A kind of glass surface decoration method

A glass surface and glass substrate technology, applied in the field of engraving, can solve the problems of poor three-dimensional and engraving sense of glass decorations, affecting the quality of glass engravings, and glass cannot be used for deep engraving. Large-scale process processing, strong color persistence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A glass surface decoration method of this embodiment, the method is to prepare one or more resin layers on the glass surface, and then engrave patterns on the surface of the resin layer. The purpose of engraving glass is to greatly improve the processing efficiency, reduce the labor intensity and process cost of workers, facilitate large-scale process processing, and promote the development of glass decoration technology in China. In addition, this embodiment can also freely adjust the depth of the glass engraving layer by coating the resin layer on the glass surface, and can obtain enough engraving space. The lack of deep carving.

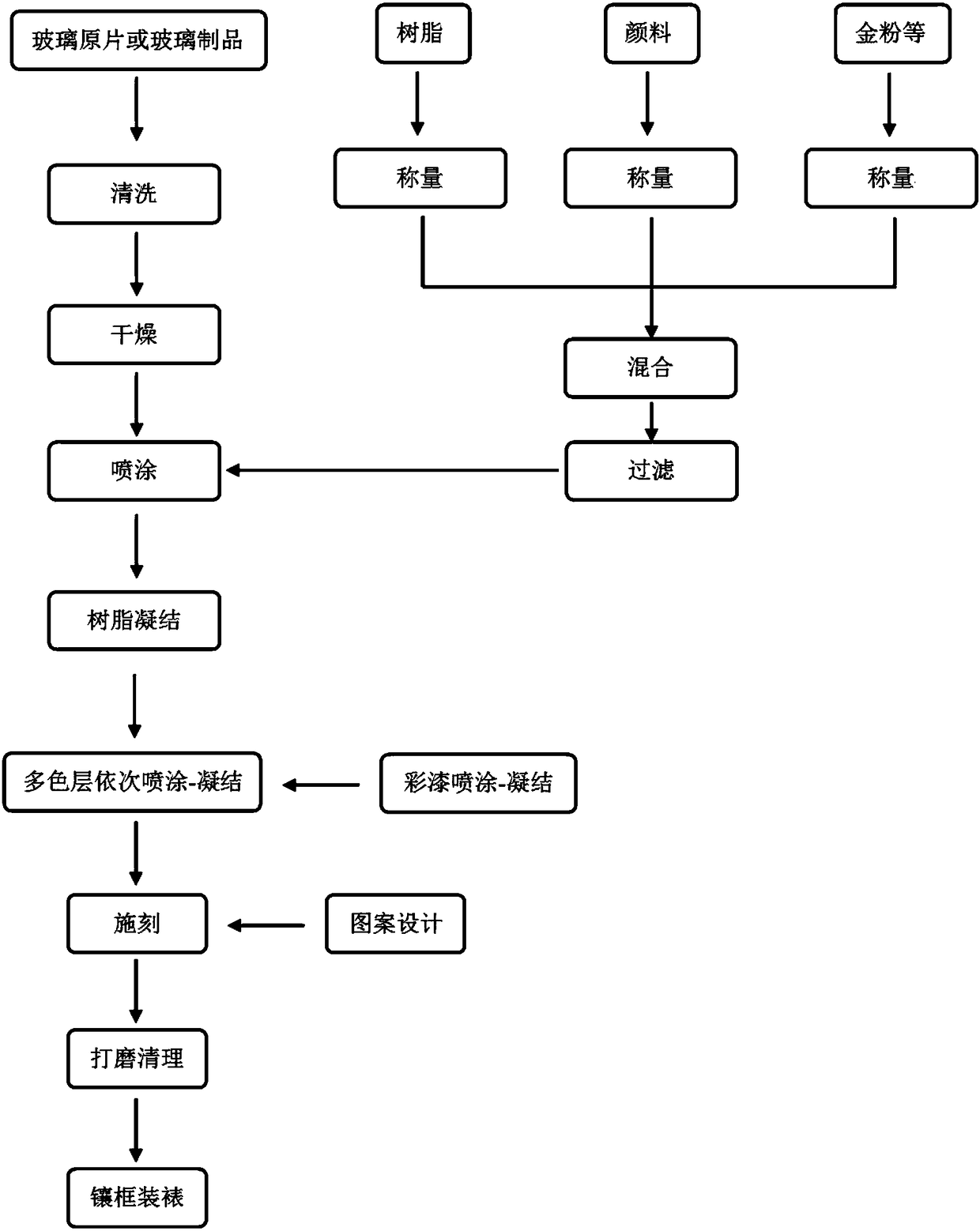

[0044] like figure 1 As shown, the concrete steps of the glass surface decoration method of the present embodiment are:

[0045] (1) Preparation of the glass substrate: the glass substrate is pretreated to prepare for the subsequent process, which specifically includes substrate cutting, edging, cleaning and drying in this embodiment. Af...

Embodiment 2

[0059] A glass surface decoration method of this embodiment, the method is to prepare one or more resin layers on the glass surface, and then engrave patterns on the surface of the resin layer. The purpose of engraving glass is to greatly improve the processing efficiency, reduce the labor intensity and process cost of workers, facilitate large-scale process processing, and promote the development of glass decoration technology in China. In addition, this embodiment can also freely adjust the depth of the glass engraving layer by coating the resin layer on the glass surface, and can obtain enough engraving space. The lack of deep carving.

[0060] The concrete steps of the glass surface decoration method of the present embodiment are:

[0061] (1) Preparation of the glass substrate: the glass substrate is pretreated to prepare for the subsequent process, which specifically includes substrate cutting, edging, cleaning and drying in this embodiment. After cutting, edge grindin...

Embodiment 3

[0068] A glass surface decoration method of this embodiment, the method is to prepare one or more resin layers on the glass surface, and then engrave patterns on the surface of the resin layer. The purpose of engraving glass is to greatly improve the processing efficiency, reduce the labor intensity and process cost of workers, facilitate large-scale process processing, and promote the development of glass decoration technology in China. In addition, this embodiment can also freely adjust the depth of the glass engraving layer by coating the resin layer on the glass surface, and can obtain enough engraving space. The lack of deep carving.

[0069] The concrete steps of the glass surface decoration method of the present embodiment are:

[0070] (1) Preparation of the glass substrate: the glass substrate is pretreated to prepare for the subsequent process, which specifically includes substrate cutting, edging, cleaning and drying in this embodiment. After cutting, edge grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com