Method for preparing full-spectrum fluorescent carbon dots by using one-pot method

A fluorescent carbon dot, full-spectrum technology, applied in chemical instruments and methods, nano-carbon, nano-optics, etc., can solve the problems of no breakthrough in synthesis technology and limit the application of carbon dots, and achieve significant nano-size effect and stable fluorescent optical properties , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

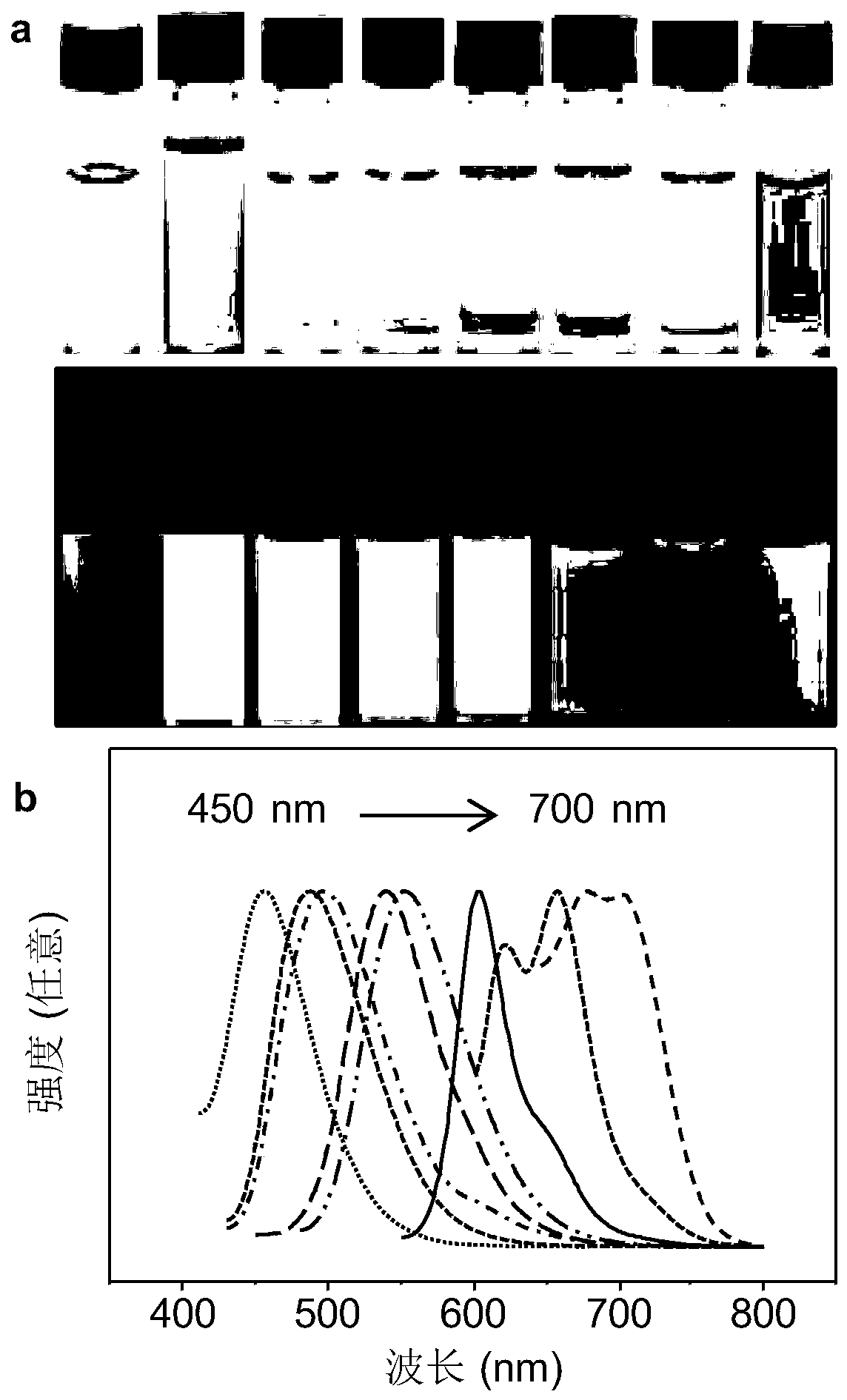

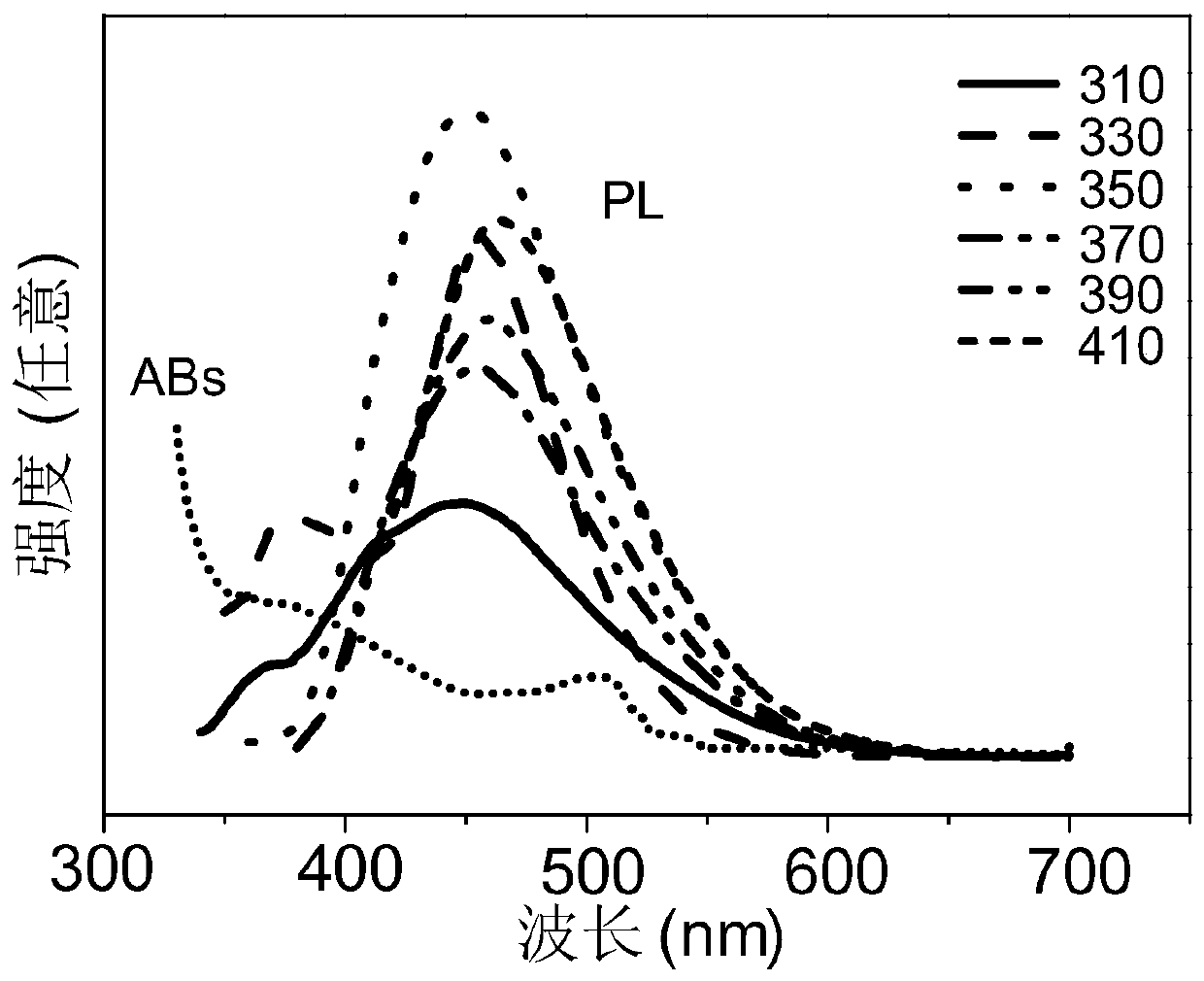

[0034] In this embodiment, a method for preparing spectrally fluorescent carbon dots, using m-phenylenediamine as a precursor, adding aminobenzenesulfonic acid, and growing fluorescent carbon dots by solvothermal method in an organic solvent of toluene, including Follow the steps below:

[0035] a. Add m-phenylenediamine and aminobenzenesulfonic acid in a molar ratio of 2:1, add toluene to dissolve, stir evenly, transfer to a polytetrafluoroethylene reactor, and then transfer the mixed solution to a polytetrafluoroethylene high-pressure In the reaction kettle, a solvothermal reaction was carried out at 120°C for 8 hours to obtain a product mixture;

[0036] b. After the product mixture prepared in the above step a is naturally cooled to room temperature, the product mixture is taken out, then filtered with a 220nm filter membrane, and the filtered solution is transferred to a dialysis bag for dialysis to obtain a carbon dot solution .

[0037] Experimental Analysis Test:

...

