Patents

Literature

85results about "High temperature gas-gas reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer nanocomposite implants with enhanced transparency and mechanical properties for administration within humans or animals

Polymer nanocomposite implants with nanofillers and additives are described. The nanofillers described can be any composition with the preferred composition being those composing barium, bismuth, cerium, dysprosium, europium, gadolinium, hafnium, indium, lanthanum, neodymium, niobium, praseodymium, strontium, tantalum, tin, tungsten, ytterbium, yttrium, zinc, and zirconium. The additives can be of any composition with the preferred form being inorganic nanopowders comprising aluminum, calcium, gallium, iron, lithium, magnesium, silicon, sodium, strontium, titanium. Such nanocomposites are particularly useful as materials for biological use in applications such as drug delivery, biomed devices, bone or dental implants.

Owner:PPG IND OHIO INC

Nanotechnology for drug delivery, contrast agents and biomedical implants

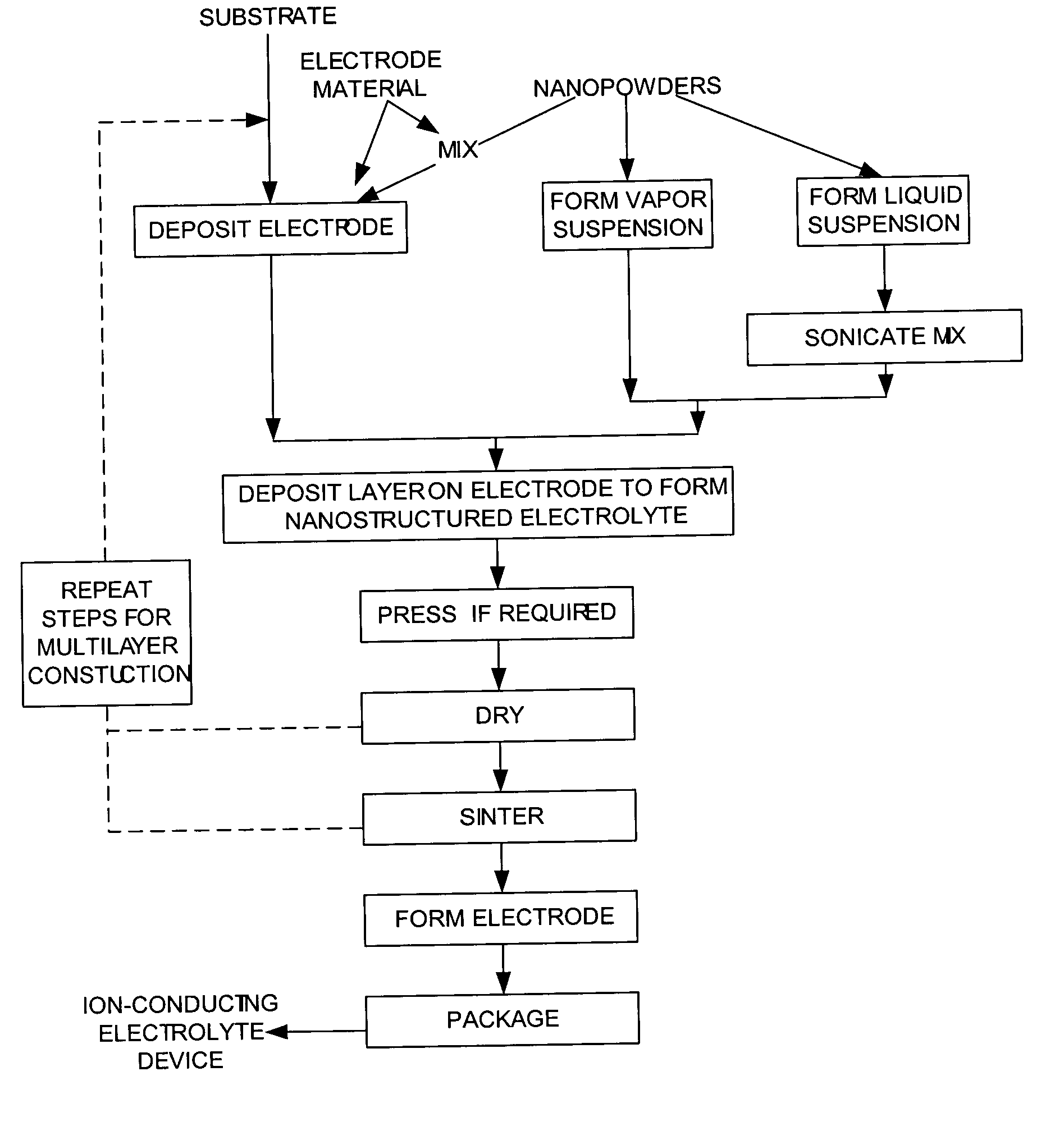

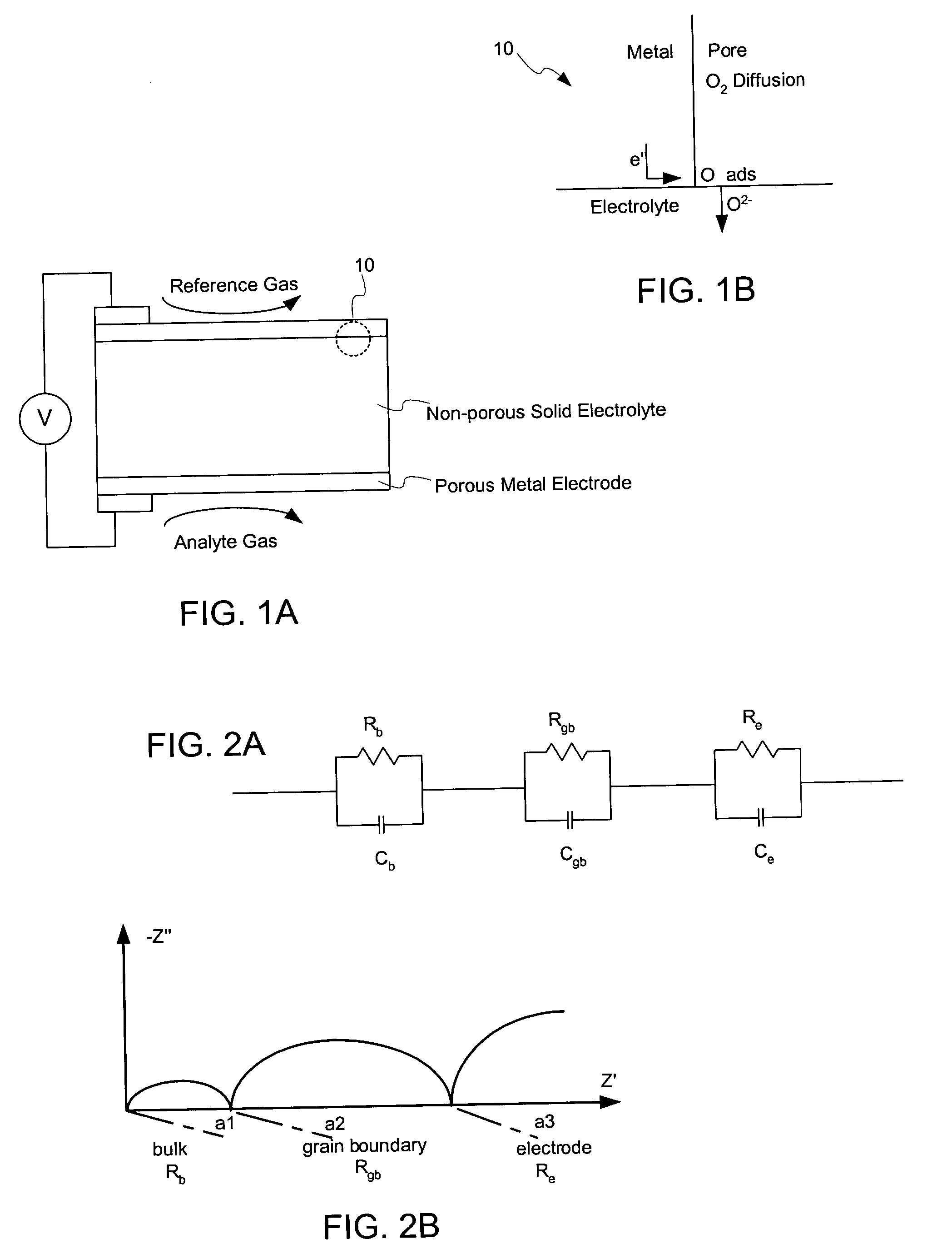

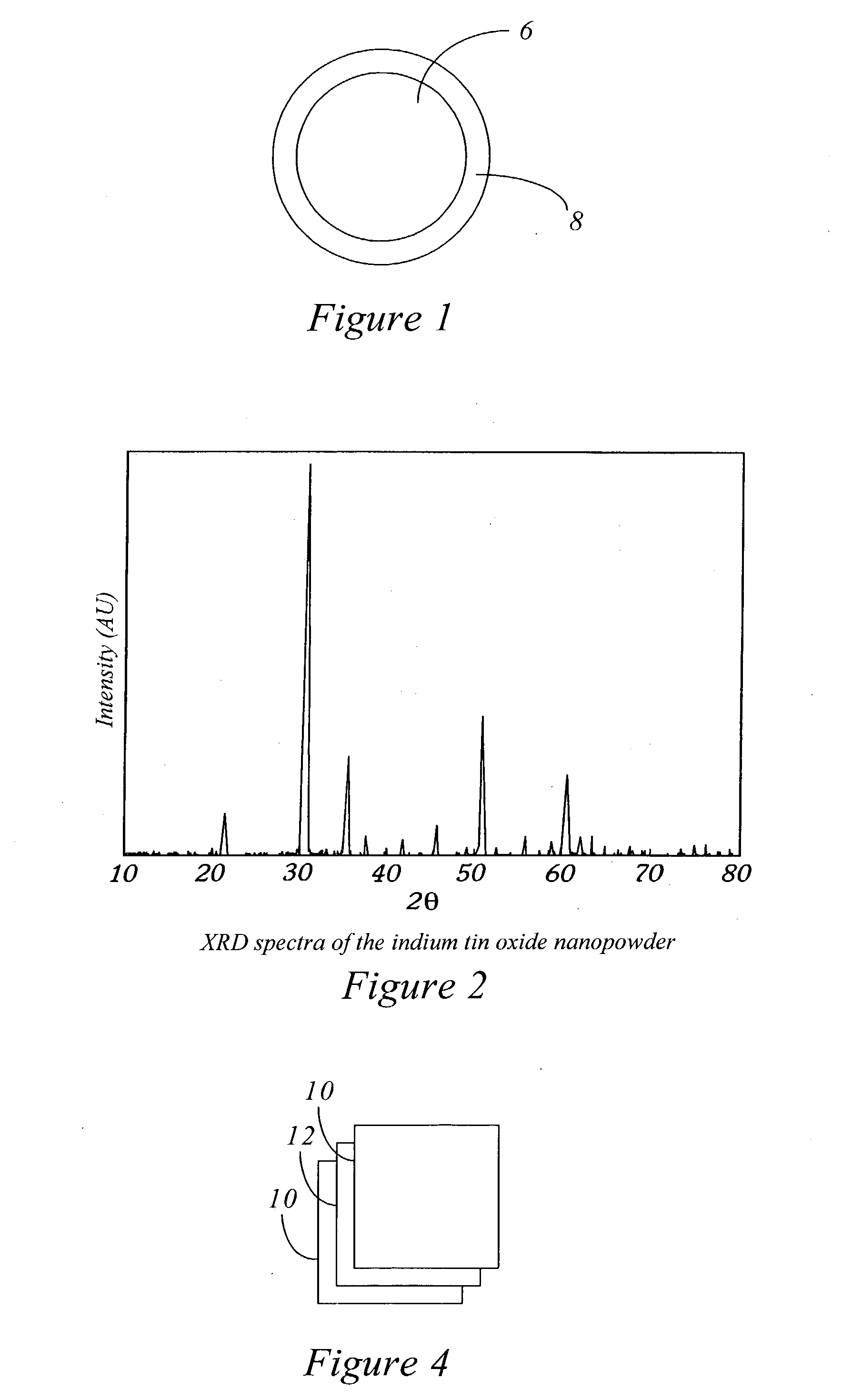

A nanocomposite structure comprising a nanostructured filler or carrier intimately mixed with a matrix, and methods of making such a structure. The nanostructured filler has a domain size sufficiently small to alter an electrical, magnetic, optical, electrochemical, chemical, thermal, biomedical, or tribological property of either filler or composite by at least 20%.

Owner:PPG IND OHIO INC

Inorganic dopants, inks and related nanotechnology

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

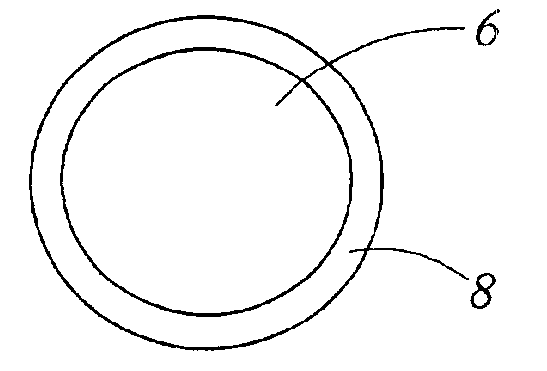

Nanostructured powders and related nanotechnology

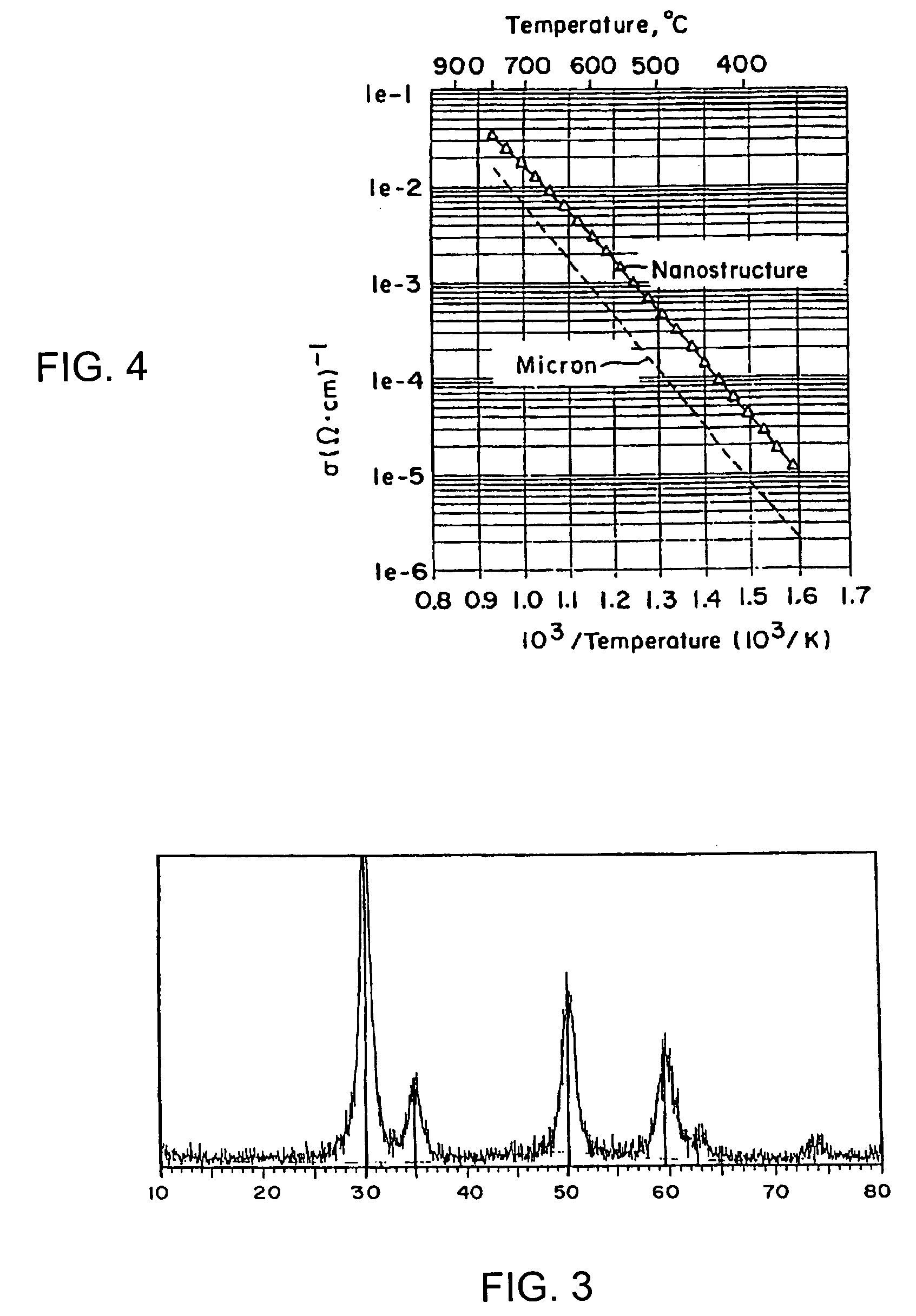

InactiveUS7081267B2Low costReduce operating costsNitrogen compoundsSelenium/tellurium compundsThermal energyOxygen

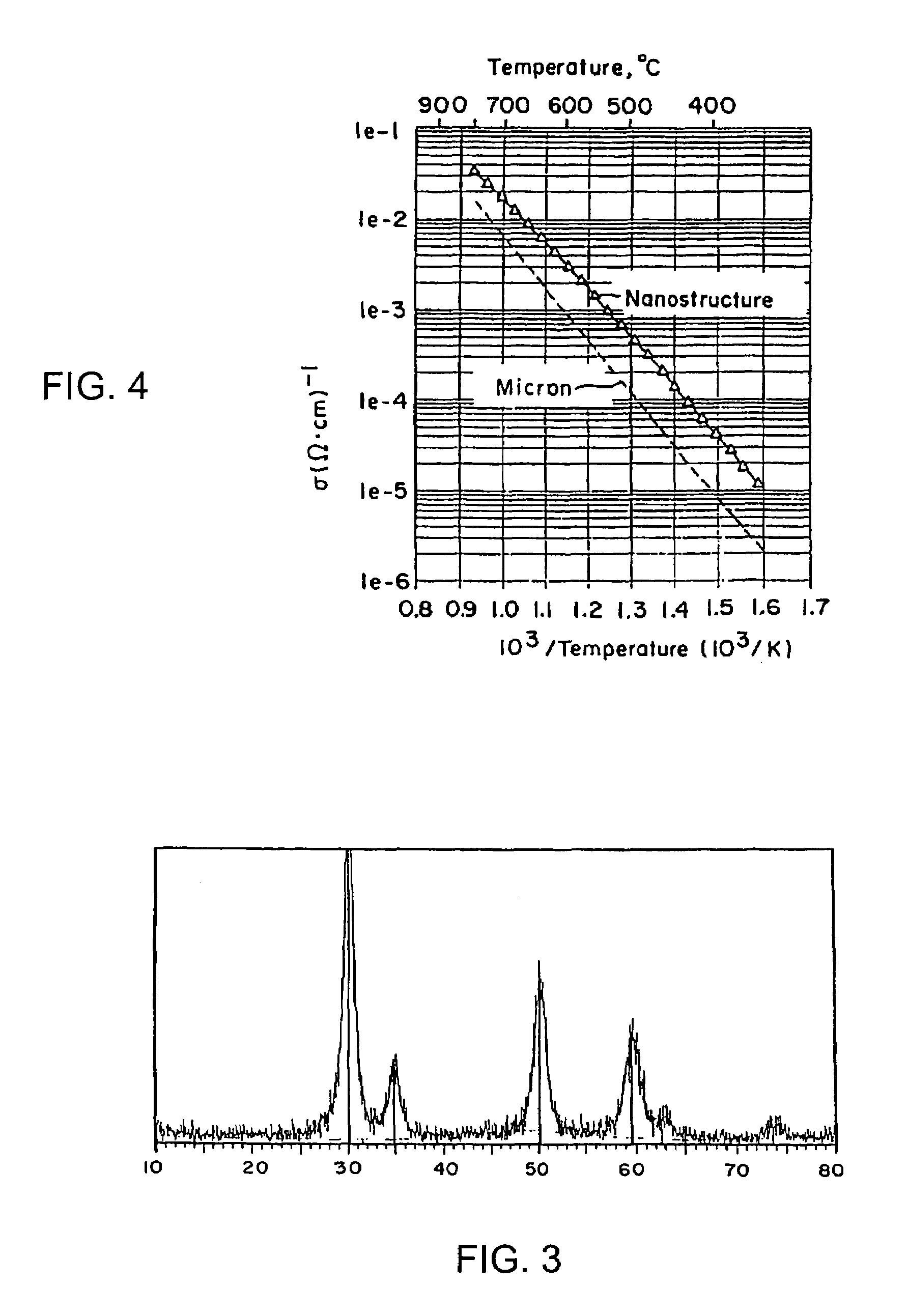

Methods to manufacture nanoscale particles comprising metals, alloys, intermetallics, ceramics are disclosed. The thermal energy is provided by plasma, internal energy, heat of reaction, microwave, electromagnetic, direct electric arc, pulsed electric arc and / or nuclear. The process is operated at some stage above 3000K and at high velocities. The invention can be utilized to prepare nanopowders for nanostructured products and devices such as ion conducting solid electrolytes for a wide range of applications, including sensors, oxygen pumps, fuel cells, batteries, electrosynthesis reactors and catalytic membranes.

