Patents

Literature

35results about How to "Alcohol resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh temperature decomposition agent of straws and cattle manure, and preparation and application of decomposition agent

ActiveCN108624539APromote degradationFully degradedFungiBio-organic fraction processingBacillus licheniformisDecomposition

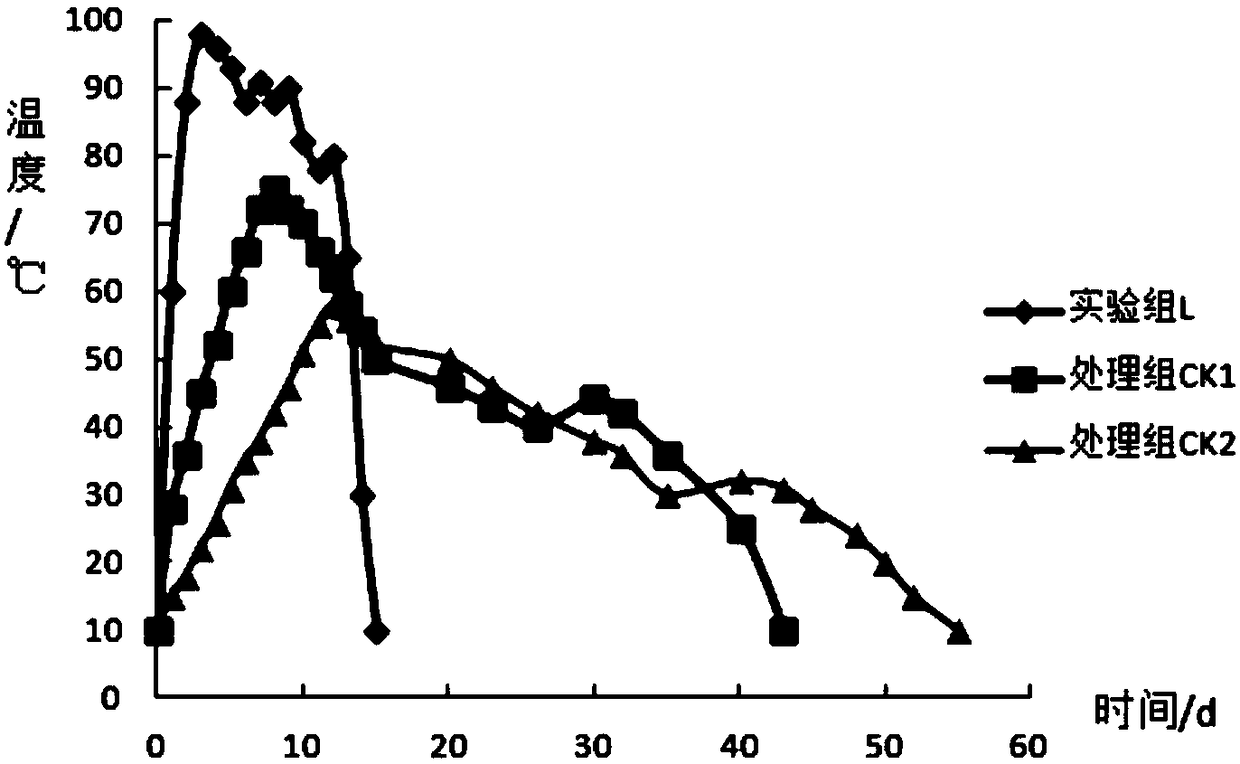

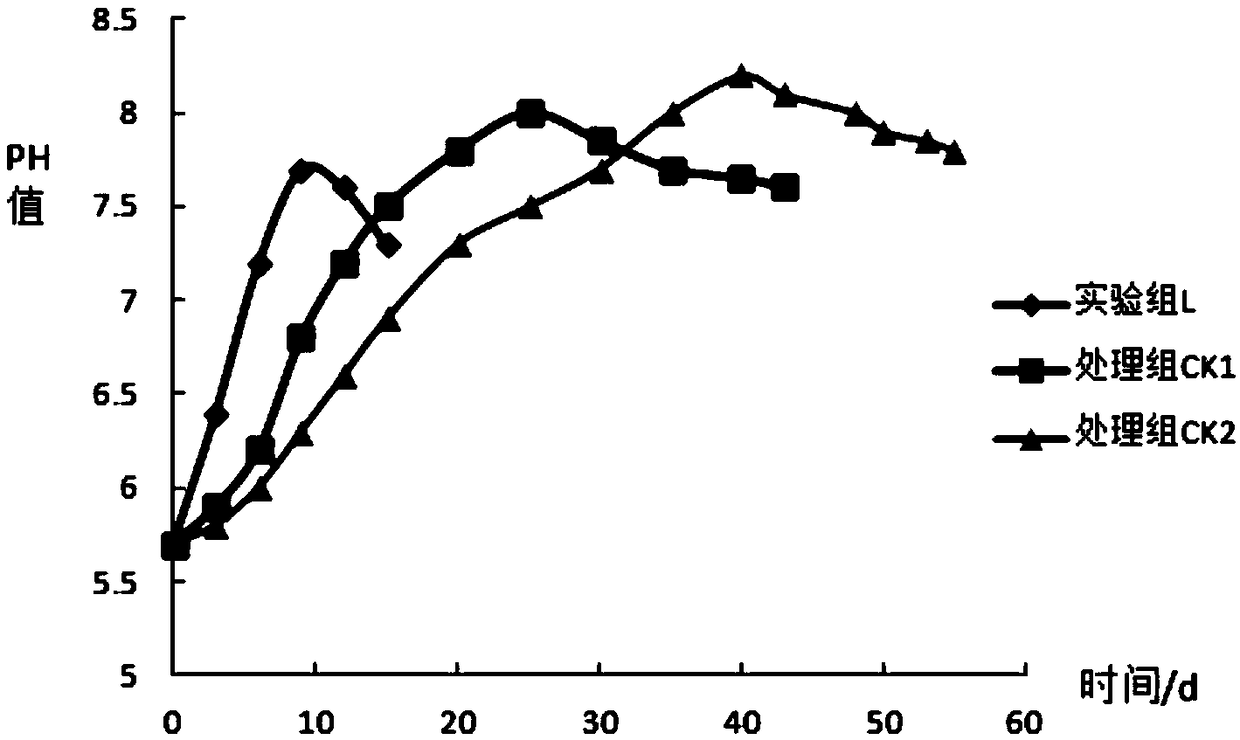

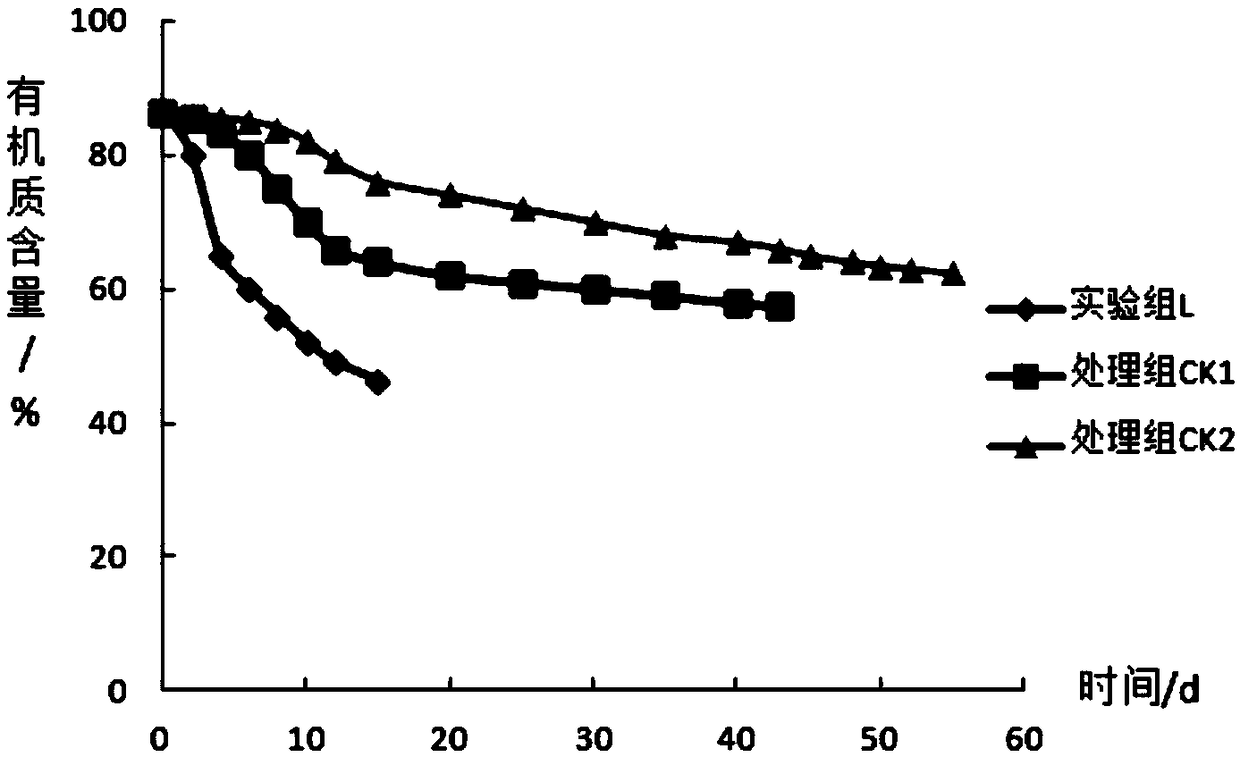

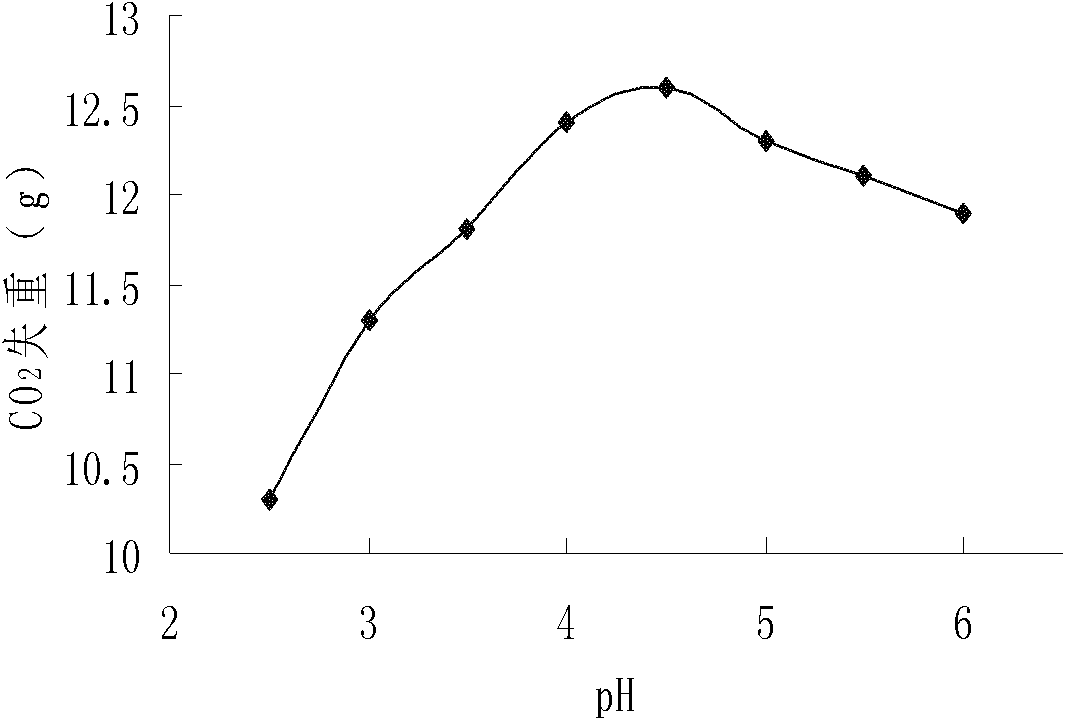

The invention discloses an ultrahigh temperature decomposition agent of straws and cattle manure, and a preparation and an application of the decomposition agent, and belongs to the field of decomposition agents. The decomposition agent is prepared by mixed fermentation and drying of the straw, the cattle manure and a complex decomposition inoculant, wherein the complex decomposition inoculant comprises 1-10 parts of thermophilic bacterium inoculant, 1-6 parts of bacillus licheniformis inoculant, 1-6 parts of aspergillus oryzae inoculant, 1-6 parts of lactobacillus plantarum inoculant, 1-6 parts of thermoactinomyces sacchari, and 1-6 parts of cold-proof brevibacterium inoculant. The decomposition agent, a composting method and the application of the decomposition agent solve the problems of slow temperature rise during composting and decomposition, low fermentation temperature, long fermentation time, incomplete decomposition, poor compost quality and the like in the fermentation of the existing complex inoculant, and the decomposition agent is quick in temperature rise during the composting and the decomposition, quick in heating-up, high in fermentation temperature, short in fermentation time, more thorough in decomposition and higher in quality.

