A kind of fracturing proppant and preparation method thereof

A fracturing proppant and curing agent technology, applied in the field of fracturing proppant, can solve the problems of easy migration of ceramsite, poor conductivity, and high breakage rate of ceramsite and quartz sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

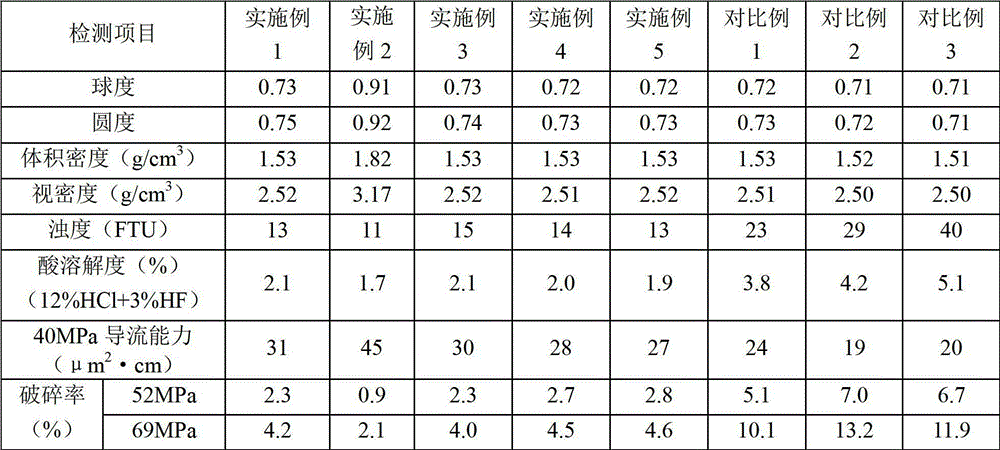

Examples

preparation example Construction

[0008] The preparation method of the fracturing proppant provided by the present invention comprises uniformly mixing and curing aggregate particles, epoxy resin and curing agent, wherein the curing agent is a curing agent composition containing an acid anhydride curing agent and an amine curing agent, And based on the total weight of the curing agent composition, the content of the acid anhydride curing agent is 80-99.8% by weight, and the content of the amine curing agent is 0.2-20% by weight.

[0009] According to the present invention, although the content of the acid anhydride curing agent and the amine curing agent can be controlled within the above range, the obtained fracturing proppant can have a lower fragmentation rate and a higher flow conductivity, but in order to make the obtained The fracturing proppant has more excellent comprehensive properties. Preferably, based on the total weight of the curing agent composition, the content of the anhydride curing agent is 9...

Embodiment 1

[0028] This embodiment is used to illustrate the curing agent composition provided by the present invention and its preparation method and application.

[0029] 40 parts by weight of tetrahydrophthalic anhydride curing agent and 1 part by weight of diethylenetriamine curing agent were uniformly mixed to obtain curing agent composition G1.

[0030] In the preparation process of the fracturing proppant, the dosages of each substance were: 2kg raw sand, 0.1kg epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-44, epoxy value 0.44mol / 100g ), 0.041kg curing agent composition G1.

[0031] At room temperature of 25°C, divide the curing agent composition into 2 parts of equal mass, divide the epoxy resin into 3 parts of equal mass, put the raw sand into the sand mixer, start stirring, first add 1 part of epoxy resin, After stirring for 1 minute, add 1 part of curing agent composition and mix evenly, then add epoxy resin in sequence according to the...

Embodiment 2

[0033] This embodiment is used to illustrate the curing agent composition provided by the present invention and its preparation method and application.

[0034] 40 parts by weight of phthalic anhydride curing agent and 2 parts by weight of ethylenediamine curing agent were uniformly mixed to obtain curing agent composition G2.

[0035] In the preparation process of the fracturing proppant, the dosages of each substance were: 2kg ceramsite, 0.1kg epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., the brand is E-44, and the epoxy value is 0.44mol / 100g ), 0.042kg curing agent composition G2.

[0036] At room temperature 25°C, divide the curing agent composition into 2 parts of equal mass, divide the epoxy resin into 2 parts of equal mass, put the ceramsite into the sand mixer, start stirring, and add 1 part of epoxy resin first, After stirring for 1 minute, add 1 part of curing agent composition and mix evenly, then add epoxy resin sequentially accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com