Electronically controlled inlet metered single piston fuel pump

A fuel pump and inlet technology, which is applied in the control field of high-pressure fuel supply pumps, can solve the problems of high audible noise, high pressure pulse, etc., and achieve the effect of reducing the noise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

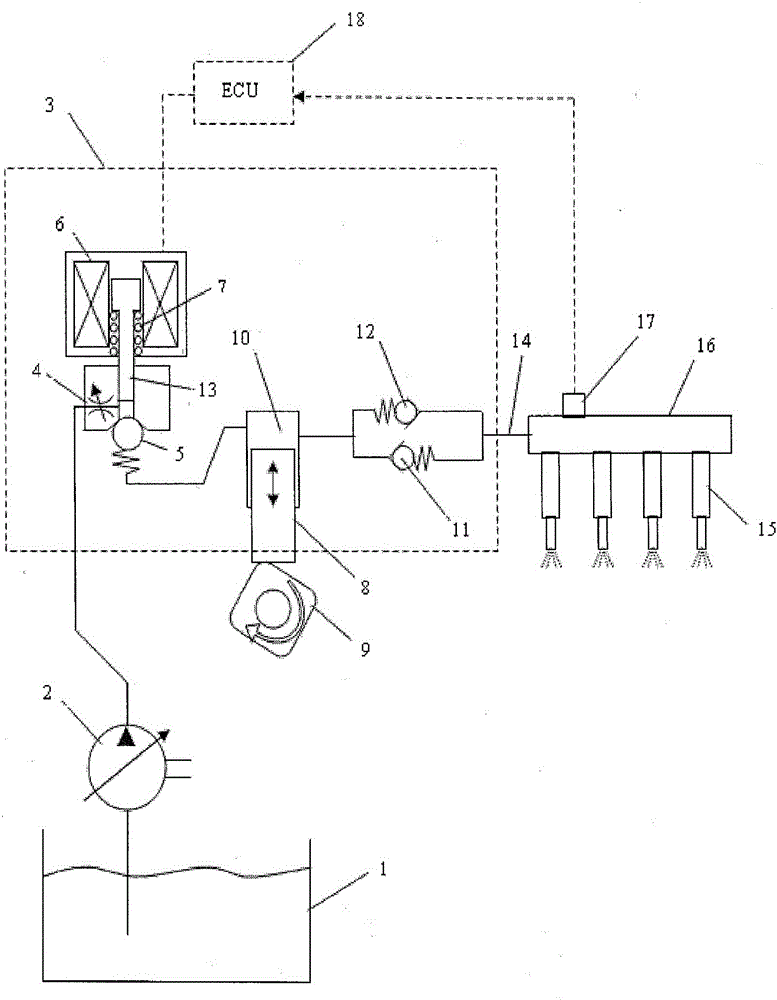

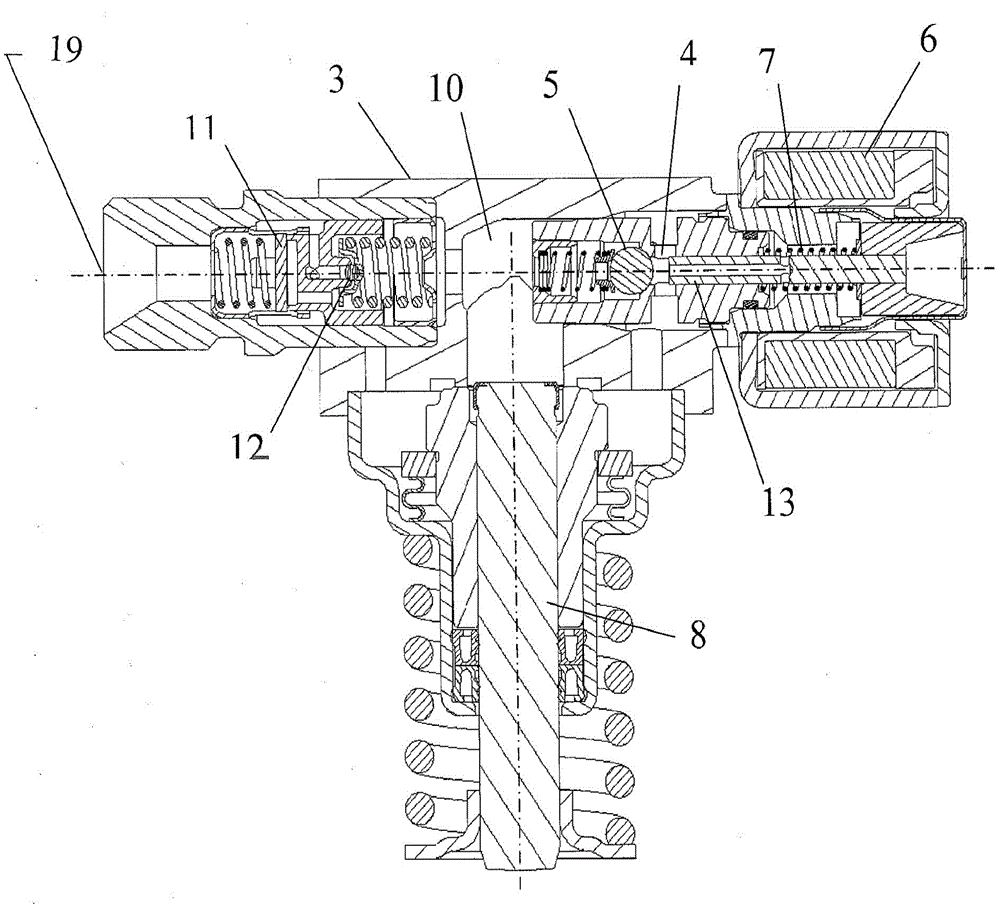

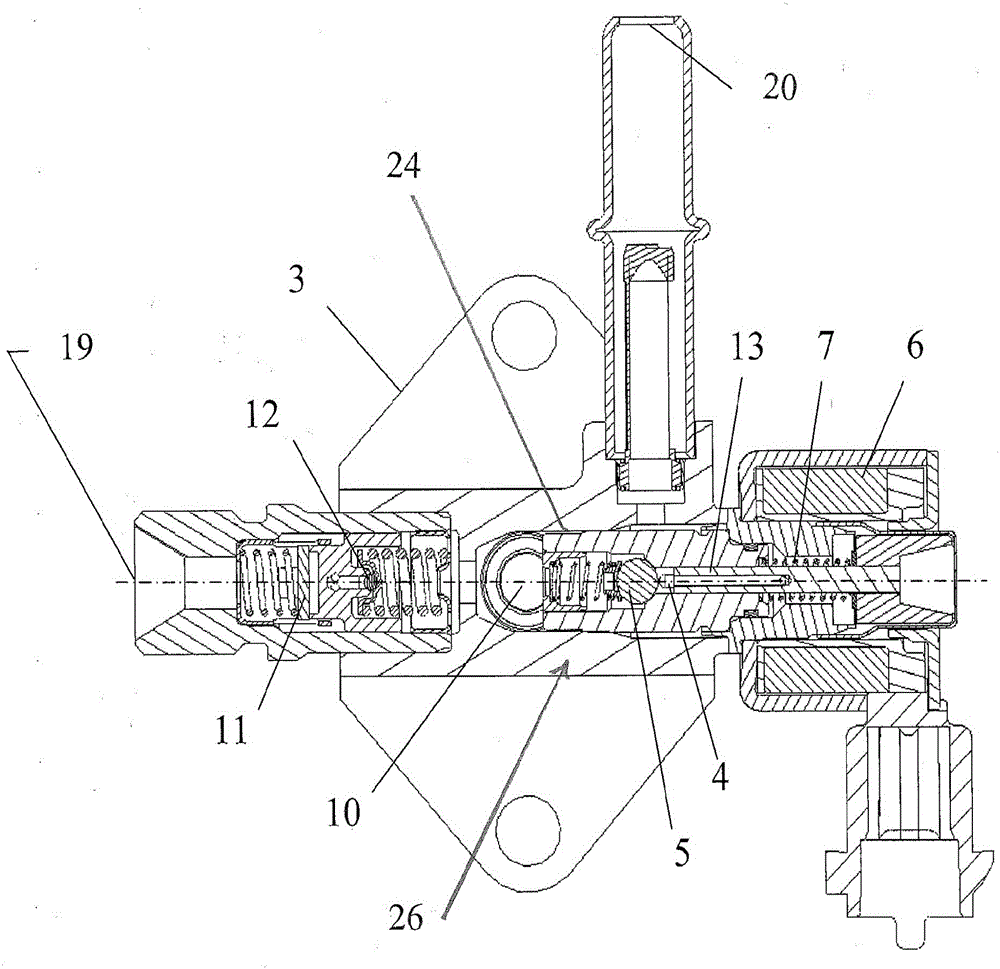

[0017] Referring to the drawings, in which like numerals represent like components, figure 1 Shown is a schematic diagram of an injection system including an electronically controlled inlet metering single-piston fuel pump.

[0018] Pump 2 draws fuel from fuel tank 1 and pumps it through the fuel line on the chassis to the inlet passage of high pressure GDI pump 3. The fuel then flows through the variable opening or orifice 4 of the inlet metering (throttling) valve, then through the inlet check valve 5, and enters during the suction stroke of the boost or during the suction stroke of the pumping plunger 8. pumping chamber 10. An inlet check valve 5 is provided between the metering valve 13 and the pumping chamber 10, said inlet check valve being biased to allow flow to be supplied to the pumping chamber at said inlet section and to prevent high pressure fuel during the pumping phase into the feed channel.

[0019] During the pumping stroke, the pumping plunger 8 is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com