Patents

Literature

290results about How to "Uniform resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

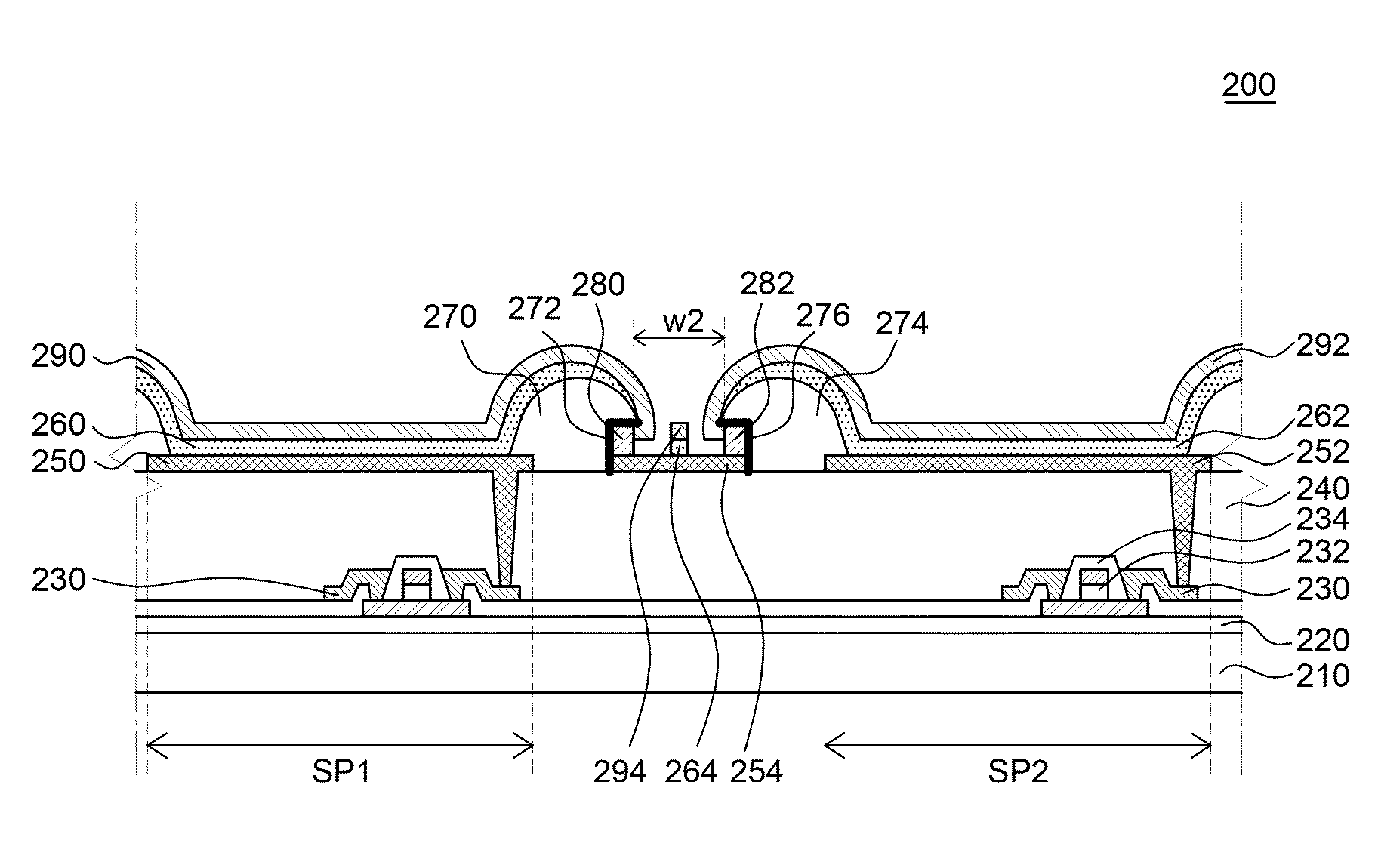

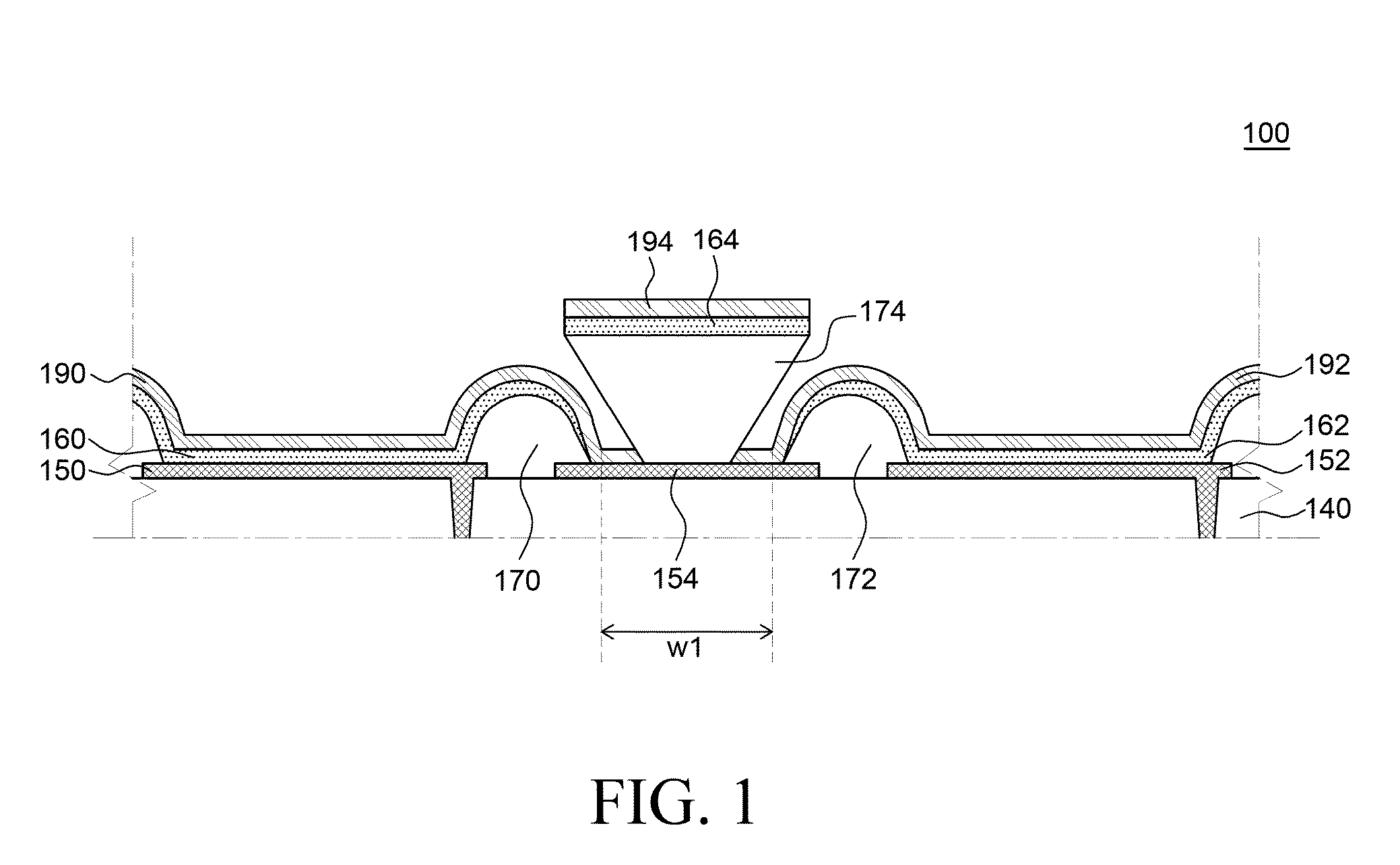

