Patents

Literature

528 results about "Fuel distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

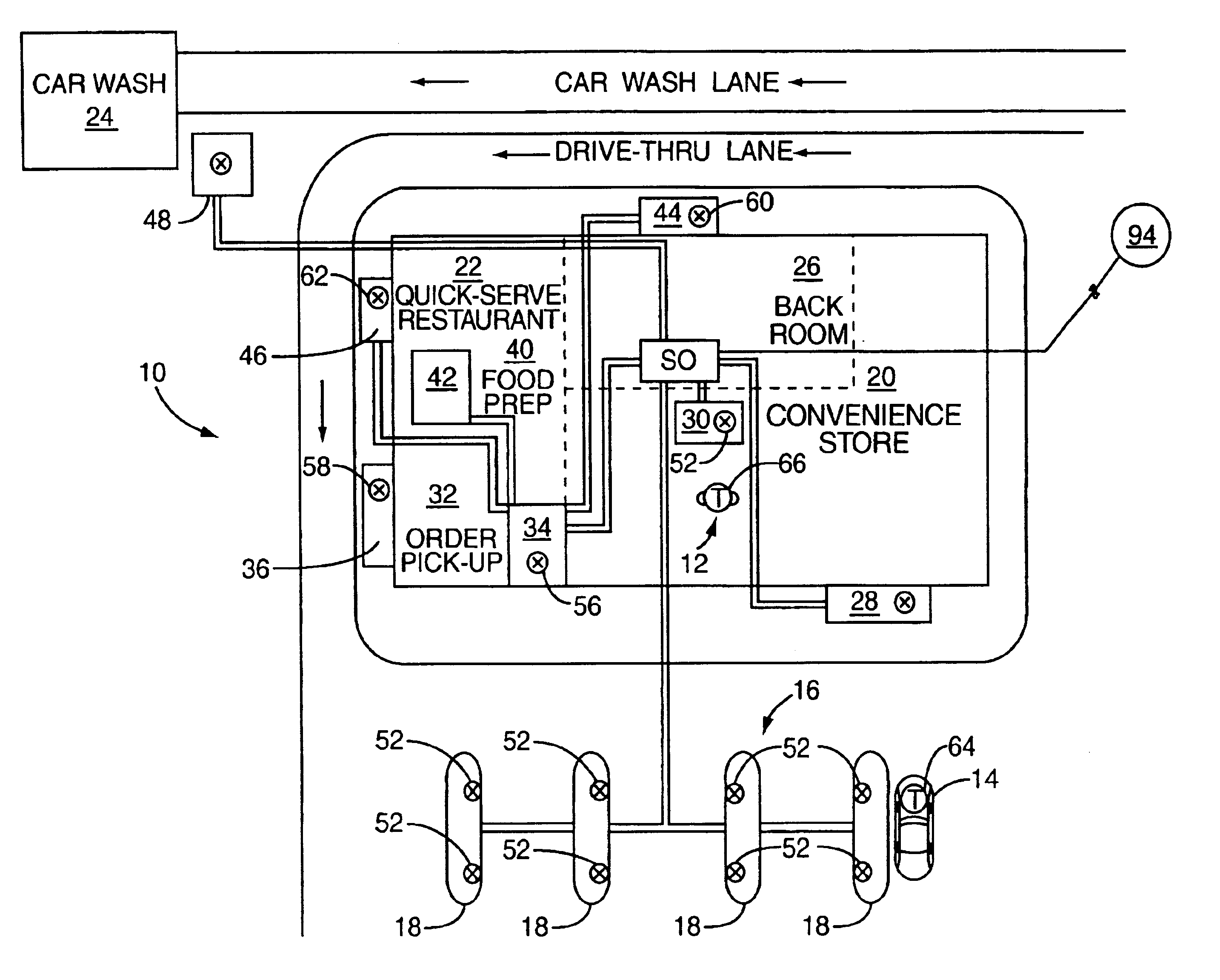

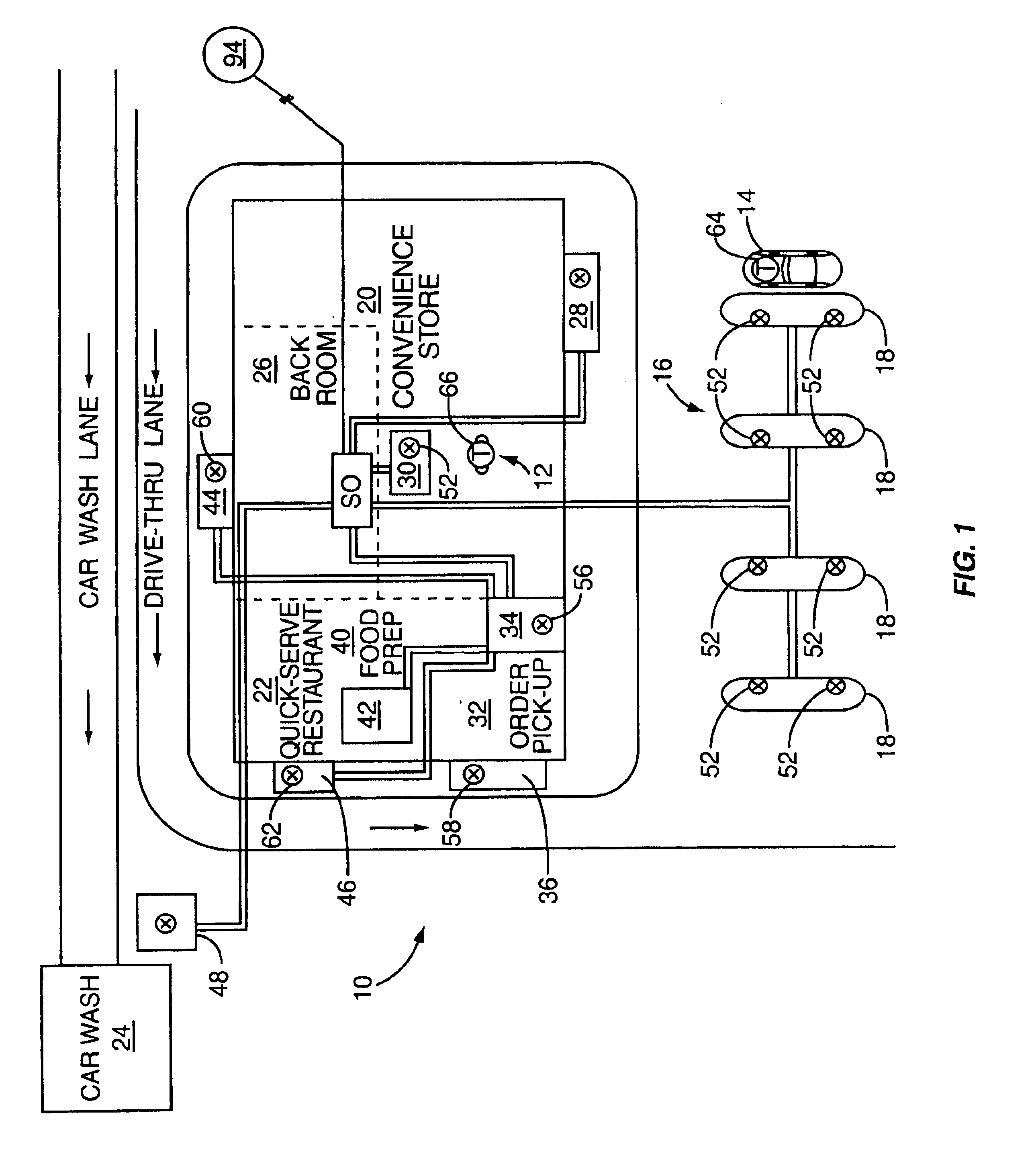

Fuel dispensing and retail system for providing customer selected guidelines and limitations

InactiveUS6882900B1Easy to controlCredit registering devices actuationRegistering/indicating working of vehiclesGuidelineControl system

The present invention provides a fuel dispensing system for setting transaction parameters in association with a remote communications unit. This system will include wireless or radio communications electronics adapted to receive signals from remote communications units, a transaction interface for carrying out transactions, and a control system and associated memory operating in conjunction with the communications electronics and a transaction interface. The control system is adapted to receive indicia from a remote communications unit and control the transaction at the transaction interface involving the remote communications unit according to predefined parameters associated with the remote communications unit. Any identification indicia and predefined parameters may be stored in the memory in association with the remote communications unit and the control system may be adapted to access these predefined parameters in the memory upon receipt of the identification indicia and control the transaction accordingly. Alternatively, the predefined parameters may be transmitted directly from the remote communications unit to the communications electronics and control system. The predefined parameters may limit a transaction to a select type or grade of fuel, a select type or amount of a product or service, as well as limiting or preventing the purchase of certain products or services. Notably, the control system may include a dispenser control system, a central site control system, a control system associated with a remote network, or a combination thereof.

Owner:GILBARCO

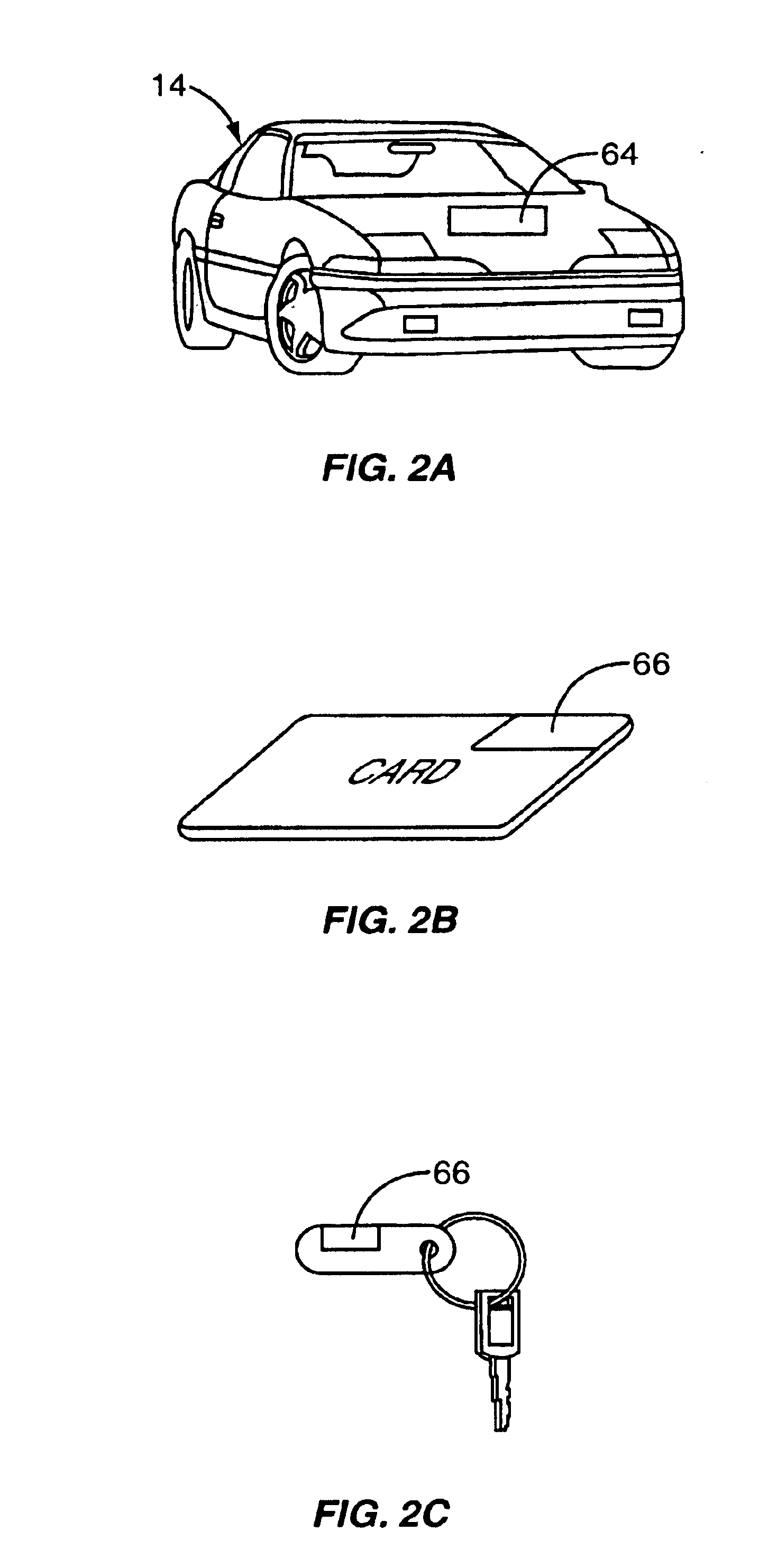

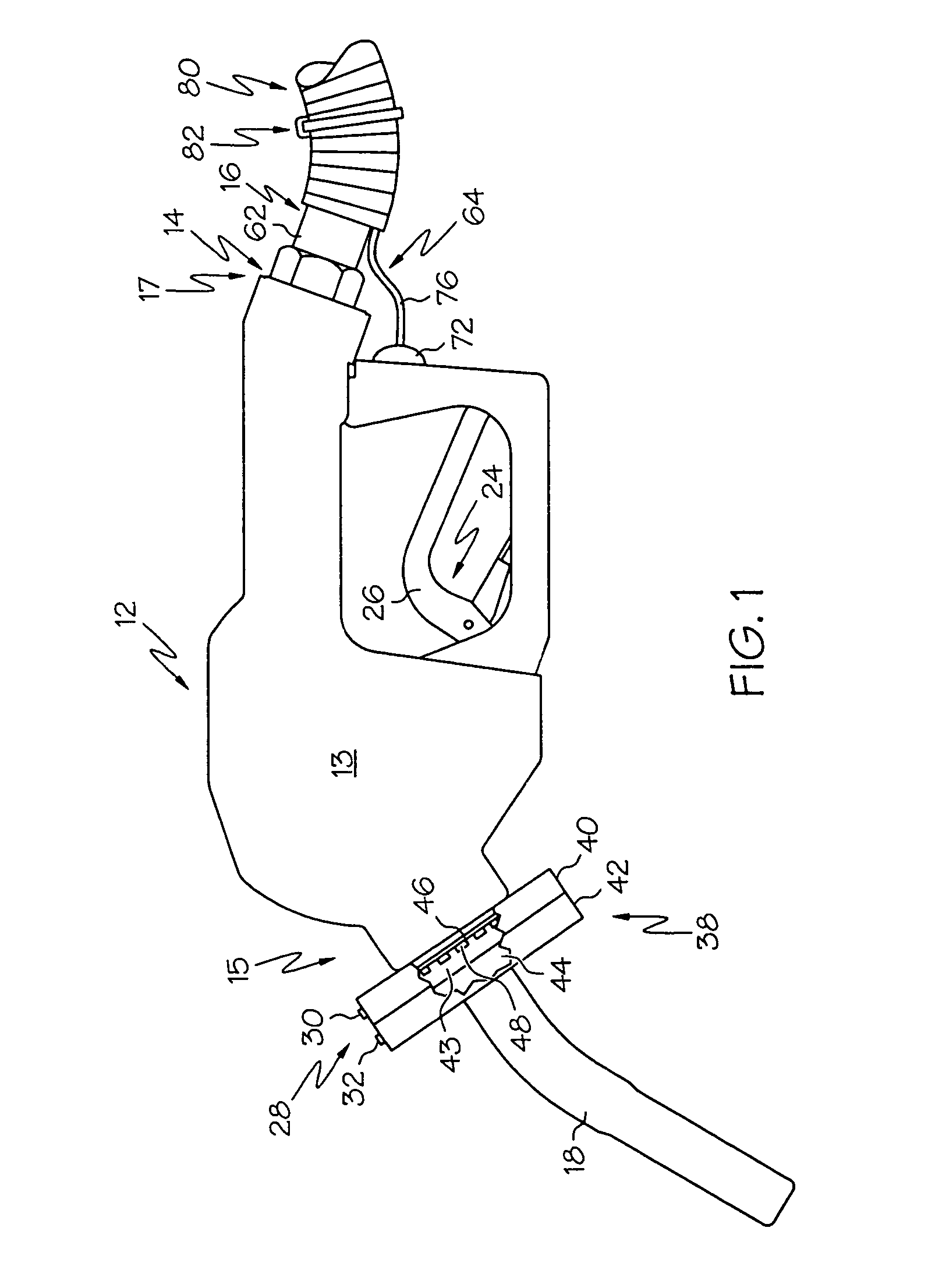

Lighted supervisory system for a fuel dispensing nozzle

ActiveUS6899151B1Low costSimple and low-costLiquid fillingLiquid transferring devicesFleet managementAs Directed

A nozzle is provided for a fleet fuel dispensing system. The nozzle includes an input port that is adapted to receive fuel through a fuel supply hose, and a spout that is configured to dispense fuel into a fuel entry receptacle of a vehicle. A valve assembly is configured to couple the input port with the spout, and is further configured to selectively facilitate the passage of fuel from the input port to the spout. A status light is associated with the nozzle and includes a single LED that is connected with a fleet management system. The status light is configured to selectively illuminate as directed by a fleet management system. The illumination provides information as to whether a vehicle is authorized to receive fuel from the spout. A fuel dispensing system having such a nozzle is also provided.

Owner:OPW FUEL MANAGEMENT SYST

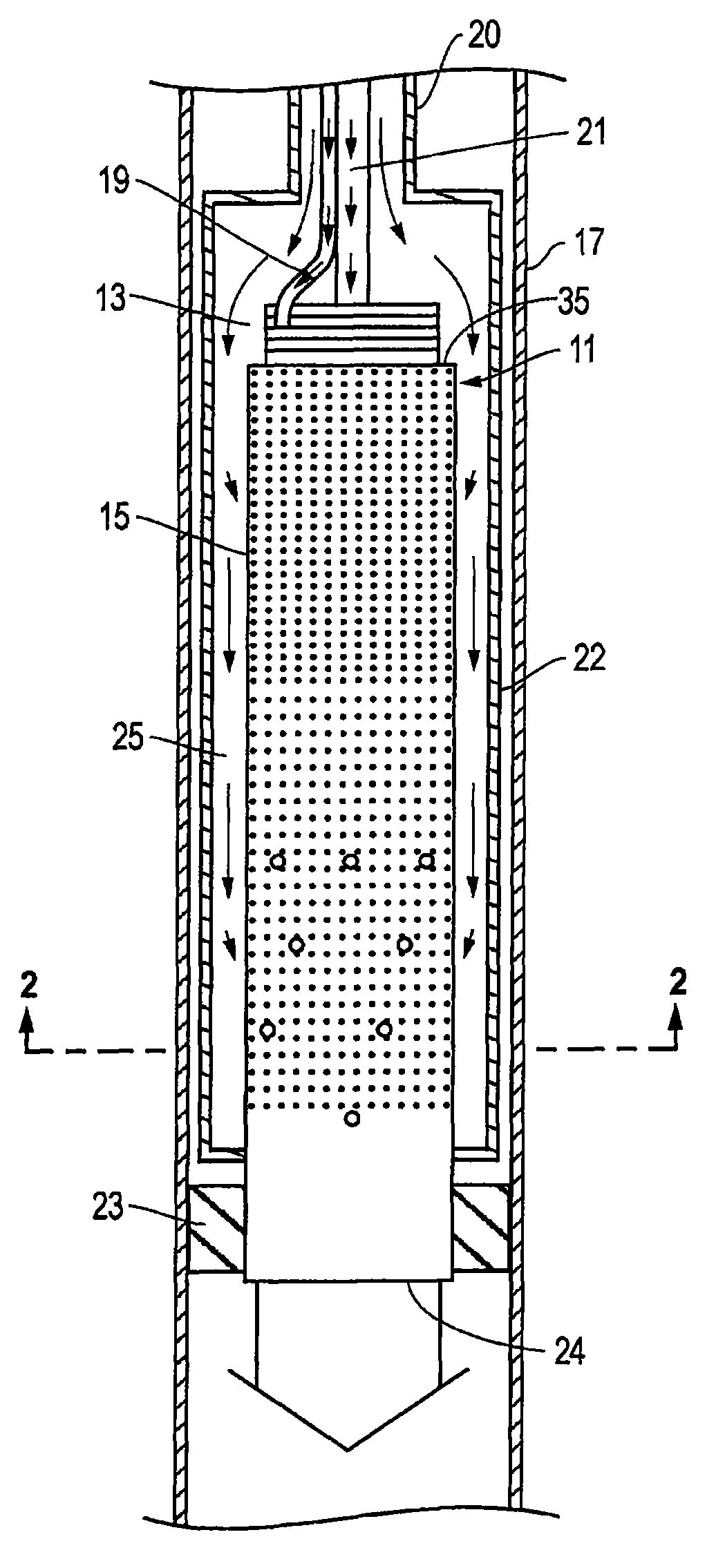

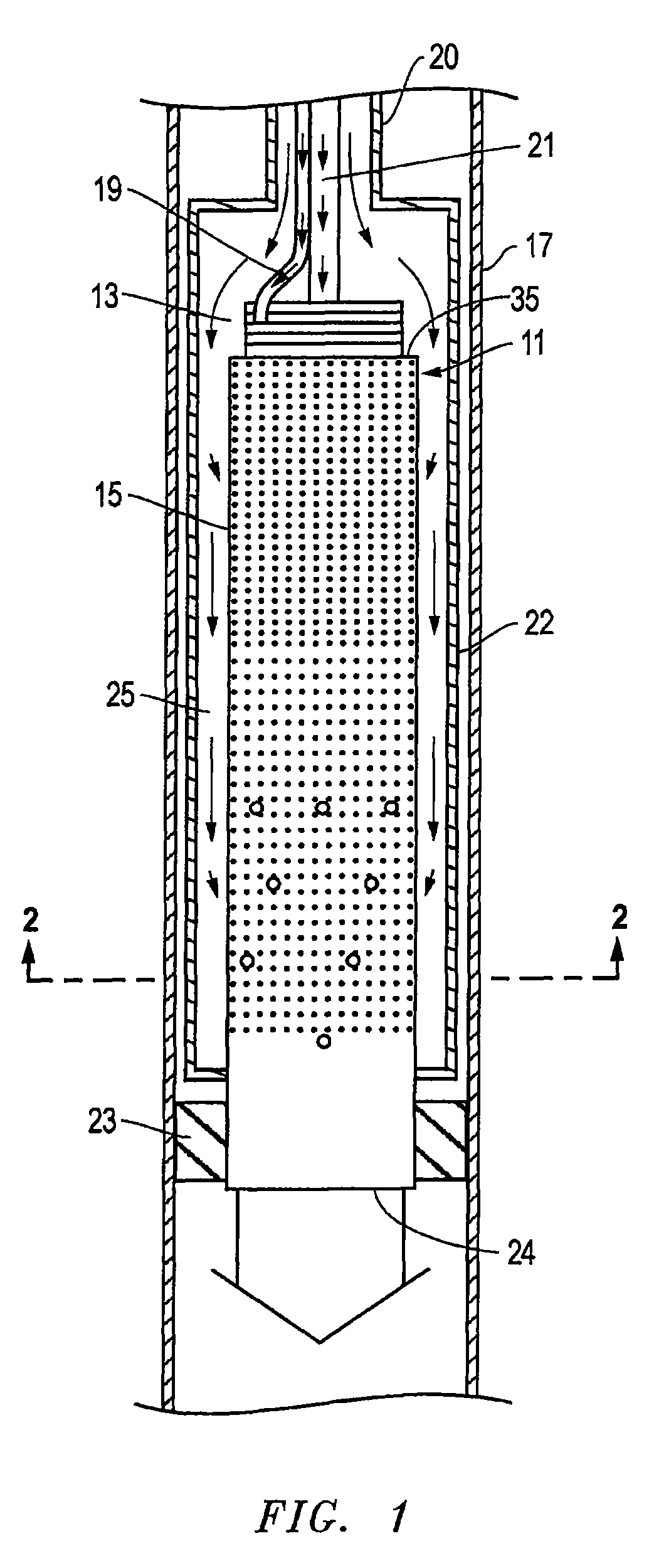

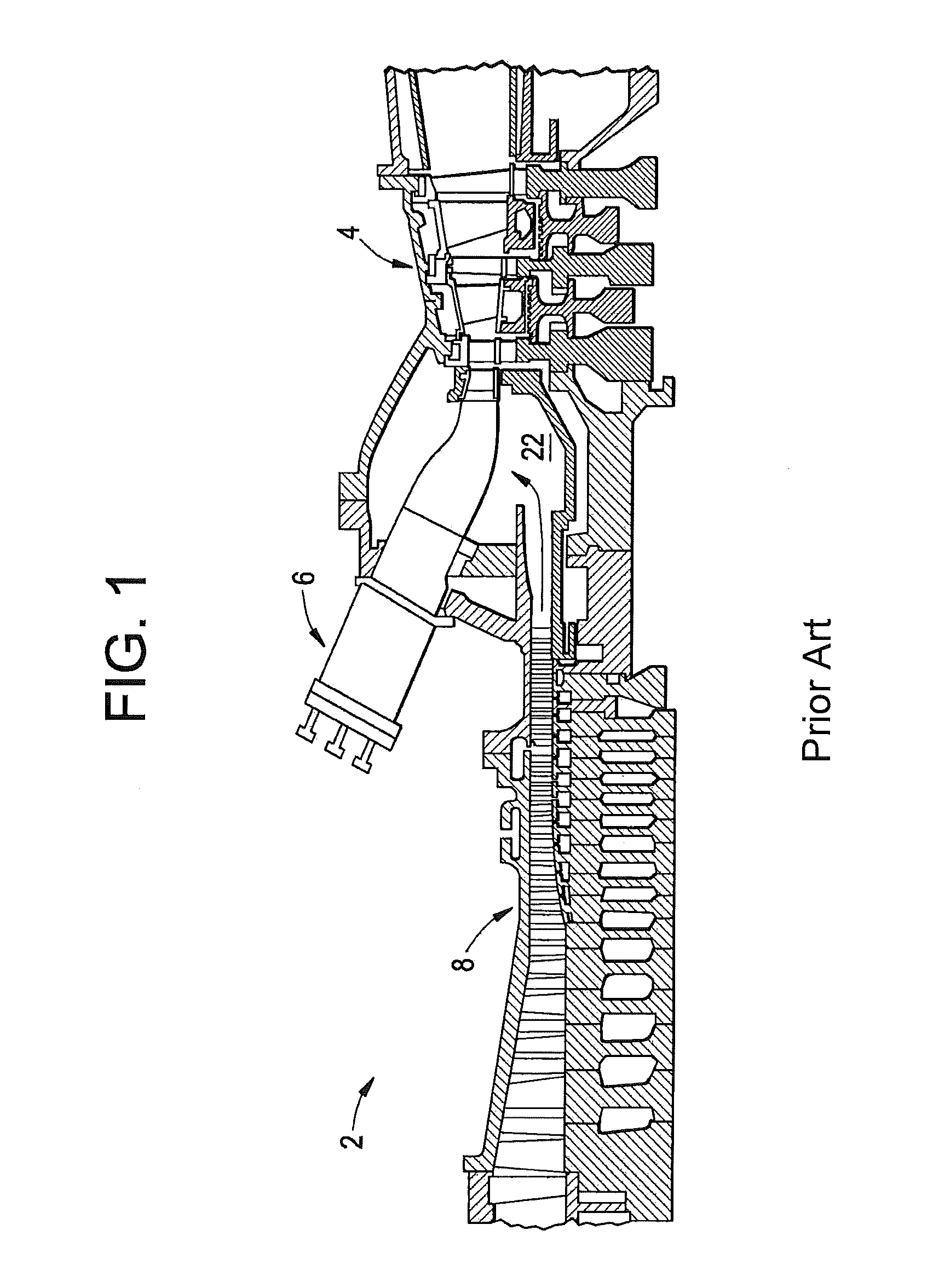

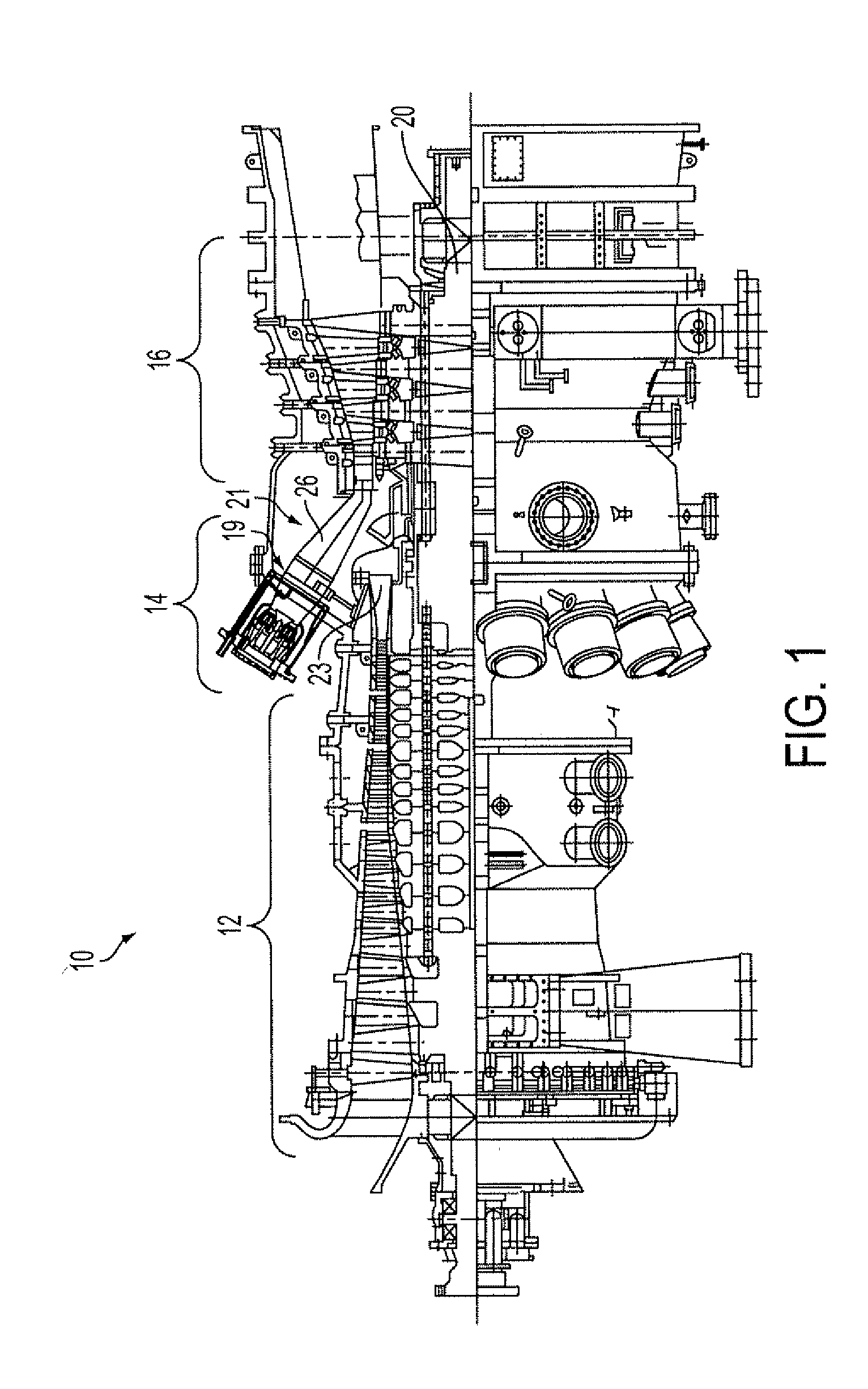

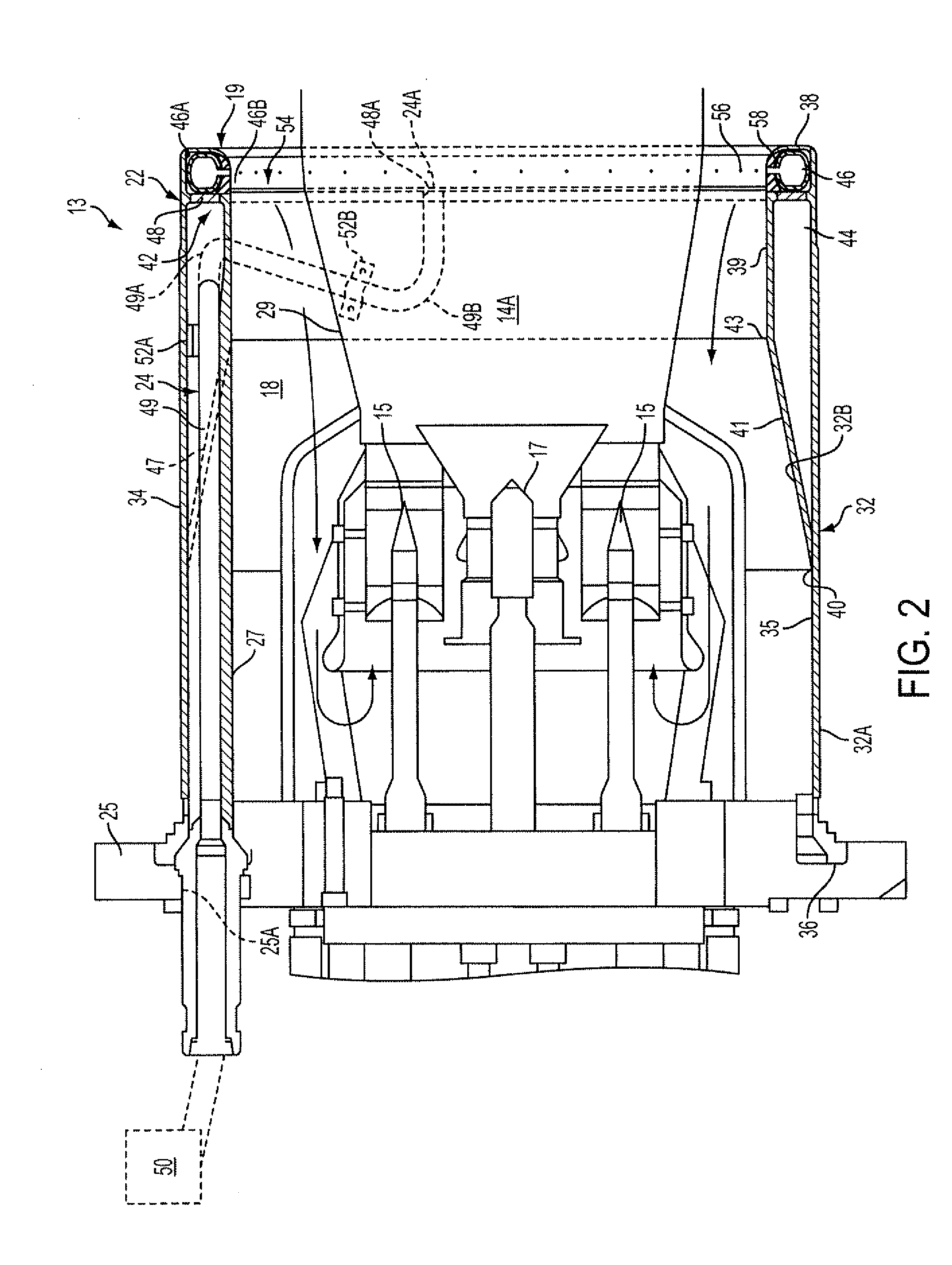

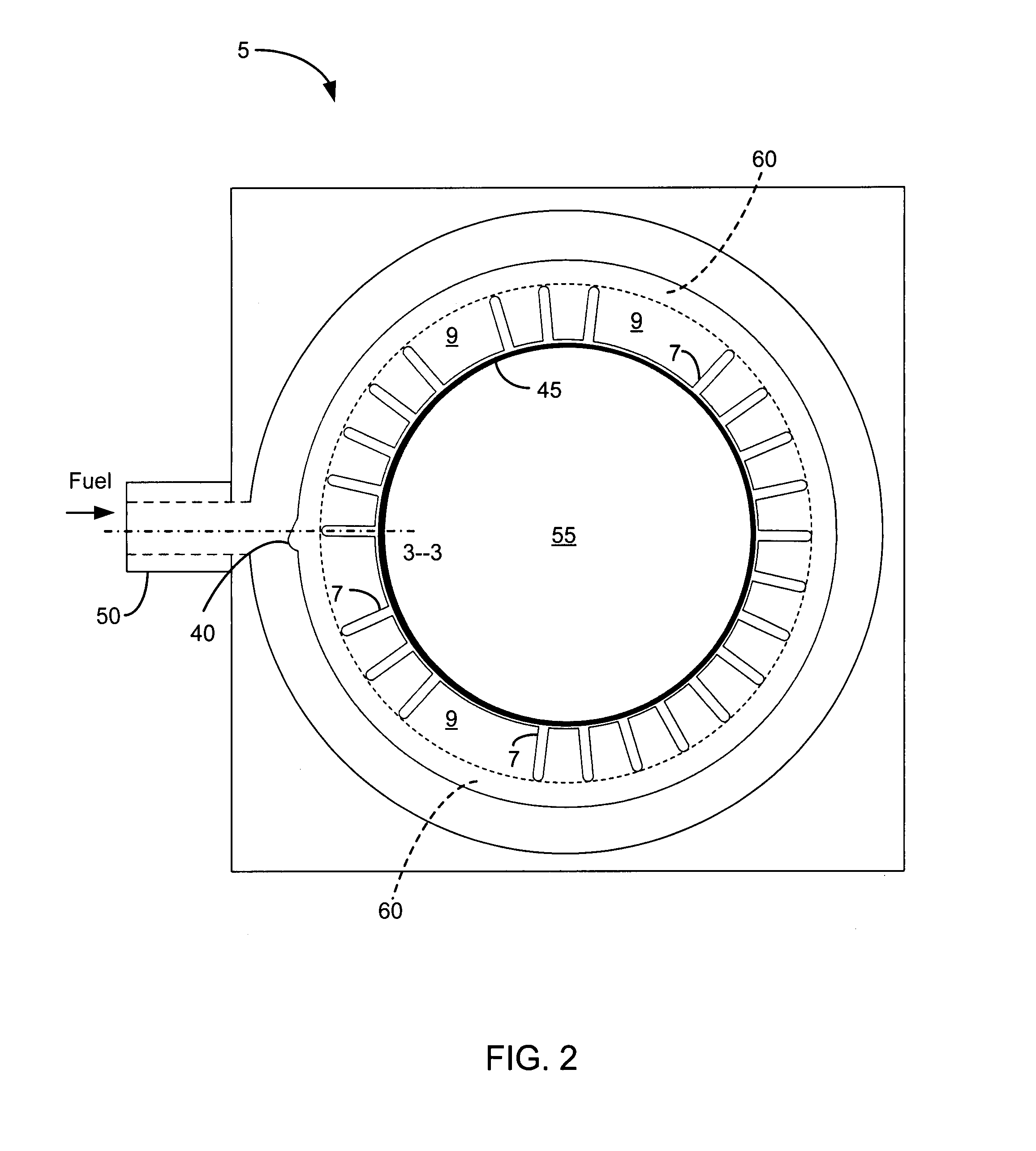

Full ring fuel distribution system for a gas turbine combustor

InactiveUS6282904B1Convenient lightingEnhancing quality and integrityBurnersContinuous combustion chamberCombustion chamberCombustor

A fuel nozzle system for use in a combustor utilized in a combustion turbine for reducing nitrogen oxides and other pollutants including an annular fuel distribution manifold separately mounted away from a diffusion nozzle, said annular manifold having a plurality of fuel emitting passages or holes disposed along the downstream side of the manifold, said manifold being mounted in a position away from the diffuser nozzle body to allow air to stream around the manifold on all sides allowing for a thorough mixture of fuel and air around the annular manifold for better premixing in the combustion chamber.

