Carbon dots with high fluorescent quantum yield, and application thereof in fluorescent color development

A technology of fluorescence quantum yield and carbon dots, which is applied in the application field of fluorescent carbon nanomaterials, can solve problems such as rare research, and achieve the effects of simple post-processing, overcoming easy photobleaching, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of fluorescent carbon dots with high quantum yield

[0028] Blend 4mmol of citric acid and 1mmol of ethylenediamine in 5mL of deionized water and transfer it to a reaction kettle for hydrothermal reaction at 200°C for 7 hours. After the reaction, the reaction kettle was cooled to room temperature to obtain quantum The resulting carbon dot aqueous solution was spin-dried with a rotary evaporator, and further dried in a vacuum oven to obtain a 4:1 carbon dot solution.

[0029] 2.4:1 carbon dots as fluorescent ink for handwriting application

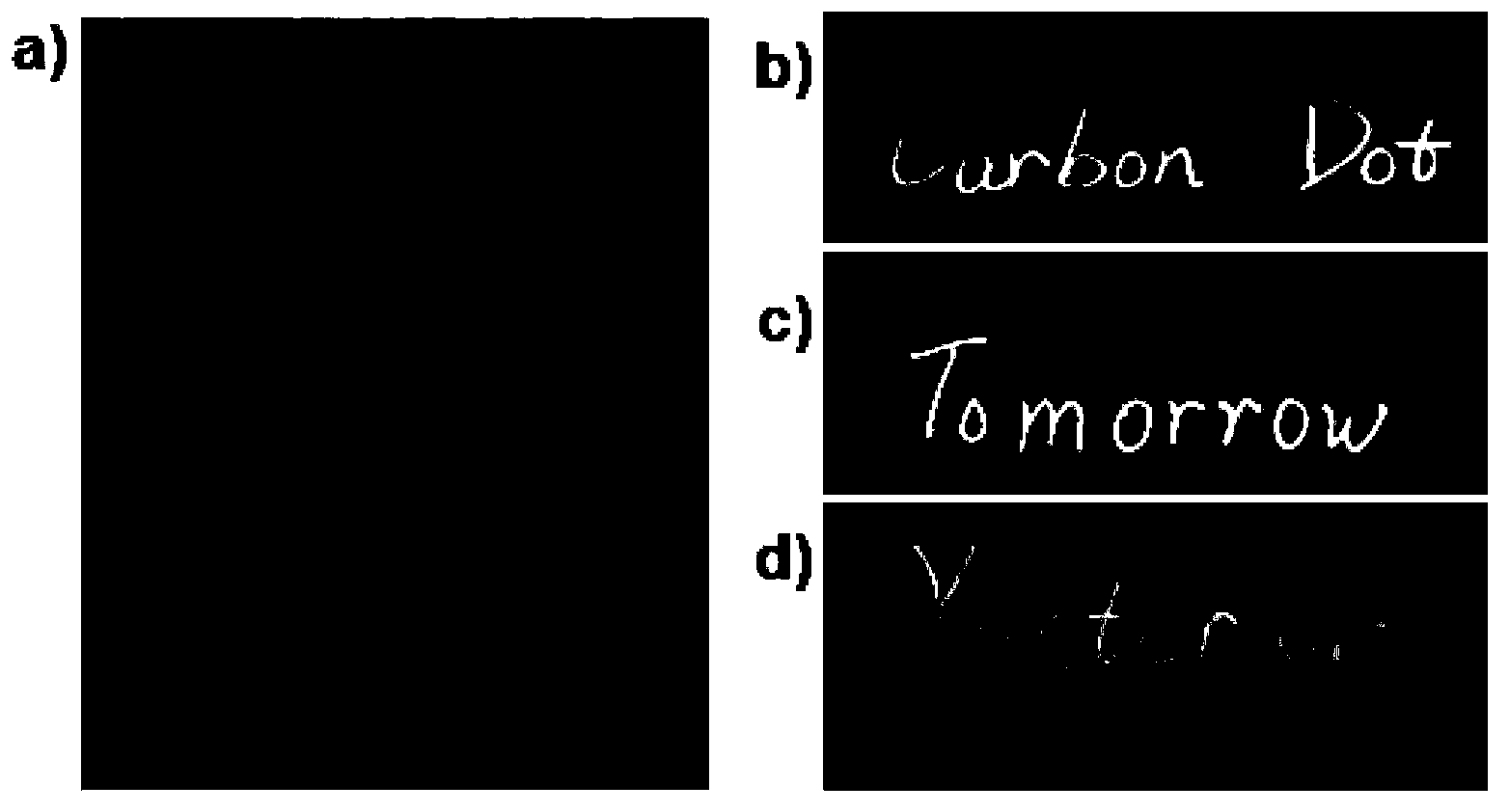

[0030] Configure 1mg / mL carbon dot aqueous solution as fluorescent ink, pour it into a commercial pen, and use the pen to write. The "fluorescent" writing cannot be observed under sunlight ( figure 1 a), only observed under UV light ( figure 1 b).

Embodiment 2

[0032] 1. Preparation of fluorescent carbon dots with high quantum yield

[0033] Blend 5mmol of citric acid and 5mmol of ethylenediamine in 10mL of deionized water and transfer to a reaction kettle for hydrothermal reaction at 200°C for 7 hours. After the reaction, the reaction kettle was cooled to room temperature to obtain quantum The carbon dot aqueous solution of productive rate, the carbon dot aqueous solution obtained is poured into the dialysis bag that molecular weight is 3500 and is dialyzed for 48h, gets the external liquid of dialysis and is spin-dried with a rotary evaporator, and further puts into a vacuum oven to dry, and obtains 5: 5 carbon dots.

[0034] 2.5:5 carbon dots as fluorescent ink for handwriting application

[0035] Configure 1mg / mL carbon dot aqueous solution as fluorescent ink, pour it into a commercial pen, and use the pen to write. The "fluorescent" writing cannot be observed under sunlight ( figure 1 a), only observed under UV light ( figure...

Embodiment 3

[0037] 1. Preparation of fluorescent carbon dots with high quantum yield

[0038] Blend 1mmol of citric acid and 4mmol of ethylenediamine in 5mL of deionized water and transfer it to a reaction kettle for hydrothermal reaction at 200°C for 7 hours. After the reaction, the reaction kettle was cooled to room temperature to obtain quantum The resulting carbon dot aqueous solution was spin-dried with a rotary evaporator, and further dried in a vacuum oven to obtain a 1:4 carbon dot solution.

[0039] 2.1:4 carbon dots as fluorescent ink for handwriting application

[0040] Configure 1mg / mL carbon dot aqueous solution as fluorescent ink, pour it into a commercial pen, and use the pen to write. The "fluorescent" writing cannot be observed under sunlight ( figure 1 a), only observed under UV light ( figure 1 d).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com