Patents

Literature

169results about "Fuel injection with fuel accumulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

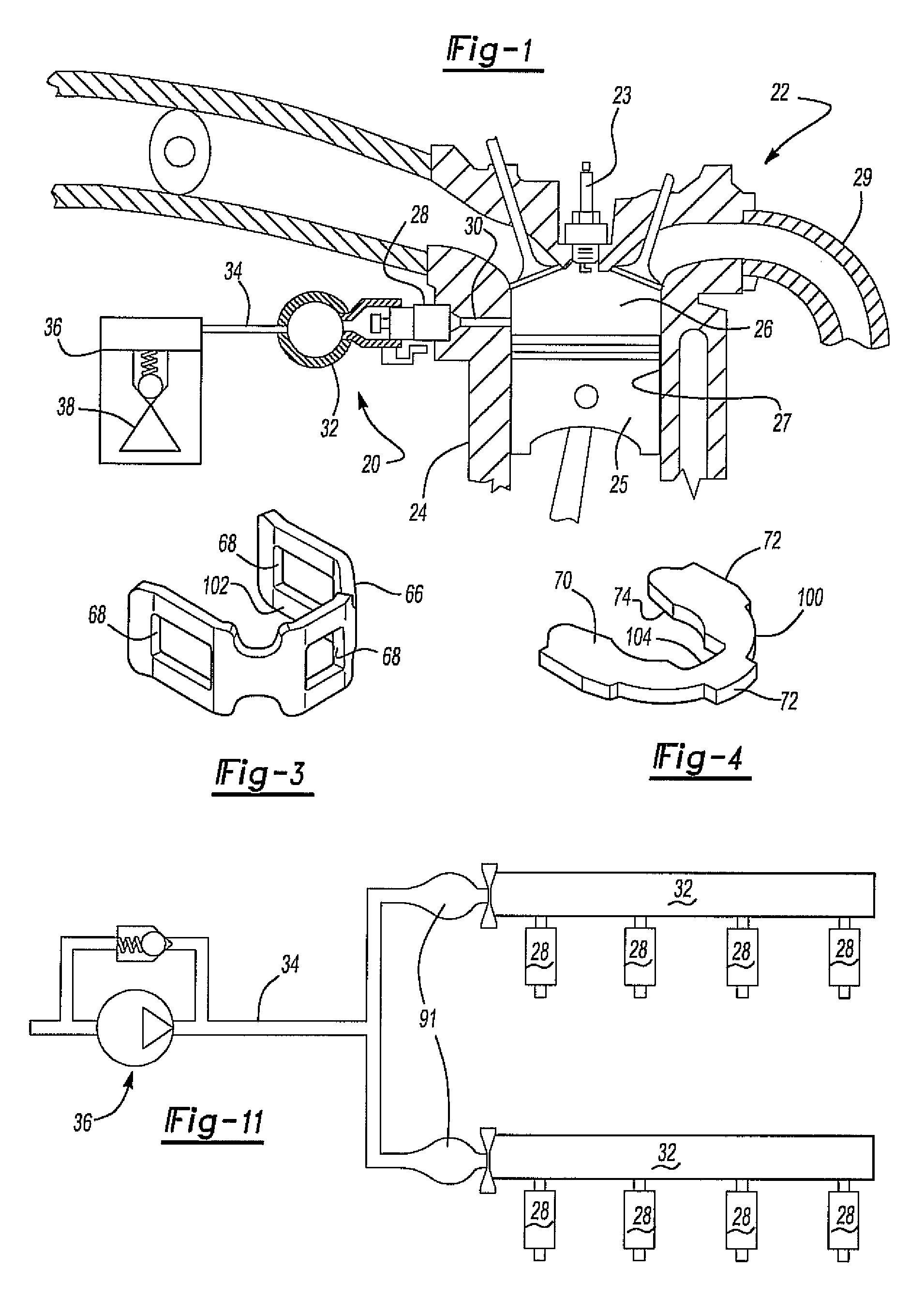

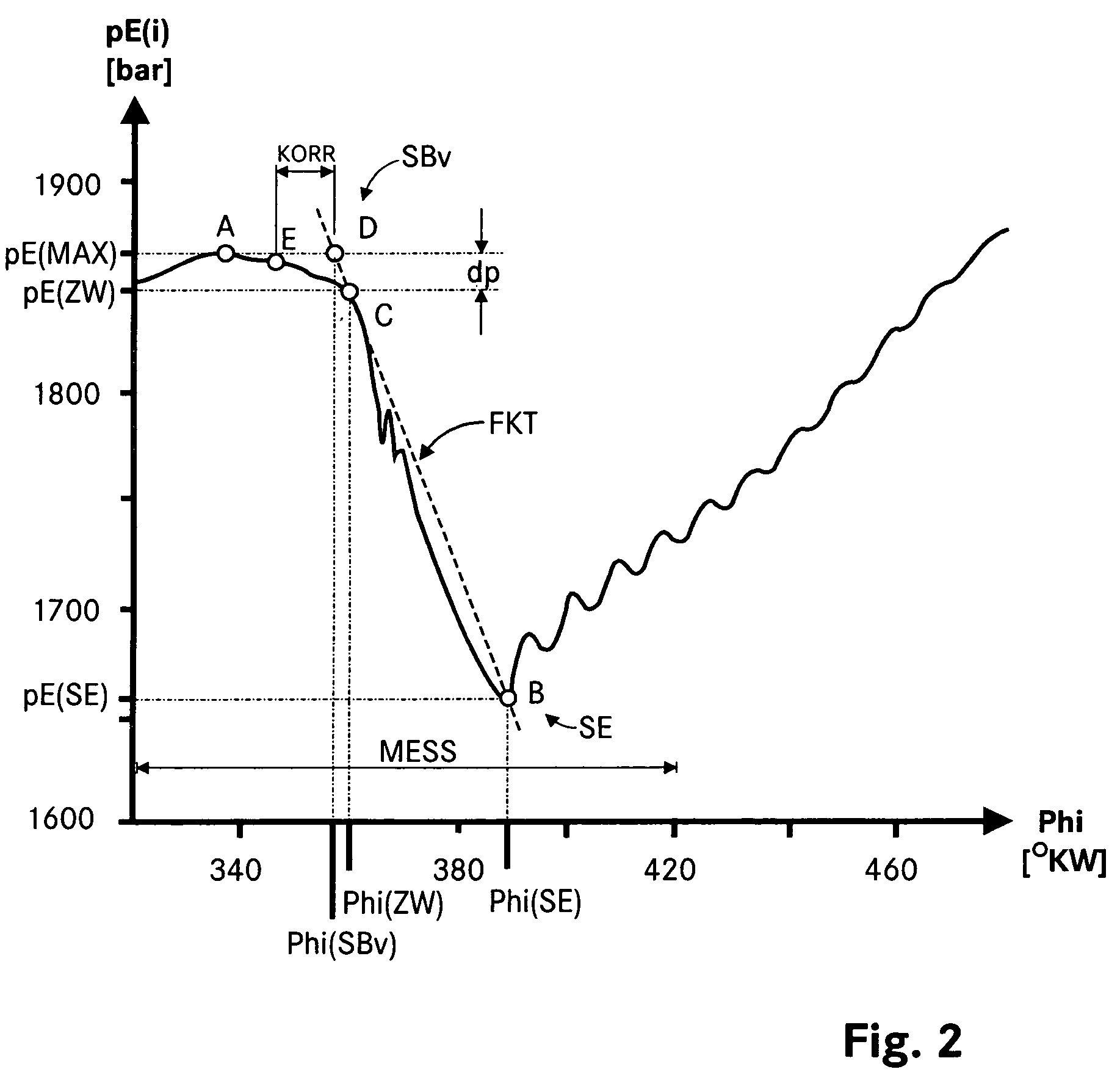

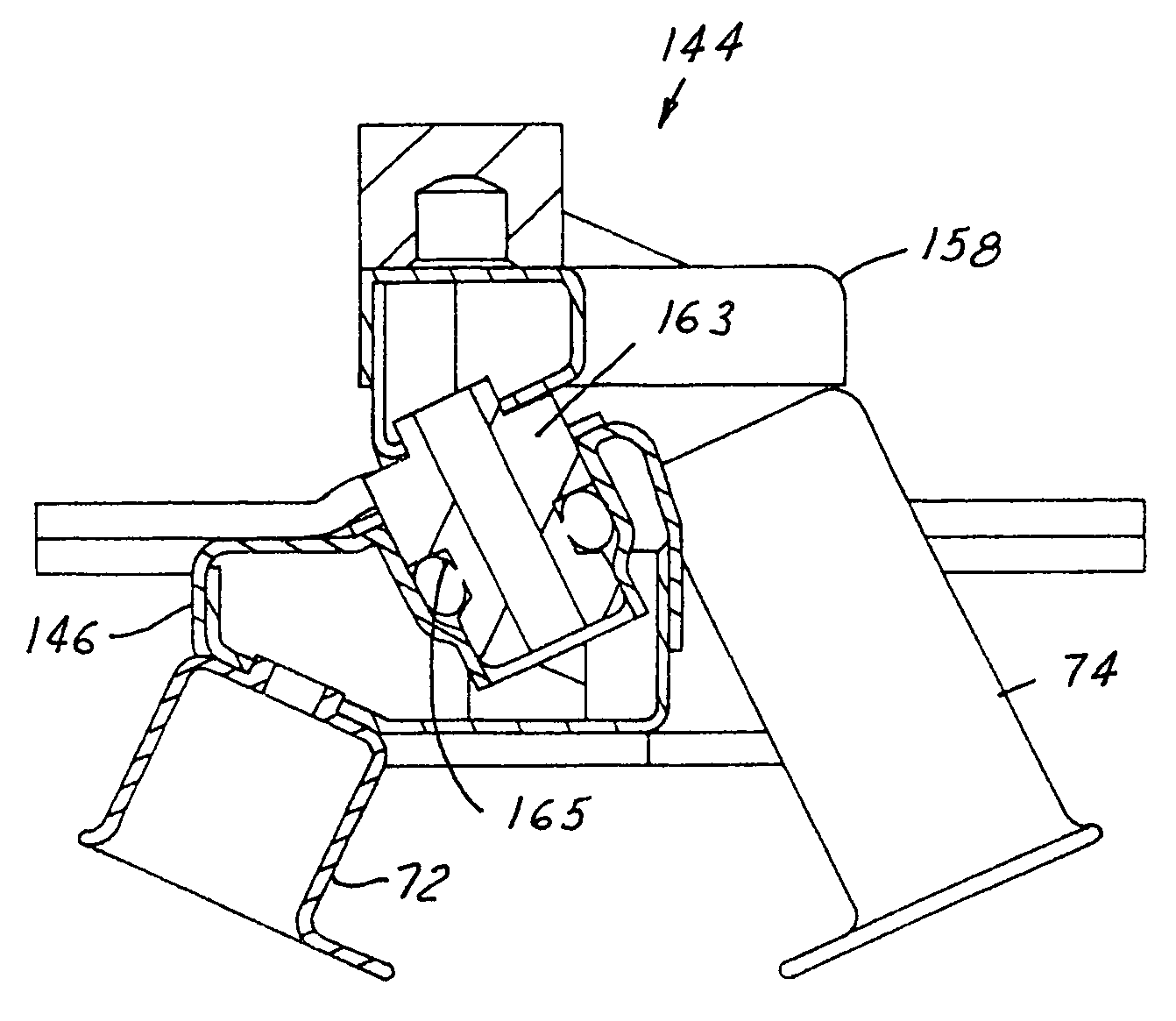

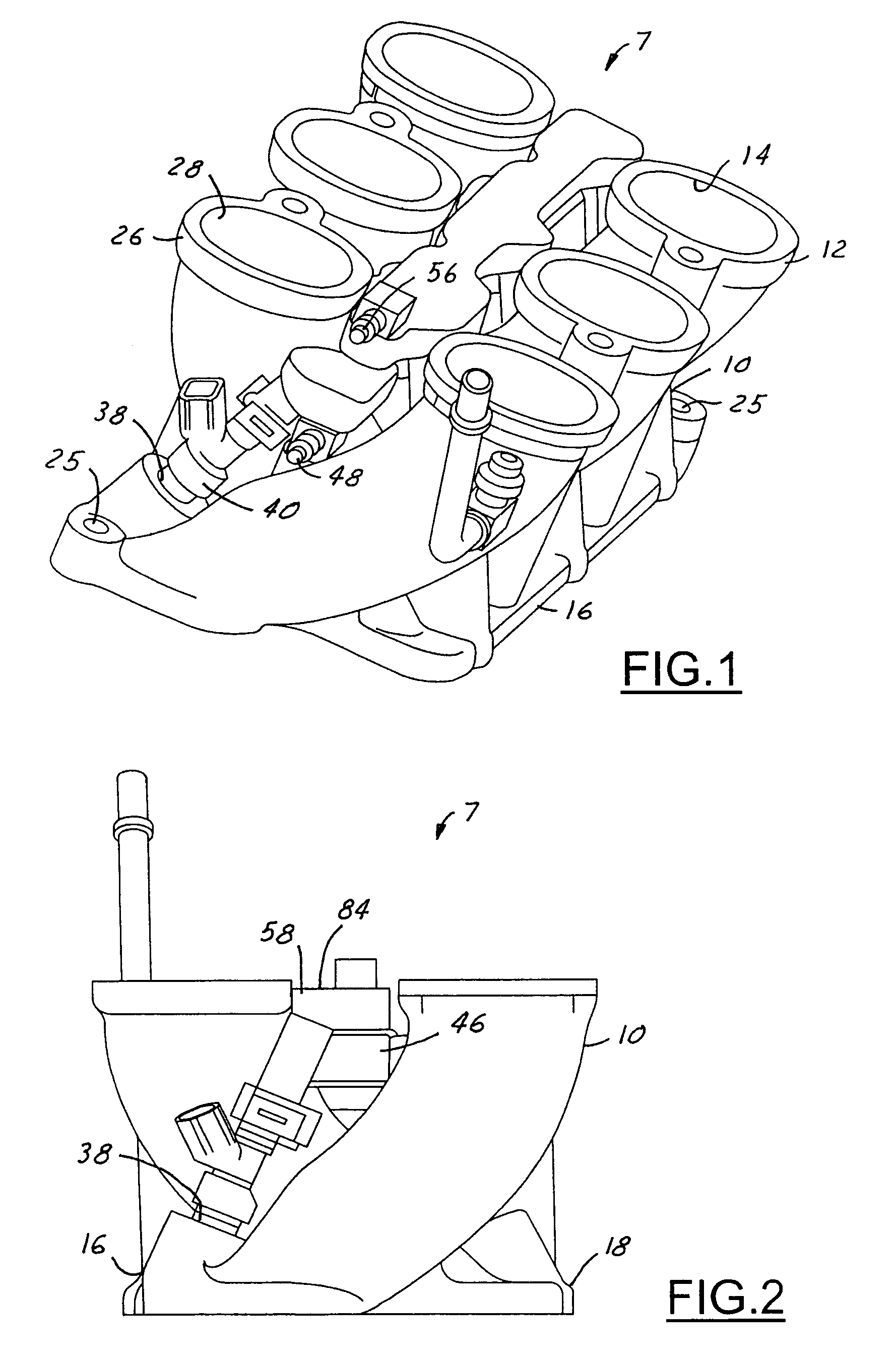

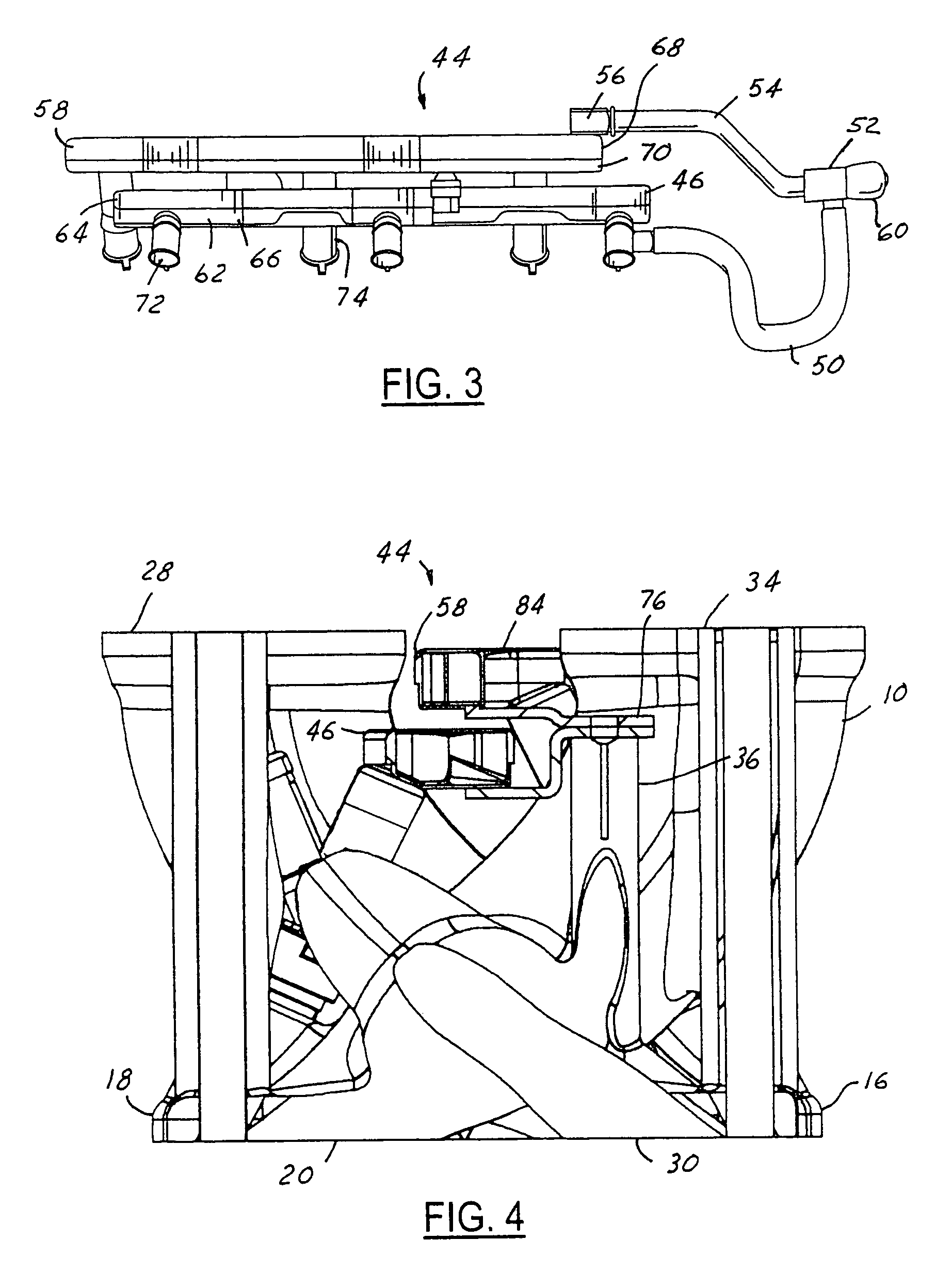

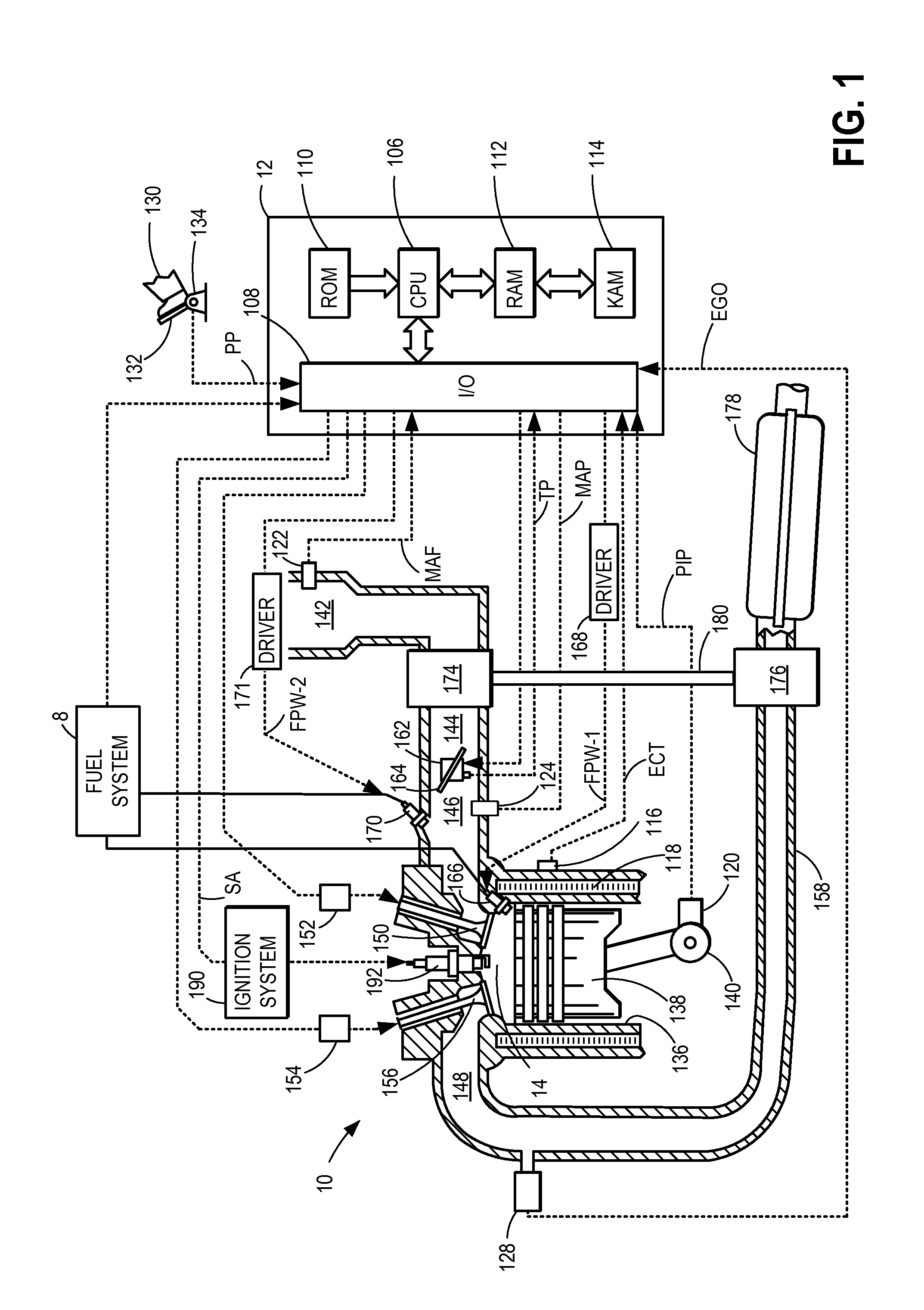

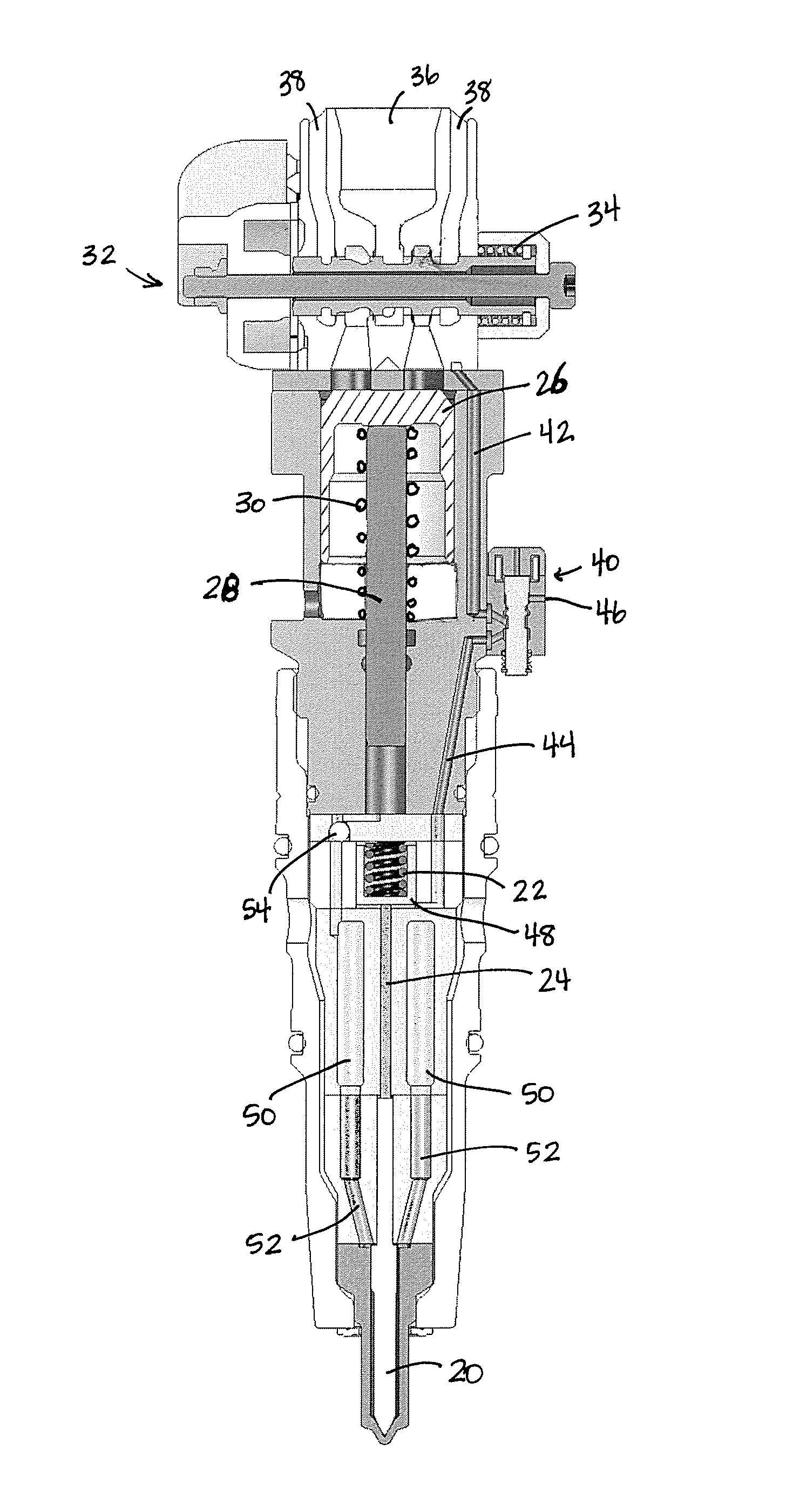

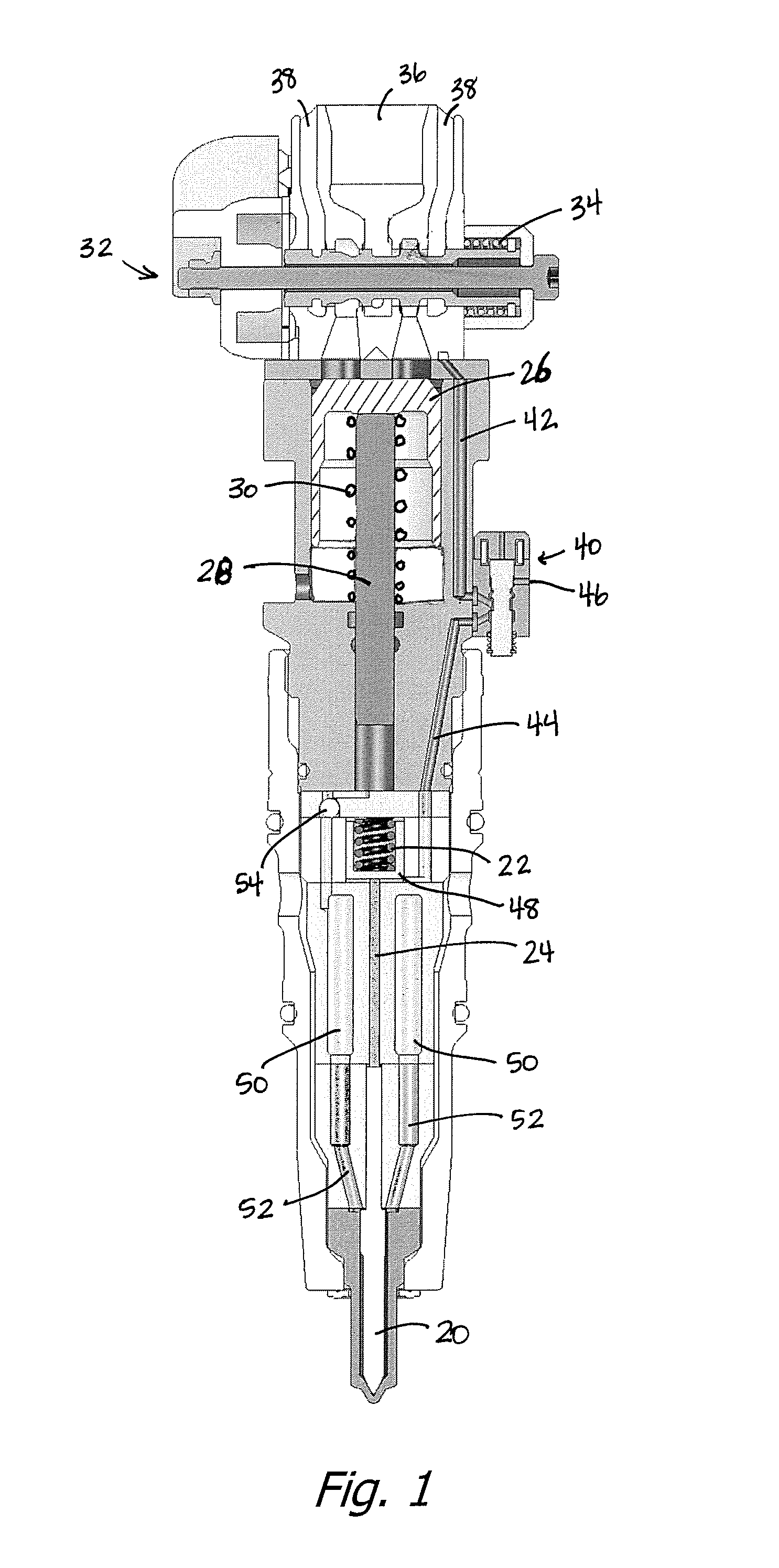

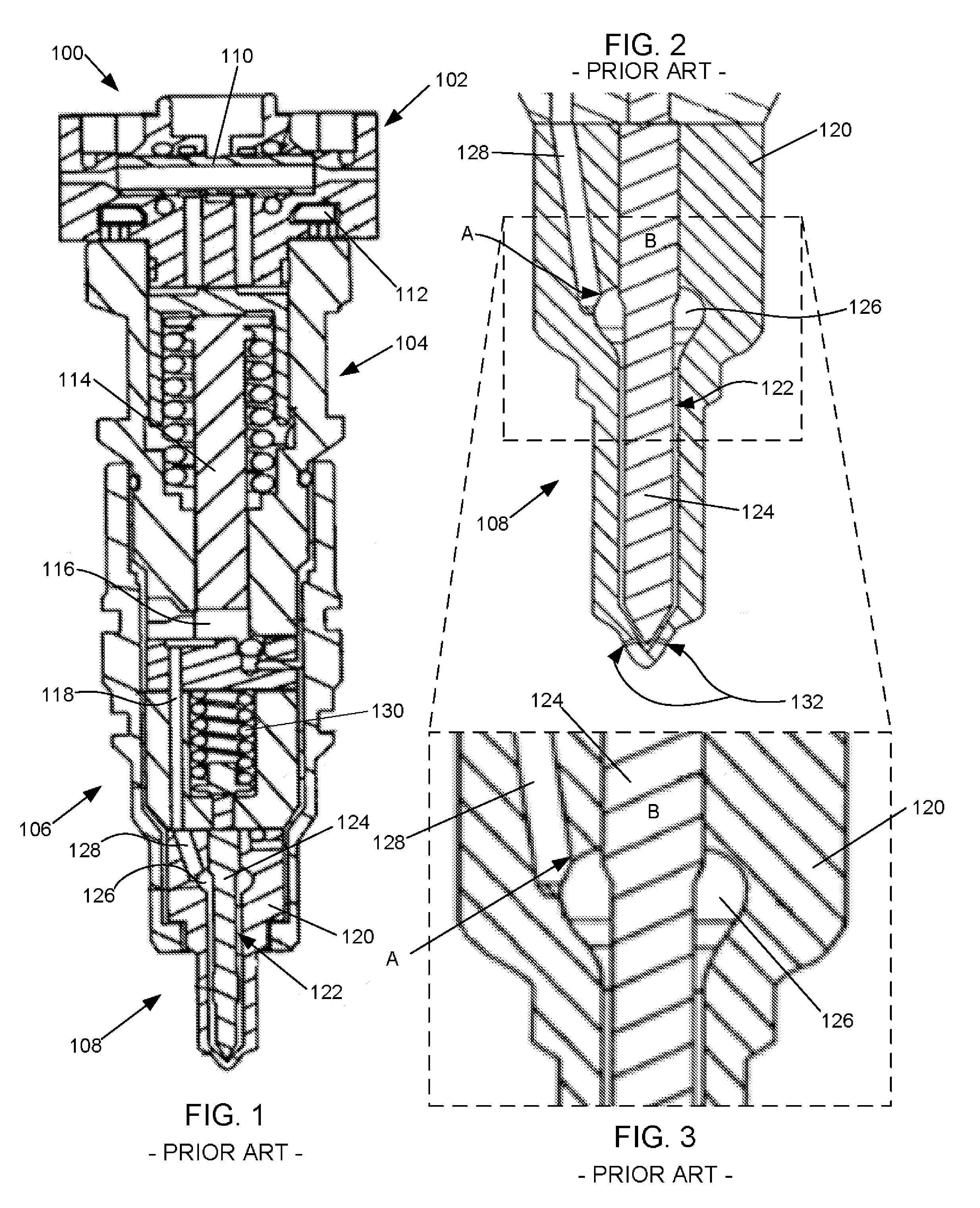

Method and apparatus for attenuating fuel pump noise in a direct injection internal combustion chamber

ActiveUS7406946B1Dampen fuel pressure pulsationDampen fuel pressure fluctuationNoise reducing fuel injectionLow-pressure fuel injectionCombustion chamberEngineering

A method and apparatus for attenuating fuel pump noise in a direct injection internal combustion engine. In one proposal, the direct injection fuel nozzle is suspended from a fuel rail in a fashion that avoids direct metal-to-metal contact between the injector and the engine block. The direct injection nozzle may also be connected to the fuel rail by a pair of spaced-apart seals which equalize the longitudinal pressure on the nozzle during operation. Enlarged diameter fuel reservoirs and / or a restricted orifice may be provided fluidly in series between the fuel pump and the direct injection nozzle in order to attenuate noise resulting from fuel pump pulsation.

Owner:HITACHI LTD

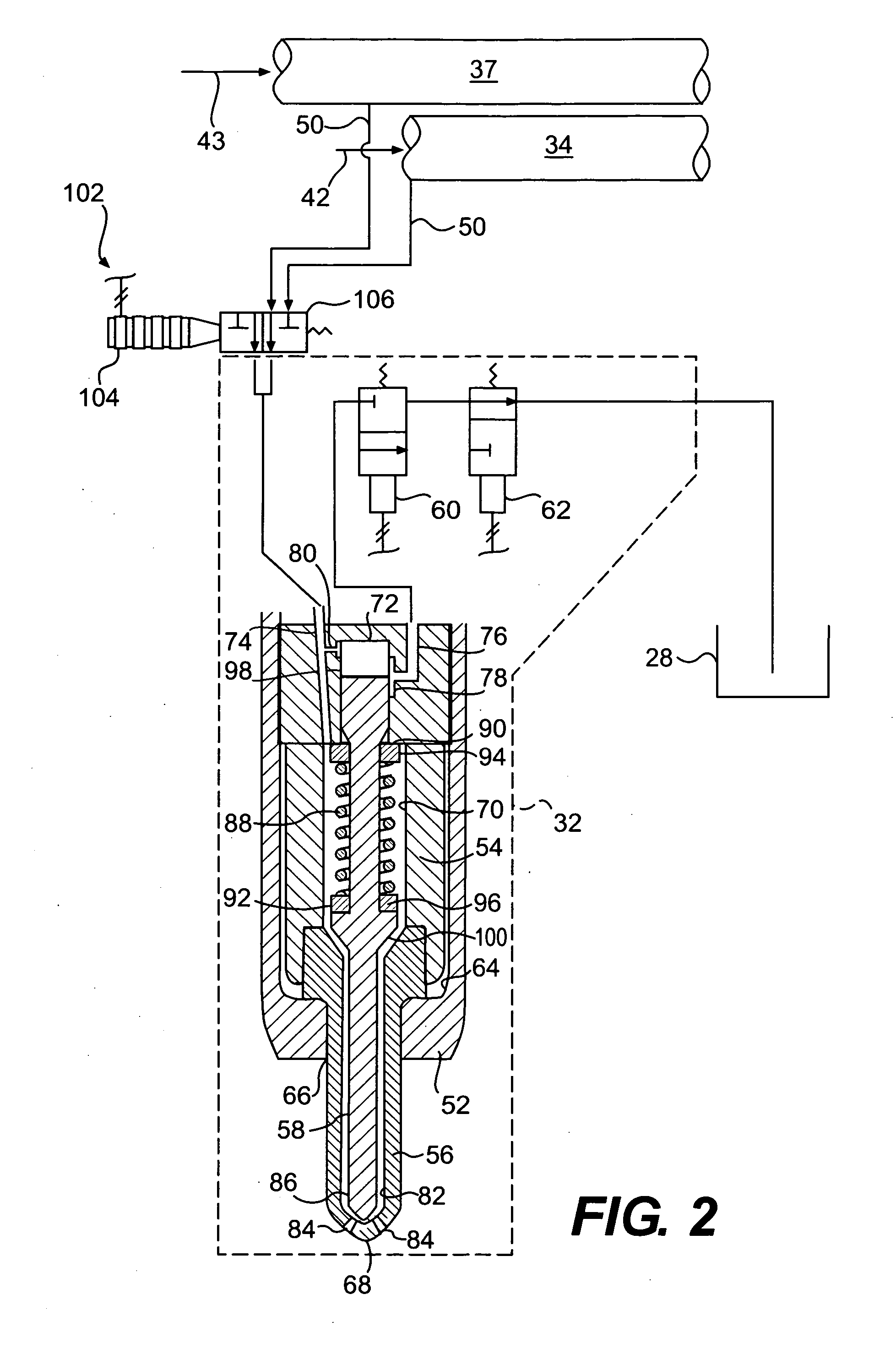

Method and systems for a leakage passageway of a fuel injector

ActiveUS9234486B2Reduce stepsReduce componentsMachines/enginesFuel injection with fuel accumulatorsCommon railAutomotive engineering

Various methods and systems are provided for a leakage passageway for a fuel injector of a common rail fuel system. In one embodiment, a fuel injector for an engine comprises an injector accumulator, an injector flow limiter valve configured to control a flow of fuel from a common fuel rail and into the injector accumulator, and a leakage passageway coupled between the injector accumulator and an inlet of the injector flow limiter valve, the leakage passageway bypassing the injector flow limiter valve.

