Method and apparatus for producing nanomaterial

A technology of nanomaterials and carbon nanomaterials, applied in the field of preparing carbonaceous nanomaterials, can solve problems such as difficulty in synthesizing carbonaceous nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

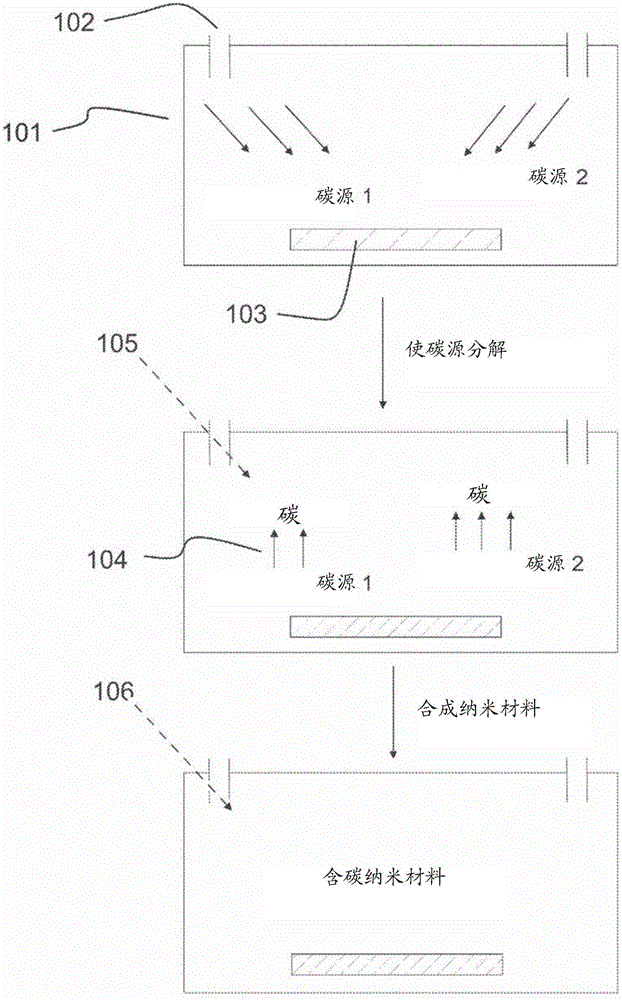

Method used

Image

Examples

Embodiment 0

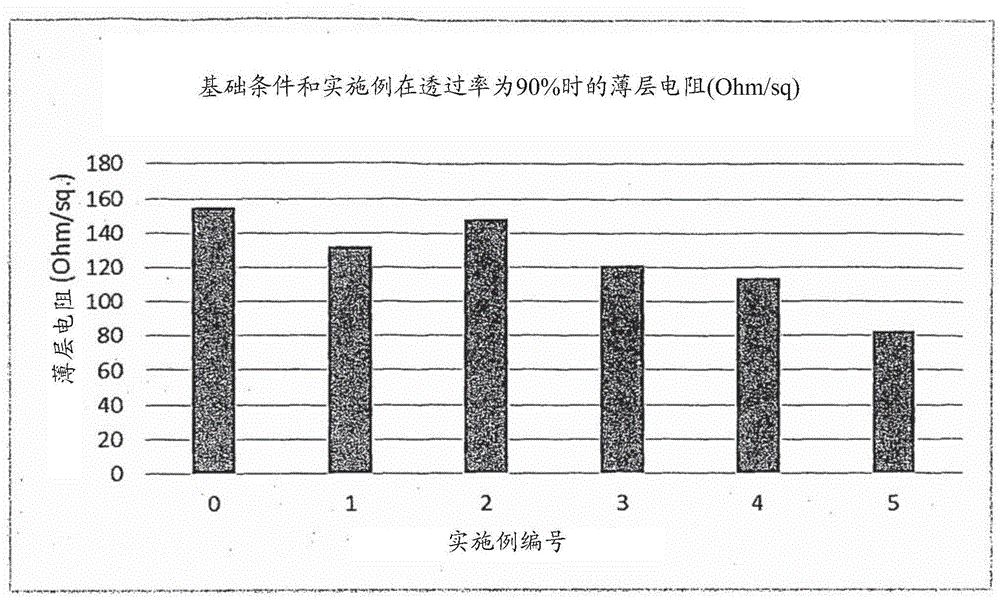

[0064] Base case for a single carbon source. This example is provided for comparative purposes only.

[0065] Single carbon source (mole fraction): CO (0.978)

[0066] Catalyst precursor (mole fraction): ferrocene (9.65e-6)

[0067] Accelerator (mole fraction): CO2 (0.02214)

[0068] Reactor peak set temperature: 840C

[0069] Sheet resistance at 90% transmittance: 155Ohm / sq.

Embodiment 1

[0071] Carbon source 1 (mole fraction): CO (0.986)

[0072] Carbon source 2 (mole fraction): Toluene (1.03e-6)

[0073] Additional carrier (mole fraction): N2 (2.76e-5)

[0074] Catalyst precursor (mole fraction): ferrocene (3.5e-6)

[0075] Accelerator (mole fraction): CO2 (0.01381)

[0076] Reactor peak set temperature: 840C

[0077] Sheet resistance at 90% transmittance: 132Ohm / sq.

Embodiment 2

[0079] Carbon source 1 (mole fraction): CO (0.984)

[0080] Carbon source 2 (mole fraction): Toluene (5.85e-6)

[0081] Additional carrier (mole fraction): N2 (1.58e-4)

[0082] Catalyst precursor (mole fraction): ferrocene (3.5e-6)

[0083] Accelerator (mole fraction): CO2 (0.01381)

[0084] Reactor peak set temperature: 840C

[0085] Sheet resistance at 90% transmittance: 148Ohm / sq.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com