Owner:ANSALDO ENERGIA SWITZERLAND AG

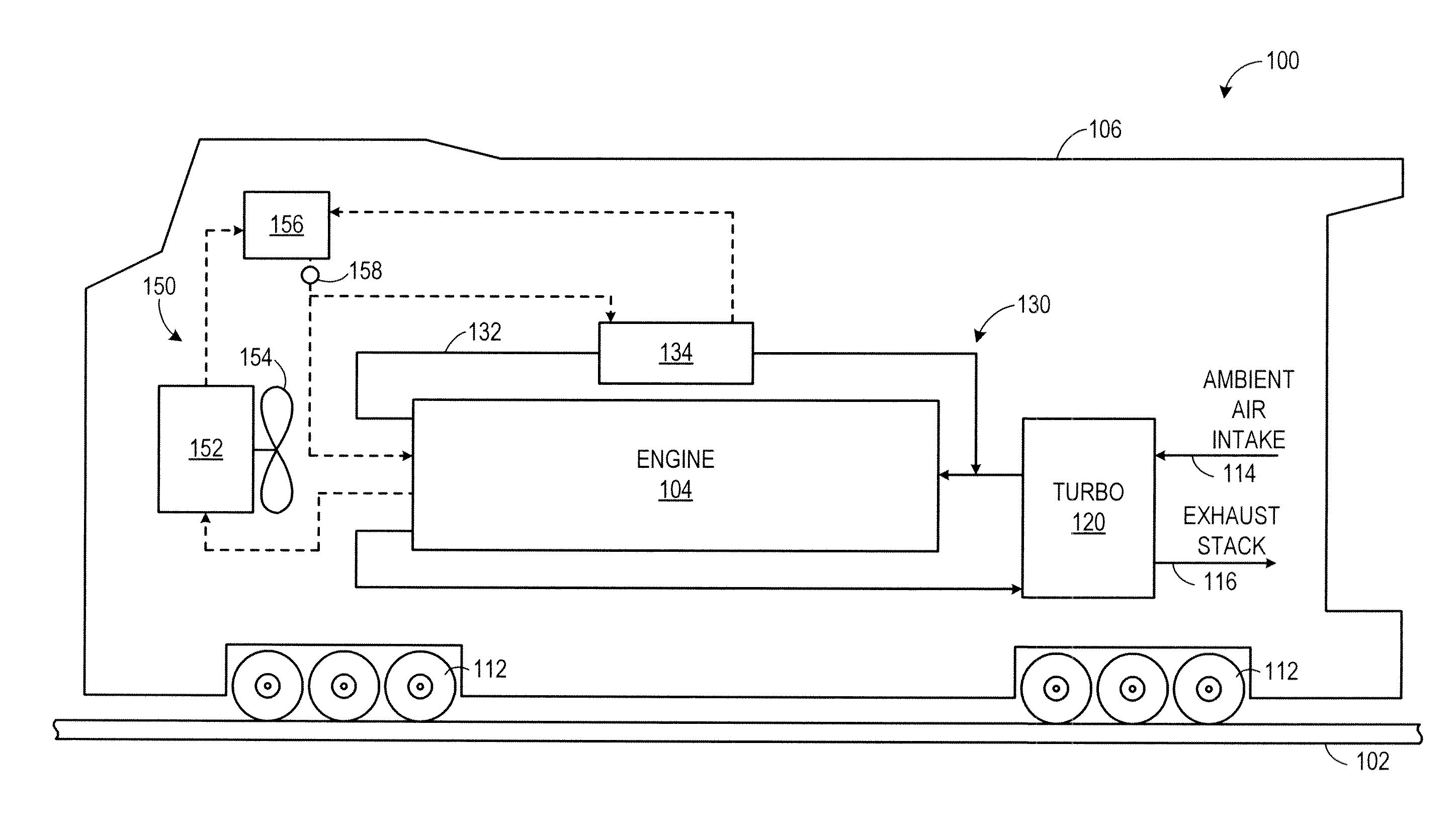

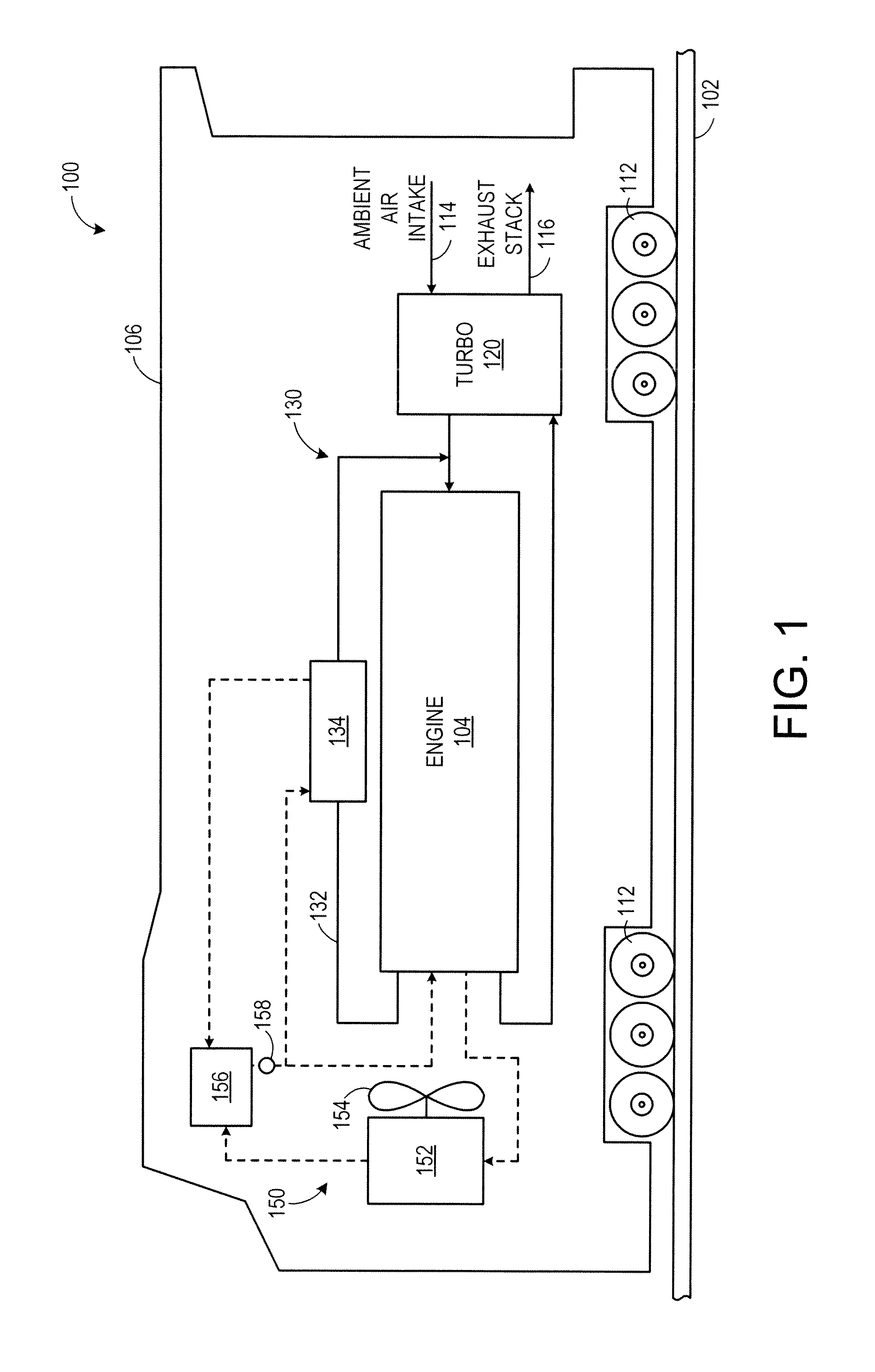

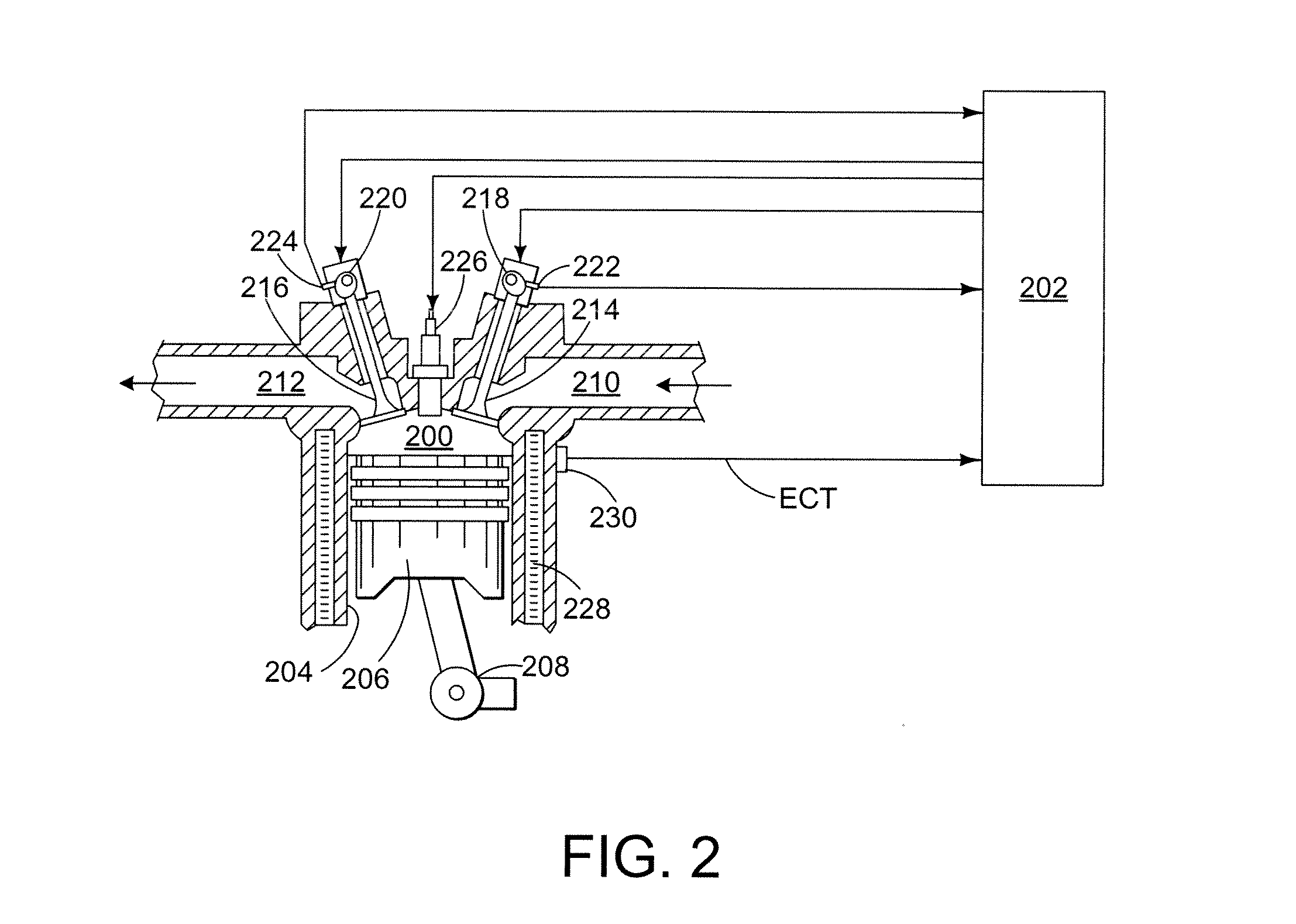

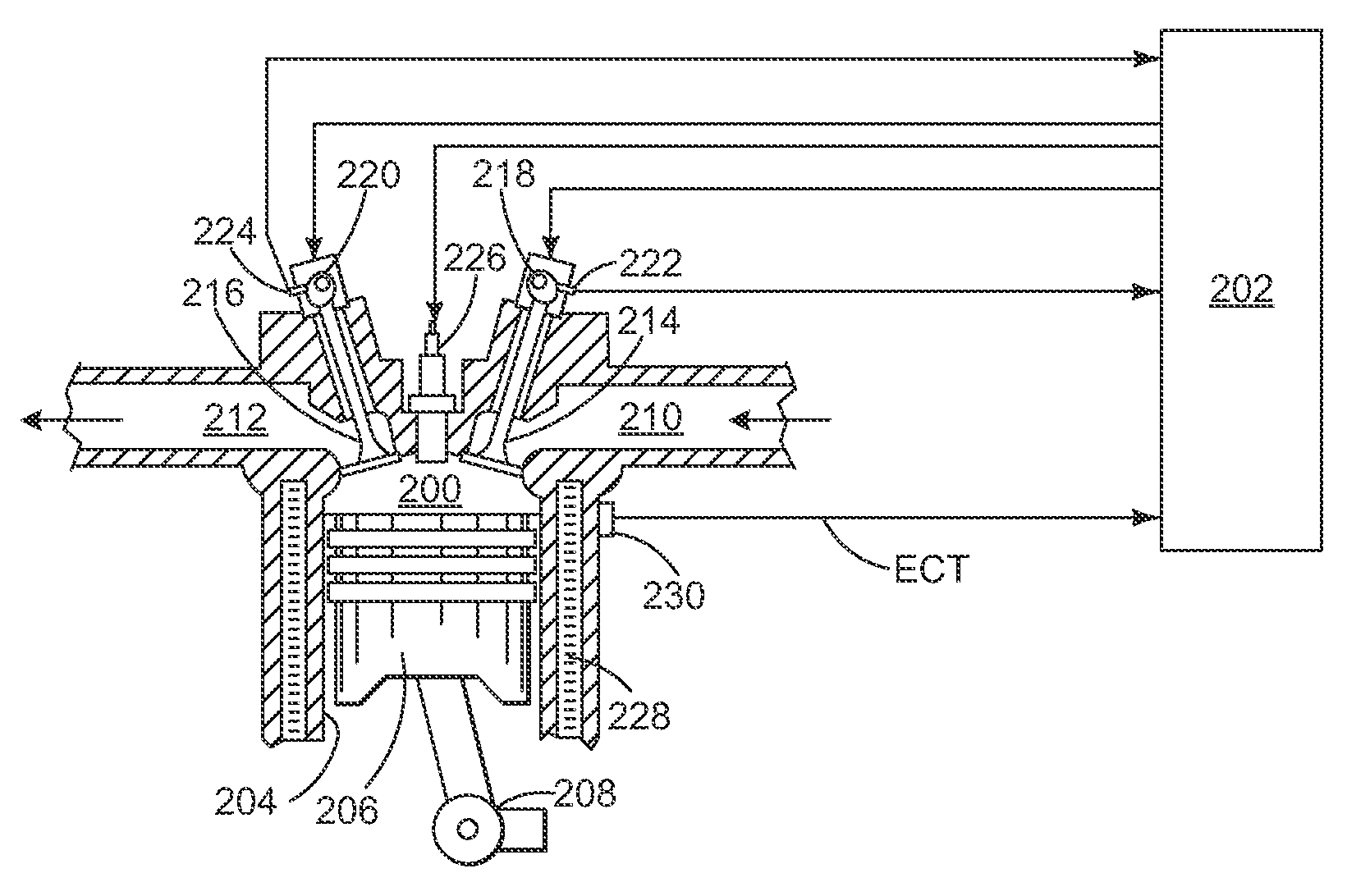

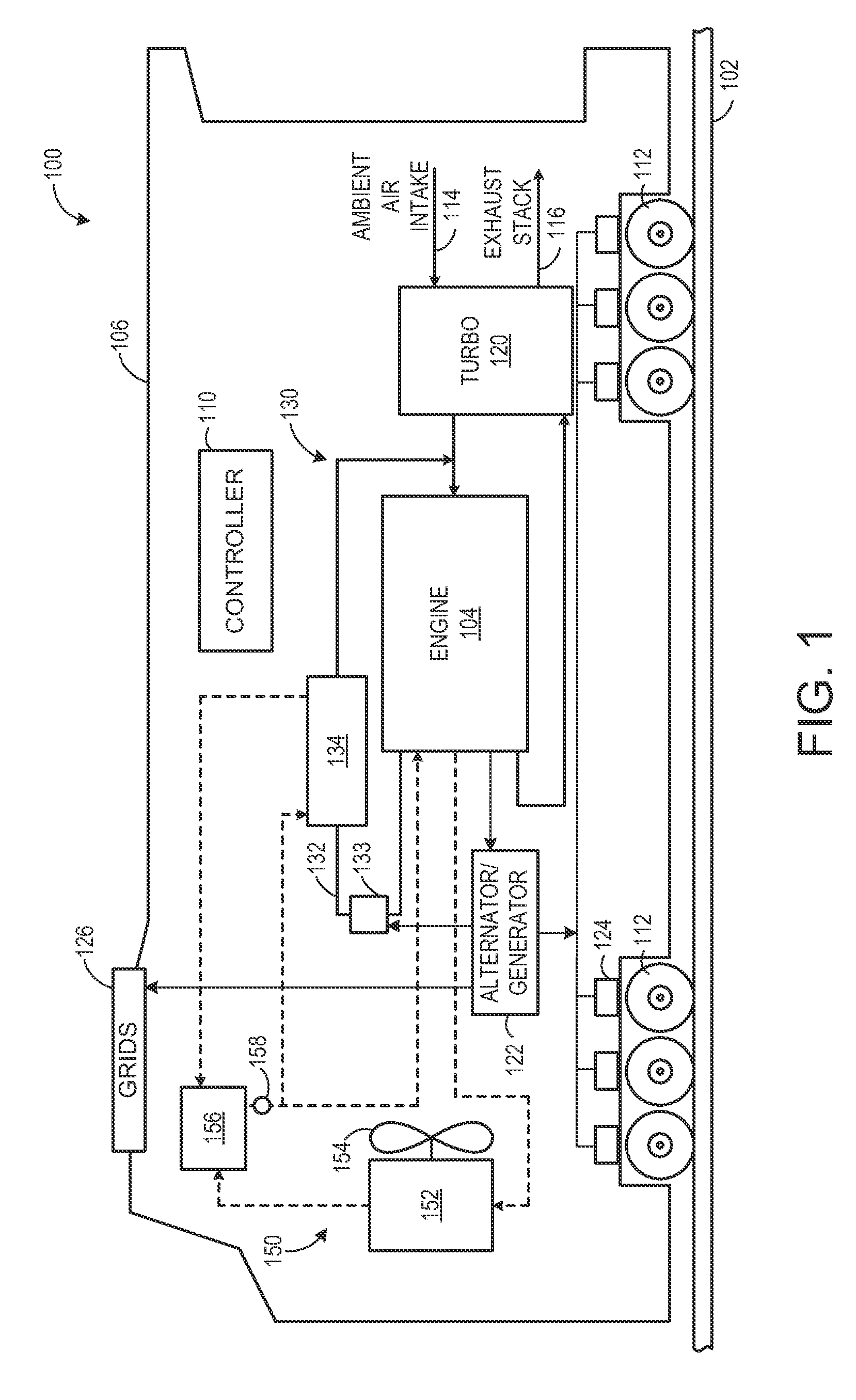

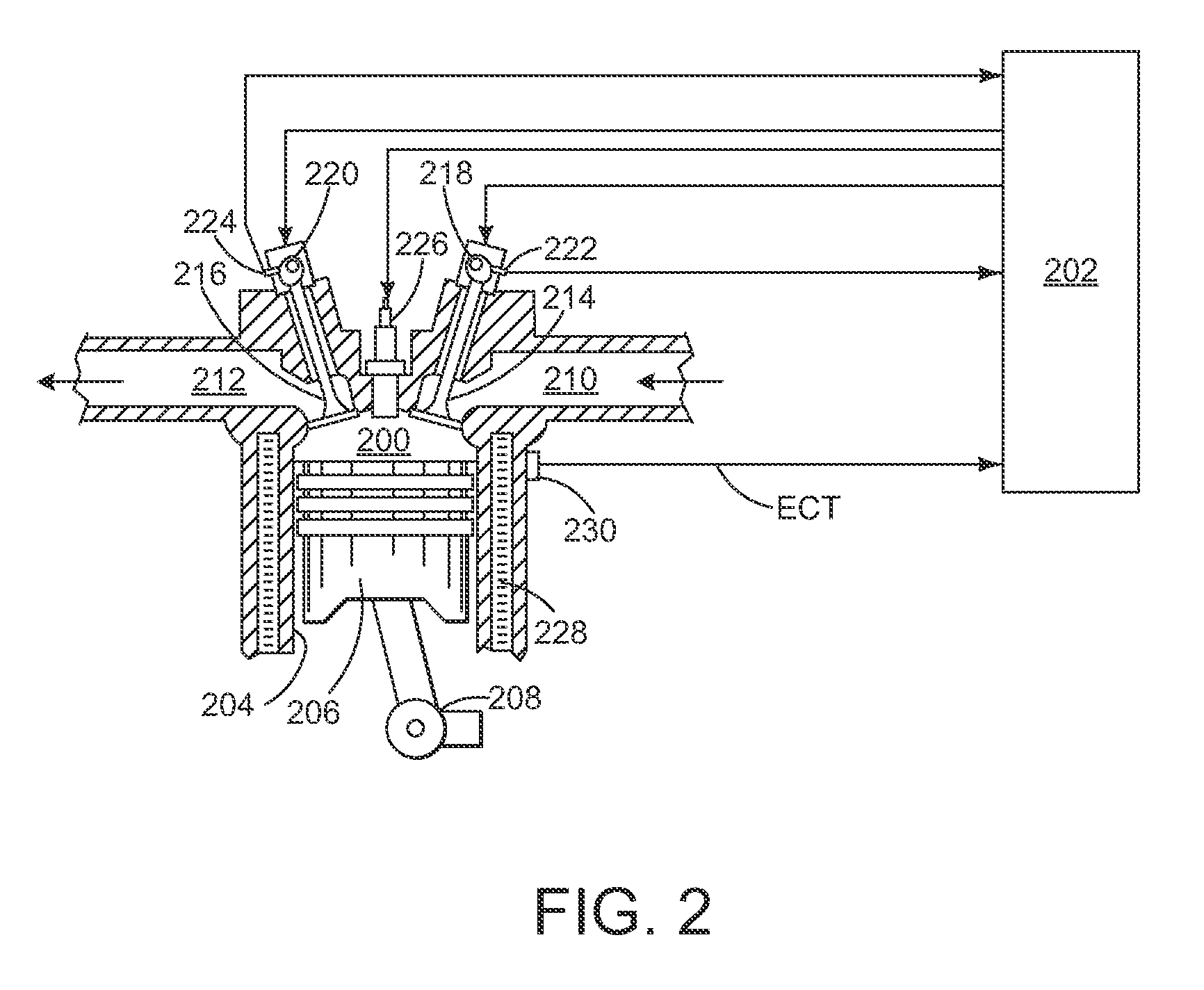

Methods and systems for exhaust gas recirculation cooler regeneration

ActiveUS20120323470A1Reduce the temperatureIncrease temperatureElectrical controlInternal combustion piston enginesFuel distributionExhaust gas recirculation

Various methods and systems are provided for regenerating an exhaust gas recirculation cooler. One example method includes, routing exhaust gas from a donor cylinder group of an engine to an intake passage of the engine through the exhaust gas recirculation cooler, routing exhaust gas from a non-donor cylinder group of the engine to an exhaust passage of the engine, and adjusting fuel distribution among the donor cylinder group and the non-donor cylinder group responsive to a temperature of the exhaust gas recirculation cooler.

Owner:GE GLOBAL SOURCING LLC

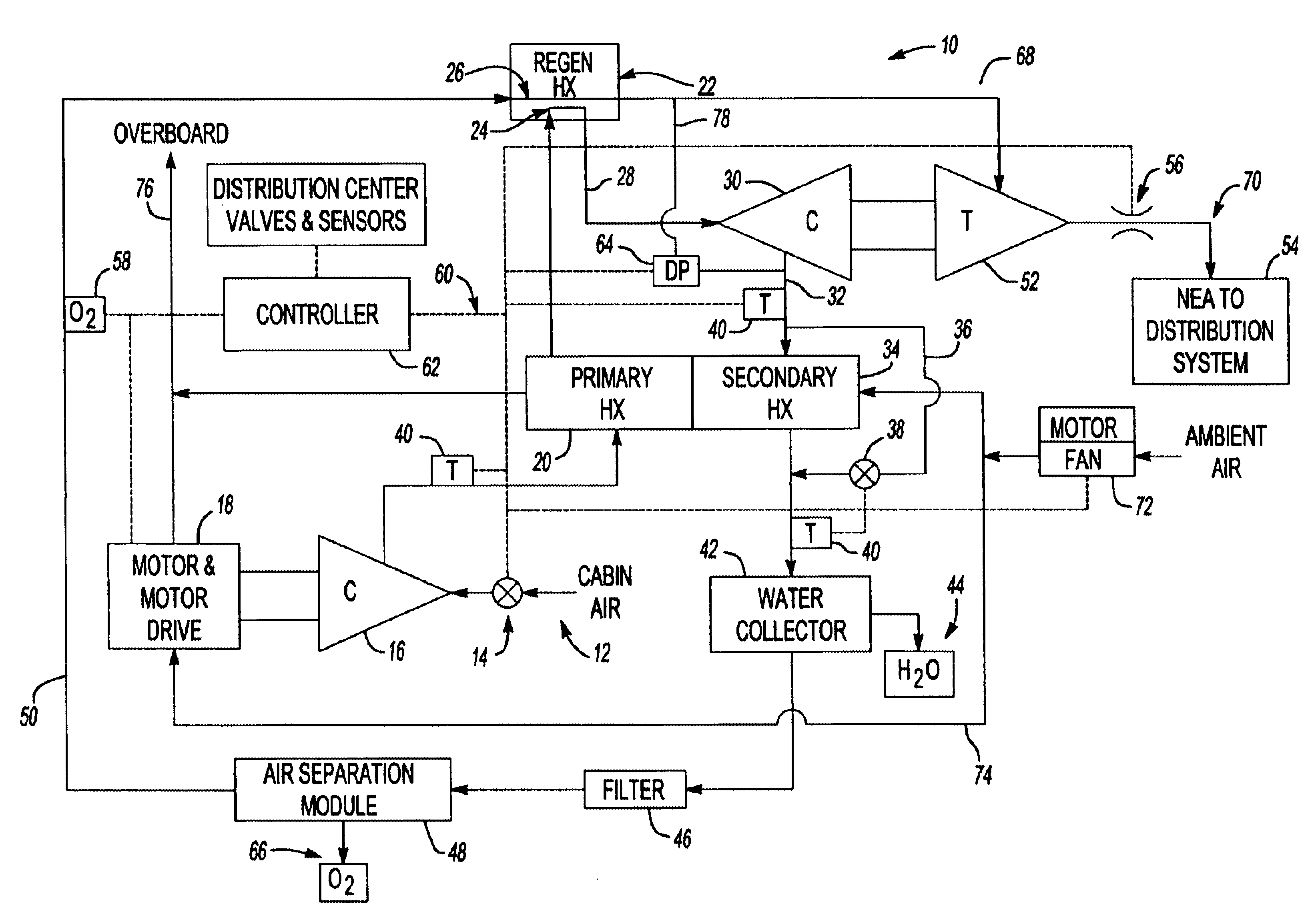

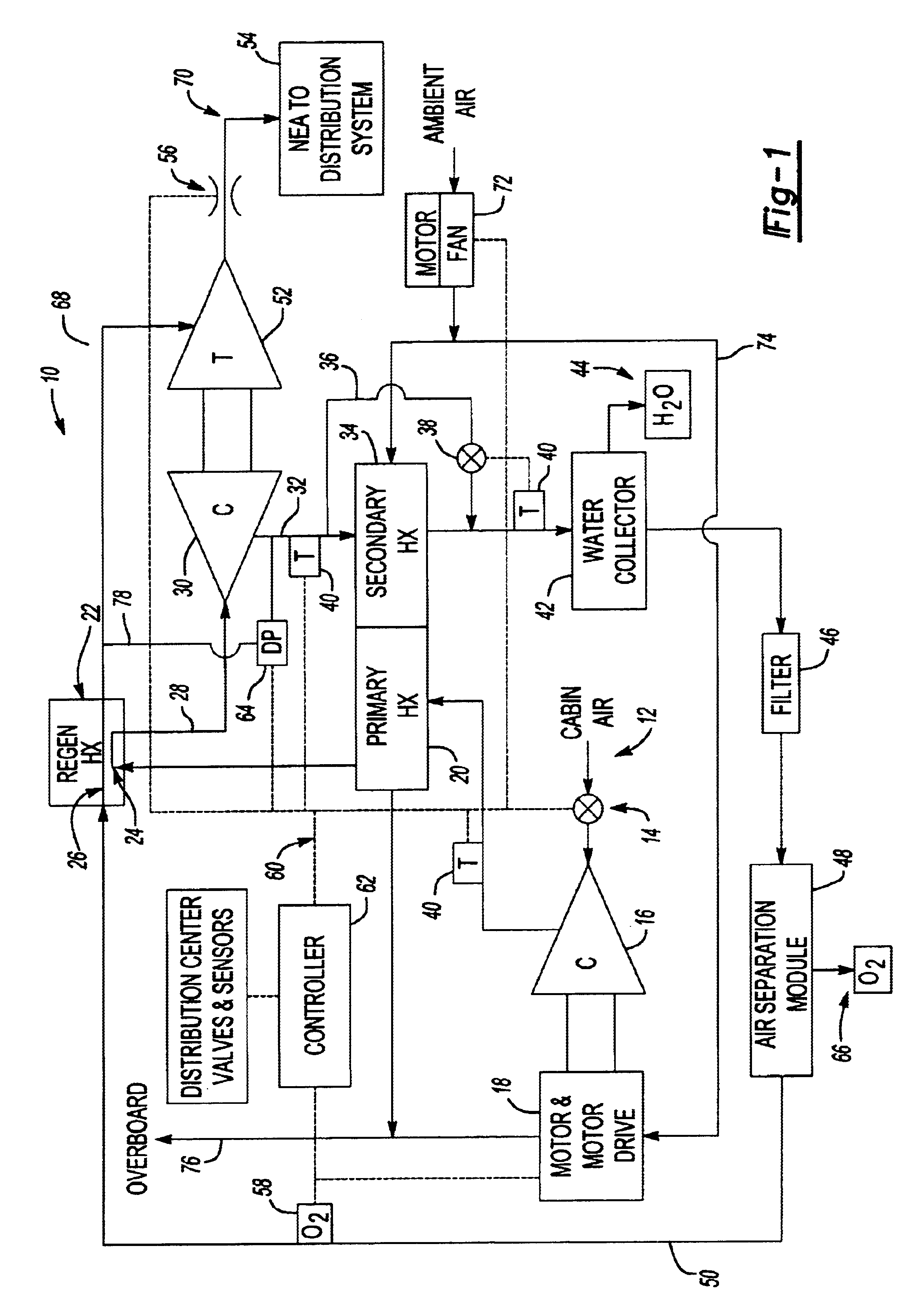

Low power nitrogen enriched air generation system

InactiveUS6913636B2Reduce capacityReduce weightDispersed particle filtrationAir-treatment apparatus arrangementsNacelleInerting system

An inerting system provides air with reduced oxygen content by flowing and directing air through an air separation module. Optimal working pressure for the air separation module is obtained with two compressors. A first compressor elevates air from the aircraft cabin to a second pressure. The second pressure is at an intermediate level below the working pressure of the air separation module. A second compressor elevates air from the second pressure to the working pressure. The second compressor is driven by air that is exhausted through a turbine. The pressure difference between air at the working pressure and air required by the fuel distribution system is used to power the turbine and drive the second compressor.

