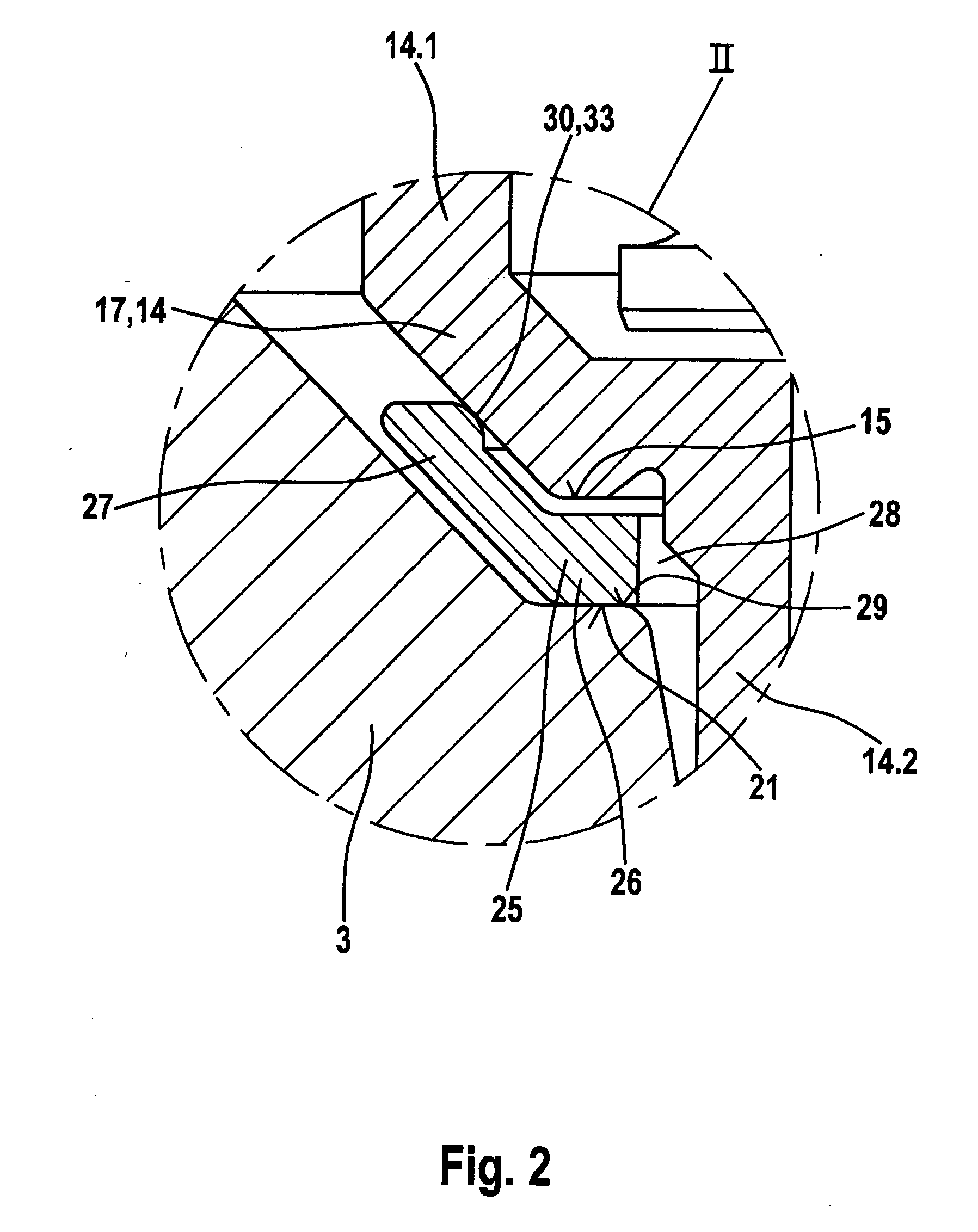

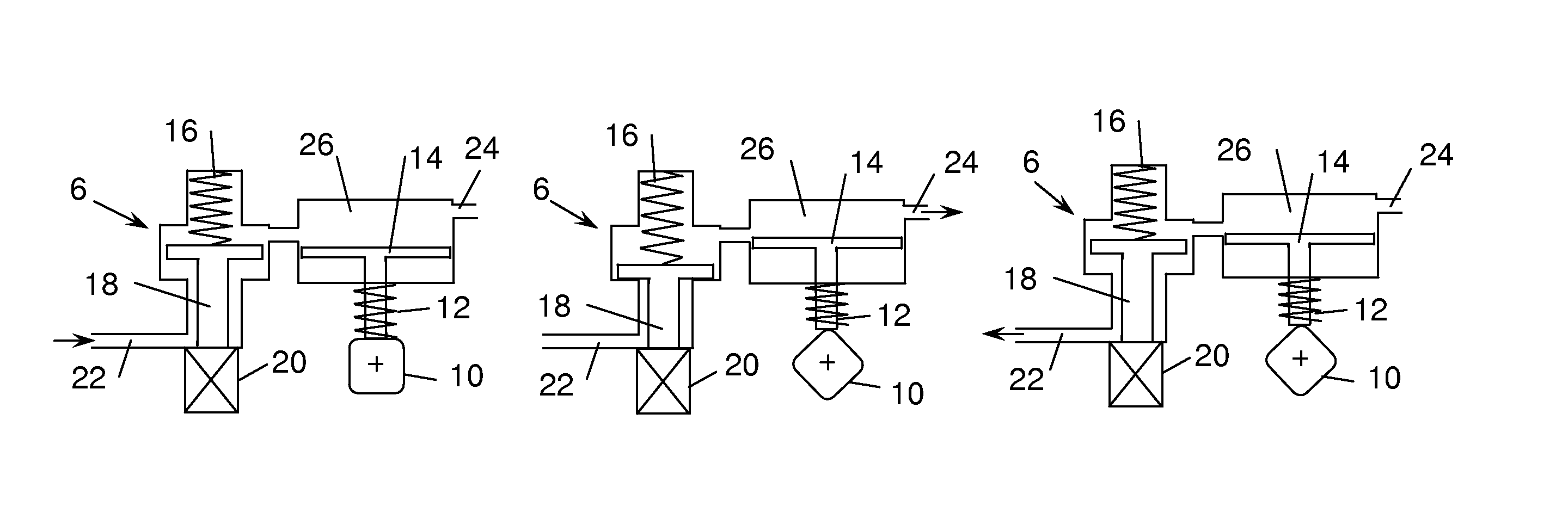

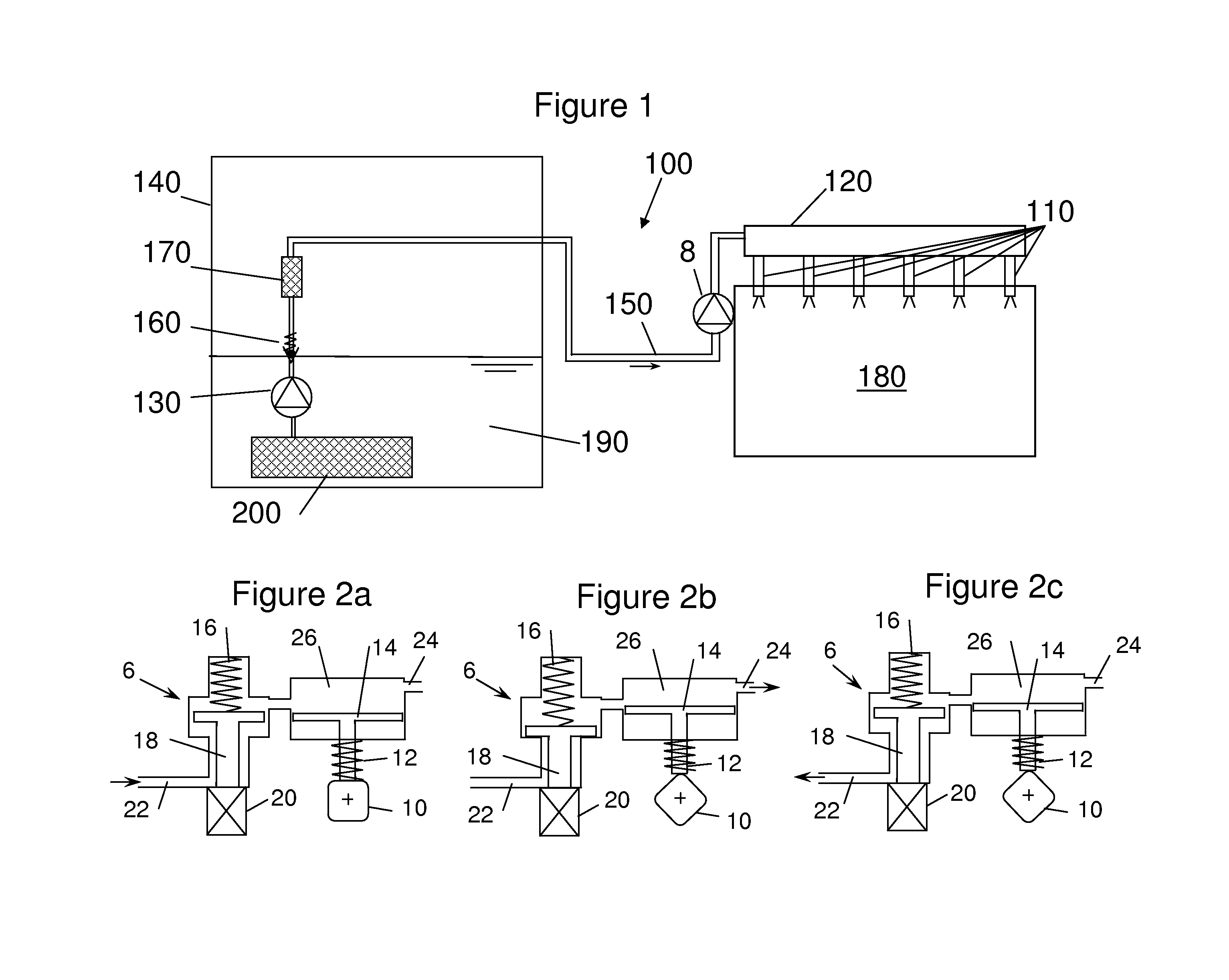

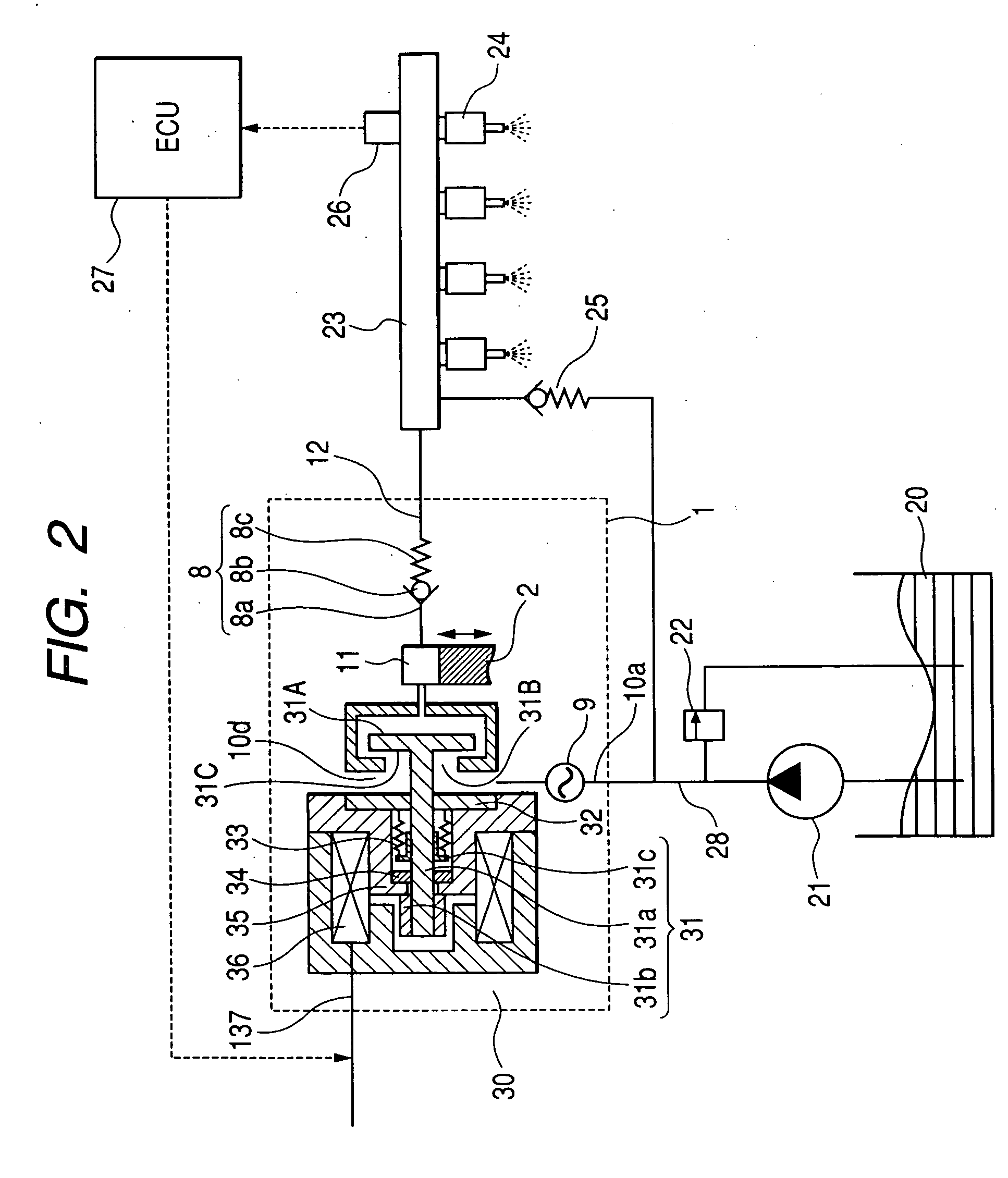

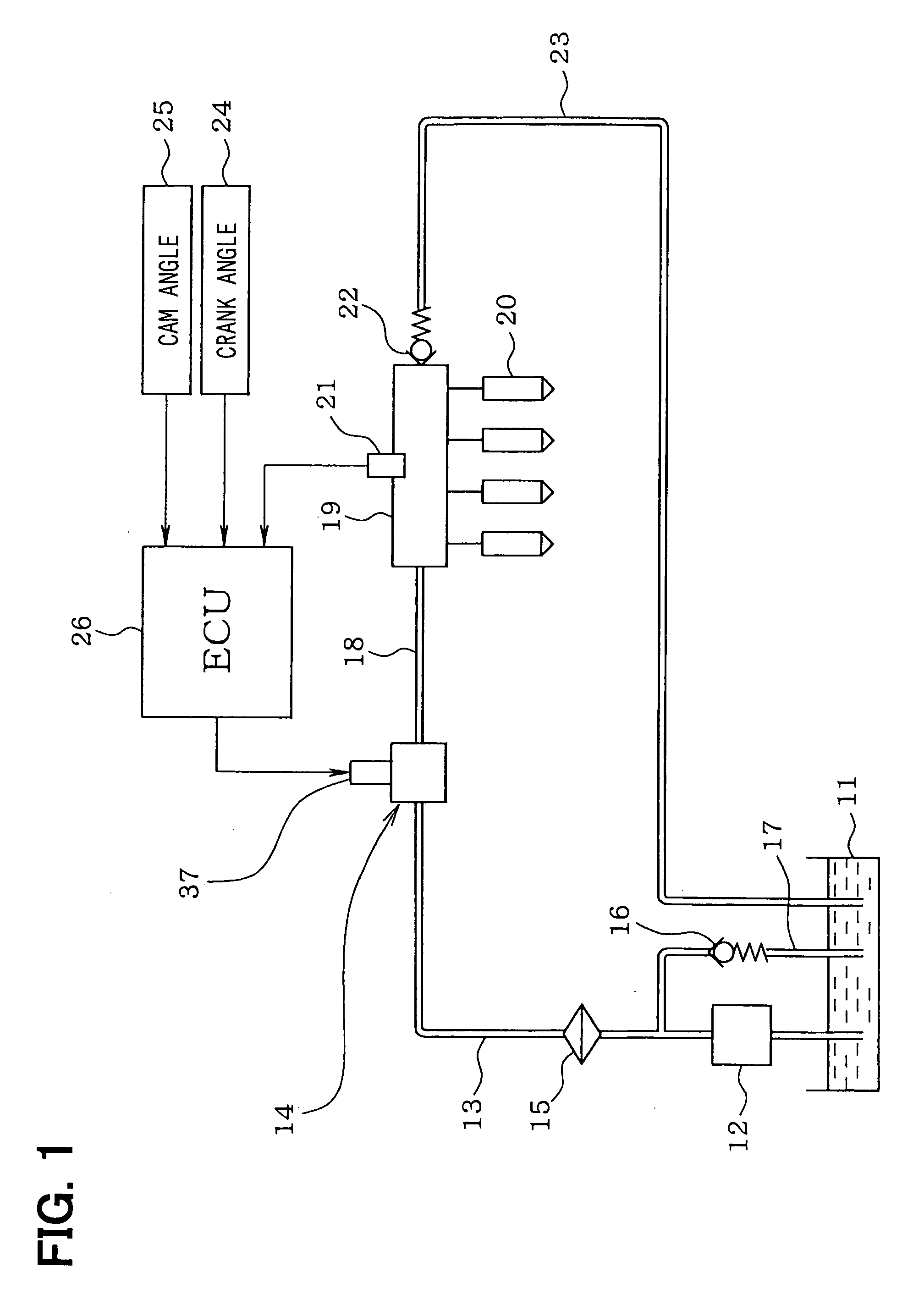

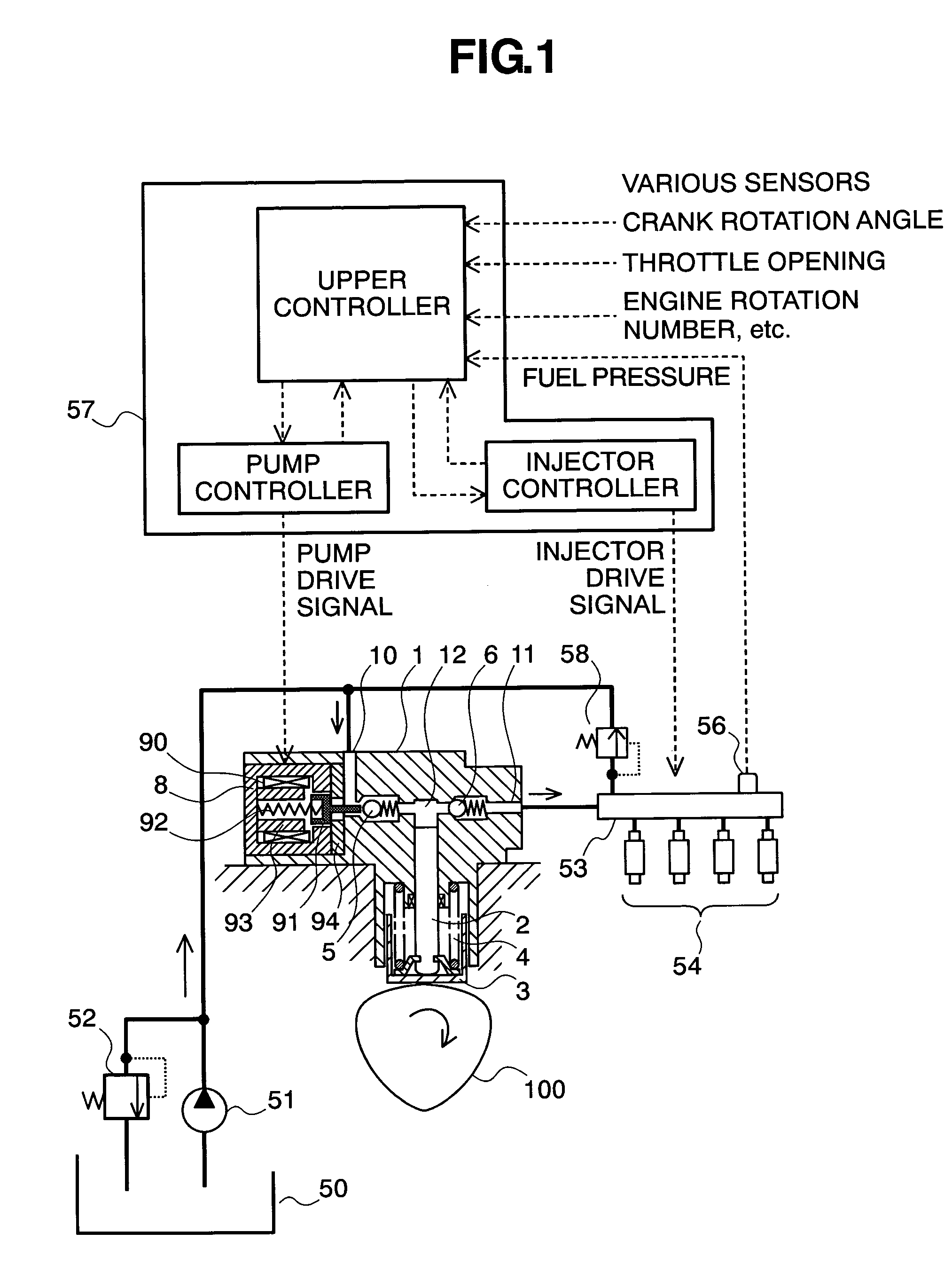

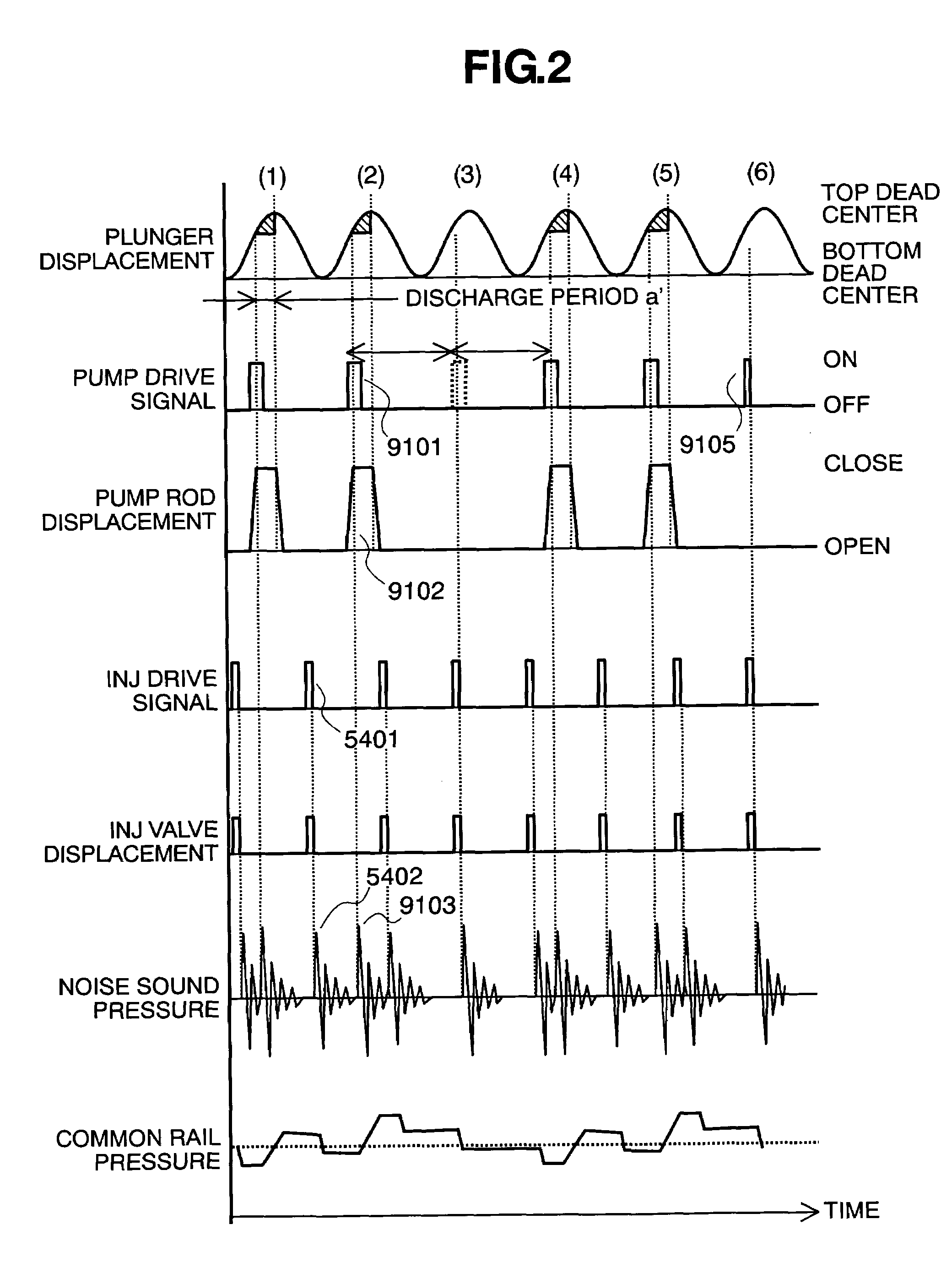

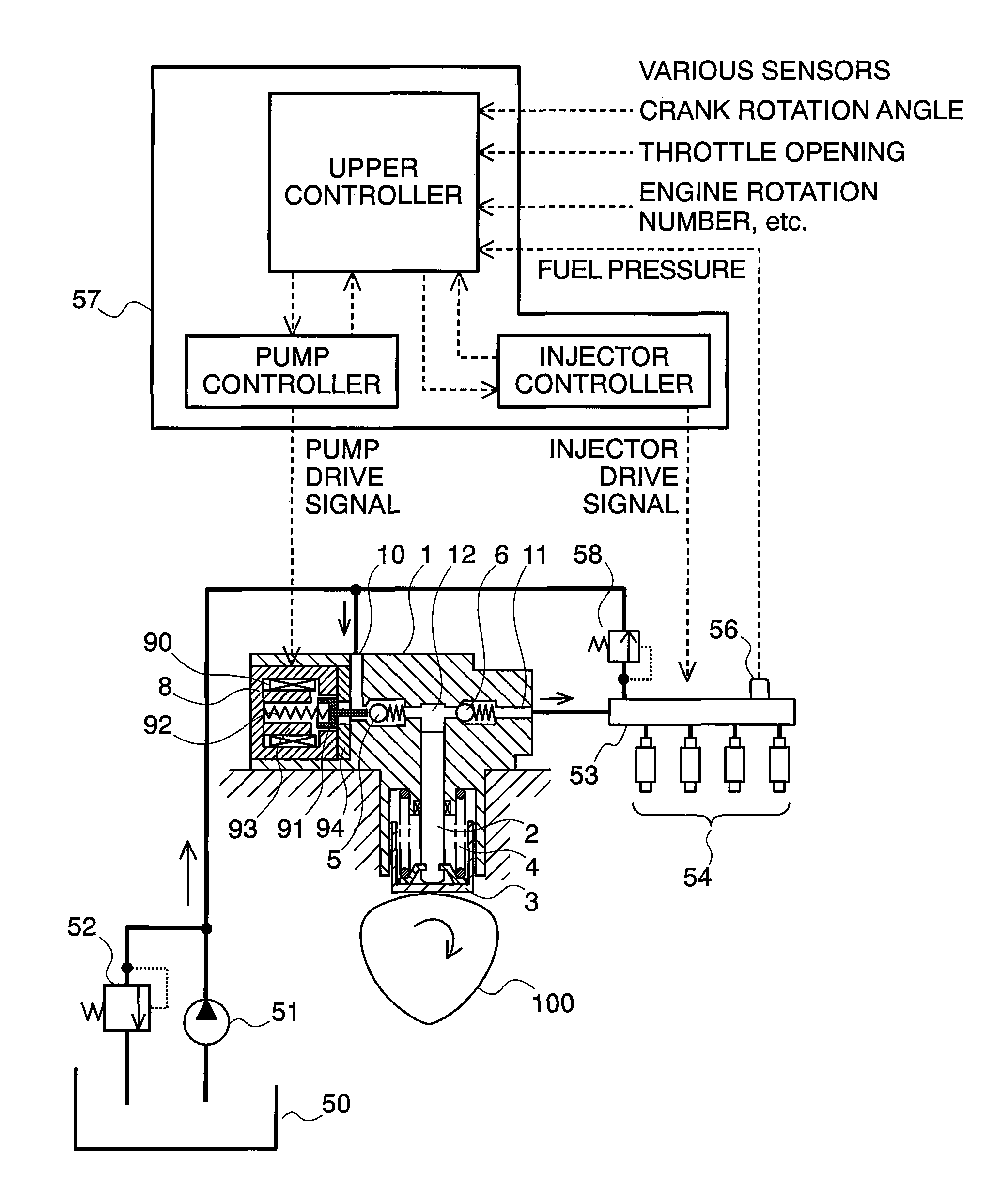

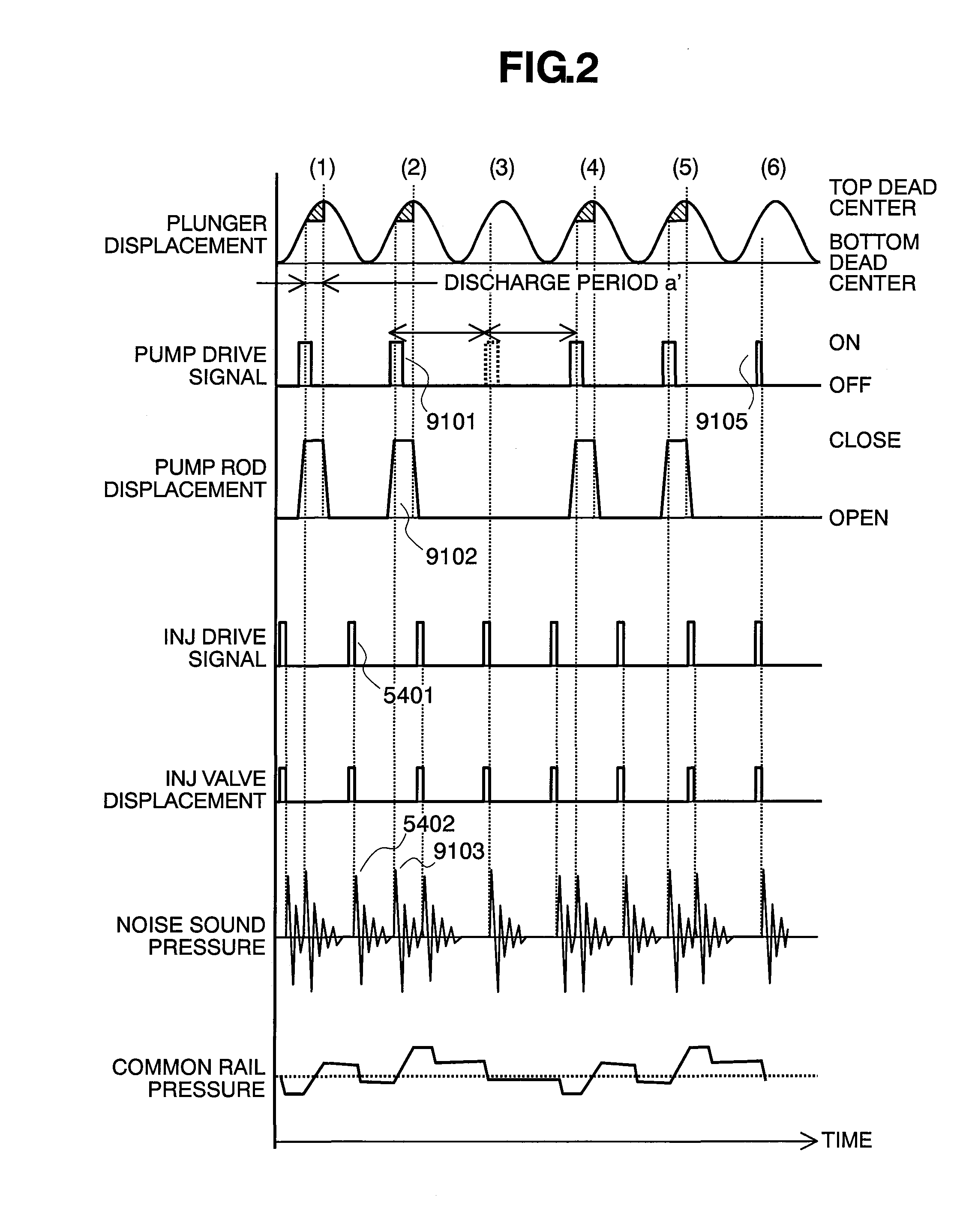

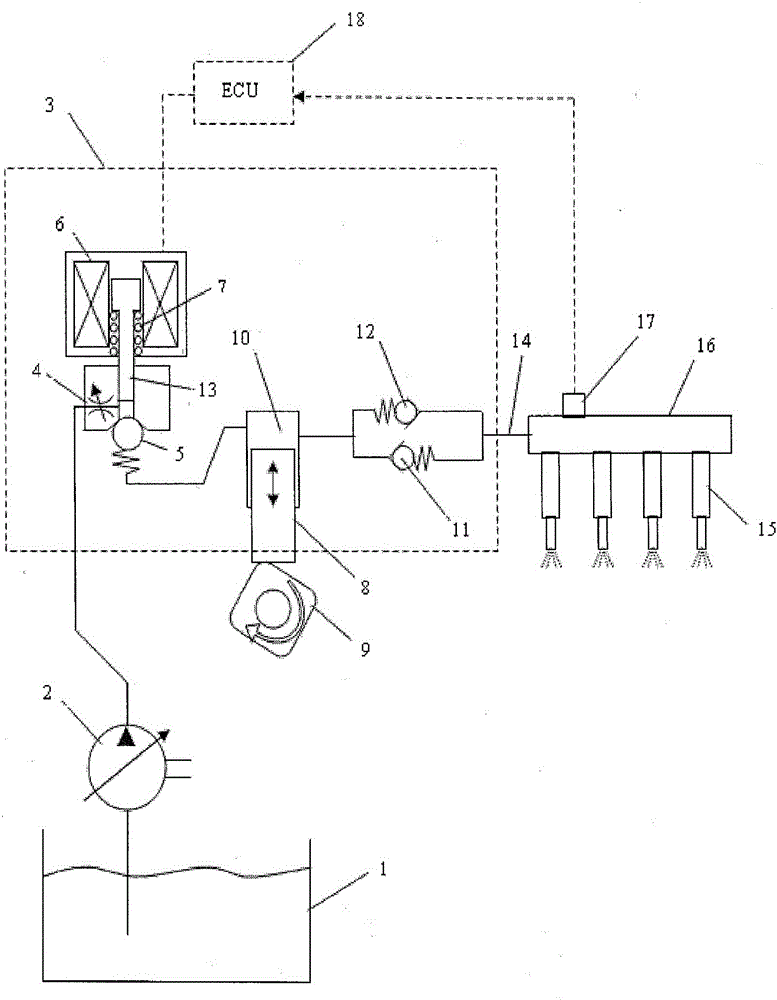

Controlling apparatus of variable capacity type fuel pump and fuel supply system

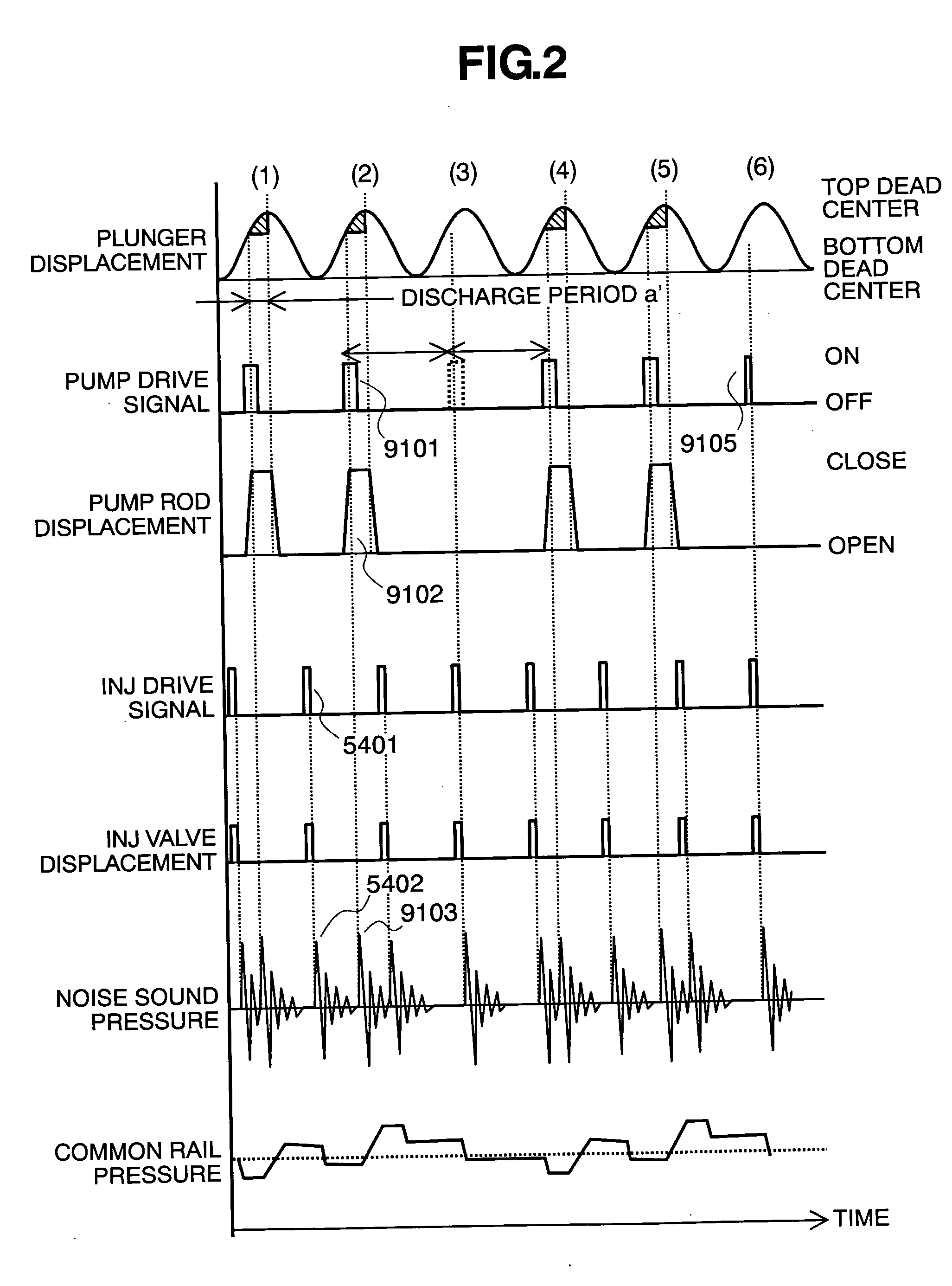

InactiveUS20060118089A1Avoid synchronizationEliminate duplicationElectrical controlNoise reducing fuel injectionEngineeringFuel supply

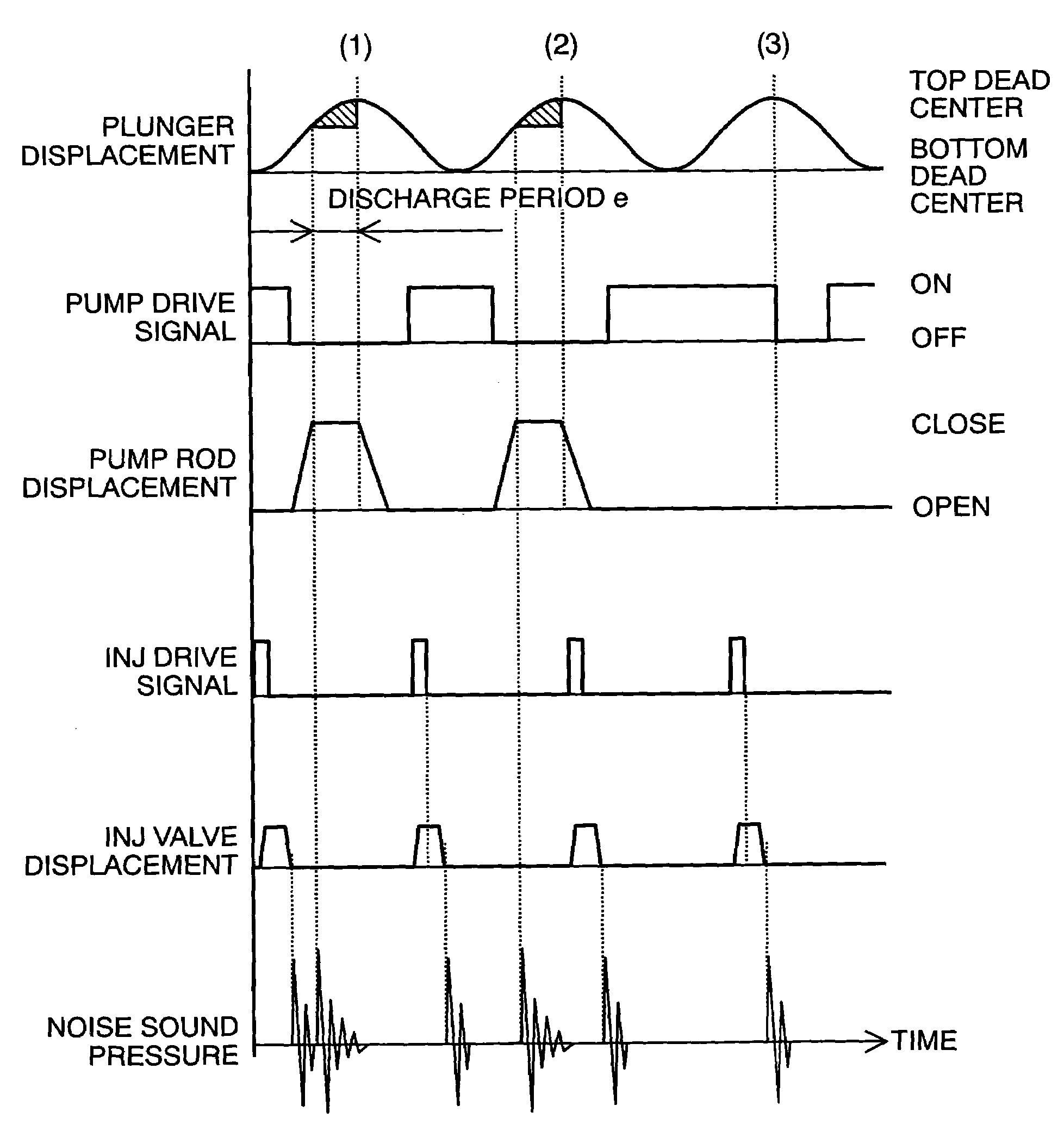

A controlling apparatus of a variable capacity type fuel pump, for avoiding noises caused due to drive of the fuel pump and noises caused due to drive of injectors from overlapping or duplicating with each other in the timing thereof, wherein signals for driving the pump reduced, or the timing thereof is shifted forward / backward, within a specific timing where the o overlapping can be prospected, or a specific timing where they are determined to overlap or duplicate with each other.