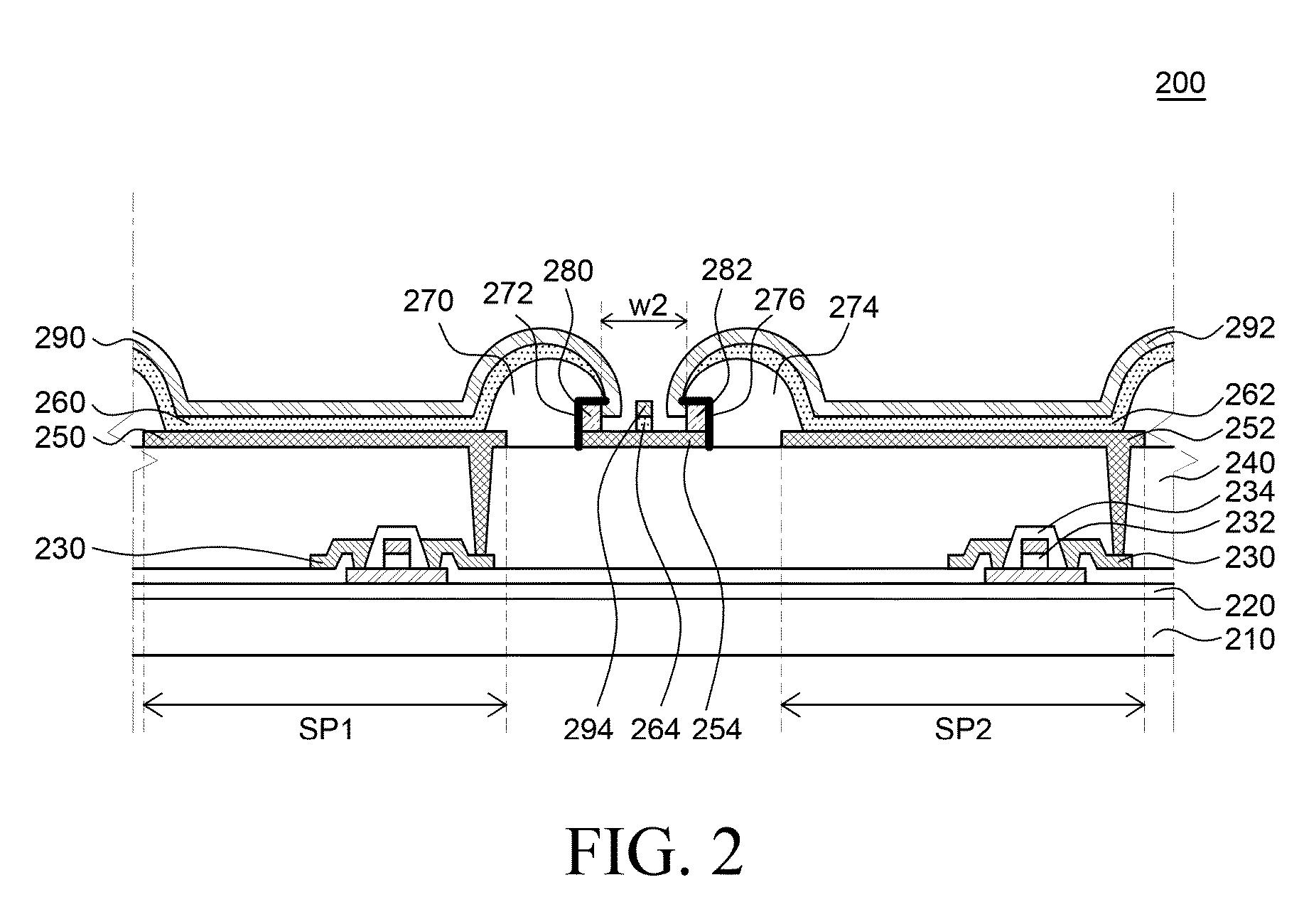

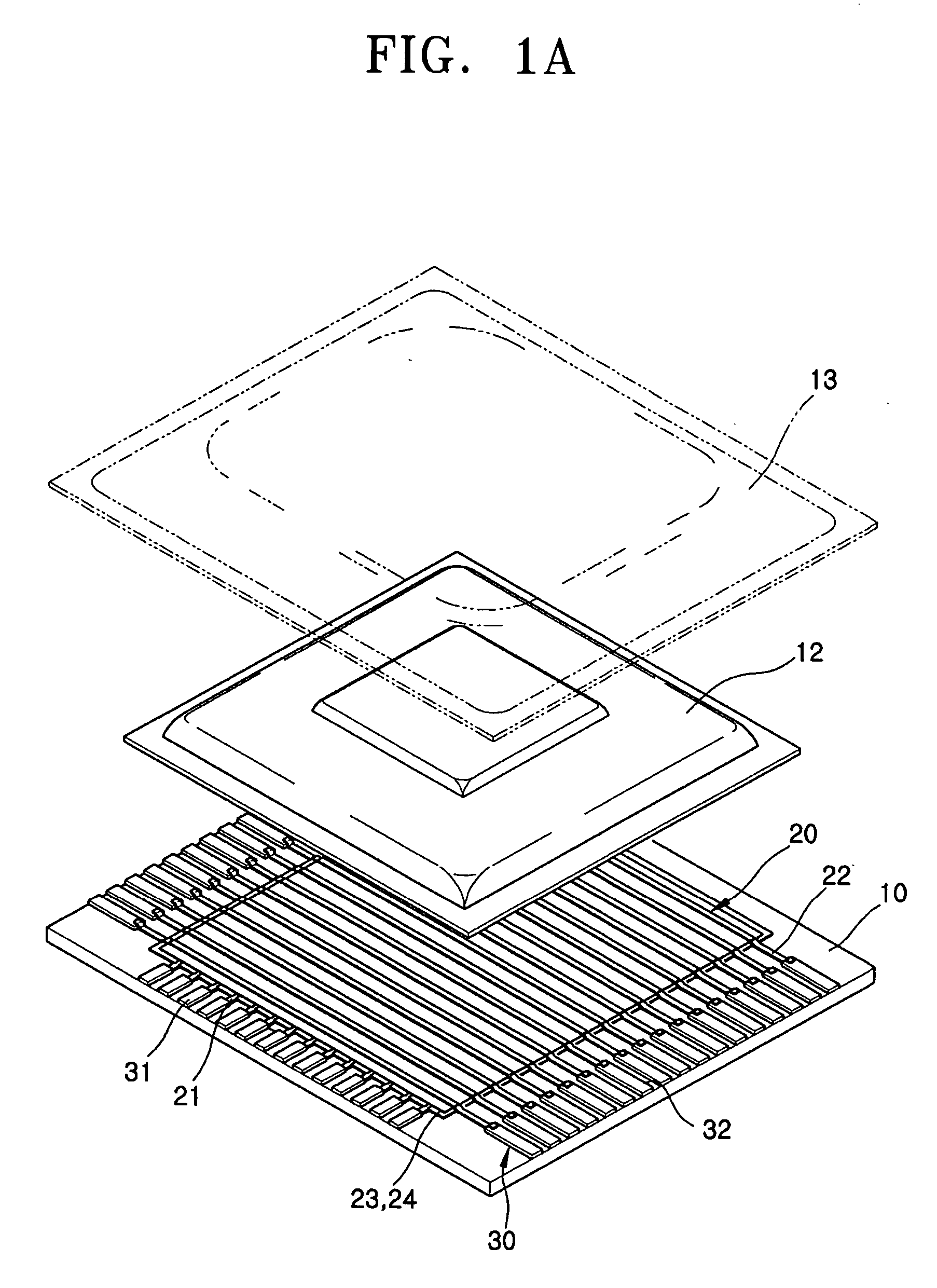

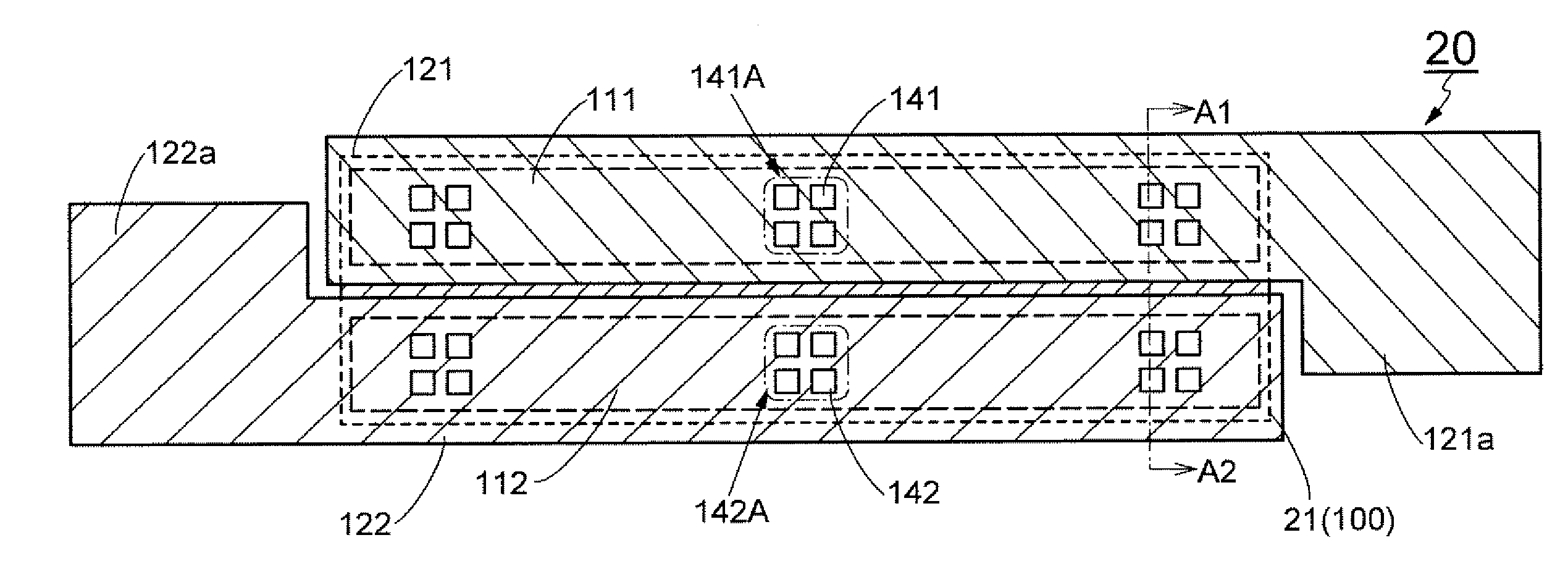

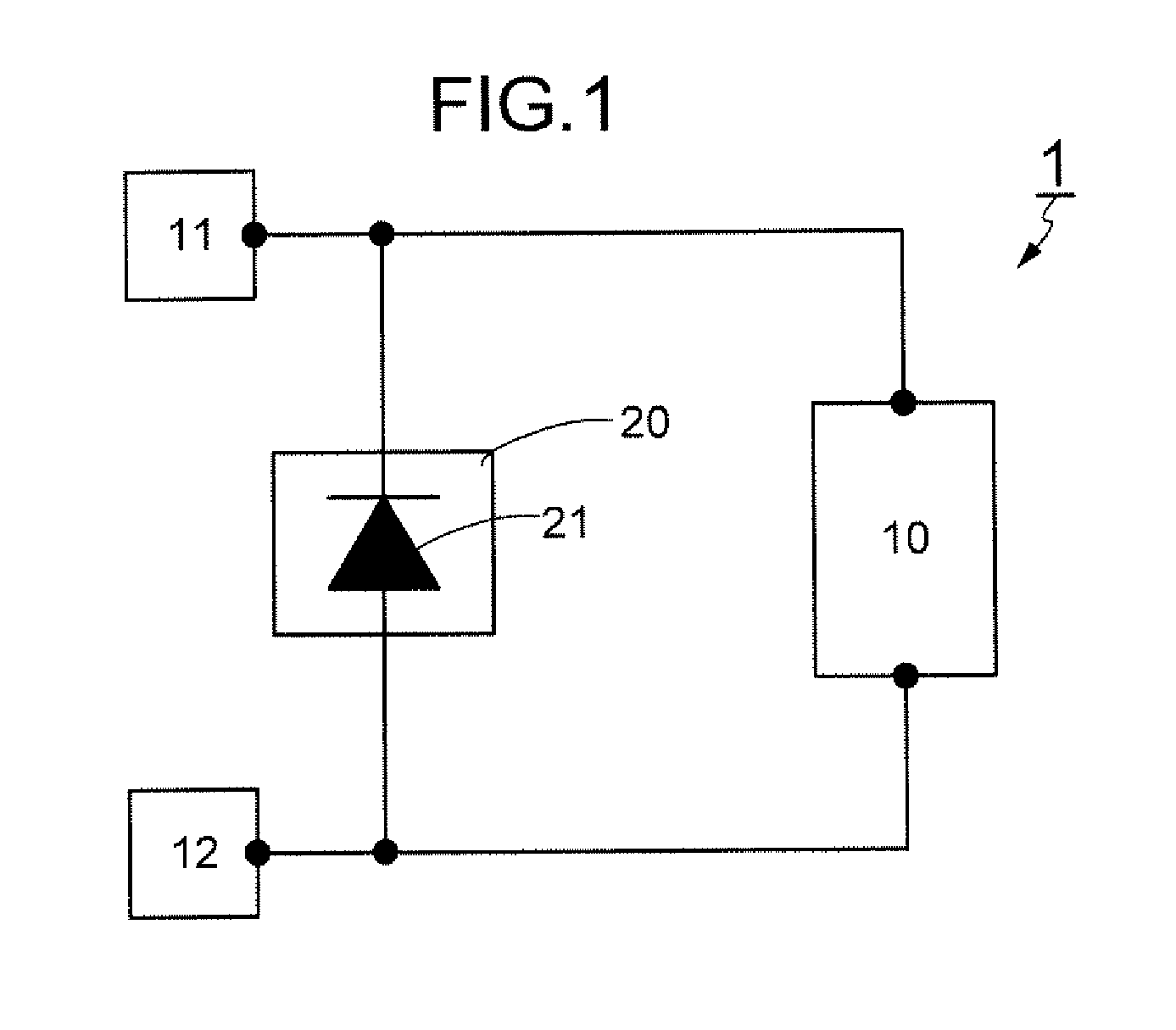

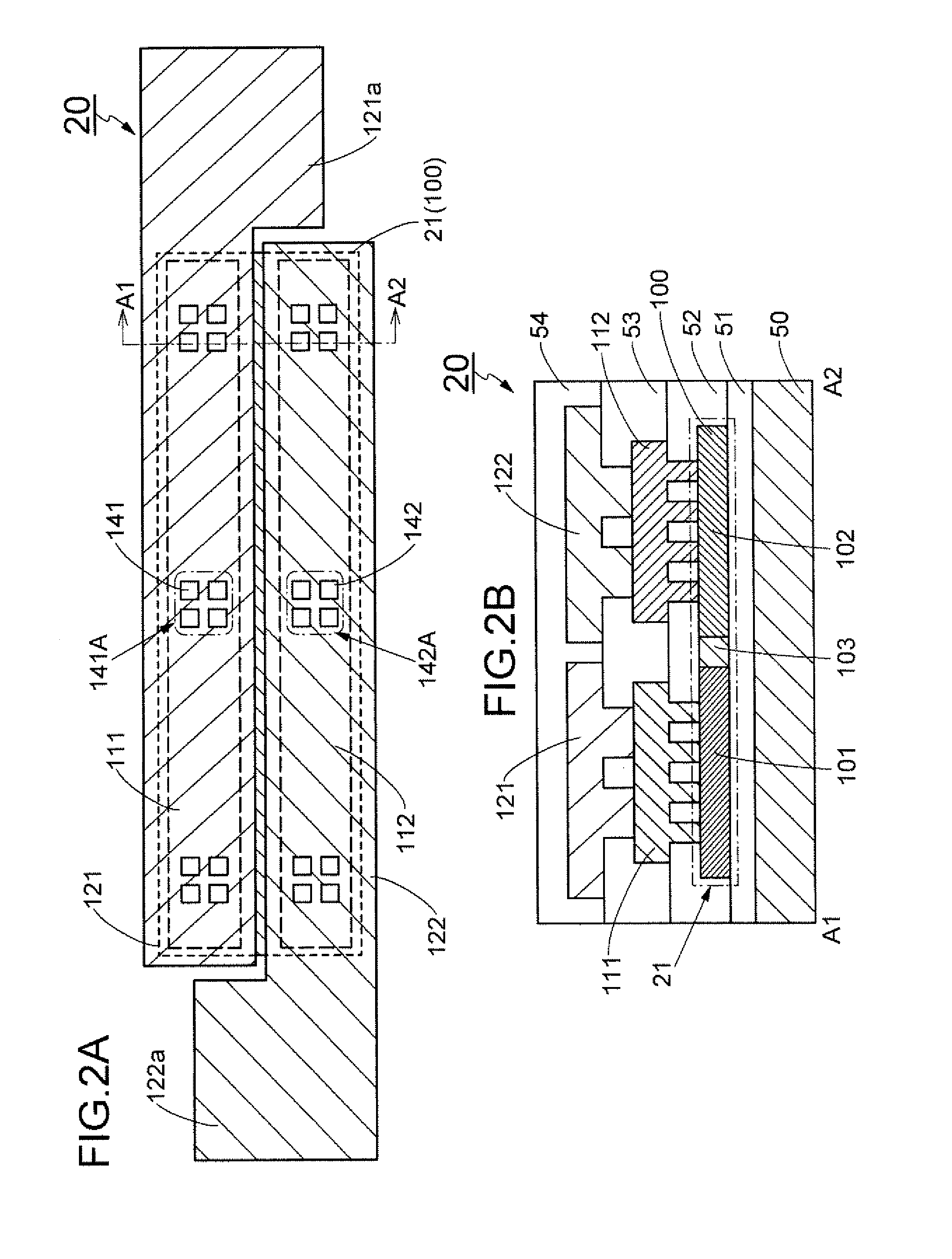

Organic light emitting display device and method of manufacturing the same

ActiveUS20160043341A1Minimize voltage dropImprove lifetime reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceAuxiliary electrode

