Patents

Literature

38results about How to "Improve conductivity uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for flexible graphene-modified knittable carbon nanofiber

InactiveCN103569997AImprove conductivity uniformityReduced electrode polarization effectMaterial nanotechnologyCell electrodesDimethyl formamideChemical industry

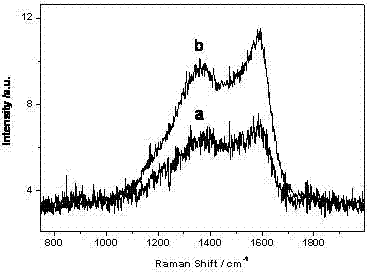

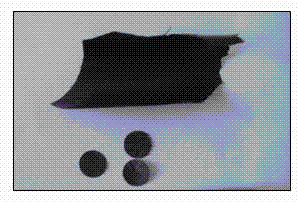

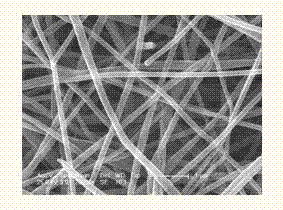

A preparation method for a flexible graphene-modified knittable carbon nanofiber belongs to the technical field of chemical industry. The preparation method comprises the following steps: at first, graphene oxide is taken to be placed in a container filled with DMF (Dimethyl Formamide) to obtain a graphene oxide saturated solution with the brown-yellow upper layer, then, polyacrylonitrile macromolecules are dissolved in the DMF to obtain a transparent macromolecular solution, the graphene oxide saturated solution and the macromolecular solution are mixed to obtain a precursor solution, a grapheme-modified polyacrylonitrile fiber is obtained through the electrostatic spinning technology or the melt spinning technology, the drying and stabilizing are performed, and at last, the carbon nanofiber is prepared from the dried polyacrylonitrile fiber in the inert gas environment or the vacuum condition. The carbon nanofiber prepared by the method can be applicable to lithium ion batteries or electrochemical capacitors, and besides, is also applicable to the fields of the war industry and the aerospace.

Owner:NORTHEAST NORMAL UNIVERSITY

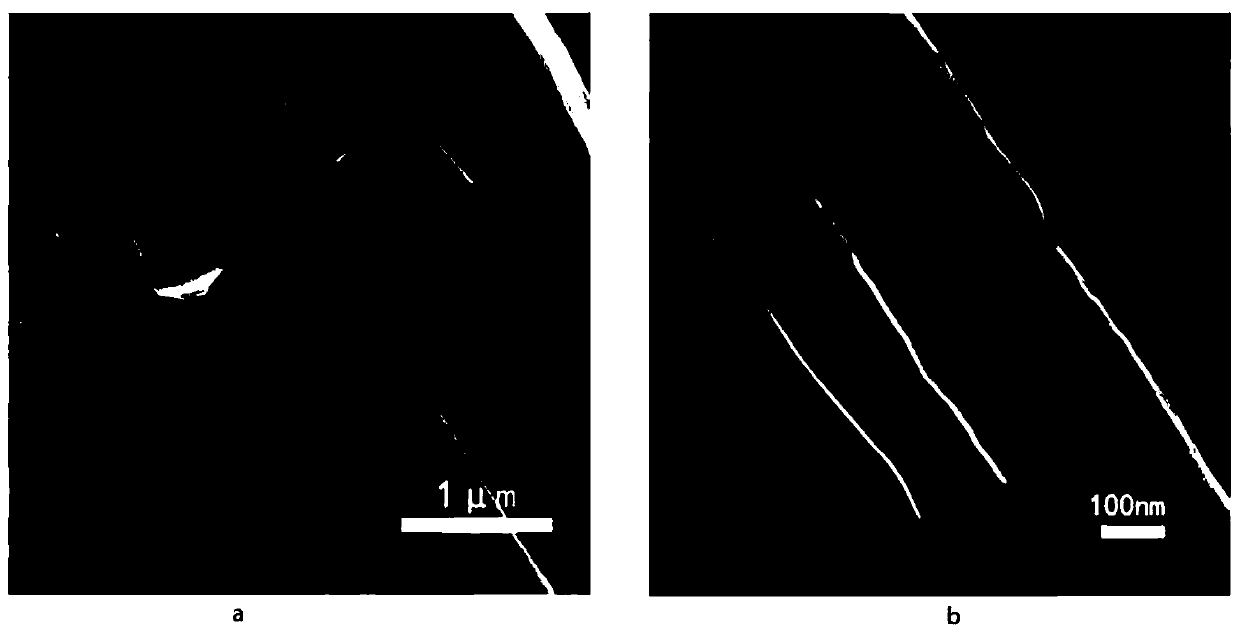

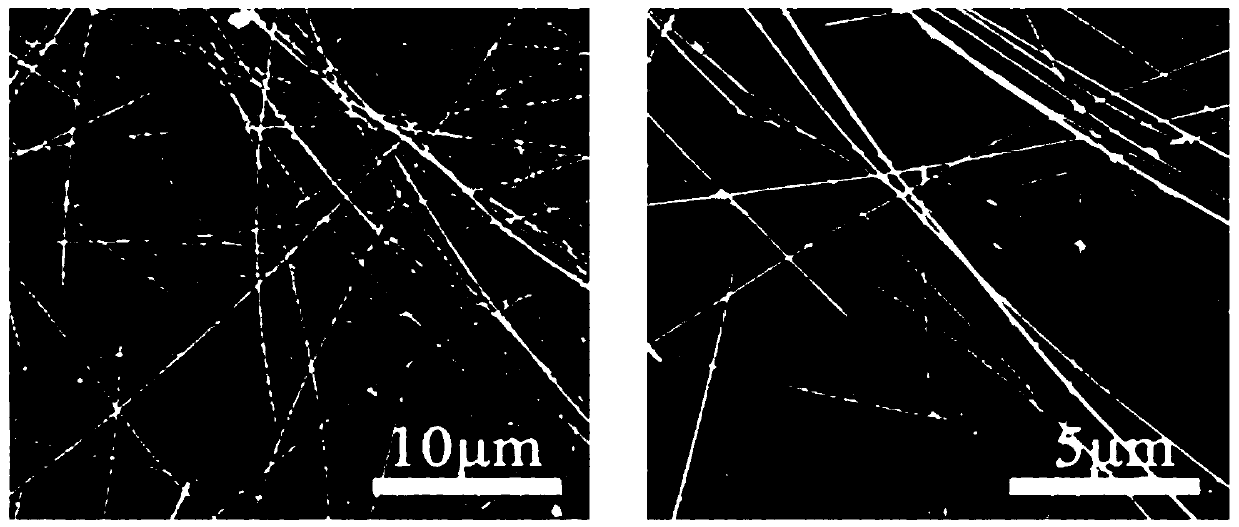

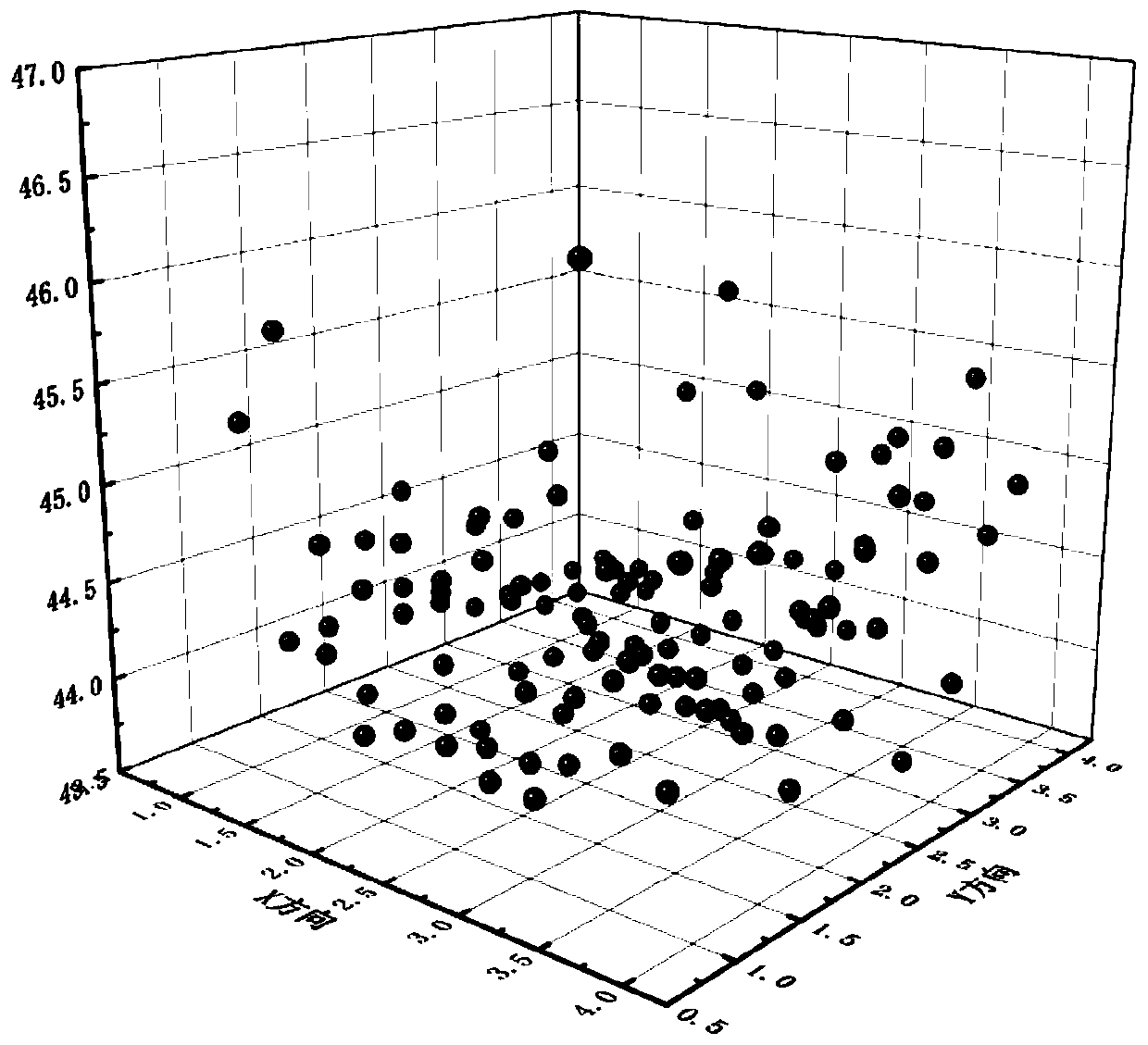

Silver nanowire transparent conductive thin film and preparation method thereof

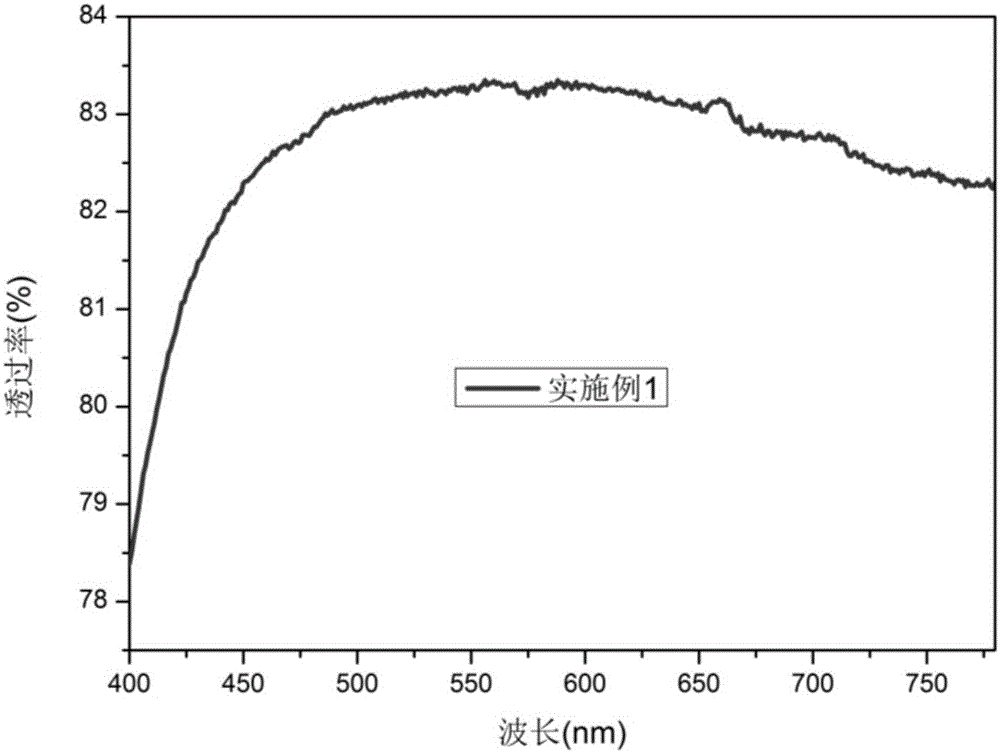

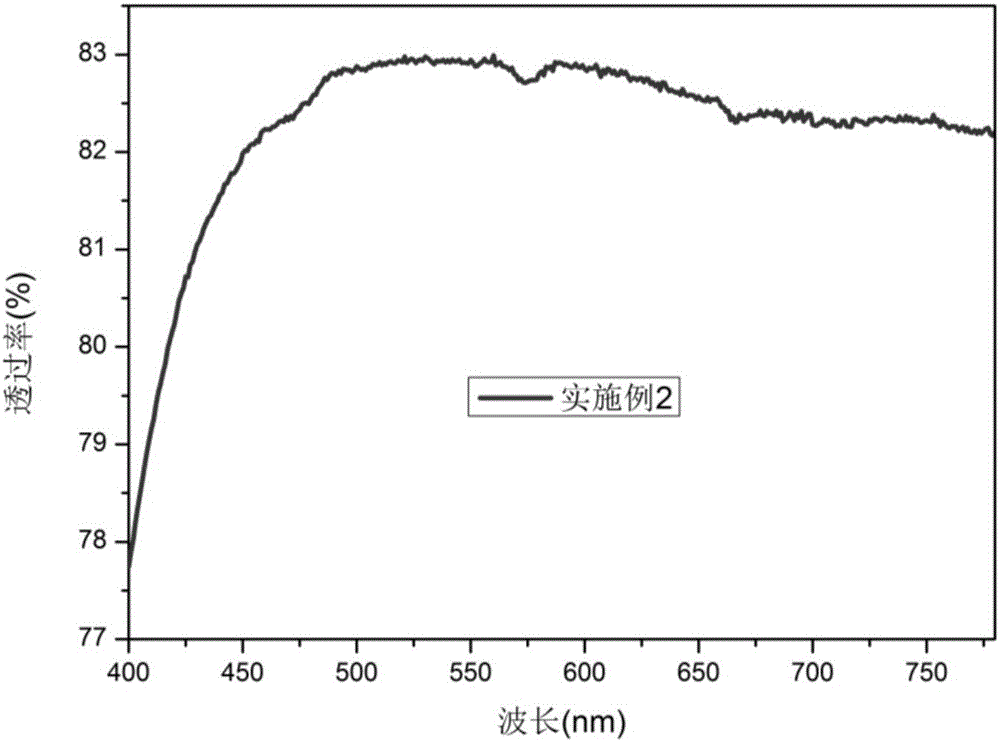

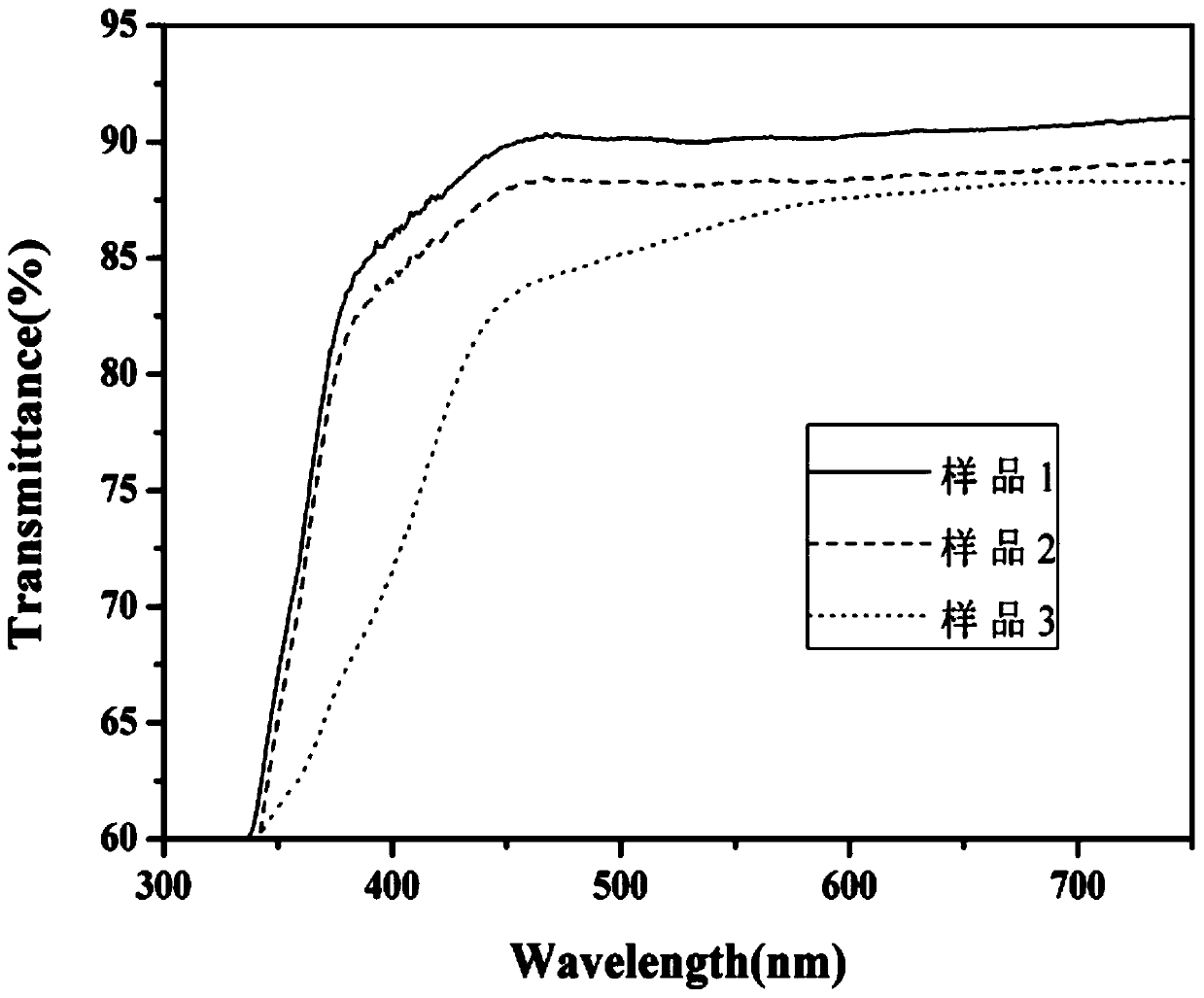

InactiveCN106098134AImprove conductivity uniformityGood optical transmissionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersOptical transmittanceAlloy

The present invention provides a silver nanowire transparent conductive thin film and a preparation method thereof. The silver nanowire transparent conductive thin film comprises a substrate as well as a silver nanowire coating and a titanium oxide coating sequentially covering the substrate; and the titanium oxide coating and silver in the silver nanowire layer form a structure similar to Ag-Ti alloy valence bond. According to the silver nanowire transparent conductive thin film and the preparation method thereof, the titanium oxide layer (TiOx) is introduced, and the titanium oxide layer and the silver in the silver nanowire layer form the structure similar to the Ag-Ti alloy valence bond, and therefore, on the one hand, electrical effective connections between silver nanowires can be enhanced, and the functions of a binder are realized, and the uniformity of the electric conduction of the transparent conductive thin film can be increased, and on the other hand, the optical transmittance of the TiOx layer is excellent, the transmittance of the thin film will not be decreased significantly; and the TiOx layer can protect the silver nanowire transparent conductive film thin from being oxidized, so that the stability of the thin film can be improved.