Owner:HITACHI LTD

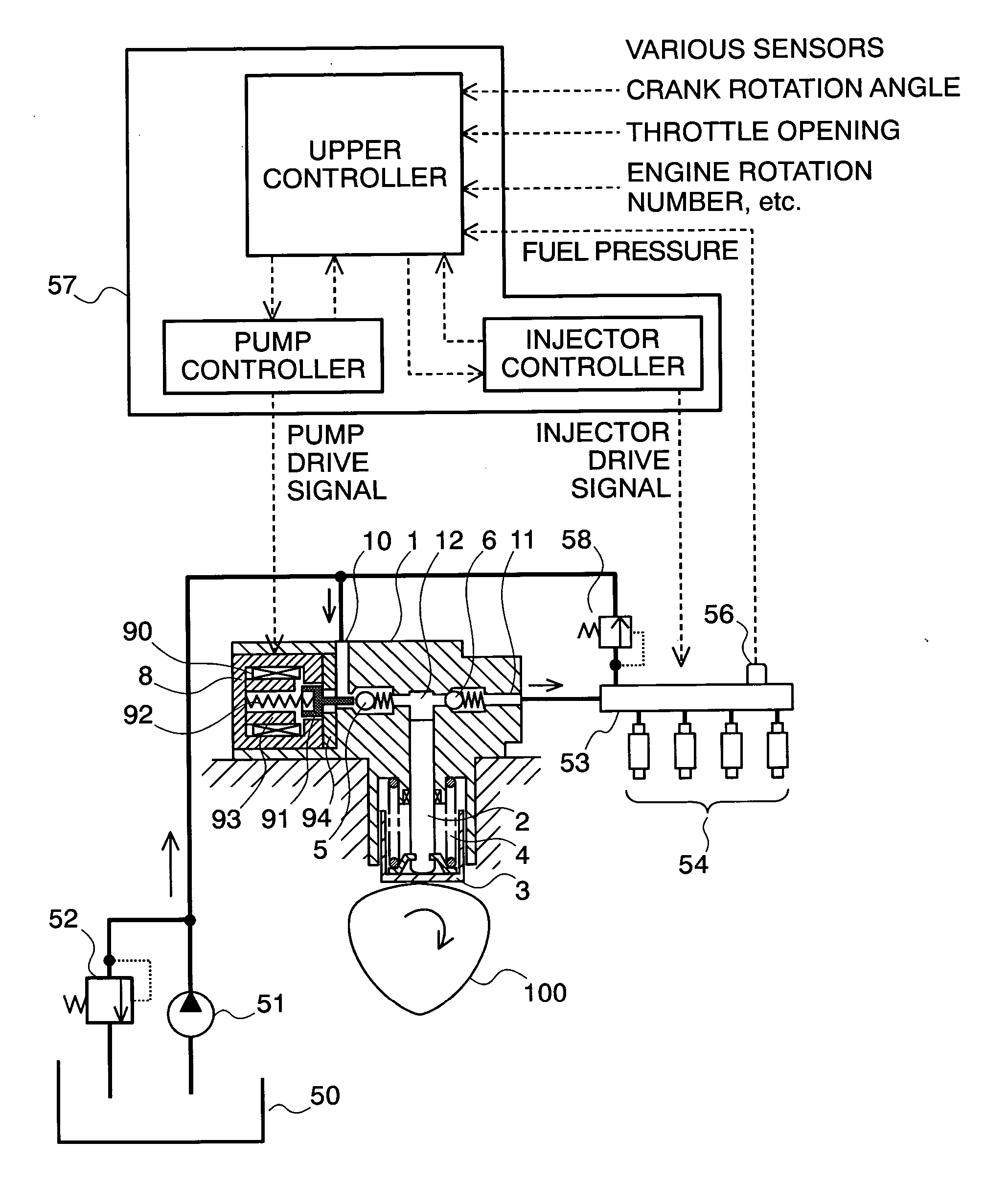

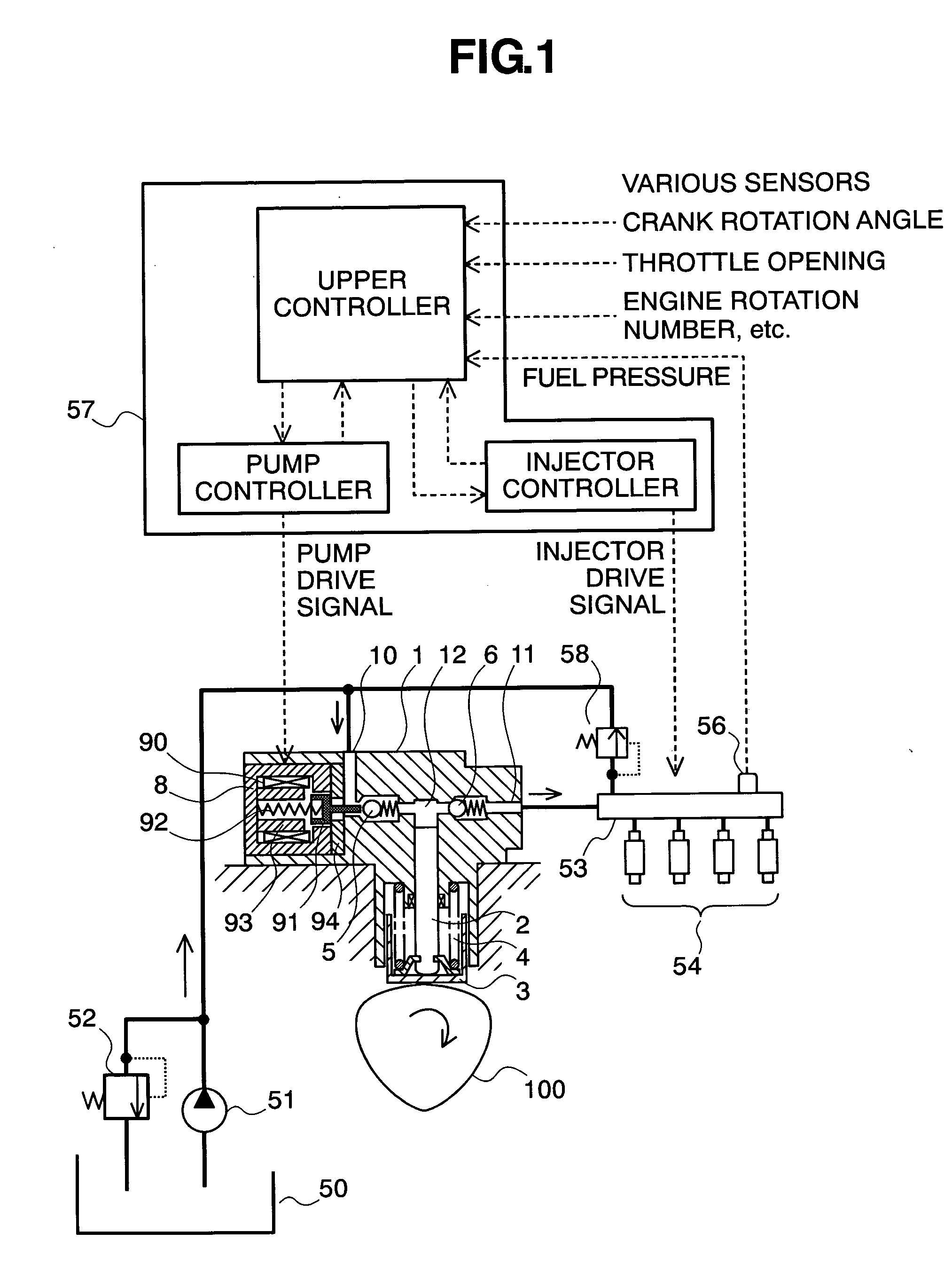

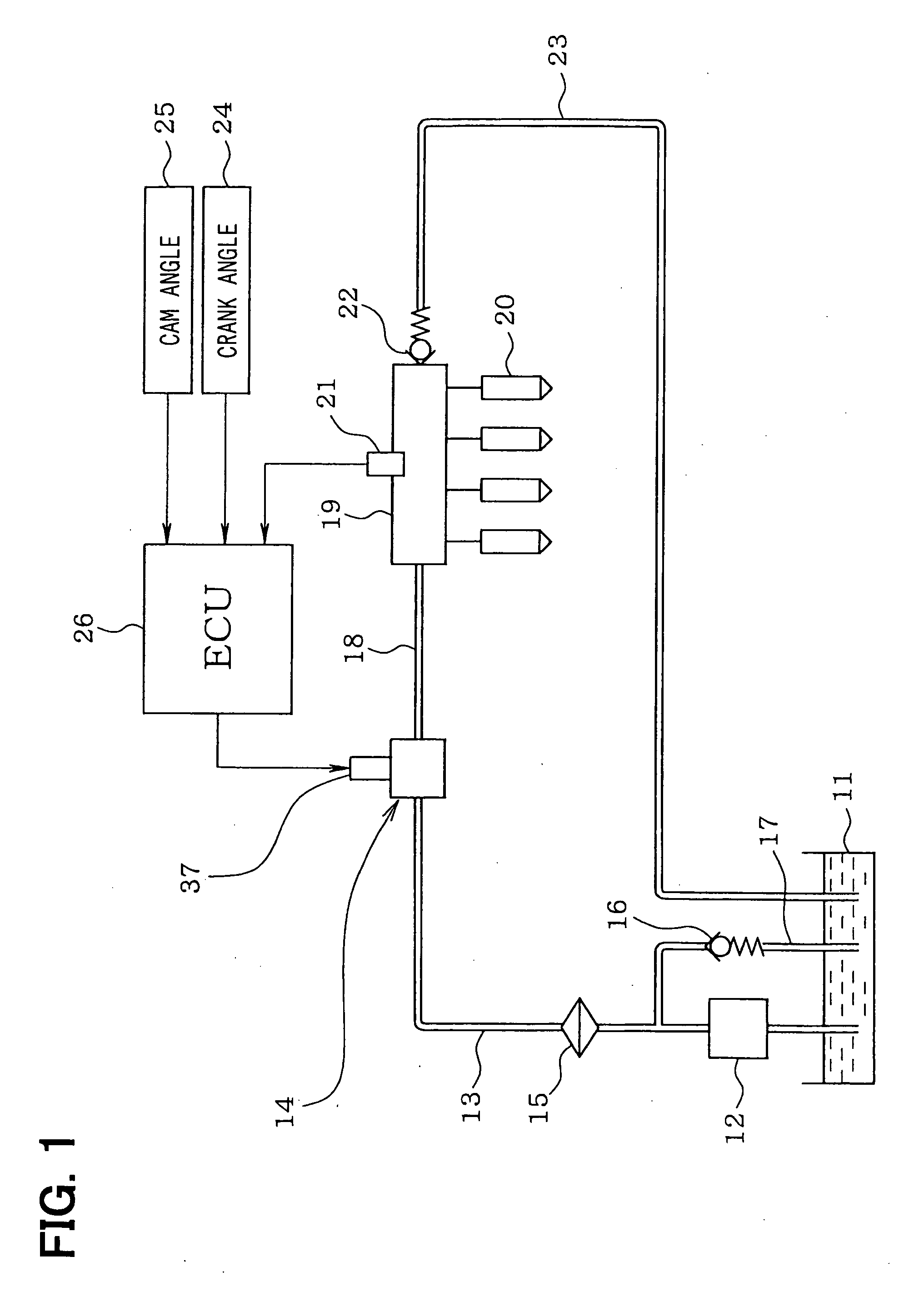

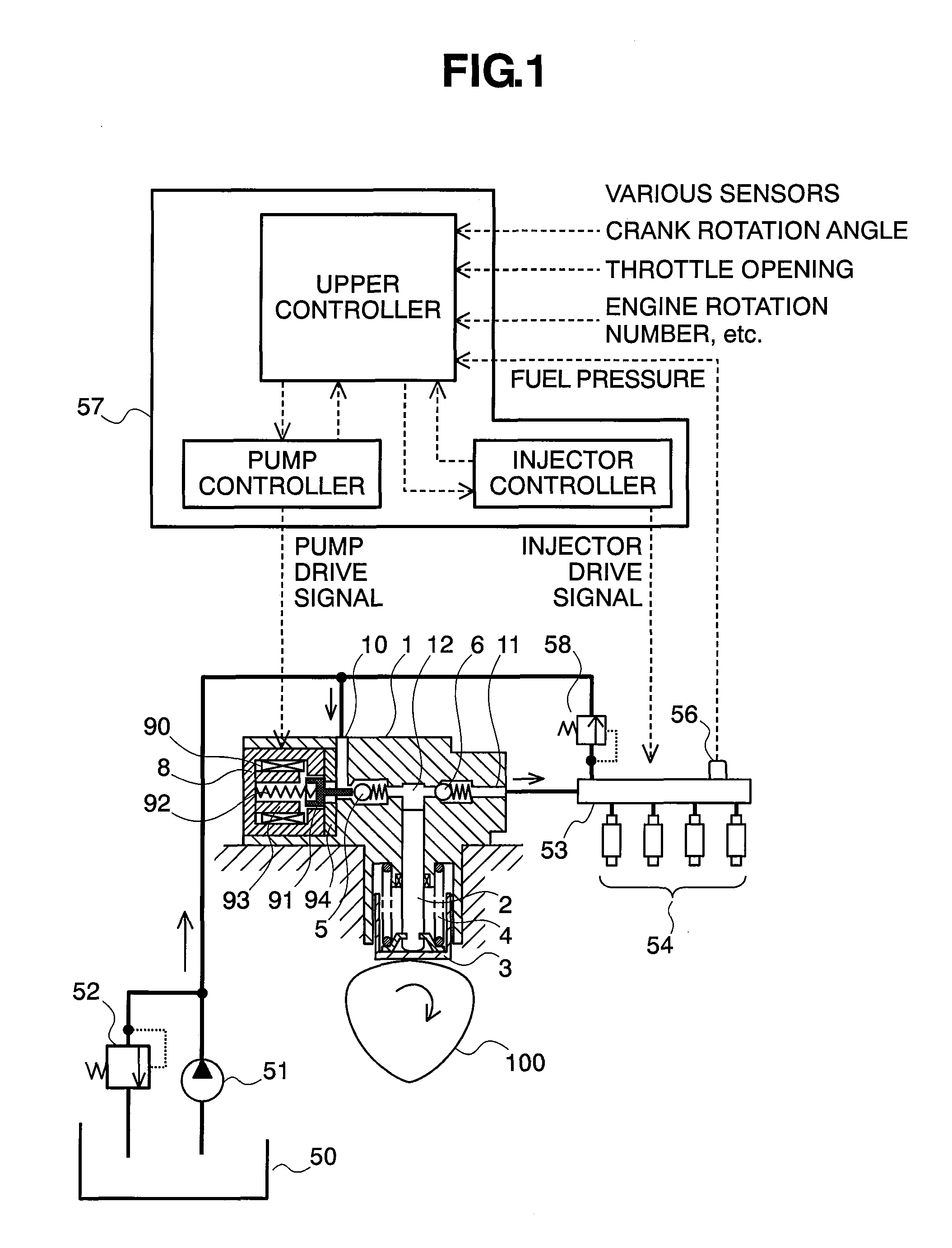

Fuel supply system of internal combustion engine

ActiveUS20050211224A1Promote atomizationImprove flammabilityElectrical controlNoise reducing fuel injectionFuel supplyCheck valve

A high-pressure pump is formed with a secondary suction passage, which branches from a fuel suction passage and communicates with a pump chamber. Check valves for preventing a backflow of fuel are disposed respectively in the secondary suction passage and a discharge passage. An electromagnetic valve for regulating a fuel discharge quantity is disposed in the fuel suction passage. Normal control for controlling the fuel discharge quantity by controlling opening timing and closing timing of the electromagnetic valve with respect to reciprocating movement of a plunger is performed when an engine rotation speed is higher than a predetermined value during operation of an engine. Valve closing control for holding the electromagnetic valve at a closed state is performed when the engine rotation speed is equal to or lower than the predetermined value.