Owner:PPG IND OHIO INC

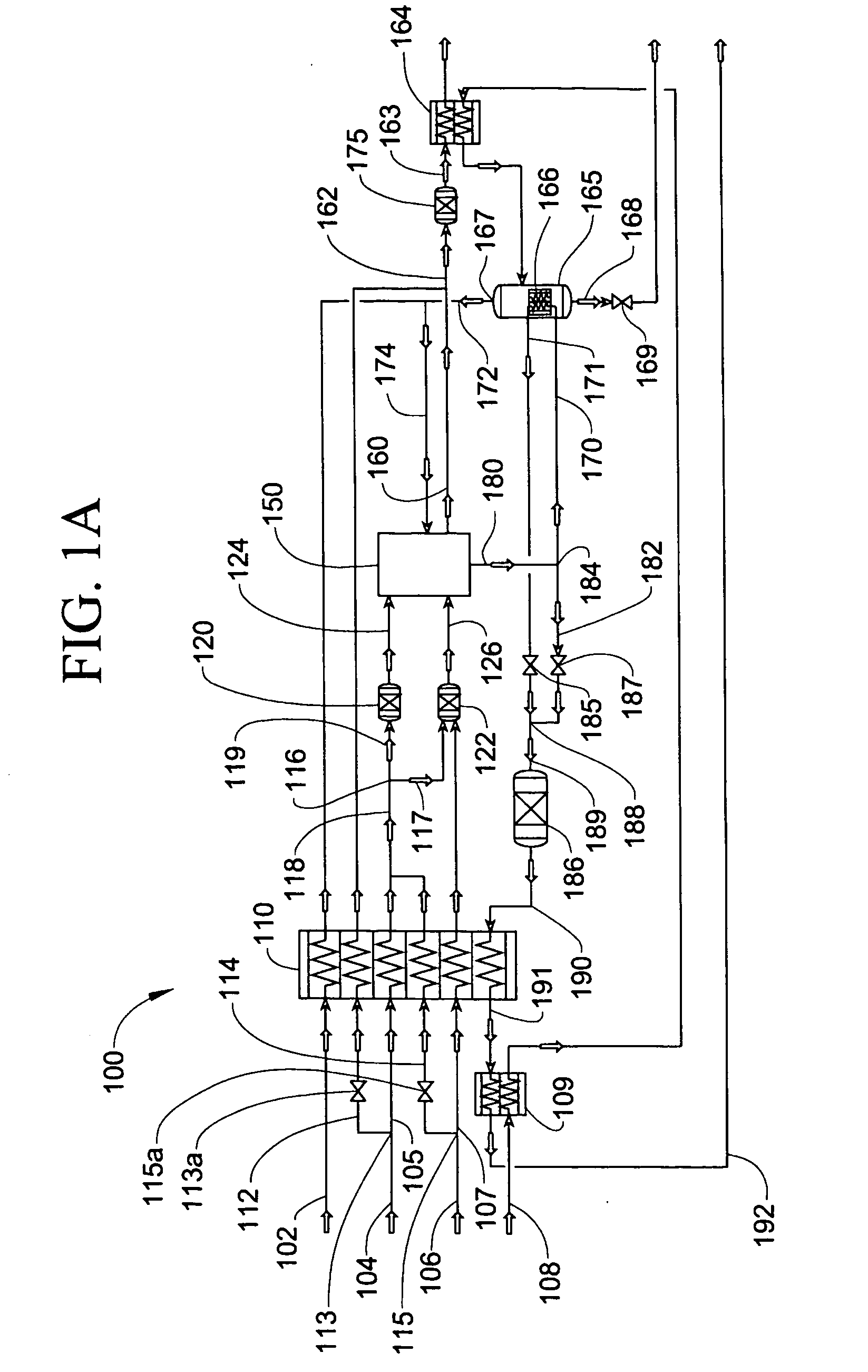

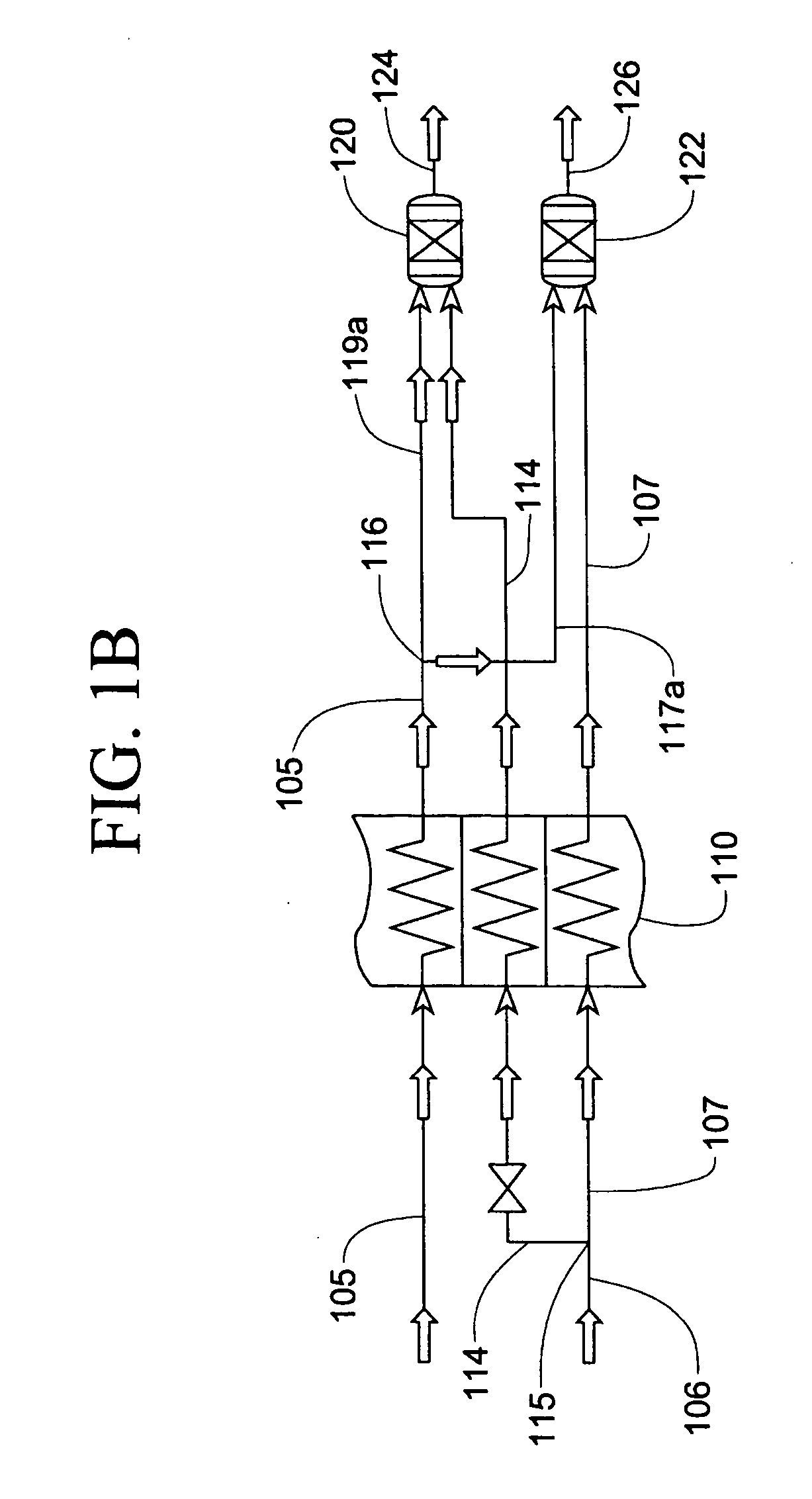

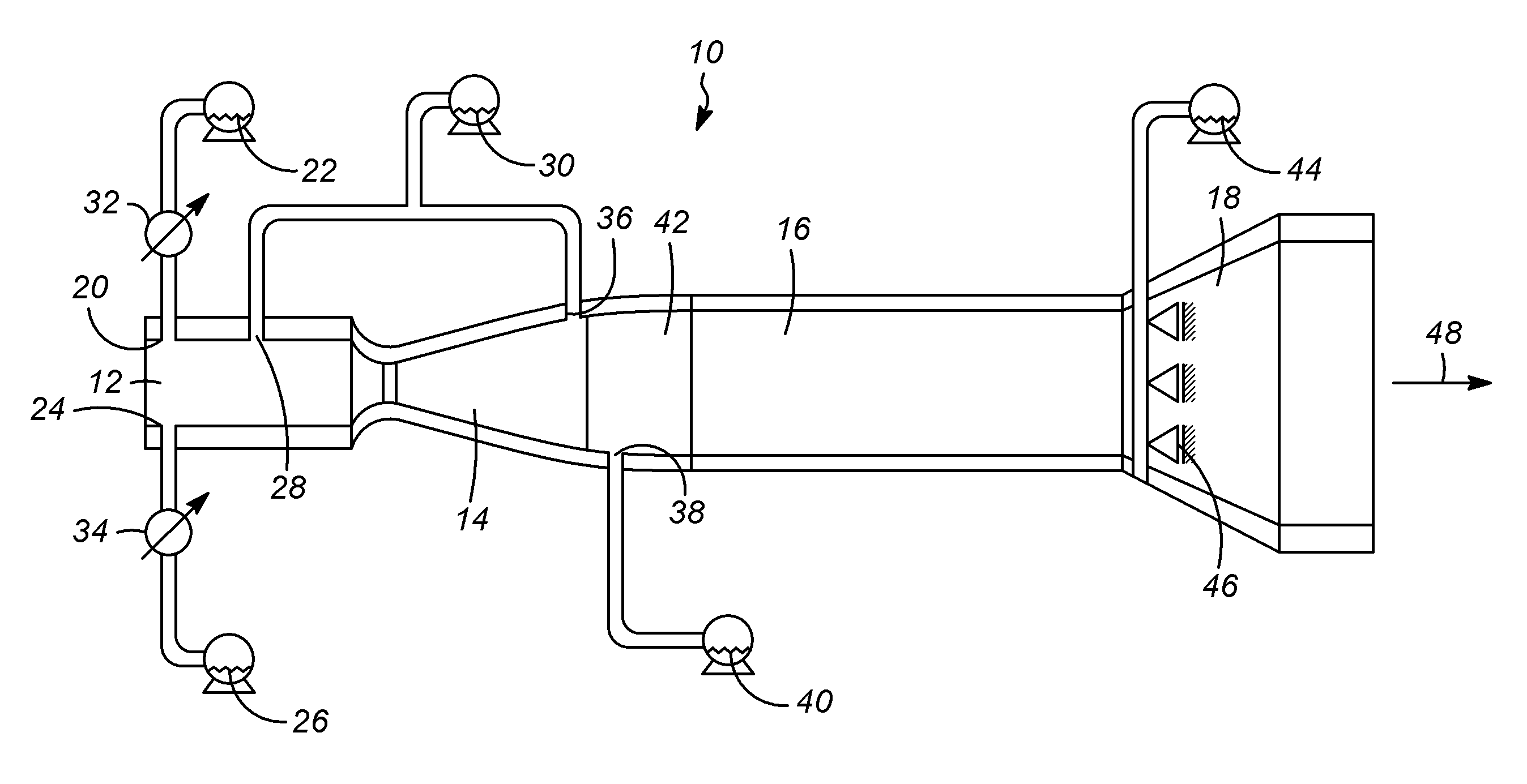

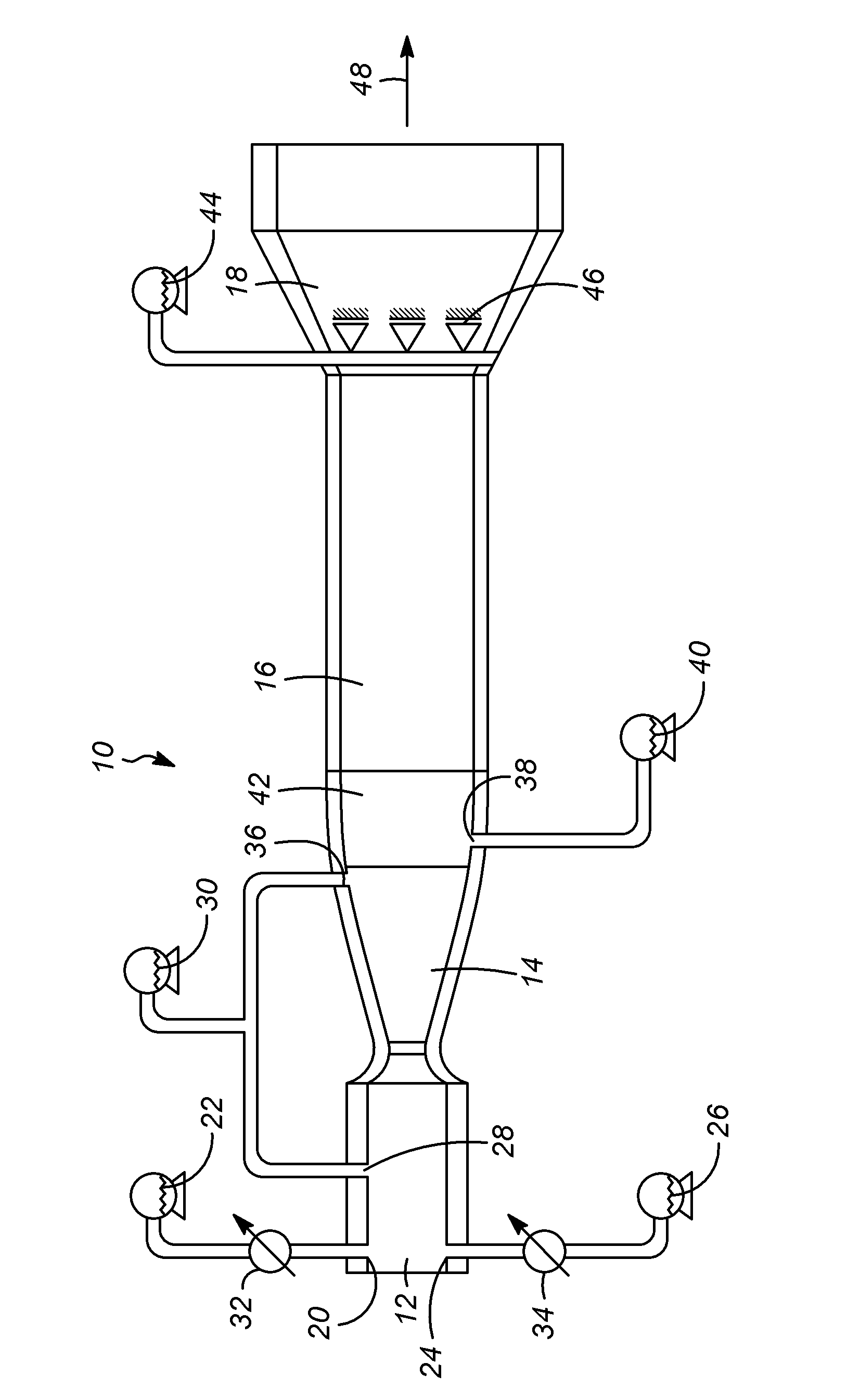

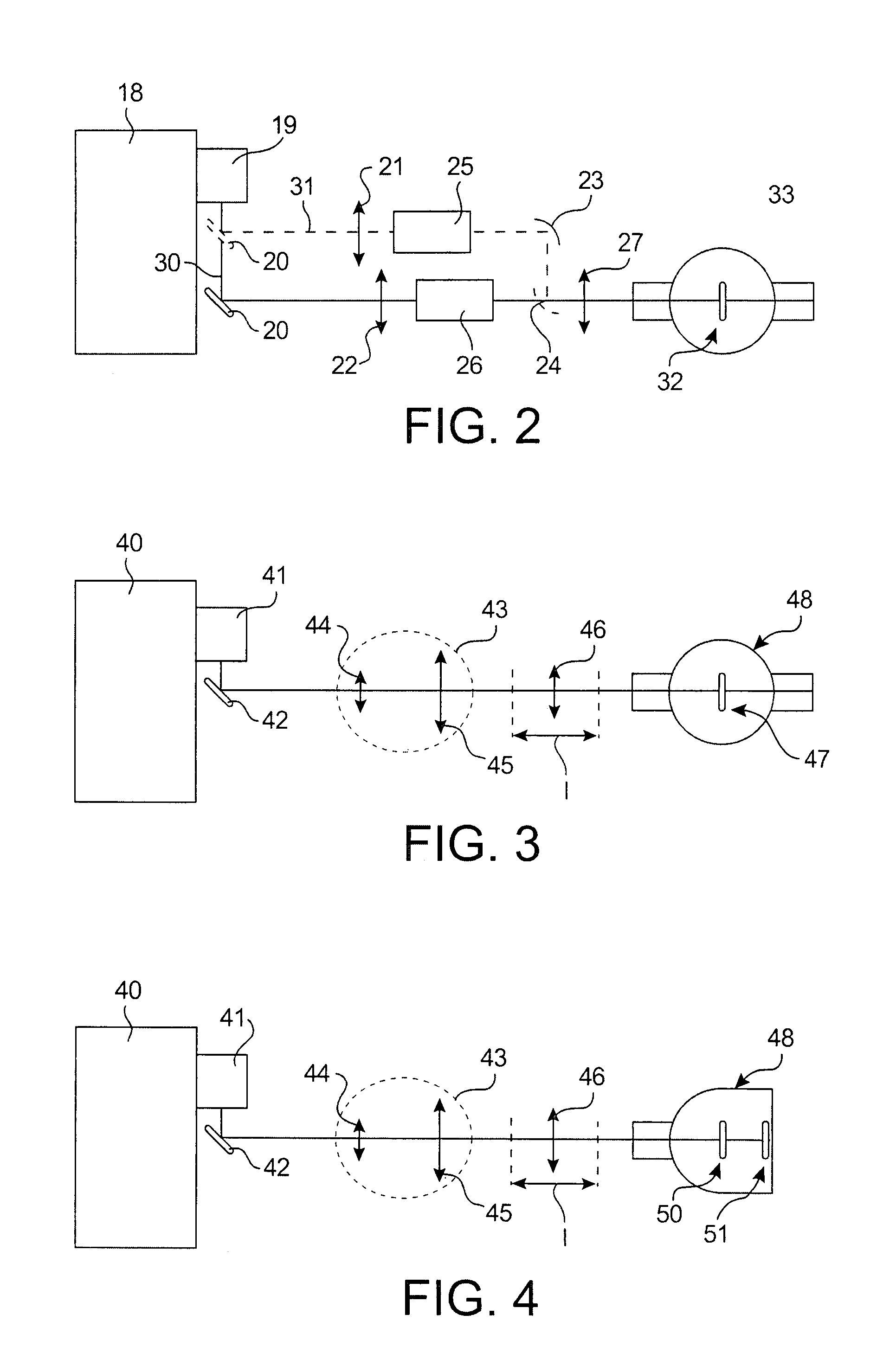

Reforming apparatus and method

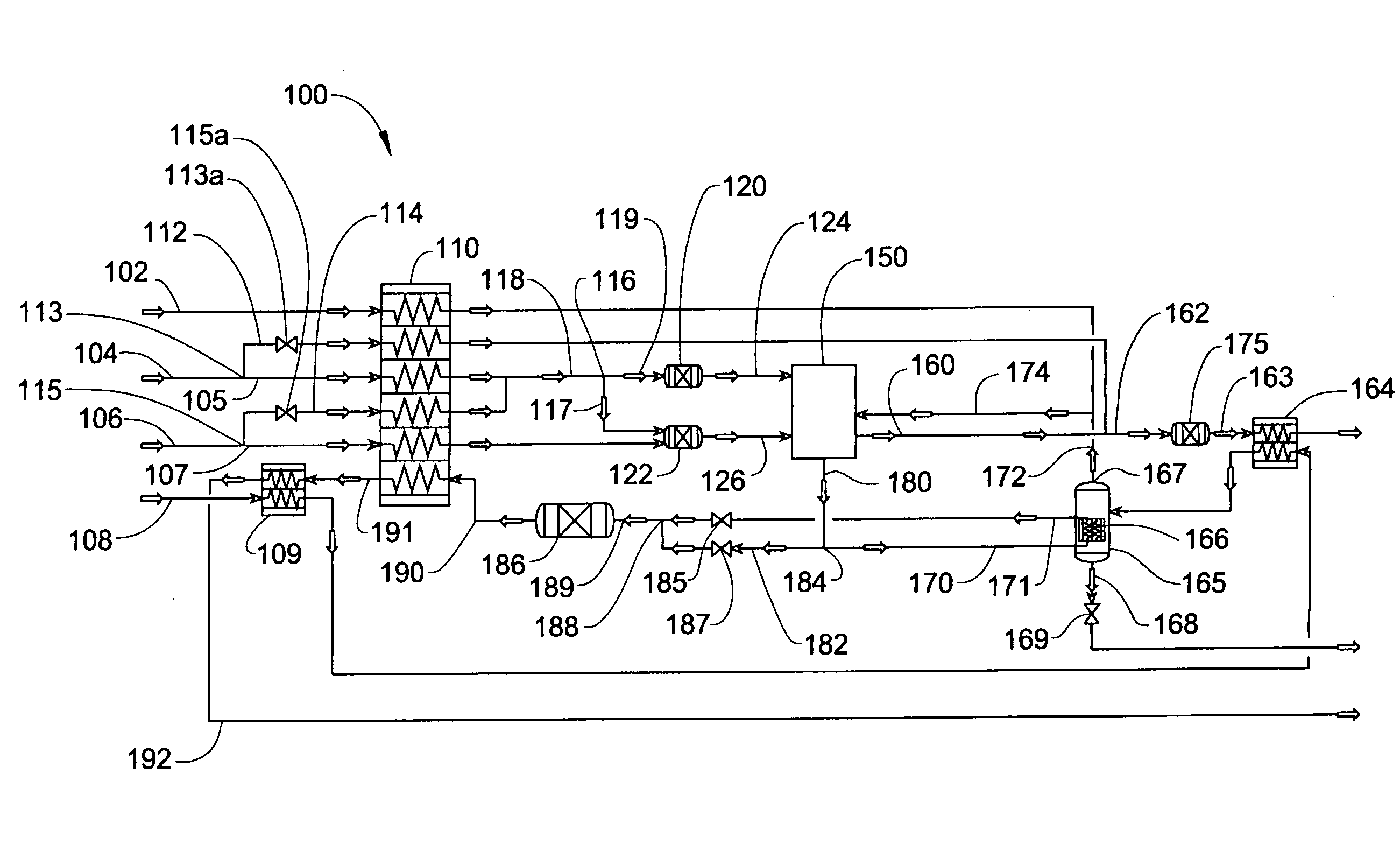

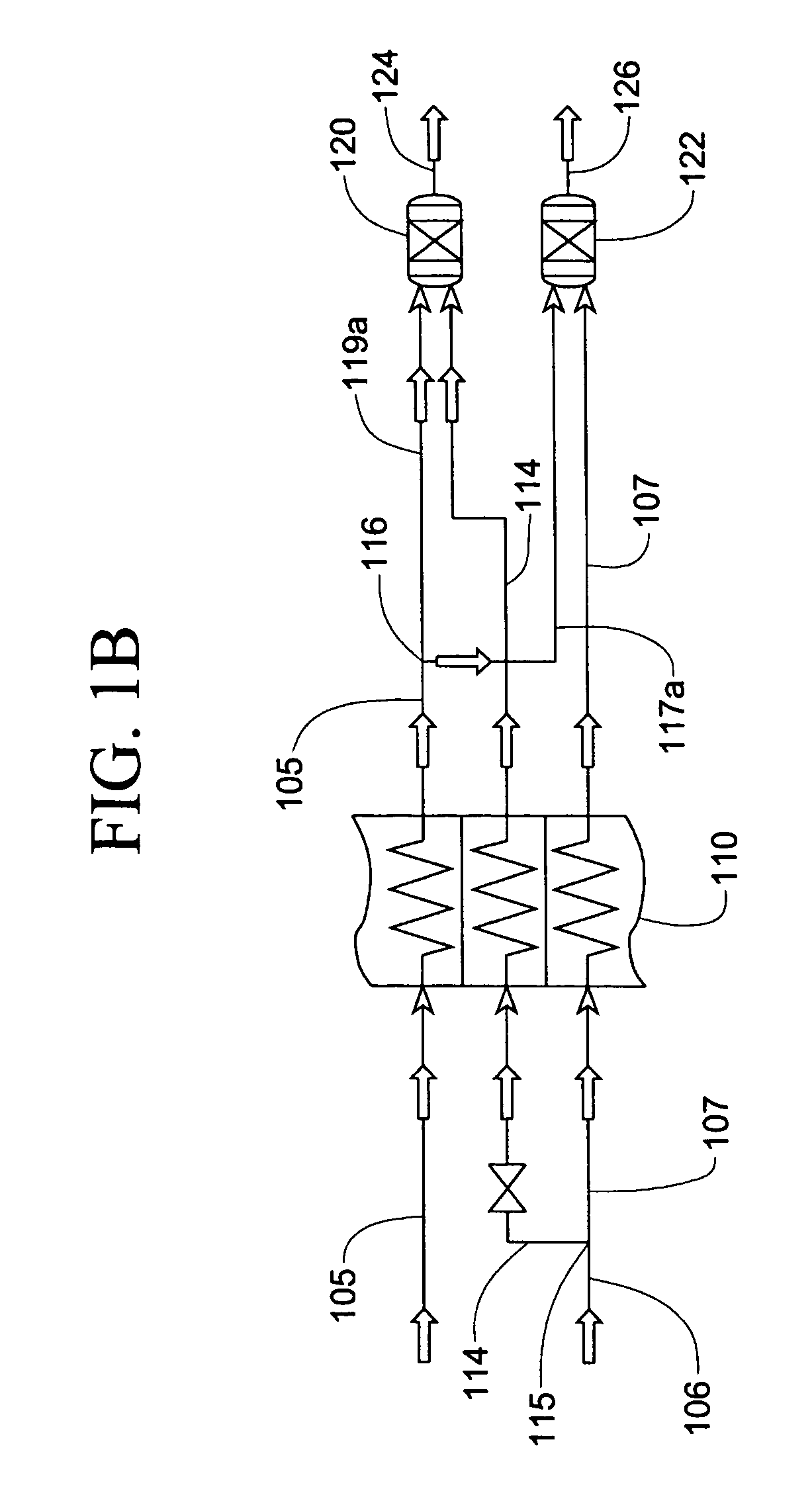

ActiveUS20080244975A1Avoid adjustmentMultiple metal hydridesHigh temperature gas-gas reactionSyngasMetal dusting

A multiple adiabatic bed reforming apparatus and process are disclosed in which stage-wise combustion, in combination with multiple reforming chambers with catalyst, utilize co-flow and cross-flow under laminar flow conditions, to provide a reformer suitable for smaller production situations as well as large scale production. A passive stage by stage fuel distribution network suitable for low pressure fuel is incorporated and the resistances in successive fuel distribution lines control the amount of fuel delivered to each combustion stage. The fuel distribution system allows relatively constant fuel and air flow during turn up or turn down conditions. High efficiency is achieved by capturing heat from reforming syngas product to preheat gases before entering the reformer. Conditions that would produce unwanted coking or metal dusting are also eliminated or localized to locations within the apparatus outside the heat exchangers, but which locations can be cost effectively protected. Also, a chemical reactor is disclosed and which has a core composed of a stack of metal plates that are diffusion bonded in face-to-face relationship. A plurality of reaction zones are located within the core, as are a plurality of catalyst receiving zones, and both the reaction zones and the catalyst receiving zones are defined by respective aligned apertures in the plates. First and second channel arrangements are provided in the plates for transporting first and second reactants to reaction zones. Portions of the first channel arrangement that interconnect the reaction zones are formed as heat exchange channels. A third channel arrangement is provided in the plates for transporting a third reactant to catalyst receiving zones. Portions of the third channel arrangement are formed as heat exchange channels in proximity to the heat exchange channels of the first channel arrangement.

Owner:MEGGIT (UK) LTD

Molten metal reactor and method of forming hydrogen, carbon monoxide and carbon dioxide using the molten alkaline metal reactor

InactiveUS20110089377A1Extended stayCarbon monoxideHydrogen/synthetic gas productionHydrogenCrucible

A molten metal reactor for converting a carbon material and steam into a gas comprising hydrogen, carbon monoxide, and carbon dioxide is disclosed. The reactor includes an interior crucible having a portion contained within an exterior crucible. The interior crucible includes an inlet and an outlet; the outlet leads to the exterior crucible and may comprise a diffuser. The exterior crucible may contain a molten alkaline metal compound. Contained between the exterior crucible and the interior crucible is at least one baffle.

Owner:BATTELLE ENERGY ALLIANCE LLC

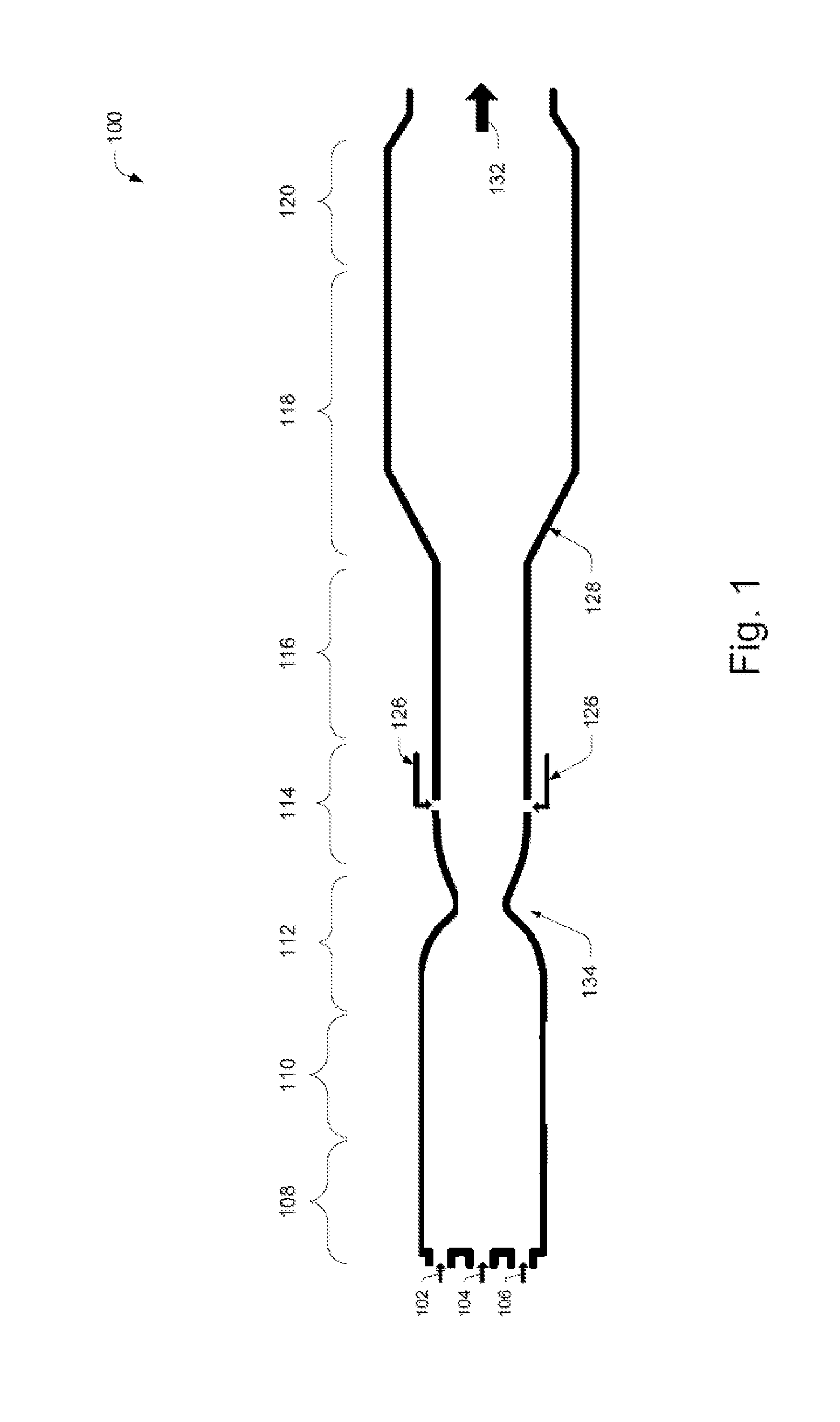

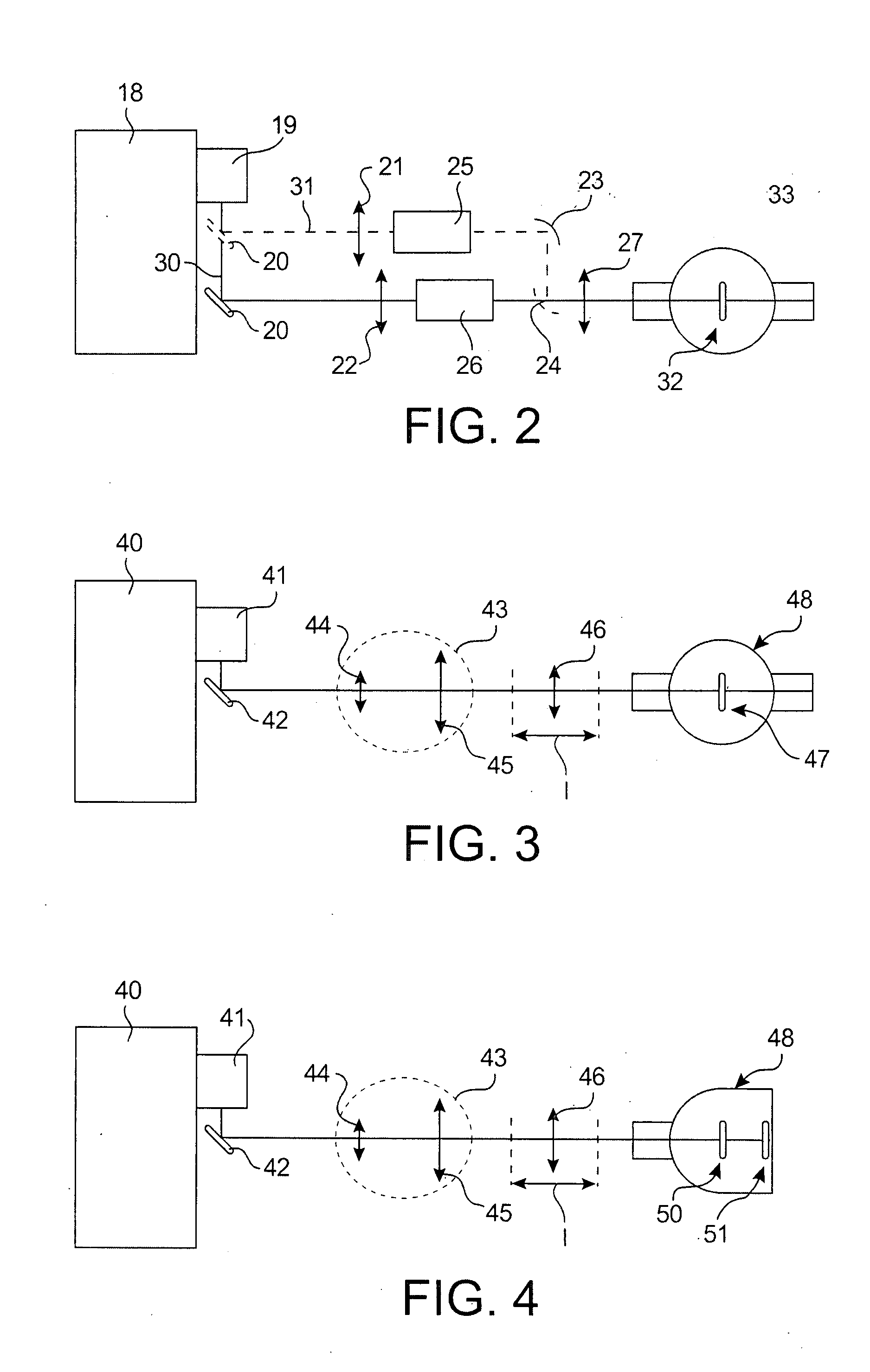

Fluid separation assembly to remove condensable contaminants and methane conversion process using a supersonic flow reactor

InactiveUS20140058095A1Fractional condensation purification/separationMechanical vibrations separationThroatTrace Amounts

Methods and systems are provided for converting methane in a feed stream to acetylene. The hydrocarbon stream is introduced into a supersonic reactor and pyrolyzed to convert at least a portion of the methane to acetylene. The reactor effluent stream may be treated to convert acetylene to another hydrocarbon process. The method according to certain aspects includes controlling the level of water, carbon dioxide and other condensable contaminants in the hydrocarbon stream by use of a fluid separation assembly such as a supersonic inertia separator. In addition, one or more adsorbent beds may be used to remove remaining trace amounts of condensable contaminants. The fluid separation assembly has a cyclonic fluid separator with a tubular throat portion arranged between a converging fluid inlet section and a diverging fluid outlet section and a swirl creating device.

Owner:UOP LLC

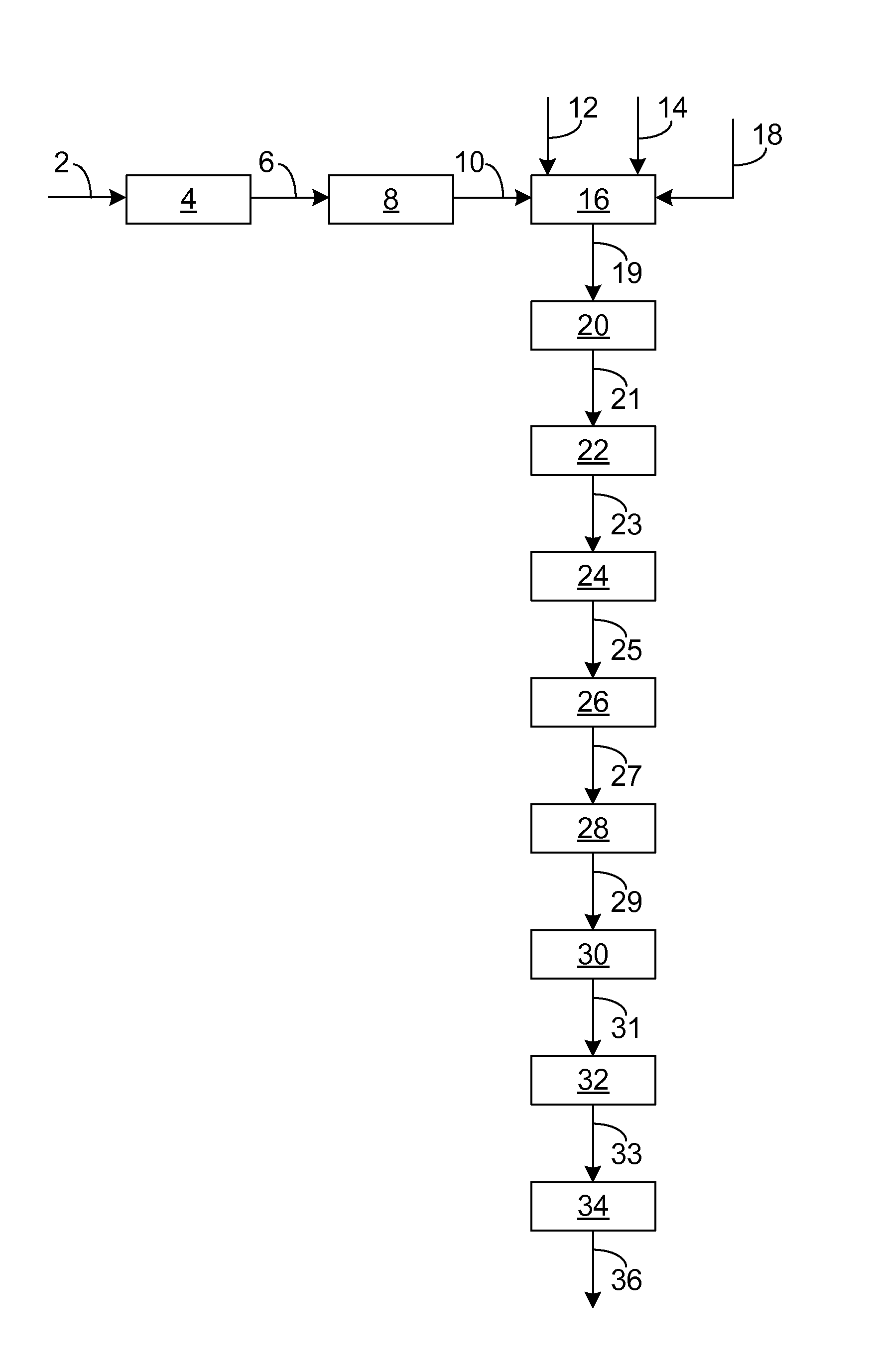

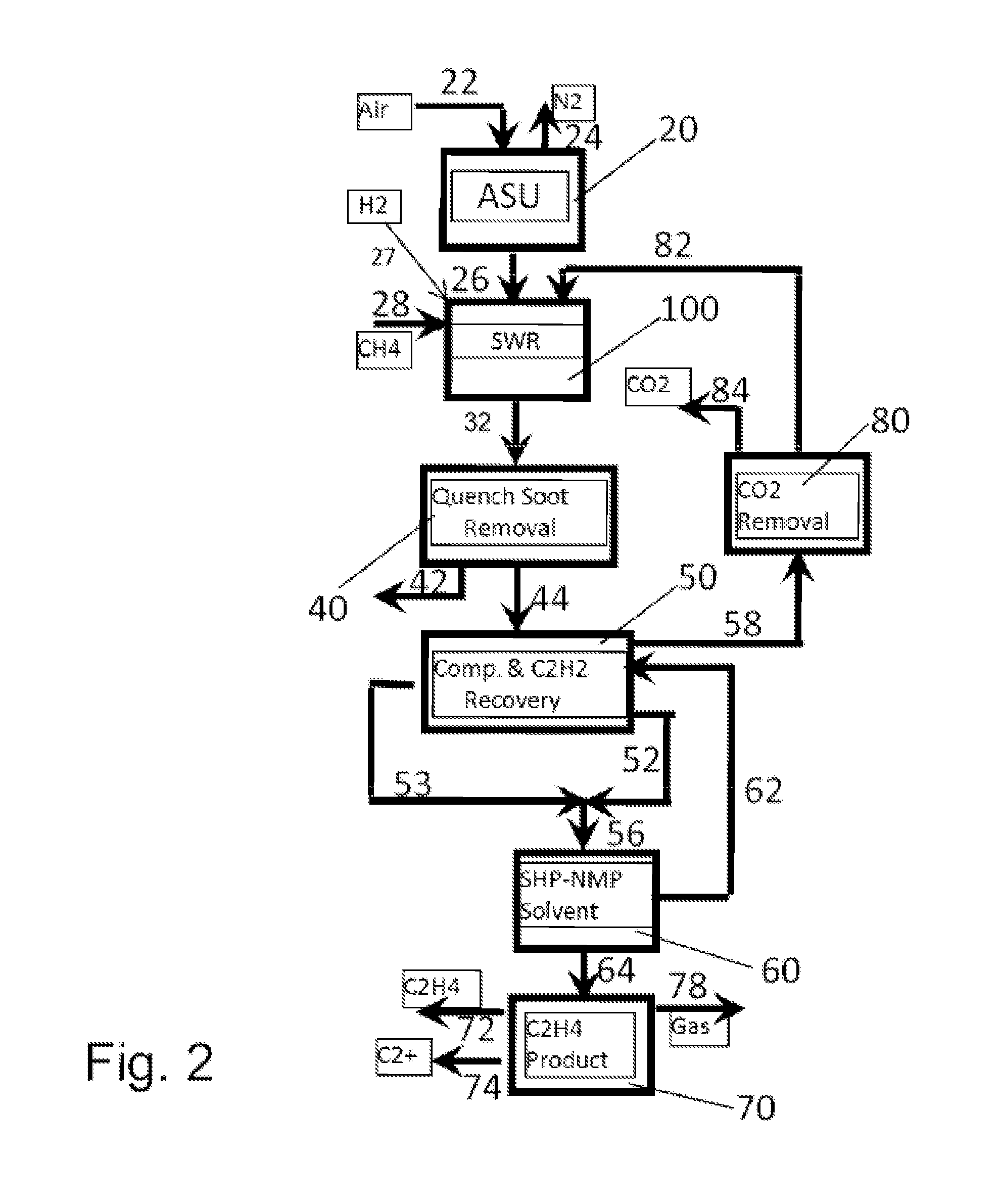

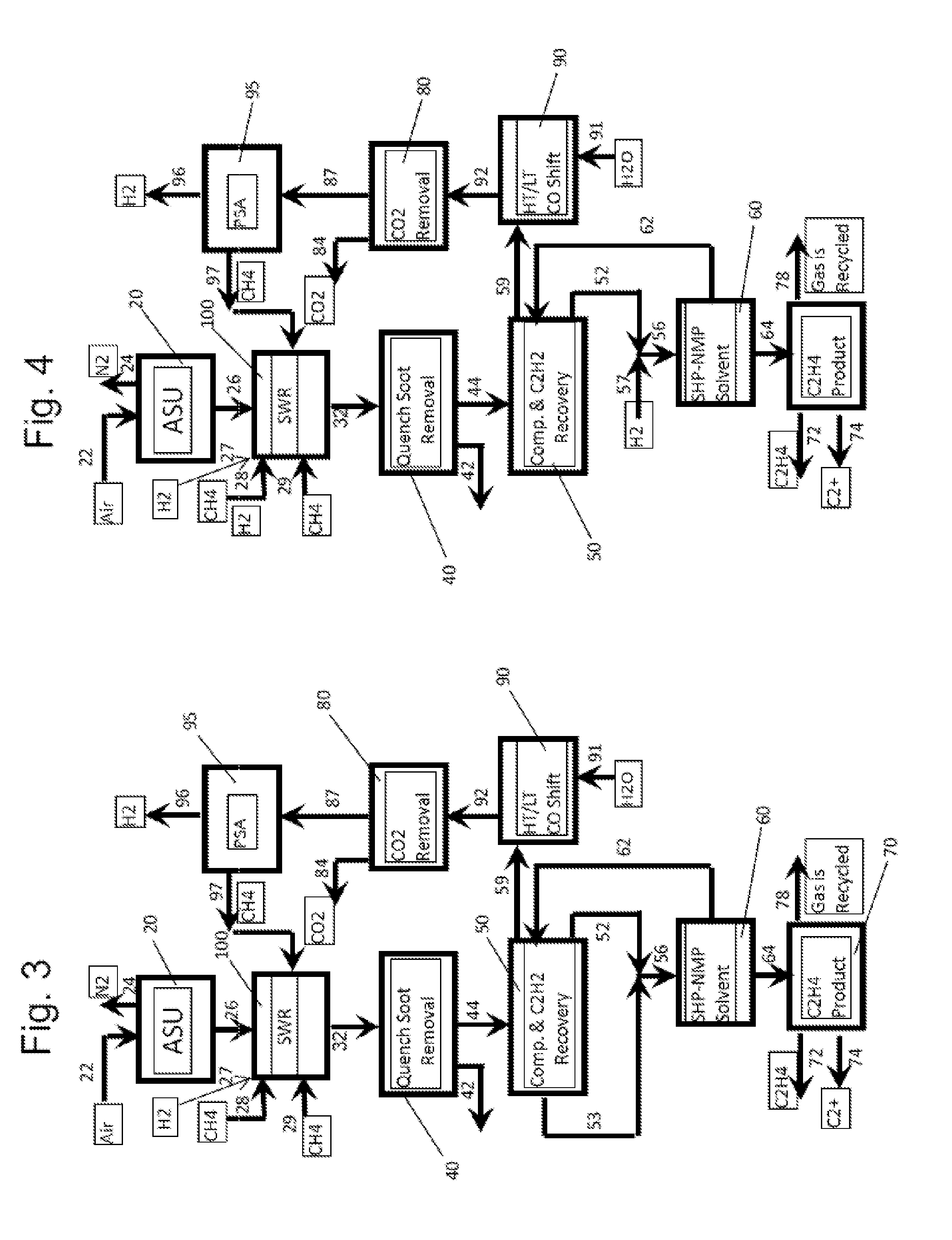

High efficiency processes for olefins, alkynes, and hydrogen co-production from light hydrocarbons such as methane

InactiveUS20140058149A1Process environmental protectionIncreases overall C selectivityThermal non-catalytic crackingHydrocarbon by hydrogenationMethanationOxygen

High efficiency processes for producing olefins, alkynes, and hydrogen co-production from light hydrocarbons are disclosed. In one version, the method includes the steps of combusting hydrogen and oxygen in a combustion zone of a pyrolytic reactor to create a combustion gas stream, transitioning a velocity of the combustion gas stream from subsonic to supersonic in an expansion zone of the pyrolytic reactor, injecting a light hydrocarbon into the supersonic combustion gas stream to create a mixed stream including the light hydrocarbon, transitioning the velocity of the mixed stream from supersonic to subsonic in a reaction zone of the pyrolytic reactor to produce acetylene, and catalytically hydrogenating the acetylene in a hydrogenation zone to produce ethylene. In certain embodiments, the carbon efficiency is improved using methanation techniques.