Owner:河北木美土里科技有限公司

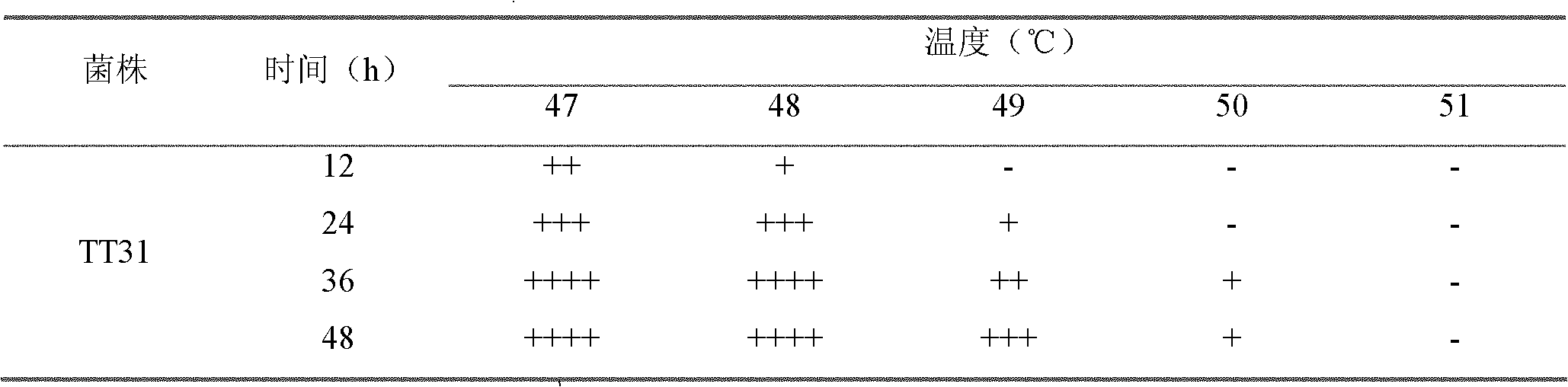

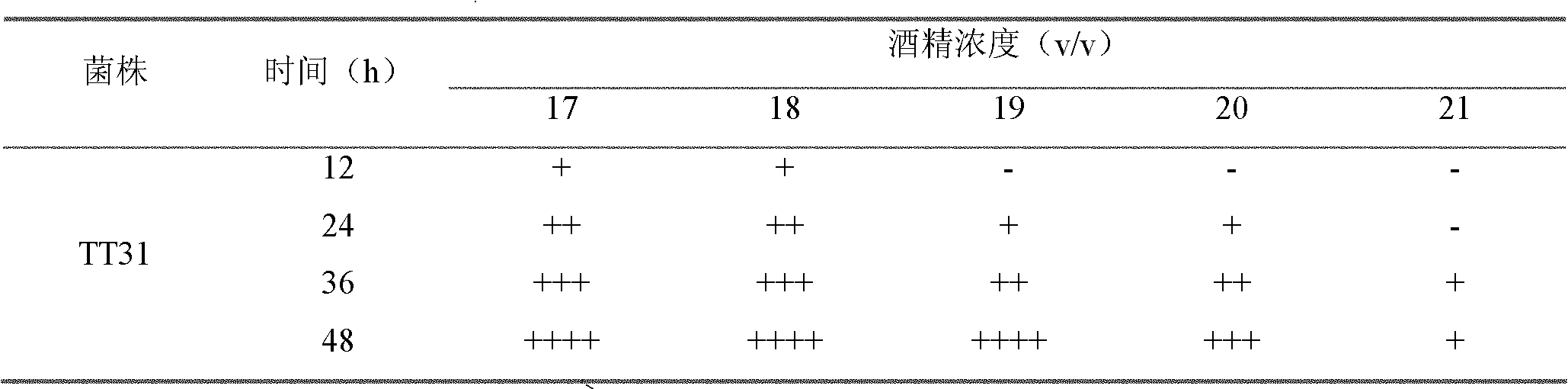

Multi-resistant high-yield alcohol yeast mutant strain TT31 and screening method thereof

InactiveCN102154138AIncrease formation rateHigh regeneration rateFungiHybrid cell preparationTriphenyltetrazolium chlorideSucrose

The invention relates to a multi-resistant high-yield alcohol yeast mutant strain TT31 and a screening method thereof. A genome reorganizing technology is used for screening high temperature-resistant, alcohol-resistant and acidity-resistant high-yield alcohol yeast mutagenic strain. The method comprises the following steps of: mutating a three-strain yeast strain by ultraviolet; selecting a ten yeast mutant strain which have three resistance and are higher in alcohol yield by a triphenyltetrazolium chloride (TTC) method at a first-level screening, a dieulafoy pipe fermentation method at a second-level screening, and a bottle shaking fermentation method at a third-level screening; preparing protoplast of the ten yeast mutant strains; and reorganizing genome at thee turns to finally obtain the yeast mutant strain TT31 which has higher improvemrnt on temperature resistance, alcohol resistance and acidity resistance. Under the condition of 35 DEG C, the mutant strain is fermented for 72h with alcohol by taking sucrose as a carbon source, and the alcohol yield reaches 101.9g / L.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

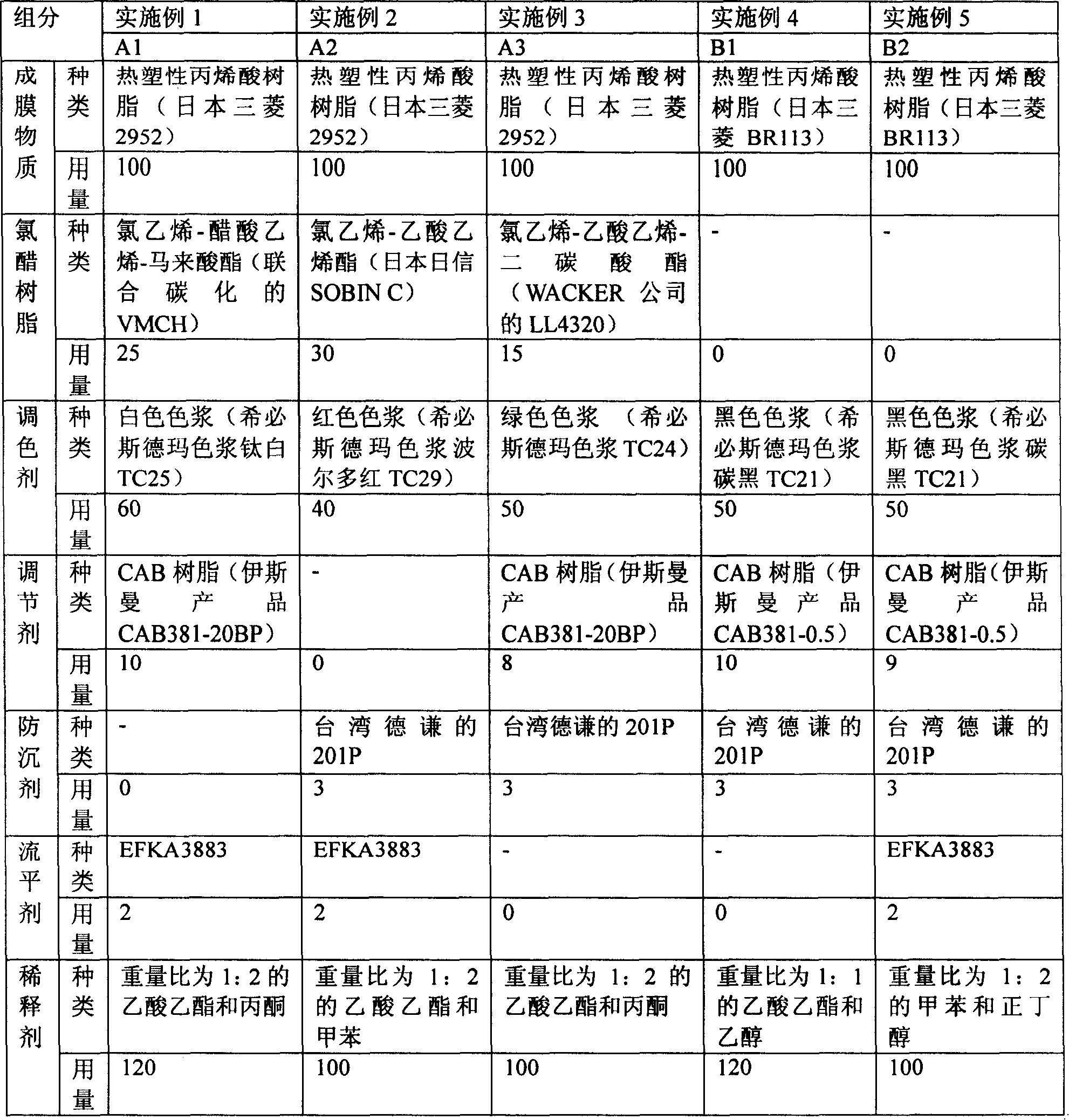

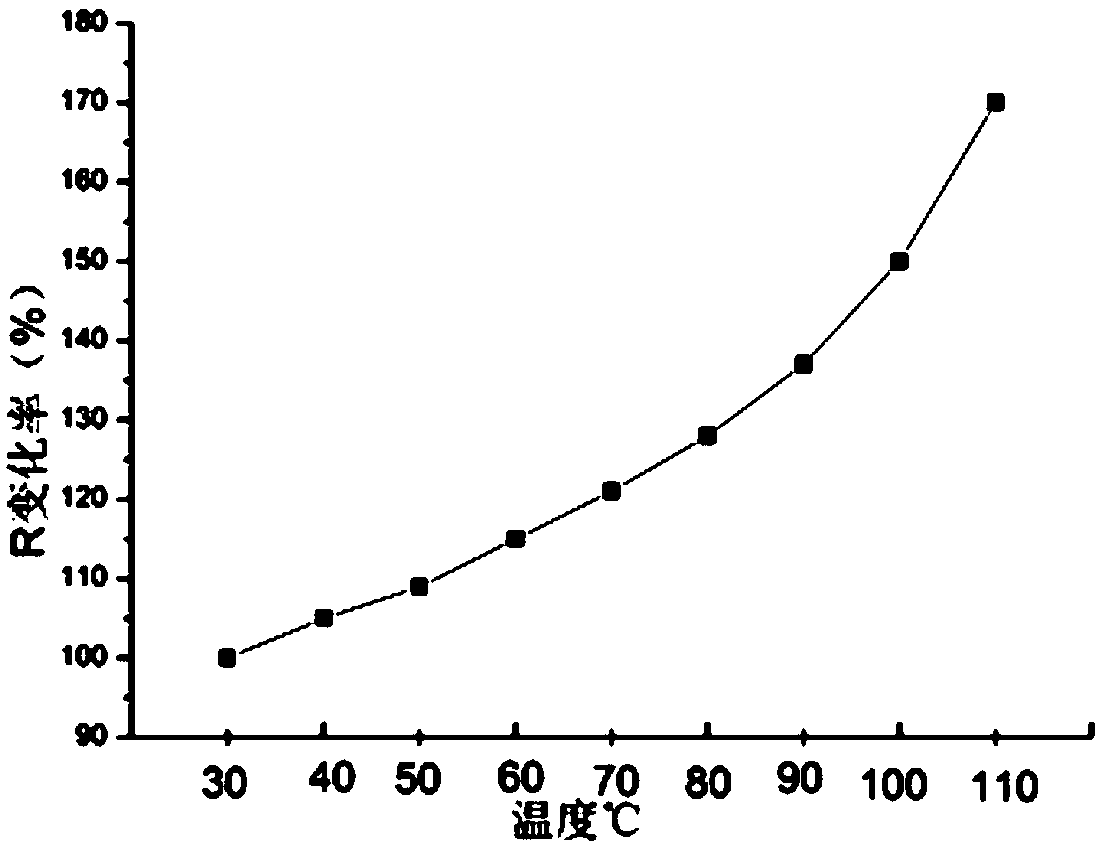

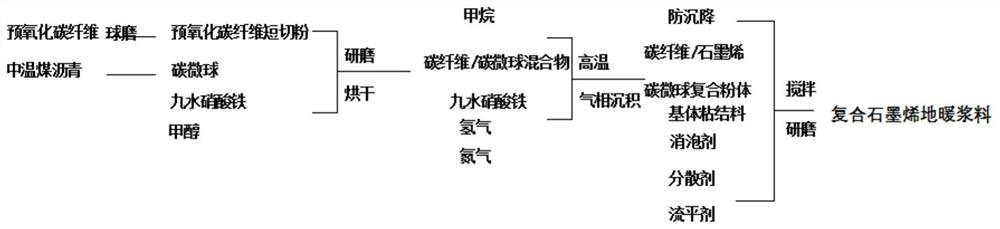

Multi-layer coating product and method for producing the same

InactiveCN101195287AIncrease productivityAlcohol resistantLayered productsPretreated surfacesEngineeringLaser intensity

A product with multi-layer coverings comprises a base material and multi-layer coverings which are disposed on the surface of the base material. The multi-layer coverings sequentially comprises a base covering and a superficial covering from the inner to exterior, the base covering and the superficial covering has alcohol resistance and are different in color, wherein the multi-layer coverings also comprise a middle covering which is disposed between the base covering and the superficial covering and which has no alcohol resistance. The invention further provides the process for preparing the product with multi-layer coverings. The middle covering of the product with multi-layer coverings provided by the invention have no alcohol resistance. When the middle covering and the superficial covering of a portion which needs light transmission are removed by radium engrave, the laser intensity is enabled to be in the range that the laser intensity is higher than the needed laser intensity which can completely engrave the superficial covering and is lower than the laser intensity which can influence the base covering, then the time used to adjust the laser intensity and used to wash is reduced, thereby increasing the working efficiency of the product with multi-layer coverings.