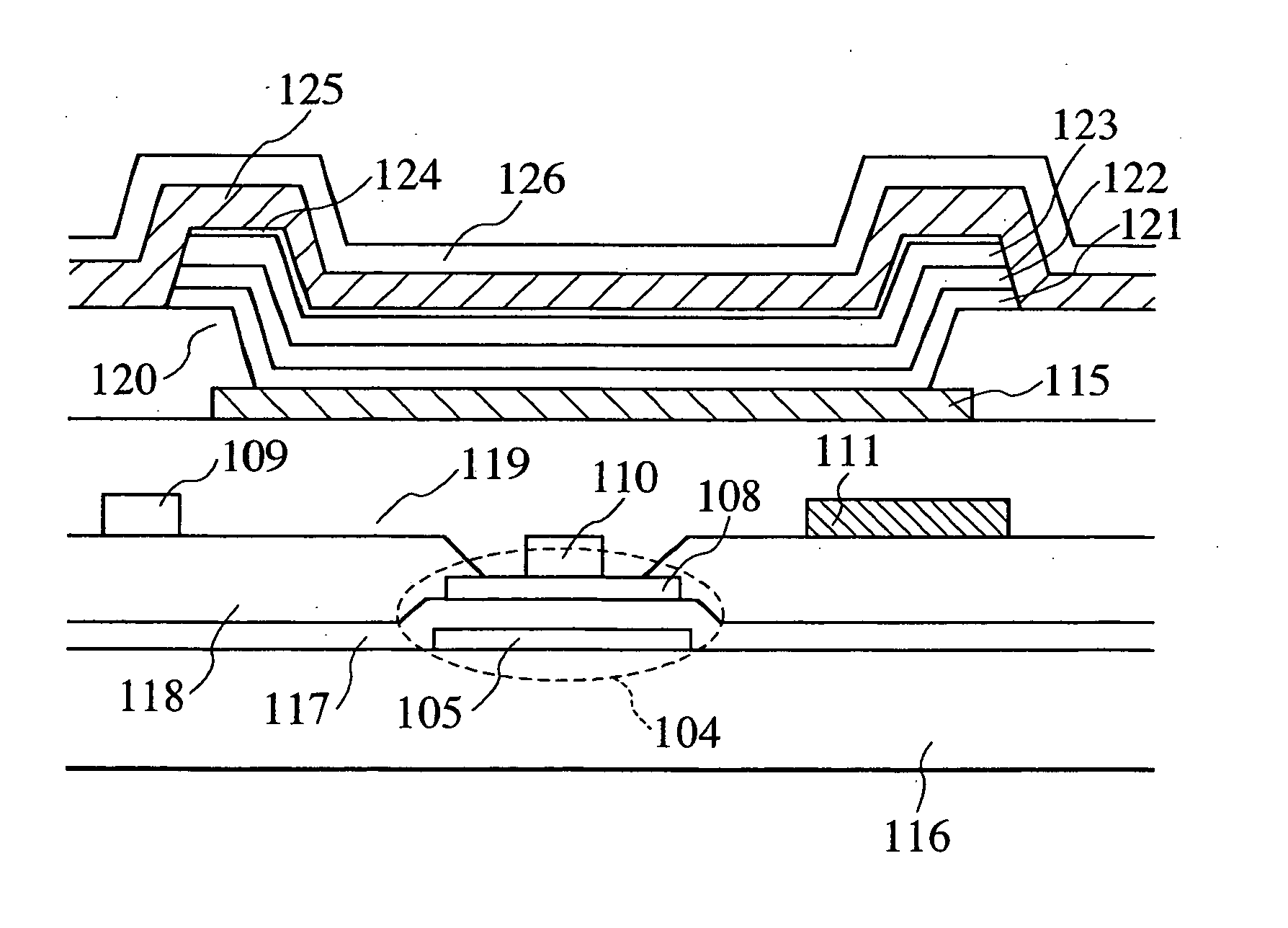

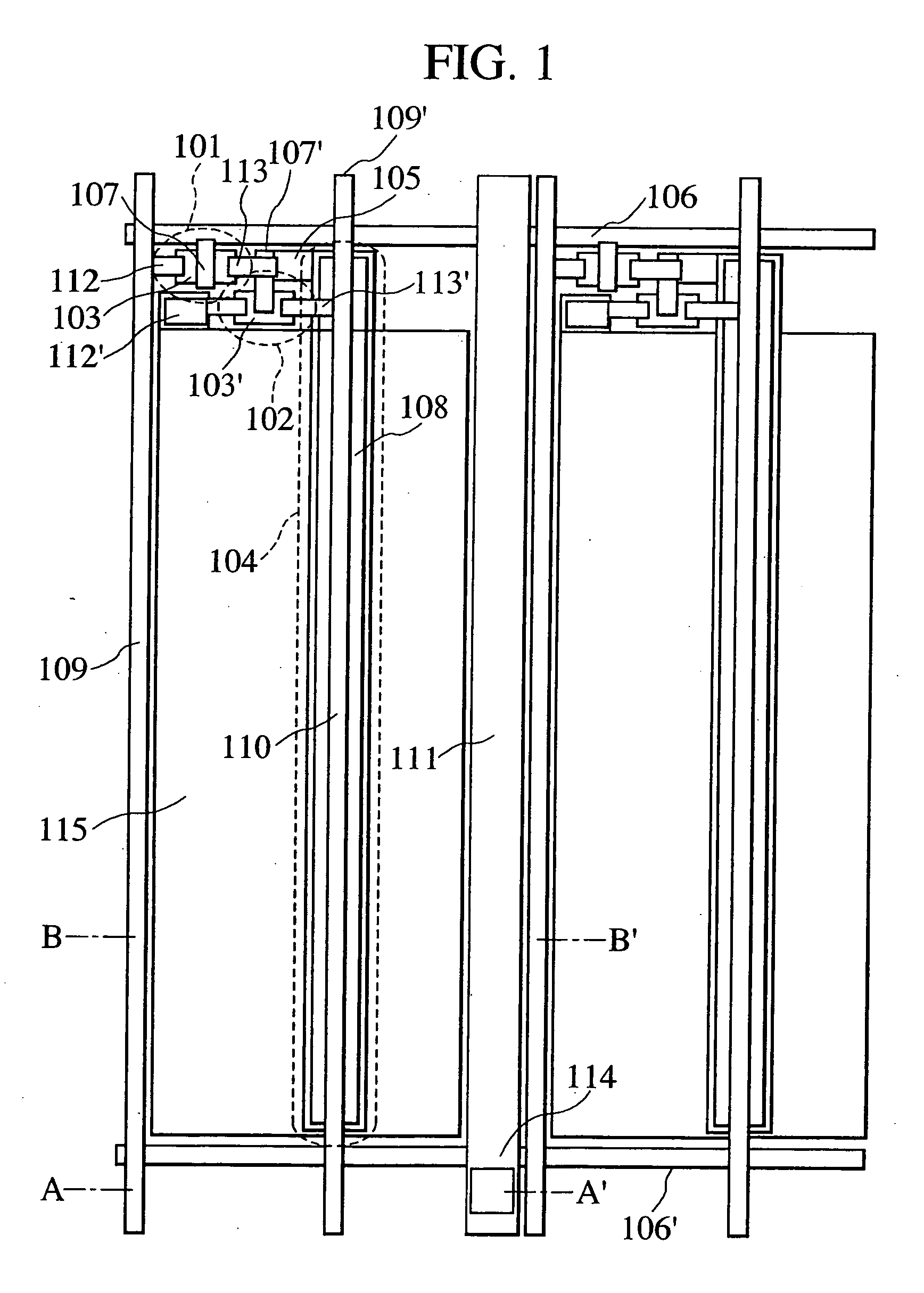

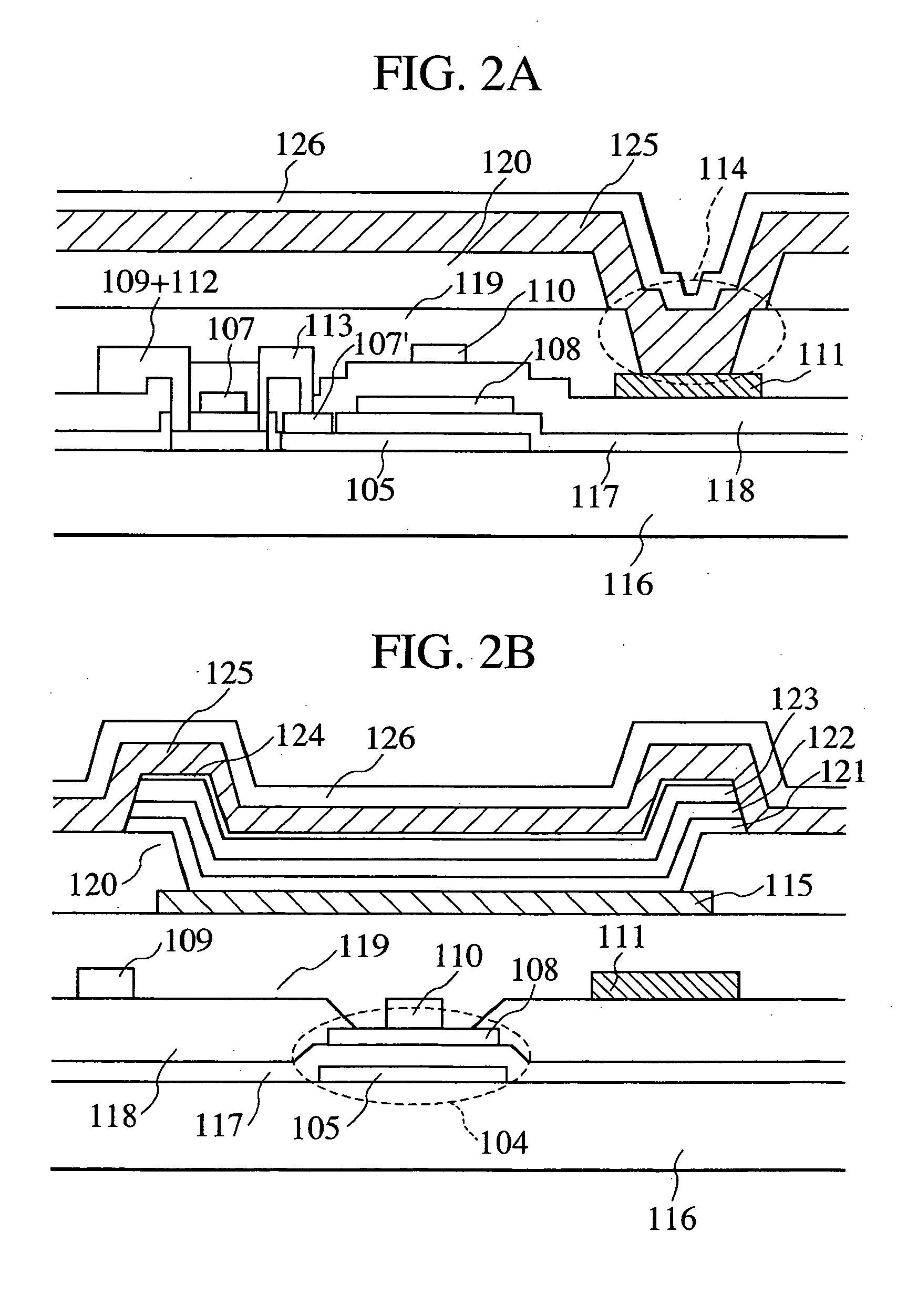

Provided is an organic light emitting display device including: a substrate; a first anode and a second anode formed on the substrate; a first auxiliary electrode formed between the first anode and the second anode; a first organic light emitting layer and a second organic light emitting layer; a first bank including an undercut formed on an upper part of a first edge of the first auxiliary electrode; a second bank including an undercut formed on an upper part of a second edge of the first auxiliary electrode; a second auxiliary electrode disposed between the undercut of the first bank and the first auxiliary electrode; a third auxiliary electrode disposed between the undercut of the second bank and the first auxiliary electrode; a first cathode electrically connected with the second auxiliary electrode; and a second cathode electrically connected with the third auxiliary electrode.