Owner:UOP LLC

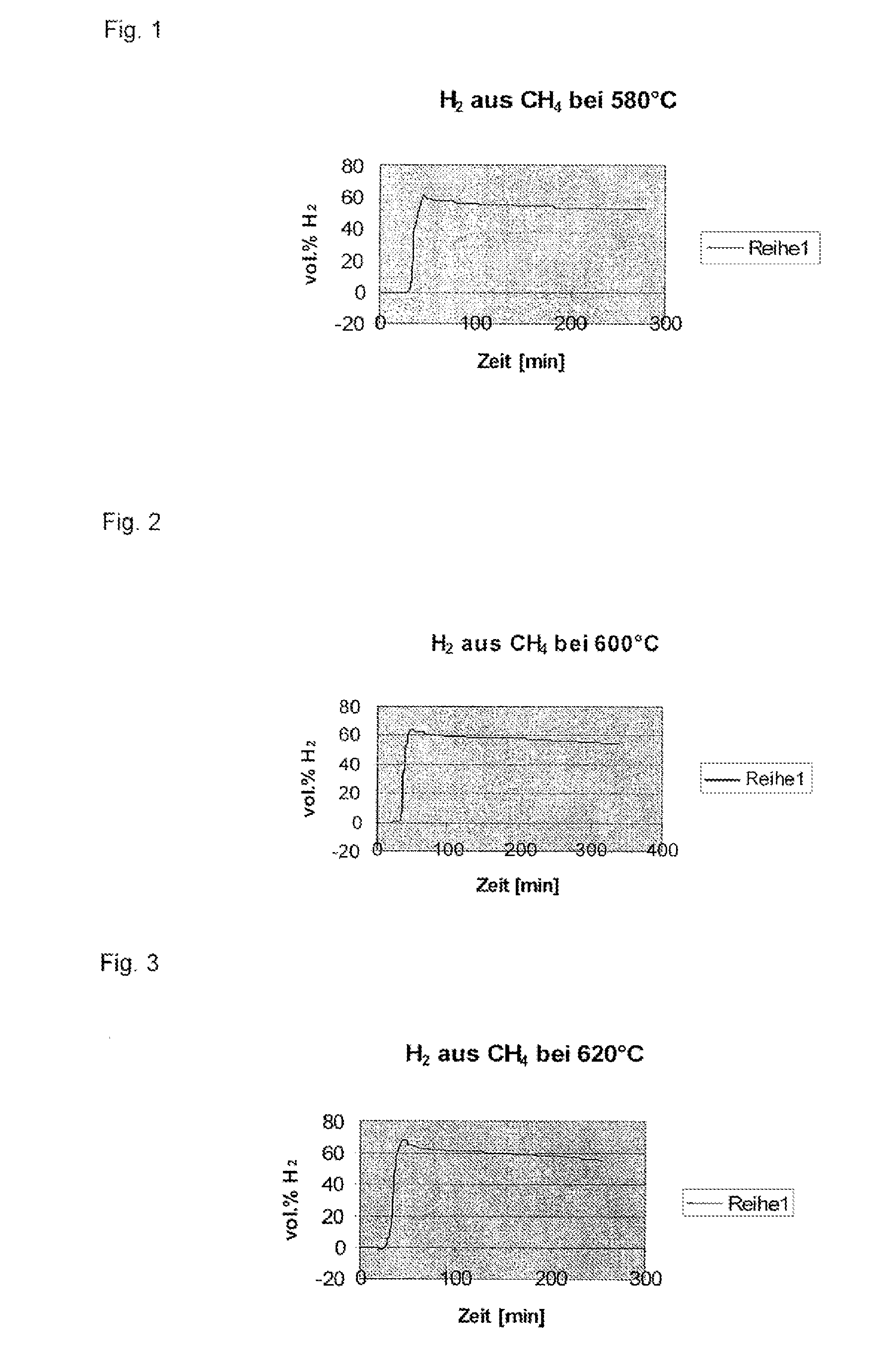

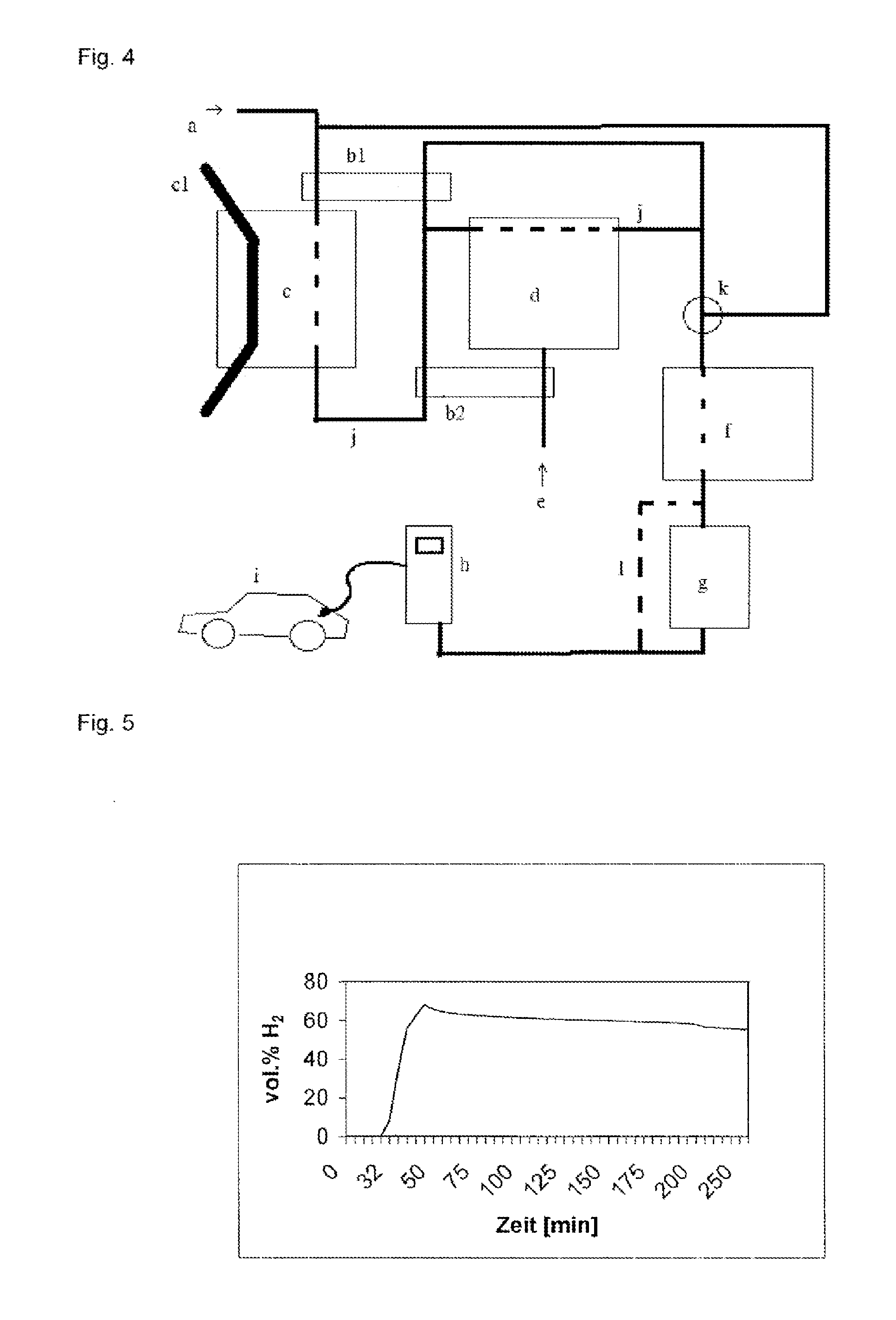

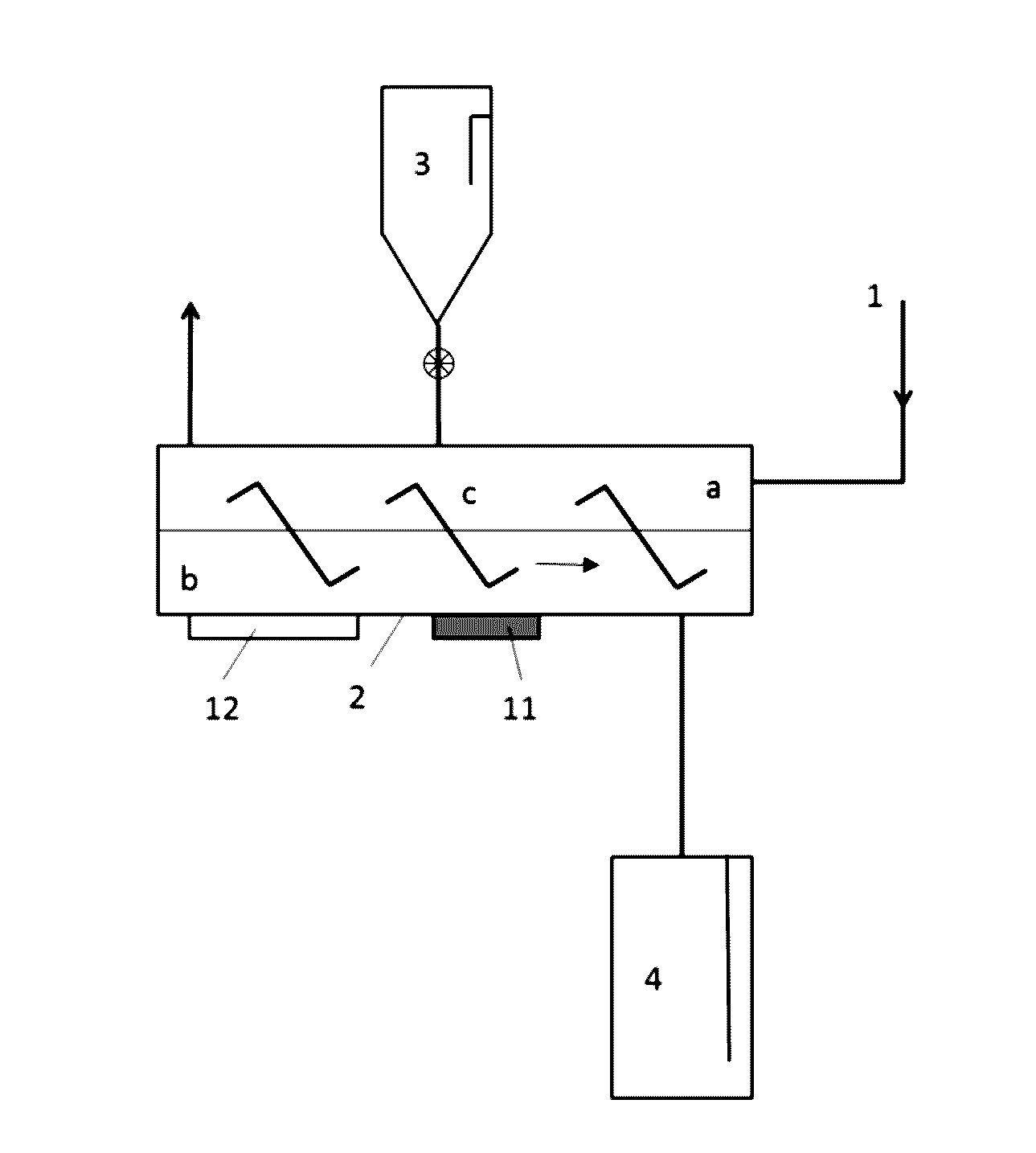

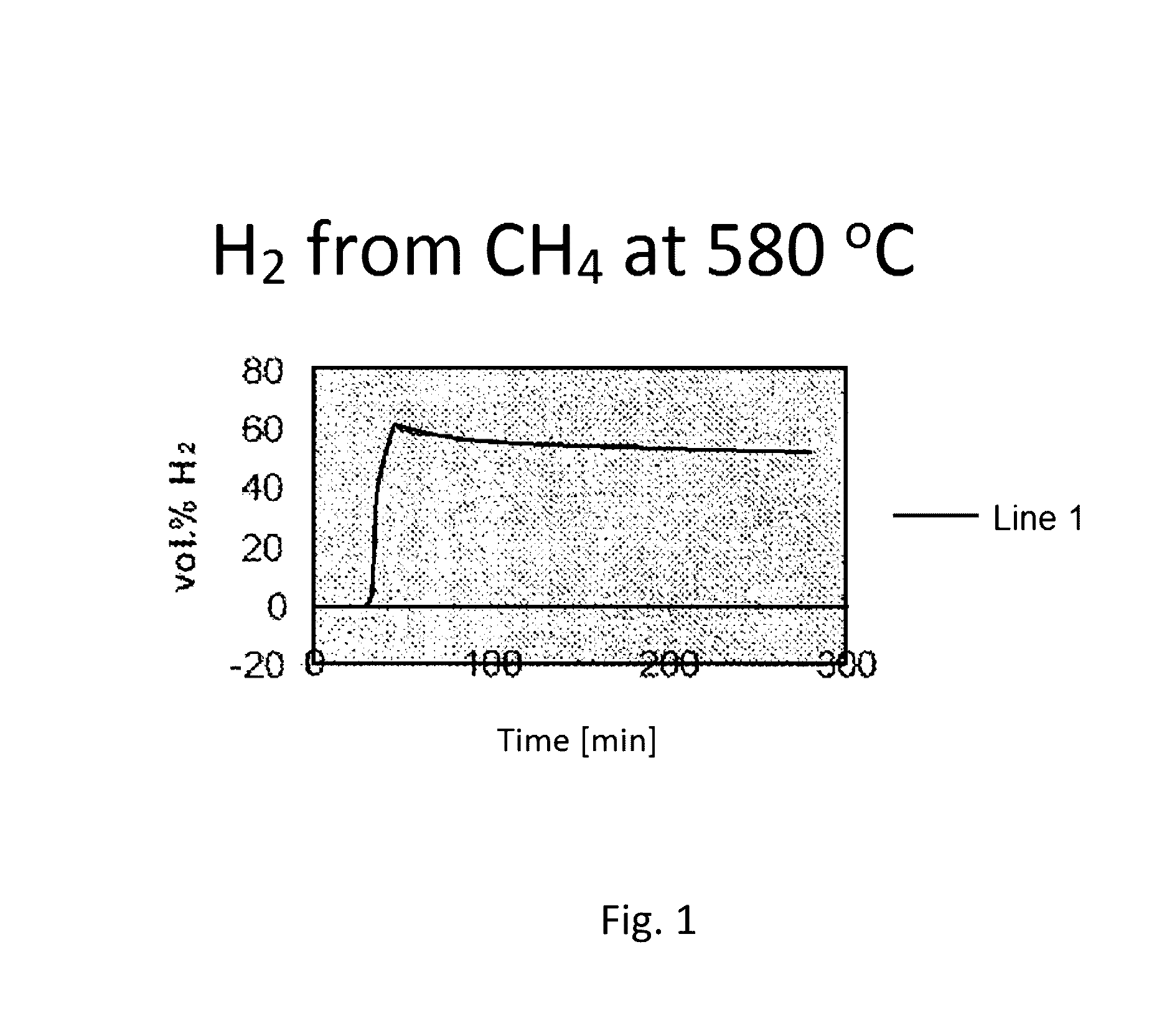

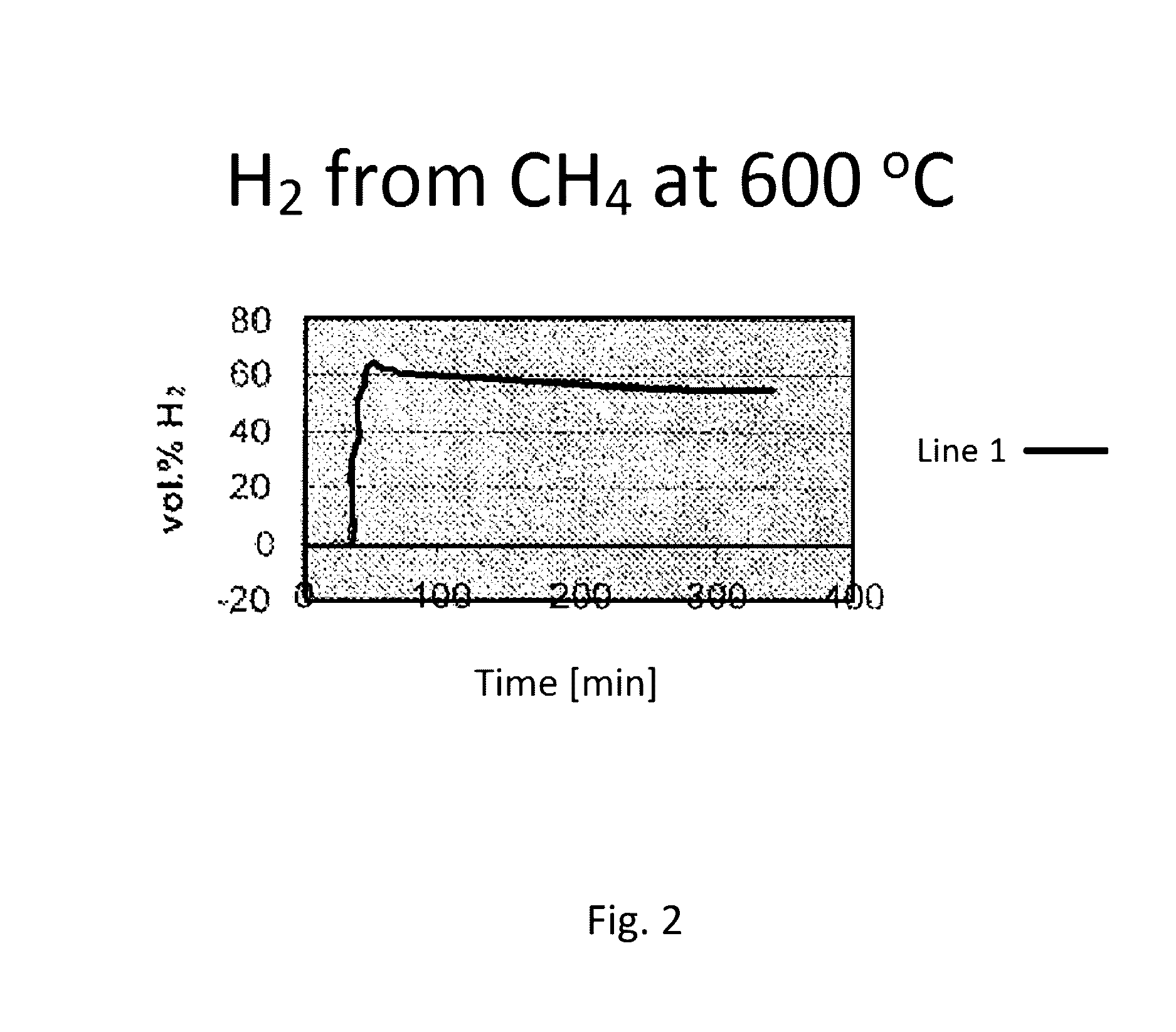

Use of a process for hydrogen production

ActiveUS20140328749A1Easy to spreadIncrease supplyMaterial nanotechnologyHydrogenSolid carbonDirect production

The present invention relates to the use of a process for hydrogen production in which at least a part of a hydrocarbonaceous feed gas (a) is passed into a reformer (c), wherein the feed gas is contacted in the reformer with a catalyst and the feed gas is converted to hydrogen and solid carbon, for the direct production of a hydrogenous gas at filling stations for sale to a consumer, and also to a reactor (d) for hydrogen production.

Owner:BESTRONG INT

Products comprising nano-precision engineered electronic components

InactiveUS7306822B2Low costEasy to incorporateNitrogen compoundsSelenium/tellurium compundsFuel cellsElectrical battery

Electronic devices prepared from nanoscale powders are described. Methods for utilizing nanoscale powders and related nanotechnology to prepare capacitors, inductors, resistors, thermistors, varistors, filters, arrays, interconnects, optical components, batteries, fuel cells, sensors and other products are discussed.

Owner:PPG IND OHIO INC

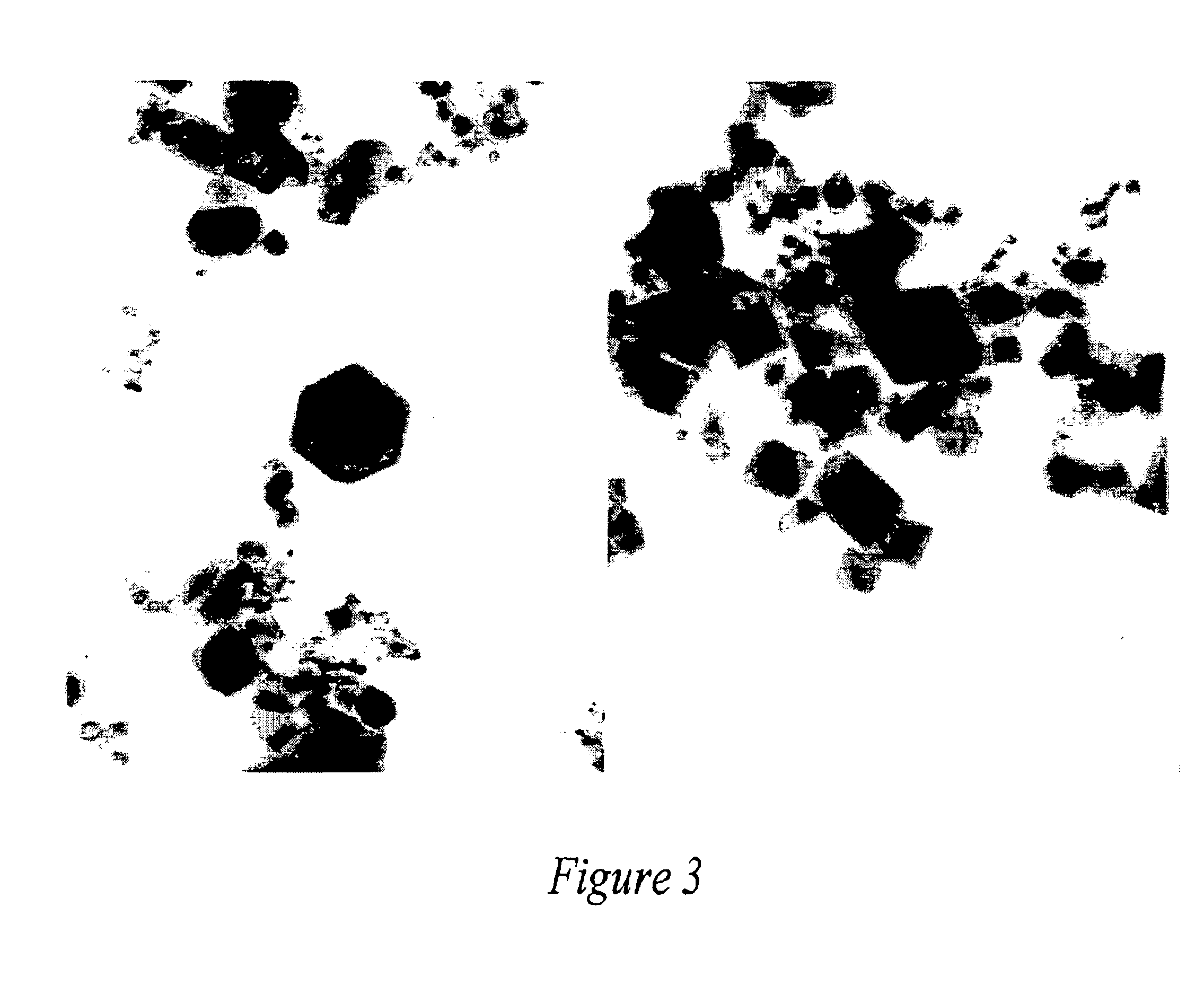

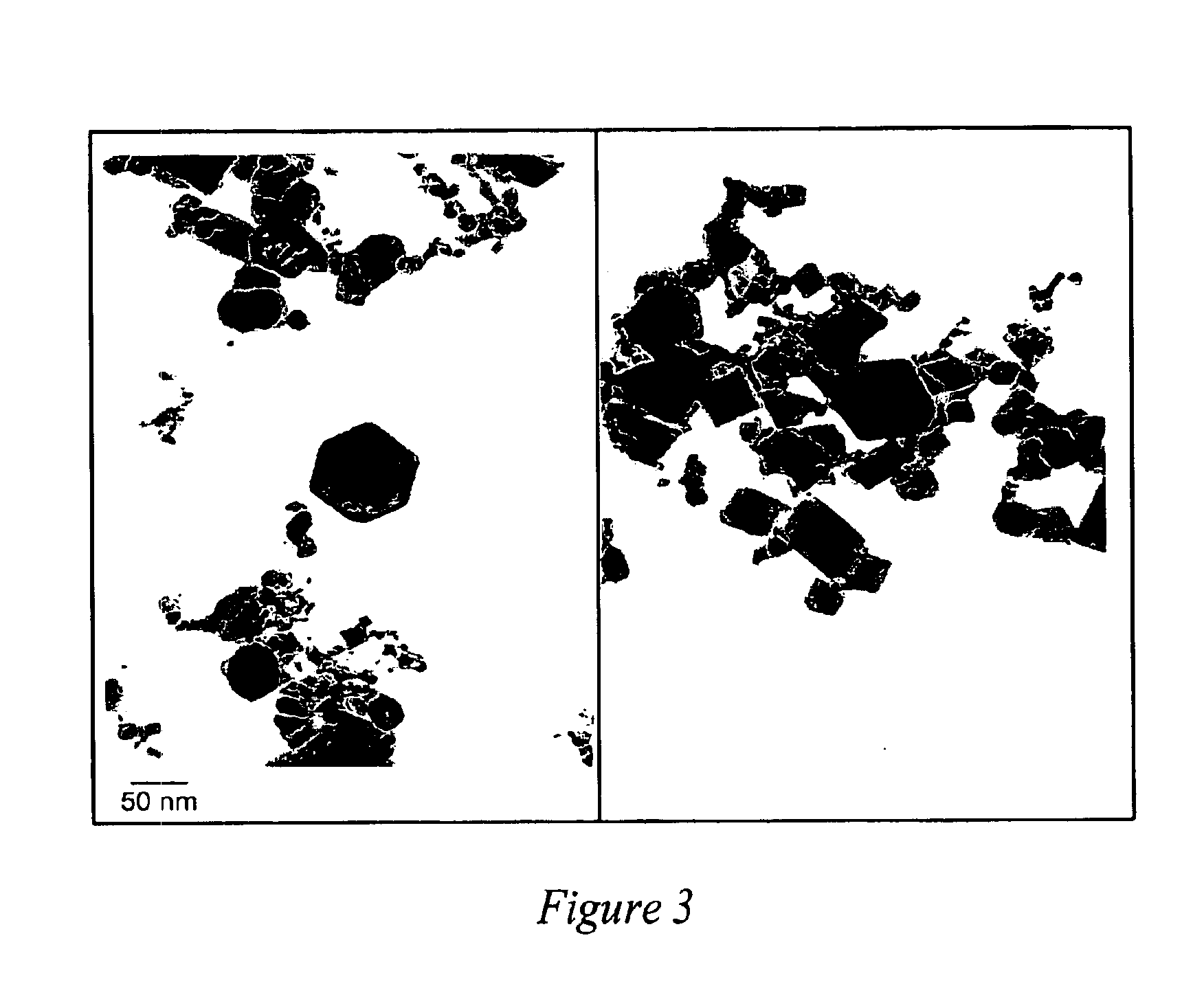

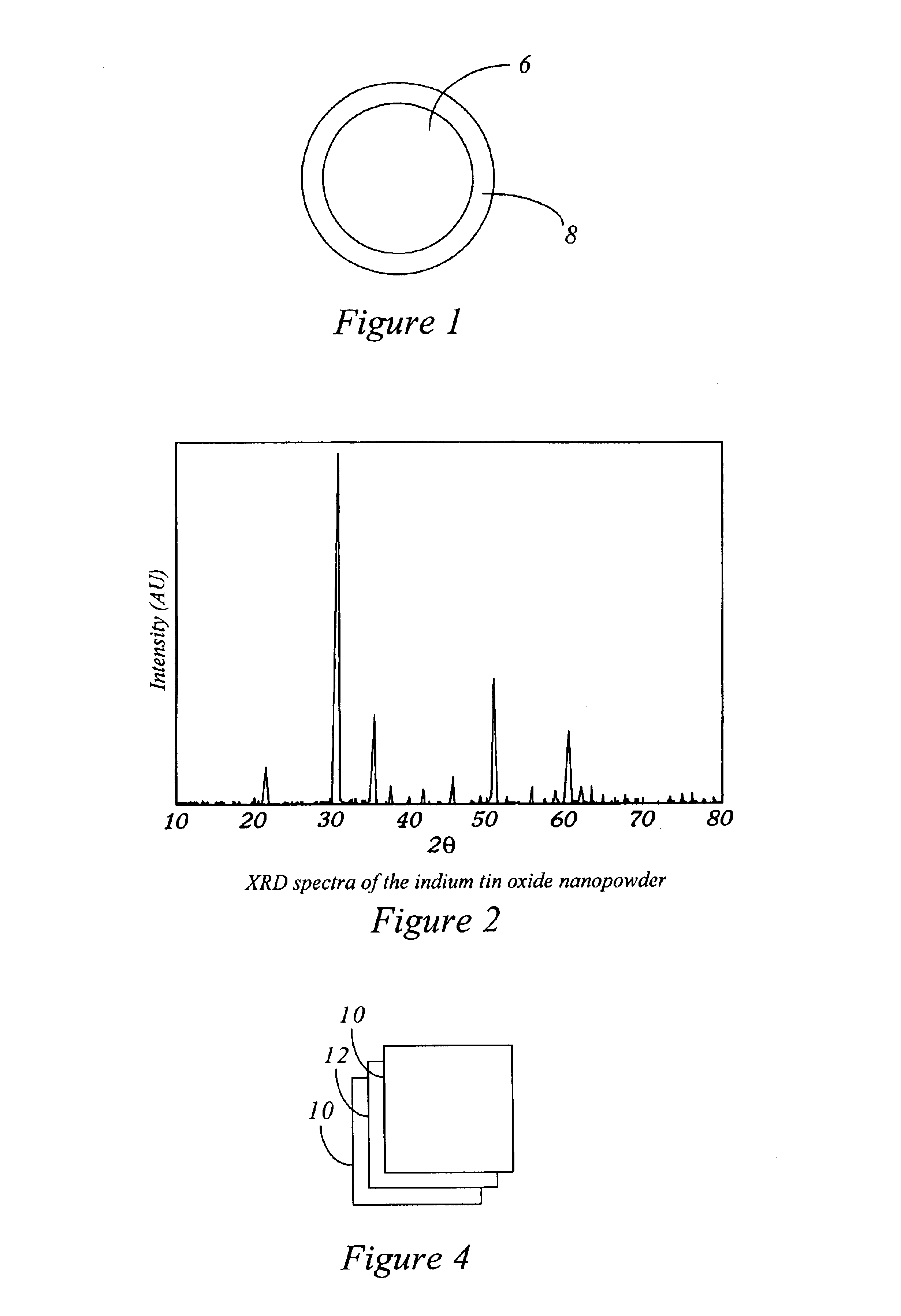

Conductive nanocomposite films

Methods for preparing low resistivity nanocomposite layers that simultaneously offer optical clarity, wear resistance and superior functional performance. Nanofillers and a substance having a polymer are mixed. Both low-loaded and highly-loaded nanocomposites are included. Nanoscale coated and un-coated fillers may be used. Nanocomposite films may be coated on substrates.