Owner:HAMILTON SUNDSTRAND CORP

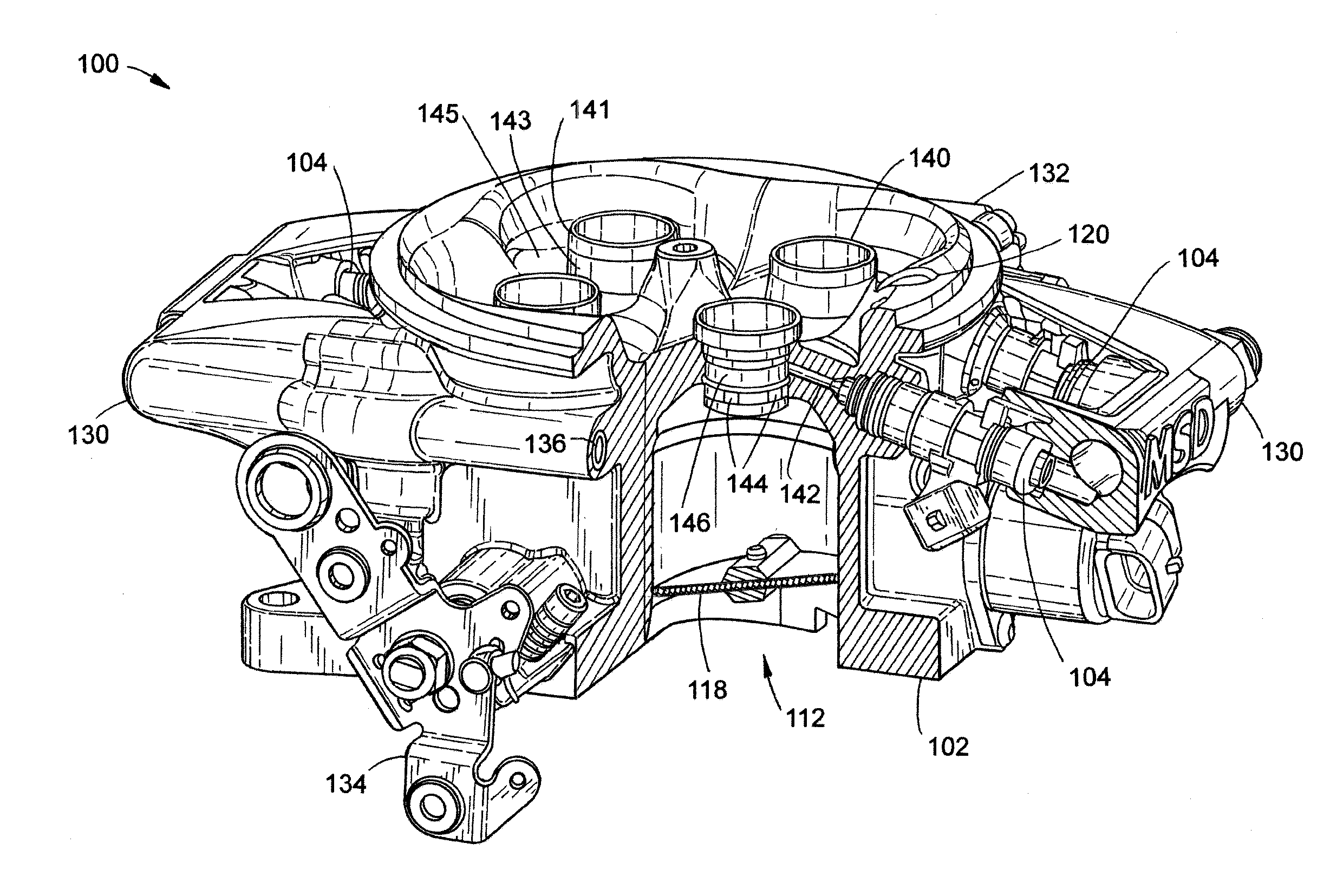

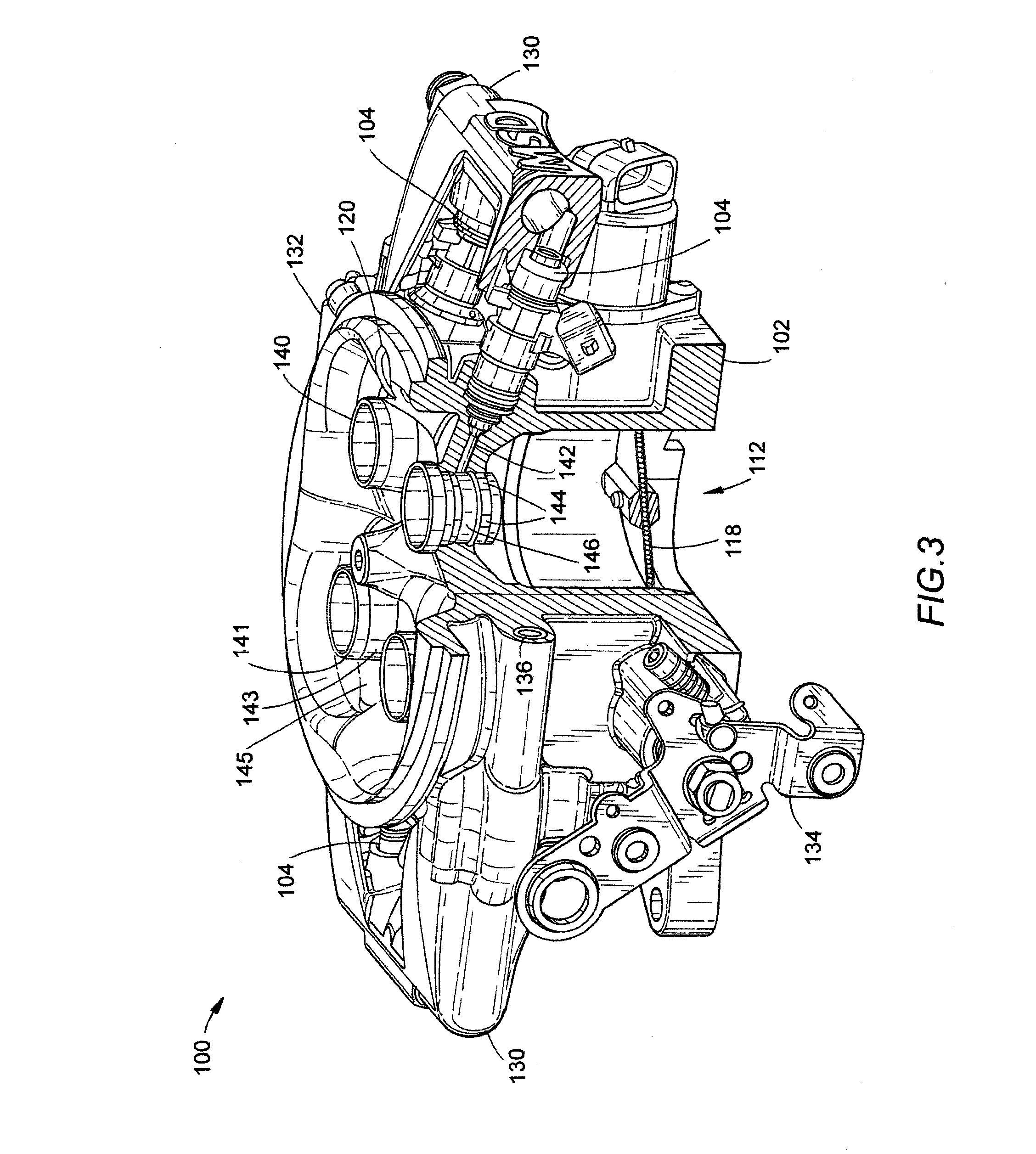

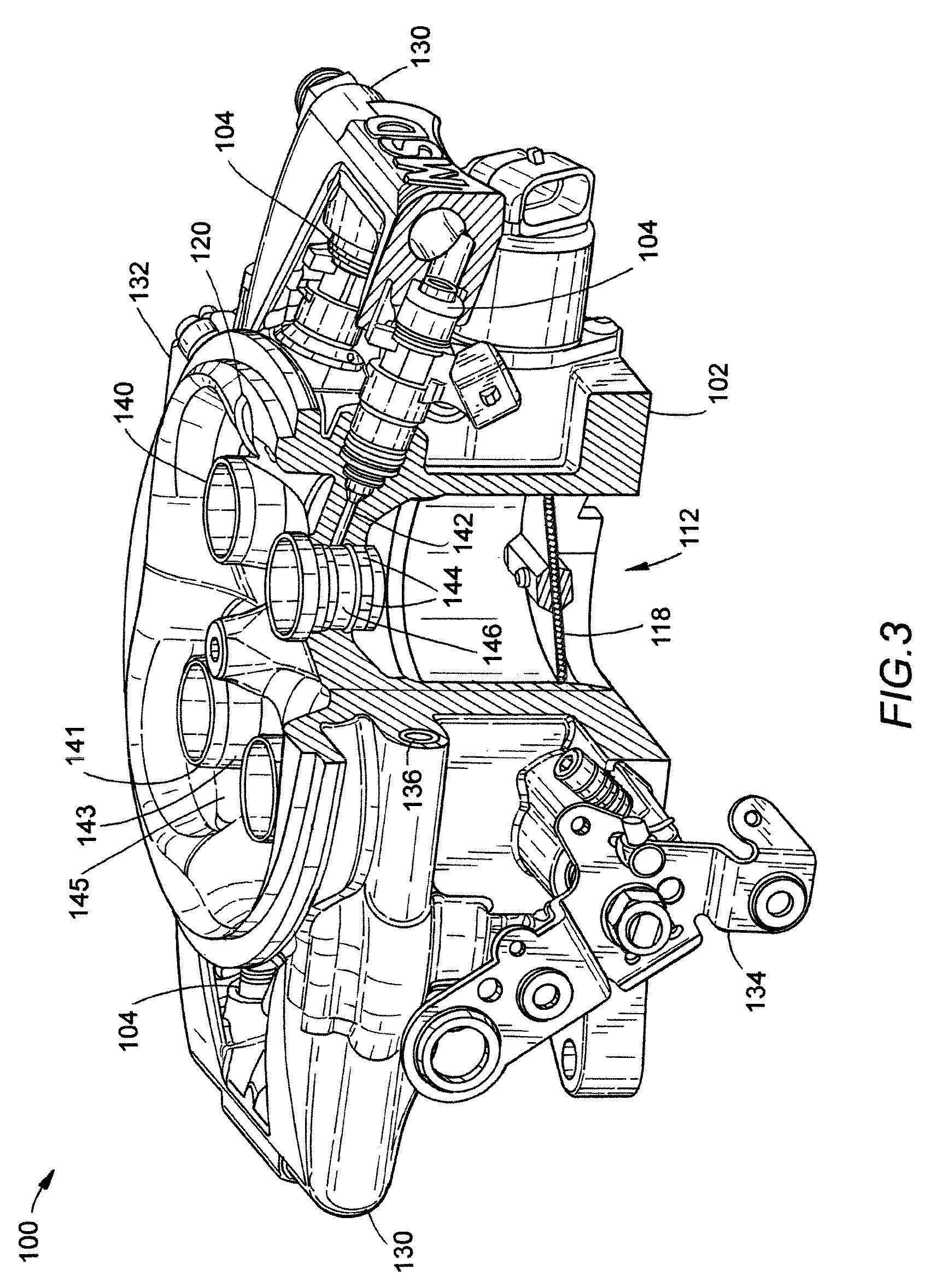

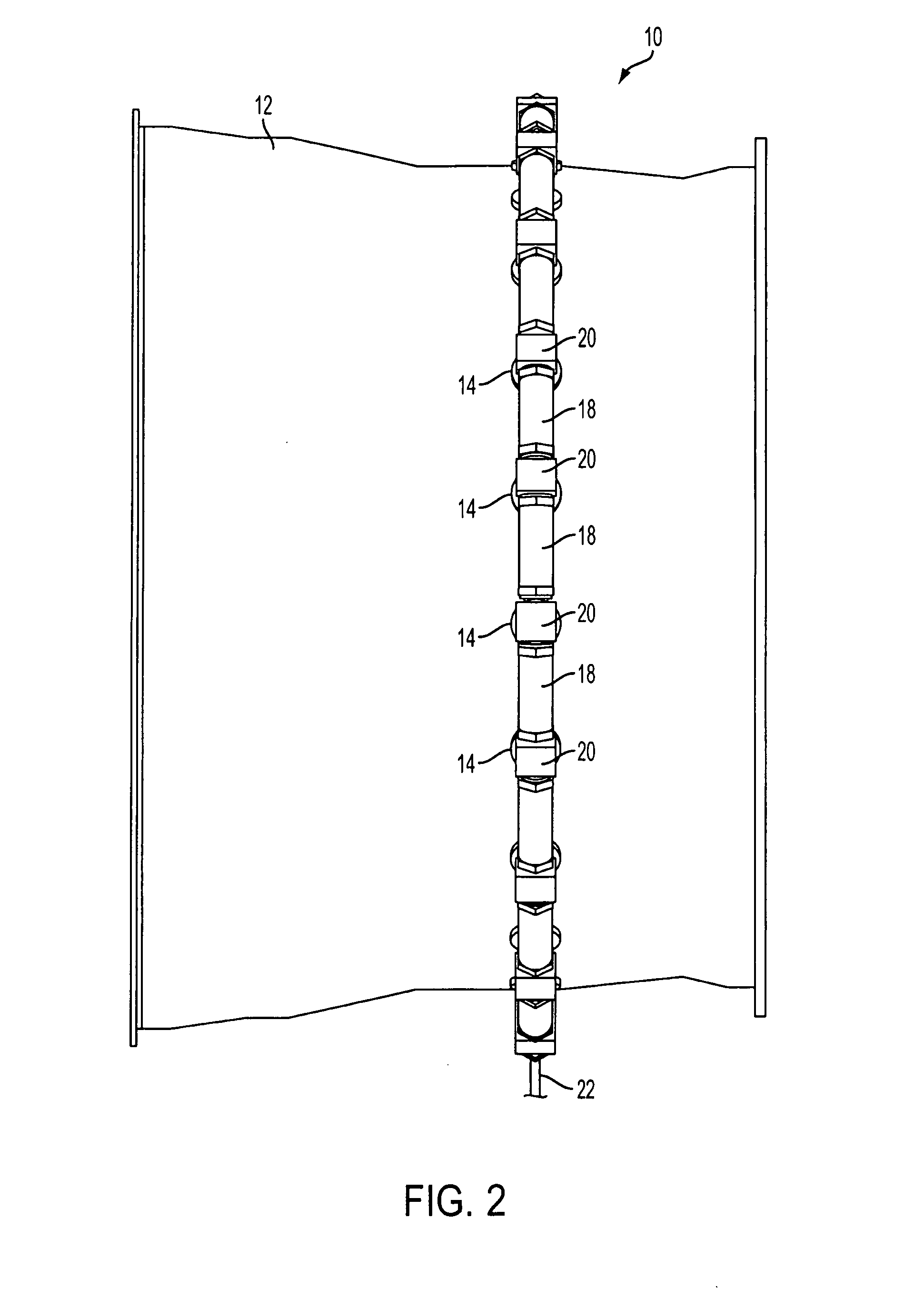

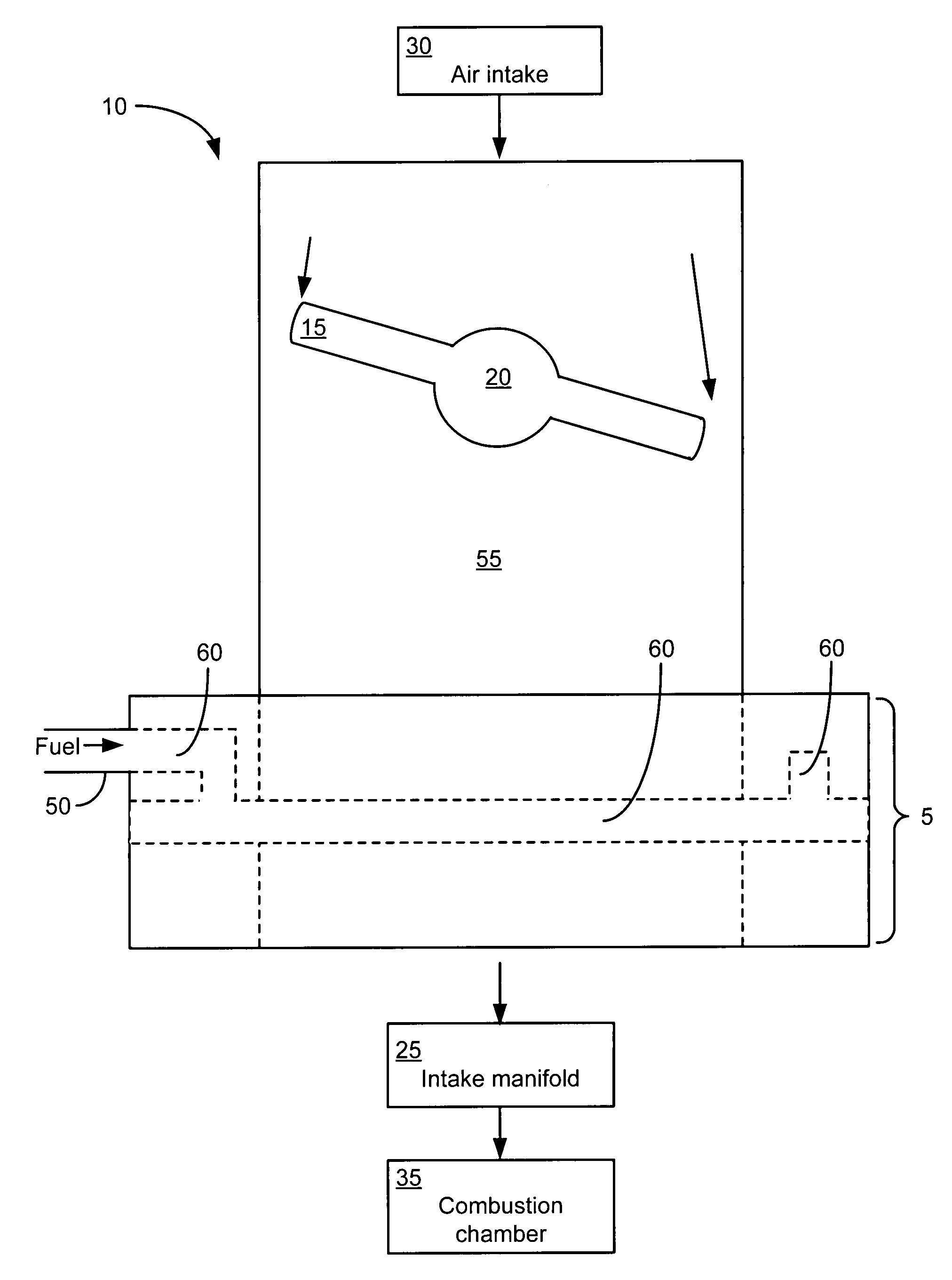

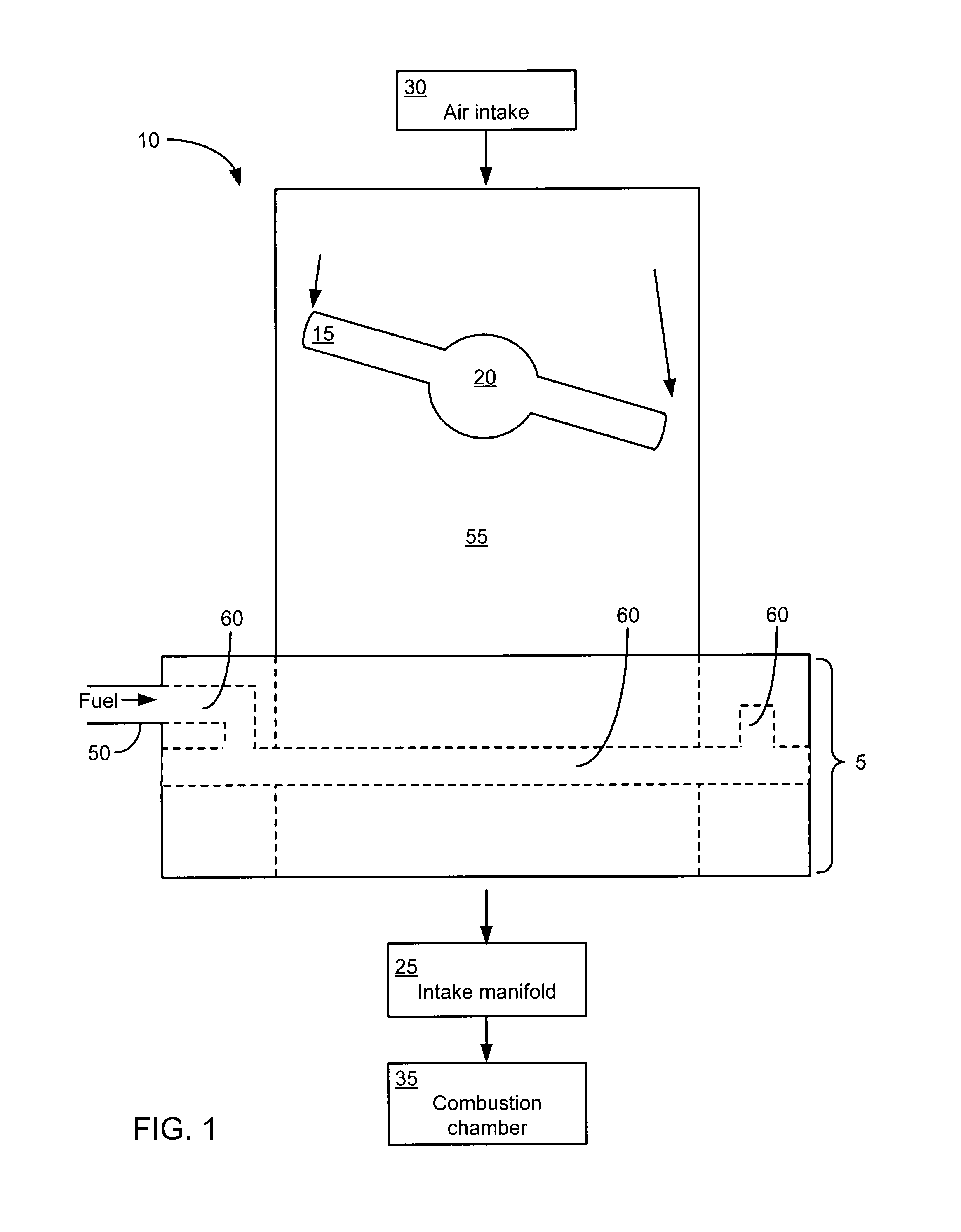

Throttle body fuel injection system with improved fuel distribution

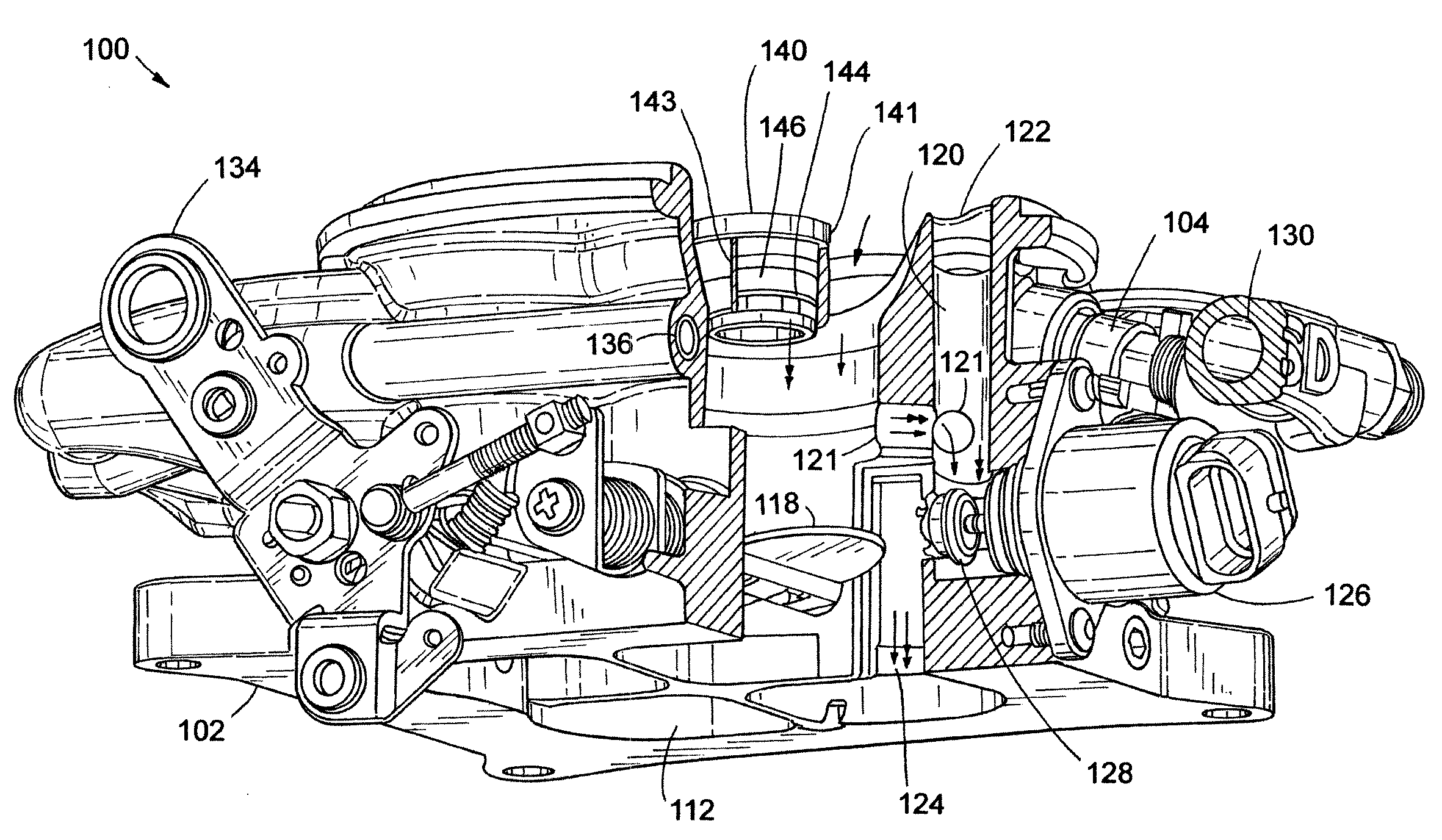

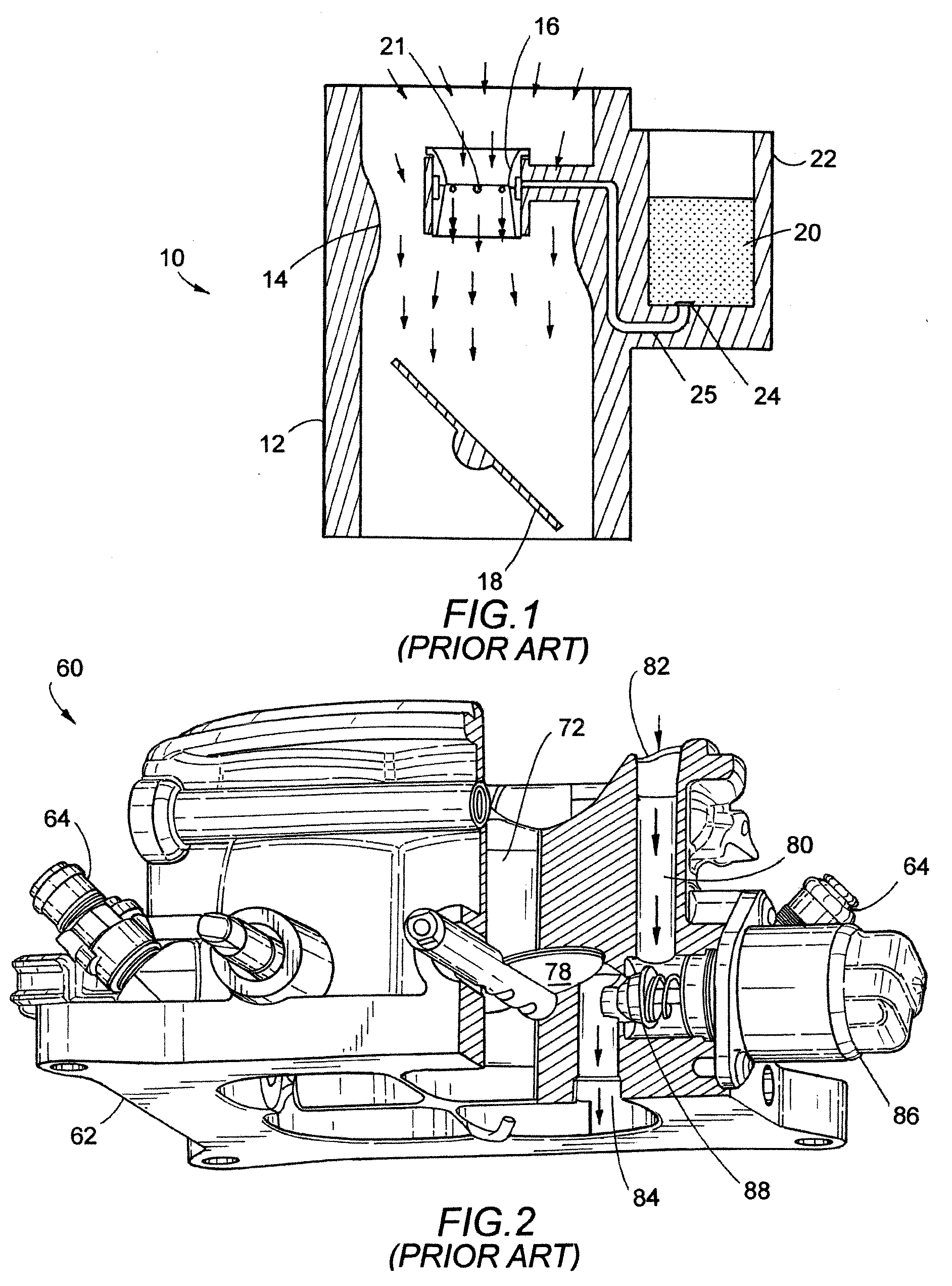

ActiveUS20130298871A1Minimizing any tendencyIncrease the pulse widthElectrical controlInternal combustion piston enginesFuel distributionEngineering

A throttle body fuel injection system and method that is arranged to easily replace four-barrel carburetors includes a throttle body assembly with four main bores, each with a throttle plate and an associated fuel injector. Each injector feeds fuel into a circular fuel distribution ring via a fuel injection conduit, which introduces pressurized fuel into the air stream. The fuel distribution rings and bores have profiles that avoid constrictions for to prevent low pressure zones according to the Venturi effect. Fuel is injected through downward-facing outlets at or near the bottom end of the rings. The fuel injection rings are two-piece, each formed of an insert pressed into an outer housing. The insert includes axial grooves intervaled about its exterior circumference of insert that are joined by a circumferential groove formed about the insert. The grooves are in fluid communication with a conduit that supplies fuel from a fuel injector.

Owner:MSD LLC

Methods and systems for exhaust gas recirculation cooler regeneration

InactiveUS20120323465A1Improve EGR cooler operationMore electrical energyAnalogue computers for vehiclesElectrical controlFuel distributionExhaust fumes

Various methods and systems are provided for regenerating an exhaust gas recirculation cooler. One example method includes, initiating an EGR cooler regeneration mode, wherein the EGR cooler regeneration mode comprises changing a fuel distribution of a donor cylinder group relative to a non-donor cylinder group of an engine, and increasing at least one of engine speed or load of the engine.

Owner:GE GLOBAL SOURCING LLC

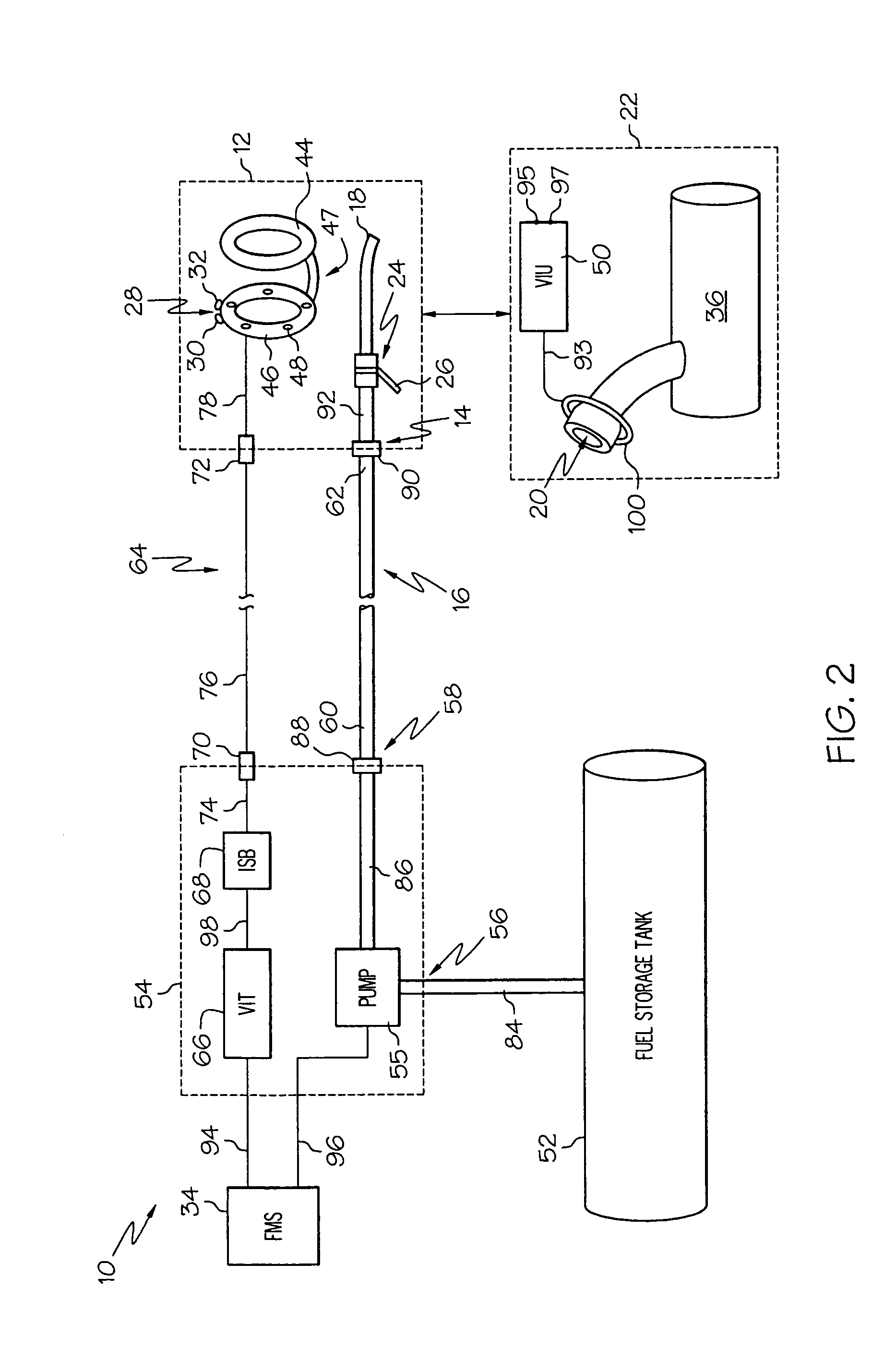

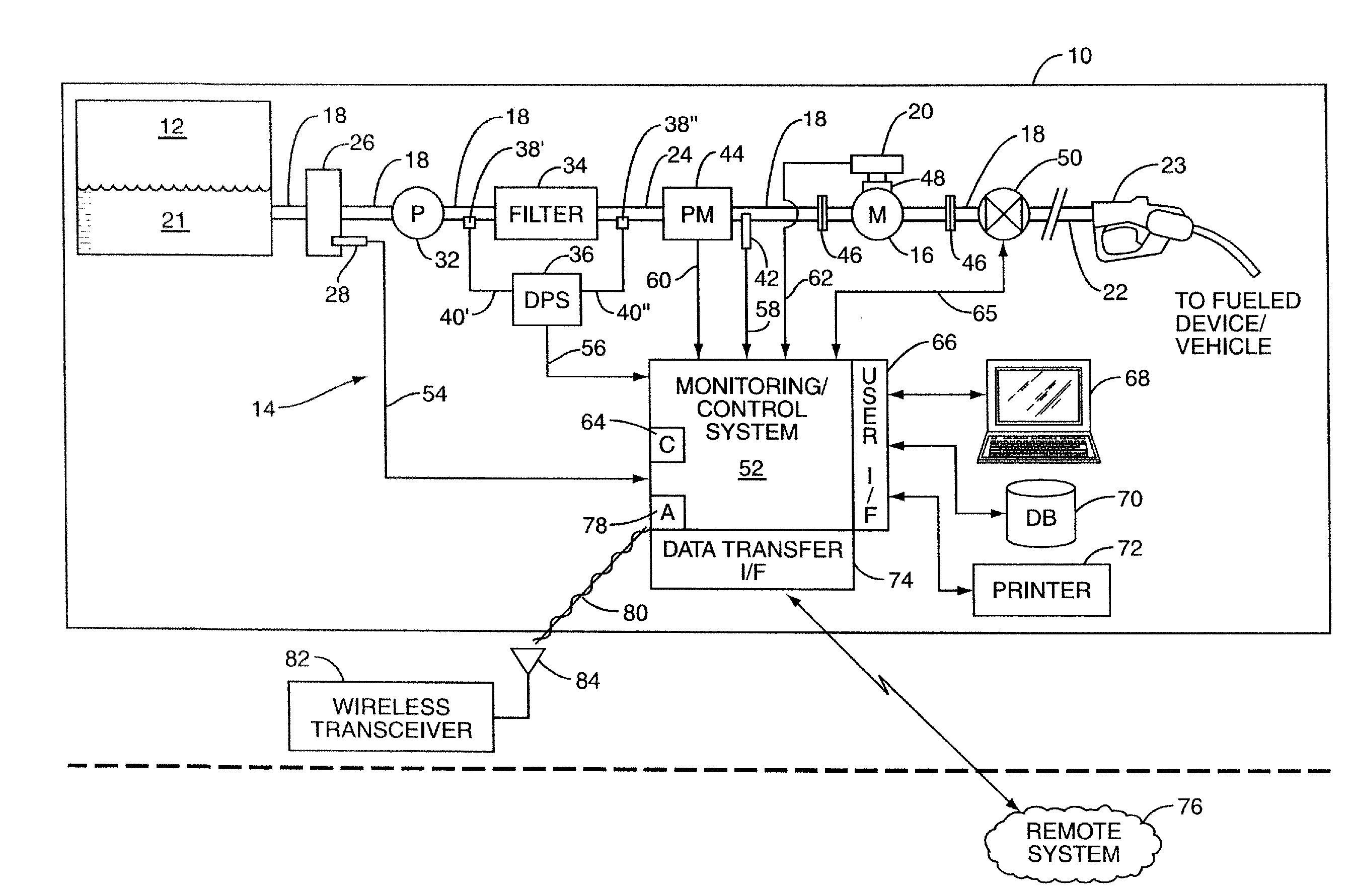

Automated Fuel Quality Detection and Dispenser Control System and Method, Particularly for Aviation Fueling Applications

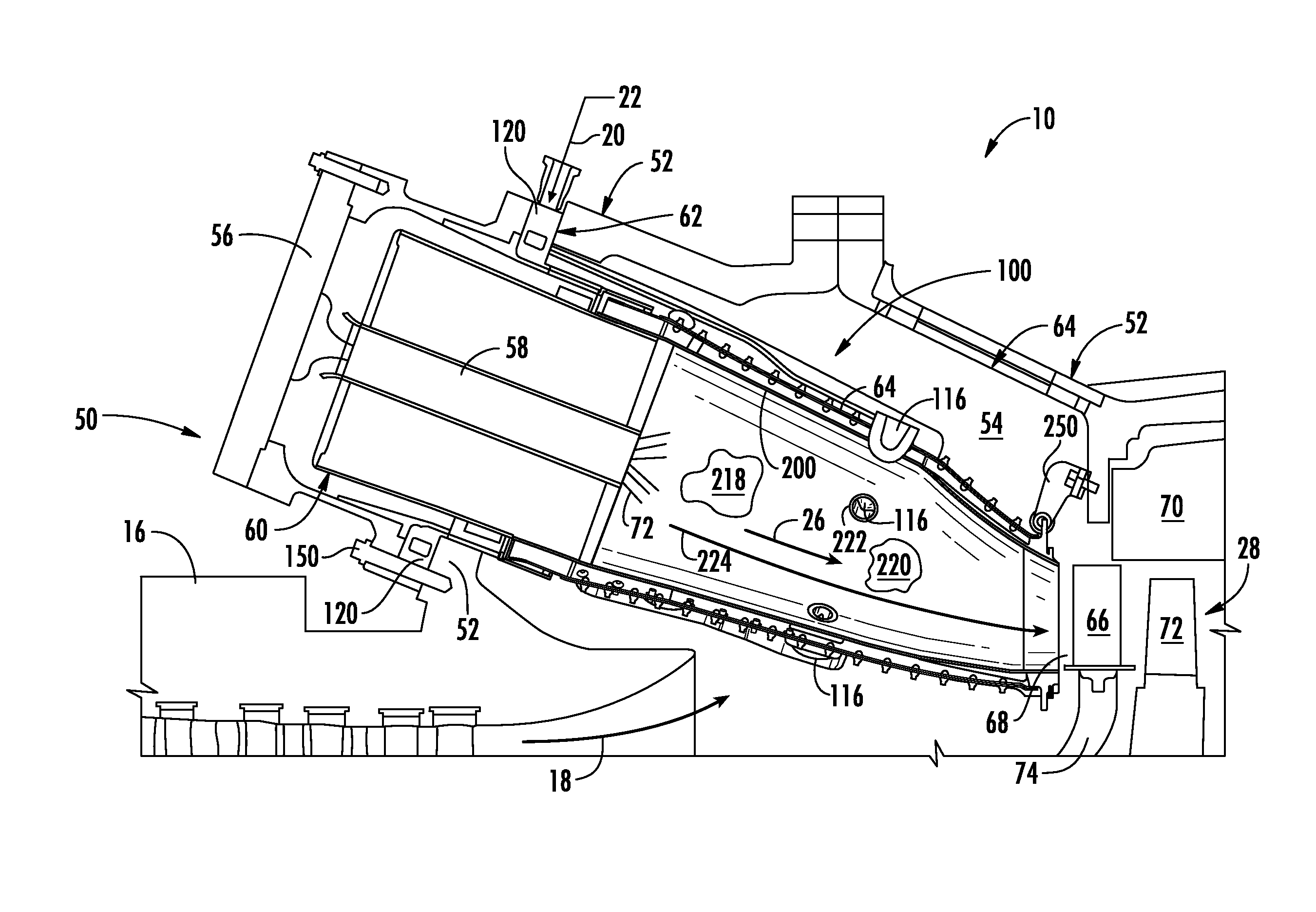

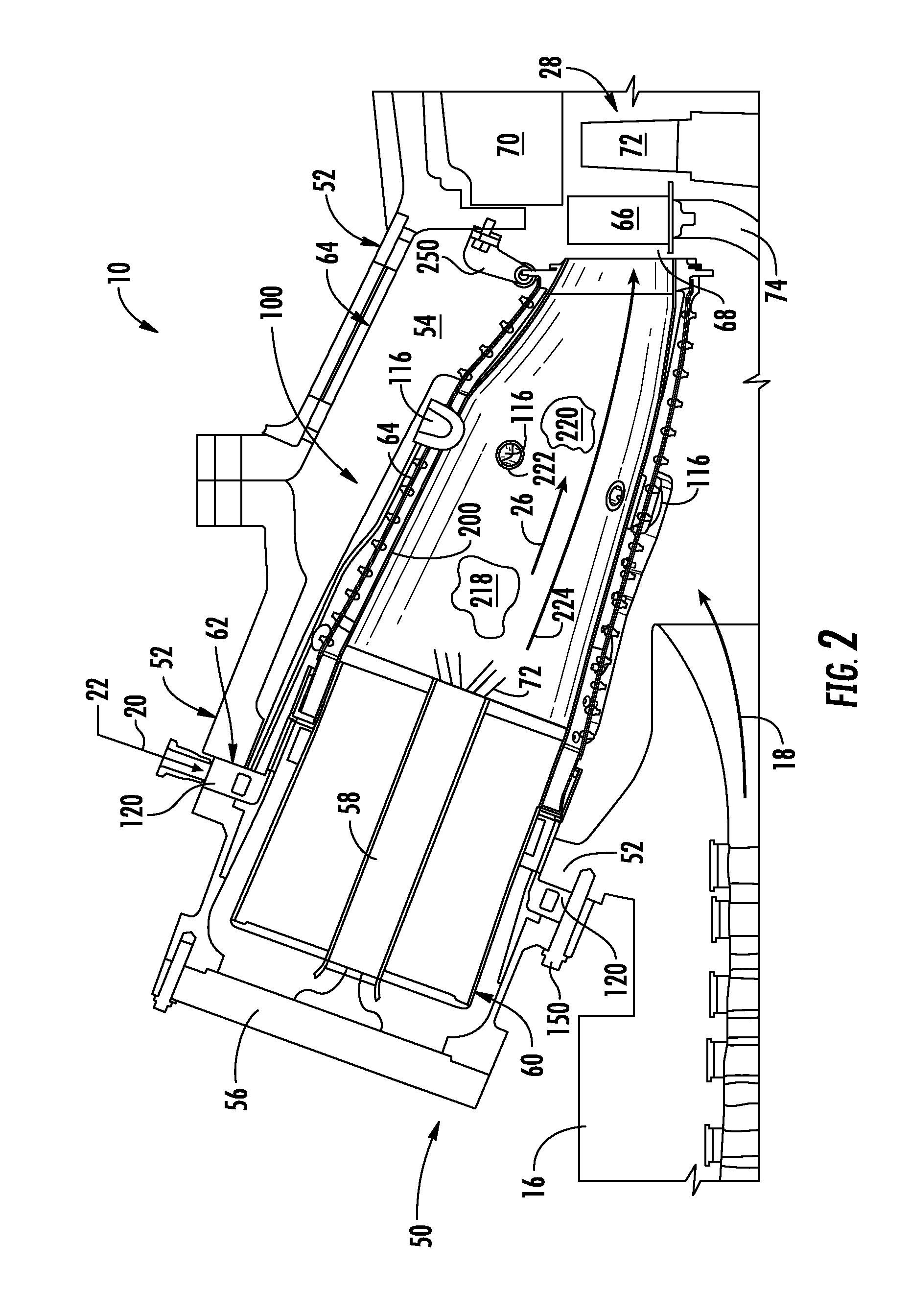

ActiveUS20080230146A1Reduce riskAvoid refuelingLiquid handling installationsLevel indicatorsWater detectorAviation

A fuel quality monitoring system and method to automatically and / or continuously monitor quality of fuel dispensed and control the operation of the fuel dispenser. The control system monitors fuel quality to prevent unsafe refuelings when the fuel quality is unacceptable. In one embodiment, a combination of a differential pressure sensor, a water detector, and / or a particle monitor is employed inline the fuel flow path of a fuel dispenser, and in particular an aviation refueling truck, to monitor the quality of the fuel. If fuel quality is at an acceptable level although not ideal, the control system can allow fueling with the generation of reports and alarms. If the fuel quality is unacceptable, fuel flow can be stopped. If the differential pressure across the filter indicates a high degree of debris and / or water retention, the control system can automatically lower the flow rate to reduce the risk of filter breakdown without completely preventing fueling until the filter can be replaced.

Owner:FUEL GUARD SYST +1

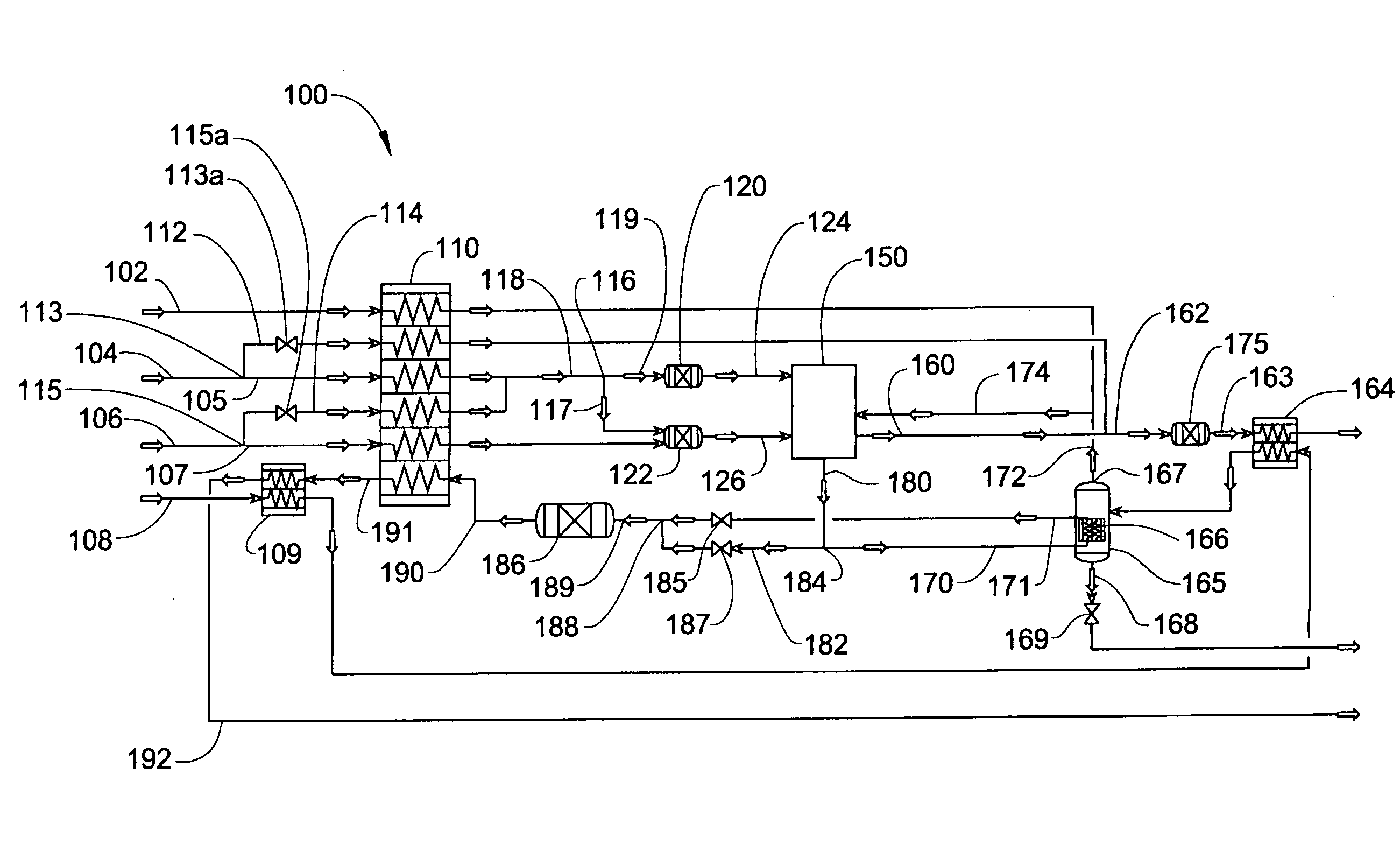

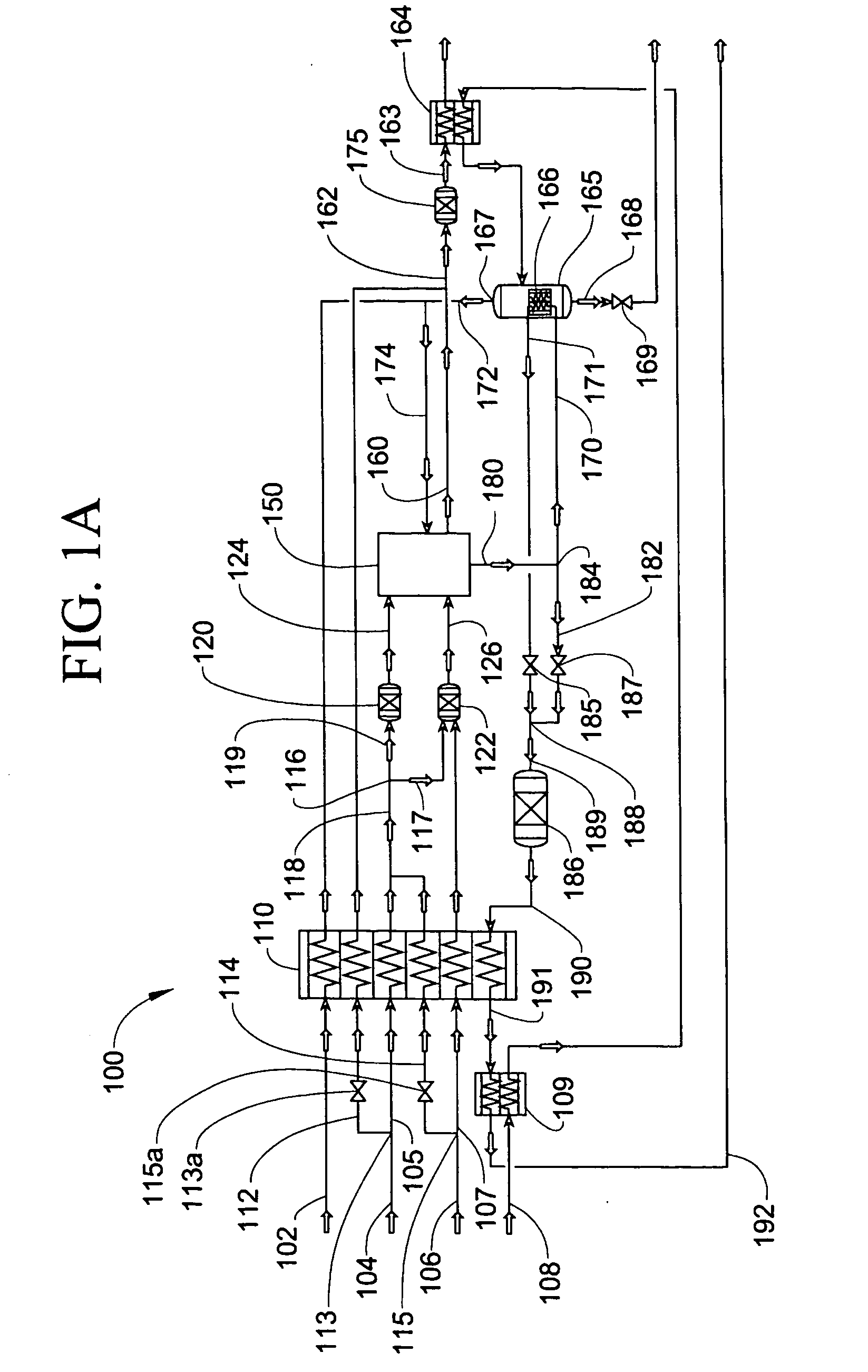

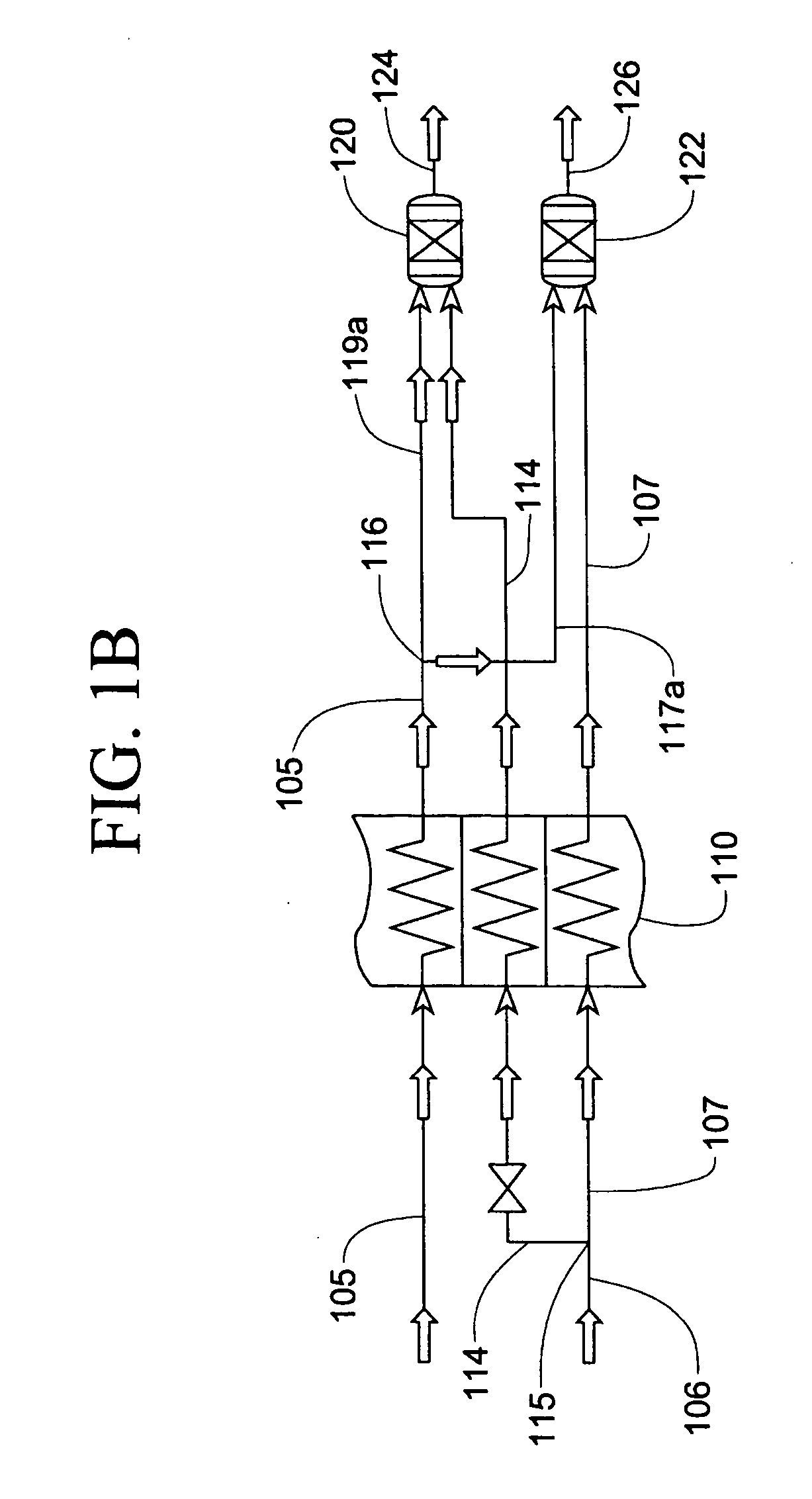

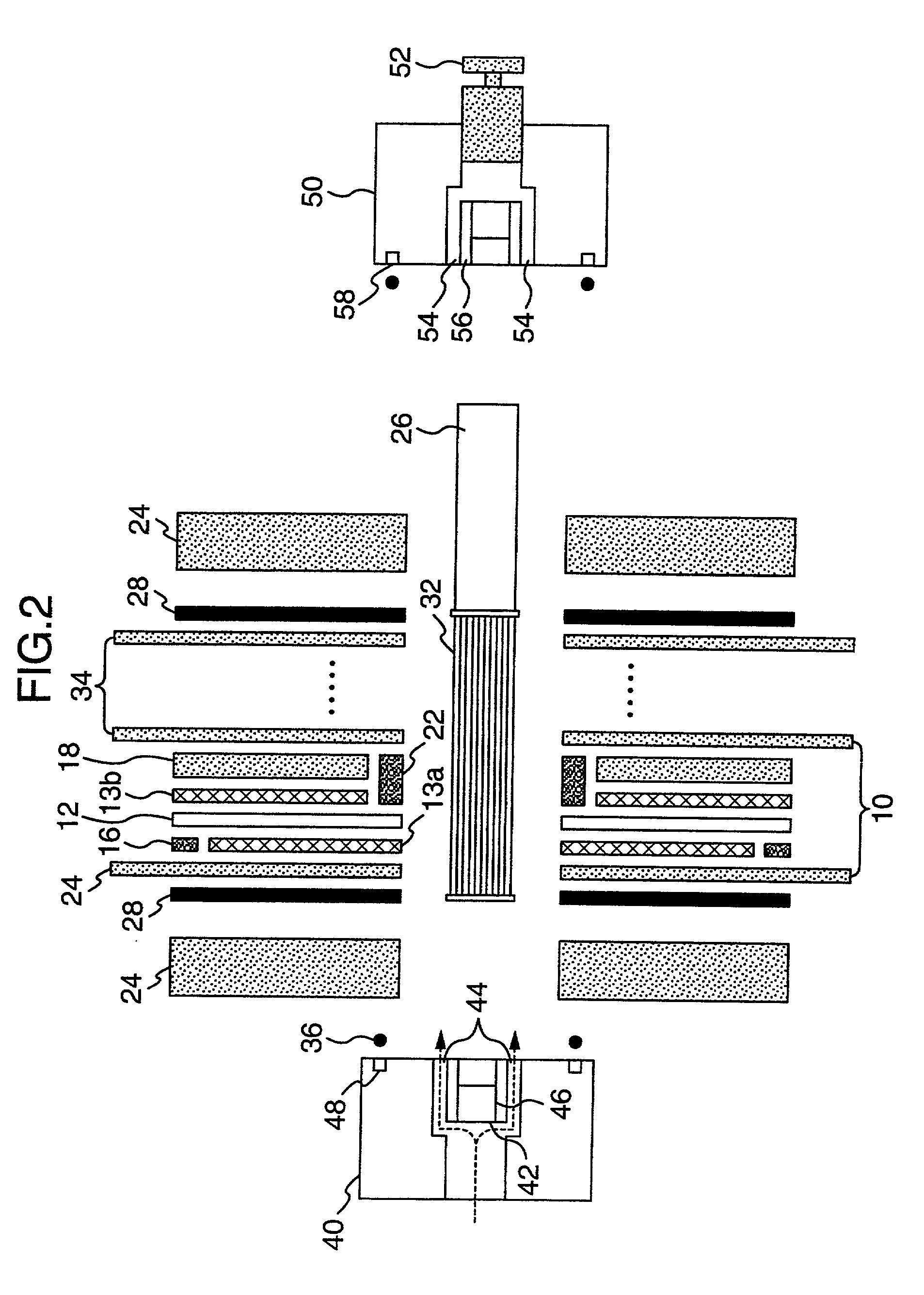

Reforming apparatus and method

ActiveUS20080244975A1Avoid adjustmentMultiple metal hydridesHigh temperature gas-gas reactionSyngasMetal dusting