Owner:LG DISPLAY CO LTD

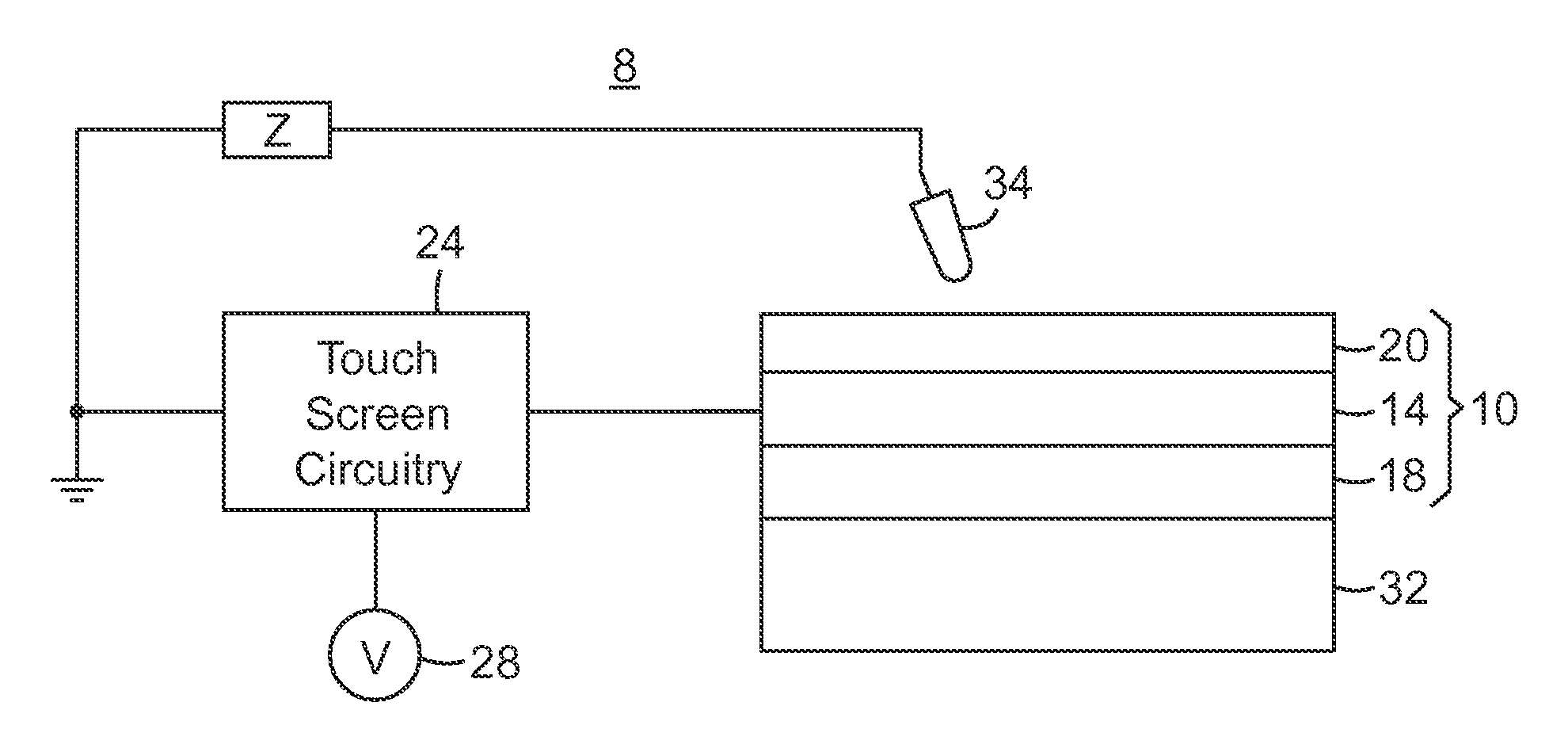

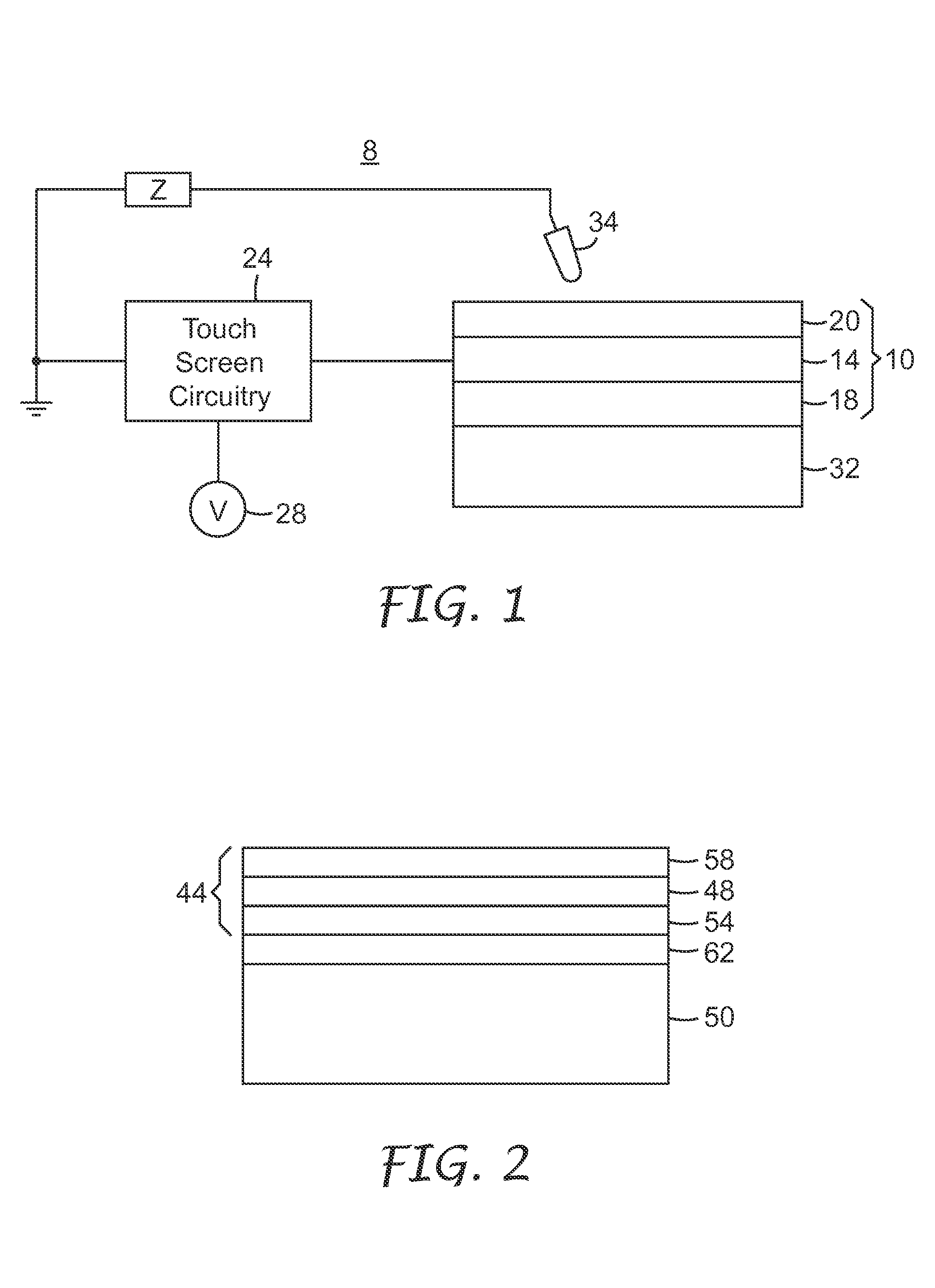

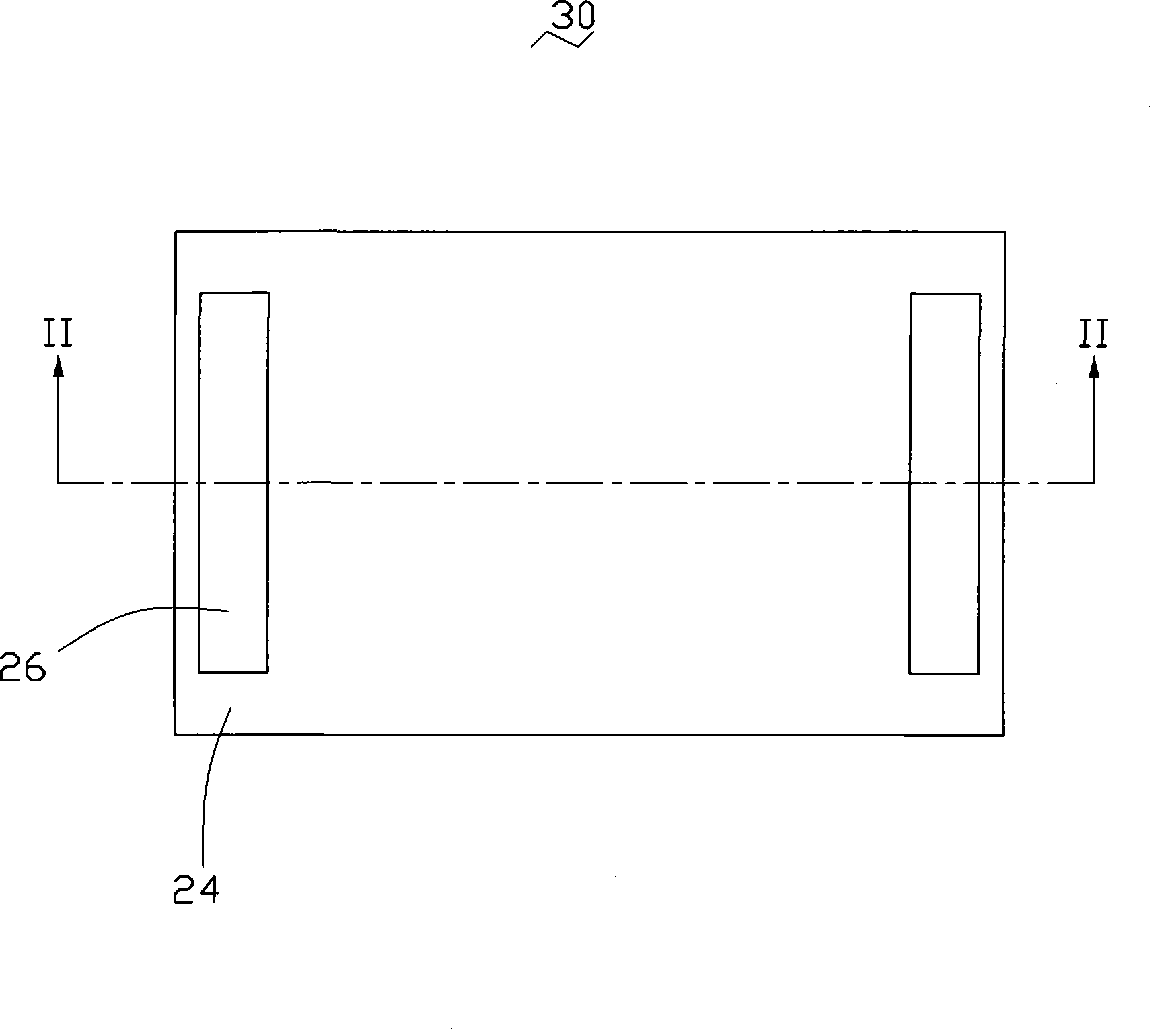

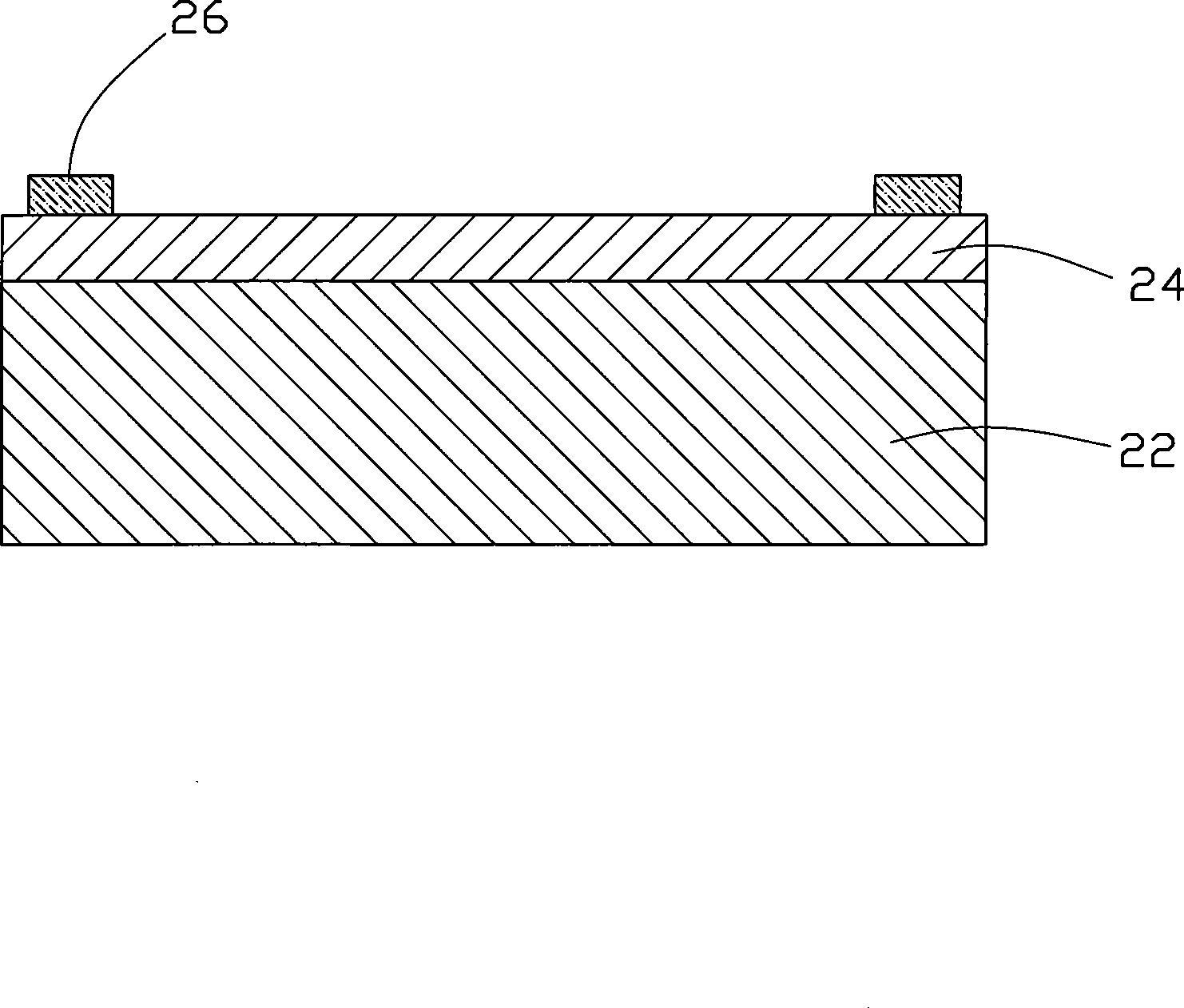

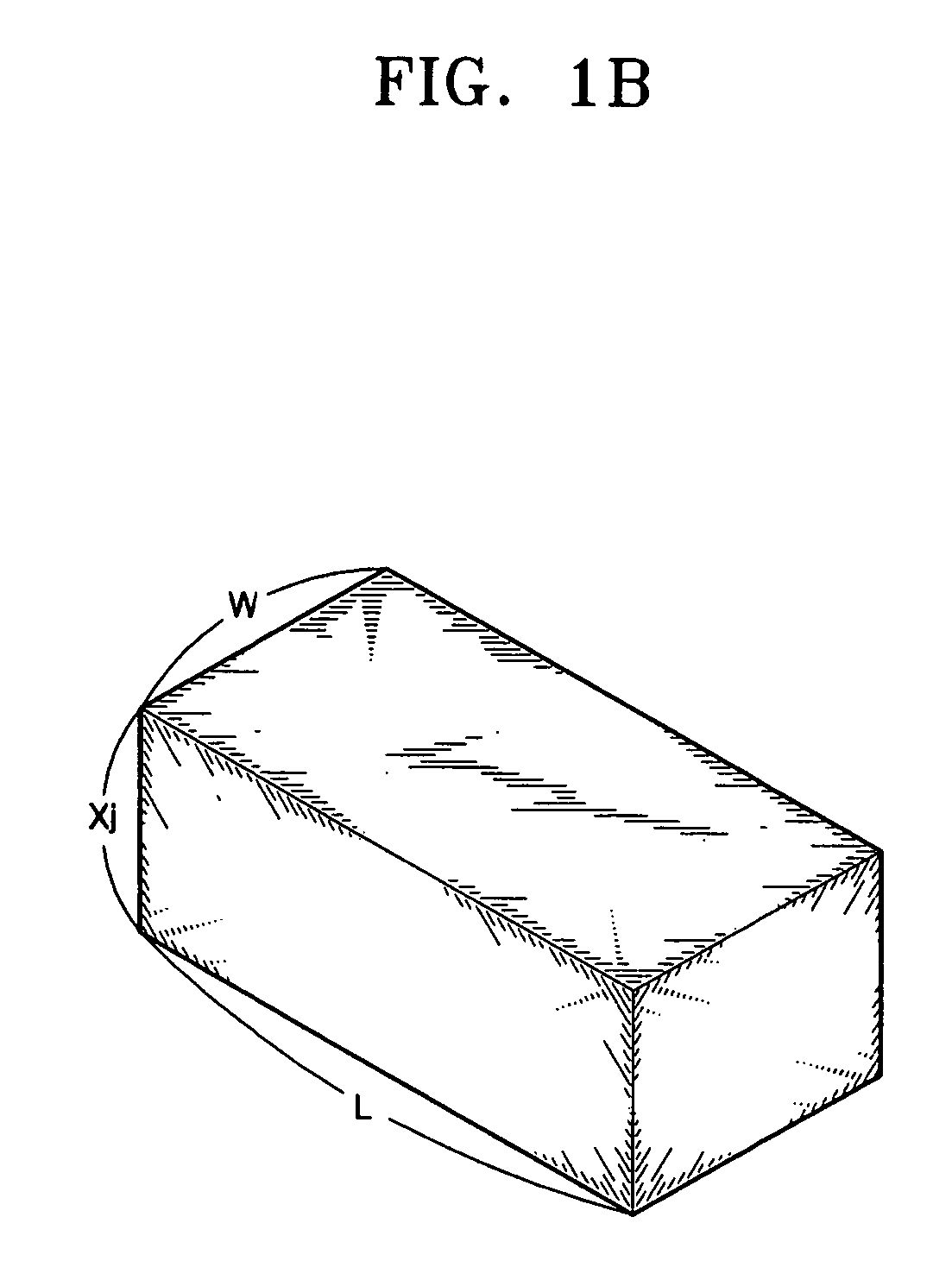

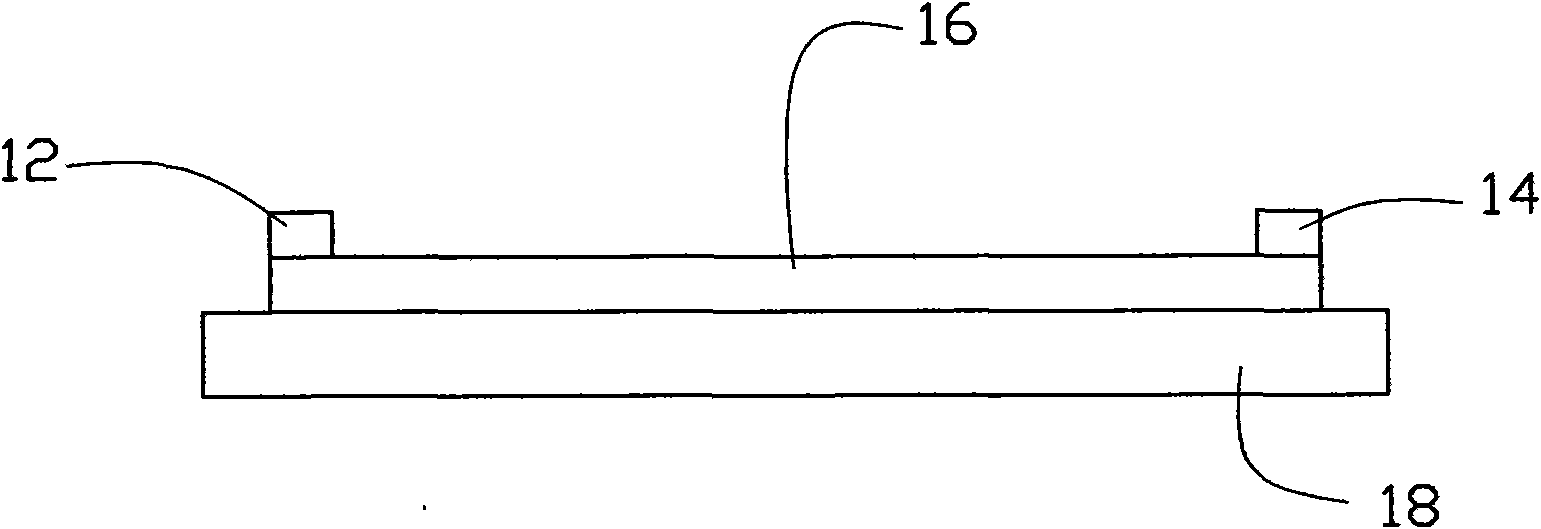