Owner:DENSO CORP

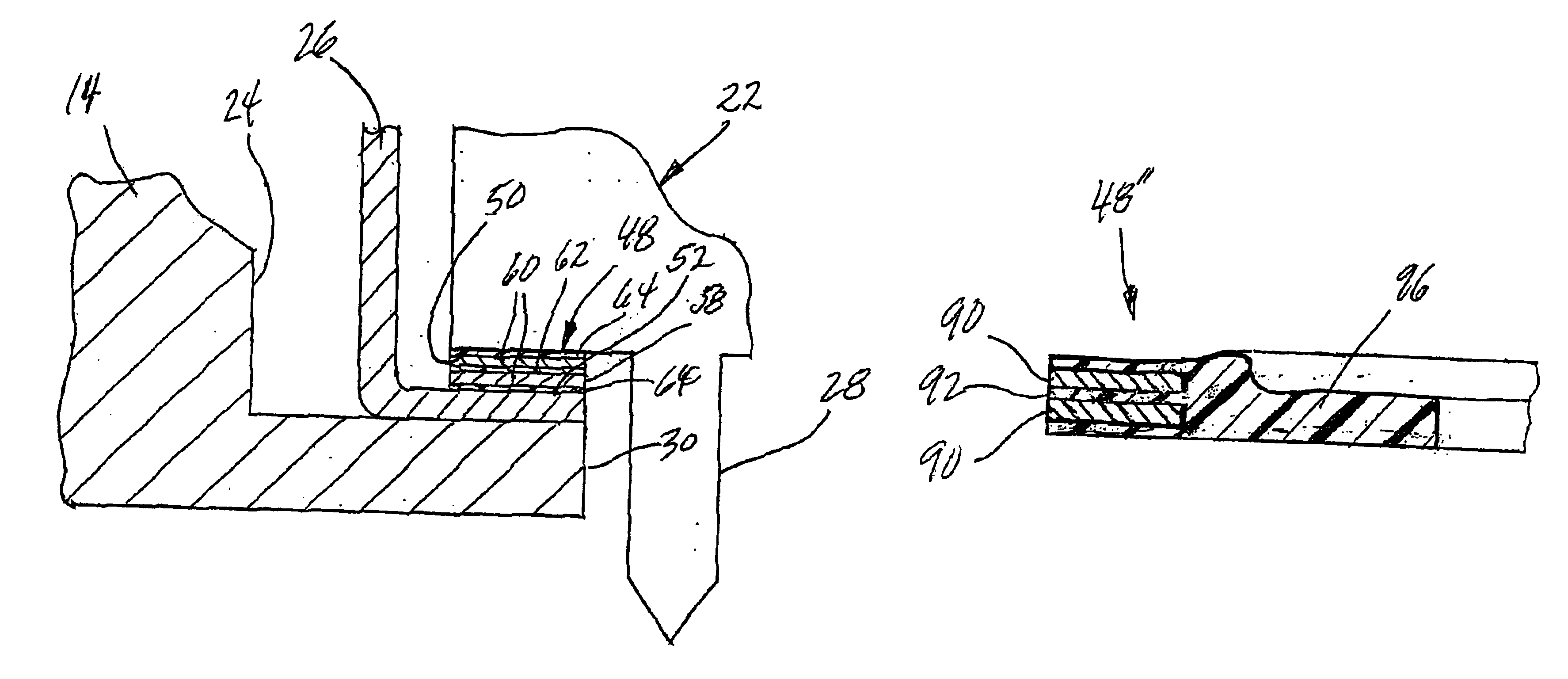

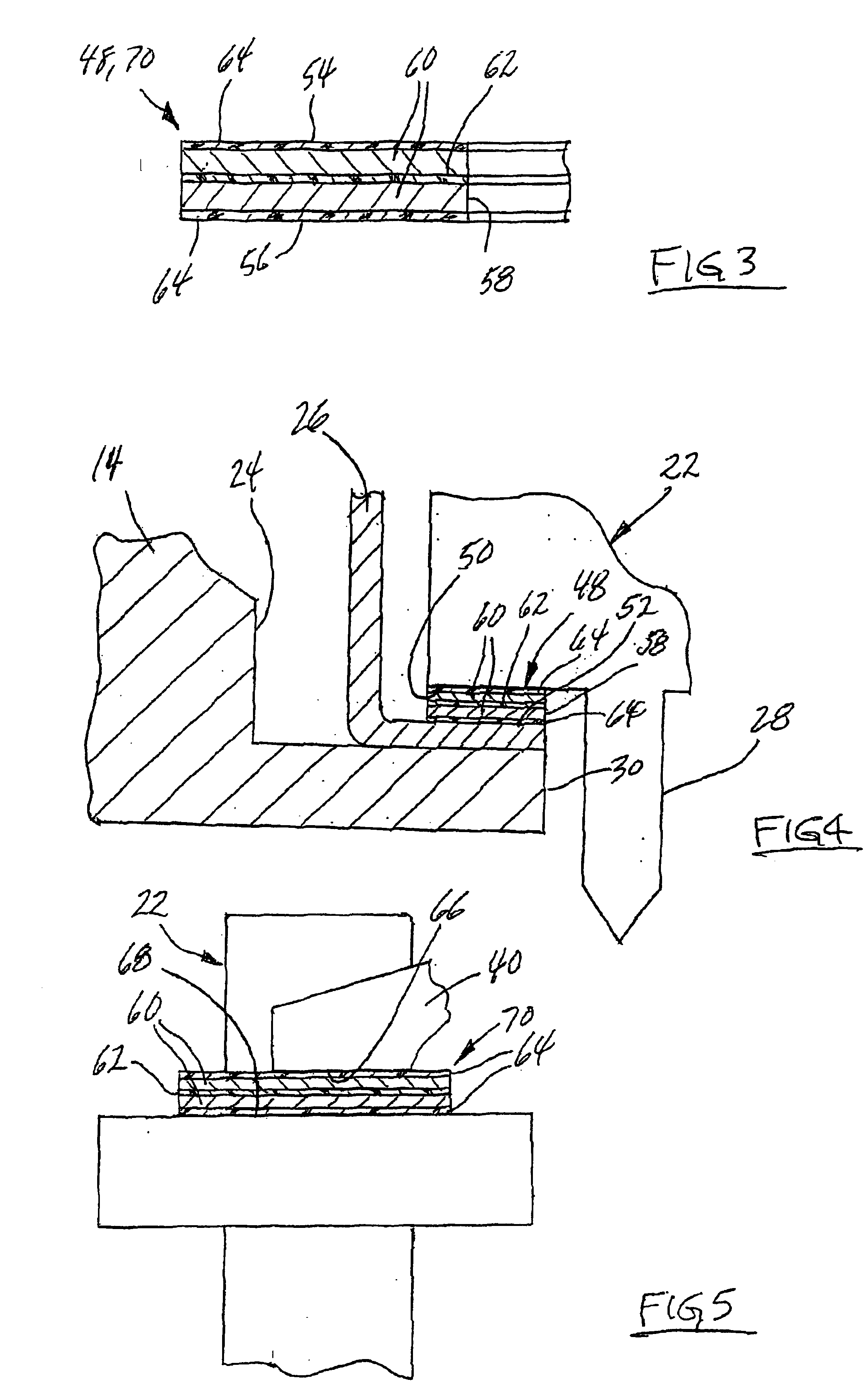

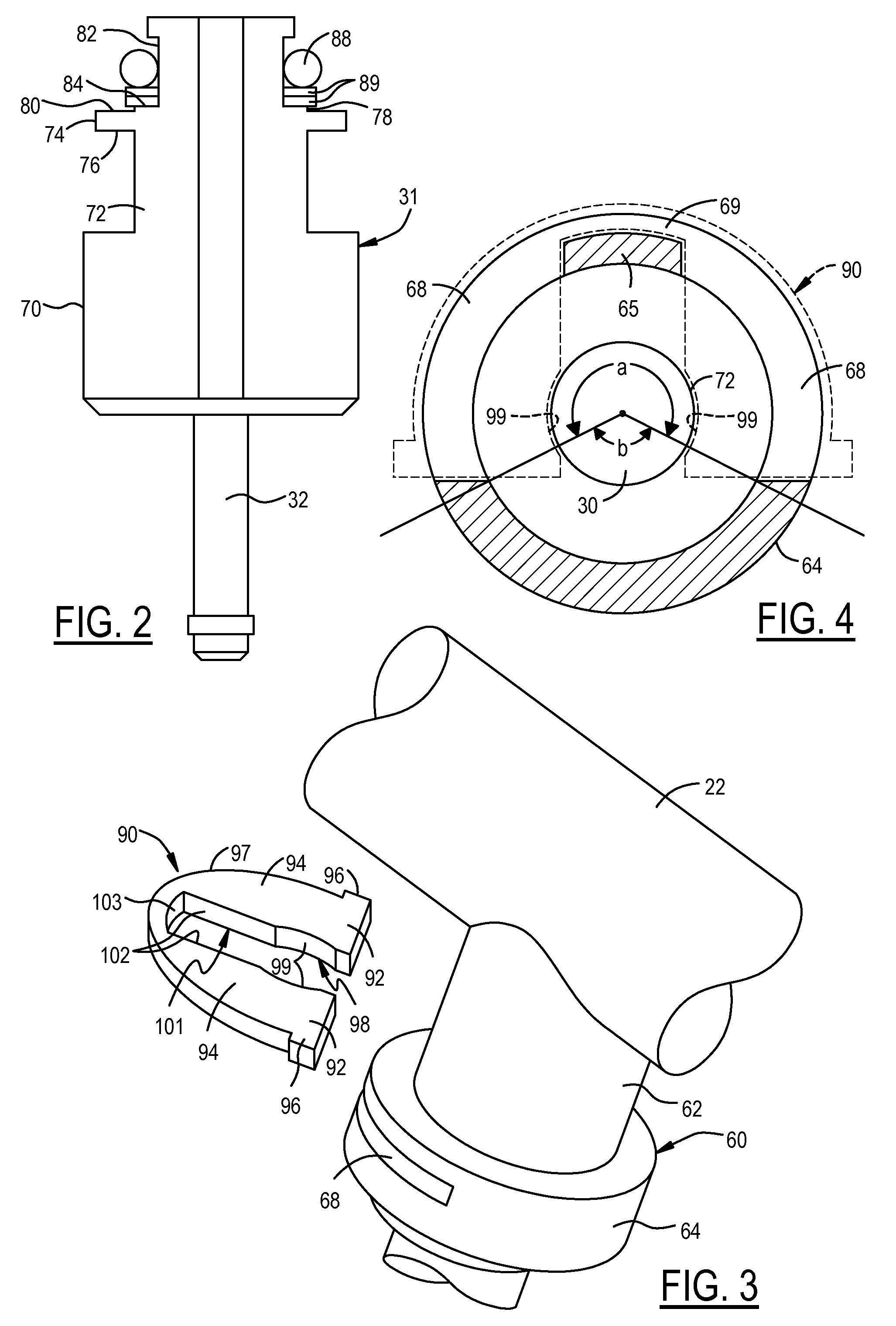

Gasket for fuel injector

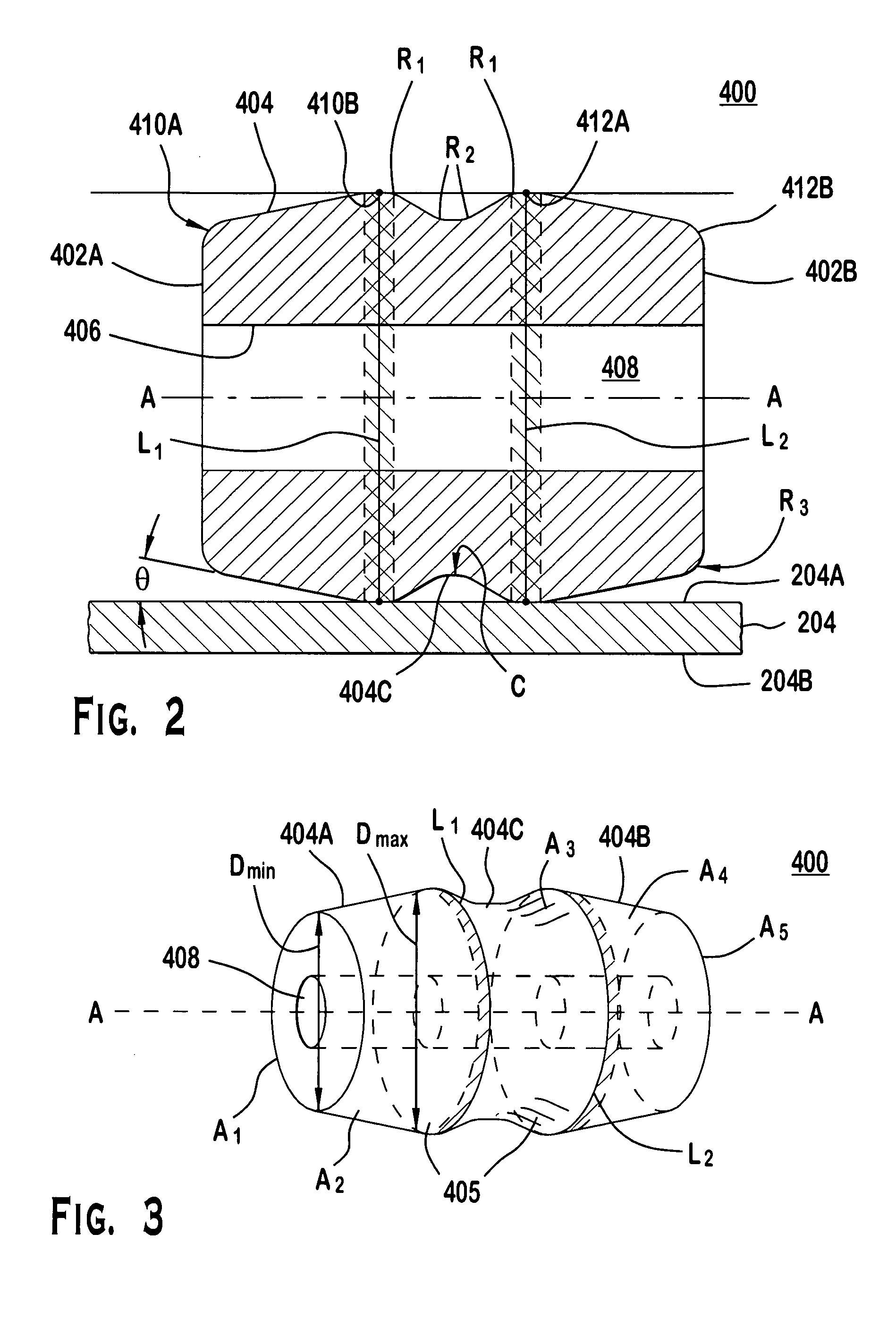

InactiveUS6866026B2Effective seal against leakageTransmission limitEngine sealsNoise reducing fuel injectionCylinder headEngineering

A gasket (48, 48′, 48″) and (70) for disposition between a fuel injector (22) and a cylinder head (14) comprises compressible polymer layers (62, 64, 74, 92) and incompressible and flat metal layers (60, 72, 90) sandwiched between the polymer layers. In the embodiments of FIGS. 6-8, a polymer body (80, 96) is disposed radially inwardly of the incompressible layer (72) or layers (90) and includes a bead portion (86) thicker than the total thickness of the incompressible and polymer layers (72), and (74, 90) and (92). The body (80, 96) also includes a recess portion (82-84) having a thickness less than the total thickness to define a recess (88) adjacent the bead portion (86). The bead portion (86) is disposed radially between the recess portion (82-84) and the incompressible layer (72 or 90).