A multiple adiabatic bed reforming apparatus and process are disclosed in which stage-wise combustion, in combination with multiple reforming chambers with catalyst, utilize co-flow and cross-flow under laminar flow conditions, to provide a reformer suitable for smaller production situations as well as large scale production. A passive stage by stage fuel distribution network suitable for low pressure fuel is incorporated and the resistances in successive fuel distribution lines control the amount of fuel delivered to each combustion stage. The fuel distribution system allows relatively constant fuel and air flow during turn up or turn down conditions. High efficiency is achieved by capturing heat from reforming syngas product to preheat gases before entering the reformer. Conditions that would produce unwanted coking or metal dusting are also eliminated or localized to locations within the apparatus outside the heat exchangers, but which locations can be cost effectively protected. Also, a chemical reactor is disclosed and which has a core composed of a stack of metal plates that are diffusion bonded in face-to-face relationship. A plurality of reaction zones are located within the core, as are a plurality of catalyst receiving zones, and both the reaction zones and the catalyst receiving zones are defined by respective aligned apertures in the plates. First and second channel arrangements are provided in the plates for transporting first and second reactants to reaction zones. Portions of the first channel arrangement that interconnect the reaction zones are formed as heat exchange channels. A third channel arrangement is provided in the plates for transporting a third reactant to catalyst receiving zones. Portions of the third channel arrangement are formed as heat exchange channels in proximity to the heat exchange channels of the first channel arrangement.

Owner:MEGGIT (UK) LTD

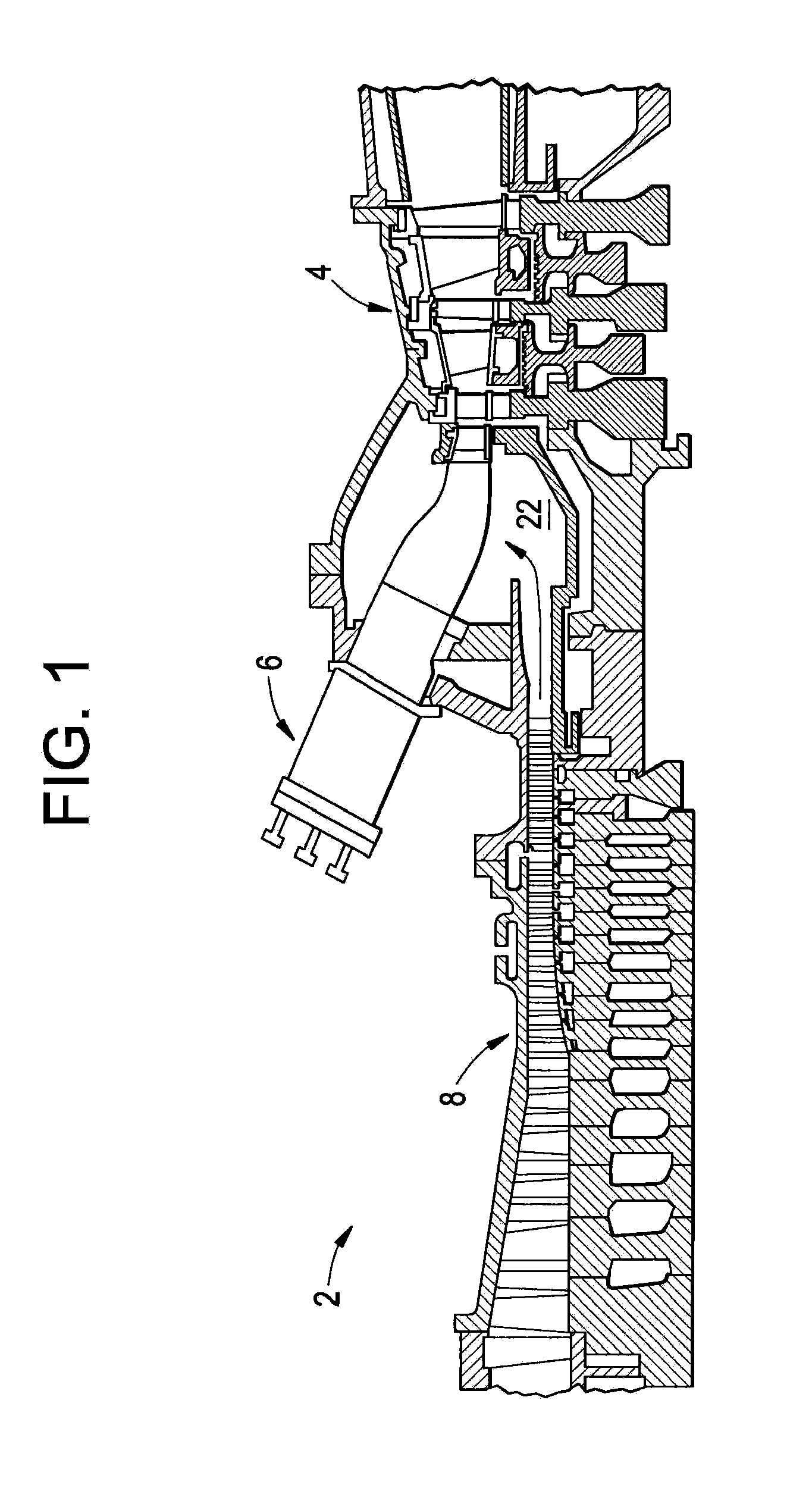

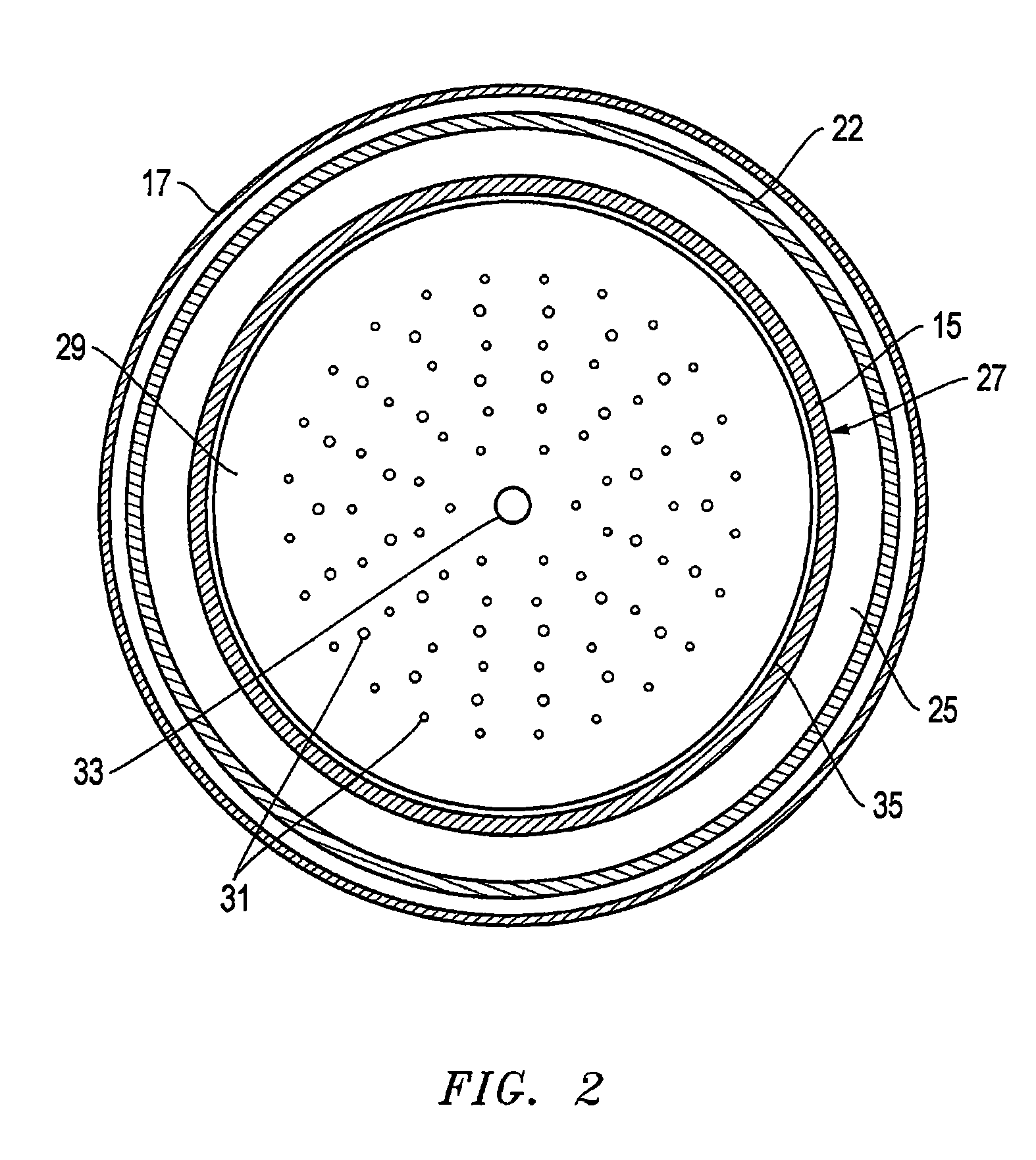

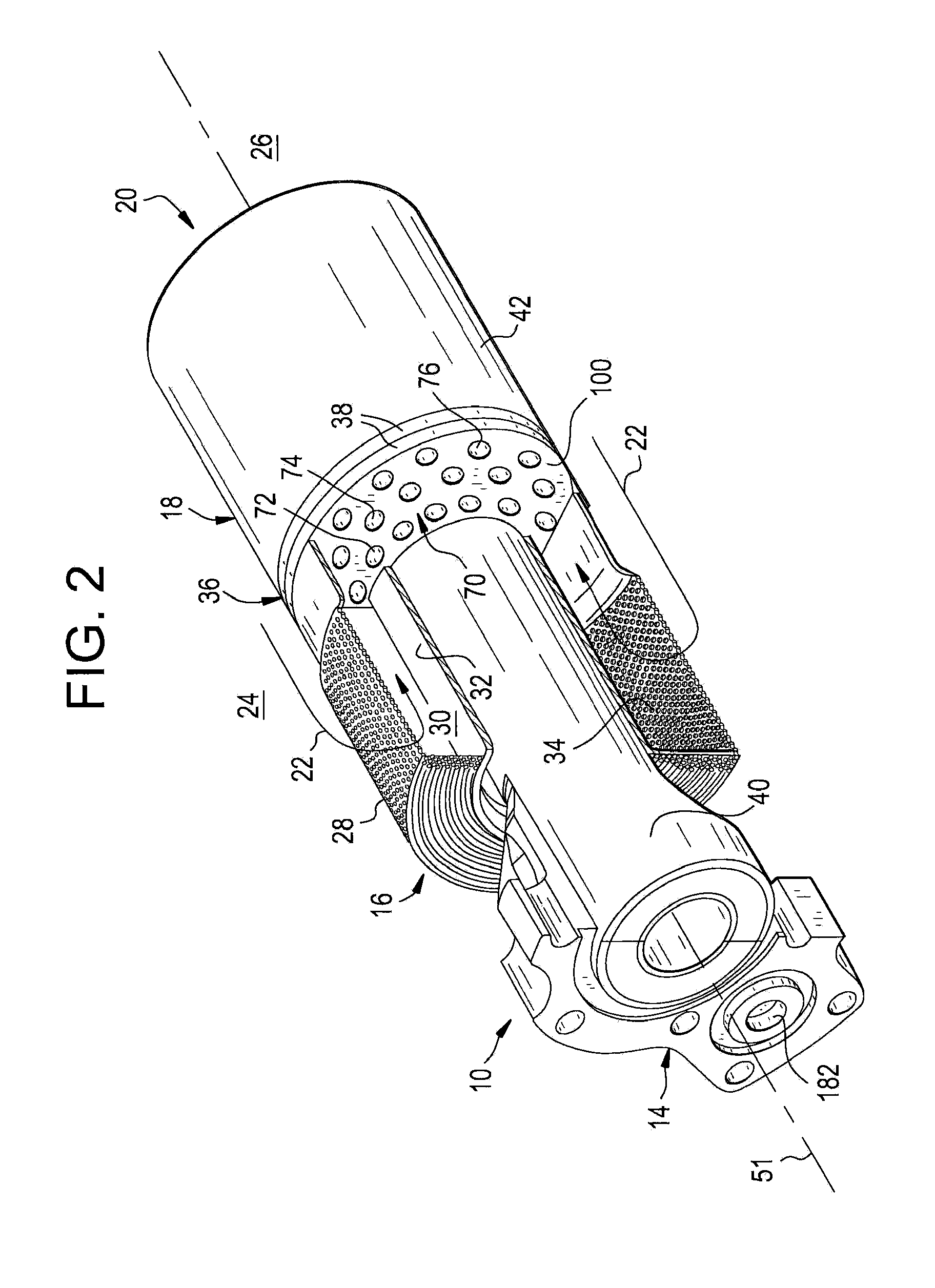

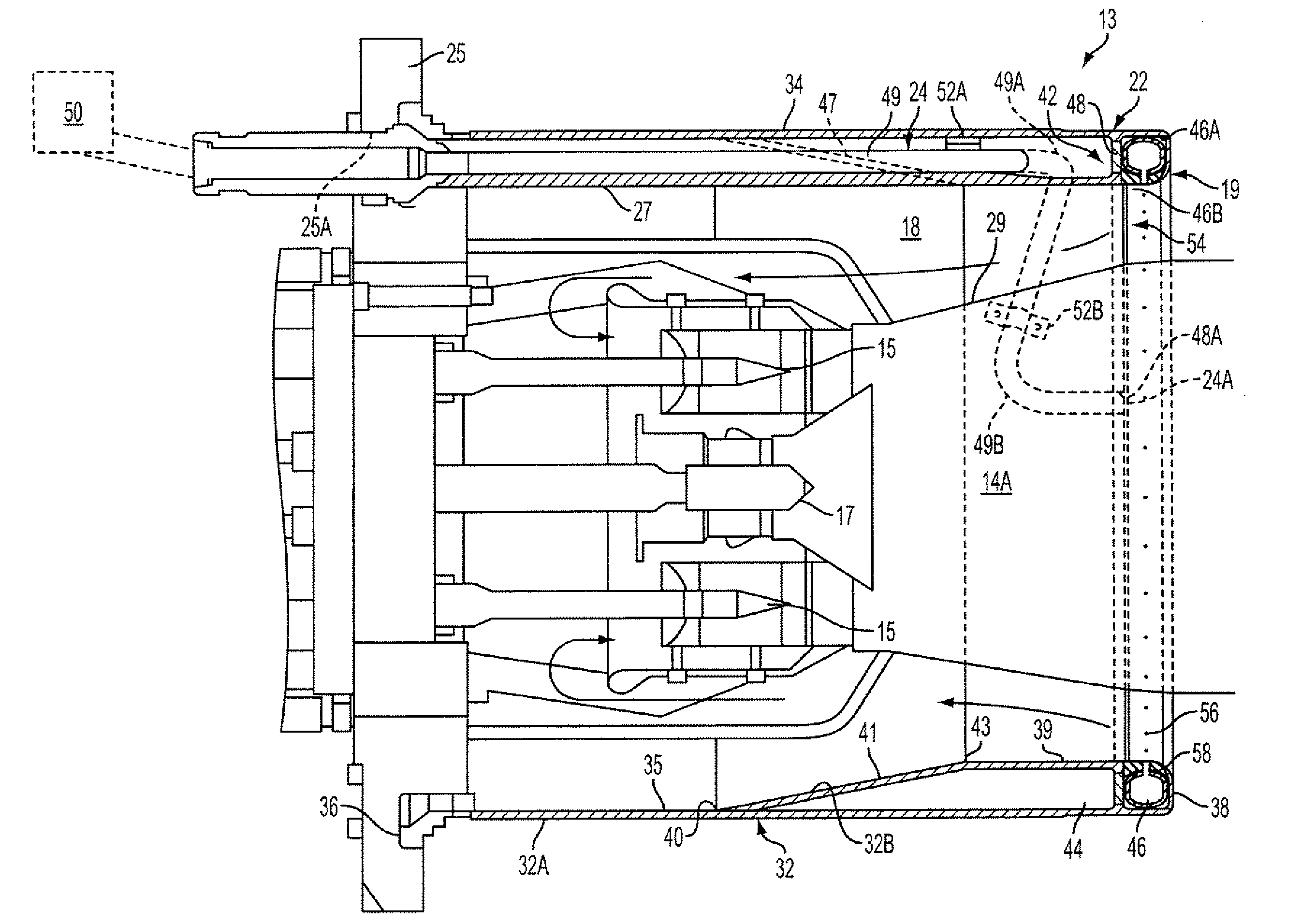

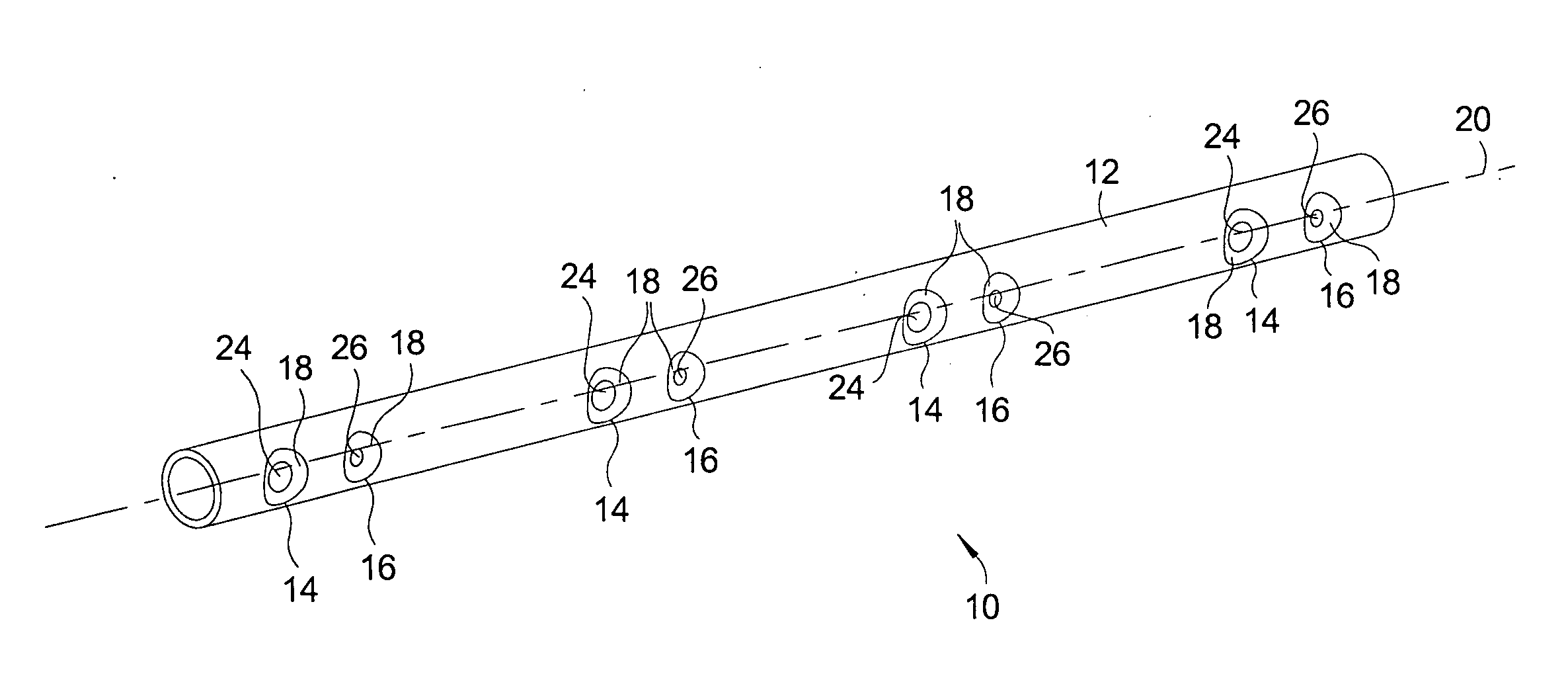

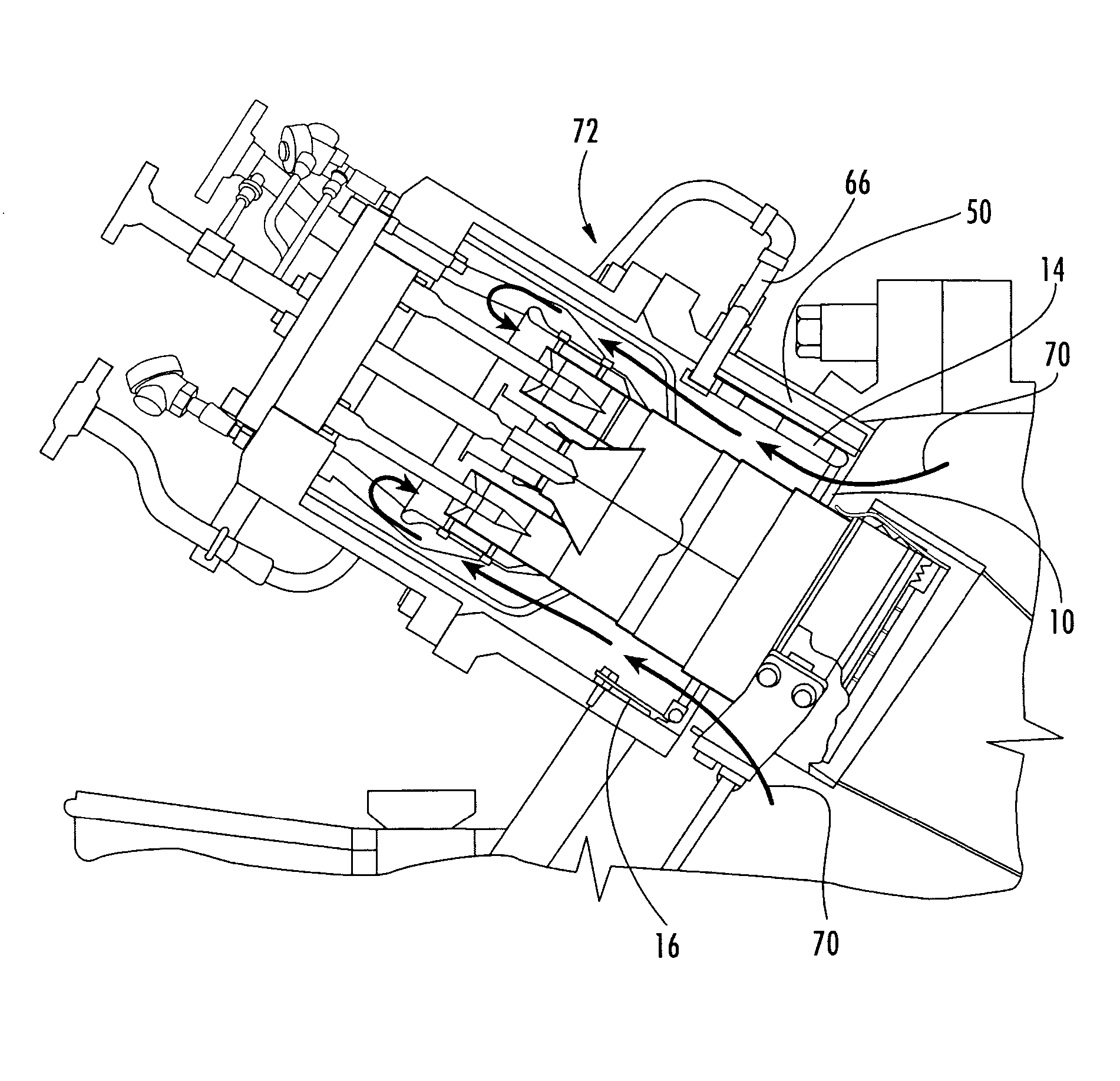

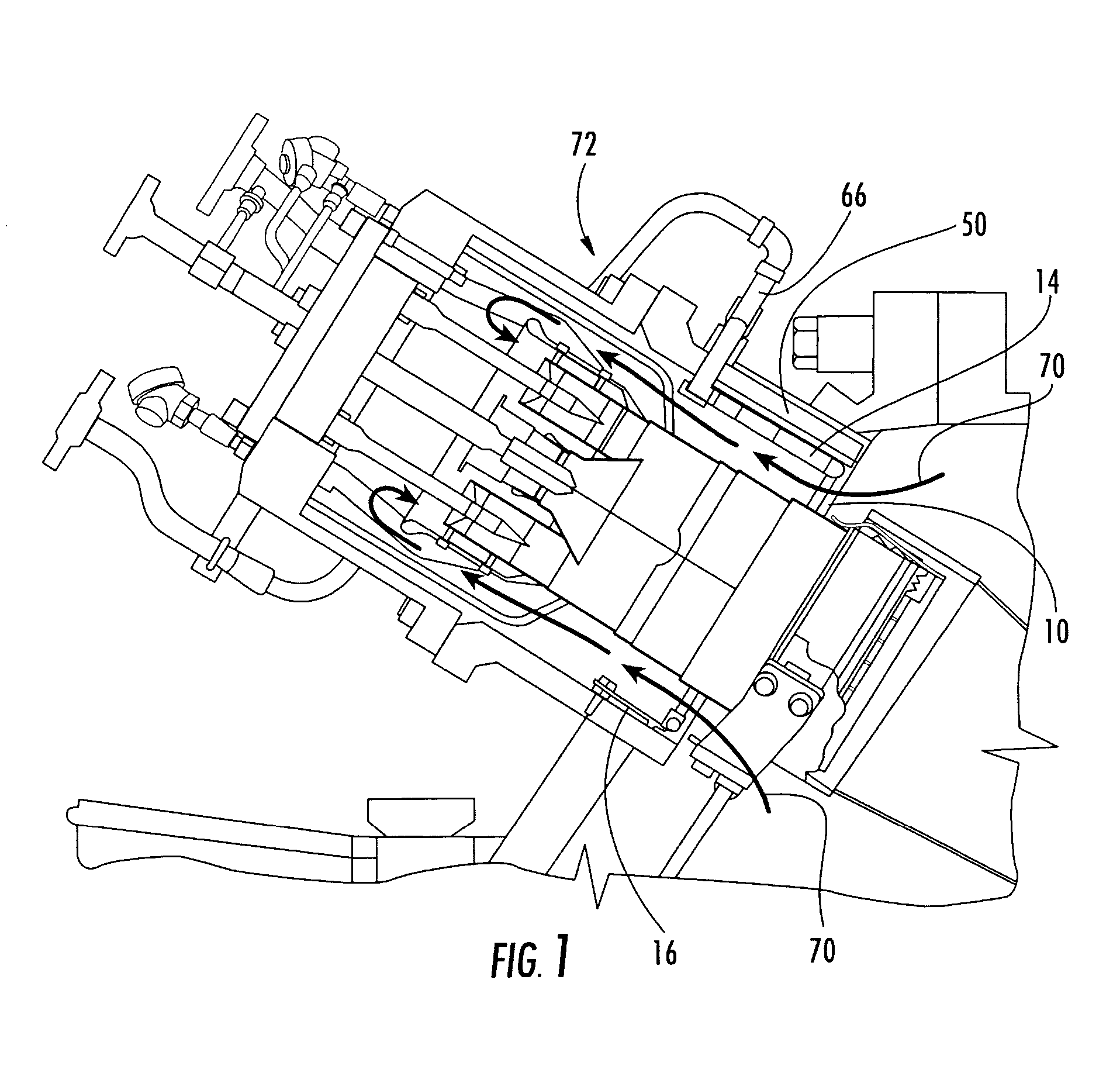

Method and apparatus for delivery of a fuel and combustion air mixture to a gas turbine engine

ActiveUS20100236247A1Continuous combustion chamberTurbine/propulsion fuel supply systemsFuel distributionEngineering

A nozzle has combustion air passages extending from a first, upstream end to a second, downstream end. A fuel distribution manifold is associated with the first, upstream end of the nozzle. Combustion air passages correspond to, and align with the air passages in the nozzle. Fuel distribution grooves are formed in one end of the fuel distribution manifold disk and extend from a central opening to the air passages. A fuel circuit cover closes the fuel distribution grooves to define fuel passages that extend from the central opening to the combustion air passages. A fuel supply conduit communicates with the central opening and the fuel passages for delivery of fuel to the combustion air in the air passages.

Owner:GENERAL ELECTRIC CO

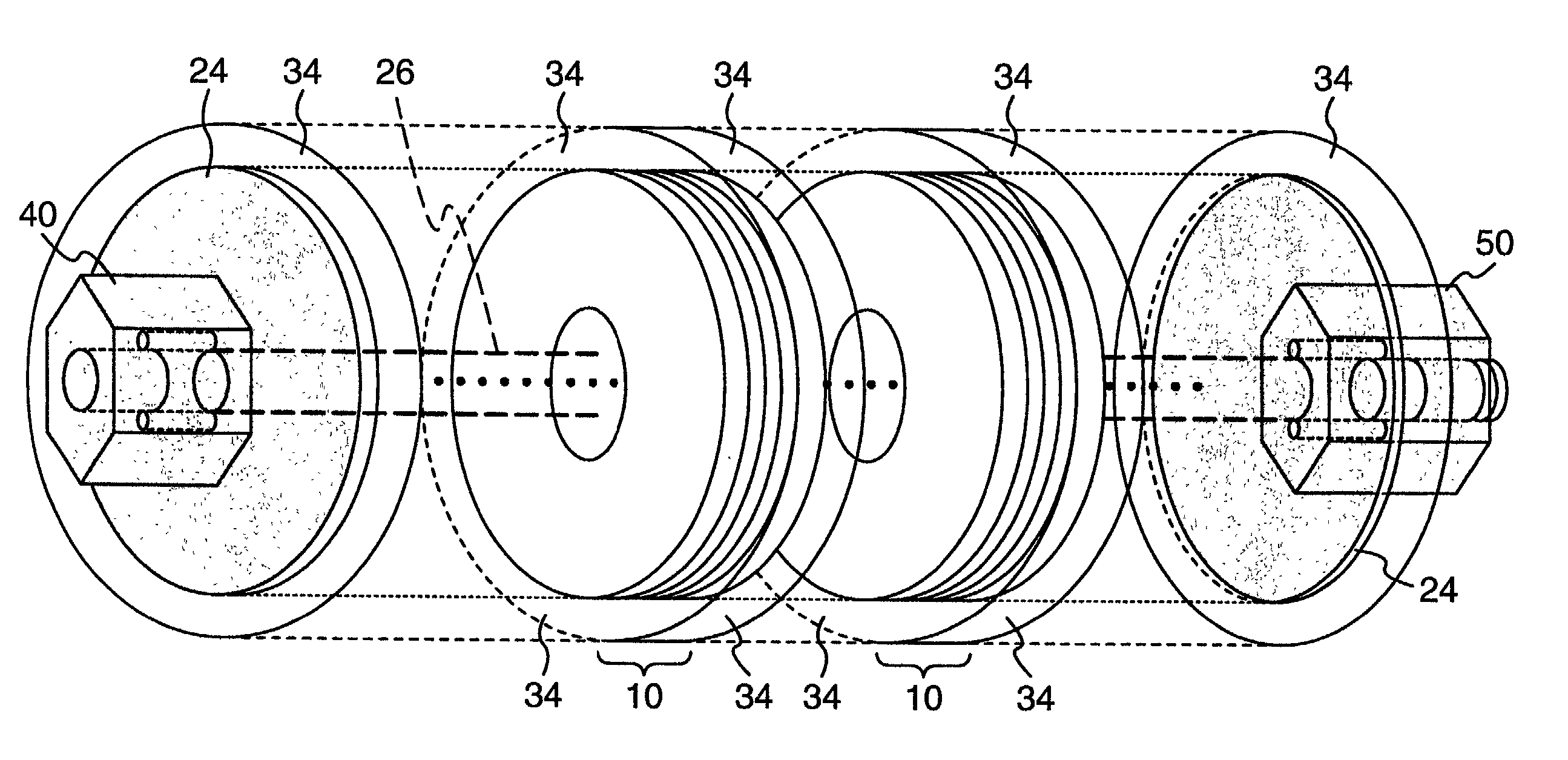

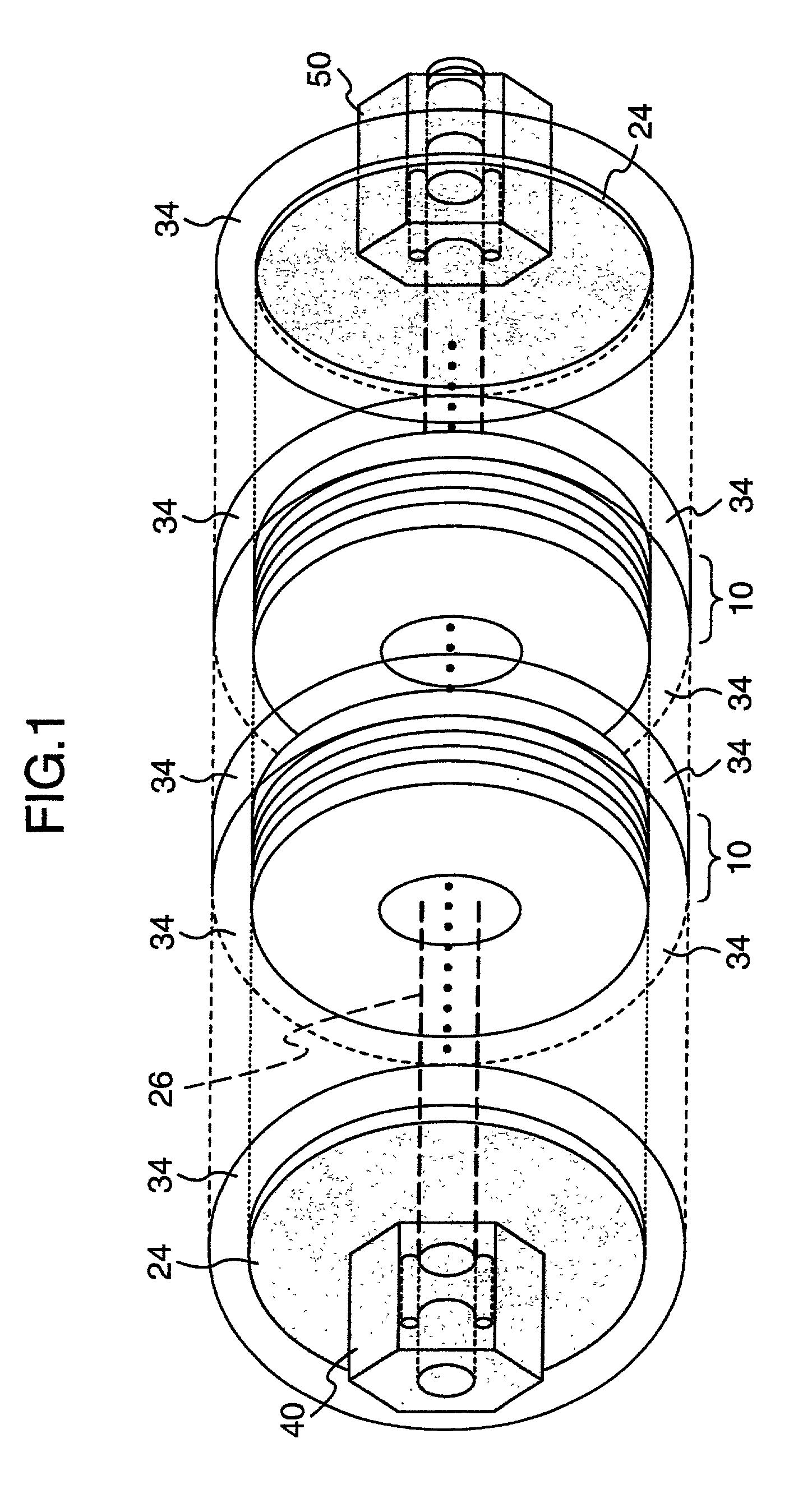

Portable fuel cell stack

InactiveUS20020127453A1Lower internal resistanceEfficient executionFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

A portable fuel cell stack is provided in which the number of components is reduced by reducing the number of flow field plates, cell performance is improved by reducing the number of contact portions to thereby lower internal resistance, and fuel is supplied from the center of an end plate directly to a fuel distribution manifold. The portable fuel cell stack includes two end plates, a plurality of unit cells positioned between the two end plates, a fuel distribution manifold positioned in the center of the unit cell for fuel supply thereto, a tie bolt passed through the centers of the fuel manifold and the unit cell for integration of these members, and fixing nuts threaded to both ends of the tie bolt for integrally clamping the plurality of unit cells together between the end plates via an O-ring, etc. The unit cell includes a polymer electrolyte membrane, an oxygen electrode and a fuel electrode installed on both sides of the polymer electrolyte membrane, a flow field plate adjacent to the oxygen electrode side, and a separator plate on the outside of the flow field plate adjacent in contact therewith and another separator plate on the outside of the fuel electrode side in contact therewith. One of the fixing nuts has a fuel supply port connecting to the fuel distribution manifold.

