Patents

Literature

51results about How to "Improve the honor rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

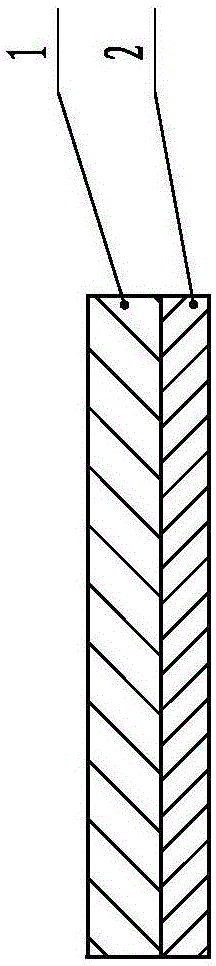

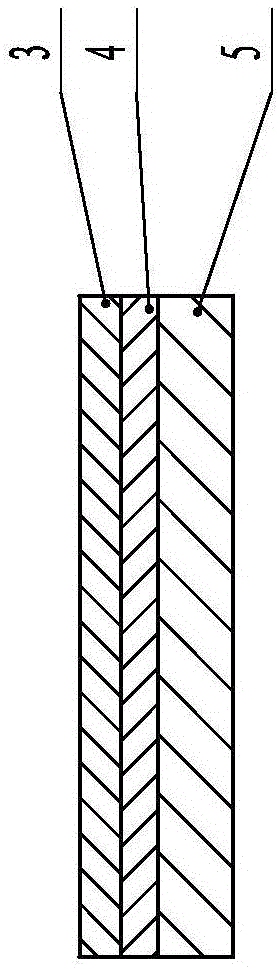

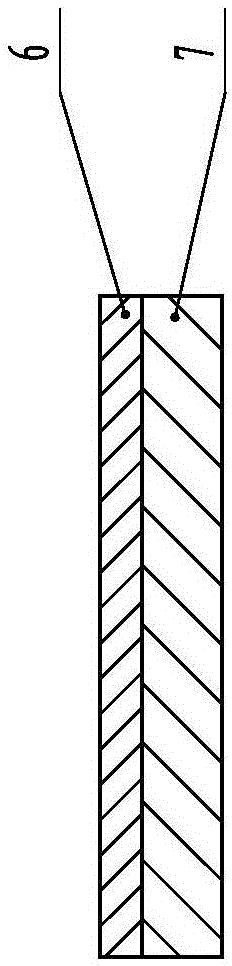

Lithium-ion battery diaphragm and preparation method thereof

InactiveCN105140451AUniform pore sizePorosity is easy to controlCell component detailsPorous coatingPorous substrate

The invention discloses a lithium-ion battery diaphragm. The lithium-ion battery diaphragm is prepared by coating the upper surface and the lower surface of a porous base material with one or more porous coatings, wherein the thickness of the porous base material is 4-80 microns; the porosity of the porous base material is 30%-90%; and each porous coating comprises the following raw materials in parts by weight: 30-100 parts of a polymer material, 0-70 parts of inorganic powder and a surface treating agent and 0-50 parts of a compatibilizer. The invention further discloses a preparation method of the lithium-ion battery diaphragm. The battery diaphragm disclosed by the invention is controllable in pore size and porosity and uniform in pore size; the finished diaphragm product is high in high-grade rate, good in wettability and high in safety; and the diaphragm is good in heat resistance, and has a thermal closing function.

Owner:郑少华

Composite stacked and coated lithium ion battery diaphragm and preparation method thereof

ActiveCN104393217AHigh strengthImprove heat resistanceCell seperators/membranes/diaphragms/spacersViscous flowLithium-ion battery

The invention relates to a composite stacked and coated lithium ion battery diaphragm and a preparation method thereof. The diaphragm is a porous diaphragm which is prepared by mixing one or many kinds of coating sizing agents and is provided with a layer or multiple layers of structures; the porous diaphragm comprises the following components in parts by weight: 30-100 parts of a polymeric material, 0-70 parts of inorganic powder bodies and a surface treating agent thereof, and 0-50 parts of a compatibilizer; the polymeric material at least selects and uses two kinds of polymeric materials, one kind of the polymeric materials is a thermoplastic material of which the melting point or the viscous flow temperature is 100-150 DEG C, and the other kind of the polymeric materials is a thermoplastic material or a thermosetting material of which the melting point or the viscous flow temperature is higher than or equivalent to that of the thermoplastic material of which the melting point or the viscous flow temperature is 100-150 DEG C. The composite stacked and coated lithium ion battery diaphragm provided by the invention is uniform in bore diameter, good in wettability, favorable in heat resistance and good in hot melting and closing function, and the preparation method for the composite stacked and coated lithium ion battery diaphragm is simple in technology, wide in the material selecting range, and controllable in the micropore forming condition.

Owner:HORIZON SPECIALTY MATERIAL

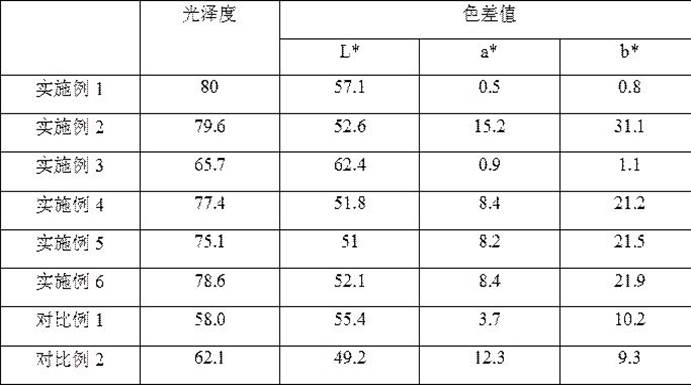

Colorful transparent polished-glazed brick and production method thereof

The invention discloses a colorful transparent polished-glazed brick and a production method thereof. The production method for the colorful transparent polished-glazed brick comprises the following steps: enameling a dried ceramic blank, spreading one or more glazes in different colors and with different burning temperature and different refractive indexes on the brick blank, and performing calcining and profiling soft polishing treatment to obtain the brick. According to the colorful transparent polished-glazed brick and the production method thereof, the layering effects and transition of the surface of the colorful transparent polished-glazed brick are closer to those of a natural stone, and the grade of the product is improved to a certain extent; original color effects can be achieved without adding a coloring material, so that process complexity is reduced, the labor intensity of a worker is reduced, and the production efficiency is favorably improved, and the colorful transparent polished-glazed brick and the production method thereof are suitable for popularization and application.

Owner:GUANGDONG JIA MEI CERAMIC

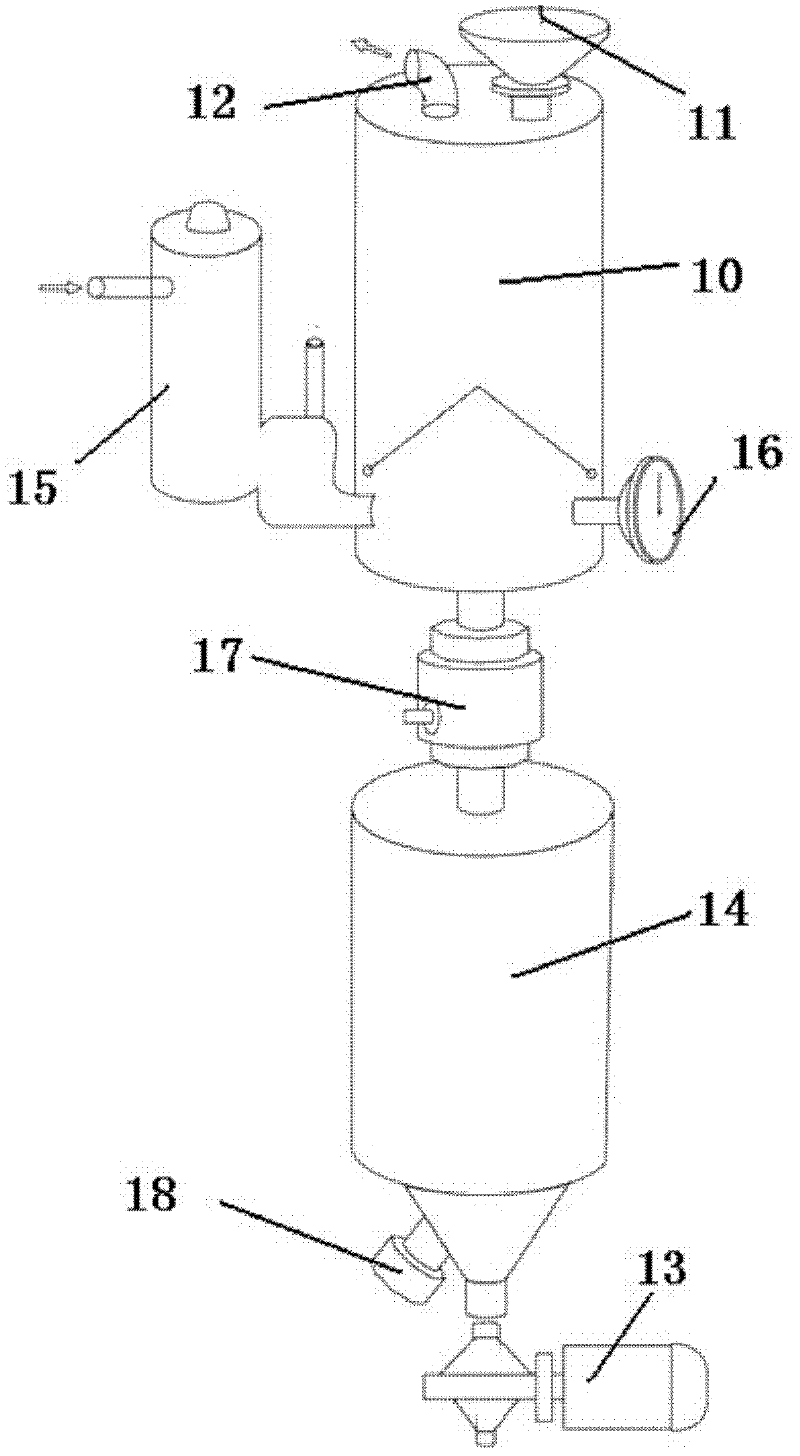

Production method of fine-denier porous POY black yarn

InactiveCN102443859AImprove spinnabilityReduced stabilitySpinnerette packsMelt spinning methodsProduction rateYarn

The invention discloses a production method of a fine-denier porous POY black yarn. The method comprises the following steps of: drying semi-dull slices, drying black masterbatch, adding the slices and the black masterbatch material into a screw extruder, fusing the added materials in the screw extruder, respectively processing the fused materials in a metering pump and a spinning beam, spinning on a pack, cooling the materials by lateral blowing, applying oil on strands, processing the strands in draw-off godets GR1 and GR2, winding and shaping, and inspecting products. The method is characterized in that the step of drying the black masterbatch comprises the following sub-steps of: based on a continuous drying mode, firstly, adding the black masterbatch into a crystallization and drying tank, introducing heated dry air from the lower part of the crystallization and drying tank, and blowing out the heated dry air from the top of the crystallization and drying tank so as to dry the black masterbatch, wherein the drying time is 2 hours, the dried black masterbatch falls into an intermediate material storage bin for storage under the crystallization and drying tank, and the black masterbatch is further injected by a masterbatch injector under the intermediate material storage bin. The production method of the fine-denier porous POY black yarn has high masterbatch spinnability and better cooling effect, and can improve the oil application uniformity of spinning cakes and the productivity.

