A kind of quaternary phosphonium salt modified mercaptan with self-catalysis activity, preparation method and ultra-high refractive index optical resin material prepared therefrom

An optical resin, refractive index technology, applied in the fields of organic chemistry, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve the problems of slowness, uneven texture, etc., achieve high optical properties, control curing rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A self-catalytic active quaternary phosphonium salt modified thiol: (3,6-dithio) octylthiol-triphenylphosphonium bromide The preparation method is as follows:

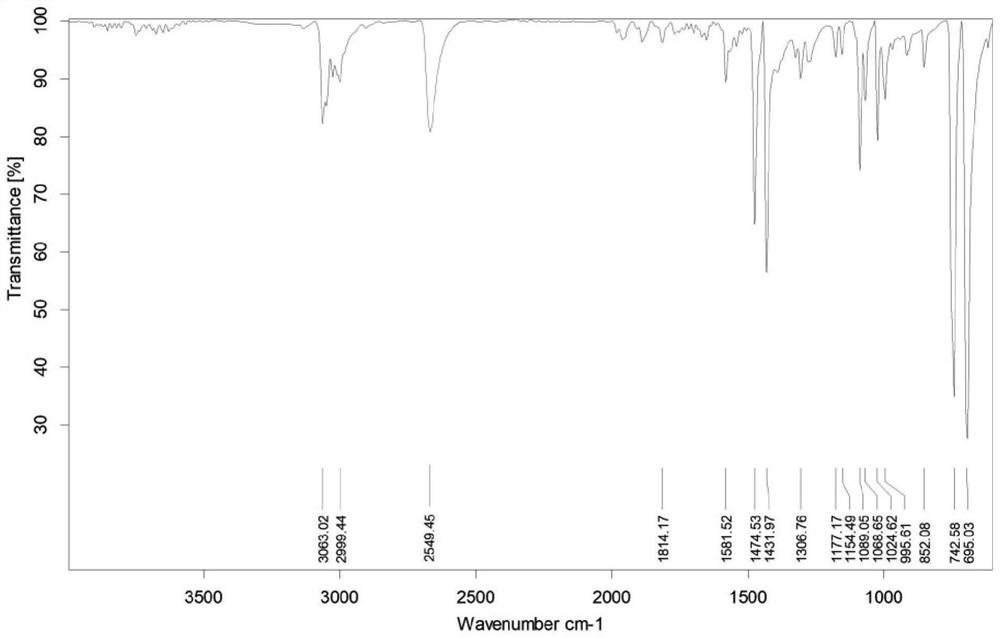

[0083] In a 250ml four-necked flask, 50g of vinyltriphenylphosphonium bromide, 146g of solvent water, 1.46g of potassium bicarbonate, 0.073 of tetrabutylammonium bromide phase transfer catalyst, 2,2'-thiobis( ethanethiol) 23g, control the reaction temperature at 35°C, monitor the content of mercapto compound during the reaction, when the content is below 3%, stop the reaction, the reaction time is 3 hours, cool down to 10°C, and filter to obtain white crystals Powder 56.7g, productive rate is 80%; Its infrared spectrogram is as figure 1 As shown, its structural formula is as follows:

[0084]

[0085] The method for preparing an ultra-high refractive index optical resin material using it, the specific steps are as follows:

[0086] (1) At 20°C, add 0.1g of UV absorber UV-324, 0.1g of dibutyl phosphate, 0.1g...

Embodiment 2

[0090] A kind of self-catalytic active quaternary phosphonium salt modified mercaptan: the preparation method of (3-thio) hexanethiol-tri-n-butylphosphonium bromide is as follows:

