Carbon fiber/gaseous carbon tube/carbon black compound conductive ink and preparation method thereof

A composite conductive and carbon fiber technology, applied in ink, household utensils, applications, etc., can solve the problems of increased cost, short service life, power attenuation, etc., and achieve the effect of uniform resistance, high conductivity, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

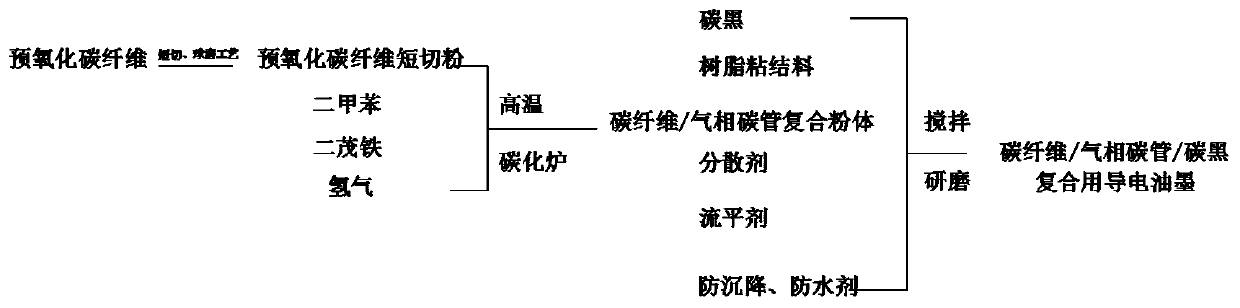

[0032] like figure 1 As shown, the preparation method of the carbon fiber / gas phase carbon tube / carbon black composite conductive ink (i.e. carbon fiber / gas phase carbon tube / carbon black composite conductive ink) of the present embodiment comprises the following steps:

[0033] 1. Preparation of pre-oxidized carbon fiber precursor powder

[0034] Put the pre-oxidized carbon fiber precursor (2kg) with a specification of 3K into a disc extrusion fiber cutting machine (3kW power), and cut the pre-oxidized carbon fiber precursor into 3mm long carbon fiber staple; then cut the carbon fiber short Transfer the fiber to a ball mill, add 50g of ferrocene, 8kg of organic solvent ethanol, and grind it with a zirconia ball with a diameter of 1mm for 0.5h, so that the ferrocene can be embedded in the surface of the carbon fiber precursor, providing a deposition point for the vapor-deposited carbon tube. Carbon tubes are deposited on the surface of micron-sized carbon fibers to provide ca...

Embodiment 2

[0040] The difference between this embodiment and the first embodiment lies in that the particle size of the carbon fiber precursor powder is different.

[0041] Specifically, the preparation method of the carbon fiber / gas phase carbon tube / carbon black composite conductive ink of this embodiment includes the following steps:

[0042] 1. Preparation of pre-oxidized carbon fiber precursor powder

[0043] Put the pre-oxidized carbon fiber precursor (2kg) with a specification of 3K into a disc extrusion fiber cutting machine (3kW power), and cut the pre-oxidized carbon fiber precursor into 3mm long carbon fiber staple; then cut the carbon fiber short Transfer the fibers to a ball mill, add 50g of ferrocene, 8kg of organic solvent ethanol, and grind with zirconia balls with a diameter of 1mm for 0.5h; wherein, the controlled temperature of the ball mill is 20-30°C, and carbon fibers with a particle size of 50μm are obtained after ball milling and drying Raw silk powder, that is, pr...

Embodiment 3

[0050] The difference between this embodiment and the first embodiment lies in that the mass ratio of ferrocene to carbon fiber precursor powder is different.

[0051] Specifically, the preparation method of the carbon fiber / gas phase carbon tube / carbon black composite conductive ink of this embodiment includes the following steps:

[0052] 1. Preparation of pre-oxidized carbon fiber precursor powder

[0053] Put the pre-oxidized carbon fiber precursor (2kg) with a specification of 3K into a disc extrusion fiber cutting machine (3kW power), and cut the pre-oxidized carbon fiber precursor into 3mm long carbon fiber staple; then cut the carbon fiber short Transfer the fibers to a ball mill, add 50g of ferrocene, 8kg of organic solvent ethanol, and grind with zirconia balls with a diameter of 1mm for 0.5h; among them, the controlled temperature of the ball mill is 20-30°C, and carbon fibers with a particle size of 20μm are obtained after ball milling and drying Raw silk powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com