Owner:SHAANXI COAL & CHEM TECH INST

Conductive silver adhesive with low solid content and capable of being rapidly cured at medium and normal temperature

ActiveCN105131881AGood coating effectImprove stamping resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseConductive polymer

The invention discloses a conductive silver adhesive with low solid content and capable of being rapidly cured at medium and normal temperature. The conductive silver adhesive is prepared from 1%-2% of silver nanowires, 13%-29% of flake silver powder, 20%-30% of bisphenol A epoxy resin, 5%-10% of rapid medium and normal temperature curing agents, 0.5%-1% of rapid medium and normal temperature curing accelerant, 1%-3% of thinning agents, 1%-3% of K-570 or K-550, 0.5%-1% of terephthalic acid, 20%-56.3% of cellulose, 0.5%-1% of nano-silicon dioxide, 0.1%-0.5% of antifoaming agents and 0.1%-0.5% of ICAM8401 or ICAM8402. The conductive silver adhesive can be rapidly cured at medium and normal temperature and is low in silver content and low in cost, and therefore the application range of the conductive silver adhesive is greatly extended.

Owner:上海巨尔希电子科技有限公司

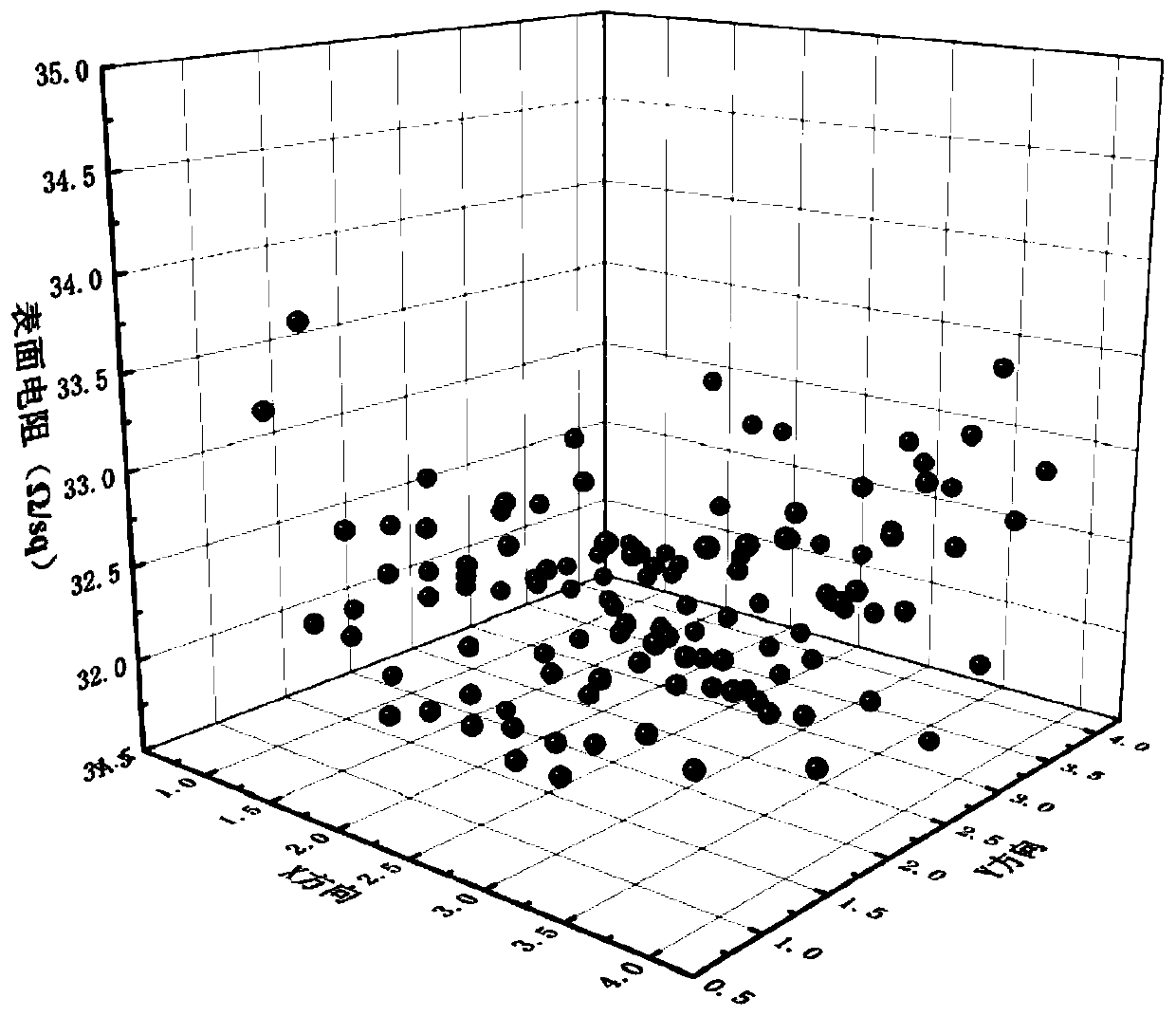

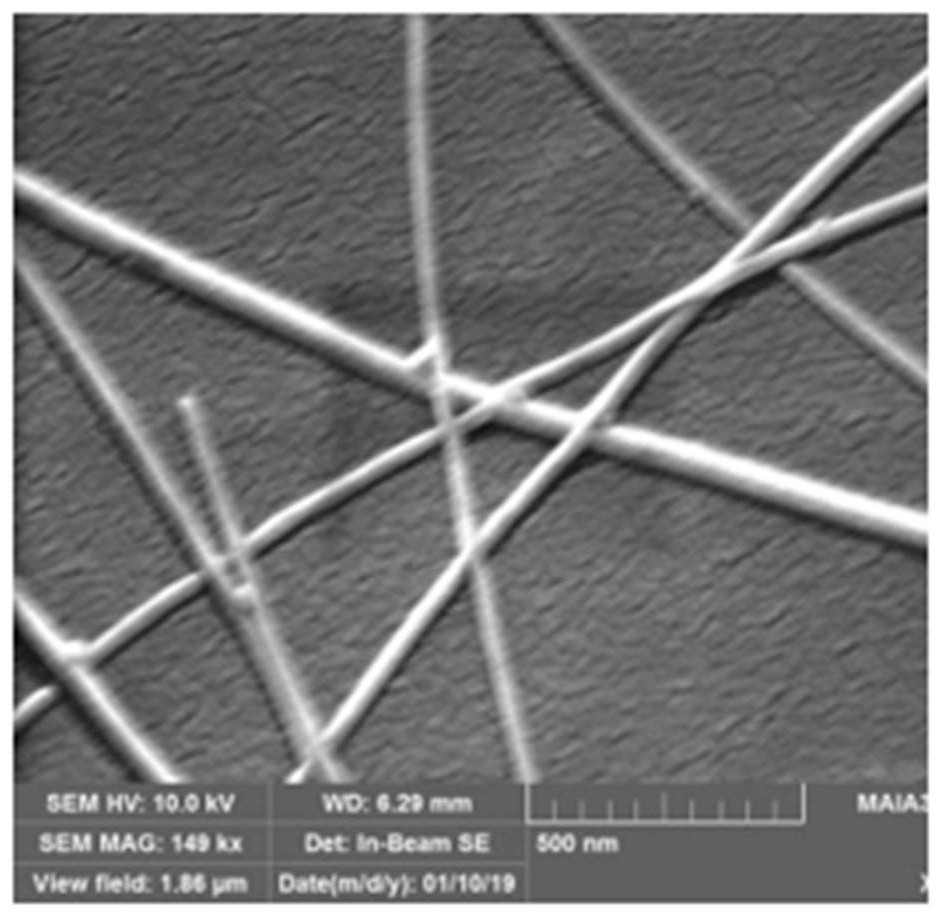

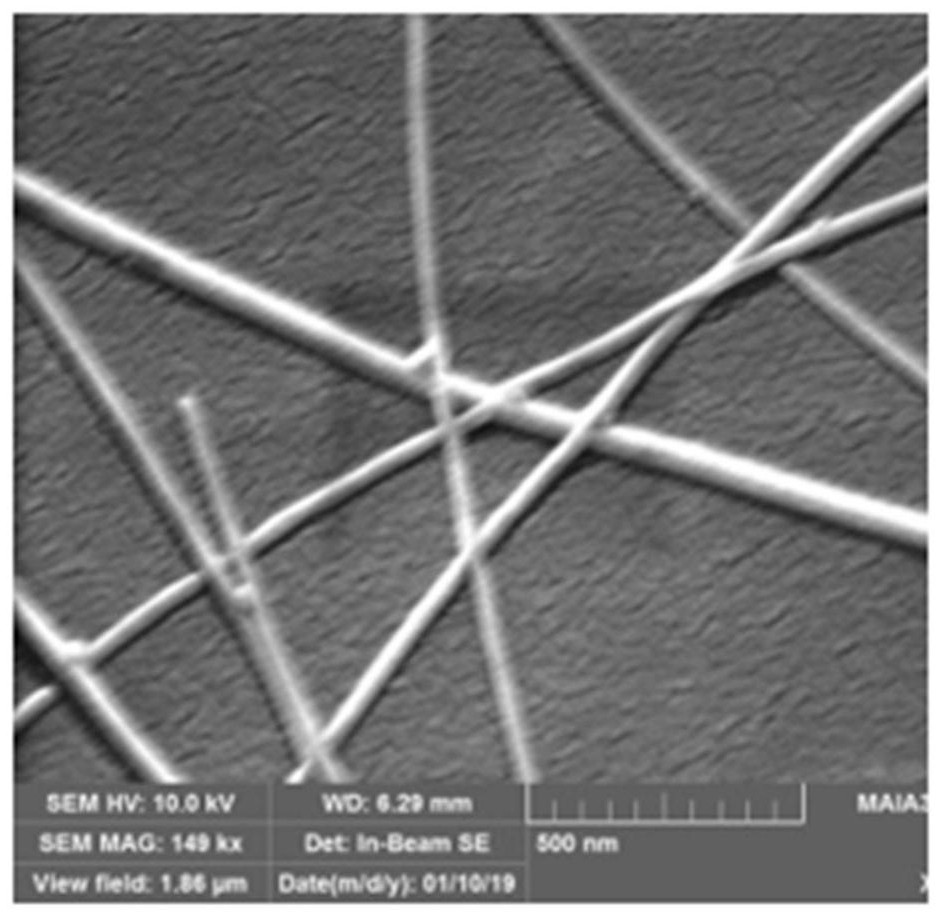

Preparation method of patterned AgNWs/PEDOT:PSS composite conductive lattice thin film

InactiveCN110233003AImprove transmittanceImprove conductivity uniformityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersScreen printingDiameter ratio

The invention provides a preparation method of a patterned AgNWs / PEDOT:PSS composite conductive lattice thin film. The preparation method comprises the steps of S1) preparing a silver nanowire with relatively high length-diameter ratio; S2) preparing AgNWs / PEDOT:PSS composite conductive ink; and S3) preparing the pattered AgNWs / PEDOT:PSS composite conductive lattice thin film. The preparation method is simple, and the patterned AgNWs / PEDOT:PSS composite conductive lattice thin film prepared by silk-screen printing has relatively high transmittance and favorable conductive uniformity; comparedwith a method employing a simple printing material, the conductivity and the adhesion of the thin film are further improved; silk-screen printing to manufacture the uniform thin film belongs to an environmental-friendly and low-cost method and is a technology capable of expanded production; the whole preparation process is simple to operate and is high in repeatability, the conductive lattice thinfilm with different photoelectric properties is achieved by changing the lattice pattern, and the demands of different application occasions are met.

Owner:WUYI UNIV

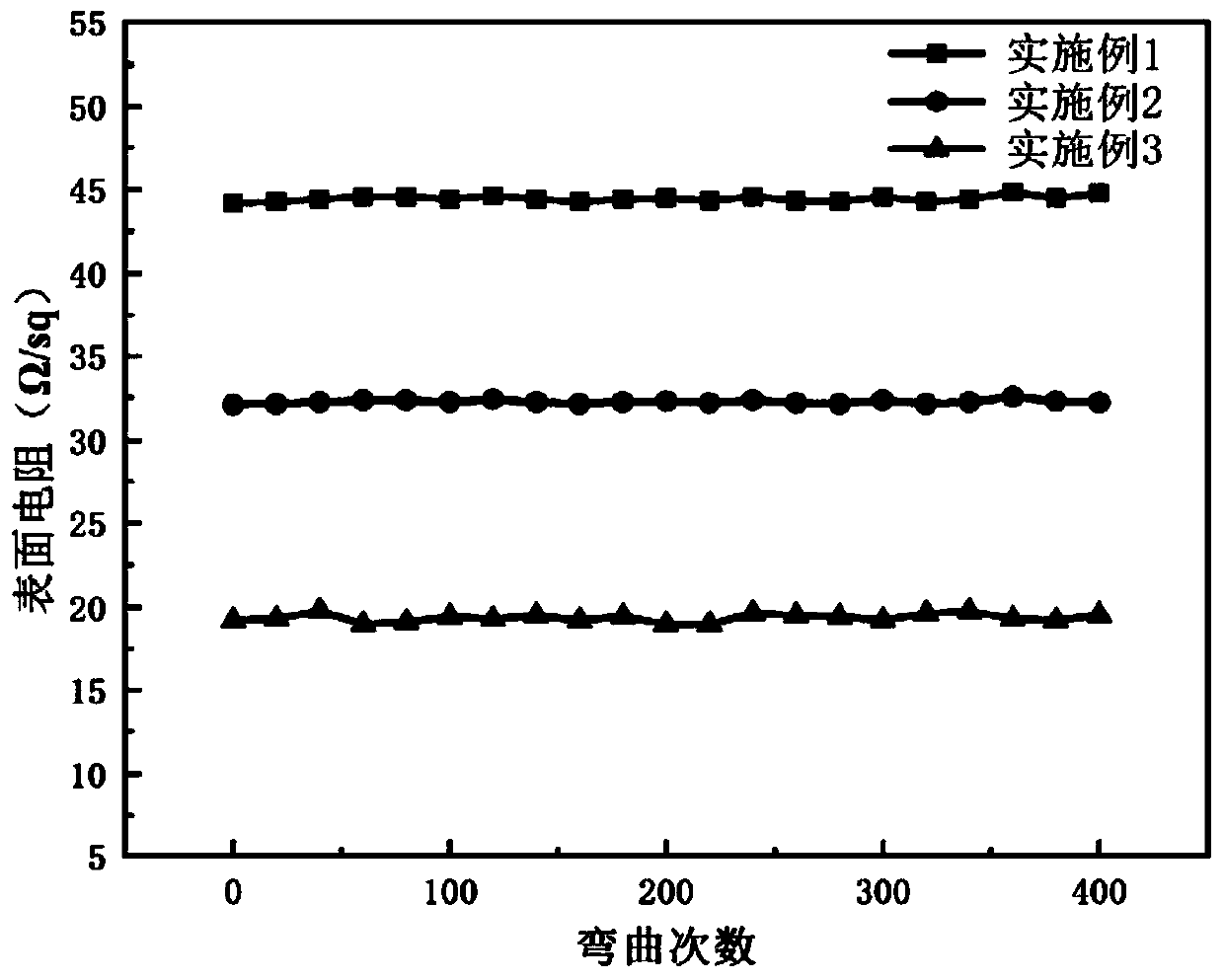

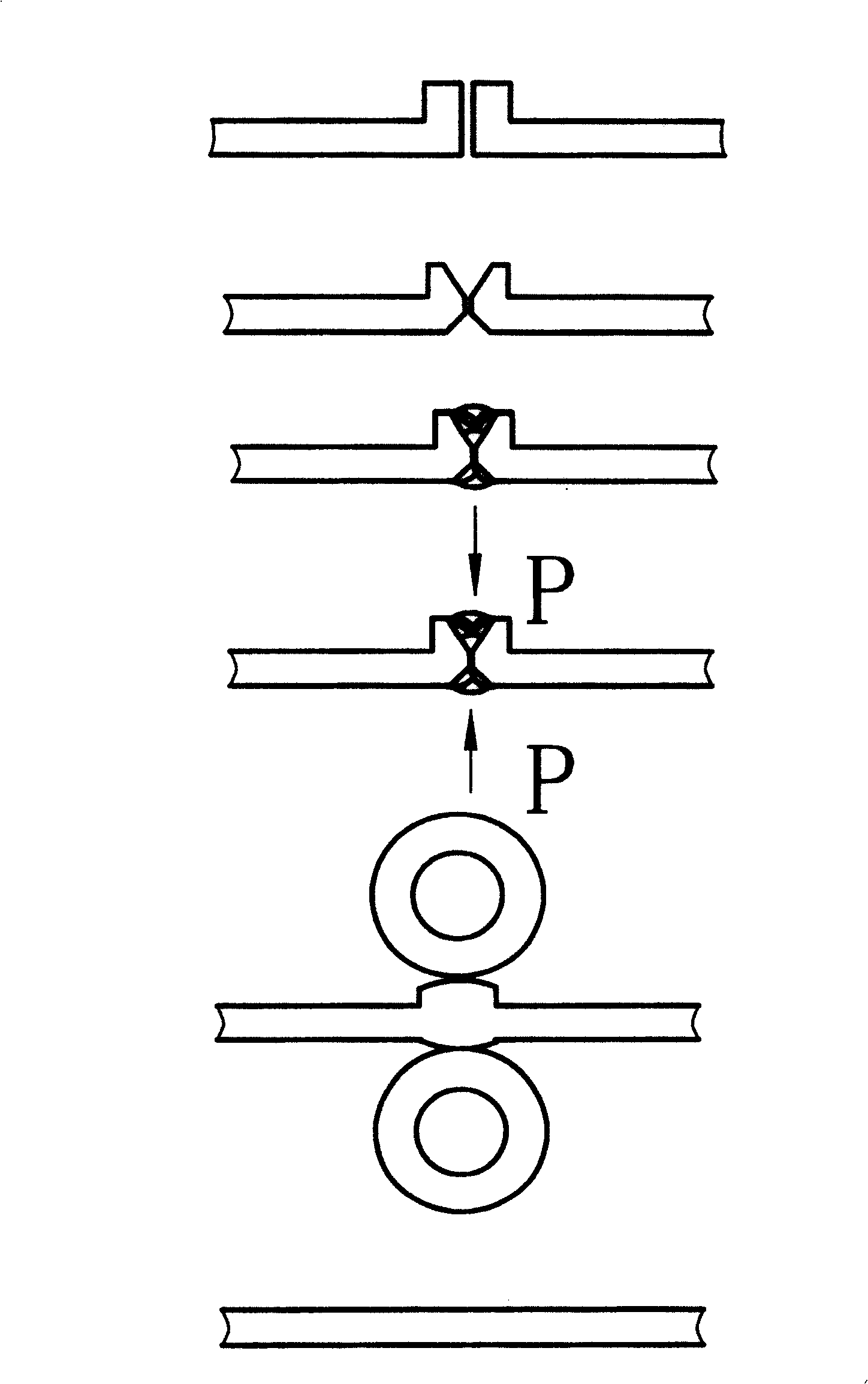

Flexible transparent conductive film and preparation method thereof

ActiveCN109727706AControl thicknessImprove conductivity uniformityConductive layers on insulating-supportsMetal/alloy conductorsPolymer scienceAlcohol

The invention discloses a flexible transparent conductive film and a preparation method thereof. The preparation method comprises the steps of adding silver nanowires into absolute ethyl alcohol, dispersing uniformly under ultrasonic assistance, applying the dispersion liquid to the surface of an organic filter membrane by means of vacuum filtration, then drying the filter membrane to obtain a filter membrane A with uniformly dispersed silver nanowires; (2) uniformly mixing liquid silicone rubber and a corresponding cross-linking agent, then uniformly dispersing the mixture on the surface of ametal film by means of spin coating, and then carrying out solidification to obtain a film B; (3) tightly fitting the side having the silver nanowires of the filter membrane A and the side having thesolidified silicone rubber of the film B, carrying out pressure treatment, and transferring the silver nanowires on the filter membrane to the surface of the silicone rubber film; and (4) soaking thesample obtained in the step (3) into a dilute acid solution, and enabling the metal film on the surface of the silicone rubber film to be completely dissolved so as to obtain the flexible transparentconductive film. The ultra-thin flexible transparent conductive film prepared according to the invention has uniform conductivity and good flexibility.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