Owner:PPG IND OHIO INC

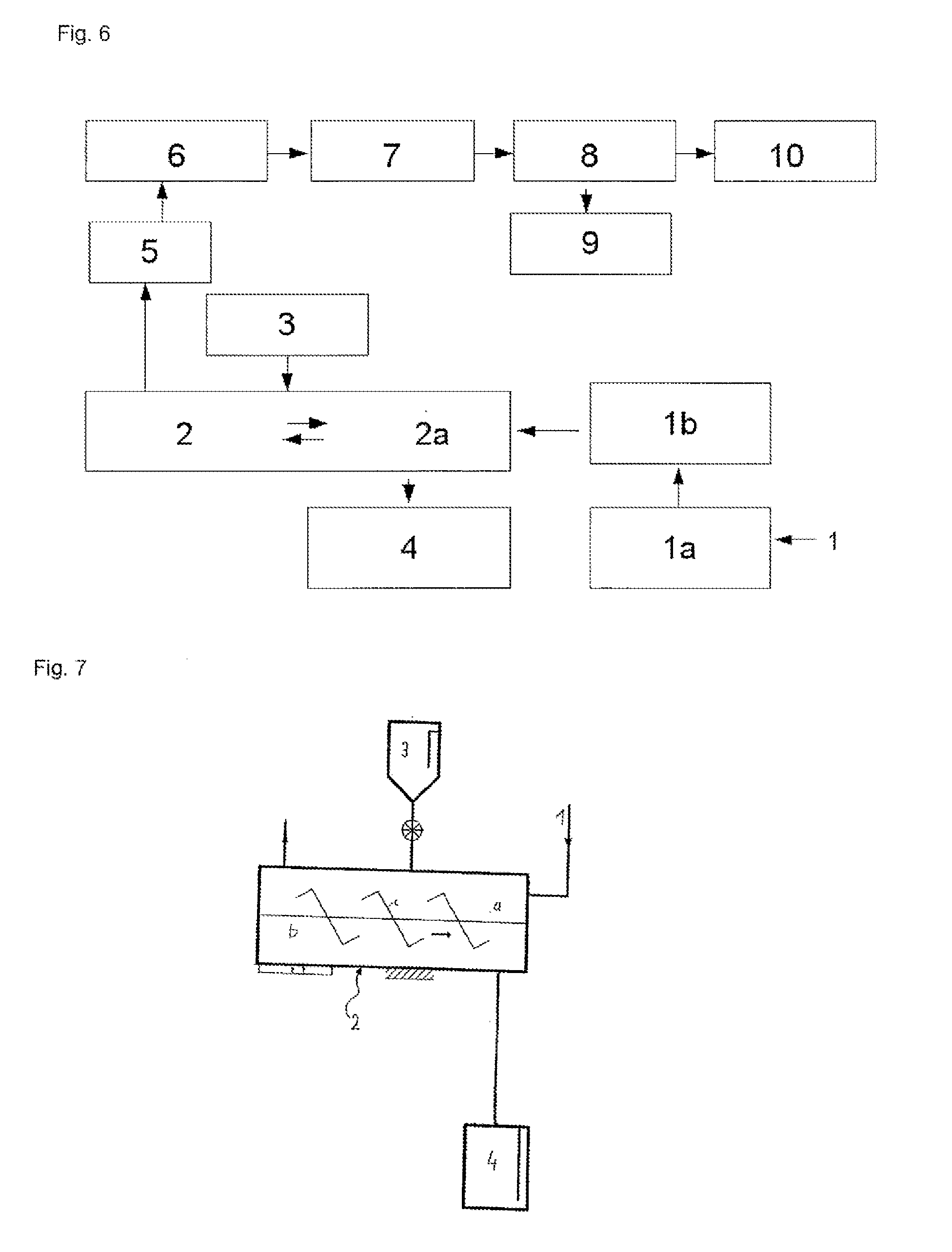

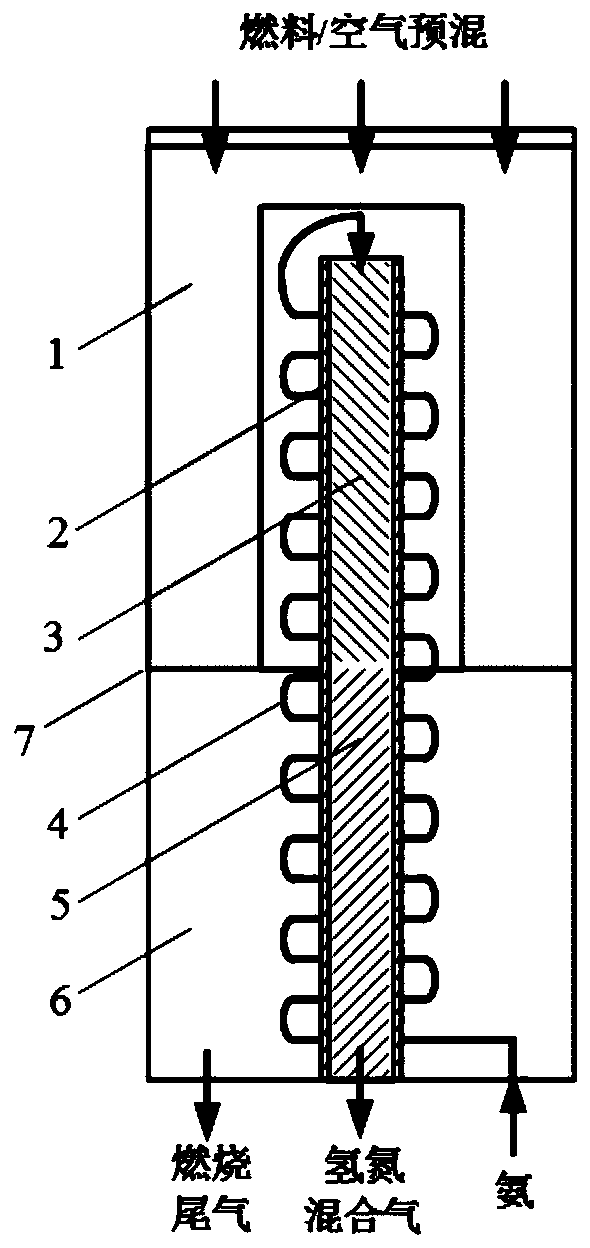

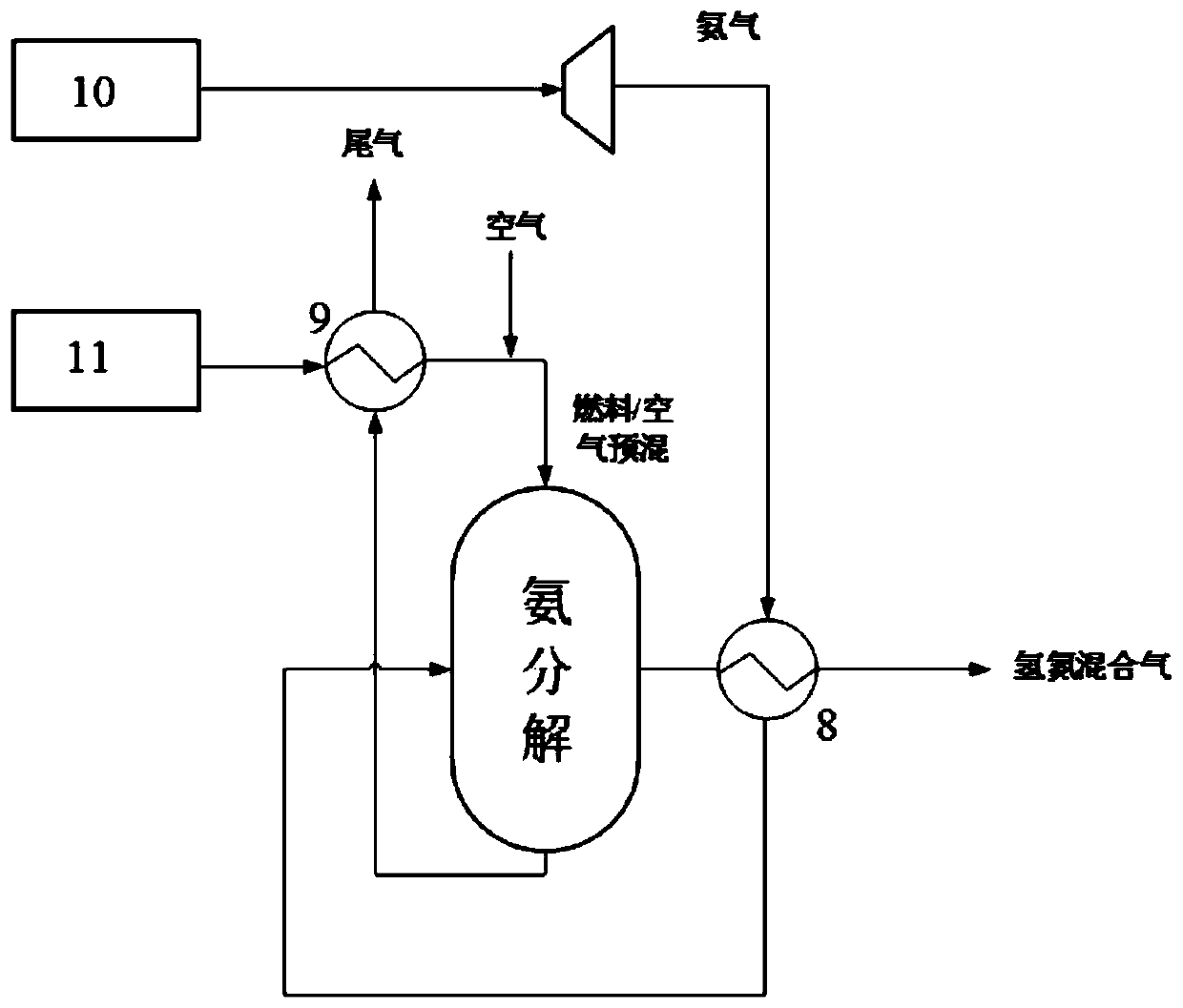

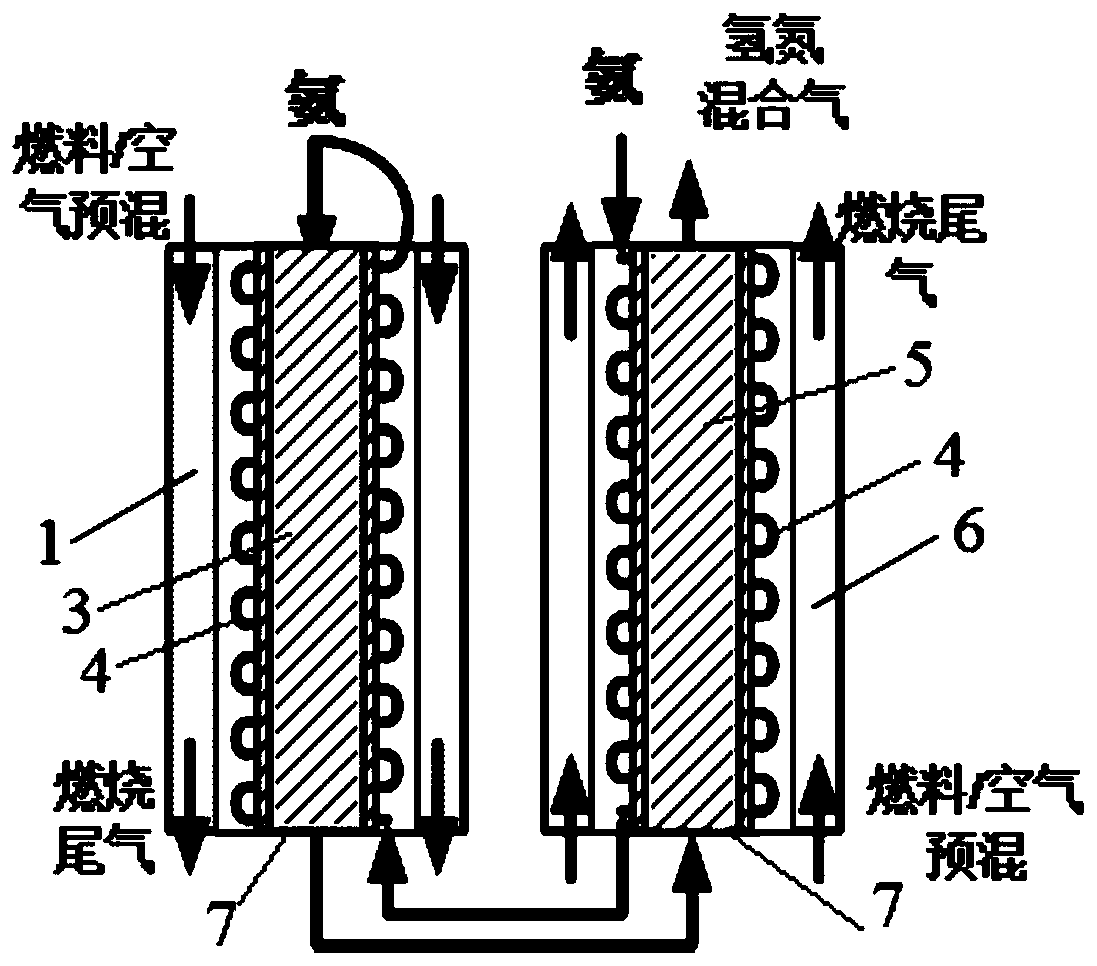

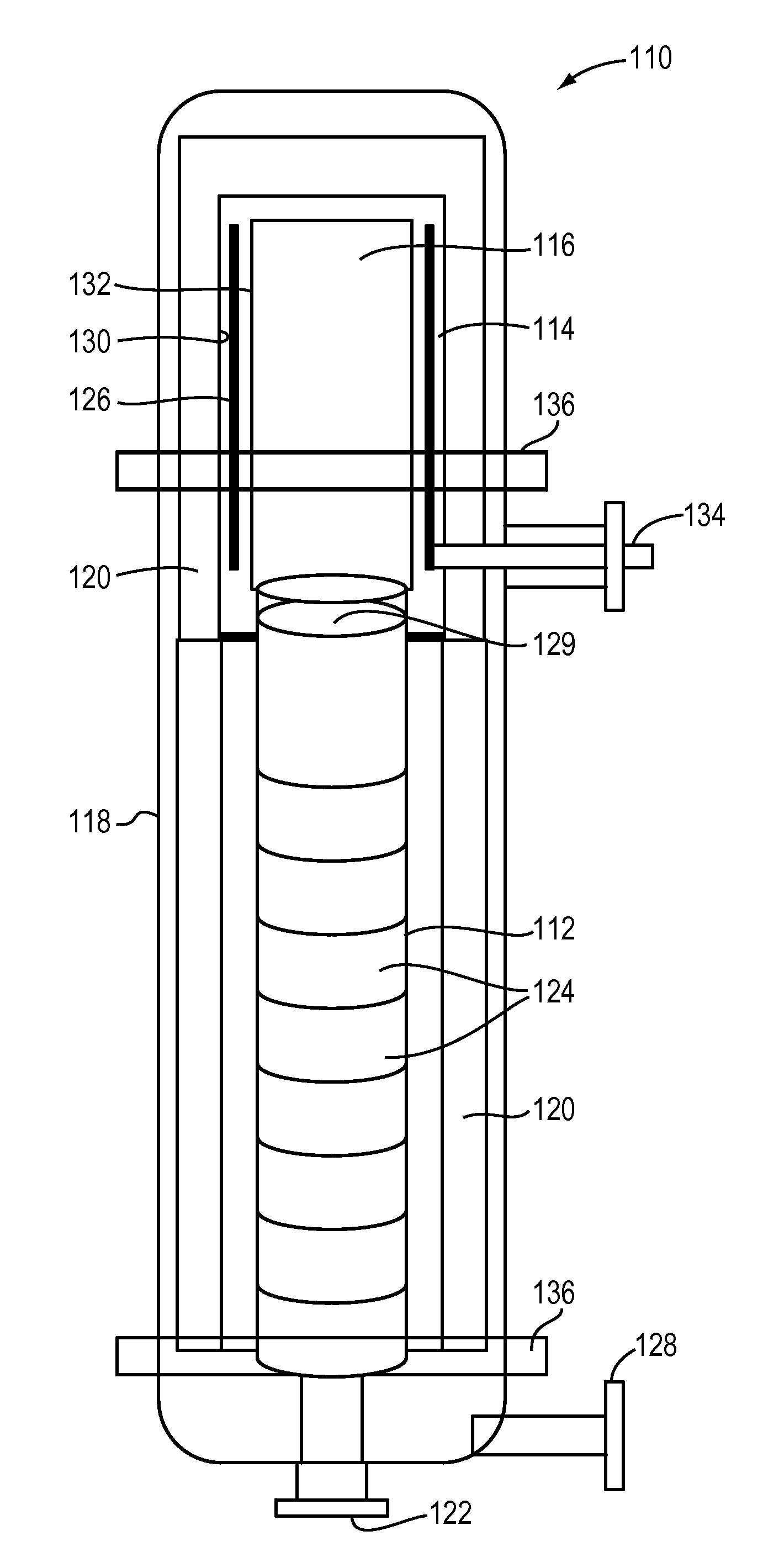

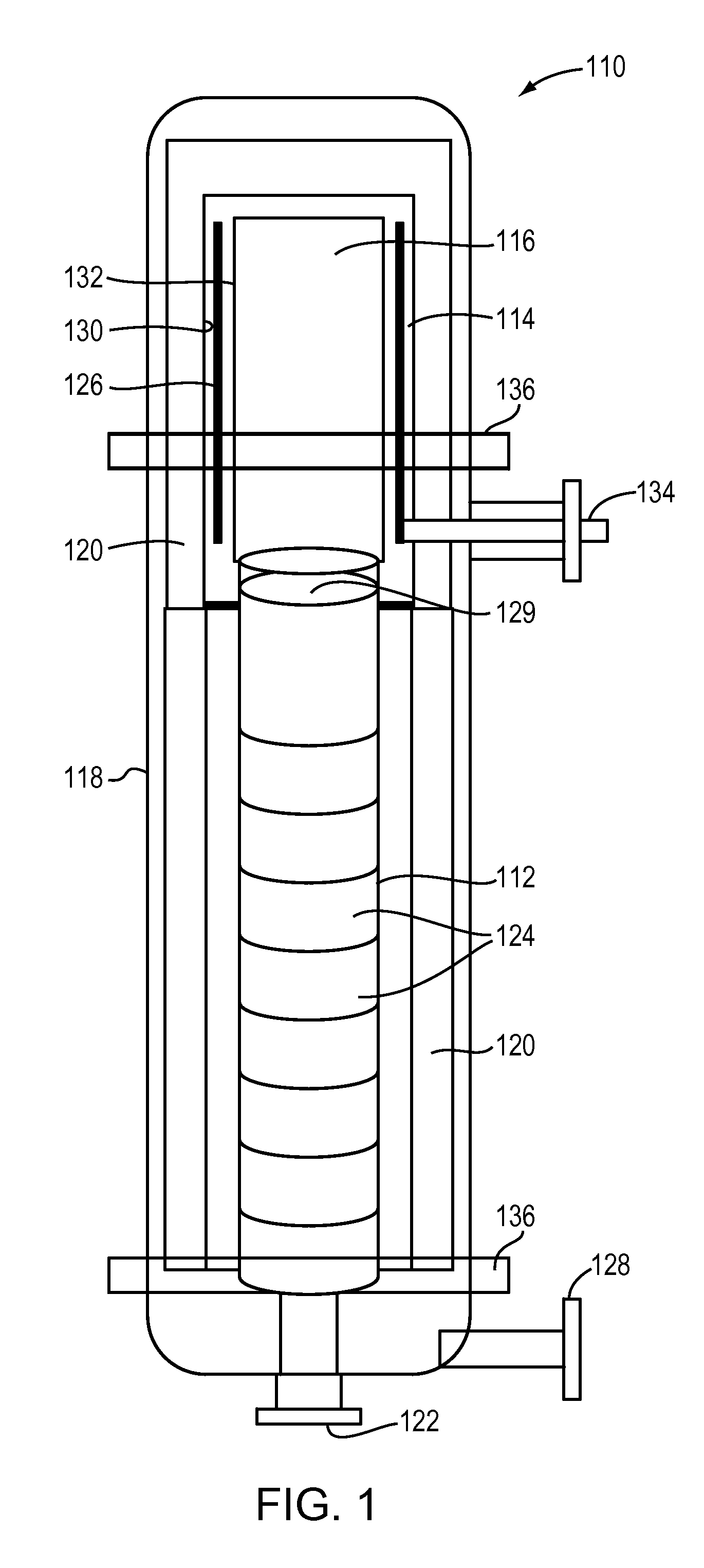

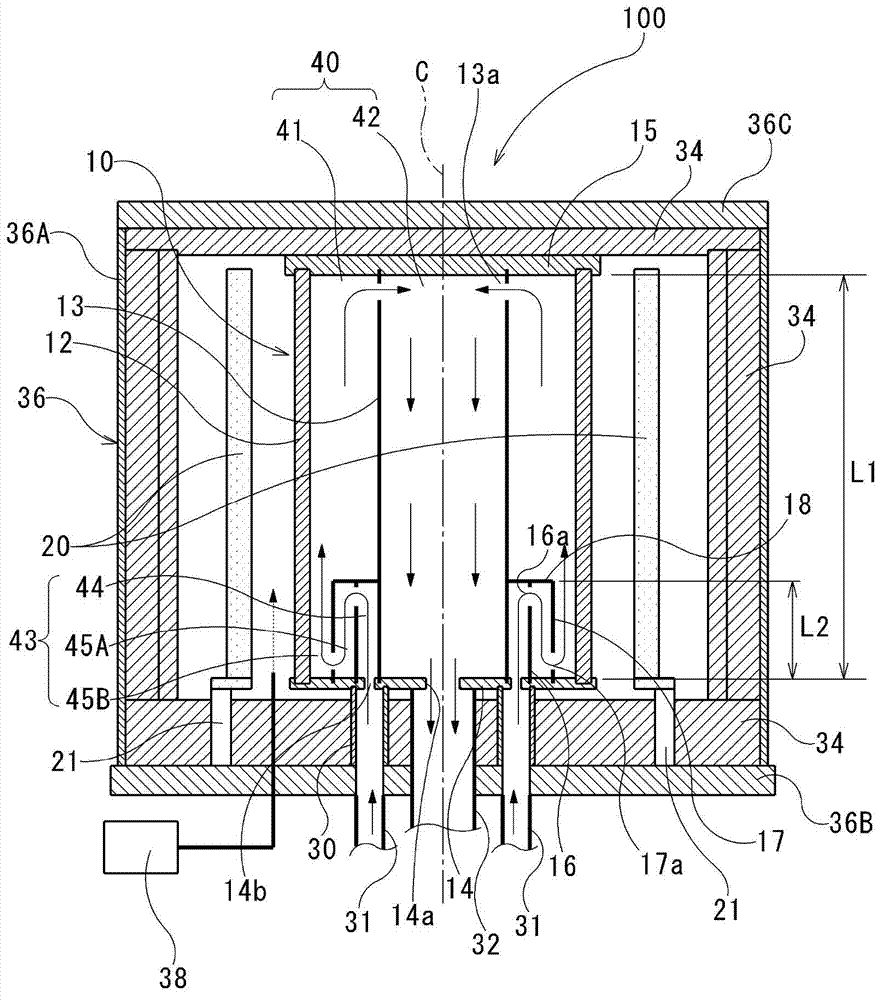

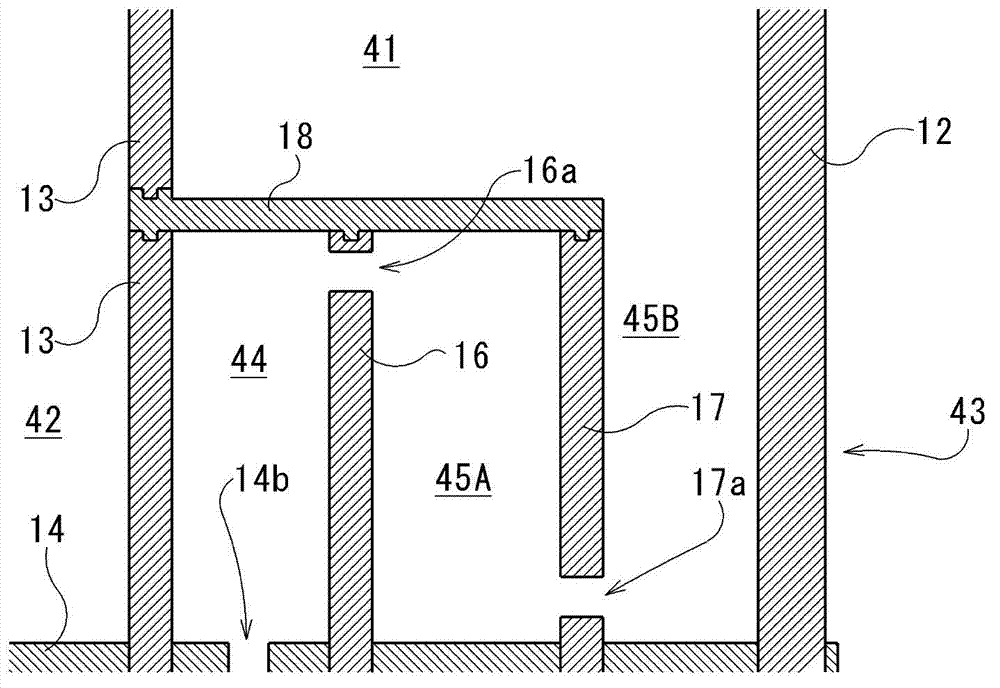

Ammonia decomposition device, ammonia decomposition system and hydrogen production method

ActiveCN110203882ADecompose thoroughlyImprove decomposition efficiencyGas treatmentHydrogen separation using solid contactDecompositionNitrogen

The invention belongs to the technical field of hydrogen production, and concretely relates to an ammonia decomposition device, an ammonia decomposition system and a hydrogen production method. The ammonia decomposition device comprises a shell, a heating zone, a heat exchange zone, a reaction section and a heat exchange coil. The heat exchange coil is spirally wound around the outer wall of the reaction section to sufficiently heat ammonia gas, so the heating efficiency of ammonia gas is increased; a first reaction section and a second reaction section which are sequentially communicated arearranged in the reaction section to ensure that the ammonia gas is decomposed after entering the first reaction section in order to generate a nitrogen and hydrogen mixture, so the decomposition efficiency of the ammonia gas is increased; and the second reaction section can perform secondary decomposition on the residual ammonia gas in the nitrogen and hydrogen mixture produced in the first reaction section, so the residual amount of ammonia gas in the nitrogen and hydrogen mixture in the second reaction section is reduced, thereby the ammonia gas is decomposed more thoroughly. The device makes the conversion rate of ammonia gas reach 99.9% or more and the residual amount of ammonia gas in the nitrogen and hydrogen mixture less than 1000 ppm.

Owner:福大紫金氢能科技股份有限公司

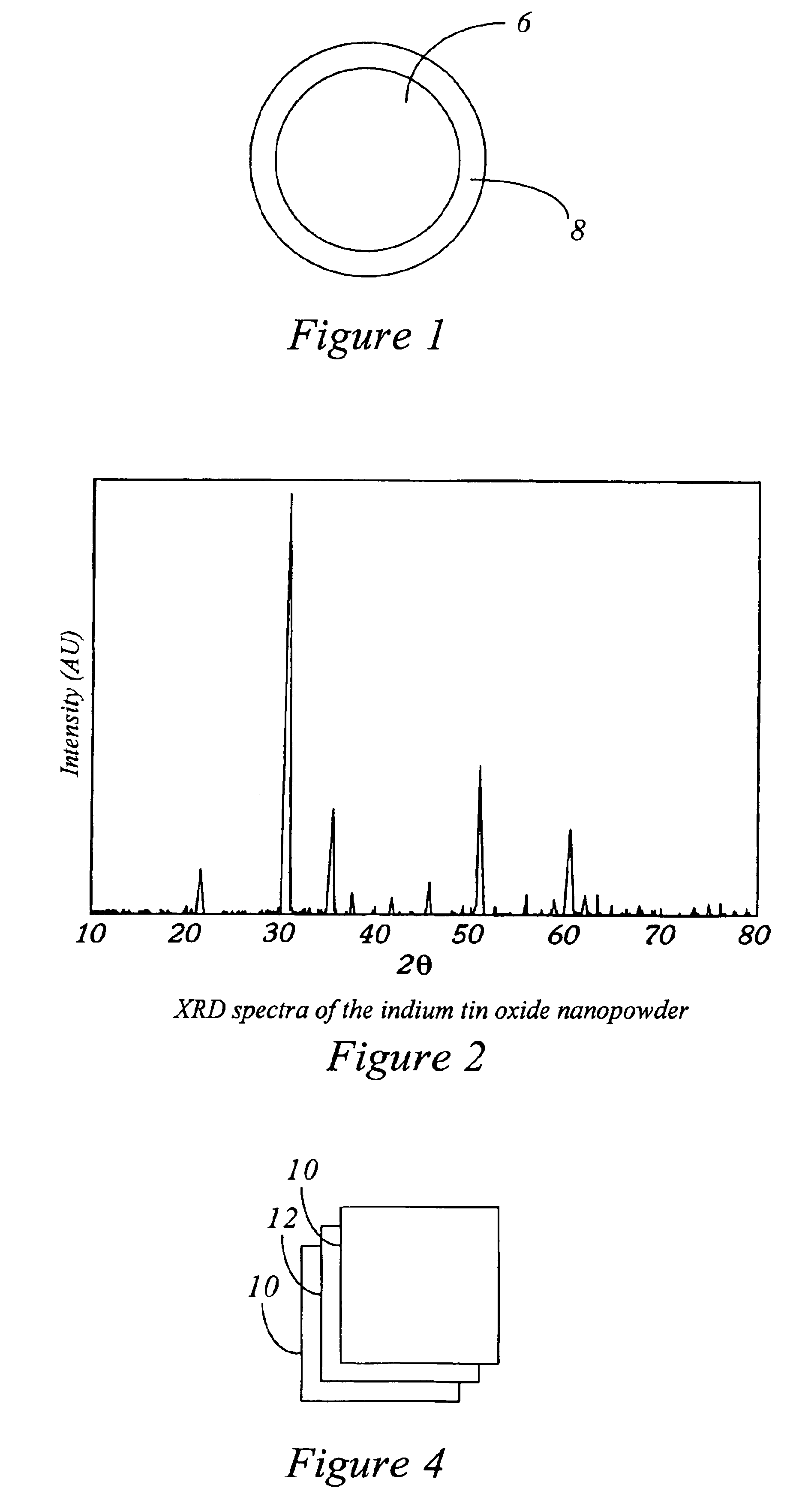

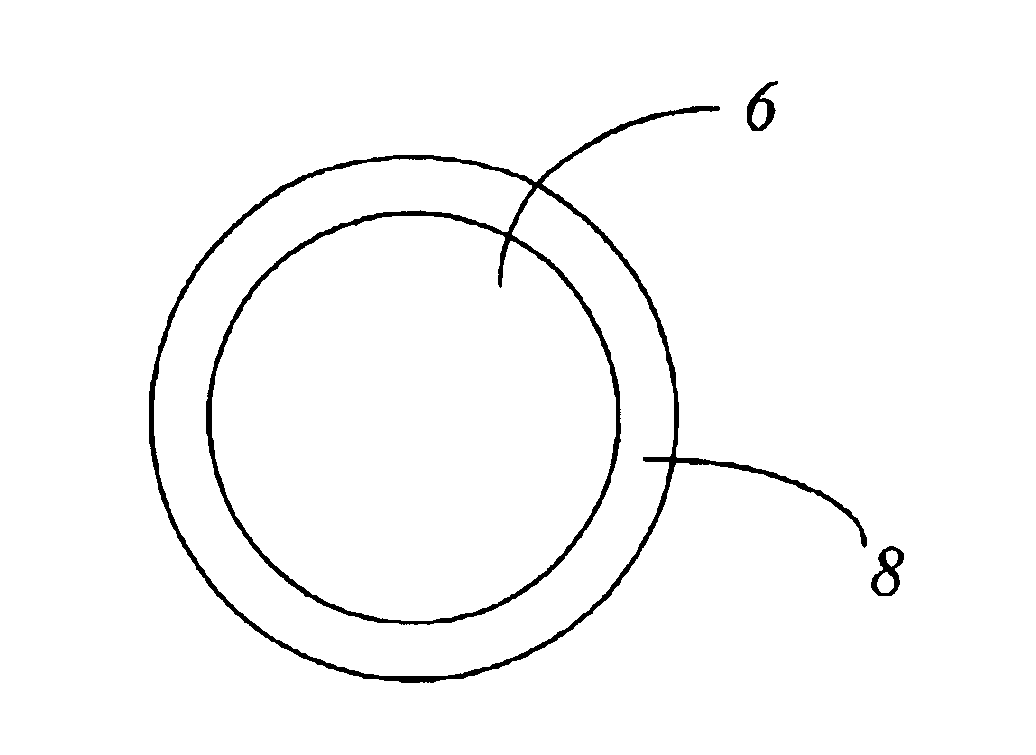

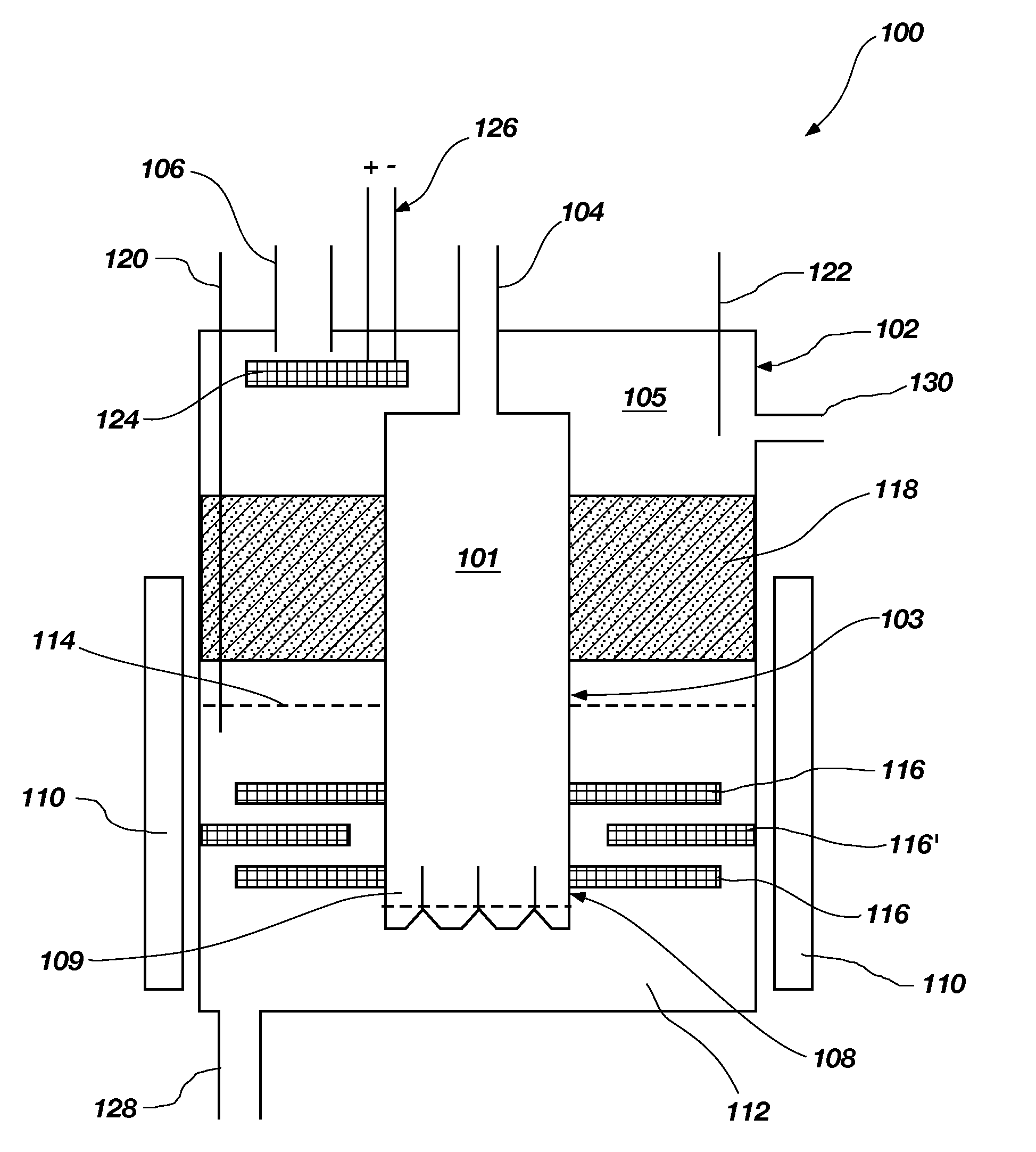

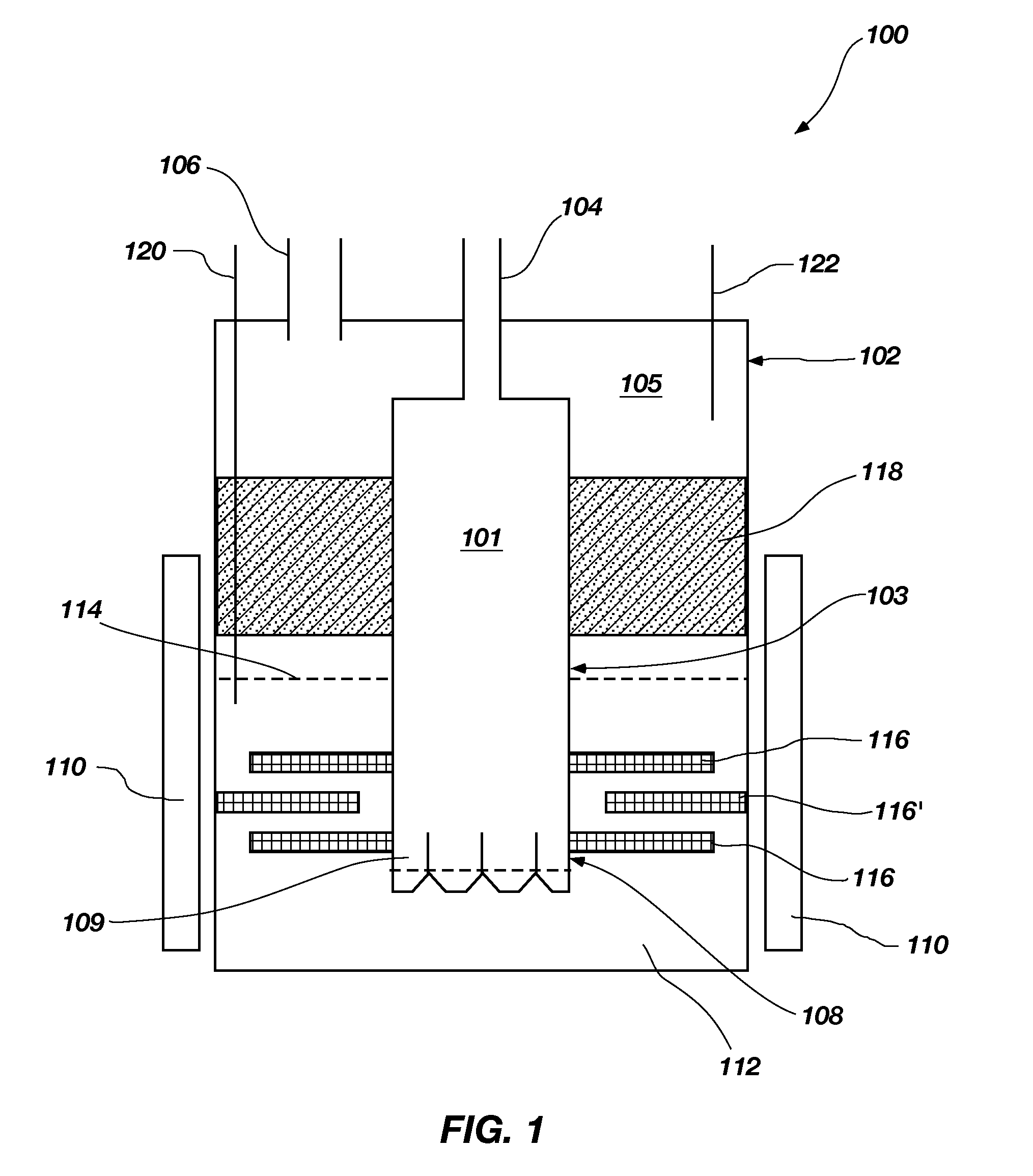

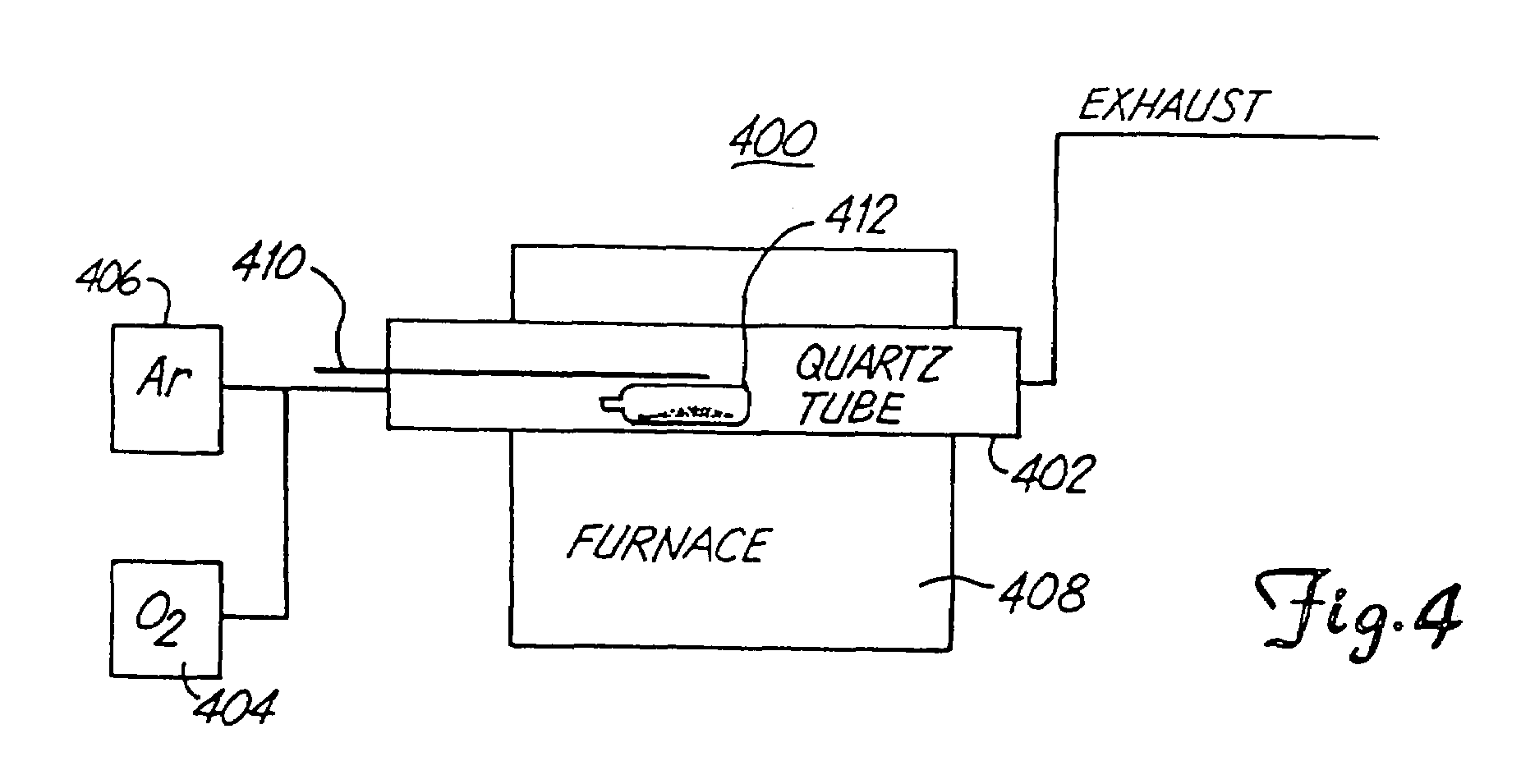

Apparatus and Methods for Conversion of Silicon Tetrachloride to Trichlorosilane

ActiveUS20120328503A1High temperature gas-gas reactionChemical industryProcess engineeringSilicon tetrachloride

The invention relates to apparatus and associated methods for conversion of silicon tetrachloride (STC) to trichlorosilane (TCS). The converter features a relatively thin annular heating zone surrounding a reaction chamber. Within the annular heating zone is a heating element that has an annular conformation about the reaction chamber. The design allows high convective heat transfer, which facilitates the use of lower heating element surface temperatures, prolonging the life of the equipment, reducing capital cost by allowing use of a smaller reactor, and greatly improving heating efficiency. A heat exchanger with a plurality of heat exchanger blocks provides further efficiency.