Embodiment 2

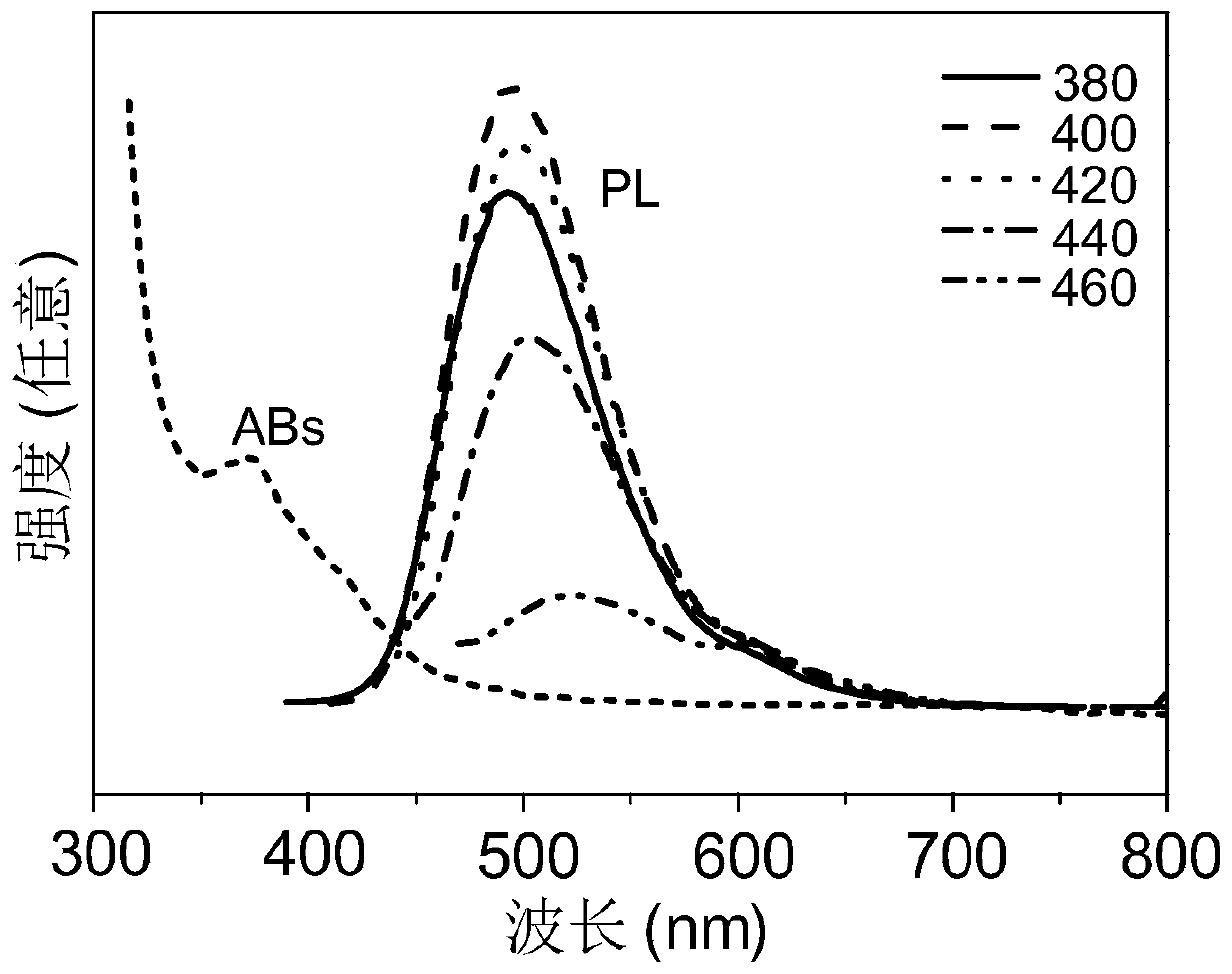

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this embodiment, a method for preparing spectrally fluorescent carbon dots, using p-phenylenediamine as a precursor, adding ascorbic acid, and growing fluorescent carbon dots by solvothermal method in an ethanol organic solvent, includes the following steps:

[0042] a. Add ethanol to dissolve p-phenylenediamine and ascorbic acid in a molar ratio of 1:1, stir evenly, transfer to a polytetrafluoroethylene reaction kettle, and then transfer the mixed solution into a polytetrafluoroethylene high-pressure reaction kettle , solvothermal reaction was carried out at 170°C for 4 hours to obtain a product mixture;

[0043] b. After the product mixture prepared in the above step a is naturally cooled to room temperature, the product mixture is taken out, then filtered with a 220nm filter membrane, and the filtered solution is transferred to a dialysis bag for dialysis to obtain a carbon dot sol...

Embodiment 3

[0047] This embodiment is basically the same as the previous embodiment, and the special features are:

[0048] In this embodiment, a method for preparing spectrally fluorescent carbon dots, using o-phenylenediamine as a precursor, adding terephthalic acid, and growing fluorescent carbon dots by solvothermal method in an acetone organic solvent, including Follow the steps below:

[0049] a. Add o-phenylenediamine and terephthalic acid in a molar ratio of 1:2, add acetone to dissolve, stir evenly, transfer to a polytetrafluoroethylene reactor, and then transfer the mixed solution to a polytetrafluoroethylene high-pressure In the reaction kettle, a solvothermal reaction was carried out at 200°C for 6 hours to obtain a product mixture;

[0050]b. After the product mixture prepared in the above step a is naturally cooled to room temperature, the product mixture is taken out, then filtered with a 220nm filter membrane, and the filtered solution is transferred to a dialysis bag for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com