Owner:桐乡市中洲化纤有限责任公司

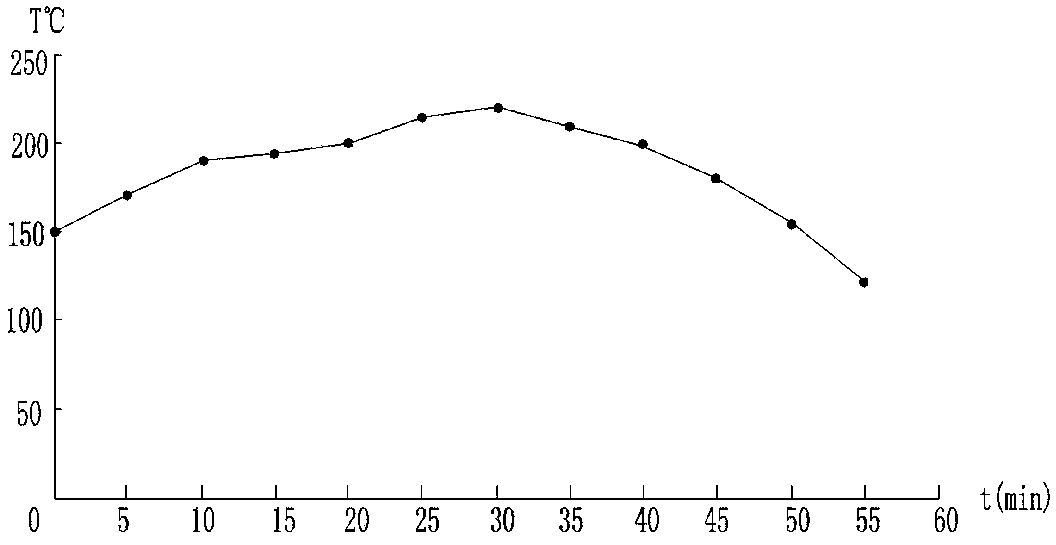

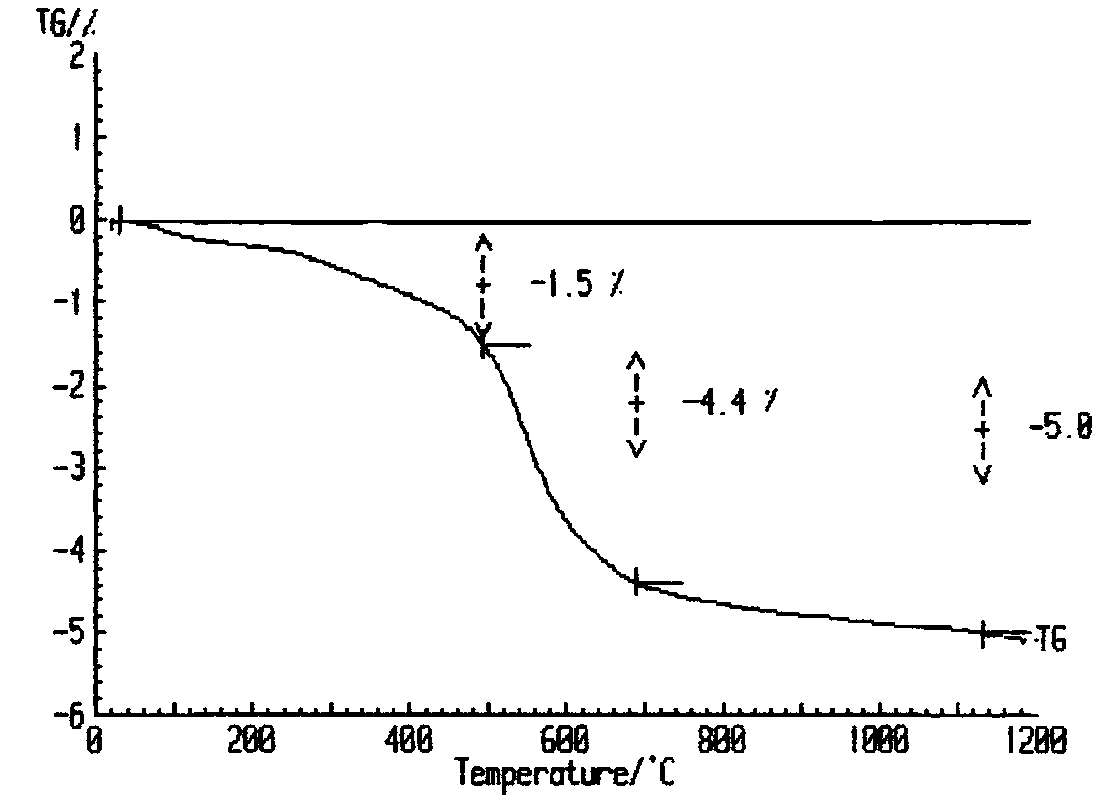

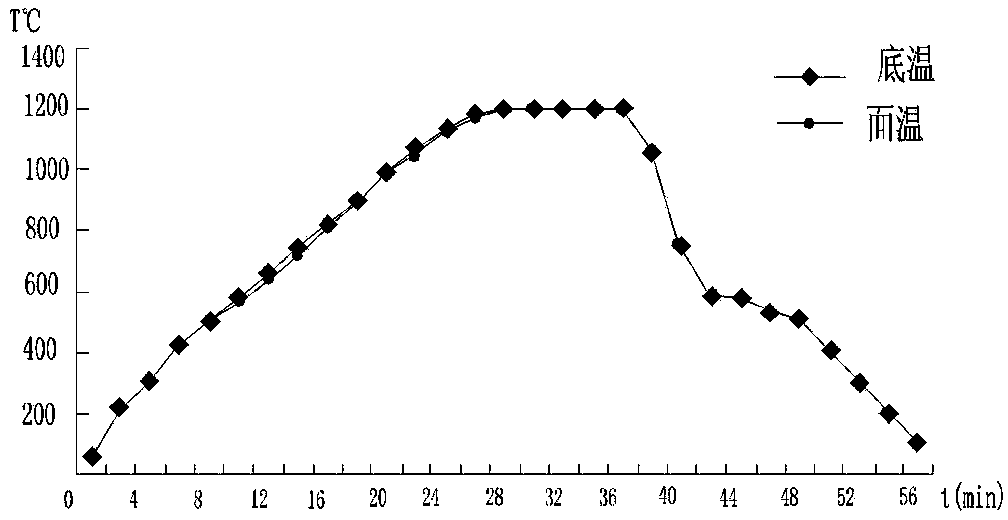

Integrally crystallization process microcrystaline glass-ceramic composite brick and its production process

The present invention discloses integral crystallization process of microcrystalline glass-ceramic composite brick and its production process. The brick includes microcrystalline glass layer and ceramic layer. The present invention features that by means of the available glass forming process, the microcrystalline glass is first produced into transparent glass mother board, then set on unglazed ceramic base and sintered in the roller kiln into semi-finished product through nucleation and crystallization of microcrystalline glass and the compounding with ceramic. The semi-finished product is strickled off, ground, polished, edge ground and sorted to form the microcrystalline glass-ceramic composite brick product. Compared with sintering process, the present invention has lowered cost, less faults and high product quality.

Owner:FOSHAN OCEANO CERAMICS

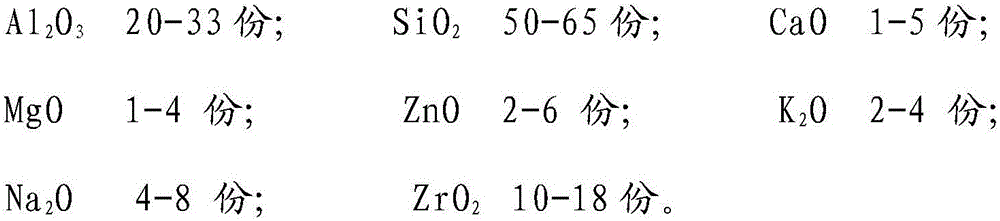

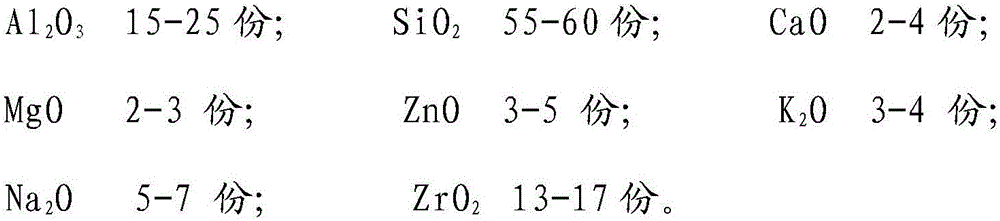

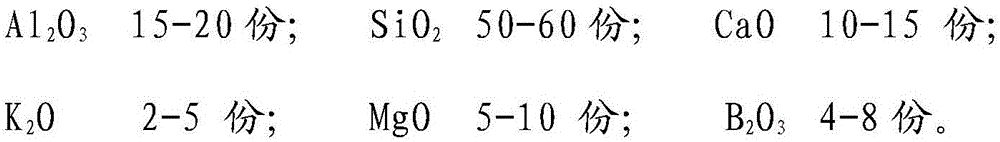

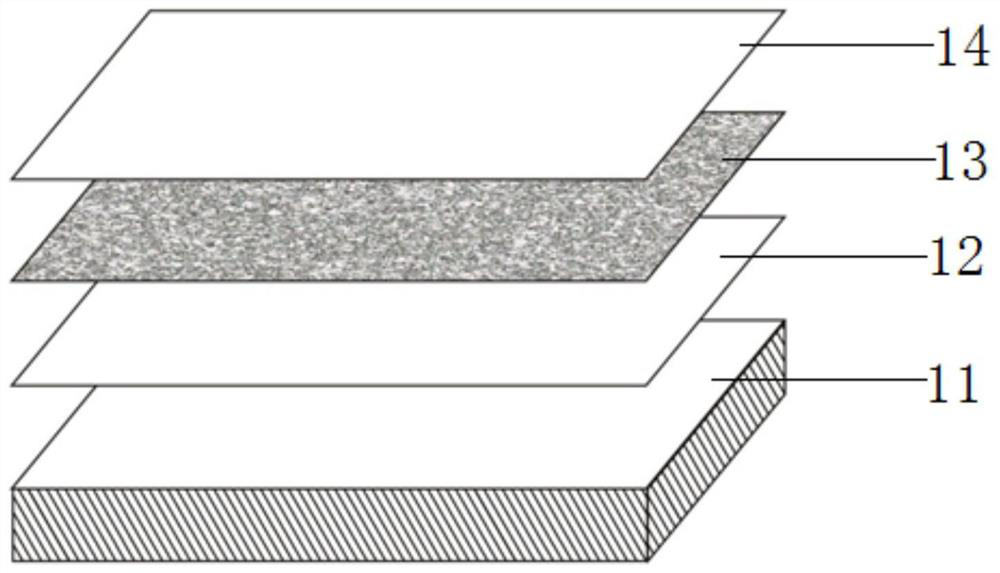

Super-flat glazed brick

ActiveCN106007377AStrong three-dimensional senseImprove the honor rateCeramic glazeMohs scale of mineral hardness

The invention provides a super-flat glazed brick. The super-flat glazed brick comprises a blank body and a glazed layer, wherein the glazed layer is attached to the upper surface of the blank body; the glazed layer comprises ground glaze and surface glaze; the surface glaze is located on the ground glaze; the thickness of the ground glaze is 0.1 to 0.8 mm; the thickness of the surface glaze is 0.5 to 1.0 mm; the ground glaze and the surface glaze are both prepared from specific ingredients. The super-flat glazed brick provided by the invention is high in Mohs hardness, large in breaking strength and low in water absorption.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

Production method of special base fertilizer for tobacco

InactiveCN103570416APromote normal growthImprove the honor rateBio-organic fraction processingOrganic fertiliser preparationChemistryHumic acid

The invention discloses a production method of a special base fertilizer for tobacco, and belongs to the field of preparation of organic-inorganic compound fertilizers. According to the production method, pig manure, cow manure, peanut cake, rape seed cake, plant ash, vinasse, rape stalk, an organic fertilizer starter, urea, monoammonium phosphate, potassium sulphate, amino acid chelated manganese, amino acid chelated boron, humic acid chelated molybdenum and humic acid chelated zinc are used as the raw materials for producing the special base fertilizer for tobacco. The fertilizer is simple in production process and full of nutrient, and has complete functions as well as stable and lasting fertilizer efficiency. The application method is that 1,500 to 2,000kg of the special base fertilizer for tobacoo is applied to a tobacco farm per mu before implantation in every spring.

Owner:江苏新港金源化肥有限公司

Full-glazed porcelain tile as well as preparation method thereof

ActiveCN103524121AAvoid sticky websAvoids \"snowflake\" defects during glaze polishingBrickMaterials science

The invention discloses a full-glazed porcelain tile as well as a preparation method thereof. The tile comprises a blank body and an overglaze on the surface of the blank body, wherein a full-glaze is applied to the overglaze. The full-glazed porcelain tile is characterized in that the overglaze comprises the following chemical components in percent by weight: 13-15% of Al2O3, 60-63% of SiO2, 0.9-1.1% of B2O3, 0.7-0.9% of CaO, 13-14% of MgO, 1.3-1.5% of ZnO, 1.3-1.45% of K2O, 1.4-1.45% of Na2O, 1.38-1.45% of ZrO2 and 3-4% of the balance; the full-glaze comprises the following chemical components in percent by weight: 19-22% of Al2O3, 49-51% of SiO2, 0.2-0.3% of B2O3, 16-18% of CaO, 1.4-1.5% of MgO, 1.5-1.8% of K2O, 2.5-2.7% of NaO2 and 6-7% of the balance. The invention provides a porcelain tile glazing technology which is simple in process and low in cost, and the full-glazed porcelain tile product is high in surface gloss, transparent in glaze layer, clear in pattern and good in antifouling effect, and the yield of superior products in quality is remarkably increased.

Owner:佛山市三水金意陶陶瓷有限公司 +2

Ceramic tile with antifouling glaze

The invention discloses a ceramic tile with antifouling glaze. The surface of the ceramic tile is spray-coated with surface glaze. The surface glaze is prepared from 30 to 45 portions by weight of albite powder, 3 to 8 portions by weight of quartz powder, 2 to 6 portions by weight of calcite, 5 to 10 portions by weight of talc powder, 10 to 16 portions by weight of calcined kaolin, 3 to 7 portions by weight of a solvent, 6 to 10 portions by weight of zirconium white frit, 5 to 9 portions by weight of washing ball clay, 3 to 8 portions by weight of a hyperdispersant, 8 to 16 portions by weight of alumina powder, 14 to 20 portions by weight of zirconium silicate, 2 to 7 portions by weight of praseodymium yellow, 1 to 3 portions by weight of zirconium iron pink, 0.1 to 0.6 portions by weight of methylcellulose and 0.3 to 0.6 portions by weight of sodium tripolyphosphate. The preparation method of the surface glaze comprises adding raw materials into a ball mill according to the above ratio, adding 0.3 to 0.5 times water into the raw materials on the basis of the mass of the raw materials and carrying out ball milling until glaze slurry fineness of 250-500 meshes. The glaze can effectively prevent the quality problem caused by the color difference.