Owner:GE GLOBAL SOURCING LLC

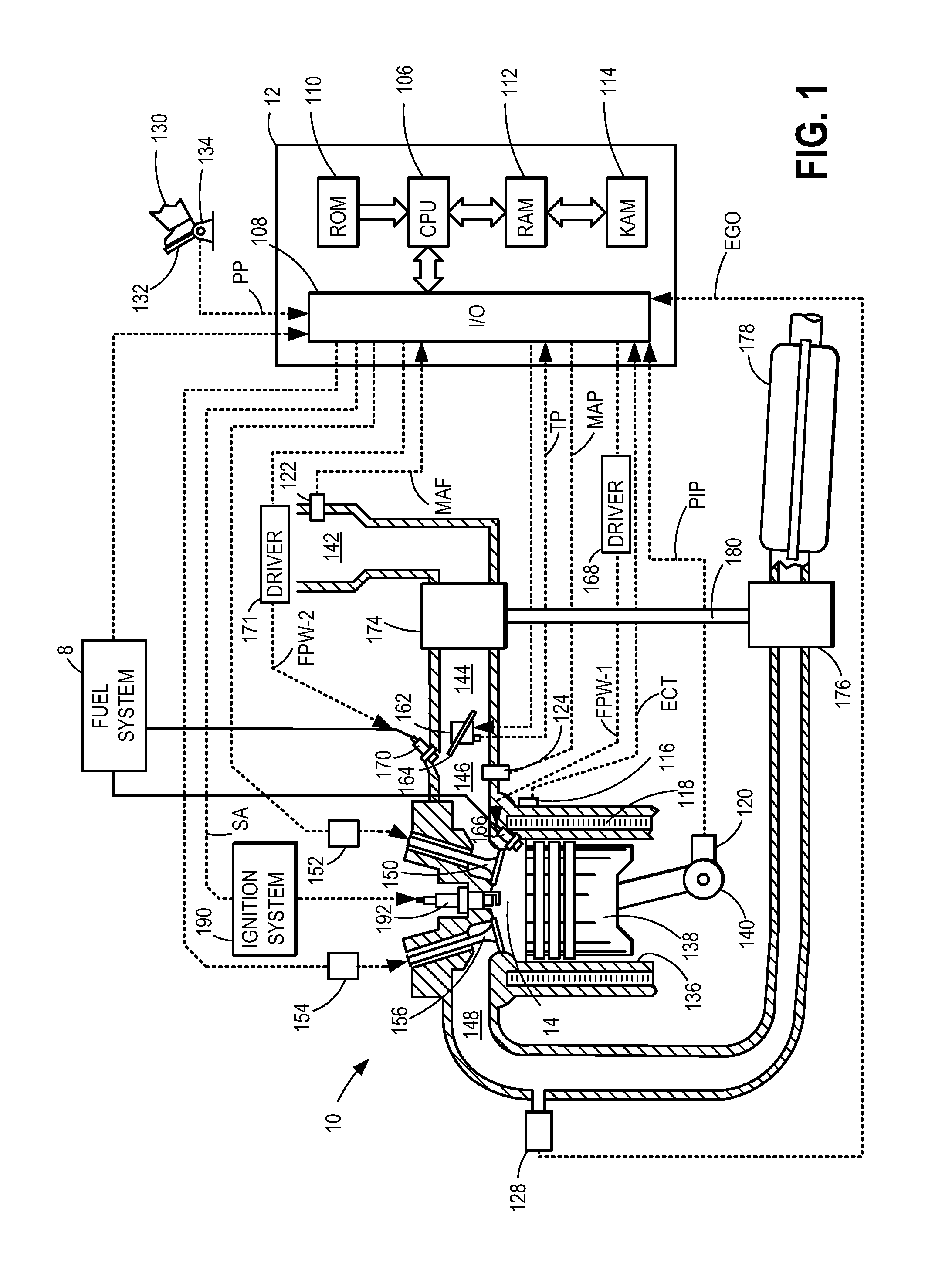

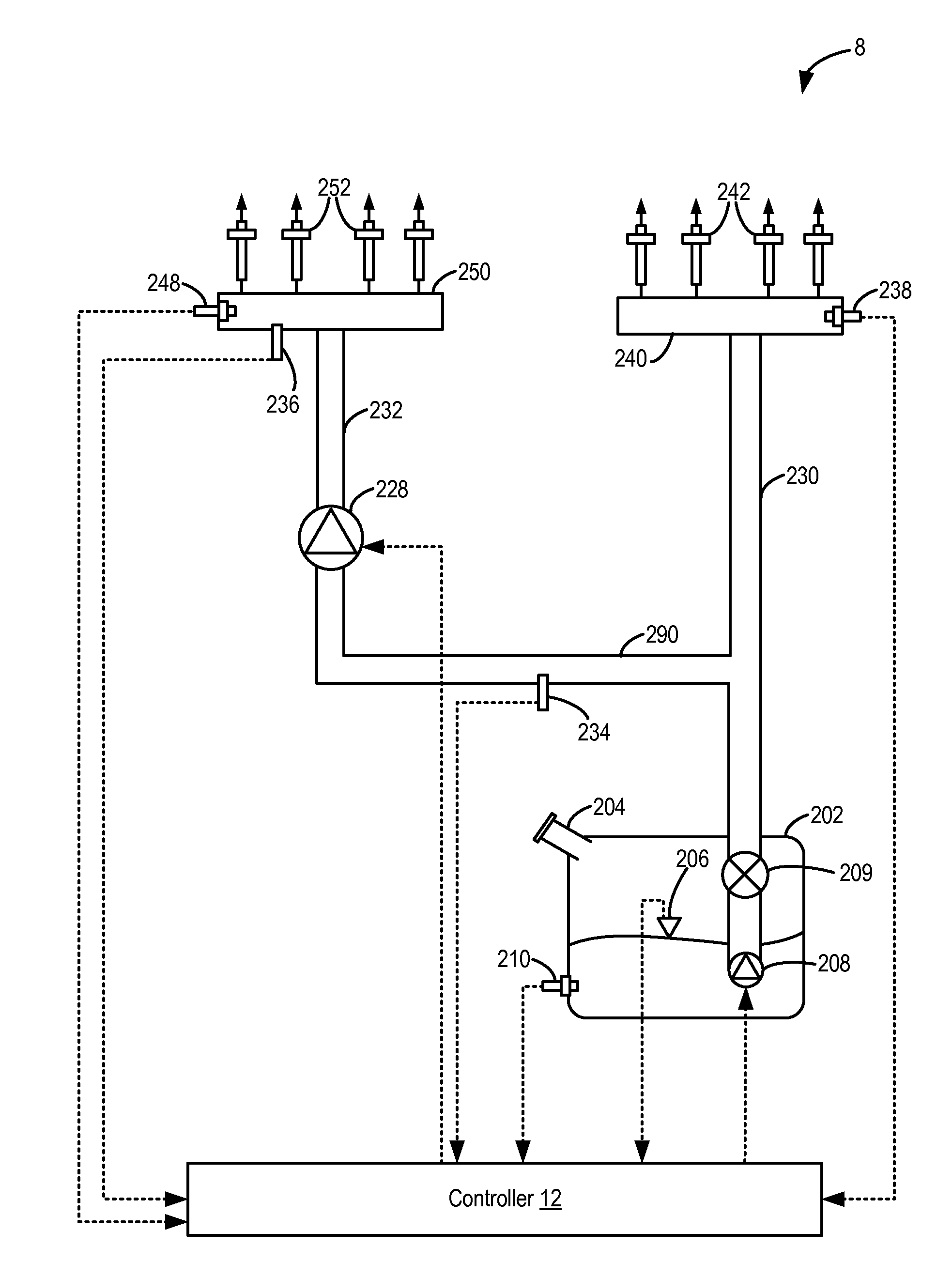

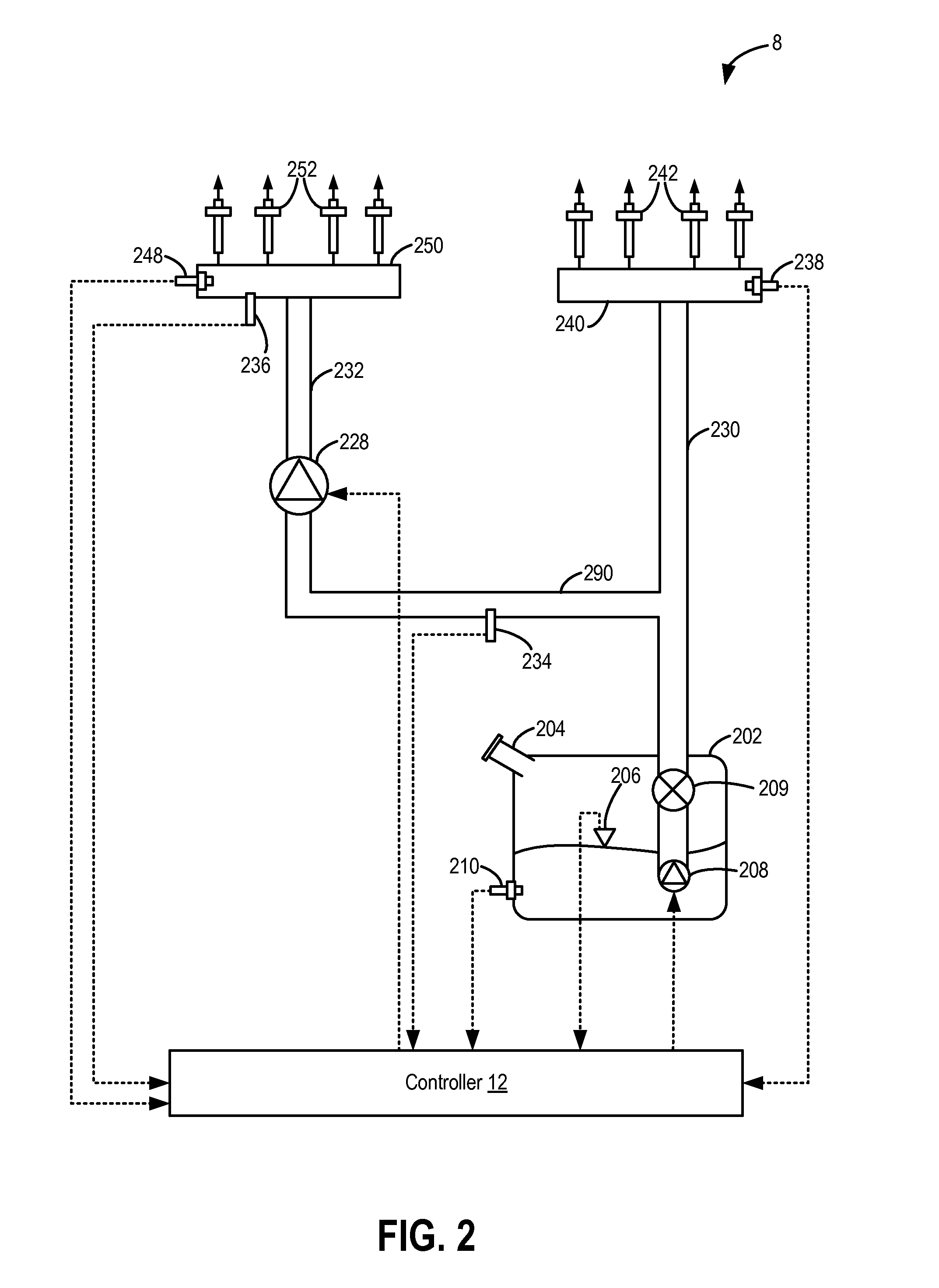

Direct injection fuel pump

ActiveUS20140224209A1Reduce degradation rateImprove fuel pump lubricationElectrical controlWear reducing fuel injectionLubricationFuel pump

Methods and systems are provided for a direct injection fuel pump. The methods and system control pressure within a compression chamber so as to improve fuel pump lubrication.

Owner:FORD GLOBAL TECH LLC

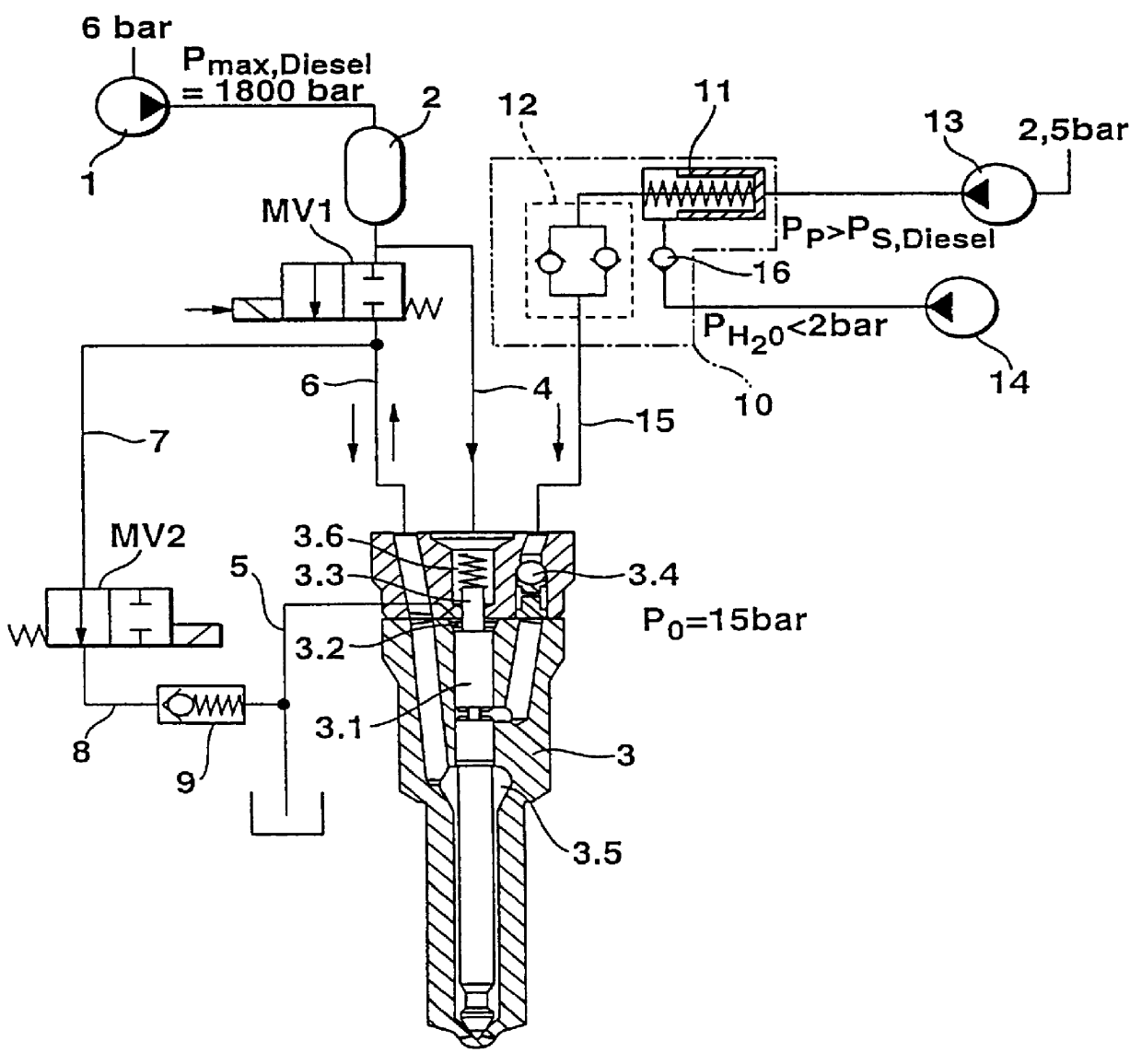

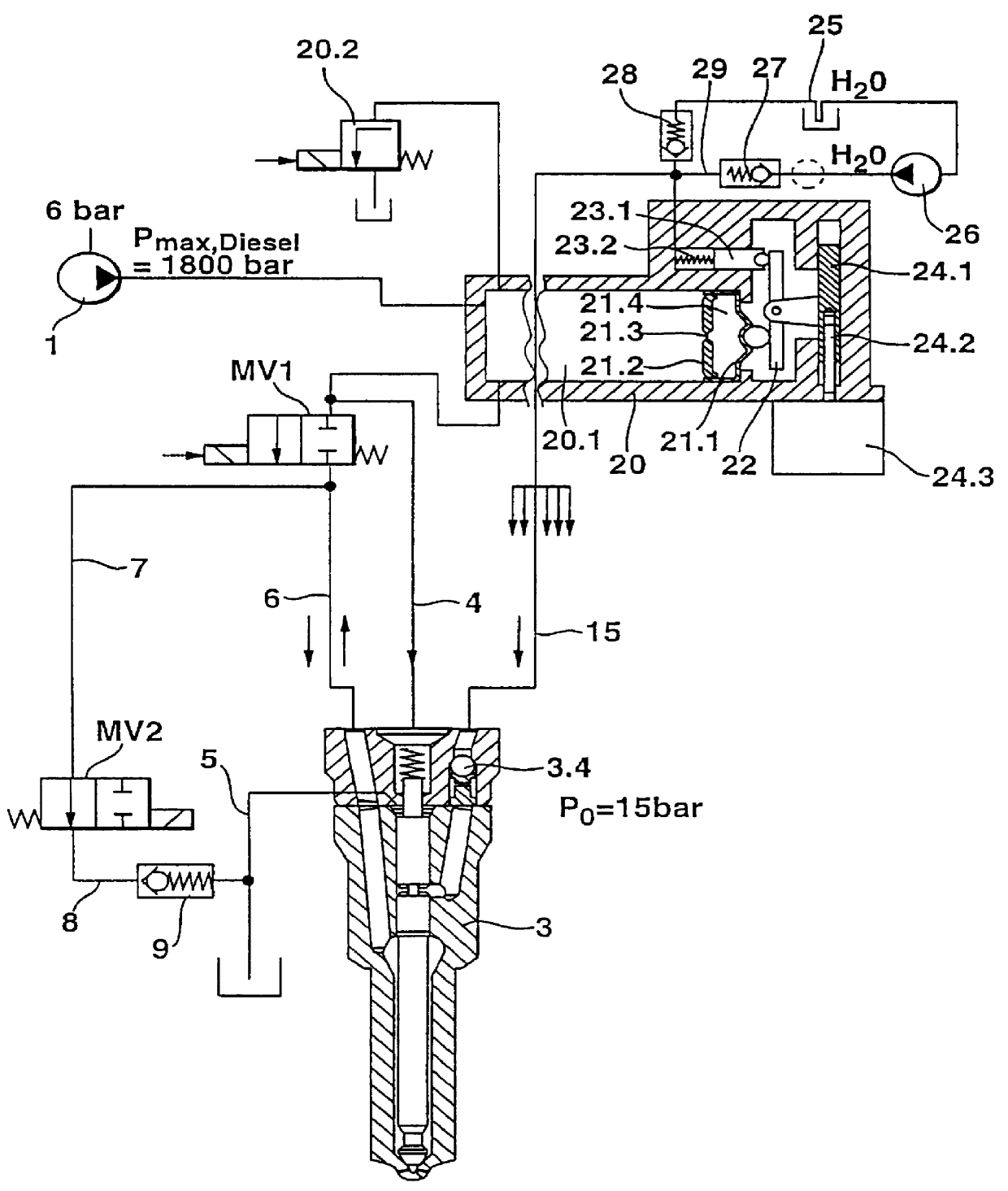

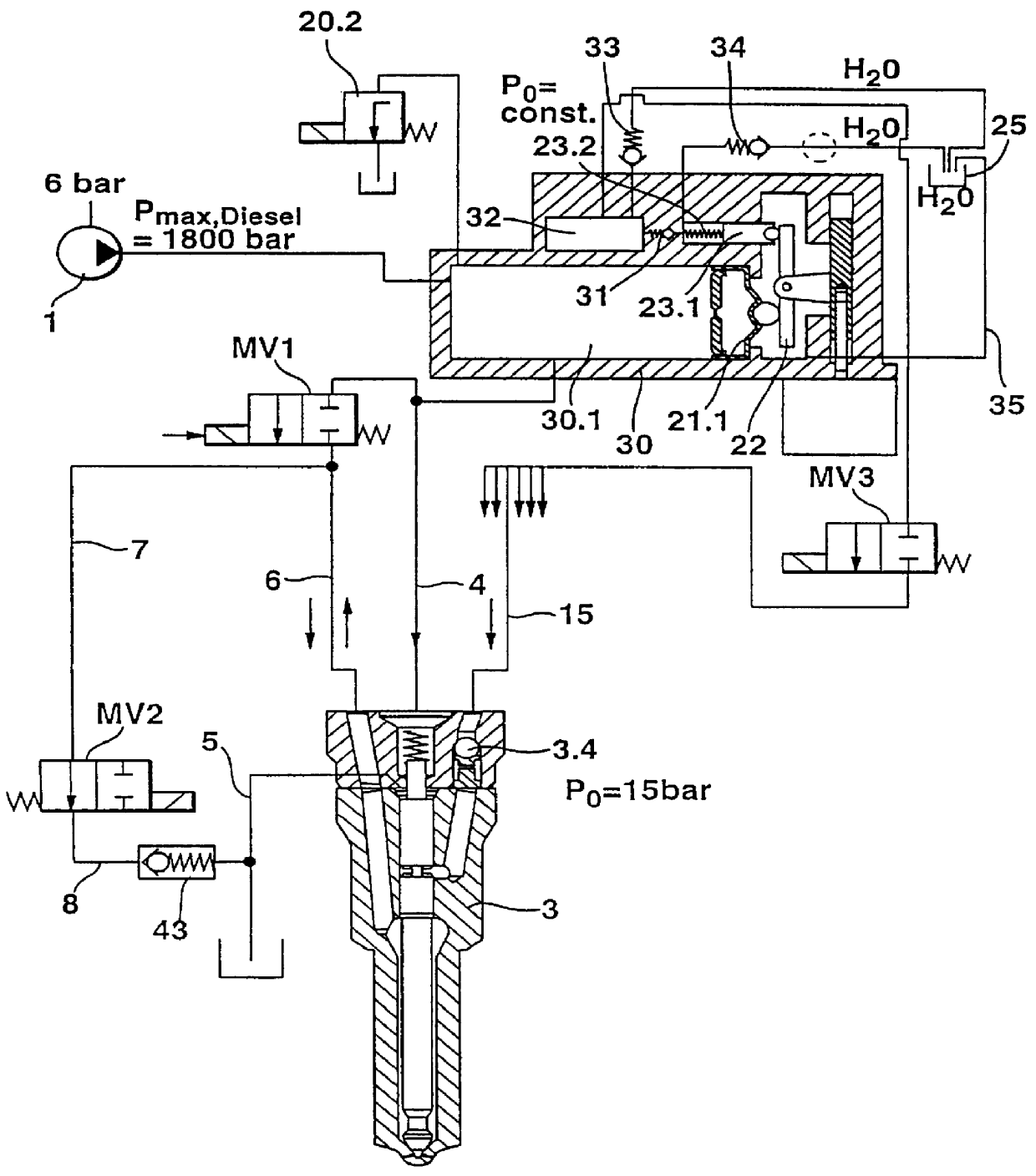

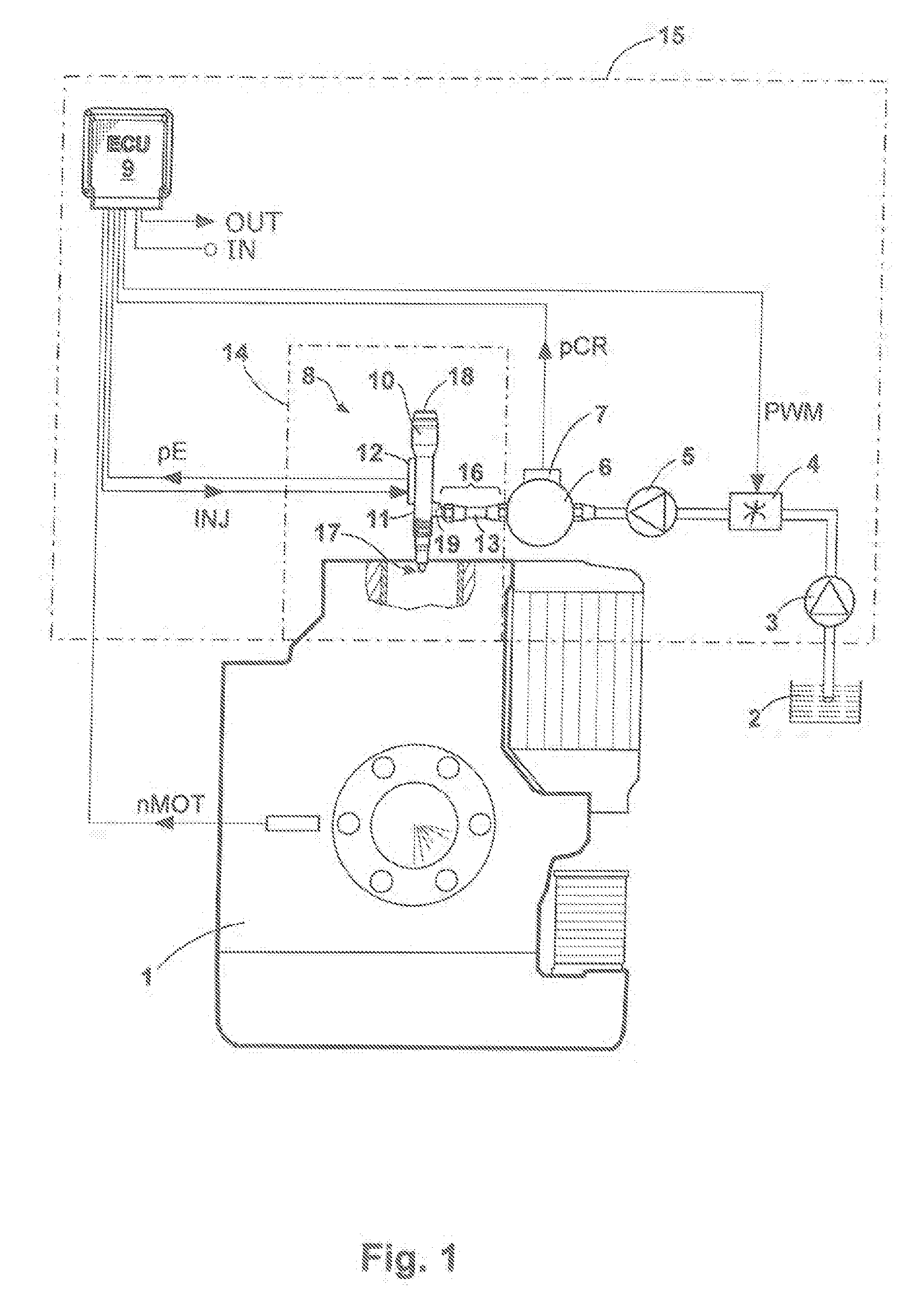

Fuel injection system for an internal combustion engine

InactiveUS6067964AAccurate supervisionHigh degreeCombustion enginesFuel injecting pumpsCommon railEngineering

PCT No. PCT / DE98 / 02771 Sec. 371 Date Jul. 23, 1999 Sec. 102(e) Date Jul. 23, 1999 PCT Filed Sep. 18, 1998 PCT Pub. No. WO99 / 20893 PCT Pub. Date Apr. 29, 1999A fuel injection system having a common rail pressure reservoir filled with high-pressure fuel and having a dual-fuel injector for a bi-fluid injection of fuel and an additive fluid into an internal combustion engine. The system includes a first 2 / 2-way valve in the injection line between the common rail pressure reservoir and a pressure chamber encompassing the injector needle of the dual-fuel injector as well as a second 2 / 2-way valve, whose inlet is connected via a supply line to the injection line at a point between the first 2 / 2-way valve and the pressure chamber, and whose outlet is connected to the low-pressure fuel side by way of an outlet line. As a result, the otherwise conventional 3 / 2-way solenoid control valves, which are significantly more complex technically, can be replaced by more reasonably priced 2 / 2-way valves. At the same time, this raises the possibility of shifting the quantity metering for additive fluid to a single metering valve that serves an entire group of injectors.

Owner:ROBERT BOSCH GMBH

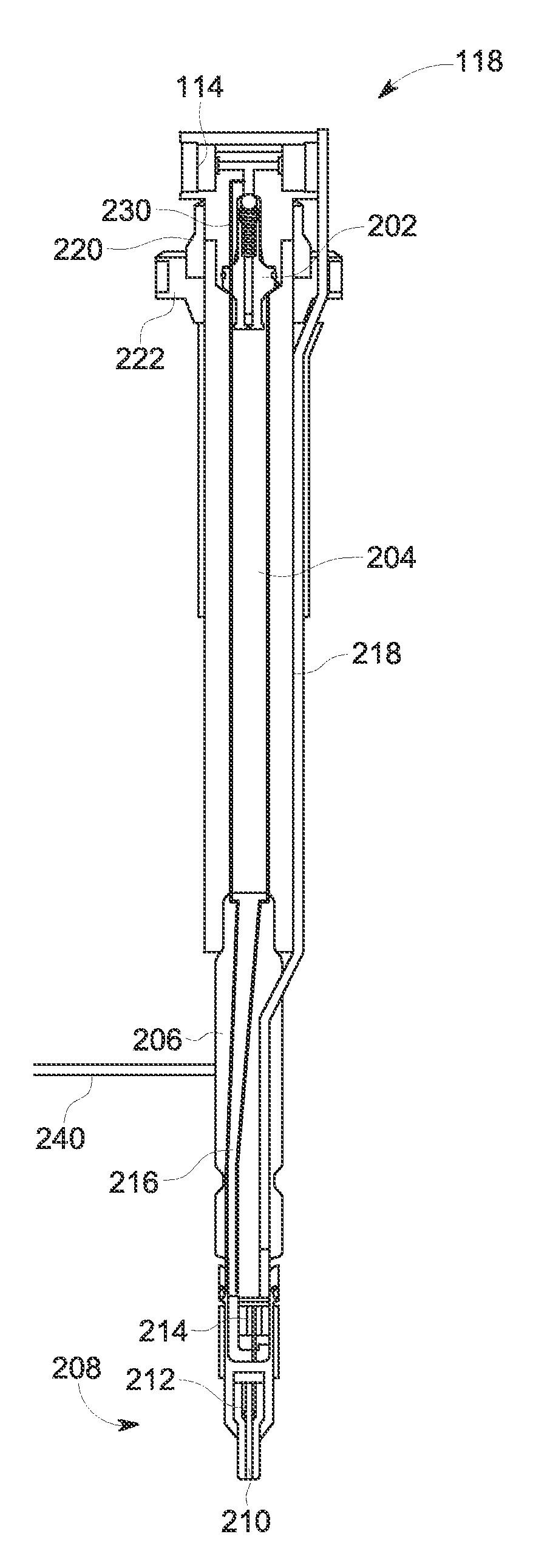

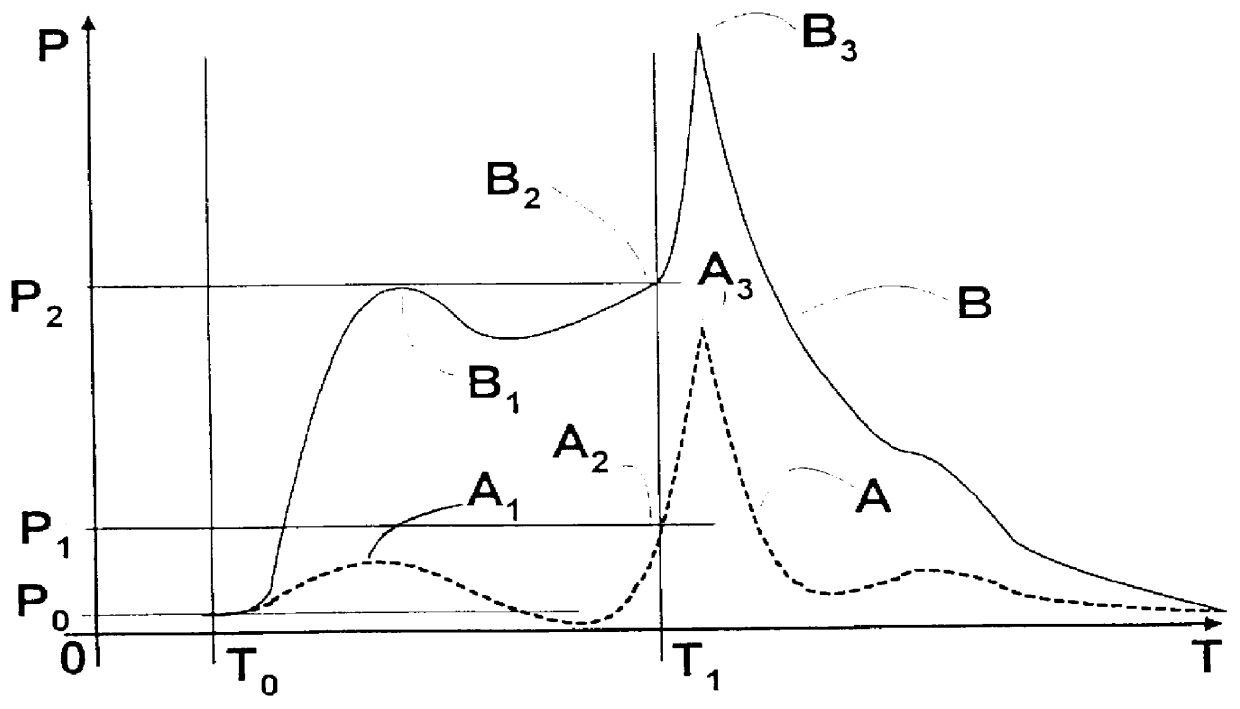

Relating to fuel injection systems

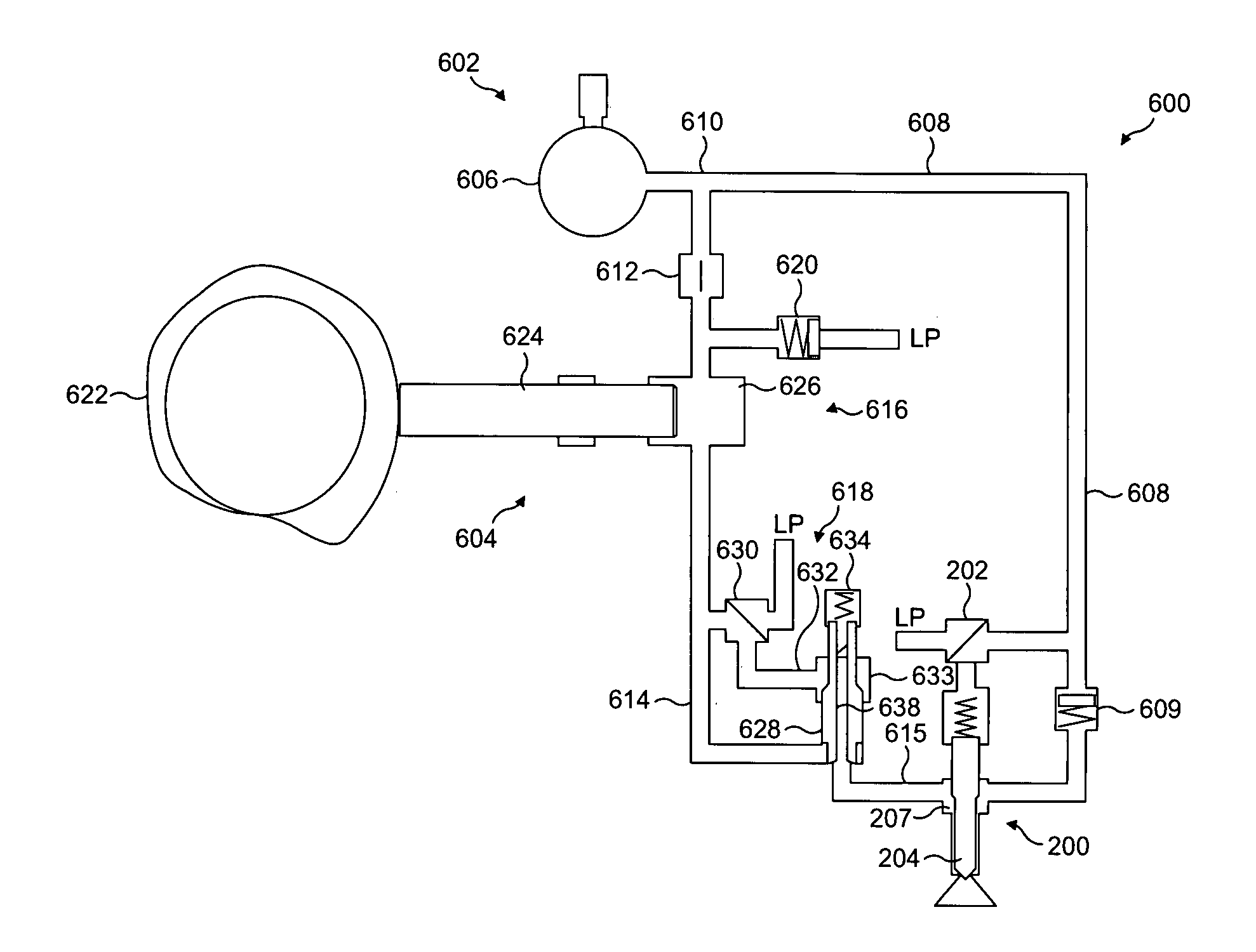

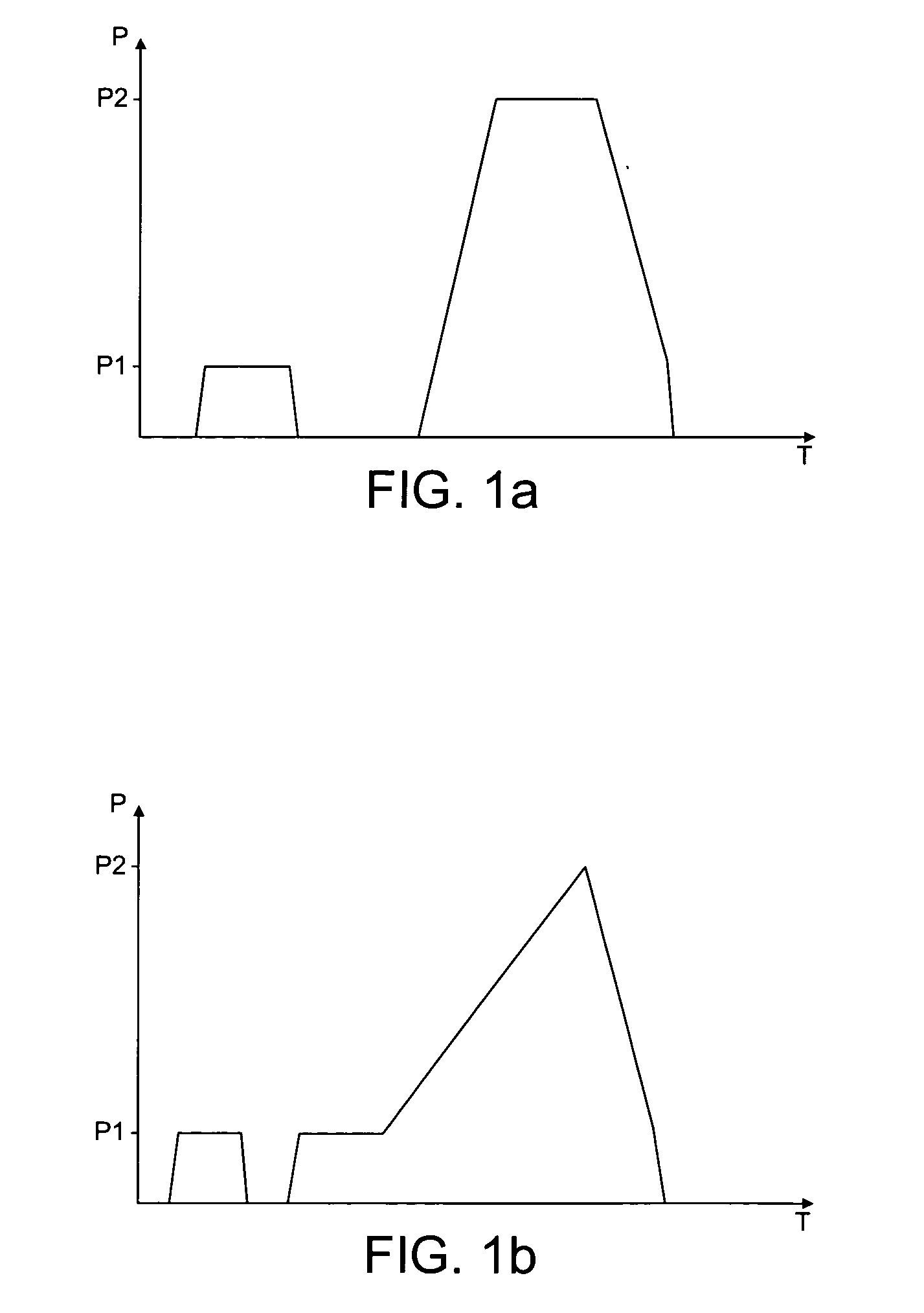

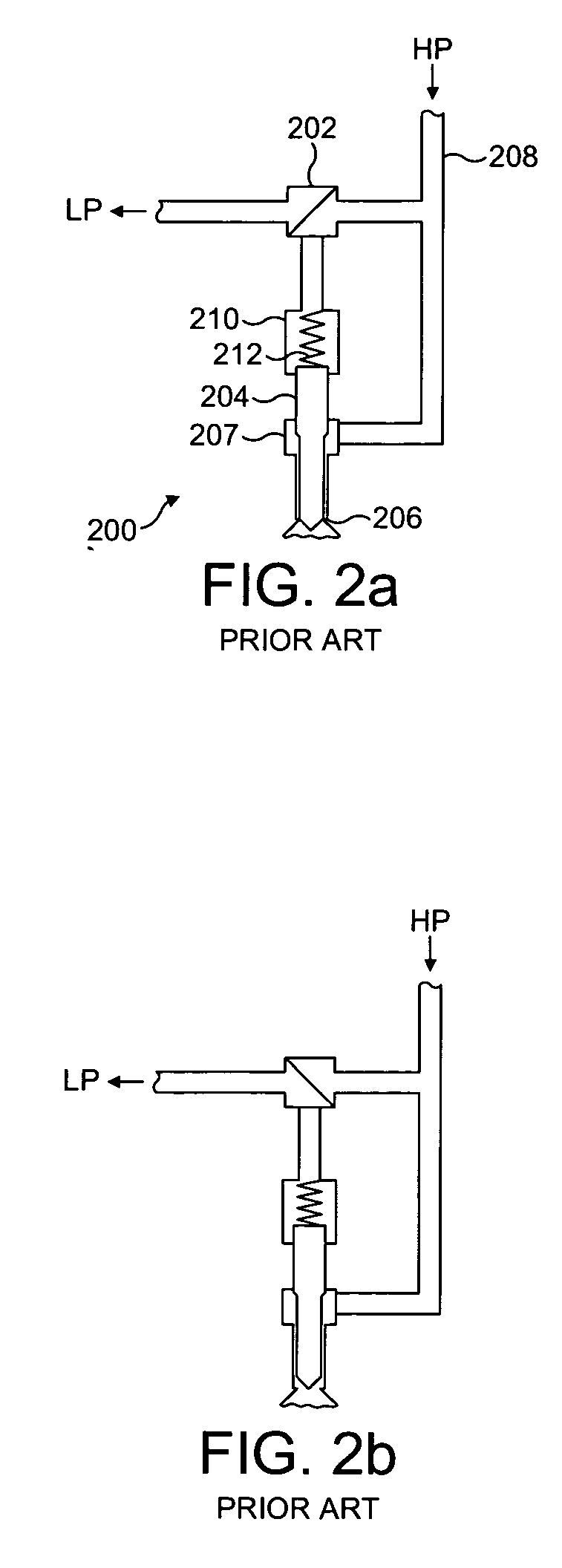

InactiveUS20060243253A1Increase pressurePrevent backflowLow-pressure fuel injectionMachines/enginesRail pressureFuel supply

A fuel injection system for supplying pressurised fuel to a fuel injector (200) comprises an accumulator volume (606) for supplying fuel at rail pressure (P1) to the fuel injector (200) through a rail fuel supply passage (608) and a fuel pressurising arrangement (604) for supplying fuel at a selected pressure greater than rail pressure (P2) to the fuel injector (200) through a pressurised fuel supply passage (614). A fuel shut-off valve (618) is provided in the system which is operable between a closed position in which fuel is retained within the pressurising arrangement (604) and an open position in which pressurised fuel is supplied to the injector (200) from the pressurising arrangement (604) during an injection of fuel from the rail fuel supply passage (608). Operating the shut-off valve in this way provides a boost in the fuel pressure delivered during an injection event.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