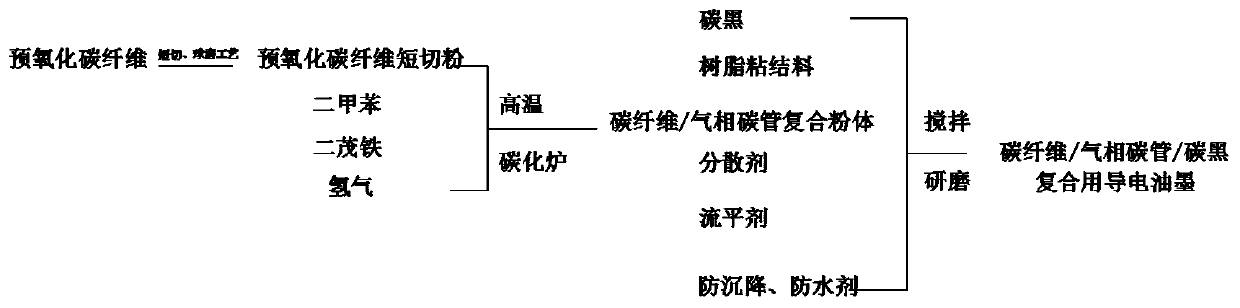

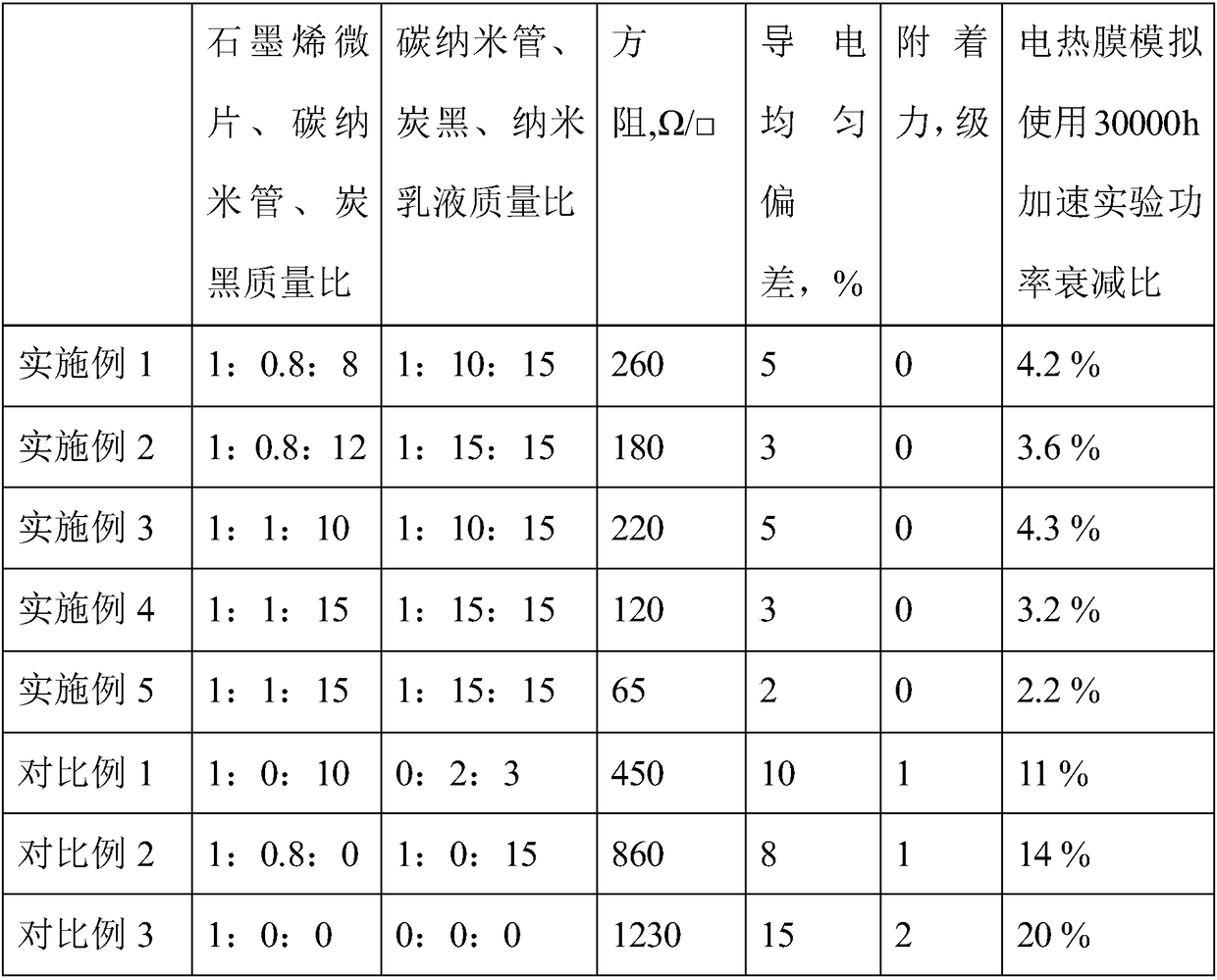

Carbon fiber/gaseous carbon tube/carbon black compound conductive ink and preparation method thereof

The invention belongs to the technical field of conductive inks and particularly relates to a carbon fiber / gaseous carbon tube / carbon black compound conductive ink and a preparation method thereof. The carbon fiber / gaseous carbon tube / carbon black compound conductive ink is composed of, by weight part, 0.1-10 parts of carbon fiber / gaseous carbon tube compound powder, 0.1-20 parts of carbon black,0.1-70 parts of resin adhesives, 0.1-5 parts of dispersant, 0.1-5 parts of flatting agent, 0.1-5 parts of anti-settling agent and 0.1-5 parts of water-repellent agent. The carbon fiber / gaseous carbontube / carbon black compound conductive ink has the advantages of being high in adhesion force, electric conductivity, water resistance, alcohol resistance and the like and achieves uniform conductive uniformity and application attenuation resistance; meanwhile, the carbon fiber / gaseous carbon tube / carbon black compound conductive ink can be applied widely as heating carbon paste, conductive carbonpaste and electromagnetic shielding carbon paste to heating floors, PCB (printed circuit board) carbon oil, electromagnetic shielding coatings and the like.

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

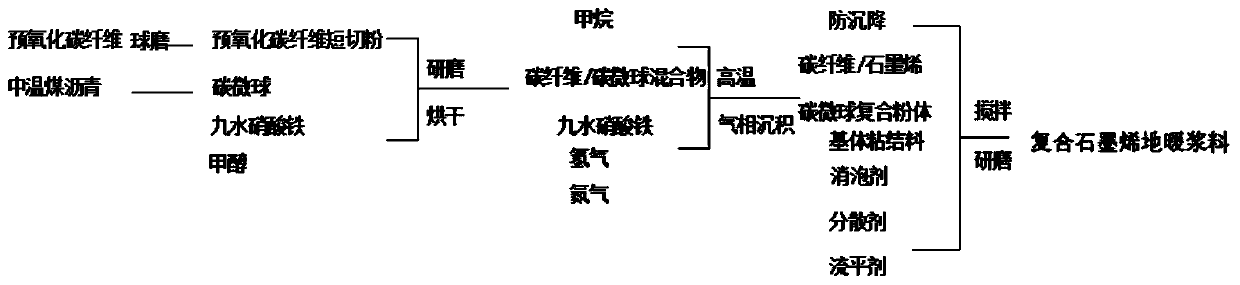

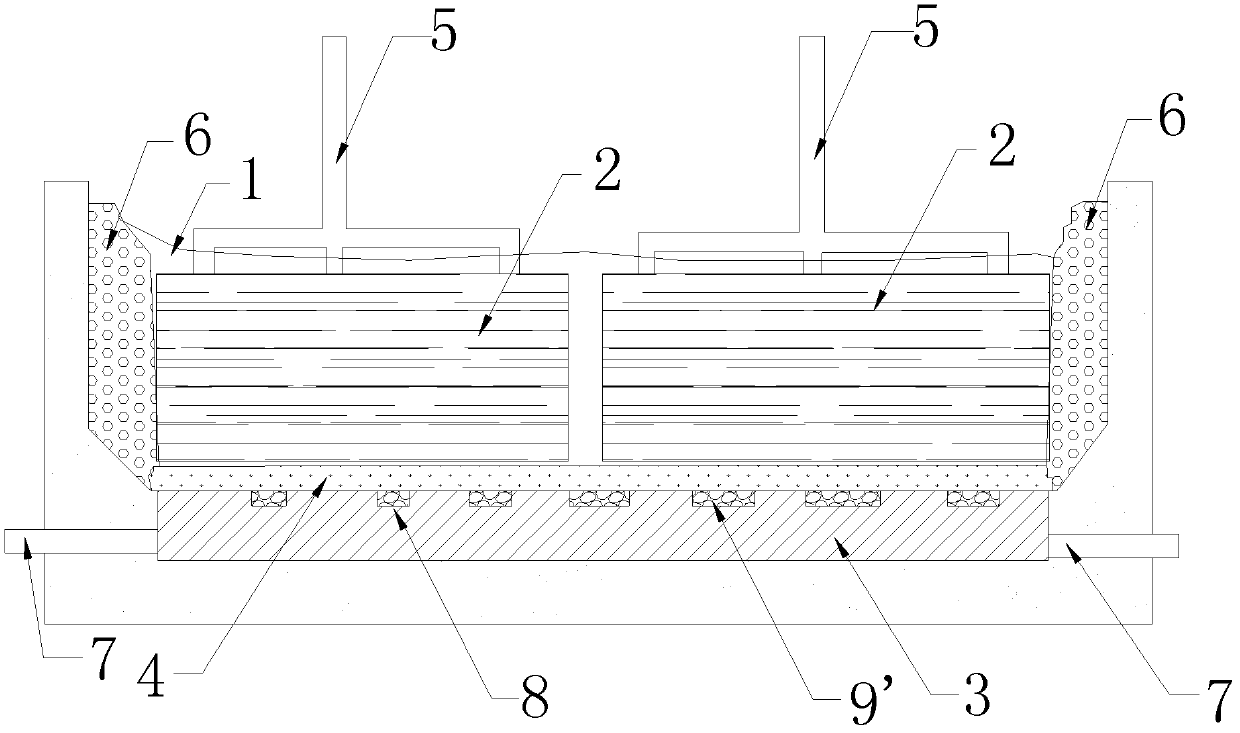

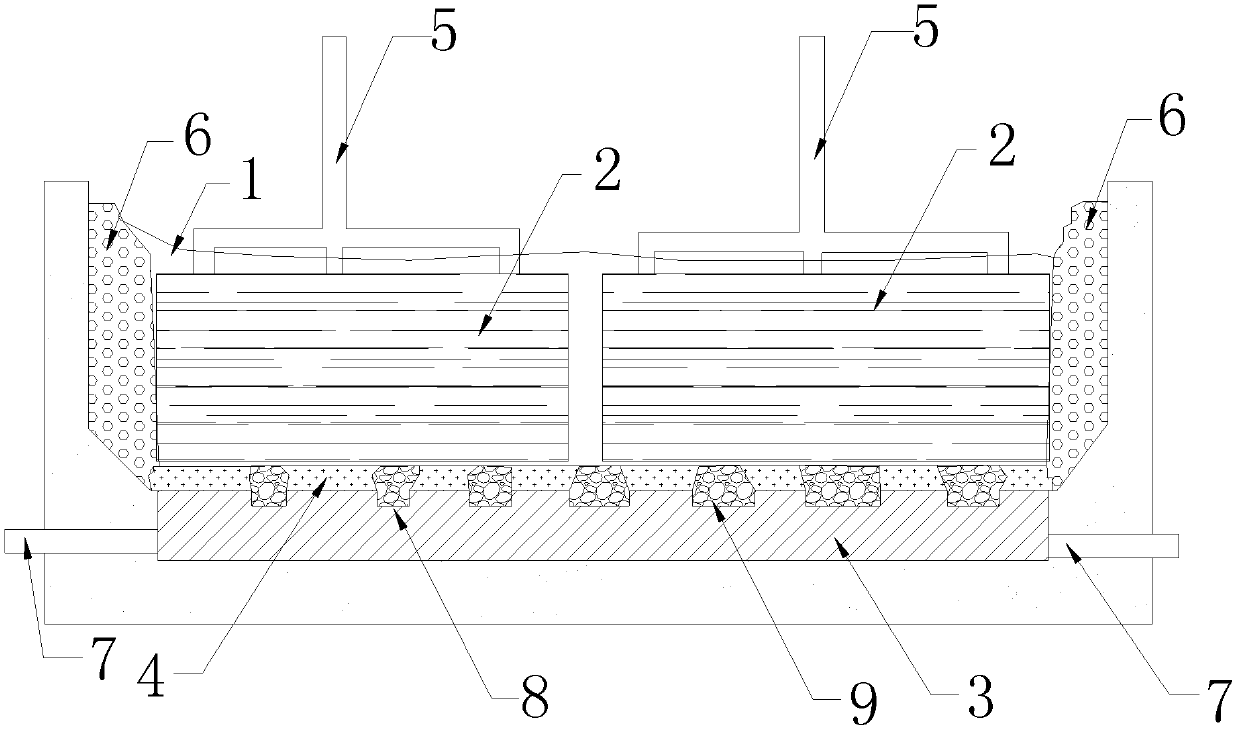

Composite graphene underfloor heating slurry and preparation method thereof

ActiveCN109749519AImprove adhesionImprove conductivityInksHeating element materialsFiberUltrasound attenuation

The invention belongs to the technical field of the underfloor heating slurry, and specifically relates to a composite graphene underfloor heating slurry and a preparation method thereof. The composite graphene underfloor heating slurry is prepared from the following raw materials in parts by weight: 0.1-30 parts of carbon fiber / graphene / carbon microsphere powder, 0.1-70 parts of a matrix bindingmaterial, 0.1-5 parts of a dispersing agent, 0.1-5 parts of a flatting agent, 0.1-5 parts of a precipitator, and 0.1-1 part of a defoaming agent. The composite graphene underfloor heating slurry prepared by adopting the carbon fiber / graphene / carbon microsphere powder has characteristics of good adhesive force, high conductivity, water resistance and alcohol resistance, and has excellent conductiveuniformity, and attenuation resistance.

Owner:浙江格来菲科技有限公司

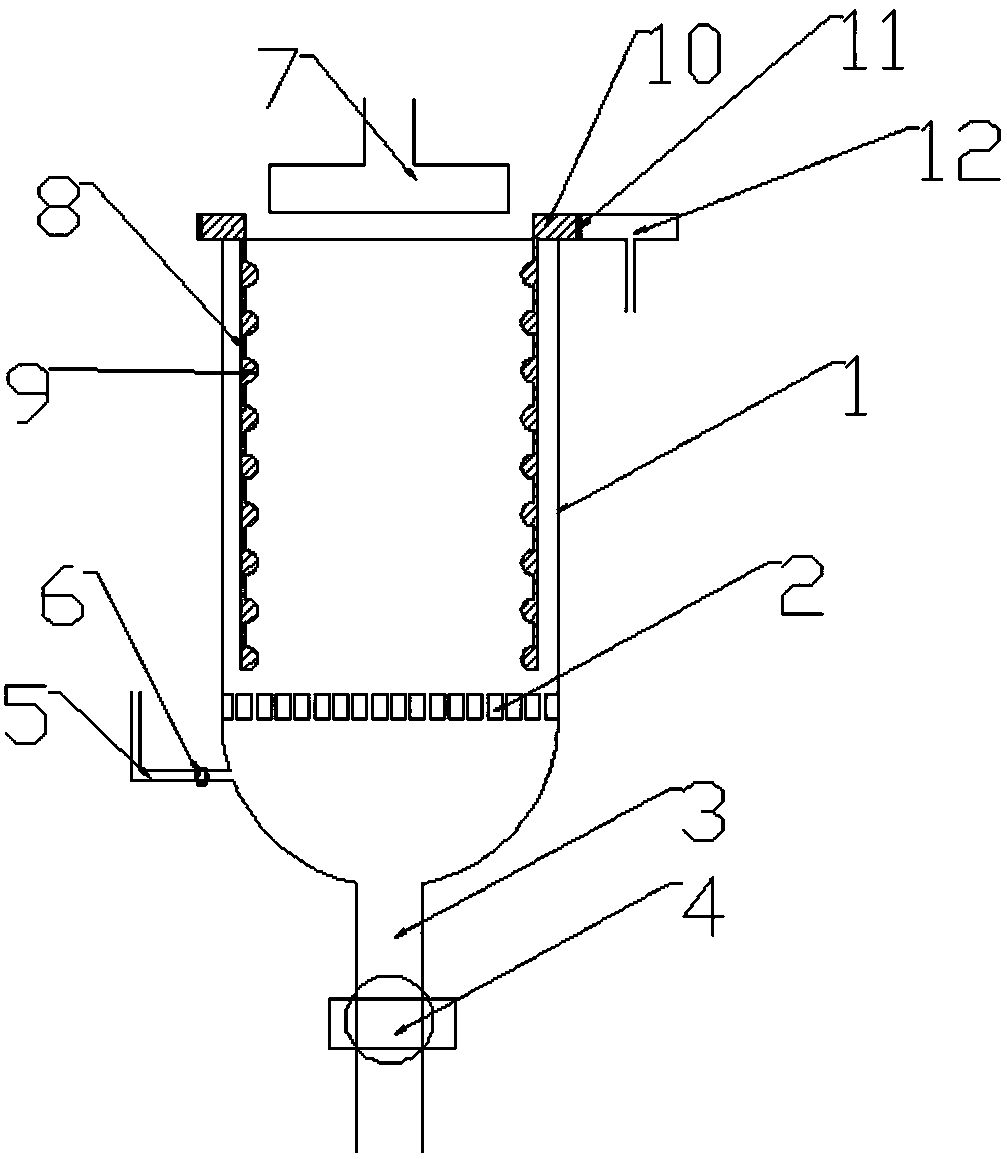

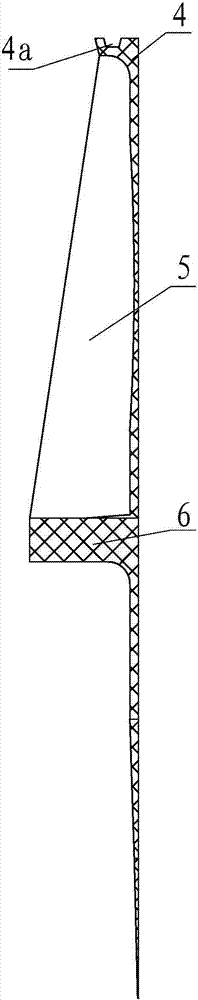

Conductive microfiber leather as well as preparation method and equipment thereof

ActiveCN108130720AImprove conductivityImprove adsorption capacityFibre typesNon-woven fabricsChemical LinkageProduction line

The invention discloses conductive microfiber leather as well as a preparation method and equipment thereof. The preparation method of the conductive microfiber leather comprises the following steps:1) activating a microfiber staple fiber; 2) impregnating graphene oxide; 3) preparing sulfur-graphene / microfiber staple fiber; 4) impregnating a faintly alkaline strong reducing agent; 5) desulfurating and reducing; 6) washing; 7) preparing a non-woven fabric; 8) preparing the microfiber leather. In addition to the conventional production line for preparing the microfiber leather through the microfiber staple fiber, the equipment further comprises an opener and a microfiber staple fiber processing tank, the microfiber staple fiber processing tank takes the shape of a funnel bucket, a porous filter plate is arranged at the bottom of a funnel, and a cake shaped extruding machine is arranged at the top of the funnel. The graphene is bounded with the microfiber staple fiber through the chemical bond, the binding force is firm, the graphene is more evenly distributed on the surface of the microfiber staple fiber, the electrical conductivity of the synthesized conductive microfiber leather is better, and the tinting strength of the synthesized conductive microfiber leather is strong.

Owner:湖北鑫楚达革业股份有限公司

Antistatic polytetrafluoroethylene film and preparation method thereof

The invention discloses an antistatic polytetrafluoroethylene film which comprises the following components in percentage by mass: 75-95% of polytetrafluoroethylene dispersion resin, 5%-20% of nano metal electric-conductive powder, 1%-5% of nano graphite. The invention discloses a preparation method of the polytetrafluoroethylene film. In the antistatic polytetrafluoroethylene film, the nano aluminum powder is coated with the nano graphite, so that the lubricity of the conductive powder is improved; and then the conductive nano powder is clamped between the two layers of films in a sandwich layer form, so that the fiber-node form of the polytetrafluoroethylene film is not influenced. The polytetrafluoroethylene film is good in flux and large in porosity.