Owner:DAIDO METAL CO LTD

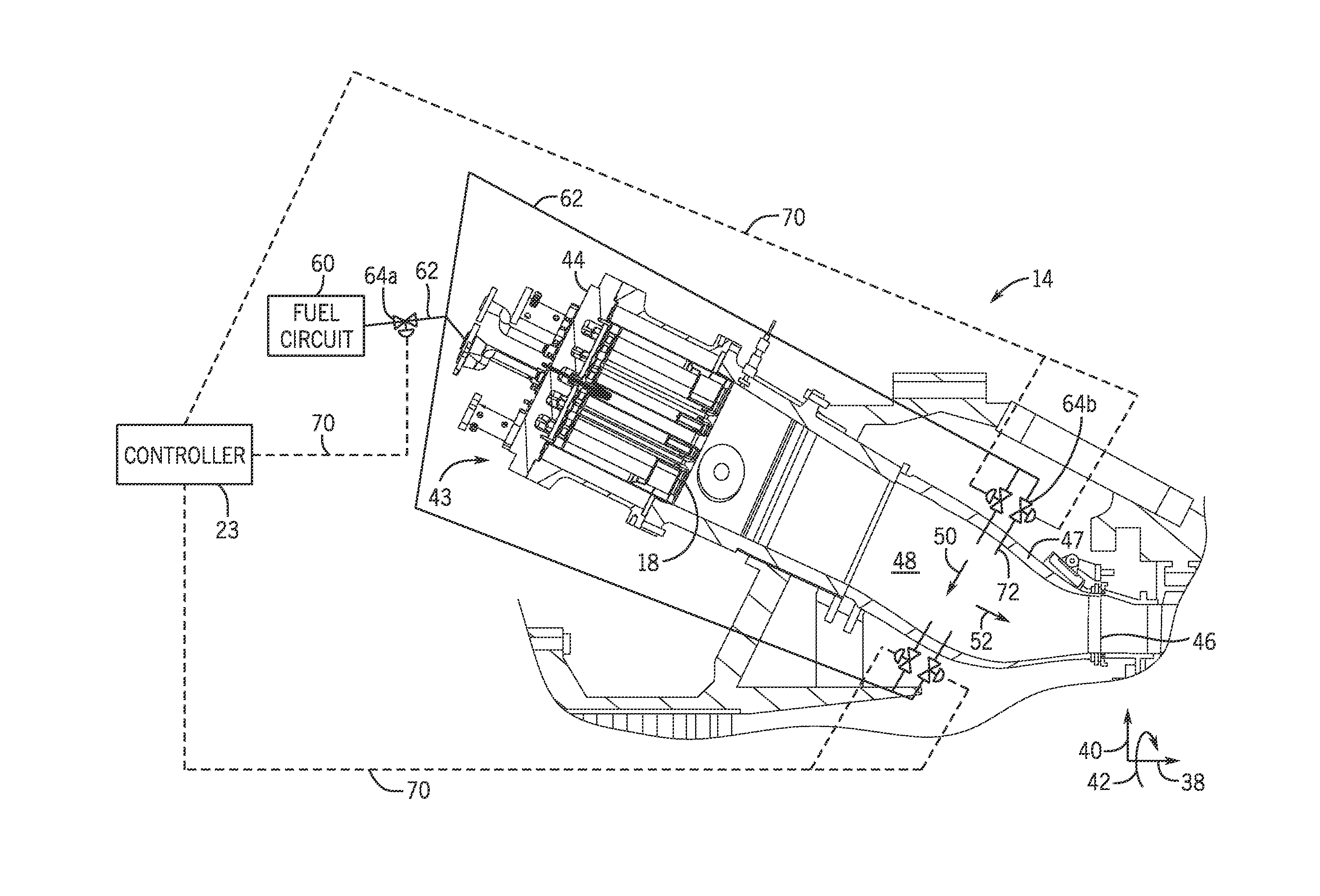

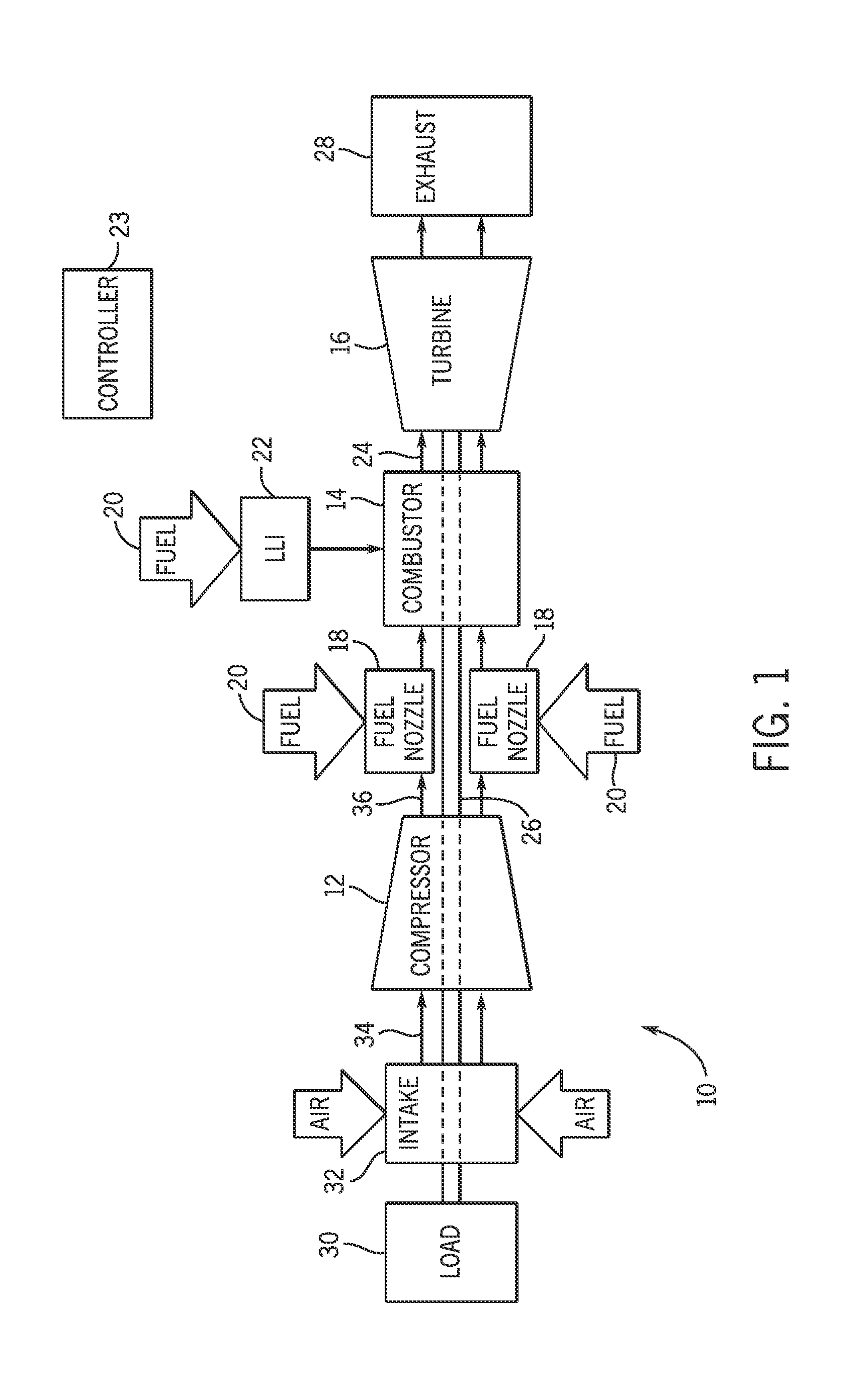

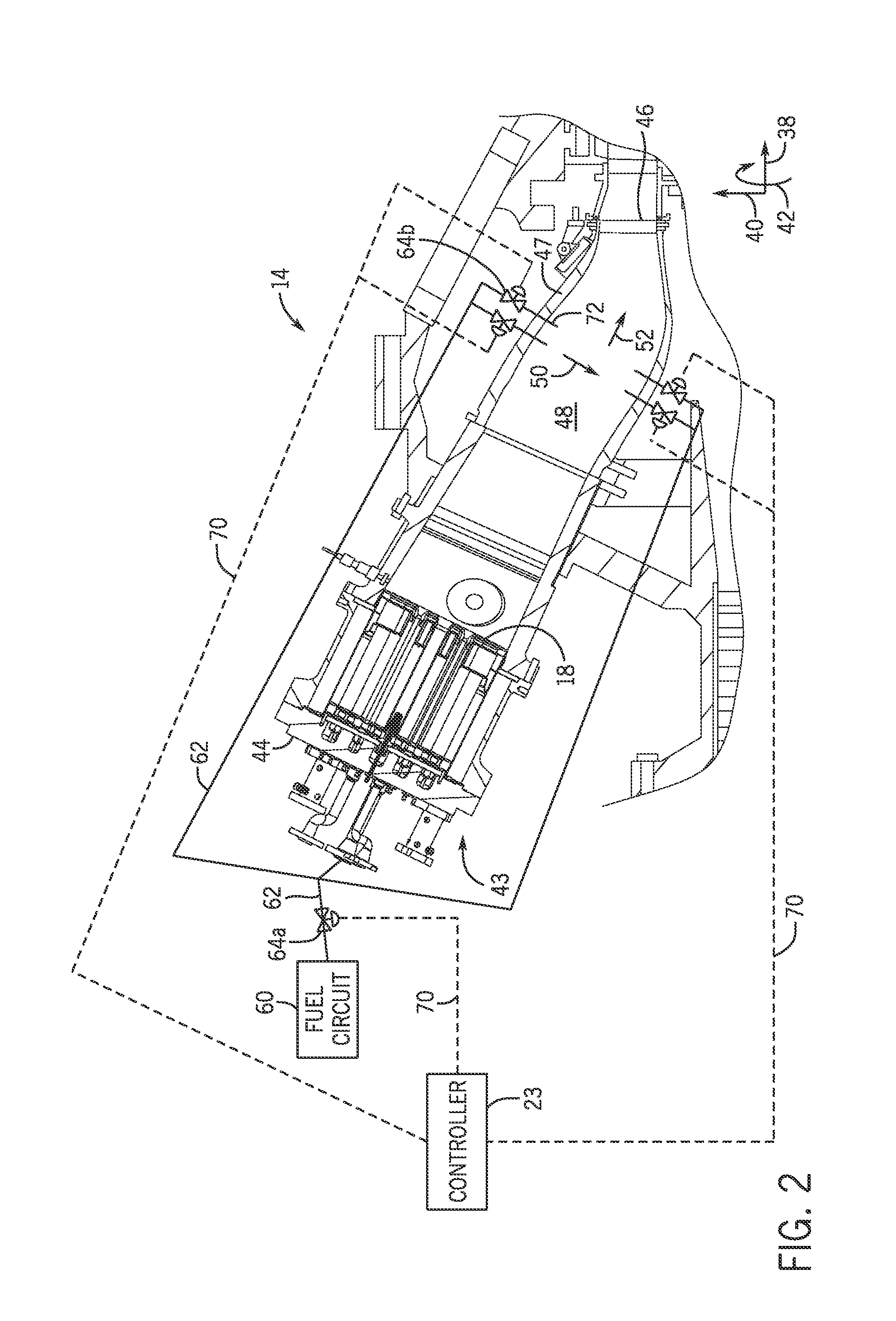

System for providing fuel to a combustor

ActiveUS20140260272A1Continuous combustion chamberTurbine/propulsion fuel flow conduitsCombustorFuel distribution

A system for providing fuel to a combustor of a gas turbine includes an annular fuel distribution manifold that at least partially defines a fuel plenum. The fuel distribution manifold includes a forward end axially separated from an aft end, a flange that extends radially outward and circumferentially around the forward end and an annular support ring that extends downstream from the flange. A LLI assembly extends downstream from the fuel distribution manifold. The LLI assembly includes a unibody liner that at least partially defines a primary combustion zone and a secondary combustion zone within the combustor. A LLI injector extends substantially radially through the unibody liner and provides for fluid communication through the unibody liner into the secondary combustion zone. A fluid conduit in fluid communication with the fuel plenum extends between the LLI injector and the fuel distribution manifold.

Owner:GENERAL ELECTRIC CO

Throttle body fuel injection system with improved idle air control

ActiveUS9303578B2Improve performanceOptimal fuel distribution and idle control circuitryElectrical controlInternal combustion piston enginesFuel distributionClosed loop

A single point fuel injection throttle body assembly including an idle air control circuit having an port opening into main intake bores downstream of the point of fuel distribution into the air stream. When the idle air control circuit is open, an air / fuel mixture, rather than simply air, is drawn into the into the intake manifold, thereby reducing the tendency for a lean fuel mixture at idle. A unique engine control unit “feed forward” algorithm controls the fuel injection as a function of the position of the idle air control motor so that as the idle air control circuit is opened, the pulse widths of the fuel injector signals are increased. This feature allows the initial open-loop-based fuel mixture supplied by system to be more accurate and eliminates rough unstable idle associated with closed-loop control lag times.

Owner:MSD LLC

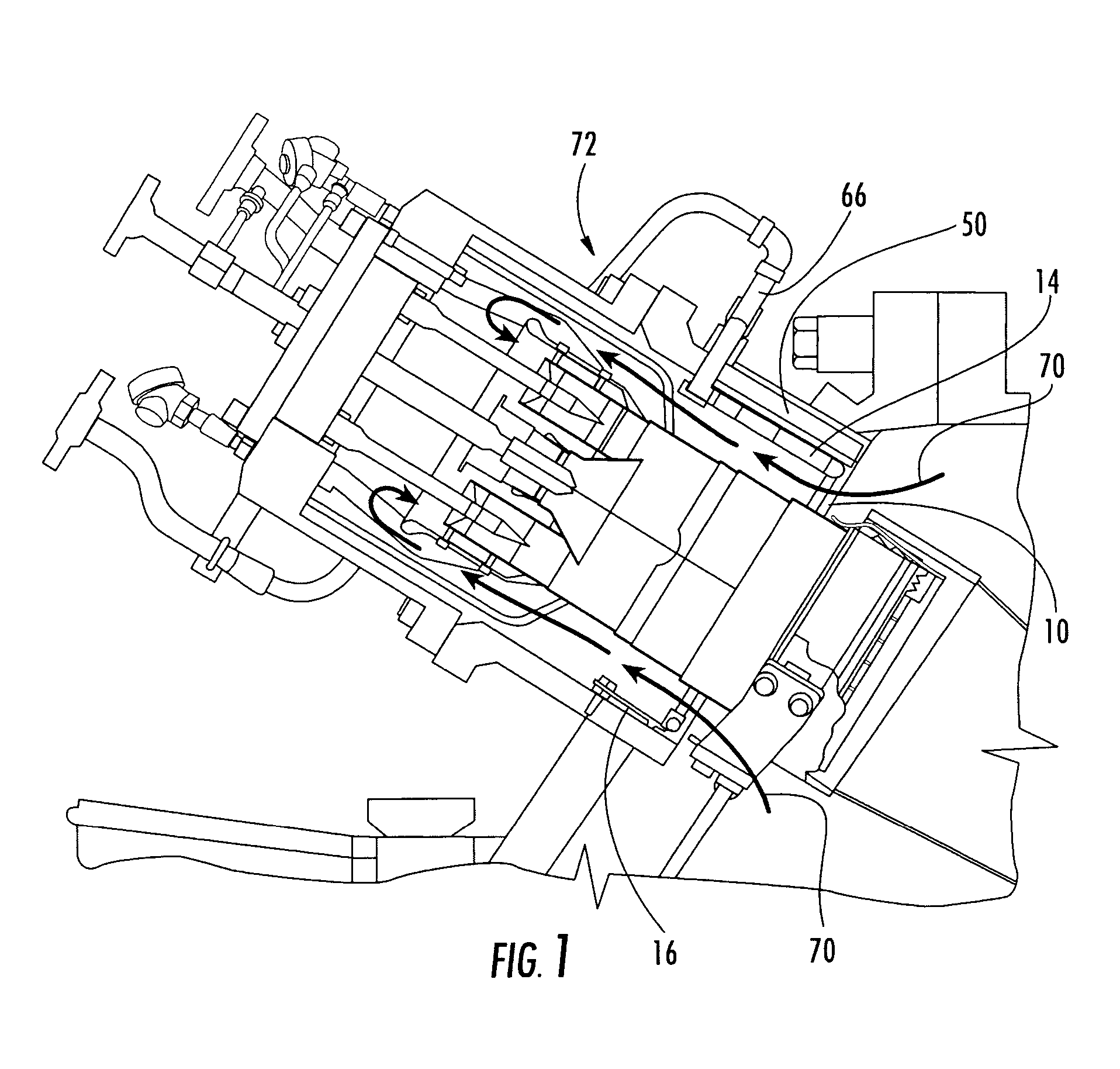

Fuel distribution manifold system for gas turbine engines

ActiveUS20100050645A1Improve engine efficiencyPromote combustionContinuous combustion chamberTurbine/propulsion fuel flow conduitsFuel distributionEngineering

A fuel distribution manifold system for a gas turbine engine is disclosed that includes a plurality of interconnected manifold segments, each manifold segment extending between a pair of fittings, each manifold segment including at least one fuel transfer tube and a sealing tube that surrounds the at least one fuel transfer tube, wherein opposed end portions of the at least one fuel transfer tube are dynamically connected to the fittings and opposed end portions of the sealing tube are statically connected to the fittings.

Owner:COLLINS ENGINE NOZZLES INC

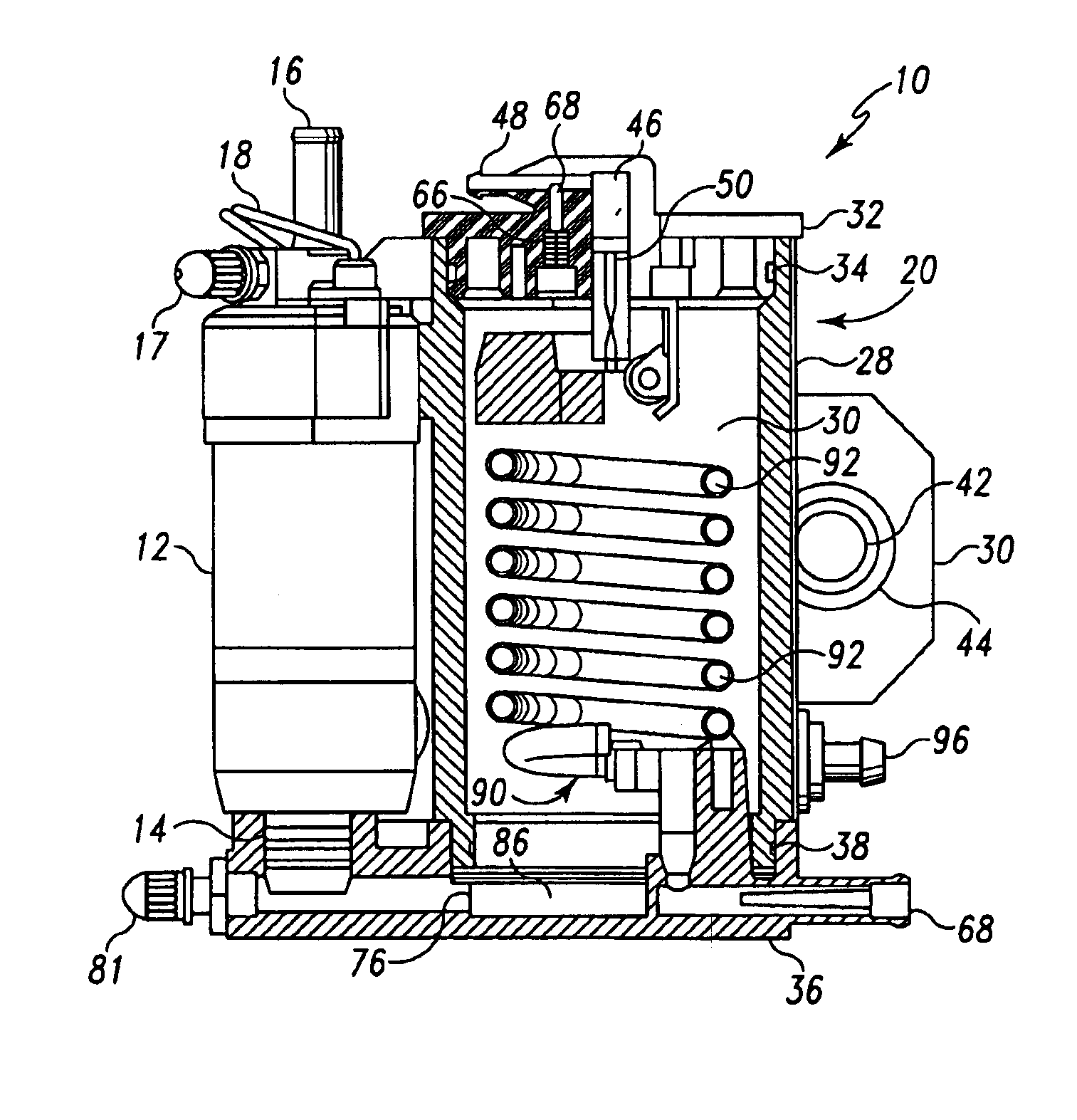

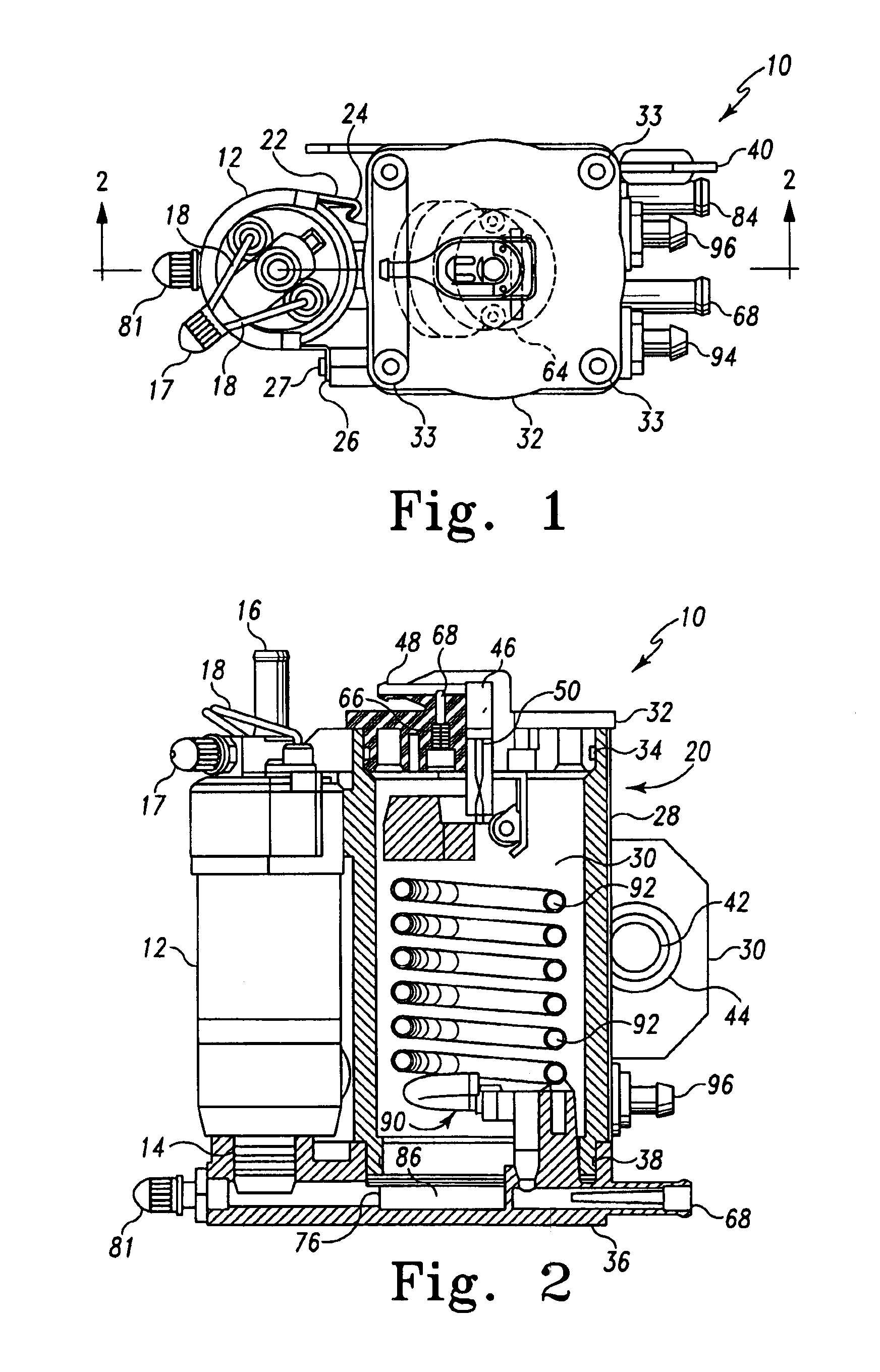

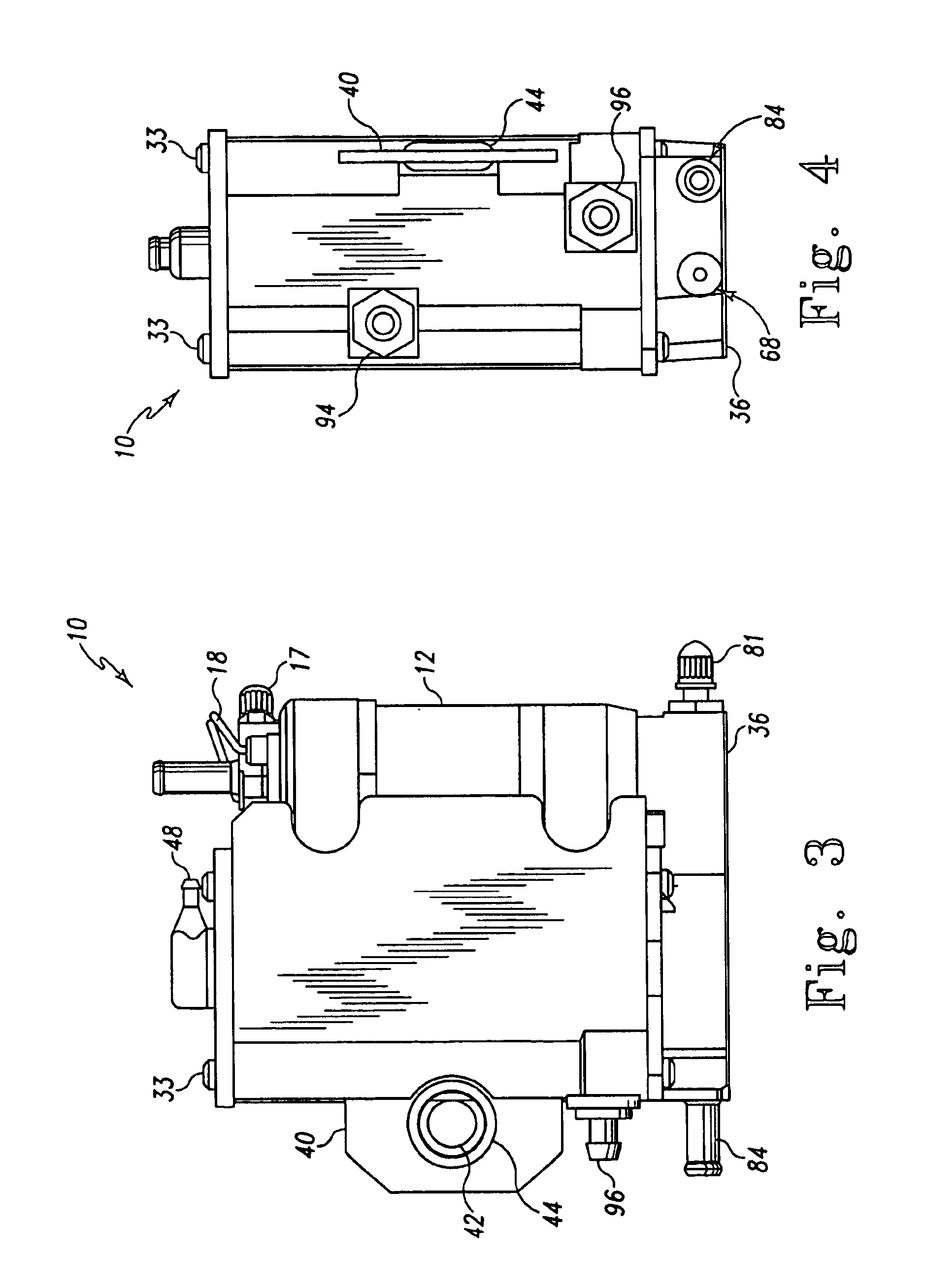

Fuel vapor separator for internal combustion engine

ActiveUS6857419B1Remove heatInternal combustion piston enginesAir coolingInternal pressureFuel distribution

A fuel separator is disclosed having a hollow interior in which a tubular coiled heat exchanger is positioned to receive a coolant liquid therethrough. Fuel is fed into the chamber through a fuel inlet and pumped out of the chamber by a high pressure pump into the fuel distribution system of an internal combustion engine. Heated excess fuel from the fuel distribution system of an internal combustion engine is returned to the chamber through a fuel return inlet at the bottom of the chamber and the heated fuel passes upwardly through the coolant coil thereby cooling the heated return fuel. Fuel vapor that is not condensed as a result of cooling can escape from the chamber through a float needle valve at the top of the chamber. A pressure relief valve is also provided at the top of the chamber to allow the vapor to escape when a predetermined internal pressure is reached.

Owner:CARTER FUEL SYST

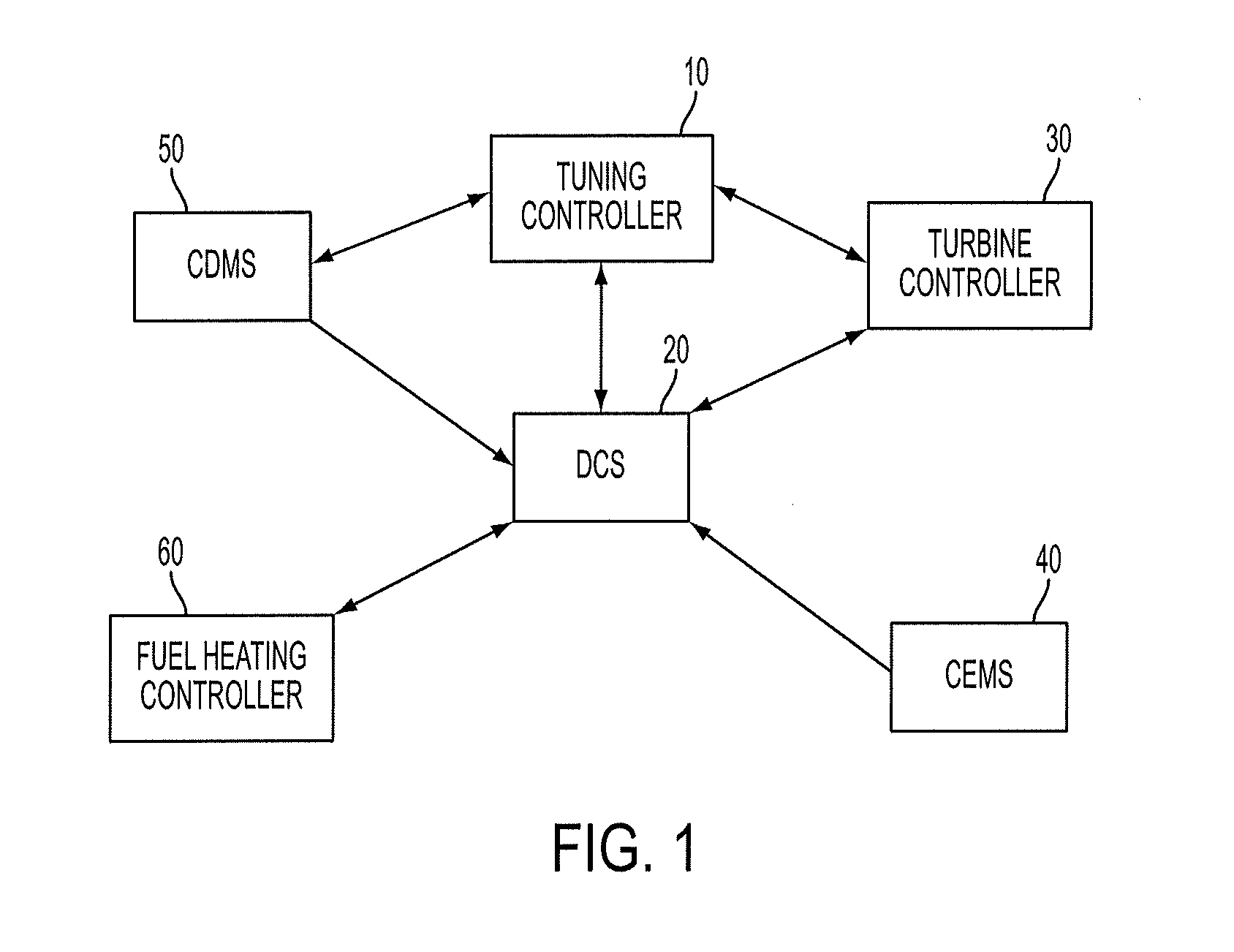

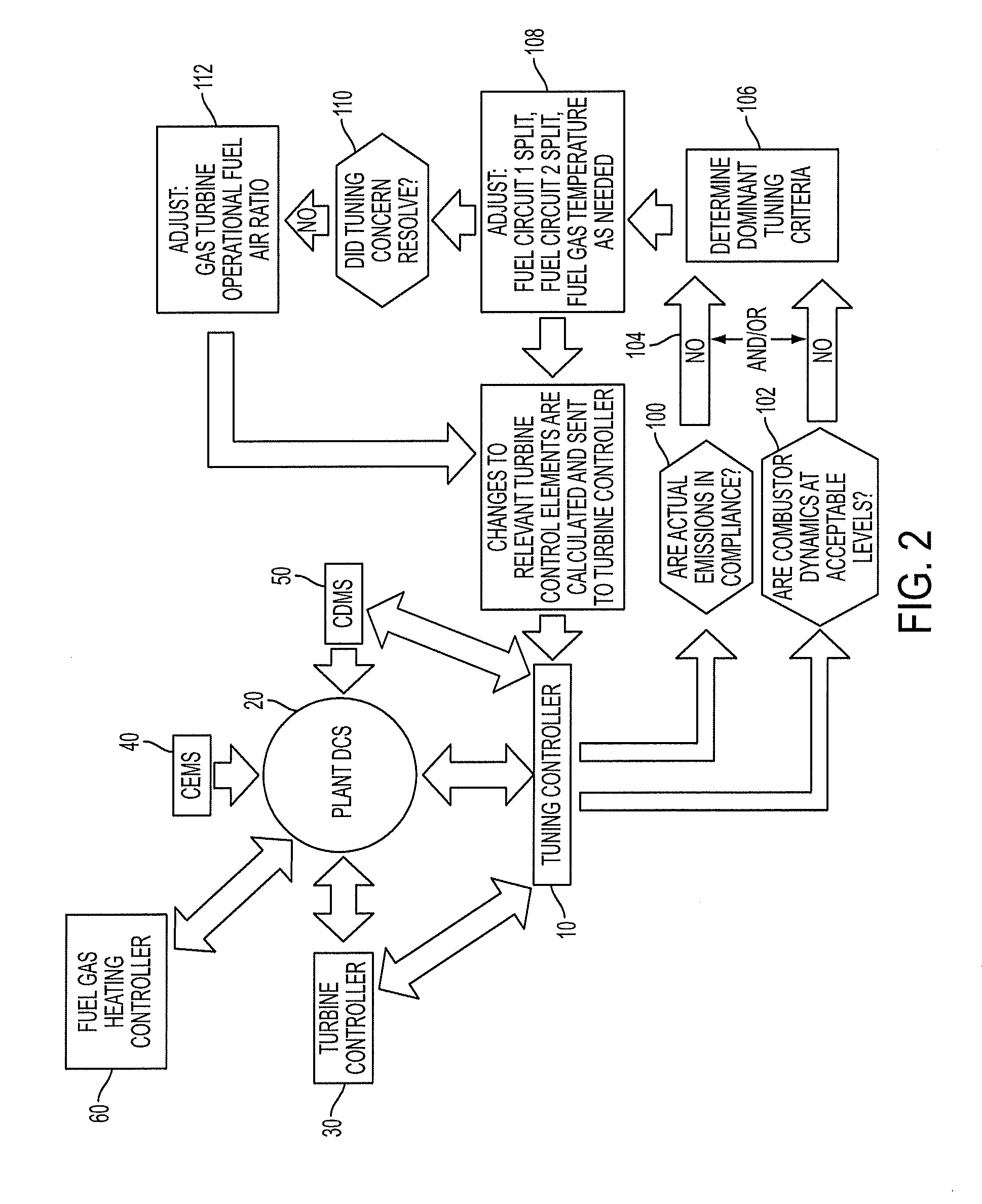

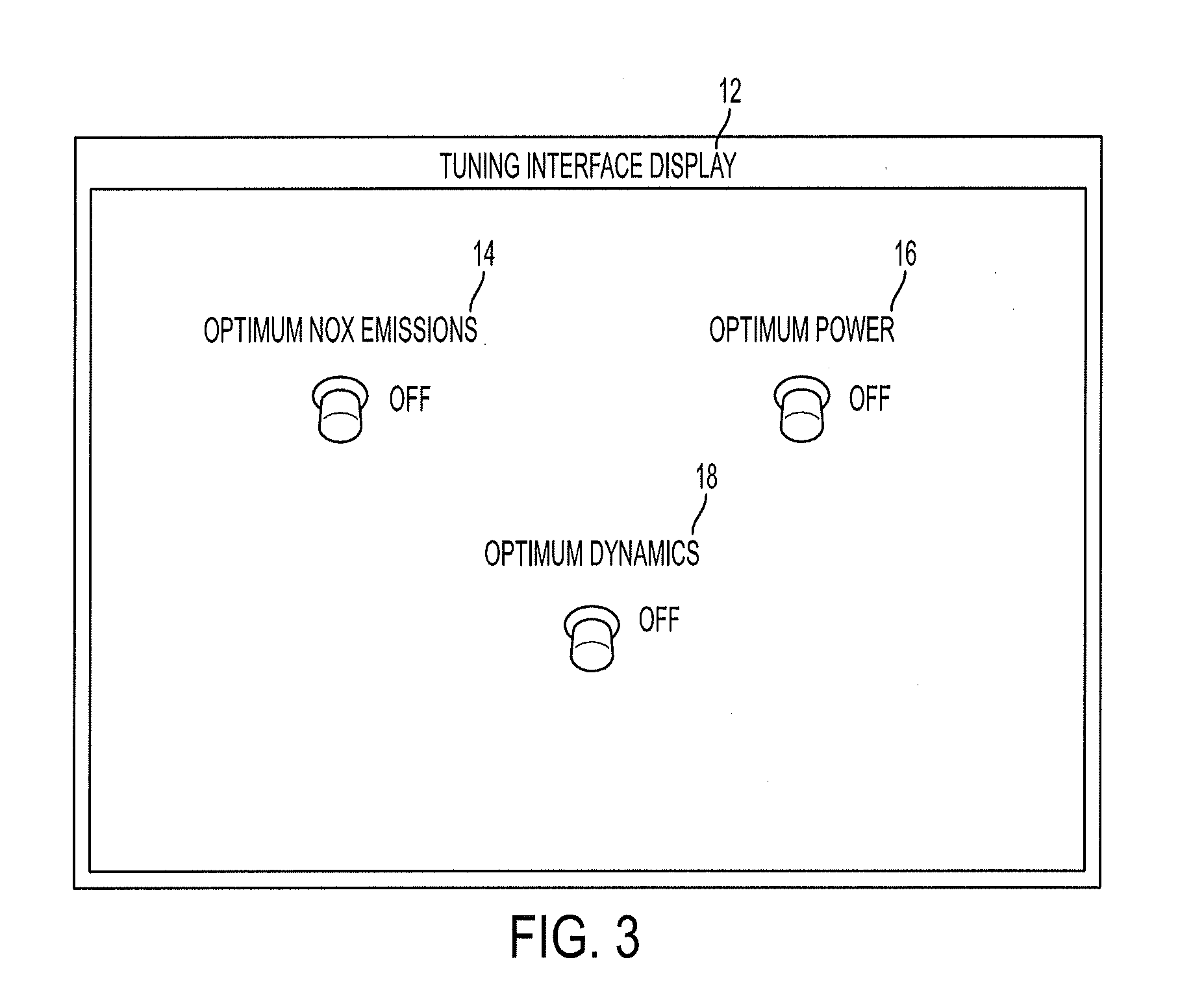

Automated tuning of gas turbine combustion systems

ActiveUS20120275899A1Improve abilitiesFuel supply regulationContinuous combustion chamberCombustion systemFuel distribution

The present disclosure provides a tuning system for tuning the operation of a gas turbine. The system comprises operational turbine controls for controlling operational control elements of the turbine, including at least one of turbine fuel distribution or the fuel temperature. The system also has a tuning controller communicating with the turbine controls. The tuning controller is configured to tune the operation of the turbine in accordance with the following steps: receiving operational data about the turbine, providing a hierarchy of tuning issues, determining whether sensed operational data is within predetermined operational limits and producing one or more indicators. If the operational data is not within predetermined operational limits, the tuning controller will rank the one or more indicators to determine dominant tuning concern, and tune the operation of the turbine based on dominant tuning concern. Also provided herein are a method and computer readable medium for tuning.

Owner:GTE TURBINE EFFICIENCY SWEDEN AB

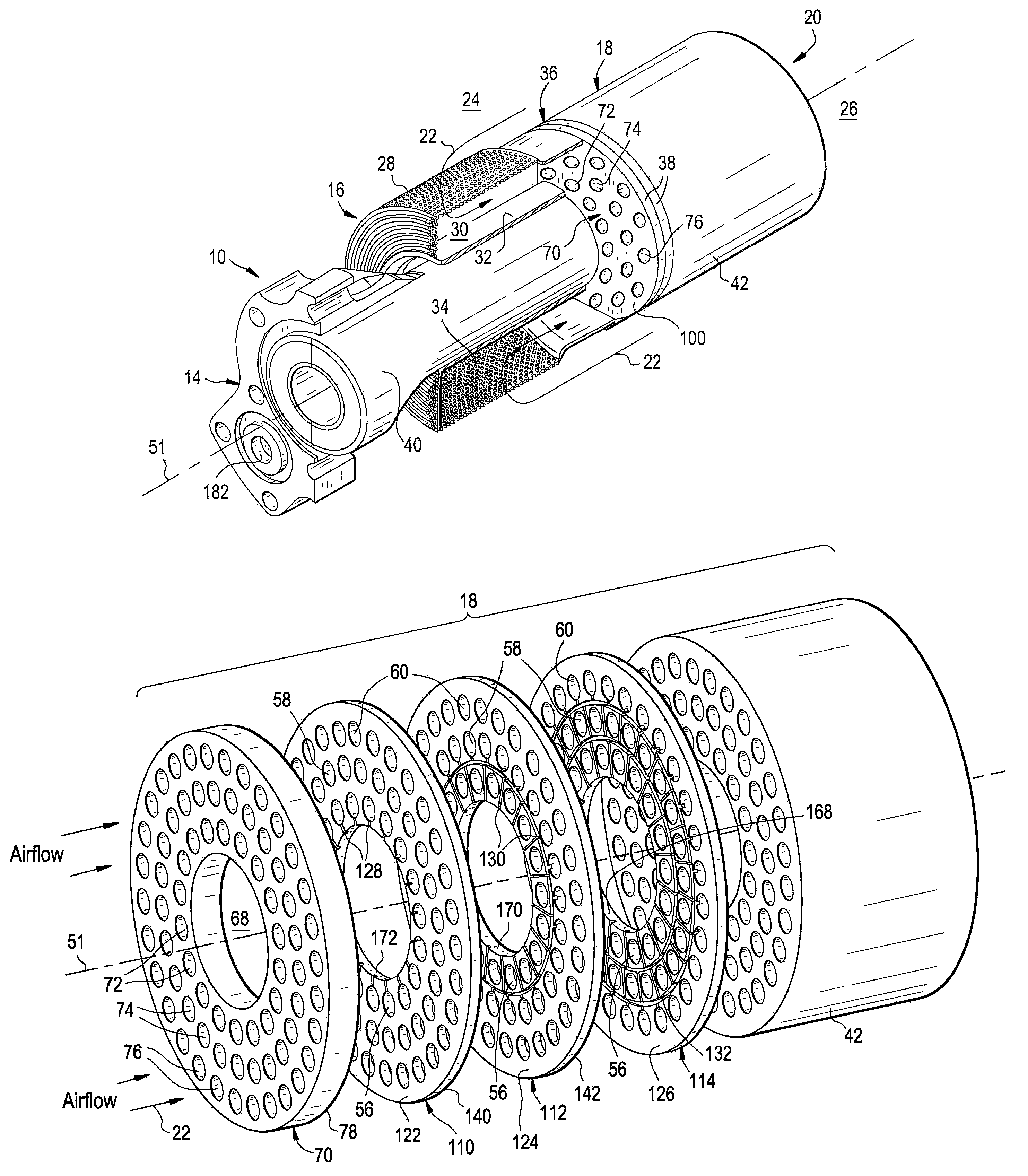

System, method and apparatus for hydrogen-oxygen burner in downhole steam generator

A downhole burner for a steam generator includes an injector and a cooling liner. Steam enters the burner through holes in the cooling liner. Combustion occurring within the cooling liner heats the steam and increases its quality and may superheat it. The heated, high-quality steam and combustion products exit the burner and enter an oil-bearing formation to upgrade and improve the mobility of heavy crude oils held in the formation. The injector includes a face plate, a cover plate, an oxidizer distribution manifold plate, and a fuel distribution manifold plate. The cooling liner has an effusion cooling section and effusion cooling and jet mixing section. The effusion cooling section includes effusion holes for injecting steam along the cooling liner surface to protect the liner. The effusion cooling and jet mixing section has both effusion holes and mixing holes for injecting steam further toward central portions of the burner.