Owner:ADVANCED MATERIAL SOLUTIONS LLC

Methods and reactors for producing acetylene

InactiveUS20150165414A1Hydrocarbon by dehydrogenationHigh temperature gas-gas reactionThermal energyCombustor

Methods and reactors are provided for producing acetylene. The method includes combusting a fuel with oxygen in a combustor to produce a carrier gas, and accelerating the carrier gas to a supersonic speed in a converging / diverging nozzle prior to the carrier gas entering a reaction zone. A nozzle exit temperature of the carrier gas is controlled from about 1,200° C. to about 2,500° C. Methane is added to the carrier gas in the reaction zone, and kinetic energy in the carrier gas is converted to thermal energy in the reaction zone to increase the temperature of the carrier gas such that the methane reacts by pyrolysis to form the acetylene.

Owner:UOP LLC

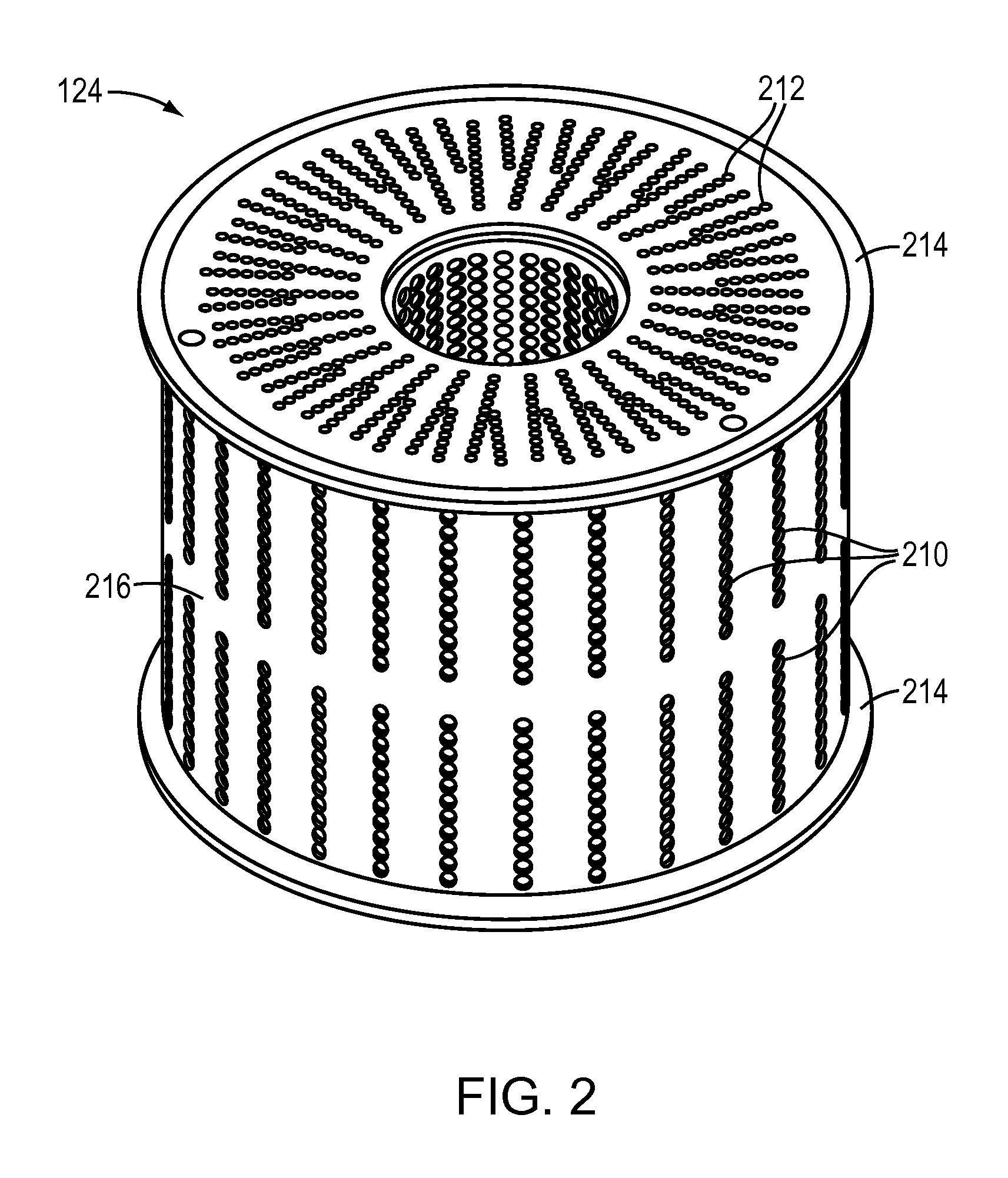

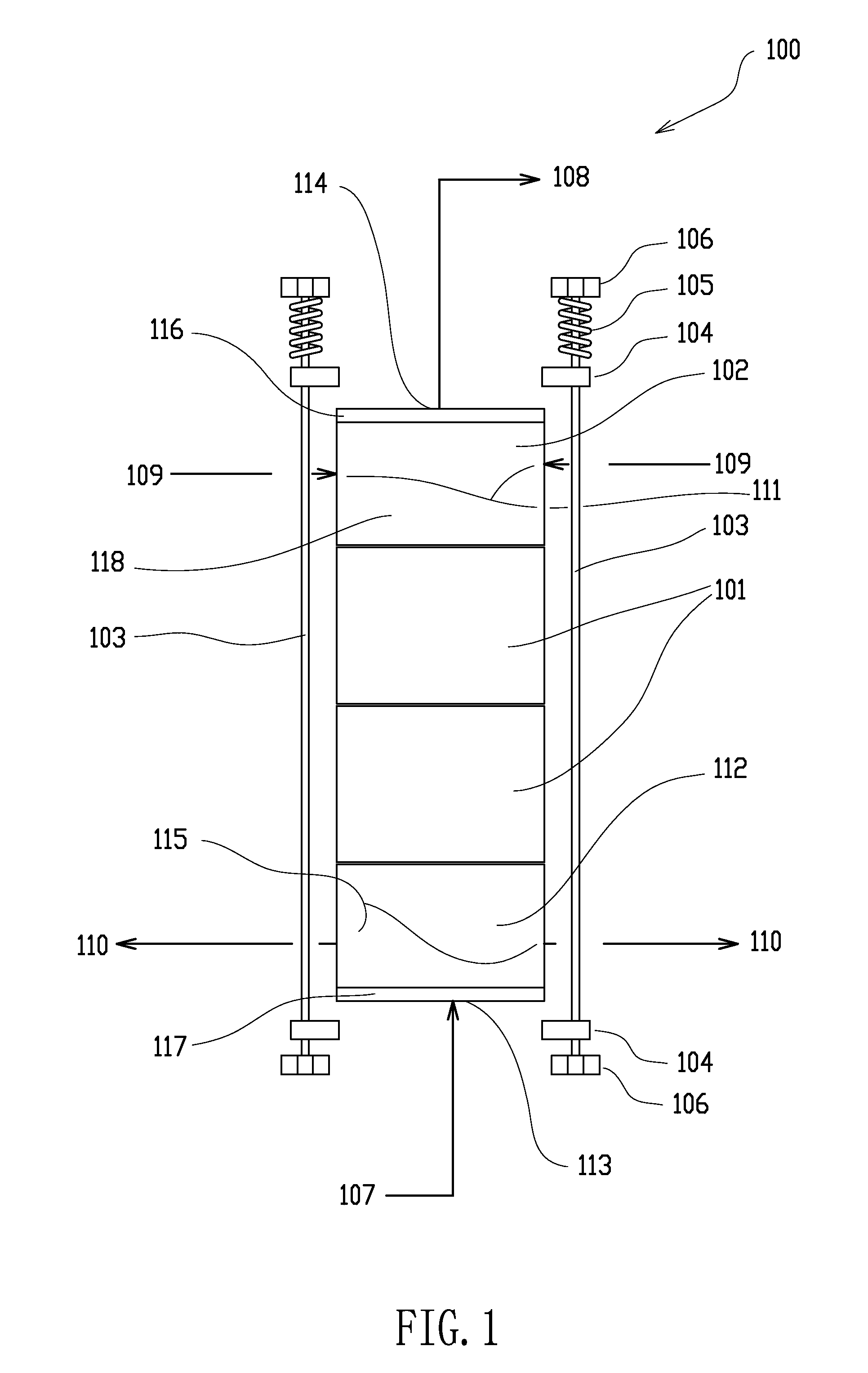

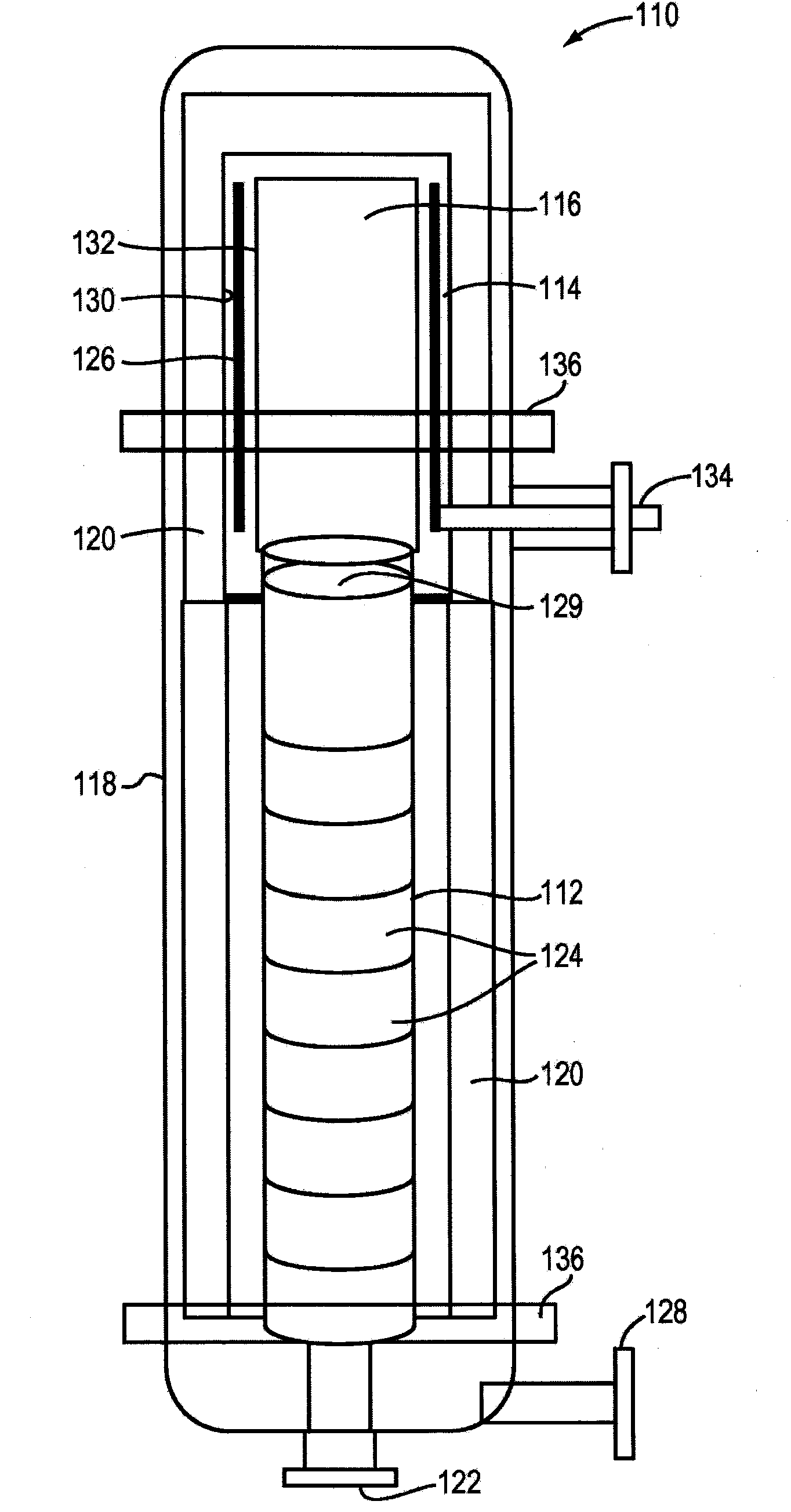

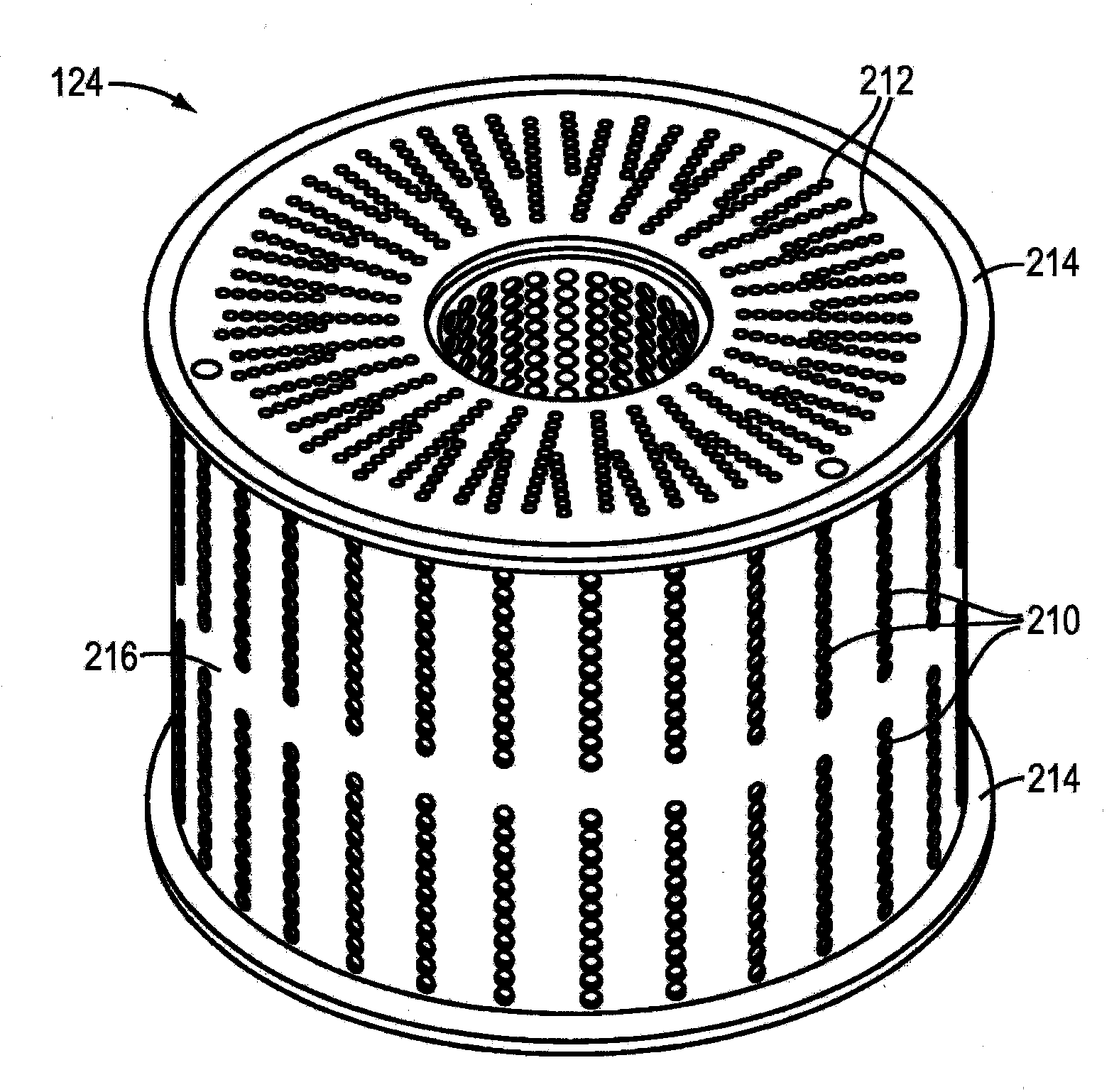

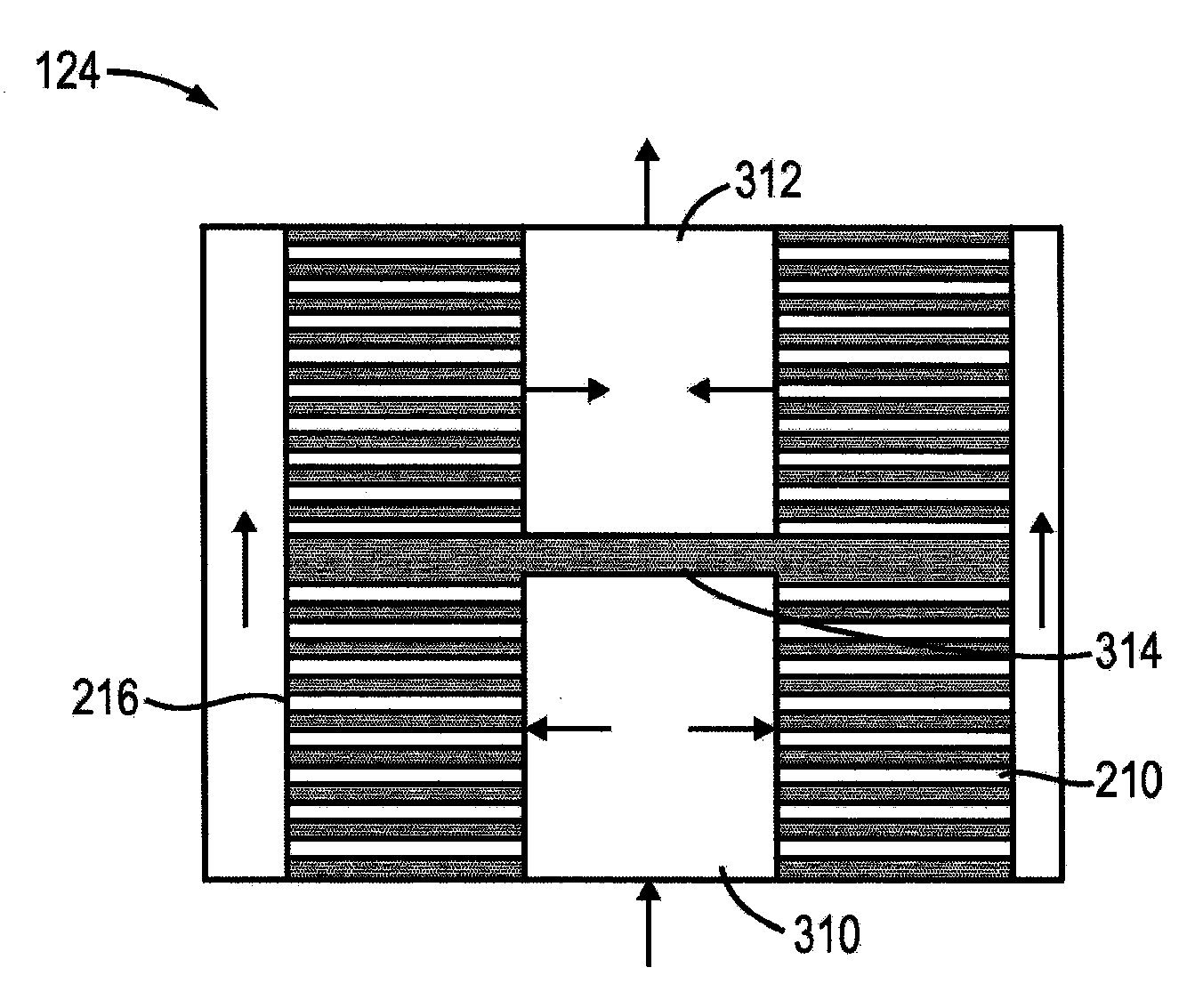

Monolithic heat exchanger and apparatus and methods for hydrogenation of a halosilane

ActiveUS9308510B2Big advantageHigh temperature gas-gas reactionSafety devices for heat exchange apparatusEngineeringHigh heat

A counter current heat exchanger amenable to fabrication from monolithic materials and particularly useful in corrosive and high temperature environments is described. The heat exchanger uses multiple series of holes bored axially through a monolithic material. Axial holes are bored in adjacent flow paths arranged in closely spaced concentric rings. In operation, counter current flow and heat transfer occurs between multiple adjacent axial flow paths. The heat exchanger design is scaleable over a wide range and particularly useful in reactors for the hydrogenation of halosilanes also using cylindrical heating elements. The design enables a small overall reactor size for a given capacity.