Owner:SHANGHAI LINFLON FILM TECH +1

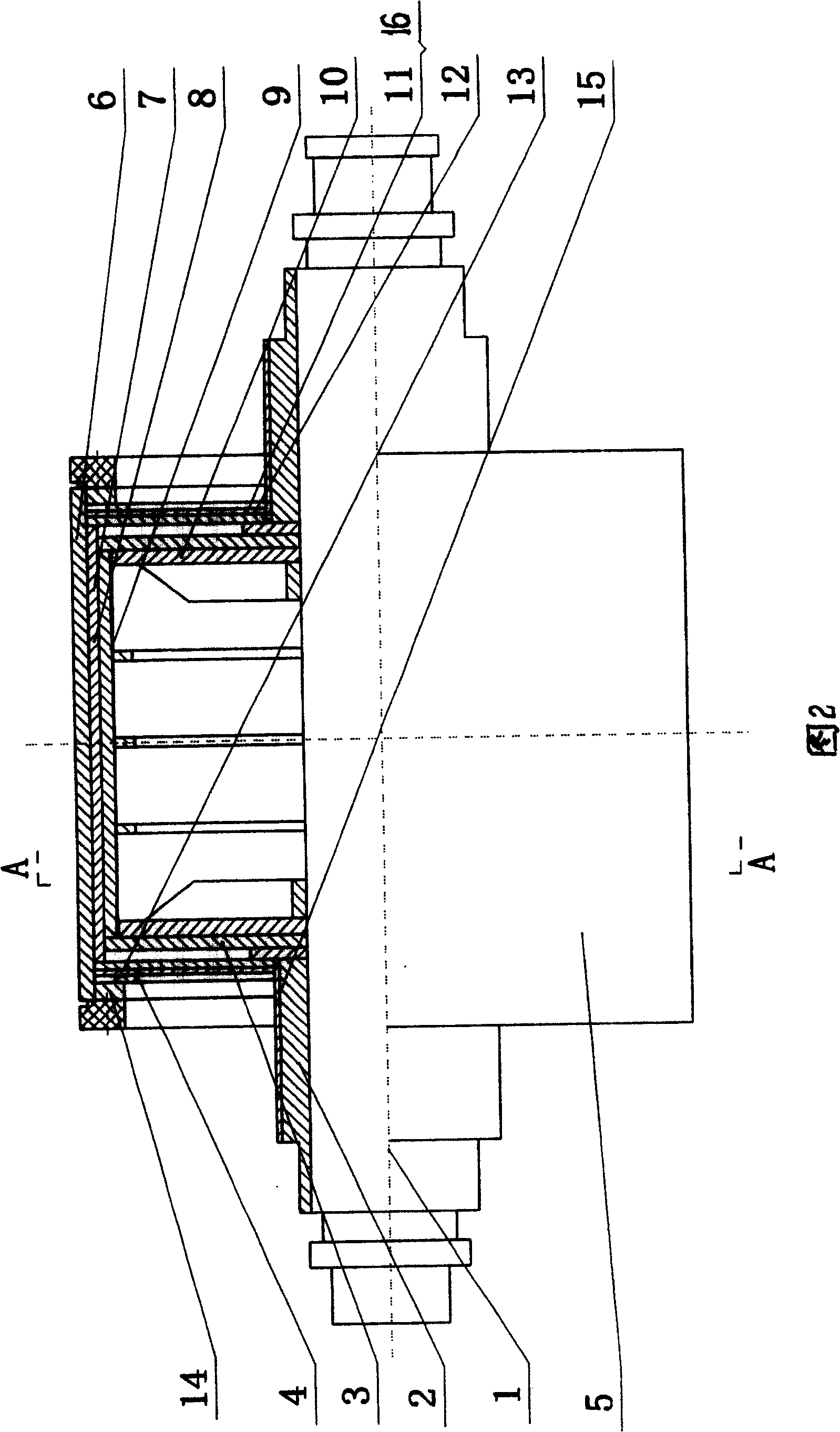

Method for roasting aluminum electrolytic tank with special-shaped cathode structure

The invention relates to an aluminum electrolytic technology, more specifically relates to a preheating and roasting method for an aluminum electrolytic tank, especially provides a method for roasting the aluminum electrolytic tank with a special-shaped cathode structure. The invention solves the technical problem that the aluminum electrolytic tank with special-shaped cathode structure can be roasted by reducing the amount of a carbon material. The roasting method comprises the following steps: A, filling a basic material in a special-shaped cathode groove, wherein the basic material can not contact with anode; B, laying the carbon material on a convex plate of the special-shaped cathode, wherein the carbon material is contact with anode; C, electrifying and roasting; wherein the basic material is an electrolyte block or / and cryolite. One of the electrolyte block and cryolite can be selected, or a mixture of the electrolyte block and cryolite can be used; any proportion can be employed for mixing. The roasting method of the invention can reduce the carbon material amount, the workload for fishing, and the phenomena of overburn and chipping. The method of the invention provides an effective method for roasting the aluminum electrolytic tank.

Owner:四川启明星铝业有限责任公司

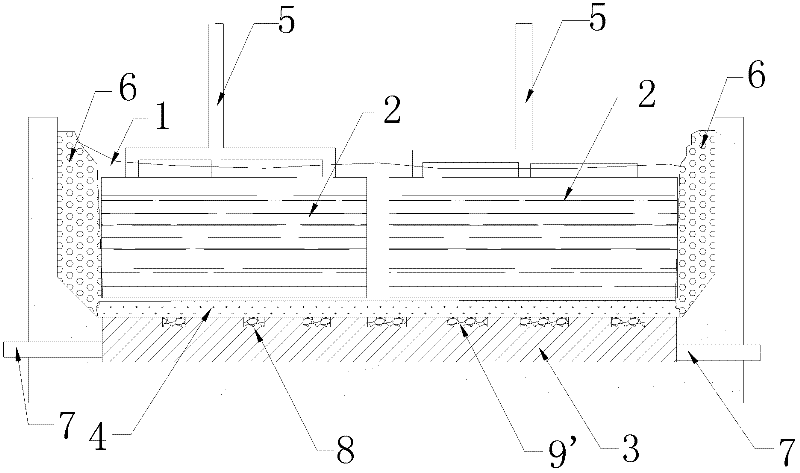

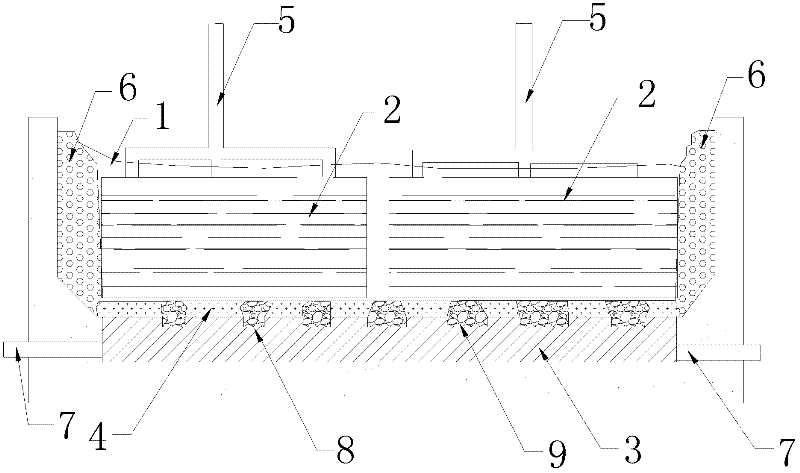

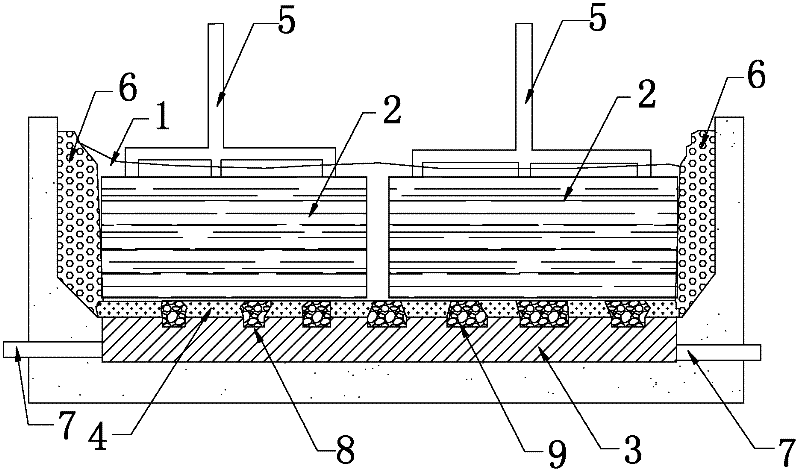

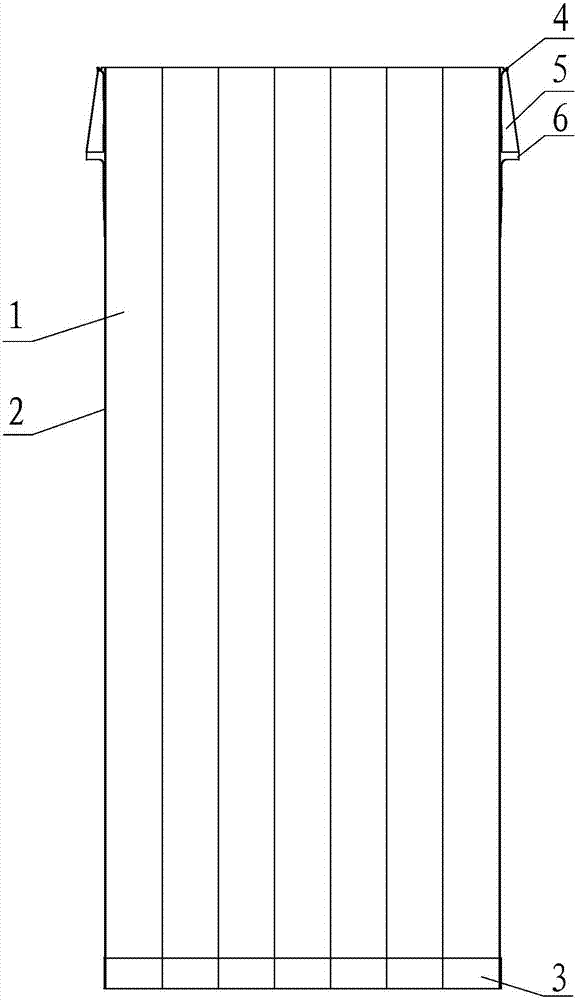

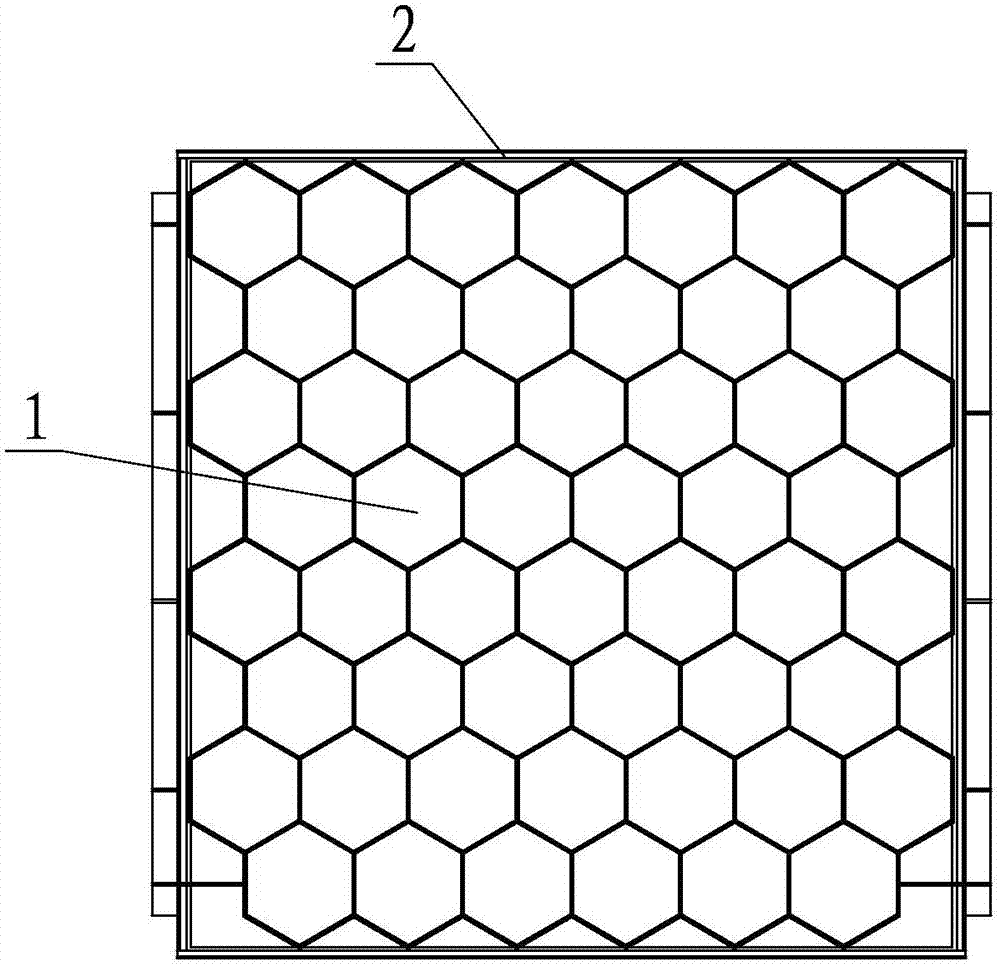

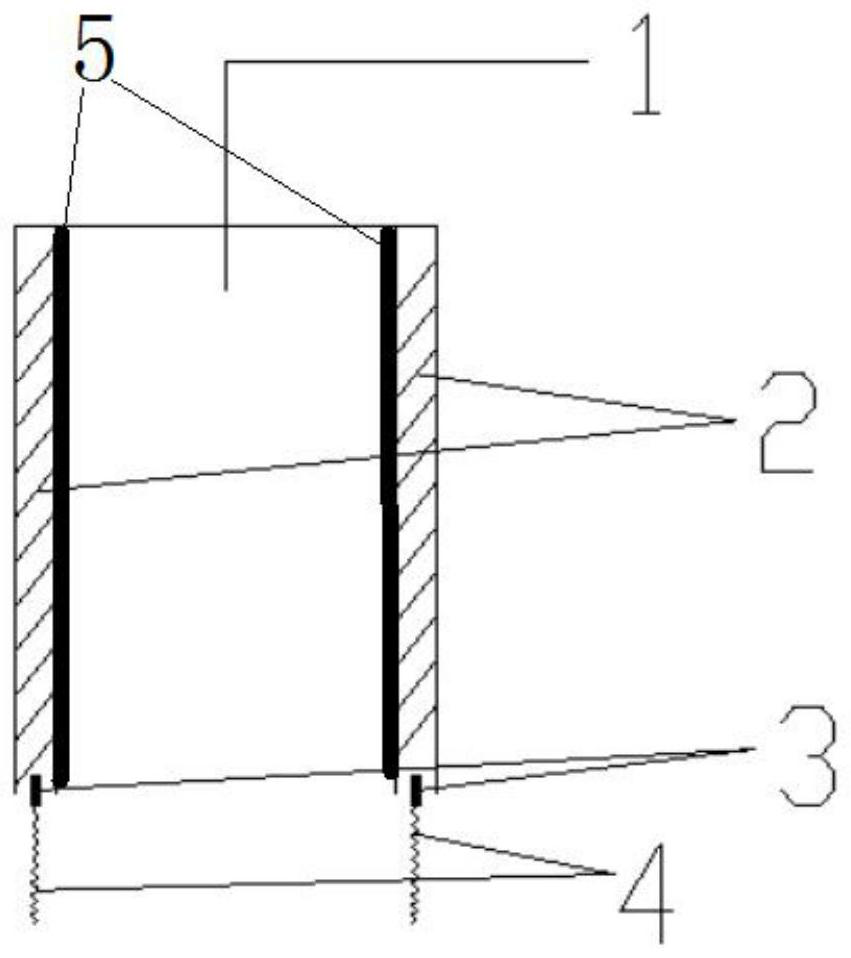

Anode module structure of tubular wet electrostatic precipitator

ActiveCN105772224BStable chargingImprove conductivity uniformityExternal electric electrostatic seperatorElectrode constructionsFiberGlass fiber

The invention provides an anode module structure of a wet type tubular electric precipitator. The anode module structure of the wet type tubular electric precipitator comprises a plurality of single conductive fiber reinforced plastic tubes. Glass fiber layers cover the outer walls of the single conductive fiber reinforced plastic tubes. The single conductive fiber reinforced plastic tubes are bonded through resin to form a honeycomb-shaped anode module. A fiber reinforced plastic layer covers the circumferential outer wall of the anode module to form an integral reinforced layer. A fiber reinforced plastic layer covers the lower end of the anode module to form a lower-end reinforced strip. A sealing flange and a load-bearing flange sleeve the upper end of the anode module, the sealing flange is located on the top edge of the anode module, a plurality of reinforcing rib plates are arranged between the sealing flange and the load-bearing flange, and an anode line channel is formed in the top surface of the sealing flange in a concave mode. Equi-potential paste heads coat the upper end and the lower end of the anode module, and further coat the inner wall of the anode line channel and the top surface of the sealing flange. Anode lines and carbon fiber resin filling materials are placed in the anode line channel, and a fiber reinforced plastic plate is arranged in the channel opening of the anode line channel in a sealing mode.

Owner:海宁国能中电节能环保设备技术有限公司

Water-based graphene flame-retardant PTC conductive paste, preparation method thereof and flexible conductive heating cloth

PendingCN112593415AImprove conductivityImprove conductivity uniformityHeat resistant fibresGrip property fibresConductive pasteGraphene

The invention provides water-based graphene flame-retardant PTC conductive paste, a preparation method thereof and a flexible conductive heating cloth, and relates to the technical field of conductivematerials. The water-based graphene flame-retardant PTC conductive paste is prepared from the following components in parts by weight: 5-20 parts of a PTC functional component, 10-20 parts of water-based flexible resin, 1-5 parts of a flame retardant, 5-20 parts of a conductive filler, 20-60 parts of water, 5-10 parts of a dispersant and 0.7-5 parts of an auxiliary agent, wherein the PTC functional component comprises one or more of a polymer PTC material and paraffin. The water-based graphene flame-retardant PTC conductive paste is a flame-retardant heating body with a PTC effect, the temperature can be controlled, and the safety is greatly improved. According to the flexible conductive heating cloth prepared from the conductive paste, the conductivity and the conductive uniformity of the heating cloth are improved, and the rubbing resistance of the heating cloth is greatly improved.

Owner:肃宁县中原纺织有限责任公司

A kind of antistatic polytetrafluoroethylene film and preparation method thereof

The invention discloses an antistatic polytetrafluoroethylene film which comprises the following components in percentage by mass: 75-95% of polytetrafluoroethylene dispersion resin, 5%-20% of nano metal electric-conductive powder, 1%-5% of nano graphite. The invention discloses a preparation method of the polytetrafluoroethylene film. In the antistatic polytetrafluoroethylene film, the nano aluminum powder is coated with the nano graphite, so that the lubricity of the conductive powder is improved; and then the conductive nano powder is clamped between the two layers of films in a sandwich layer form, so that the fiber-node form of the polytetrafluoroethylene film is not influenced. The polytetrafluoroethylene film is good in flux and large in porosity.

