Film making method capable of precisely controlling film thickness and area of nanometer-thickness film

A nano-scale, film-forming technology, which is applied in the direction of nanotechnology, nanotechnology, and the preparation of test samples. It can solve the problem that the thickness of film materials is difficult to achieve uniformity, high dispersion requirements for film-forming substances, and low viscosity. problem, to achieve the effect of efficient and precise control of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

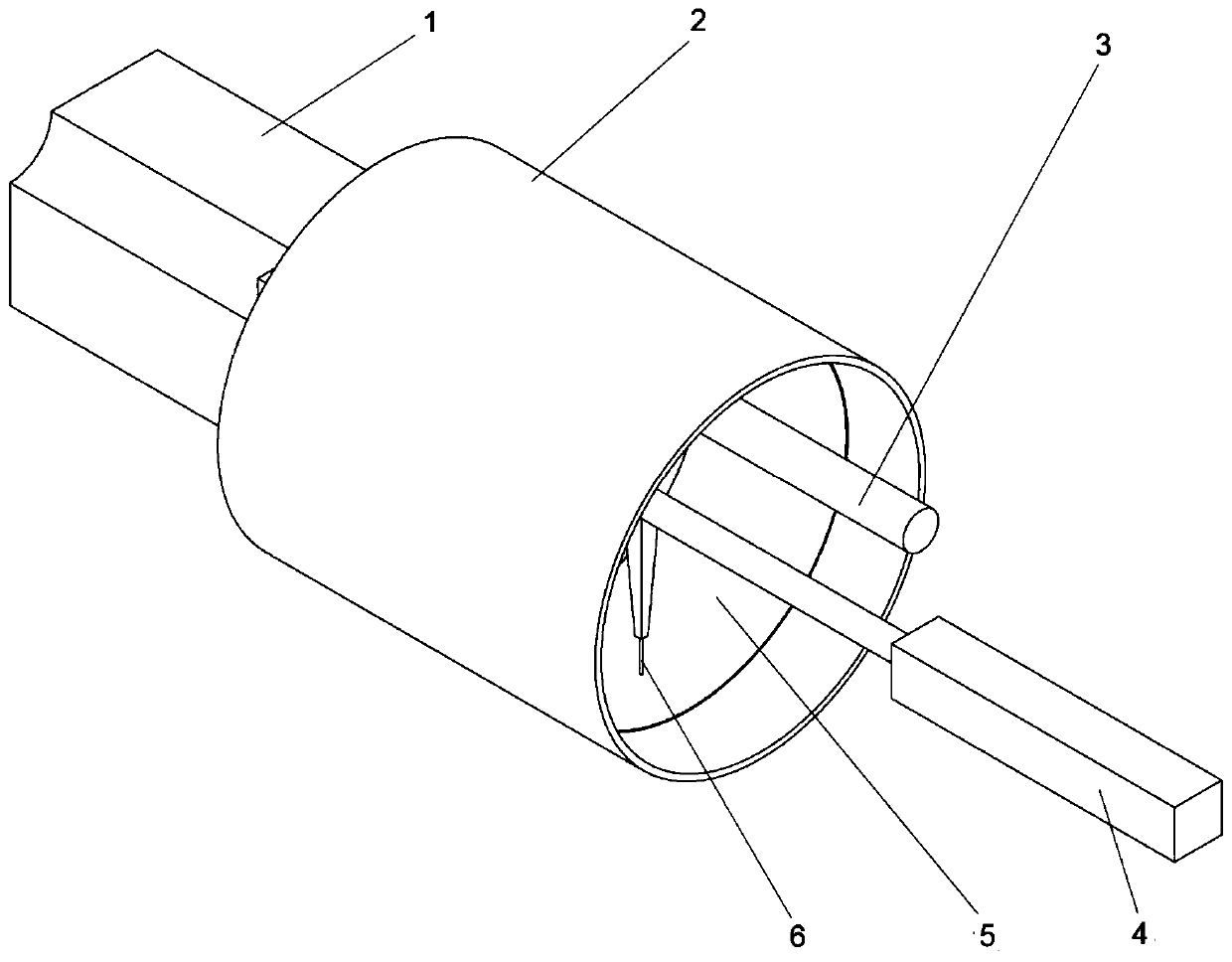

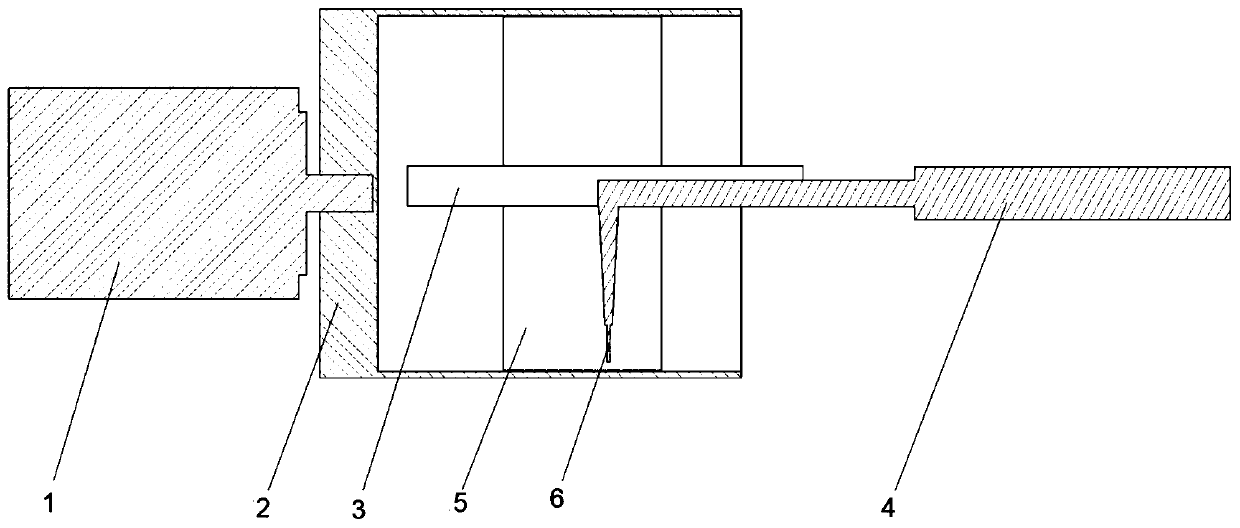

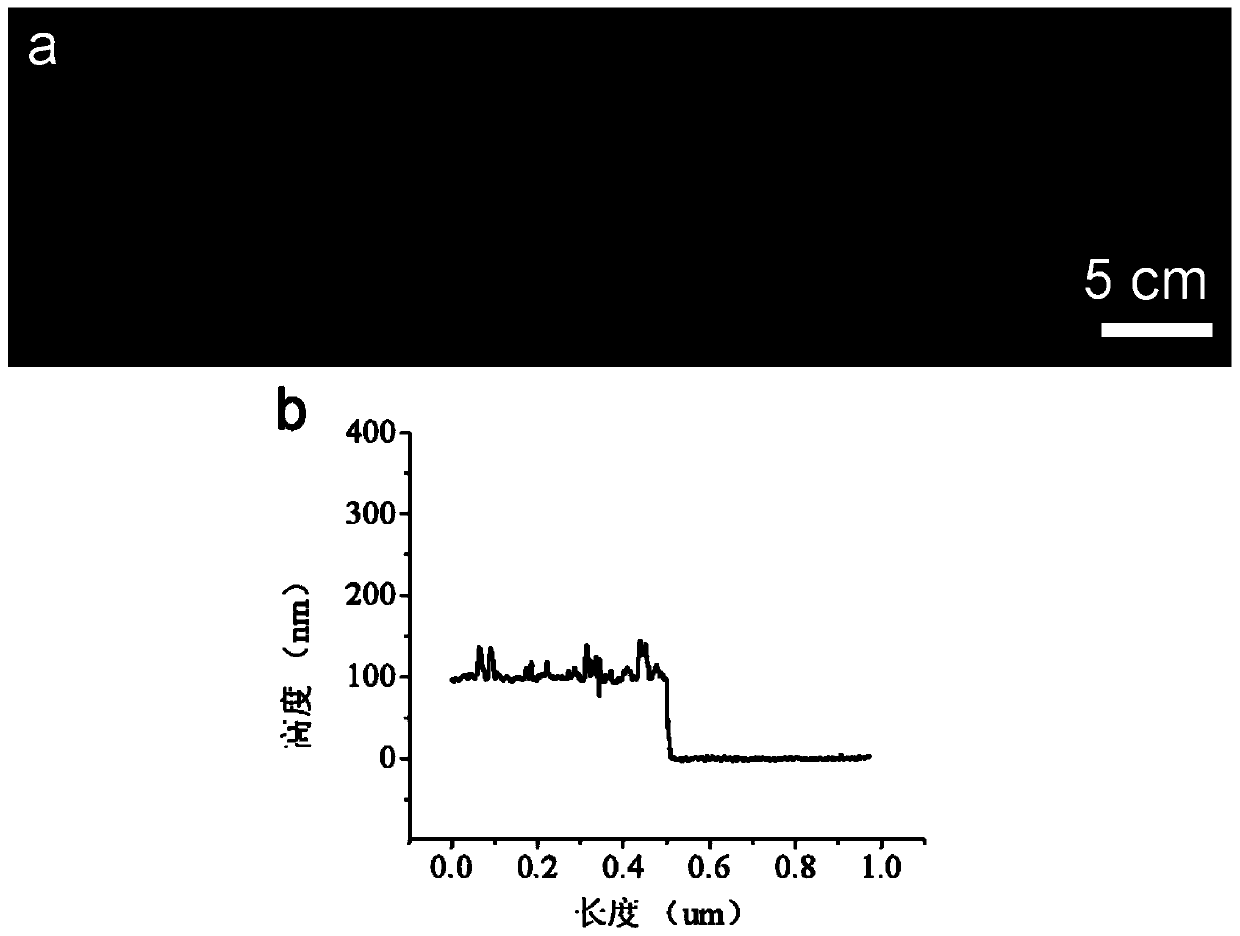

[0055] Such as figure 2 As shown in a, the film-forming base material used in this example is a 125 μm thick PET film with a surface hydrophilic treatment, and an aluminum alloy cylinder with an inner diameter of 150 mm and a length of 100 mm is used as a rotating drum, and PET is bonded to the aluminum alloy drum with ethanol On the inner wall, the centrifugal acceleration applied on the surface of the PET substrate is 380g (g is the acceleration of gravity, and the value is 9.8m / s 2 ). The injection nozzle adopts a stainless steel needle, the inner diameter of the