Owner:FEDERAL MOGUL WORLD WIDE LLC

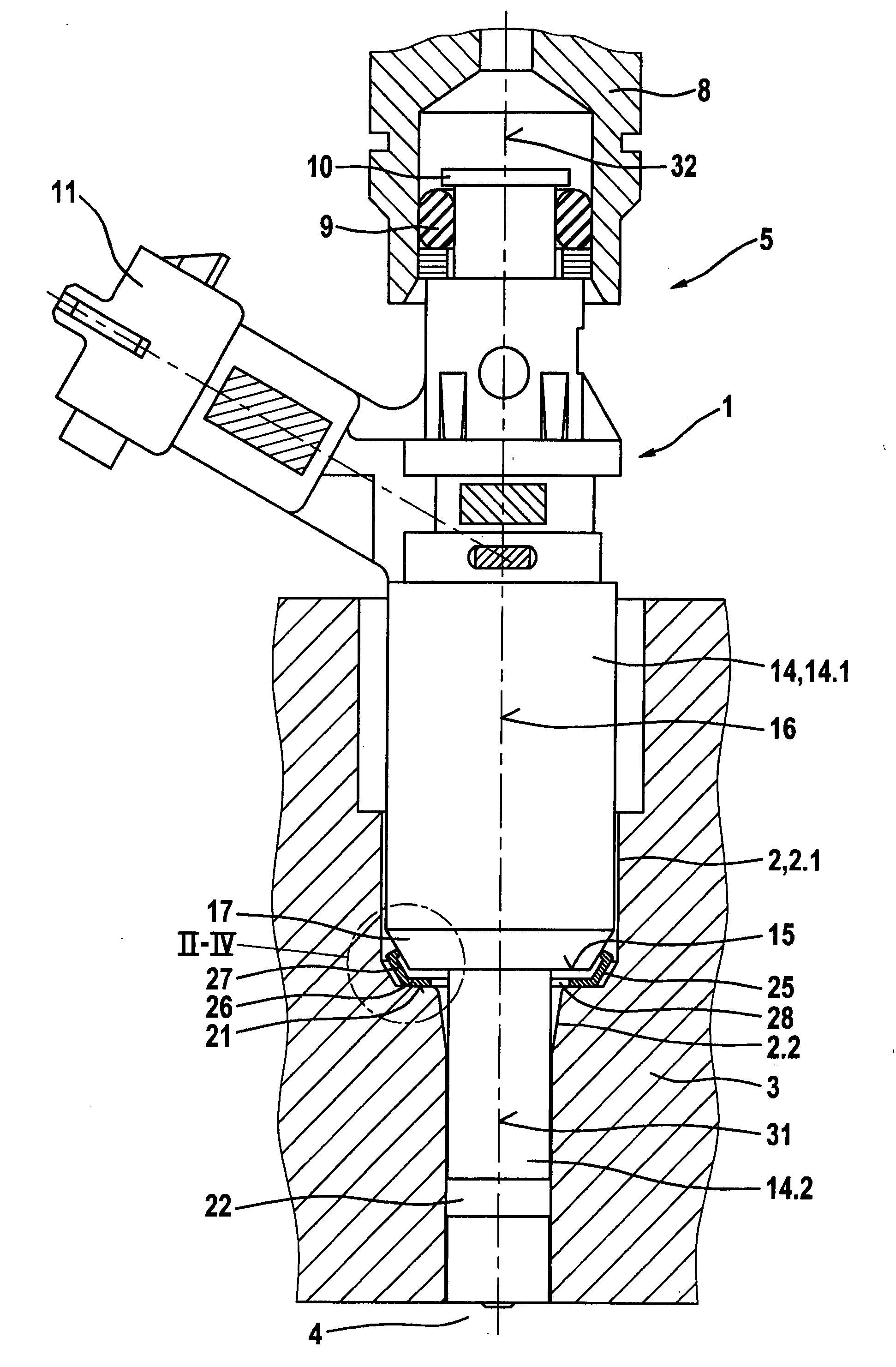

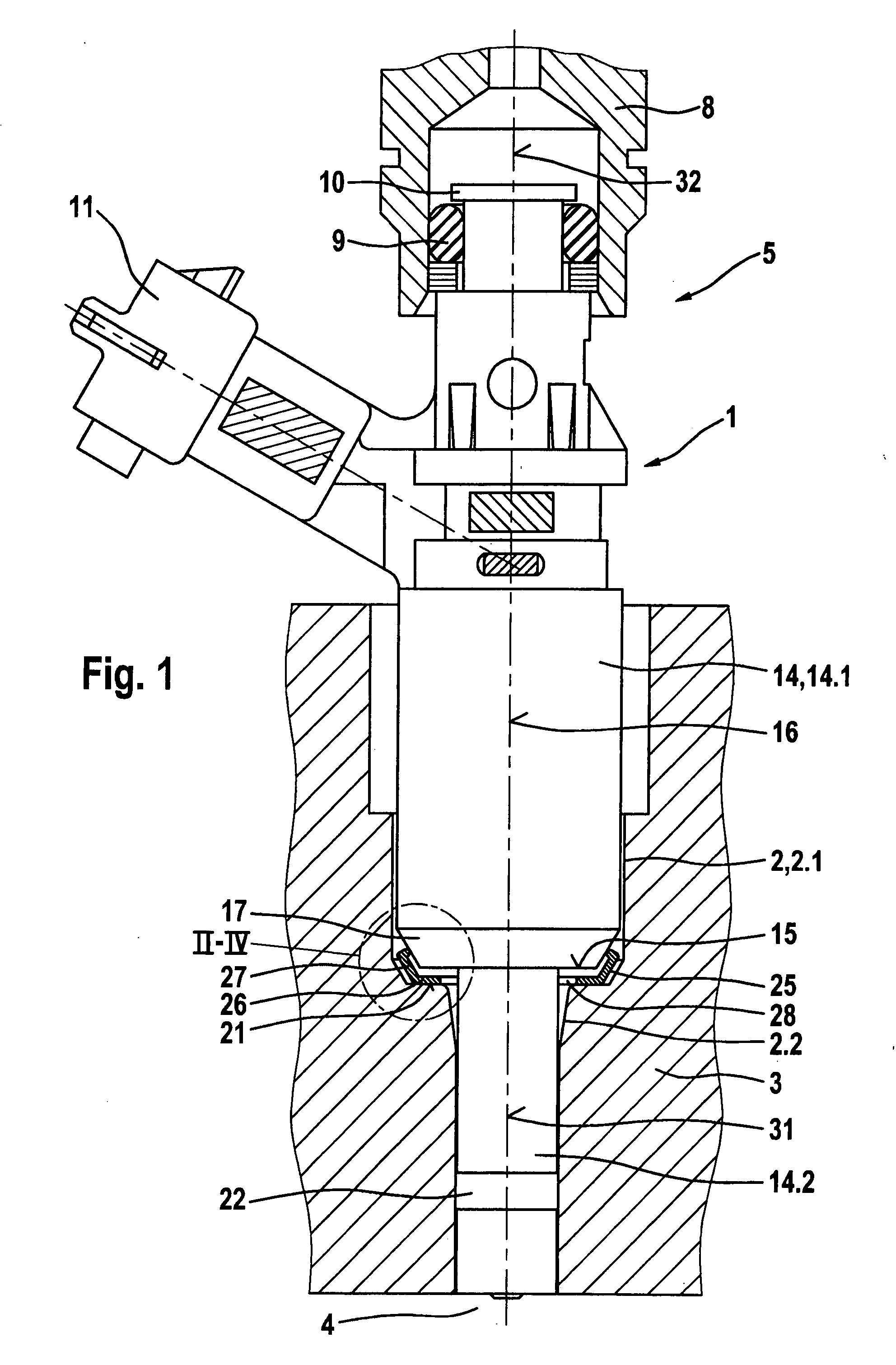

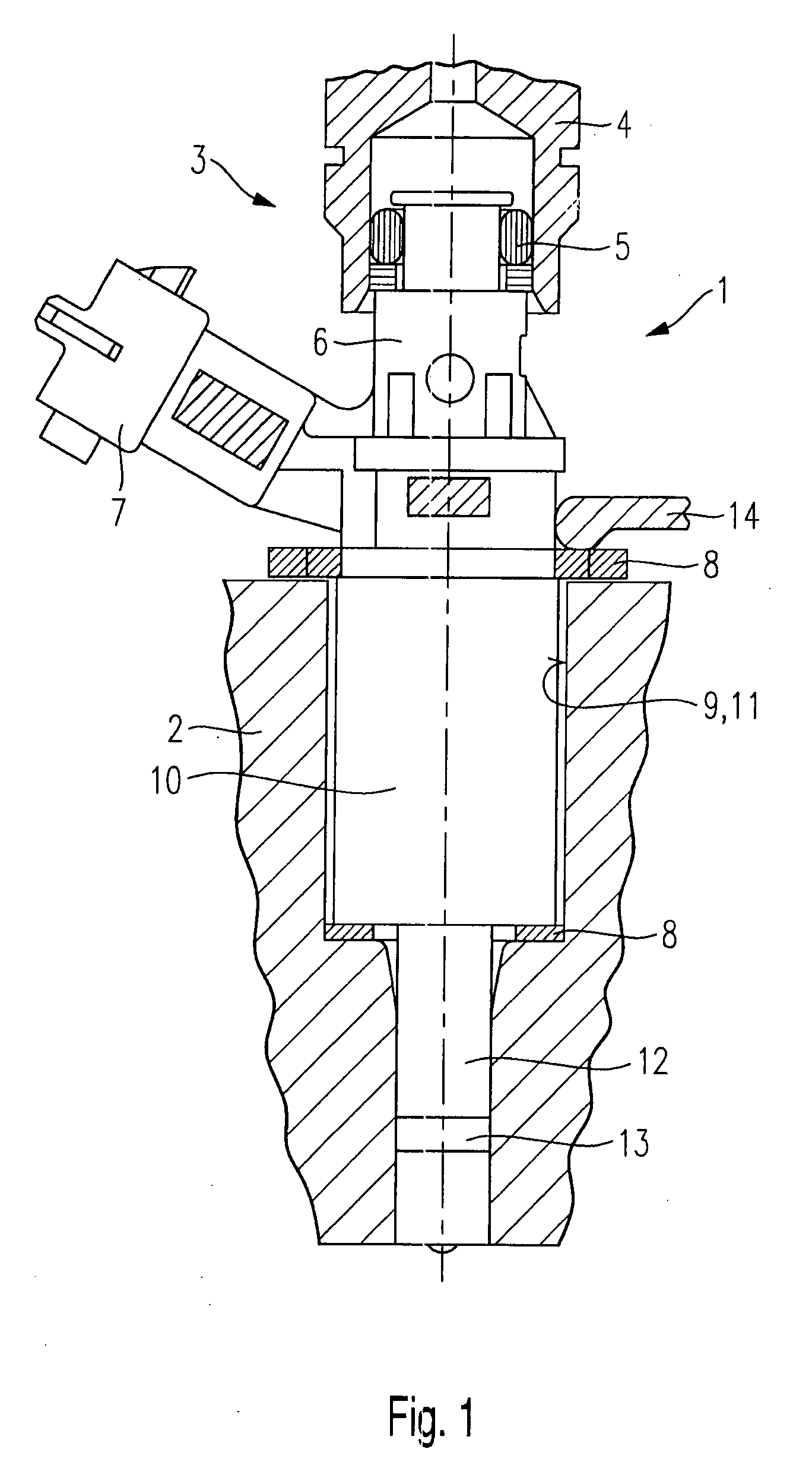

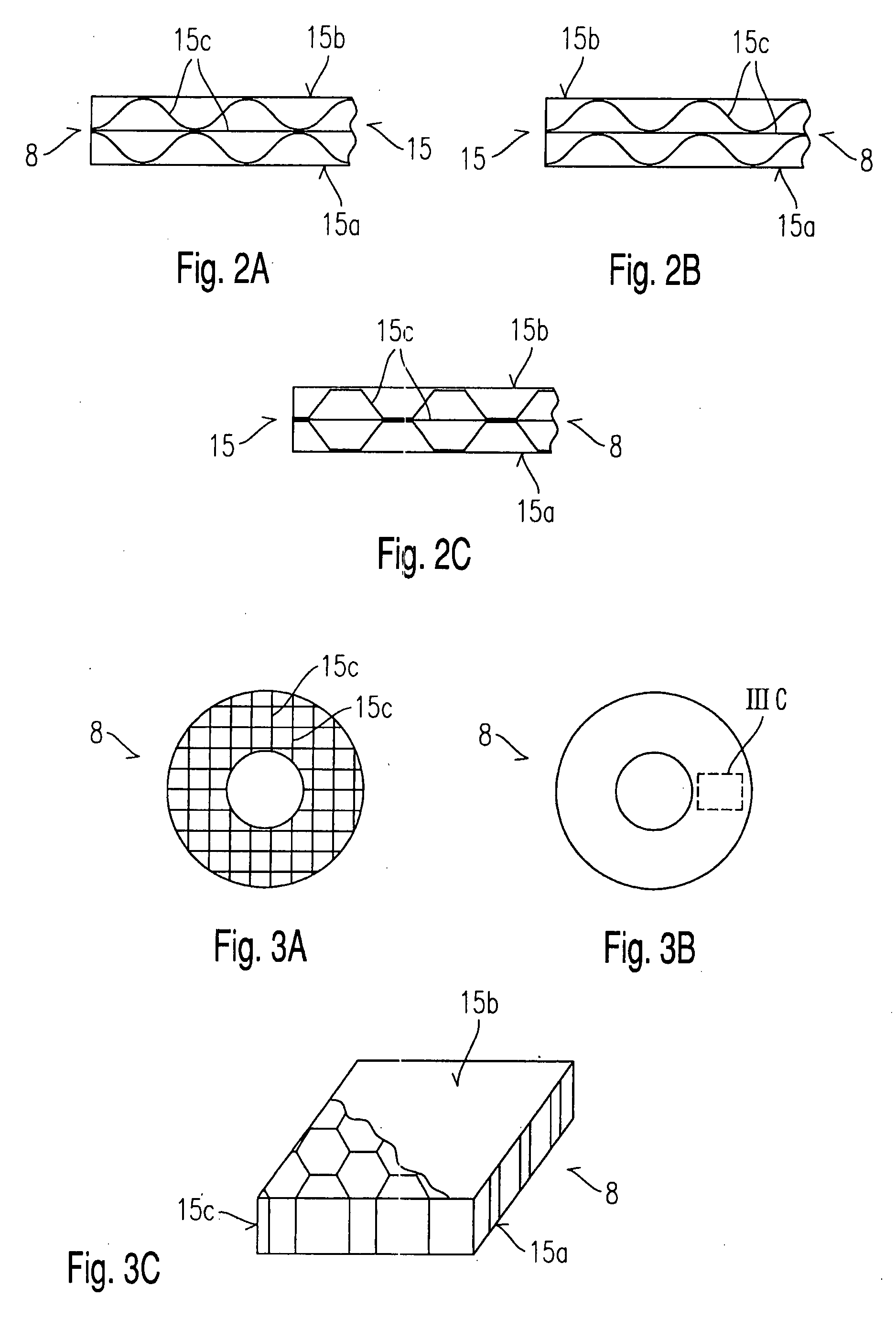

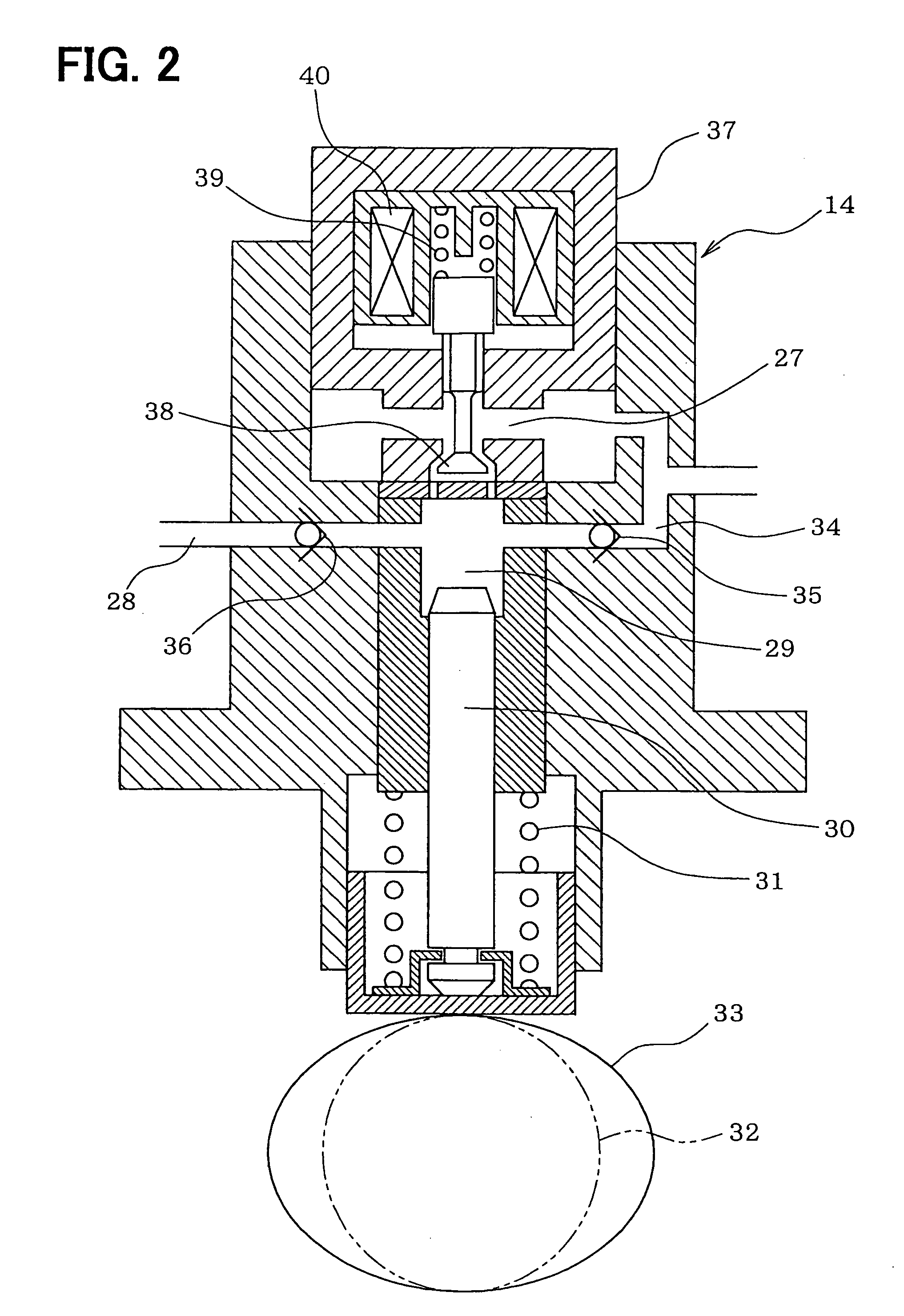

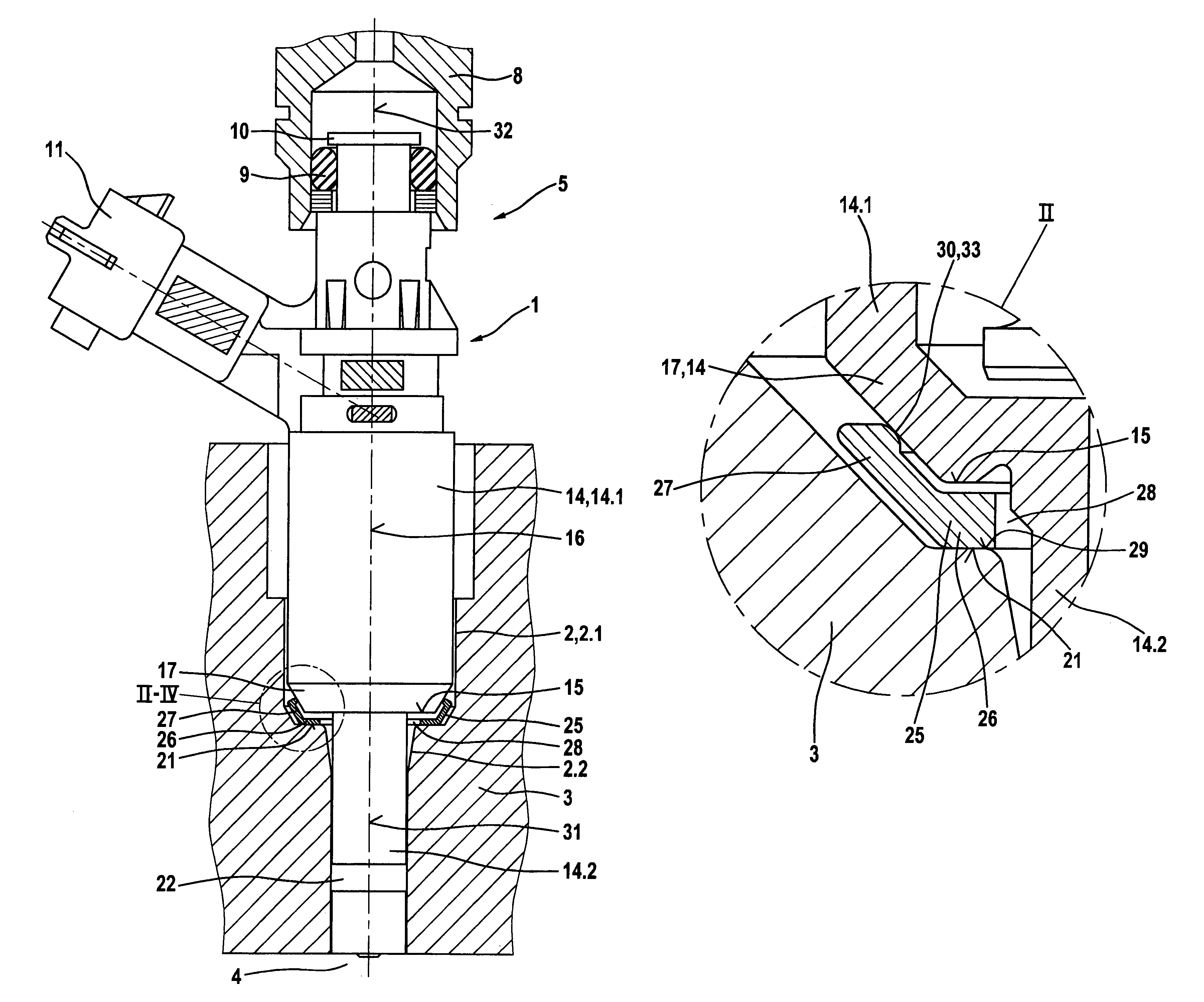

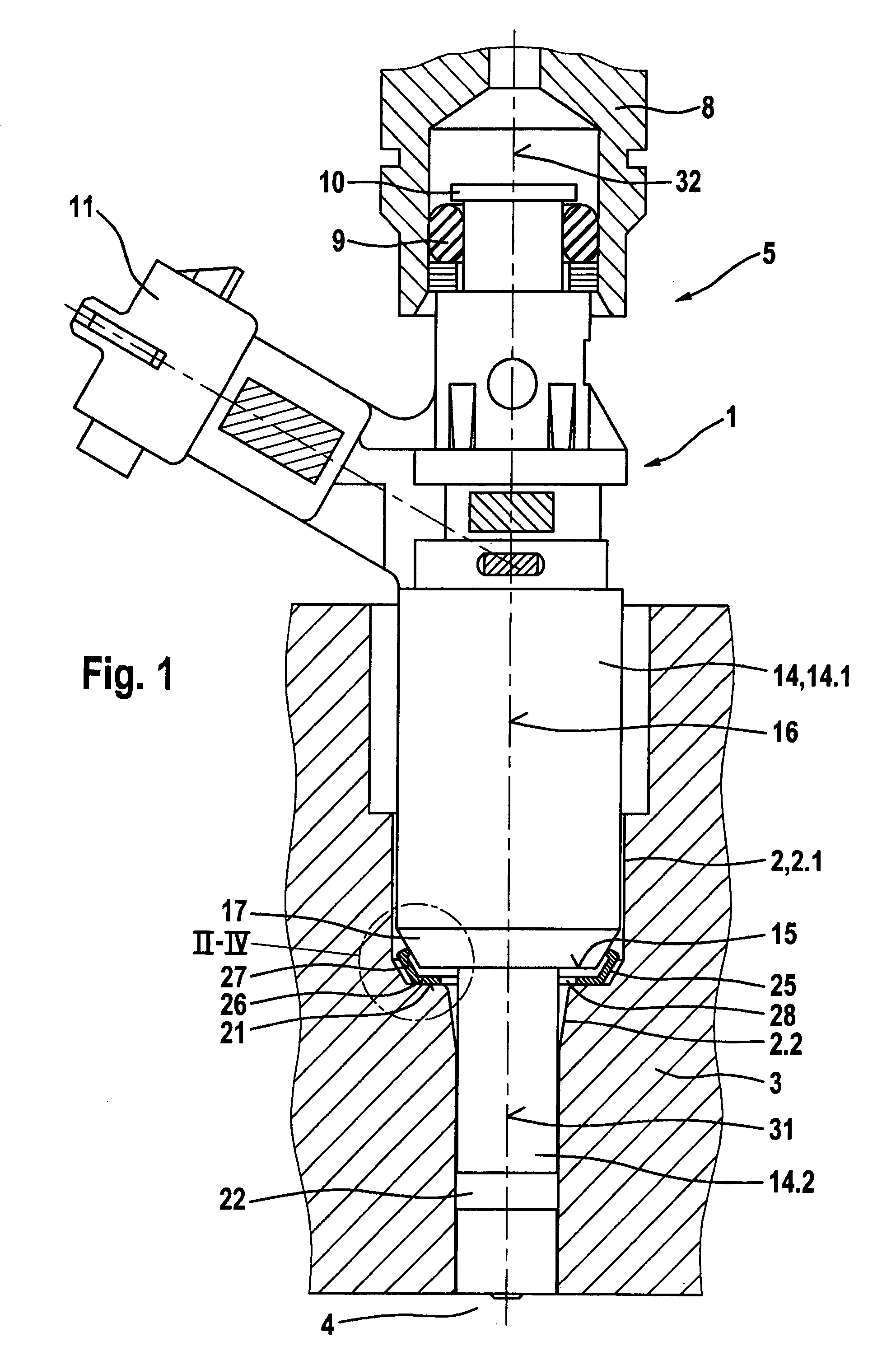

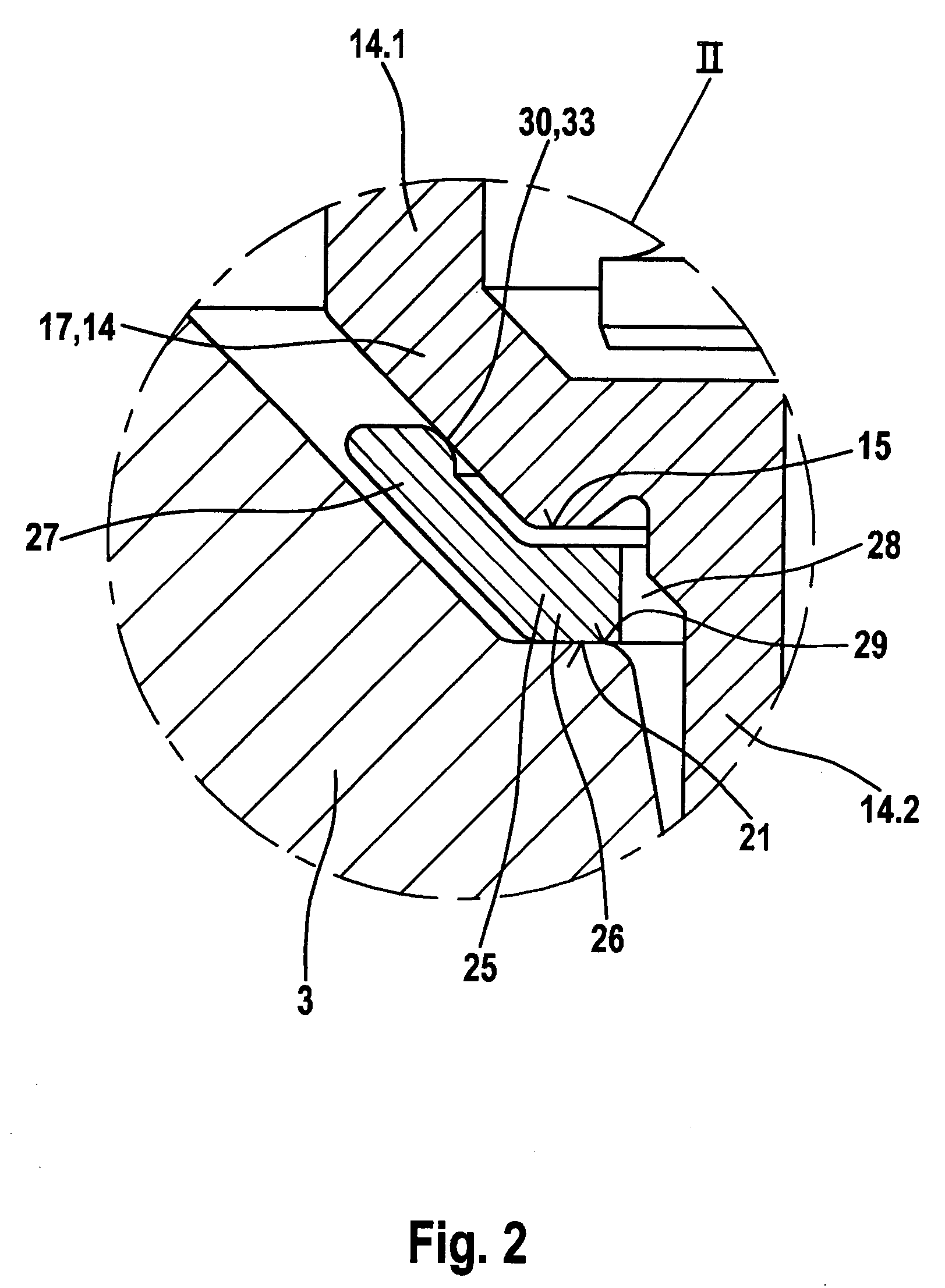

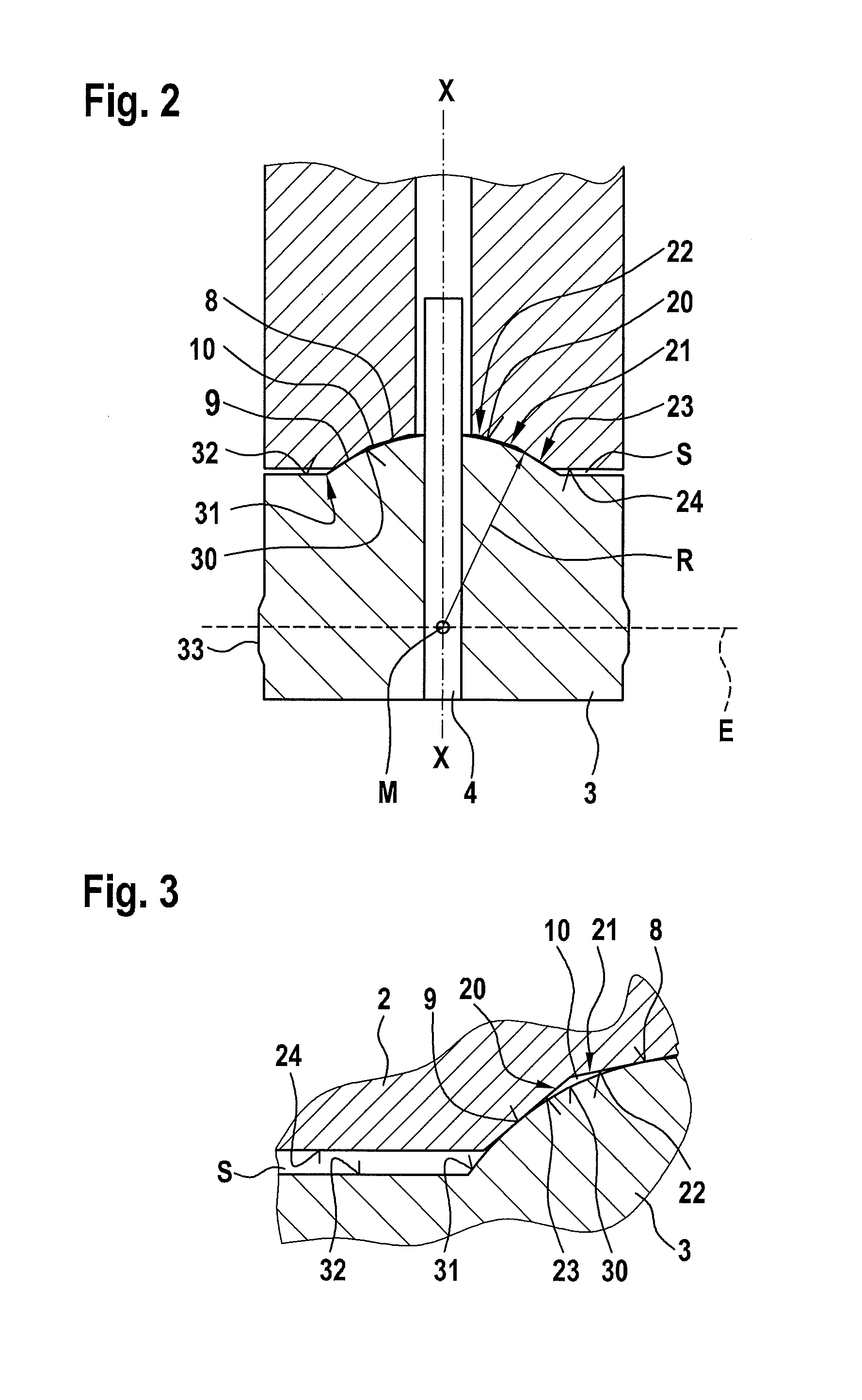

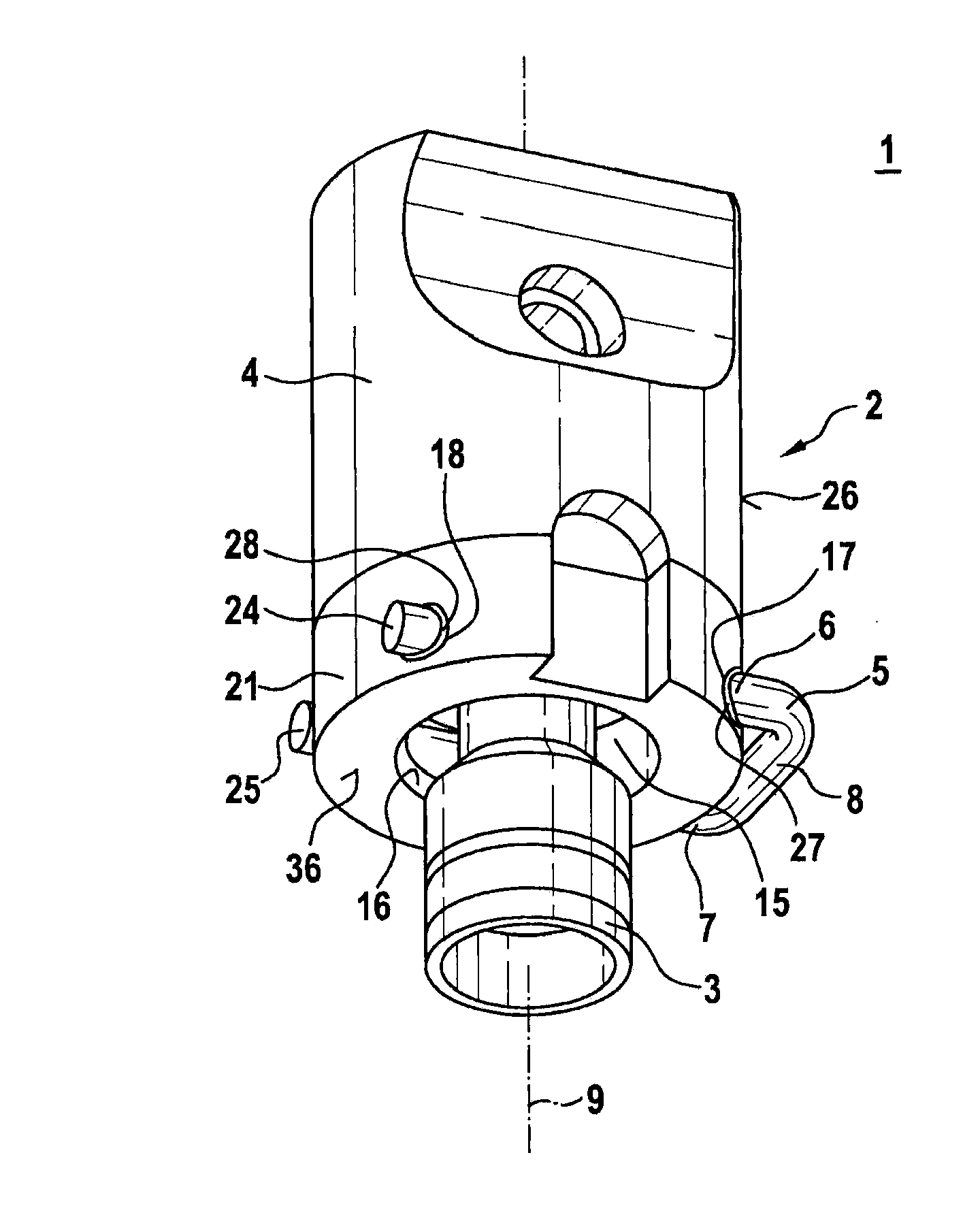

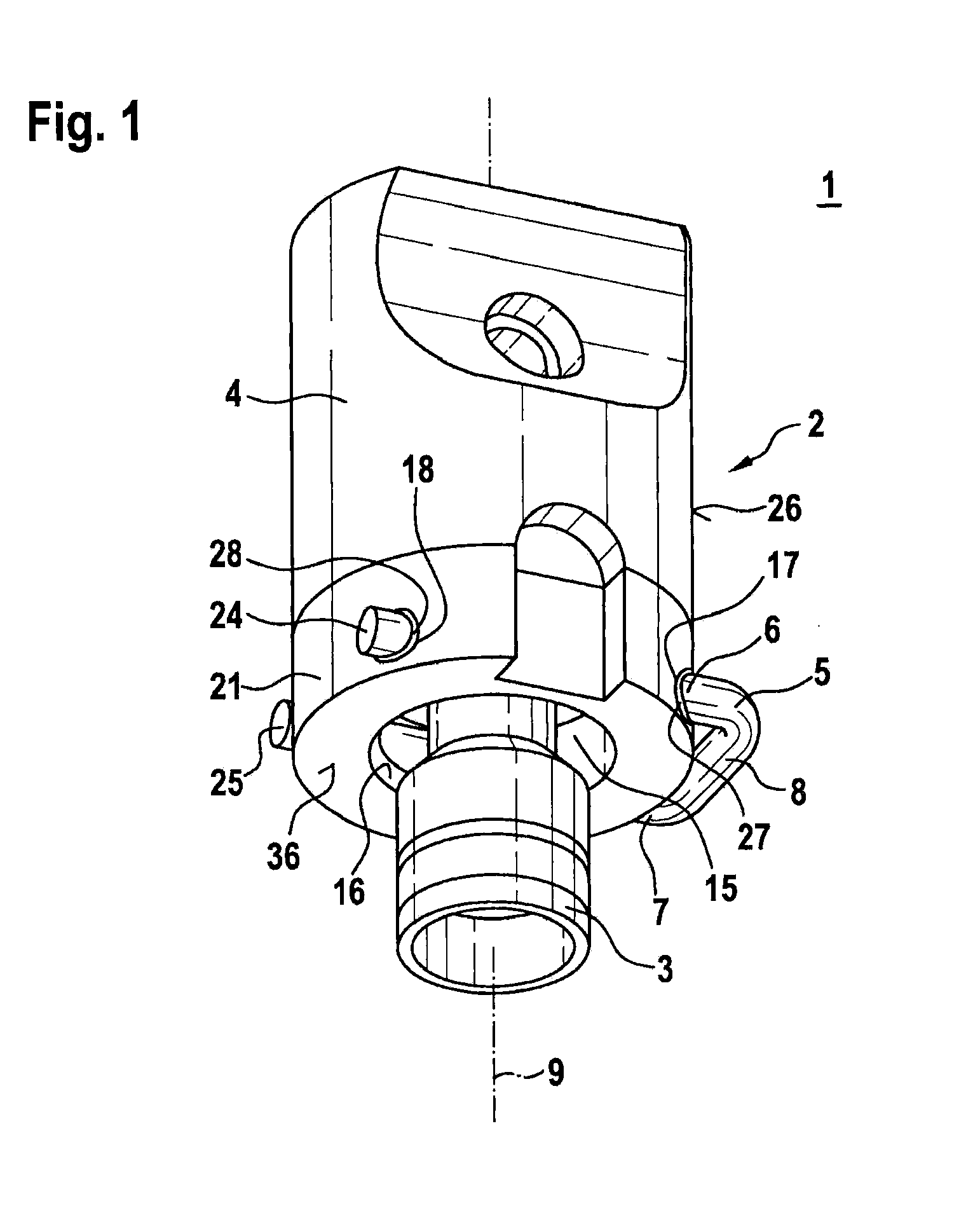

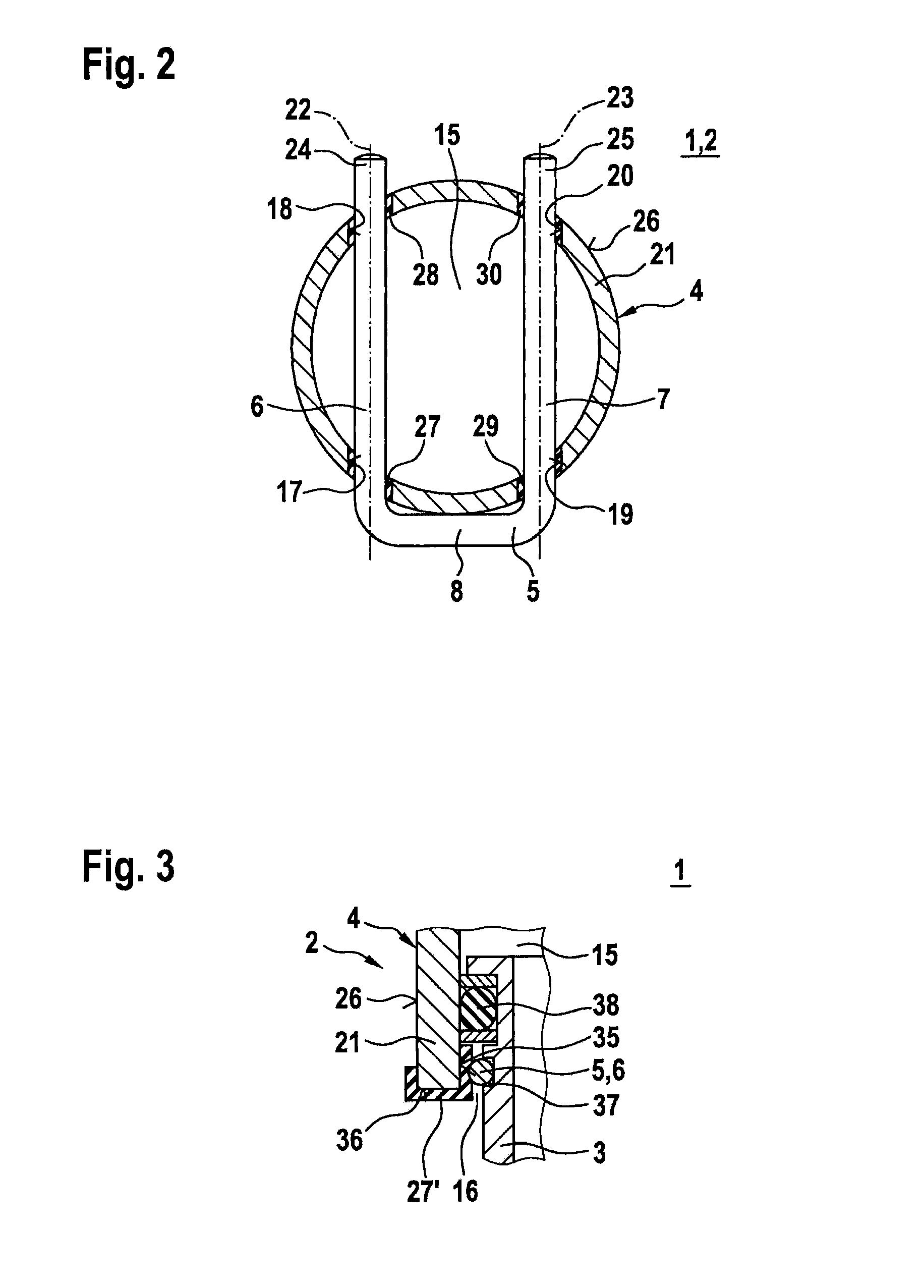

Damping element for a fuel injection valve

Known damping elements (25) for a fuel injection valve (1) insertable into a receiving conduit (2) of a cylinder head (3) of an internal combustion engine are disposed between a valve housing (14) of the fuel injection valve (1) and a wall of the receiving conduit (2) of the cylinder head (3). These damping elements (25), inter alia, decrease acoustic transfer from the fuel injection valve to the cylinder head (3). It is disadvantageous that the damping elements known hitherto require a great deal of axial installation space with respect to a valve axis and have comparatively high manufacturing costs. With the damping element (25) according to the present invention, the installation space required is reduced. Provision is made, according to the present invention, for the damping element (25) to be in plate-shaped fashion.

Owner:ROBERT BOSCH GMBH

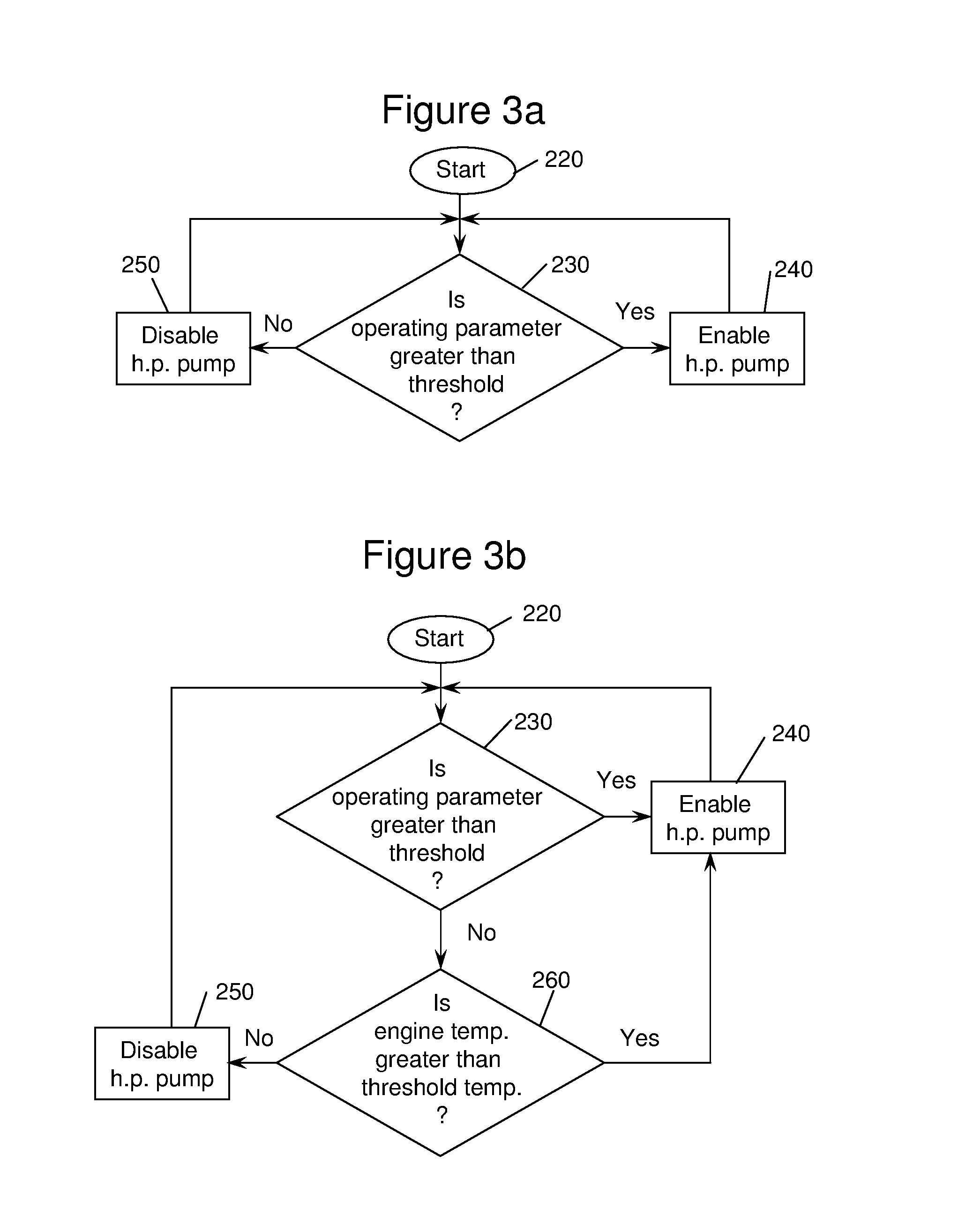

Method and system to mitigate pump noise in a direct injection, spark ignition engine

InactiveUS7373924B1High measurement accuracyIncrease pressureElectrical controlInternal combustion piston enginesLow speedSolenoid valve

A method and system for controlling a fuel pressurizing system in a direct-injection, spark-ignition engine is disclosed such that the ticking sound of a solenoid valve in the high pressure pump is disabled at certain engine operating conditions. The fuel pressurizing system includes two pumps in series: a low pressure lift pump and a high pressure pump. Based on an engine operating parameter (speed, load, temperature, fuel delivery rate, as examples) the high pressure fuel pump is disabled when the engine operating parameter is below a threshold. The disablement of the pump is accomplished by turning off the normally-open solenoid valve on the inlet side of the high pressure pump, particularly at low speed and / or low torque conditions, e.g., idle, when the ticking of the injector is particularly noticeable. When the pump is disabled, fuel is supplied to the fuel injectors at lift pump pressure.