Owner:SHANGHAI LINFLON FILM TECH +1

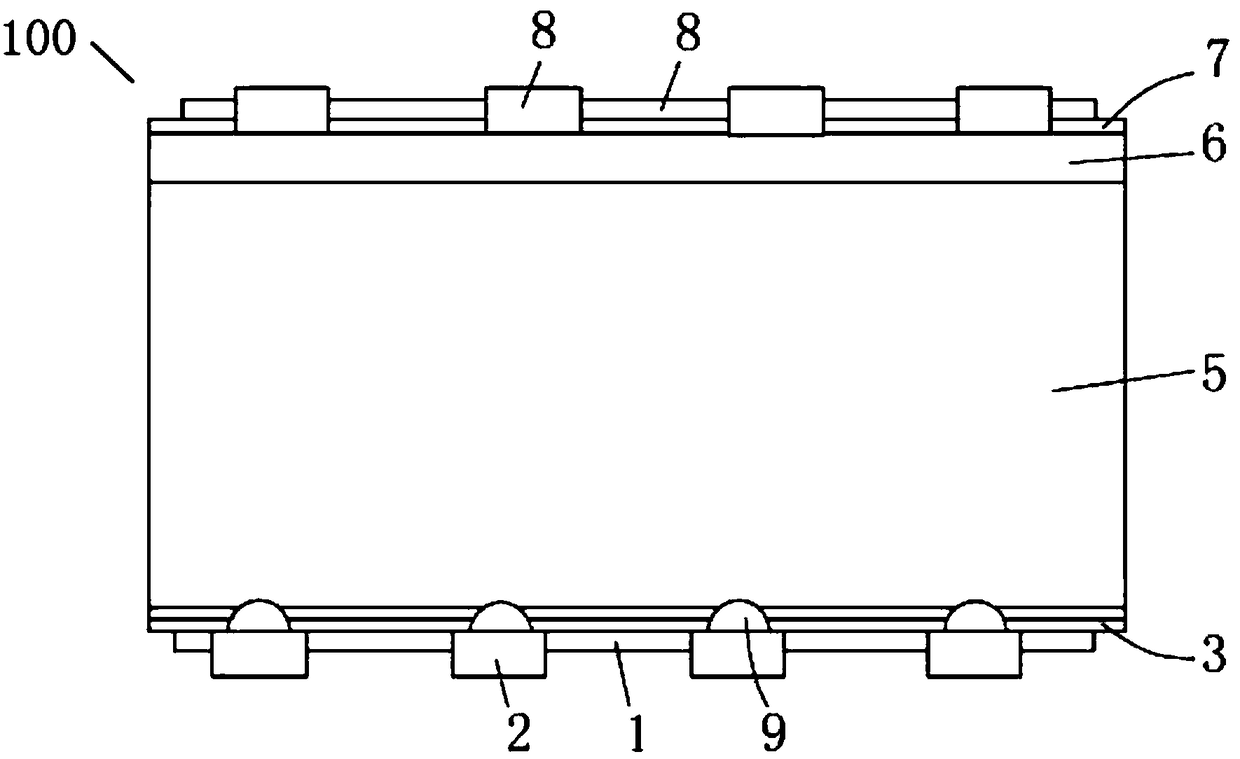

Tubular PERC two-sided solar cell, preparing method thereof and electroplating equipment special for tubular PERC two-sided solar cell

PendingCN108074997ADoes not affect appearance yieldImprove uniformityFinal product manufacturePhotovoltaic energy generationComposite filmEngineering

The invention discloses a tubular PERC two-sided solar cell. The tubular PERC two-sided solar cell comprises back silver main girds, back aluminum gate lines, reverse composite film, P-type silica, N-type emitting electrodes, front passive film and positive electrodes, wherein the positive electrodes are prepared through electroplating equipment, the front of the cell faces downwards and is in contact with electroplating liquid of an electroplating tank, and LED lamps irradiate the back of the tubular PERC two-sided solar cell. The electroplating tank is internally provided with an anode plateand an electric brush, a positive electrode of a power supply is connected with the anode plate, a negative electrode of the power supply is connected with the electric brush, and the electric brushis connected with the back silver main gird at the back of the tubular PERC two-sided solar cell. Accordingly, the invention further discloses a preparing method of the tubular PERC two-sided solar cell and the electroplating equipment special for the tubular PERC two-sided solar cell. By means of the tubular PERC two-sided solar cell, the preparing method thereof and the electroplating equipmentspecial for the tubular PERC two-sided solar cell, the conducting uniformity of the electrodes at the back of the cell is improved, the uniformity of the electroplating electrodes at the front of thecell is improved, and the good appearance of the cell is maintained.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

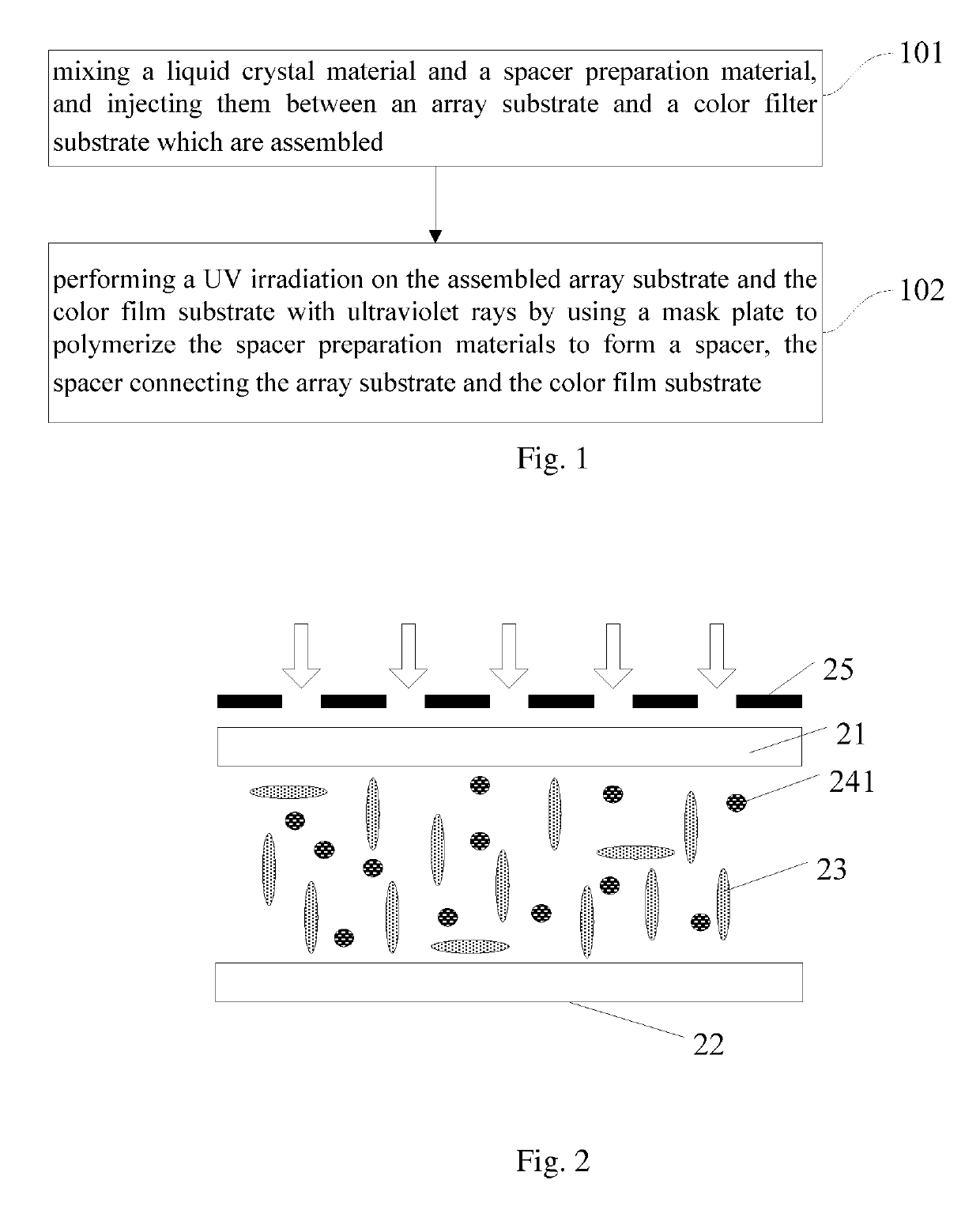

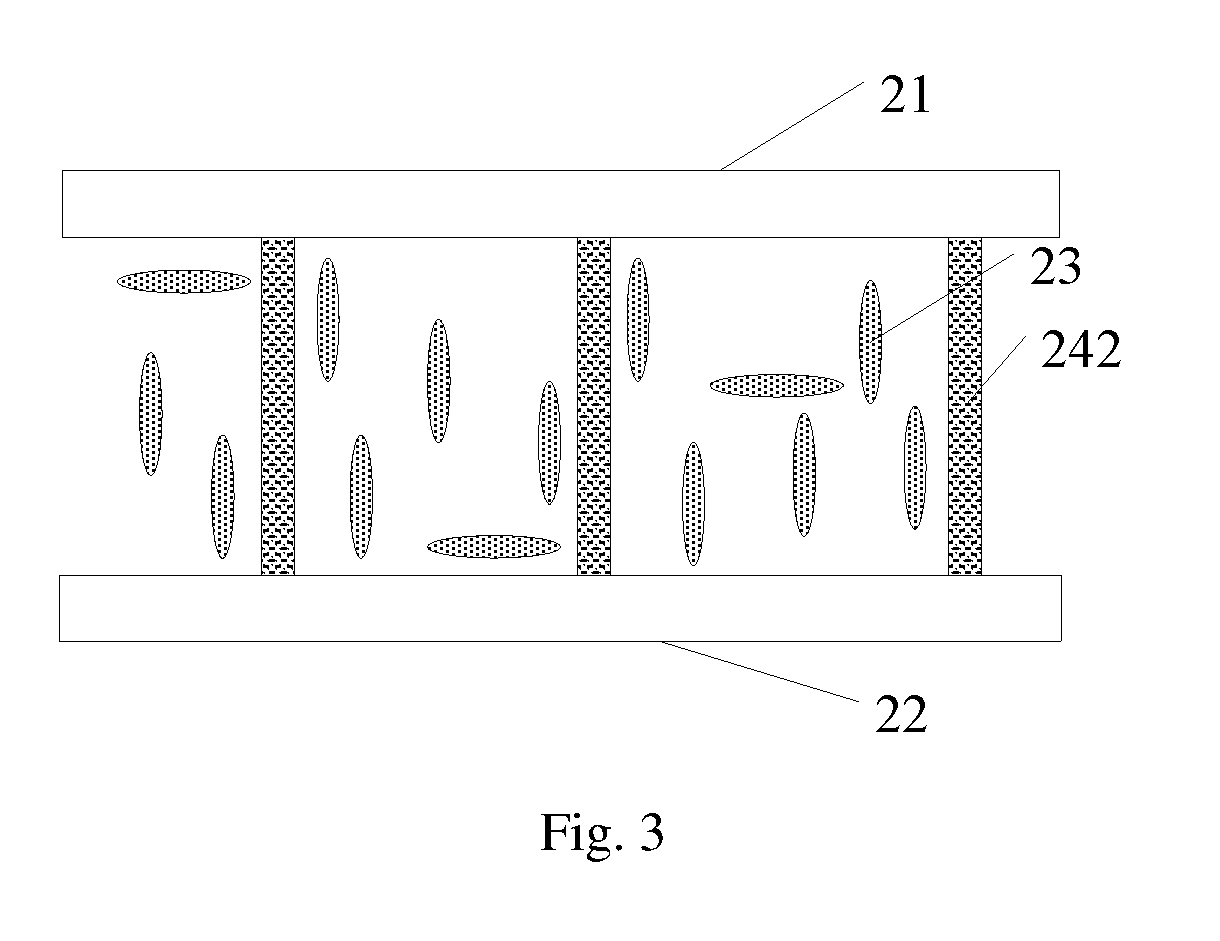

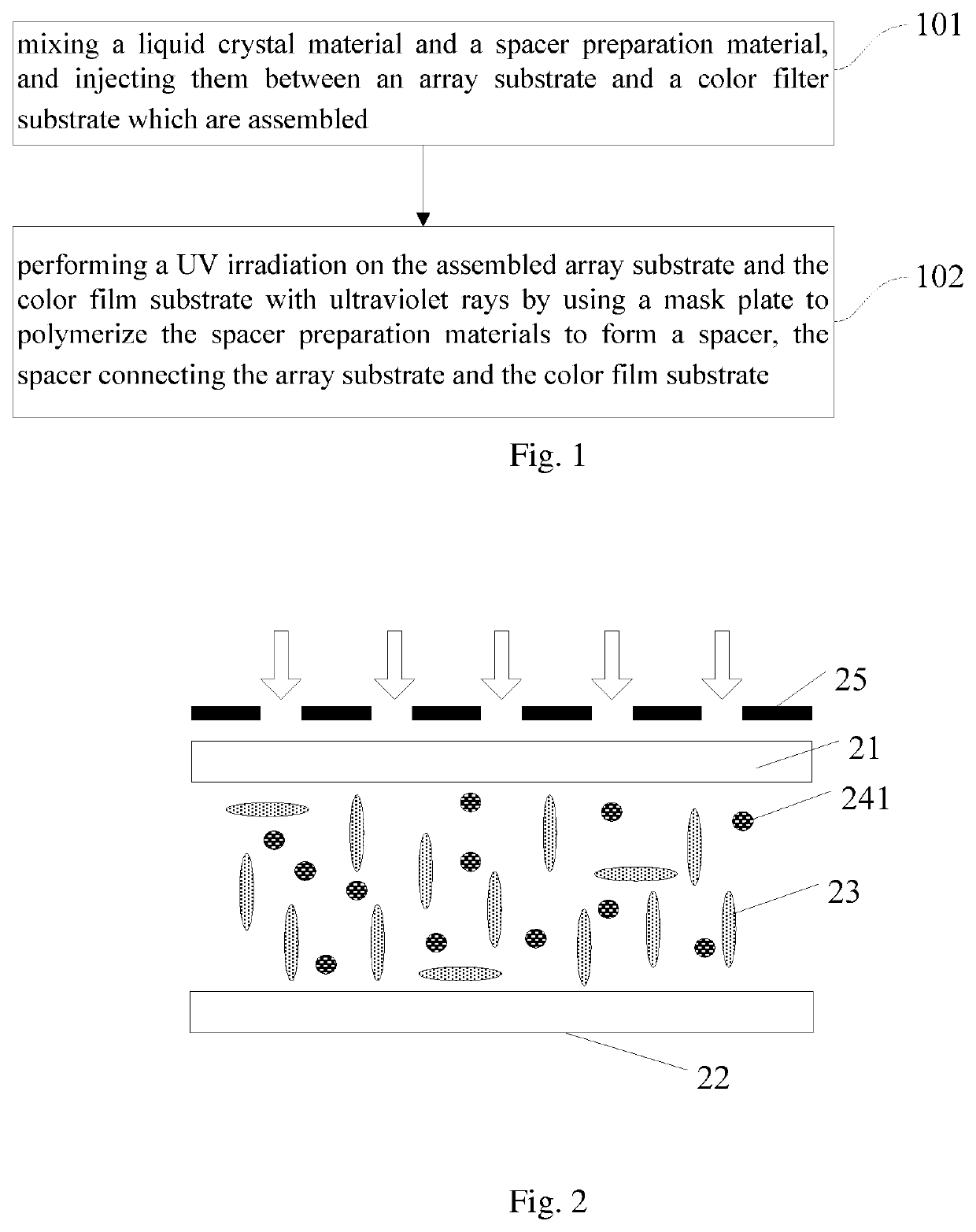

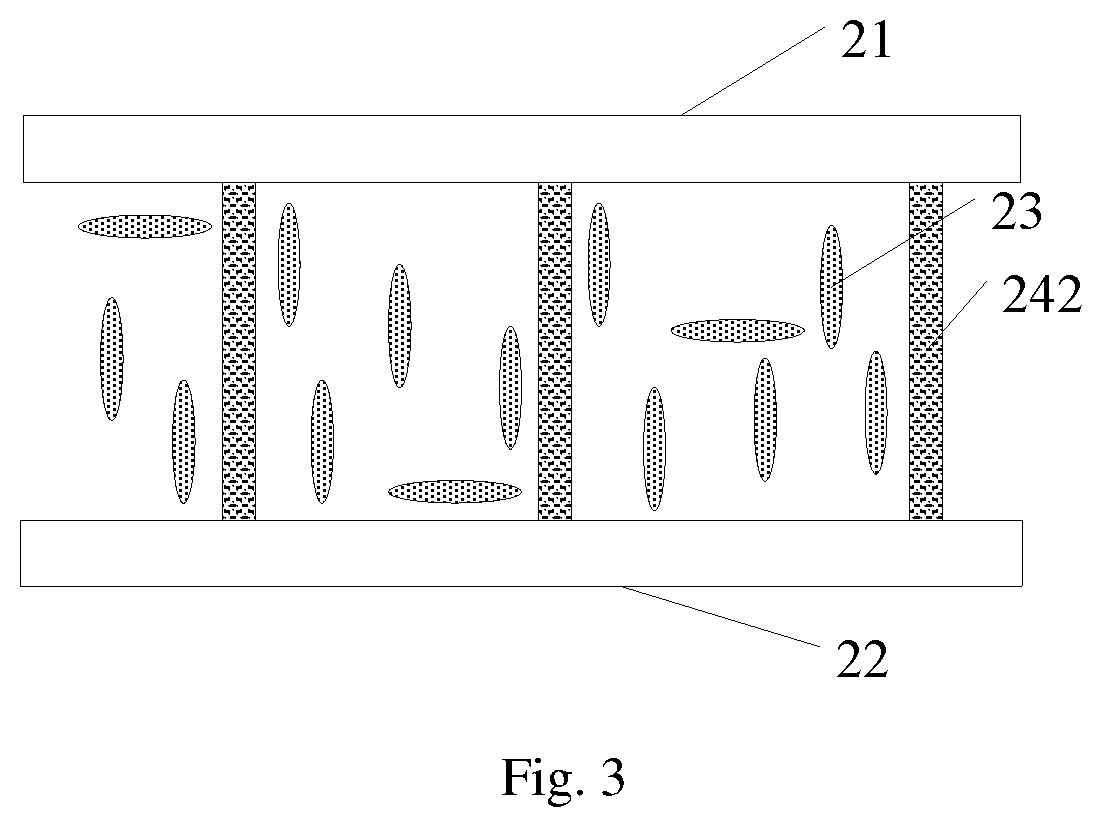

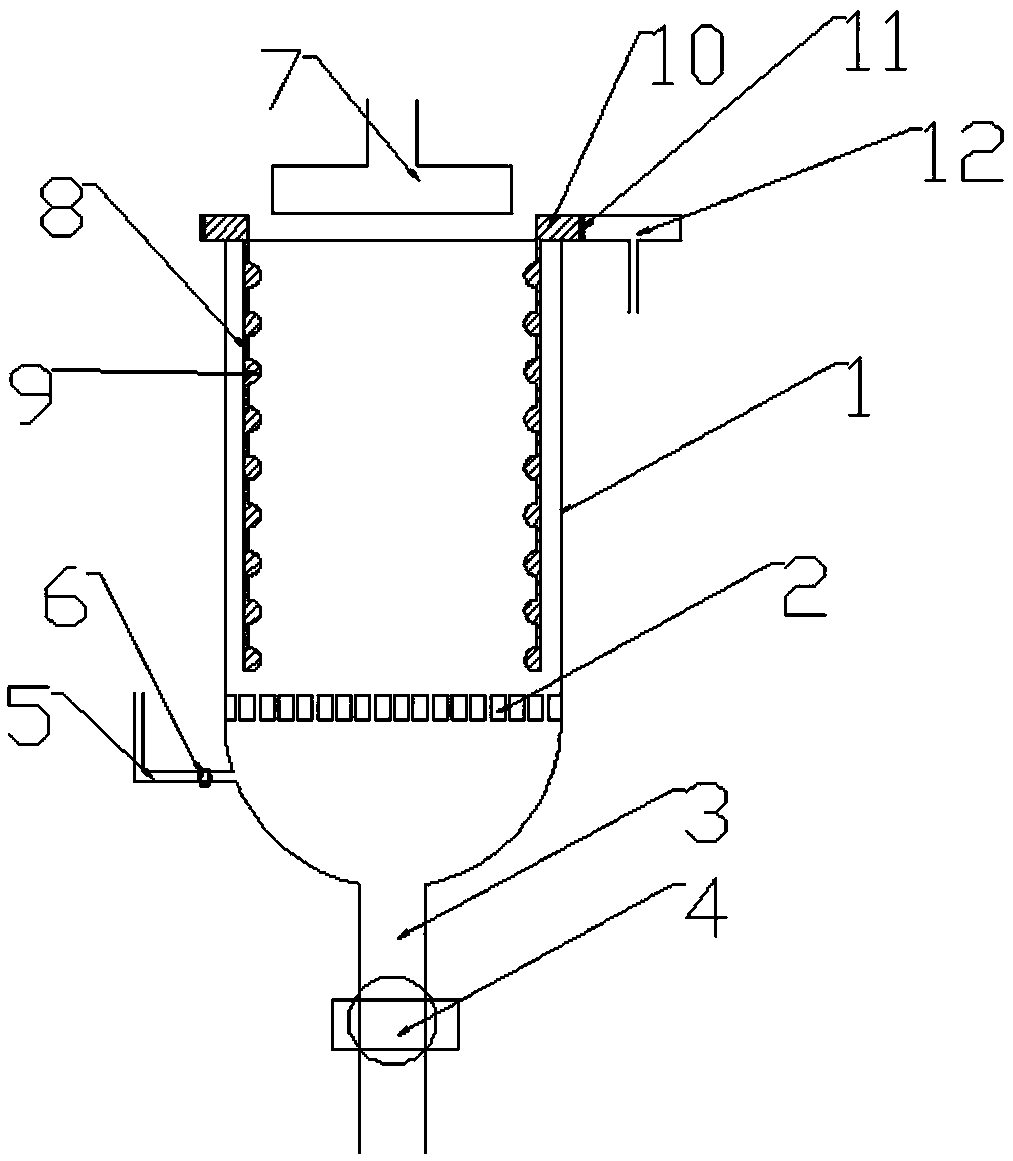

Method for manufacturing display panel, display panel and display device

ActiveUS20190101781A1Thermal degradationImprove conductivity uniformityLiquid crystal compositionsCarbon compoundsColor filmDisplay device

A method for manufacturing a display panel, a display panel and a display device are provided. The method for manufacturing a display panel includes: mixing a liquid crystal material and a spacer preparation material, and injecting them between an array substrate and a color filter substrate which are assembled; performing a UV irradiation on the assembled array substrate and the color film substrate with ultraviolet rays by using a mask plate to polymerize the spacer preparation material to form spacers, the spacers connecting the array substrate and the color film substrate.