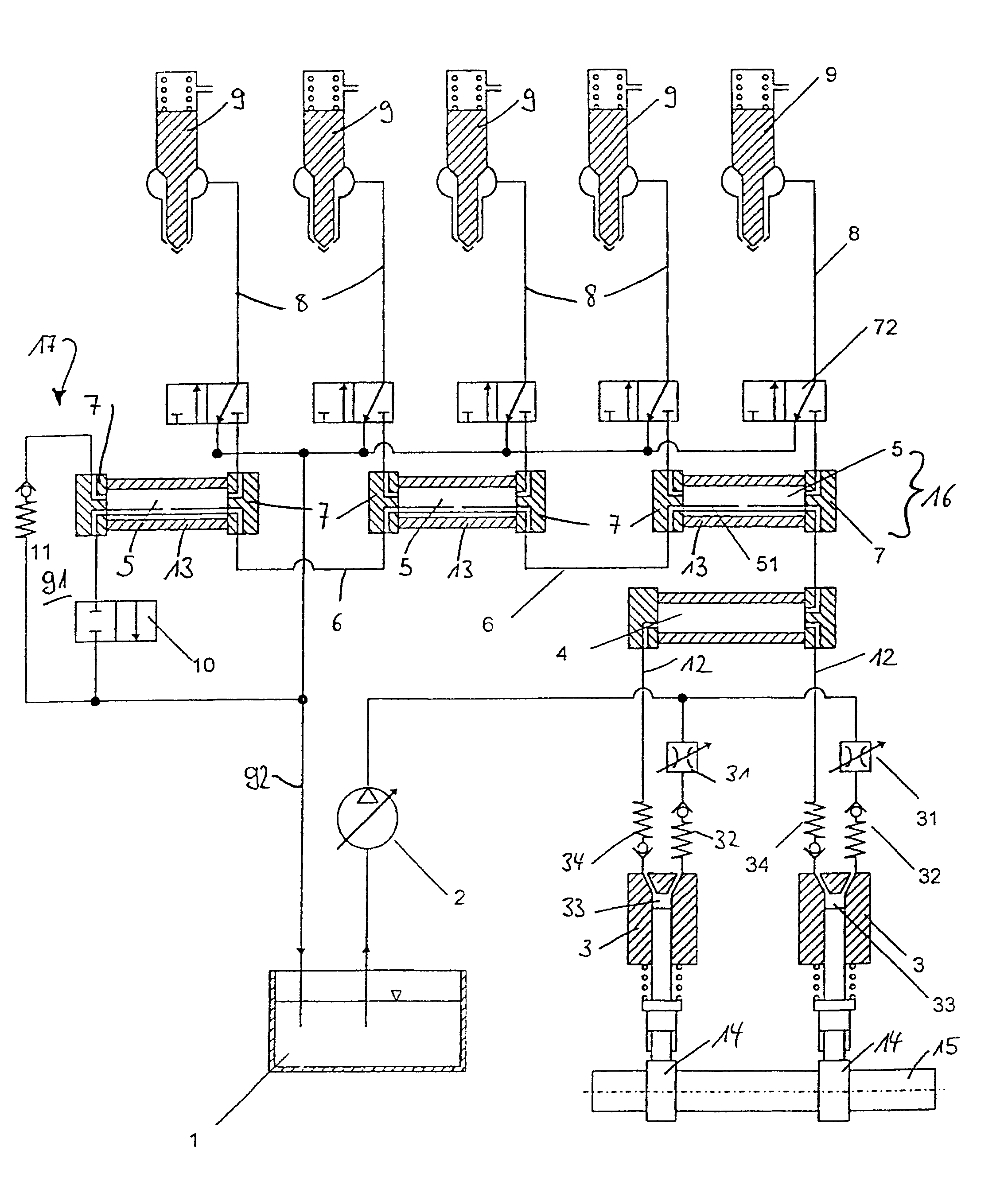

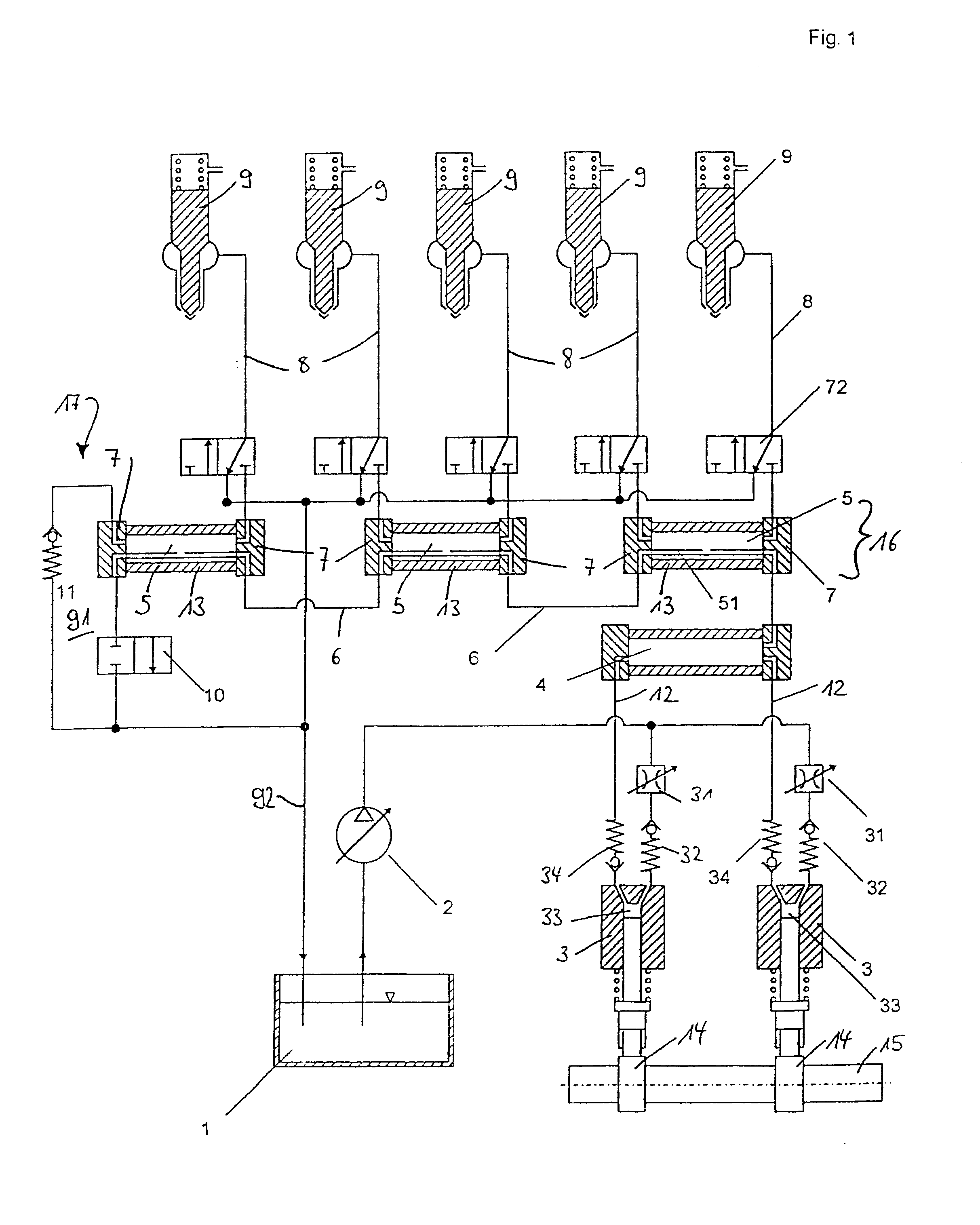

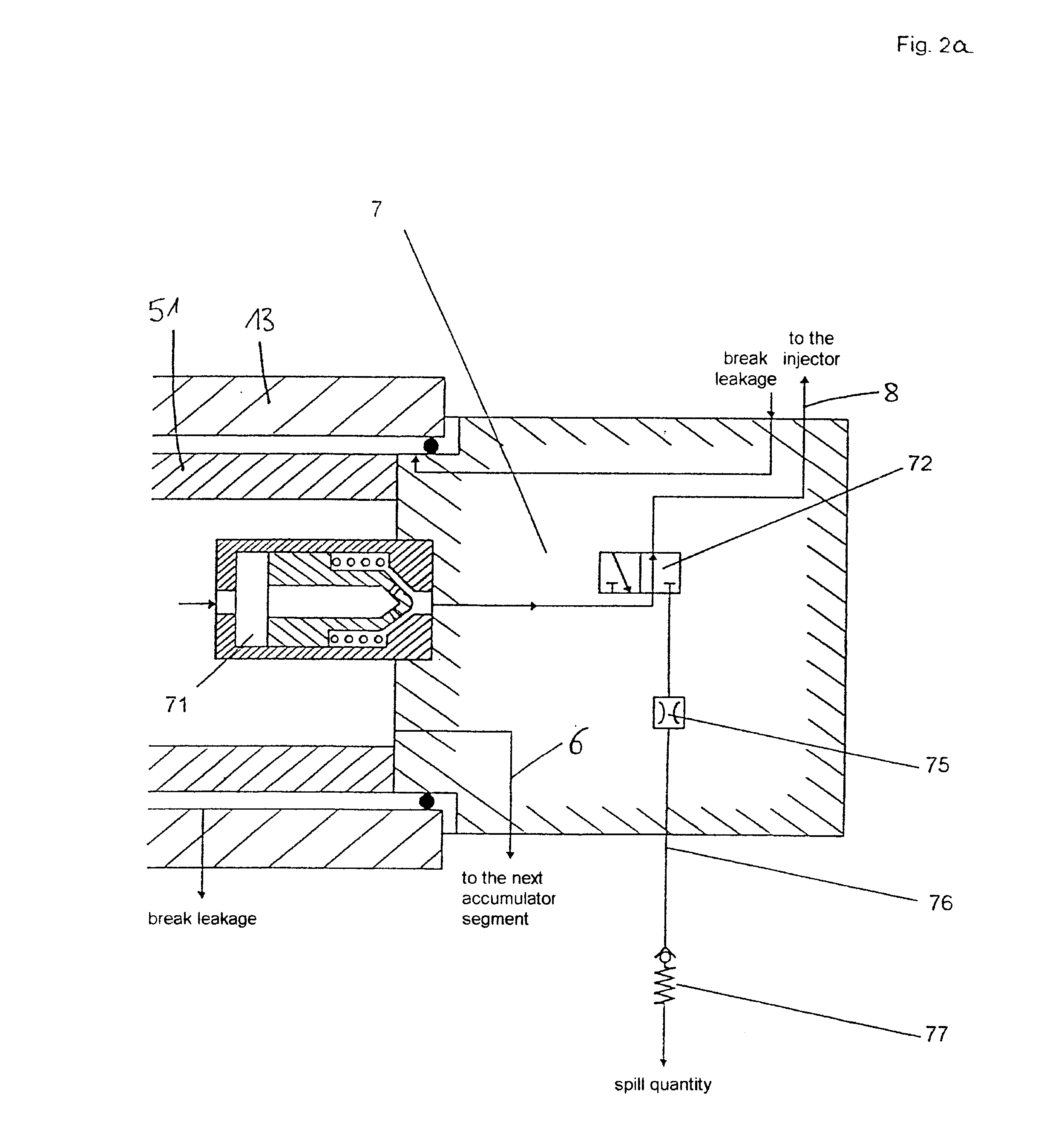

Device for injecting fuel to stationary internal combustion engines

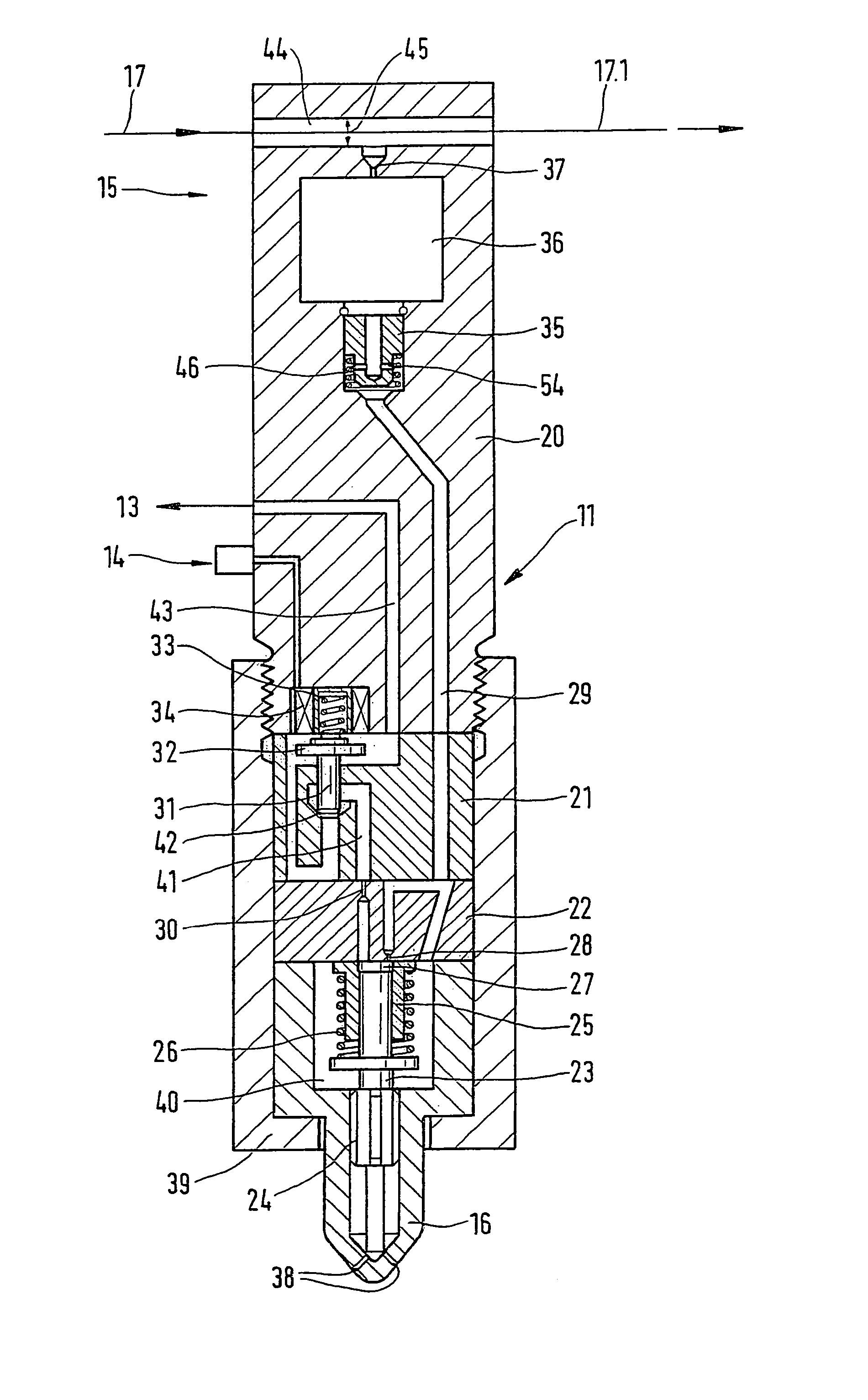

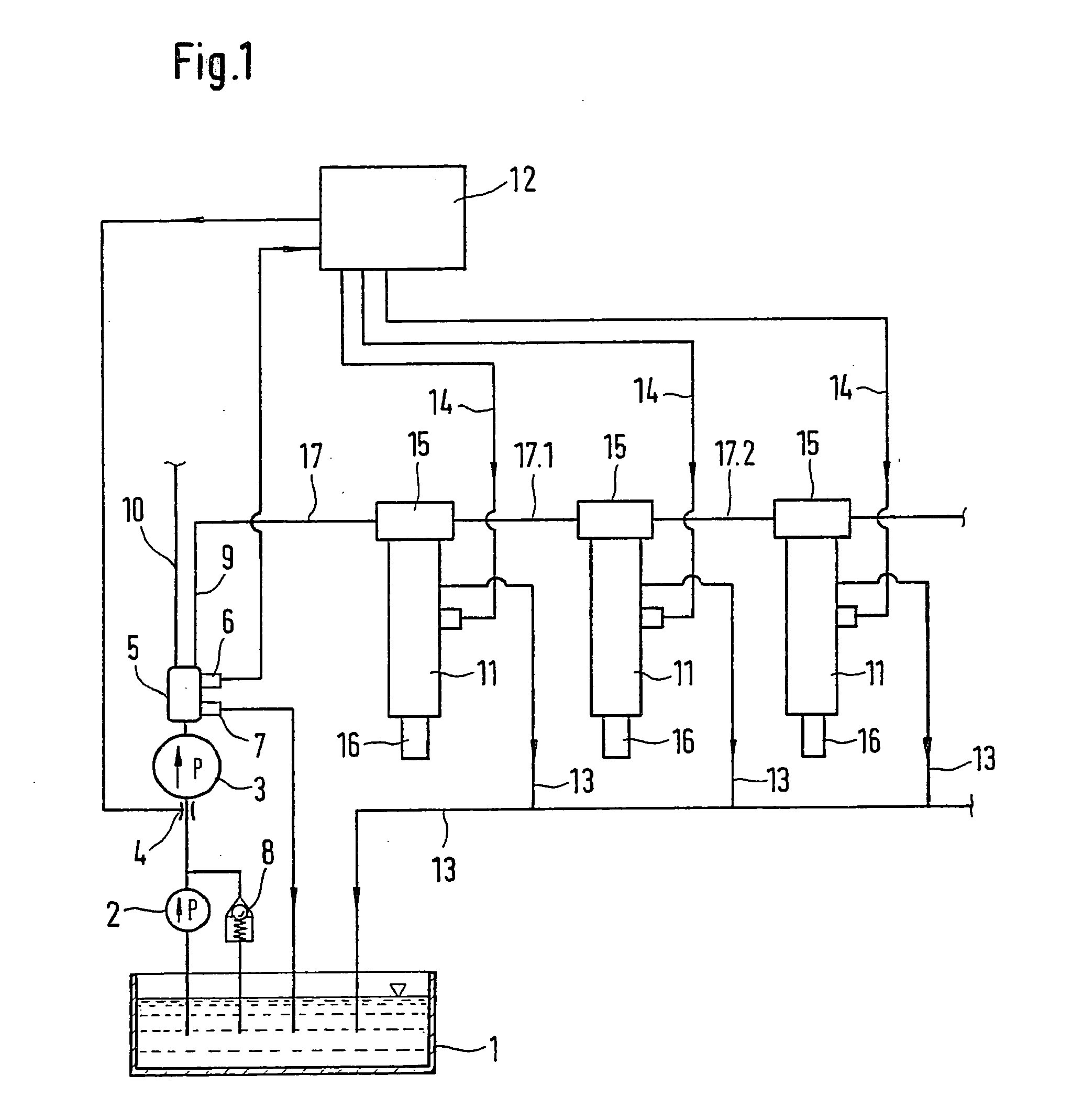

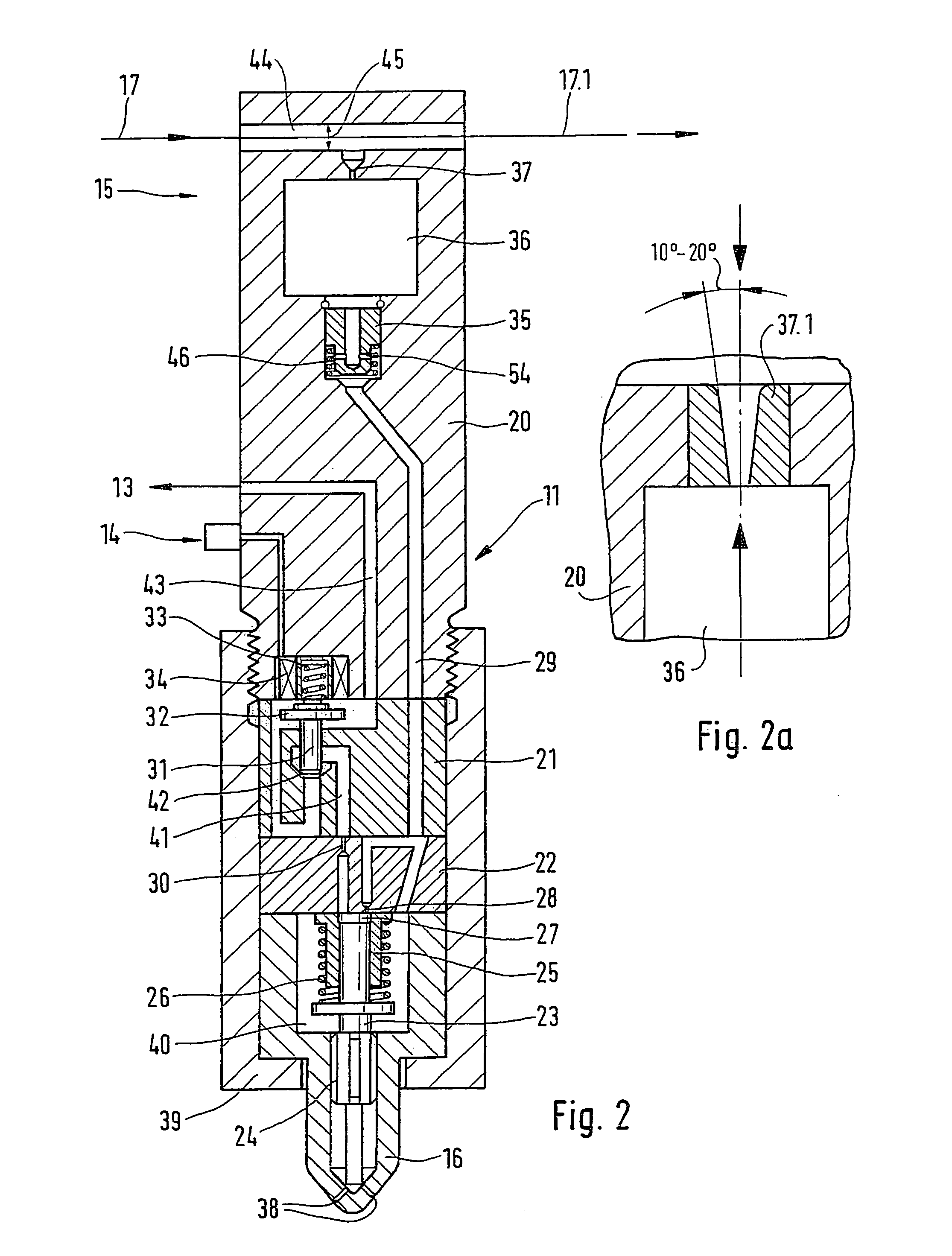

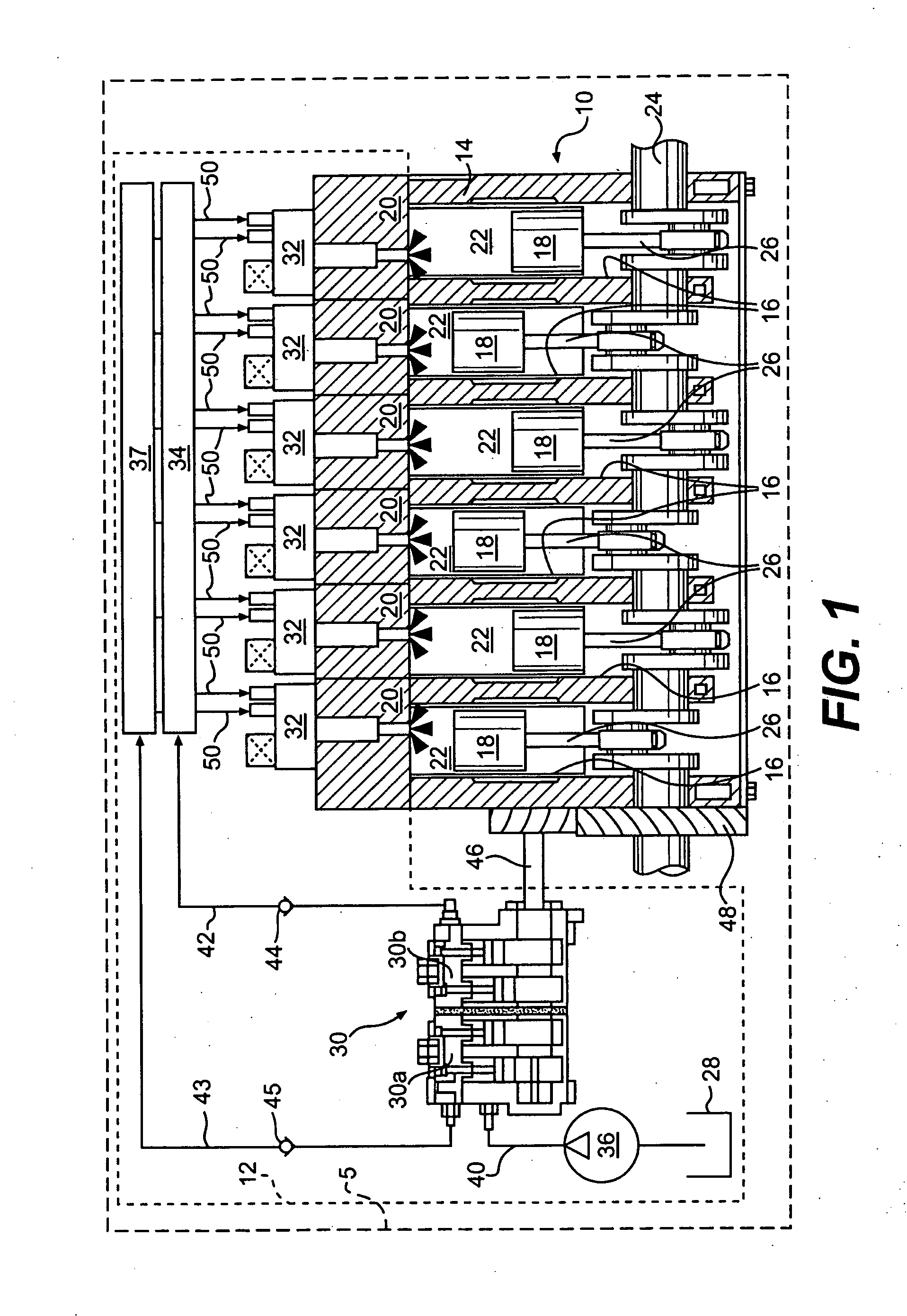

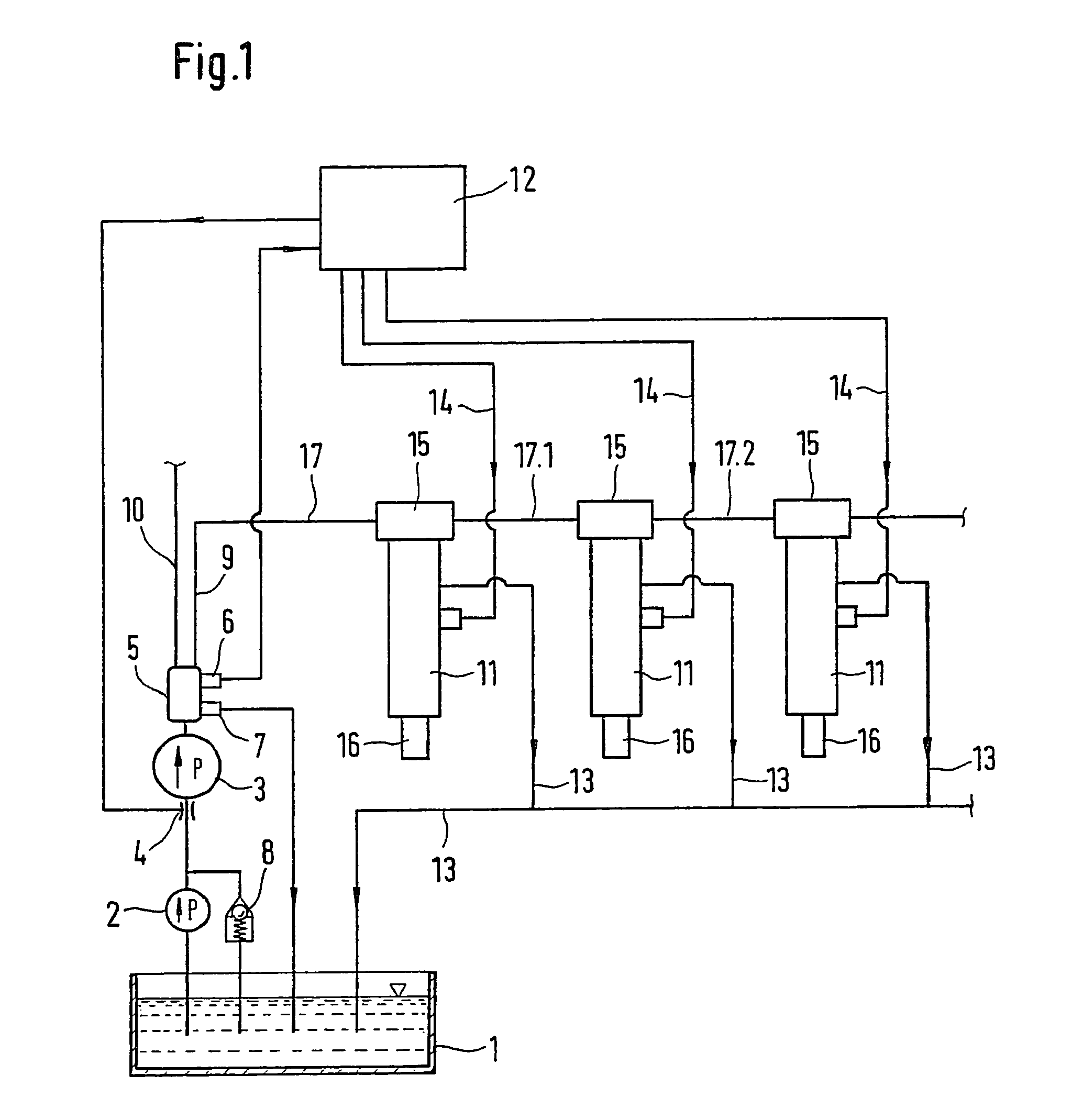

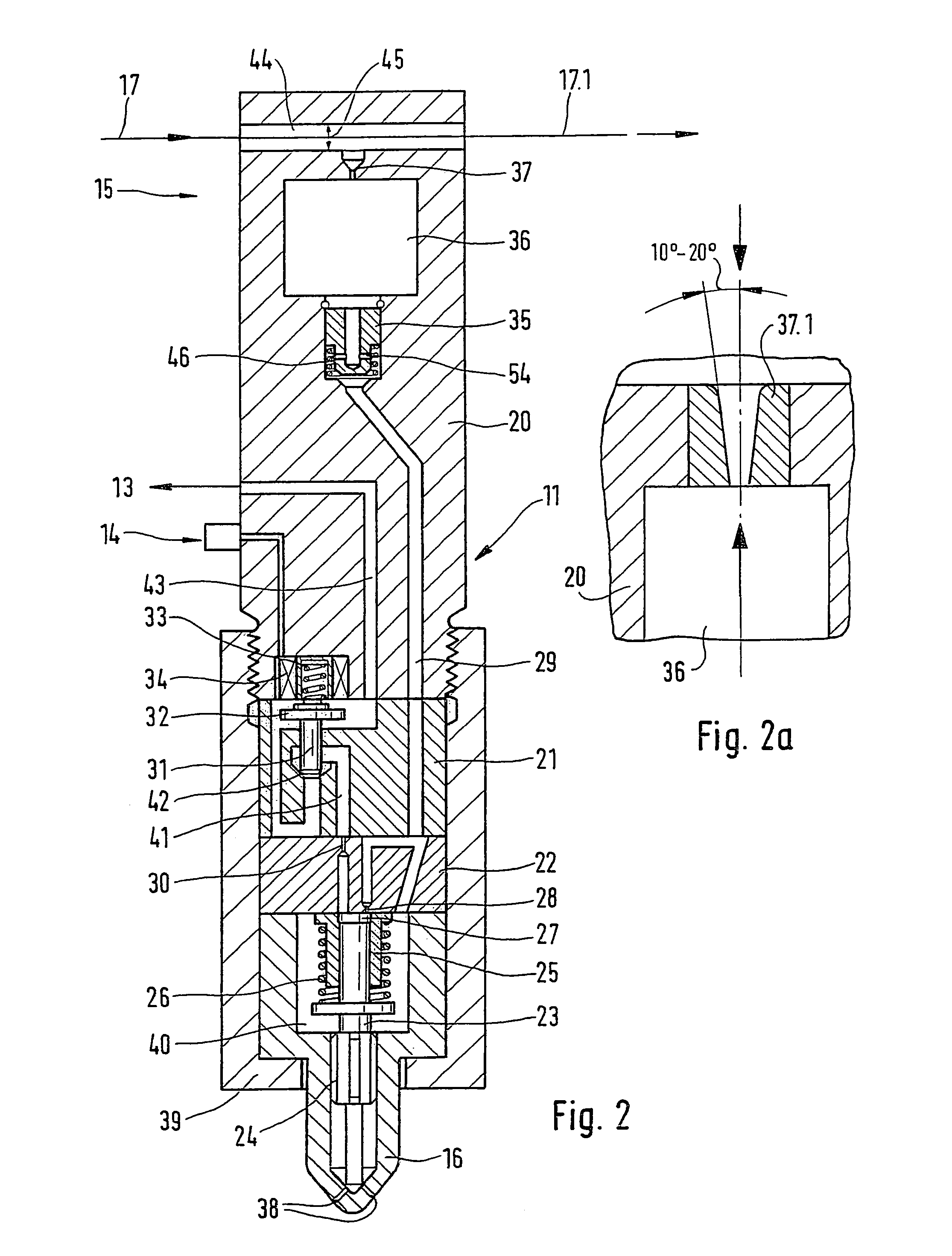

InactiveUS20040187848A1Easy to adaptAchieve modularityCasingsCombustion enginesCombustion chamberLine tubing

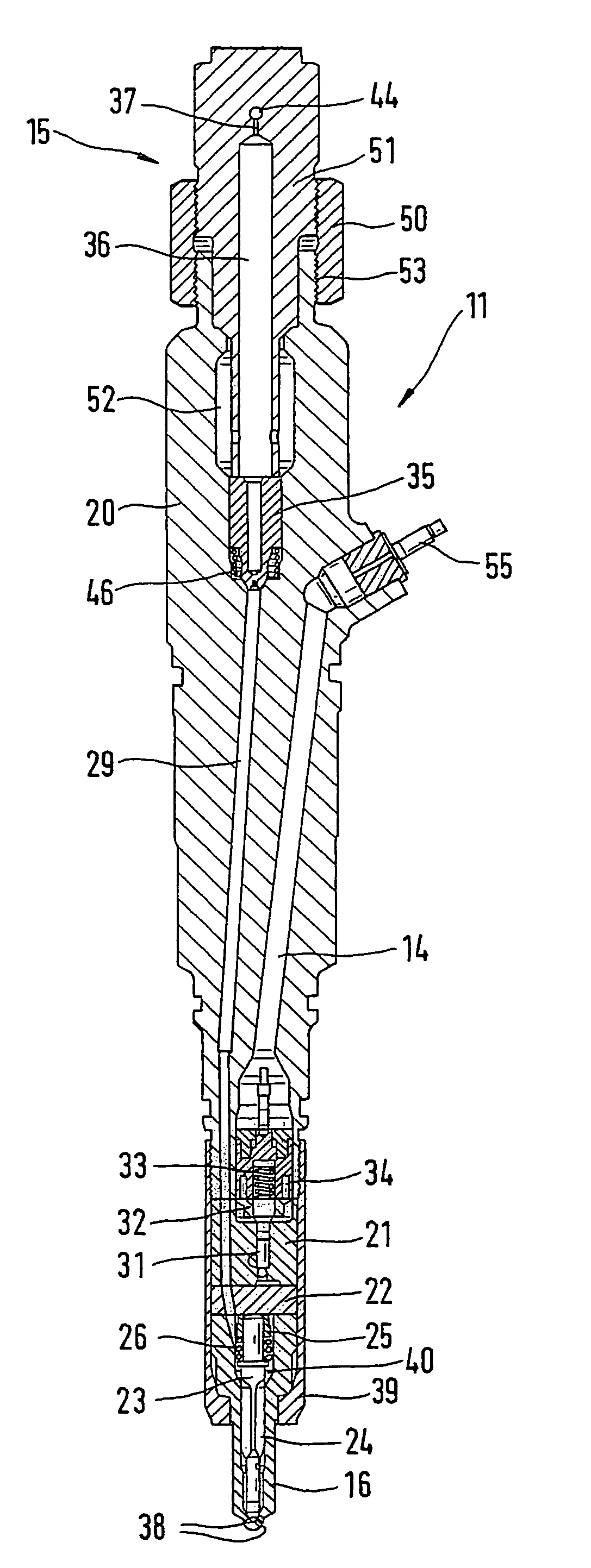

The invention relates to a fuel injection system for use in internal combustion engines. The injection system has having delivery units (2, 3) for delivering fuel from a fuel reservoir (1) in order to supply at least one high-pressure line (9, 10) to the cylinders of the engine. The at least one high-pressure line (9, 10) supplies a number of fuel injectors (11), which each include an injector nozzle (16) that supplies fuel to a combustion chamber of the engine. The at least one high-pressure line (9, 10) and includes line segments (17, 17.1, 17.2) that connect the individual fuel injectors (11) to one another. The injector bodies (20) of the fuel injectors (11) each have an accumulator chamber (36, 36.1) integrated into them.

Owner:ROBERT BOSCH GMBH

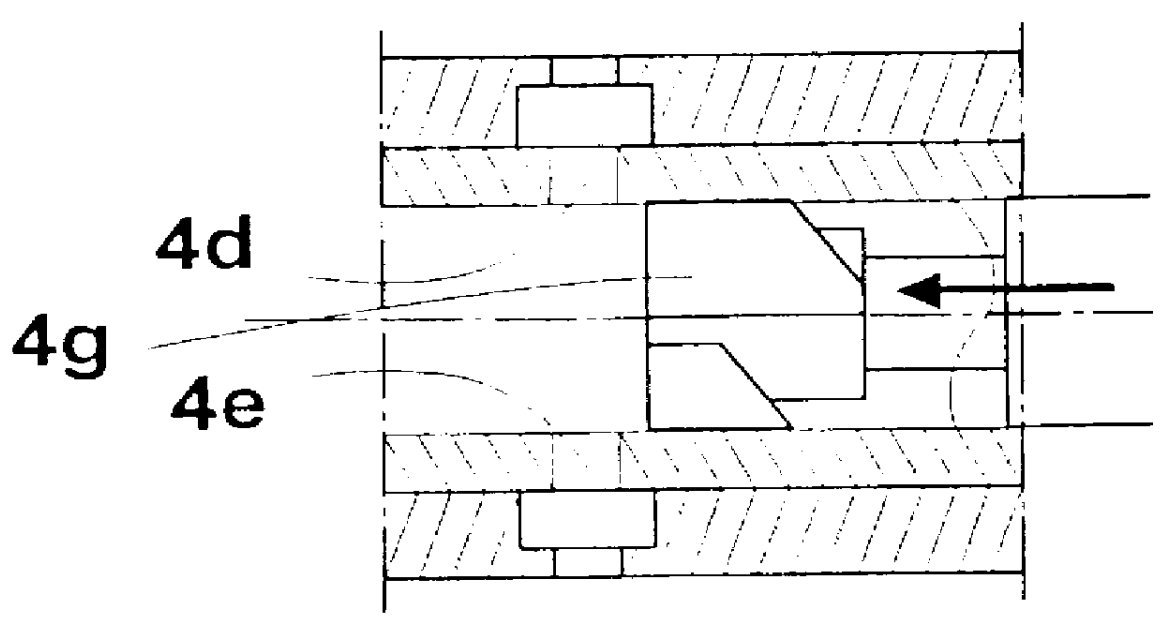

Device for avoiding cavitation in injection pumps

InactiveUS6065453AReduced component wearMinimize dispersionMachines/enginesFuel injecting pumpsCavitationInternal combustion engine

The invention provides a device for eliminating cavitation in the excess fuel return orifice(s) in the compression chamber of a fuel injection pump of an internal combustion engine after the end of the injection stage, said injection pump being connected firstly to a feed duct including a first check valve having low headloss enabling fuel to reach the compression chamber, and secondly to an excess fuel return duct, wherein the return duct comprises in parallel and close to the return orifice of the injection pump, a second check valve that is rated to cause the pressure in said return orifice of the injection pump to rise, and a two-port valve that is normally open and that is caused to close by the appearance of pressure in the return orifice greater than the pressure which obtains in the feed duct upstream from said first check valve.