Owner:FORD GLOBAL TECH LLC

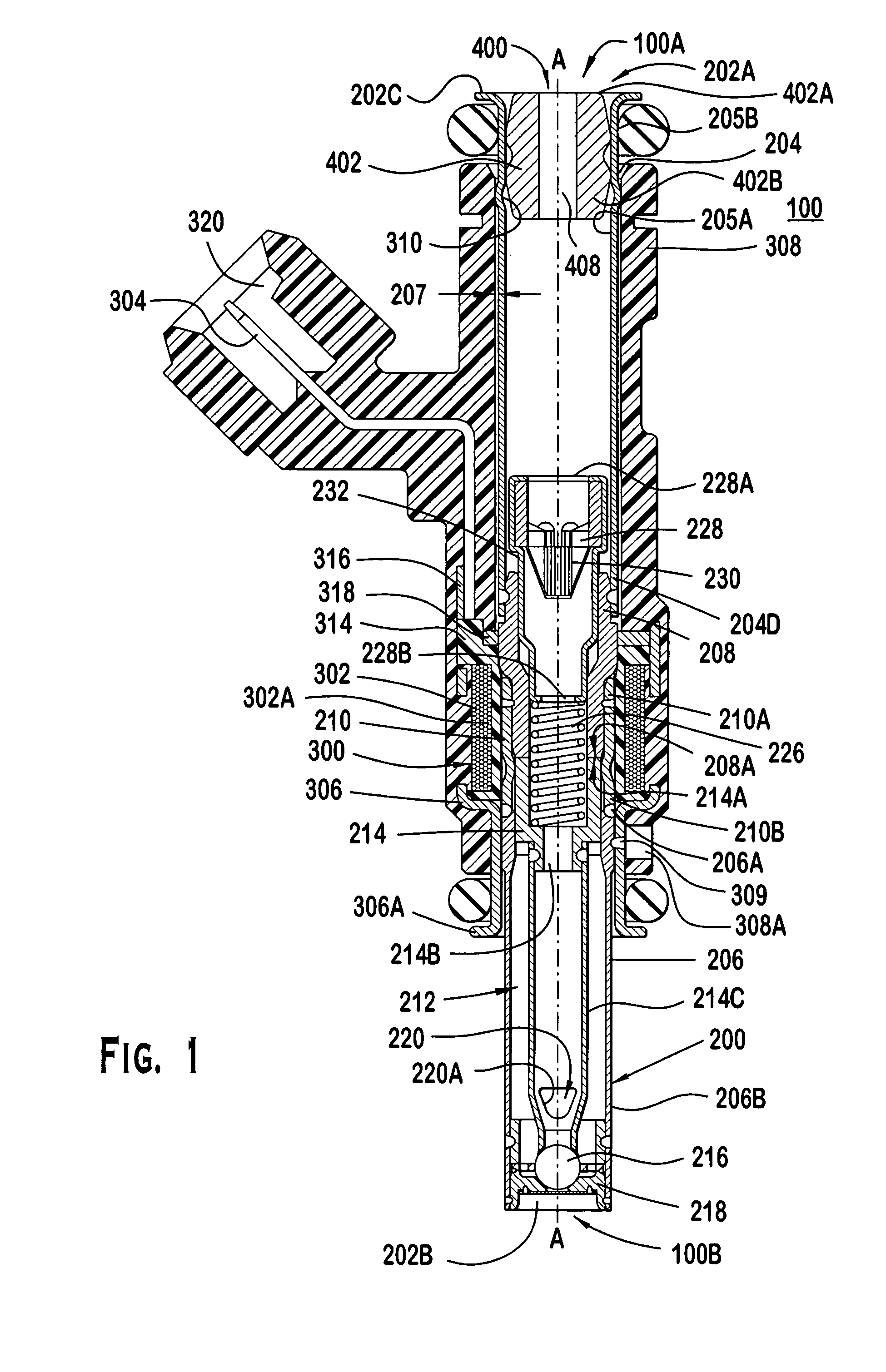

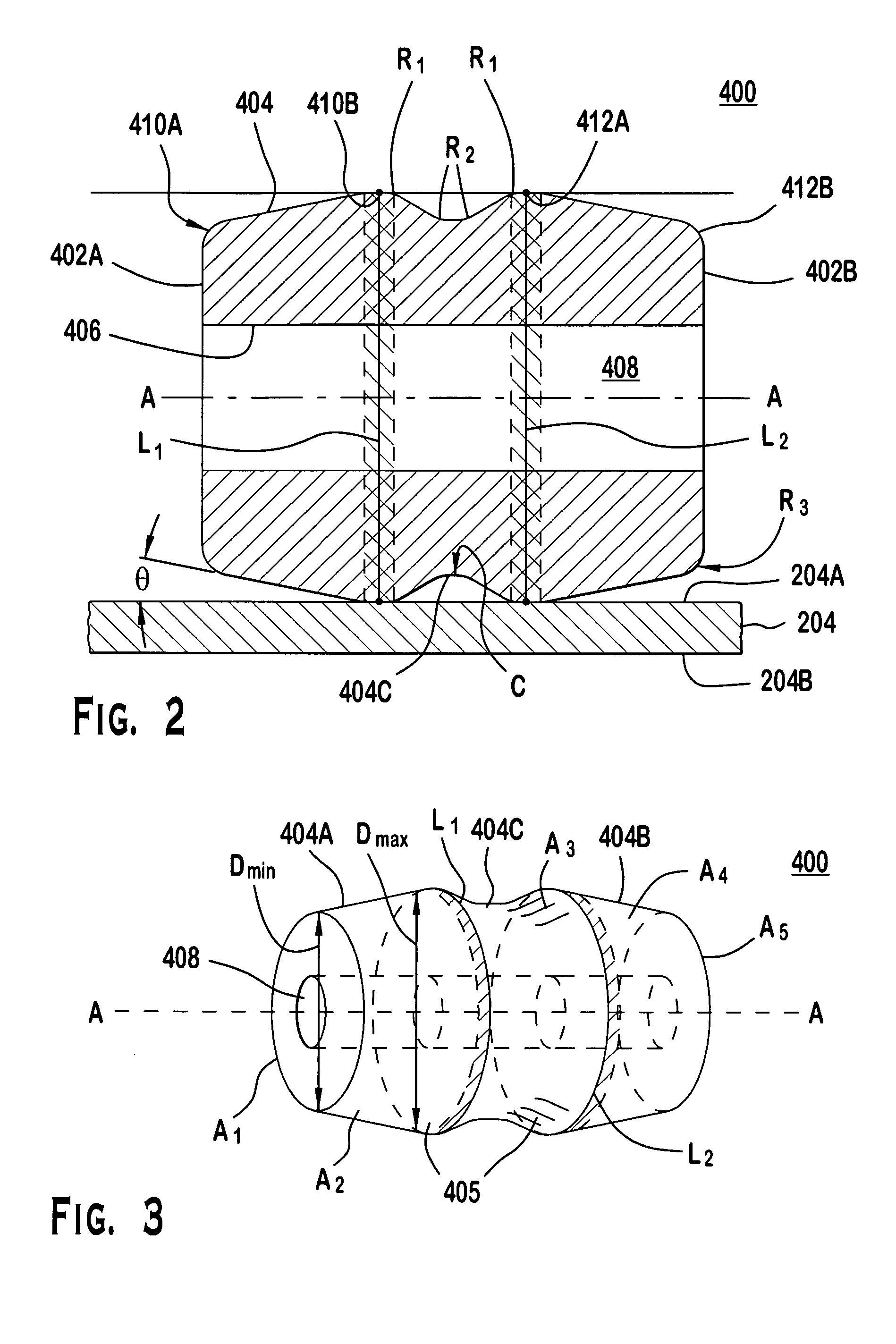

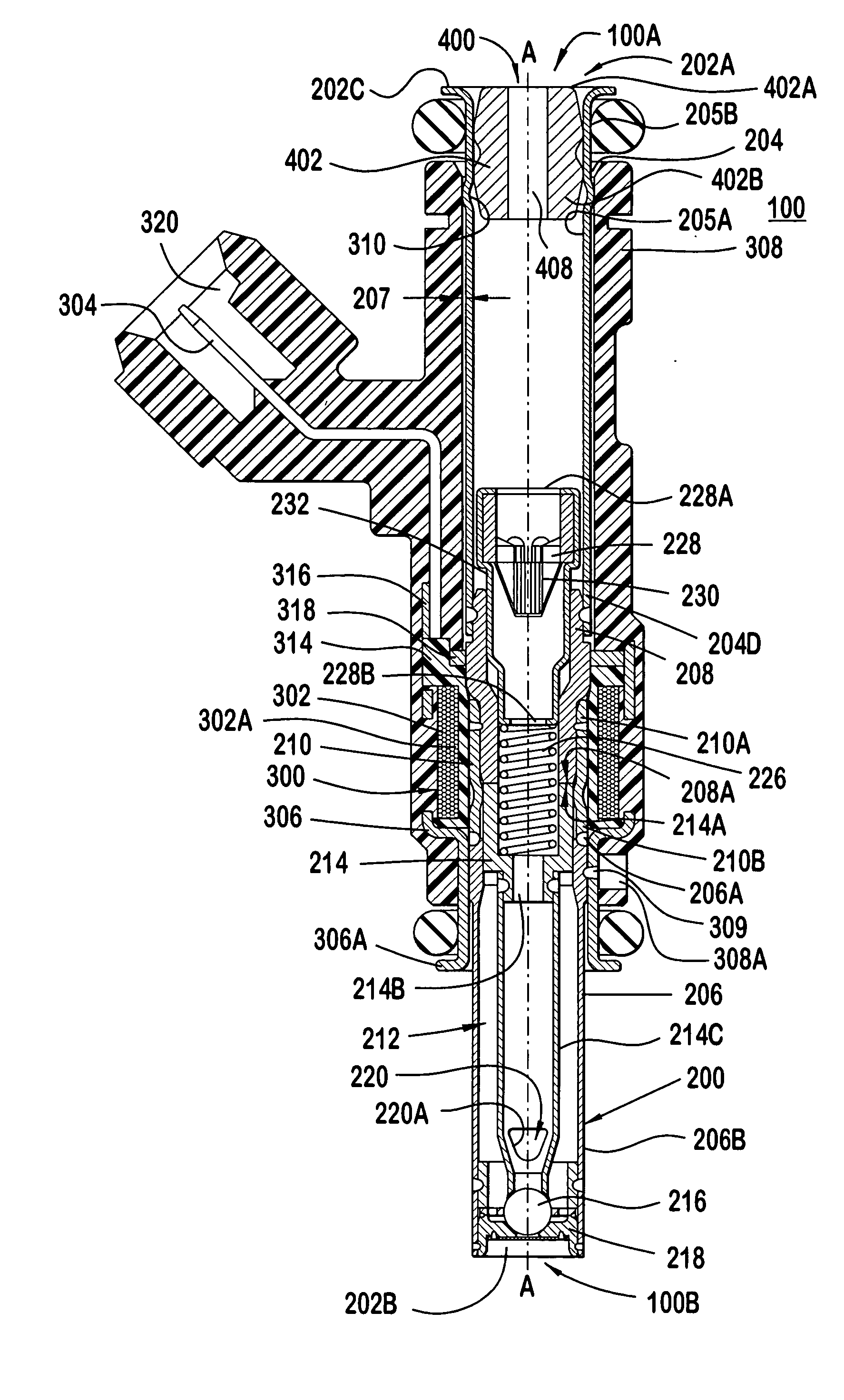

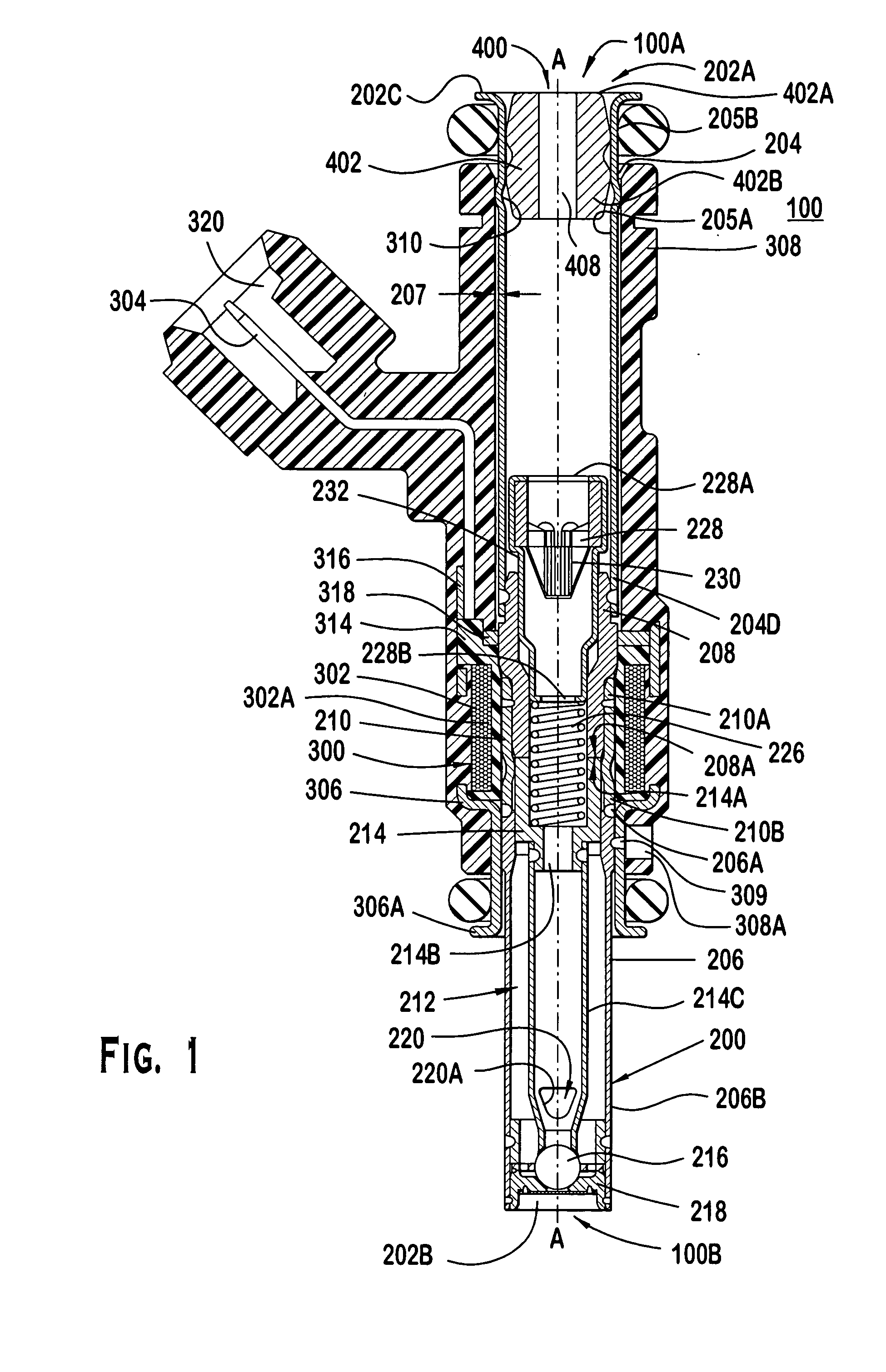

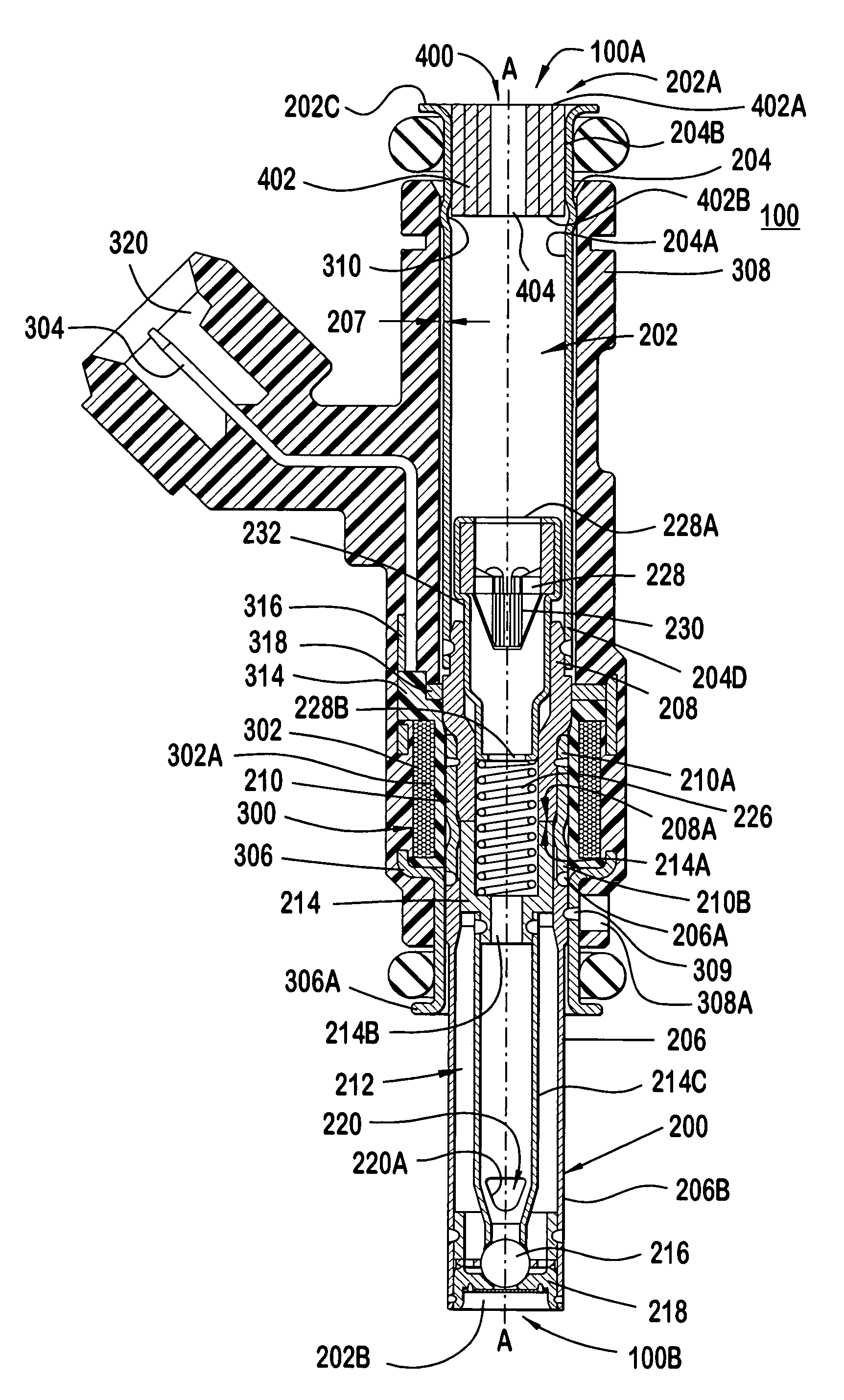

Modular fuel injector with a harmonic damper and method of reducing noise

InactiveUS20050269426A1Reduce the amplitudeMaintaining operational noiseEngine testingNoise reducing fuel injectionAcoustic noise reductionPower group

A fuel injector with various embodiments of a damper that reduces noise generated between a valve group subassembly and a power group subassembly during operation of the fuel injector. A mass damper is also shown and described. A method of reducing sound in the valve group subassembly is also disclosed.