Owner:BOE TECH GRP CO LTD +1

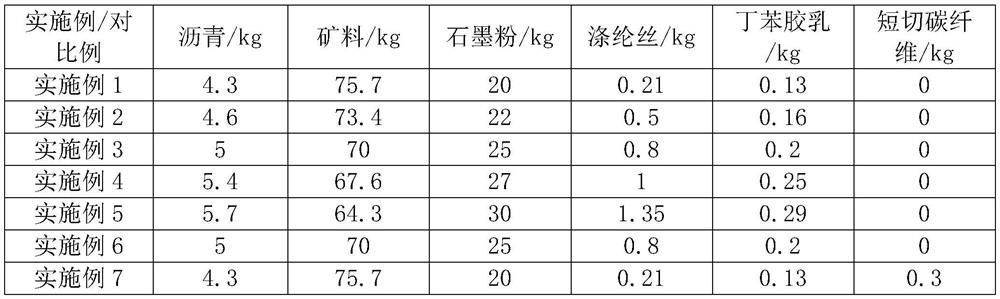

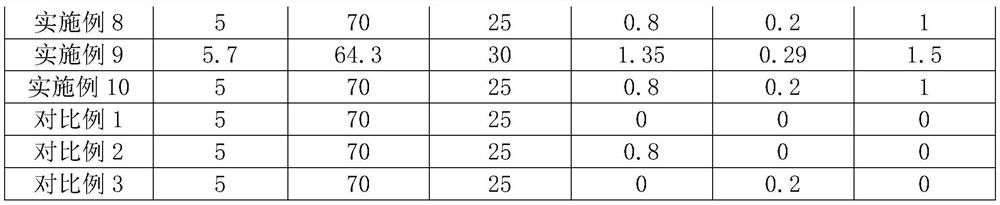

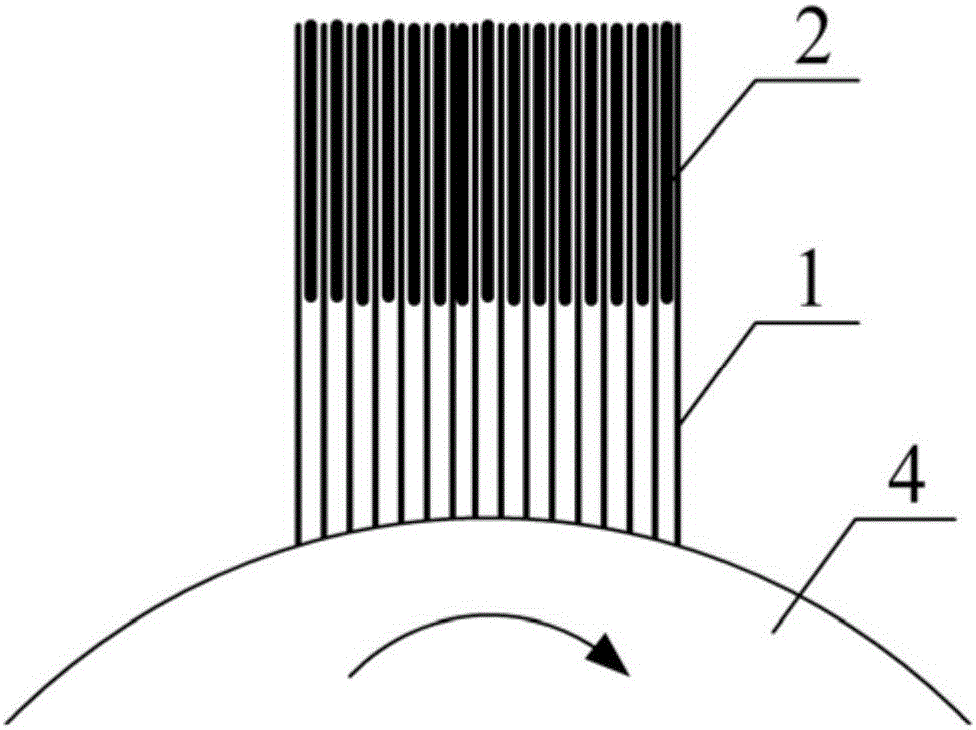

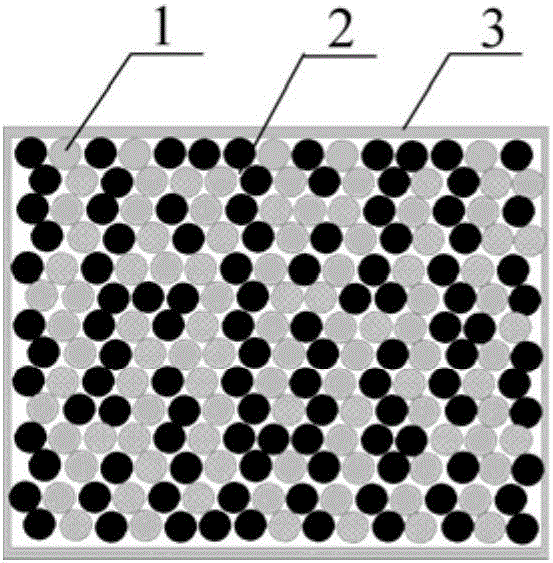

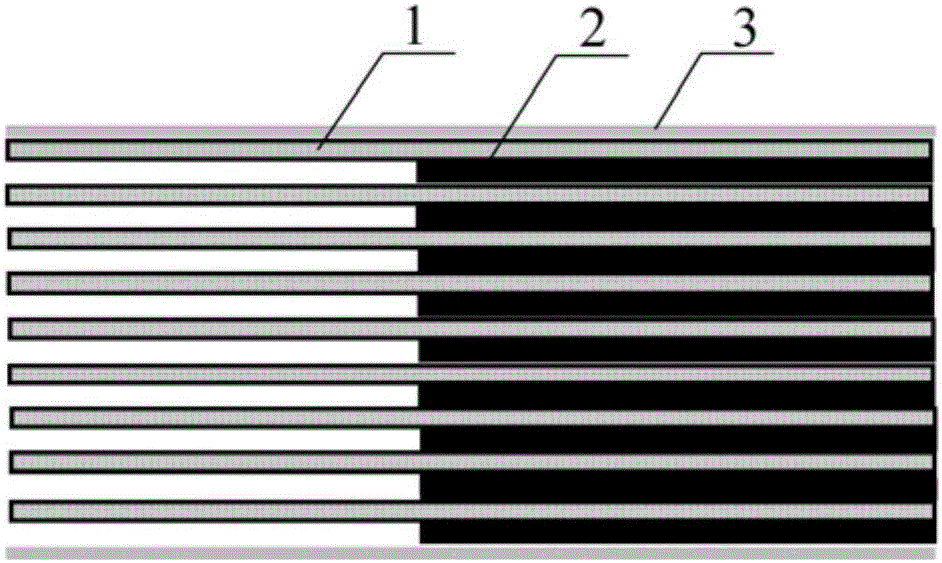

Construction method of asphalt concrete and asphalt concrete pavement

ActiveCN113772997BGood extensibilityGood dispersionIn situ pavingsSolid waste managementPolyesterRoad engineering

The present application relates to the field of road engineering, and specifically discloses a construction method of asphalt concrete and asphalt concrete pavement. An asphalt concrete comprises the following raw materials by weight: 4.3-5.7 parts of asphalt; 64.3-75.7 parts of mineral material; 20-30 parts of graphite powder; 0.21-1.35 parts of polyester yarn; A construction method for asphalt concrete pavement, comprising the following steps: S1, preparing asphalt concrete; S2, cleaning and leveling the roadbed, paving and rolling the asphalt concrete; S3, maintaining. The asphalt concrete of the present application has the advantages of improving the water stability of the asphalt concrete after adding graphite powder, and reducing the damage of the asphalt concrete pavement caused by the infiltration of snow water.

Owner:SHANDONG LUQIAO CONSTR

A kind of metal fiber electric brush and preparation method thereof

ActiveCN104332795BCompact structureImprove current carrying capacityRotary current collectorBrushes manufactureMetallurgyMetal fibers

The invention discloses a metal fiber brush and a preparation method thereof. The brush comprises conductive metal fibers and filling metal fibers. The length of the filling metal fibers is shorter than the length of the conductive metal fibers, one end of each filling metal fiber is flush with one end of each conductive metal fiber, the conductive metal fibers and the filling metal fibers are uniformly arranged along a length direction, and after compacting molding, the filling metal fibers and the conductive metal fibers are integrally wrapped by a metal wrapping sleeve. The preparation method comprises: winding the conductive metal fibers and the filling metal fibers together on a wire reel to form a metal fiber ring; and cutting the metal fiber ring, after the compacting molding, immersing one end of the metal fiber ring in an acid solution or aqueous alkali, and dissolving the filling metal fibers to obtain the metal fiber brush. The metal fiber brush is compact and reasonable in structure, high in fiber bonding strength, simple in preparation process, large in current carrying capability, small in contact resistance, long in service life, fast in sliding speed, small in heat productivity and small in debris amount, is suitable for industrial production, can replace a conventional carbon brush or a conventional metal fiber brush, and can satisfy the application demand for a large-power high-precision conductive slip ring.

Owner:CENT SOUTH UNIV

Carbon-based conductive ink filler and preparation method thereof

The invention discloses a carbon-based conductive ink filler and a preparation method thereof. The carbon-based conductive ink filler comprises the following components by mass percentage: 40-50% of epoxy resin, 20-30% of graphene, 10-20% of conductive carbon black, 2-5% of a hyperdispersant and 8-15% of a mixed solvent, and the total mass percentage is 100%. According to the invention, graphene and conductive carbon black are used as conductive additives, the graphene and the conductive carbon black are compounded with the epoxy resin under the action of the hyperdispersant and the compositesolvent, so that the graphene in the prepared carbon-based conductive ink filler can enable the conductivity of the ink to be better on one hand, and on the other hand, the conductive performance complementation is realized by compounding the conductive carbon black and the graphene, thereby achieving the most ideal conductive effect; and the conductive ink can be better dispersed in the connecting resin, so that the conductive uniformity of the conductive ink is improved.

Owner:SUZHOU ZHONGYA INK

Method for manufacturing display panel, display panel and display device

ActiveUS10871682B2Improve conductivity uniformityImprove the display effectLiquid crystal compositionsCarbon compoundsPhoto irradiationColor film

A method for manufacturing a display panel, a display panel and a display device are provided. The method for manufacturing a display panel includes: mixing a liquid crystal material and a spacer preparation material, and injecting them between an array substrate and a color filter substrate which are assembled; performing a UV irradiation on the assembled array substrate and the color film substrate with ultraviolet rays by using a mask plate to polymerize the spacer preparation material to form spacers, the spacers connecting the array substrate and the color film substrate.

Owner:BOE TECH GRP CO LTD +1

A kind of conductive microfiber leather and its preparation method and equipment

ActiveCN108130720BEvenly combinedImprove bindingFibre typesNon-woven fabricsProduction lineChemical Linkage

The invention discloses conductive microfiber leather as well as a preparation method and equipment thereof. The preparation method of the conductive microfiber leather comprises the following steps:1) activating a microfiber staple fiber; 2) impregnating graphene oxide; 3) preparing sulfur-graphene / microfiber staple fiber; 4) impregnating a faintly alkaline strong reducing agent; 5) desulfurating and reducing; 6) washing; 7) preparing a non-woven fabric; 8) preparing the microfiber leather. In addition to the conventional production line for preparing the microfiber leather through the microfiber staple fiber, the equipment further comprises an opener and a microfiber staple fiber processing tank, the microfiber staple fiber processing tank takes the shape of a funnel bucket, a porous filter plate is arranged at the bottom of a funnel, and a cake shaped extruding machine is arranged at the top of the funnel. The graphene is bounded with the microfiber staple fiber through the chemical bond, the binding force is firm, the graphene is more evenly distributed on the surface of the microfiber staple fiber, the electrical conductivity of the synthesized conductive microfiber leather is better, and the tinting strength of the synthesized conductive microfiber leather is strong.

Owner:湖北鑫楚达革业股份有限公司

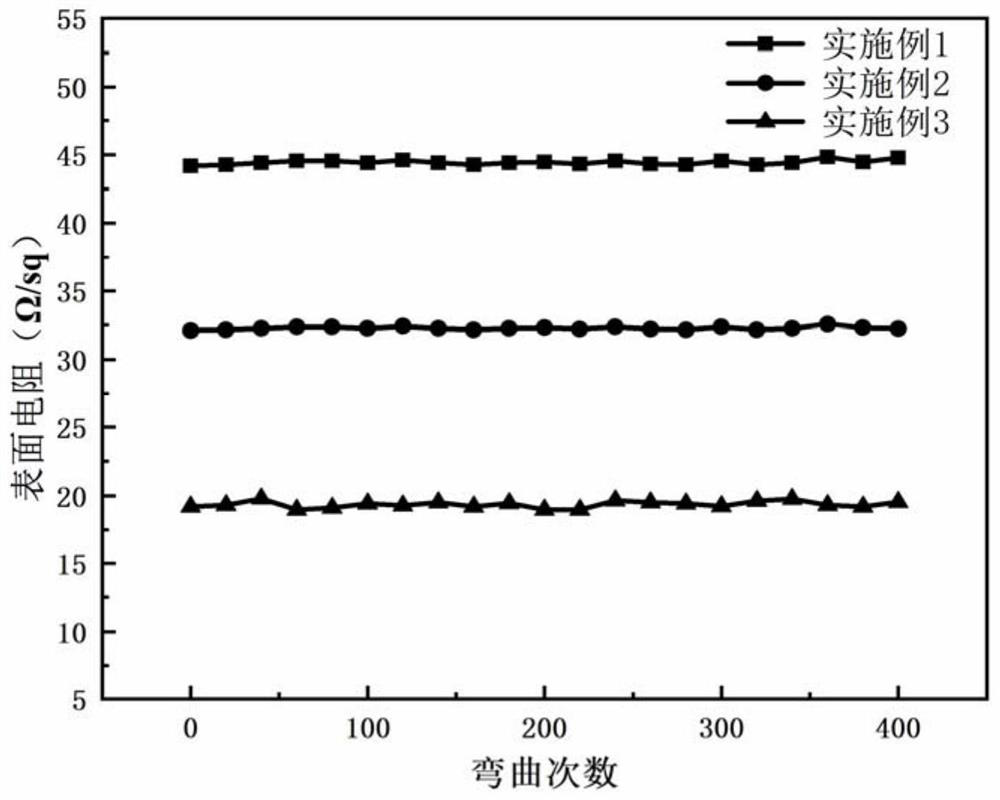

A kind of flexible transparent conductive film and preparation method thereof

ActiveCN109727706BControl thicknessImprove conductivity uniformityConductive layers on insulating-supportsMetal/alloy conductorsPolymer scienceAlcohol

The invention discloses a flexible transparent conductive film and a preparation method thereof. The preparation method comprises the steps of adding silver nanowires into absolute ethyl alcohol, dispersing uniformly under ultrasonic assistance, applying the dispersion liquid to the surface of an organic filter membrane by means of vacuum filtration, then drying the filter membrane to obtain a filter membrane A with uniformly dispersed silver nanowires; (2) uniformly mixing liquid silicone rubber and a corresponding cross-linking agent, then uniformly dispersing the mixture on the surface of ametal film by means of spin coating, and then carrying out solidification to obtain a film B; (3) tightly fitting the side having the silver nanowires of the filter membrane A and the side having thesolidified silicone rubber of the film B, carrying out pressure treatment, and transferring the silver nanowires on the filter membrane to the surface of the silicone rubber film; and (4) soaking thesample obtained in the step (3) into a dilute acid solution, and enabling the metal film on the surface of the silicone rubber film to be completely dissolved so as to obtain the flexible transparentconductive film. The ultra-thin flexible transparent conductive film prepared according to the invention has uniform conductivity and good flexibility.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

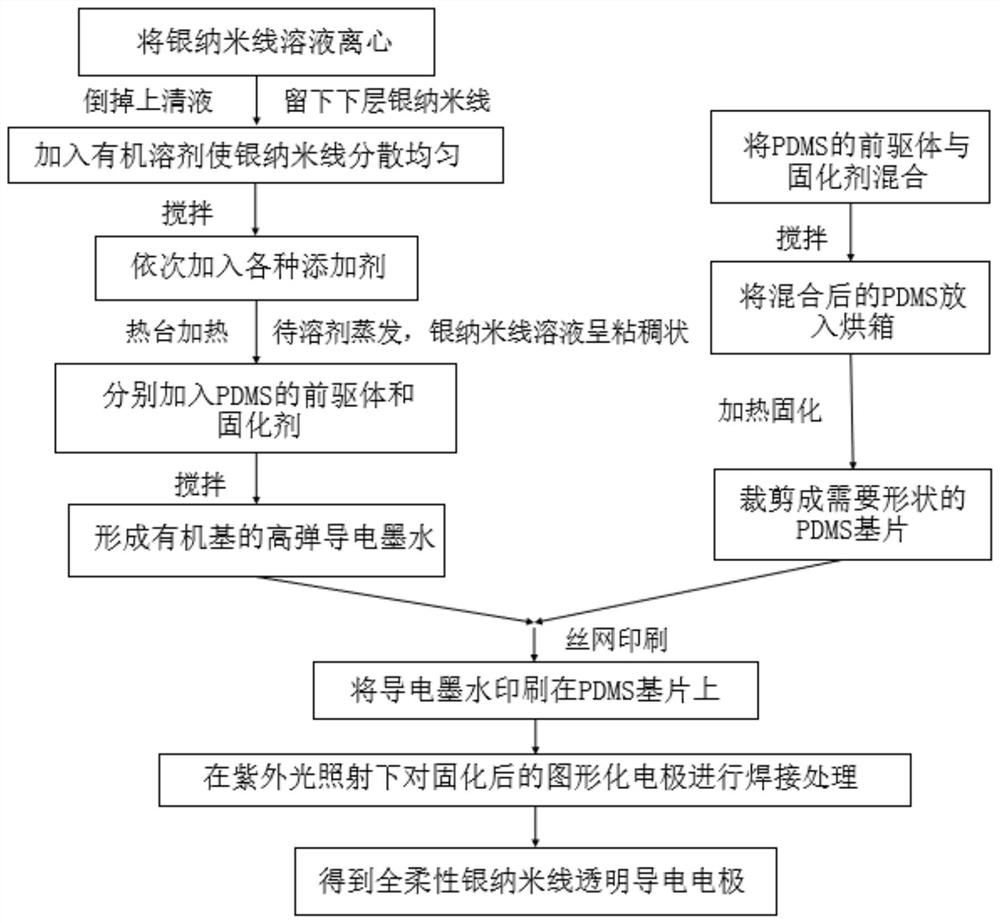

Preparation method of full-flexible printable patterned electrode

ActiveCN113773545AGood dispersionImprove conductivity uniformityApparatus for manufacturing conducting/semi-conducting layersInksDevice materialActive agent