Owner:WORLD ENERGY SYST

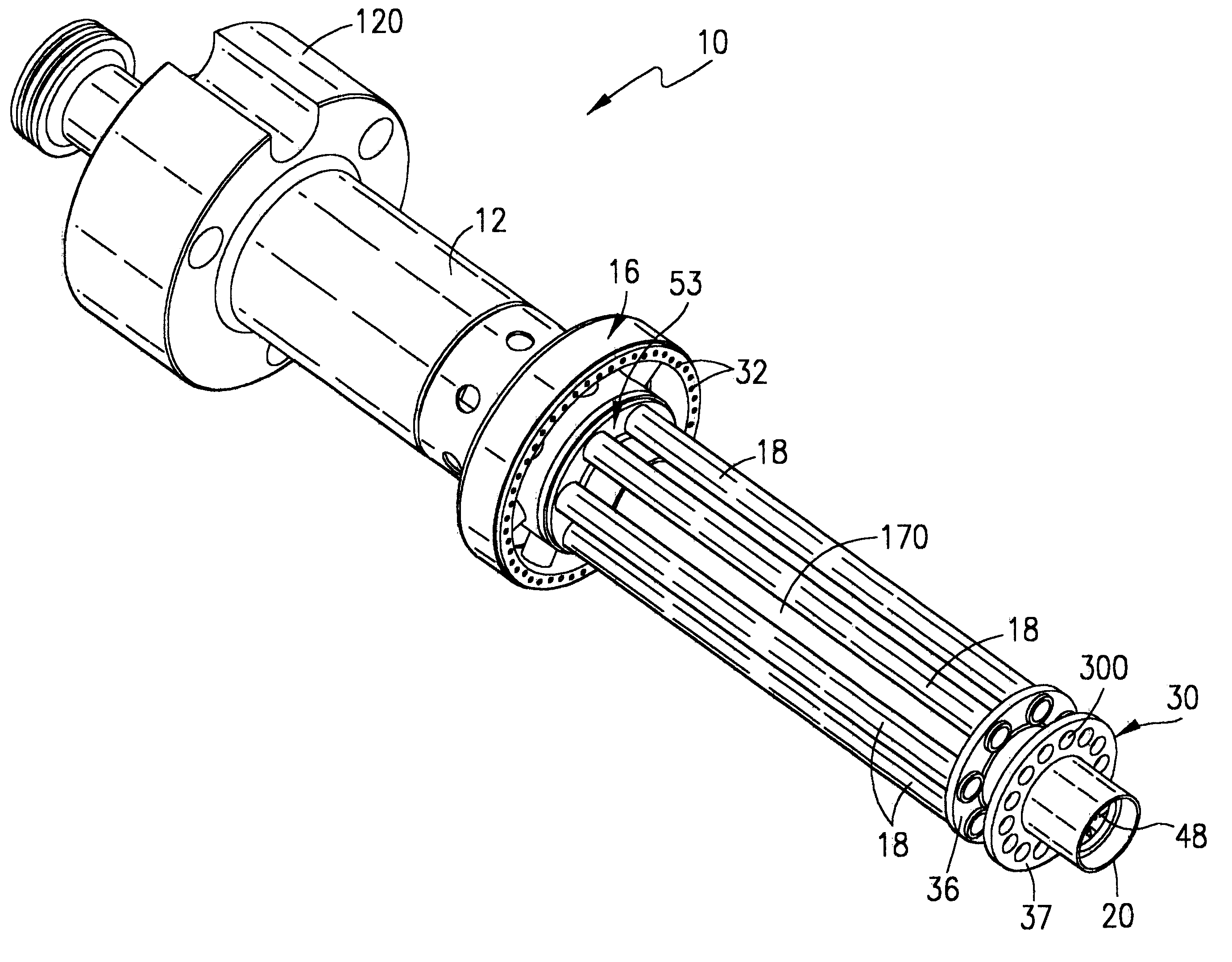

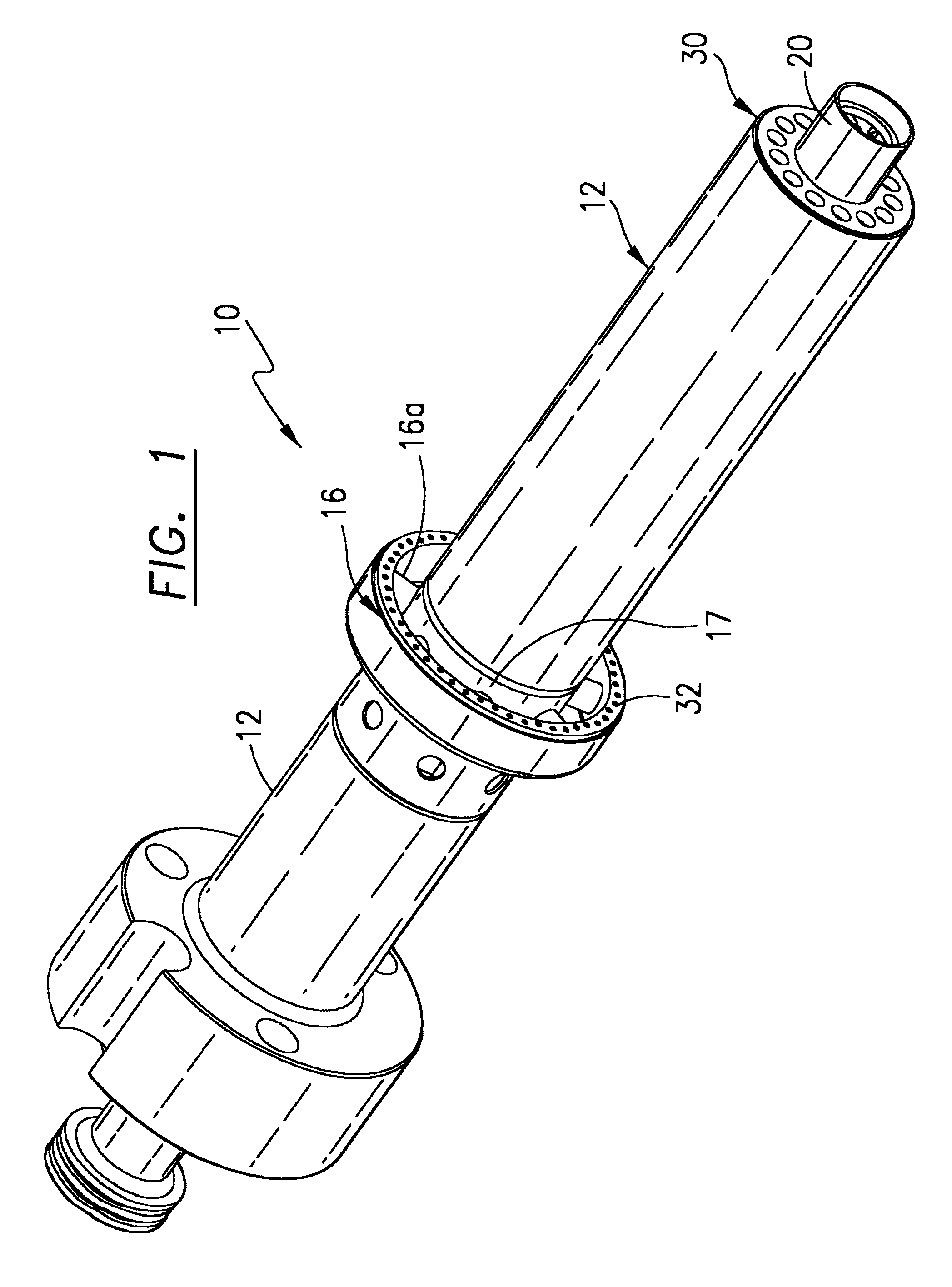

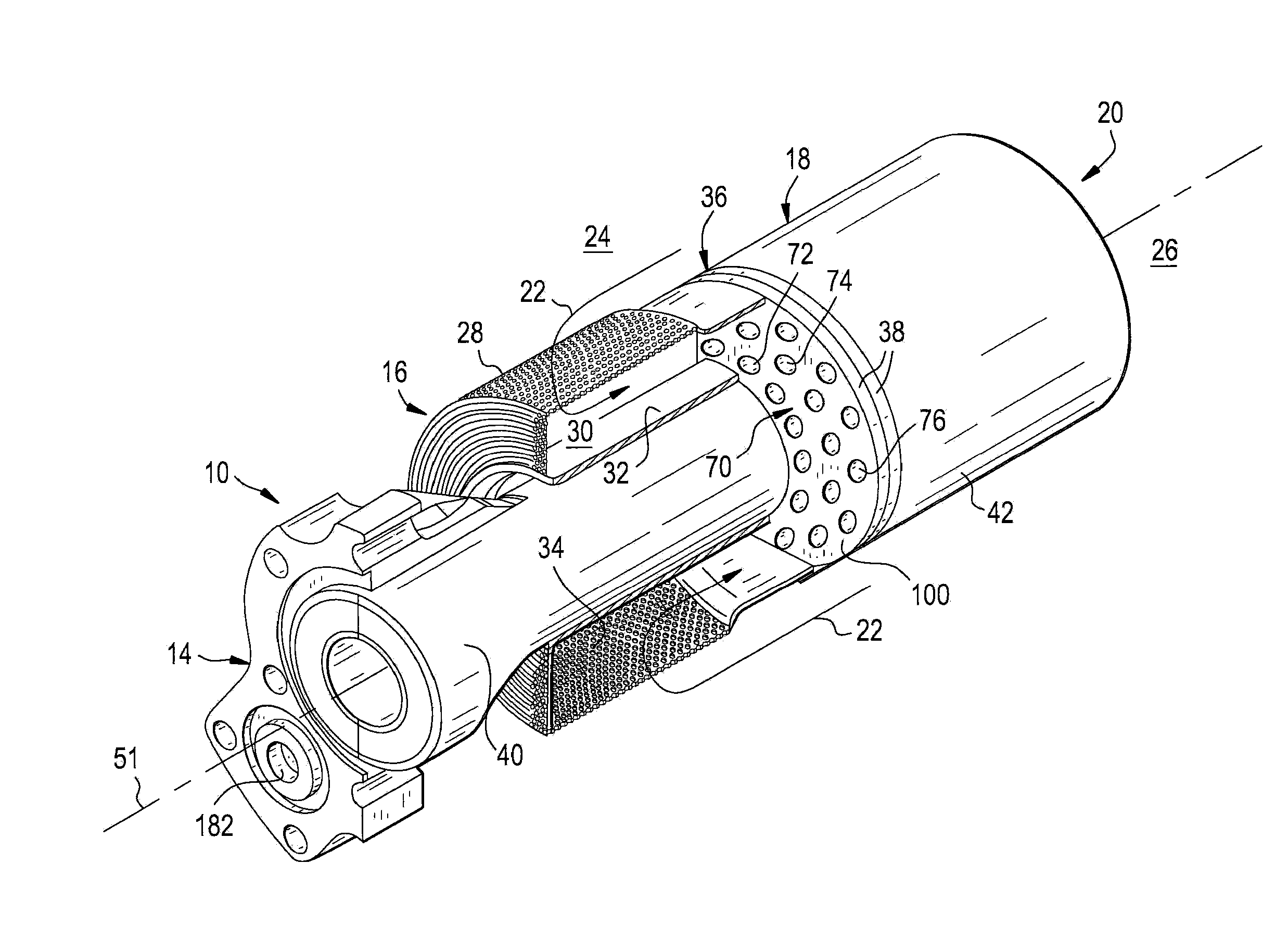

Method and apparatus for delivery of a fuel and combustion air mixture to a gas turbine engine using fuel distribution grooves in a manifold disk with discrete air passages

ActiveUS8234871B2Continuous combustion chamberTurbine/propulsion fuel supply systemsFuel distributionFuel supply

A nozzle has combustion air passages extending from a first, upstream end to a second, downstream end. A fuel distribution manifold is associated with the first, upstream end of the nozzle. Combustion air passages correspond to, and align with the air passages in the nozzle. Fuel distribution grooves are formed in one end of the fuel distribution manifold disk and extend from a central opening to the air passages. A fuel circuit cover closes the fuel distribution grooves to define fuel passages that extend from the central opening to the combustion air passages. A fuel supply conduit communicates with the central opening and the fuel passages for delivery of fuel to the combustion air in the air passages.

Owner:GENERAL ELECTRIC CO

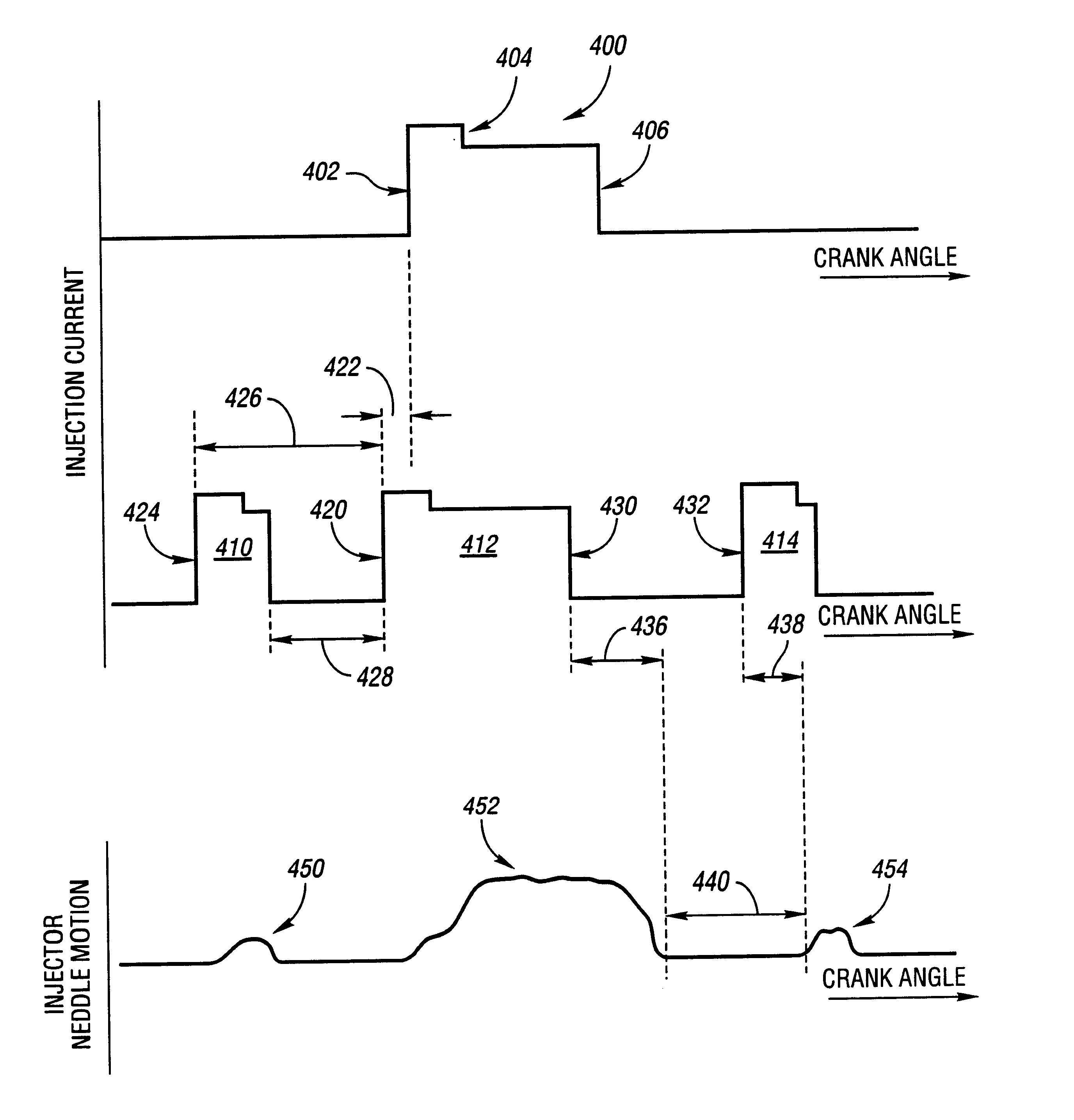

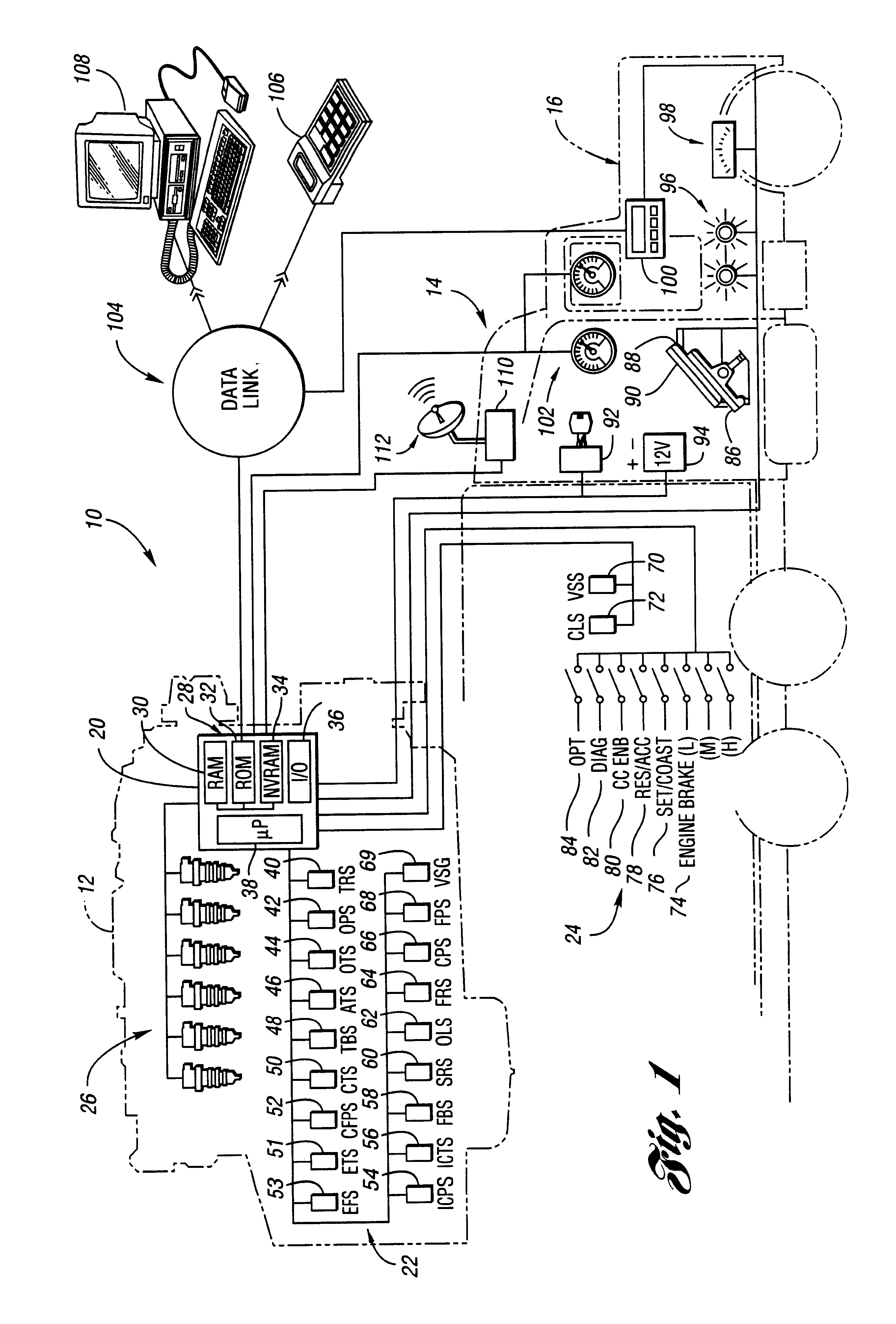

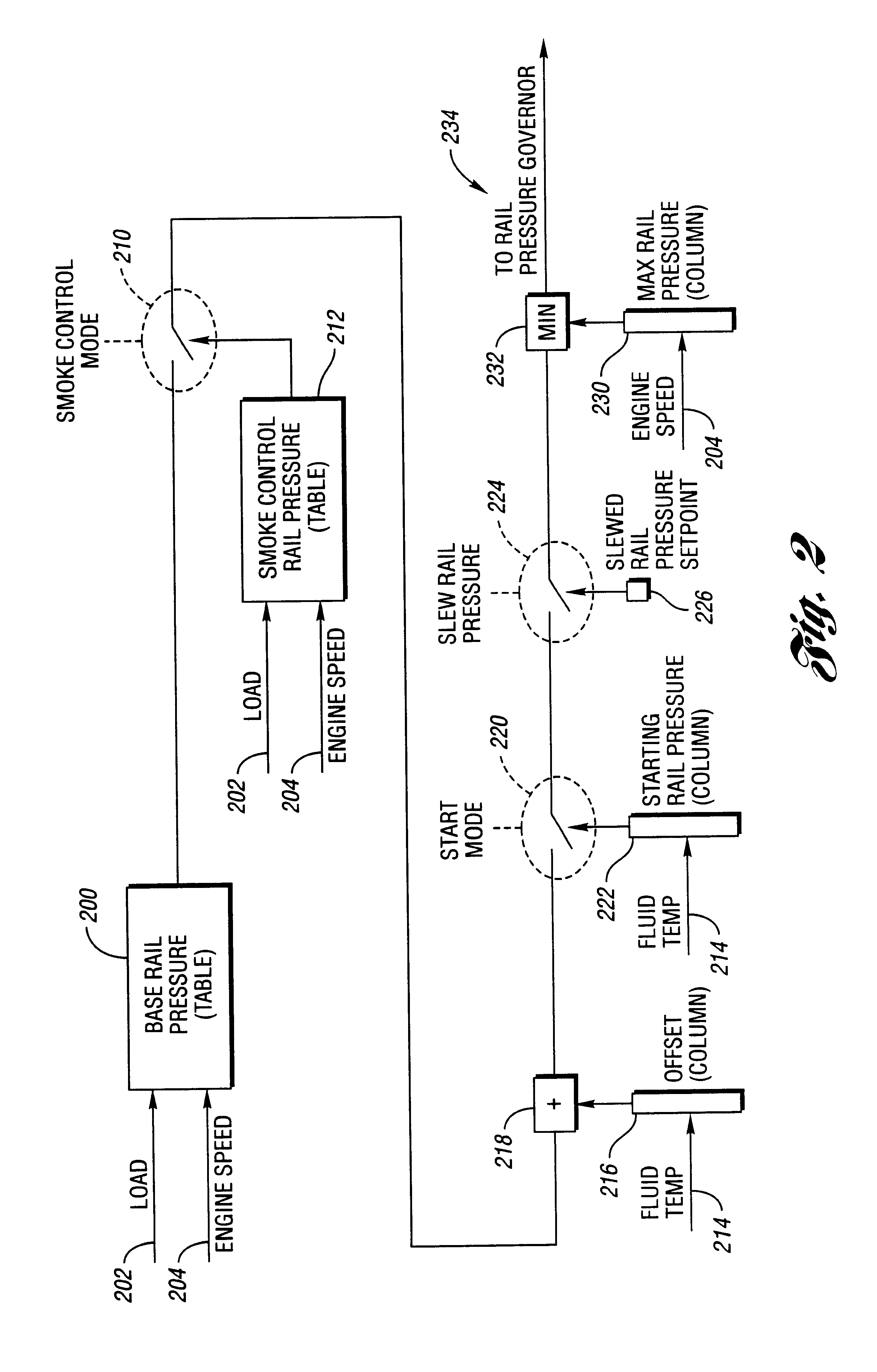

Injection control for a common rail fuel system

InactiveUS6848414B2Accurate injection controlEasy to controlElectrical controlInternal combustion piston enginesRail pressureFuel distribution

A system and method for controlling multiple fuel injections during a single combustion cycle for a multiple cylinder internal combustion engine having a common rail fuel distribution system determine the beginning of injection for the pilot and main injections based on crankshaft position while post injections are based on the main injection timing and an injector turn off delay determined using actual rail pressure. A rail pressure setpoint is determined based on current engine operating conditions including one or more fluid temperatures and current operating mode to provide more accurate injection control.

Owner:DETROIT DIESEL CORP

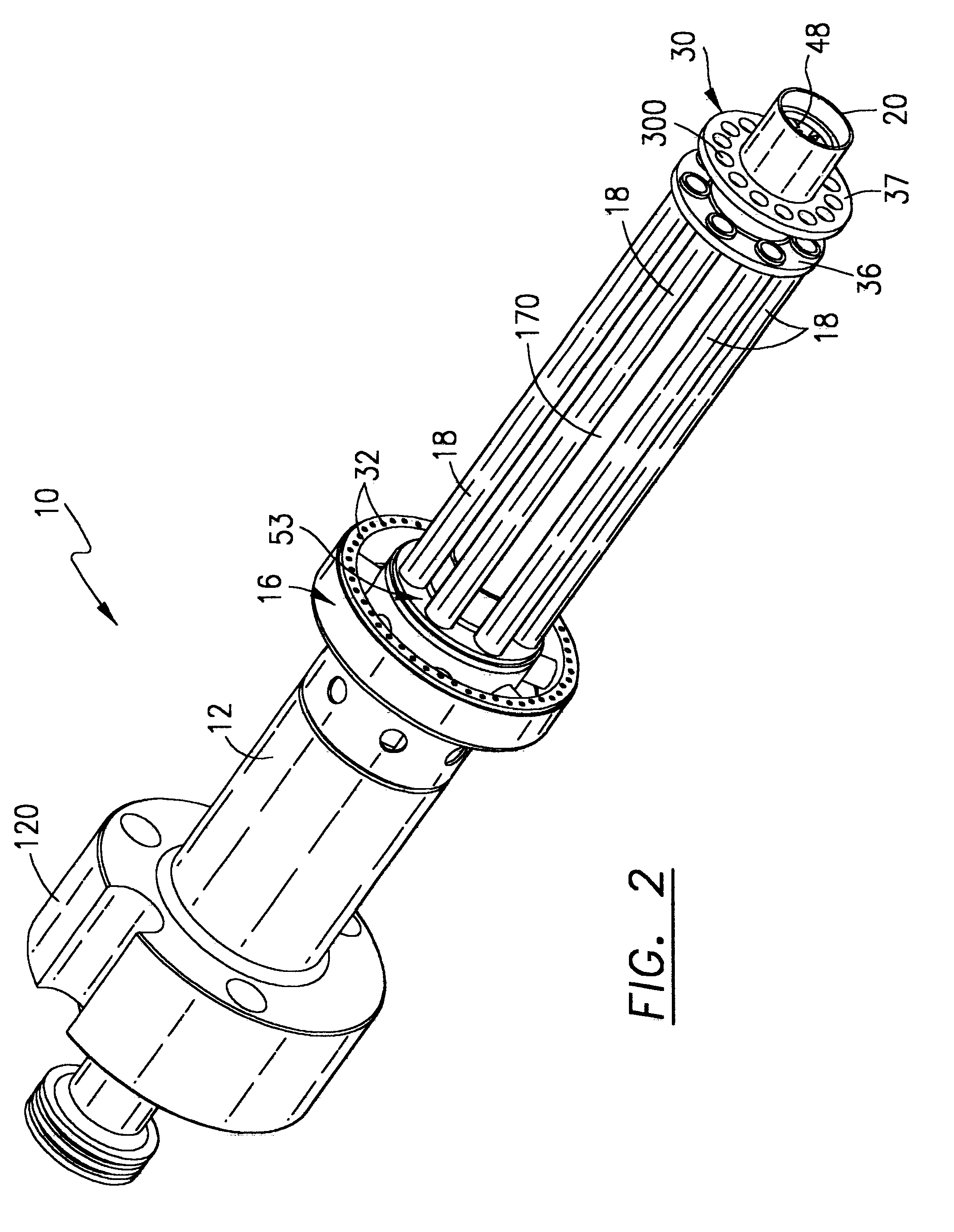

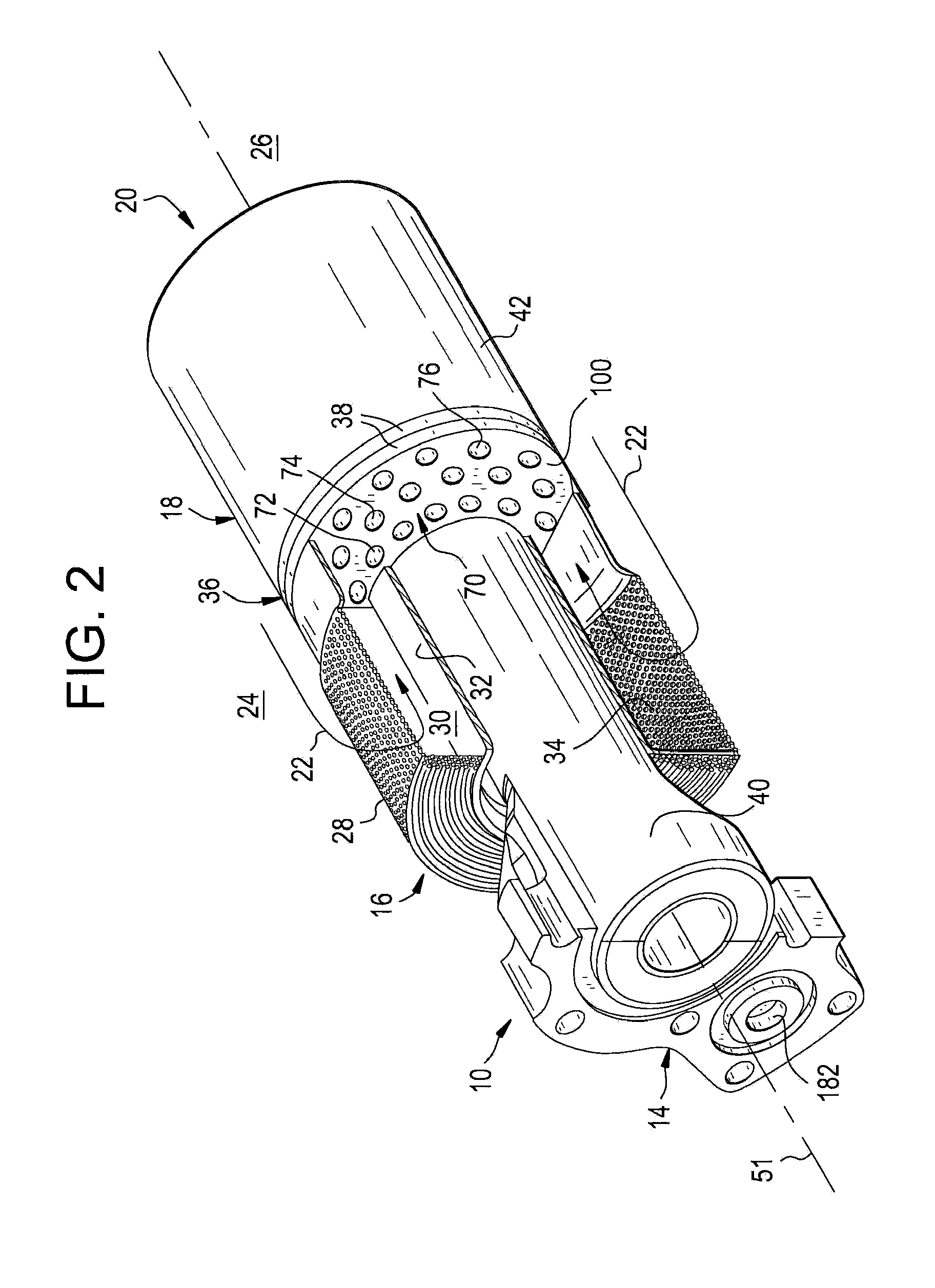

Integral flow sleeve and fuel injector assembly

InactiveUS20100018209A1Continuous combustion chamberTurbine/propulsion fuel supply systemsFuel distributionTurbine

A fuel injector assembly for use in a turbine engine having a combustion section and a turbine section downstream from the combustion section. The fuel injector assembly includes a flow sleeve defining a pre-mixing passage of the combustion section and including a sleeve wall having a forward end proximate to a cover plate of the combustion section and an opposed aft end. An annular cavity in fluid communication with a source of fuel is formed in the sleeve wall adjacent the aft end. A fuel dispensing structure is associated with the cavity and includes at least one fuel distribution aperture for distributing fuel from the cavity to the pre-mixing passage.

Owner:SIEMENS ENERGY INC

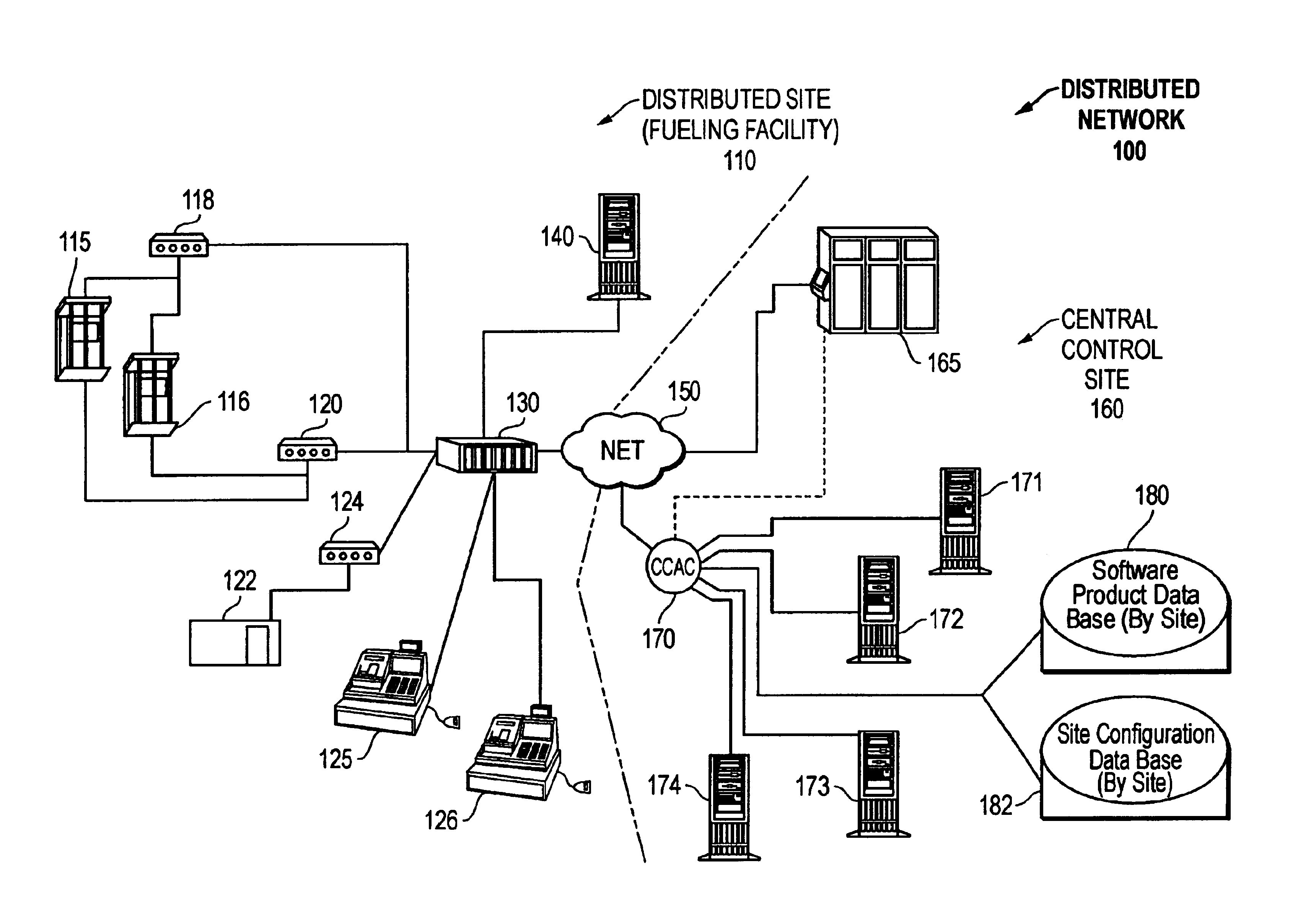

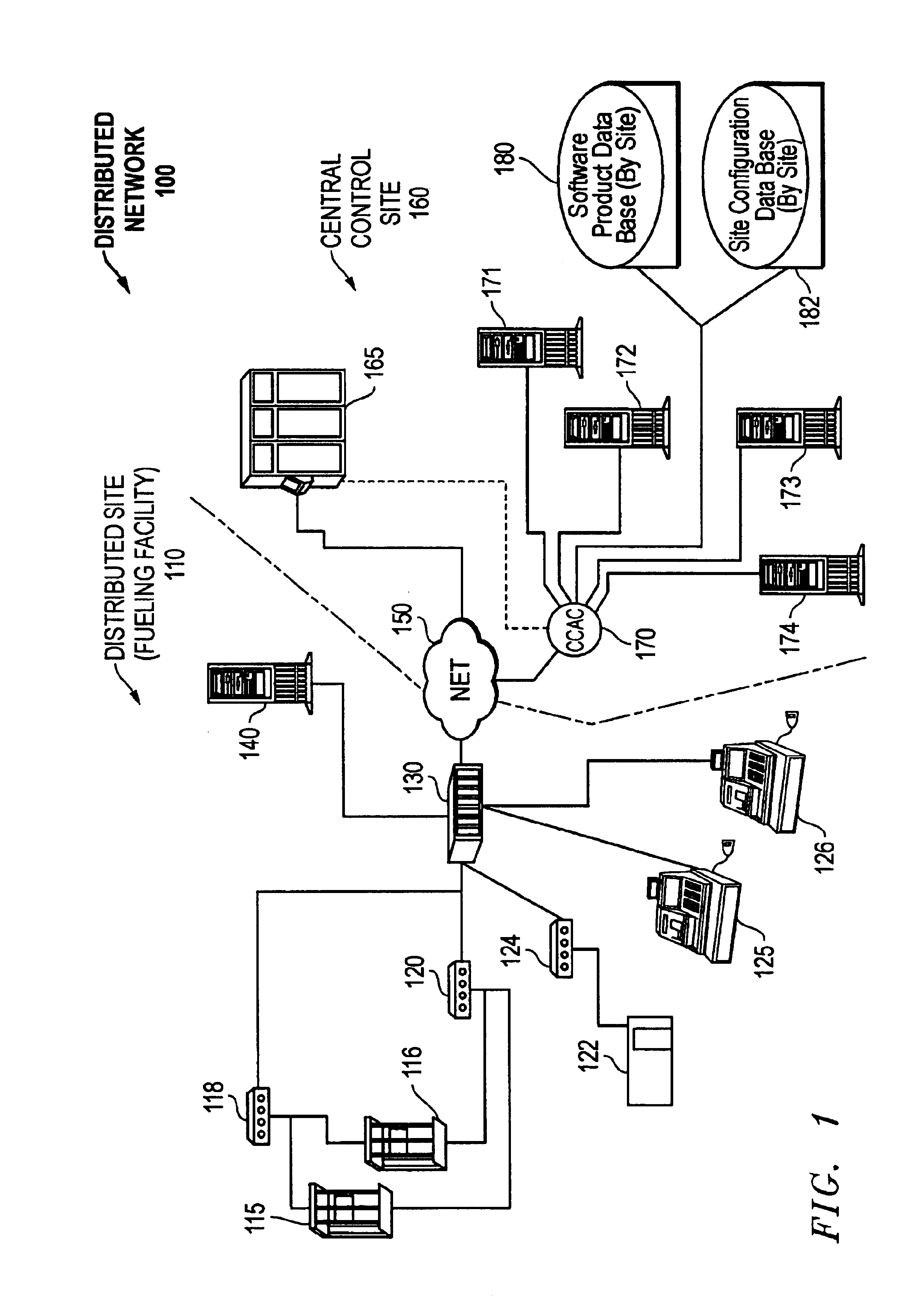

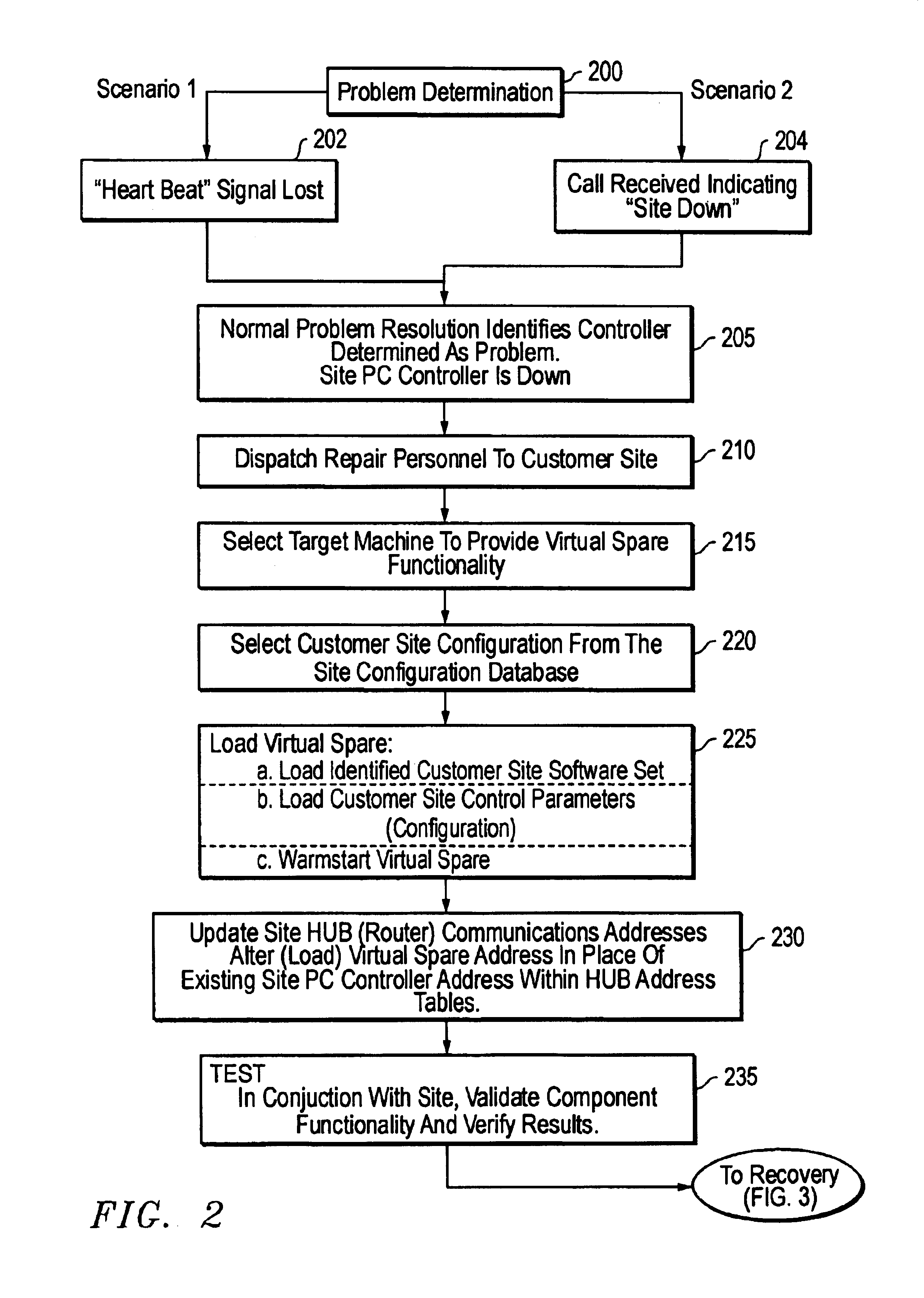

System and method for backing up distributed controllers in a data network

InactiveUS6725106B1Controlling coin-freed apparatusRecord information storageCredit cardInternet communication

A system and method for the rapid configuration and connection of a backup controller in a distributed data network such as an automated fuel distribution network. Each service-station site in the network has a site controller that supervises operations of the site components, such as the fuel dispenser and credit-card reader, communicating with them through an on-site router, or hub. The fuel-distribution site also communicates with the central network controller through the same hub. In the event of a site-controller outage, one of several spare controllers, usually co-located with the network controller, is loaded and configured to function as the site controller. It is then placed in communication with the site components via a data-network connection, such as through the Internet. The hub switches communications protocols from serial data to packets suitable for Internet communications.