needle is 200 μm, and the length of the needle is 50 mm. The film-forming material is water-based polyurethane (WTPU), the solvent is water, and the concentration of the water-based polyurethane is 1 mg / ml. The needle is connected to the liquid pump with silicone tubing, and the needle is fixed on a bracket that can move automatically according to the program. The liquid pump sends the water-based polyurethane s...

Embodiment 2

[0058] Such as image 3 As shown in a, the film-forming base material used in this example is PET film with a thickness of 188 μm, and an aluminum alloy cylinder with a length of 150 mm and an inner diameter of 100 mm is used as a rotating drum. The PET substrate is directly attached to the inner wall of the aluminum alloy roller, and centrifugal acceleration is applied to the surface of the PET substrate. is 500g (g is the acceleration of gravity, the value is 9.8m / s 2 ), the injection nozzle adopts a stainless steel needle, the inner diameter of the needle is 300 μm, and the length of the needle is 50 mm. Silver nanowires are used as the film-forming raw material, the solvent is absolute ethanol, and the concentration of the silver nanowires is 2 mg / ml. The needle is fixed on a stand that can be programmed to move automatically. The liquid pump sends the silver nanowire dispersion liquid into the needle and injects it onto the surface of the rotating PET film. The liquid pu...

Embodiment 3

[0061] Such as Figure 4 As shown in a, the film-forming base material used in this example is a fluorinated release film, and an aluminum alloy cylinder with an inner diameter of 350 mm and a length of 250 mm is used as a rotating drum, and the fluorinated release film is bonded to the inner wall of the aluminum alloy drum with ethanol. The centrifugal acceleration applied on the surface of the fluorinated release film substrate is 400g (g is the acceleration of gravity, and the value is 9.8m / s 2). The injection nozzle is made of polytetrafluoroethylene needle, the inner diameter of the needle is 350 μm, and the length of the needle is 100 mm. The intrinsic graphene is used as the film-forming raw material, water is used as the solvent, and the intrinsic graphene concentration is 2.5 mg / ml. The needle is connected to the liquid pump with a polytetrafluoroethylene pipeline. The liquid pump sends the intrinsic graphene dispersion into the needle and injects it onto the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com