Owner:SEMT PIELSTICK

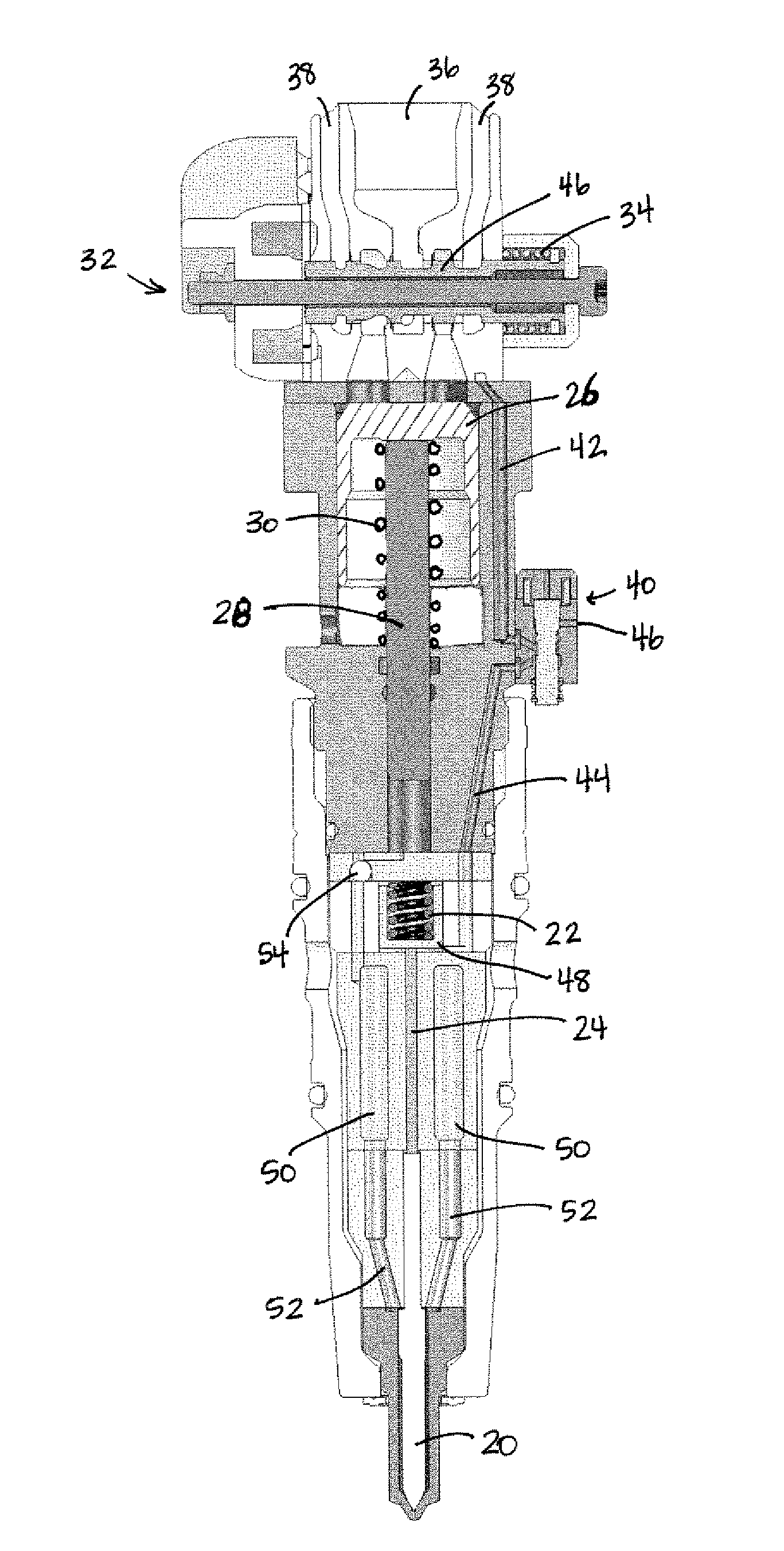

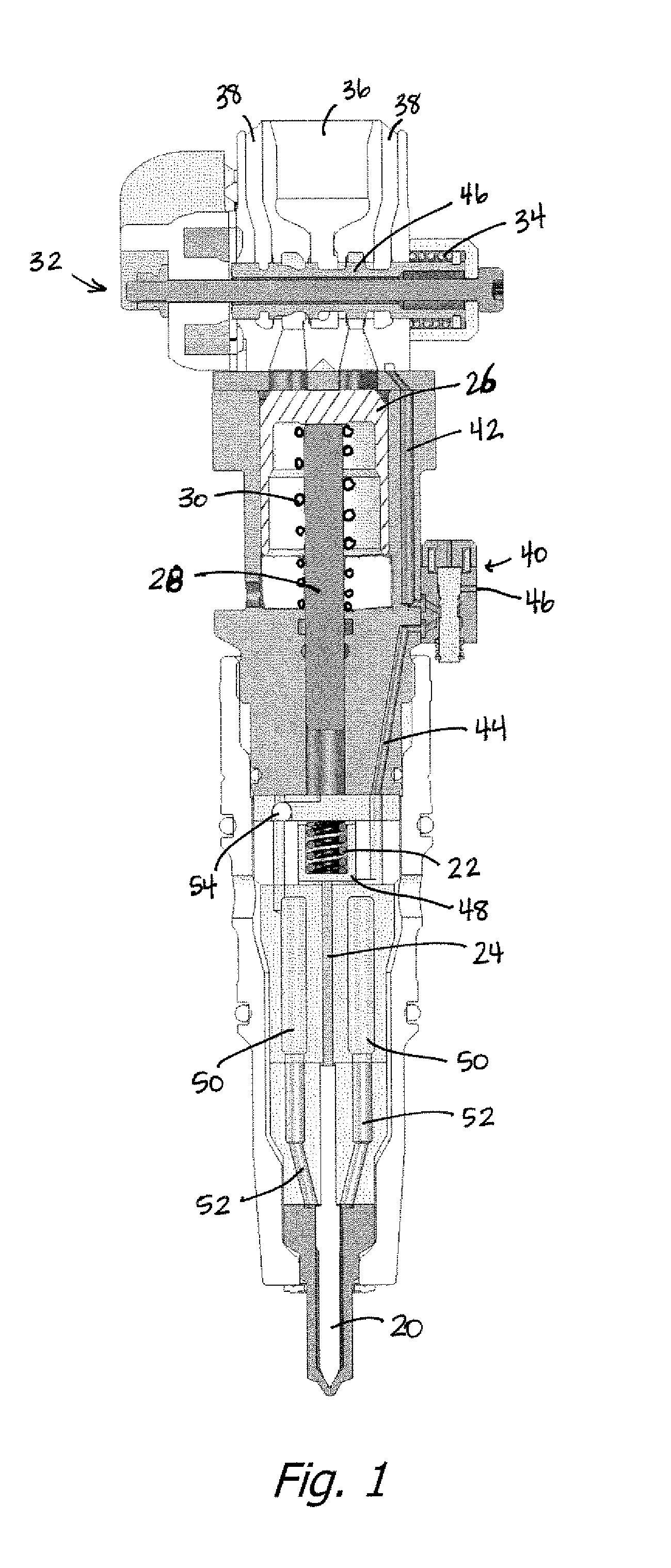

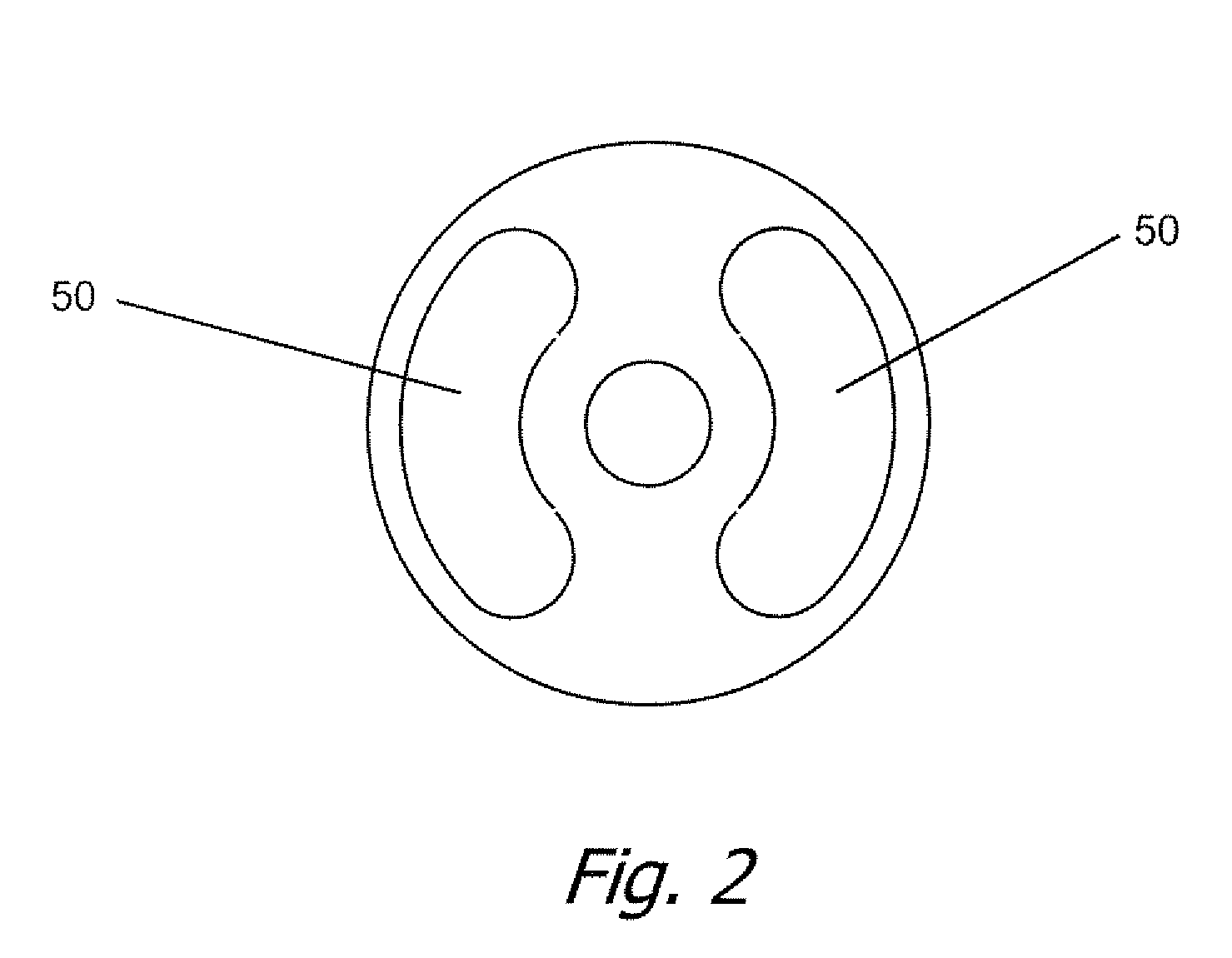

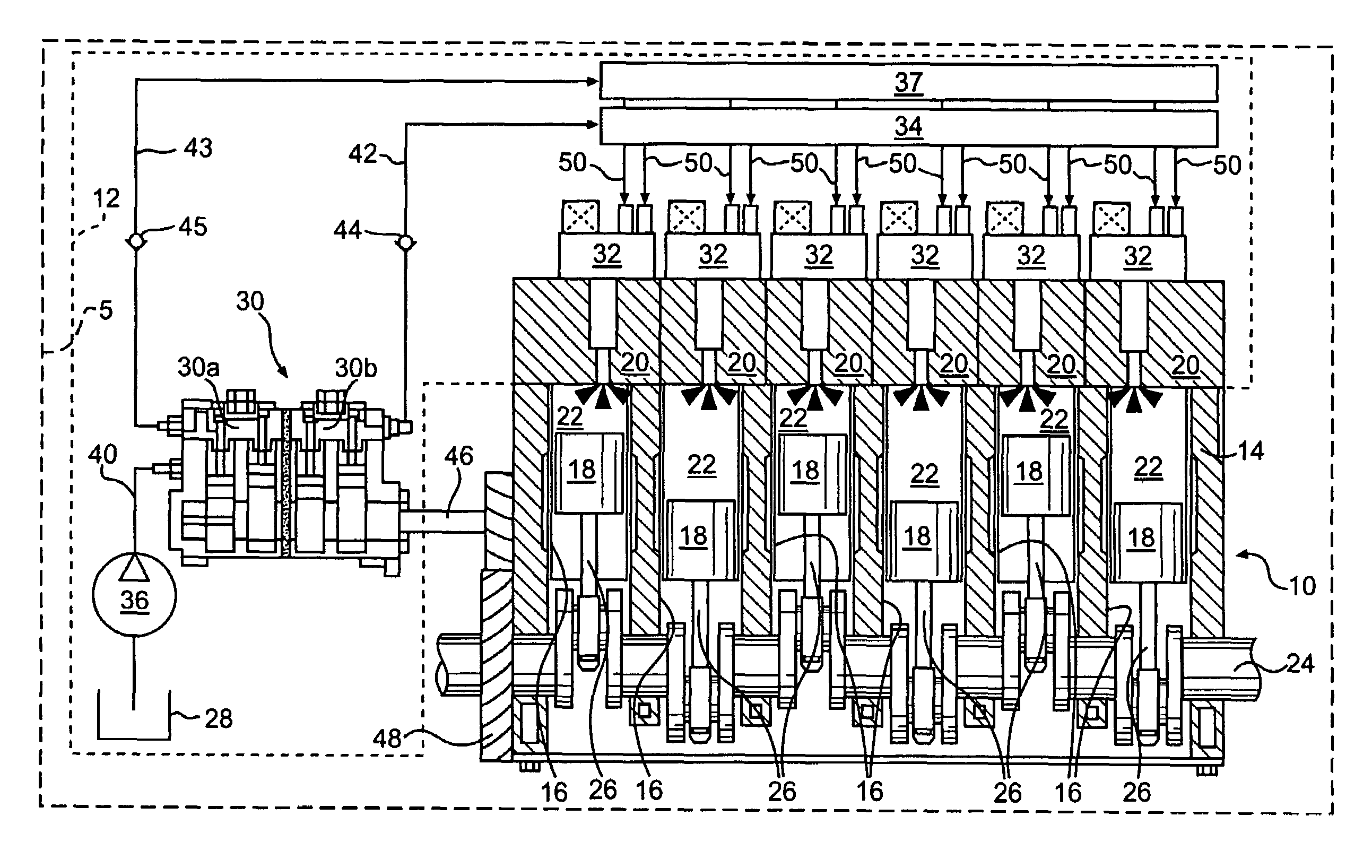

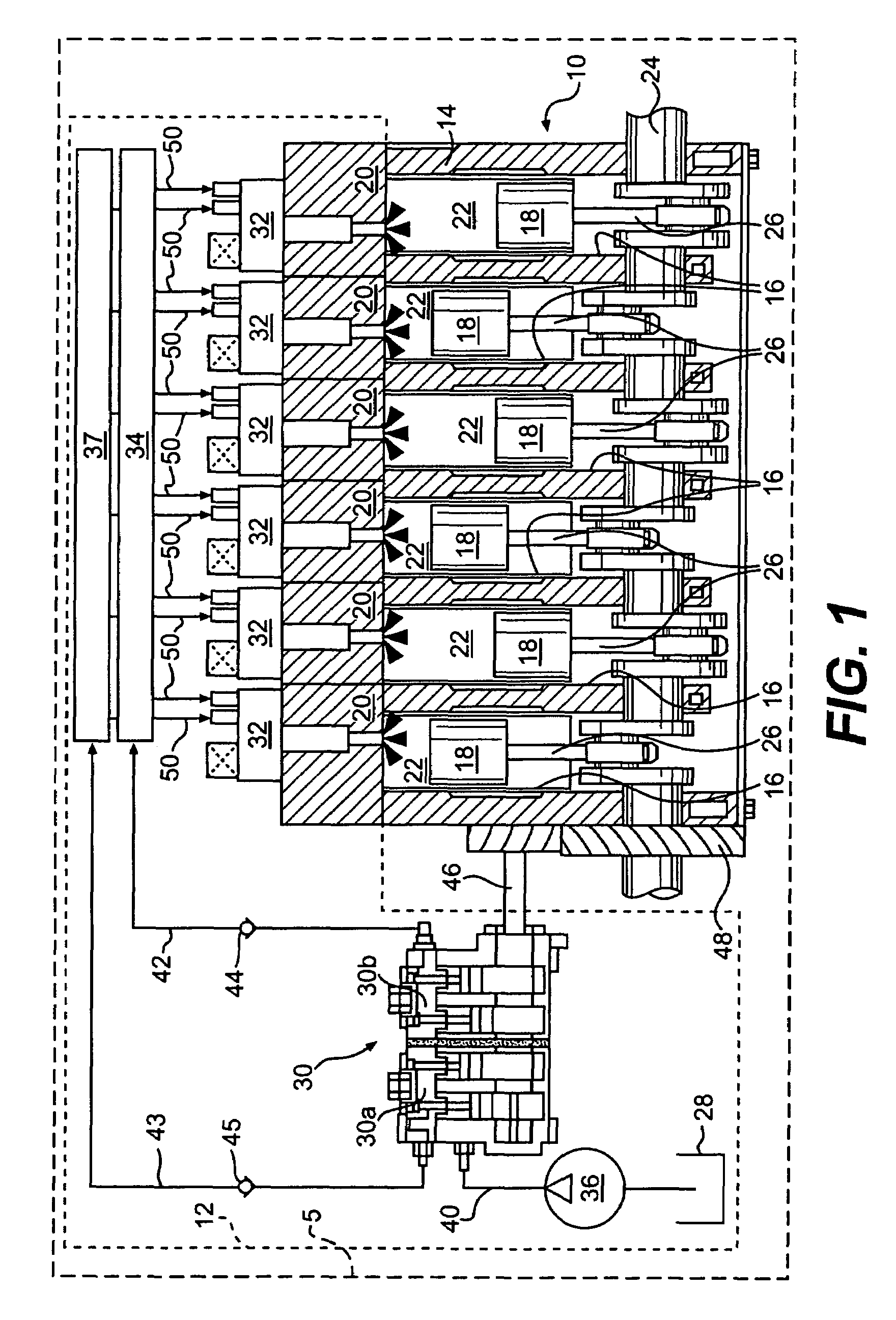

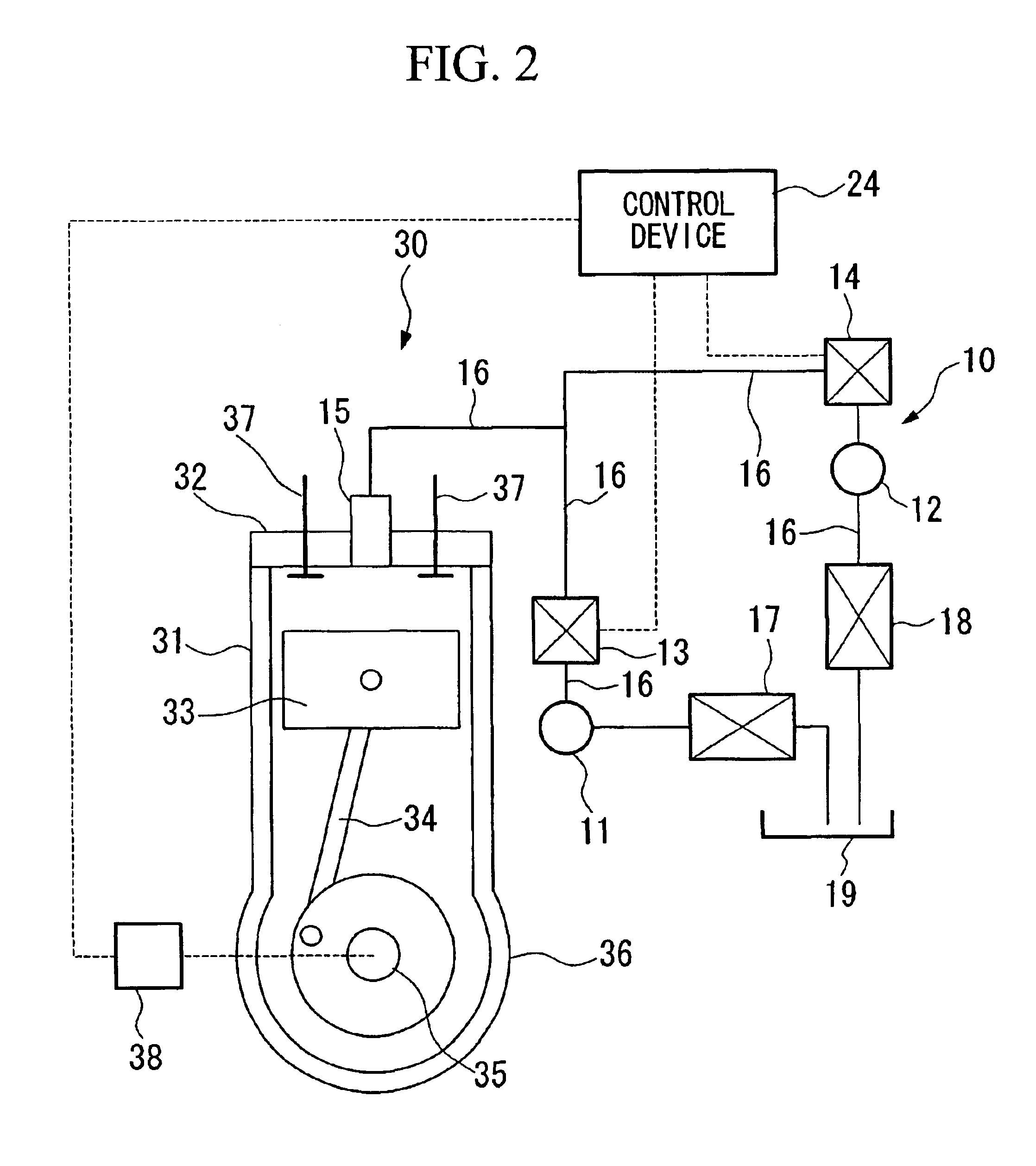

Fuel Injectors with Intensified Fuel Storage and Methods of Operating an Engine Therewith

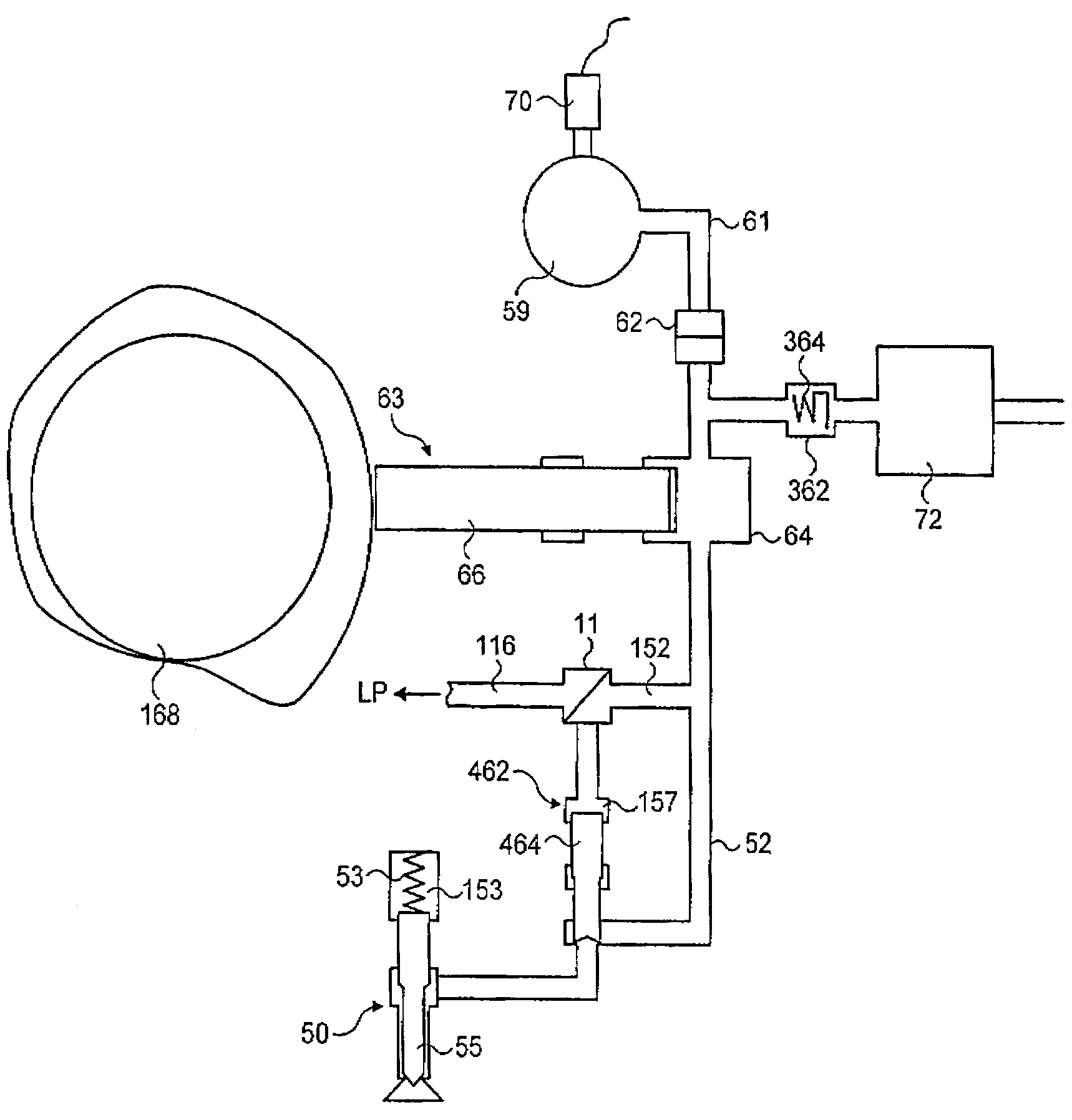

InactiveUS20100012745A1Eliminate disadvantagesMachines/enginesFuel injecting pumpsInjection pressureCheck valve

Fuel injectors with intensified fuel storage and methods of operating an engine therewith. At least one storage cavity is provided in the intensifier type fuel injector, with a check valve between the intensifier and the needle chamber and storage cavity preventing loss of injection pressure while the intensifier plunger cylinder is refilling with fuel. This provides very efficient injector operation, particularly at low engine loads, by eliminating the wasted energy of compressing, venting and recompressing fuel for injection. Various injector designs and methods of operating the same in an engine are disclosed.

Owner:STURMAN DIGITAL SYST

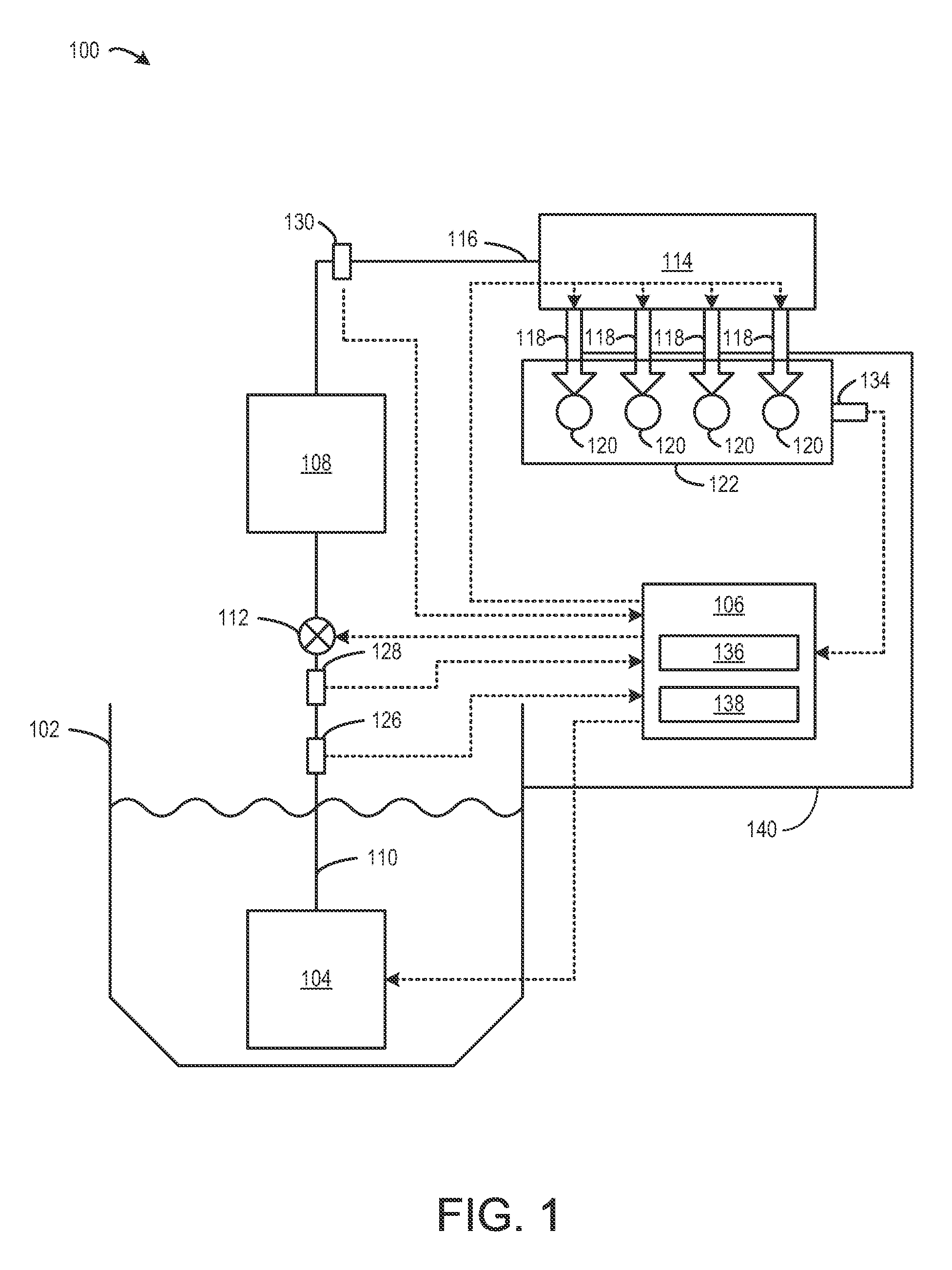

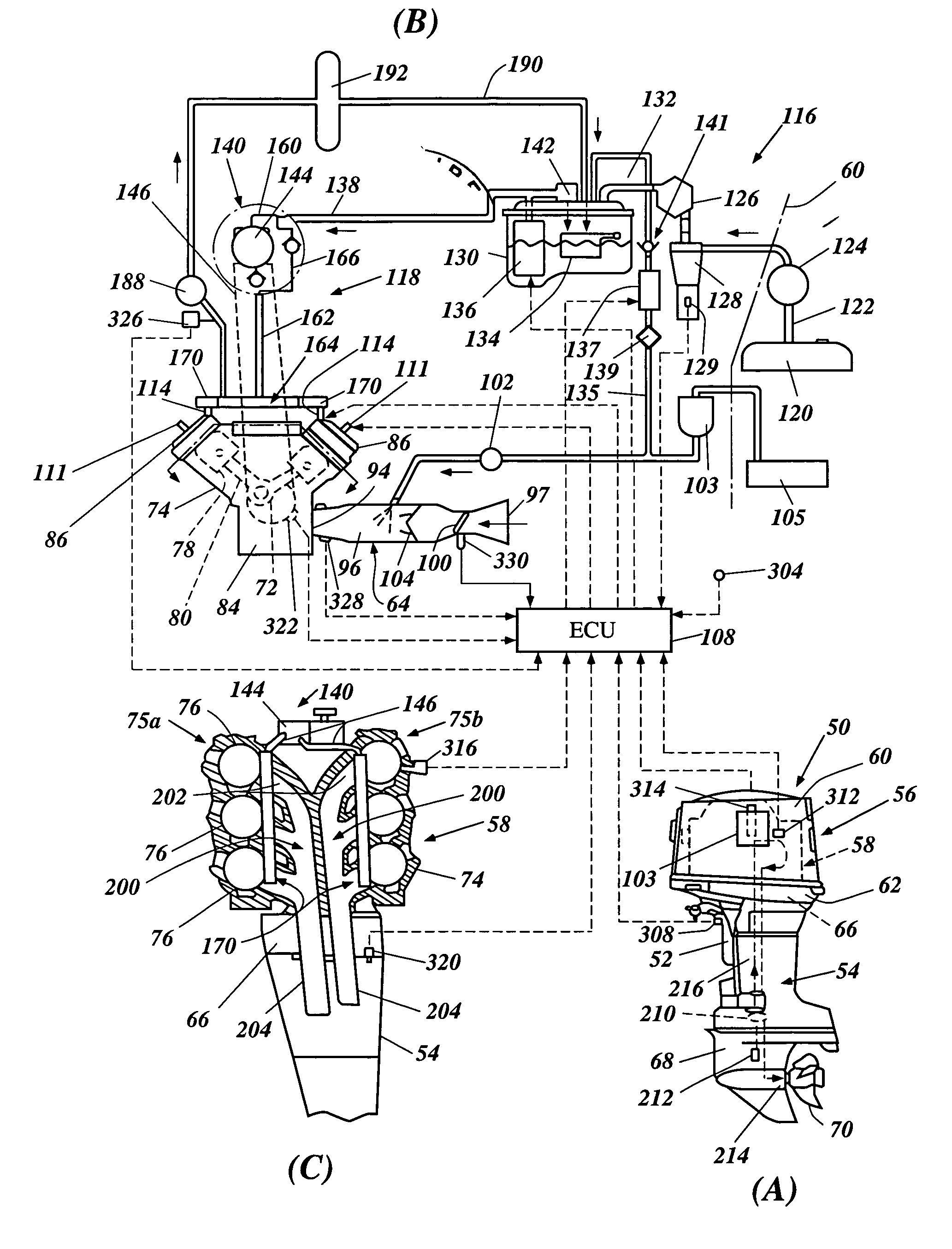

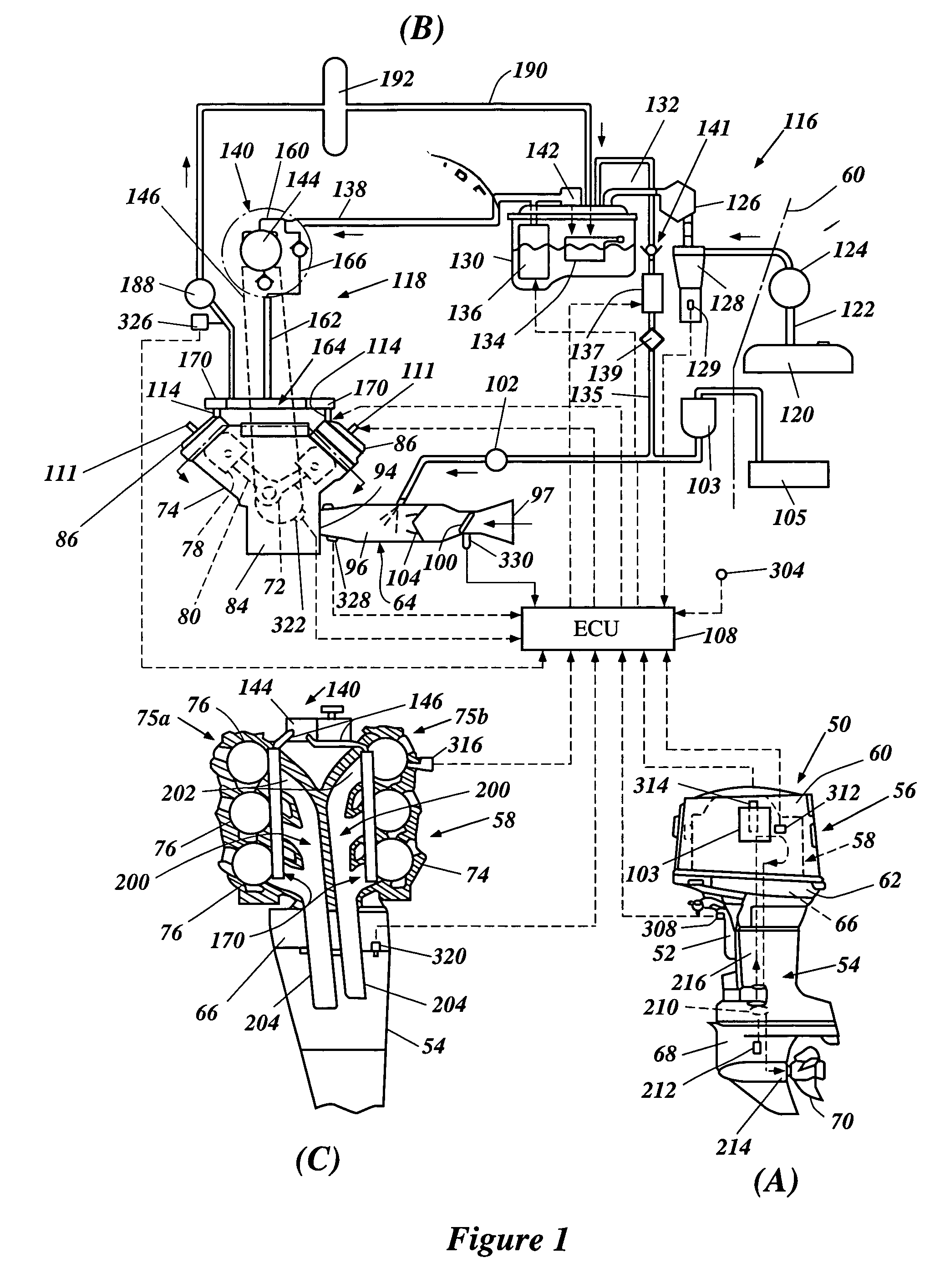

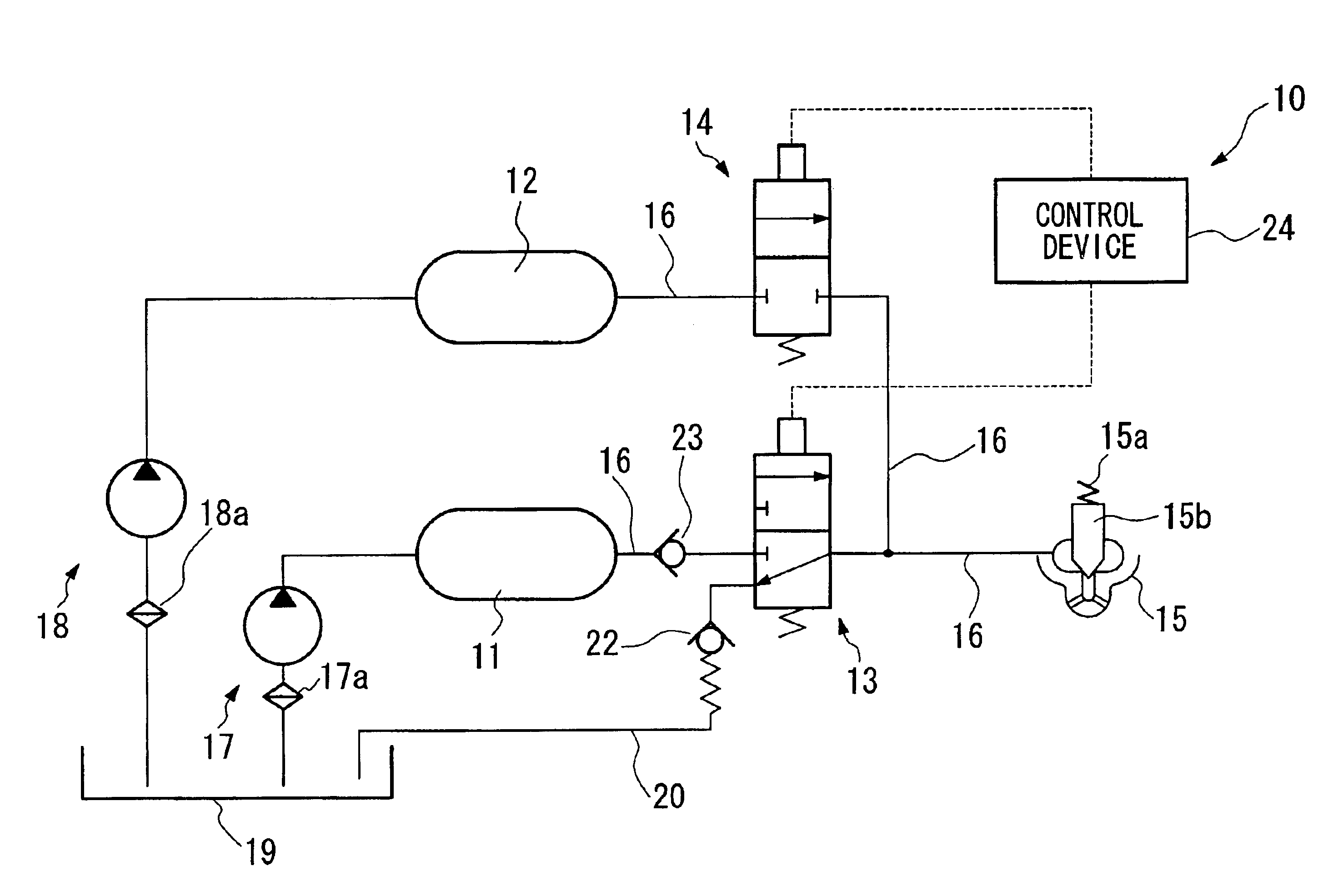

Fuel injection system for outboard motor

InactiveUS7004146B1Reduce pressure pulsationReduce fuel pressure fluctuationsCasingsMachines/enginesForce sensorPressure measurement

An engine of an outboard motor includes a fuel injection system that is configured to increase the accuracy of fuel pressure measurements and more precisely control the amount of fuel injected. In a preferred mode, the fuel injection system can include a pressure dampening device that is connected to the direct fuel injected system. The system can also include a vibration dampening apparatus that protects a pressure sensor from damage that can be caused by engine vibrations.

Owner:YAMAHA MARINE KK

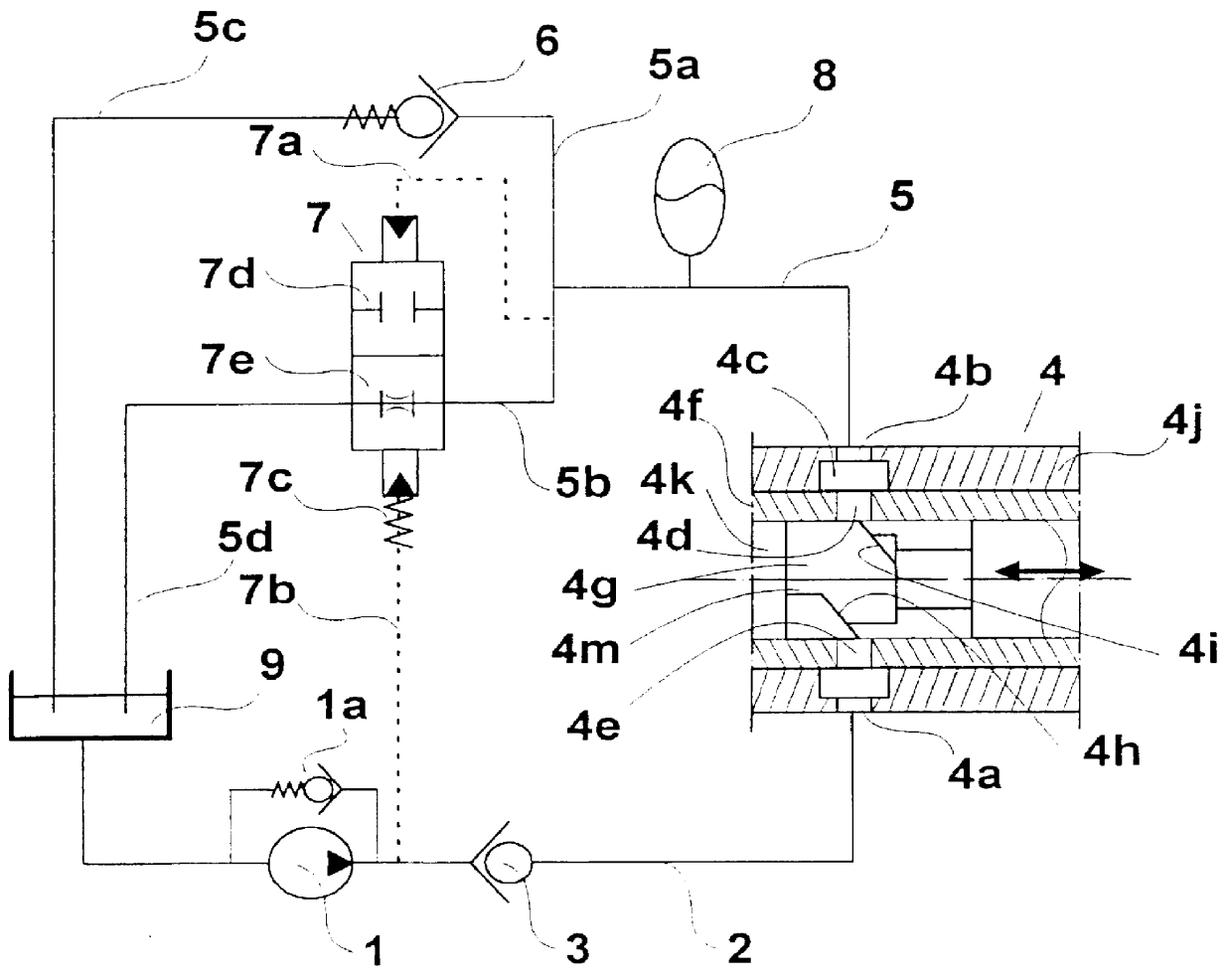

Multi-source fuel system for variable pressure injection

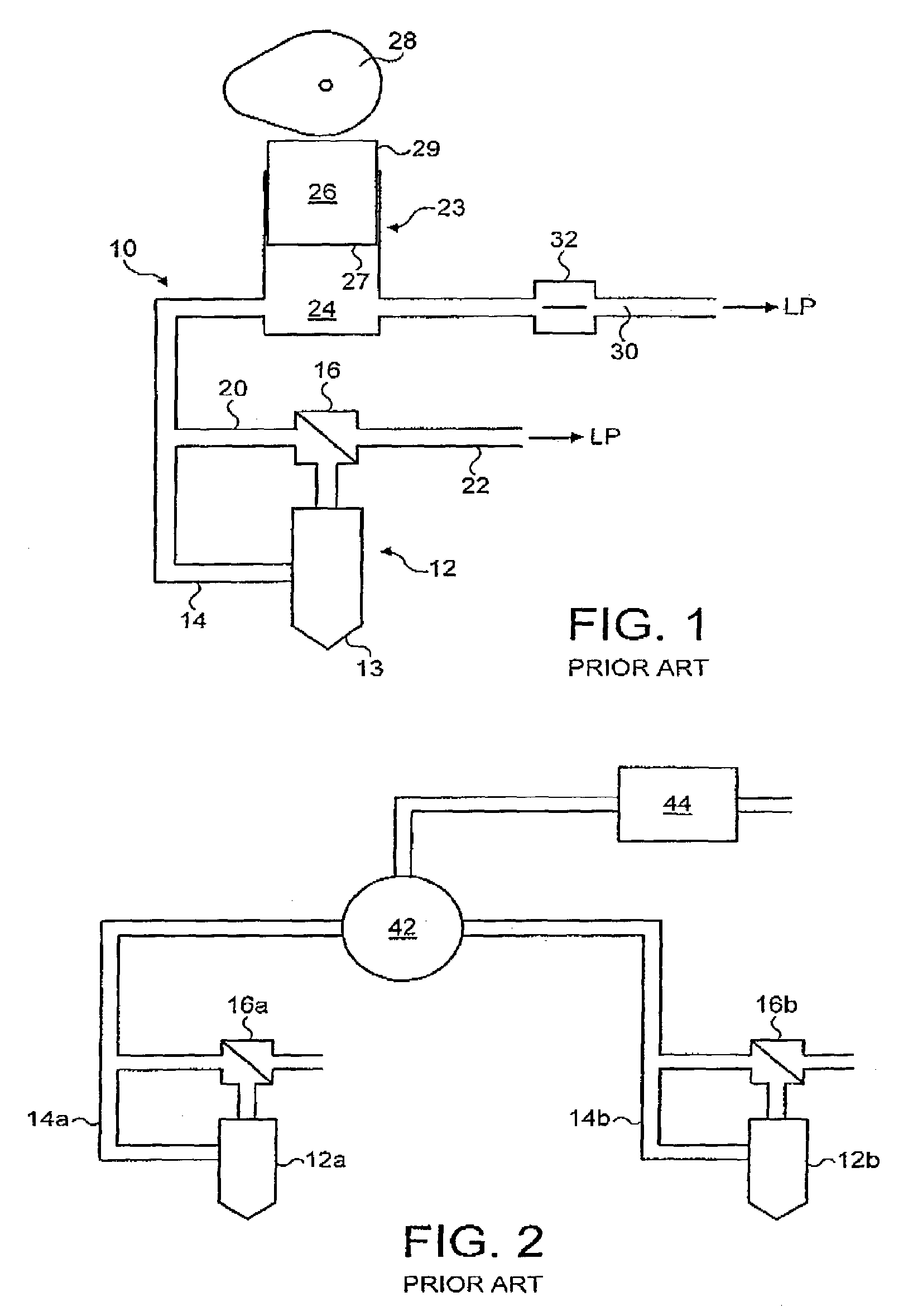

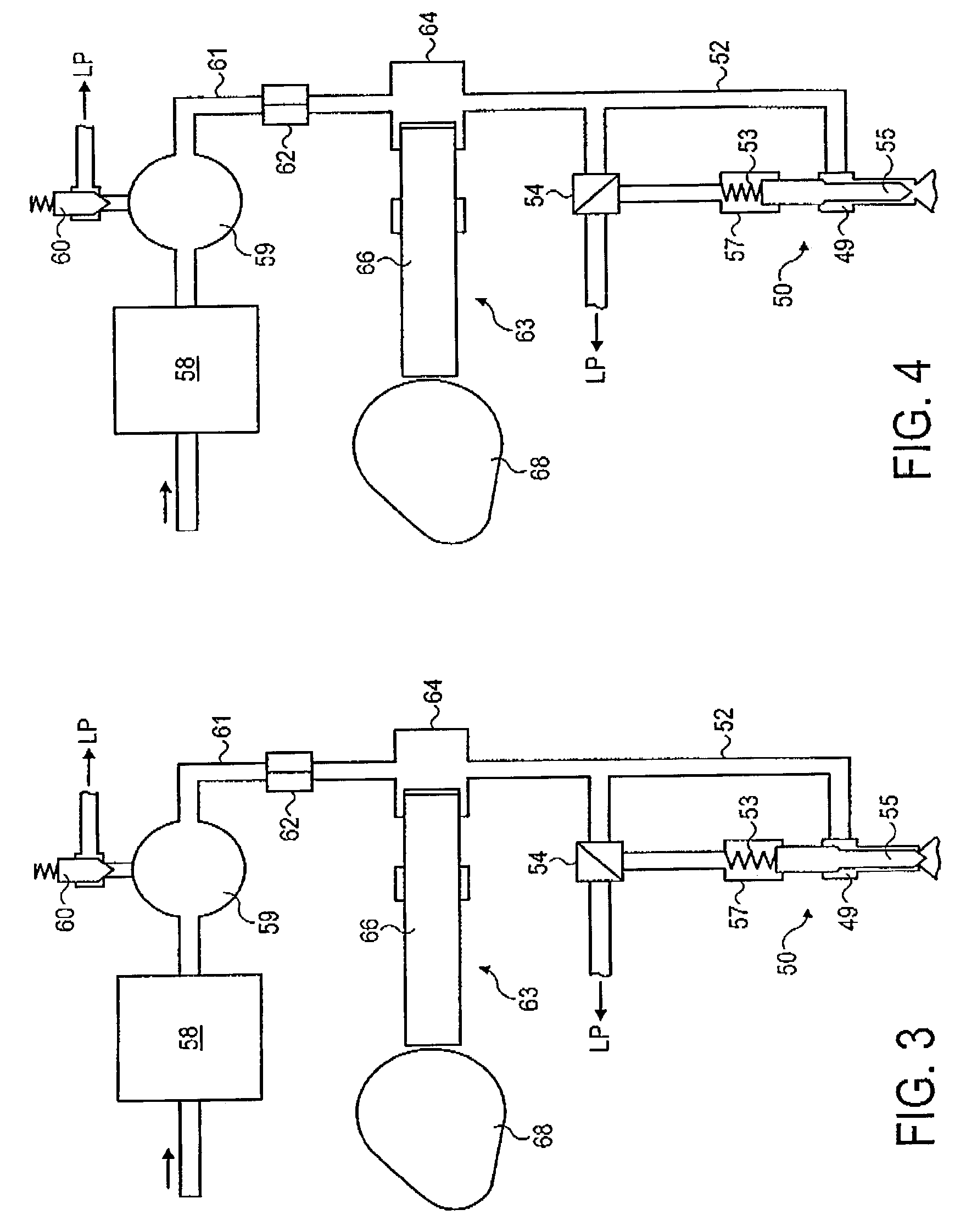

InactiveUS20070101968A1Combustion enginesFuel injecting pumpsPressure controlled ventilationVariable pressure

A fuel system for a work machine is disclosed. The fuel system has a fuel injector, a first source of fuel at a first pressure, a second source of fuel at a second pressure, and a pressure control device. The pressure control device is disposed between the fuel injector and the first and second sources. The pressure control device is configured to selectively direct the fuel at the first pressure and the fuel at the second pressure to the fuel injector.