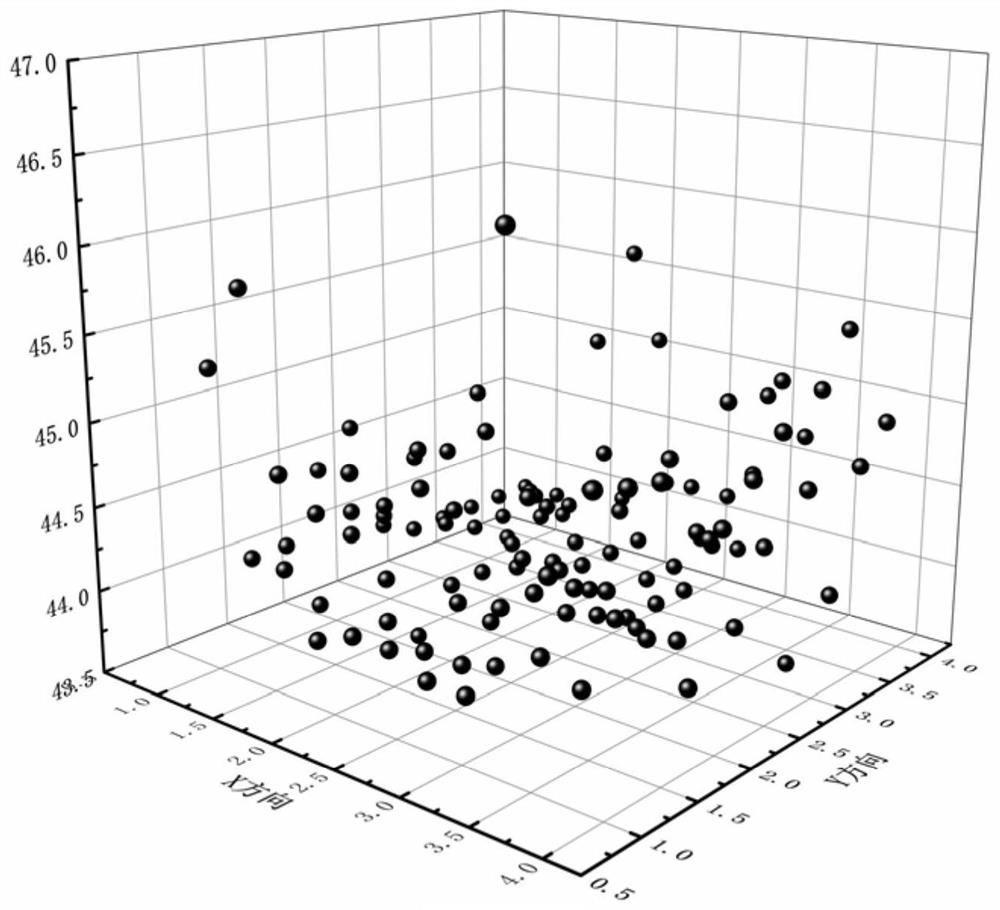

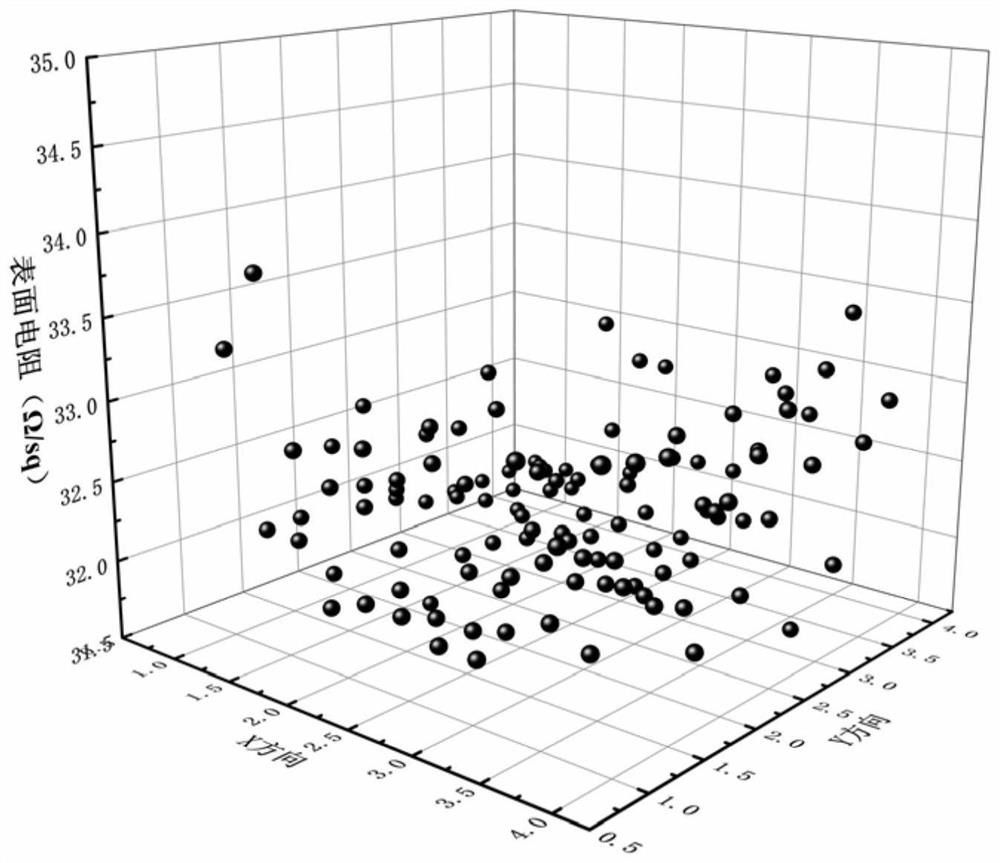

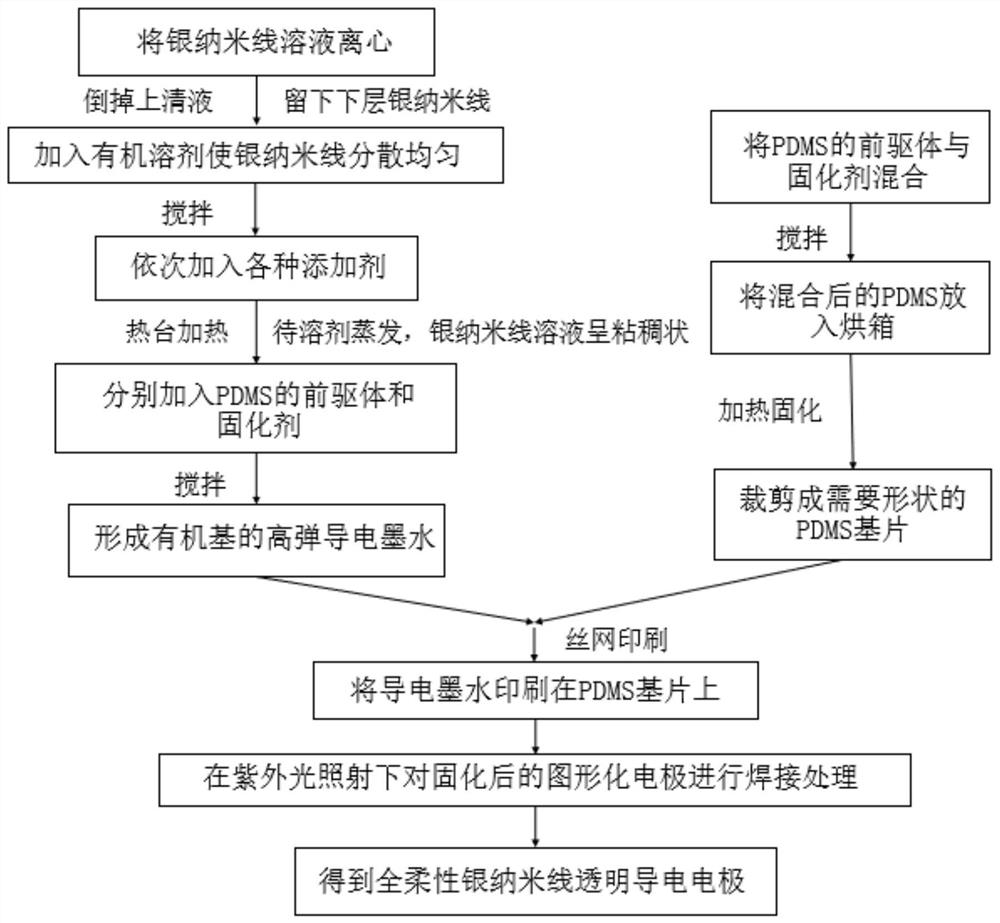

The invention discloses a preparation method of a full-flexible printable patterned electrode, and mainly solves the problems of poor conductivity and low resolution of a flexible electrode in the prior art. According to the scheme, the method comprises the following steps: heating and curing a PDMS precursor and a curing agent, and cutting into a PDMS substrate; adding an organic solvent into silver nanowire, sequentially adding a thickening agent, a surfactant, a leveling agent, a dispersing agent, an ultraviolet finishing agent and a defoaming agent, and heating; after the solvent is evaporated until the silver nanowire solution is viscous, respectively adding a PDMS precursor and a curing agent to form organic-based high-elastic conductive ink; taking the conductive ink, placing on a screen printing plate, and carrying out patterned electrode printing and curing; and carrying out welding treatment on the patterned electrode under ultraviolet irradiation to obtain the full-flexible transparent conductive electrode. According to the invention, the conductive uniformity and the resolution ratio of the electrode are improved, the structural and performance stability under the flexible deformation condition is improved, and the method can be used for manufacturing displays and semiconductor devices.

Owner:XIDIAN UNIV

A fully flexible and printable electrode preparation method

ActiveCN113773545BGood dispersionImprove conductivity uniformityApparatus for manufacturing conducting/semi-conducting layersInksDevice materialActive agent

The invention discloses a fully flexible and printable patterned electrode preparation method, which mainly solves the problems of poor electrical conductivity and low resolution of flexible electrodes in the prior art. The scheme is: heating and curing the PDMS precursor and curing agent, and cutting into PDMS substrates; adding organic solvent to silver nanowires, and adding thickener, surfactant, leveling agent, dispersant, and ultraviolet finishing agent in sequence , defoaming agent, and heating; wait for the solvent to evaporate until the silver nanowire solution is viscous, then add PDMS precursor and curing agent respectively to form an organic-based high-elastic conductive ink; take the conductive ink and place it on the screen. The patterned electrode is printed and cured; the patterned electrode is welded under ultraviolet light irradiation to obtain a fully flexible transparent conductive electrode. The invention improves the conductivity uniformity and resolution of the electrode, improves the structure and performance stability under the condition of flexible deformation, and can be used for the manufacture of displays and semiconductor devices.

Owner:XIDIAN UNIV

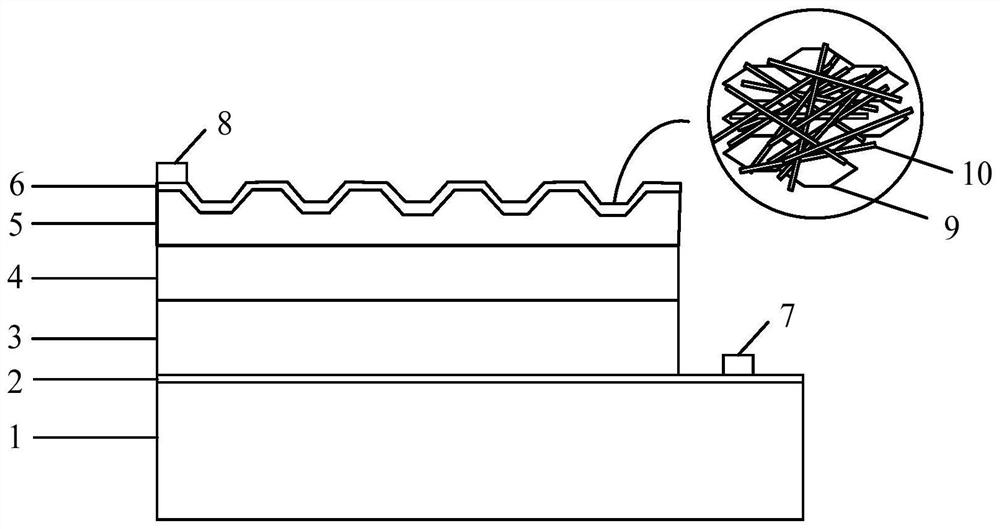

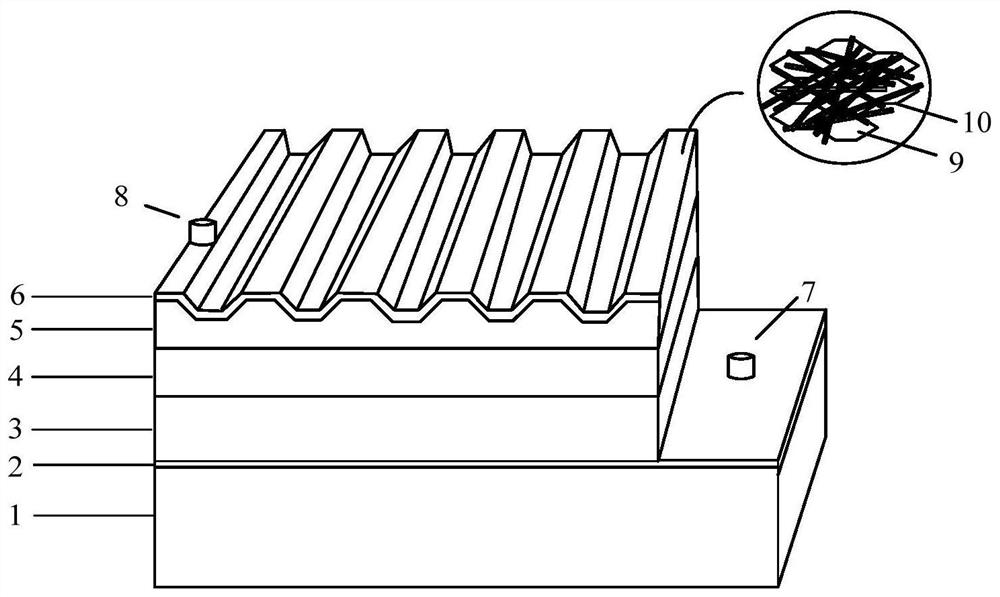

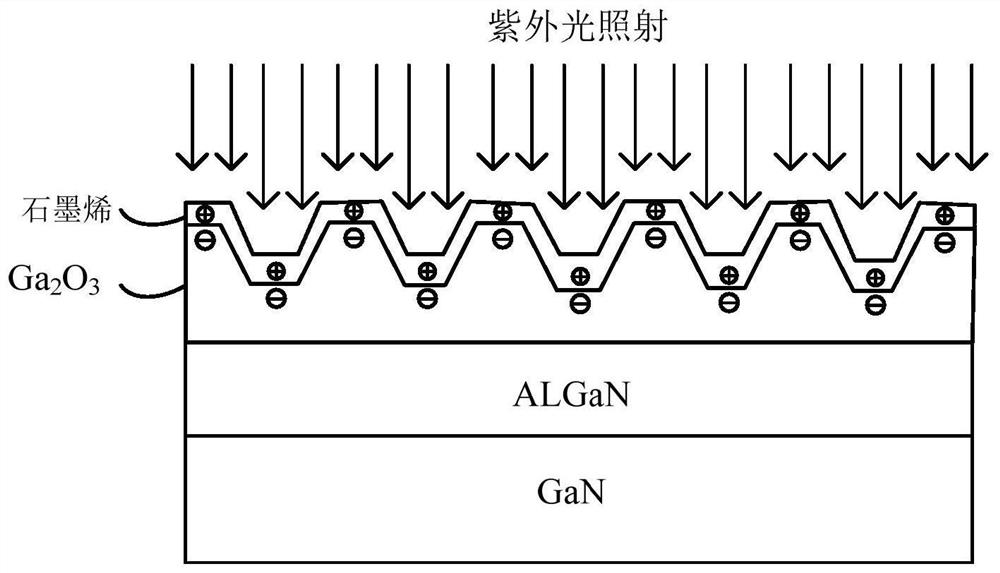

Ultraviolet band adjustable photoelectric detector with transparent conductive structure and production method of ultraviolet band adjustable photoelectric detector

InactiveCN113644148AImprove conductivity uniformityImprove growth qualityFinal product manufactureSemiconductor devicesSchottky barrierConductive materials

The invention belongs to the technical field of photoelectric detection, and discloses an ultraviolet band adjustable photoelectric detector with a transparent conductive structure and a production method of the ultraviolet band adjustable photoelectric detector. The structure of the detector comprises a detector substrate, a graphene insertion layer, a first GaN layer, an AlGaN layer, a Ga2O3 layer and a transparent conductive layer which are sequentially arranged, and electrodes are arranged on the graphene insertion layer and the transparent conductive layer. The detector has the advantages that the graphene serves as the insertion layer and is bonded with the GaN layer through a Van der Waals force, lattice constant mismatch with the sapphire substrate is greatly relieved, dislocation density is reduced, and the growth quality of the epitaxial layer is improved; and compared with a photoelectric detector prepared by a conventional GaN / AlGaN epitaxial structure, the photoelectric detector has the advantages that the ladder-shaped Ga2O3 layer is added, on one hand, the Ga2O3 layer and the transparent conductive layer form a Schottky barrier to reduce a dark current, on the other hand, the ladder-shaped Ga2O3 layer can effectively increase the light receiving area, and the light current is increased in cooperation with the high mobility characteristic of the graphene transparent conductive material.

Owner:迪优未来科技(清远)有限公司 +1

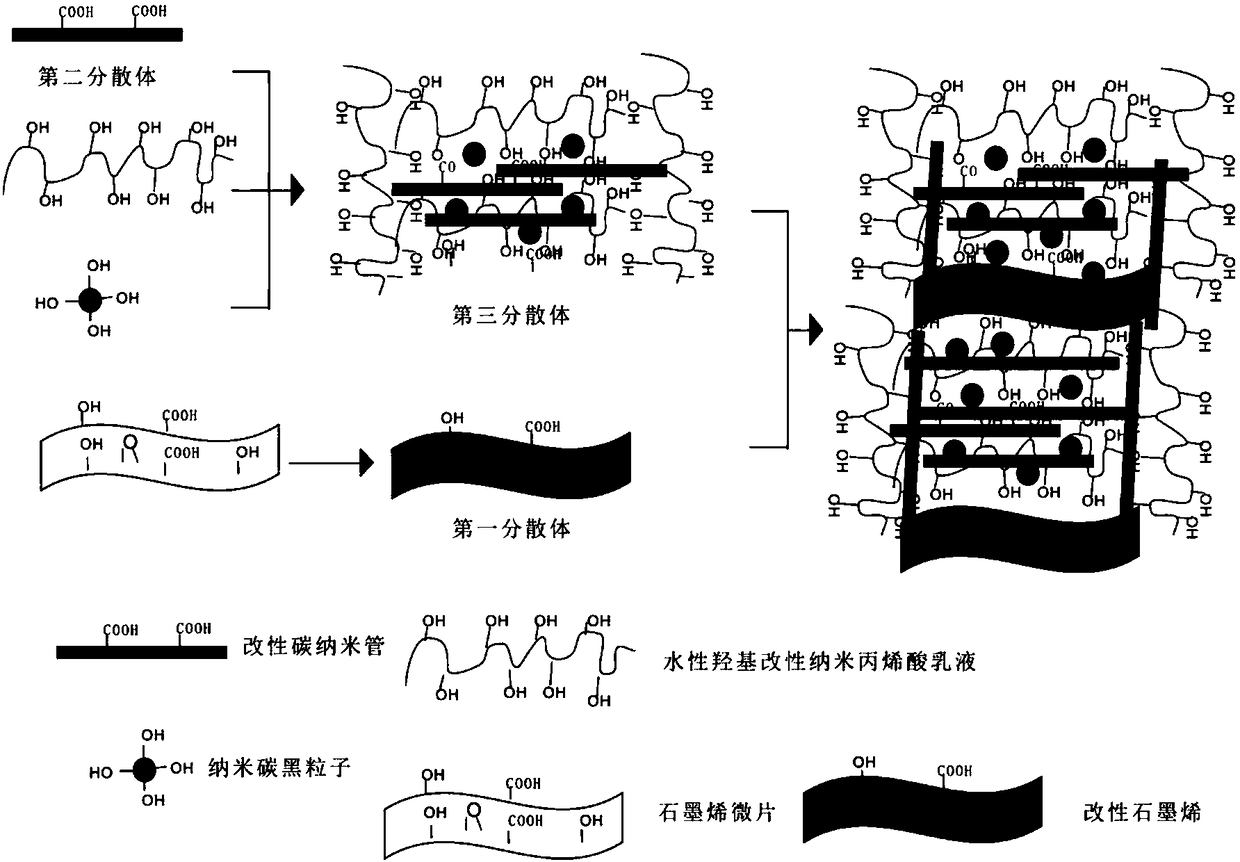

A kind of water-based graphene/carbon nanotube composite electrothermal conversion ink and its preparation method

The invention discloses water-based graphene / carbon nanotube composite electric-heating conversion printing ink and a preparation method thereof. The preparation method comprises the following steps: uniformly stirring a graphene microchip, a water-based non-ionic high-polymer dispersant and water, and then dispersing so as to obtain a first dispersion; putting one-dimensional nano-powder into inorganic strong acid, carrying out heating reflux, carrying out ultrasonic treatment, washing with water, and drying, so as to obtain a second dispersion; uniformly mixing the second dispersion with carbon black powder, a water-based anionic dispersant, sodium dodecyl benzene sulfonate, a water-based hydroxyl-modified nano-acrylic emulsion and dimethylethanolamine, and then dispersing so as to obtain a third dispersion; and mixing the first dispersion, the third dispersion and water-based resin, grinding, adding a flatting agent, a defoamer, a pH adjusting agent, a preservative and an anti-settling agent, and uniformly mixing, so as to obtain the water-based graphene / carbon nanotube composite electric-heating conversion printing ink. The invention further discloses the water-based graphene / carbon nanotube composite electric-heating conversion printing ink.

