Preparation method of CuInS2/ZnS core-shell structure quantum dot and CuInS2/CdS/ZnS core-shell structure quantum dot

A technology of core-shell structure and quantum dots, which is applied in the field of semiconductor nanomaterials preparation, can solve the problems of low quantum yield, blue shift of fluorescence emission spectrum, low fluorescence efficiency of quantum dots, etc., and achieve the improvement of fluorescence quantum yield and equipment requirements Low, reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

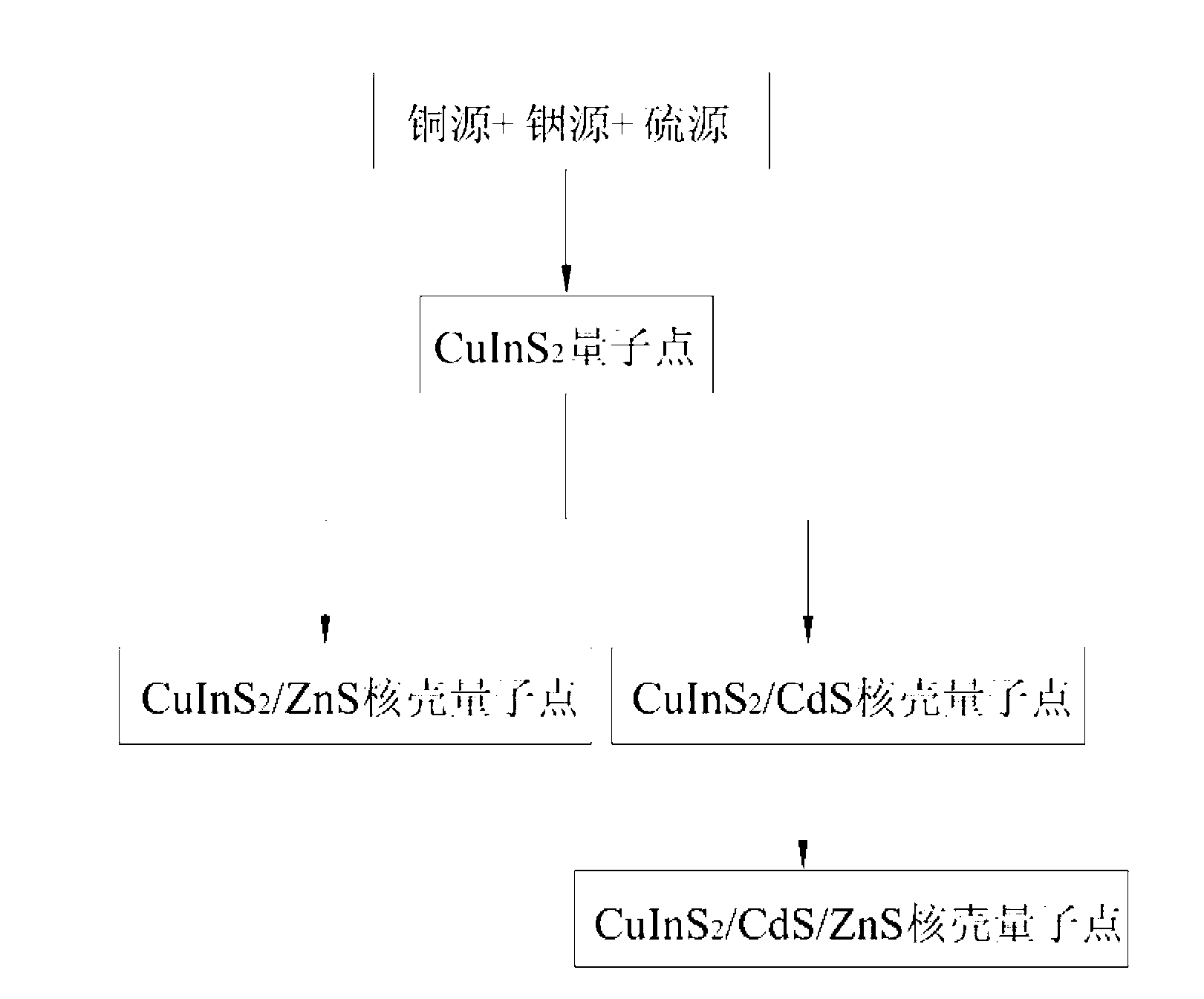

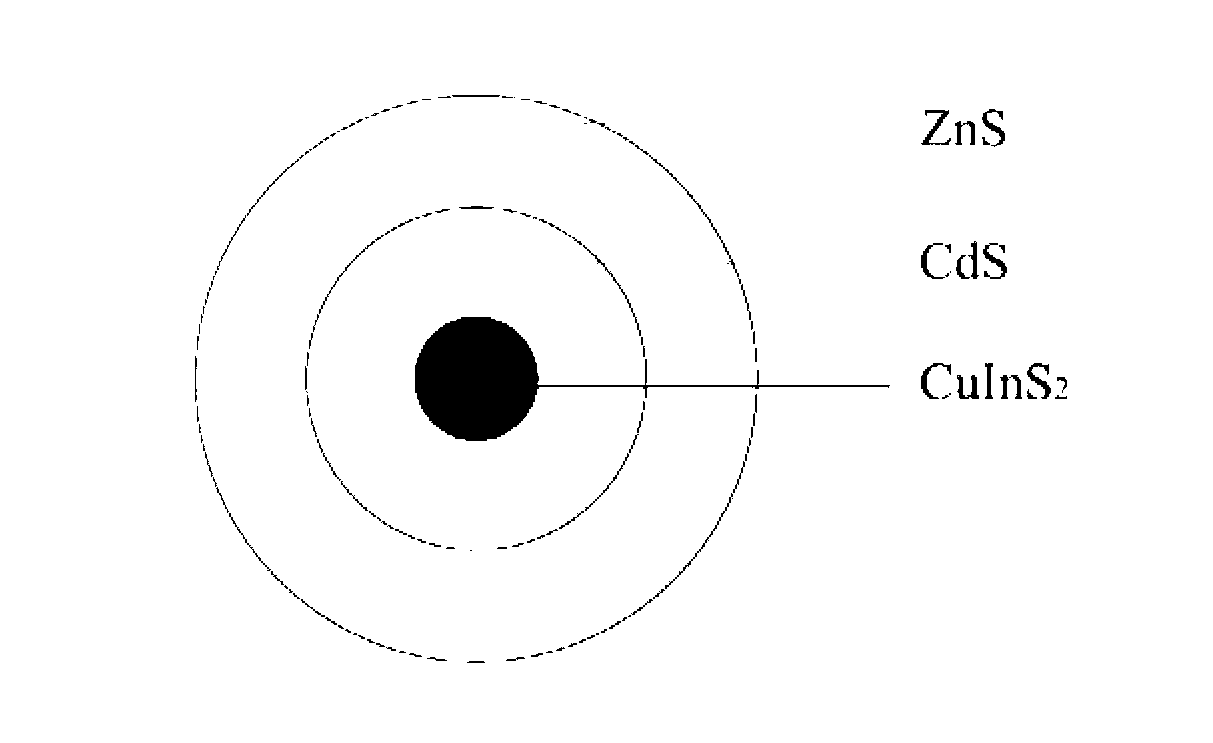

[0041] Such as Figure 1 to Figure 7 As shown, CuInS 2 The preparation method of / ZnS core-shell structure quantum dot comprises the following steps:

[0042] (1) Dissolve the copper source and indium source in the ratio of specific substances in the sulfur source, under the protection of nitrogen, heat to 120°C, keep warm until the solid particles are completely dissolved, and obtain the copper indium precursor liquid; continue to heat up to 220°C °C and incubated for 10-25 minutes to obtain CuInS with different particle sizes and fluorescence characteristics 2 Quantum dot solution;