Owner:CHO YONG D

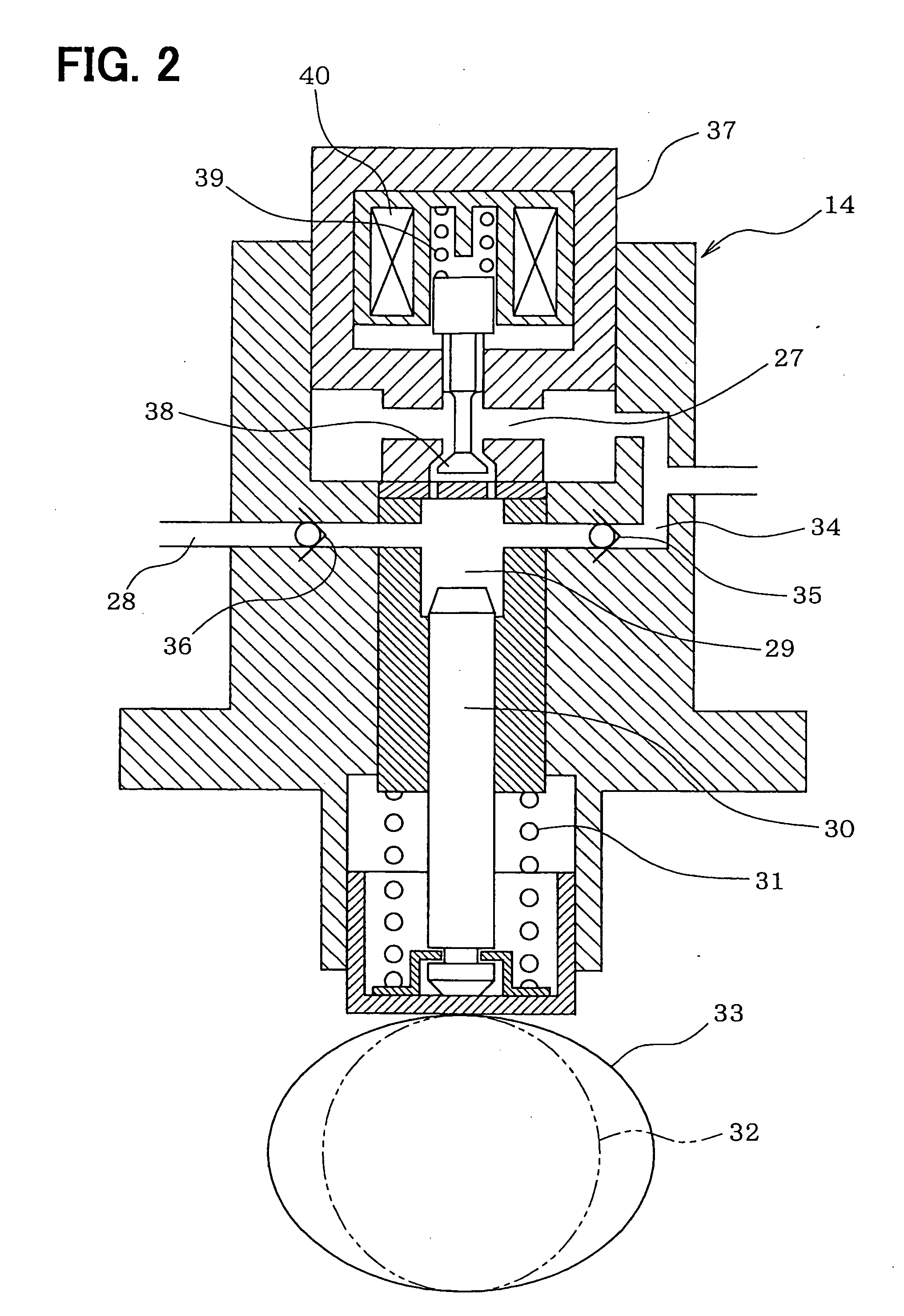

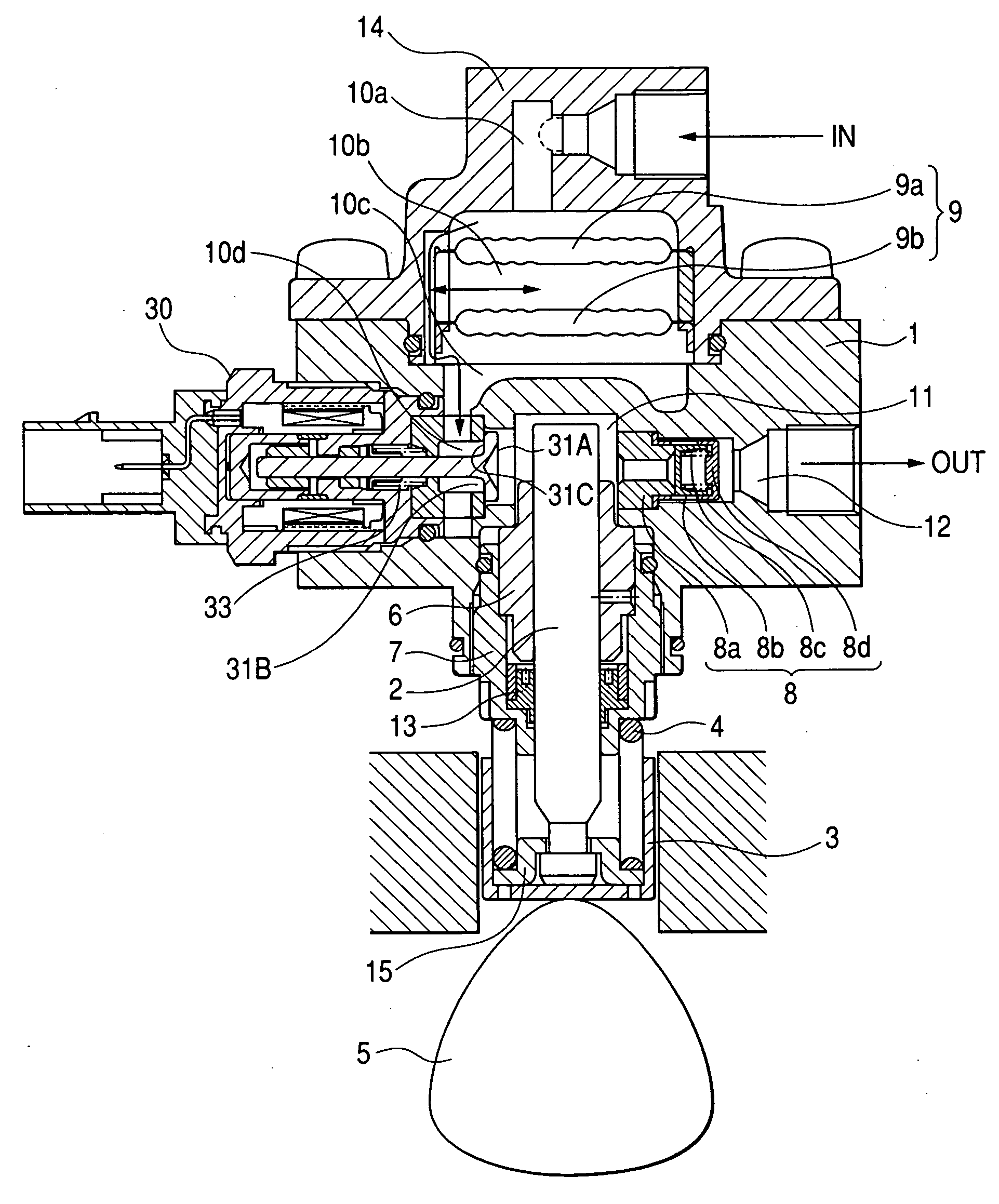

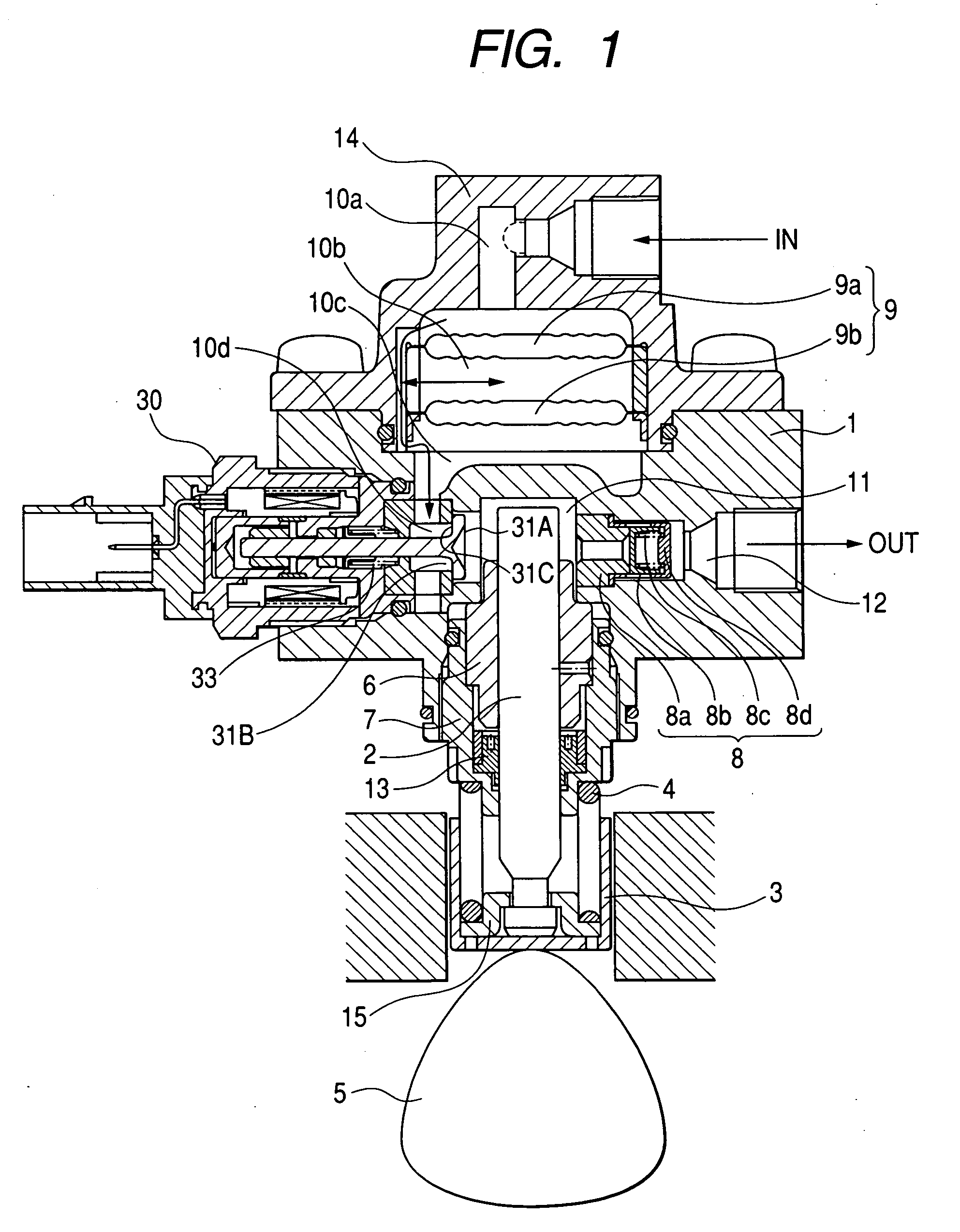

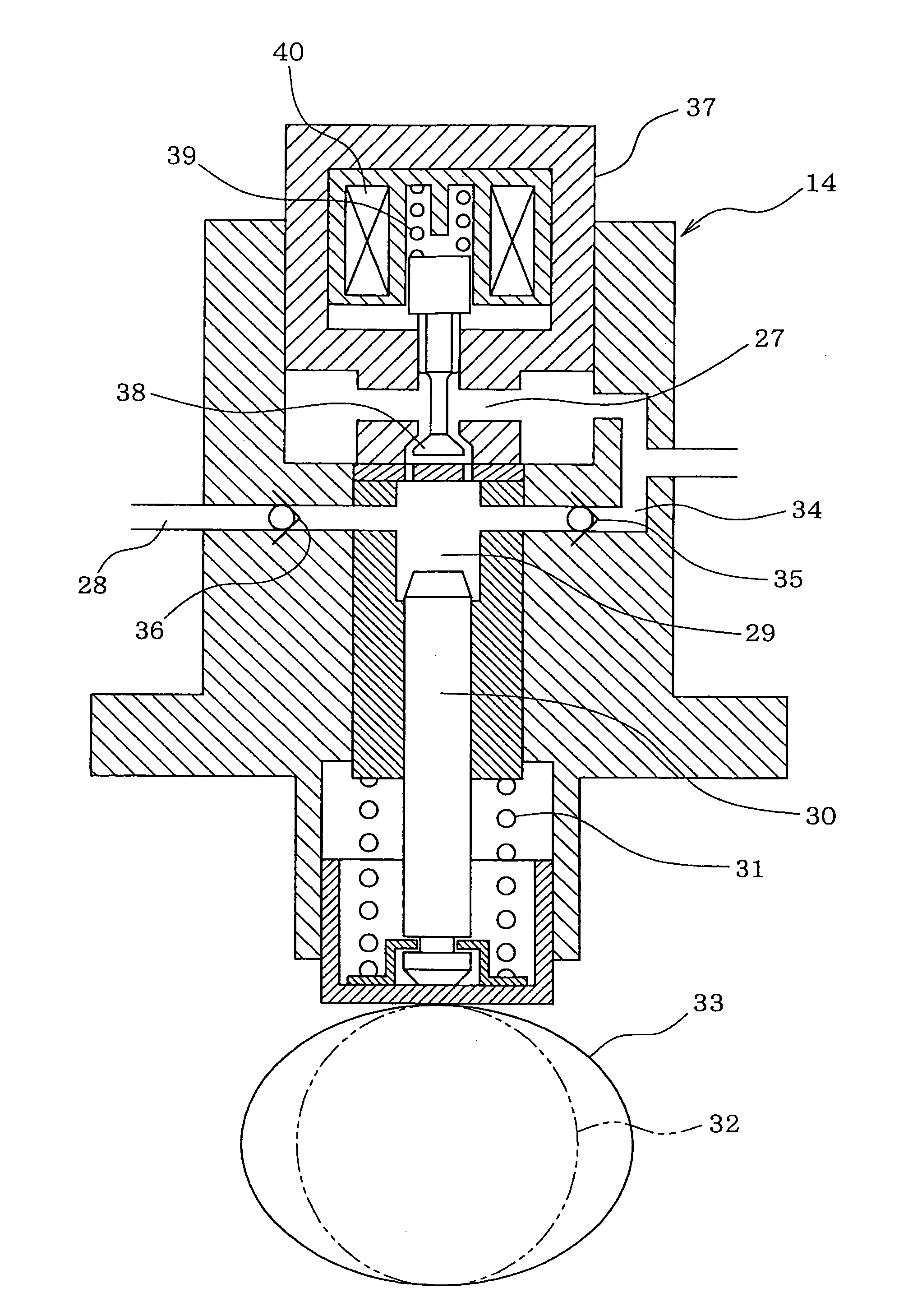

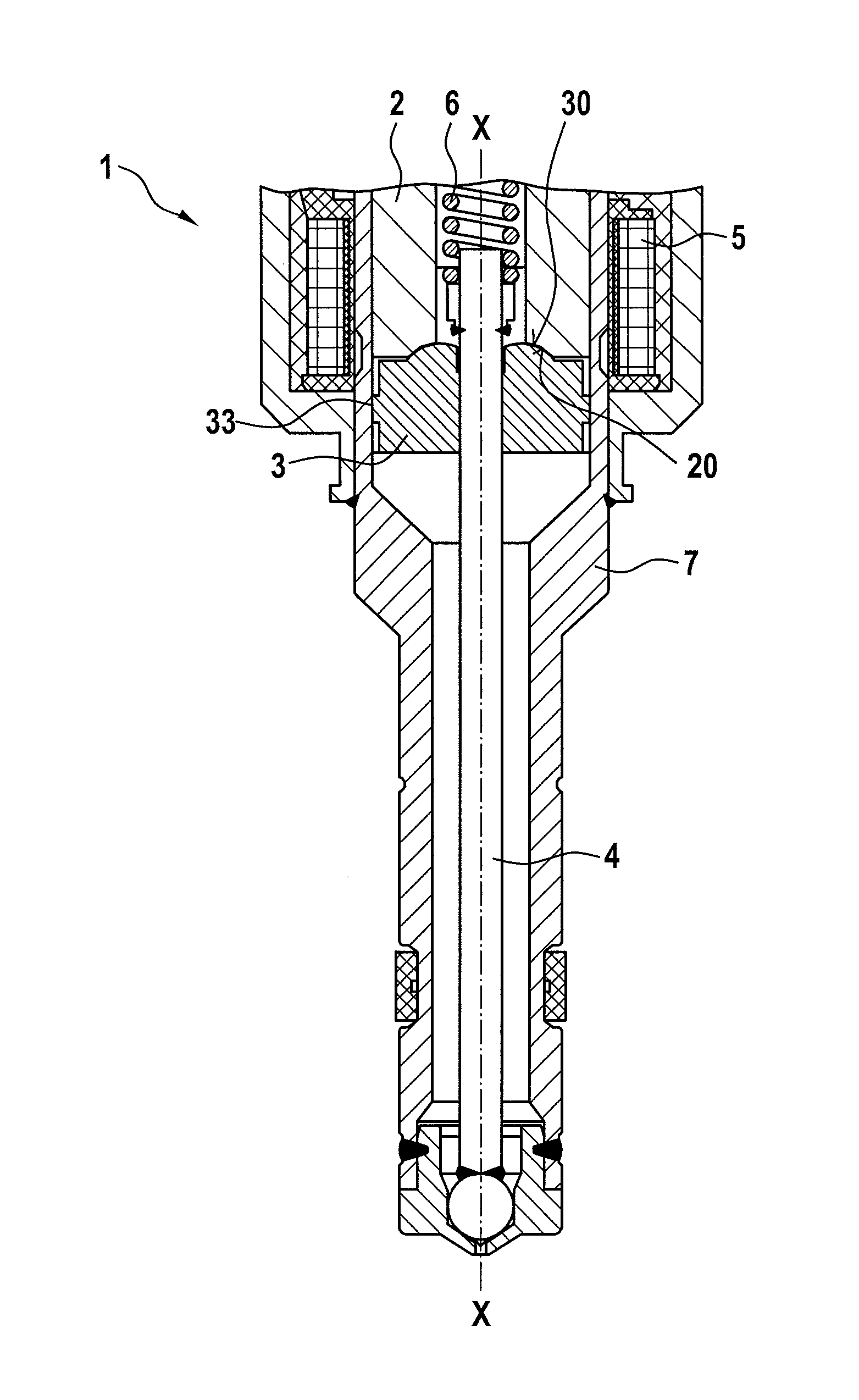

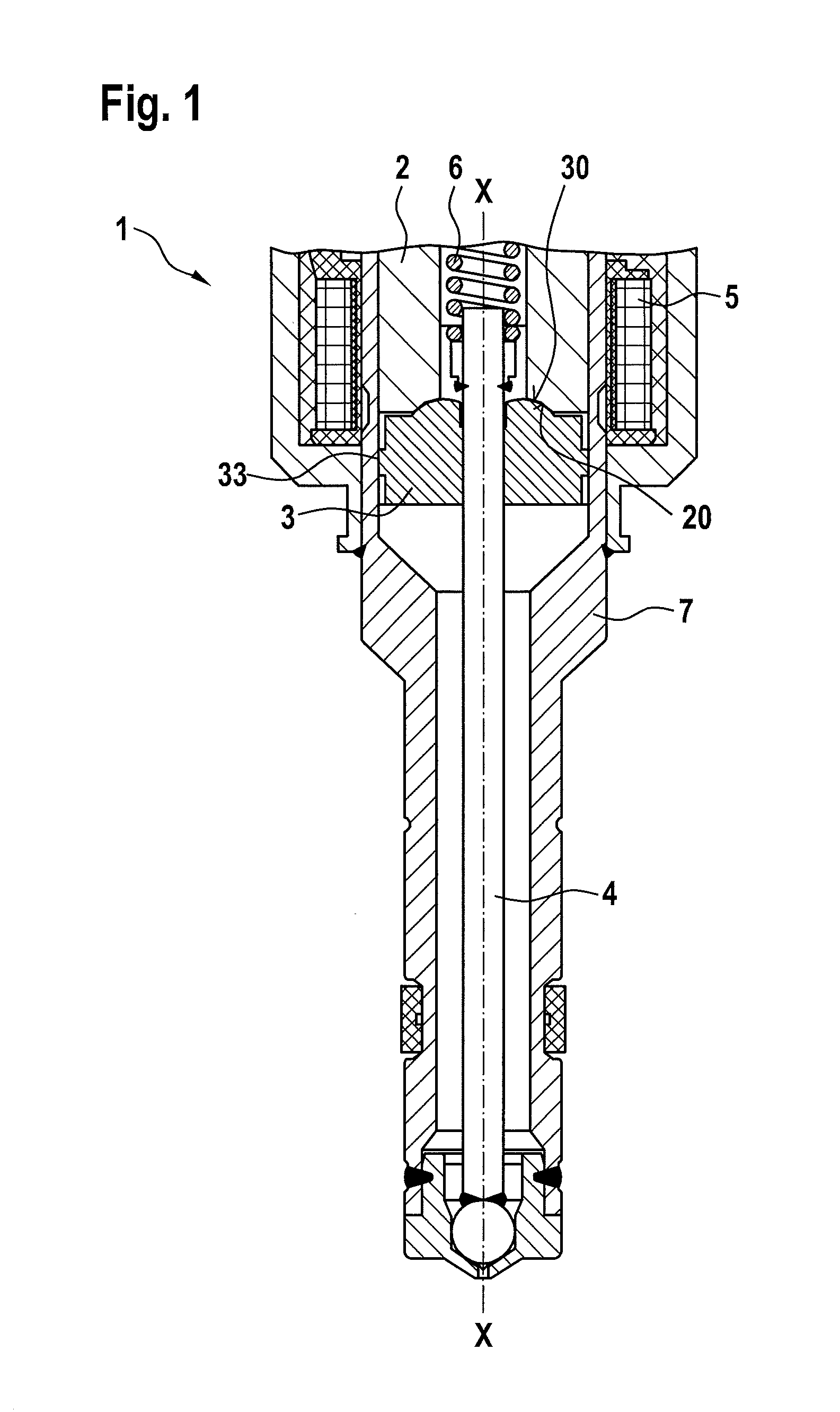

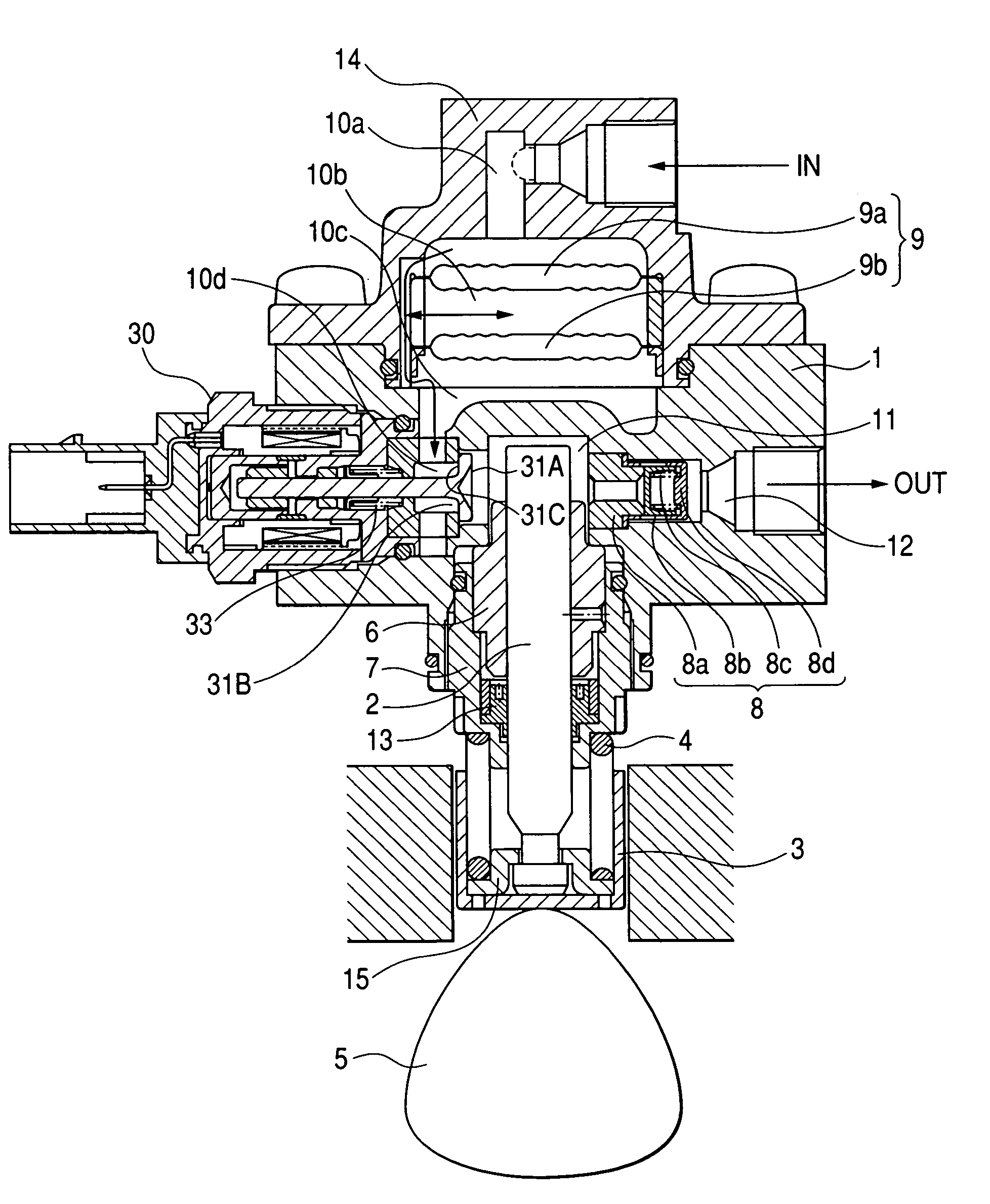

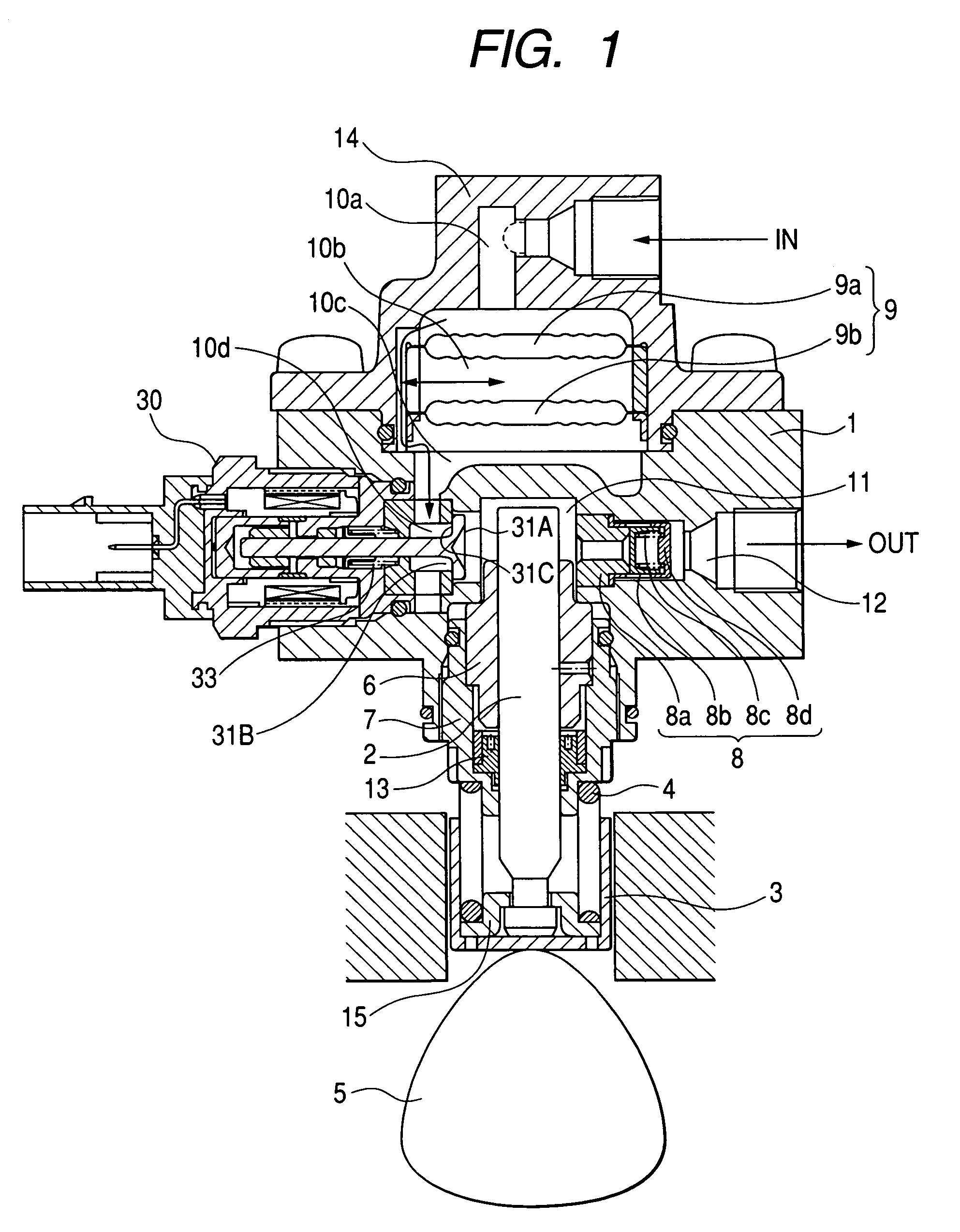

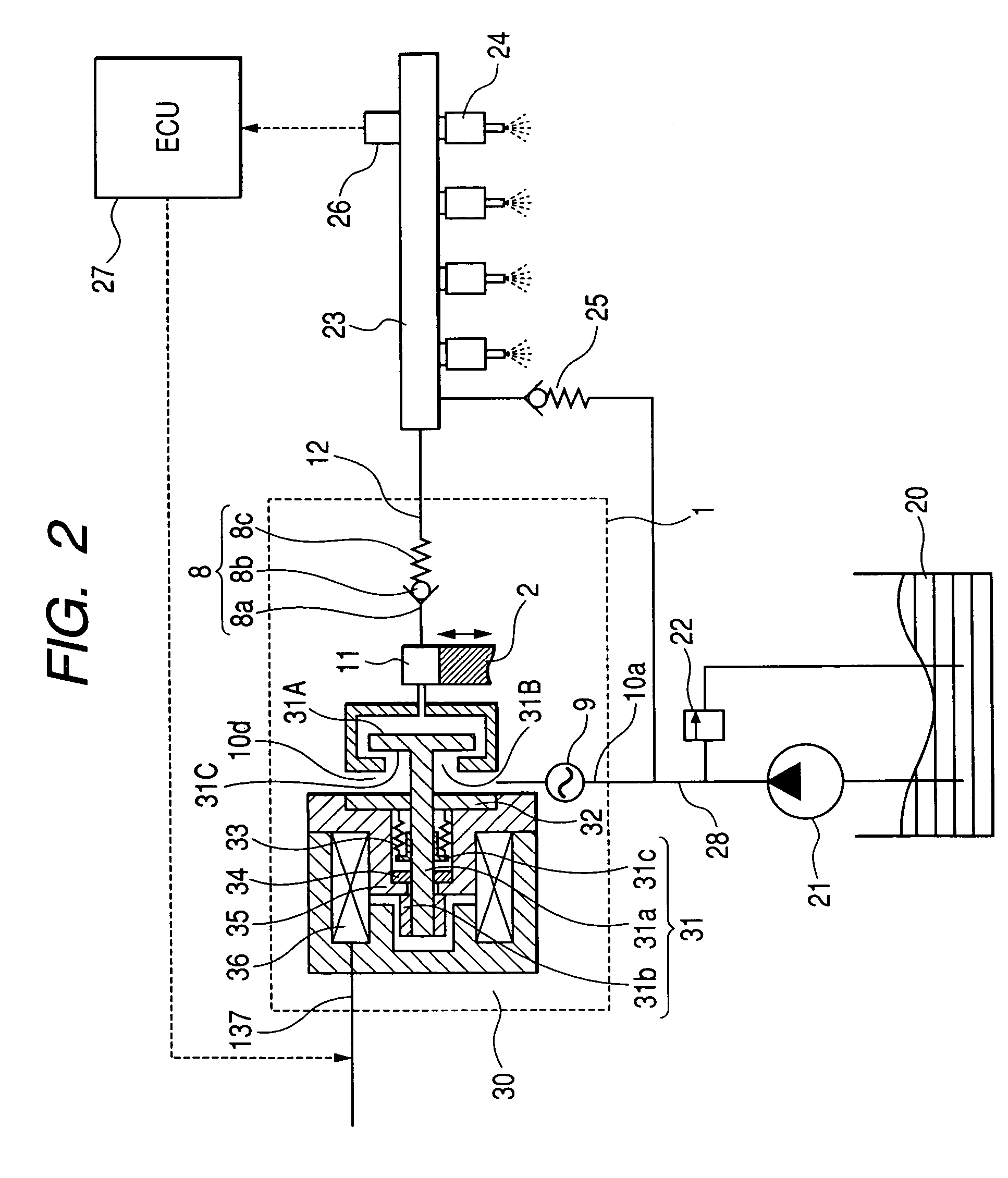

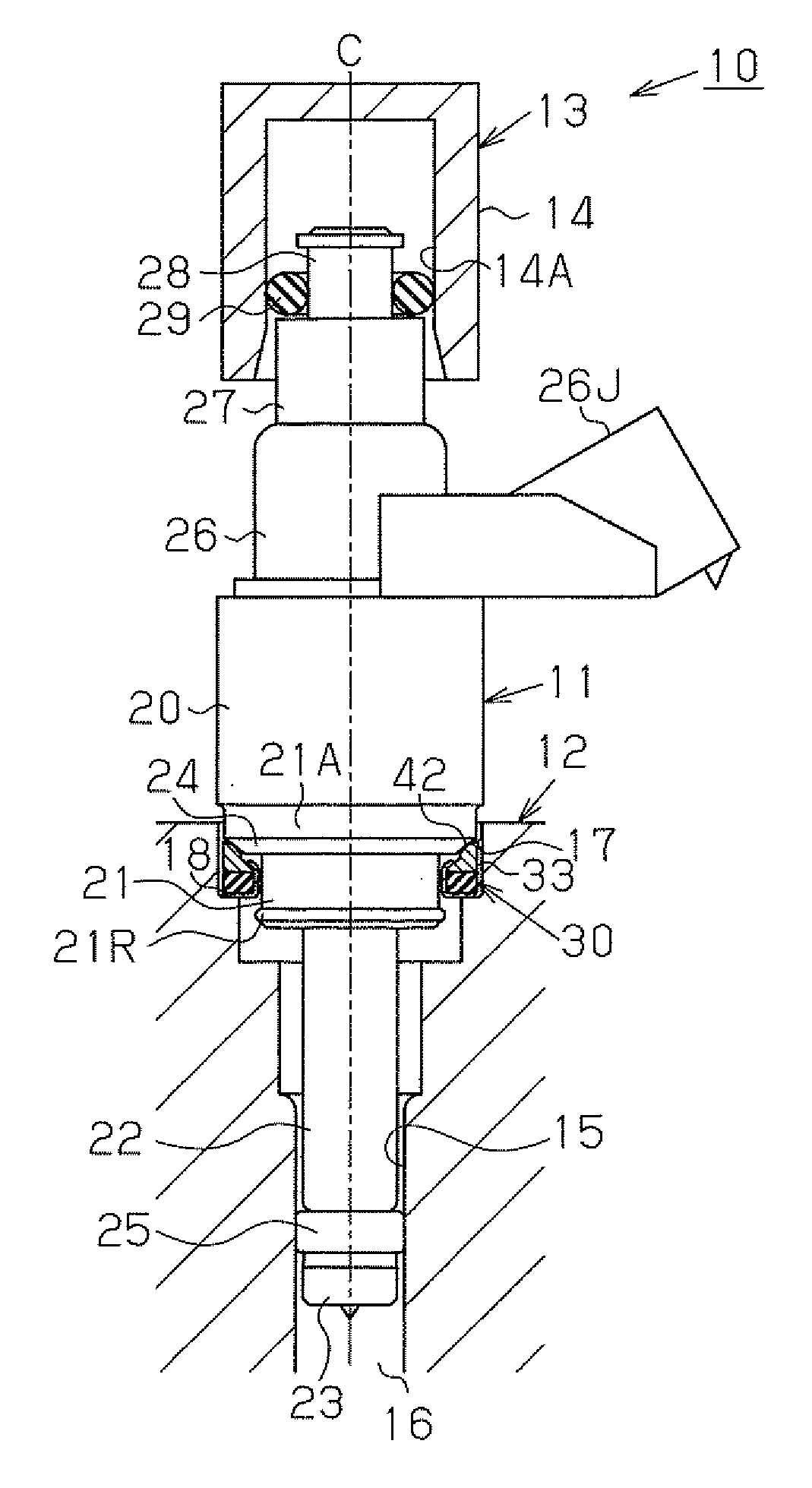

Electromagnetic drive mechanism and a high-pressure fuel supply pump

ActiveUS20060201485A1Reduce individual differencesReduce impactElectrical controlNoise reducing fuel injectionEngineeringHigh pressure

The objective of the present invention is to dampen operating sounds of an electromagnetic drive mechanism used for a variable displacement control mechanism in a high-pressure fuel supply pump to reduce an individual difference depending on apparatus due to the change over time or installation tolerance. To achieve the above objective, the present invention is configured such that before the electromagnetic drive mechanism supplies a drive force to a plunger which is electromagnetically driven by the electromagnetic drive mechanism, another displacement force situates the plunger in a specific position. When compared to an occasion where the plunger is displaced all strokes by a magnetic biasing force, the above configuration is able to reduce the force of impact on a member (for example, valve body) mounted to the plunger and a restricting member, thereby damping the collision noise. Furthermore, since an extra member, such as a damping member, is not required, individual difference depending on apparatus do not easily occur.

Owner:HITACHI ASTEMO LTD

Intermediate Element for a Fuel Injector

InactiveUS20090050113A1Reduce transmissionIncrease contactNoise reducing fuel injectionMachines/enginesCylinder headExternal combustion engine

An intermediate element for a fuel injector situated in a cylinder head of an internal combustion engine is disposed between a valve housing of the fuel injector and a wall of a receiving bore of the cylinder head, and / or between the valve housing and a clamping shoe holding the fuel injector down in the cylinder head. The intermediate element is made up of a plurality of layers having different patterning and / or being made of different materials.

Owner:ROBERT BOSCH GMBH

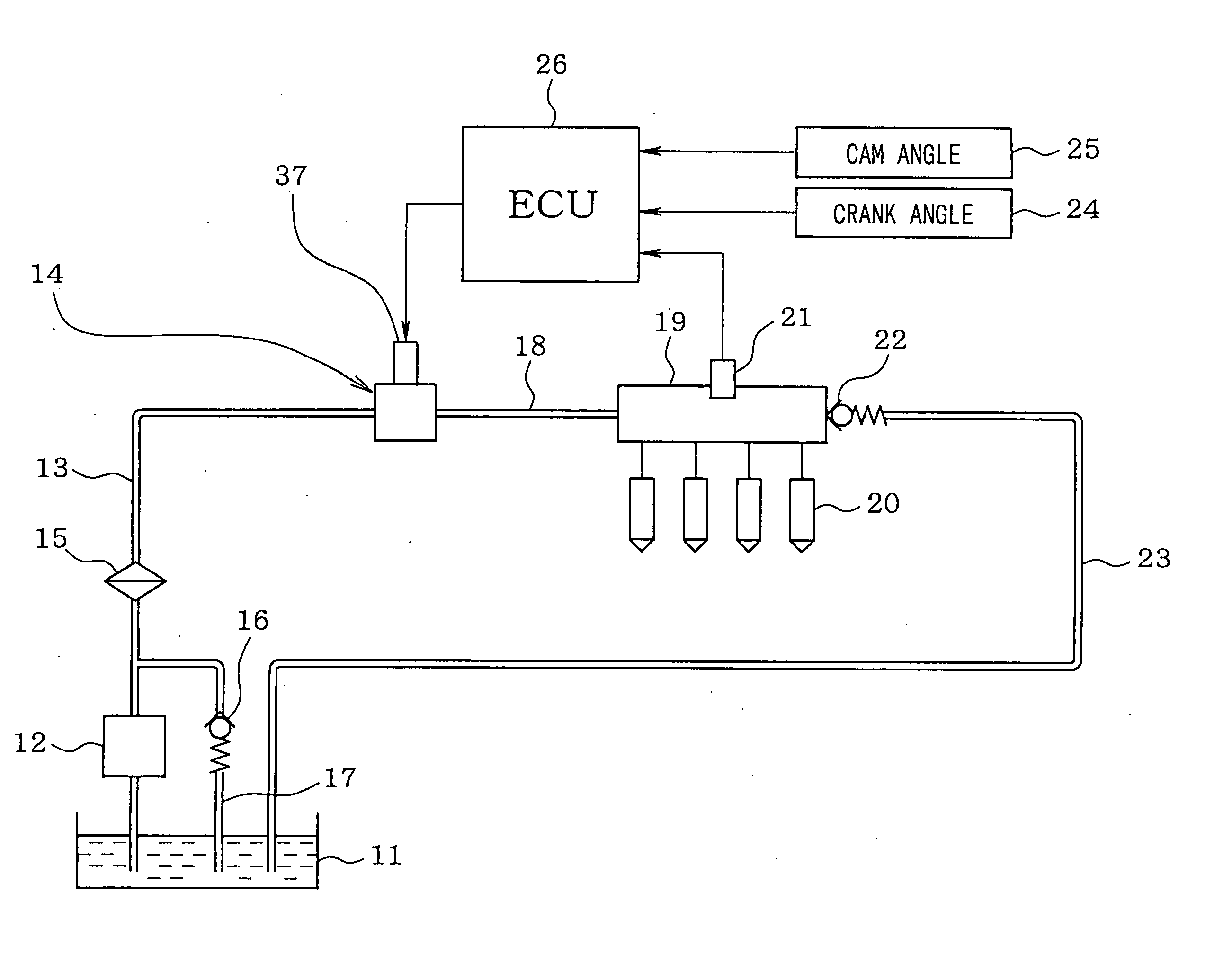

Fuel supply system of internal combustion engine

ActiveUS7198033B2Improve quietnessAccelerate emissionsElectrical controlNoise reducing fuel injectionSolenoid valveExternal combustion engine

A high-pressure pump is formed with a secondary suction passage, which branches from a fuel suction passage and communicates with a pump chamber. Check valves for preventing a backflow of fuel are disposed respectively in the secondary suction passage and a discharge passage. An electromagnetic valve for regulating a fuel discharge quantity is disposed in the fuel suction passage. Normal control for controlling the fuel discharge quantity by controlling opening timing and closing timing of the electromagnetic valve with respect to reciprocating movement of a plunger is performed when an engine rotation speed is higher than a predetermined value during operation of an engine. Valve closing control for holding the electromagnetic valve at a closed state is performed when the engine rotation speed is equal to or lower than the predetermined value.

Owner:DENSO CORP

Damping element for a fuel injection valve

InactiveUS7832376B2Solving the Insufficiency of ElasticityEasy to manufactureNoise reducing fuel injectionMachines/enginesCylinder headEngineering

Damping elements for a fuel injection valve insertable into a receiving conduit of a cylinder head of an internal combustion engine are disposed between a valve housing of the fuel injection valve and a wall of the receiving conduit of the cylinder head. These damping elements, inter alia, decrease acoustic transfer from the fuel injection valve to the cylinder head. It is disadvantageous that conventional damping elements require a great deal of axial installation space with respect to a valve axis and have comparatively high manufacturing costs. With the damping element according to example embodiments of the present invention, the installation space required is reduced. Provision is made, according to example embodiments of the present invention, for the damping element to be in plate-shaped fashion.

Owner:ROBERT BOSCH GMBH

Fuel injection system for internal combustion engine with injector isolator ring

InactiveUS7823565B2Easy to adjustNoise reducing fuel injectionMachines/enginesCylinder headEngineering

A fuel injection system for internal combustion engine includes an injector mounted within a pocket formed in the cylinder head, and an isolator which defines a radial clearance gap with the injector pocket. The isolator expands radially outwardly into a clearance gap in response to axially directed force imposed upon the isolator by the injector, so that a dual rate force / displacement effect is achieved by the isolator.

Owner:FORD GLOBAL TECH LLC

Controlling apparatus of variable capacity type fuel pump and fuel supply system

InactiveUS7559313B2Avoid synchronizationEliminate duplicationElectrical controlNoise reducing fuel injectionEngineeringFuel supply

Owner:HITACHI LTD

Electromagnetically actuatable valve

ActiveUS20140346382A1Reduce impactImprove wear characteristicsOperating means/releasing devices for valvesWear reducing fuel injectionContact lineElectrical and Electronics engineering

An electromagnetically actuatable valve is described, for controlling fluids, having an inner pole and a magnetic armature, the inner pole having a first end face oriented to the magnetic armature, and the magnetic armature having a second end face oriented to the inner pole, a first contact line and a second contact line being present between the first and second end face when the inner pole and the magnetic armature come into contact with one another, and a damping volume being present between the first and second contact line when the inner pole and the magnetic armature come into contact with one another.

Owner:ROBERT BOSCH GMBH

Controlling Apparatus of Variable Capacity Type Fuel Pump and Fuel Supply System

InactiveUS20090241908A1Avoid synchronizationEliminate duplicationElectrical controlNoise reducing fuel injectionFuel supplyFuel pump

A controlling apparatus of a variable capacity type fuel pump, for avoiding noises caused due to drive of the fuel pump and noises caused due to drive of injectors from overlapping or duplicating with each other in the timing thereof, wherein signals for driving the pump reduced, or the timing thereof is shifted forward / backward, within a specific timing where the o overlapping can be prospected, or a specific timing where they are determined to overlap or duplicate with each other.

Owner:HITACHI LTD

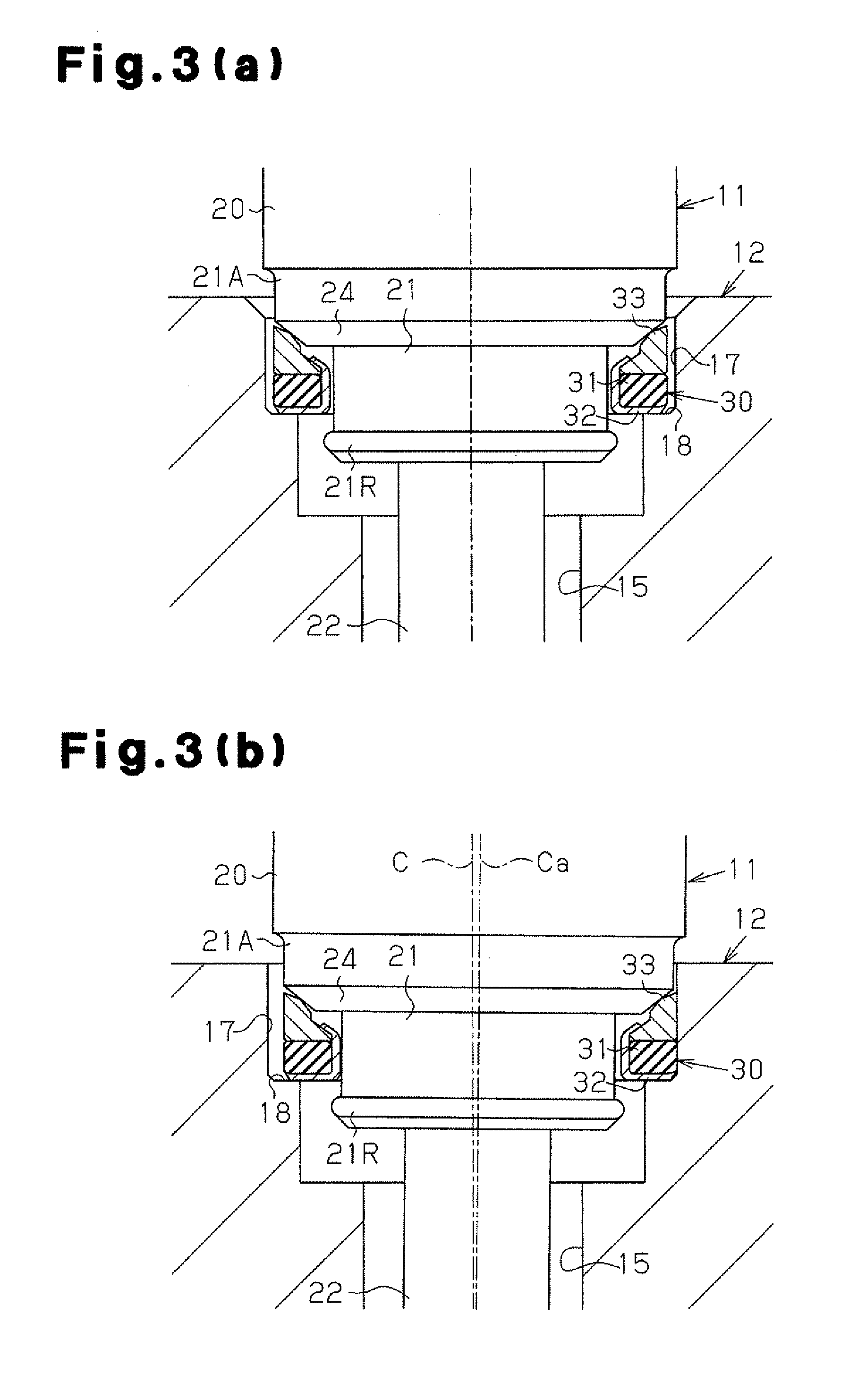

Isolater for fuel injector

InactiveUS20110265767A1Sufficient compressibilitySufficient resilienceNoise reducing fuel injectionMachines/enginesThermal isolationInjector

A fuel injector-engine component assembly includes an engine component with a stepped bore defined along an axis and having a stepped bore stop surface facing axially upward. A fuel injector extending along the axis is disposed in the stepped bore and includes a fuel injector stop surface facing axially downward and axially opposing the stepped bore stop surface. An isolation ring is disposed between the engine component and fuel injector stop surfaces for axially isolating the fuel injector from the engine component. The isolation ring includes a rigid support member for limiting the axial motion of the engine component and fuel injector stop surfaces together. The isolation ring also includes a resilient and compliant isolation member located axially between the engine component and fuel injector stop surfaces to provide acoustic and thermal isolation between the fuel injector and the engine component below a predetermined pressure of the fuel injector.