Owner:佛山市石湾裕龙陶瓷有限公司

Metal-resin composite type binding agent diamond edge grinding wheel and manufacturing method thereof

ActiveCN110640640AExtended service lifeImprove grinding sharpnessTransportation and packagingAbrasion apparatusCarbide siliconAlloy

The invention discloses a metal-resin composite type binding agent diamond edge grinding wheel and a manufacturing method thereof. The edge grinding wheel is prepared from, by weight, 8-14 parts of diamond, 8-14 parts of electrolytic copper powder, 2-8 parts of cobalt powder, 0.5-3 parts of electrolytic nickel powder, 1-5 parts of tin powder, 8-12 parts of copper-tin alloy powder, 35-42 parts of ahigh-intensity high-temperature-resistance resin binding agent, 8-12 parts of silicon carbide, 4-8 parts of aluminum oxide and 1-3 parts of zinc stearate. By preparing the metal-resin composite typebinding agent, the service life of the diamond edge grinding wheel can be prolonged, the grinding sharpness of the diamond edge grinding wheel can be improved, the ground green brick high-grade rate is increased, power consumption is saved, the production efficiency is improved, and a higher price is created for the green brick grinding step.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

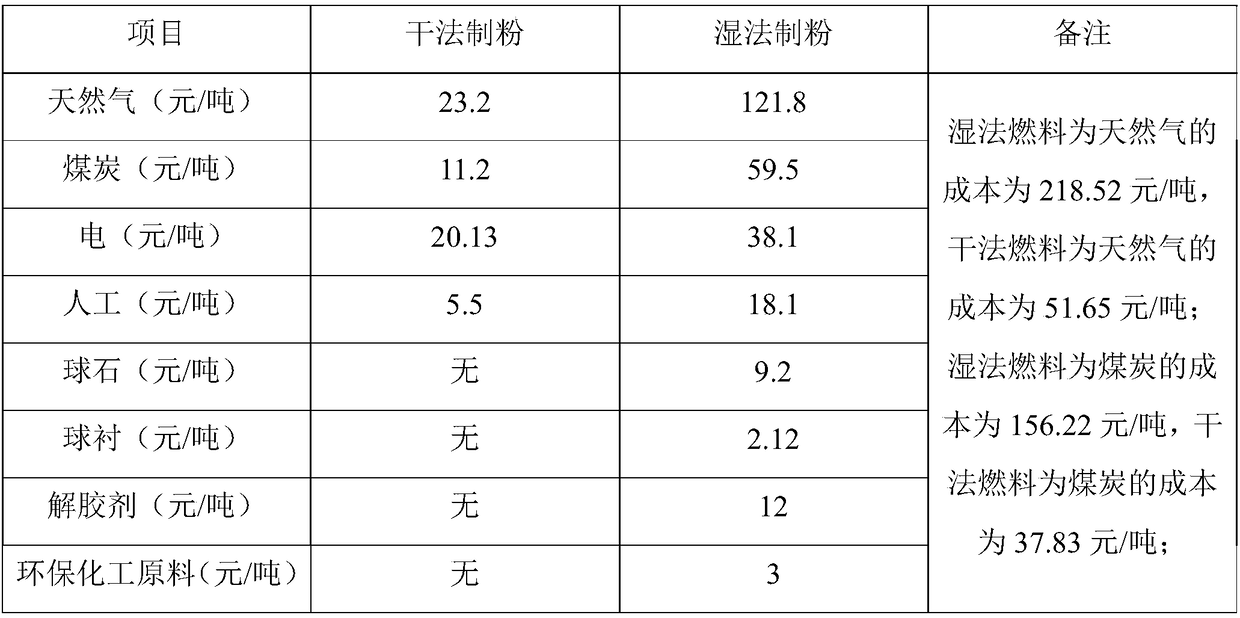

Large-sized porcelain glazed tile dry powder manufacturing process

InactiveCN108658580AAvoid pollutionEffective energy saving and emission reductionClaywaresIron removalMaterial selection

The invention relates to a large-sized porcelain glazed tile dry powder manufacturing process, and belongs to the field of architectural ceramics. The large-sized porcelain glazed tile dry powder manufacturing process comprises the following steps: material selection, raw ore crushing, batching, mixing, vertical milling and fine grinding, fine powder collection and storage, floatation granulation,sulfuration drying, powder sieving, iron removal, powder storage and obsolescence, compact forming, green body drying, glazing, ink jetting (surface decoration), firing, cooling, polishing trimming,super clean anti-fouling treatment, inspection, sorting, packaging and warehousing. According to the invention, dry powder manufacturing is applied to replace original wet powder manufacturing, so that energy can be effectively saved, emission can be effectively reduced, meanwhile, environmental pollution can also be avoided, and product quality is stabilized.

Owner:河北金汇陶瓷有限公司

Shrink-proof glazing agent and its application

ActiveCN102976791ALow dynamic surface tensionImprove flow spreadabilityActive agentNonionic surfactant

The invention discloses a shrink-proof glazing agent and its application. The shrink-proof glazing agent comprises 50-80mass% of an aqueous base material wetting agent, 3-5mass% of a polyether nonionic-surfactant, and the balance solvent. The shrink-proof glazing agent can be applied to ceramic inkjet printing. The shrink-proof glazing agent has the advantages of effective reduction of the dynamic surface tension of a glaze slip for the ceramic inkjet printing, no foaming, no bubble stabilizing, great improvement of the flow spreadability of the glaze slip and the wetting performance of the glaze slip to a base material and a pigment, effective solving of the occurrence of a glaze shrinkage phenomenon, and improvement of the superior finished product rate; and additionally, the above formula of the shrink-proof glazing agent has the advantages of production completing at normal temperature under normal pressure, simple technology, and convenience of the wide popularization and use.

Owner:广东道氏陶瓷材料有限公司

Metal glaze as well as preparation method and application method thereof

The invention belongs to the technical field of ceramic glaze, and relates to metal glaze as well as a preparation method and an application method thereof. The metal glaze comprises the following raw materials in percentage by weight: 30-37% of albite, 8-15% of quartz, 0-4% of wollastonite, 9-16% of calcined kaolin, 4-6% of calcined zinc oxide, 19-23% of calcined iron phosphate and 13-20% of self-made high-phosphorus frit powder. On the basis of calcined iron phosphate, self-made high-phosphorus frit powder is added as a crystallization accelerant into the metal glaze, so that the metal luster is more easily presented. The element P is introduced into the self-made high-phosphorus frit powder in a frit form, and compared with a high-phosphorus raw material system, the self-made high-phosphorus frit powder has a wider firing temperature range, and the metal effect is more stably presented. By finely adjusting the ratio of the self-made high-phosphorus frit powder to the silicon-aluminum of the metal glaze, the adjustment of metal to different colors can be realized. In addition, the metal glaze is combined with a roller printing process, so that the glaze surface can present a good three-dimensional effect.

Owner:FOSHAN SANSHUI CREATE TIDE

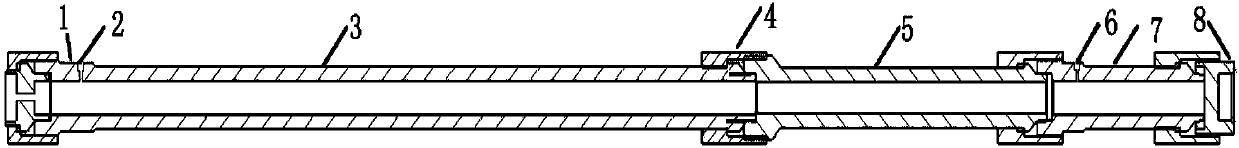

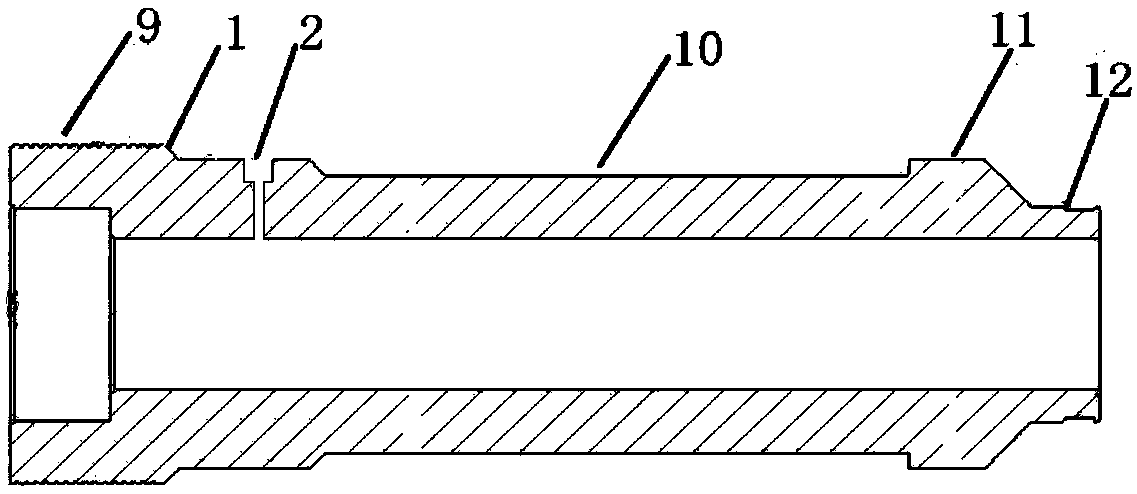

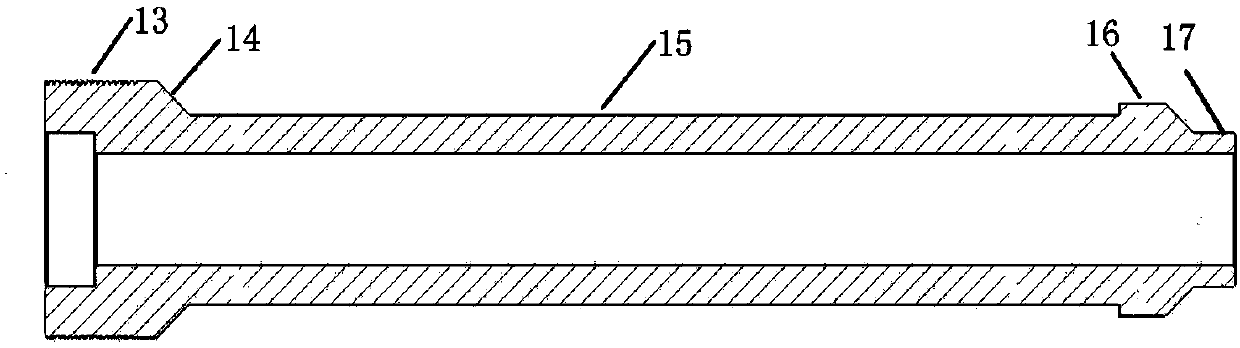

Testing device for bridge plug setting test

PendingCN107677496AImprove the honor rateThe test results are intuitiveStructural/machines measurementAutomotive engineeringPressure curve

The invention relates to a testing device for a bridge plug setting test. An upper joint of a mechanical pressure testing unit is provided with three upper pressure transmitting holes including a screw plug port, a pressure transmitter connector and an inflating port. The inflating port is connected with a pneumatic pressure pump and an air pump. The right end of the mechanical pressure testing unit is connected with a bridge plug pressure bearing test unit and an electronic pressure test monitoring device. The electronic pressure test monitoring device is connected with a lower joint. The electronic pressure test monitoring device is provided with three lower pressure transmitting holes including a screw plug port, a pressure transmitter connector and a pressure release port. By adoptingthe device provided by the invention, the to-be-tested bridge plug or bridge plug setting tool is placed into a sleeve of the bridge plug pressure bearing unit. The pneumatic pressure pump or the airpump is driven, and high pressure liquid is injected from the inflating port and is then released from the pressure release port after ignition, setting and ball delivery of the bridge plug. The pressure transmitter records pressure change curves, analyzes the pressure change curves output by different units and obtains parameters and conclusions. The device provided by the invention is convenientto mount and dismount, wide in application and easy for promotion and application.