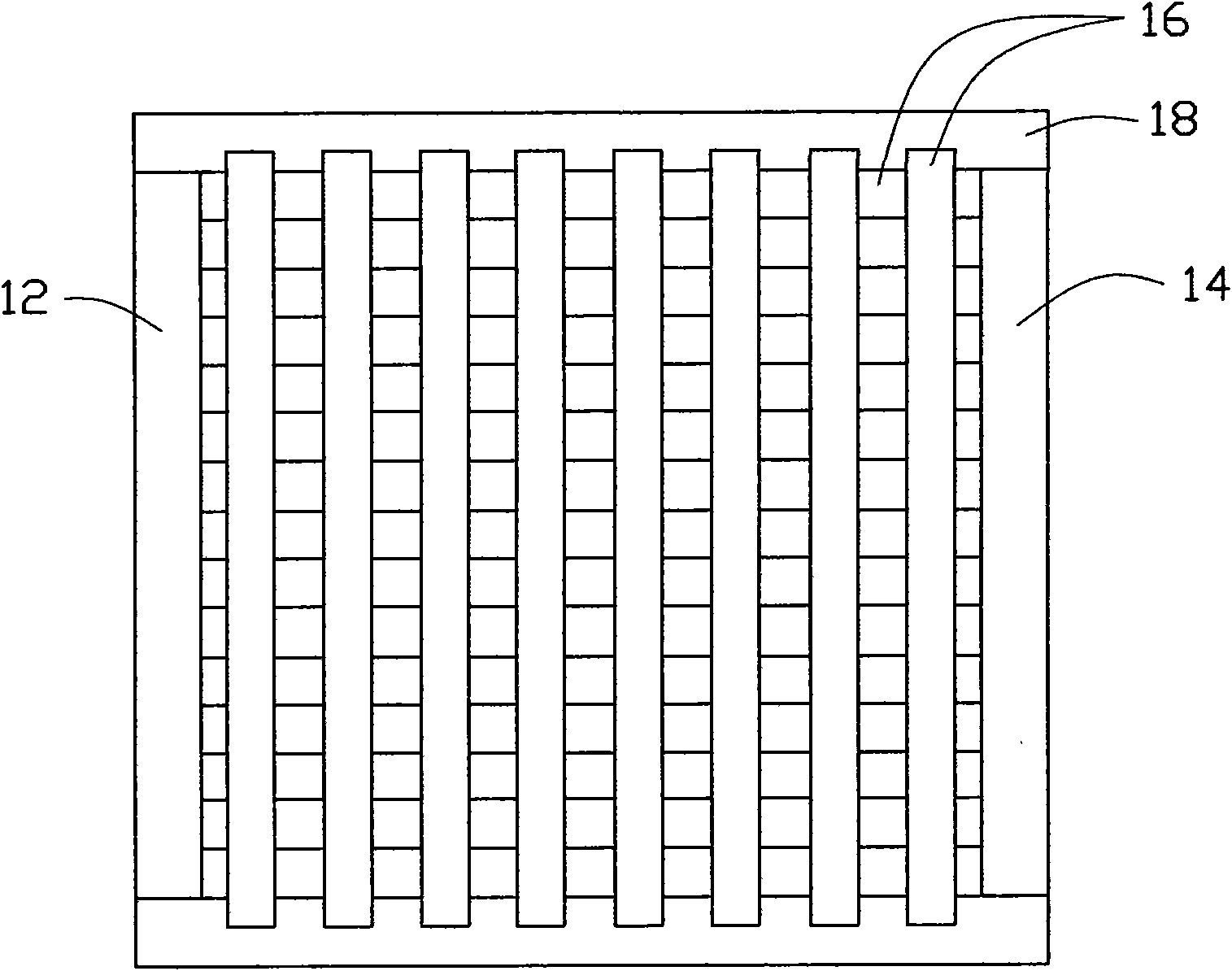

Capacitive touch screen with conductive polymer

InactiveUS7477242B2Uniform resistanceInferior optical and electrical propertyInput/output for user-computer interactionTransmission systemsCapacitanceConductive polymer

A capacitive touch screen is described with a touch area including a substantially transparent conductive polymer. The capacitive touch screen also includes circuitry connecting the conductive polymer of the touch area to a power source, where the circuitry is configured to determine a location of a capacitive coupling on the touch area.