Owner:DELPHI TECH INC

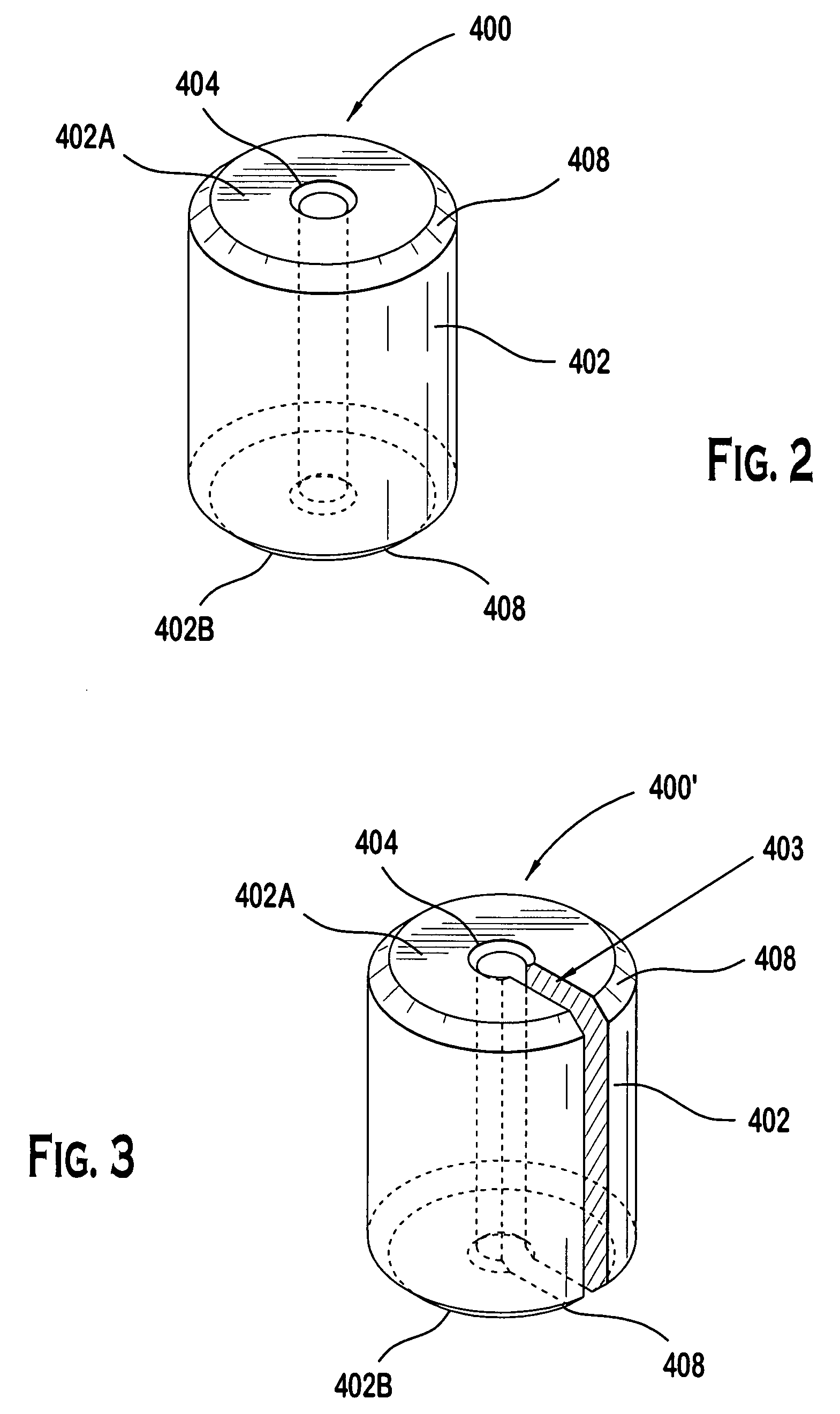

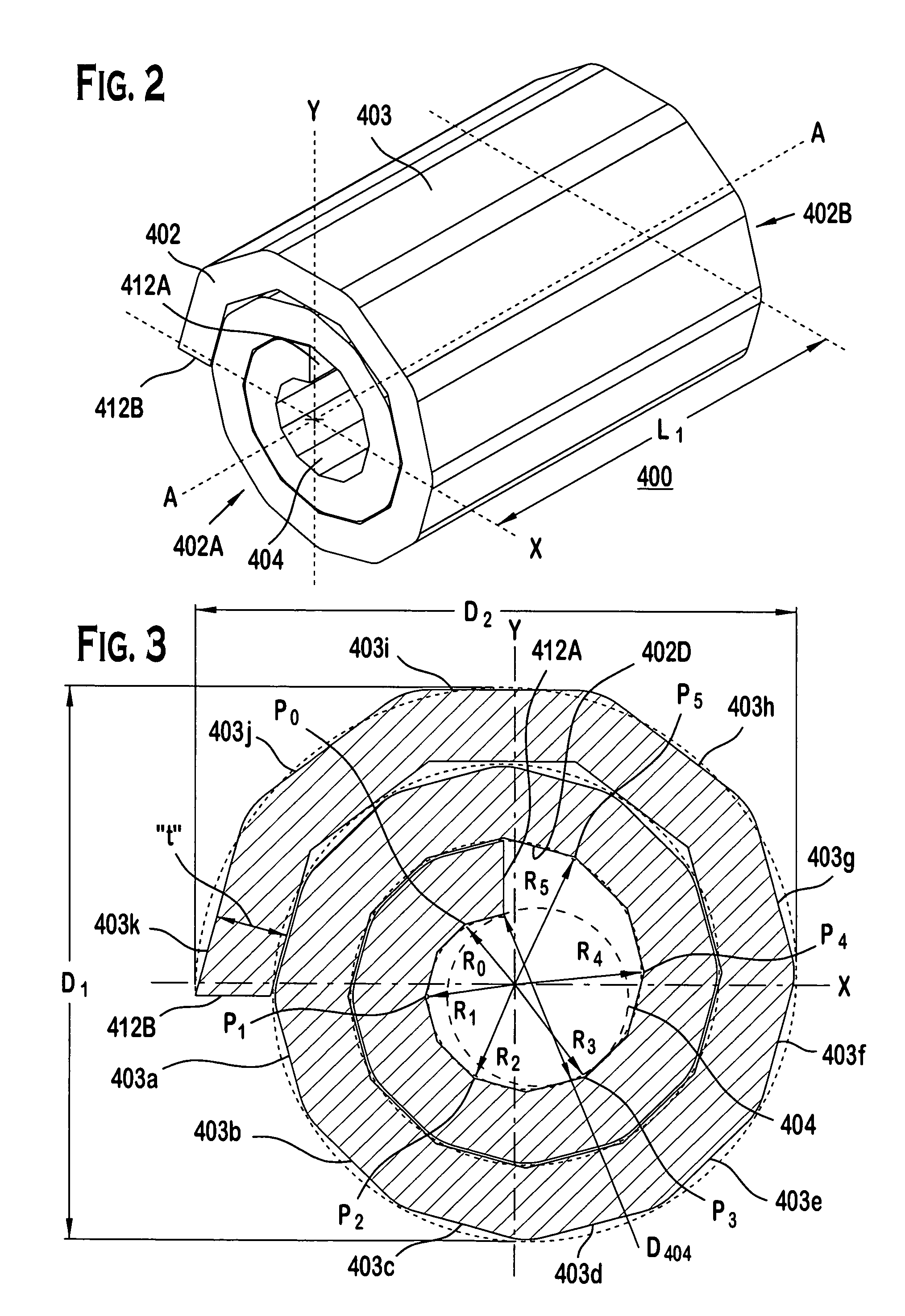

Modular fuel injector with a damper member and method of reducing noise

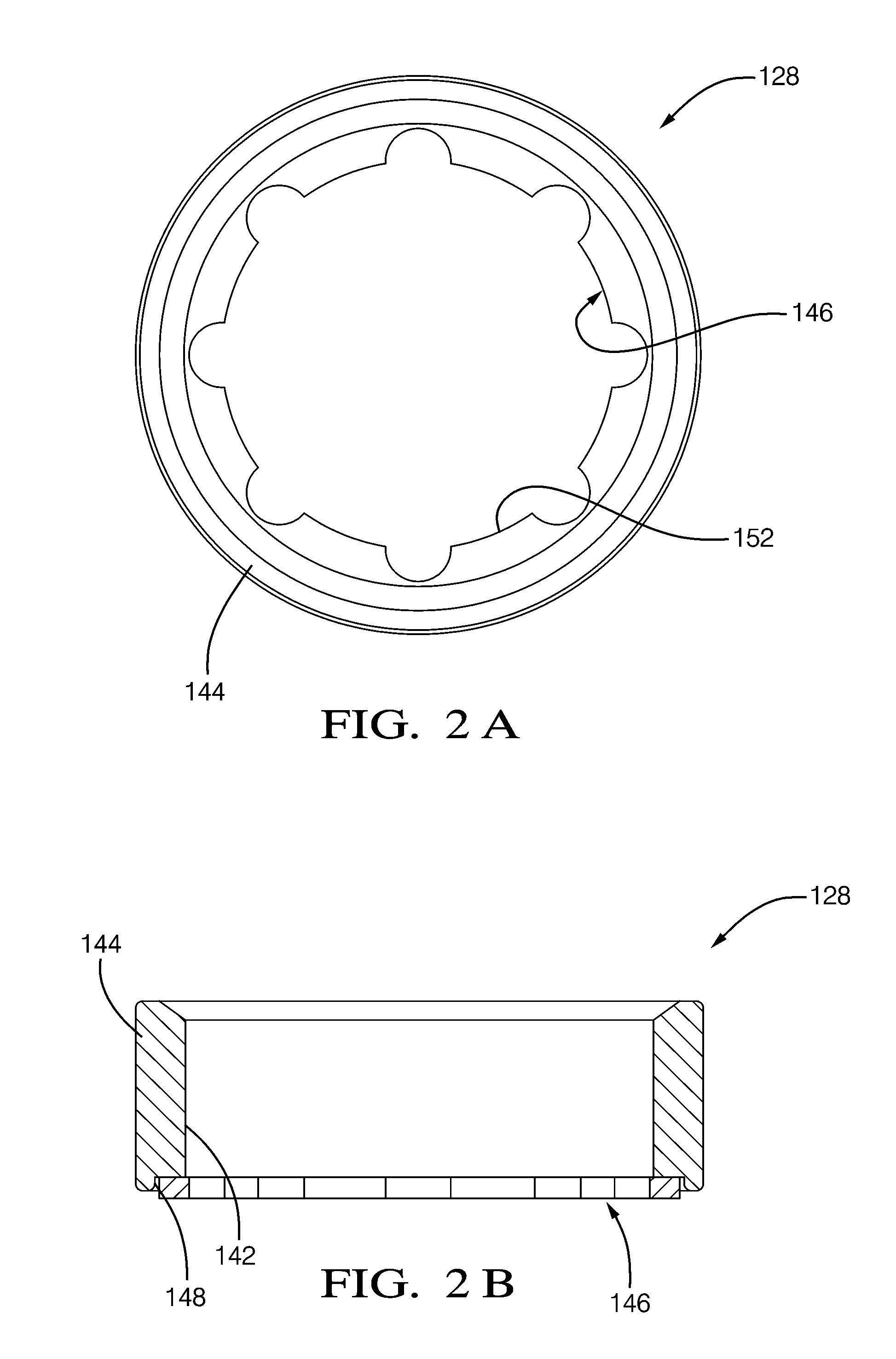

InactiveUS7128281B2Reduce the amplitudeMaintaining operational noiseNoise reducing fuel injectionSpray nozzlesEngineeringShock absorber

A fuel injector includes a body, filter, and damper member. The body extends along a longitudinal axis between an inlet end and an outlet end and has a wall defining a flow passage extending therebetween. The filter is disposed in the flow passage proximate the inlet end. The damper member is secured to the flow passage between the inlet end and the filter. The damper member has outer and inner surfaces surrounding the longitudinal axis, the outer surface being contiguous to the wall of the flow passage to define at least one circumferential band about the longitudinal axis in the flow passage. The inner surface defines an aperture that extends through the damper member to permit fluid communication between the inlet end and the filter. A damper member is also shown and described. A method of reducing sound in the valve group subassembly is also disclosed.

Owner:SIEMENS VDO AUTOMOTIVE CORP

Modular fuel injector with a damper member and method of reducing noise

InactiveUS20050269427A1Reduce the amplitudeMaintaining operational noiseNoise reducing fuel injectionSpray nozzlesEngineeringInjector

A fuel injector includes a body, filter, and damper member. The body extends along a longitudinal axis between an inlet end and an outlet end and has a wall defining a flow passage extending therebetween. The filter is disposed in the flow passage proximate the inlet end. The damper member is secured to the flow passage between the inlet end and the filter. The damper member has outer and inner surfaces surrounding the longitudinal axis, the outer surface being contiguous to the wall of the flow passage to define at least one circumferential band about the longitudinal axis in the flow passage. The inner surface defines an aperture that extends through the damper member to permit fluid communication between the inlet end and the filter. A damper member is also shown and described. A method of reducing sound in the valve group subassembly is also disclosed.

Owner:SIEMENS VDO AUTOMOTIVE CORP

Electromagnetic drive mechanism and a high-pressure fuel supply pump

ActiveUS7398768B2Reduce individual differencesReduce impactElectrical controlNoise reducing fuel injectionEngineeringHigh pressure

The objective of the present invention is to dampen operating sounds of an electromagnetic drive mechanism used for a variable displacement control mechanism in a high-pressure fuel supply pump to reduce an individual difference depending on apparatus due to the change over time or installation tolerance.To achieve the above objective, the present invention is configured such that before the electromagnetic drive mechanism supplies a drive force to a plunger which is electromagnetically driven by the electromagnetic drive mechanism, another displacement force situates the plunger in a specific position. When compared to an occasion where the plunger is displaced all strokes by a magnetic biasing force, the above configuration is able to reduce the force of impact on a member (for example, valve body) mounted to the plunger and a restricting member, thereby damping the collision noise. Furthermore, since an extra member, such as a damping member, is not required, individual difference depending on apparatus do not easily occur.

Owner:HITACHI ASTEMO LTD

Direct injection fuel pump system

InactiveUS20160208757A1Improve engine performanceWell mixedWear reducing fuel injectionPositive displacement pump componentsEngineeringHigh pressure

Systems and methods are provided for operating a direct injection fuel pump. One example system comprises an accumulator positioned within a bore of the direct injection fuel pump in a coaxial manner wherein the accumulator is positioned downstream from a solenoid activated check valve. The accumulator may regulate pressure in a compression chamber of the direct injection fuel pump and a high pressure fuel rail when the direct injection fuel pump is operating in a default pressure mode.

Owner:FORD GLOBAL TECH LLC

Modular fuel injector with a spiral damper member and method of reducing noise

InactiveUS7258287B2Reduce the amplitudeMaintaining operational noiseEngine testingNoise reducing fuel injectionInjector

A fuel injector includes a body, filter, and damper member. The body extends along a longitudinal axis between an inlet end and an outlet end with a flow passage extending therebetween. The filter is disposed in the flow passage proximate the inlet end. The damper member extends from a first terminus to a second terminus. The first terminus is proximal to the longitudinal axis, and the second terminus is distal to the longitudinal axis. The damper member extends from the first terminus about the longitudinal axis towards the second terminus in a generally circular path to define an aperture that permits fluid communication between inlet end and the filter. The damper member is secured to the flow passage between the inlet end and the filter. A damper member is also shown and described. A method of reducing sound in the valve group subassembly is also disclosed.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Fuel injection system having a fuel-conducting component, a fuel injection valve and a connection element

ActiveUS20160025053A1Smooth connectionReduce noiseSleeve/socket jointsEngine sealsEngineeringFuel injection

A connecting element connecting a fuel injection valve to a fuel-conducting component includes: a main body having a receptacle space into which a fuel connector of the fuel injection valve is introduced; and a fastening element. At least one opening is provided in a wall of the main body surrounding the receptacle space. The fastening element for fastening the fuel connector on the main body is brought into the receptacle space at least partly through the at least one opening. At least one elastic bearing element is provided, and the fastening element brought at least partly through the opening into the receptacle space is supported on the wall of the main body via the at least one elastic bearing element.

Owner:ROBERT BOSCH GMBH

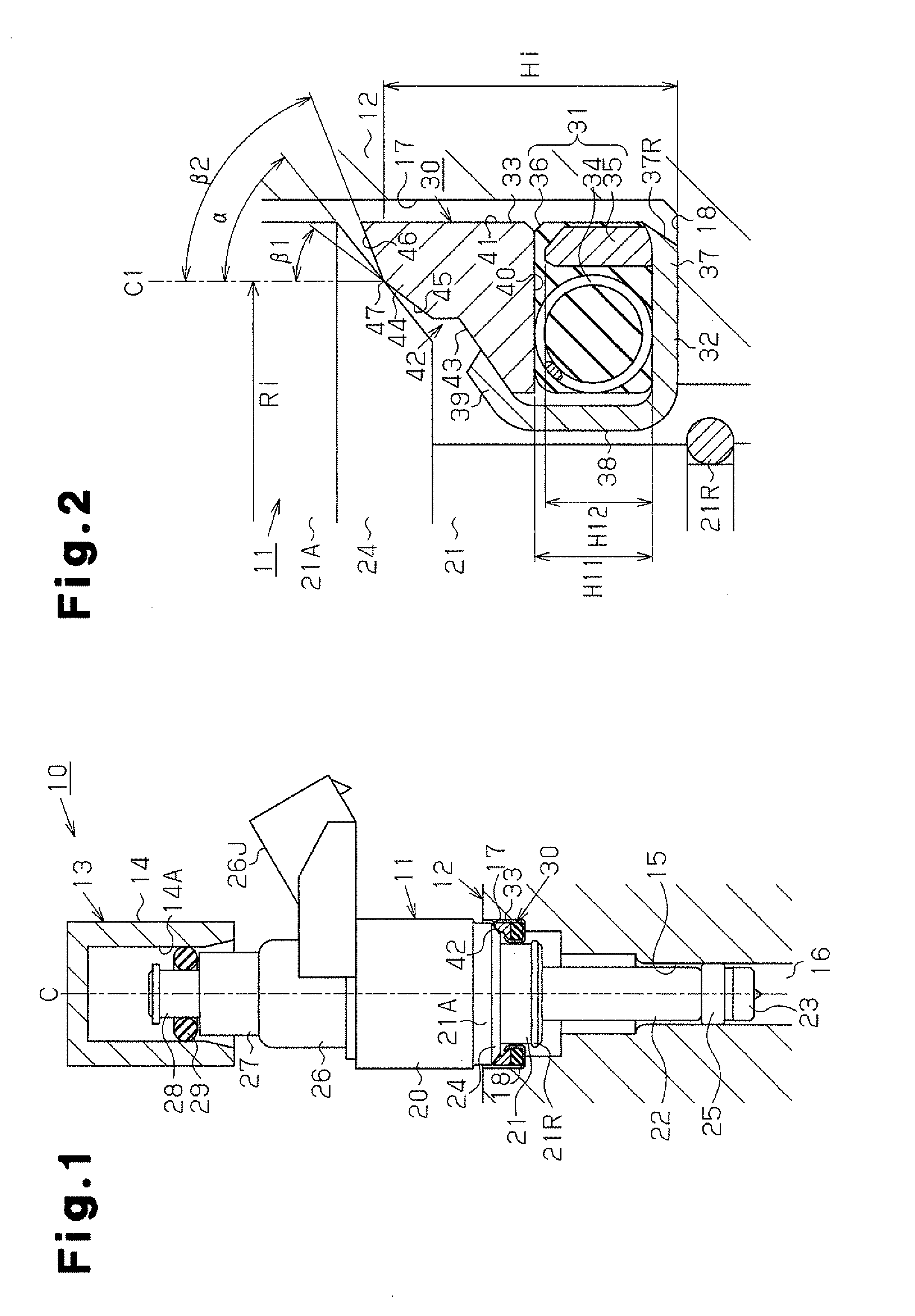

Vibration insulator for fuel injection valve, and support structure for fuel injection valve

ActiveUS20130014719A1Reduced tightnessIncrease frictionNoise reducing fuel injectionMachines/enginesCombustionCylinder head

A vibration insulator which can compensate for axial eccentricity occurring in a fuel injection valve and suppress vibrations of the valve during operation of a combustion engine and a support structure for the valve. The vibration insulator is interposed between a step height portion of the valve and a shoulder portion. The step height portion is increased in diameter in a tapered fashion and inserted into an insertion hole of a cylinder head. The shoulder portion is annularly extended in an inlet portion of the insertion hole opposed to the step height portion. The vibration insulator includes an annular tolerance ring on an inner circumferential inclined face thereof with recessed tapered faces opposed to the tapered face of the step height portion and which abuts the tapered face. The taper angles of the tolerance ring and of the step height portion are set so as to be different.

Owner:TOYOTA JIDOSHA KK +1

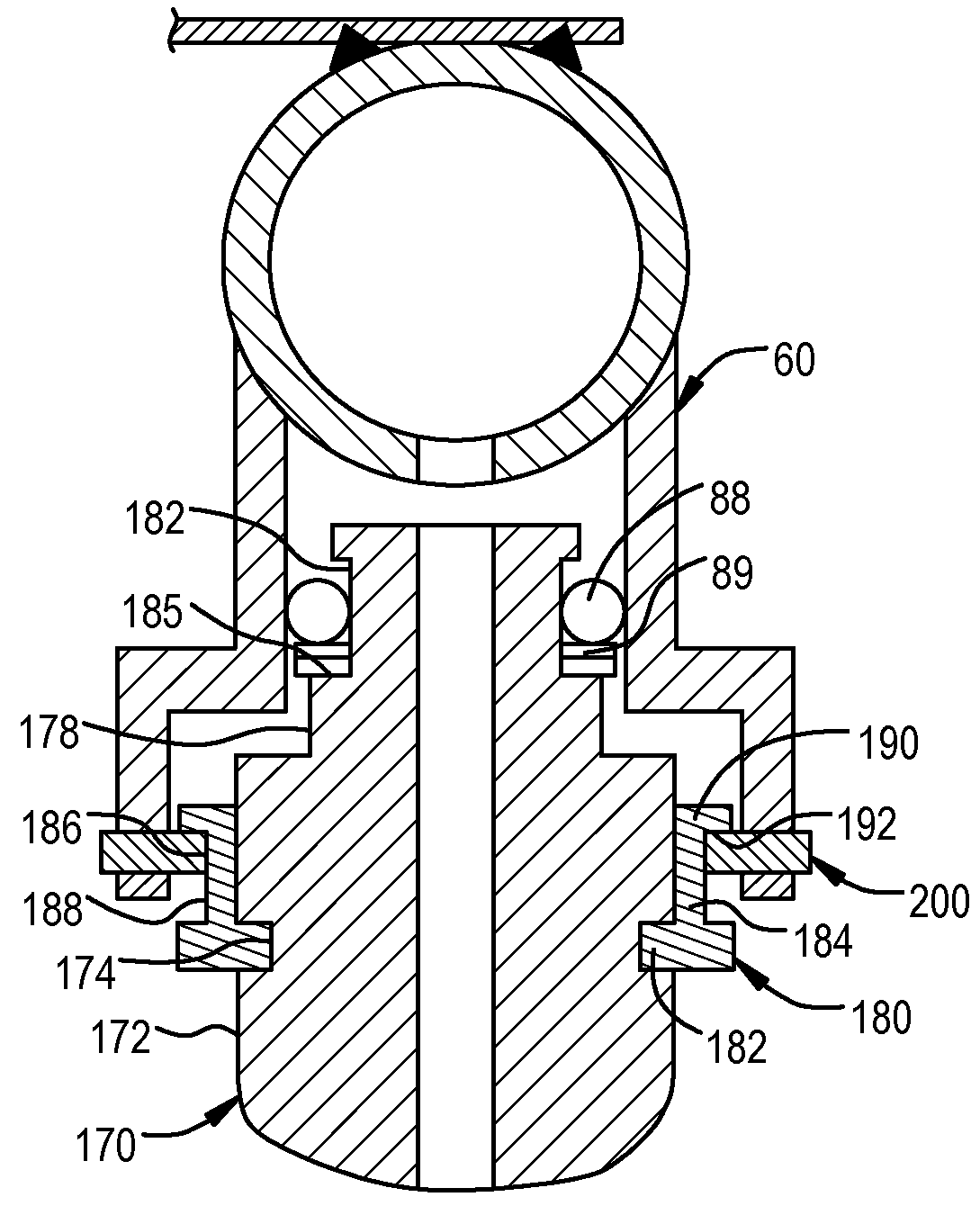

Fuel injector mount

A direct fuel injection fuel system includes a fuel rail cap and a fuel injector received within the fuel rail cap. A clip extends through slots in the fuel rail cap and engages the fuel rail to support the fuel rail within the fuel rail cap. The fuel rail cap includes a groove adjoining the slots to accept a portion of the clip. The clip engages a shoulder on the fuel injector assembly. The shoulder may be on the injector body or on an adapter secured to the injector body.

Owner:FORD GLOBAL TECH LLC

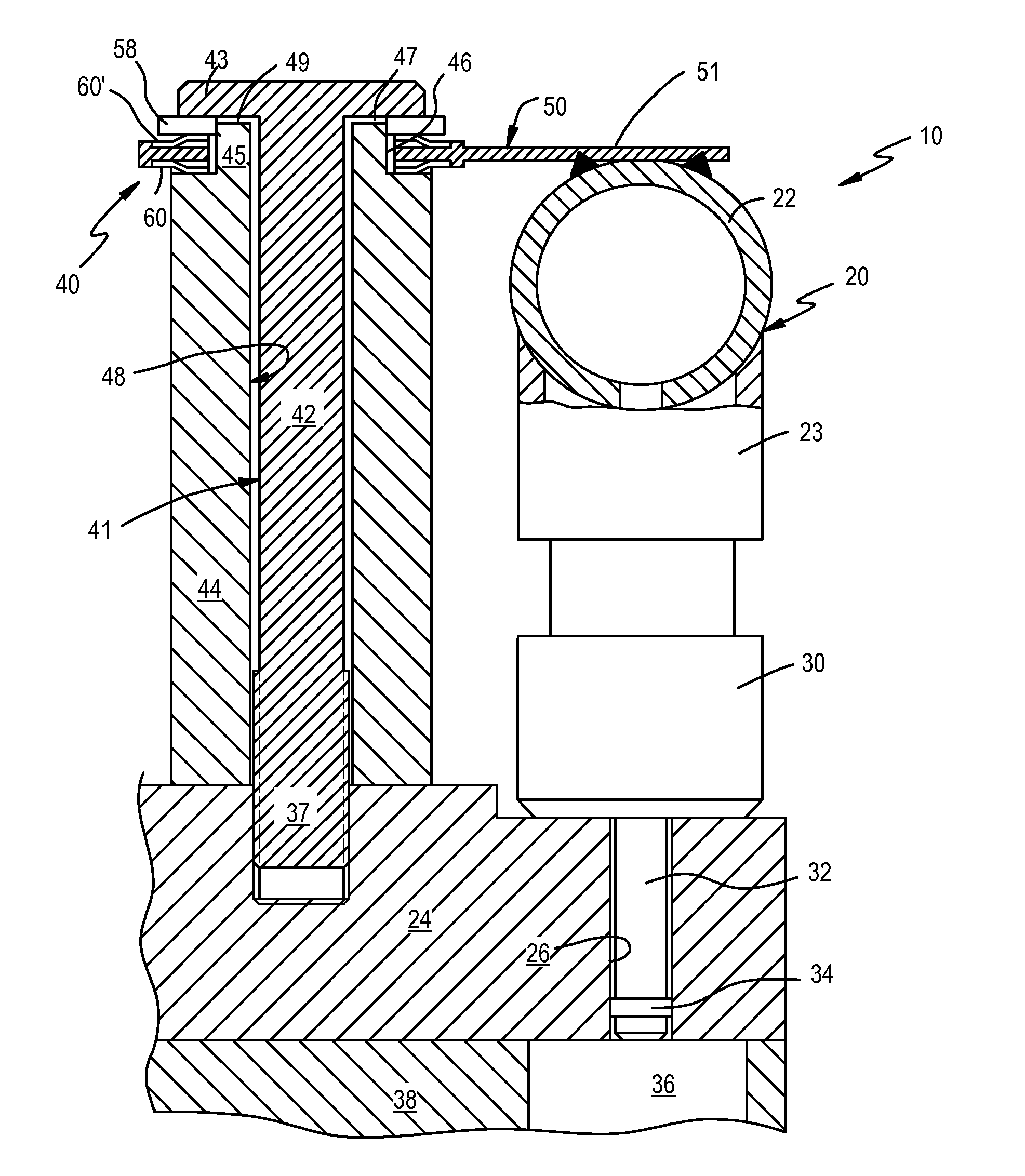

Fuel rail mount

ActiveUS8844502B2Reduce vibrationPrecise positioningBelleville-type springsWashersCylinder headEngineering

An internal combustion engine direct injection fuel injector system includes a fuel rail which is welded to a fuel rail bracket. A fuel rail mounting sleeve has a flange and is bolted to the engine cylinder head. The bracket fits around the flange and is held in place by a steel washer and a pair of stepped isolator washers which are positioned in pockets formed on either side of the bracket. The isolator washers serve as springs which form a shock absorber between the bracket and cylinder head. Compression forces on the bracket and isolator washers are controlled by bolt tension.