Owner:SINOPEC SSC +1

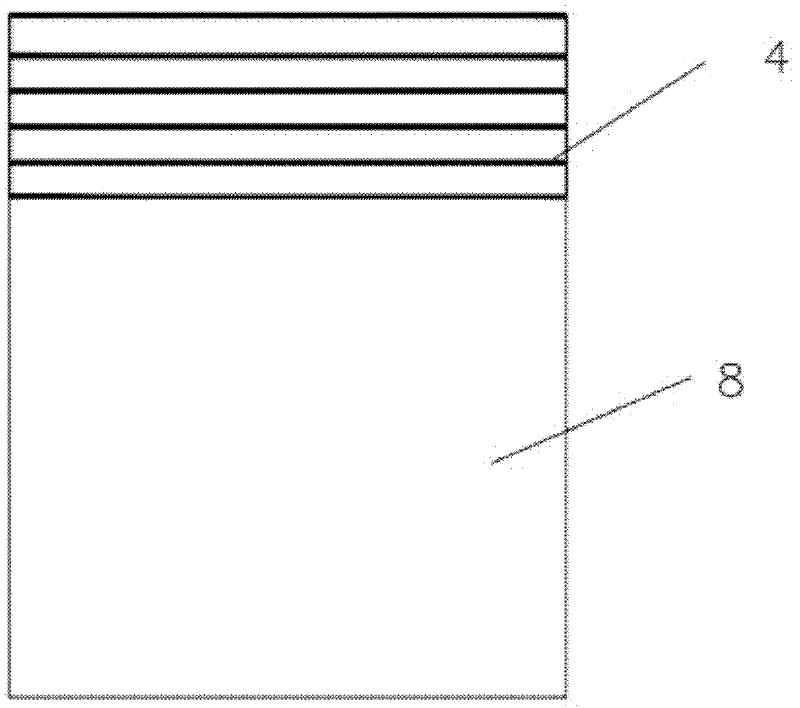

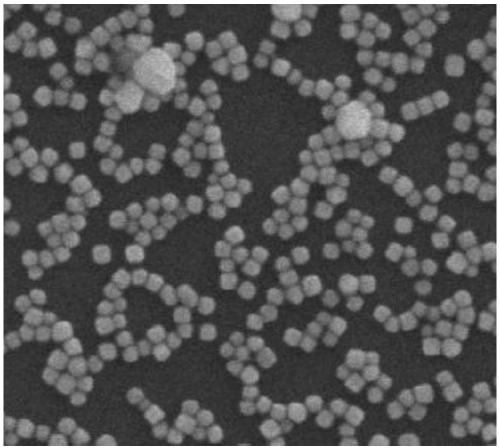

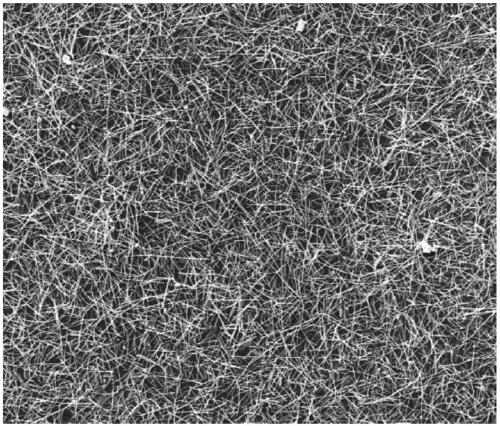

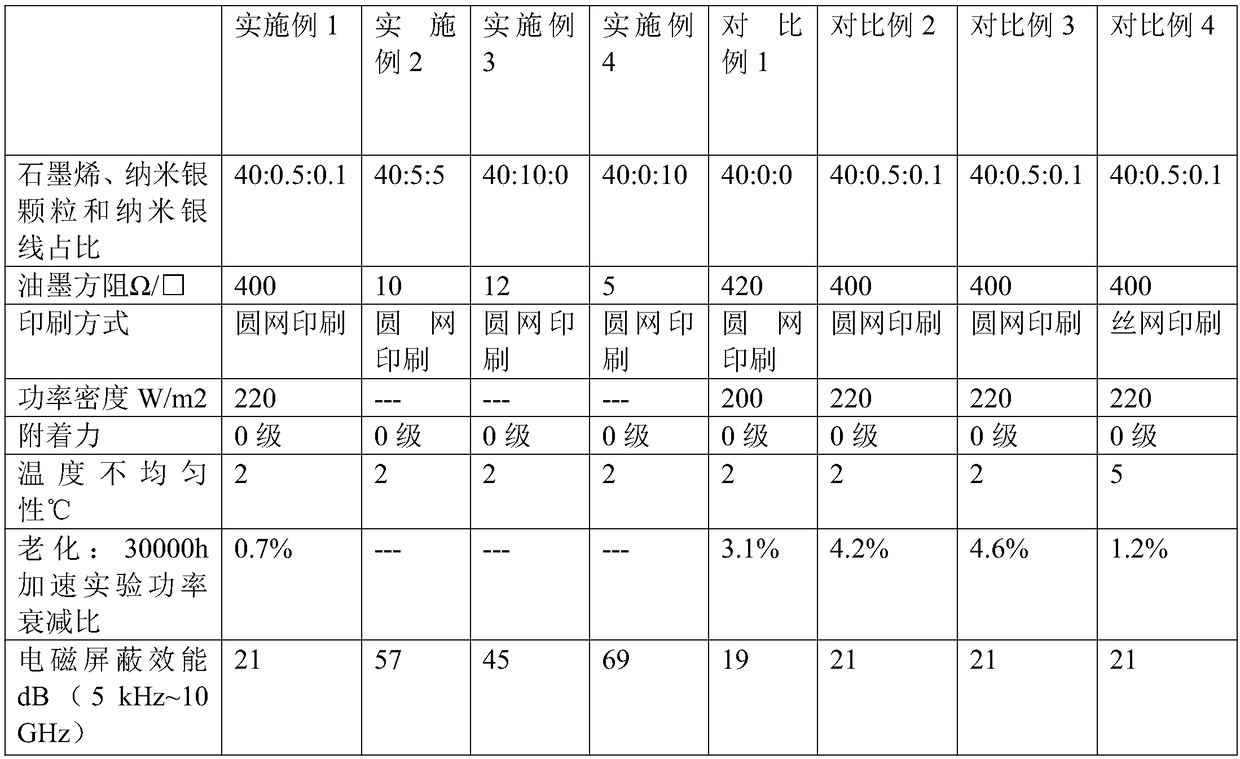

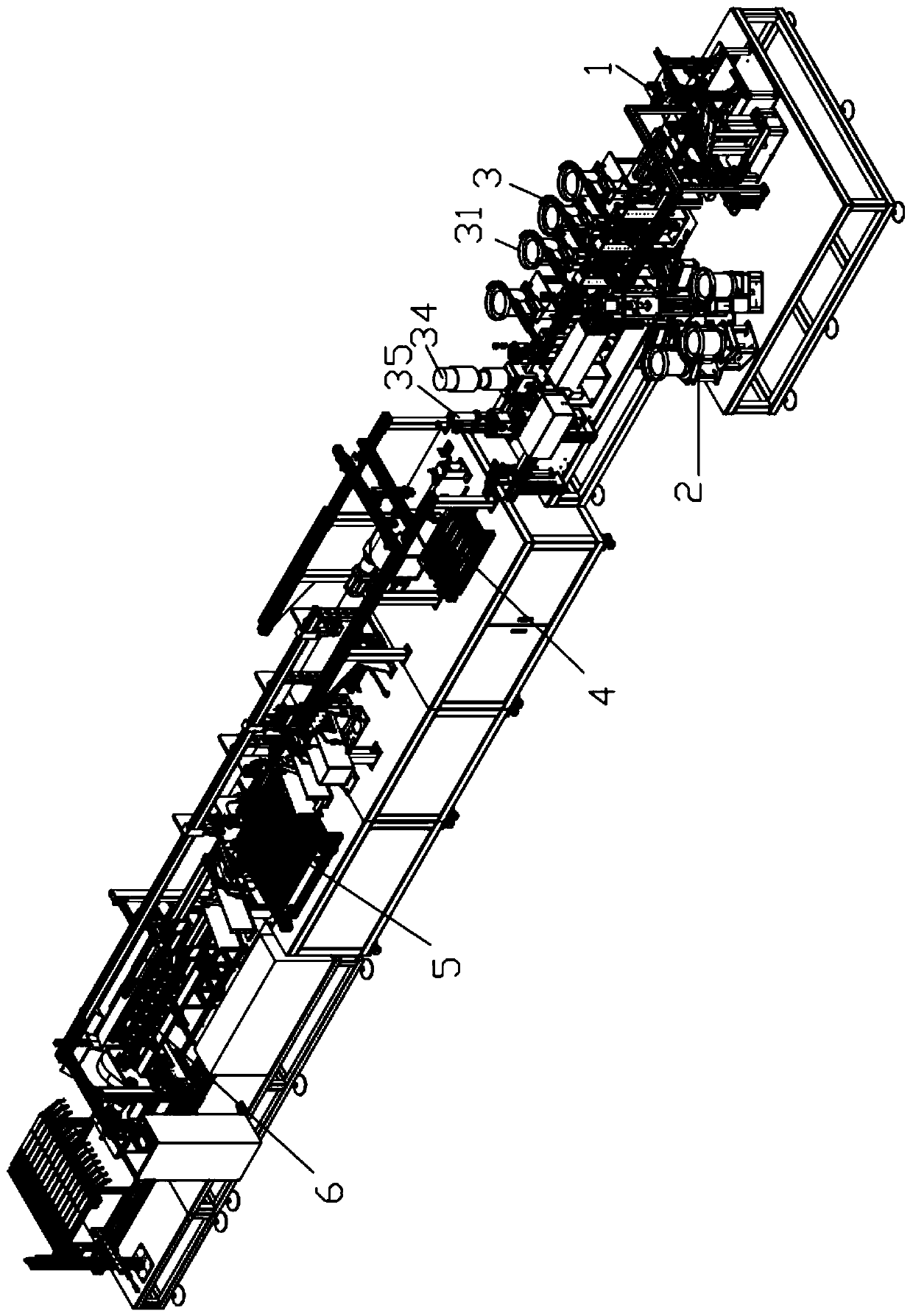

Method for preparing microchip graphene electrothermic ink, preparation method and application of electrothermic wall cloth

InactiveCN109370315ASolve the shortcomings of only choosing soft substratesEvenly heatedInksOther printing apparatusScreen printingSilver electrode

The invention provides a method for preparing a microchip graphene electrothermic ink, a preparation method and an application of an electrothermic wall cloth. The method for preparing the microchip graphene electrothermic ink comprises the following steps: preparing a silver nano-wire; preparing few-layer microchip graphene filter cake; and preparing the microchip graphene electrothermic ink. Themicrochip graphene electrothermic ink has the advantages of uniform dispersibility, high conductivity and the like. The preparation method of an electrothermic wall cloth comprises the following steps: compounding the microchip graphene electrothermic ink with a diluting agent; pumping to an ink outlet nozzle of a rotary screen printing device through a pipeline, uniformly feeding to a rotary screen inner tube under the pressure of a pump, regulating the depth, angle and position of a rotary screen printing scraper to uniformly extrude and print the ink from a rotary screen to a base material; and roasting in an oven, printing a silver electrode and preparing an electrothermic wall cloth semi-finished product. The method is simple in process and easy to operate, can overcome the limitation of a traditional printing mode to a base material. The electrothermic wall cloth can be applied to electromagnetic shielding cloth of a machine room.