Owner:HAZELTINE BRUCE

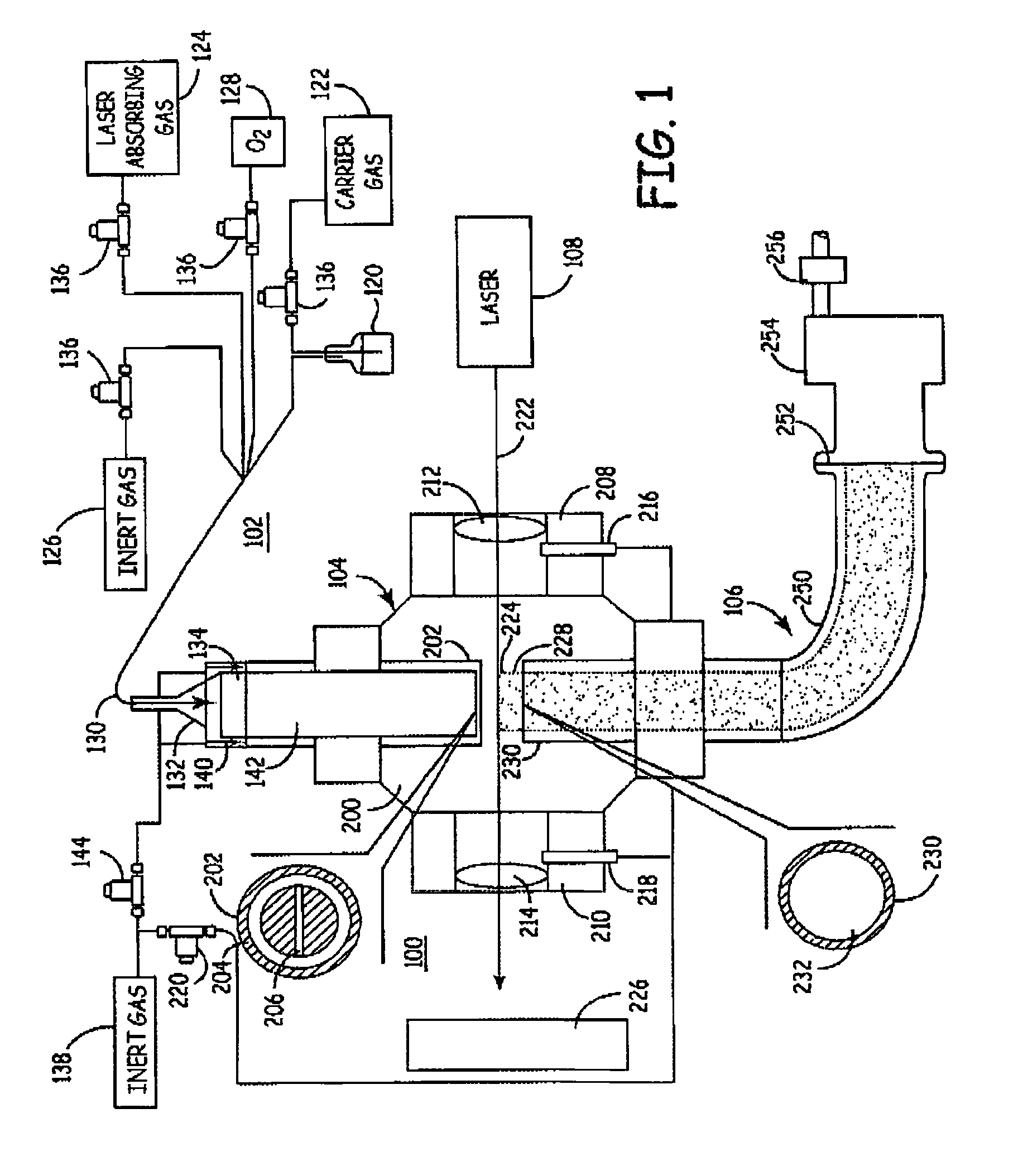

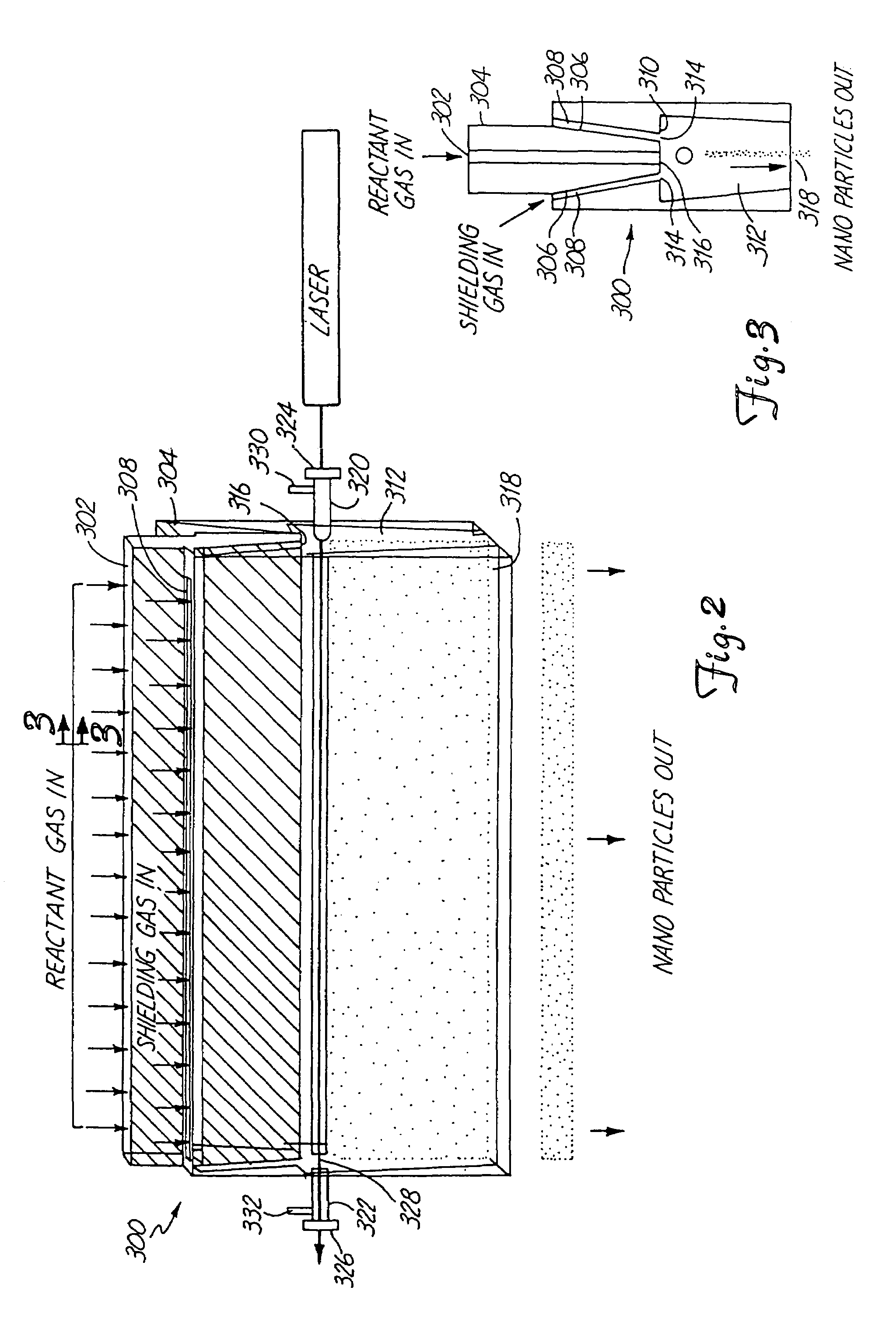

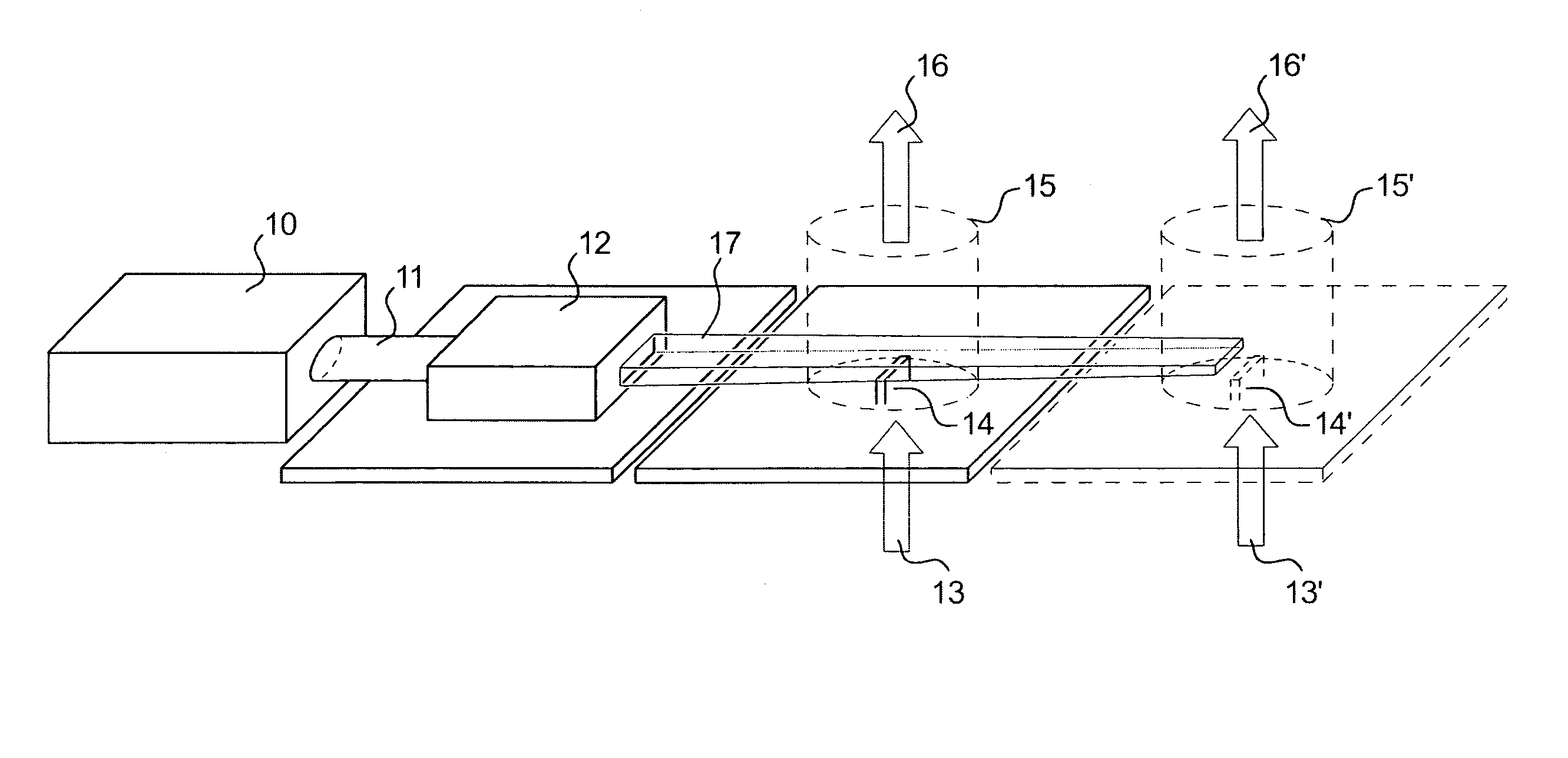

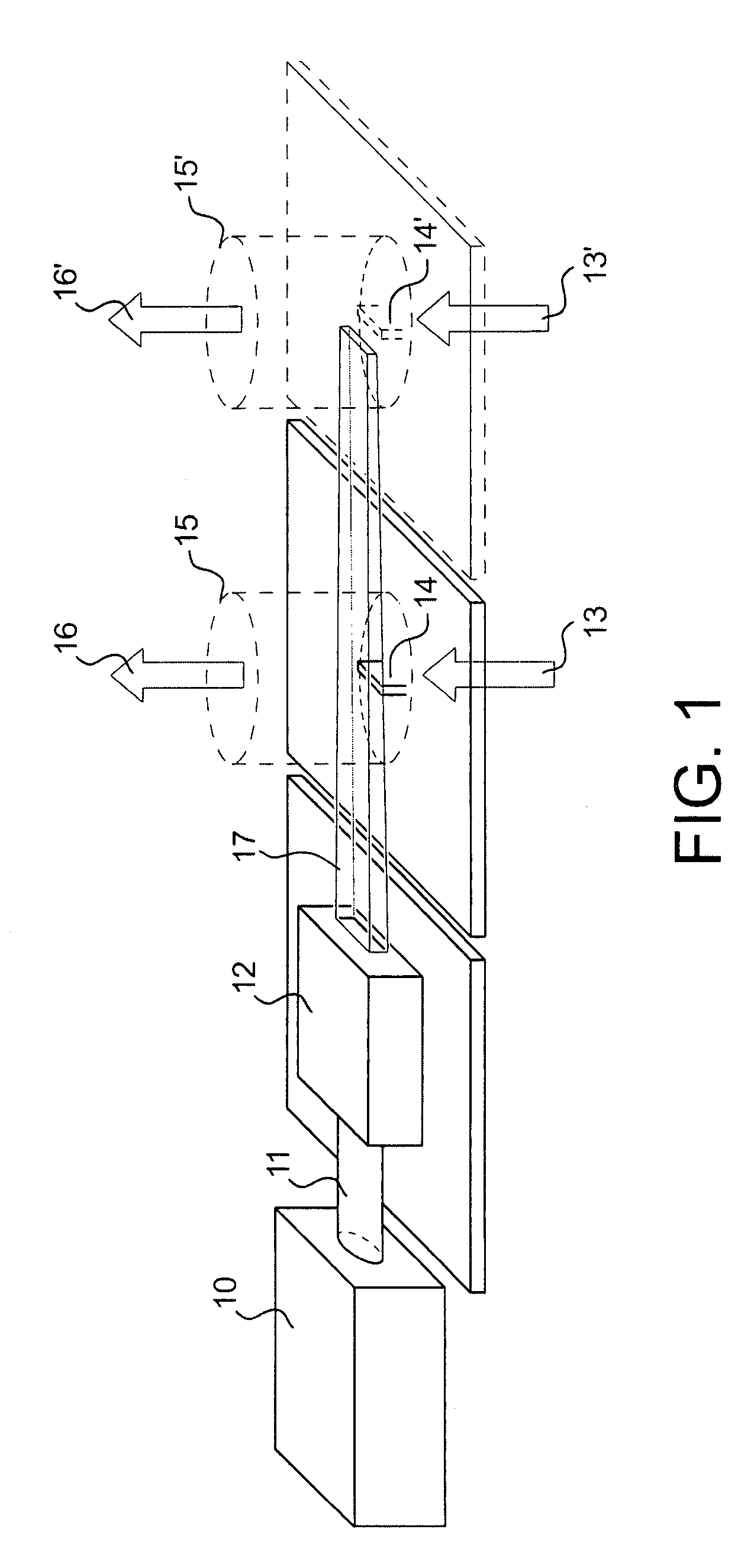

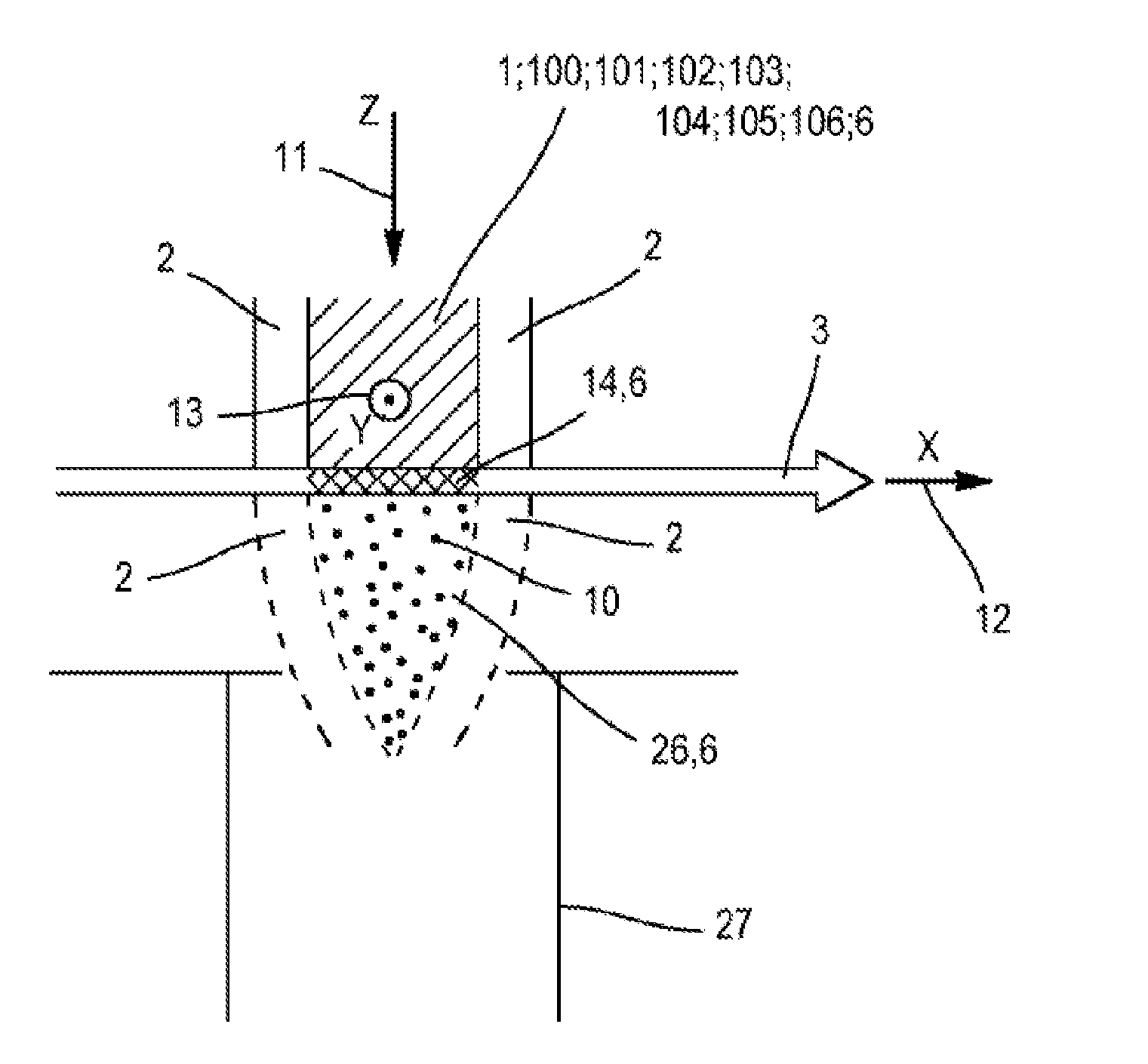

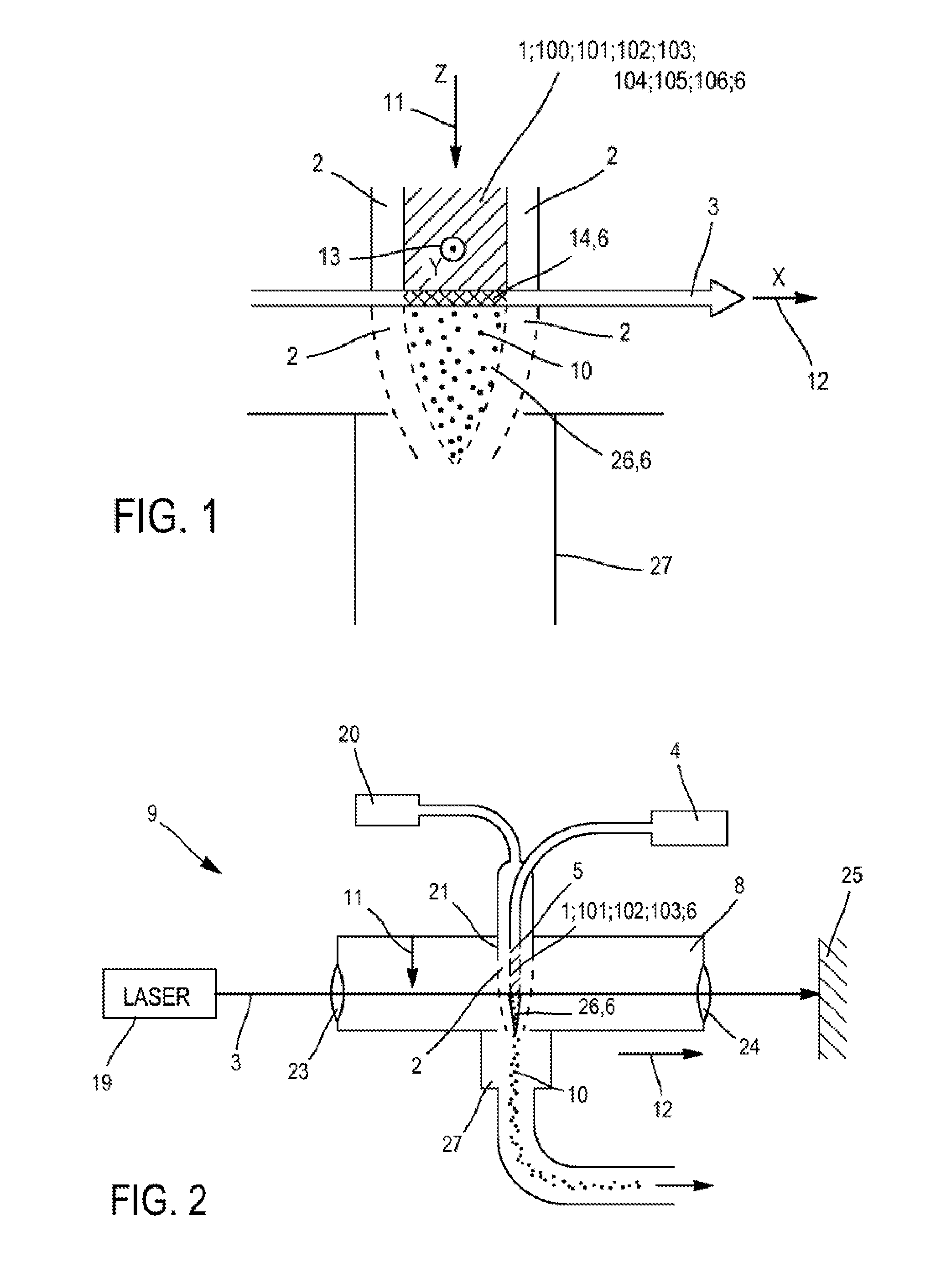

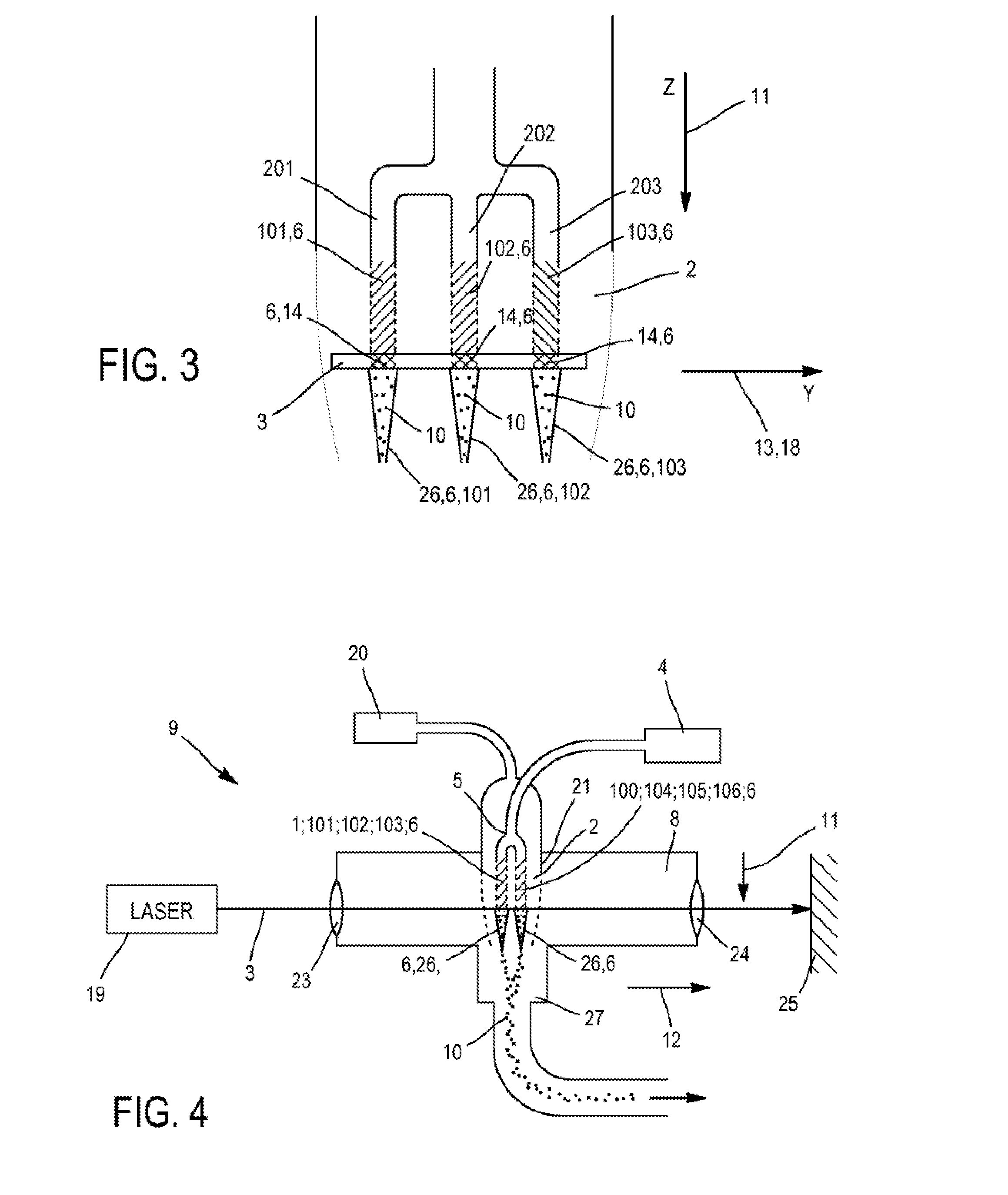

System and Process for Production of Nanometric or Sub-Micrometric Powders in Continuous Flus Under the Action of a Pyrolysis Laser

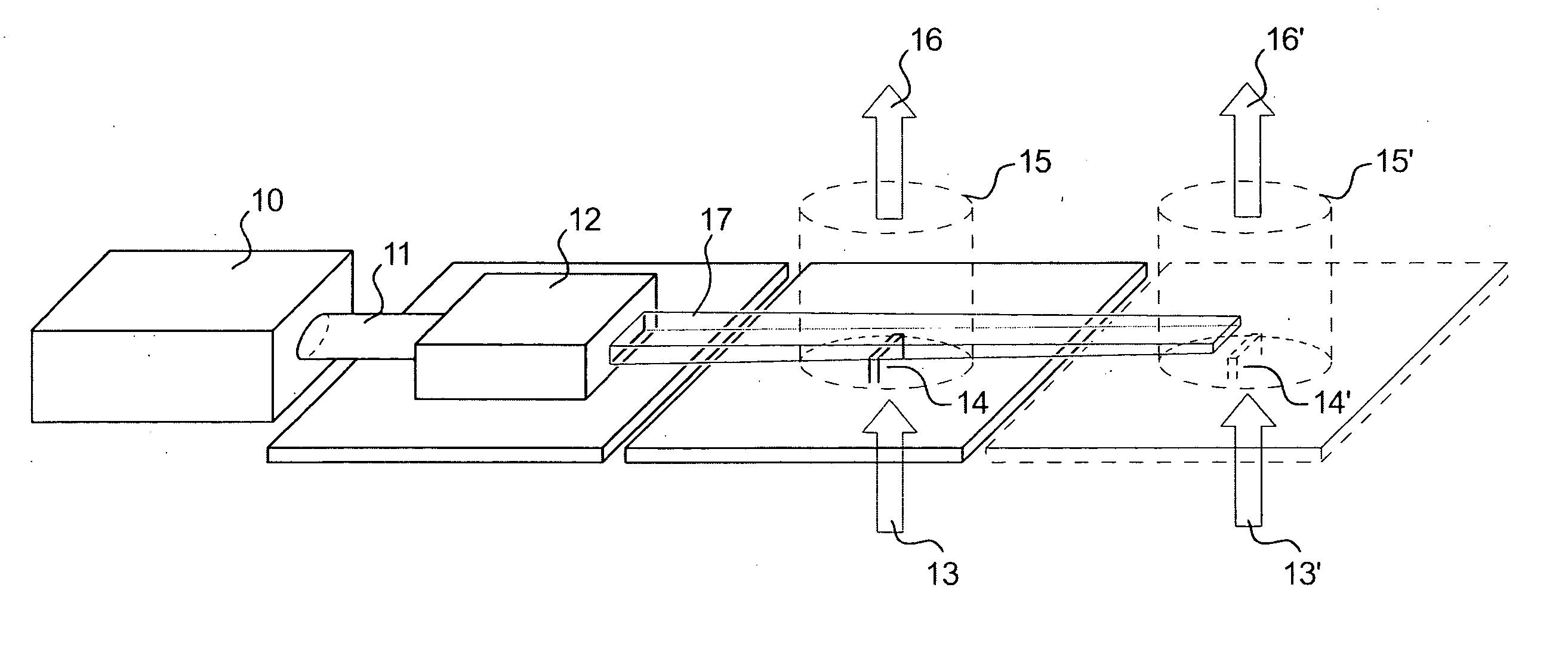

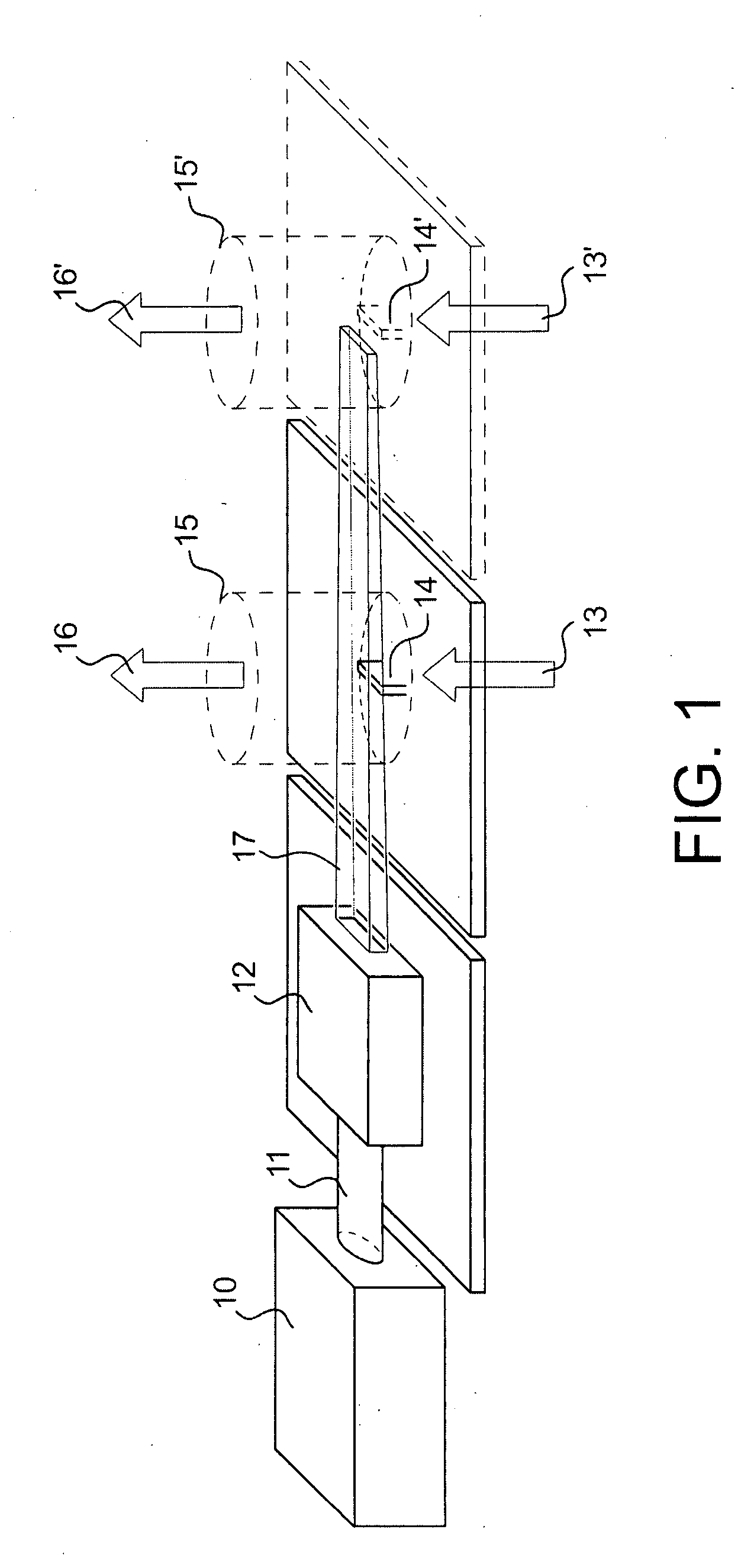

ActiveUS20070295702A1High temperature gas-gas reactionChemical/physical/physico-chemical processesLight beamLaser pyrolysis

The invention relates to a system for production of nanometric or sub-micrometric powders in continuous flux under the action of laser pyrolysis in at least one interaction zone between a beam (11) emitted by a laser (10) and a flux of reagents (13) emitted by an injector (14), in which the laser is followed by optical means (12) for distributing the energy of the beam emitted by the latter according to an axis perpendicular to the axis of each flux of reagents, in an elongated cross-section having adjustable dimensions at the level of this at least one interaction zone. It also relates to a process for production of such powders.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Use of a process for hydrogen production

The present invention relates to the use of a process for hydrogen production in which at least a part of a hydrocarbonaceous feed gas (a) is passed into a reformer (c), wherein the feed gas is contacted in the reformer with a catalyst and the feed gas is converted to hydrogen and solid carbon, for the direct production of a hydrogenous gas at filling stations for sale to a consumer, and also to a reactor (d) for hydrogen production.

Owner:BESTRONG INT

Abrasive particles for surface polishing

InactiveUS7258706B2Controlling polishing processHigh purityMaterial nanotechnologyPigmenting treatmentCarbideMetallic sulfide

Polishing compositions are described that are appropriate for fine polishing to very low tolerances. The polishing compositions include particles with small diameters with very narrow distributions in size and effectively no particles with diameters several times larger than the average diameter. Furthermore, the particles generally have very high uniformity with respect to having a single crystalline phase. Preferred particles have an average diameter less than about 200 nm. Laser pyrolysis processes are described for the production of the appropriate particles including metal oxides, metal carbides, metal sulfides, SiO2 and SiC.

Owner:NANOGRAM

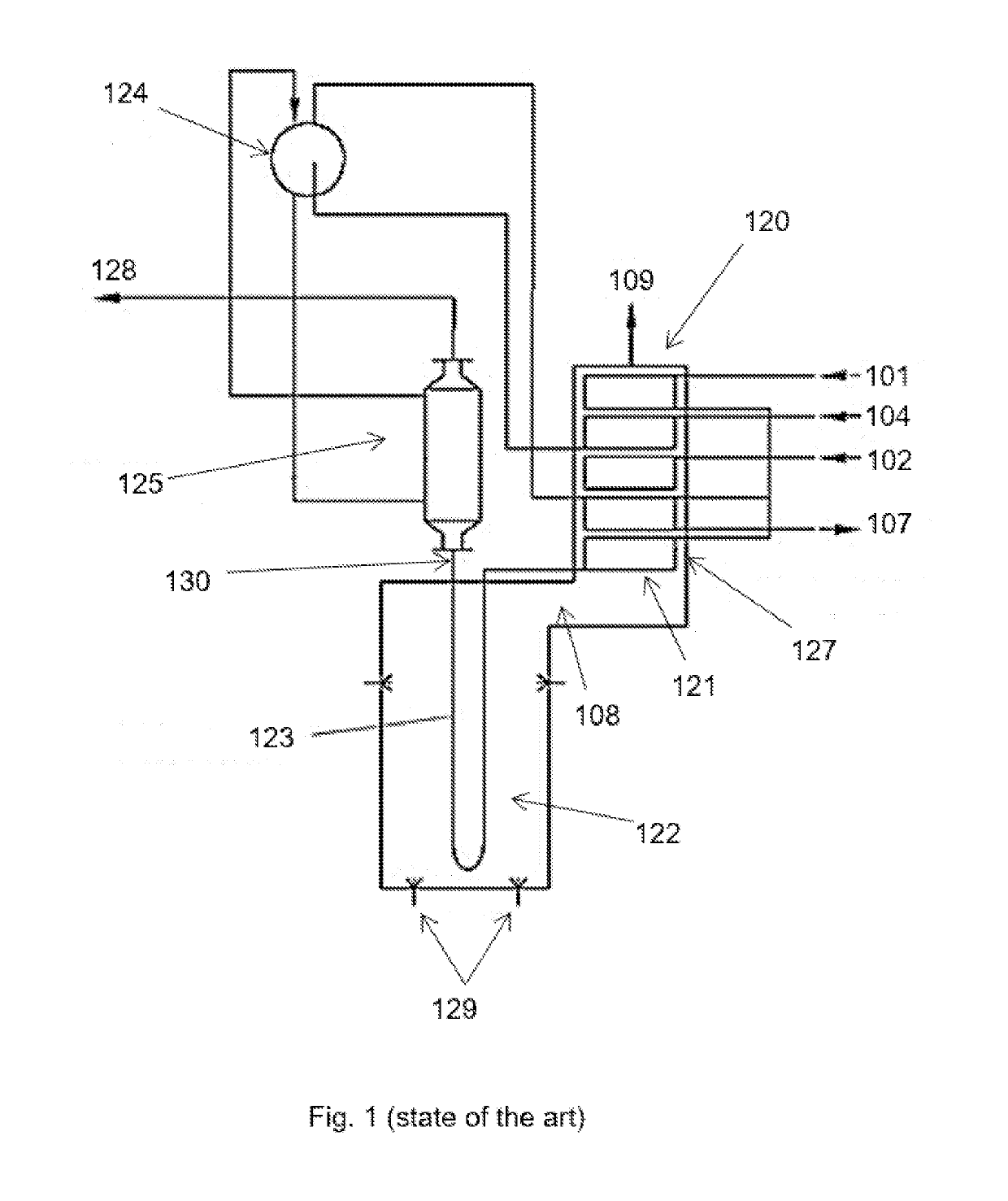

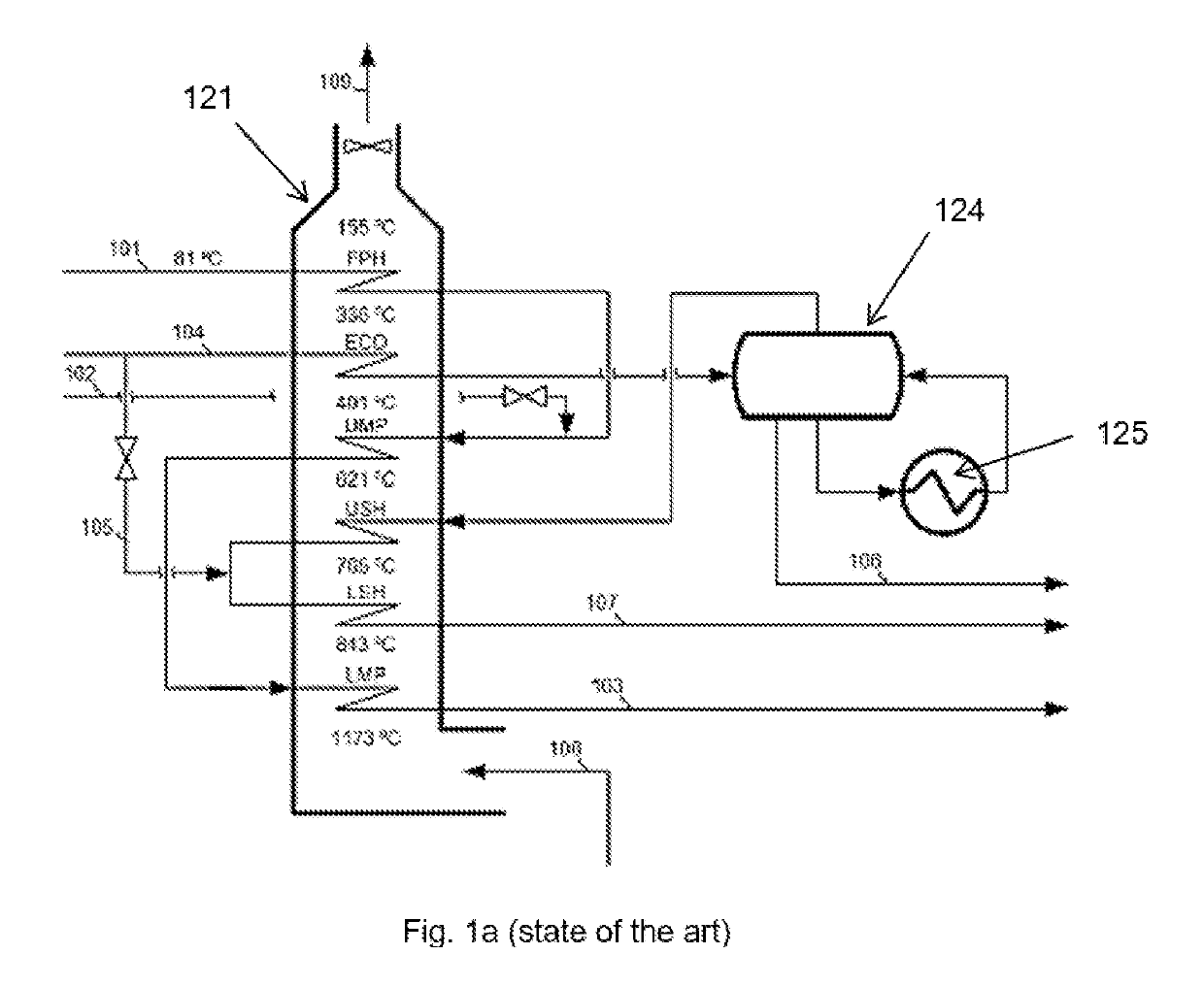

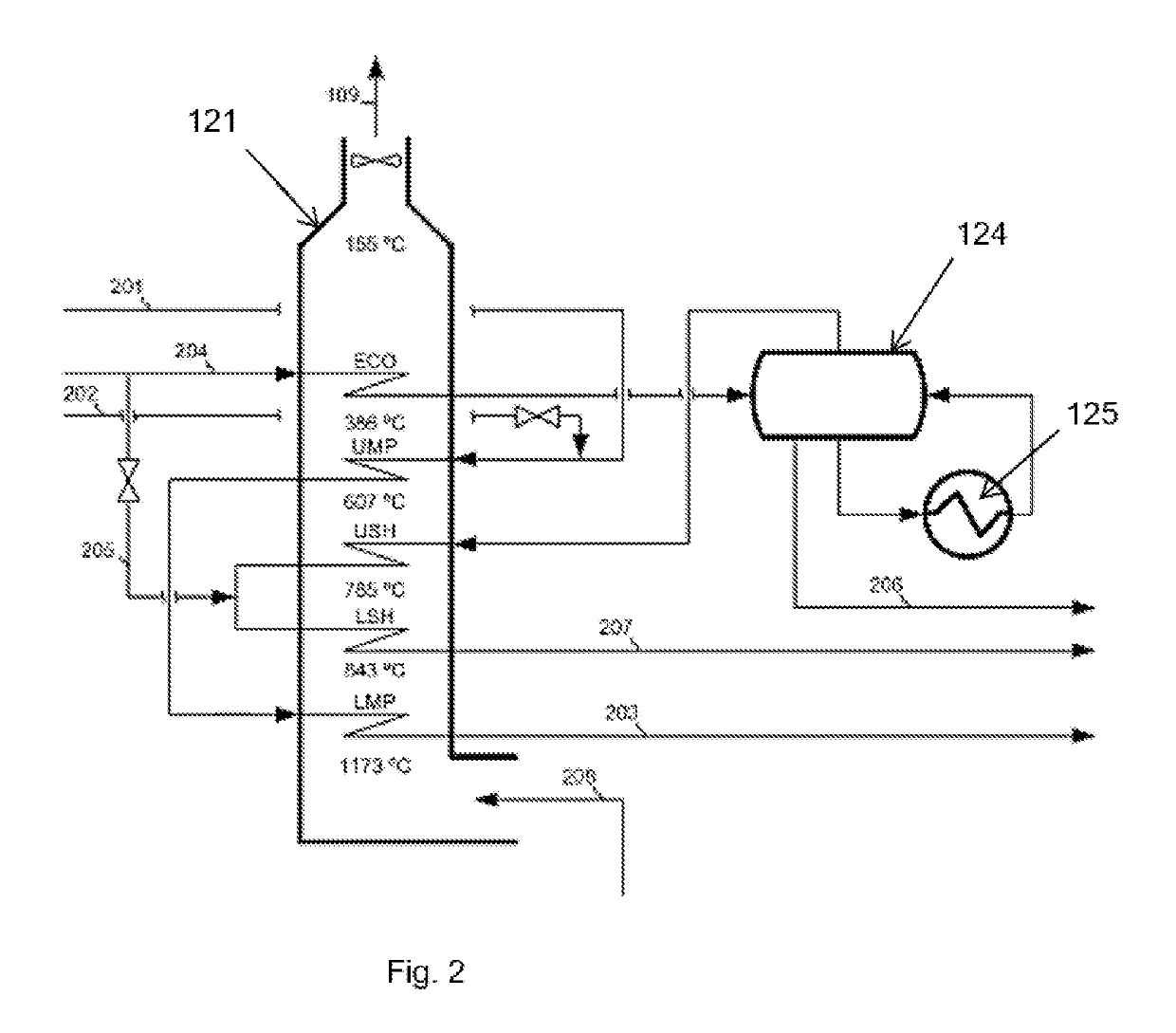

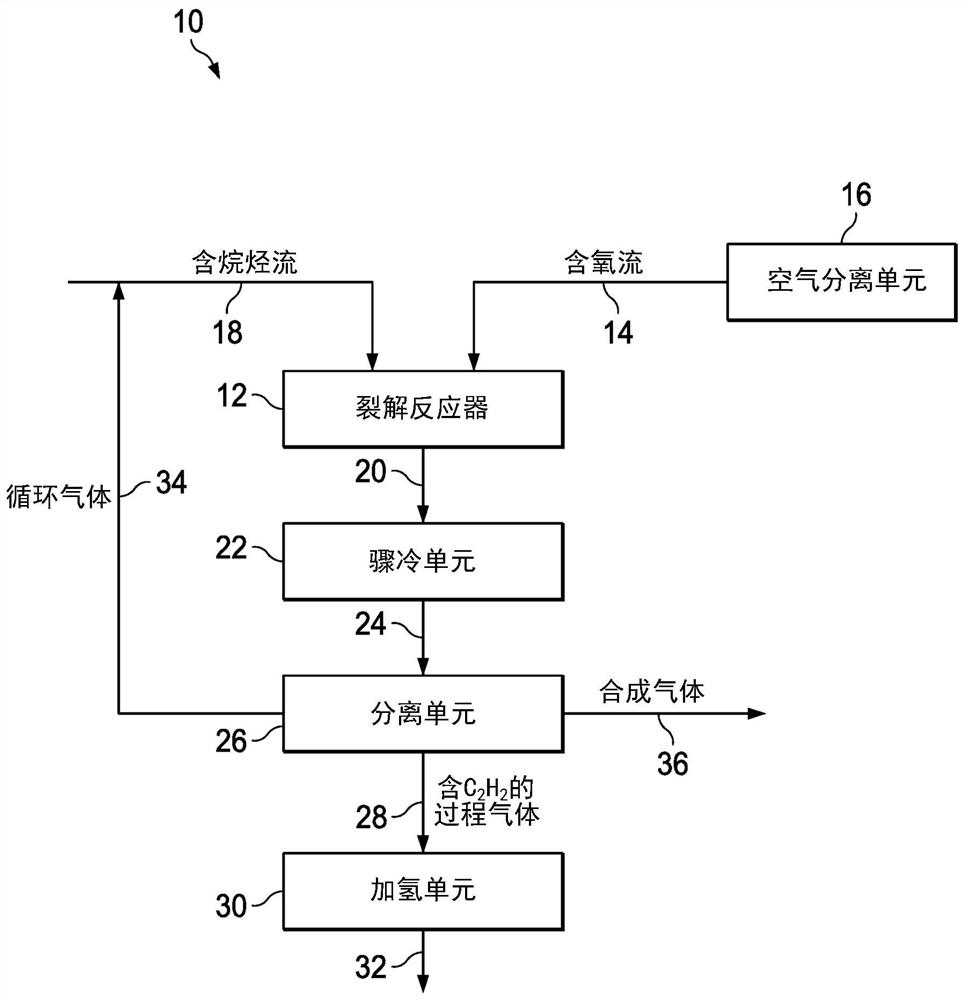

Process and a system for hydrocarbon steam cracking

ActiveUS20190284485A1Simpler and economical processSimple and economical processThermal non-catalytic crackingHigh temperature gas-gas reactionFlue gasSuperheater

A process for steam cracking hydrocarbon feedstock in a steam cracking furnace, the process comprising superheating hydrocarbon feedstock using flue gas from a radiant section of the steam cracking furnace in hydrocarbon feedstock superheating means or the hydrocarbon feedstock superheater, superheating steam from the steam generator using the flue gas from the radiant section of the steam cracking furnace in second heat exchanging means or a second heat exchanger, steam cracking the super-heated hydrocarbon feedstock from the hydrocarbon feedstock superheating means or the hydrocarbon feedstock superheater into cracked gas in a fired tubular reactor, vaporizing the hydrocarbon feedstock, using hydrocarbon feedstock vaporizing means, wherein the hydrocarbon feed-stock vaporizing means or the hydrocarbon feedstock vaporizer are heated with a heat transfer medium having a temperature less than or equal to 350° C. and feeding the vaporized hydrocarbon feedstock to the steam cracking furnace.