Owner:BYD CO LTD

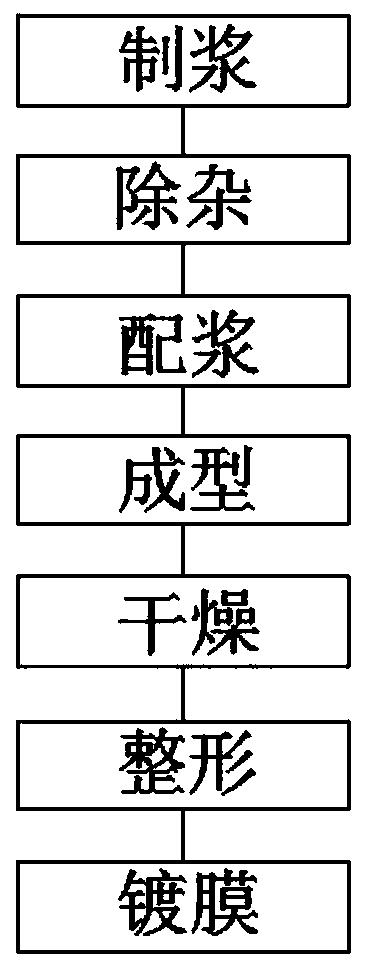

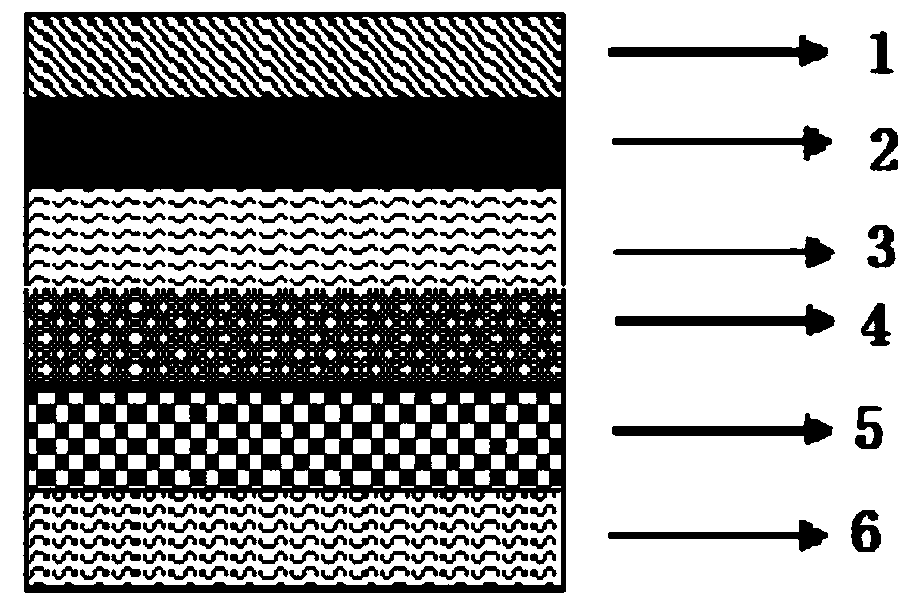

Preparation method of floor-heating electric heating plate

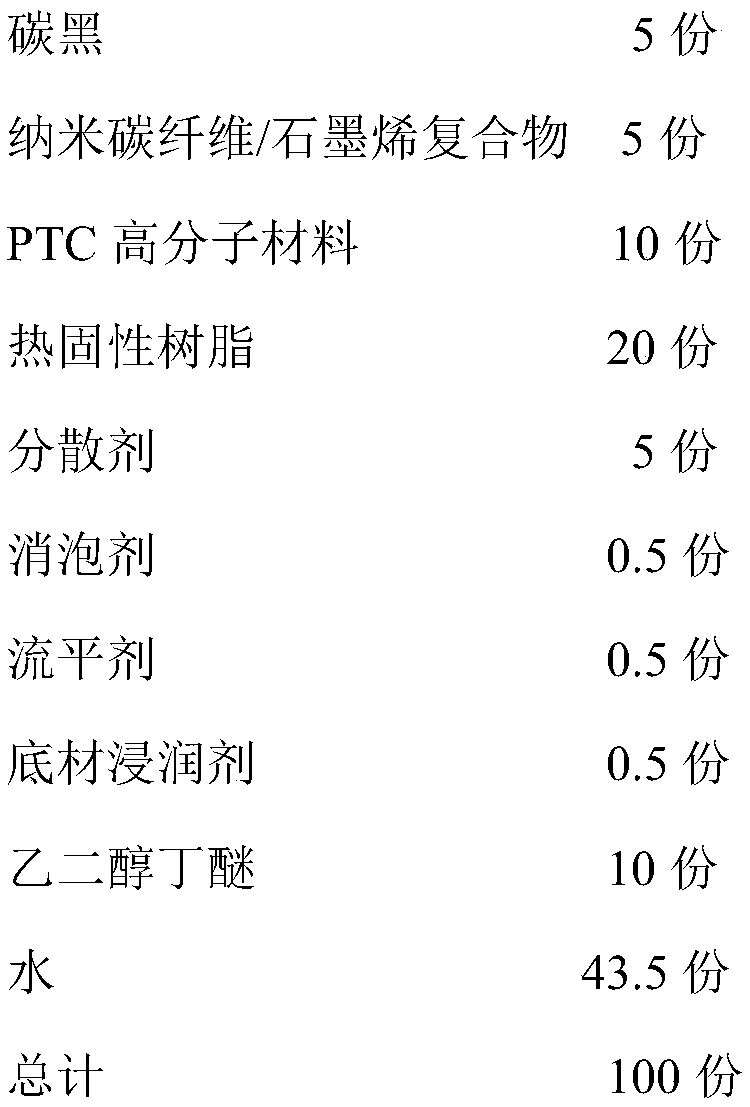

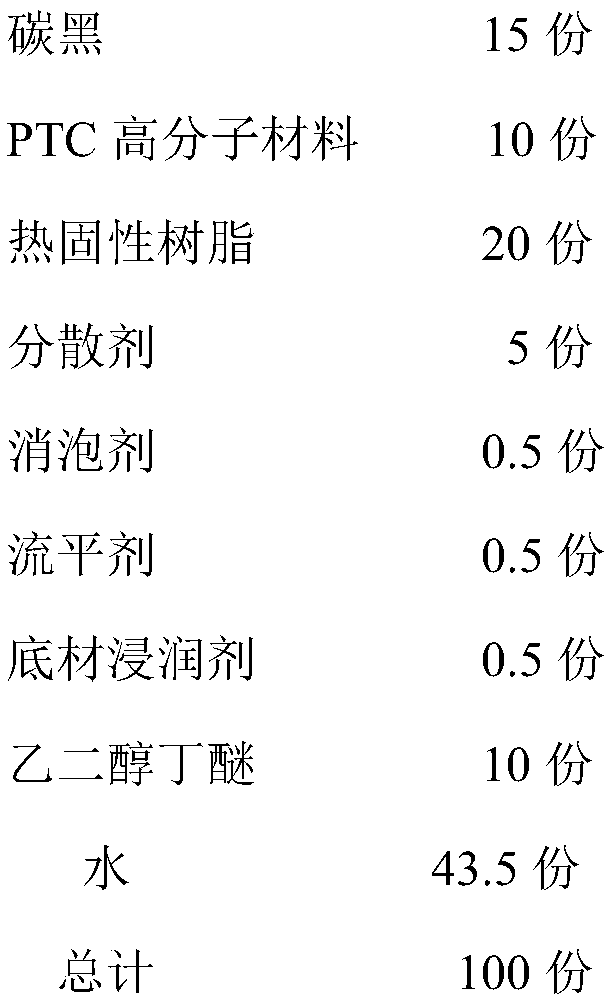

InactiveCN109280425AImprove adhesionImprove conductivityInksHeating element materialsFiberCarbon fibers

The invention discloses a preparation method of a floor-heating electric heating plate. The method comprises the following steps: (1) preparing gas-phase nano carbon fiber / graphene; (2) preparing gas-phase nano carbon fiber / graphene positive temperature coefficient (PTC) conductive ink; and (3) preparing the floor-heating electric heating plate. The PTC conductive ink is prepared by mixing the following components in parts by mass: 5 parts of carbon black, 5 parts of a gas-phase nano carbon fiber / graphene compound, 10 parts of a PTC polymer material, 20 parts of thermosetting resin, 5 parts ofa dispersing agent, 0.5 part of a defoaming agent, 0.5 part of a flattening agent, 0.5 part of a base material sizing agent, 10 parts of 2-butoxyethanol and 43.5 parts of water. The method is simplein process and is easy to operate, and the prepared floor-heating electric heating plate solves the construction problems such as high-temperature safety, leaked current generated during laying, and the like.

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

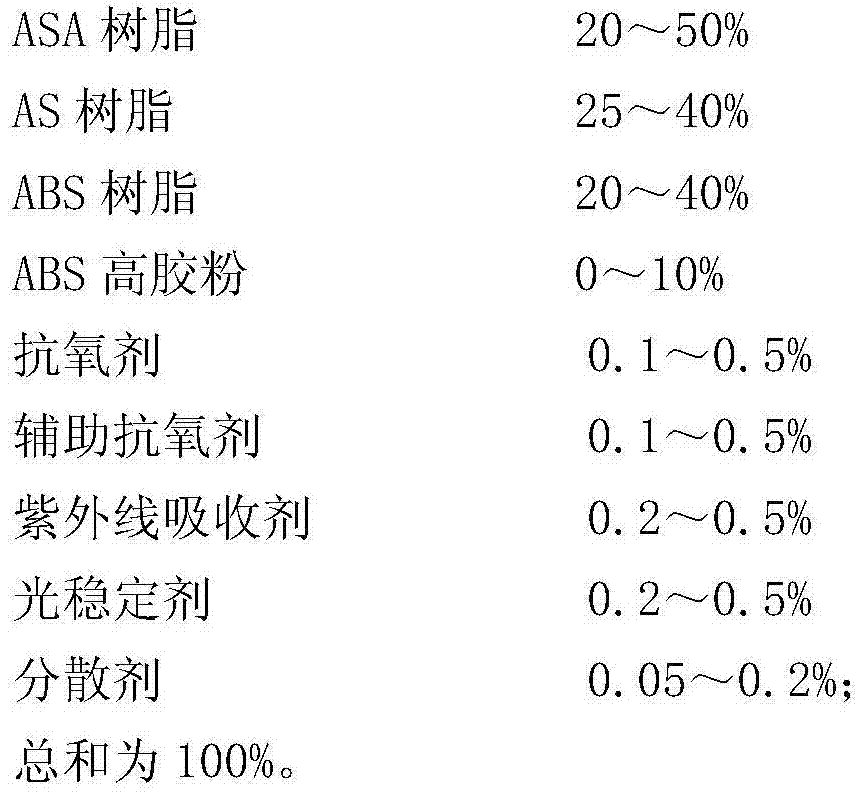

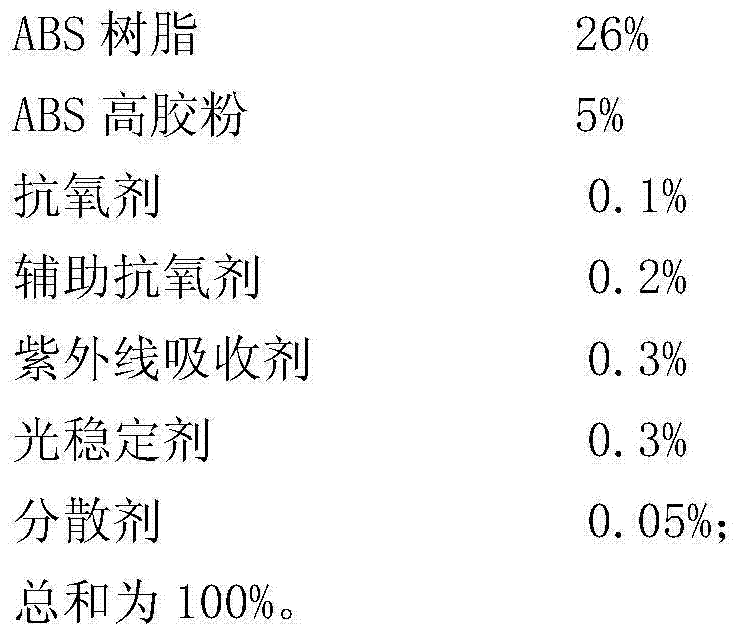

Automotive weatherproof ASA material, and preparation method and application thereof

The invention discloses an automotive weatherproof ASA material, and a preparation method and an application thereof. The material comprises the following components, by weight: 20-50% of ASA resin, 25-40% of AS resin, 20-40% of ABS resin, 0-10% of ABS high-rubber powder, 0.1-0.5% of an antioxidant, 0.1-0.5% of an auxiliary antioxidant 168, 0.2-0.5% of an ultraviolet absorber UV-770, 0.2-0.5% of a light stabilizer, and 0.05-0.2% of a dispersant. The ASA material prepared with the method provided by the invention has the advantages of low cost, good weather resistance, good processability, and the like. The ASA material provided by the invention can pass the low temperature -40 DEG C and high temperature 90 DEG C thermo-cycling test of FAW-Volkswagen with still qualified mechanical performances.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

NCVM (non conductive vacuum metallization) film coating method

InactiveCN102534474AWear-resistantAlcohol resistantVacuum evaporation coatingSputtering coatingHigh humidityEvaporation

The invention discloses an NCVM (non conductive vacuum metallization) film coating method and is characterized in that the method comprises the following steps: A, activating treatment and cleaning treatment, that is, conducting activating treatment and cleaning treatment to the surface of a product to be coated, wherein the treatment time is 60 S, the degree of vacuum in a vacuum chamber reaches 70 Pa, and the voltage output to the vacuum chamber through transformation by an electric cabinet for film coating is 3600 V; and B, putting the product to be coated in the vacuum chamber for evaporation coating of a tin film, wherein the thickness of the tin film is 30 nanometers, the degree of vacuum in the vacuum chamber reaches 75 Pa, the voltage output to the vacuum chamber through transformation by the electric cabinet for film coating is 4000 V, and the tin coating time is not more than 80 S. As the surface of the product is activated and cleaned before film coating, and the technical parameter of evaporation coating of an NCVM film is optimized, the adhesion property of the NCVM film on the product is greatly improved, and the film is endowed with the characteristics of abrasion resistance, alcohol resistance, human sweat resistance, high-temperature and high-humidity storage, and the like.