Owner:江苏天创新材料科技有限公司

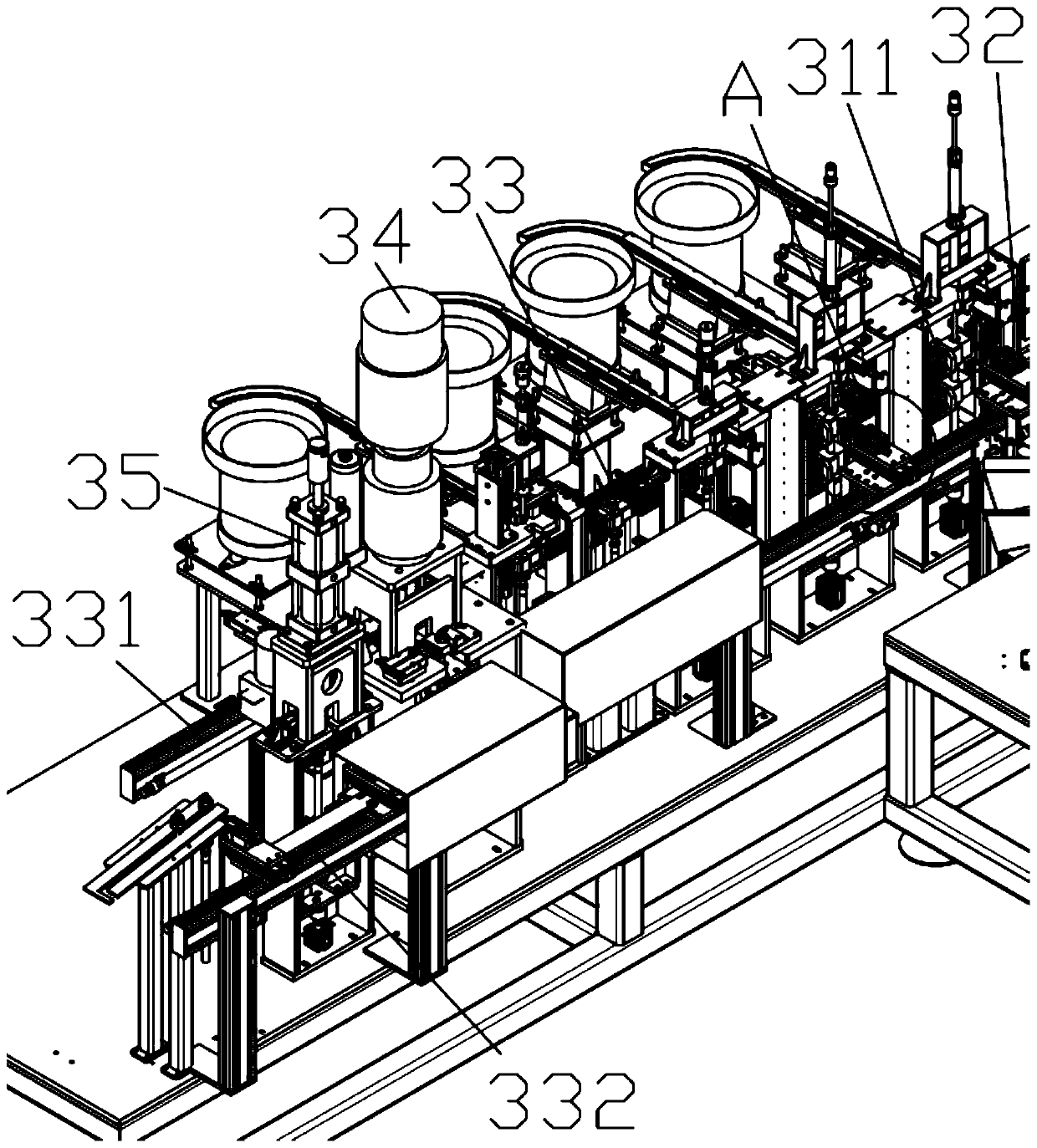

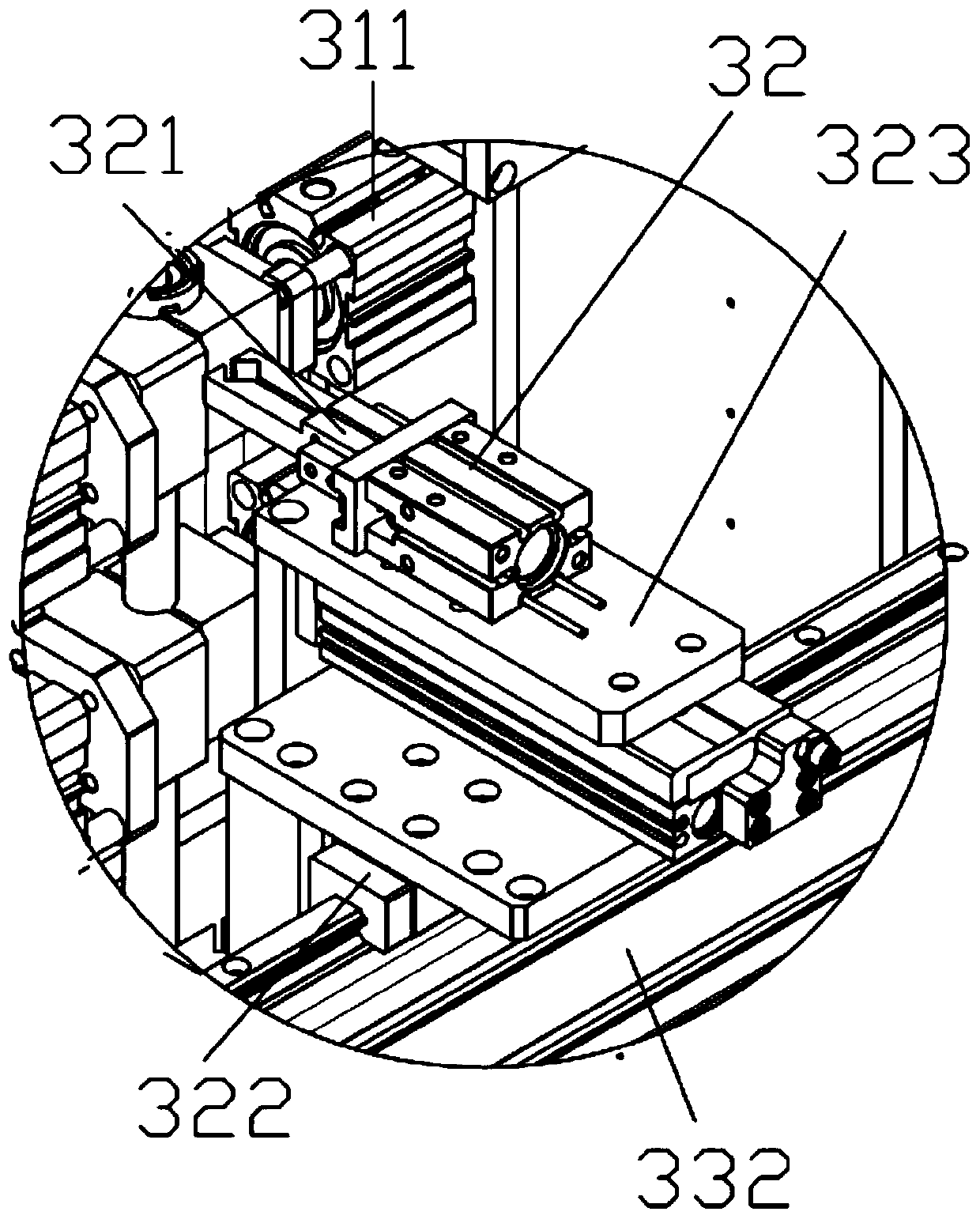

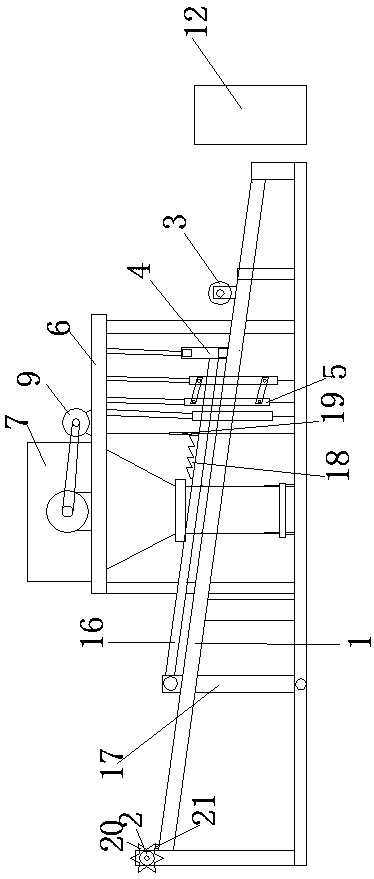

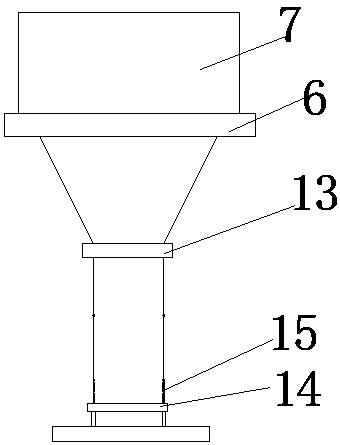

Production line of back door stay assy

PendingCN110340656AReasonable layoutImprove production efficiency and product quality rateAssembly machinesEngineeringProduction line

The invention relates to the technical field of automated machines, and particularly discloses a production line of a back door stay assy. The production line of the back door stay assy is characterized by comprising a screw rod kit assembling device and an annular part assembling device, wherein the screw rod kit assembling device is used for sleeving a screw rod into an inner guide pipe; the annular part assembling device is used for installing an annular part to the end part of a screw rod kit; a drive assembly assembling device for installing a drive assembly to the end part of the screw rod kit and a sleeve spring assembling device for assembling a sleeve and a spring are arranged at the downstream end of the annular part assembling device; the annular part assembling device comprisesmultiple annular part assembling mechanisms arranged linearly; a conveying mechanism is arranged between each two adjacent annular part assembling mechanisms; and each two adjacent conveying mechanisms are staggeredly arranged inside and outside relative to the corresponding annular part assembling mechanism. The production line of the back door stay assy provided by the invention is reasonable in layout, and the production efficiency and the product high-grade rate are effectively improved.

Owner:佛山市艾菲尔智能科技有限公司

A metal-resin composite bond diamond edge grinding wheel and its production method

ActiveCN110640640BExtended service lifeImprove grinding sharpnessTransportation and packagingAbrasion apparatusCarbide siliconAlloy

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

A kind of overcoating composite lithium-ion battery diaphragm and preparation method thereof

ActiveCN104393217BUniform pore sizeEasy to prepareCell seperators/membranes/diaphragms/spacersPhysical chemistryViscous flow

A kind of laminated composite lithium-ion battery diaphragm and preparation method thereof, described diaphragm is a porous diaphragm with one or more layers of structure prepared by mixing one or more coating slurries; the composition of described porous diaphragm comprises: 30-100 parts of polymer material, 0-70 parts of inorganic powder and its surface treatment agent, 0-50 parts of compatibilizer; the polymer material is at least two types of polymer materials, one of which is the polymer The material is a thermoplastic material with a melting point or a viscous flow temperature of 100-150°C, and another type of polymer material is a thermoplastic material with a melting point or a viscous flow temperature higher than or equivalent to the melting point or a viscous flow temperature of 100-150°C thermoplastic or thermosetting materials. The invention proposes a laminated composite lithium-ion battery diaphragm with uniform pore size, good wettability, good heat resistance, and thermal fusion function, and a preparation method for producing the above-mentioned laminated composite lithium-ion battery diaphragm, with simple process , a wide range of material selection, and controllable micropore forming conditions.

Owner:HORIZON SPECIALTY MATERIAL

Electronic brocade puller loom

PendingCN109371525ASolve the electronic jacquard machine system programReduce stepsJacquardsLoomsElectromagnetic clutchEngineering

The invention discloses an electronic brocade puller loom which comprises a rack. One end of the rack is provided with a let-off shaft, the other end of the rack is provided with a take-up shaft, a beating-up frame, a harness frame and a bibcock frame are sequentially arranged between the take-up shaft and the let-off shaft, an electronic jacquard weave system is arranged above the bibcock frame and comprises an electronic jacquard weave machine, an electromagnetic clutch and a motor, the motor is connected with the electromagnetic clutch, the electromagnetic clutch is connected to a signal disc on the electronic jacquard weave machine, the phase angle of the signal disc is 180 degrees, the upper end of the beating-up frame and the upper end of the harness frame are connected to the bibcock frame through lines, an inching switch for controlling the electromagnetic clutch is arranged under one side of the rack, and a control box connected with the electronic jacquard weave system is also arranged. The electronic brocade puller loom utilizes the electronic jacquard weave system to control jacquard weave, is suitable for a brocade weaving process and reduces the labor intensity of workers while improving the efficiency, electronic jacquard weave greatly improves accuracy.

Owner:NANJING YUNJIN RES INST

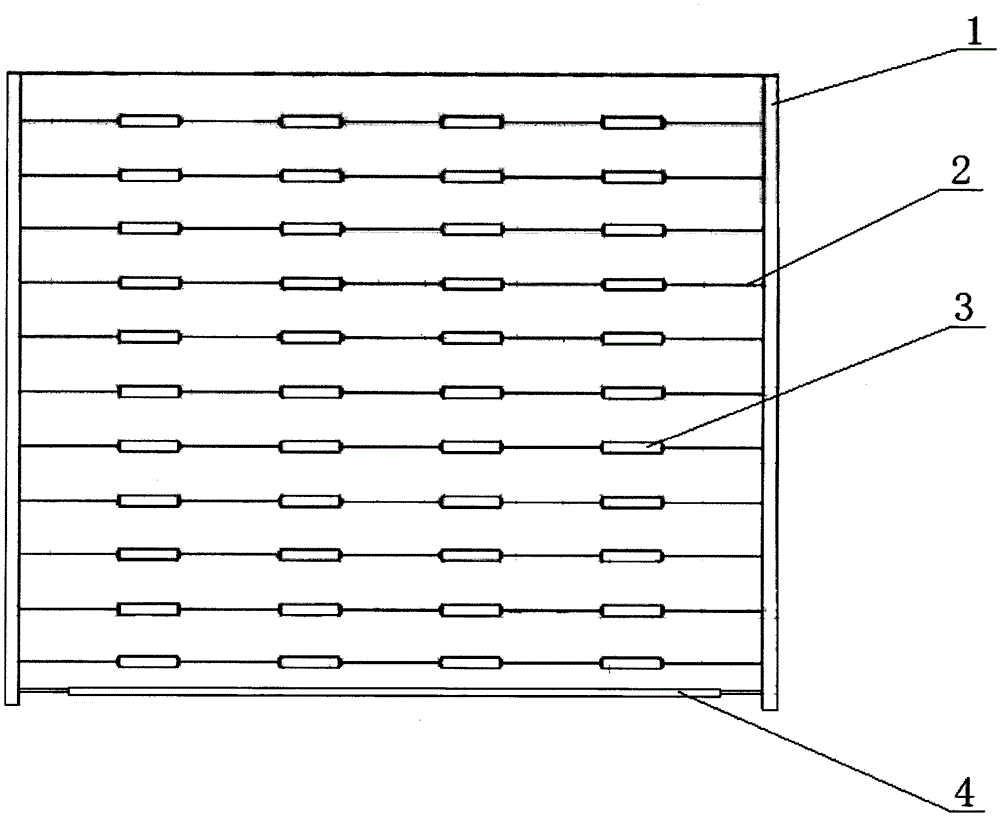

Panel sliding frame

InactiveCN105253572AScientific and reasonable structure designObvious effectRollersEconomic benefitsEngineering

A panel sliding frame specifically comprises a frame body, rotating shafts, carrier rollers and a baffle frame. The carrier rollers are placed on the rotating shafts, the multiple sets of rotating shafts are arranged on the frame body, the baffle frame is placed in front of the frame body, and then the whole panel sliding frame is formed. The carrier rollers are large in size, no traces can be left on panels when the panels are transmitted outwards after hot pressing for panel synthesis is finished, the veneer high-class rate is increased, and economic benefits are improved. When the panel sliding frame is applied, panel heat dissipation is balanced, and veneer quality is ensured. Meanwhile, by means of the panel sliding frame, the labor intensity is lowered, the labor cost is reduced, and the work efficiency is improved. In addition, the panel sliding frame is simple in structure and low in manufacturing cost. After the panel sliding frame is used in the field, economic benefits are obviously improved, and the panel sliding frame is easy to popularize.

Owner:广西平果北融林木业发展有限公司

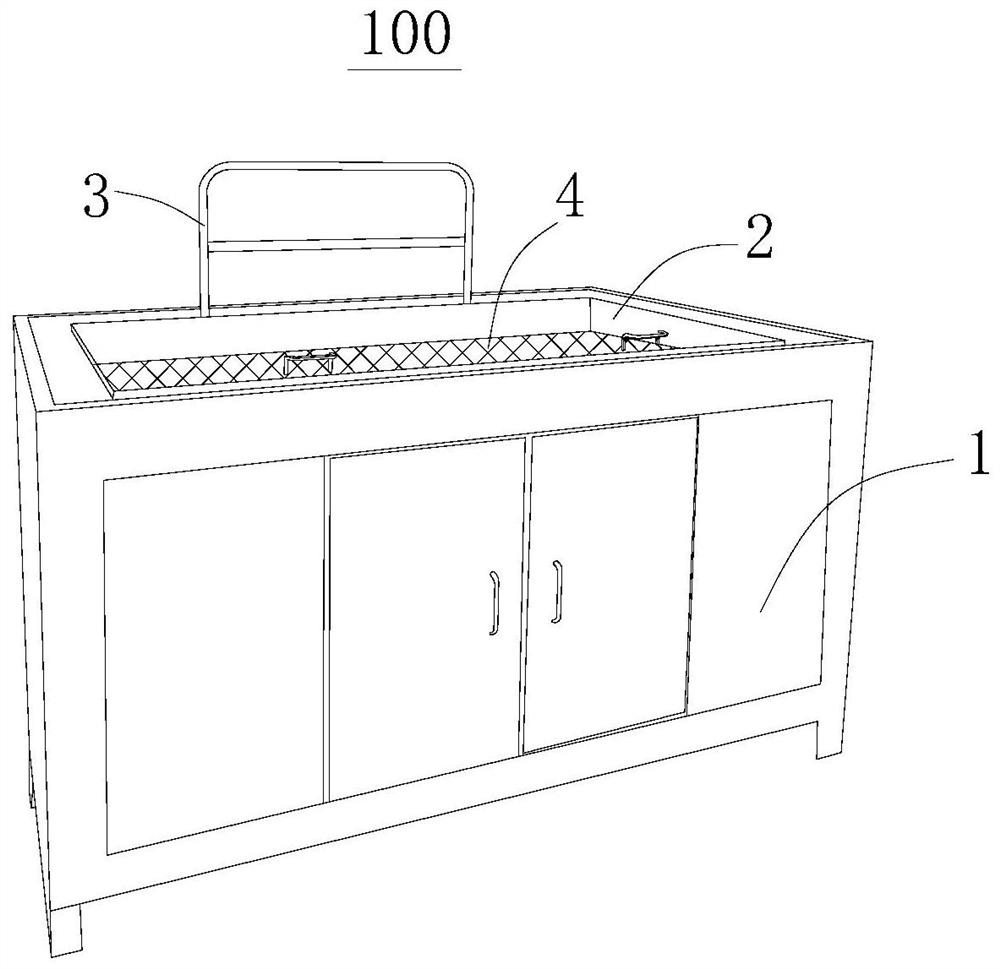

Small alkaline washing tank of hot rails in elasticizer and alkaline washing process