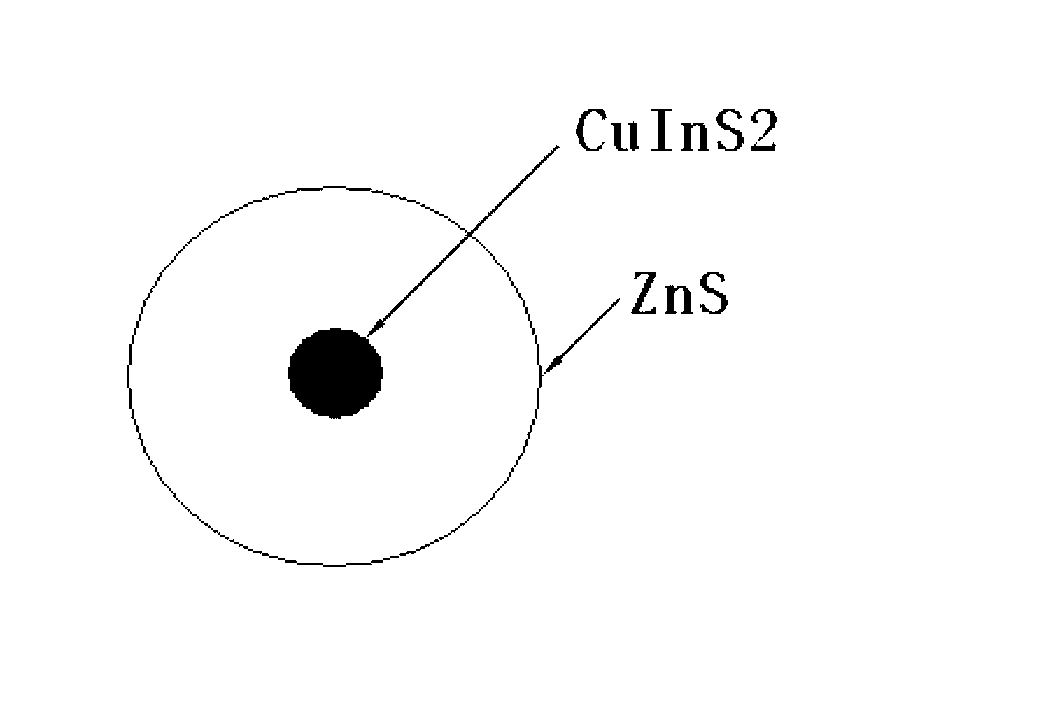

[0043] (2) The CuInS obtained in step (1) 2 CuInS was obtained after the quantum dot solution was purified by centrifugation 2 quantum dots, will result in CuInS 2 Quantum dots are dispersed in octadecene and then heated to 230°C, zinc and sulfur precursor solutions are added dropwise within 20 to 30 minutes, and then incubated for 30 minutes to obtain CuInS 2 / ZnS core-shell quantum dot so...

Embodiment 1

[0051] Dodecanethiol was used as the sulfur source and solvent.

[0052] Preparation of zinc and sulfur precursor liquid: Disperse 4.8 mmol of zinc dibutyldithiocarbamate in 10 ml of octadecene solution and 4.8 mmol of sulfur powder into 15 ml of tributylphosphine.

[0053] Preparation of copper indium precursor liquid: 2.4mmol cuprous iodide, 2.4mmol indium acetate, and 30ml dodecanethiol were placed in a three-necked flask, heated to 120°C under the protection of nitrogen, and kept warm until the solid particles were completely dissolved.

[0054] CuInS 2 Preparation of quantum dots: Under the protection of nitrogen, the copper indium precursor solution was heated up to 220°C and reacted for 20 minutes to prepare CuInS 2 Quantum dot solution.

[0055] CuInS 2 Preparation of / ZnS core-shell quantum dots: CuInS obtained above 2 After the quantum dot solution was purified by centrifugation, CuInS 2 quantum dots, will result in CuInS 2 Quantum dots were dispersed into 30ml...

Embodiment 2

[0058] Octadecanol was used as the sulfur source and solvent.

[0059] Preparation of zinc and sulfur precursor liquid: Disperse 4.8 mmol of zinc diethyldithiocarbamate in 10 ml of octadecene and 4.8 mmol of sulfur powder into 15 ml of tributylphosphine.

[0060] Preparation of copper indium precursor liquid: disperse 2.4mmol cuprous iodide and 2.4mmol indium acetate in 30ml octadecyl mercaptan, place in a three-necked flask, heat to 120°C under the protection of nitrogen, and keep warm until the solid particles are completely dissolve.

[0061] CuInS 2 Preparation of quantum dots: under the protection of nitrogen, continue to heat up to 220 ° C, react for 25 minutes, and prepare CuInS 2 Quantum dot solution.

[0062] CuInS 2 Preparation of / ZnS core-shell quantum dots: CuInS obtained above 2 After the quantum dot solution was purified by centrifugation, CuInS 2 quantum dots, will result in CuInS 2 Quantum dots were dispersed into 30ml of octadecene, heated to 230°C aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com