Owner:CATERPILLAR INC

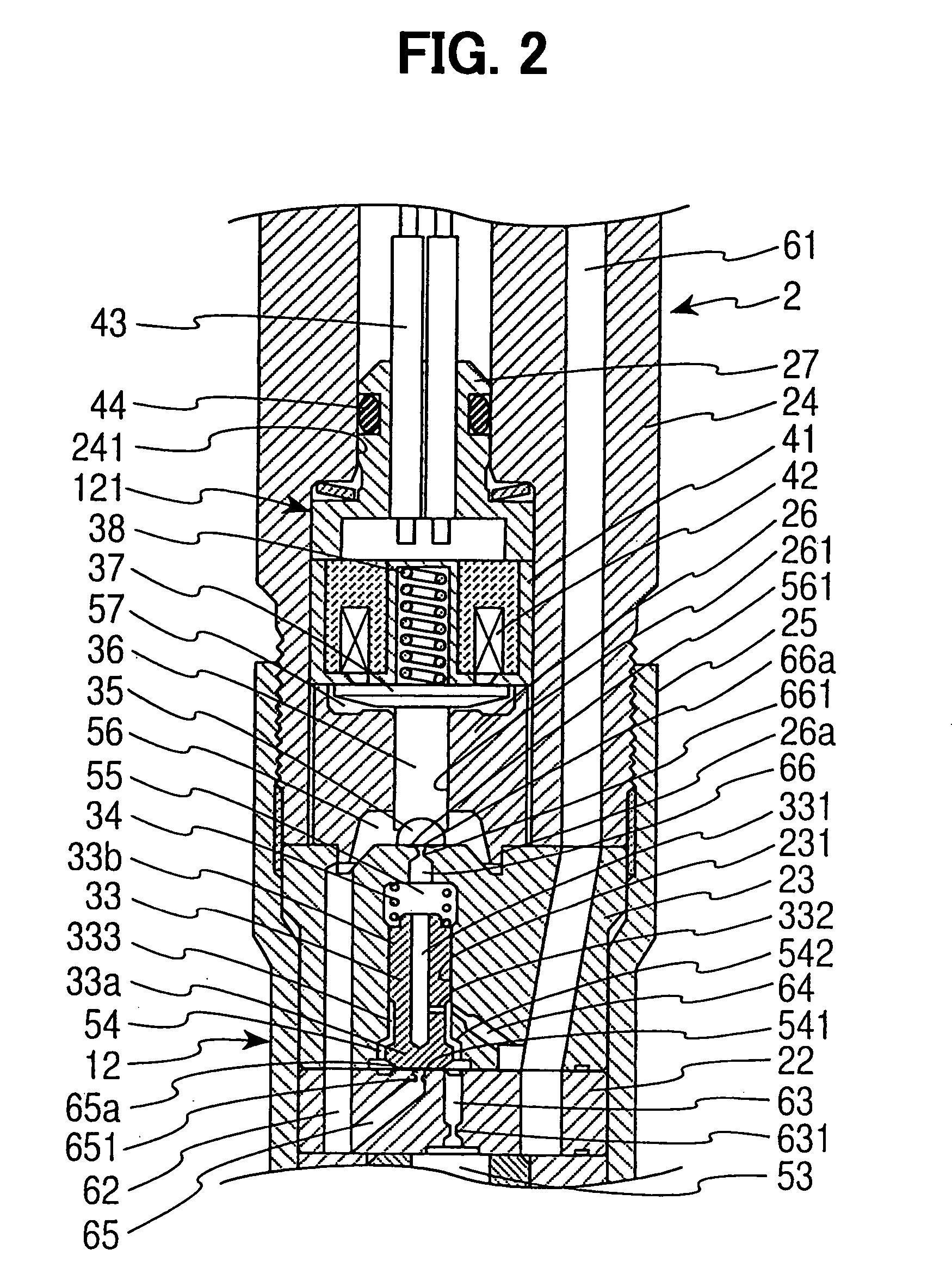

Injector having structure for controlling nozzle needle

A valve back pressure chamber is provided to exert a back pressure of a first valve needle. Furthermore, a hydraulic pressure passage is provided to extend through the valve back pressure chamber. A valve body is provided to a second valve needle and is driven to connect and disconnect between the hydraulic pressure passage and a fuel tank and thereby to drive the first valve needle. The second valve needle is driven by hydraulic pressure induced by an actuator.