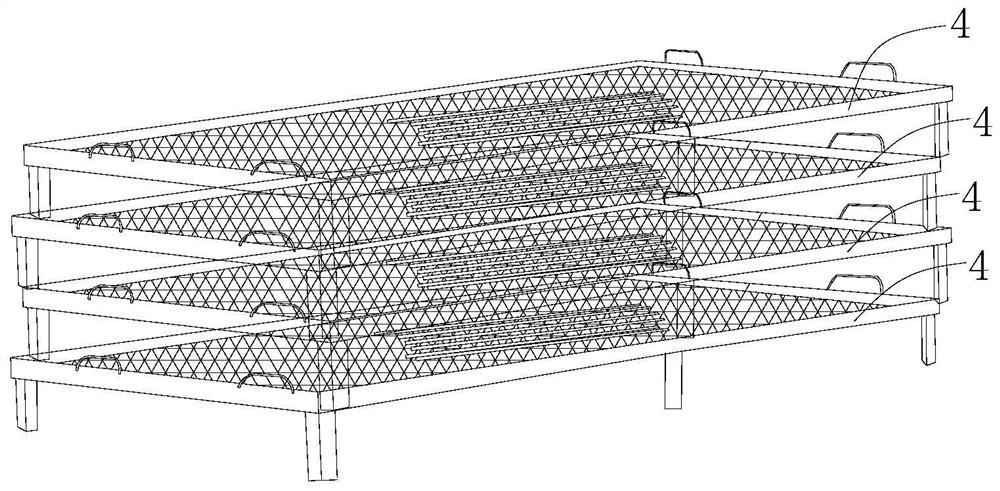

PendingCN112676239AImprove surface smoothnessImprove the honor rateLiquid surface applicatorsCoatingsWaste oilFilament yarn

The invention relates to a small alkaline washing tank of hot rails in an elasticizer. The small alkaline washing tank comprises a tank body, an inner cavity is vacant in the tank body, and a blocking frame is fixed on the outer side edge of the edge of the tank body; at least one net rack is accommodated in the tank body; the inner cavity of the tank body and the net rack are both of cuboid structures, and the net rack is immersed in ]solution in the inner cavity of the tank body; the strip-shaped hot rails are uniformly arranged on the net rack; and the net rack is provided with a rectangular cavity inner frame, and grids are fixedly arranged on the cavity inner frame in a cage mode. The small alkaline washing tank is used for soaking and coating more hot rails with waste oil agents, the surface smoothness of the hot rails is improved, dyed striped yarn of polyester filament yarn is reduced, the superior rate of the polyester filament yarn is increased, and the production cost of the polyester filament yarn is reduced.

Owner:TONGKUN GRP

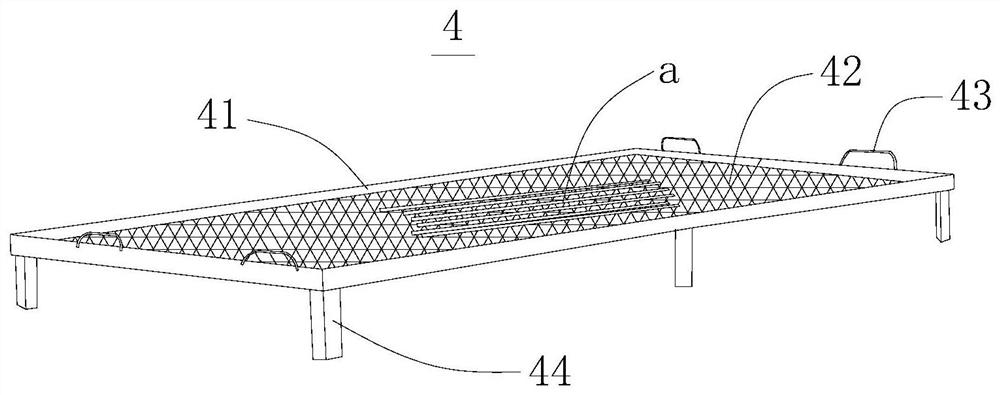

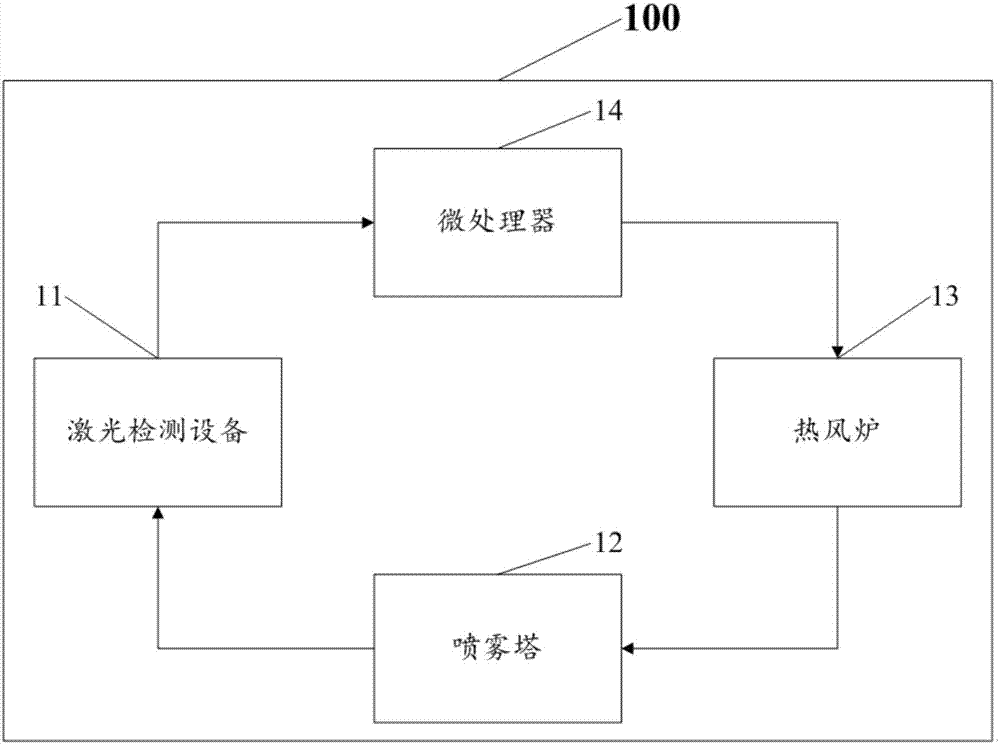

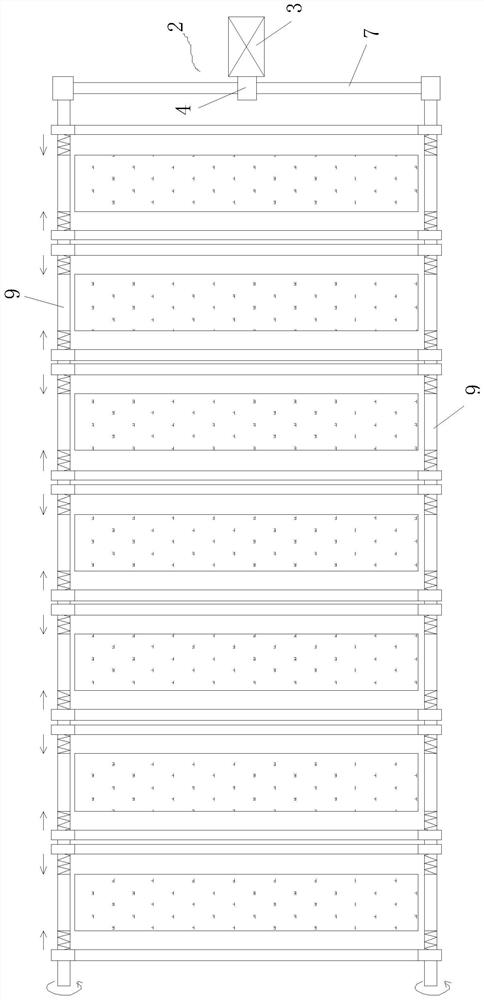

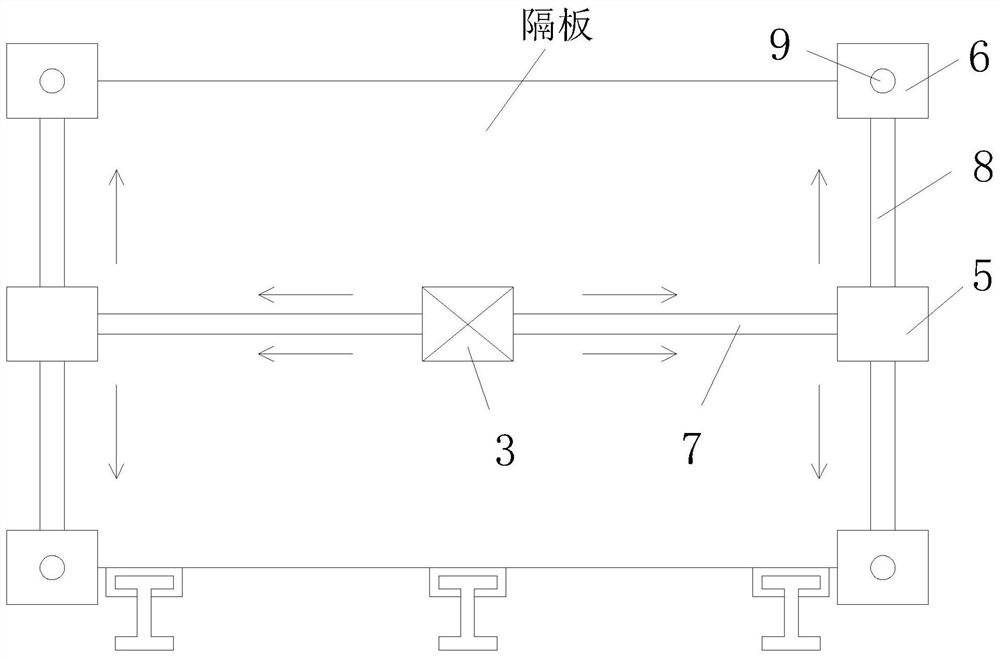

Automation system for powder from spray tower

InactiveCN106964171ASolve quality fluctuationsImprove the honor rateEvaporator regulation/controlEvaporation by sprayingWater contentSpray tower

The invention discloses an automation system for powder from a spray tower. The automation system for powder from the spray tower comprises a laser detection system, the spray tower, an air heating furnace and a micro processor. Laser detection equipment monitors the water content of the powder from the spray tower in real time; the micro processor judges whether the moisture content is within a preset threshold value range according to a detection result; when the moisture content is not within the preset threshold value range, the micro processor outputs a control instruction to adjust a workingenvironment of the air heating furnace or the spray tower, so that the moisture content of the powder can be kept within the preset threshold value range all the time. By the mode, the problem of quality fluctuation of a ceramic enterprise, which is caused by a water disqualification factor of the powder, is solved, so that the qualification rate of a product is increased, automatic control is realized, the employment rate is decreased, and the product production efficiency is also improved.

Owner:佛山市爱摩生科技有限公司

Mold opening and closing mechanism

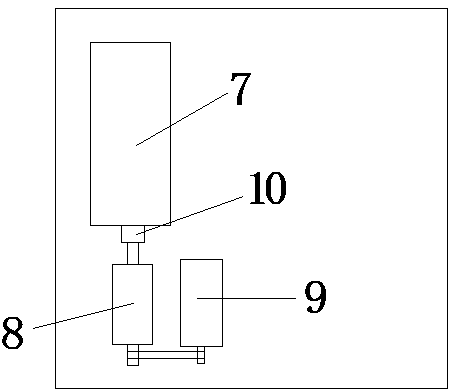

PendingCN113001722AShort tripIncrease productivityDischarging arrangementMould separation apparatusDrive shaftElectric machinery

The invention discloses a mold opening and closing mechanism. The mold opening and closing mechanism mainly comprises a combined mold and a driving mechanism. When a rotary driving mode is adopted, a motor drives a lead screw to rotate through a reversing apparatus and a transmission shaft, partition plates connected to the lead screw move forwards or backwards along with rotation of the lead screw, and due to the fact that the two partition plates of the same set of combined mold are connected to right-hand threads and left-hand threads respectively, when the lead screw rotates, the two partition plates move face to face or back to back at the same time, and mold closing or mold opening of the mold is achieved; when a direct driving mode is adopted, driving cylinders are arranged at the two sides respectively, the driving cylinder at one side is fixedly connected to the partition plate at one side of the combined mold through a driving frame and a driving rod, and the driving cylinder at the other side is fixedly connected to the partition plate at the other side of the combined mold; and when the driving cylinders at the two sides push towards middle or pull towards two sides at the same time, the partition plates at the two sides of the combined mold move face to face or back to back at the same time, and mold closing or mold opening of the mold is achieved. The mold opening and closing mechanism has the advantages of being simple in structure, convenient to operate and easy to implement.

