Composite graphene underfloor heating slurry and preparation method thereof

A composite graphene and graphene technology, applied in the field of floor heating slurry, can solve the problems of increased cost, power attenuation, short service life, etc., and achieve the effects of uniform resistance, high conductivity, and improved resistance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

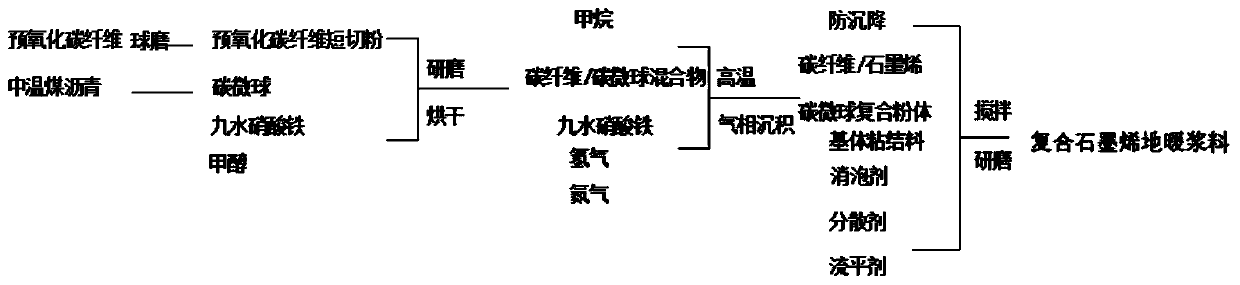

[0029] like figure 1 Shown, the preparation method of the composite graphene floor heating slurry of the present embodiment comprises the following steps:

[0030] 1. Preparation of preoxidized carbon fiber short fibers and carbon microspheres

[0031] (1) The pre-oxidized carbon fiber precursors (2kg) with a specification of 3K are put into a disc extrusion fiber cutter (3kW power), and the pre-oxidized carbon fiber precursors are cut into short fibers of 3mm length.

[0032] (2) Preparation of carbon microspheres by medium-temperature thermal polymerization method: take medium-temperature coal tar pitch, put it into a pressurized and sealed reaction kettle, the pressure is 1.0MPa, the temperature rises to 350°C, the stirring speed is 400r / min, and the time is 4 hours to obtain carbon microspheres. The mixture of microspheres is separated and extracted by the organic solvent toluene and n-hexane, and the carbon microspheres are obtained by extraction; drying and washing with...

Embodiment 2

[0038] The difference between this embodiment and the first embodiment lies in that the particle diameters of the carbon fiber precursor powder and the carbon microspheres are different.

[0039] The preparation method of the composite graphene floor heating slurry of the present embodiment may further comprise the steps:

[0040] 1. Preparation of preoxidized carbon fiber short fibers and carbon microspheres

[0041] (1) The pre-oxidized carbon fiber precursors (2kg) with a specification of 3K are put into a disc extrusion fiber cutter (3kW power), and the pre-oxidized carbon fiber precursors are cut into short fibers of 3mm length.

[0042] (2) Preparation of carbon microspheres by medium-temperature thermal polymerization method: take medium-temperature coal tar pitch, put it into a pressurized and sealed reactor, the pressure is 1.0MPa, the temperature rises to 390°C, the stirring speed is 500r / min, and the time is 4 hours to obtain carbon microspheres. The mixture of mic...

Embodiment 3

[0049] The difference between this embodiment and the first embodiment lies in that the mass ratio of carbon fiber precursor powder to carbon microspheres is different.

[0050] Specifically, the preparation method of the composite graphene floor heating slurry of the present embodiment comprises the following steps:

[0051] 1. Preparation of preoxidized carbon fiber short fibers and carbon microspheres

[0052] (1) The pre-oxidized carbon fiber precursor (5kg) with a specification of 3K is put into a disc extrusion fiber cutter (3kW power), and the pre-oxidized carbon fiber precursor is cut into short fibers of 3mm length.

[0053] (2) Preparation of carbon microspheres by medium-temperature thermal polymerization method: take medium-temperature coal tar pitch, put it into a pressurized and sealed reaction kettle, the pressure is 1.0MPa, the temperature rises to 350°C, the stirring speed is 400r / min, and the time is 4 hours to obtain carbon microspheres. The mixture of micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com