ITO-Ag-ITO etching liquid for AMOLED

An etching solution, ito-ag-ito technology, applied in the direction of surface etching composition, chemical instrument and method, etc., can solve the problem of poor etching stability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

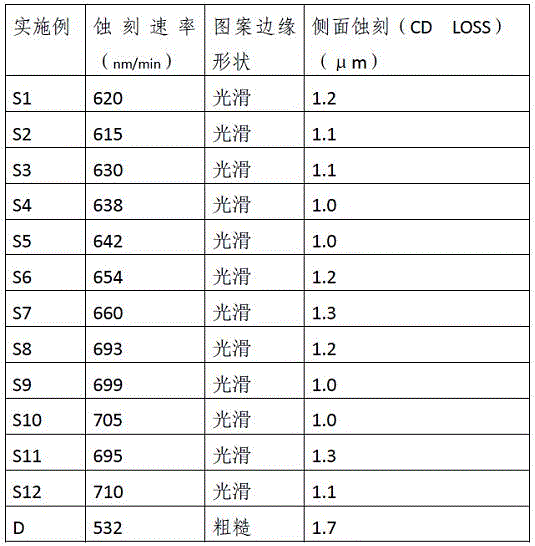

Examples

Embodiment 1

[0028] The components of the ITO-Ag-ITO etchant for AMOLED in Example 1 (corresponding to S1 in the table, the same below) include by weight percent: 3% by weight of nitric acid, 25% by weight of acetic acid, 60% by weight of phosphoric acid and soluble A mixture of orthophosphate, 5% additive, and deionized water in the balance; the additive is sodium nitrate. Soluble orthophosphate is sodium phosphate.

[0029] The weight percent of sodium phosphate in the mixture of phosphoric acid and sodium phosphate is 5%.

Embodiment 2

[0031] The difference between embodiment 2 and embodiment 1 is: the components of the ITO-Ag-ITO etchant for AMOLED in embodiment 2 include by weight percentage: 10% by weight of nitric acid, 10% by weight of acetic acid, 30% by weight of phosphoric acid and soluble orthophosphate, 1% additive, the balance deionized water; additives are potassium nitrate and ammonium nitrate. Soluble orthophosphate is sodium phosphate.

[0032] The weight percent of sodium phosphate in the mixture of phosphoric acid and sodium phosphate is 30%.

Embodiment 3

[0034] The difference between embodiment 3 and embodiment 1 is: the component of AMOLED ITO-Ag-ITO etchant comprises by weight percent: the nitric acid of 6% by weight, the acetic acid of 18% by weight, the phosphoric acid of 48% by weight and soluble orthophosphoric acid A mixture of salt, 2% by weight of additives, and the balance of deionized water; the additive is a 1:1 mixture of sodium nitrate and potassium nitrate. Soluble orthophosphate is sodium phosphate.

[0035] The weight percent of sodium phosphate in the mixture of phosphoric acid and sodium phosphate is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com