A kind of organosilicon connection coating suitable for ships below the waterline and its preparation method

A technology of silicone and waterline, applied in the direction of coating, etc., can solve the problems of low connection performance of antifouling paint, influence on adhesion and connection, poor recoatability, etc., and achieve difficult control of reaction rate, small steric hindrance, and improved The effect of adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

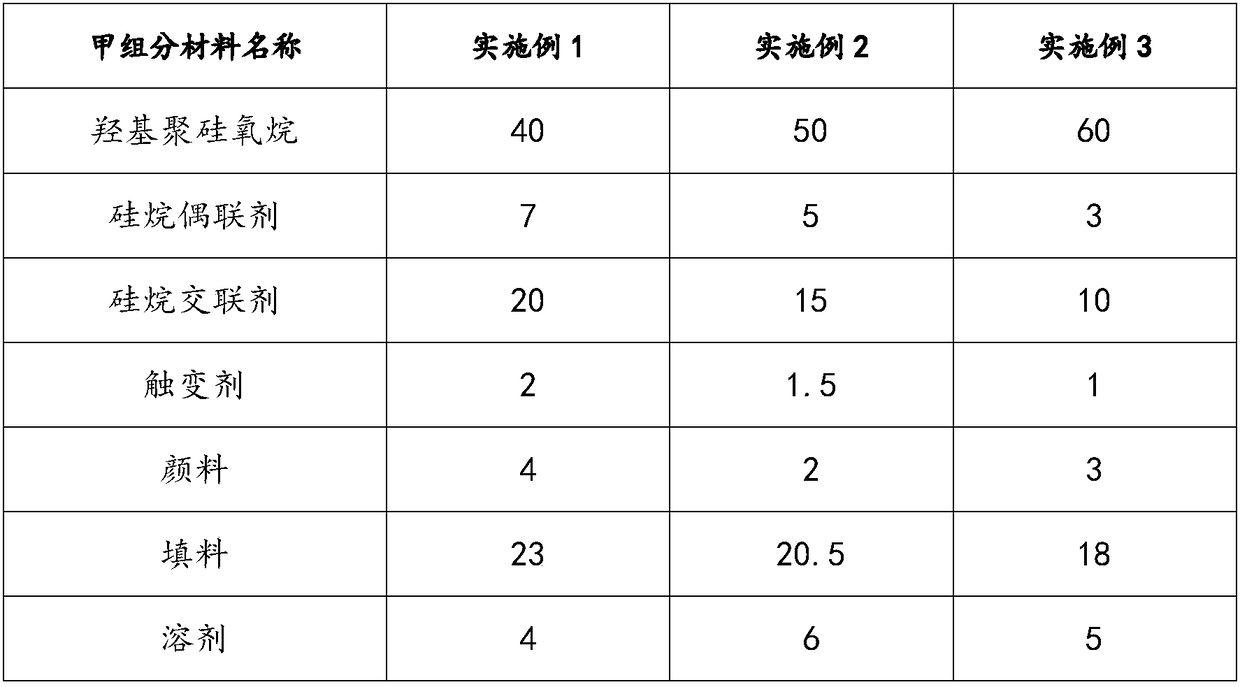

Examples

preparation example Construction

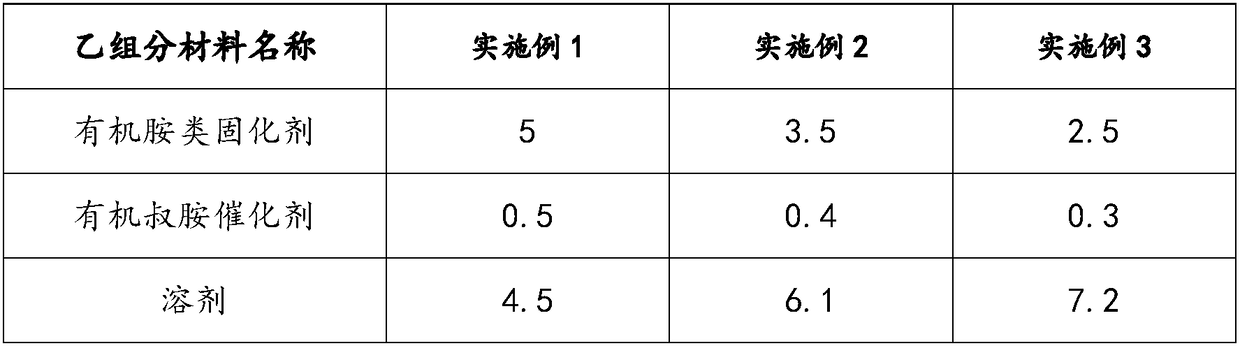

[0032] The preparation method of the second component is as follows: adding an organic tertiary amine catalyst into the organic amine curing agent, and blending uniformly to obtain the second component.

[0033] in:

Embodiment 1

[0034] The specific composition of the organic amine curing agent in Example 1 is cashew nut shell oil modified phenalkamine, the specific composition of the organic tertiary amine catalyst is dodecyl tertiary amine, and the specific composition of the solvent is xylene or acetone;

Embodiment 2

[0035] In Example 2, the specific composition of the organic amine curing agent is polyamide, the specific composition of the organic tertiary amine catalyst is tetradecyl tertiary amine, and the specific composition of the solvent is xylene or acetone;

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com