Owner:SABIC GLOBAL TECH BV

Apparatus and methods for conversion of silicon tetrachloride to trichlorosilane

ActiveCN103987453AHigh temperature gas-gas reactionChemical industryProcess engineeringSilicon tetrachloride

The invention relates to apparatus and associated methods for conversion of silicon tetrachloride (STC) to trichlorosilane (TCS). The converter features a relatively thin annular heating zone surrounding a reaction chamber. Within the annular heating zone is a heating element that has an annular conformation about the reaction chamber. The design allows high convective heat transfer, which facilitates the use of lower heating element surface temperatures, prolonging the life of the equipment, reducing capital cost by allowing use of a smaller reactor, and greatly improving heating efficiency. A heat exchanger with a plurality of heat exchanger blocks provides further efficiency.

Owner:ADVANCED MATERIAL SOLUTIONS LLC

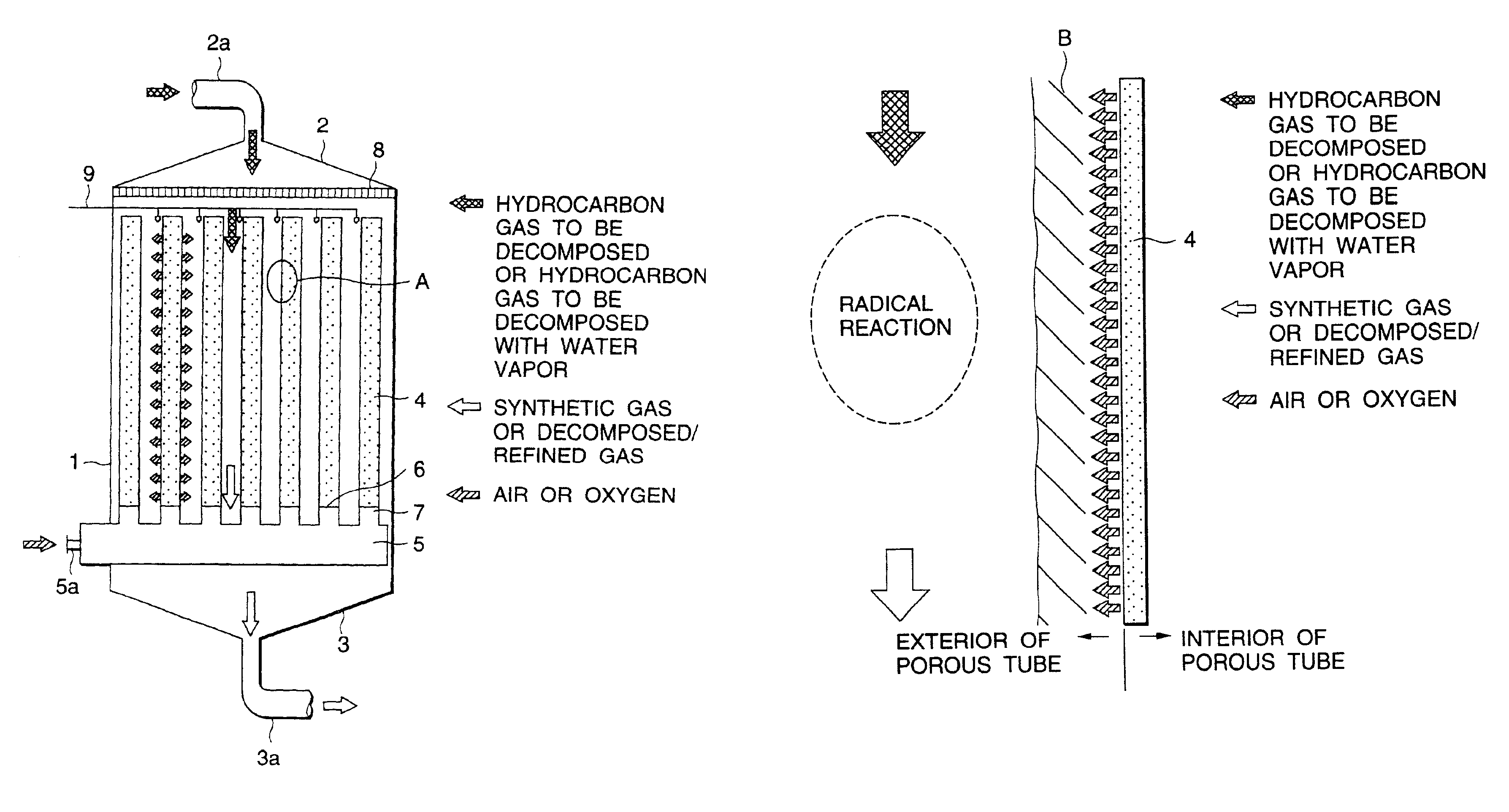

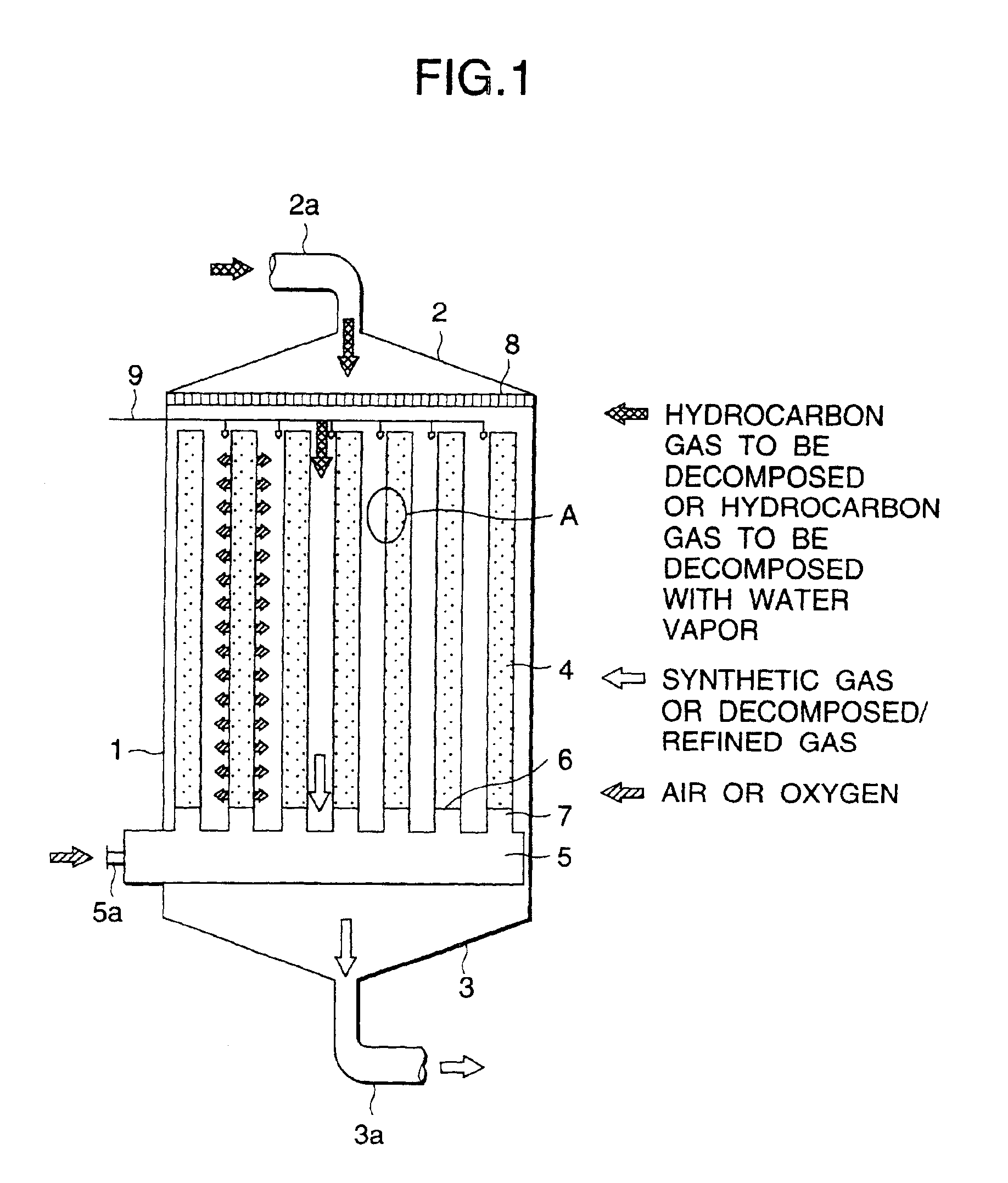

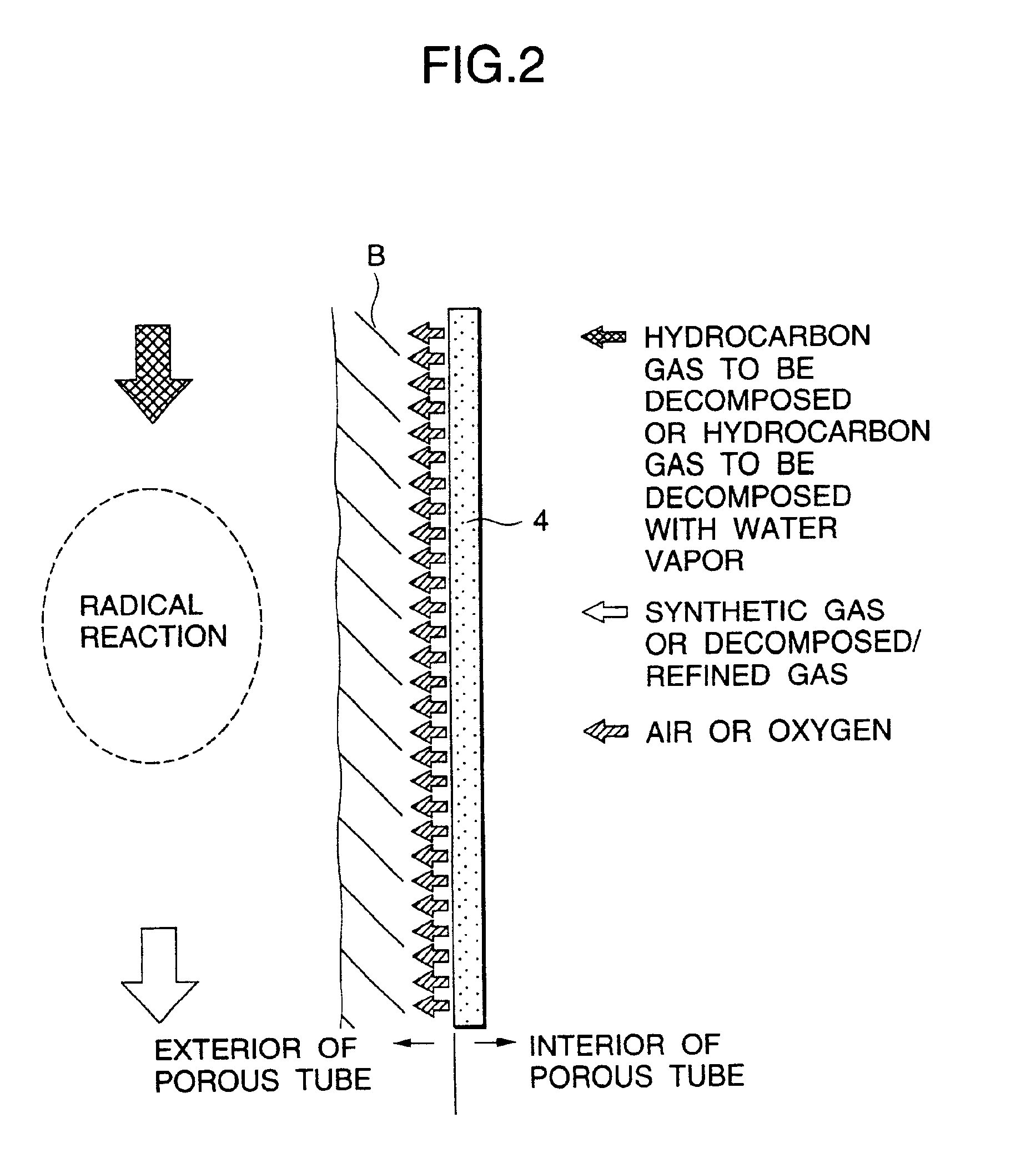

Process and apparatus for the pyrolysis of hydrocarbon gas

InactiveUS6921517B2Reduce facility costsRaise the ratioThermal non-catalytic crackingHydrogenDiffusion flameWater vapor

A hydrocarbon gas to be decomposed, optionally mixed with water vapor, is allowed to flow through the gap between various porous tubes 4 constituting a group of porous tubes provided extending vertically in a decomposition reaction column 1 while air or oxygen is jetted homogeneously from the interior to the exterior of the porous tubes in the direction perpendicular to the stream of the hydrocarbon gas to be decomposed, optionally mixed with water vapor. The mixture is then ignited to form a diffusion flame layer B on the outer surface of the porous tubes 4. With the diffusion flame layer as a heat source, the hydrocarbon gas to be decomposed, optionally mixed with water vapor, undergoes pyrolysis.

Owner:MATSUMURA SHUZO +1

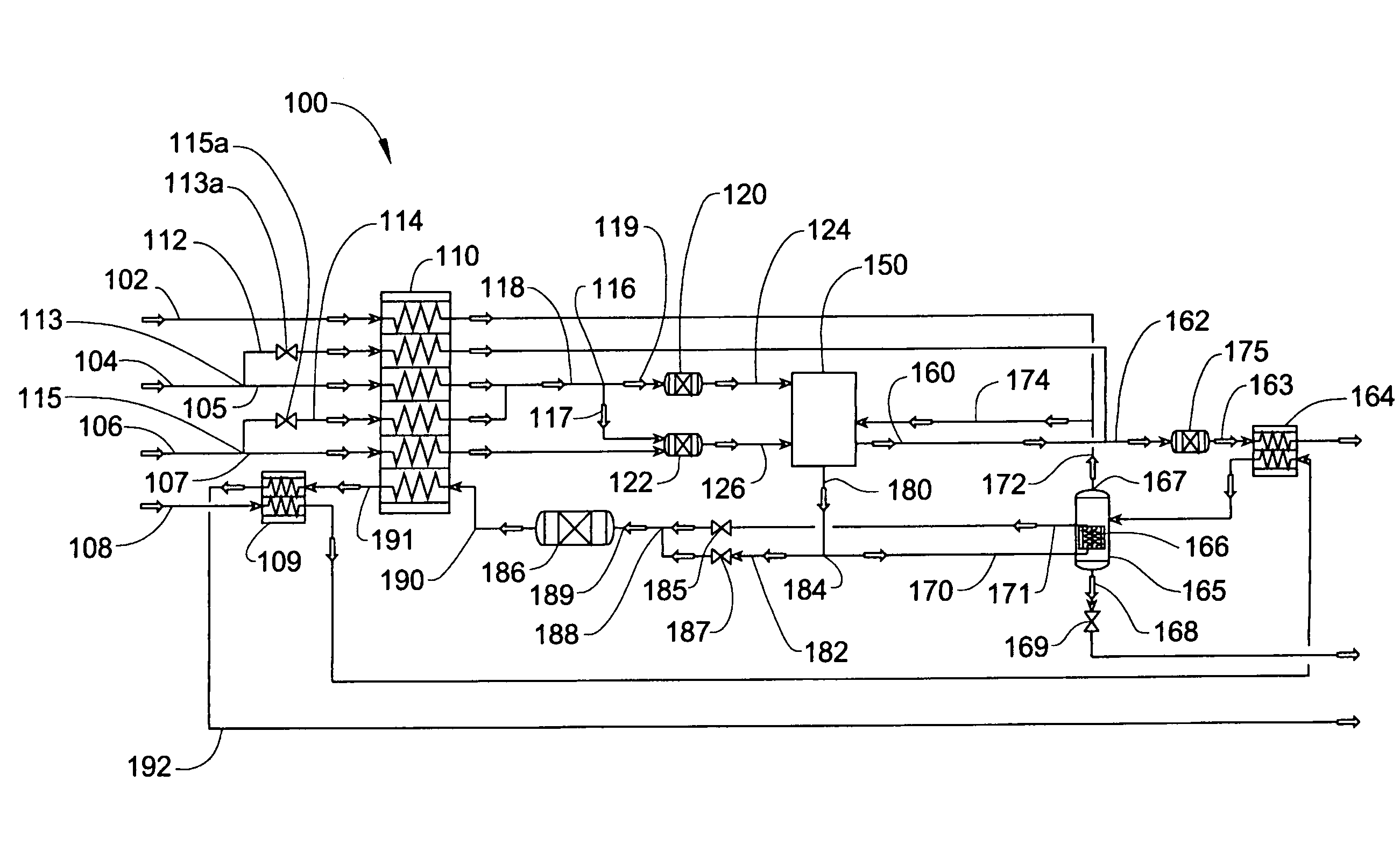

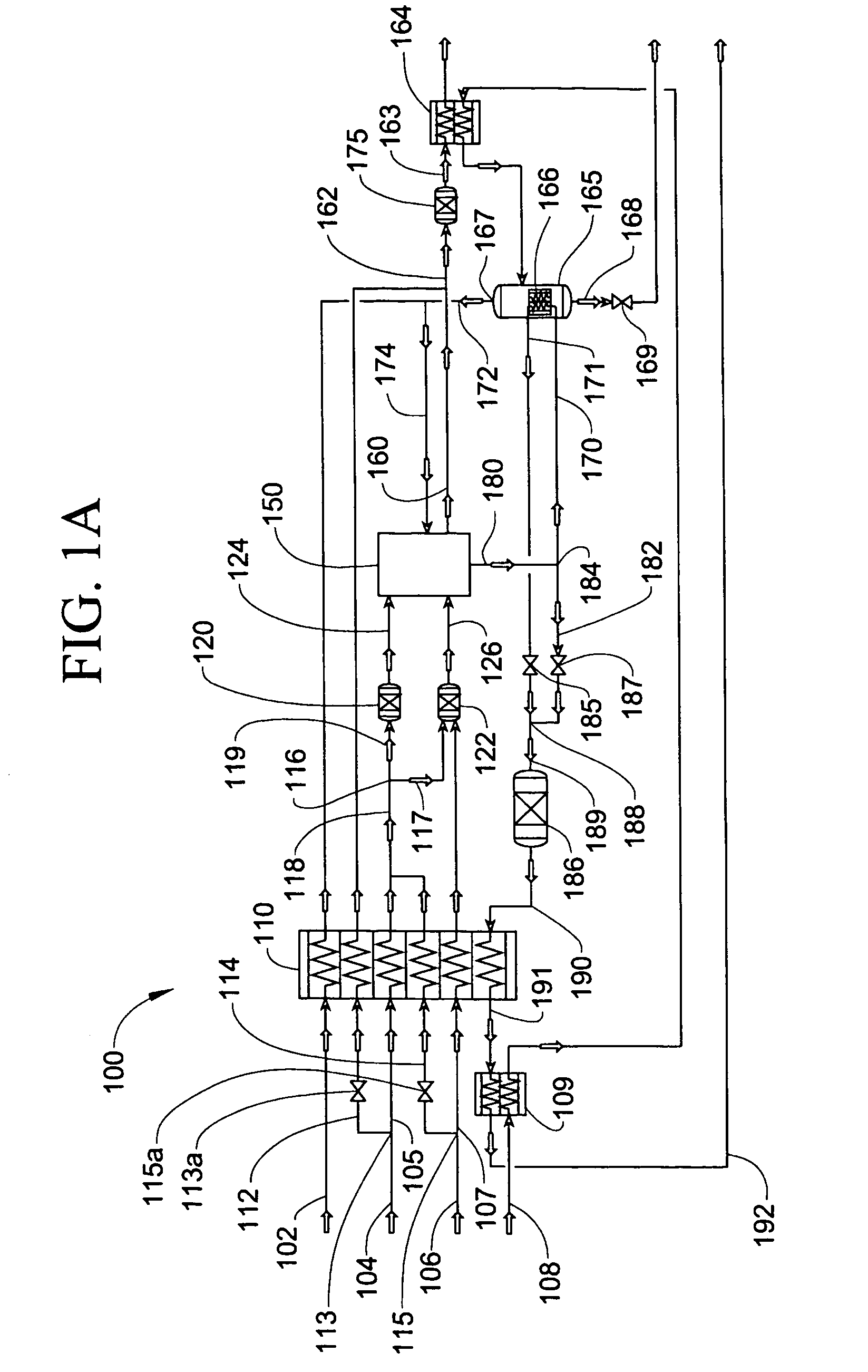

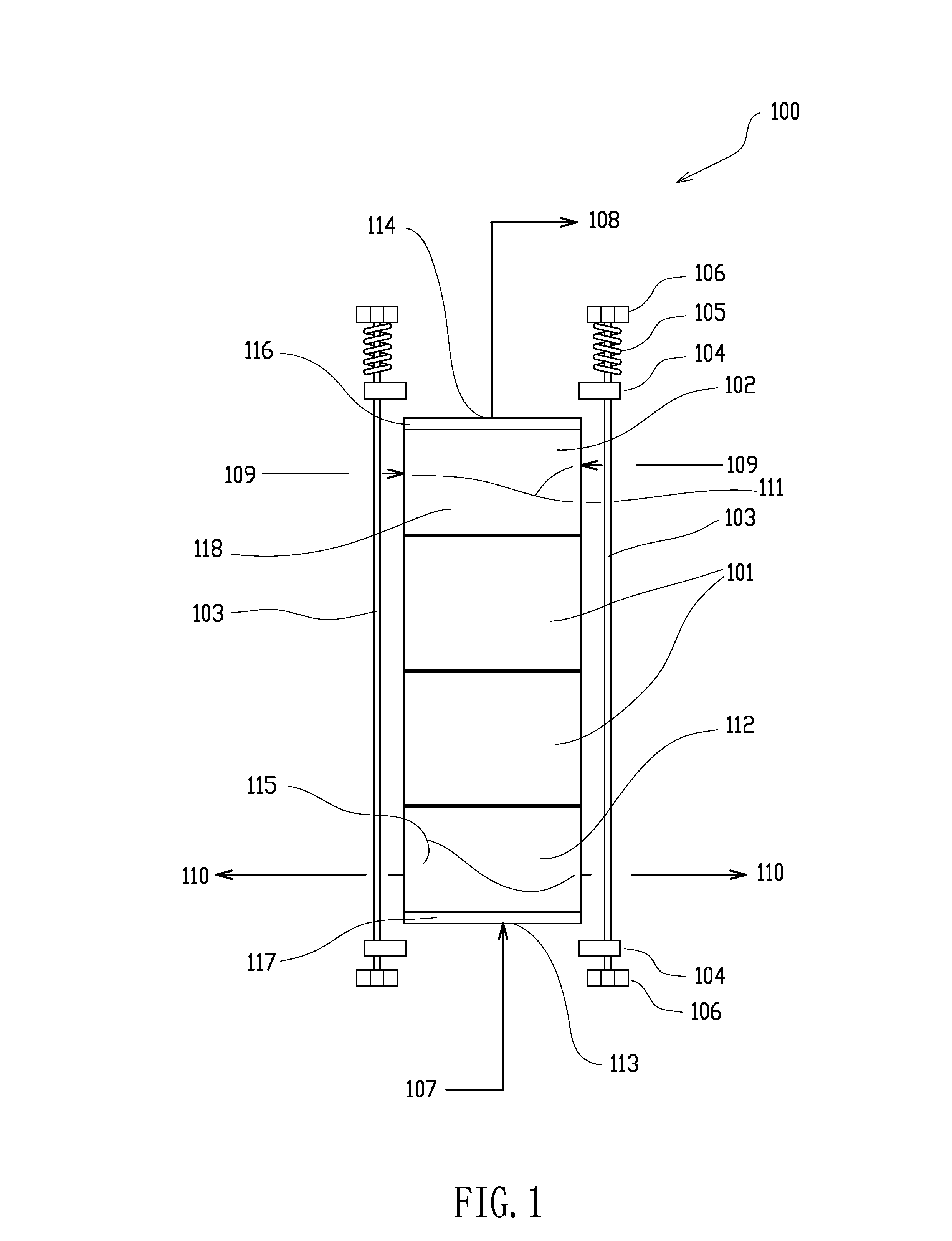

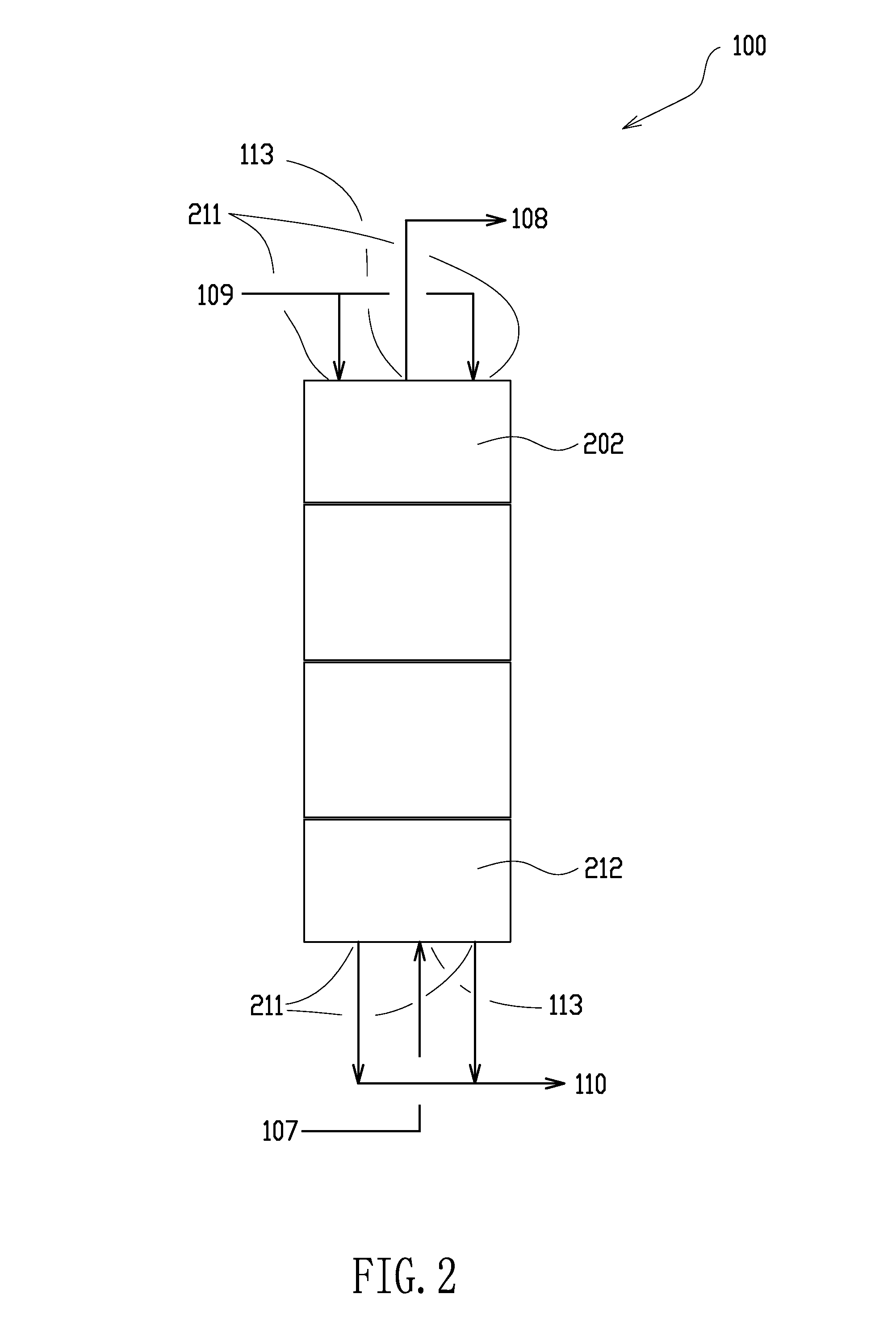

Reforming apparatus and method

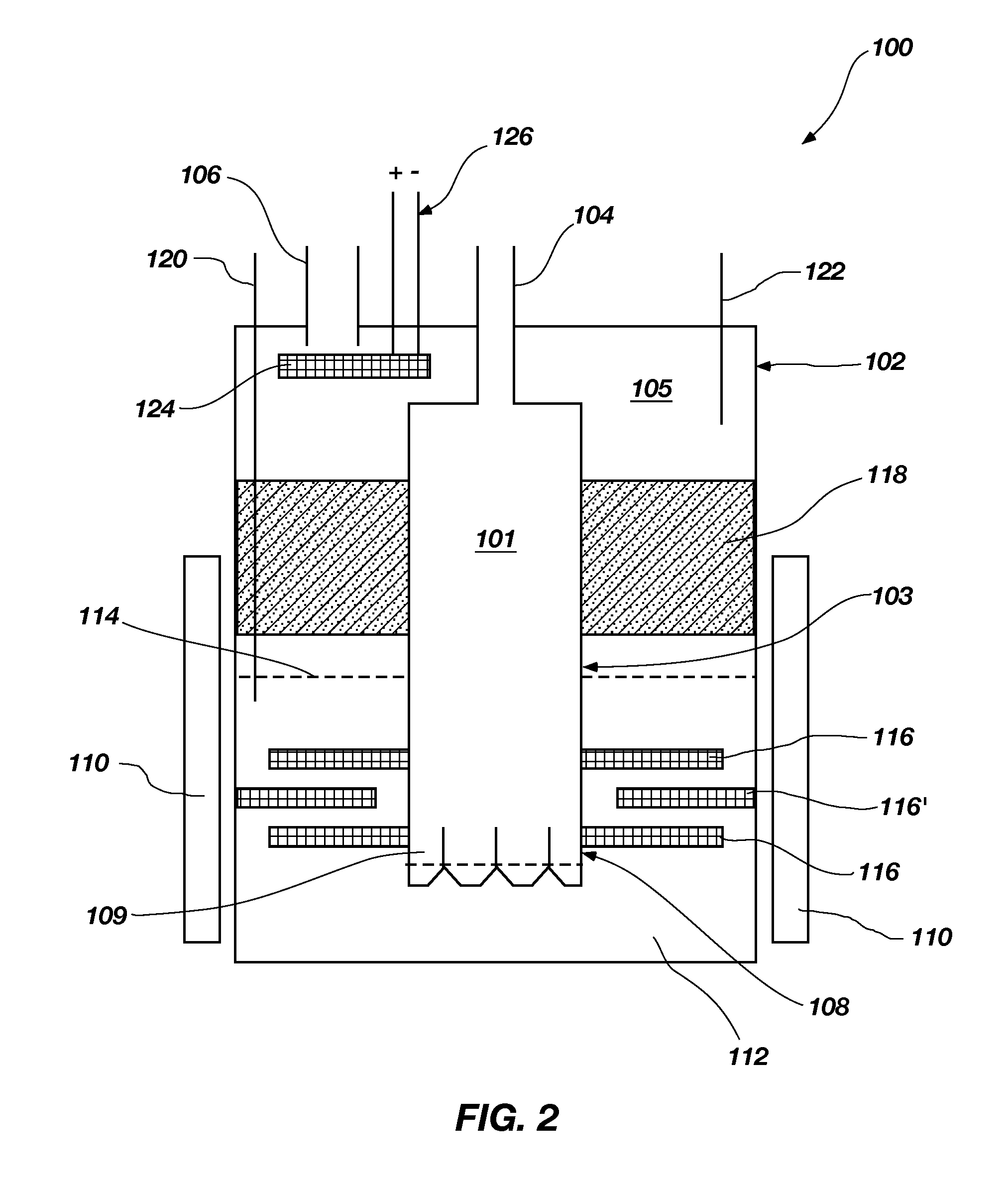

ActiveUS8177868B2Avoid adjustmentMultiple metal hydridesHigh temperature gas-gas reactionElectrical resistance and conductanceSyngas

A multiple adiabatic bed reforming apparatus and process are disclosed in which stage-wise combustion, in combination with multiple reforming chambers with catalyst, utilize co-flow and cross-flow under laminar flow conditions, to provide a reformer suitable for smaller production situations as well as large scale production. A passive stage by stage fuel distribution network suitable for low pressure fuel is incorporated and the resistances in successive fuel distribution lines control the amount of fuel delivered to each combustion stage. The fuel distribution system allows relatively constant fuel and air flow during turn up or turn down conditions. High efficiency is achieved by capturing heat from reforming syngas product to preheat gases before entering the reformer. Conditions that would produce unwanted coking or metal dusting are also eliminated or localized to locations within the apparatus outside the heat exchangers, but which locations can be cost effectively protected.