Owner:GUANGDONG ZHENHUA TECH CO LTD

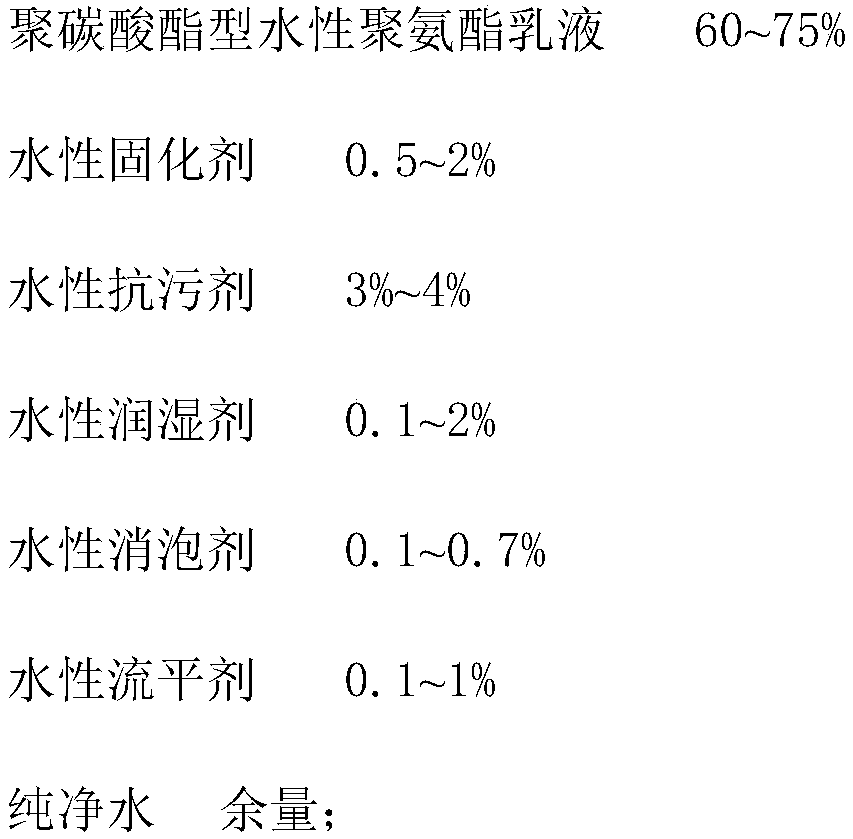

High-light anti-fouling wear-proof water-based paint special for PVC surface decoration and preparation method thereof

ActiveCN109486393AReduce usageEmission reductionAntifouling/underwater paintsPaints with biocidesCross-linkWater based

The invention discloses high-light anti-fouling wear-proof water-based paint special for PVC surface decoration and a preparation method thereof. The high-light anti-fouling wear-proof water-based paint special for the PVC surface decoration comprises polycarbonate-type waterborne polyurethane emulsion, a water-based anti-fouling agent, a water-based curing agent, a water-based wetting agent, a water-based defoaming agent, a water-based flatting agent and the like. The special paint is environment-friendly, strong in adhesive force, and capable of solving a problem that the paint is destructedby precipitation of a plasticizer of dioctyl phthalate in a printing process of a PVC base material. The paint is capable of using an amino water-based resin cross-linking agent as the curing agent,and printed in a normal temperature condition. A formed coating has good adhesion fastness, water resistance and adhesion resistance. In a follow-up pasting technology of a decoration faceplate, and through a pasting cylinder in 150-180 DEG C, the curing agent contained in the paint generates a cross-linking reaction, and finally the high-light anti-fouling wear-proof water-based coating of whichglossiness is greater than or equal to 90 degrees and hardness is greater than or equal to 2H is formed, so the characteristics of wear resistance, alcohol resistance, anti-fouling and the like are increased.

Owner:福建格林春天新材料股份有限公司

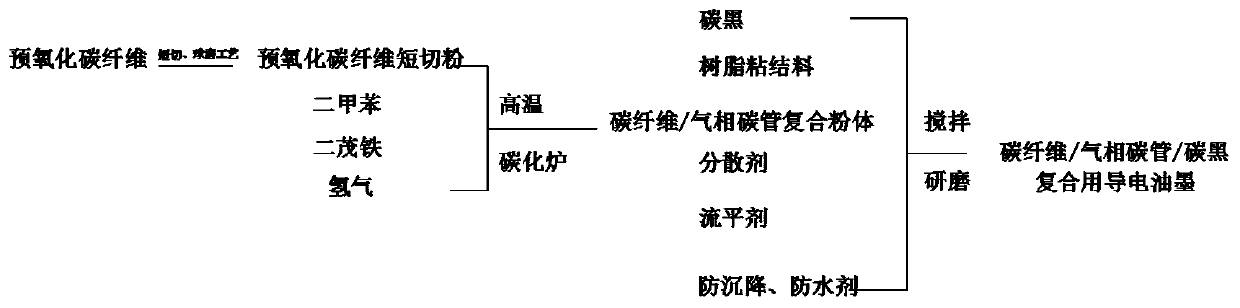

Carbon fiber/gaseous carbon tube/carbon black compound conductive ink and preparation method thereof

The invention belongs to the technical field of conductive inks and particularly relates to a carbon fiber / gaseous carbon tube / carbon black compound conductive ink and a preparation method thereof. The carbon fiber / gaseous carbon tube / carbon black compound conductive ink is composed of, by weight part, 0.1-10 parts of carbon fiber / gaseous carbon tube compound powder, 0.1-20 parts of carbon black,0.1-70 parts of resin adhesives, 0.1-5 parts of dispersant, 0.1-5 parts of flatting agent, 0.1-5 parts of anti-settling agent and 0.1-5 parts of water-repellent agent. The carbon fiber / gaseous carbontube / carbon black compound conductive ink has the advantages of being high in adhesion force, electric conductivity, water resistance, alcohol resistance and the like and achieves uniform conductive uniformity and application attenuation resistance; meanwhile, the carbon fiber / gaseous carbon tube / carbon black compound conductive ink can be applied widely as heating carbon paste, conductive carbonpaste and electromagnetic shielding carbon paste to heating floors, PCB (printed circuit board) carbon oil, electromagnetic shielding coatings and the like.

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

Local matt and light heat transfer film preparation process

InactiveCN107652809AHigh value propositionPartial matte hasPattern printingCoatingsAlcoholEngineering

The invention discloses a local matt and light heat transfer film preparation process which includes the steps: 1) engraving matt finish checkered plate lines; 2) applying matt finish coatings; 3) performing curing by a constant temperature oven; 4) applying OP wax and an anti-sticking layer; 5) performing manual overprinting; 6) applying a release layer; 7) printing image-texts and colors; 8) applying a glue layer; 9) performing heat transfer printing. The value proposition of a product is 20%-25% higher than that of a full matt product, and the product has the advantages of local light, local matt, bright color, clear lines, concave-convex hand feeling, sweat resistance, palm oil resistance and alcohol resistance.

Owner:JIANGSU XUETAI PRINTING

Environment-friendly glass baking varnish and preparation method thereof

InactiveCN110698945ASimple and easy preparation methodSimple and easy to usePolyurea/polyurethane coatingsPolymer scienceWeather resistance

The invention discloses an environment-friendly glass baking varnish. The glass baking varnish is prepared from the following raw materials in parts by weight: 45 to 65 parts of a water-soluble fluorine-containing selenocyano amino triazine resin, 15 to 25 parts of a cationic waterborne polyurethane, 2 to 5 parts of an enclosed cross-linking agent UN-7038, 1 to 5 parts of a leveling agent, 20 to 30 parts of deionized water, 3 to 7 parts of a pigment and 1 to 3 parts of an antifoaming agent. The invention also discloses a preparation method of the environment-friendly glass baking varnish. Theenvironment-friendly glass baking paint disclosed by the invention is good in dry and wet adhesion, excellent in alcohol resistance, water resistance and wear resistance, high in hardness, excellent in comprehensive performance, safe and environment-friendly in production and use processes, good in paint film weather resistance and long in service life.

Owner:刘艳蕊

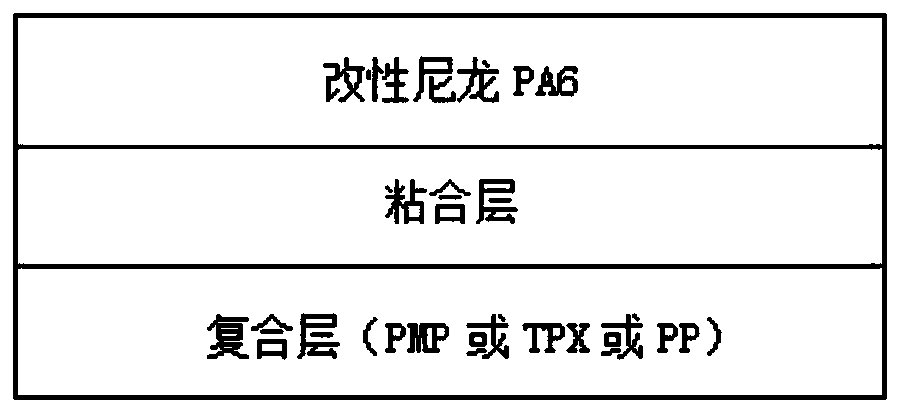

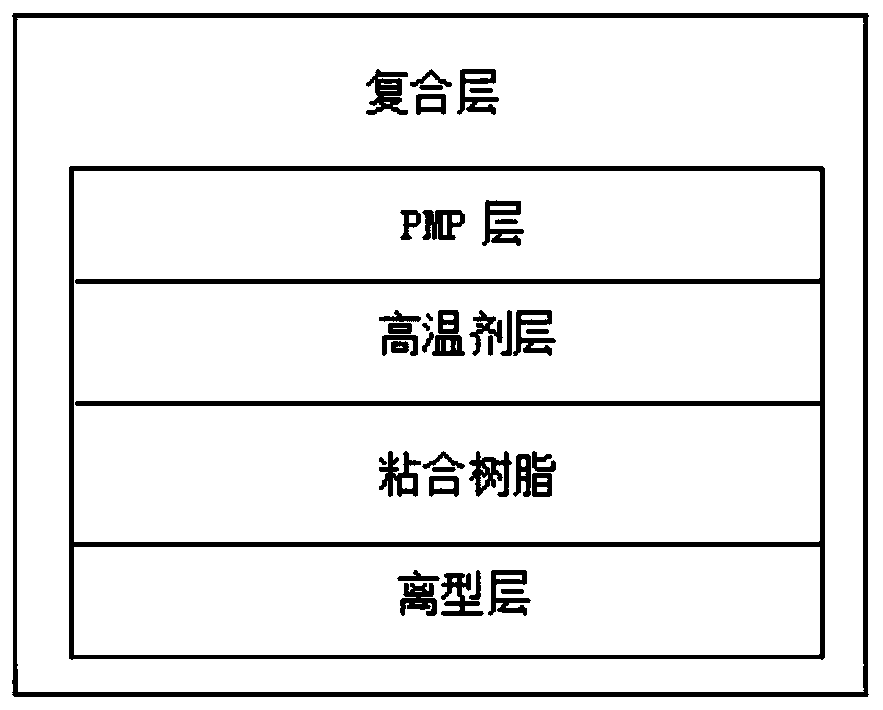

Multi-layer co-extrusion release film

InactiveCN110527452AAddressing Insufficient ElongationSolve the phenomenon of easy breakageFilm/foil adhesivesEngineeringCo extrusion

The invention discloses a multi-layer co-extrusion release film. Multi-layer composite structural design is adopted, the first layer is modified nylon PA6, the second layer is a bonding layer, the third layer is a composite layer, and the composite layer comprises a multilayer structure consisting of a PMP layer, a TPX layer or a PP layer. According to the multi-layer co-extrusion release film, the problems that the existing release film has insufficient elongation and is prone to cracking are solved, and practicability of the release film is improved.