Owner:FORD GLOBAL TECH LLC

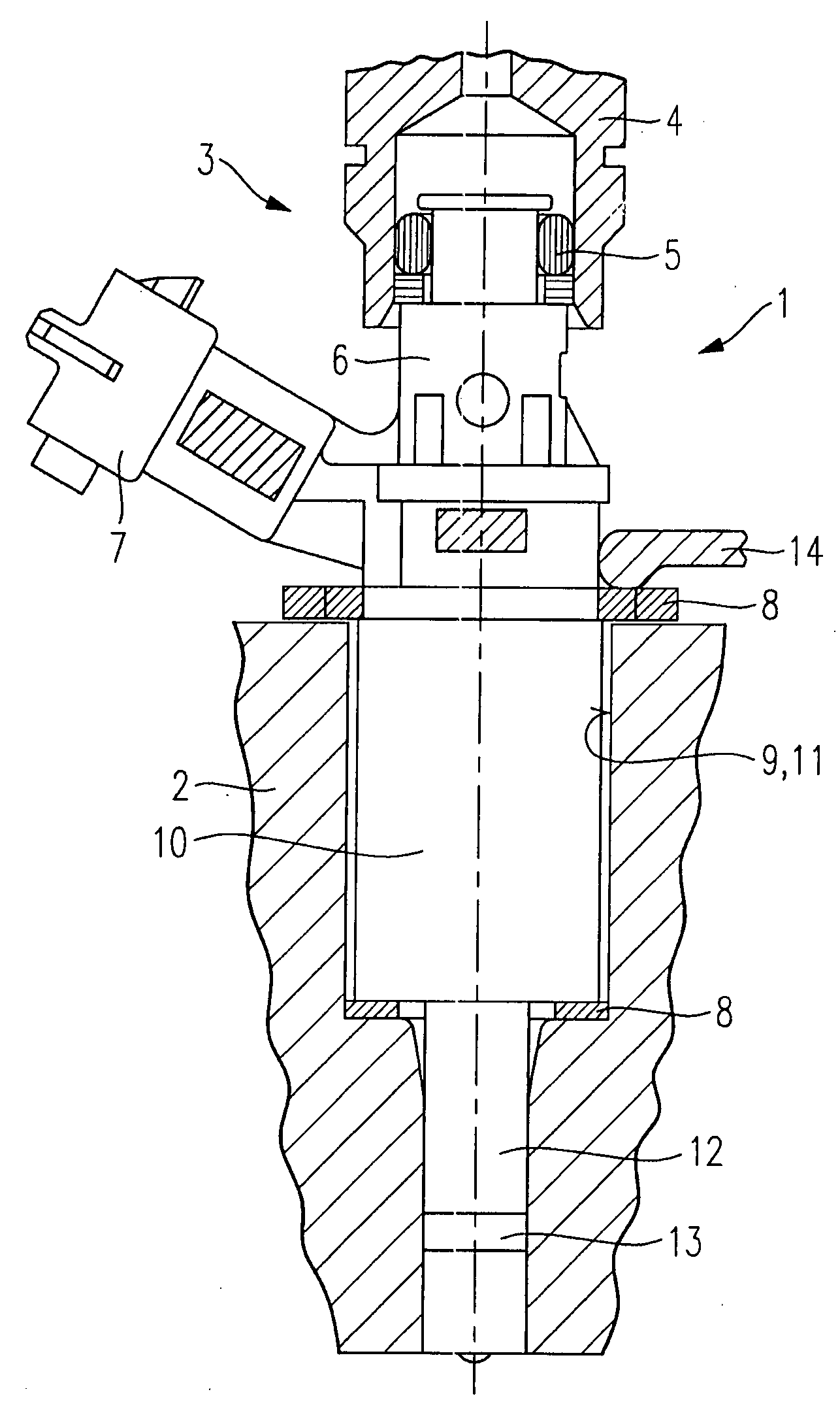

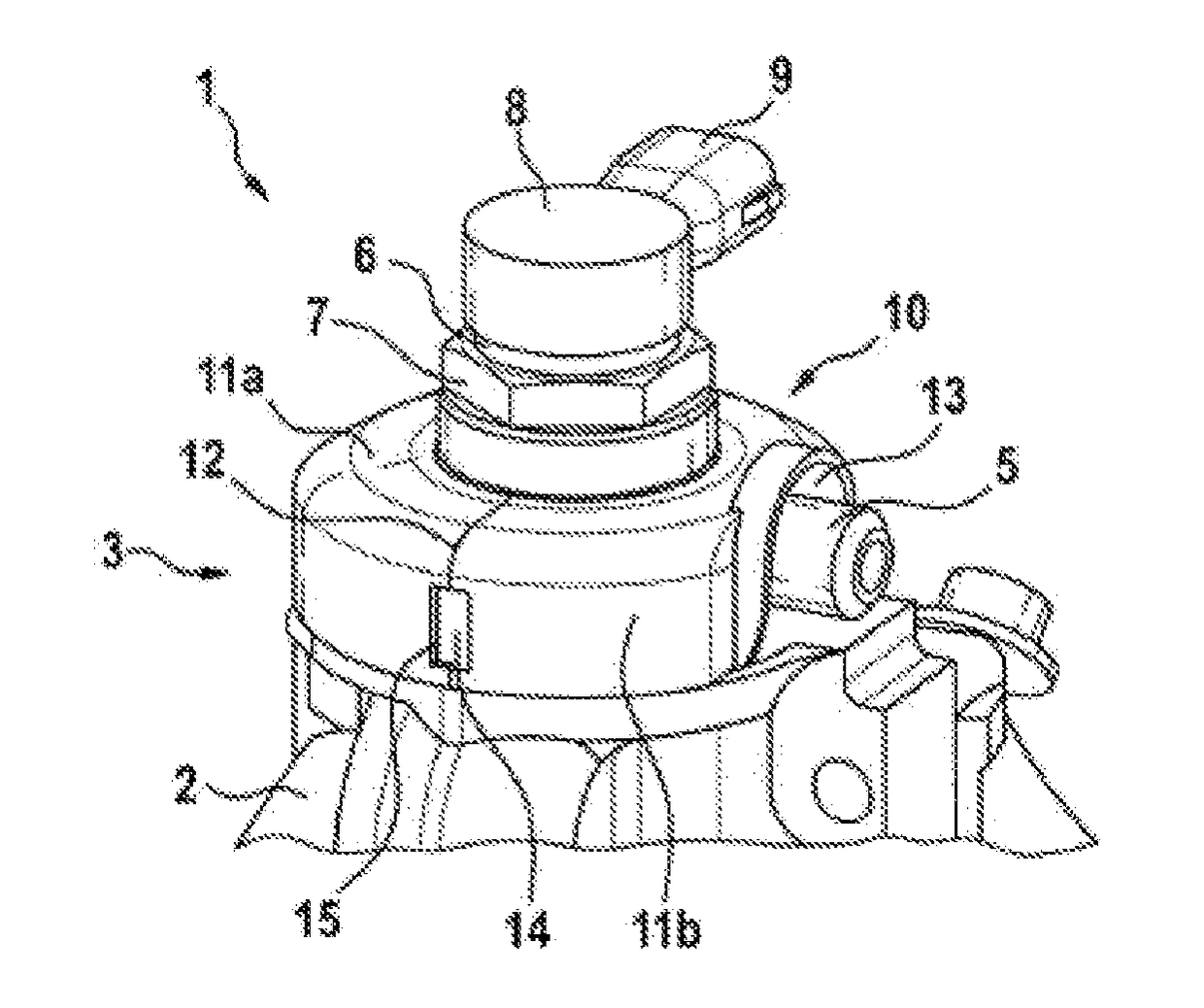

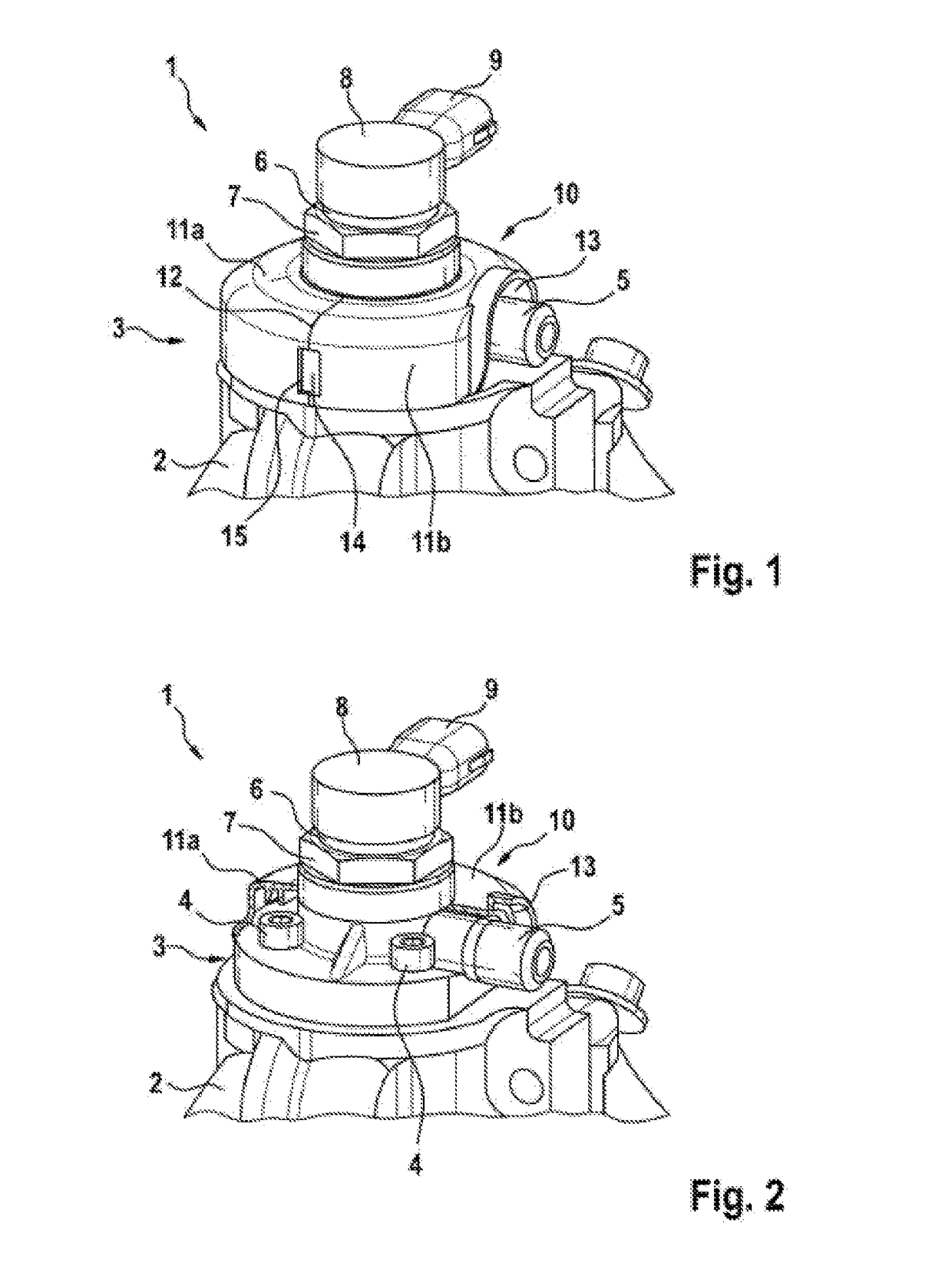

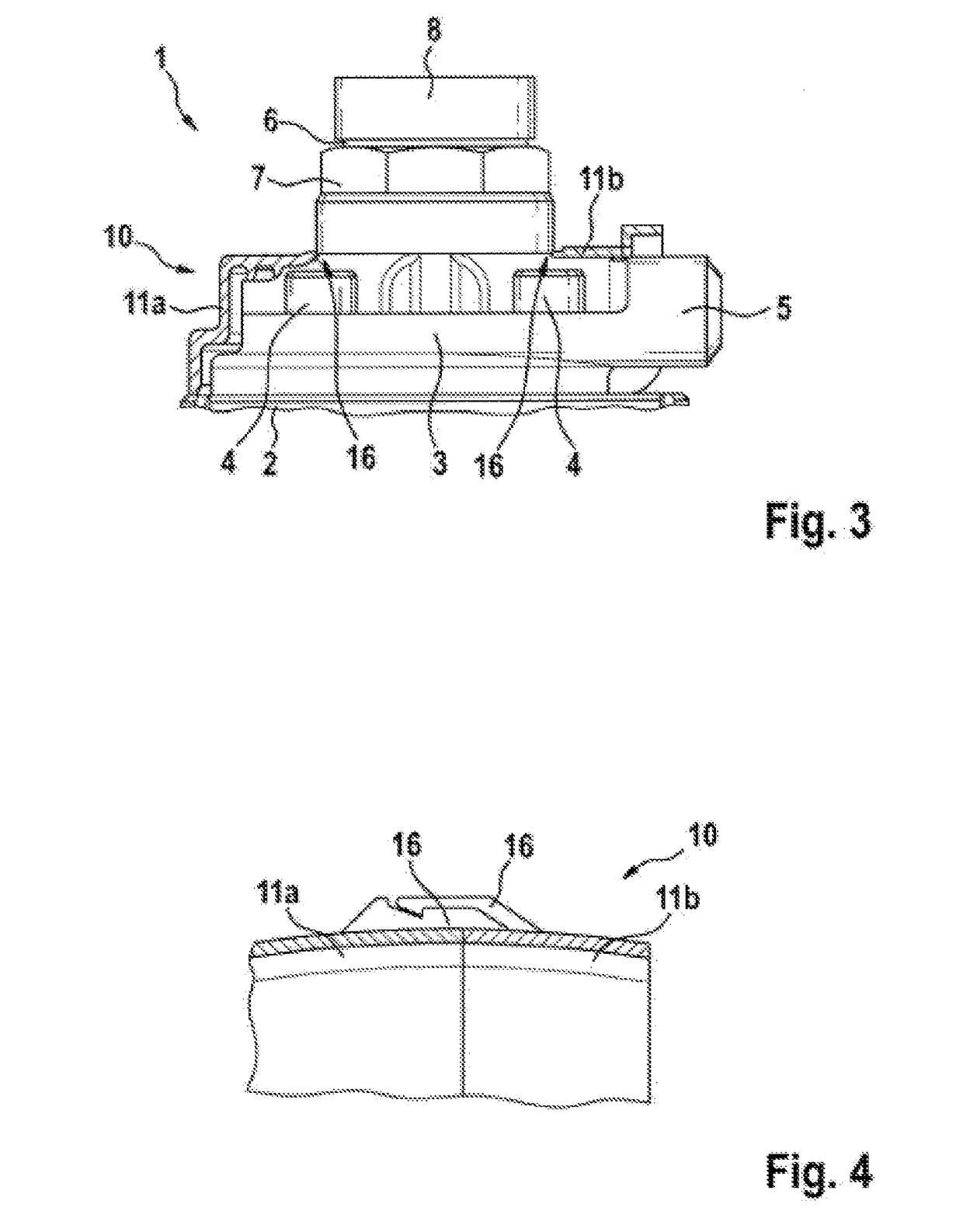

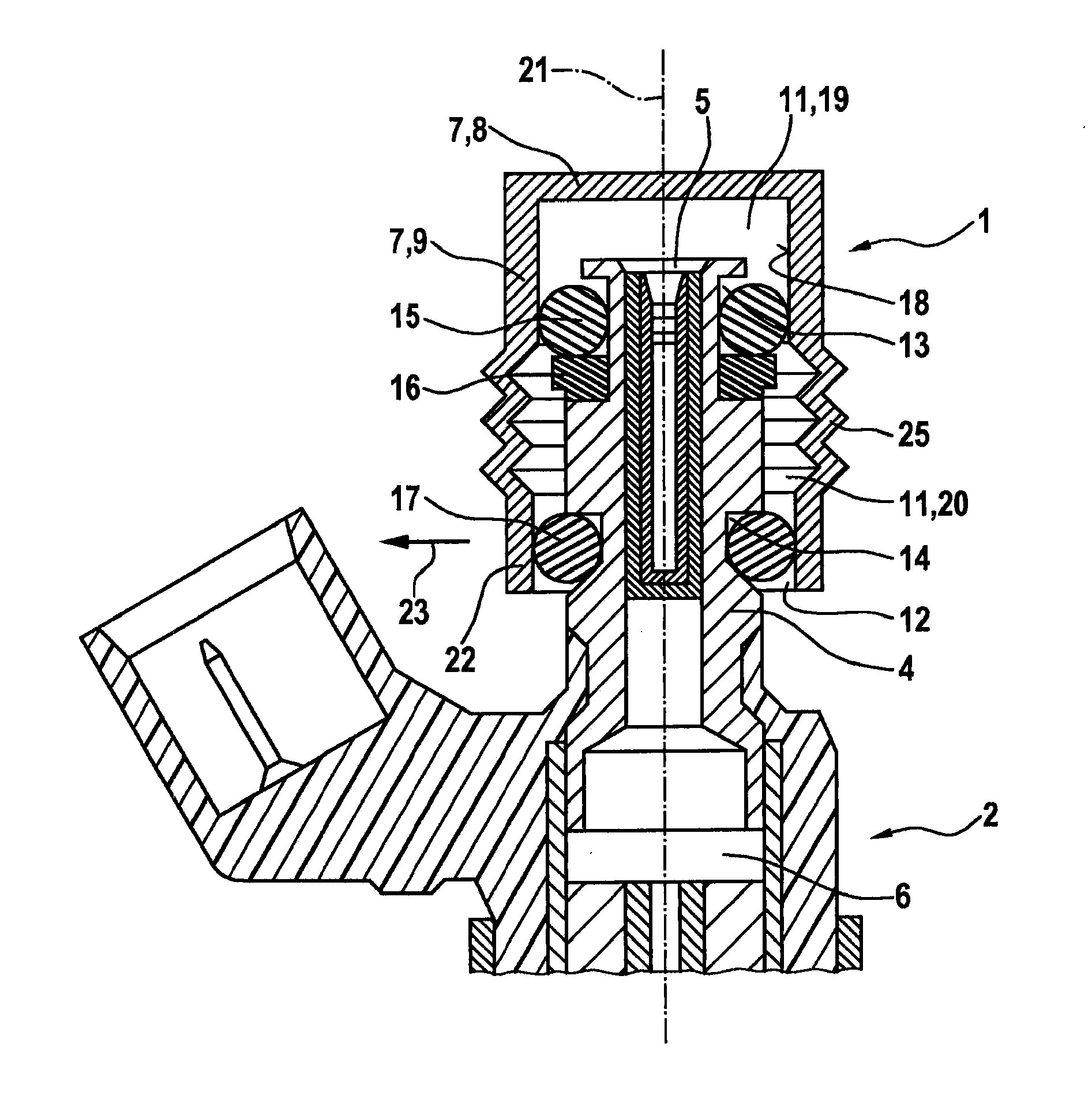

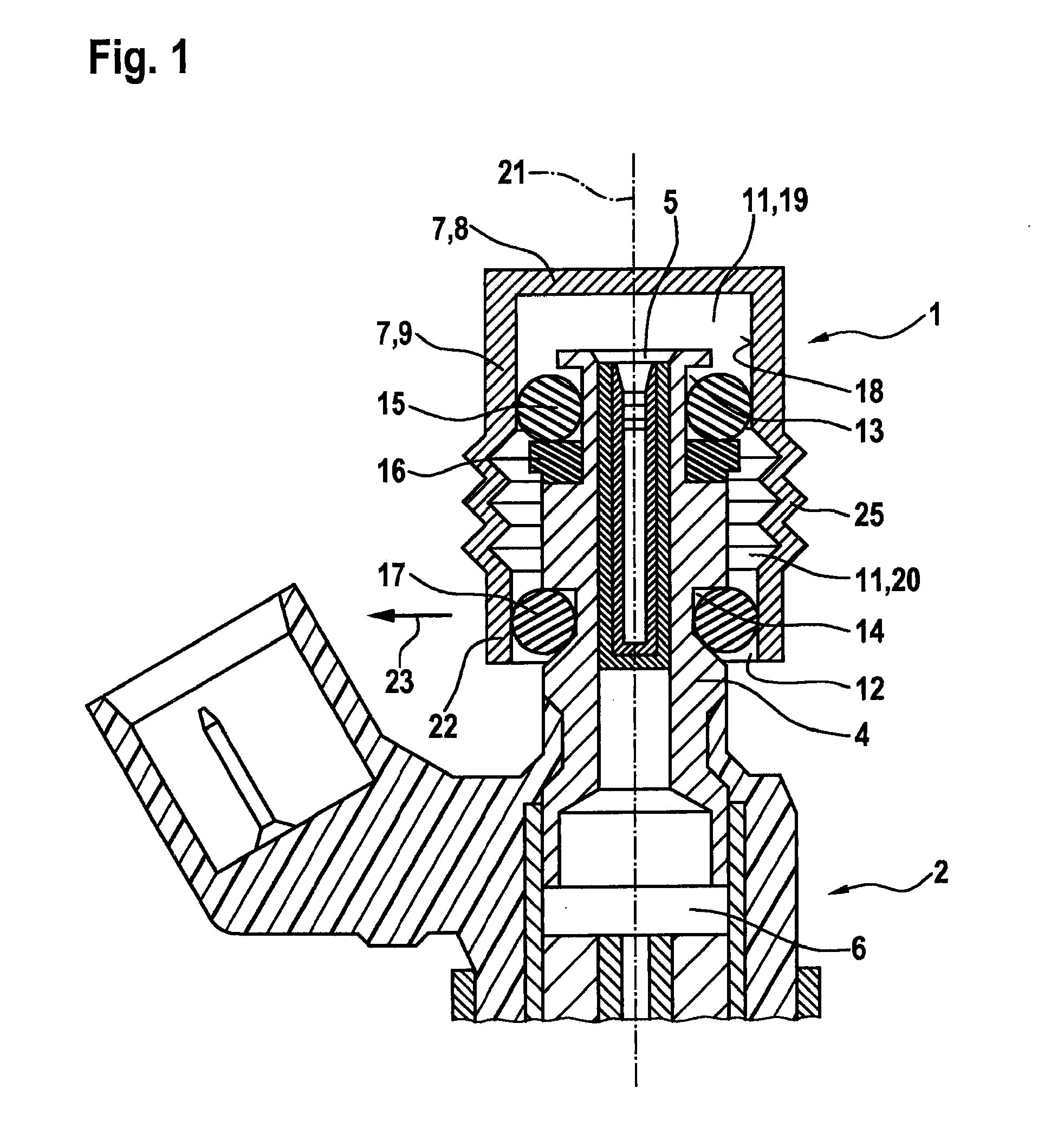

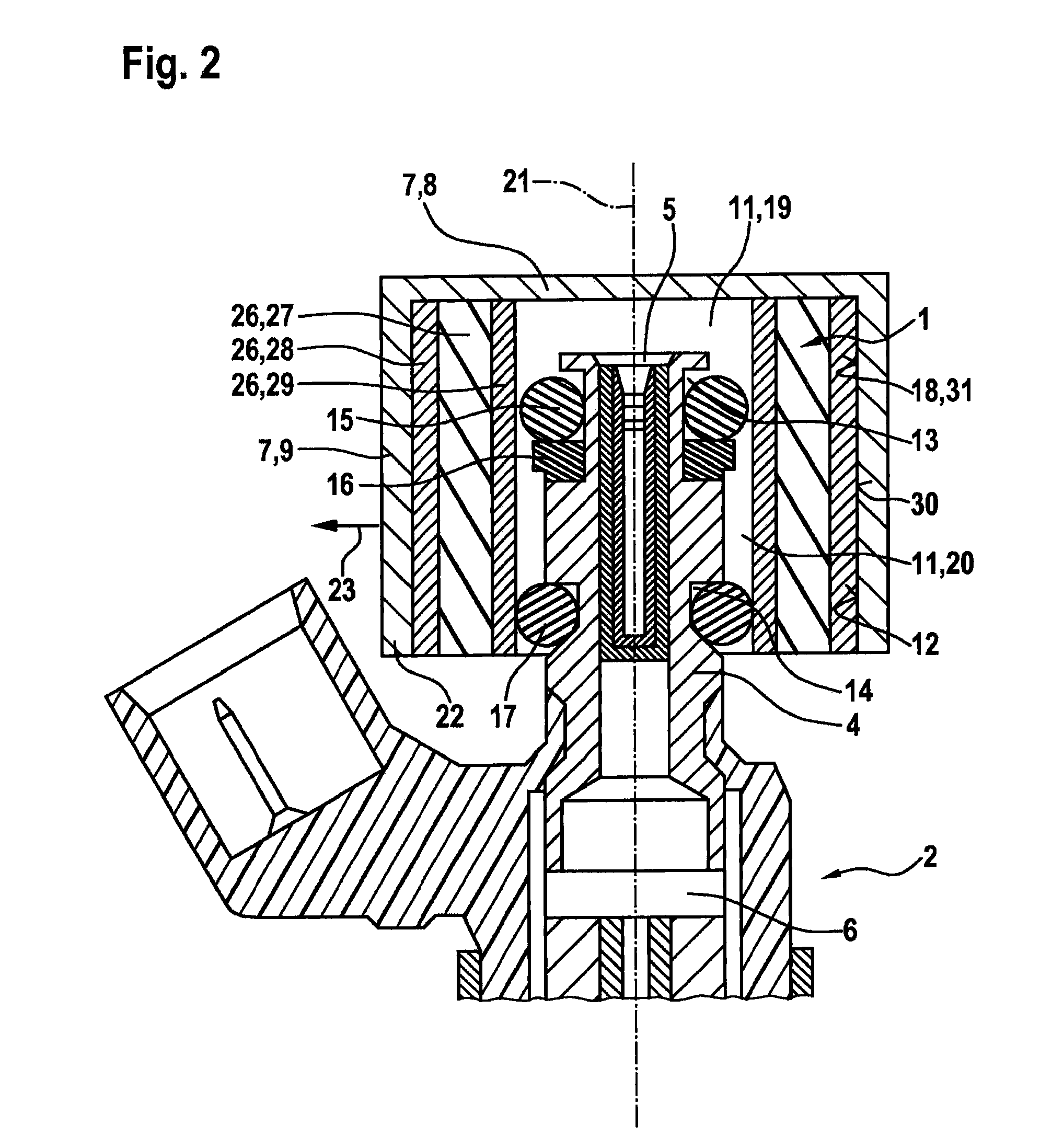

High-pressure fuel pump

ActiveUS20180306151A1Improve installation reliabilityAvoid problemsPositive displacement pump componentsCorrosion preventing fuel injectionCommon railCylinder head

The invention relates to a high-pressure fuel pump (1), in particular of a common rail injection system of an internal combustion engine, having a pump cylinder head (3), having an intake valve (6) arranged in the pump cylinder head (3) in the direction of a pump cylinder axis, and a high-pressure fuel outlet (5) arranged laterally on the pump cylinder head (3), wherein a protective cap (10, 10a) at least partly covering the high-pressure fuel pump (1) is provided. According to the invention, a high-pressure fuel pump (1) having a protective cap (10, 10a) is provided, in which the protective cap (10, 10a) can be mounted without difficulty on an assembled high-pressure fuel pump (1). This is achieved in that a plug (8) having a lateral lead connection (9) is placed on the electrically operated intake valve (6), and the protective cap (10) is formed in two pieces and has two protective cap parts (11a, 11b) that can be fitted to each other, or else in that a plug (8) having a lateral lead connection (9) is placed on the electrically operated intake valve (6), and the protective cap (10a) is formed annularly and has a free clearance slot (19) interrupting the ring.

Owner:ROBERT BOSCH GMBH

Fuel injection system including a fuel-guiding component, a fuel injector, and a connecting element

InactiveUS20150345445A1Reliable absorptionEasy to hangSleeve/socket jointsPipeline expansion-compensationFuel injectionInjector

A connecting element for connecting a fuel injector of a fuel injection system to a fuel-guiding component includes a base body in which a receiving chamber for a fuel connector of the fuel injector is provided. The fuel connector, which is situated at least partially in the receiving chamber, is supported at least indirectly on the base body. The fuel connector is elastically supported on the base body in a radial direction.

Owner:ROBERT BOSCH GMBH

Fuel injection system for internal combustion engine with injector isolator ring

InactiveUS20100175667A1Easy to adjustNoise reducing fuel injectionMachines/enginesCylinder headEngineering

A fuel injection system for internal combustion engine includes an injector mounted within a pocket formed in the cylinder head, and an isolator which defines a radial clearance gap with the injector pocket. The isolator expands radially outwardly into a clearance gap in response to axially directed force imposed upon the isolator by the injector, so that a dual rate force / displacement effect is achieved by the isolator.

Owner:FORD GLOBAL TECH LLC

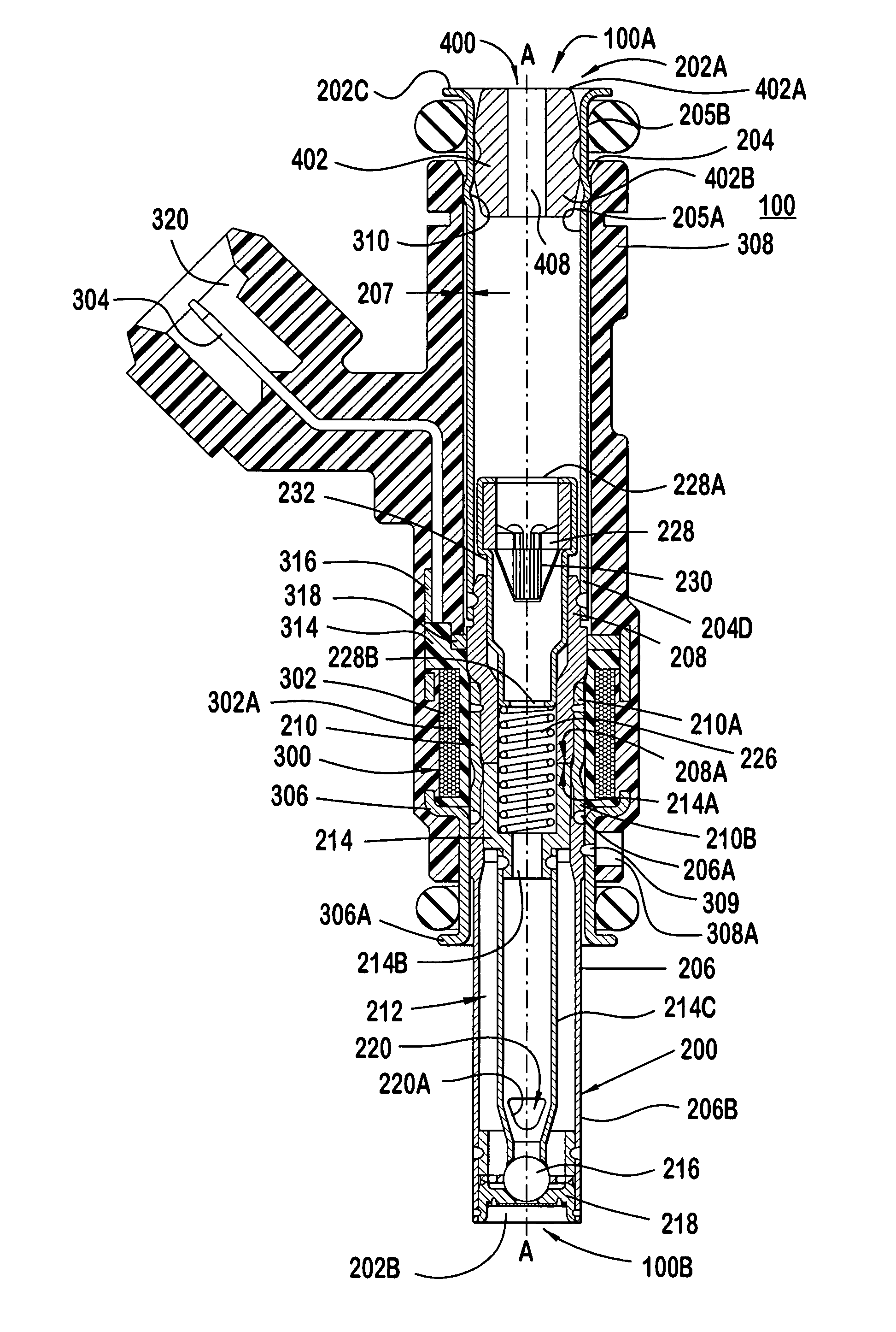

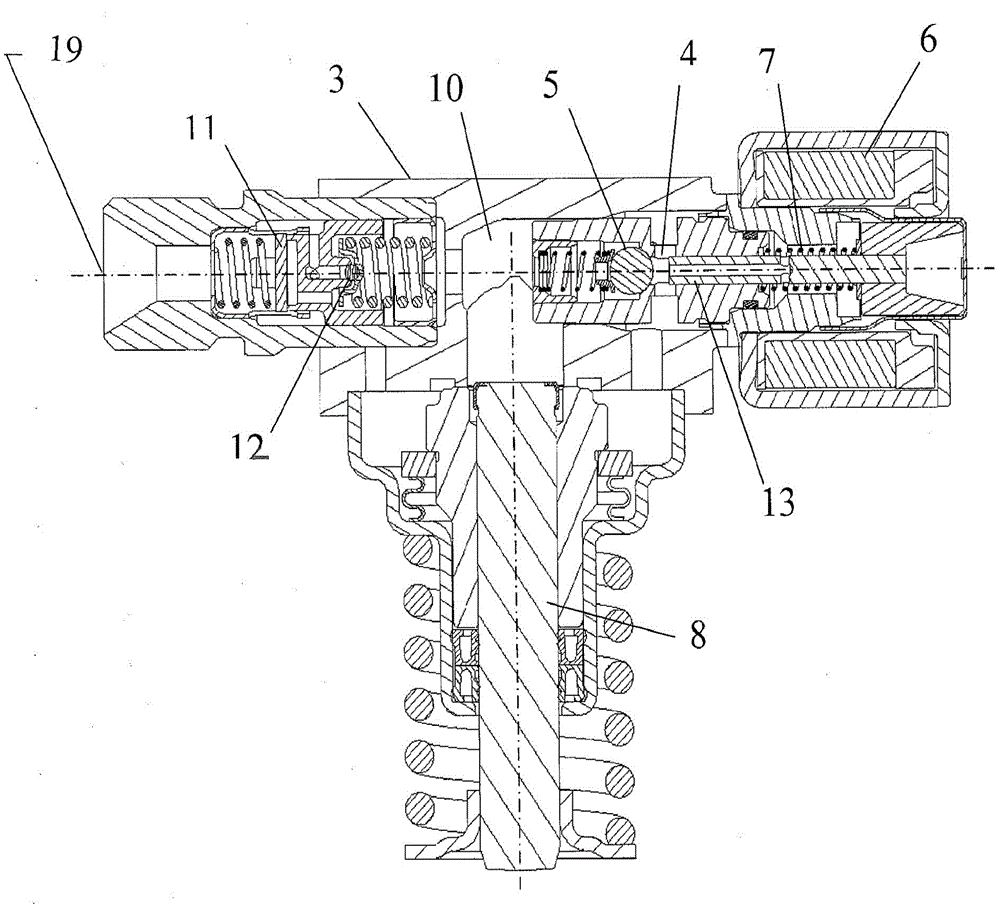

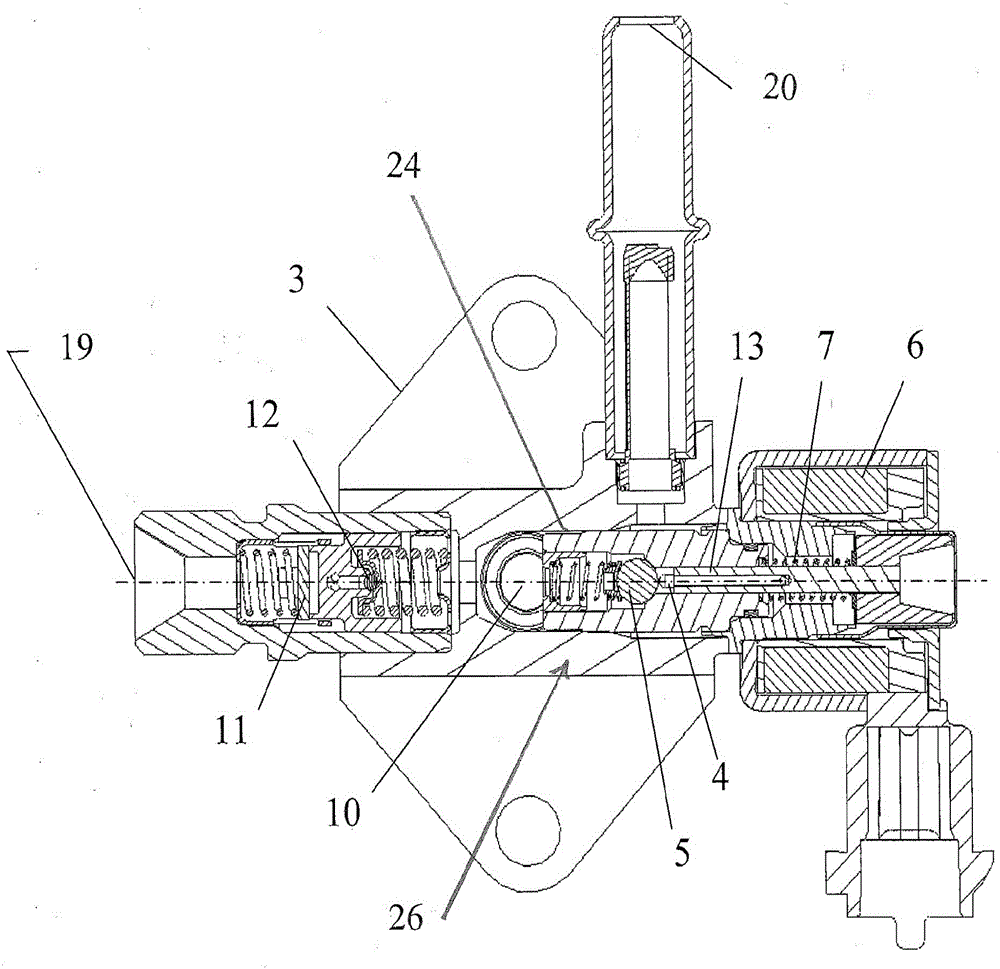

Electronically controlled inlet metered single piston fuel pump

ActiveCN105008709ASimple structureLow costPositive displacement pump componentsNoise reducing fuel injectionProportional controlPump chamber

A single piston fuel pump comprising a pump housing a pump inlet and an outlet. The pump housing mounts a proportional solenoid operated inlet metering valve with variable orifice, an inlet check valve, a pumping chamber, a pumping piston, an outlet check valve, and a pressure relief valve, wherein the inlet metering valve, the inlet check valve, the outlet check valve, and the pressure relief valve are all mounted on a common axis.

Owner:STANDYNE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com