Owner:FOSHAN YUANFANG GENERAL MACHINERY TECH CO LTD

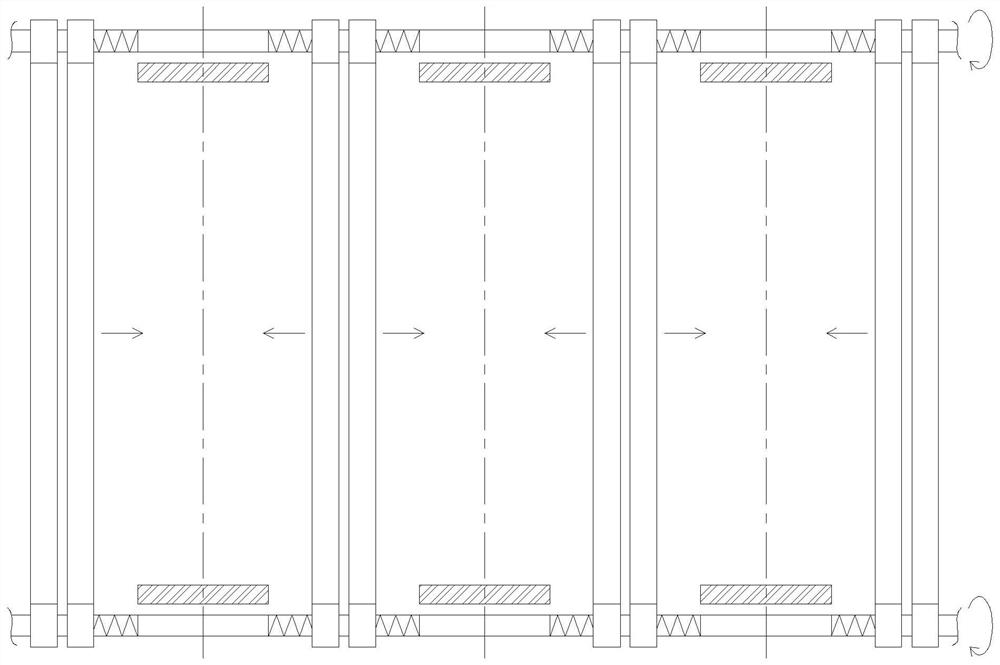

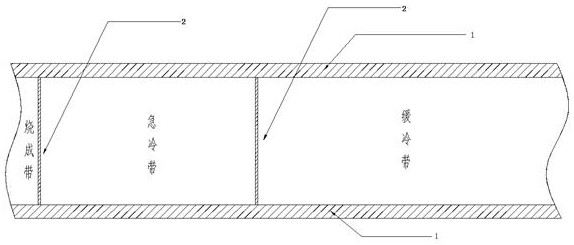

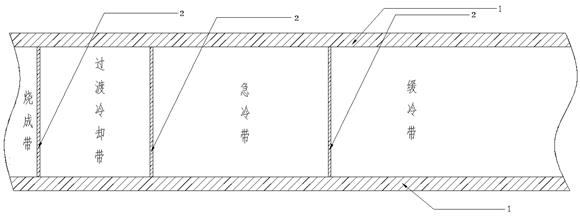

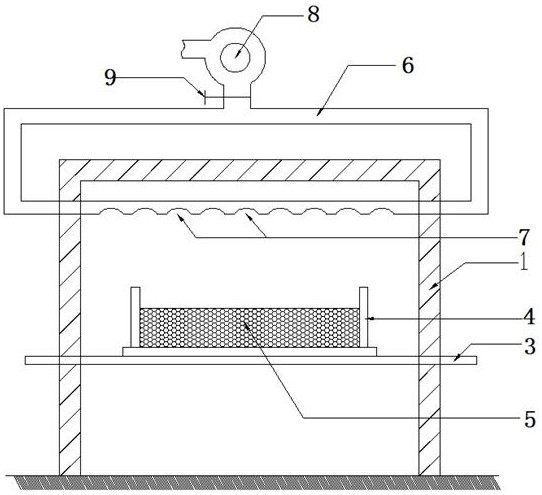

Roller kiln cooling system for foamed ceramic production

ActiveCN112762708AStable coolingImprove uniformityCharge composition/stateCharge treatment typeThermal engineeringCold air

The invention relates to the field of kiln thermal engineering, in particular to a roller kiln cooling system for foamed ceramic production. The roller kiln cooling system comprises a transition cooling zone, a quenching zone and a slow cooling zone which are sequentially arranged in a roller conveying direction, the transition cooling zone is positioned at the rear end of a roller kiln firing zone, and a fire barrier for separating flames is arranged between the transition cooling zone and the roller kiln firing zone. A quenching air pipe extending into a kiln cavity of a roller kiln is arranged on the side wall of the kiln of the quenching zone, one end of the quenching air pipe extends into the kiln cavity, the opening direction of the quenching air pipe is parallel to the top face of a foaming ceramic green body, the other end of the quenching air pipe is connected with an air blower, and external cold air is extracted through the air blower and sent into the kiln cavity of the quenching zone. According to the roller kiln cooling system for foamed ceramic production, the foamed ceramic cooling process can be more stable, the uniformity of air holes is better, and then the performance of foamed ceramic products is improved; and in addition, the superior rate of the products is greatly improved, the error-tolerant rate of the process and the formula is increased, and the debugging loss caused by formula adjustment is reduced.

Owner:FOSHAN JINYI GREEN ENERGY NEW MATERIAL TECH CO LTD +1

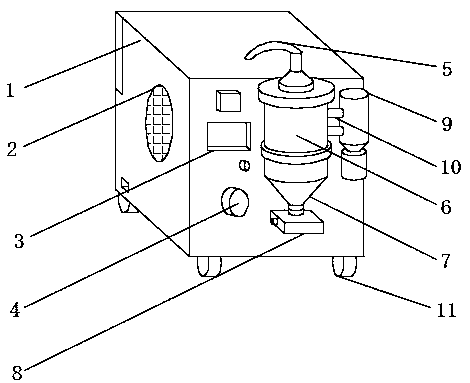

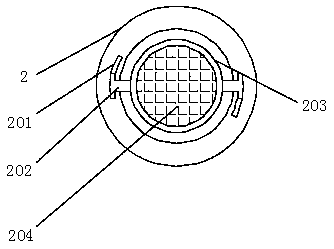

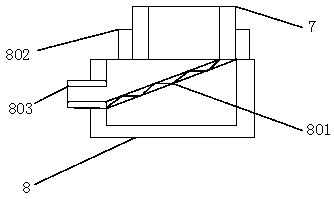

Spraying granulating machine for nano metal powder production process with sundry cleaning function

The invention discloses a spraying granulating machine for a nano metal powder production process with a sundry cleaning function. The spraying granulating machine comprises a machine body, wherein adisplay screen is embedded on the outer surface of the front end of the machine body, a pressure gauge is arranged on a position, close to the display screen, of the front end outer surface of the machine body, a conveying pipe is fixedly installed on the upper end outer surface of the machine body, a drying tower is fixedly installed on the front end of the machine body, and a dust removal box isfixedly installed on a position close to one side of the front end of the machine body. By arranging a series of structures, a filter screen can be conveniently cleaned or replaced by the working personnel, the dust or unqualified particles can be collected, the product is finally discharged by virtue of a discharging cylinder, and the qualification rate of the discharged product can be improved;a scraper plate is closely fitted to the inner wall of the discharging cylinder, so that sundries on the inner wall can be cleaned, the discharging cylinder can be conveniently cleaned by a user, theblockage of a discharging opening can be avoided, and the operation of the user can be facilitated.

Owner:浙江埃普瑞纳米新材料股份有限公司

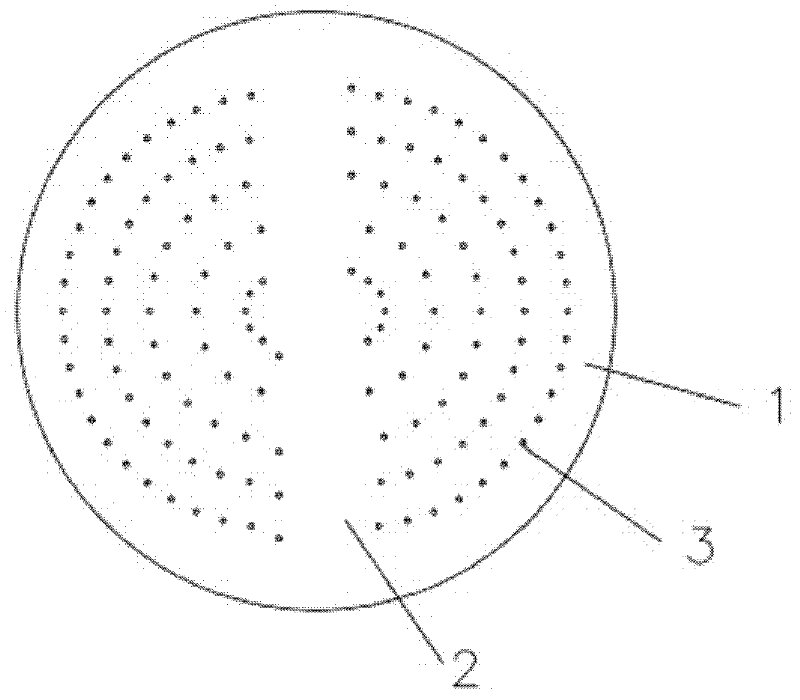

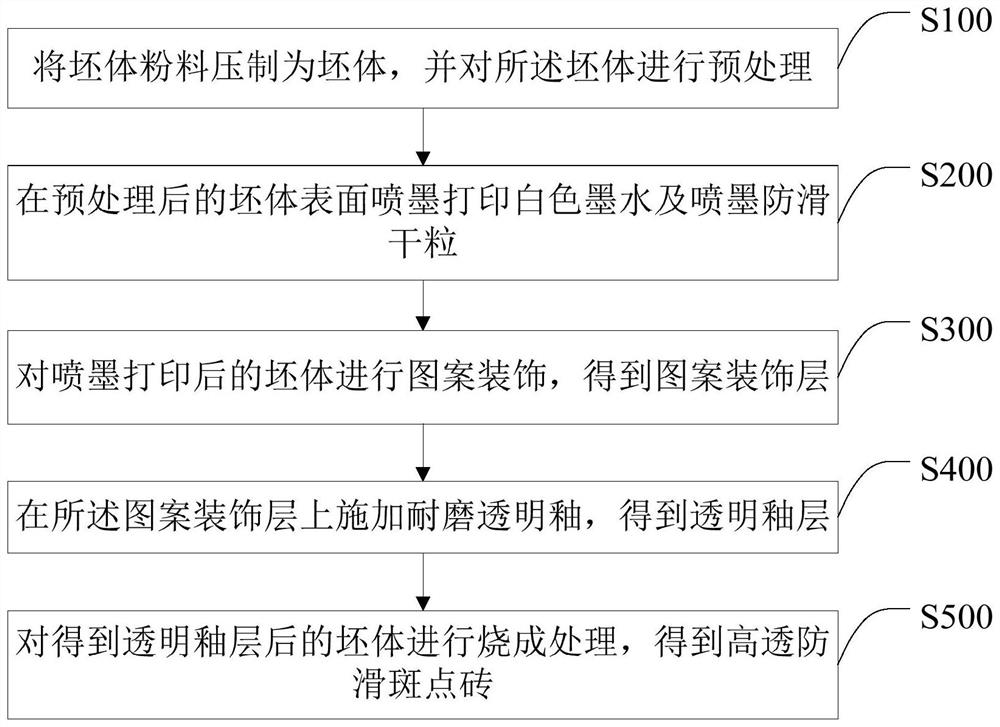

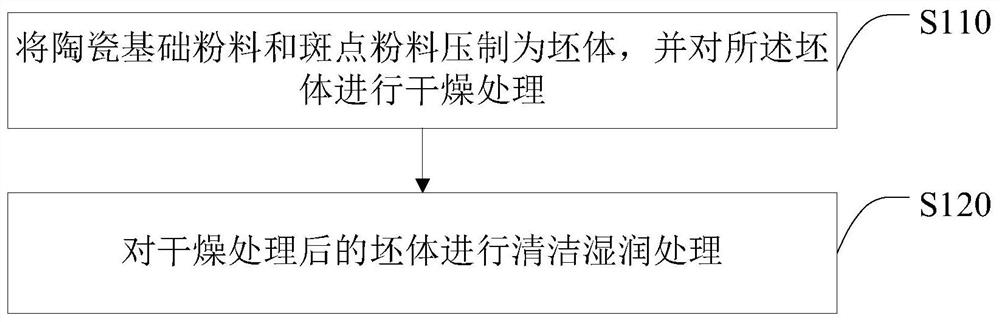

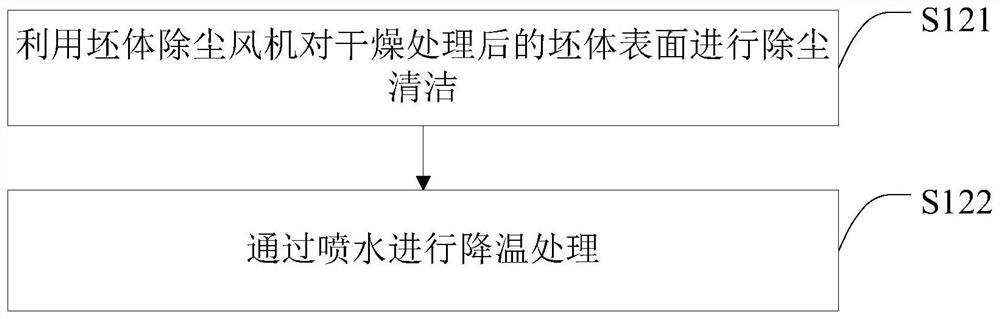

Preparation method of high-transmittance anti-skid spot brick and high-transmittance anti-skid spot brick