Owner:东莞市宇川塑胶制品有限公司

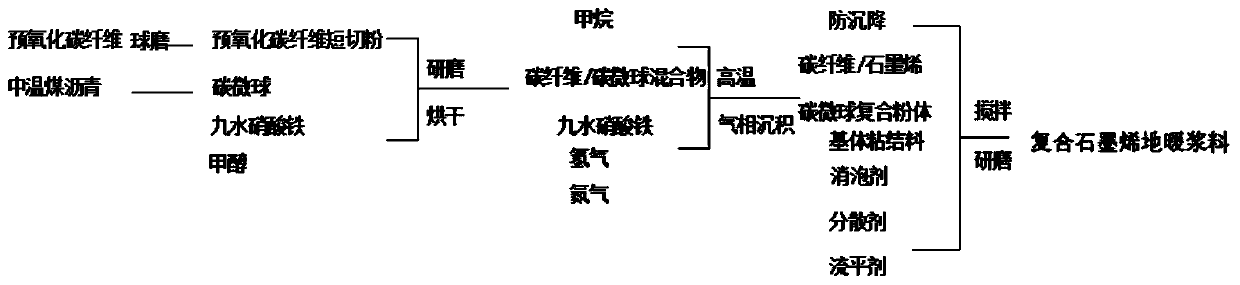

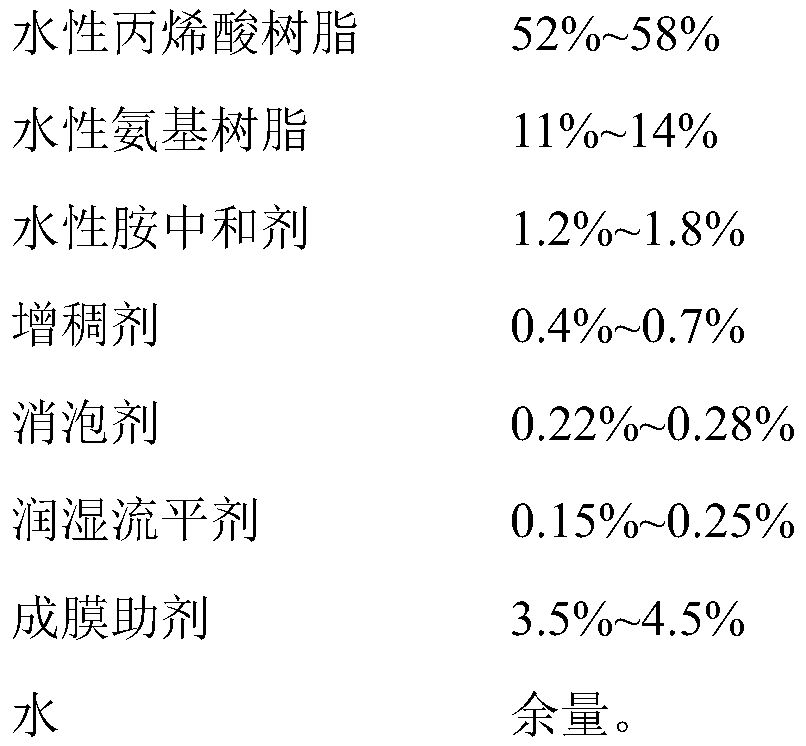

Composite graphene underfloor heating slurry and preparation method thereof

ActiveCN109749519AImprove adhesionImprove conductivityInksHeating element materialsFiberUltrasound attenuation

The invention belongs to the technical field of the underfloor heating slurry, and specifically relates to a composite graphene underfloor heating slurry and a preparation method thereof. The composite graphene underfloor heating slurry is prepared from the following raw materials in parts by weight: 0.1-30 parts of carbon fiber / graphene / carbon microsphere powder, 0.1-70 parts of a matrix bindingmaterial, 0.1-5 parts of a dispersing agent, 0.1-5 parts of a flatting agent, 0.1-5 parts of a precipitator, and 0.1-1 part of a defoaming agent. The composite graphene underfloor heating slurry prepared by adopting the carbon fiber / graphene / carbon microsphere powder has characteristics of good adhesive force, high conductivity, water resistance and alcohol resistance, and has excellent conductiveuniformity, and attenuation resistance.

Owner:浙江格来菲科技有限公司

Three-dimensional recycled paper pulp molded product material and preparation method

The invention discloses a three-dimensional recycled paper pulp molded product material which is characterized by being prepared from the following components in parts by weight: 60-90 parts of regenerated plant paper pulp (based on dry fibers), 5-10 parts of acrylic emulsion (with the solid content of 50%), 0.1-0.5 parts of a soap deinking agent, 0.01-0.03 parts of a volatile agent, 2-4 parts ofrosin size, 0.1-1 part of a dispersing agent, 0.1-0.3 parts of pigment, 0.5-1 part of waterborne ceramic coating and 10-20 parts of water. The invention further discloses a preparation method of the three-dimensional recycled paper pulp molded product. The formula and the preparation method of the material are matched with each other. The preparation process is simplified, and the comprehensive performance of the material and the product is greatly improved. Ink and adhesive tape plastic doped in paper pulp can be removed, and later coloring of paper and plastic is facilitated. The situation that the structure of the paper and plastic is unstable due to the fact that broken paper pulp of the plastic is separated is avoided. The surface of the paper and plastic is sprayed with waterborne ceramic coating after the paper and plastic are manufactured, a paper and plastic product is not prone to deformation and damage, and the service life of the paper and plastic product is prolonged.

Owner:QINGYUAN HUAYUAN INST OF SCI & TECH COLLABORATIVE INNOVATION CO LTD

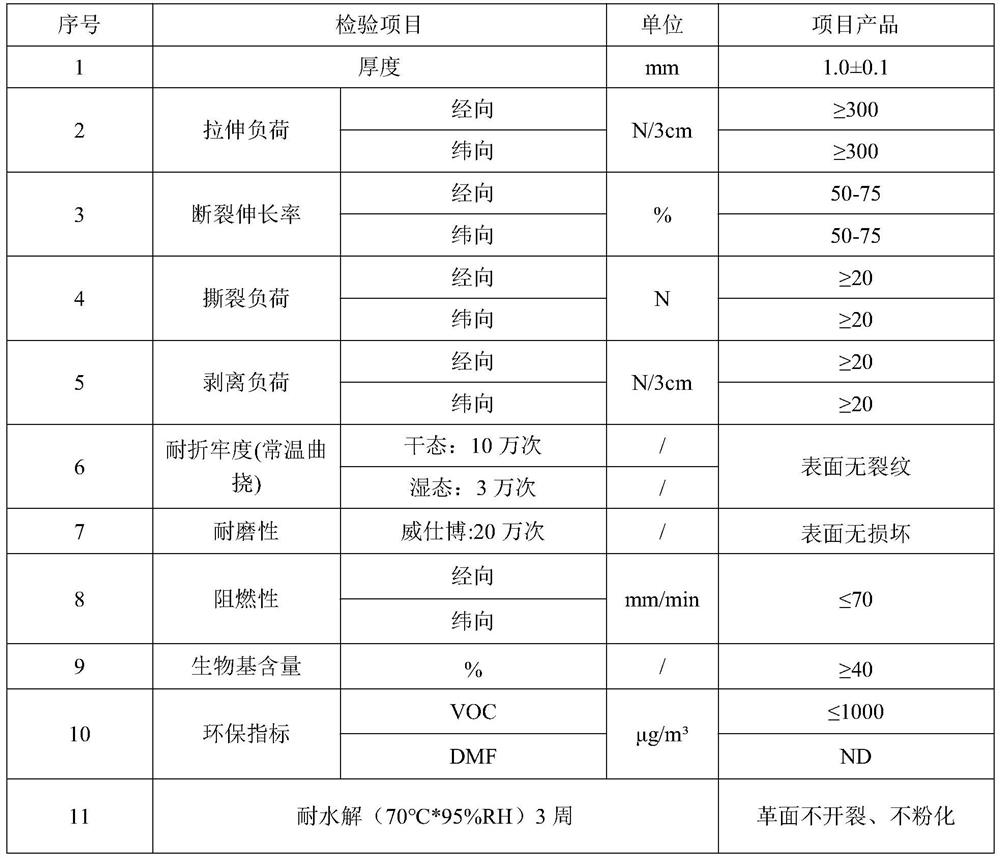

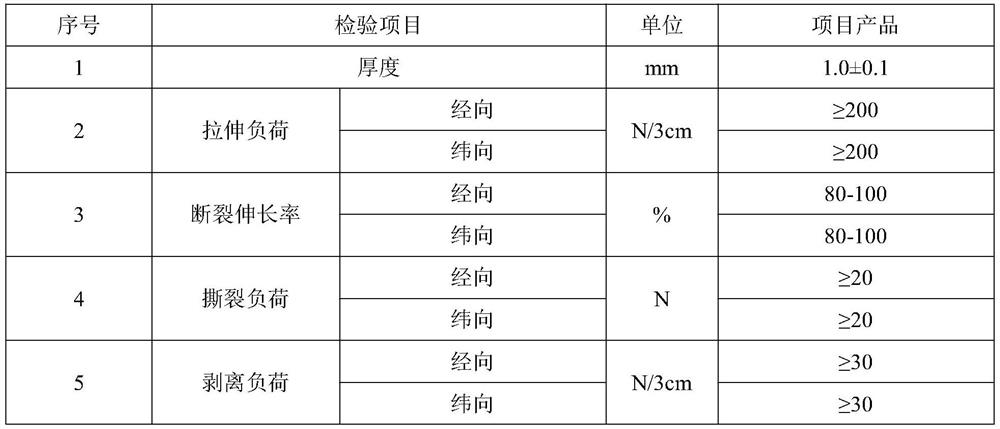

Solvent-free polylactic acid bio-based polyurethane synthetic leather, preparation method and application

PendingCN113699802AHigh peel strengthHigh flexure at room temperatureFibre treatmentFurniture partsPolymer chemistryPolylactic acid

The invention relates to solvent-free polylactic acid bio-based polyurethane synthetic leather, a preparation method and application. The synthetic leather is composed of waterborne polyurethane surface layer slurry, solvent-free polyurethane bonding layer slurry and polylactic acid treated base cloth. The preparation method of the synthetic leather comprises the following steps of coating release paper with the waterborne polyurethane surface layer slurry, and performing drying to obtain a surface layer composite film; uniformly coating the obtained surface layer composite film with the solvent-free polyurethane bonding layer slurry, performing drying, and enabling a coating layer to keep certain adhesion; and attaching the polylactic acid treated base cloth to an obtained bonding layer, and stripping the release paper after drying and curing, so that the solvent-free polylactic acid bio-based polyurethane synthetic leather is obtained. The solvent-free polylactic acid bio-based polyurethane synthetic leather prepared by the invention has the advantages of alcohol resistance, hydrolysis resistance, higher peel strength, high normal-temperature deflection and good wear resistance, and has degradability.

Owner:ANHUI ANLI MATERIAL TECH

Heat transfer printing adhesive for glass paint-spraying wine bottles

InactiveCN110551464AImprove slipperinessPrevent sticky backNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolefinAlcohol

The invention relates to a heat transfer printing adhesive for glass paint-spraying wine bottles, wherein the heat transfer printing adhesive is prepared from the raw materials comprising the following components in parts by weight: 5-60 parts of chlorinated polyolefin modified resin, 5-60 parts of epoxy resin, 5-60 parts of modified acrylic resin, 5-60 parts of polyurethane resin, 5-50 parts of acuring agent, 0.1-20 parts of an anti-sticking assistant and 20-90 parts of an organic solvent. Compared with the prior art, the heat transfer printing adhesive for the glass paint-spraying wine bottles can smoothly transfer a heat transfer printed image and text to wine bottles with different shapes, the heat transfer printed film after transfer printing is initially attached to the glass paintsurface, and then after a certain baking temperature and time, the heat transfer printed film is firmly adhered to the glass paint surface, and has the advantages of no discoloration, no cracking, wear resistance, water immersing resistance and alcohol resistance.

Owner:RESPLENDENT SHANGHAI SPECIALDECAL CO LTD

Water-based gold powder coating for ABS plastic material as well as preparation method and application thereof

InactiveCN111961393AImprove adhesionAlcohol resistantPaints with free metalsPolyester coatingsSilver pasteEmulsion

The invention provides a water-based gold powder coating for an ABS plastic material as well as a preparation method and application thereof, and belongs to the field of coating layers. The water-based gold powder coating is prepared from the following raw materials: water-based acrylic emulsion, water-based polyester resin, water-based amino resin, flashing silver paste, bronze powder, a cosolvent, a dispersing agent, a defoaming agent, a directional arrangement aid and deionized water. The water-based gold powder coating has the characteristics of good adhesion and alcohol resistance, can beused to coat the surface of an ABS plastic material, has the adhesion gradation of 1 grade and the alcohol wiping resistance of more than 100 times / 500g, and has excellent metallic luster.

Owner:西北永新涂料有限公司

UV (ultraviolet) photocured water-based fluorine-containing polyurethane latex film and preparation method thereof

InactiveCN102977758BStrong mechanical propertiesHigh hardnessPolyurea/polyurethane coatingsTetrafluoroethylenePolymer science

The invention discloses a UV (ultraviolet) photocured water-based fluorine-containing polyurethane latex film and a preparation method thereof. The UV photocured water-based fluorine-containing polyurethane latex film is prepared by the following specific steps: adding photoinitiator IRGACURE184 or IRGACURE907 into a UV-cured water-based fluorine-containing polyurethane emulsion, evenly stirring, coating on a tetrafluoroethylene board, and drying at 60 DEG C to a constant weight, wherein the photoinitiator IRGACURE184 or IRGACURE907 accounts for 3.73-4% of the UV-cured water-based fluorine-containing polyurethane emulsion in percentage by weight; and then, performing UV irradiation curing on a UV curing machine to obtain the UV photocured water-based fluorine-containing polyurethane latex film. The preparation method comprises the preparation of an isophorone diisocyanate tripolymer-fluorine alcohol addition compound, the preparation of the UV-cured water-based fluorine-containing polyurethane emulsion and the preparation of the UV photocured water-based fluorine-containing polyurethane latex film. The finally obtained UV photocured water-based fluorine-containing polyurethane latex film transparent, can not be yellowed, and has favorable acid resistance, alkali resistance, water resistance and high hardness.