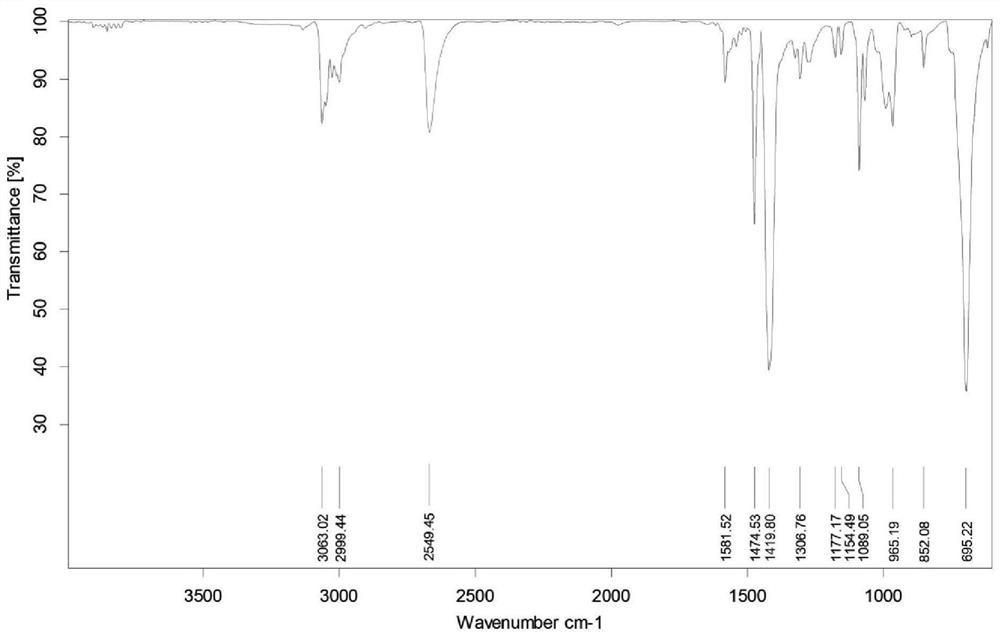

[0091] In a 250ml four-necked flask, add vinyl tri-n-butylphosphonium bromide 50g, solvent water 138g, potassium bicarbonate 1.38g, tetrabutylammonium bromide phase transfer catalyst 0.069g, propanedithiol 19g, control The reaction temperature is 30°C. During the reaction, the content of the mercapto compound is monitored. When the content is below 3%, the reaction is terminated. At this time, the reaction time is 3.5 hours, cooled to 5°C, and filtered to obtain 56g of white crystalline powder with a yield of 83 %, its infrared spectrum as figure 2 As shown, its structural formula is as follows:

[0092]

[0093] The method for preparing an ultra-high refractive index optical resin material using it, the specific steps are as follows:

[0094] (1) At 20°C, add 0.1g of UV absorber UV-324, 0.1g...

Embodiment 3

[0098] A self-catalytic active quaternary phosphonium salt modified mercaptan: [1,2-dithio (2-mercapto)-3-thio] pentane-triphenylphosphonium bromide The preparation method is as follows:

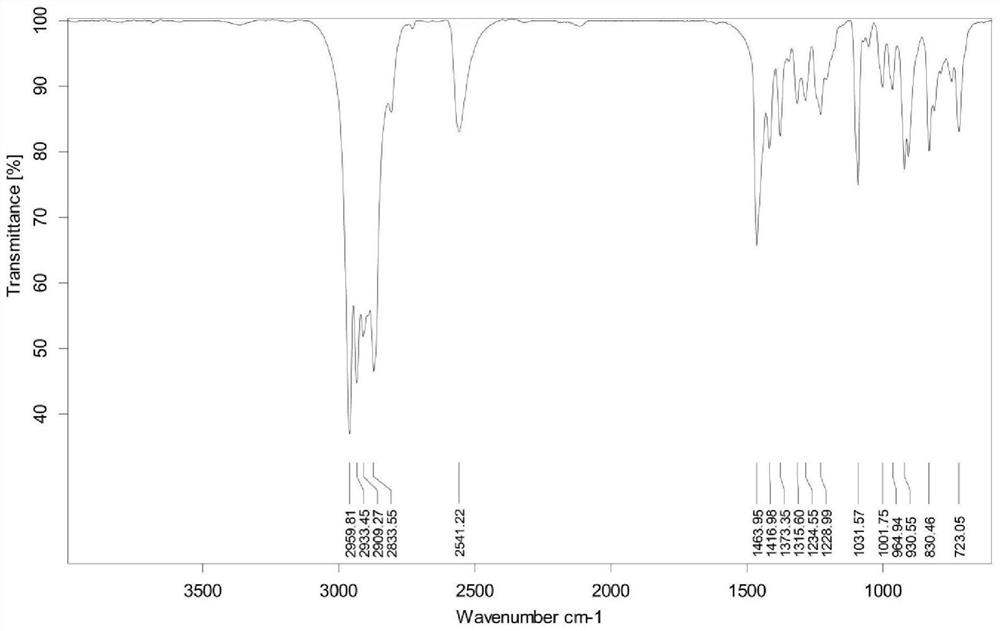

[0099] In a 250ml four-necked flask, 40g of vinyltriphenylphosphonium bromide, 100g of solvent water, 1.42g of potassium bicarbonate, 0.071g of tetrabutylammonium bromide phase transfer catalyst, 2,3-bis(2- Mercaptoethylthio)-3-propane-1-mercaptan 31.1g, control the reaction temperature 50°C, monitor the content of mercapto compound during the reaction, when the content is below 3%, stop the reaction, the reaction time is 4h now, Cool down to 5°C, filter to obtain 51.8g of white crystalline powder, the yield is 76%, and its infrared spectrum is as follows: image 3 As shown, its structural formula is as follows:

[0100]

[0101] The method for preparing an ultra-high refractive index optical resin material using it, the specific steps are as follows:

[0102] (1) At 20°C, add 0.1g UV a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com