Owner:安徽华惠福科技有限公司

A kind of preparation method of mesh copper foil for lithium ion battery

ActiveCN109183033BHigh degree of automationIncrease productivityElectrode carriers/collectorsMetallic material coating processesCopper foilLithium-ion battery

The invention discloses a preparation method of a net-shaped copper foil for a lithium ion battery, belonging to the technical field of the preparation of lithium ion batteries. The preparation methodis characterized by comprising the following steps: (1) carrying out activated cleaning treatment on the surface of a copper foil; (2) pasting a sensitization dry film to the activated cleaned copperfoil, and carrying out exposure development; (3) etching the developed copper foil, and sequentially carrying out film striping and cleaning; and (4) carrying out surface passivation on the cleaned copper foil by virtue of passivation liquid, and carrying out washing and drying, so as to obtain the net-shaped copper foil. The preparation method has the beneficial effects that the requirements ona grinding mill is relatively low in requirement, a punched hole is unlikely to be deformed, no burr is formed on the surface of a through hole, the copper foil is unlikely to be worn during the striping, and the cost is relatively low; and the preparation method is used for preparing the net-shaped copper foil.

Owner:梅州市嘉应学院教育科研服务公司

Method for roasting aluminum electrolytic tank with special-shaped cathode structure

The invention relates to an aluminum electrolytic technology, more specifically relates to a preheating and roasting method for an aluminum electrolytic tank, especially provides a method for roasting the aluminum electrolytic tank with a special-shaped cathode structure. The invention solves the technical problem that the aluminum electrolytic tank with special-shaped cathode structure can be roasted by reducing the amount of a carbon material. The roasting method comprises the following steps: A, filling a basic material in a special-shaped cathode groove, wherein the basic material can not contact with anode; B, laying the carbon material on a convex plate of the special-shaped cathode, wherein the carbon material is contact with anode; C, electrifying and roasting; wherein the basic material is an electrolyte block or / and cryolite. One of the electrolyte block and cryolite can be selected, or a mixture of the electrolyte block and cryolite can be used; any proportion can be employed for mixing. The roasting method of the invention can reduce the carbon material amount, the workload for fishing, and the phenomena of overburn and chipping. The method of the invention provides an effective method for roasting the aluminum electrolytic tank.

Owner:四川启明星铝业有限责任公司

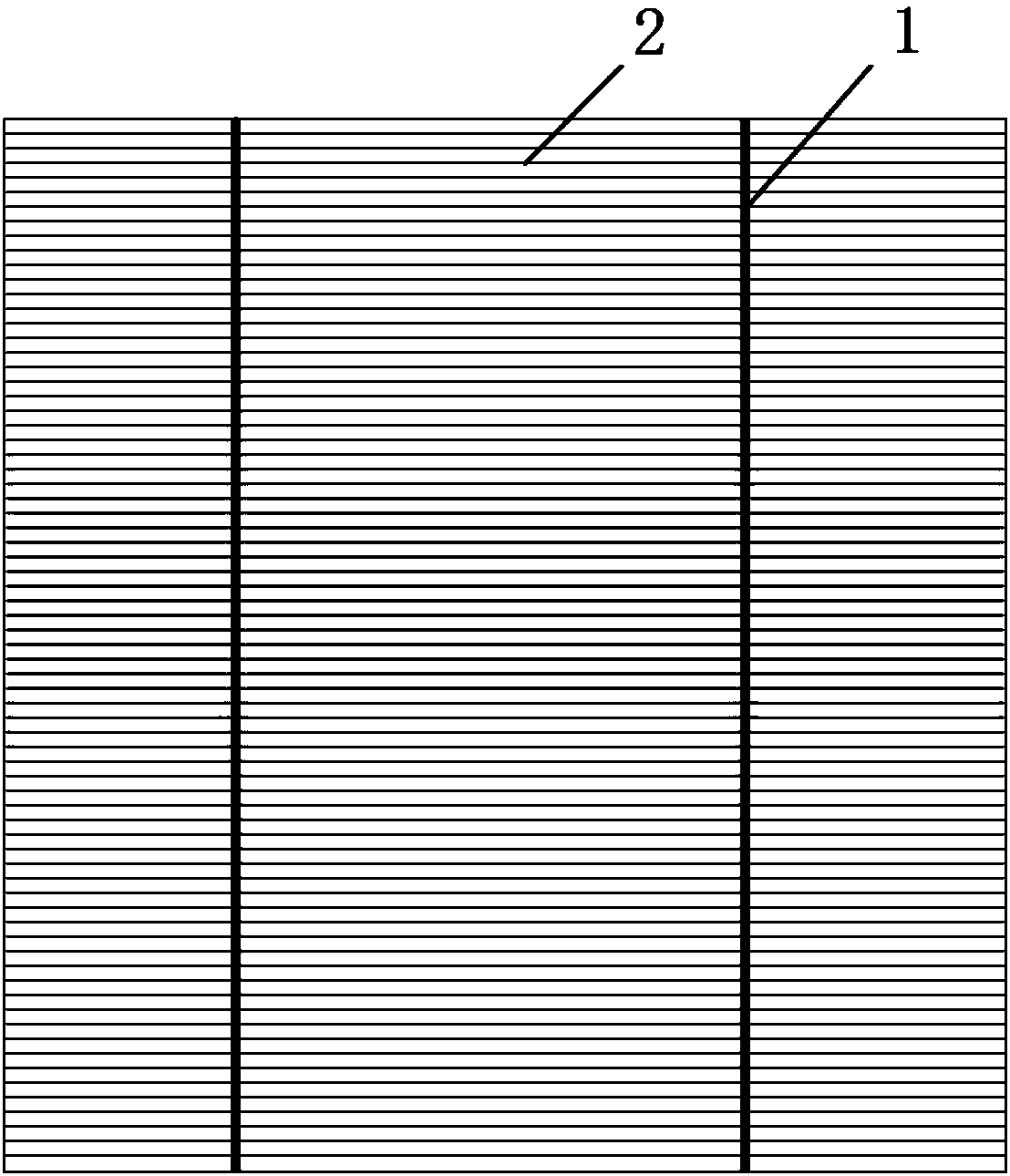

Making process of large titanium cathode roller cylinder and composite great current cathode roller

The present invention is making process of large titanium cathode roller cylinder and composite great current cathode roller. The making process includes the steps of: heating ends of titanium plate and molding to form flanges of certain height; winding the titanium plate into cylinder and butt welding the formed flanges; heating the weld seam, forging and rolling the weld seam, and heat treatment the whole titanium cylinder. The composite great current cathode roller with the titanium cylinder has main shaft inside the cylinder, conducting wheel, copper conducting plate, and steel-copper cylinder assembled together. The titanium cylinder has low cost and high quality, and the composite great current cathode roller has homogeneous current, no overheat and long service life.

Owner:宝钛特种金属有限公司

Copper compound carbon fiber material and preparation method and application thereof

ActiveCN111850649AImprove dispersion uniformityImprove conductivity uniformitySingle bars/rods/wires/strips conductorsFlexible cablesFiberCarbon fibers

The invention provides a copper compound carbon fiber material and a preparation method and application thereof. The copper compound carbon fiber material is prepared from the following components inpercent by mass: 50-75% of carbon fibers, 25-50% of copper and the balance of inevitable impurities. The copper compound carbon fiber material can improve the dispersing uniformity of copper in the carbon fibers by limiting proportion of the carbon fibers and copper, so that the conducting uniformity, the conductivity, the flexibility, the strength and the reliability of the copper compound carbonfiber material are improved. When the copper compound carbon fiber material is used as a high voltage ground lead material, compared with a same condition, the total mass of the ground lead is 1 / 4 ofthe copper material ground lead in a same current-carrying condition and the total mass of the high voltage ground lead is about 1 / 3-1 / 2 of that of a conventional high voltage ground lead. In addition, the copper compound carbon fiber material provided by the invention can be placed by winding and is not broken or corroded. Matched with a detachable insulating operation rod, it is convenient to carry and use in overhaul work.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +4

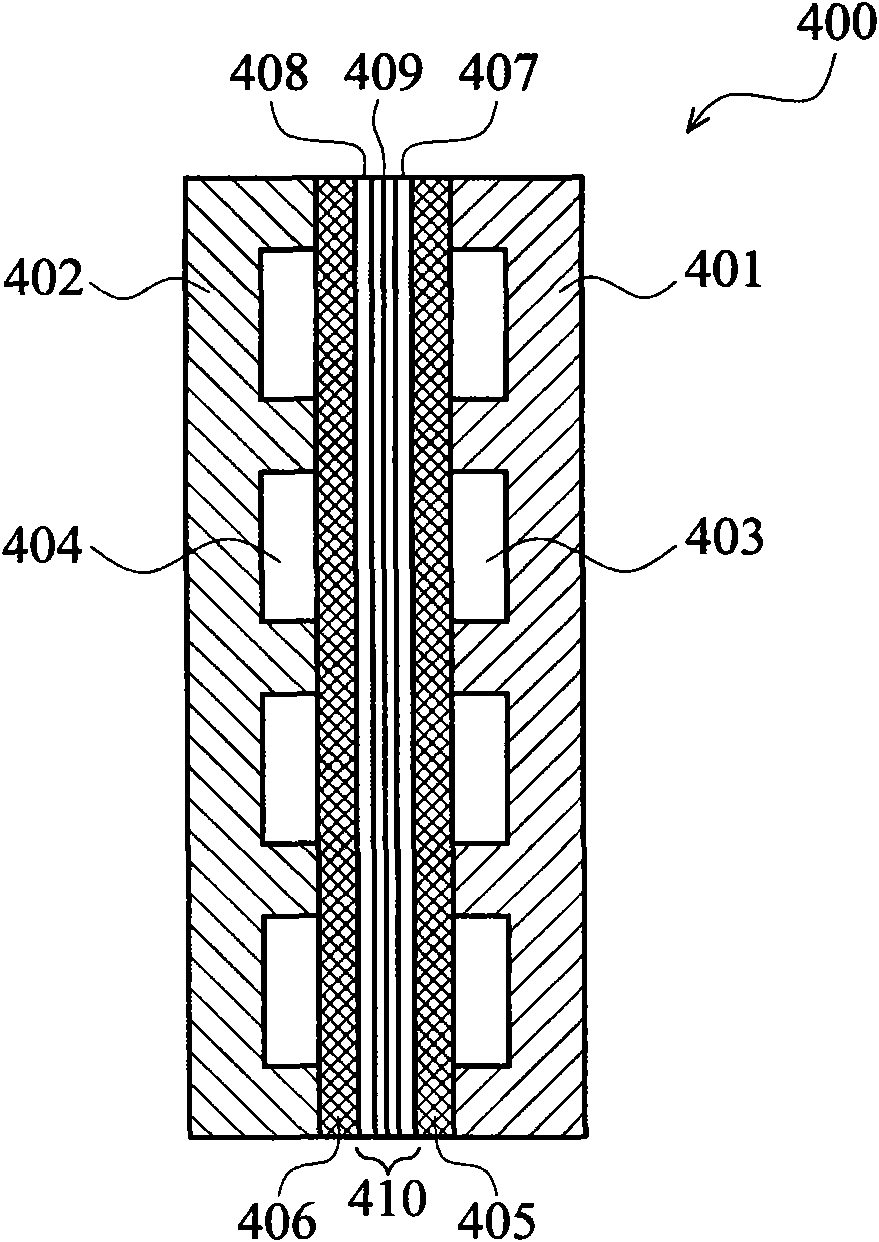

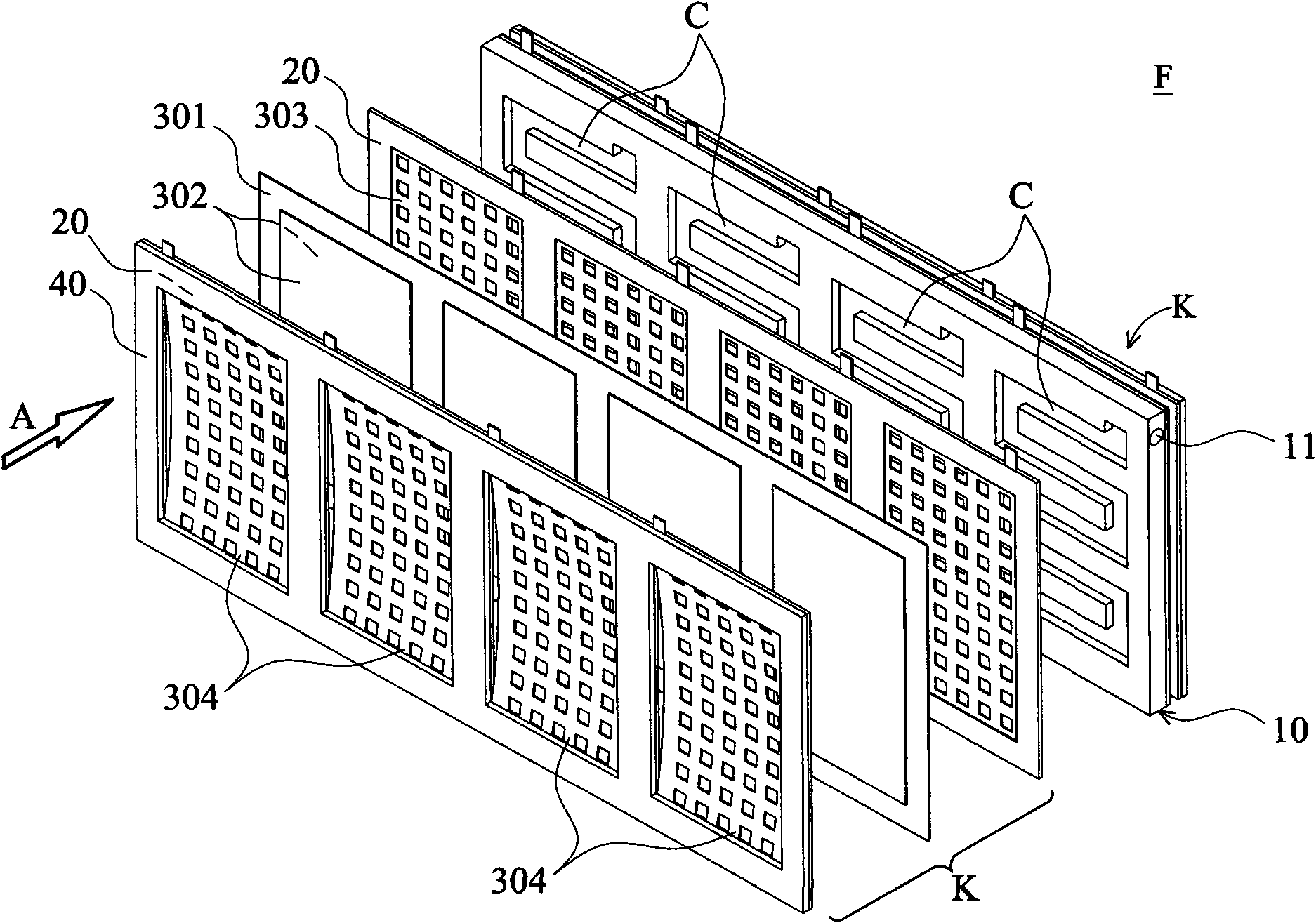

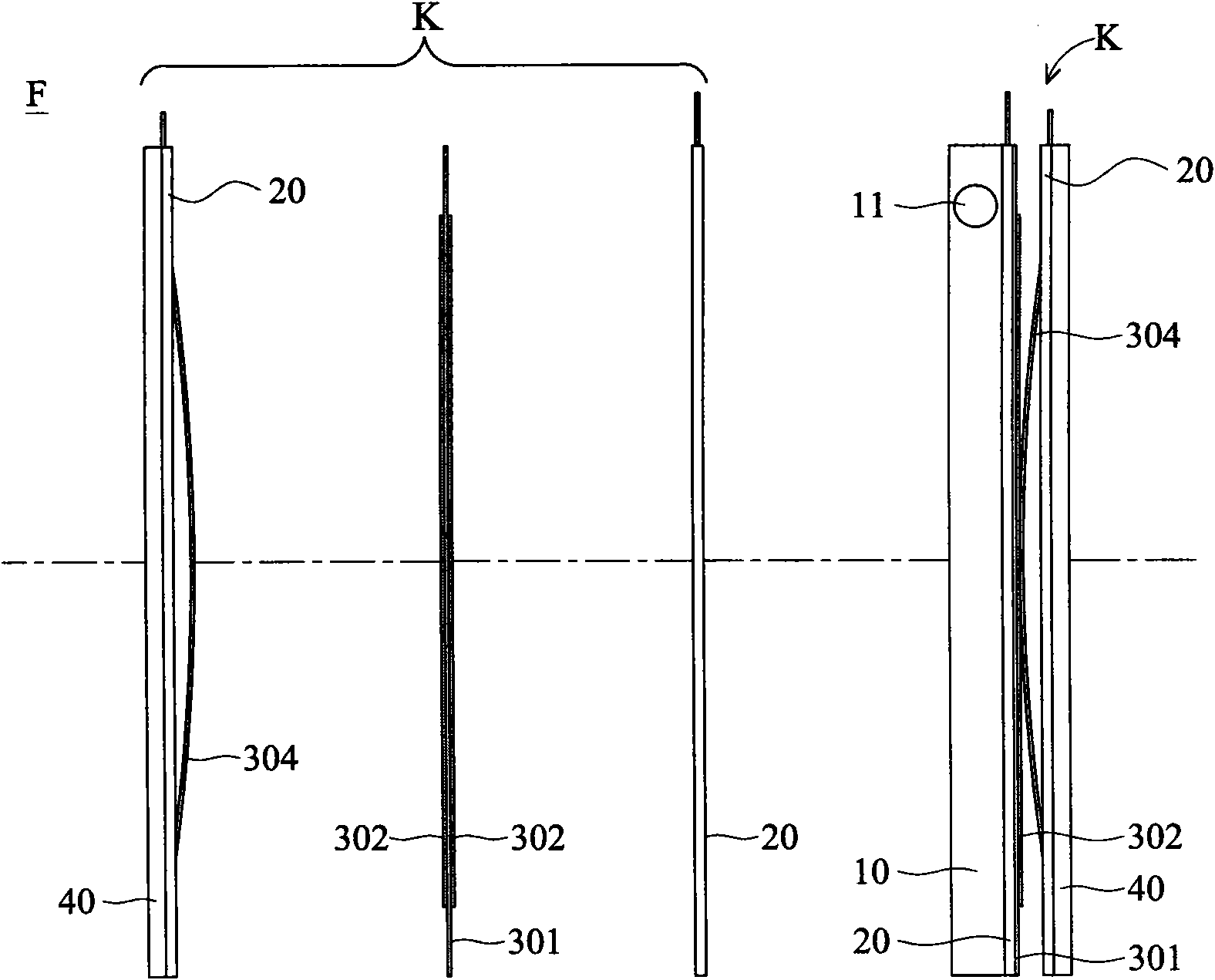

Fuel cell system and fuel cell module thereof

InactiveCN102255099AImprove conductivityImprove conductivity uniformityFuel cells groupingElectrolyte stream managementFuel cellsEngineering

A fuel cell module may include a membrane electrode assembly, two gas diffusion layers, two current collectors, two sealing members, and a fluid flow plate assembly. The two gas diffusion layers are coupled with opposite sides of the membrane electrode assembly. The current collectors are coupled with the gas diffusion layers and the sealing members. The fluid flow plate assembly is coupled with the membrane electrode assembly at a first side thereof and has a channel. At least one of the membrane electrode assembly, the gas diffusion layers, the current collectors, and the sealing members has a non-planar surface at least partially flattened when the assembly occurs.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com