Owner:SHANGHAI INST OF TECH

Fire-retardant water-based dual-component top-coat paint for wood ware, and preparation method of paint

ActiveCN104592874AAlcohol resistantHas acid and alkali resistanceFireproof paintsPolyurea/polyurethane coatingsWater basedAlcohol

The invention relates to fire-retardant water-based dual-component top-coat paint for wood ware and a preparation method of the paint. The fire-retardant water-based dual-component top-coat paint for the wood ware consists of a component A and a component B, wherein the ratio of the component A to the component B is 100 to 20. The preparation method of the fire-retardant water-based dual-component top-coat paint for the wood ware comprises the following steps: a. preparing the component A as the follows; b, preparing the component B from Bayer XP2487-1; and c. before construction, uniformly stirring the component A and the component B fully in a weight ratio of 100 to 20. The fire-retardant water-based dual-component top-coat paint for the wood ware can be used for achieving a fire-retardant effect under the circumstance of not adding a fire retardant; the paint coating the wood ware and metal can be used for avoiding ignition in burning, bubbling, scorching, peeling off and pulverizing. The fire-retardant water-based dual-component top-coat paint for the wood ware has the effects of alcohol resistance, acid and alkali resistance, yellowing resistance, high hardness, stain resistance, and the like.

Owner:SKSHU PAINT

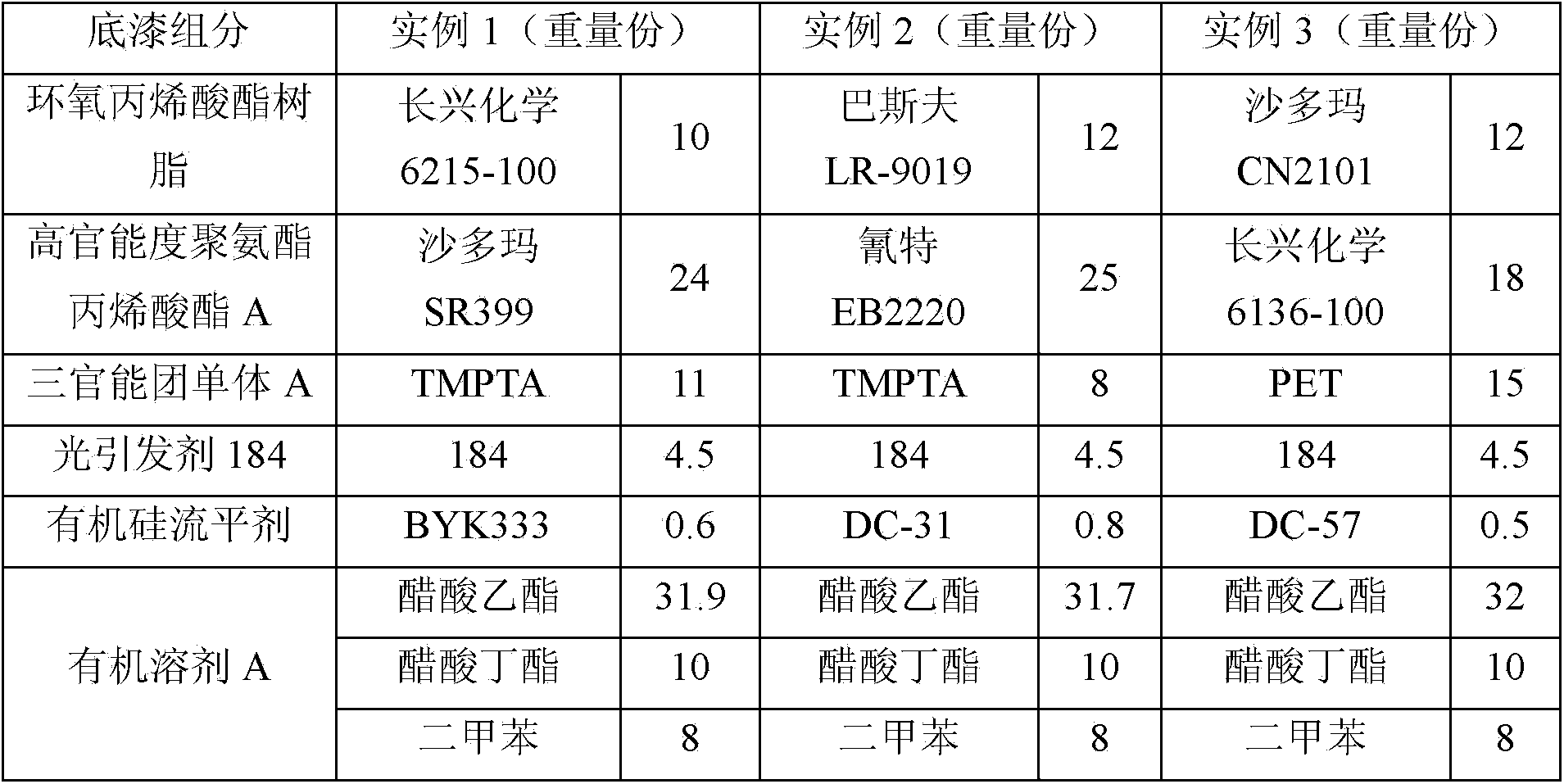

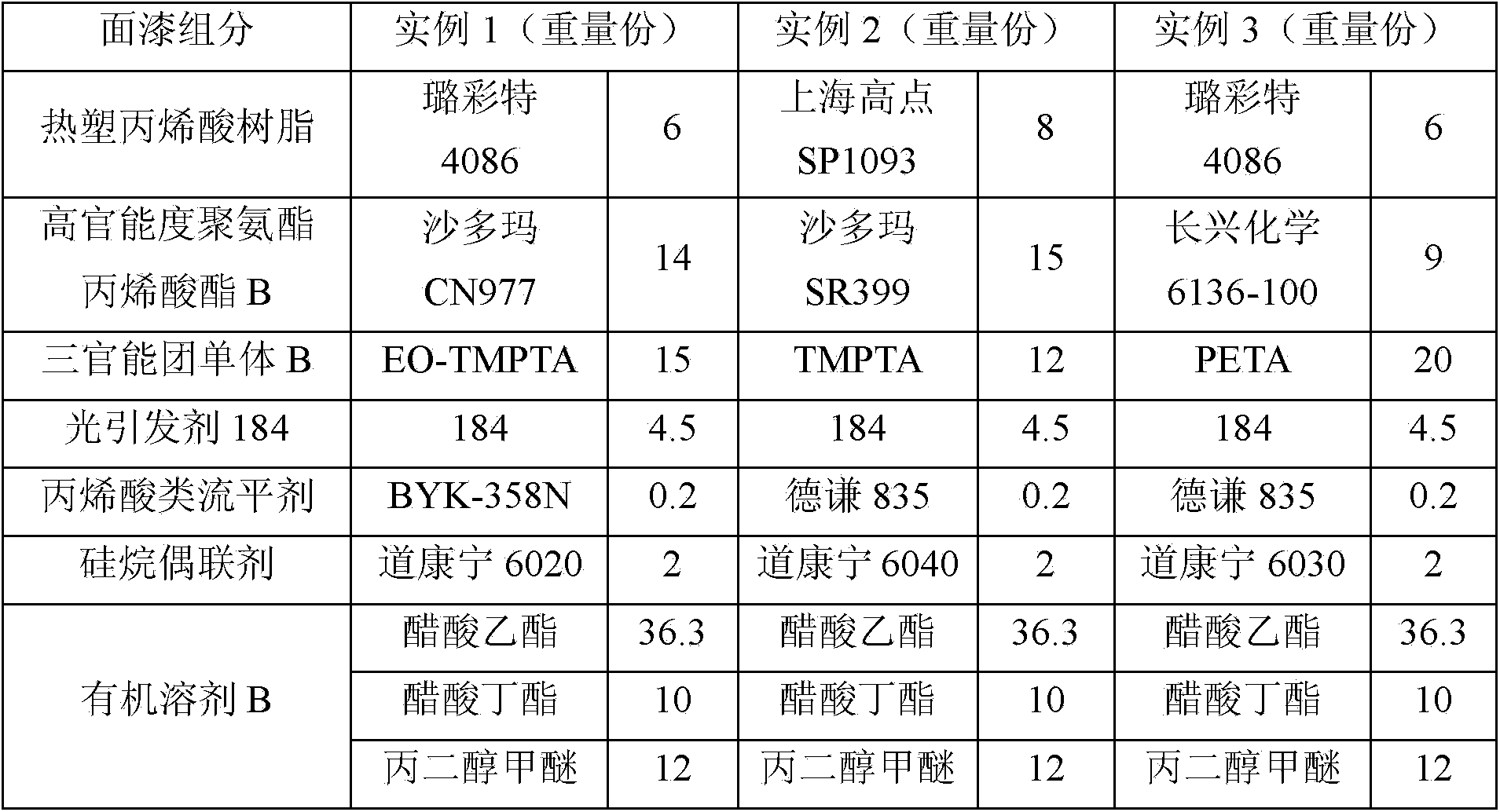

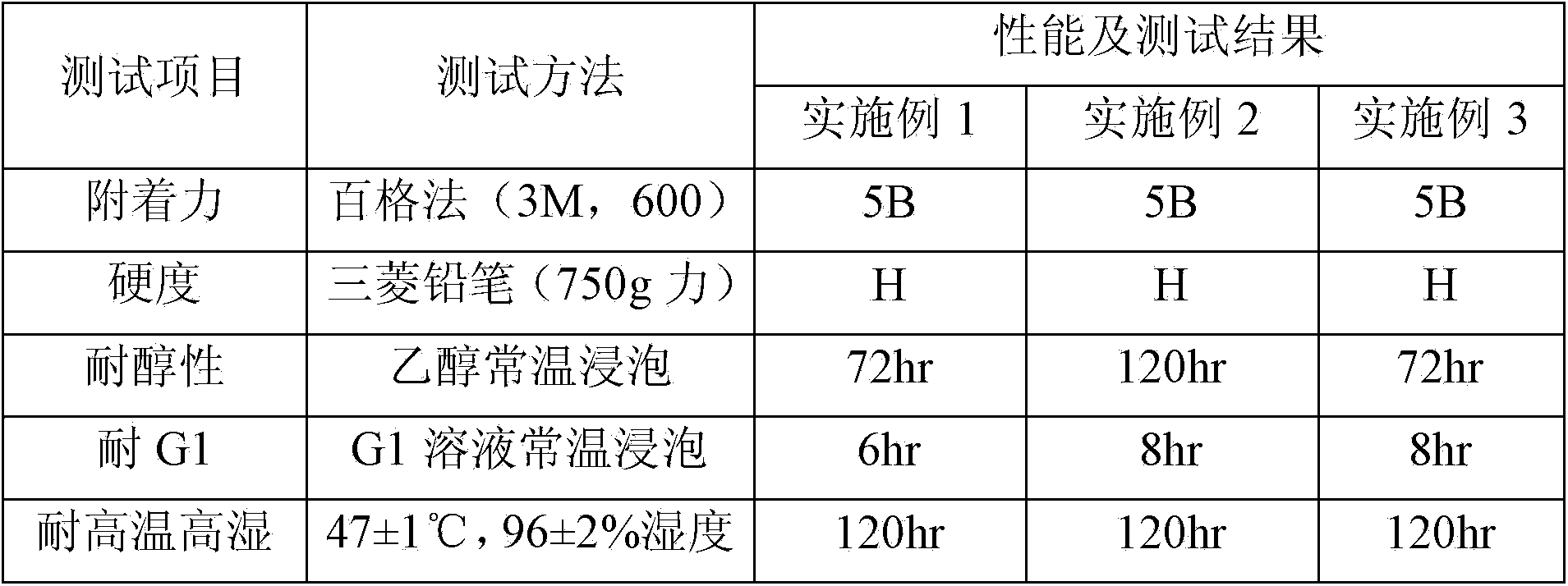

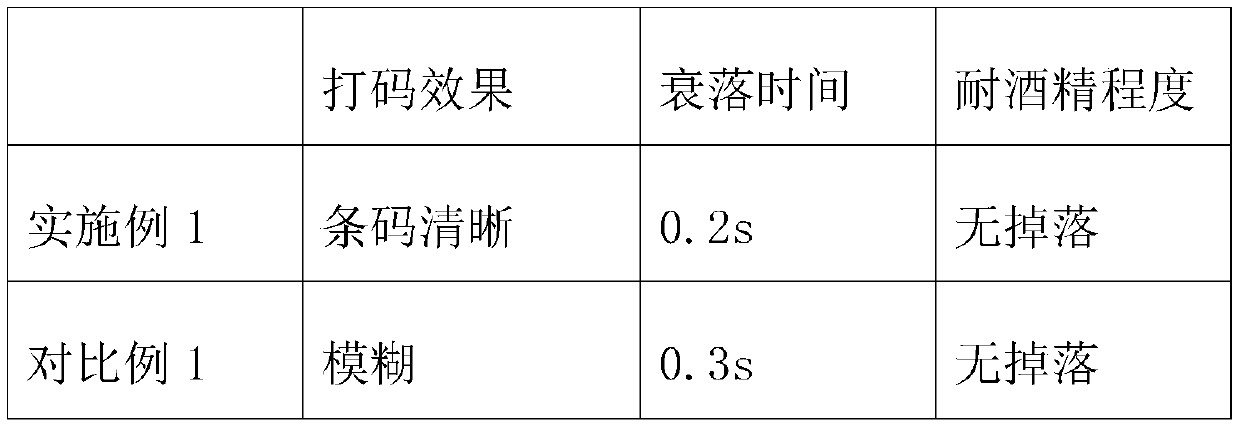

Ultraviolet light curable coating with dewdrop effect and preparation method and coating method thereof

ActiveCN103113822BWith dewdrop effectEasy curingPolyurea/polyurethane coatingsSpecial surfacesOrganic solventAcrylic resin