Owner:DENSO CORP

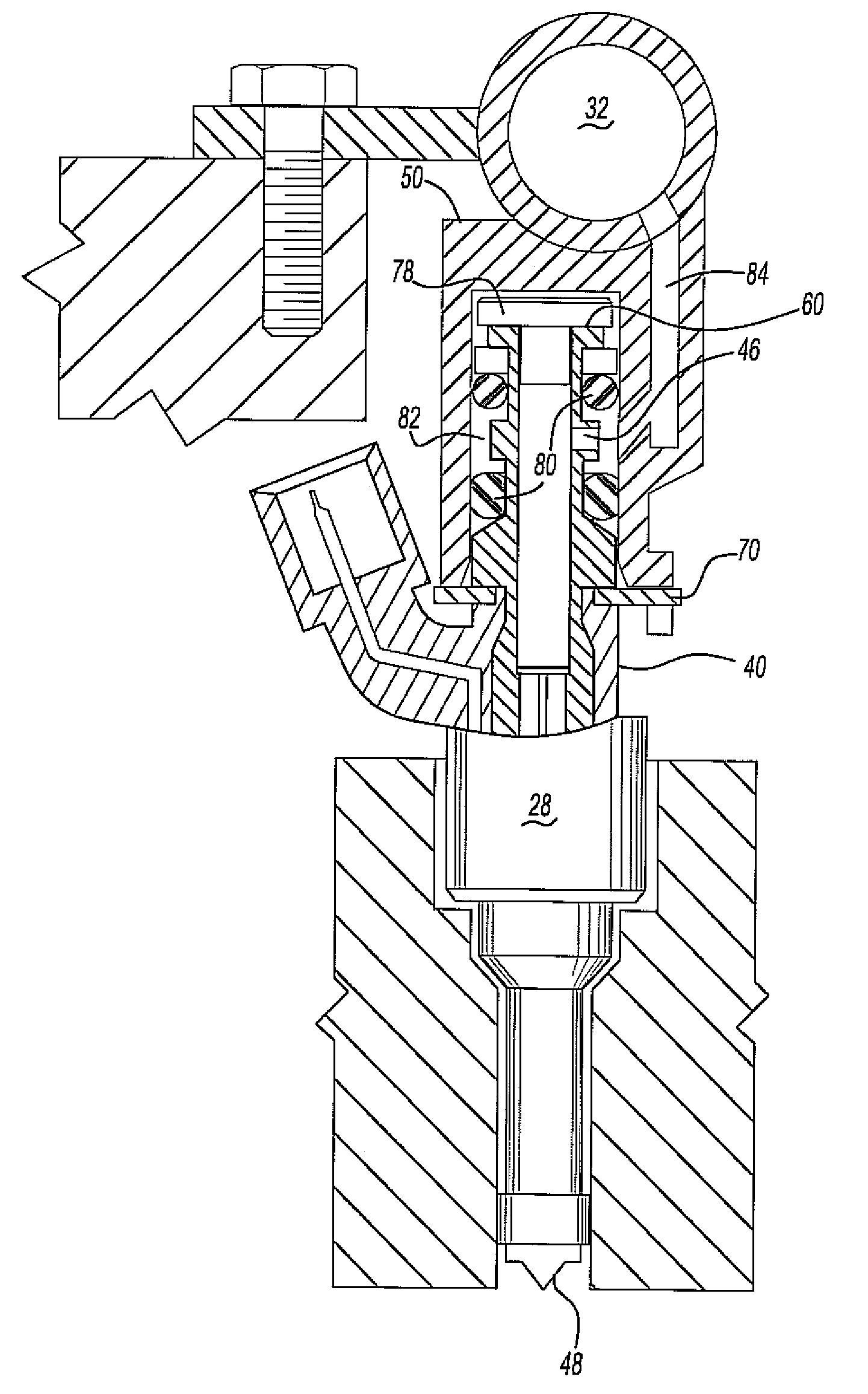

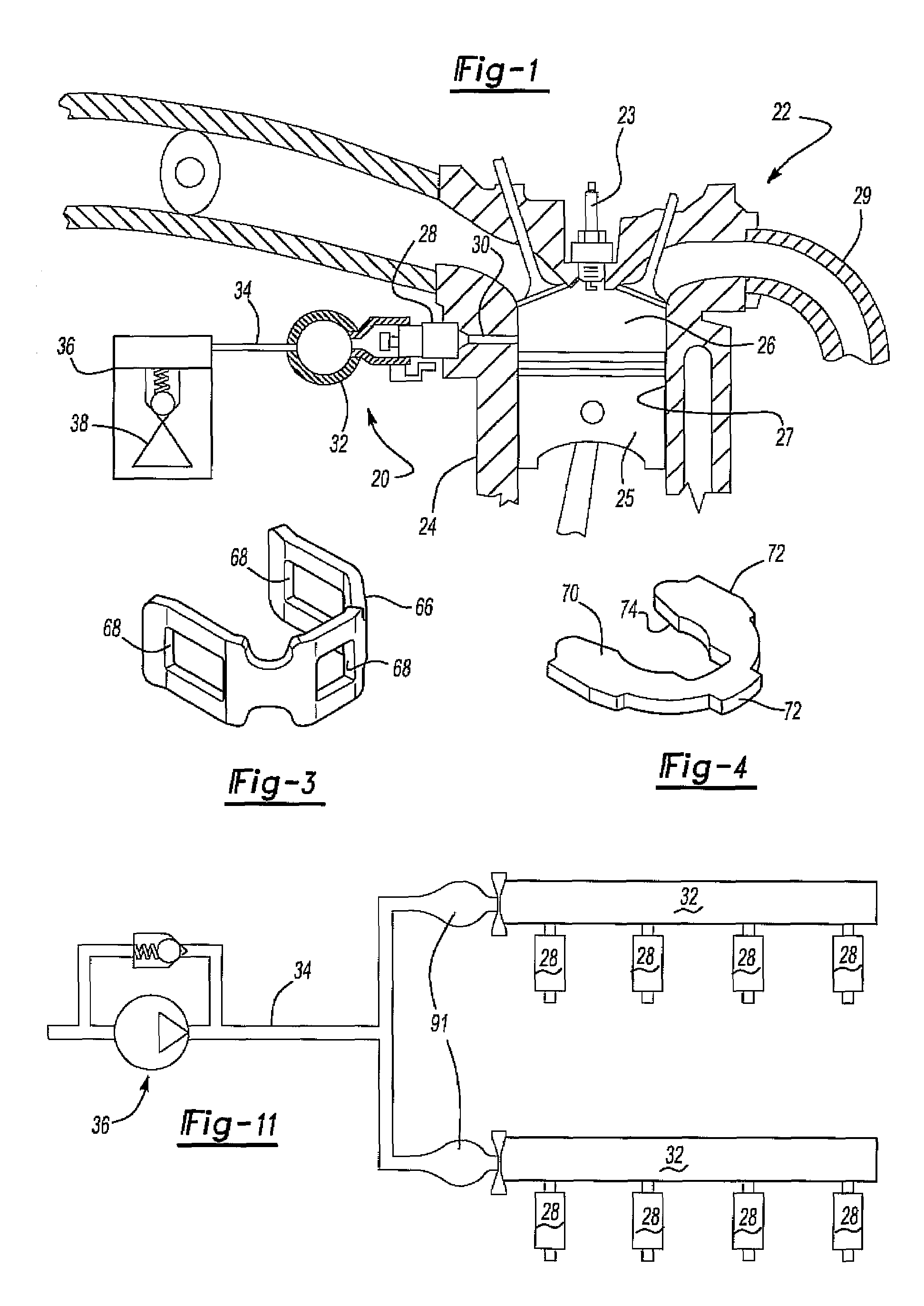

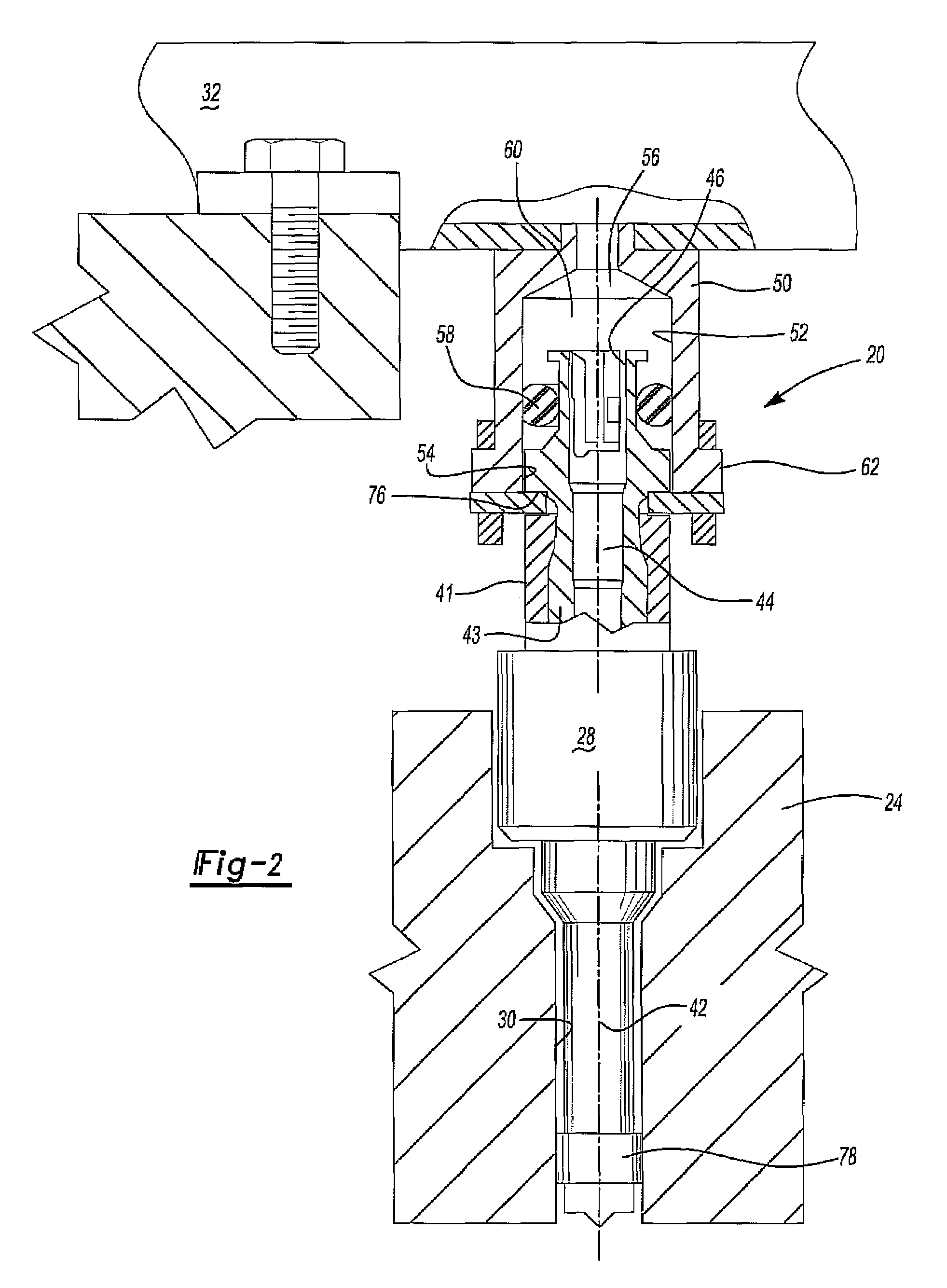

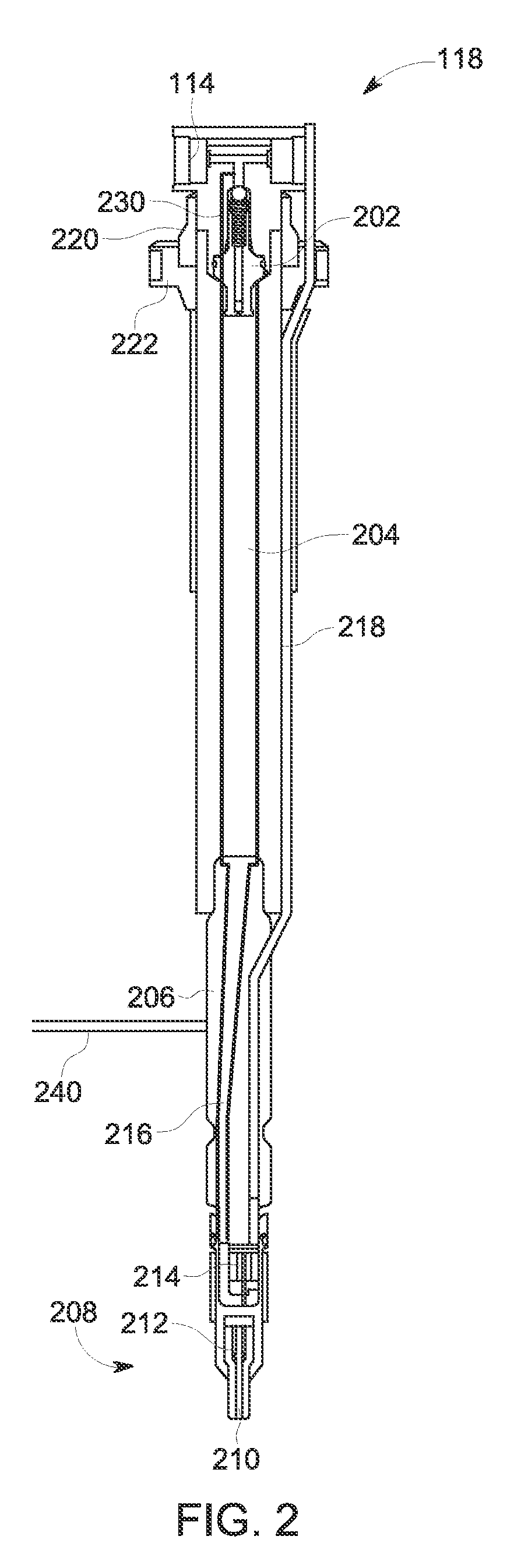

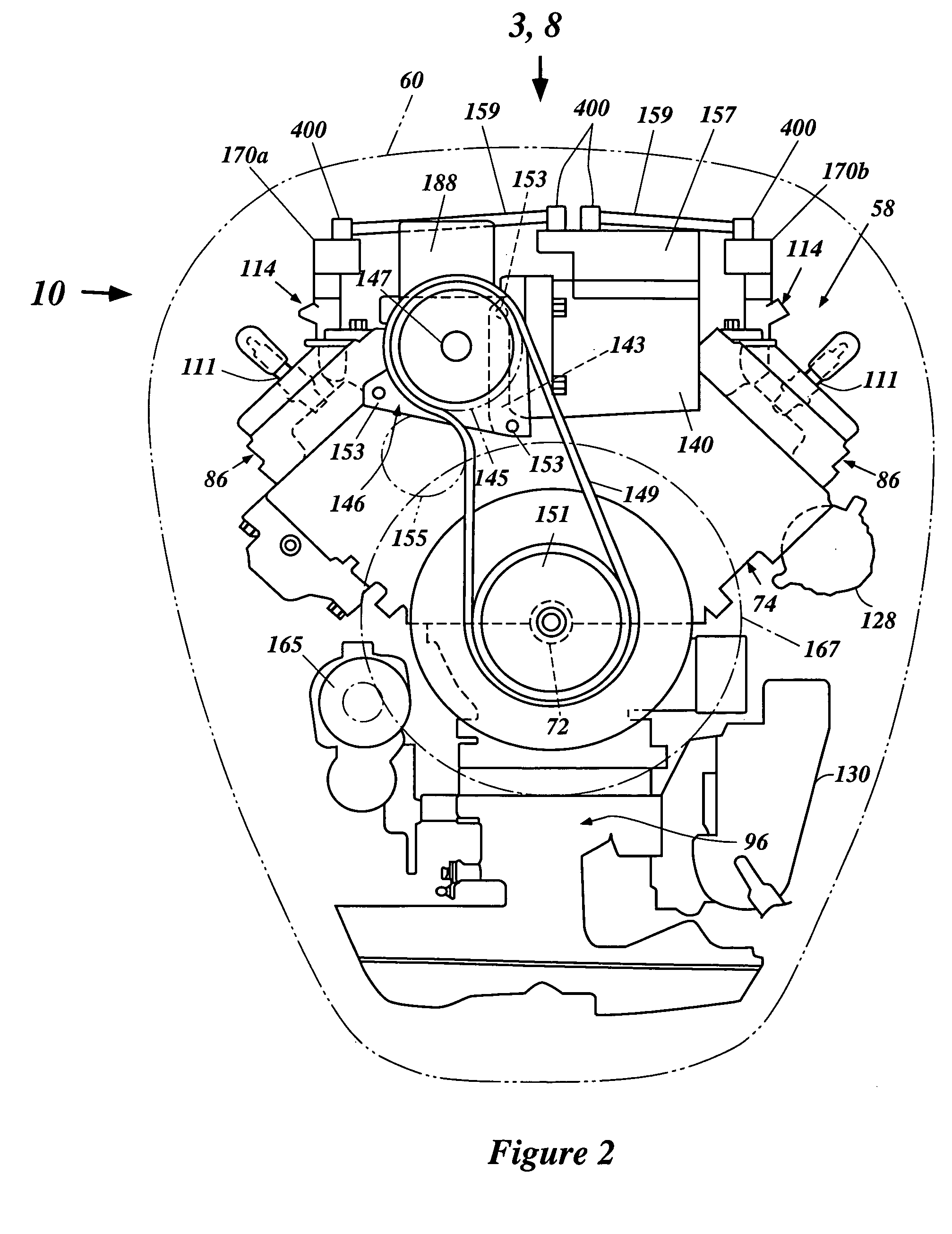

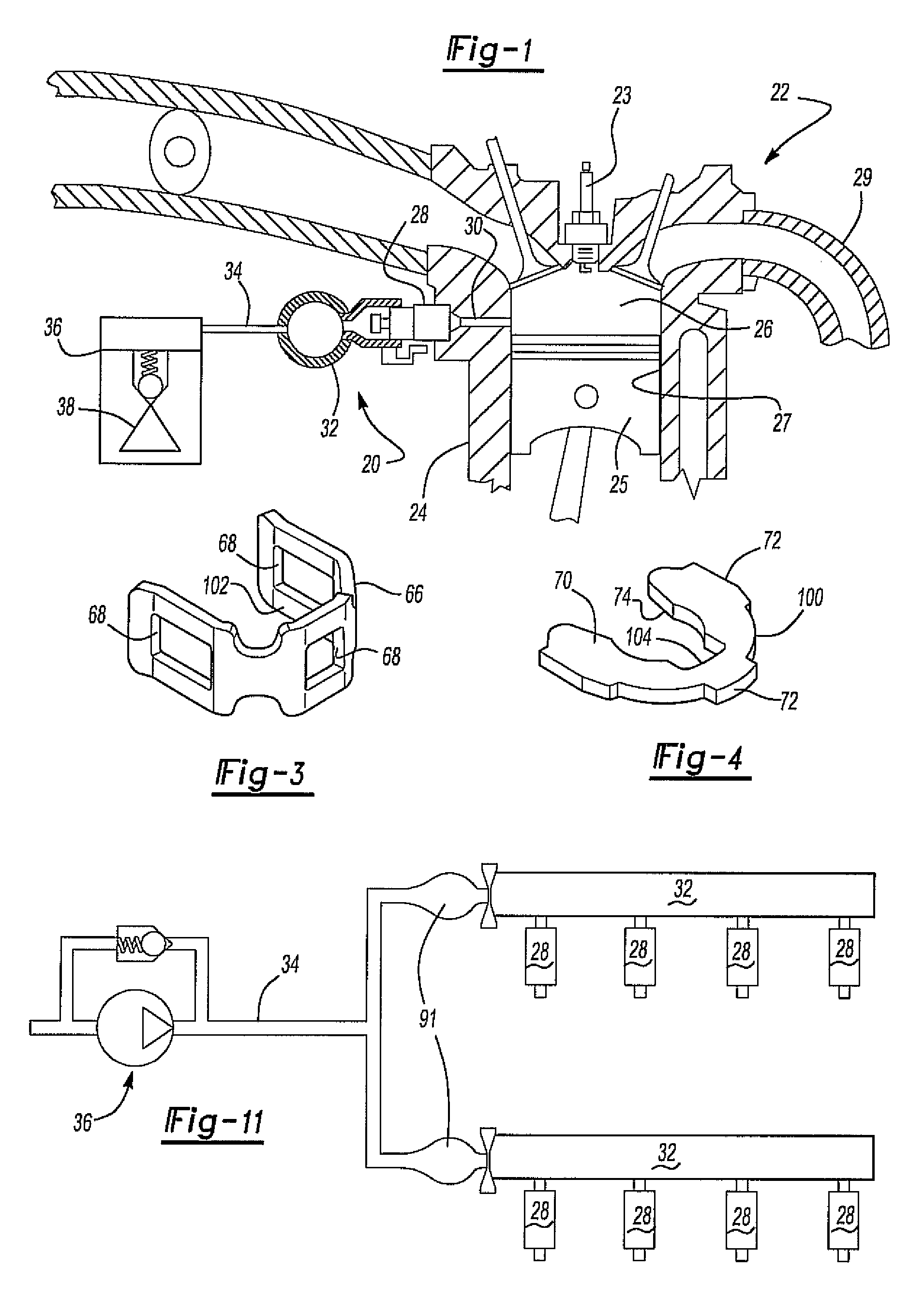

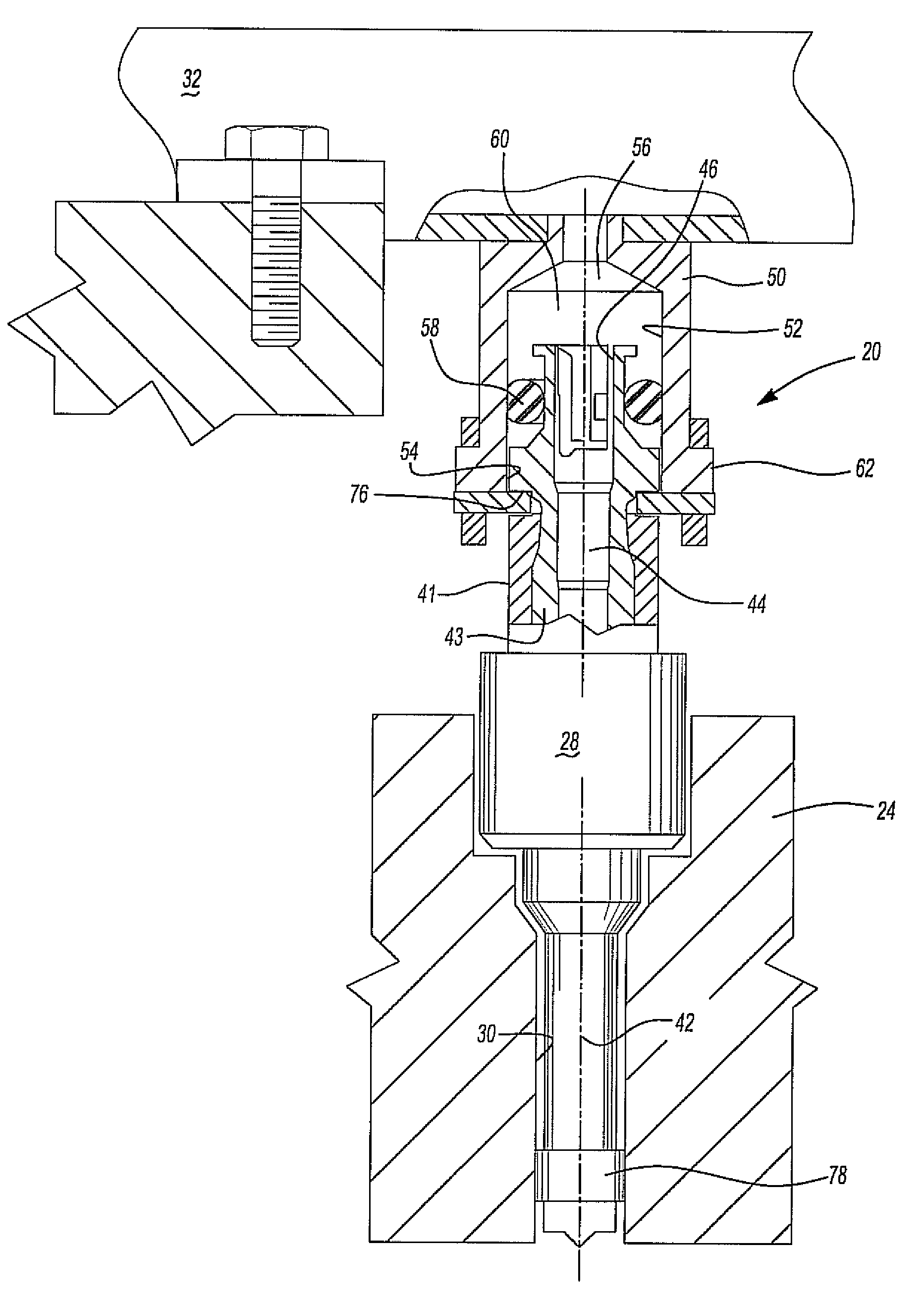

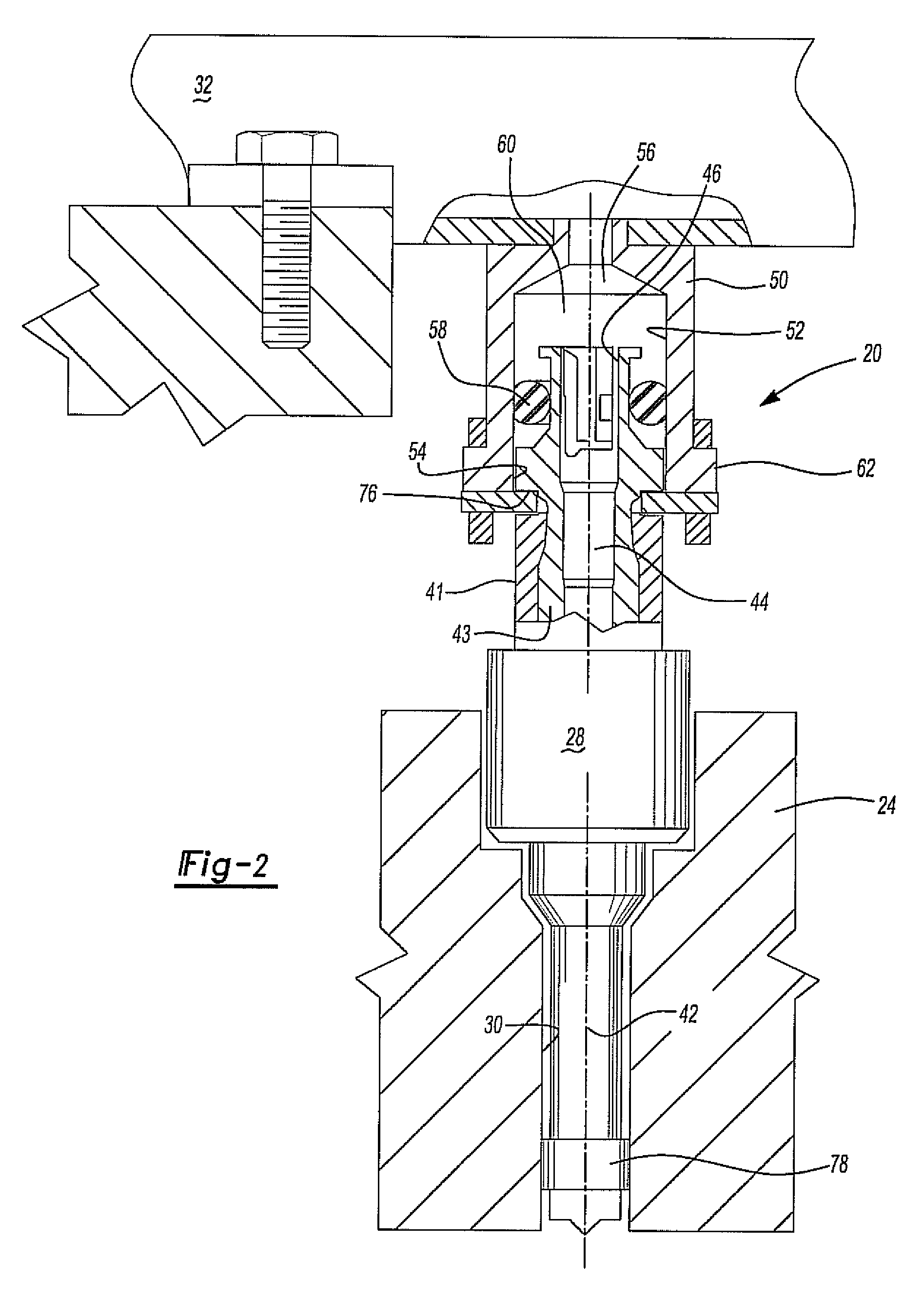

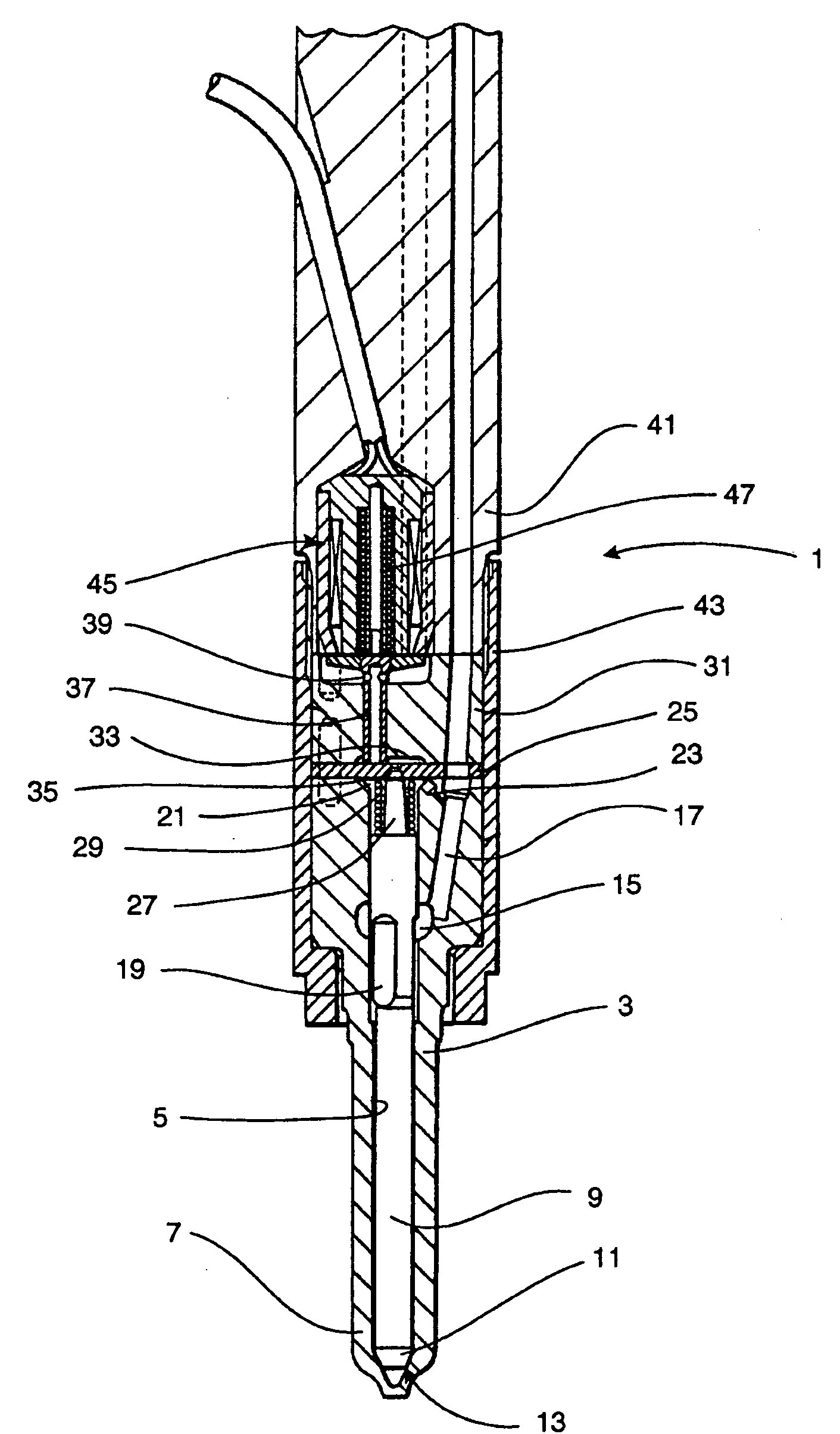

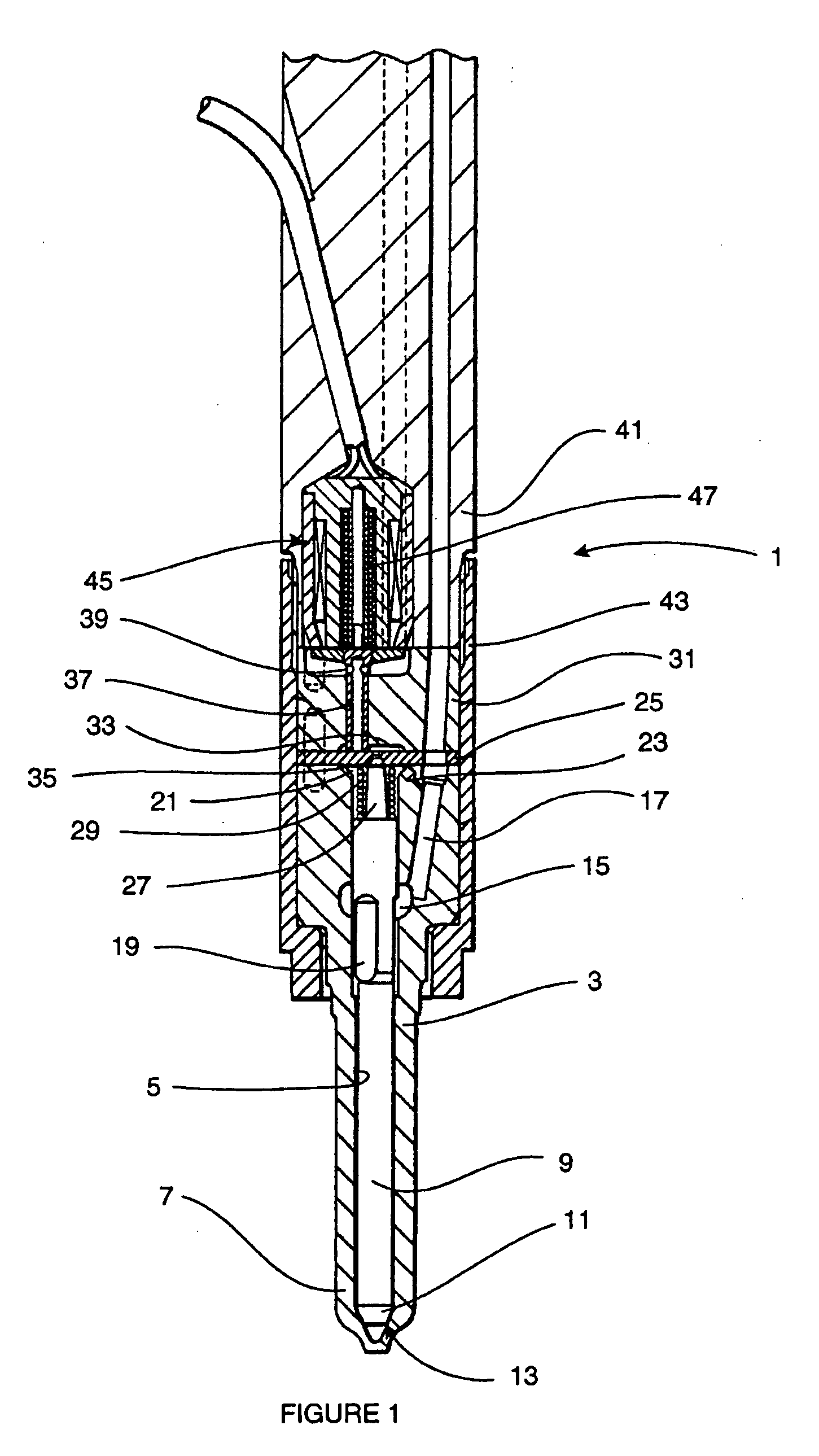

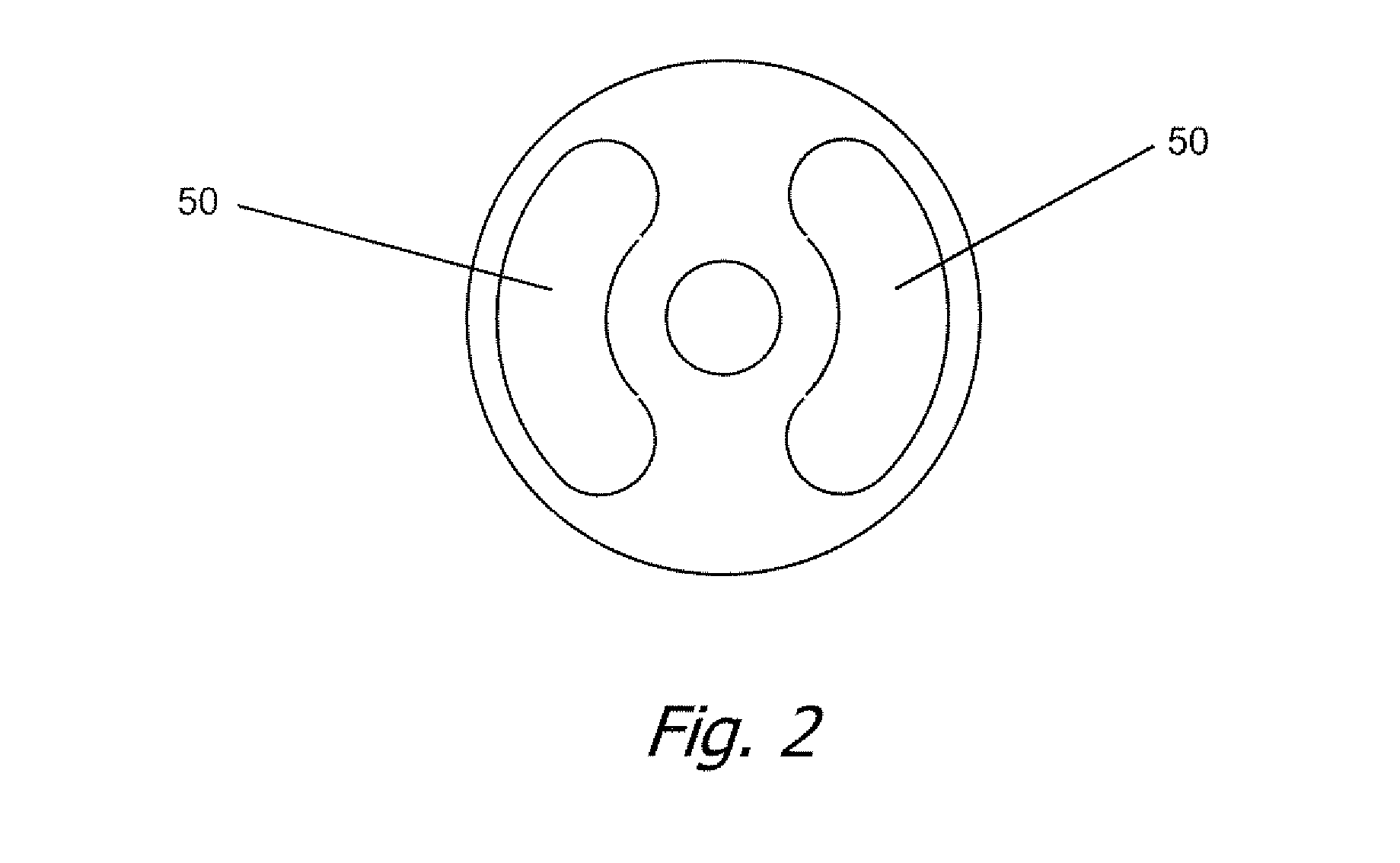

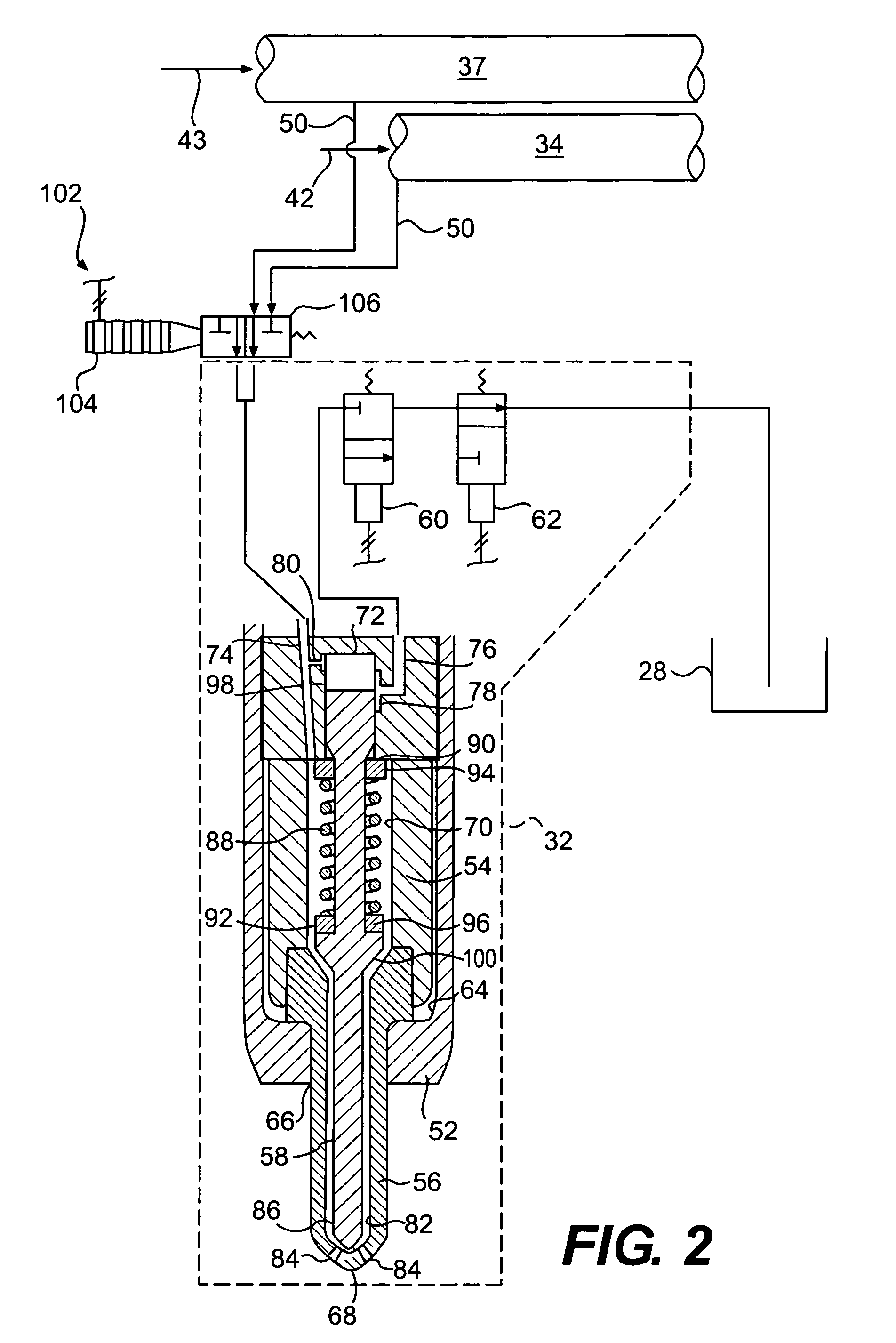

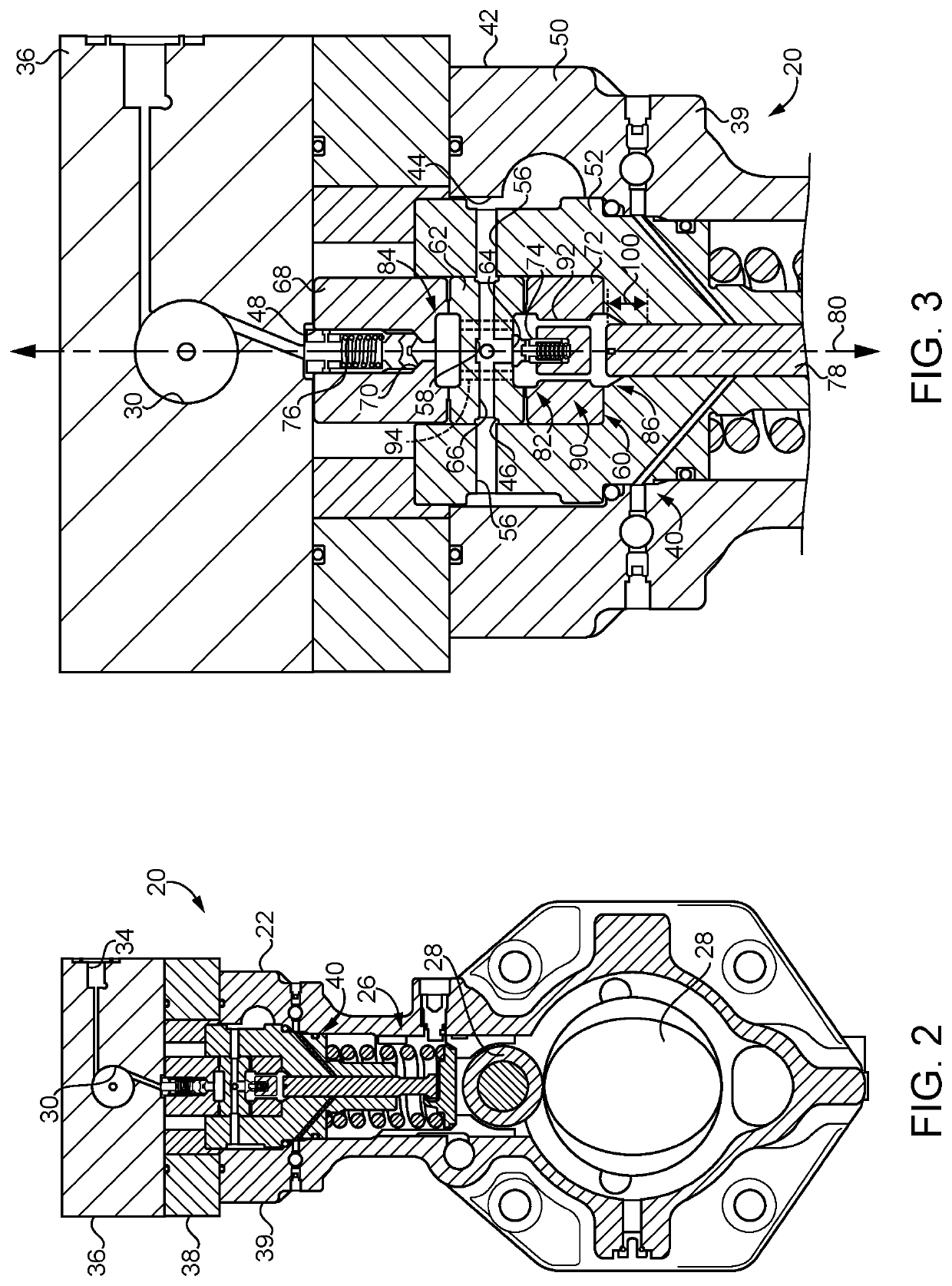

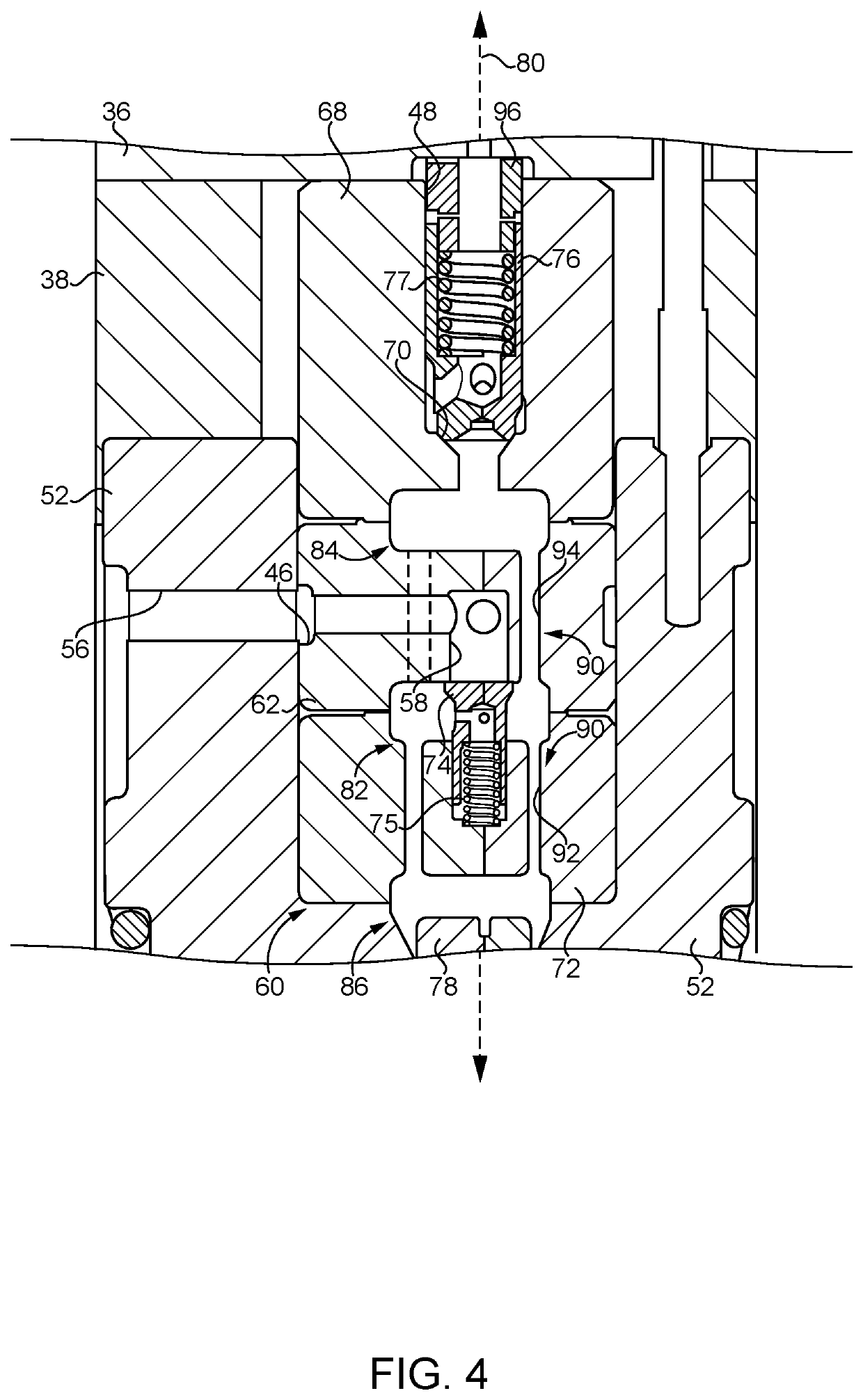

Method and apparatus for attenuating fuel pump noise in a direct injection internal combustion chamber

ActiveUS20080264386A1Reduce the bending armRelieve pressureSpray nozzlesLow-pressure fuel injectionCombustion chamberEngineering

An apparatus for attenuating fuel pump noise in a direct injection internal combustion engine. In one proposal, the direct injection fuel nozzle is suspended from a fuel rail in a fashion that avoids direct metal-to-metal contact between the injector and the engine block. The direct injection nozzle may also be connected to the fuel rail by a pair of spaced-apart seals which equalize the longitudinal pressure on the nozzle during operation. Enlarged diameter fuel reservoirs and / or a restricted orifice may be provided fluidly in series between the fuel pump and the direct injection nozzle in order to attenuate noise resulting from fuel pump pulsation. A clip holder and clip plate mount the fuel injector to the injector cup.

Owner:HITACHI LTD

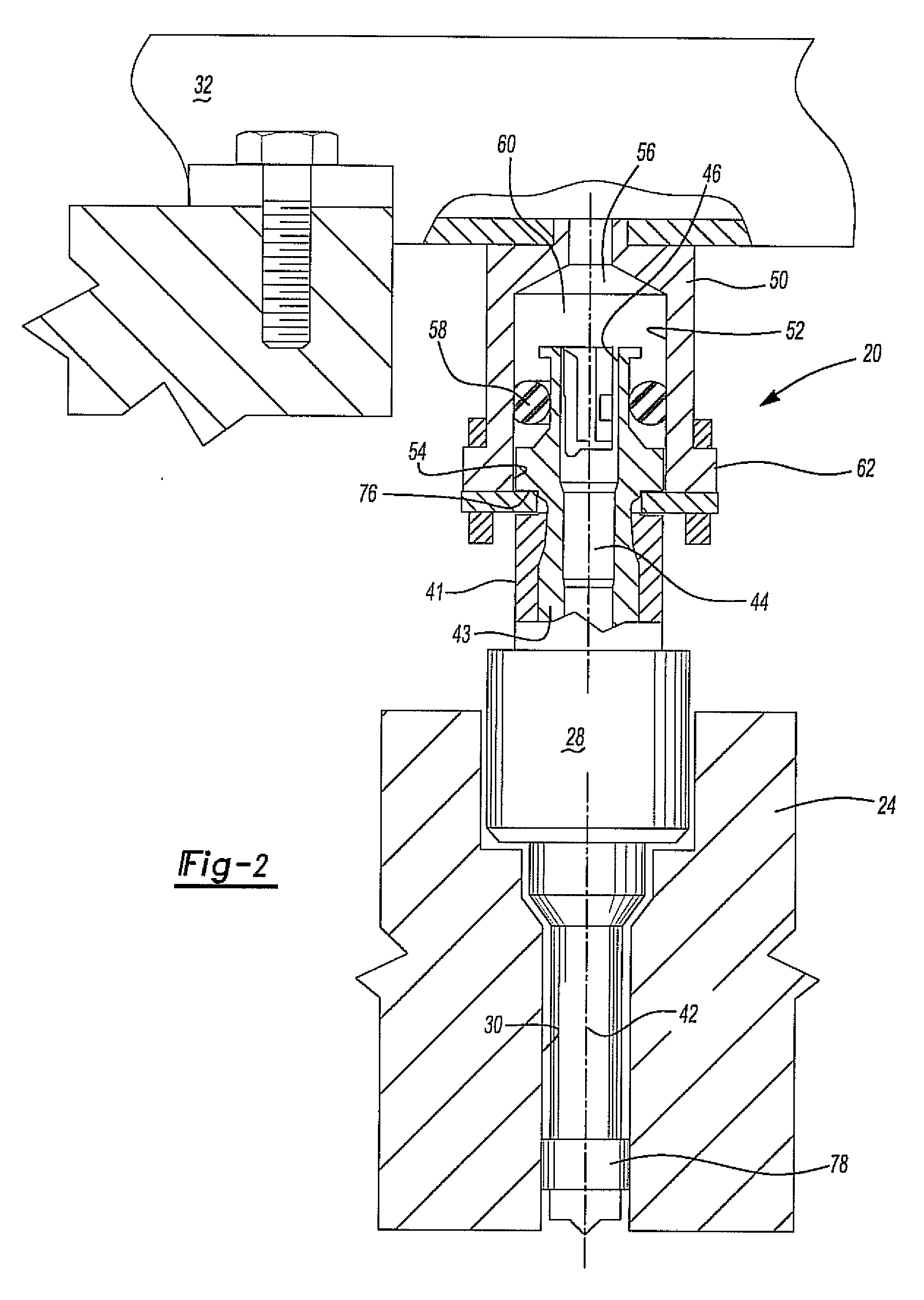

Variable delivery fuel supply device

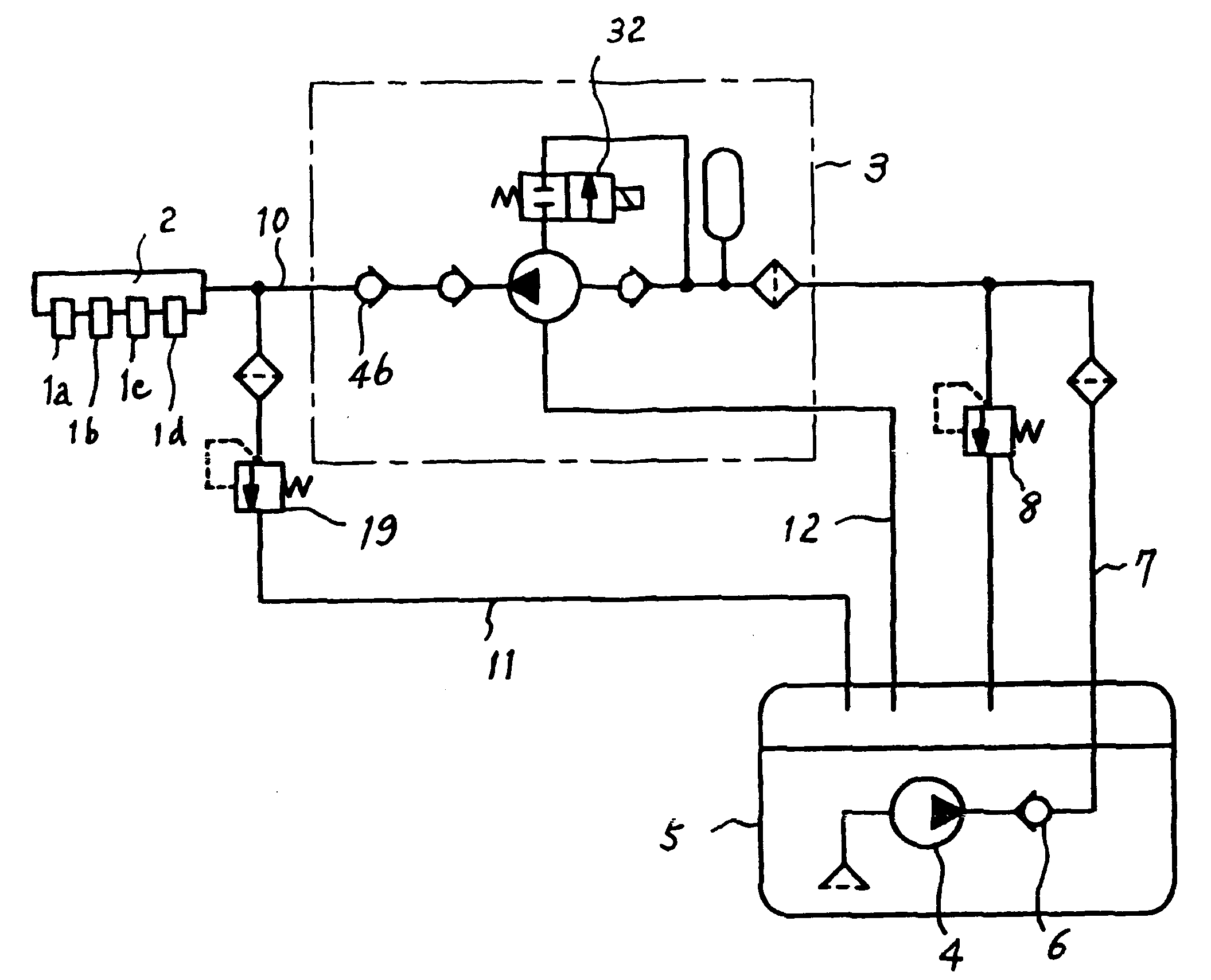

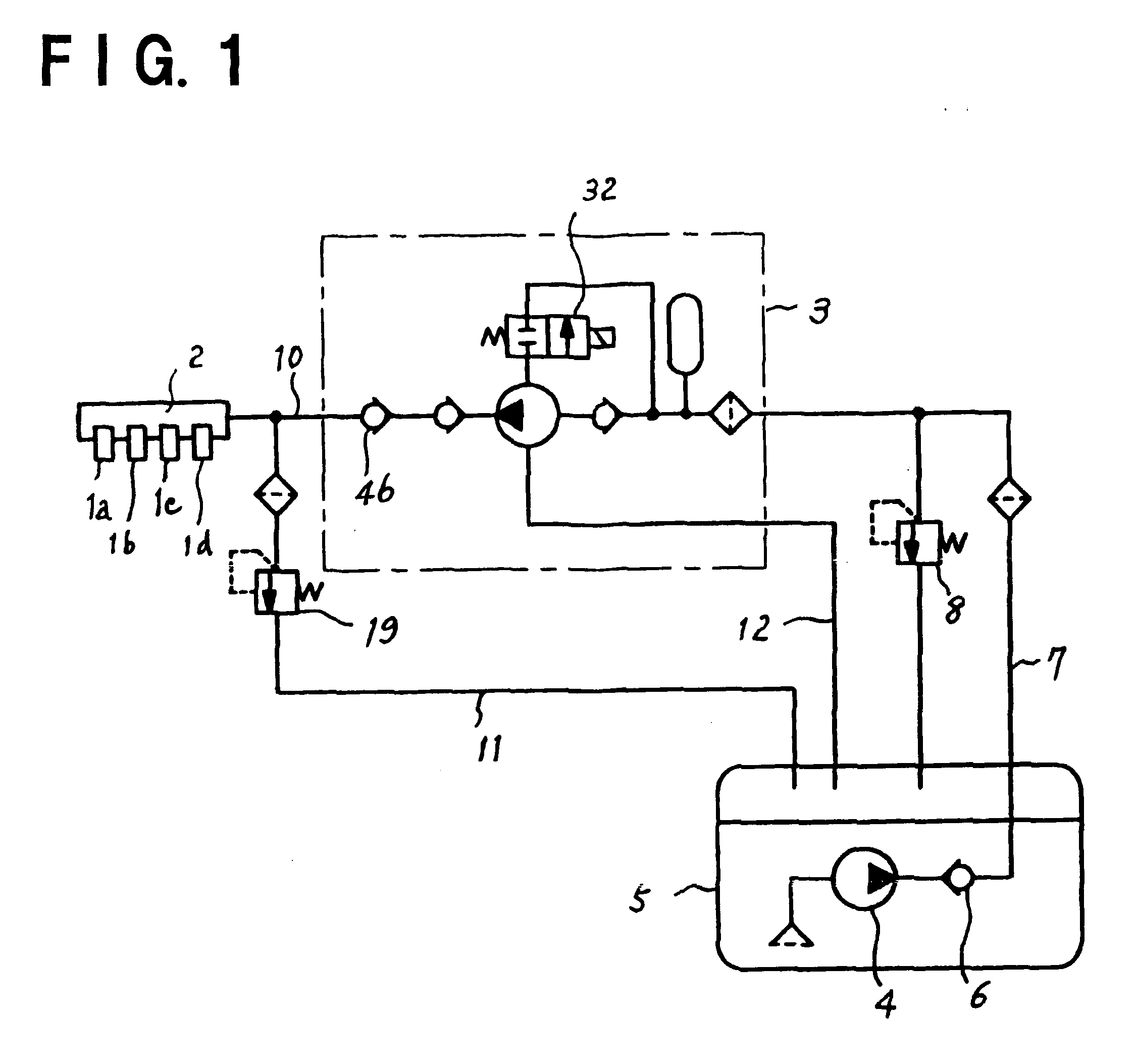

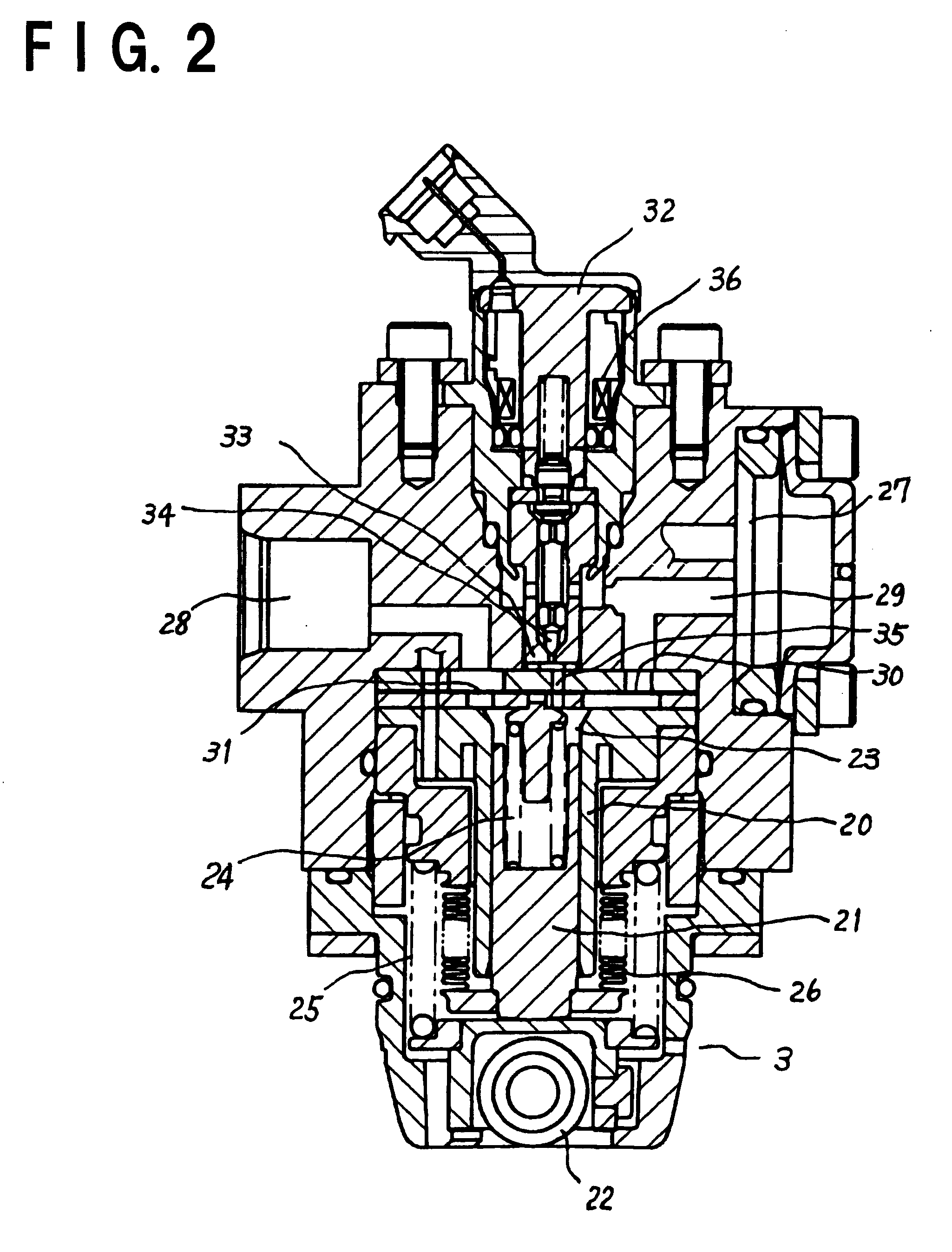

A variable delivery fuel supply device capable of obtaining a stable fuel pressure even in a case of inoperability of an electromagnetic valve and capable of improving the durability of the electromagnetic valve, which comprises fuel injection valves 1a through 1d for injecting fuel to respective cylinders of an internal combustion engine, a delivery pipe 2 connected with the fuel injection valves 1a through 1d, a fuel pump 3 which sucks fuel from a fuel intake valve into a pressurizing chamber 23 by a reciprocating action of a plunger 21 in a cylinder 20 and supplies the pressurized fuel into the delivery pipe 2 through a discharge valve 31, an electromagnetic valve 32 located in a relief passage 35 communicating the pressurizing chamber 23 of the fuel pump 32 with the fuel intake port 27 and is adapted to control a discharge quantity of the pressurized fuel by relieving the pressurized fuel in the pressurizing chamber 23 into the fuel intake port 27 at the time of opening the valve to thereby control a fuel pressure in the delivery pipe 2, and a high pressure regulator 19 for controlling a fuel pressure by relieving the pressurized fuel in a high-pressure fuel passage including the delivery pipe 2.

Owner:MITSUBISHI ELECTRIC CORP

Device for injecting fuel to stationary internal combustion engines

InactiveUS7025045B2Increase flexibilityEasy to adaptCasingsCombustion enginesCombustion chamberInternal combustion engine

The invention relates to a fuel injection system for use in internal combustion engines having delivery units for delivering fuel from a fuel reservoir in order to supply at least one high-pressure line to the cylinders of the engine. The at least one high-pressure line supplies a number of fuel injectors, which each include an injector nozzle that supplies fuel to a combustion chamber of the engine and includes line segments that connect the individual fuel injectors to one another. The injector bodies of the fuel injectors each have an accumulator chamber integrated into them.

Owner:ROBERT BOSCH GMBH

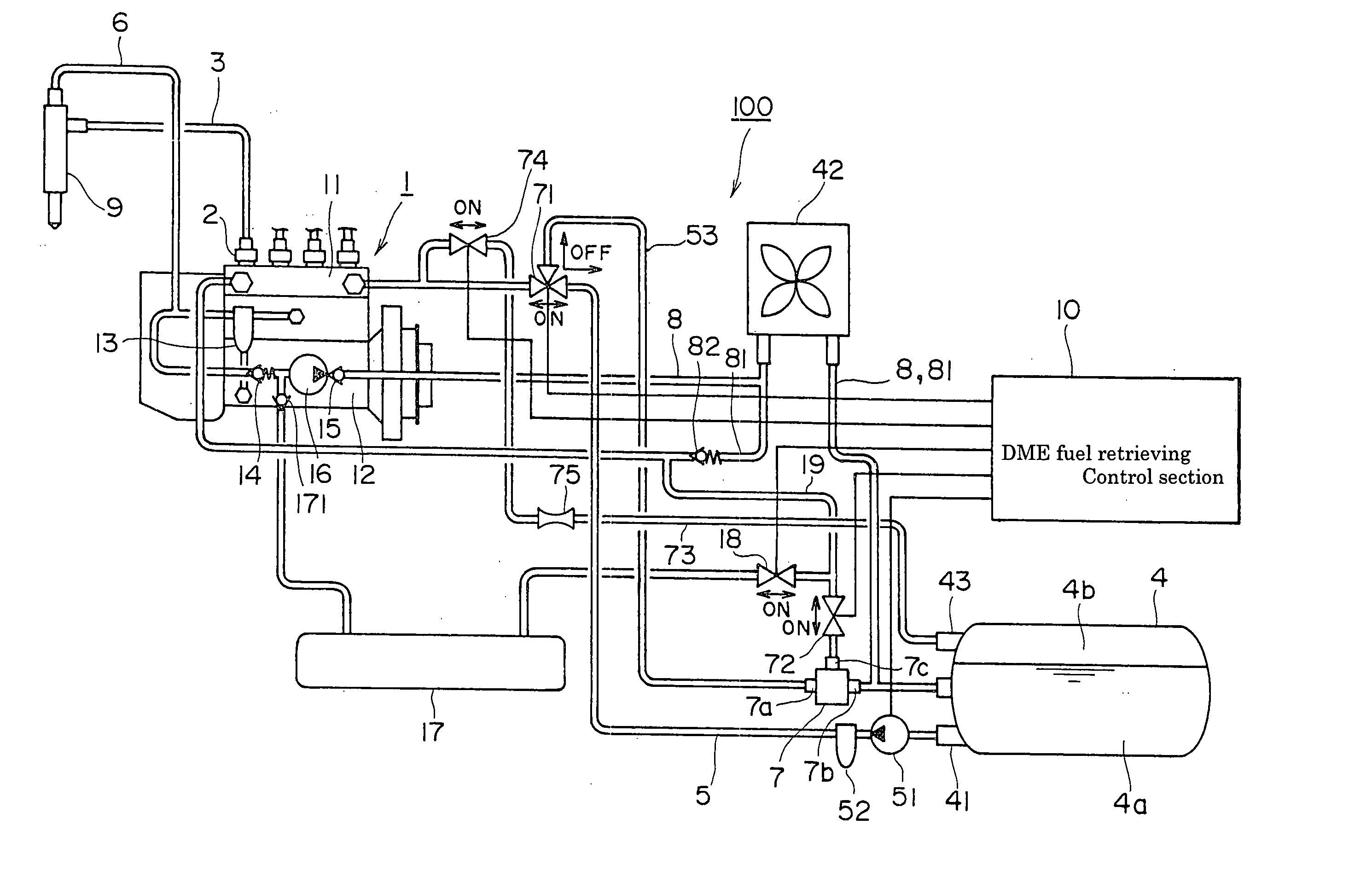

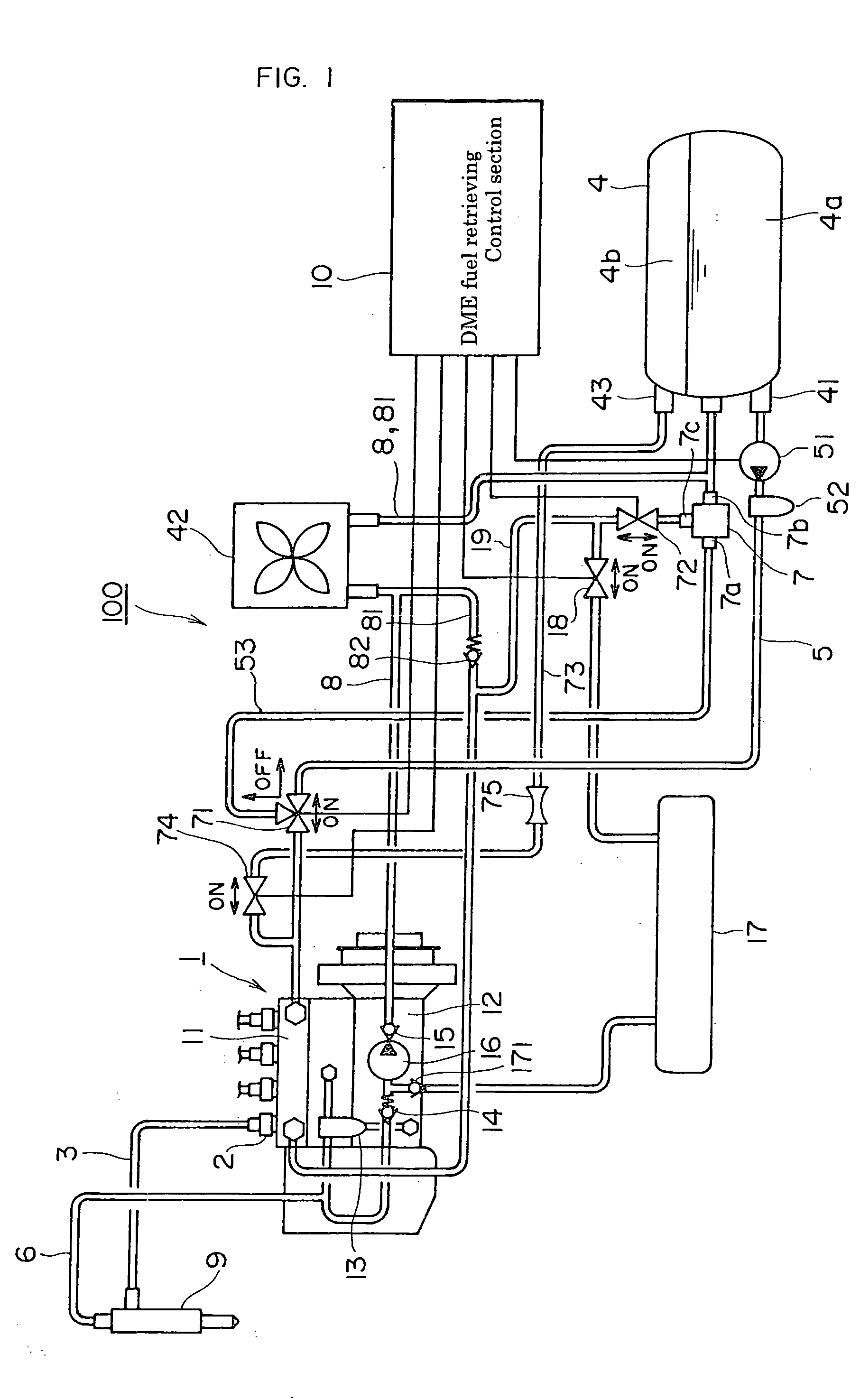

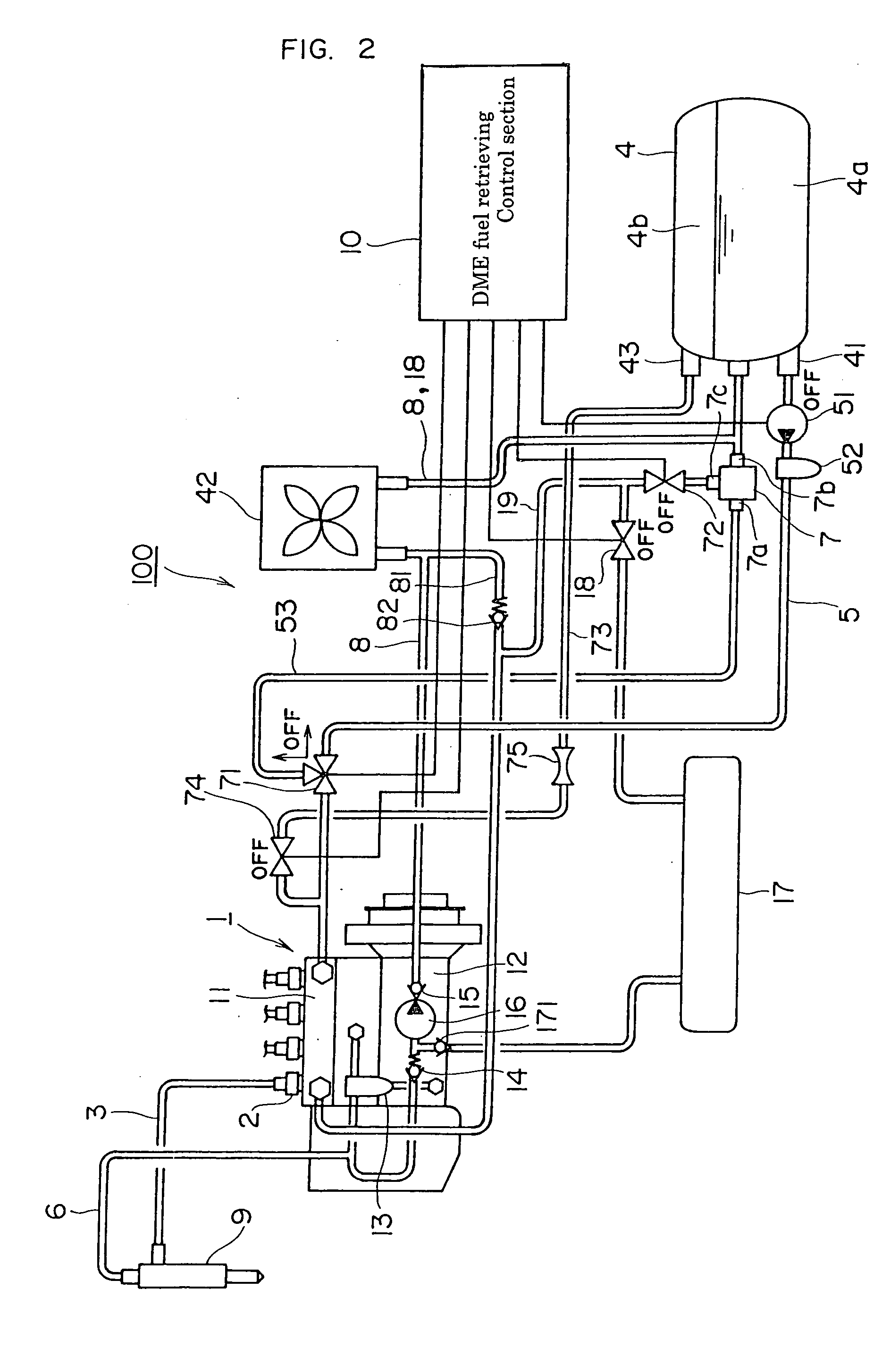

Liquefied gas-delivering device for diesel engine

InactiveUS20060054141A1Shorten the timeSpend less timeElectrical controlInternal combustion piston enginesSuction forceGas phase

Since an aspirator 7 is disposed at a position lower than a fuel gallery 11 and an overflow fuel pipe 81, DME fuel remaining in the fuel gallery 11 and the overflow fuel pipe 81 can be more efficiently retrieved to a fuel tank 4 by a combined force of gravity and suction force produced in a suction port 7c of the aspirator 7. Since the vapor-phase pressure delivery pipe opening / closing solenoid valve 74 is disposed at a position higher than the fuel gallery 11, DME fuel in a liquid state remaining in the fuel gallery 11 and the overflow fuel pipe 81 is forcedly delivered under pressure to the suction port 7c of the aspirator 7 by a combined force of gravity and the pressure of a vapor phase 4b in the fuel tank 4. Accordingly, time taken to retrieve the DME fuel in an injection system to the fuel tank after the stop of a diesel engine.