Owner:RETAILSTACK LLC

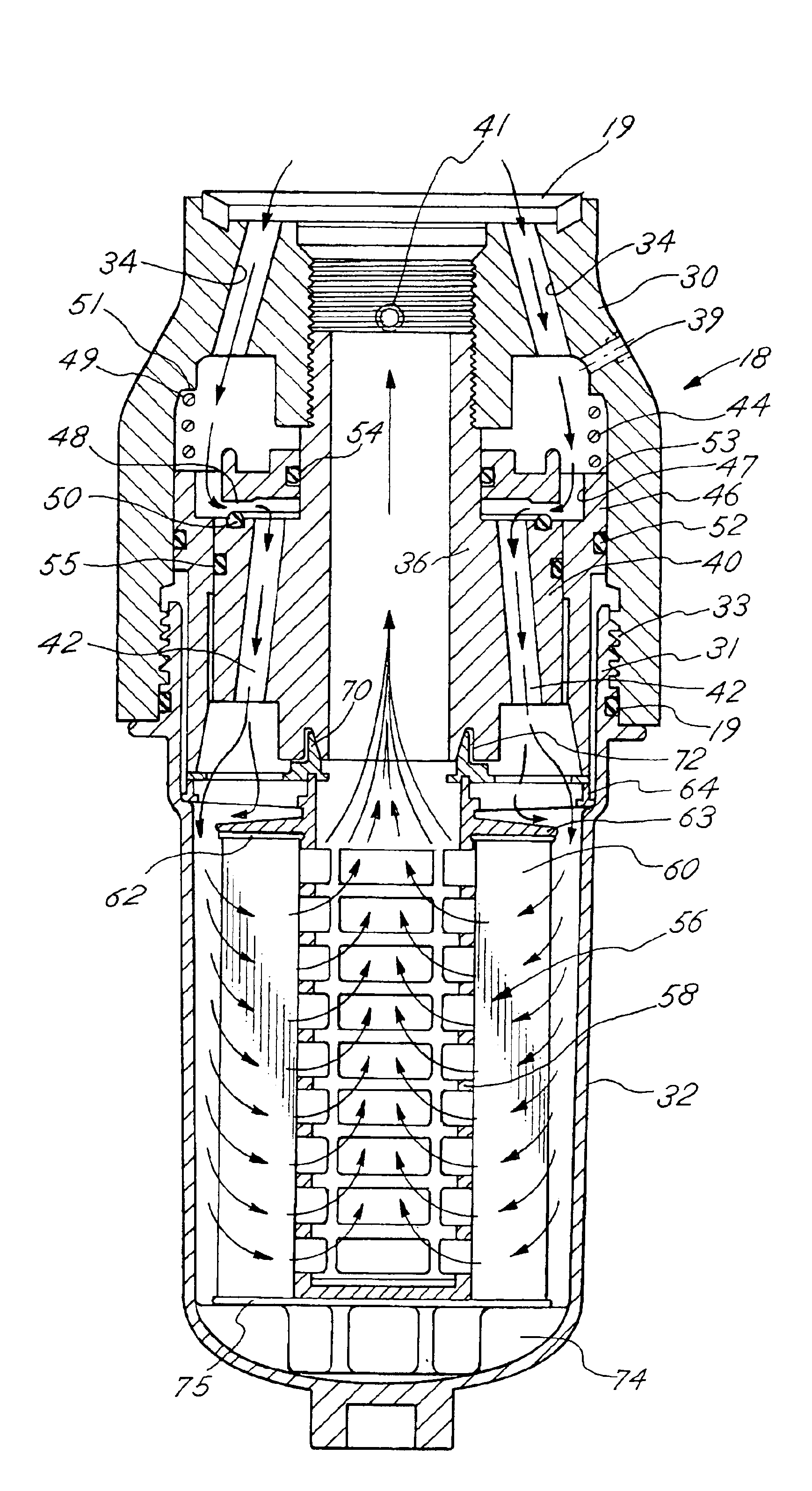

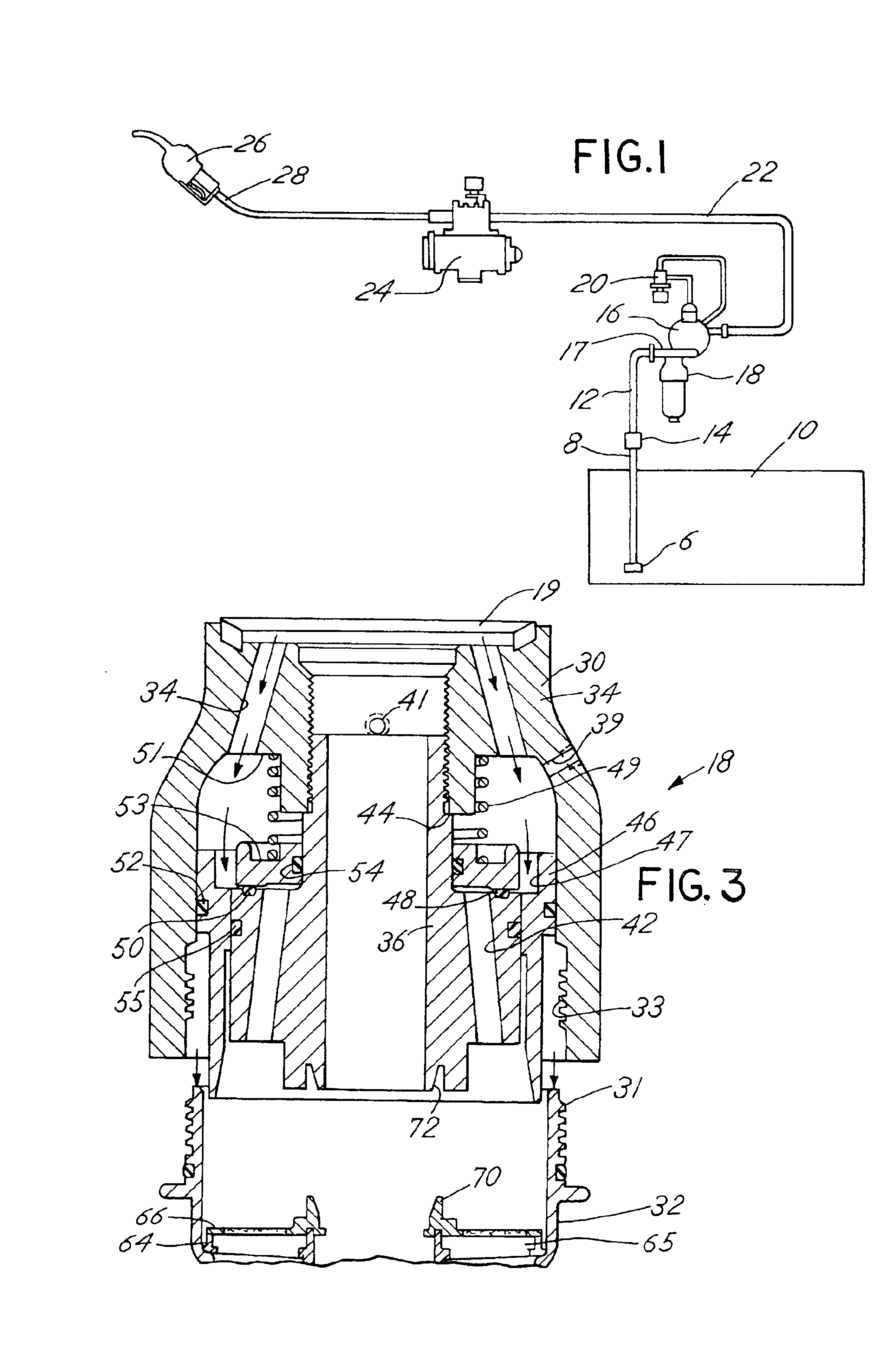

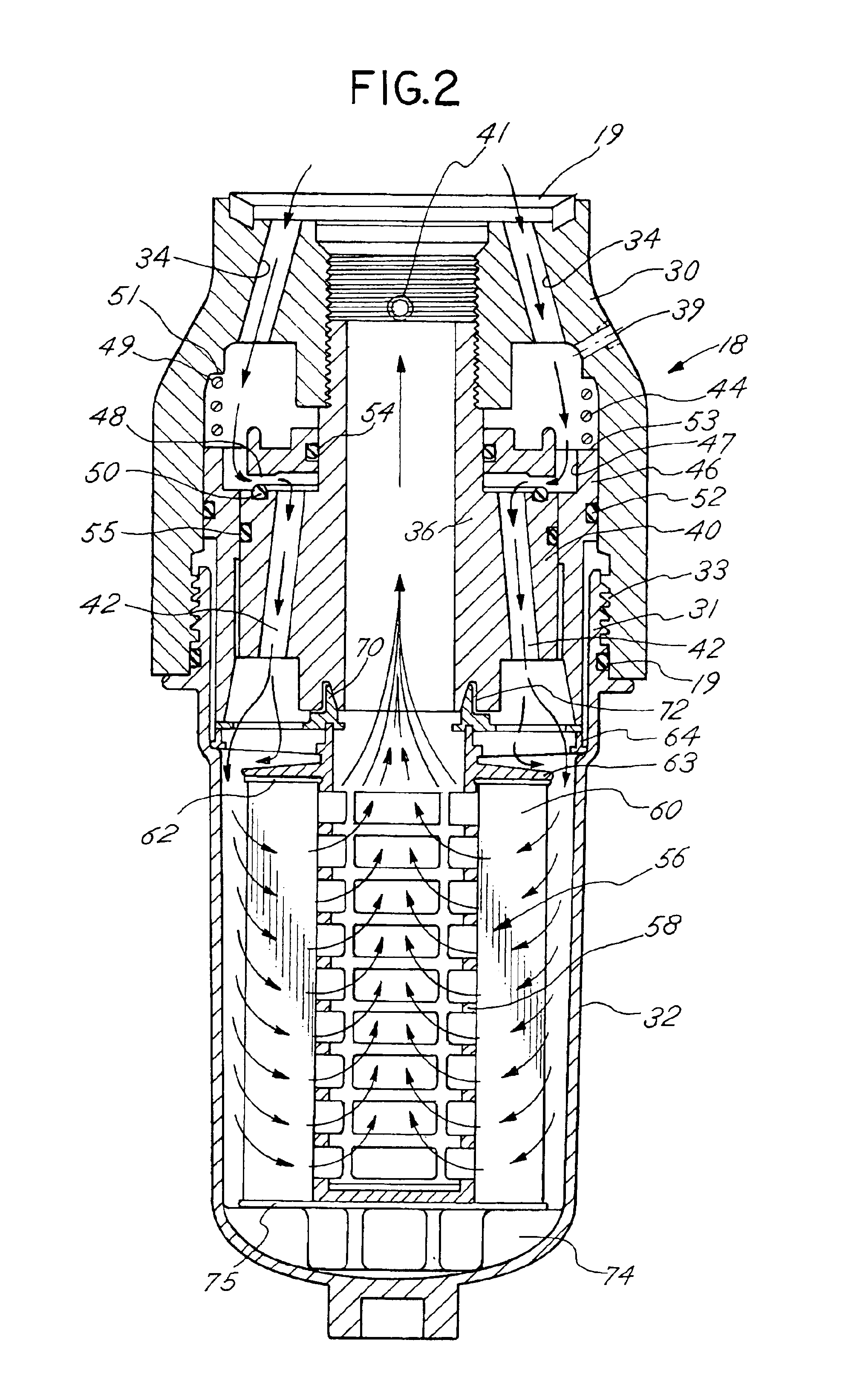

Fuel dispenser filter with removable filter media

InactiveUS6926827B2Reduce hazardous wasteReduce overflowIon-exchanger regenerationWater/sewage treatmentFuel distributionFilter media

A fuel dispenser filter for filtering fuel is adapted to be connected to a support in a fuel distribution system. The filter comprises a housing including an adaptor constructed and arranged to be secured to the support and a bowl operatively connected to the adaptor. A stud / spacer is secured in the adaptor. The stud / spacer defines a centrally disposed outlet flow passage and outwardly disposed inlet flow passages. A sleeve member is movably supported in the adaptor between the stud / spacer and the adaptor. The sleeve member is constructed and arranged to open and close the fuel flow through the inlet flow passages. A filter assembly including filter media is provided in the bowl for filtering the fuel passing through the filter. When the bowl is firmly engaged with the adaptor, the sleeve member is moved to open position to permit the flow of fuel through the filter and when the bowl is removed from the adaptor, the sleeve member is moved to a closed position to stop the flow of fuel. A spring is provided to bias the sleeve member to the closed position when the bowl is removed from the adaptor. Various seals are provided within the filter to confine fuel flow to the desired flow paths.

Owner:CHAMPION LAB

System and method for controlling fuel distributions in a combustor in a gas turbine engine

InactiveUS20150059348A1Continuous combustion chamberFlow control using electric meansCombustorFuel distribution

The present disclosure relates to a gas turbine engine system having a plurality of combustors, wherein a first combustor includes one or more fuel nozzles and one or more fuel injectors positioned downstream from the fuel nozzles. The gas turbine engine may also include a first valve disposed along a fuel delivery line between a fuel circuit and the first combustor to adjust a first flow of the fuel to the first combustor. The gas turbine engine may also include a second valve disposed along a fuel delivery line between the first valve and at least one of the one or more fuel injectors to adjust a second flow of the fuel to at least one of the one or more fuel injectors.

Owner:GENERAL ELECTRIC CO

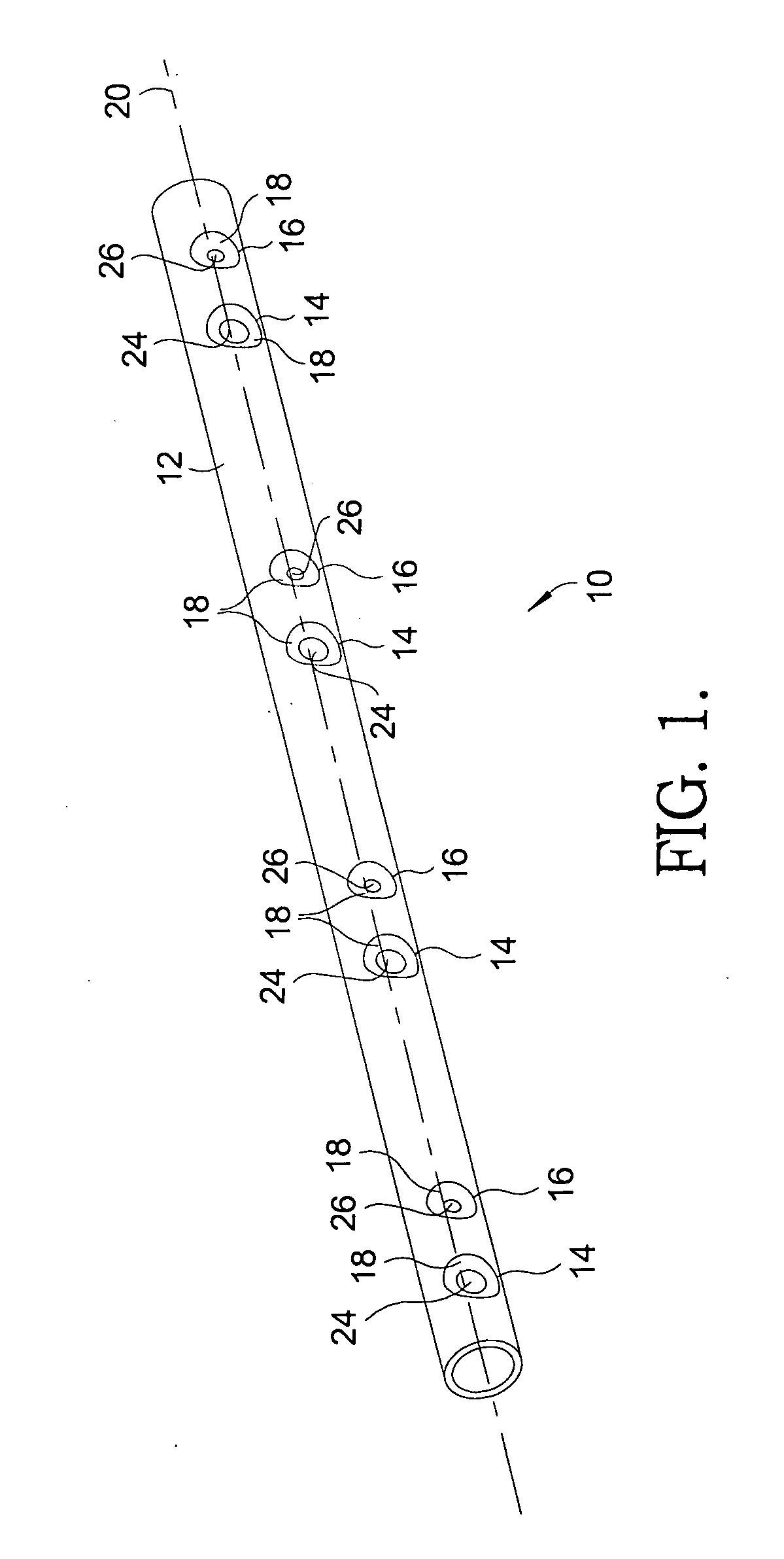

Fuel distribution tube for direct injection fuel rail assemblies

InactiveUS20090145504A1Eliminate needAccurate locationLow-pressure fuel injectionPipe elementsFuel distributionEngineering

A fuel distribution tube for a direct injection fuel rail assembly includes an elongate cylindrical conduit, a plurality of first scalloped features that receive fuel injector sockets formed in the conduit, and plurality of second scalloped features that receive mounting bosses formed in the conduit. The scalloped features are designed to closely match the outer radii of the injector sockets and the mounting bosses. The scalloped features provide necessary dimensional control to injector sockets and mounting bosses and fuel passage from the fuel distribution tube to the fuel injector sockets. The scalloped features enable a leak test of the braze joints of the fuel rail assembly. By providing a direct injection fuel rail assembly that includes the fuel distribution tube having scalloped features formed in the conduit, optimization of true position location of fuel injector sockets and improved braze joints are enabled.

Owner:DELPHI TECH INC

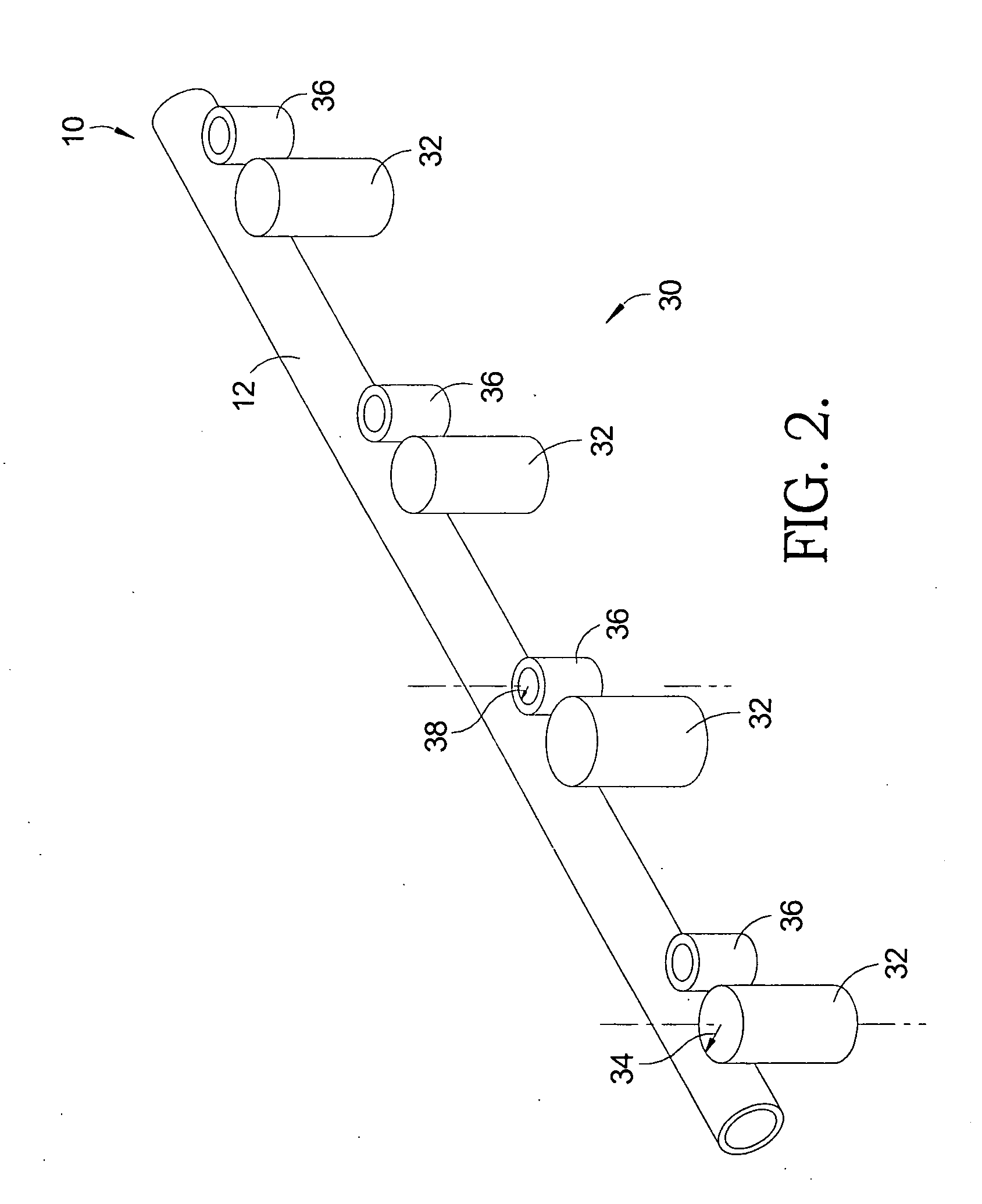

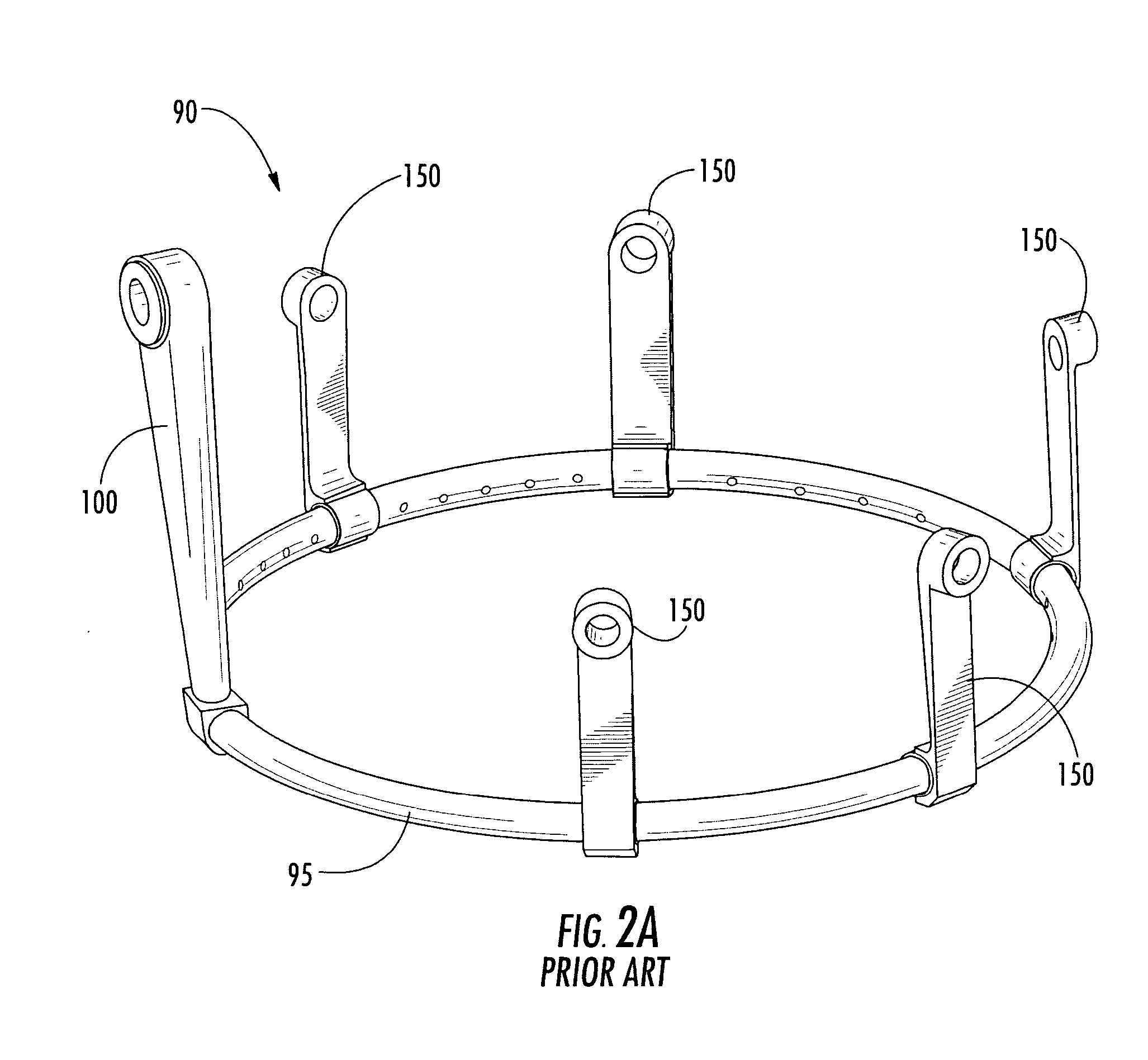

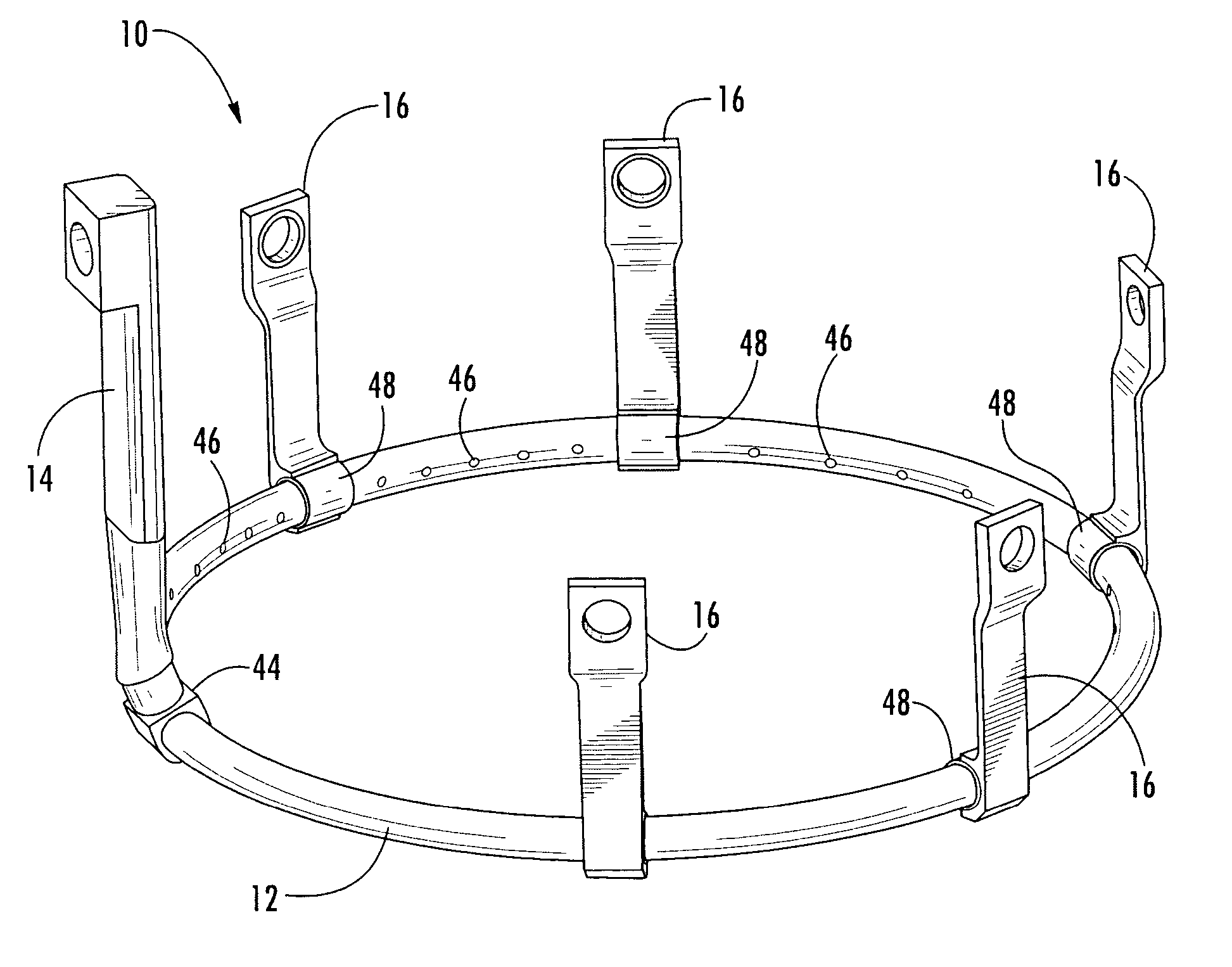

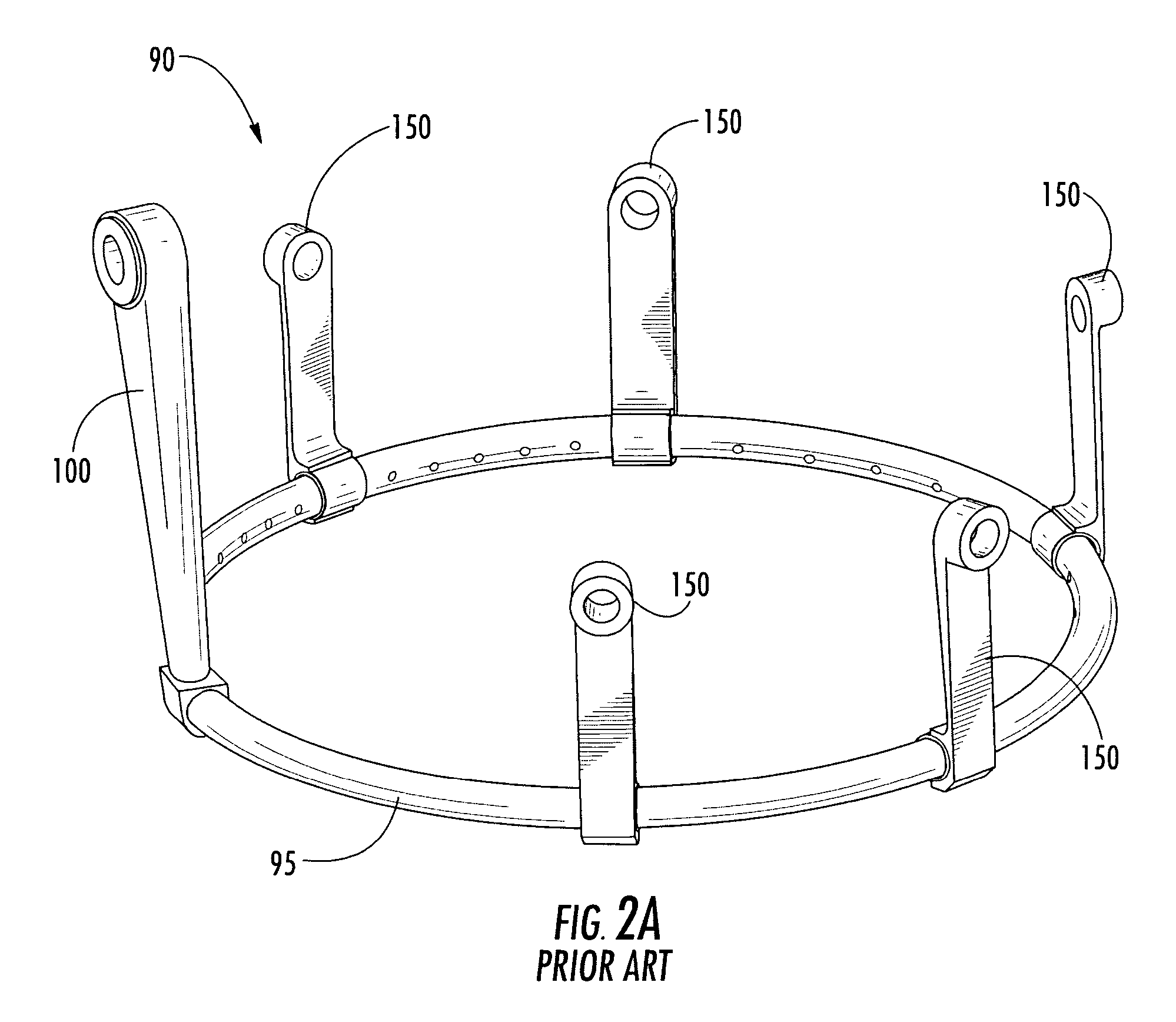

Turbine fuel ring assembly

ActiveUS20050039457A1Continuous combustion chamberTurbine/propulsion fuel flow conduitsThermal dilatationFuel distribution

A turbine fuel ring assembly includes a fuel distribution ring, at least one fuel supply tube attached to the fuel distribution ring and at least one attachment leg connected to the fuel distribution ring. The fuel ring has a hollow interior and a plurality of apertures for expelling a fluid. The attachment leg is configured to allow flexibility due to thermal expansion induced under certain load conditions such as during engine start-up or shut-down. Further, the configuration of the attachment legs provides improved stress distribution characteristics. The fuel supply tube includes a rectangular passage and a round passage that are disposed substantially transverse to each other and in fluid communication with each other and with the hollow interior of the fuel distribution ring. The rectangular passage and the round passage have substantially identical cross-sectional areas. The fuel supply tube is configured to avoid structural interferences with neighboring components.