The invention discloses an ultraviolet light curable coating with a dewdrop effect. The coating comprises base paint and finish paint, wherein the base paint comprises the following ingredients by weight percent: 10-15% of epoxy acrylate, 18-30% of high-functionality-degree polyurethane acrylic ester A, 8-15% of a tri-functional group monomer A, 3-5% of a photoinitiator A, 0.4-0.8% of an organic silicon flatting agent and 45-55% of an organic solvent A; and the finish paint comprises the following ingredients by weight percent: 5-10% of a thermoplastic acrylic resin, 8-18% of the high-functionality-degree polyurethane acrylic ester B, 15-20% of the tri-functional group monomer B, 3-5% of the photoinitiator B, 0.1-0.3% of an acrylic acid flatting agent, 1-3% of a silane coupling agent and 50-60% of the organic solvent B. The ultraviolet light curable coating with the dewdrop effect is simple to prepare and easy to cure, and has the dewdrop effect after being cured into a coating.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

Manufacturing process of waterborne polyurethane resin

The invention relates to the technical field of high-molecular polymers, in particular to a manufacturing process of waterborne polyurethane resin, which comprises the following steps of: S1, selecting a mixture of polytetramethylene ether glycol and polycarbon polyol, isophorone diisocyanate, diaminosulfonate, a catalyst, water, 1, 4-butanediol, 2, 2-dimethylolpropionic acid and a solvent in parts by weight; S2, mixing and stirring the raw materials, and heating the mixed raw materials; S3, adding one of ethylenediamine and isophorone diamine into the preliminary product, fully stirring, andcarrying out a second-stage heating reaction; S4, adding water into the product, and then heating the product for emulsifying; S5, carrying out heat preservation treatment on the product in a reactionkettle; and S6, vacuumizing the reaction kettle, and carrying out cooling and discharging to obtain the waterborne polyurethane resin. The manufacturing process is more environment-friendly, harm tohealth of operators is reduced, and after the waterborne polyurethane resin is applied to the synthetic leather, the surface of the synthetic leather is natural in light sensation, the synthetic leather is close to real leather in due physical property, and the waterproofness and air permeability are excellent.

Owner:安徽锐乐升新材料科技有限公司

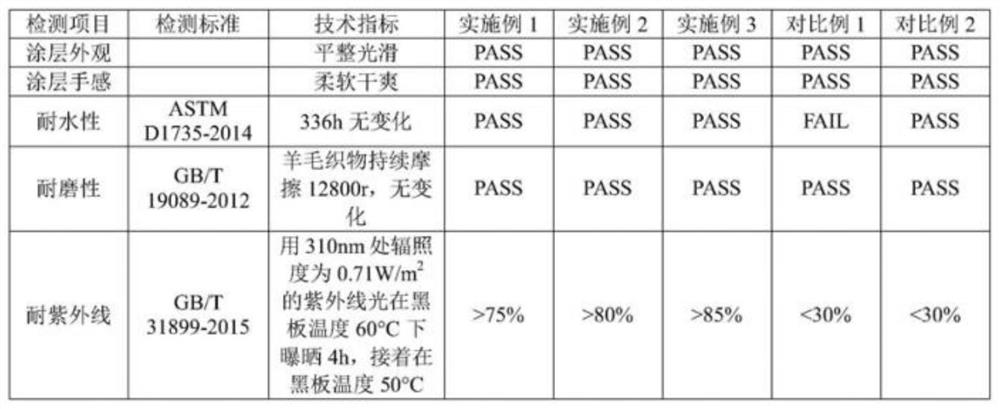

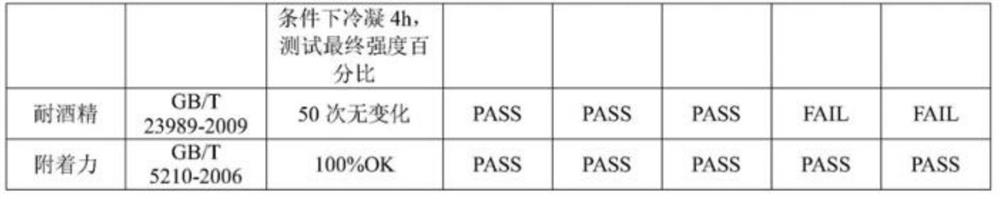

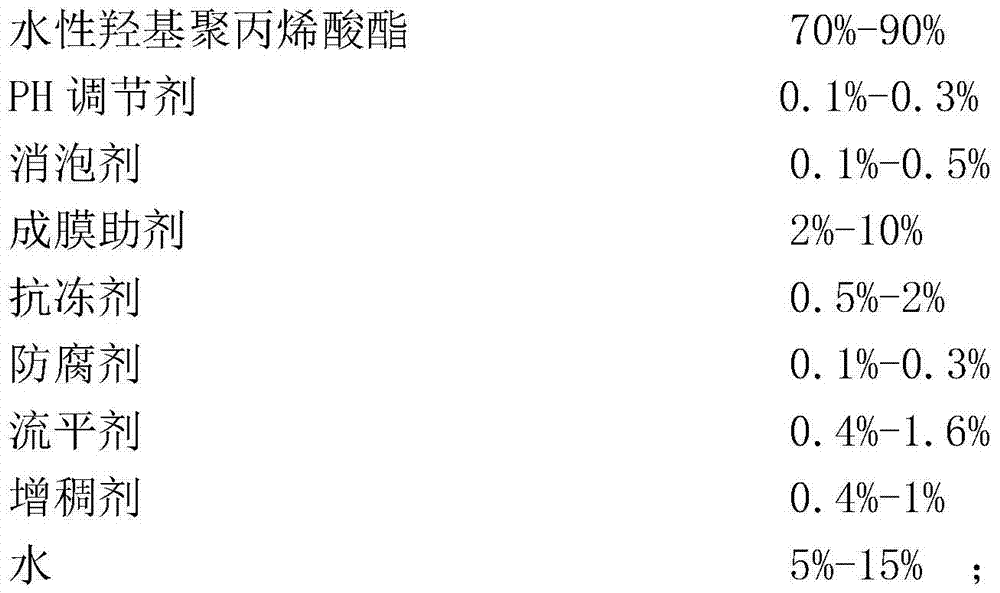

A kind of super-sub-skin-feeling wear-resistant water-based paint special for PVC surface decoration and preparation method thereof

ActiveCN109207047BReduce usageEmission reductionAntifouling/underwater paintsPaints with biocidesPolymer scienceEmulsion

The invention discloses a super sub-skin-feeling wear-resistant water-based paint specially used for PVC surface decoration and a preparation method thereof. The coating contains ultra-matt water-based polyurethane emulsion, polycarbonate water-based polyurethane emulsion, water-based antifouling agent, water-based curing agent, water-based velvet agent, water-based wetting agent, water-based defoamer, water-based leveling agent, etc. The paint of the present invention adopts the ultra-matt water-based polyurethane emulsion as one of the two-component linking materials, and the formed coating has extremely low gloss, and does not need to add matting agent additionally. The coating of the present invention uses an amino-based water-based resin crosslinking agent as a curing agent. When printed at room temperature, the coating can achieve good adhesion fastness, water resistance, and anti-blocking properties, with a hardness ≥ 2H and a glossiness ≤ 2 degrees. Ultra-matte visual effect, velvet touch and skin-friendly, and added properties such as wear resistance, alcohol resistance, and stain resistance.

Owner:福建格林春天新材料股份有限公司

A special high-gloss, anti-fouling and wear-resistant water-based paint for pvc surface decoration and preparation method thereof

ActiveCN109486393BReduce usageEmission reductionAntifouling/underwater paintsPaints with biocidesPlasticizerFirming agent

The invention discloses a special high-gloss anti-fouling and wear-resistant water-based paint for PVC surface decoration and a preparation method thereof. High-gloss anti-fouling and wear-resistant water-based coatings for PVC surface decoration include polycarbonate-based water-based polyurethane emulsion, water-based anti-fouling agent, water-based curing agent, water-based wetting agent, water-based defoamer, water-based leveling agent, etc. The special coating of the invention is friendly to the environment and has strong adhesion, and solves the damage to the coating caused by the precipitation of the plasticizer dioctyl phthalate during the printing process of the PVC substrate. The coating of the present invention uses an amino-based water-based resin crosslinking agent as a curing agent, and is printed at room temperature, and the formed coating can achieve good adhesion fastness, water resistance, and anti-blocking properties, and can be passed in the subsequent decorative panel bonding process. 150 ℃ ~ 180 ℃ fit the tank, the curing agent contained in the coating will undergo a cross-linking reaction, and finally form a high-gloss anti-fouling and wear-resistant water-based coating with a gloss of ≥ 90 degrees and a hardness of ≥ 2H, which increases wear resistance, alcohol resistance, and water resistance. characteristics such as pollution.

Owner:福建格林春天新材料股份有限公司

Alcohol-friction-resistant ultra-fine coding electronic tag material and preparation method thereof

InactiveCN111073537AWith antistatic functionImprove antistatic performanceStampsFilm/foil adhesivesFiberAlcohol

The invention provides an alcohol-friction-resistant ultra-fine coding electronic tag material and a preparation method thereof. The alcohol-friction-resistant ultra-fine coding electronic tag material comprises a nanoscale ultra-fine coding printing coating, nanoscale antistatic matte black ink, matte black PET, a high-viscosity oily acrylic acid adhesive layer and PET release backing paper fromtop to bottom, wherein the nanoscale ultra-fine coding printing coating is prepared from the following raw materials: polyurethane, water-soluble nanoscale silica sol, hydrogen peroxide, ethylenediamine tetraacetic acid and water; the nanoscale antistatic matte black ink comprises the following components: ordered mesoporous carbon, nano carbon fibers and ink.

Owner:SHENZHEN LICHANGSHI ADHESIVE PROD

Thermal transfer printing glue for flat glasses

InactiveCN109385231AModerate viscosityGood storage stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemical treatmentEpoxy

The invention relates to a thermal transfer printing glue for flat glasses, wherein the thermal transfer printing glue is prepared from the following raw materials by weight: 1-50 parts of a chlorinated polyolefin modified resin, 1-50 parts of an epoxy resin, 1-30 parts of cellulose acetate, 0.1-10 parts of a curing agent, 0.1-10 parts of an anti-adhesion aid, and 50-90 parts of an organic solvent. Compared with the thermal transfer printing glue in the prior art, the thermal transfer printing glue of the present invention has the following advantages that the transferred glass can be easily subjected to transfer printing without any chemical treatment, the thermal transfer printing film is initially attached to the glass surface, and then is firmly adhered to the surface of the glass by baking for a certain time at a certain temperature, and the thermal transfer printing glue has characteristics of no discoloration and no cracking during baking, abrasion resistance, water immersion resistance, alcohol resistance and the like.