Owner:MEGGIT (UK) LTD

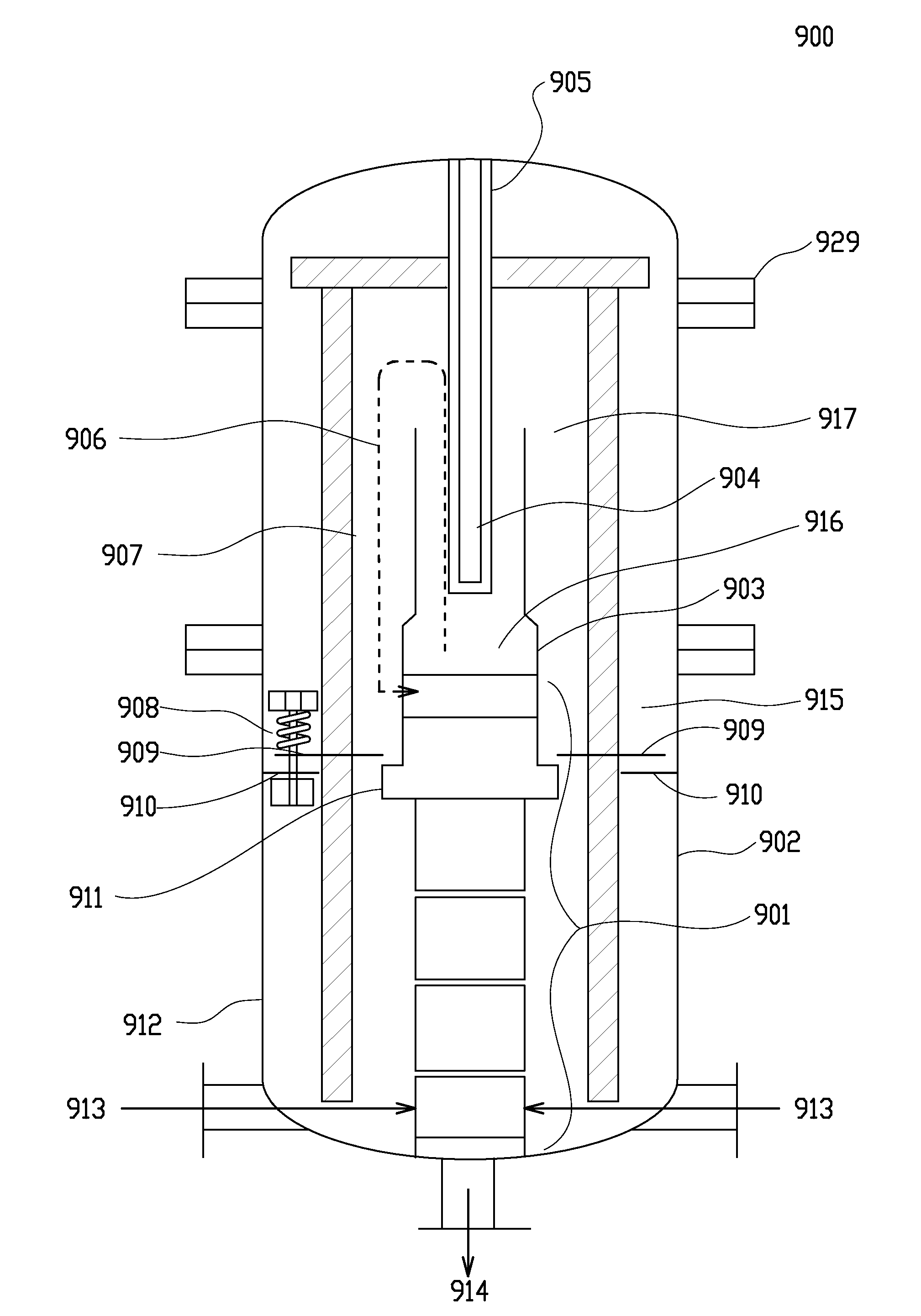

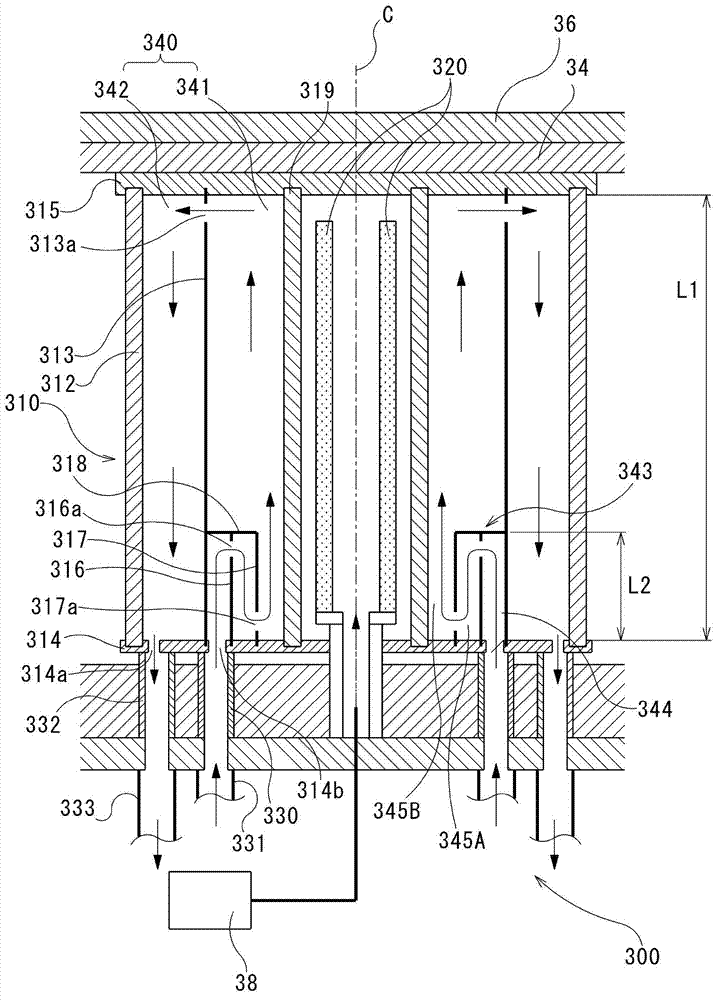

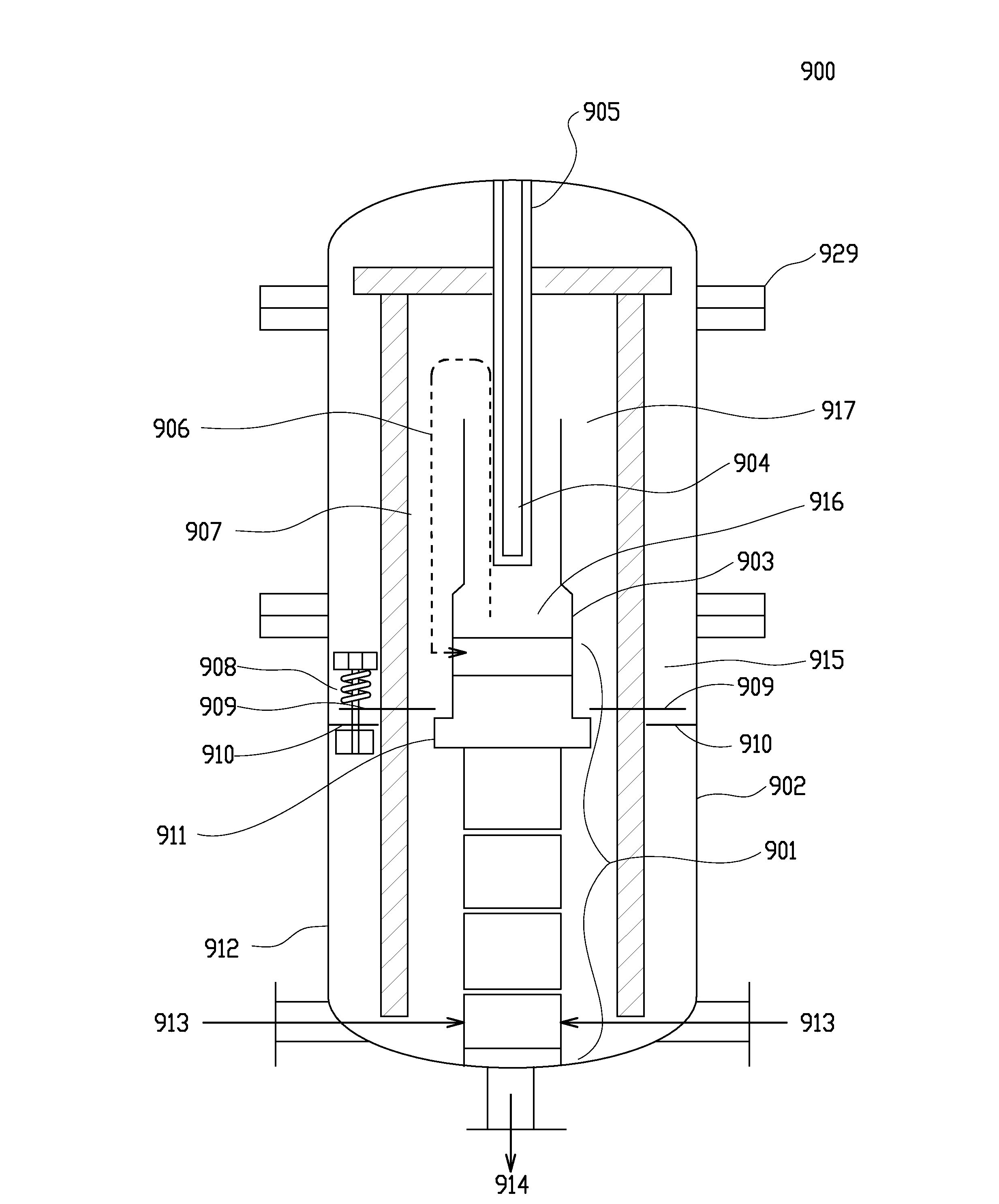

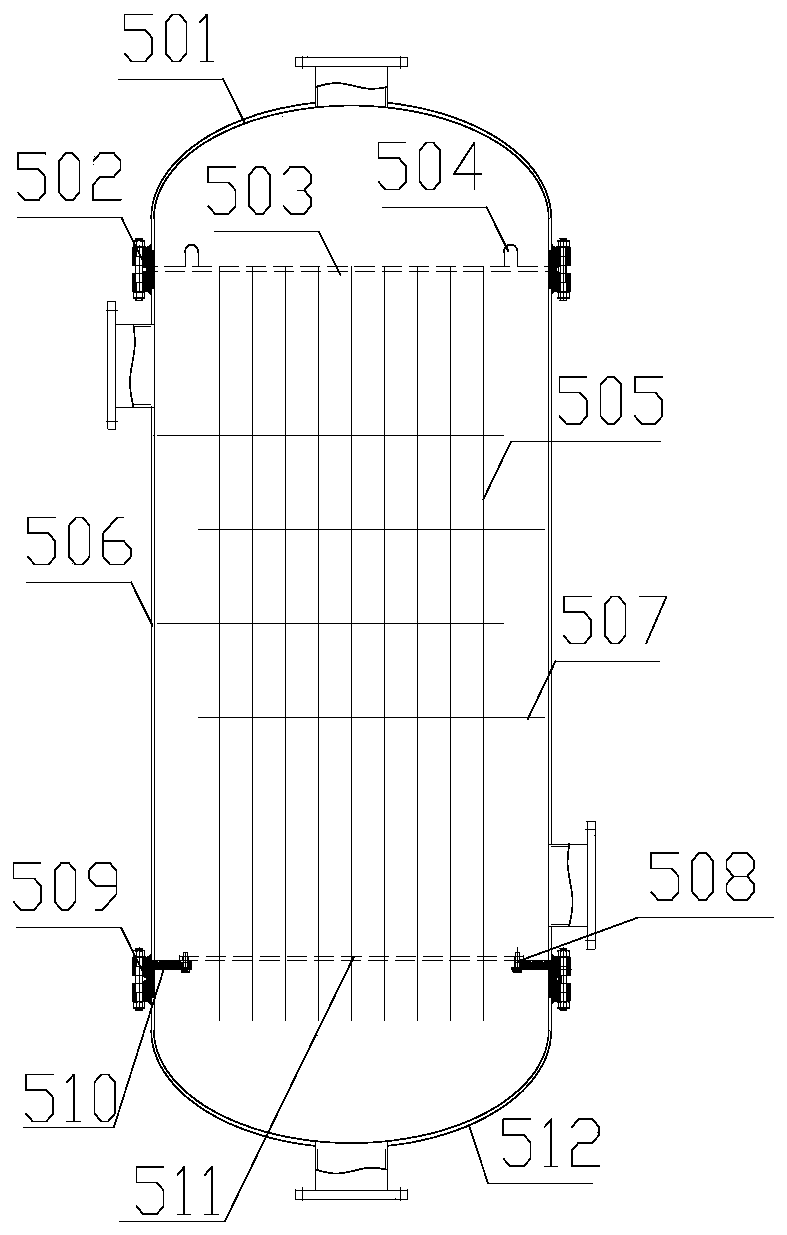

Apparatus for producing trichlorosilane

ActiveCN103130226AAvoid breakingHigh temperature gas-gas reactionChemical/physical/physico-chemical processesHydrogenProduct gas

An apparatus for producing trichlorosilane in which reacted gas including trichlorosilane and hydrogen chloride is produced by heating raw gas including silicon tetrachloride and hydrogen, the apparatus having: a reaction vessel having a substantially cylindrical shape and being provided with a heated wall forming a gas flow-passage along an axis direction; and a heater heating the heated wall, wherein a folding flow-passage is provided at an uppermost stream of the gas flow-passage and has: an inlet flow-passage in which raw gas is introduced; and a turning part connected to a downstream of the inlet flow-passage in which a flow direction of the raw gas is turned at least once in an opposite direction, the turning part is formed between the inlet flow-passage and the heated wall in the folding flow-passage, and a turning length of the folding flow-passage along the axis direction is smaller than a maximum length of the gas flow-passage along the axis direction.

Owner:MITSUBISHI MATERIALS CORP

Monolithic Heat Exchanger and Apparatus and Methods for Hydrogenation of a Halosilane

ActiveUS20140334992A1Increase the areaReduce the temperatureHigh temperature gas-gas reactionSafety devices for heat exchange apparatusEngineeringCounter current

A counter current heat exchanger amenable to fabrication from monolithic materials and particularly useful in corrosive and high temperature environments is described. The heat exchanger uses multiple series of holes bored axially through a monolithic material. Axial holes are bored in adjacent flow paths arranged in closely spaced concentric rings. In operation, counter current flow and heat transfer occurs between multiple adjacent axial flow paths. The heat exchanger design is scaleable over a wide range and particularly useful in reactors for the hydrogenation of halosilanes also using cylindrical heating elements. The design enables a small overall reactor size for a given capacity.

Owner:HAZELTINE BRUCE

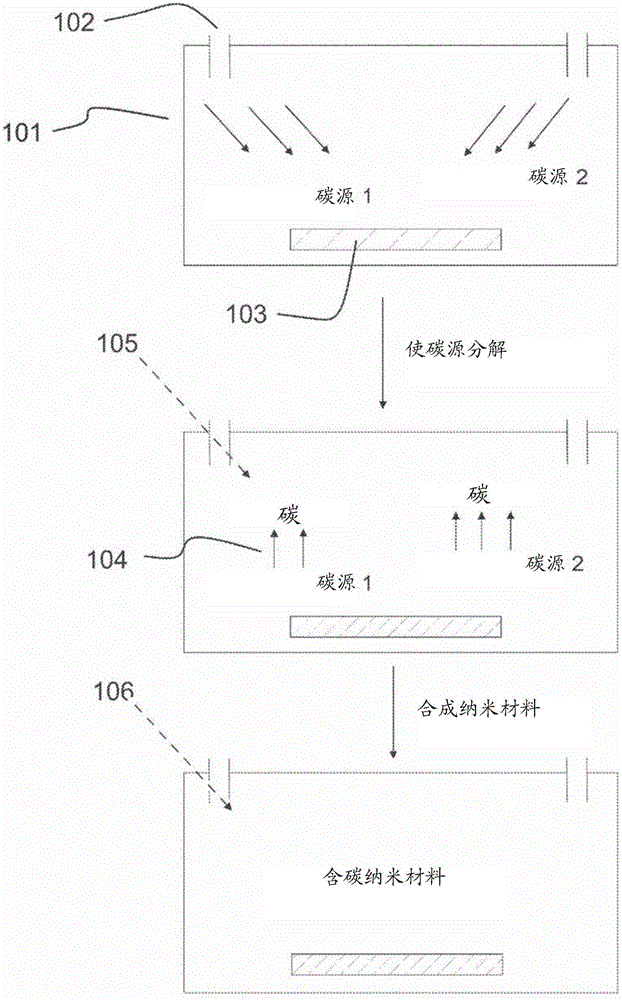

Method and apparatus for producing nanomaterial

InactiveCN106458590AMaterial nanotechnologyCatalytic gas-gas reactionCarbon nanomaterialsCarbon source

Owner:CANATU OY

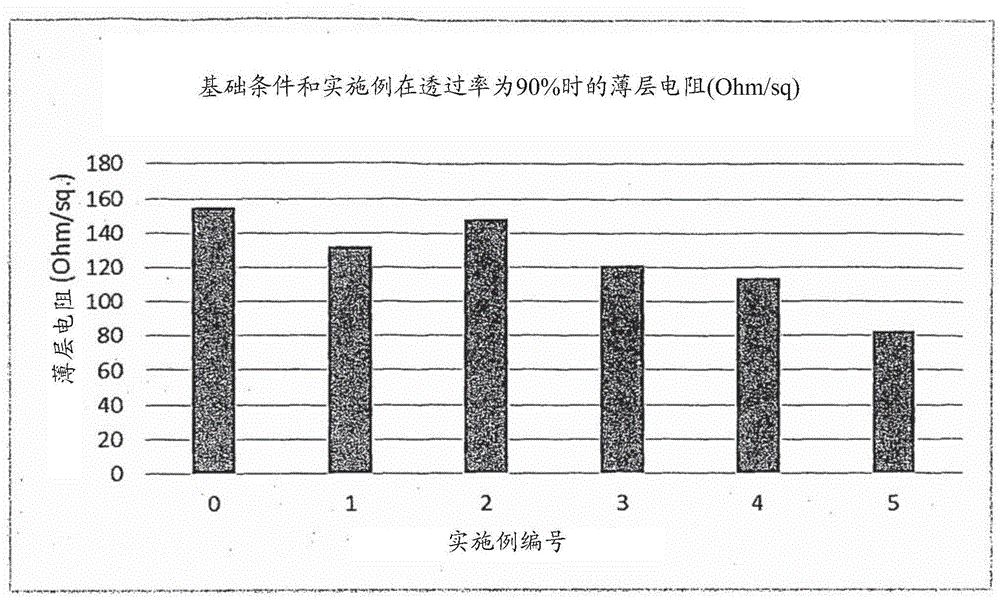

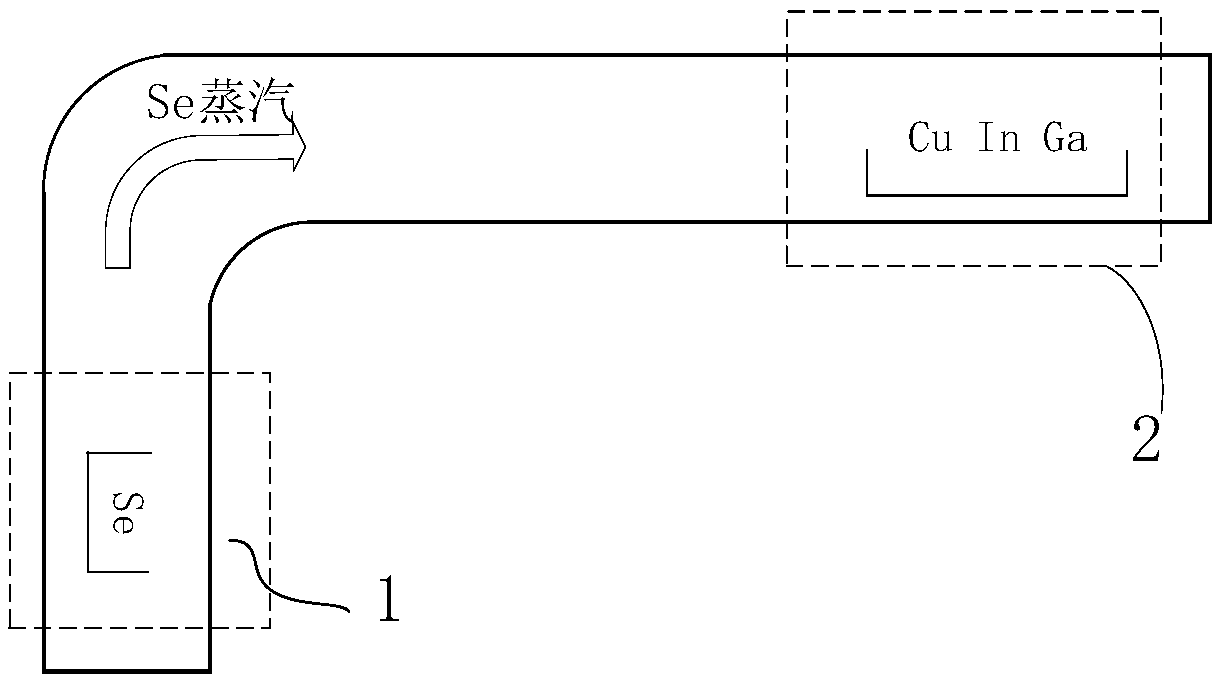

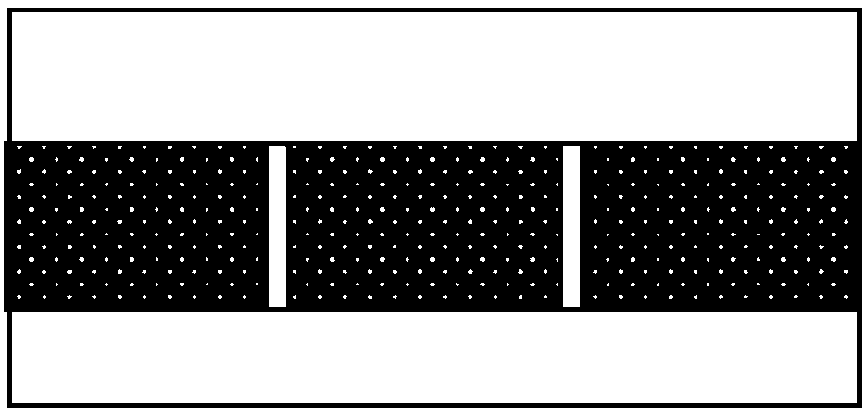

Preparation method of CIGS compound, printing ink and film absorbing layer

InactiveCN108039392AHigh temperature gas-gas reactionTransportation and packagingMolten stateSingle substance

The invention discloses a preparation method of a CIGS compound, printing ink and film absorbing layer. The preparation method of the CIGS compound comprises the following steps that a vacuum container is provided, wherein the vacuum container includes a high temperature synthesis area and a low temperature evaporation area which are arranged in a spaced way; single substances of copper, indium and gallium are arranged in the high temperature synthesis area and the single substance of selenium is arranged in the low temperature evaporation area; the copper, the indium and the gallium of the high temperature synthesis area are heated to the molten state, and the selenium of the low temperature evaporation area is heated to the gaseous state; the time when the selenium of the low temperatureevaporation area starts to turn to the gaseous state is not early than the molten time of the copper, the indium and the gallium; the temperature of the high temperature synthesis area and the low temperature evaporation area is preserved; the temperature of the high temperature synthesis area is reduced to be not lower than the molten temperature of the alloy of the copper, the indium and the gallium and the temperature is preserved, then the temperature of high temperature synthesis area and the low temperature evaporation area is reduced to be lower than 100 DEG C; and the forward temperature gradient between the low temperature evaporation area and the high temperature synthesis area is constantly kept in the steps.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

Production of nanometric or sub-micrometric powders in continuous flux

ActiveUS8822878B2High temperature gas-gas reactionChemical/physical/physico-chemical processesLaser pyrolysisMolecular physics

A system and process for production of nanometric or sub-micrometric powders in continuous flux under the action of laser pyrolysis in at least one interaction zone between a beam emitted by a laser and a flux of reagents emitted by an injector, in which the laser is followed by optical means for distributing the energy of the beam emitted by the latter according to an axis perpendicular to the axis of each flux of reagents, in an elongated cross-section having adjustable dimensions at the level of this at least one interaction zone.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Submicron-sized particles including aluminum

InactiveUS20160376158A1Complete flexibilityEasy to controlPigmenting treatmentGlass/slag layered productsChemical physicsChemical element

A method for producing particles, includes the following steps: introducing into a reaction chamber at least one reaction flow including a first chemical element (typically silicon) and propagating in a flow direction; projecting a ray beam through the reaction chamber, intersecting each reaction flow in an reaction flow interaction area, in order to form, in each reaction flow, the cores of particles including the first chemical element, and introducing, in the reaction chamber, a second chemical element, interacting with each reaction flow in order to cover the cores of particles with a layer including the second chemical element. Each reaction flow is preferably free of an agent oxidizing the first chemical element.

Owner:NANOMAKERS

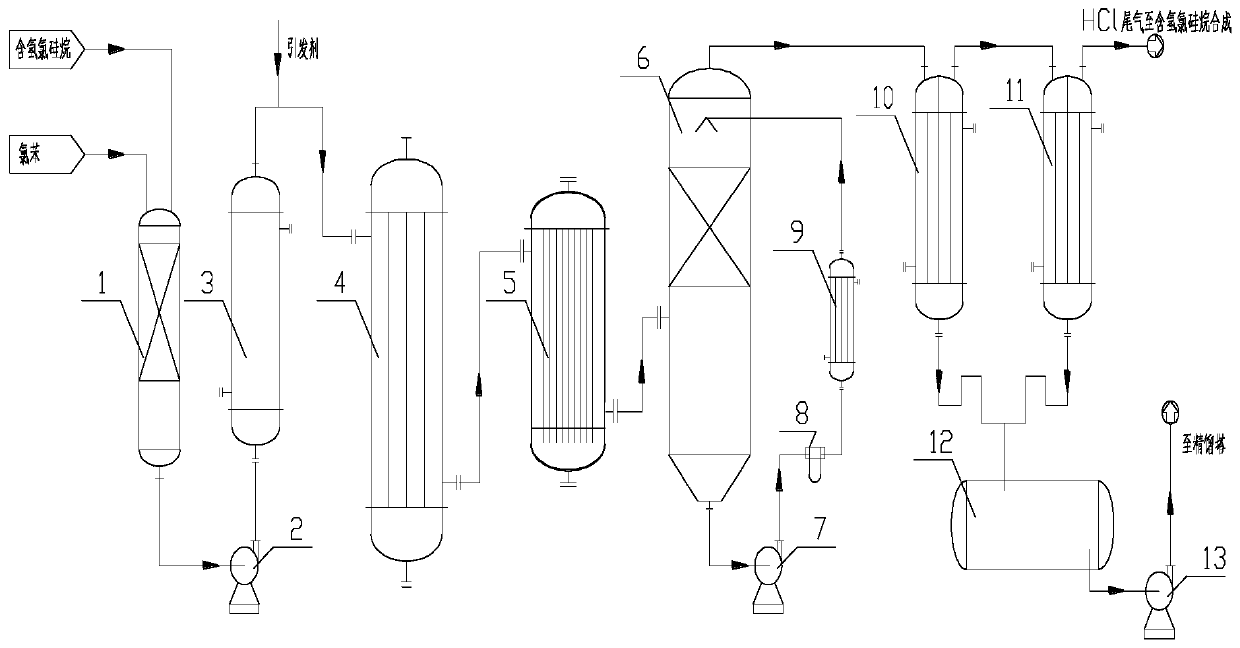

Method and device for synthesizing phenyl chlorosilane

PendingCN111548364AAvoid cloggingAvoid efficiencySilicon organic compoundsHigh temperature gas-gas reactionCombinatorial chemistryCarbon deposit

The invention provides a method and a device for synthesizing phenyl chlorosilane. The method comprises the following steps: S1, mixing and vaporizing raw materials; S2, carrying out a thermal condensation reaction; S3, cooling and washing a product; S4, separating phenyl chlorosilane; and S5, purifying the phenyl chlorosilane crude product. Through the synthesis method and device of phenyl chlorosilane, carbon deposits in a reactor and a tail gas system can be removed in time; the problems of system blockage, low reaction efficiency, poor selectivity and tail gas system blockage caused by carbon deposition in the production process are effectively solved, and then the purposes of continuous and stable production, convenient operation, high conversion rate and low cost are achieved.

Owner:江西宏柏新材料股份有限公司

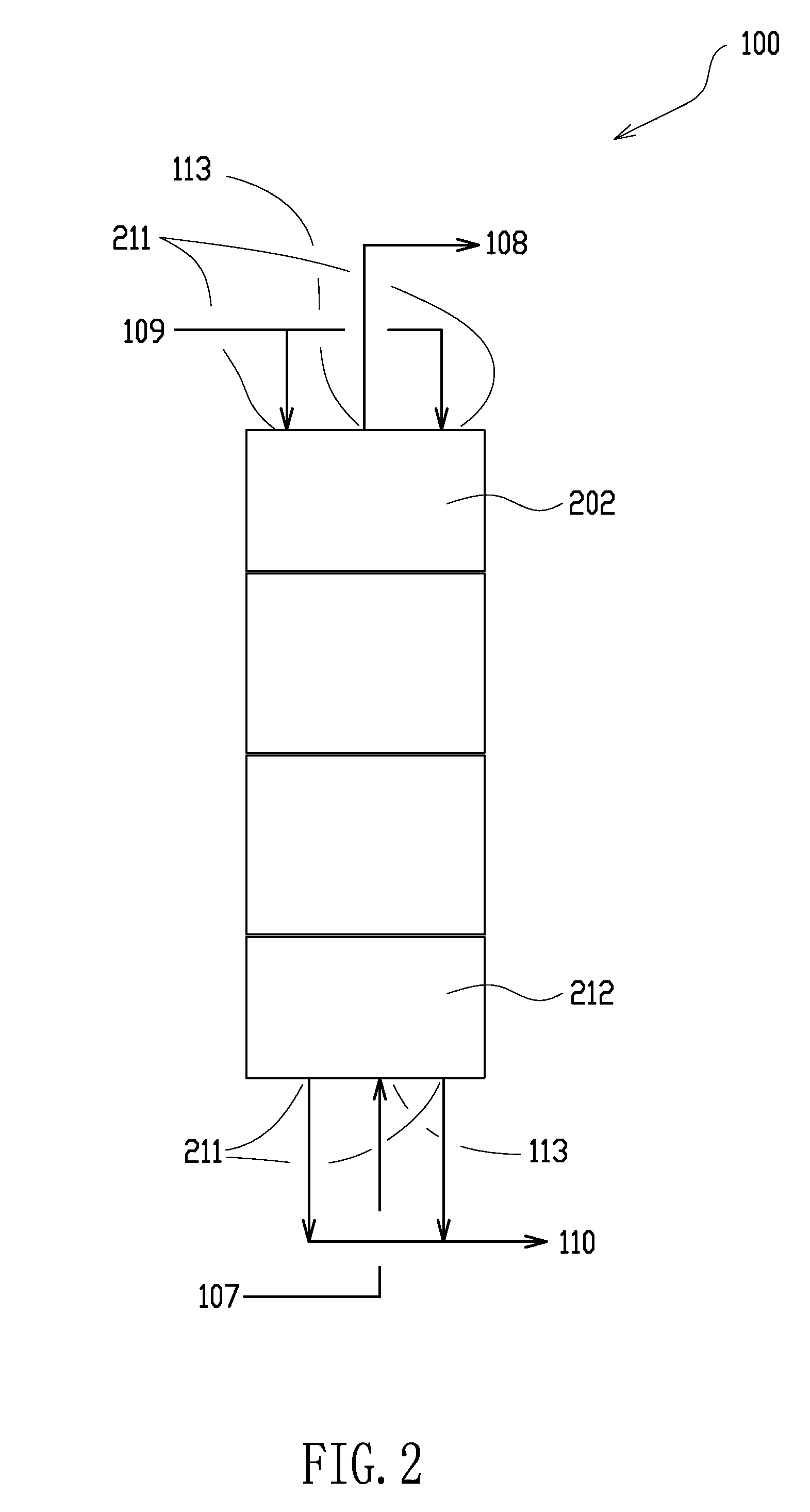

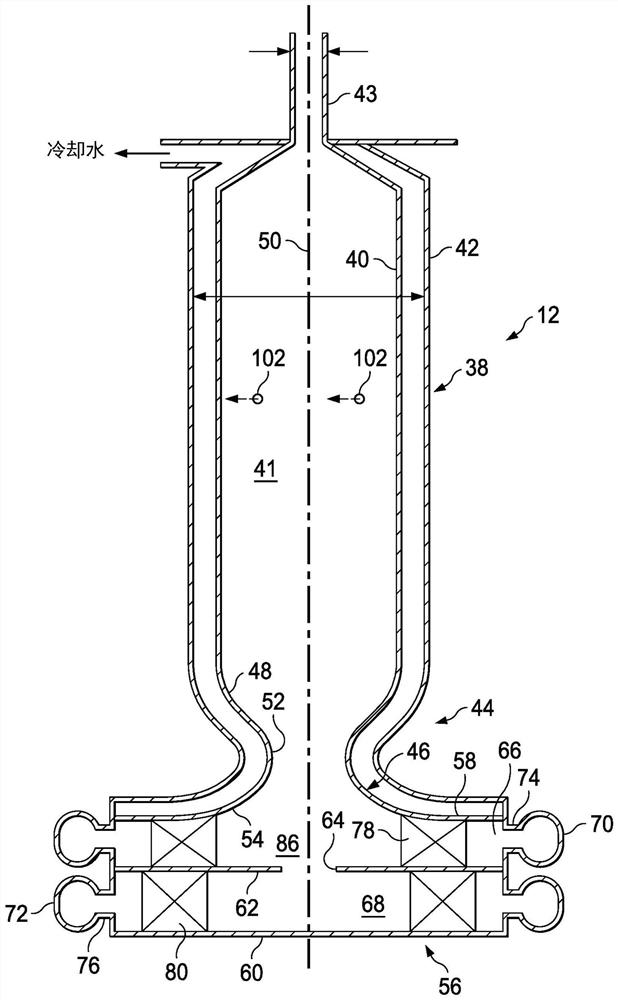

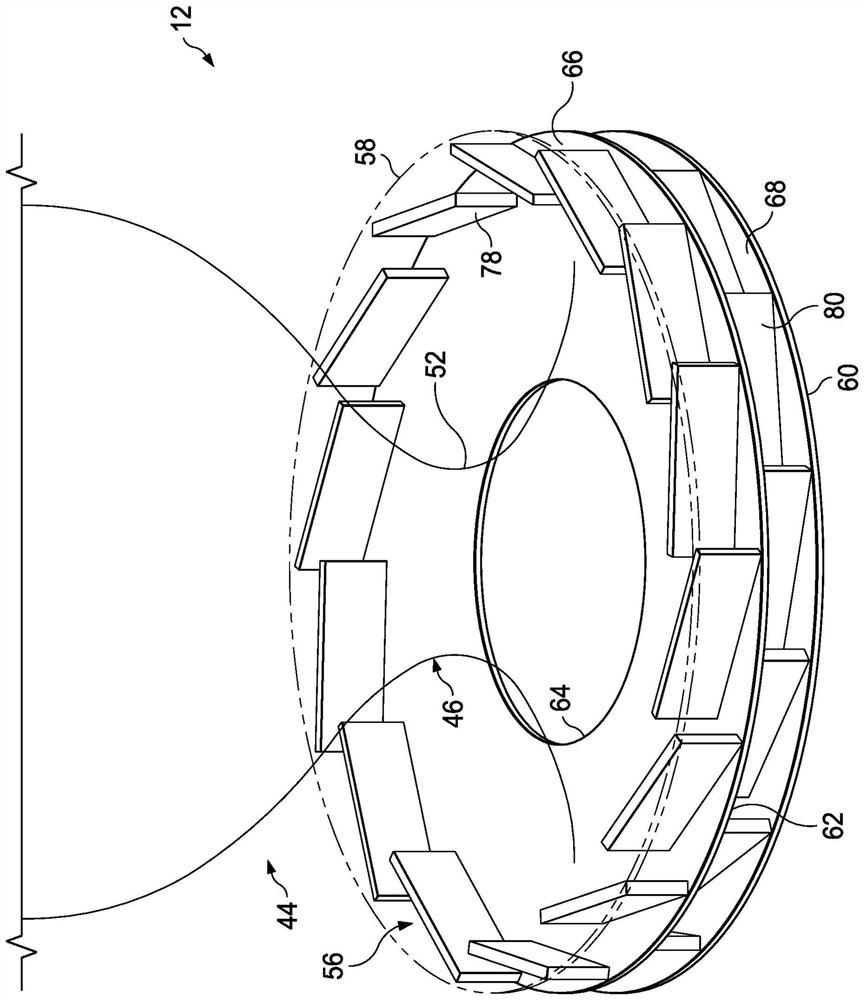

Method and reactor for pyrolysis conversion of hydrocarbon gases

A pyrolysis reactor (12) and a method for the pyrolysis of hydrocarbon gases (e.g., methane) are provided. The method utilizes a pyrolysis reactor (12) having a unique burner assembly (44) and a pyrolysis feed assembly (56) that creates an inwardly spiraling fluid flow pattern of the feed gases to form a swirling gas mixture that passes through a burner conduit (46) with a constricted neck portionor nozzle (52). At least a portion of the swirling gas mixture forms a thin, annular mixed gas flow layer immediately adjacent to the burner conduit (46). A portion of the swirling gas mixture is combusted as the swirling gas mixture passes through the burner conduit (46) and a portion of combustion products circulates in the burner assembly (44). This provides conditions suitable for pyrolysis of hydrocarbons or light alkane gas, such as methane or natural gas.

Owner:SABIC GLOBAL TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com