Owner:BOSCH AUTOMOTIVE SYST CORP

Method and apparatus for attenuating fuel pump noise in a direct injection internal combustion chamber

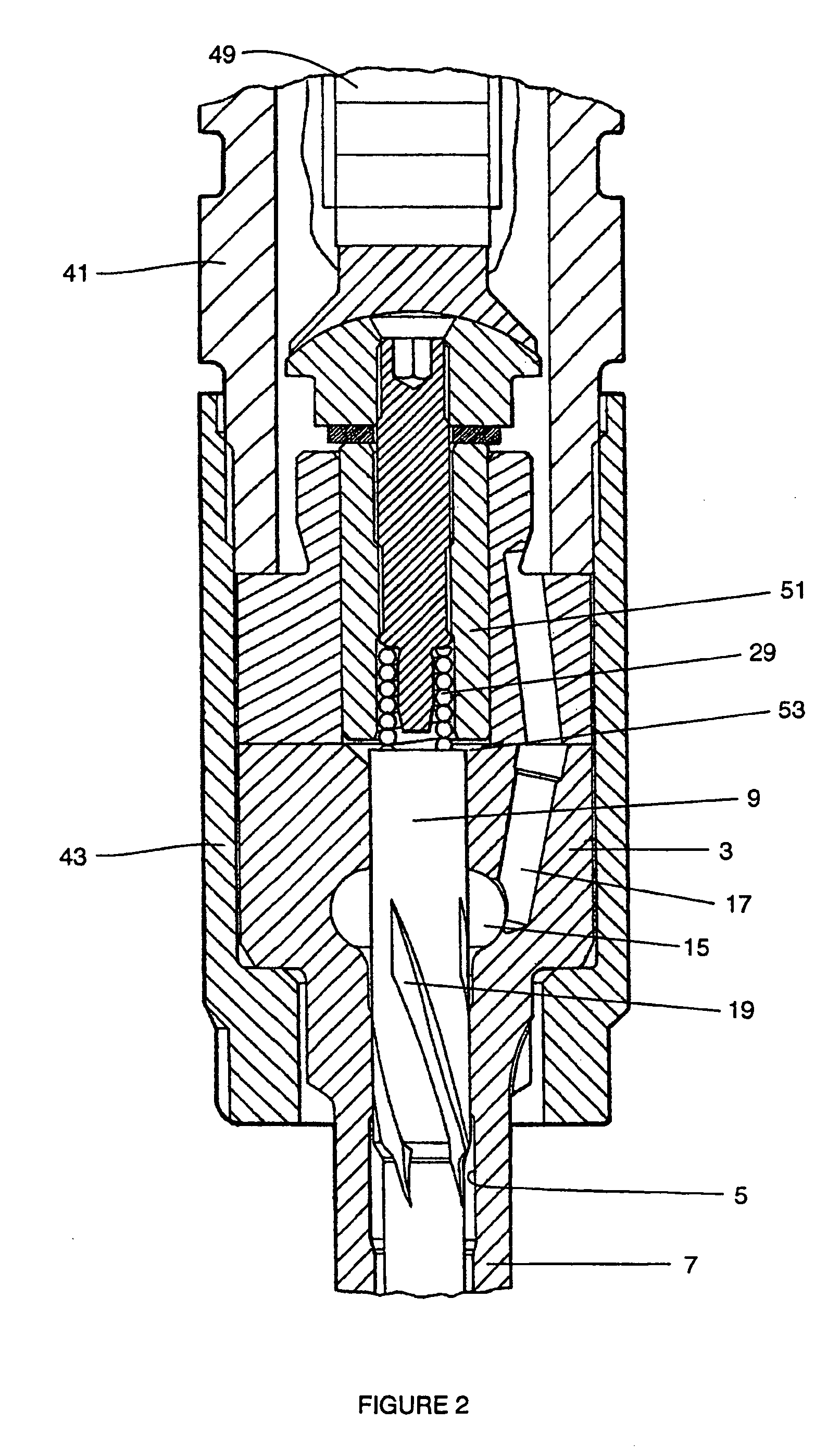

ActiveUS7527038B2Reduce the bending armRelieve pressureMachines/enginesFuel injection with fuel accumulatorsCombustion chamberInternal combustion engine

An apparatus for attenuating fuel pump noise in a direct injection internal combustion engine. In one proposal, the direct injection fuel nozzle is suspended from a fuel rail in a fashion that avoids direct metal-to-metal contact between the injector and the engine block. The direct injection nozzle may also be connected to the fuel rail by a pair of spaced-apart seals which equalize the longitudinal pressure on the nozzle during operation. Enlarged diameter fuel reservoirs and / or a restricted orifice may be provided fluidly in series between the fuel pump and the direct injection nozzle in order to attenuate noise resulting from fuel pump pulsation. A clip holder and clip plate mount the fuel injector to the injector cup.

Owner:HITACHI LTD

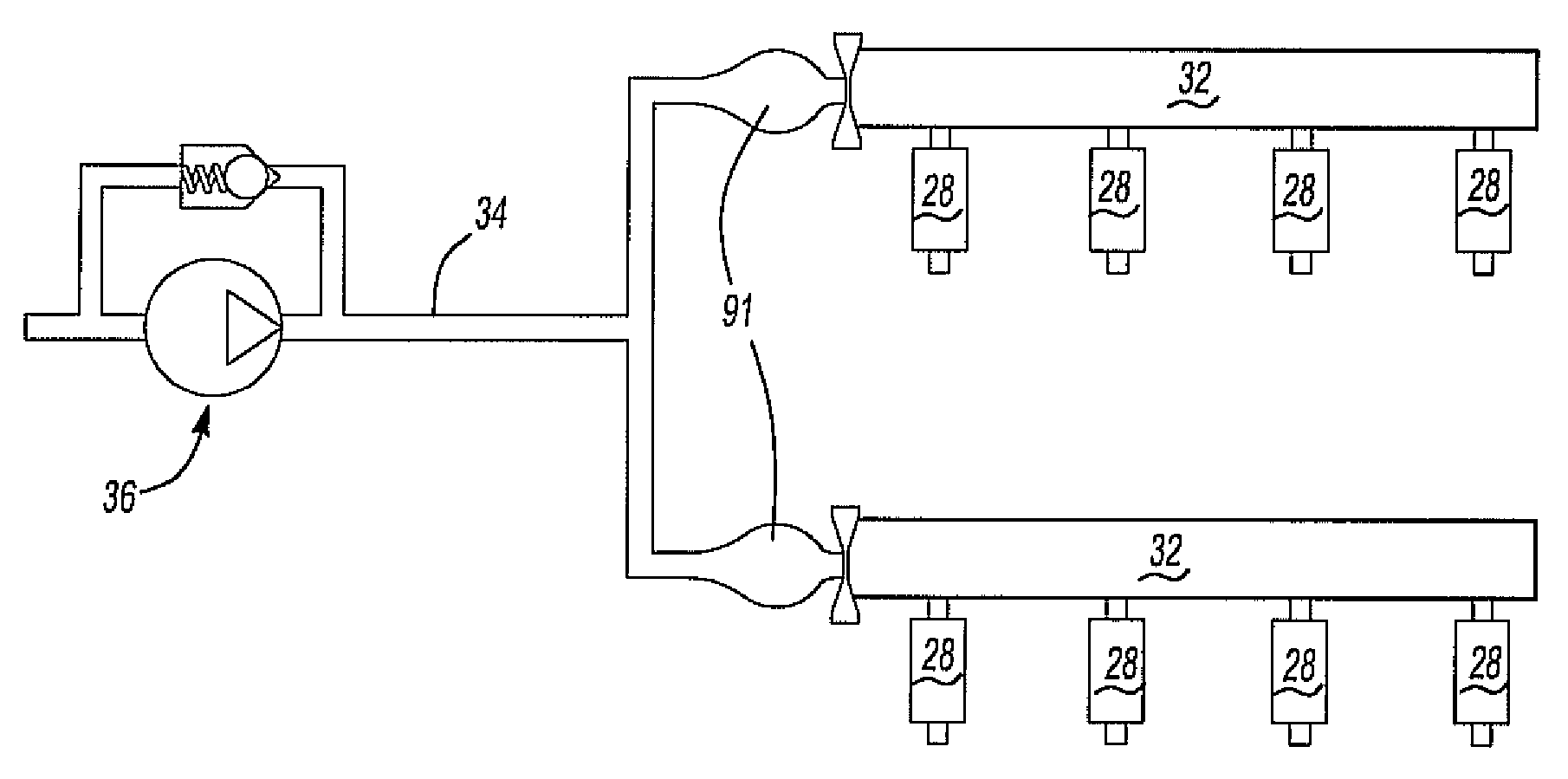

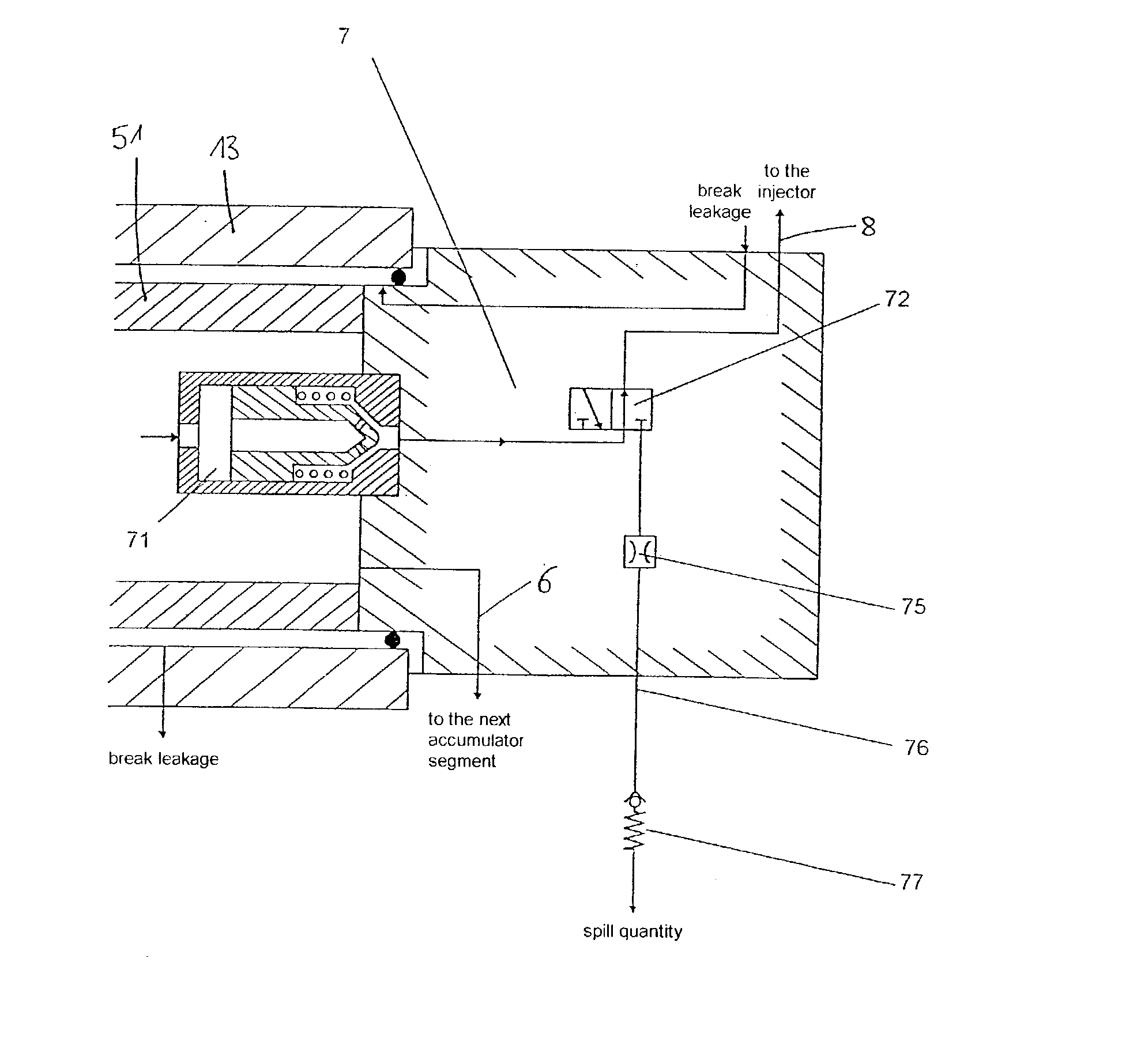

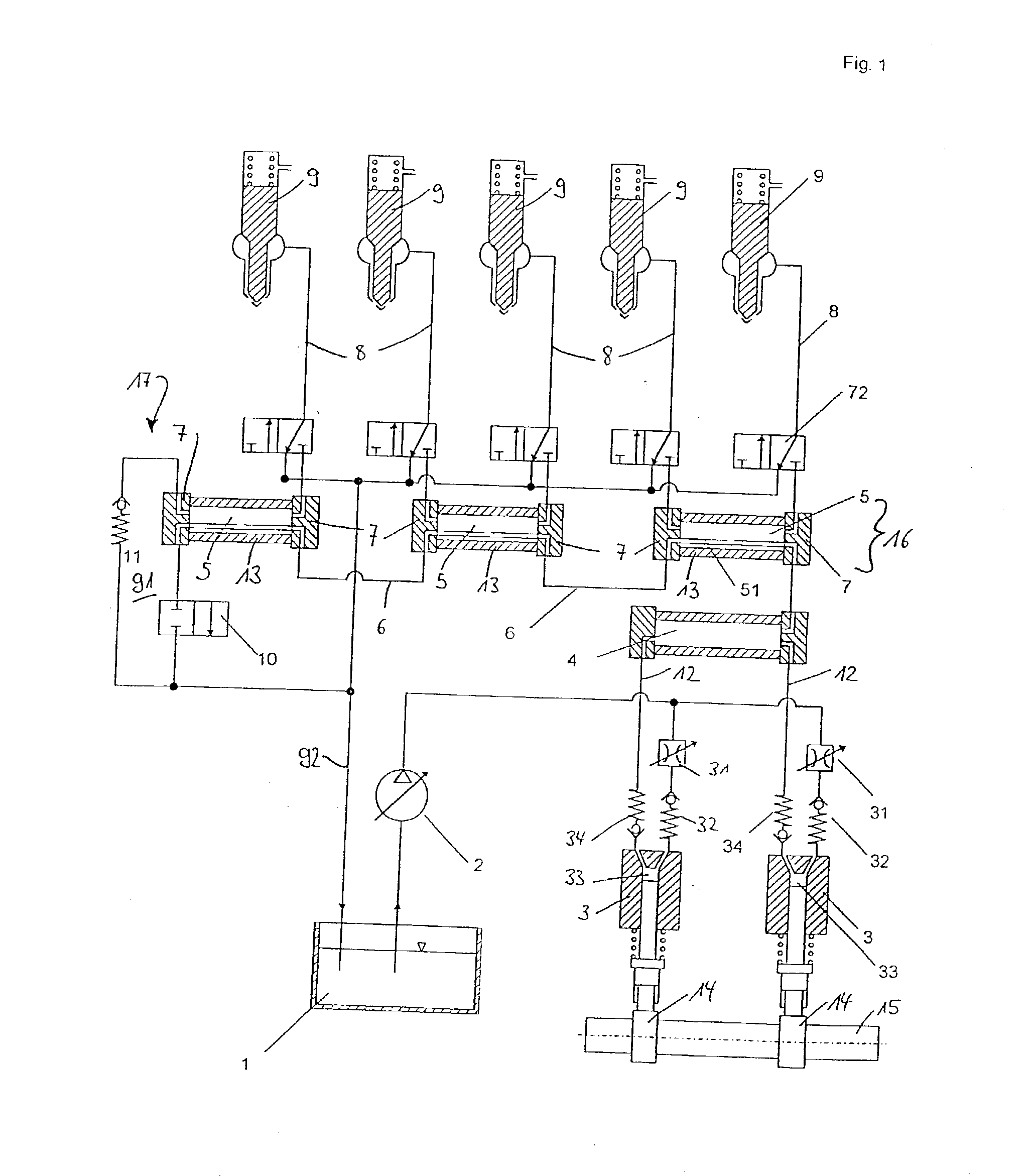

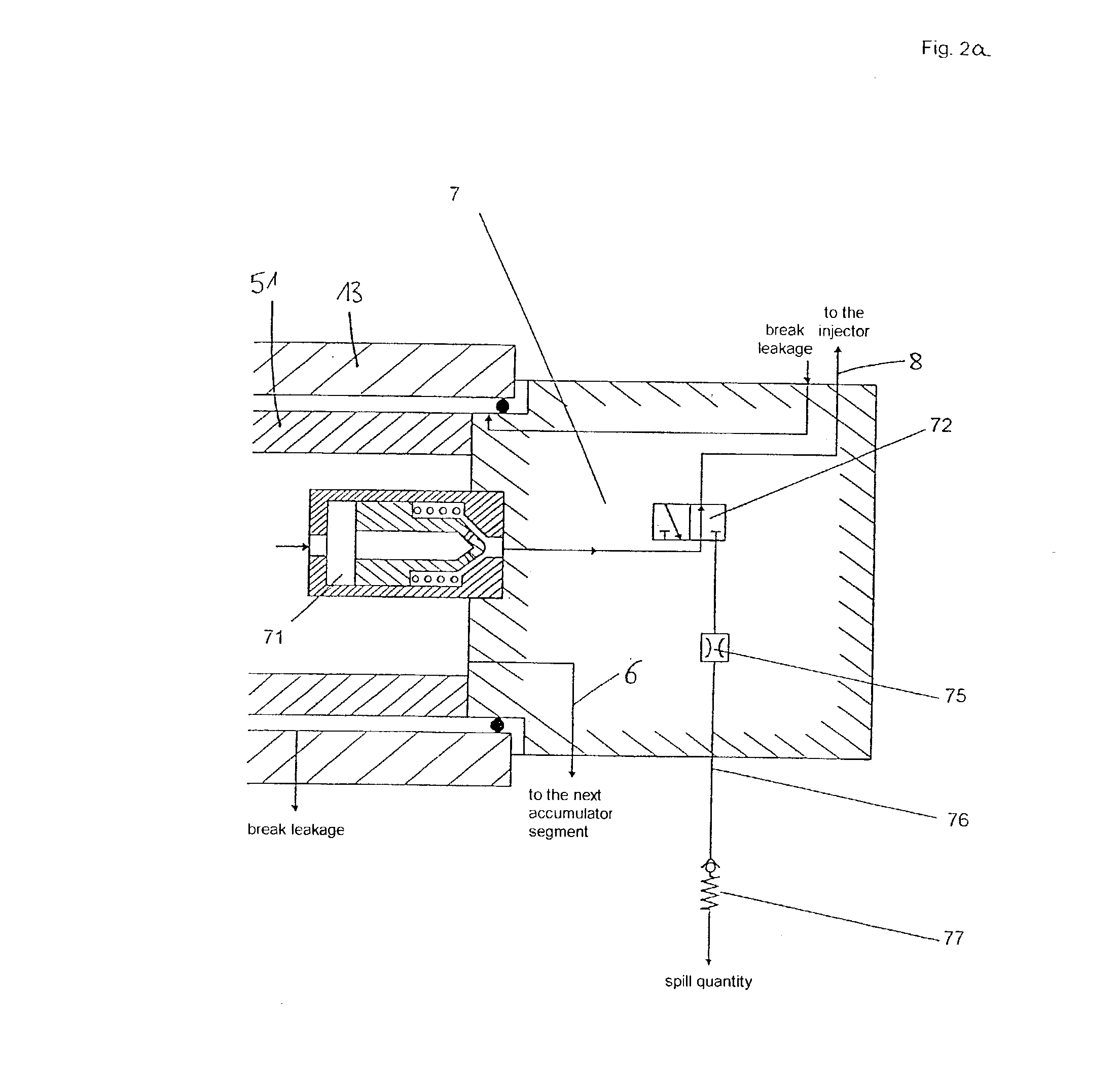

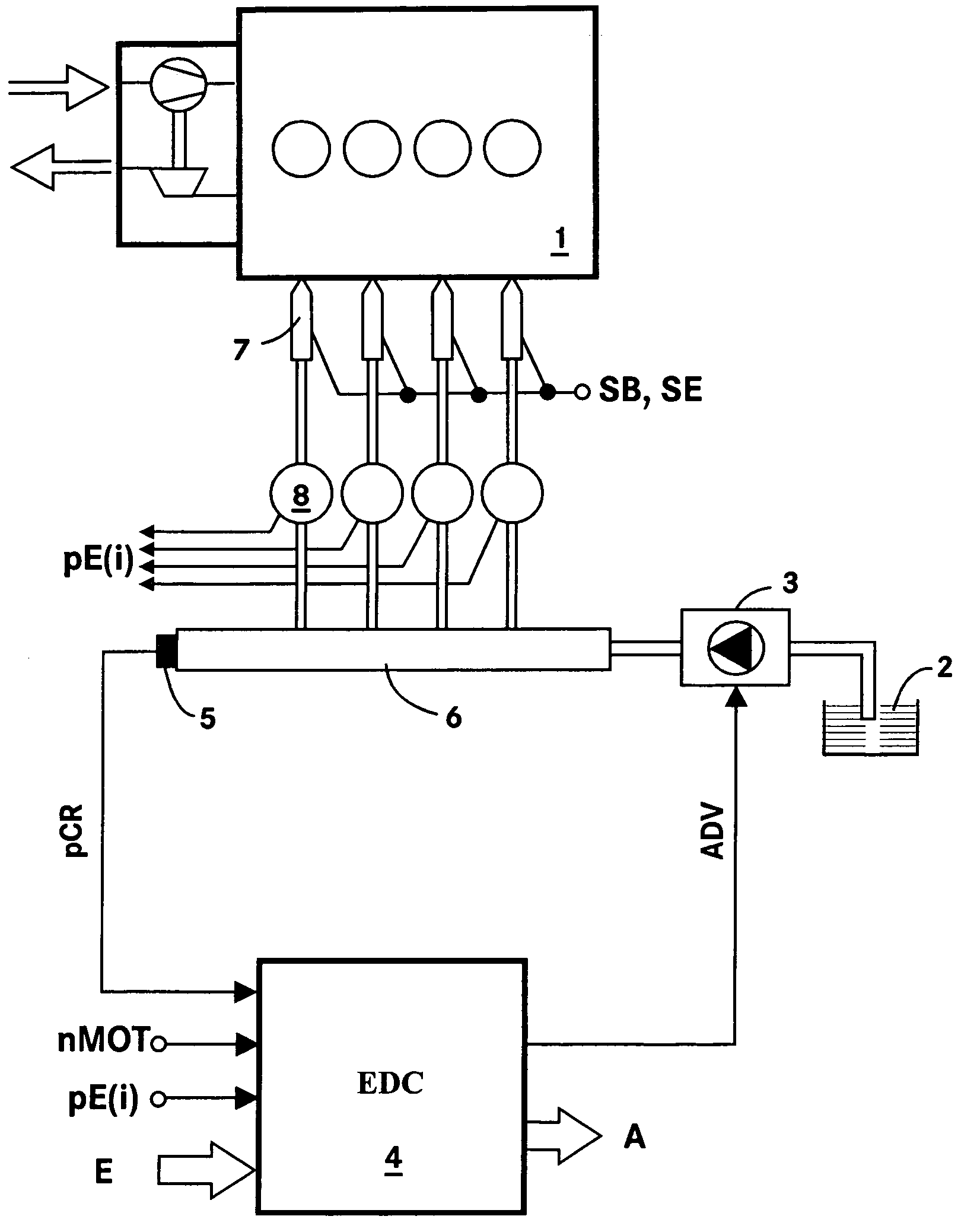

Fuel supply installation in the form of a common-rail system of an internal combustion engine having a plurality of cylinders

InactiveUS20030094158A1Guaranteed uptimeReduce dynamic pressureCasingsInternal combustion piston enginesCommon railEngineering

Fuel is conveyed by at least one high-pressure pump from a low-pressure region into a high-pressure region including a pressure-accumulator line consisting of at least two separate accumulator units connected to one another by means of feed lines, and to fuel injectors for the cylinders. The accumulator units each have an accumulator volume for serving at least two cylinders, and accumulator covers provided on both end faces. All the functional units are integrated into these accumulator covers in terms of fuel delivery and transfer, and at least one separate pump accumulator is arranged in the high-pressure region between the high-pressure pump and the assembled pressure-accumulator line. The pump accumulator is connected to at least one accumulator cover of an accumulator unit of the pressure-accumulator line for fuel conveyance and is capable of being acted upon by at least one high-pressure pump.

Owner:MAN ENERGY SOLUTIONS SA

Individual accumulator, high-pressure component, and common rail fuel injection system, as well as an internal combustion engine, electronic control unit, and method for the open-loop and/or closed-loop control of an internal combustion engine

InactiveUS20100280743A1Improve accuracyElectrical controlDigital data processing detailsLoop controlExternal combustion engine

An individual accumulator for a high-pressure component of a high-pressure fuel guide of a common rail fuel injection system. The individual accumulator is equipped with a pressure sensor, and the common rail fuel injection system is equipped with a source of high pressure and a fuel injector, which has a fluid connection with this source of high pressure via the high-pressure fuel guide, for injecting the fuel into a working chamber of an internal combustion engine. The pressure sensor is designed as a strain sensor.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

Fuel injector

InactiveUS20090277423A1Reduce disadvantagesLow costMovable spraying apparatusSpray nozzlesControl roomInternal combustion engine

A fuel injector for use in an internal combustion engine comprises a first valve member and a second valve member, an injection control chamber for fuel, and a set of nozzle outlets; wherein actuation of the second valve member controls the fuel pressure within the injection control chamber, and actuation of the first valve member is regulated by the fuel pressure within the injection control chamber; and wherein the fuel injector is arranged such that actuation of the second valve member establishes a fuel flow path between the injection control chamber and the set of nozzle outlets. The first valve member may be provided with a first valve bore within which the second valve member is received. An injection nozzle and a method of operating a fuel injector are also described.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

Fuel injection system

InactiveUS7047941B2Improve efficiencyReduce noiseElectrical controlLow-pressure fuel injectionEngineeringFuel supply

A fuel injection system for supplying pressurized fuel to a fuel injector, the fuel injection system comprising an accumulator volume for supplying fuel at a first injectable pressure level to the fuel injector through a fuel supply passage, a pump arrangement for increasing the pressure of fuel supplied to the injector to a second injectable pressure level, and a valve arrangement operable between a first position in which fuel at the first injectable pressure level is supplied to the injector and a second position in which communication between the injector and the accumulator volume is broken so as to permit fuel at the second injectable pressure to be supplied to the injector. The injection system may include a valve arrangement in the form of a three-position valve or may include a shut off valve for controlling the supply of fuel through the fuel supply passage.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

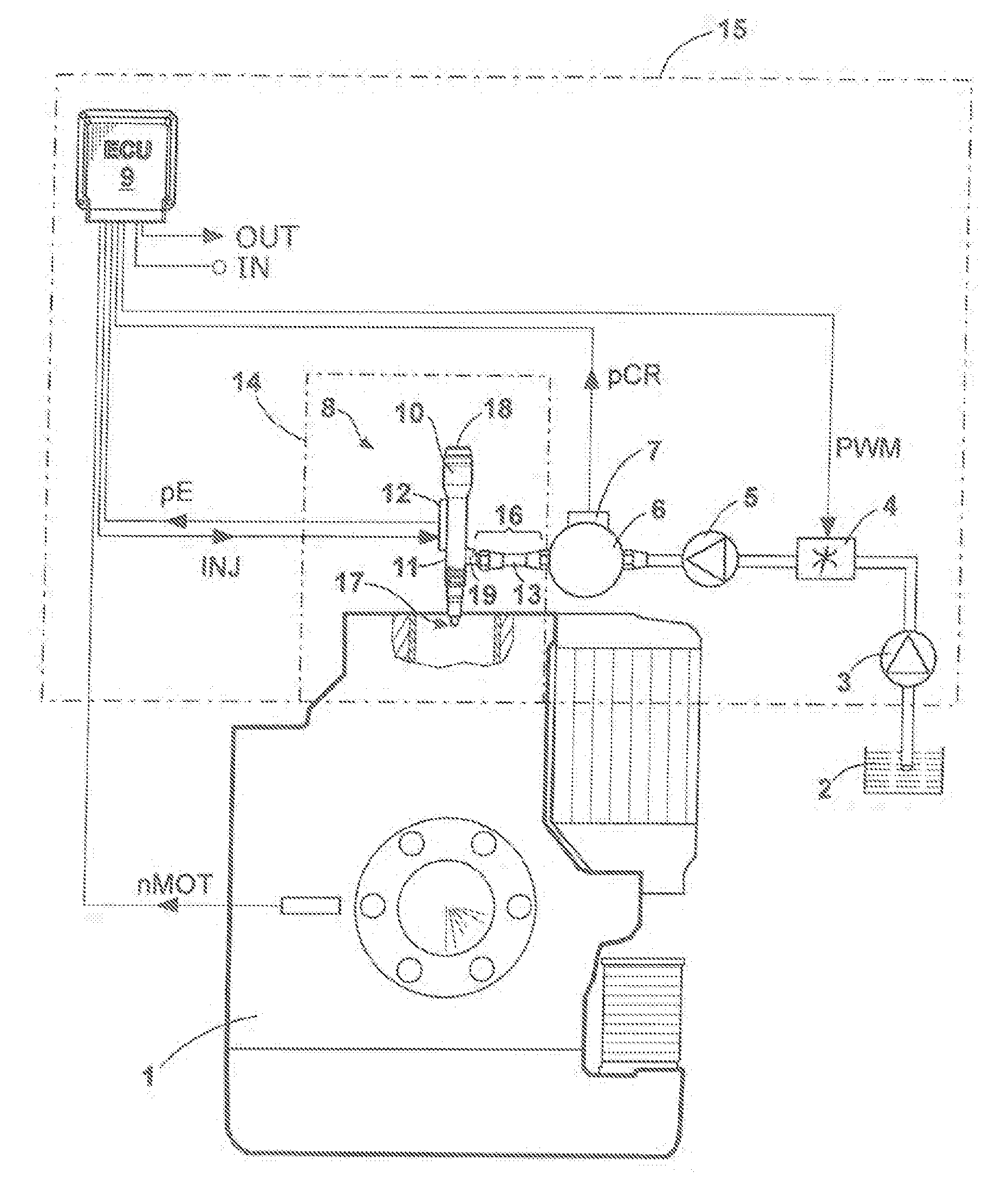

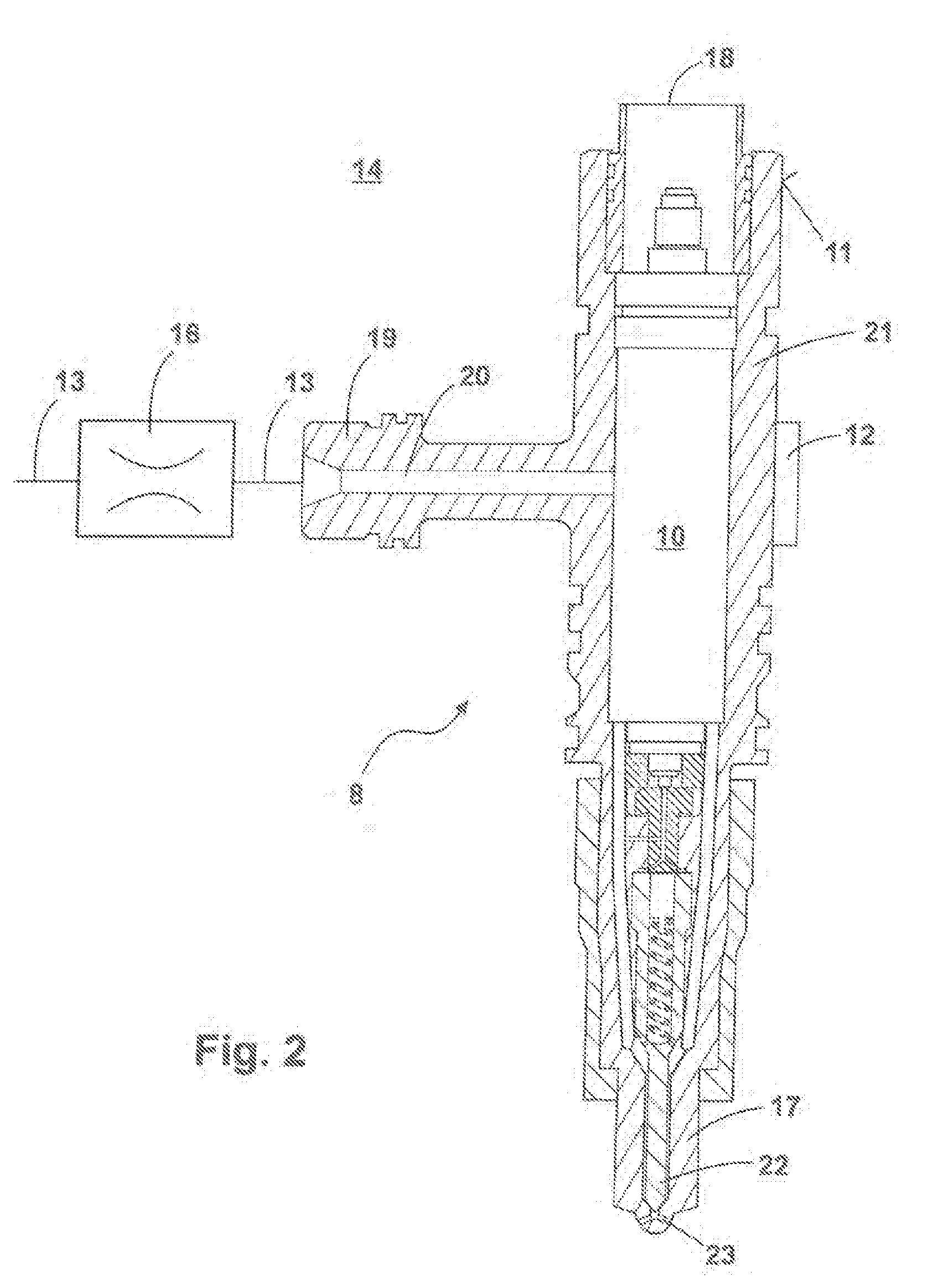

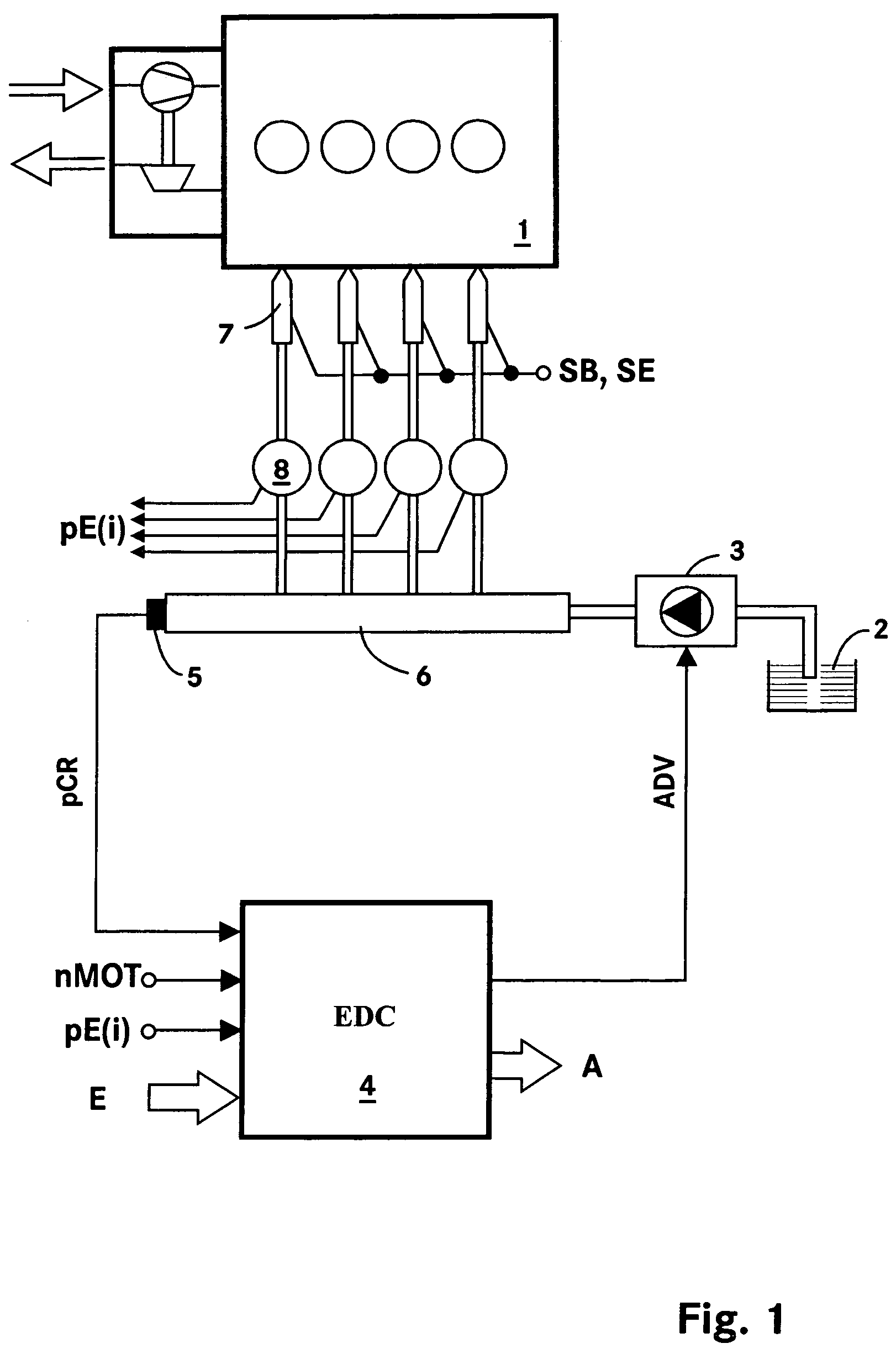

Method of controlling an internal combustion engine with a common rail fuel injection system

ActiveUS7272486B2Avoid misunderstandingMore directionalElectrical controlInternal combustion piston enginesCommon railInternal combustion engine

In a method of controlling an internal combustion engine with a common rail fuel injection system including individual fuel storage chambers for the supply of fuel to the various cylinders of the internal combustion engine, a fuel pressure (pE(i)) is determined during a measuring interval (MESS) and is stored, the existence of a significant change in the fuel pressure is determined as an injection begin (SB=f(pE(i), Phi)) or an injection end (SE=f(pE(i)), Phi), a virtual injection begin is calculated by way of a mathematical function (FKT) depending on the injection end (SE), and the virtual injection begin (SBv) is used as the actual injection begin (SB) for the subsequent control of the internal combustion engine.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

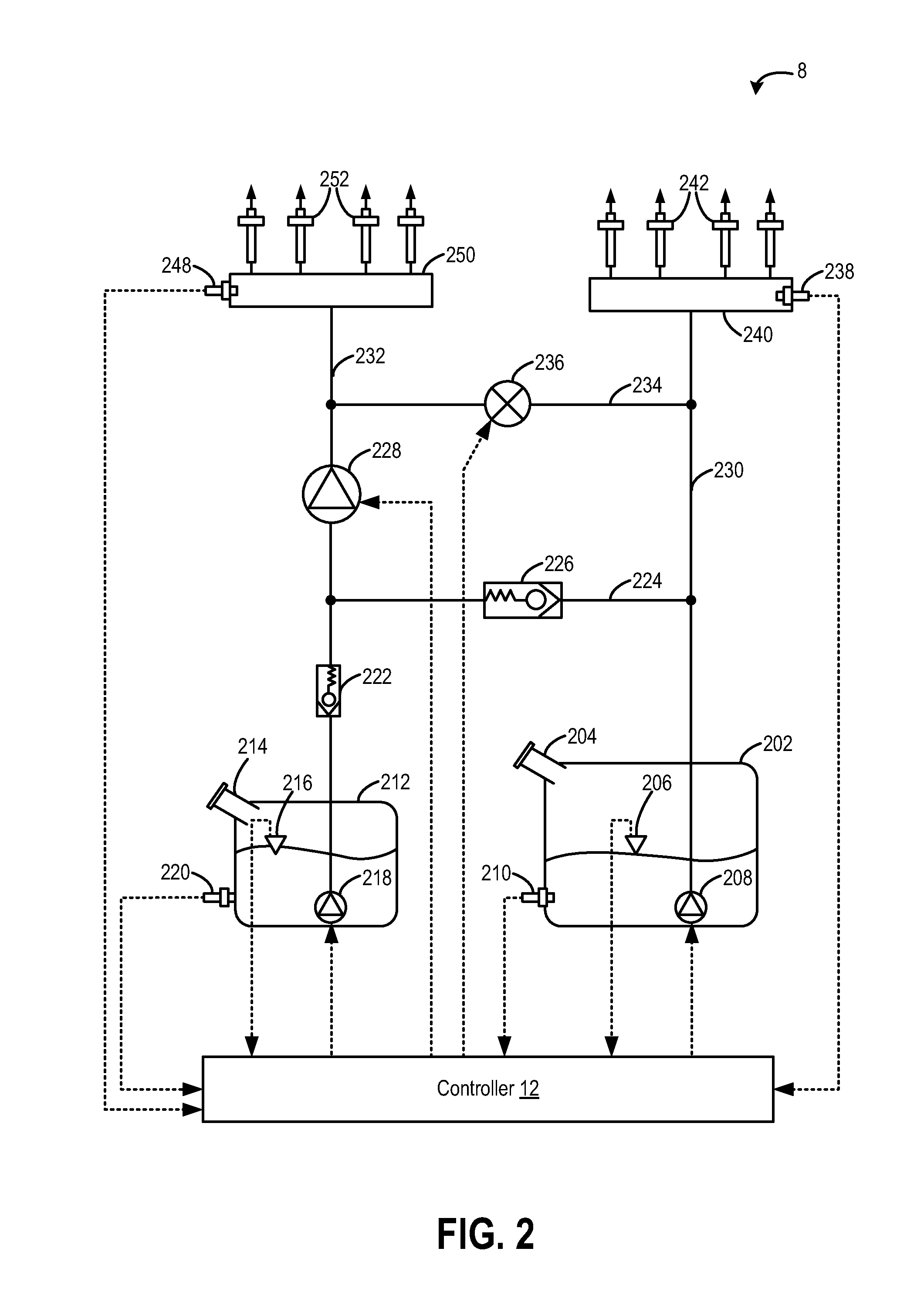

Fuel rail delivery system arrangement

InactiveUS6990959B1Easy to installMinimize opportunityLow pressure fuel injectionMachines/enginesEngineeringDelivery system

An air fuel delivery system arrangement for an engine is provided, including an air manifold body, having a first set of runners for a first cylinder bank with inlets on a first side and outlets on a second side of the manifold body and a second set of runners for a second cylinder bank with inlets on a second side and outlets on a first side. And a first fuel rail is included, having outlets for connection with fuel injectors for delivering fuel to the first cylinder bank being positioned generally between the inlets of the manifold body. A second fuel rail is also included, having outlets for connection with fuel injectors for delivering fuel to the second cylinder bank being positioned generally between the inlets of the manifold body being generally vertically aligned with the first fuel rail.