The invention provides a preparation method of a high-transmittance anti-skid spot brick and the high-transmittance anti-skid spot brick, and the preparation method of the high-transmittance anti-skid spot brick comprises the following steps: pressing green body powder into a green body, and pretreating the green body; carrying out ink-jet printing of white ink and ink-jet anti-skid dry particles on the surface of the pretreated green body; performing pattern decoration on the green body subjected to ink-jet printing to obtain a pattern decoration layer; applying wear-resistant transparent glaze to the pattern decoration layer to obtain a transparent glaze layer; and sintering the green body with the transparent glaze layer, so as to obtain the high-transmittance anti-skid spot brick. The white ink and the ink-jet anti-skid dry particles are printed on the green body in an ink-jet mode, an existing engobe and anti-skid dry particle (or transparent glaze) glaze layer process is replaced, the glaze layer thickness of the spot brick is greatly reduced, the transparency of spots is not affected, and the high-transmittance spot performance of the anti-skid spot brick is achieved.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

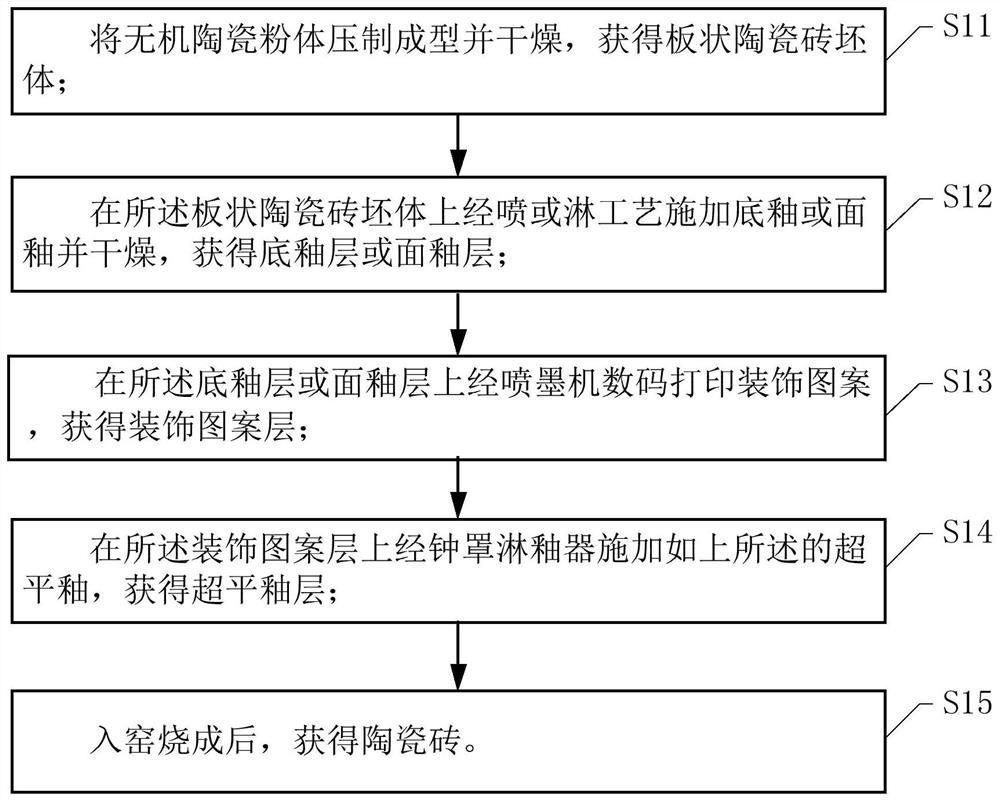

Ultra-flat glaze for ceramic tile, ceramic tile and manufacturing method of ceramic tile

ActiveCN112429967AAvoid lack of glazePrevent secondary agglomeration and flocculationCeramic tilesOrganic solvent

The invention discloses an ultra-flat glaze for a ceramic tile, the ceramic tile and a manufacturing method of the ceramic tile. The ultra-flat glaze comprises the following components in percentage by mass: 20-40% of an organic solvent, 40%-70% of inorganic ceramic powder and 8%-25% of a polymer organic dispersant. According to the invention, the inorganic ceramic powder is dispersed by the organic solvent, and the organic solvent is used for replacing a water medium in traditional glaze slip, so oily decorative ink can be covered with the super-flat glaze, and glaze shortage on the decorative ink is avoided; by adding the polymer organic dispersant and the organic solvent into the ultra-flat glaze, secondary agglomeration and flocculation of ultrafine powder particles are prevented, theviscosity of glaze slip is reduced, the flowing property of the glaze slip is improved, the solid content of the ultra-flat glaze is increased, a uniformly-dispersed glaze is formed, and a compact andfine glaze layer is formed on the decorative ink; so an ultra-flat glaze layer can be flatly distributed without a polishing process, ripples are avoided, and the superior product rate of finished ceramic tile products is increased.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

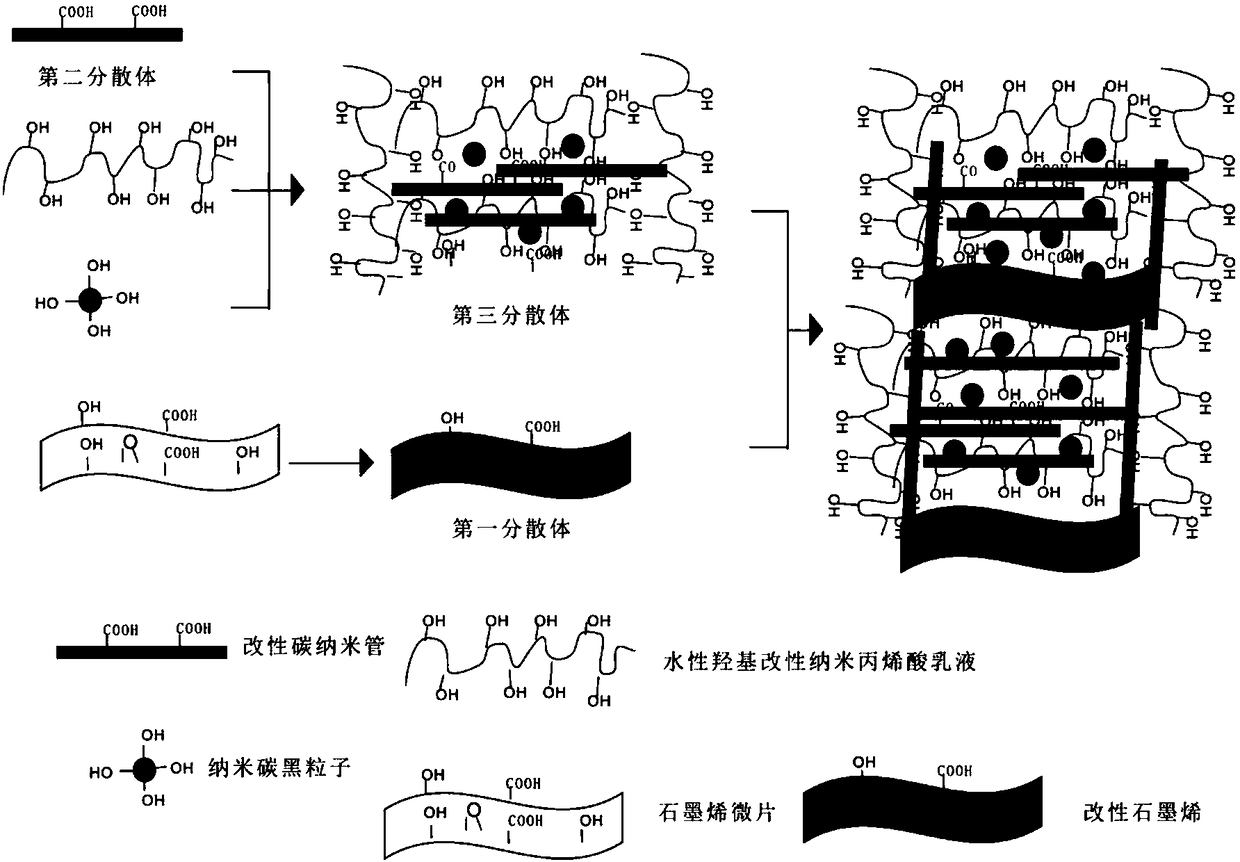

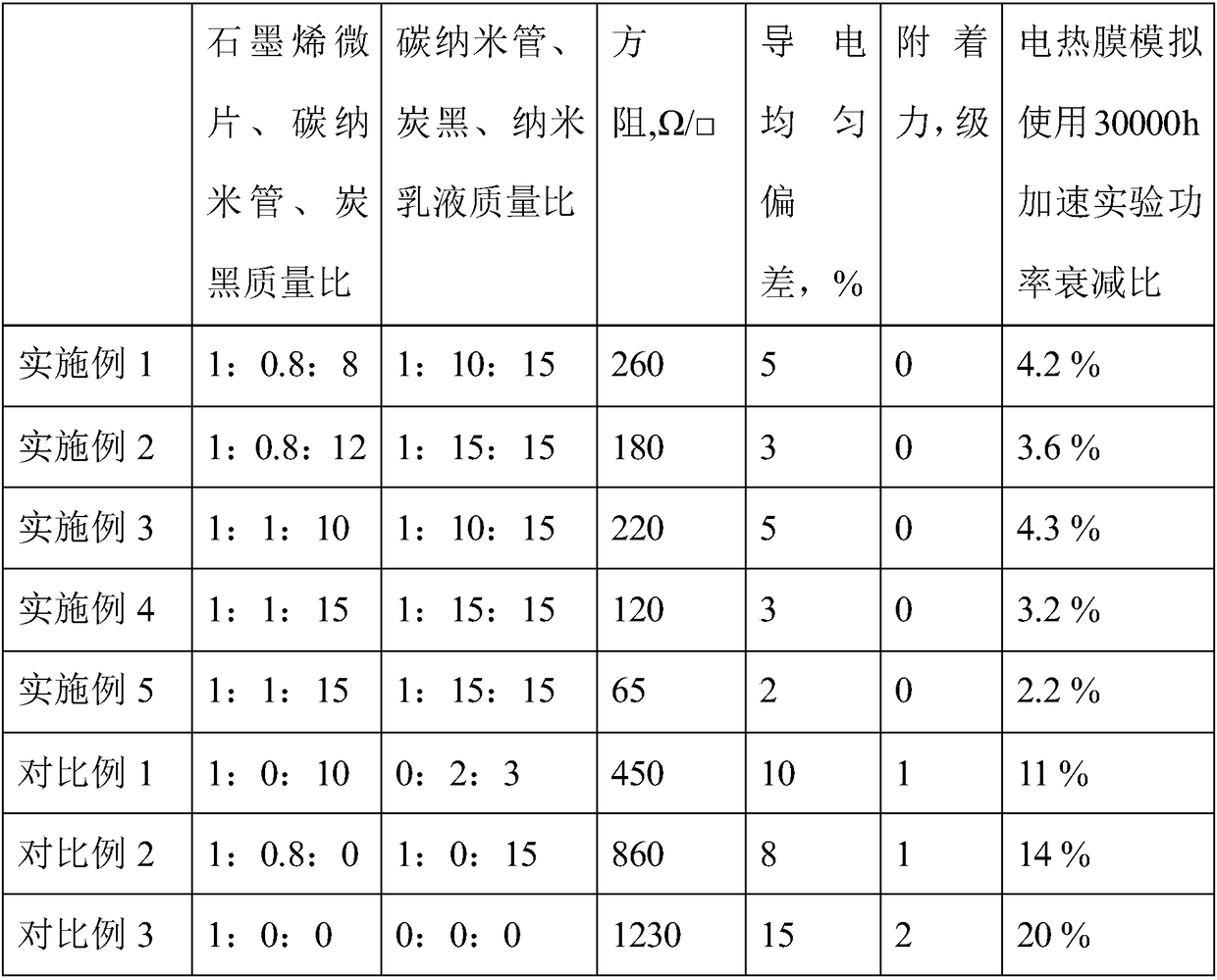

A kind of water-based graphene/carbon nanotube composite electrothermal conversion ink and its preparation method

The invention discloses water-based graphene / carbon nanotube composite electric-heating conversion printing ink and a preparation method thereof. The preparation method comprises the following steps: uniformly stirring a graphene microchip, a water-based non-ionic high-polymer dispersant and water, and then dispersing so as to obtain a first dispersion; putting one-dimensional nano-powder into inorganic strong acid, carrying out heating reflux, carrying out ultrasonic treatment, washing with water, and drying, so as to obtain a second dispersion; uniformly mixing the second dispersion with carbon black powder, a water-based anionic dispersant, sodium dodecyl benzene sulfonate, a water-based hydroxyl-modified nano-acrylic emulsion and dimethylethanolamine, and then dispersing so as to obtain a third dispersion; and mixing the first dispersion, the third dispersion and water-based resin, grinding, adding a flatting agent, a defoamer, a pH adjusting agent, a preservative and an anti-settling agent, and uniformly mixing, so as to obtain the water-based graphene / carbon nanotube composite electric-heating conversion printing ink. The invention further discloses the water-based graphene / carbon nanotube composite electric-heating conversion printing ink.

Owner:安徽华惠福科技有限公司

Shrink-proof glazing agent and its application

The invention discloses an anti-shrinkage glaze and its application. The anti-shrinkage glaze is calculated by mass percentage and consists of the following components: 50-80% of a water-based substrate wetting agent, 3% of a polyether-type nonionic surfactant ~5%, the balance is solvent. The anti-shrinkage glaze is used in inkjet printing of ceramics. The anti-shrinkage glaze agent of the present invention can effectively reduce the dynamic surface tension of the glaze slurry for ceramic inkjet printing, without foaming and stable foaming, and can also greatly improve the flow and spreadability of the glaze slurry and the wetting of the substrate and pigments It can effectively solve the phenomenon of glaze shrinkage and improve the excellent rate of finished products. In addition, the formula can be produced under normal temperature and pressure, and the process is simple, which is convenient for widespread popularization and use.

Owner:广东道氏陶瓷材料有限公司

A ceramic tile with antifouling glaze

Owner:佛山市石湾裕龙陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com