Owner:RESPLENDENT SHANGHAI SPECIALDECAL CO LTD

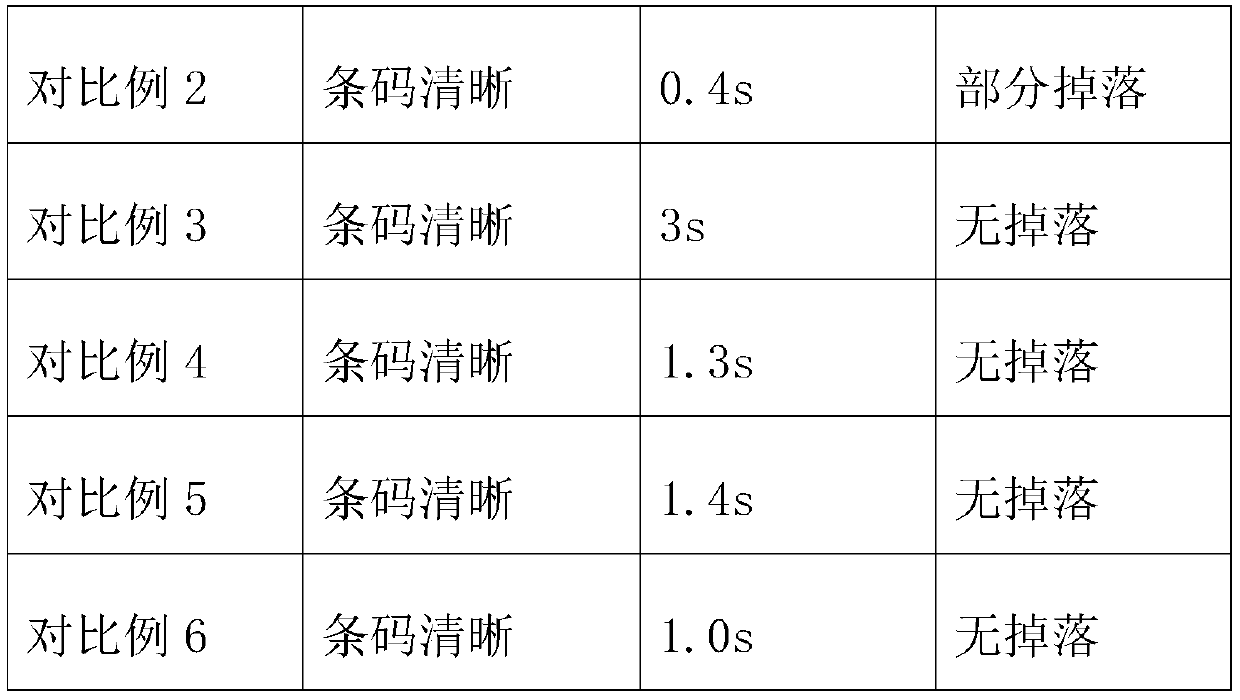

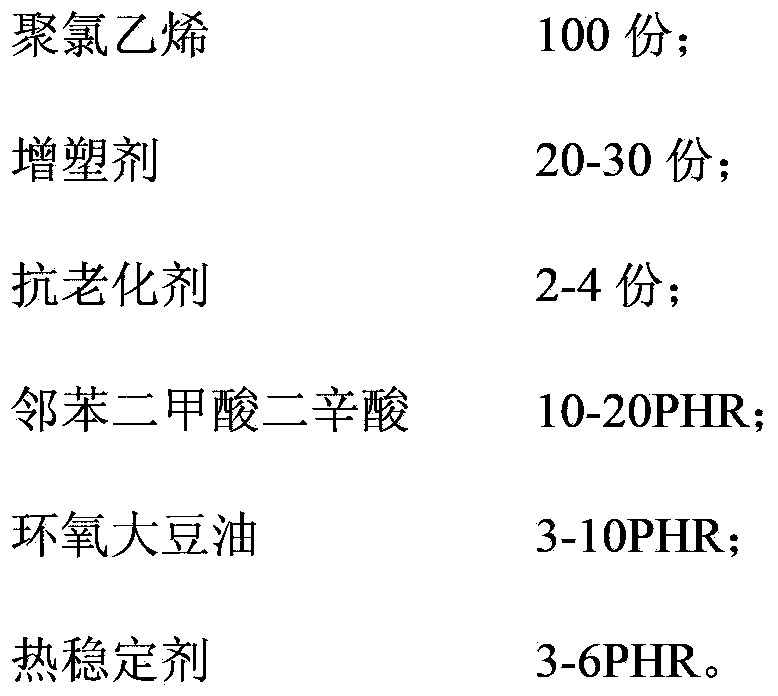

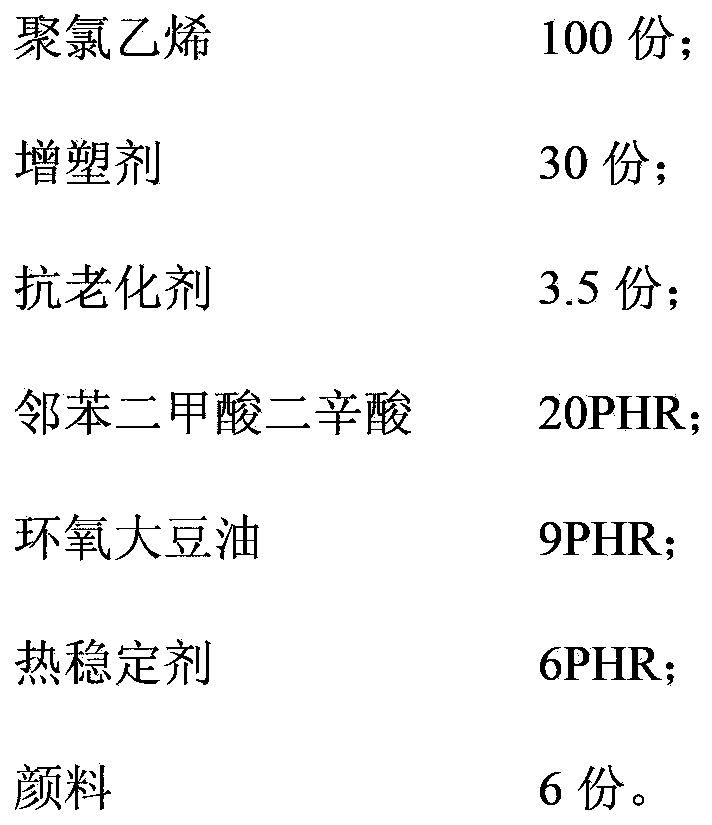

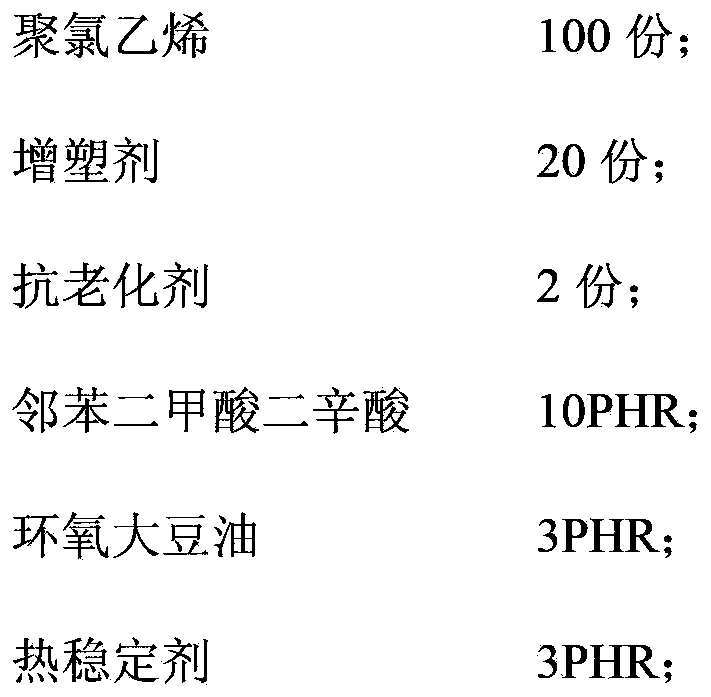

PVC plastic cement floor and production technology thereof

The invention relates to a PVC plastic cement floor. The PVC plastic cement floor is characterized by comprising 100 parts of by weight of polyvinyl chloride, 20-30 parts by weight of a plasticizer, 2-4 parts by weight of an ageing inhibitor, 10-20 PHR of dioctyl phthalate, 3-10 PHR of epoxidized soybean oil and 3-6 PHR of a heat stabilizer. The PVC plastic cement floor can resist corrosion, alcohol, acetone, HCL, NaOH, aqueous solution, gasoline and a general washing agent, is environmentally friendly, utilizes a nontoxic and eco-friendly reproducible PVC material as a main raw material, has no toxicity and corrosion, is a green product espoused by the country, and has high mechanical properties, very good mucous membrane performances, impact resistance, no deformation, environmental friendliness and renewability.

Owner:TIANJIN FUMIN RUBBER PROD CO LTD

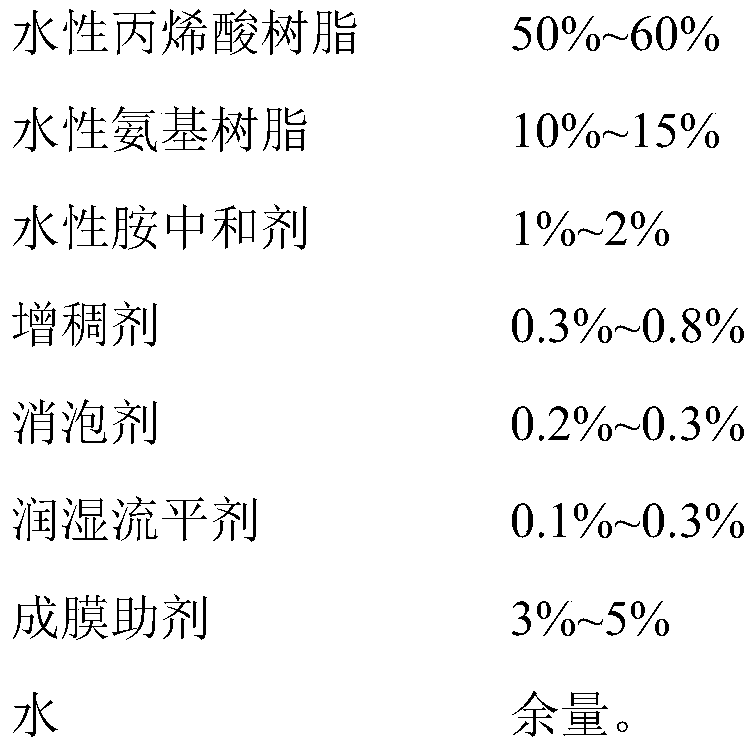

Aqueous baking varnish stainless steel gold oil and preparation method thereof

The invention relates to the technical field of coating materials, particularly to an aqueous baking varnish stainless steel gold oil and a preparation method thereof, wherein the aqueous baking varnish stainless steel gold oil comprises an aqueous acrylic resin, an aqueous amino resin, an aqueous amine neutralizer, a thickener, a defoamer, a wetting leveling agent, a film forming aid and water. According to the present invention, the aqueous acrylic resin has characteristics of high hardness and good adherence, and the aqueous amino resin has characteristics of good water solubility, good flexibility, low reaction temperature and high cross-linking degree, such that the prepared aqueous baking varnish stainless steel gold oil has advantages of excellent adherence and no paint shedding andremoving through the synergistic effect of the components, further has advantages of low odor, alcohol resistance, good acid resistance, good alkali resistance, bending resistance and excellent impact resistance, has excellent adherence to most metal products, especially stainless steel products, and has further high gold oil glossiness; and the preparation method has characteristics of simple process and low production cost, and is suitable for large-scale production.

Owner:东莞大宝化工制品有限公司 +1

A kind of composite graphene ground heating slurry and preparation method thereof

ActiveCN109749519BImprove adhesionImprove conductivityInksHeating element materialsFiberCarbon fibers

The invention belongs to the technical field of floor heating slurry, and specifically relates to a composite graphene floor heating slurry and a preparation method thereof; wherein, the composite graphene floor heating slurry, in parts by weight, comprises: carbon fiber / graphene / carbon microsphere powder 0.1-30, matrix binder 0.1-70, dispersant 0.1-5, leveling agent 0.1-5, anti-sedimentation agent 0.1-5, defoamer 0.1-1. The composite graphene floor heating slurry prepared by the carbon fiber / graphene / carbon microsphere composite powder in the present invention has the characteristics of good adhesion, high conductivity, water resistance, alcohol resistance, etc.; it also has excellent conductivity uniformity and anti-attenuation characteristics in use .

Owner:浙江格来菲科技有限公司

A kind of laser bronzing film for aluminum substrate and its production process and application

The invention relates to the technical field of laser gliding membranes, in particular to a laser gilding membrane for an aluminum substrate and a production process and an application thereof. The laser gliding membrane is composed of a PET membrane layer, a release layer, a wear-resistant resin layer, a three-dimensional picture layer, an aluminizing layer and a glue layer which are laminated, wherein the release layer, the wear-resistant resin layer and the glue layer are separately prepared from raw materials in percentage by weight, so that the laser gilding membrane for the aluminum substrate can be better attached to the aluminum substrate and has the advantages of being good in adhesiveness, friction resistant, solvent resistant and good in laser effect. The production process of the laser gilding membrane for the aluminum substrate comprises the following steps: preparing a coating of the release layer, the wear-resistant resin layer and the glue layer; and then carrying out coating, coining a pattern, carrying out aluminizing and coating the glue layer. The membrane has the advantage of simple production process. The laser gilding membrane can be applied to stamping anti-fake gliding trademarks of aluminum liquor lids, so that the anti-fake technology of the aluminum liquor lid is carried forward.

Owner:DONGGUAN K LASER TECH

A kind of multifunctional foaming water-based resin and preparation method thereof

ActiveCN112708096BGood weather resistanceImprove water resistancePolyurethane dispersionPolymer science

The invention discloses a multifunctional foaming water-based resin and a preparation method thereof. The following components are prepared in the following parts by weight: 65-75 parts of macromolecular polyol, 10-20 parts of isocyanate, and a hydrophilic chain extender. 5-10 parts, 0.5-2 parts of small molecular alcohol chain extender, 5-10 parts of modified organosilicon with light stability, 0.1-0.3 parts of catalyst, 3-7 parts of neutralizer, 5-10 parts of organic solvent parts, 1-10 parts of post-chain extender and 100-150 parts of deionized water. The present invention adopts the preparation method of anionic water-based polyurethane resin, selects DMBA or DMPA as the hydrophilic chain extender, introduces carboxyl groups, adds a neutralizing agent for neutralization, adds water for emulsification to form water-based polyurethane dispersion, and introduces Modified silicone resin, a light stabilizer is introduced into the modified silicone resin, so the obtained resin not only has the excellent weather resistance, water resistance and physical properties of the silicone modified polyurethane itself, but also has UV resistance and resistance. Properties of alcohol.

Owner:HUAIAN KAIYUE TECH DEV +1

A kind of fire-proof water-based two-component clear topcoat for woodware and its preparation method

ActiveCN104592874BAlcohol resistantHas acid and alkali resistanceFireproof paintsPolyurea/polyurethane coatingsWater basedAlcohol

The invention relates to fire-retardant water-based dual-component top-coat paint for wood ware and a preparation method of the paint. The fire-retardant water-based dual-component top-coat paint for the wood ware consists of a component A and a component B, wherein the ratio of the component A to the component B is 100 to 20. The preparation method of the fire-retardant water-based dual-component top-coat paint for the wood ware comprises the following steps: a. preparing the component A as the follows; b, preparing the component B from Bayer XP2487-1; and c. before construction, uniformly stirring the component A and the component B fully in a weight ratio of 100 to 20. The fire-retardant water-based dual-component top-coat paint for the wood ware can be used for achieving a fire-retardant effect under the circumstance of not adding a fire retardant; the paint coating the wood ware and metal can be used for avoiding ignition in burning, bubbling, scorching, peeling off and pulverizing. The fire-retardant water-based dual-component top-coat paint for the wood ware has the effects of alcohol resistance, acid and alkali resistance, yellowing resistance, high hardness, stain resistance, and the like.

Owner:SKSHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com