Owner:MILLENNIUM INDS

Fuel supply installation in the form of a common-rail system of an internal combustion engine having a plurality of cylinders

InactiveUS6776140B2Guaranteed uptimeReduce dynamic pressureCasingsInternal combustion piston enginesCommon railInternal combustion engine

Owner:MAN ENERGY SOLUTIONS SA

Direct injection fuel pump system

InactiveUS20160208757A1Improve engine performanceWell mixedWear reducing fuel injectionPositive displacement pump componentsEngineeringHigh pressure

Systems and methods are provided for operating a direct injection fuel pump. One example system comprises an accumulator positioned within a bore of the direct injection fuel pump in a coaxial manner wherein the accumulator is positioned downstream from a solenoid activated check valve. The accumulator may regulate pressure in a compression chamber of the direct injection fuel pump and a high pressure fuel rail when the direct injection fuel pump is operating in a default pressure mode.

Owner:FORD GLOBAL TECH LLC

Methods of Operation of Fuel Injectors with Intensified Fuel Storage

ActiveUS20140138454A1Reduce pressureControl performanceElectrical controlWear reducing fuel injectionInjection pressureEngineering

Methods of operating fuel injectors with intensified fuel storage. At least one storage volume is provided in the intensifier type fuel injector, with a check valve between the intensifier and the needle chamber and storage volume preventing loss of injection pressure while the intensifier plunger cylinder is refilling with fuel. Using the check valve to isolate the storage volume from the intensifier to reduce and control pressure spikes that effect injector operation. This provides very efficient injector operation, particularly at low engine loads, by eliminating the wasted energy of compressing, venting and recompressing fuel for injection and reducing and controlling pressure spikes that effect injector operation.

Owner:STURMAN DIGITAL SYST

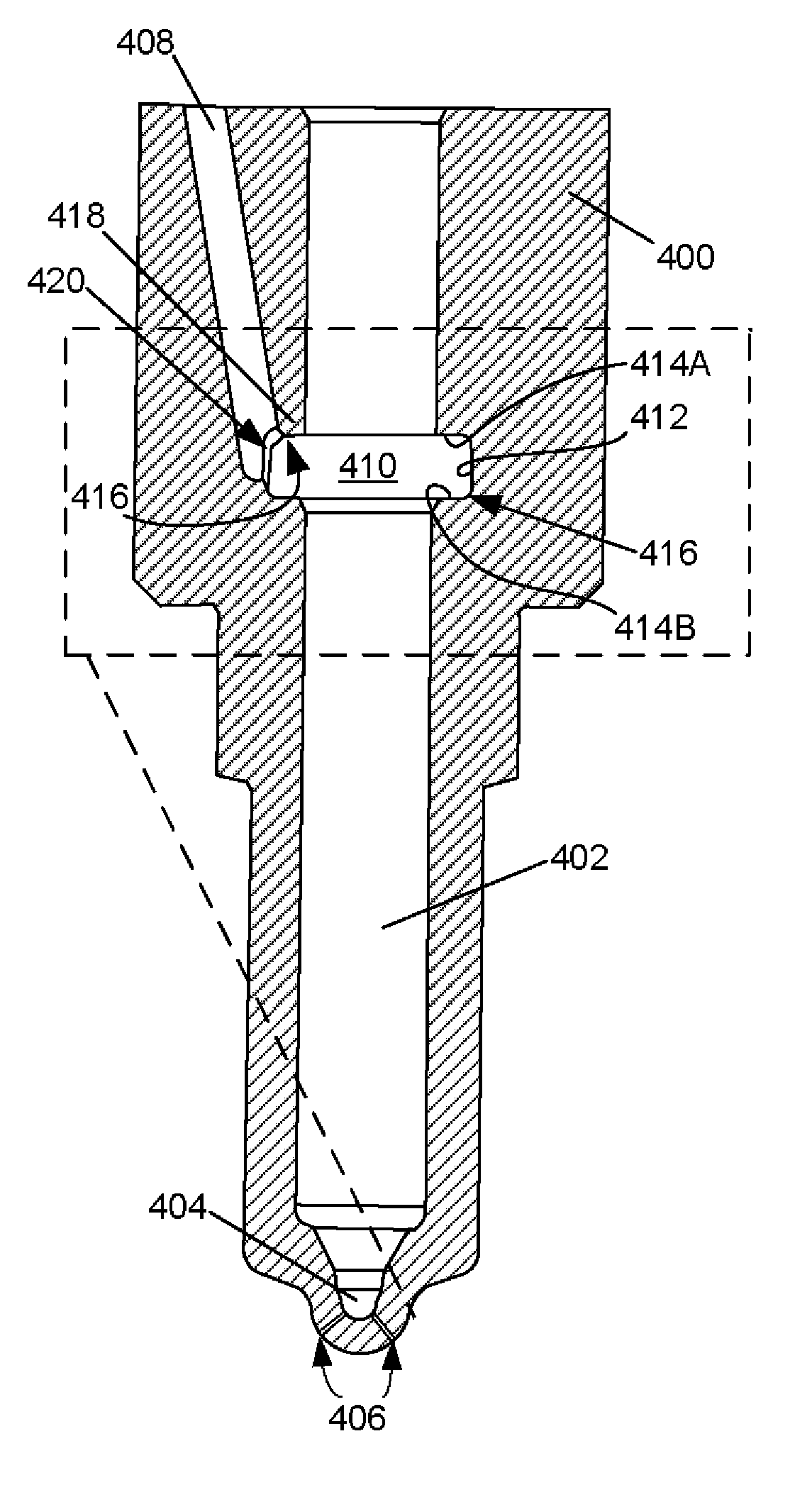

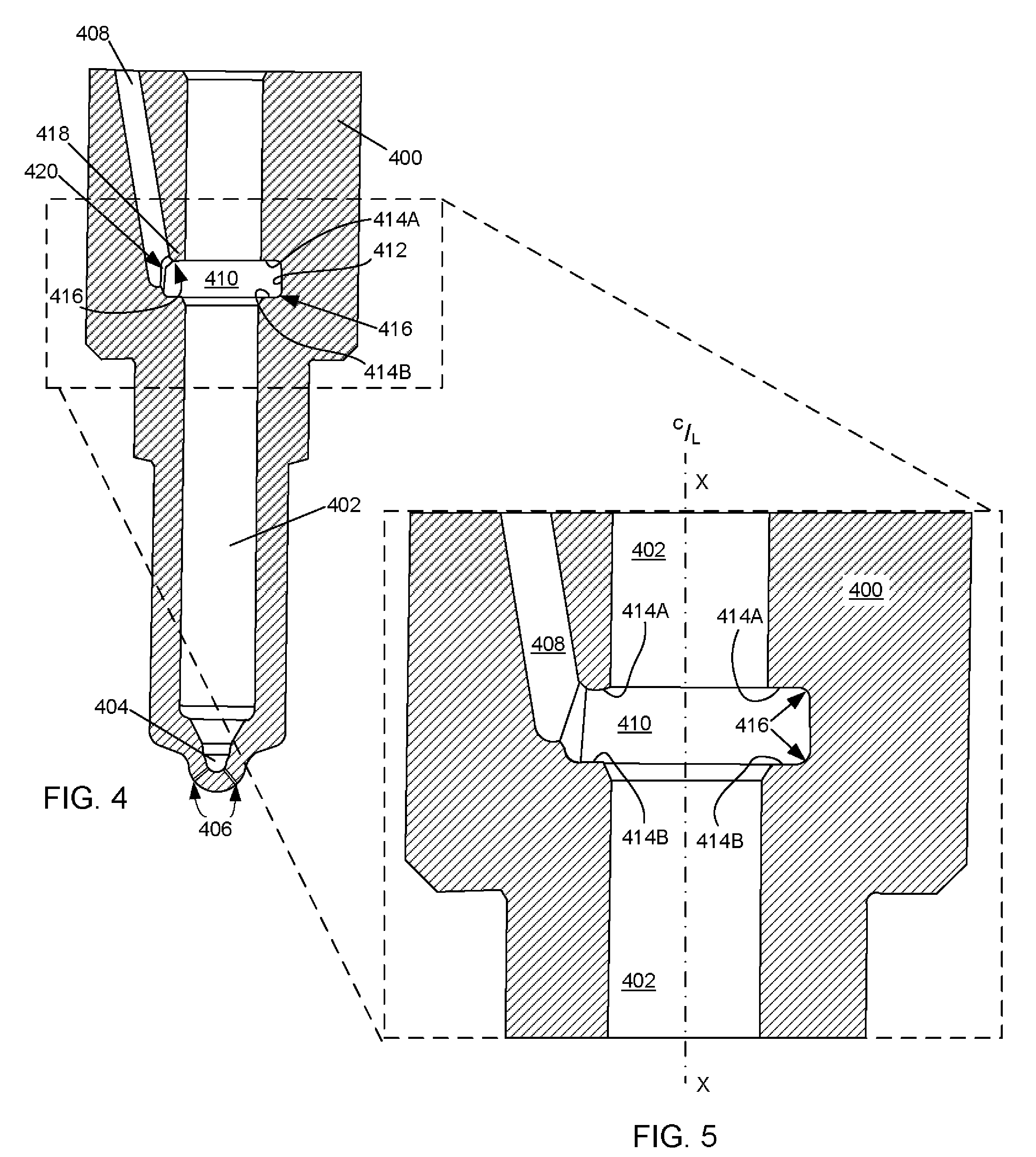

Fuel injector needle housing

InactiveUS20080290188A1Low pressure fuel injectionMachines/enginesHigh pressureInternal combustion engine

A fuel injector for injecting fuel into a cylinder of an internal combustion engine includes an injector body and a needle valve. A feed passage (408) fluidly connects a needle chamber (402) with a source of high pressure fuel. The needle chamber (402) is formed in a needle housing (400) and has a centerline (X) extending along its length. The needle valve is located in the needle chamber (402). A collection cavity (410) is formed in the needle housing (400) and in fluid communication with the needle chamber (402). The collection cavity (410) is positioned between the needle chamber (402) and the feed passage (408). The collection cavity (410) is advantageously substantially symmetrical about a plane that is perpendicular to the centerline (X) of the needle chamber (402).

Owner:INT ENGINE INTPROP CO LLC

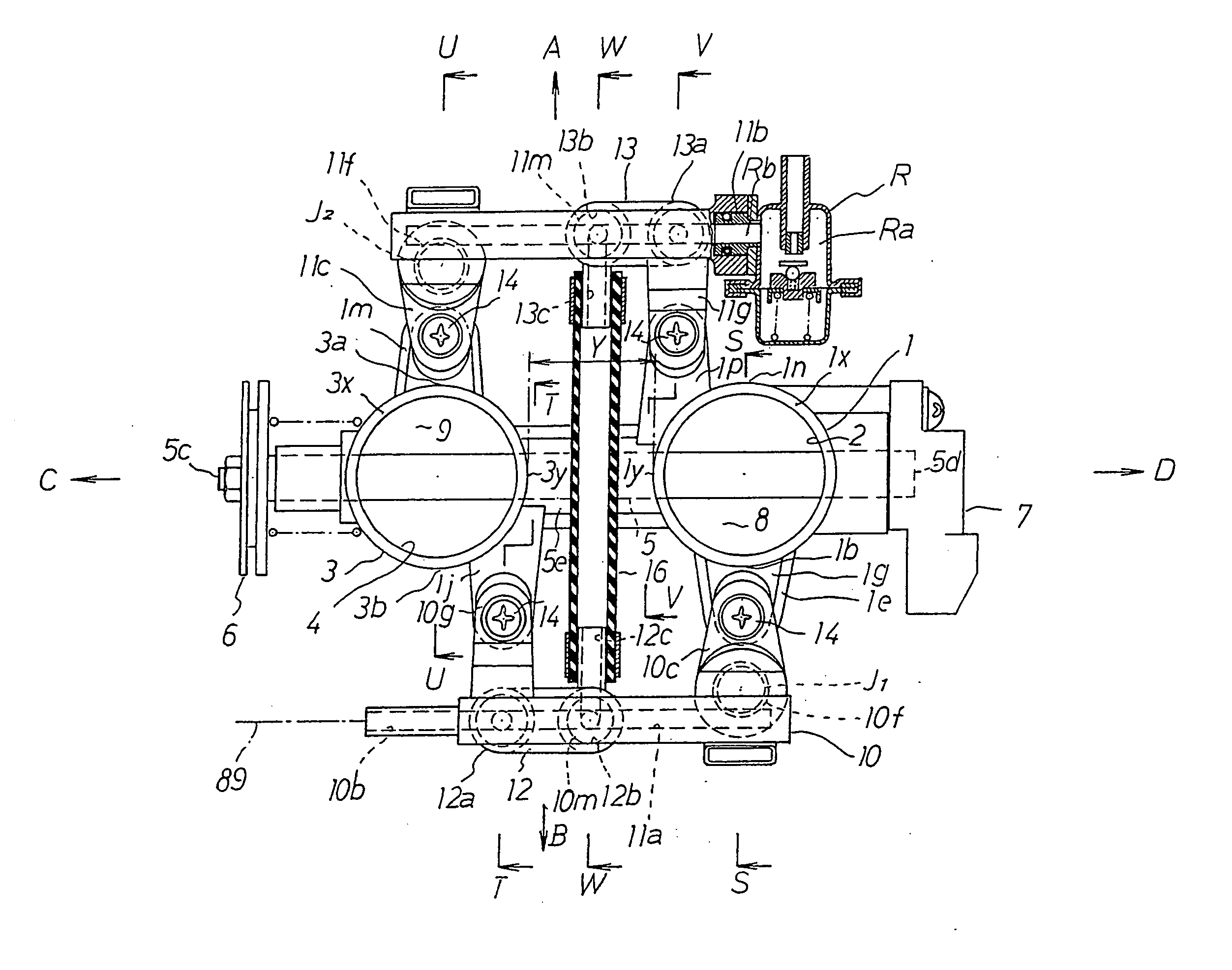

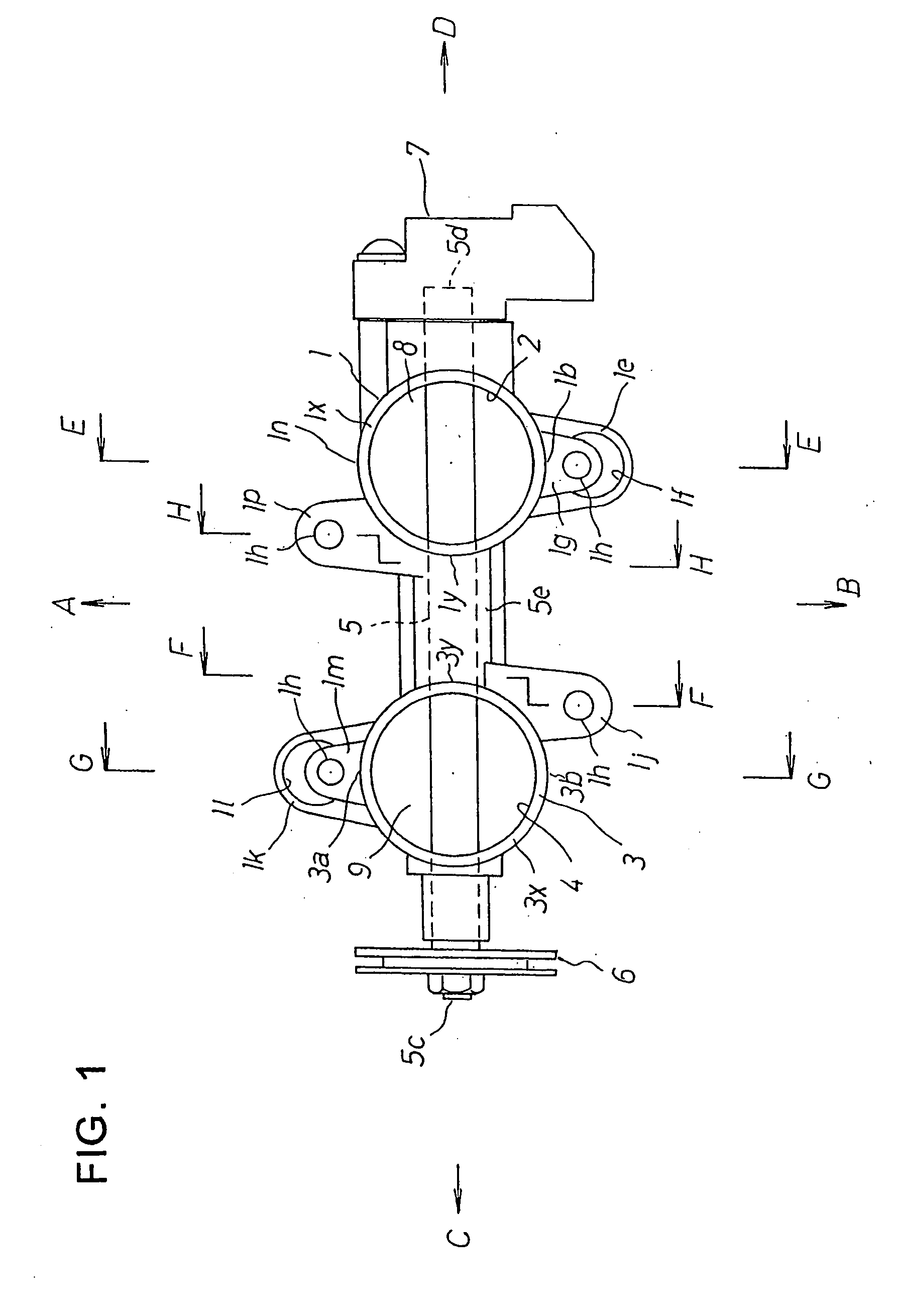

Fuel supply apparatus

InactiveUS20050229902A1Improve stabilityShort pipe lengthLow pressure fuel injectionMachines/enginesFuel distributionControl theory

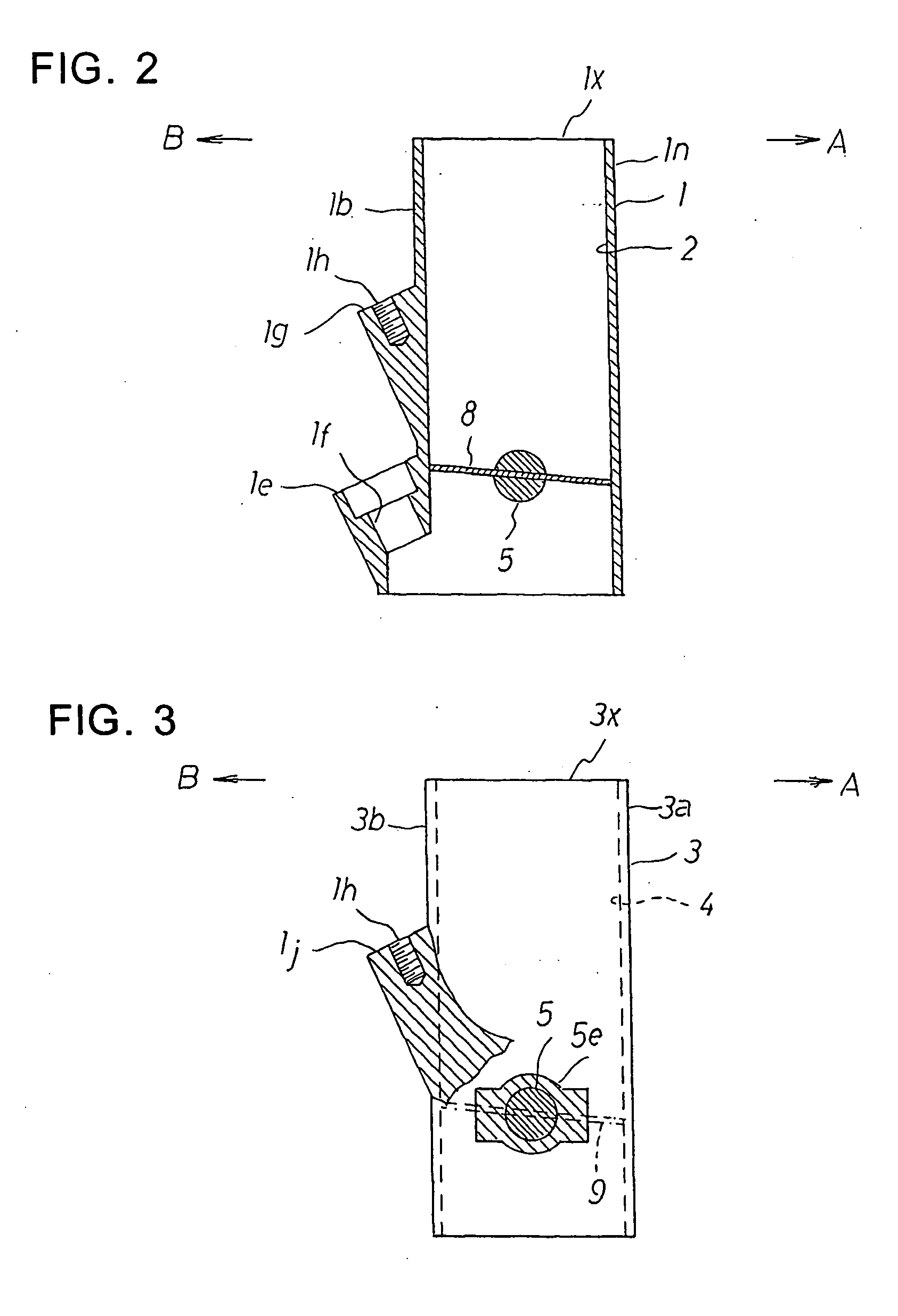

To inhibit vapor in a fuel flowing to a second fuel distribution path by shortening a fuel communicating pipe between first and second fuel distribution paths in respective sides of a throttle body, first and second throttle bodies (1, 3) are arranged in parallel, first and second throttle valves (8, 9) are attached to a single throttle valve shaft (5), a throttle drum (6) is attached to a left end (5c) of the throttle valve shaft (5), first and second fuel supply bodies (10, 11) including first and second fuel injection valves (J1, J2) are arranged respectively in one side (B) and the other side (A) of the throttle bodies, both the fuel supply bodies (10, 11) are connected by a fuel communicating path (16), and the fuel communicating path (16) is arranged inn a space among throttle valve shaft (5), upper ends (1x, 3x) of the throttle bodies, opposing side surfaces of both the throttle bodies (1, 3).

Owner:KEIHIN CORP

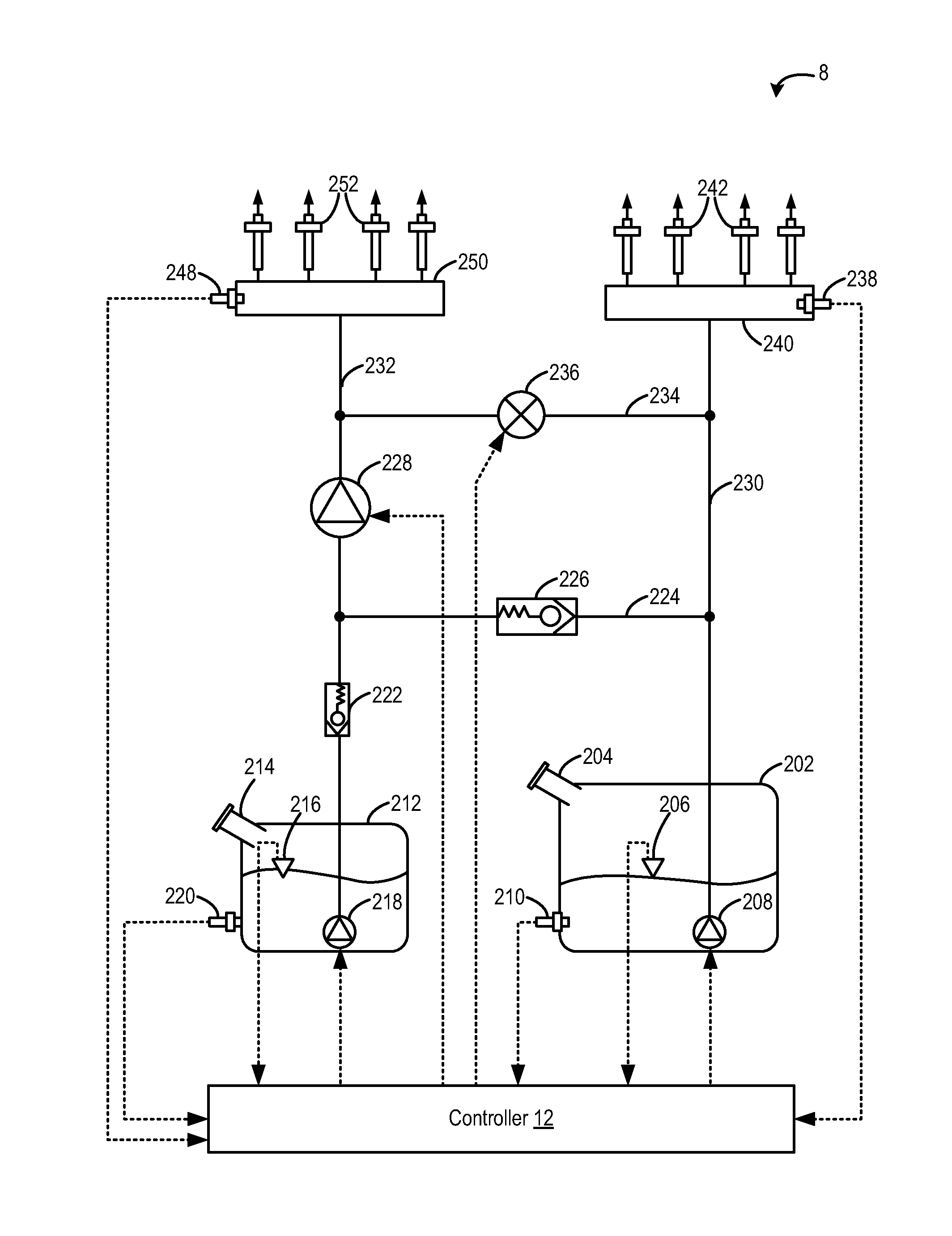

Multi-source fuel system for variable pressure injection

InactiveUS7398763B2Combustion enginesFuel injecting pumpsVariable pressurePressure controlled ventilation

A fuel system for a work machine is disclosed. The fuel system has a fuel injector, a first source of fuel at a first pressure, a second source of fuel at a second pressure, and a pressure control device. The pressure control device is disposed between the fuel injector and the first and second sources. The pressure control device is configured to selectively direct the fuel at the first pressure and the fuel at the second pressure to the fuel injector.

Owner:CATERPILLAR INC

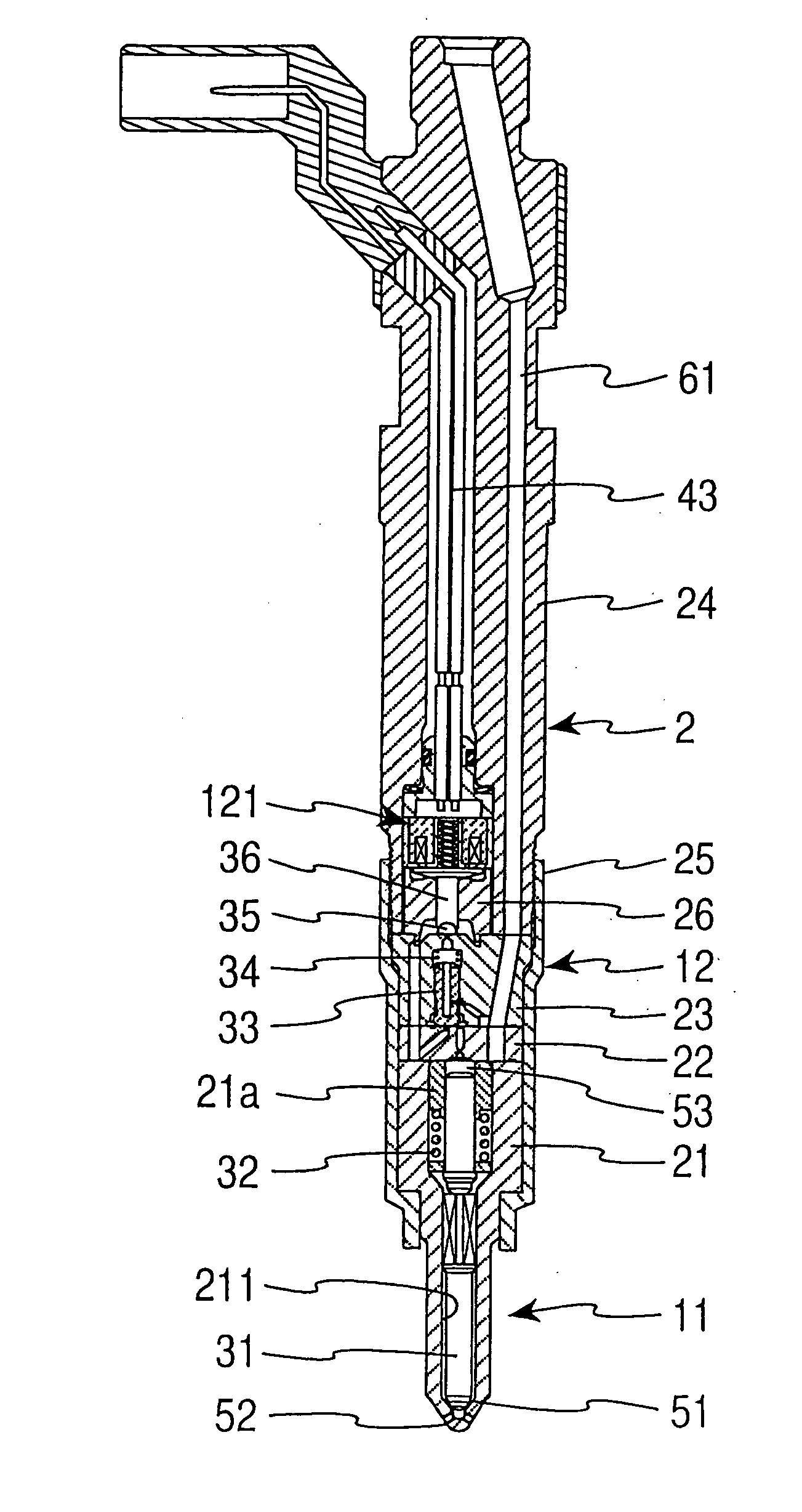

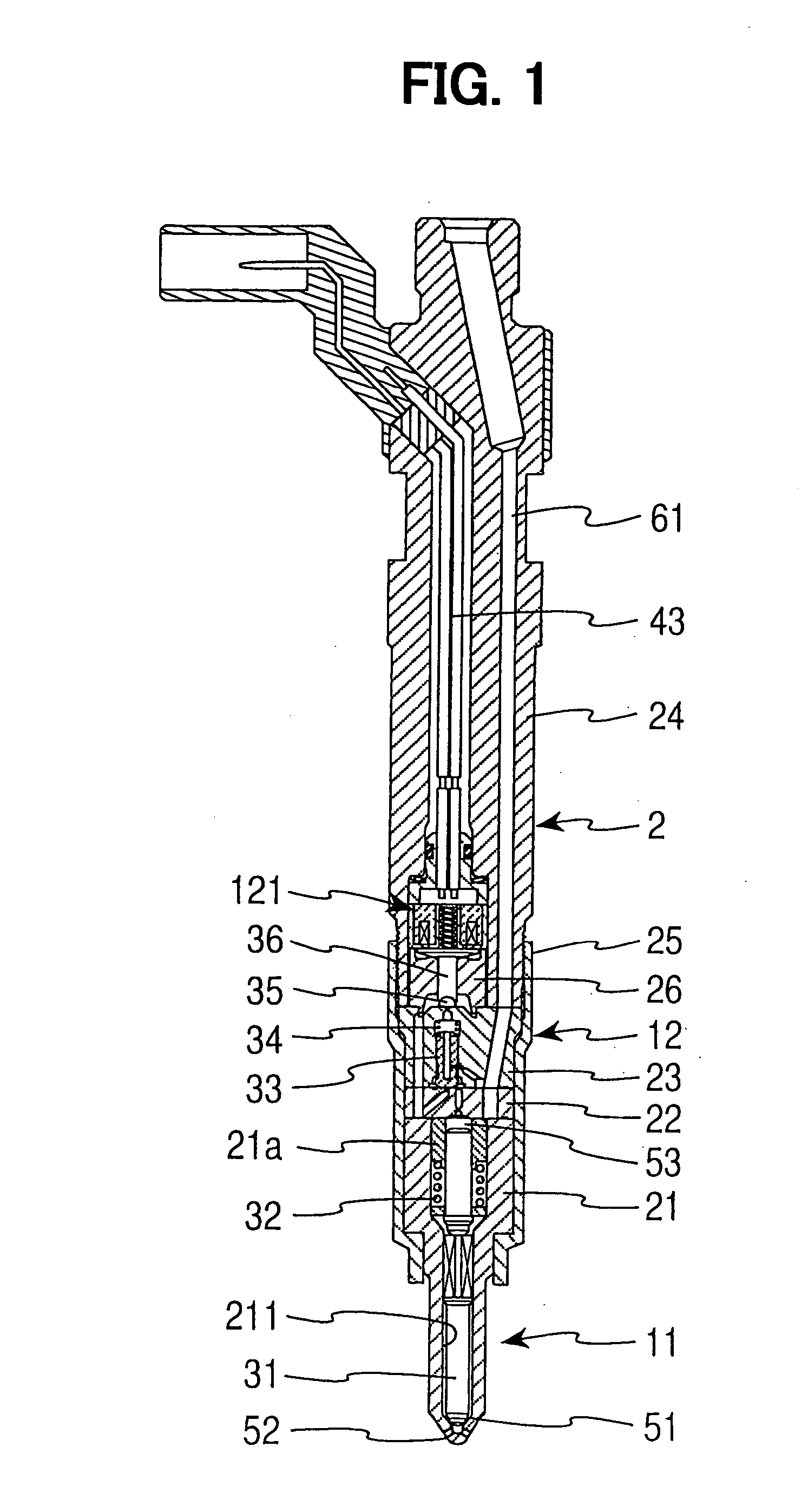

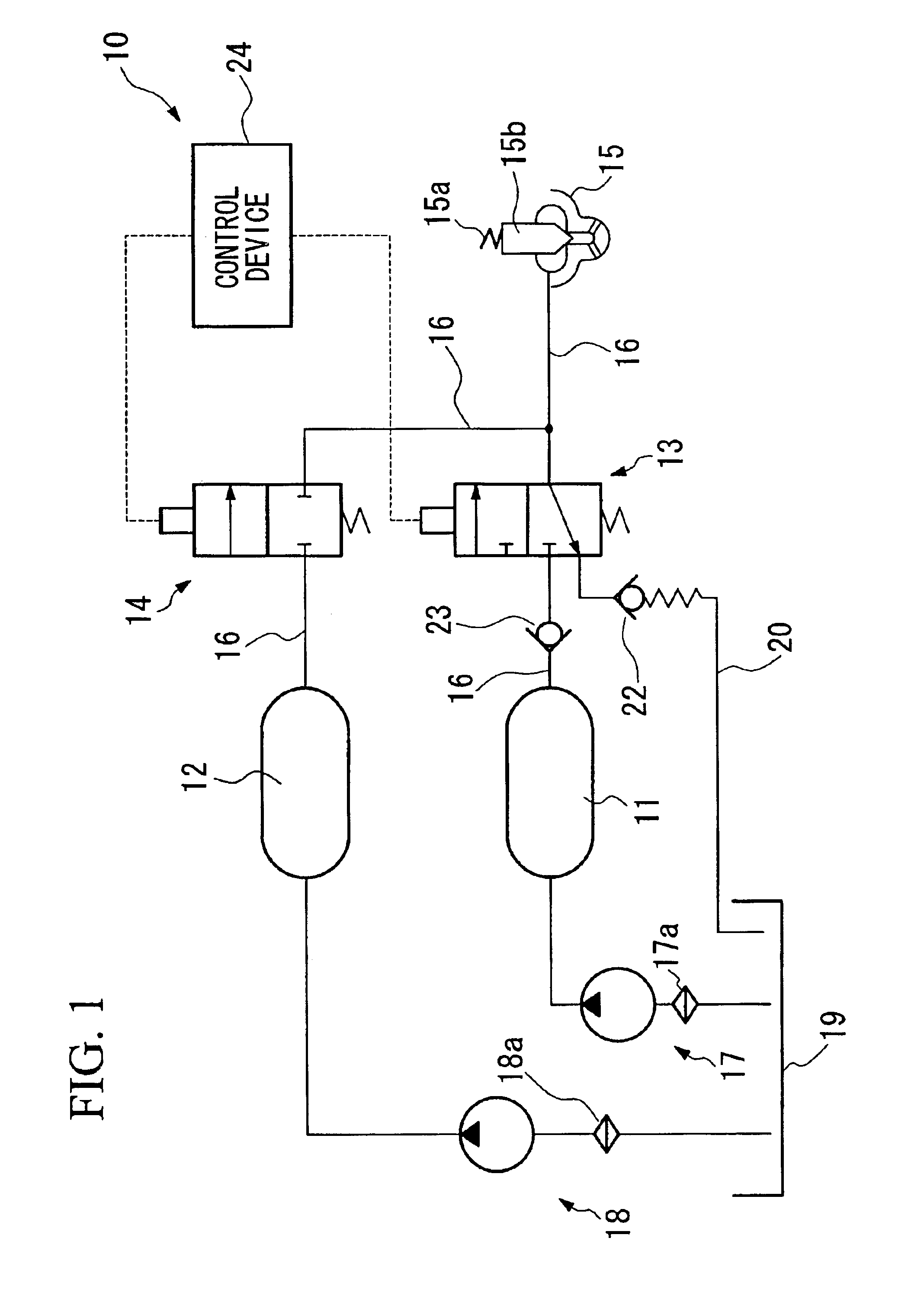

Fuel injector and diesel engine comprising the same

InactiveUS6895937B2Reduce smoke emissionsDecrease of NOxMachines/enginesFuel injection with fuel accumulatorsLow loadEngineering

A fuel injector can reduce the smoke emissions generated during low load and decrease NOx during high load. The fuel injector comprises a first accumulator for accumulating a pressurized fuel, a second accumulator for accumulating a fuel having a higher pressure than the pressure of the fuel in the first accumulator, fuel injection valves to which the fuel from the first and second accumulators is supplied and thereby the fuel injection valves are opened, and the fuel is injected, fuel feeding pipes for feeding the fuel accumulated in the first and second accumulators to the fuel injection valves; a first valve mechanism which is provided at the fuel feeding pipe and which opens and allows the flow of the fuel in the first accumulator to the fuel injection valves, a second valve mechanism which is provided at the fuel feeding pipe and which opens and allows the flow of the fuel in the second accumulator to the fuel injection valves, and a control device for controlling the first and second valve mechanisms. The first accumulator and the first valve mechanism, and the second accumulator and the second valve mechanism, are provided in parallel to each other to the fuel feeding pipe. In a normal injection mode, the control device makes the first and second valve mechanisms open at the same time. In an injection rate control mode, the control device makes an open timing of the first valve mechanism earlier than an open timing in the normal injection mode.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Liquid pump with cavitation mitigation

A liquid pump applicable in a fuel system such as a common rail fuel system includes a valve assembly having a valve stack with axially aligned components, dead volume, and vapor-distributing flow channels, for cavitation mitigation. An inlet valve meters a flow of liquid into the pump for pressurization by a plurality of reciprocating plungers operated by way of a rotating camshaft.

Owner:CATERPILLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com