Owner:SIEMENS ENERGY INC

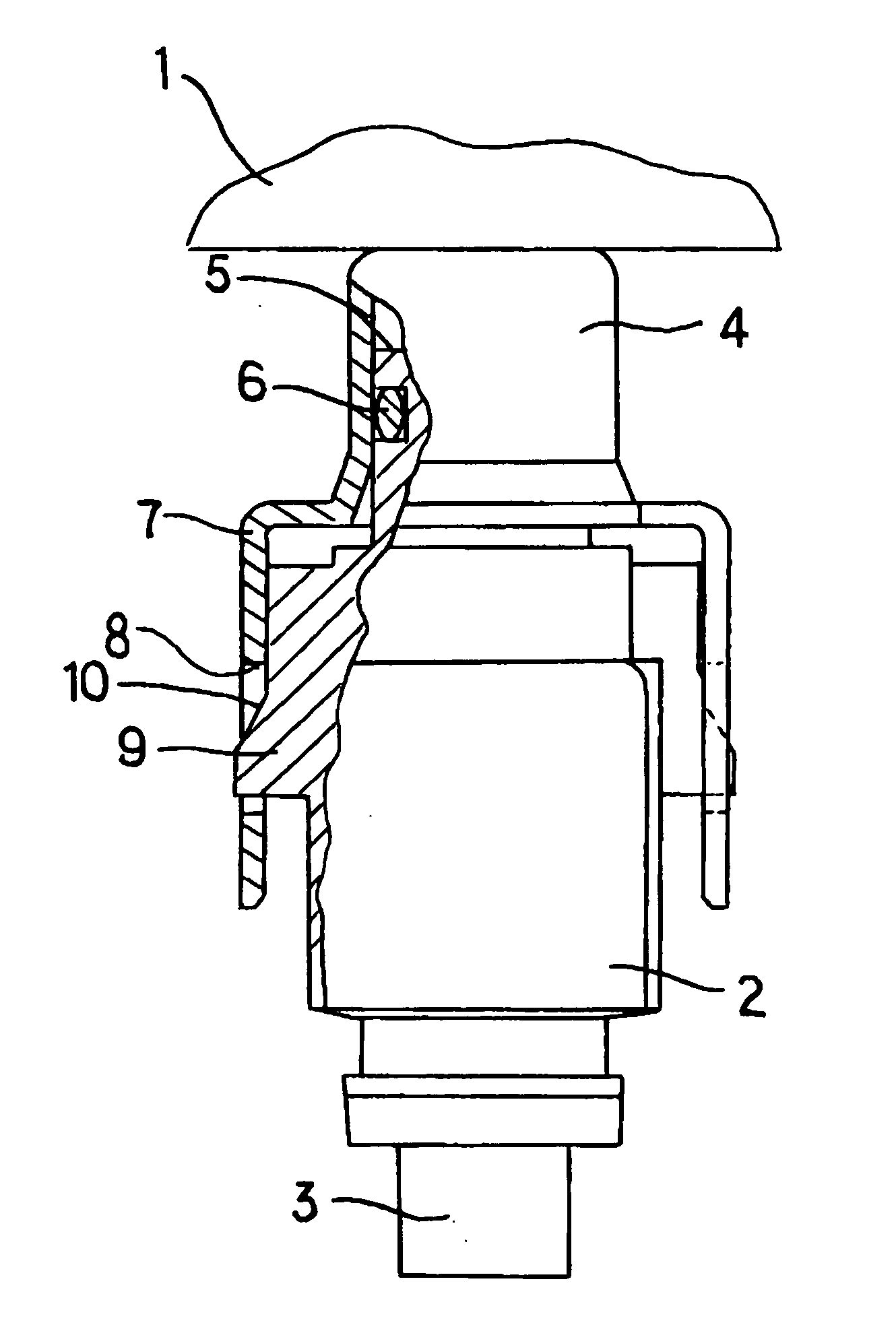

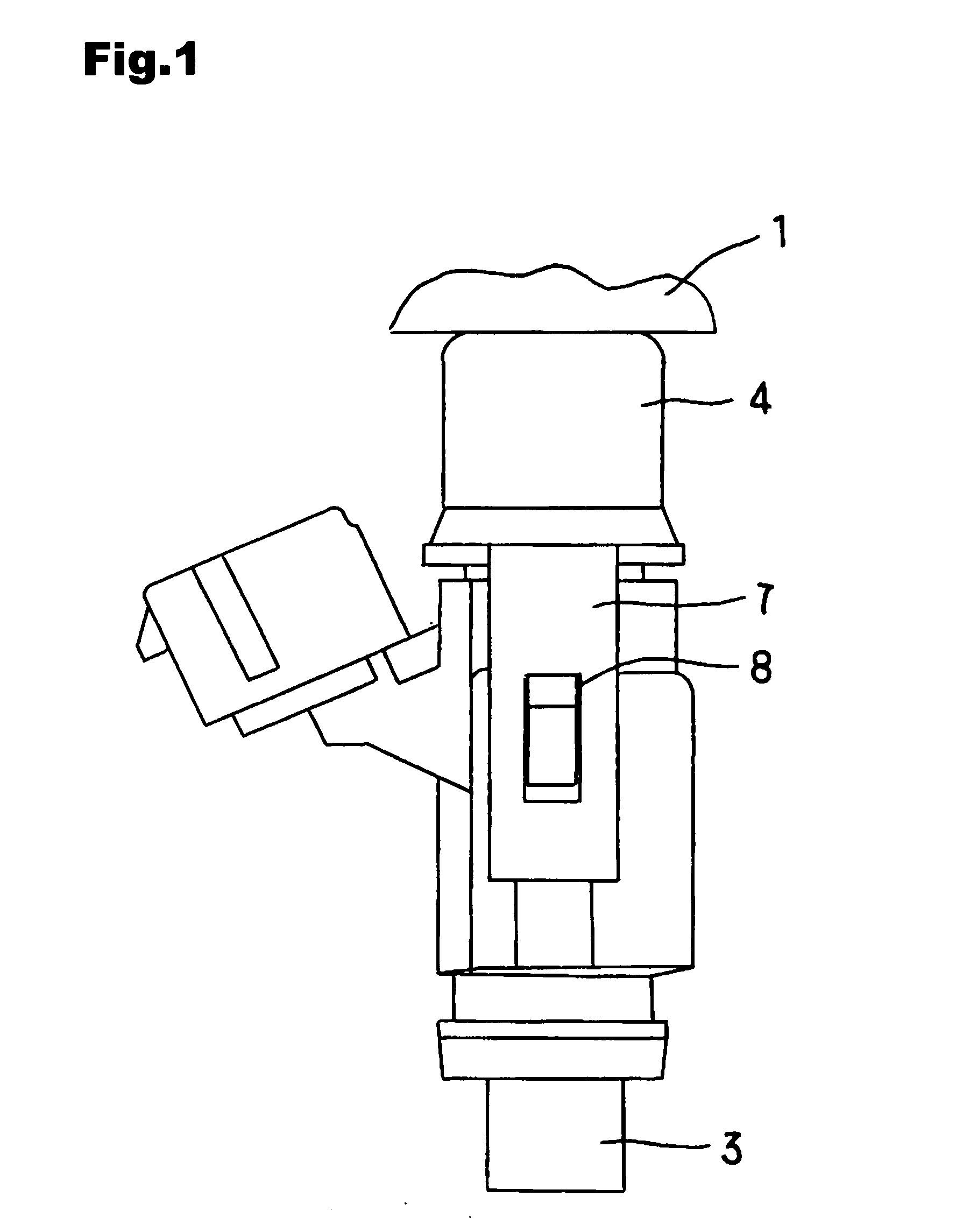

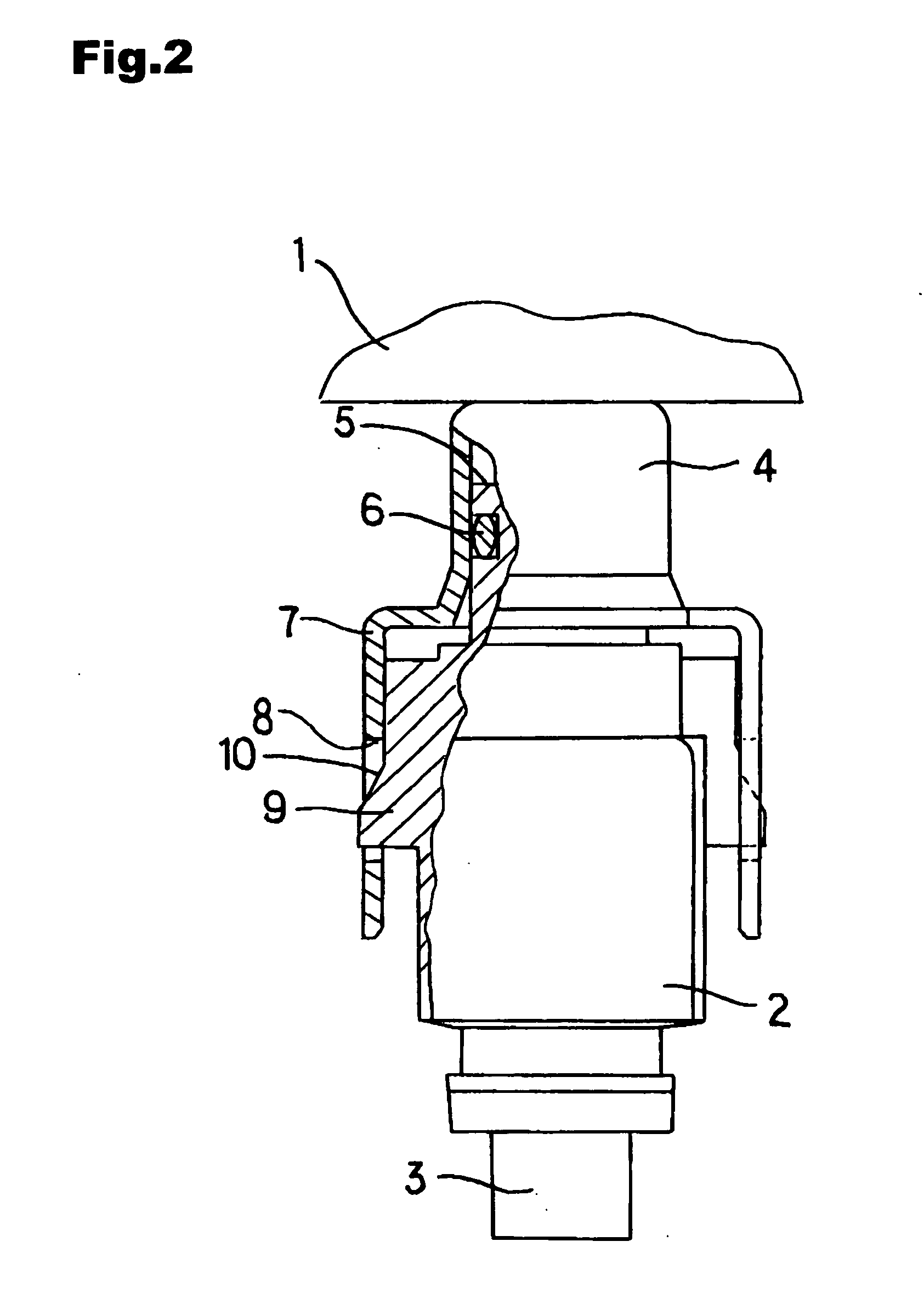

Fuel injection device

InactiveUS20040237939A1Low pressure fuel injectionMachines/enginesExternal combustion engineBand shape

Any specific member for fixation is omitted from a fuel injection device so that number of parts is reduced and the fuel injection device is constructed at a reasonable cost. The fuel injection device for use in an internal combustion engine is provided with a fuel distribution pipe 1, plural connecting pipe members 4, and plural fuel injection valves 2, and each of the fuel injection valves 2 is inserted into a connecting pipe member 4. A band-shaped protrusion 7 extends in the radial direction from a flange portion of the connecting pipe member 4 and further extends in parallel to the axis of the fuel injection valve 2. The band-shaped protrusion 7 is provided with a fitting hole 8, and each fuel injection valve 2 is provided with a protrusion 9 fitted into the fitting hole 8.

Owner:MITSUBISHI ELECTRIC CORP

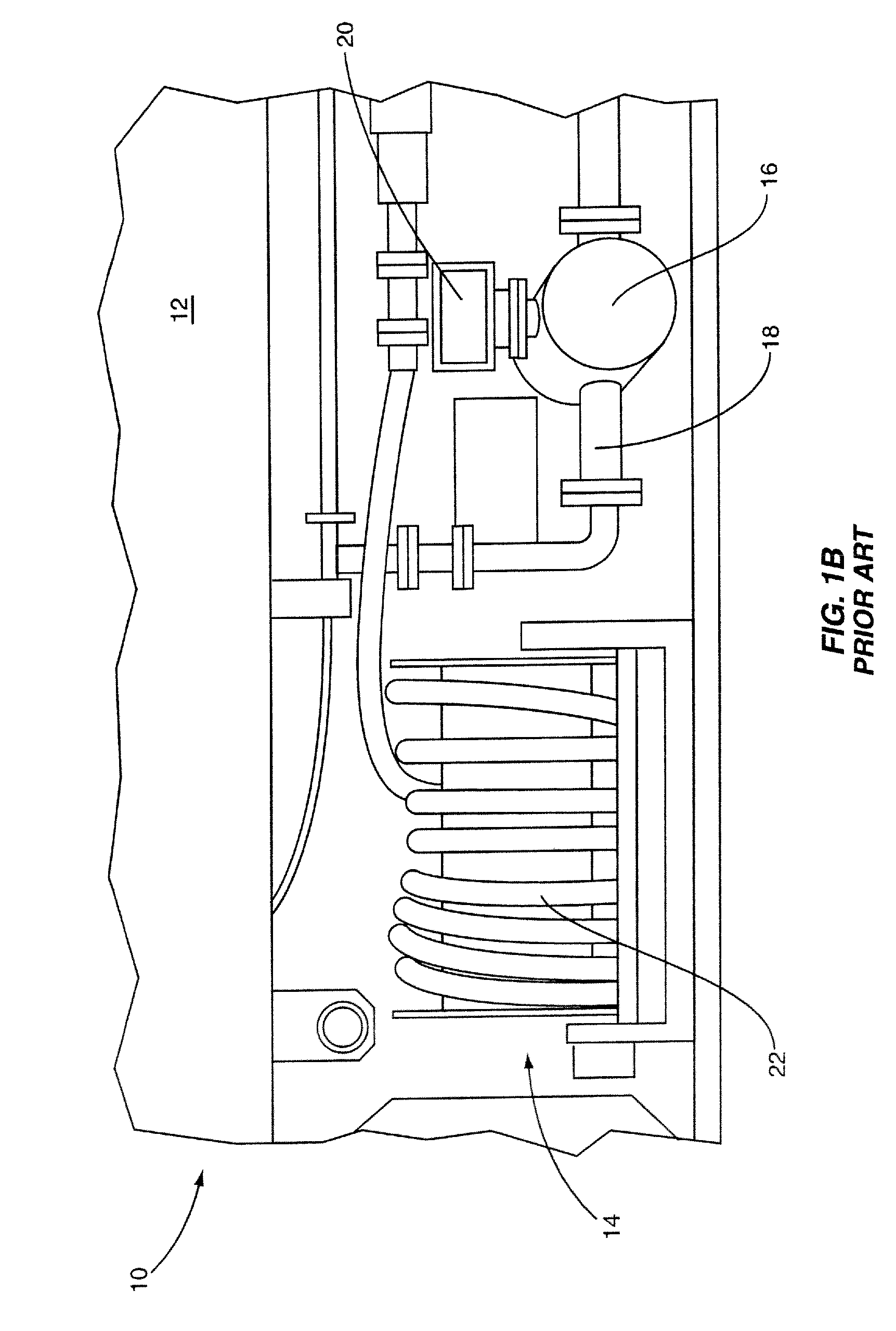

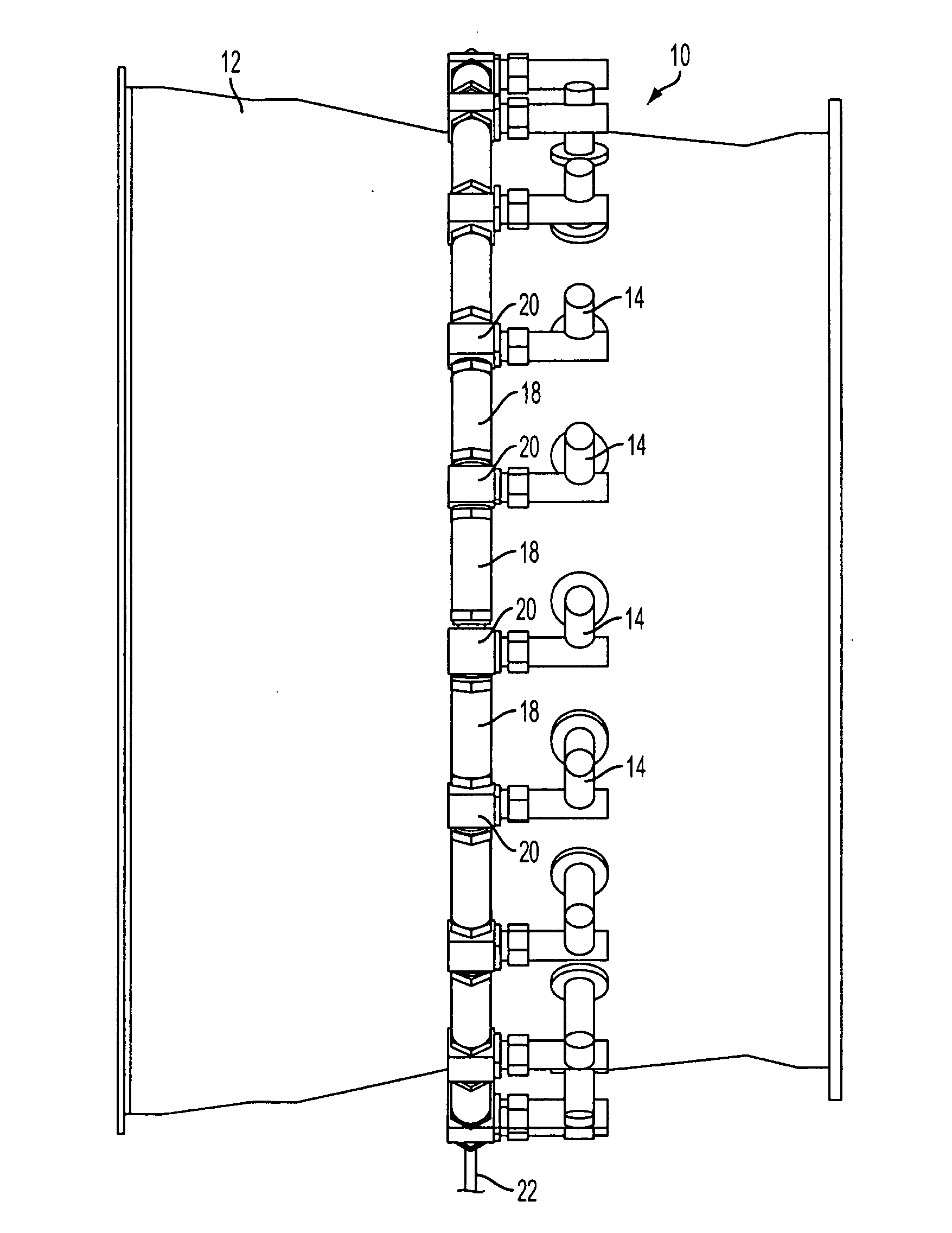

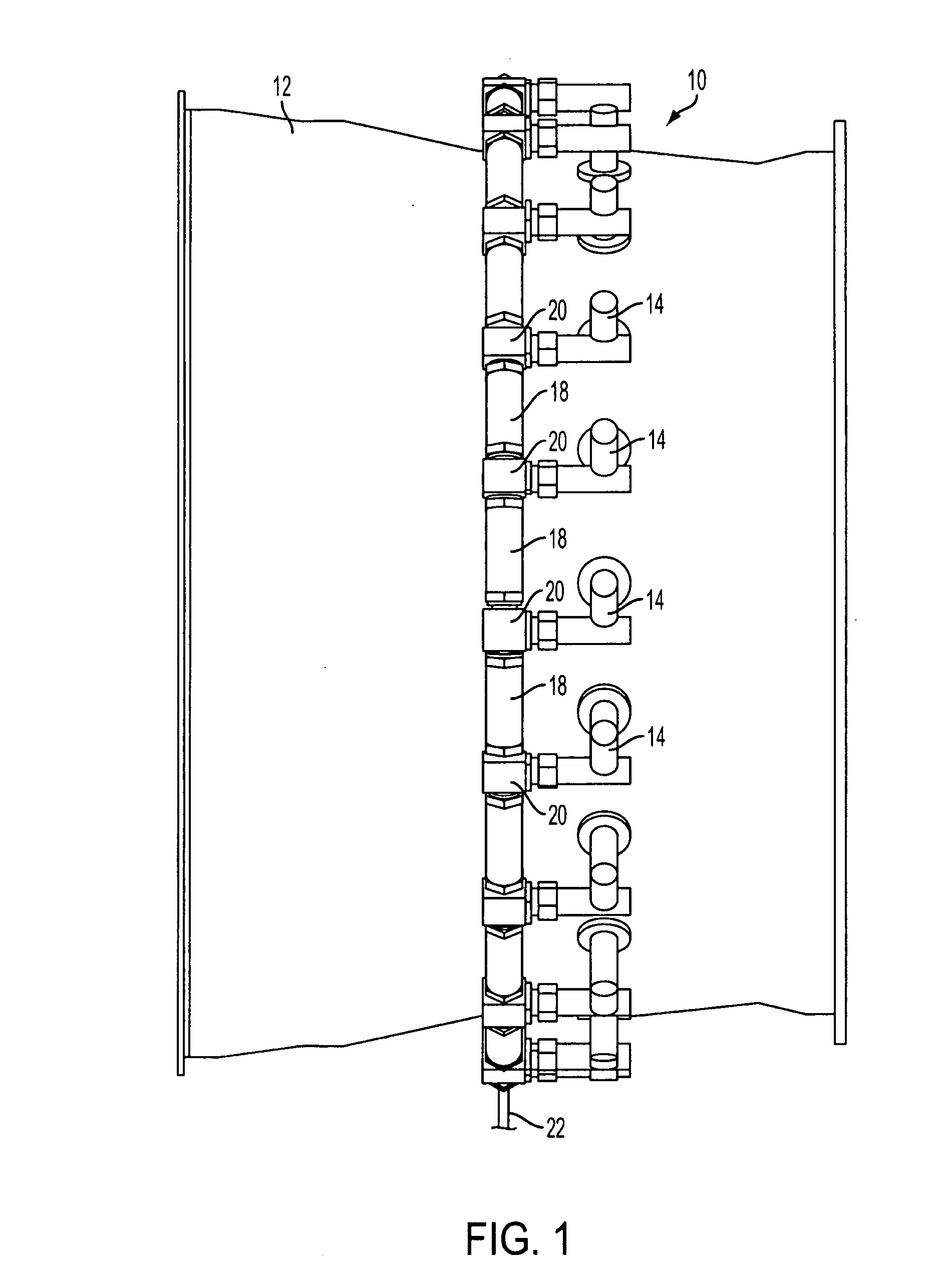

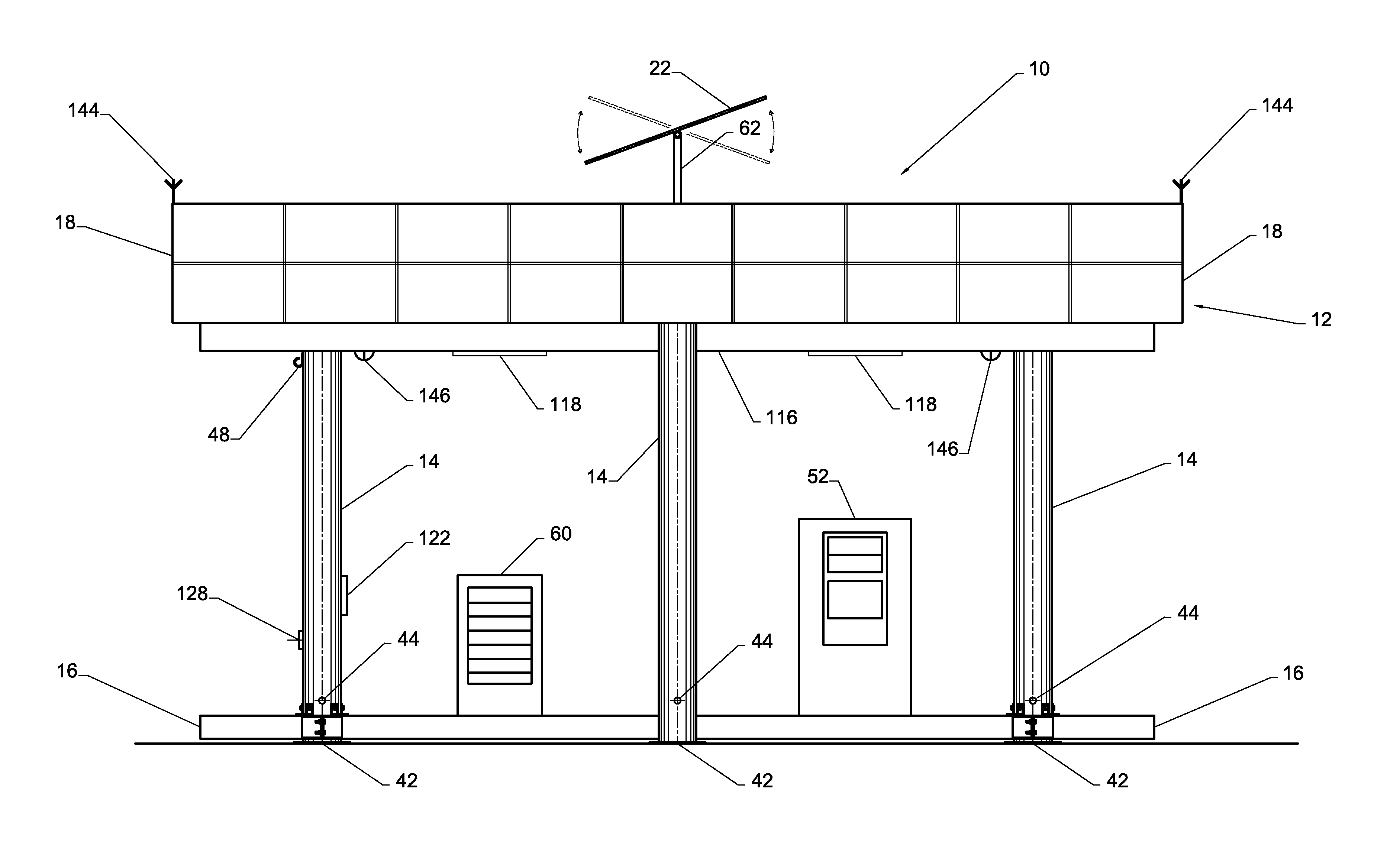

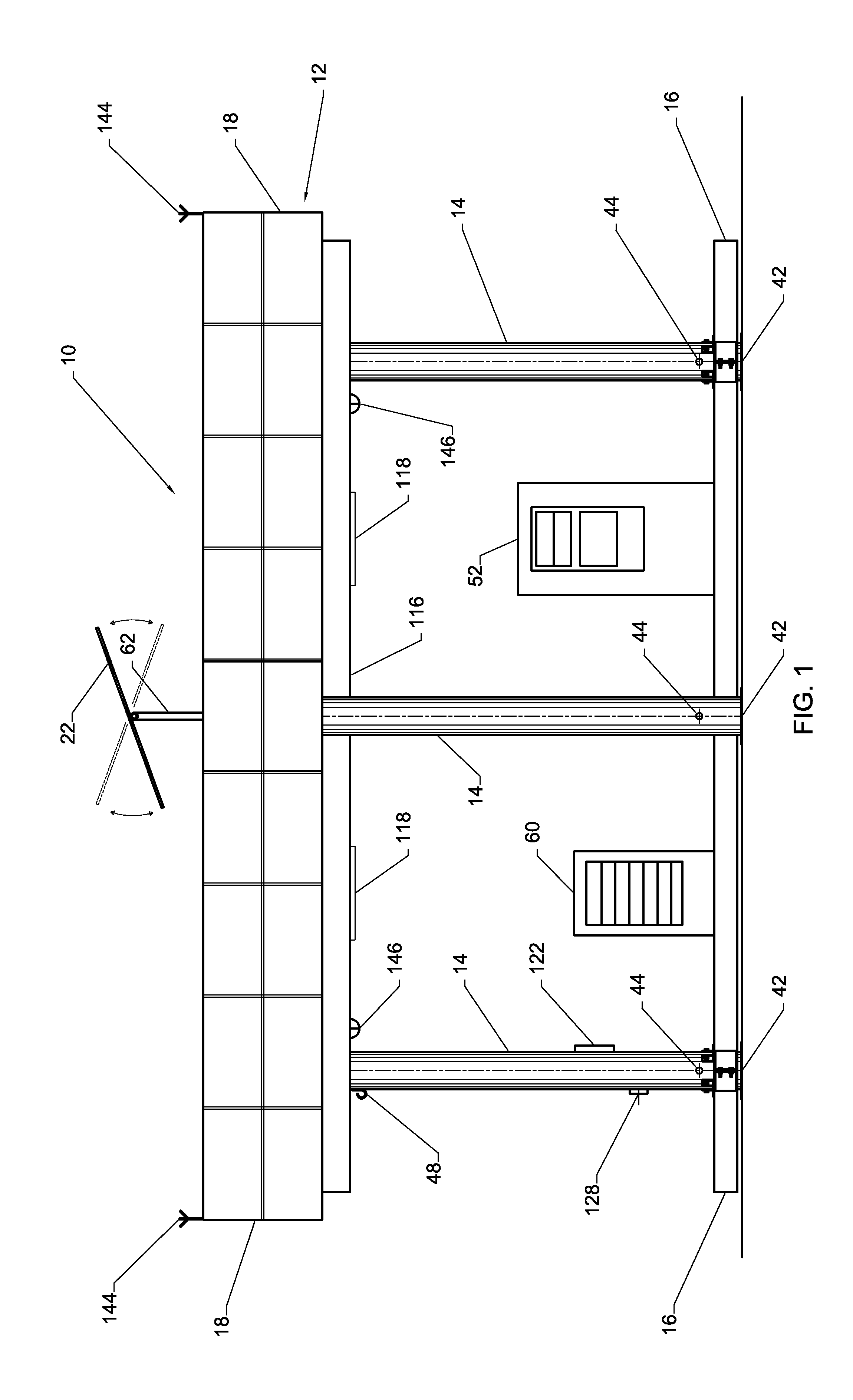

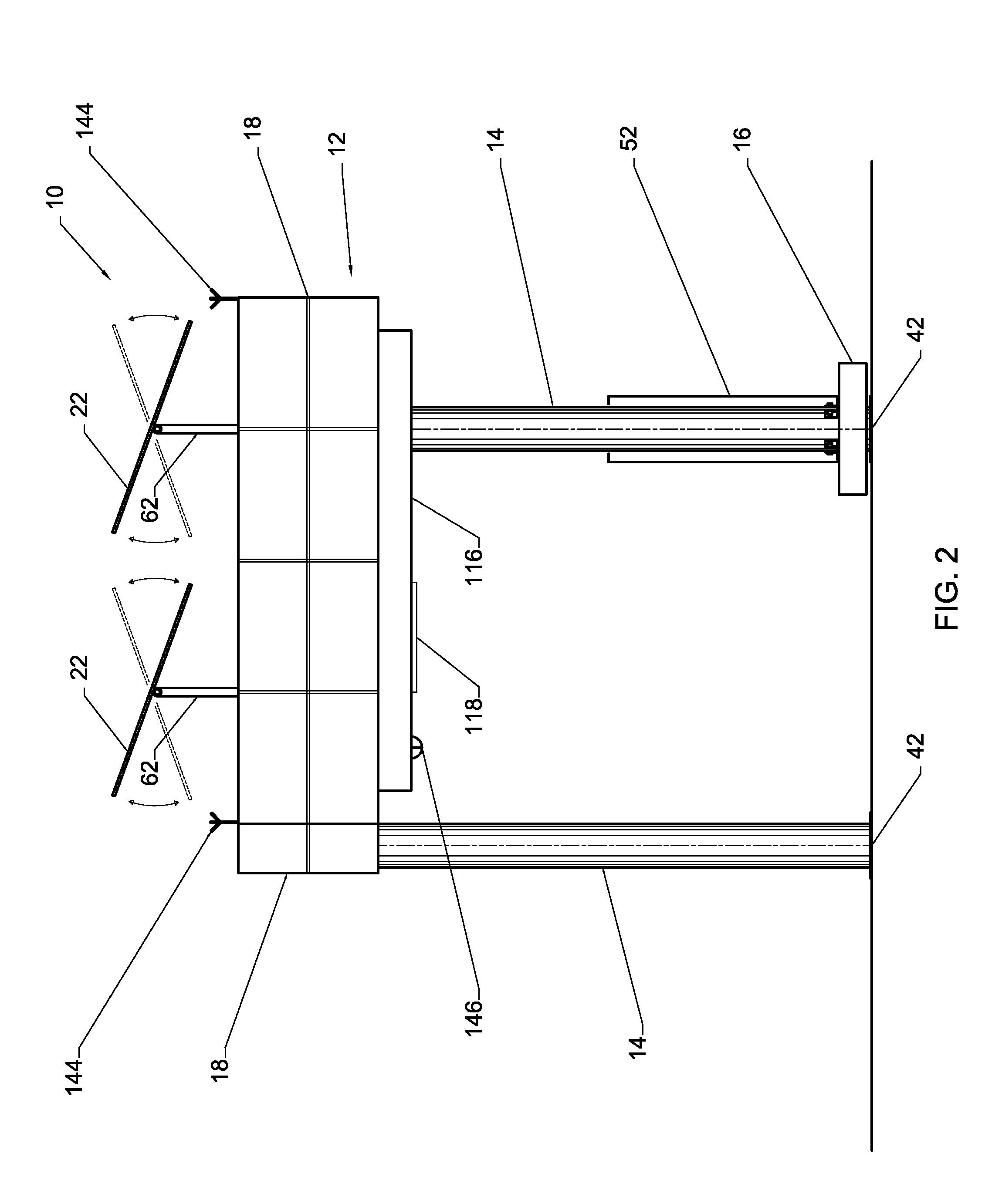

Mobile fuel distribution system

ActiveUS8573242B2Quick installationMinimal spaceWatering devicesVehicle cleaning apparatusAbove groundSolar generator

A modular, environmentally friendly mobile fuel distribution station includes a fuel tank, a support structure having a plurality of legs for supporting an operation platform in an elevated position a predetermined distance above ground, an alternative power generation device, the alternative power generation device being one of a solar power generator and a wind power generator for providing primary power to the mobile fuel distribution station and a central platform operatively connected to at least two of the legs, the at least two of the legs bearing the weight of the central platform, wherein the fuel tank and the alternative power generation device are disposed on the operation platform.

Owner:CAPAT LLC

Turbine fuel ring assembly

ActiveUS7249461B2Continuous combustion chamberTurbine/propulsion fuel flow conduitsStress distributionFuel distribution

A turbine fuel ring assembly includes a fuel distribution ring, at least one fuel supply tube attached to the fuel distribution ring and at least one attachment leg connected to the fuel distribution ring. The fuel ring has a hollow interior and a plurality of apertures for expelling a fluid. The attachment leg is configured to allow flexibility due to thermal expansion induced under certain load conditions such as during engine start-up or shut-down. Further, the configuration of the attachment legs provides improved stress distribution characteristics. The fuel supply tube includes a rectangular passage and a round passage that are disposed substantially transverse to each other and in fluid communication with each other and with the hollow interior of the fuel distribution ring. The rectangular passage and the round passage have substantially identical cross-sectional areas. The fuel supply tube is configured to avoid structural interferences with neighboring components.

Owner:SIEMENS ENERGY INC

Fuel mixer apparatus and method

An apparatus to deliver a fuel into a chamber is provided. In one embodiment, the apparatus includes a fuel inlet and a substantially circular fuel distribution canal communicating with the fuel inlet. A biasing element is coupled to the substantially circular fuel distribution canal, with the biasing element having a plurality of slots arranged to non-uniformly dispense the fuel into the chamber. Another embodiment includes a flange positioned in the substantially circular fuel canal, with the flange structured to perturb a fuel passing into the chamber. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:OMNITEK ENG

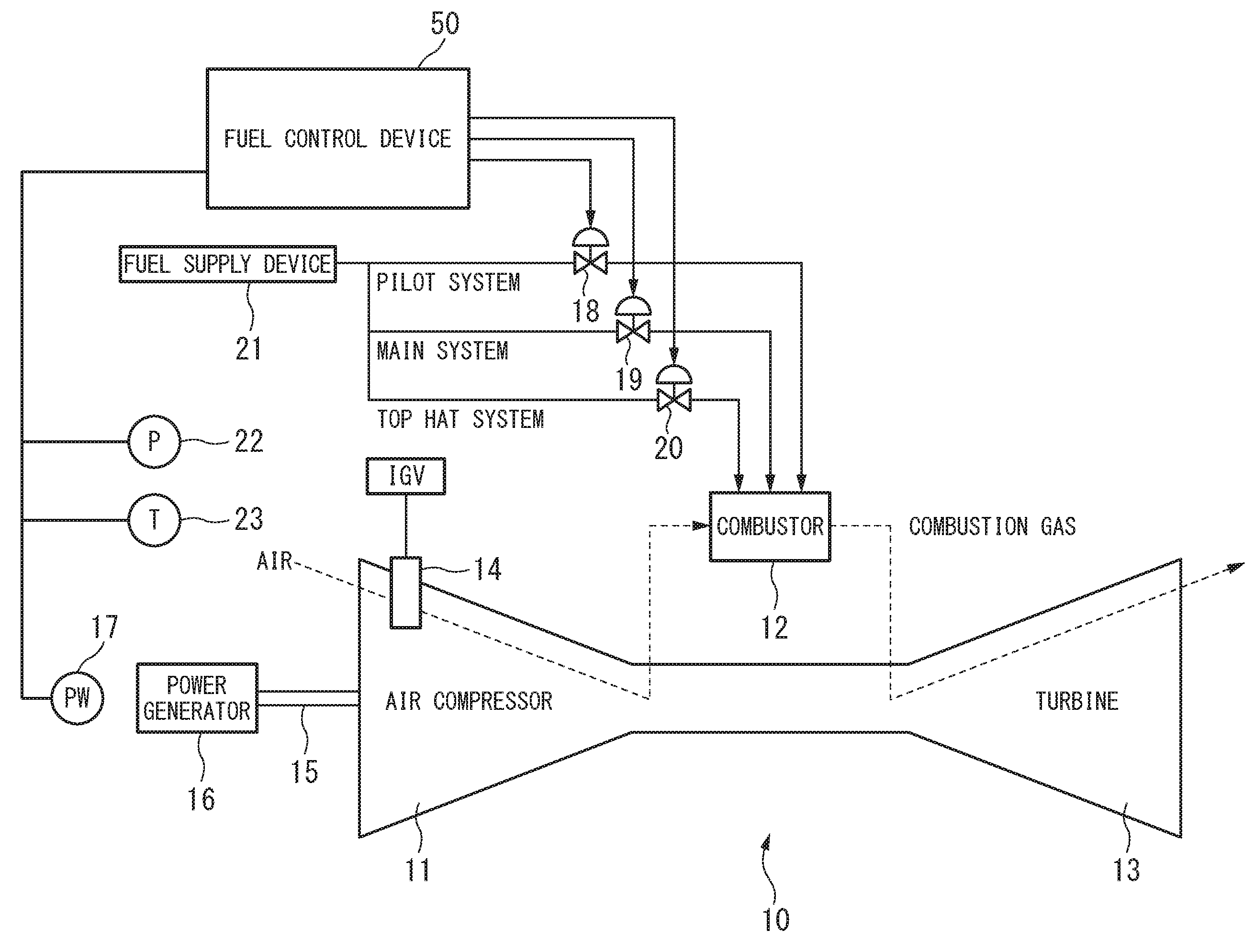

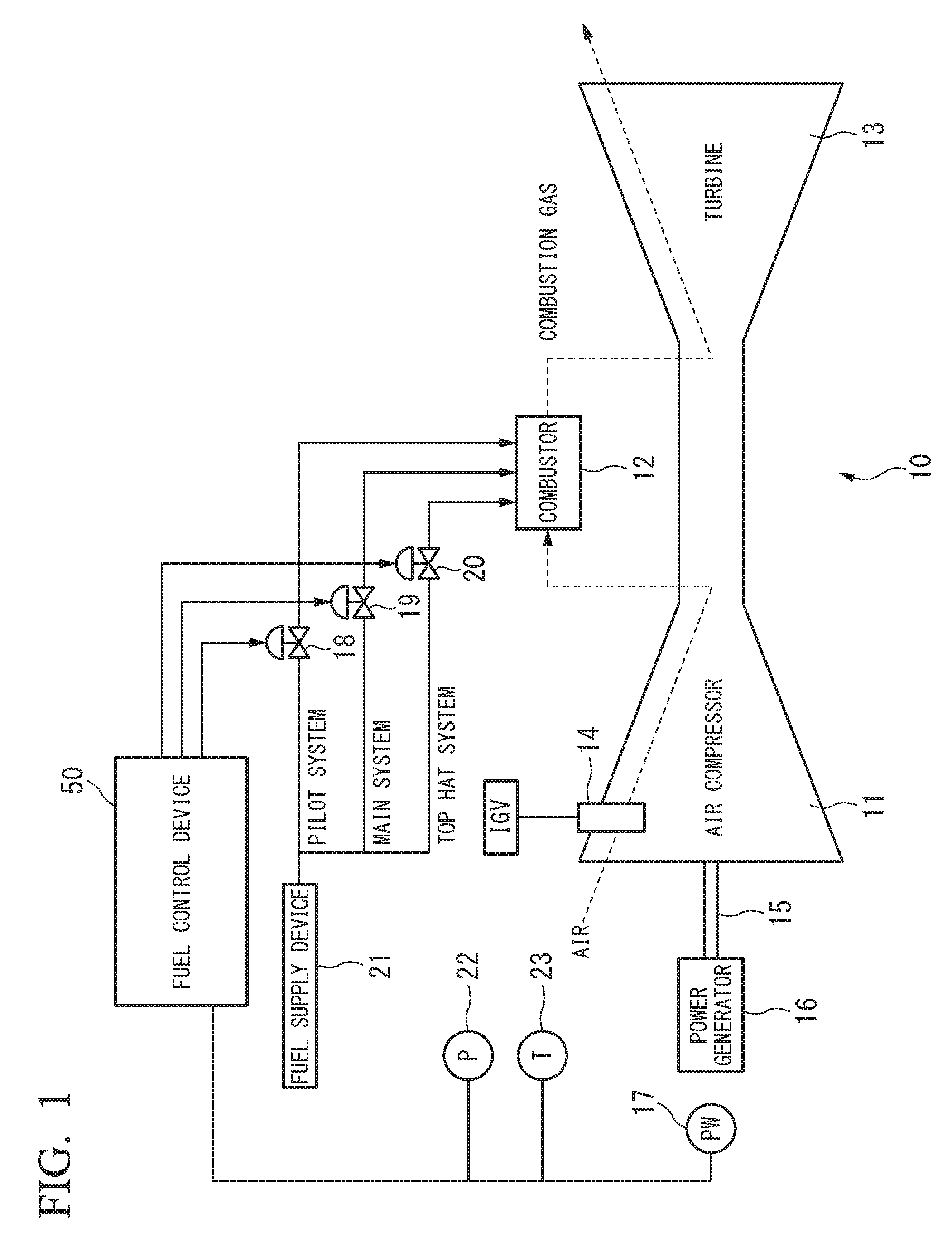

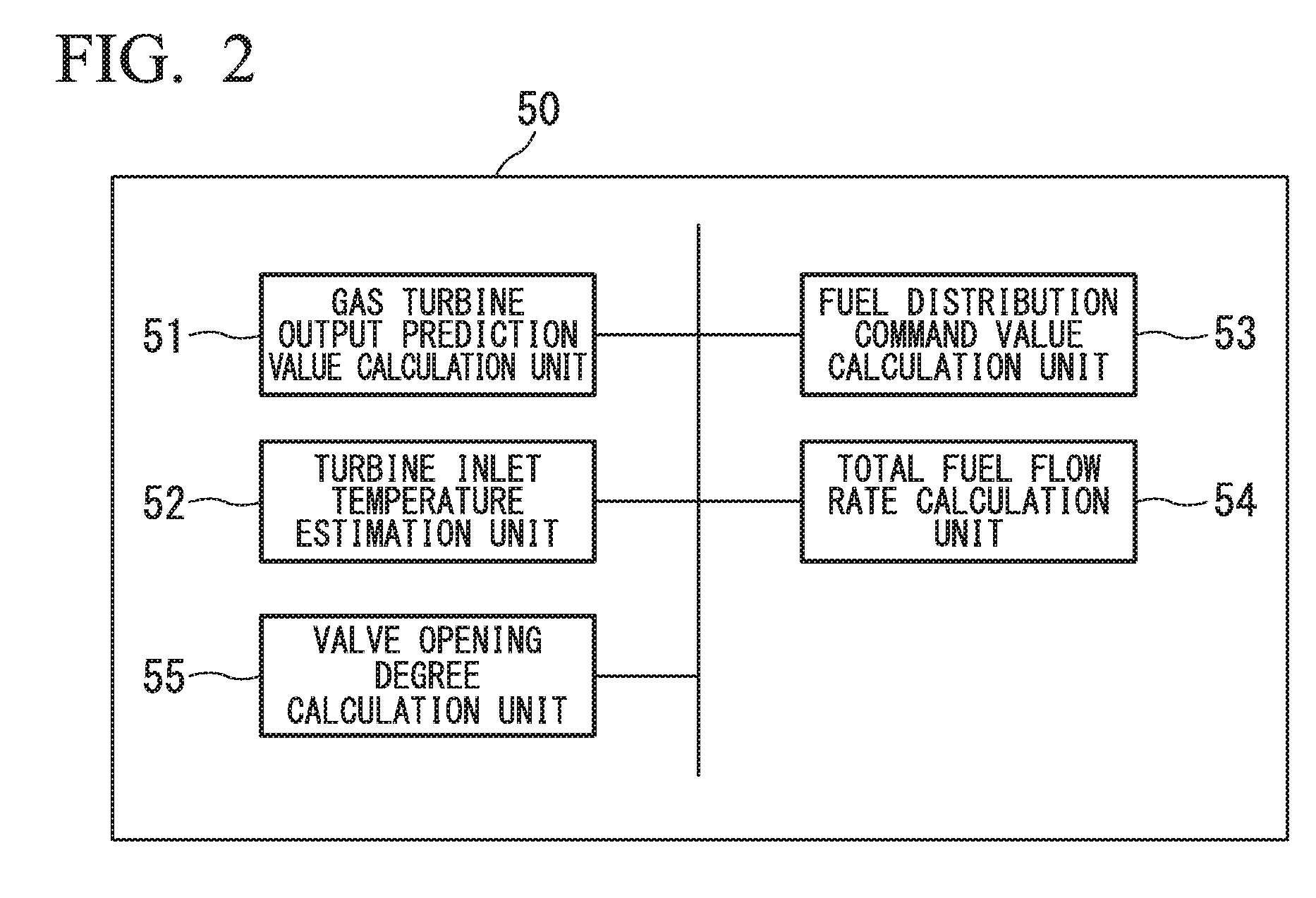

Fuel control device, combustor, gas turbine, control method, and program

ActiveUS20160326967A1Inhibition biasFuel supply regulationContinuous combustion chamberCombustorFuel distribution

A fuel control device includes a combustion temperature estimation value calculation unit that calculates a temperature estimation value when a mixture of fuel and inflow air is burned using an atmospheric condition, an opening degree command value of a valve that controls the amount of air that is mixed with the fuel and burned, and an output prediction value calculated on the basis of a fuel control signal command value used for calculation of a total fuel flow rate flowing through a plurality of fuel supply systems, a fuel distribution command value calculation unit that calculates a fuel distribution command value indicating a distribution of fuel output from the fuel supply systems based on the temperature estimation value, and outputs the fuel distribution command value, and a valve opening degree calculation unit that calculates each valve opening degree of a fuel flow rate control valve of the fuel supply systems.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com