Owner:3M INNOVATIVE PROPERTIES CO

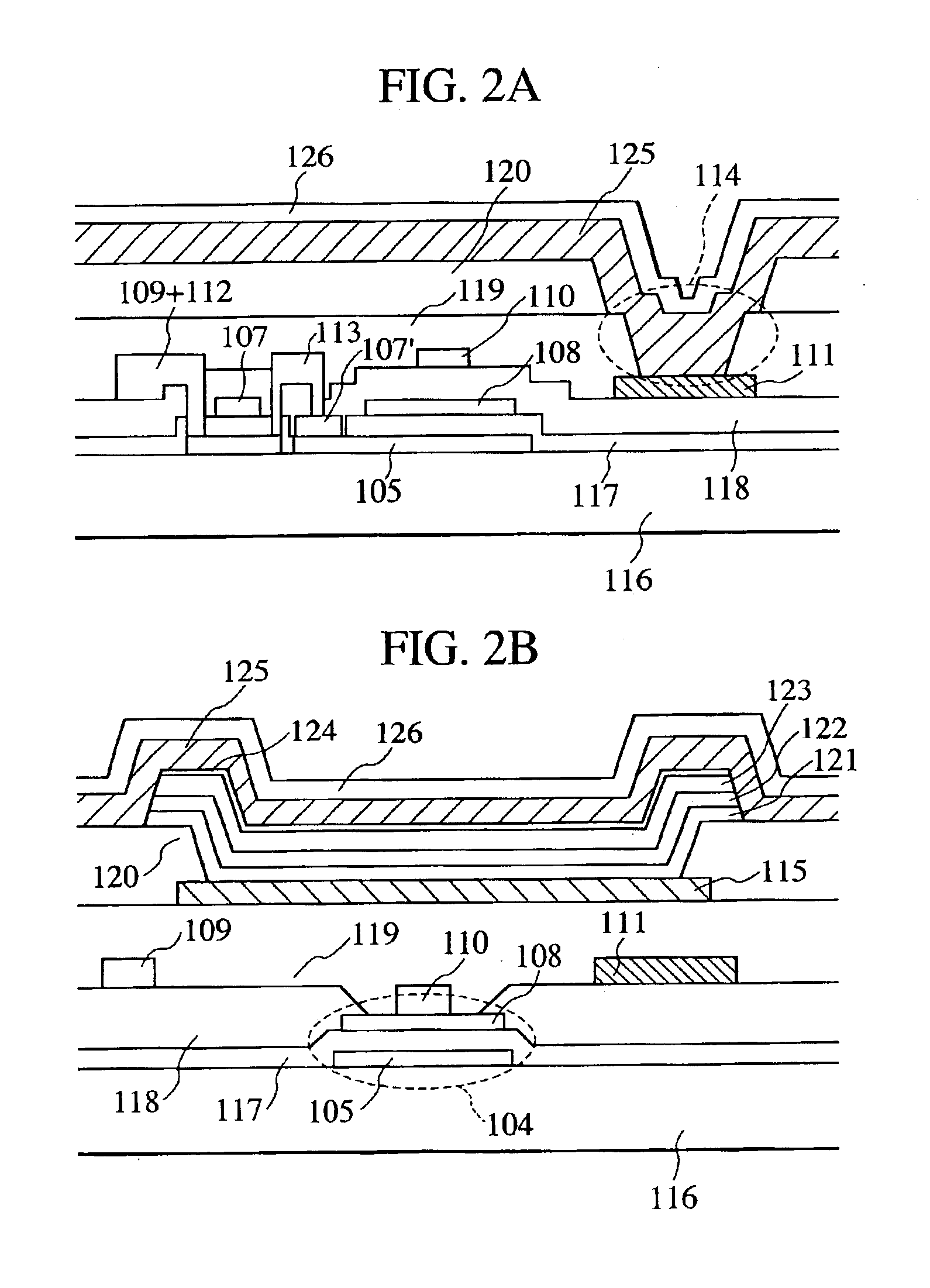

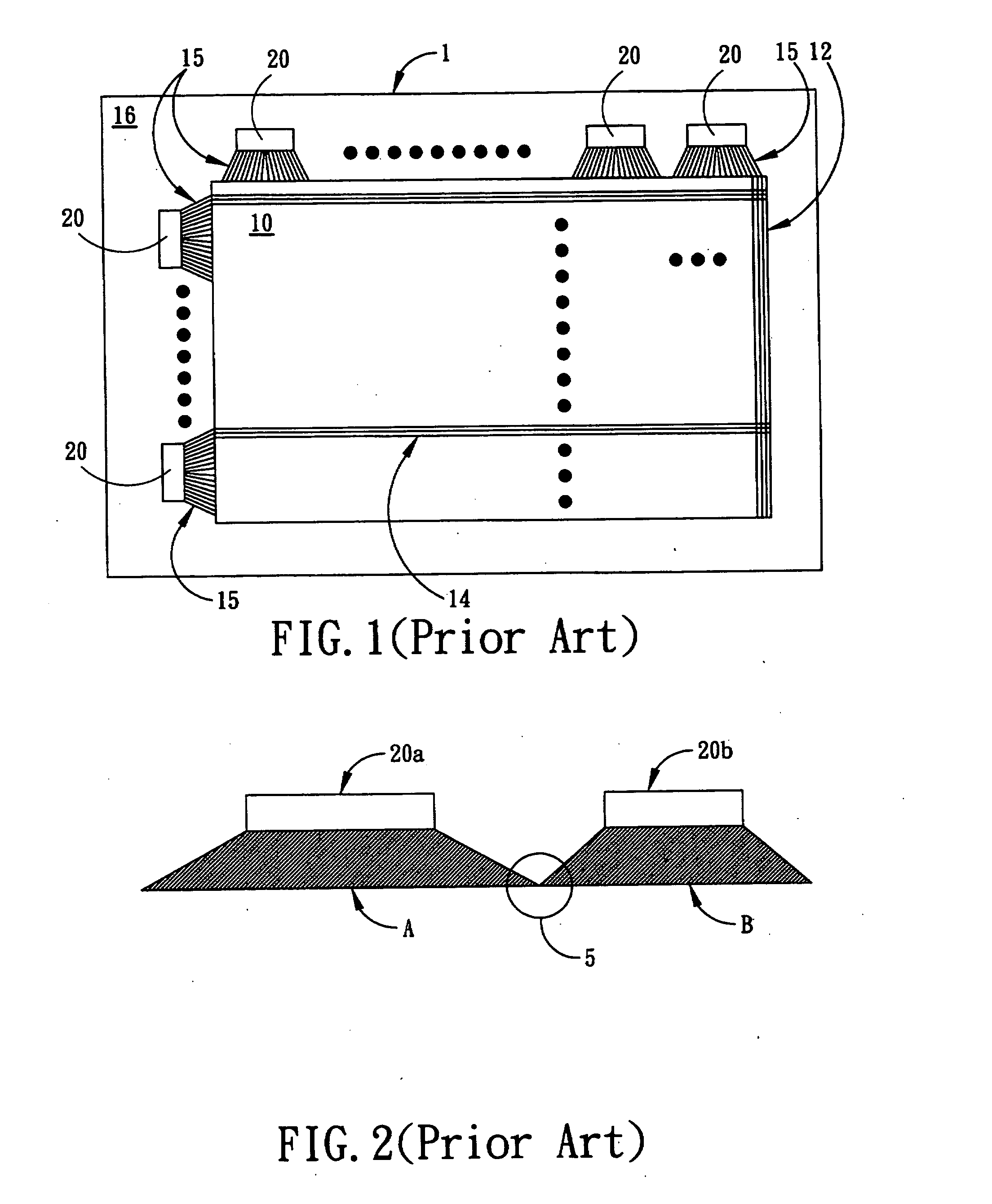

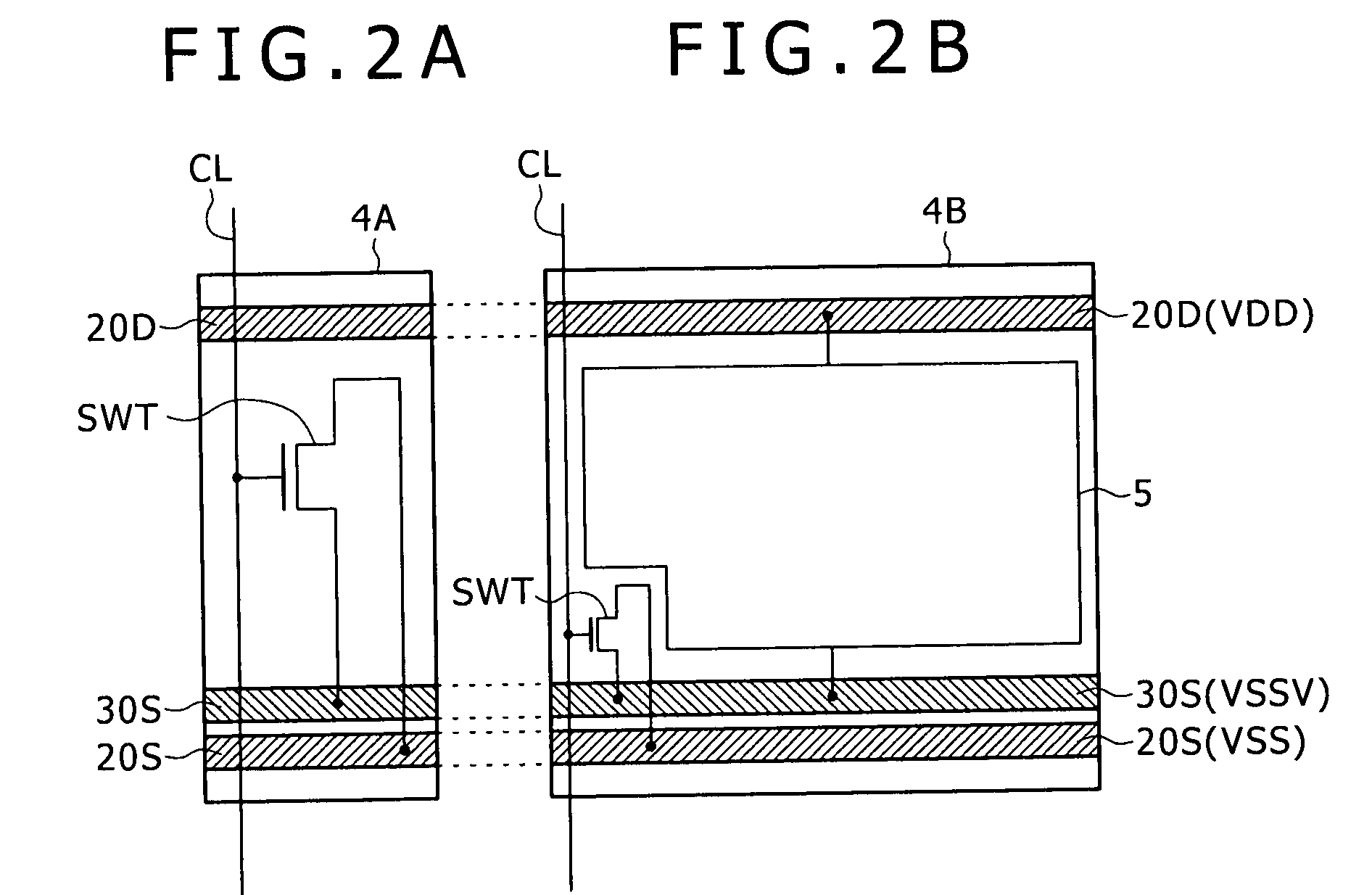

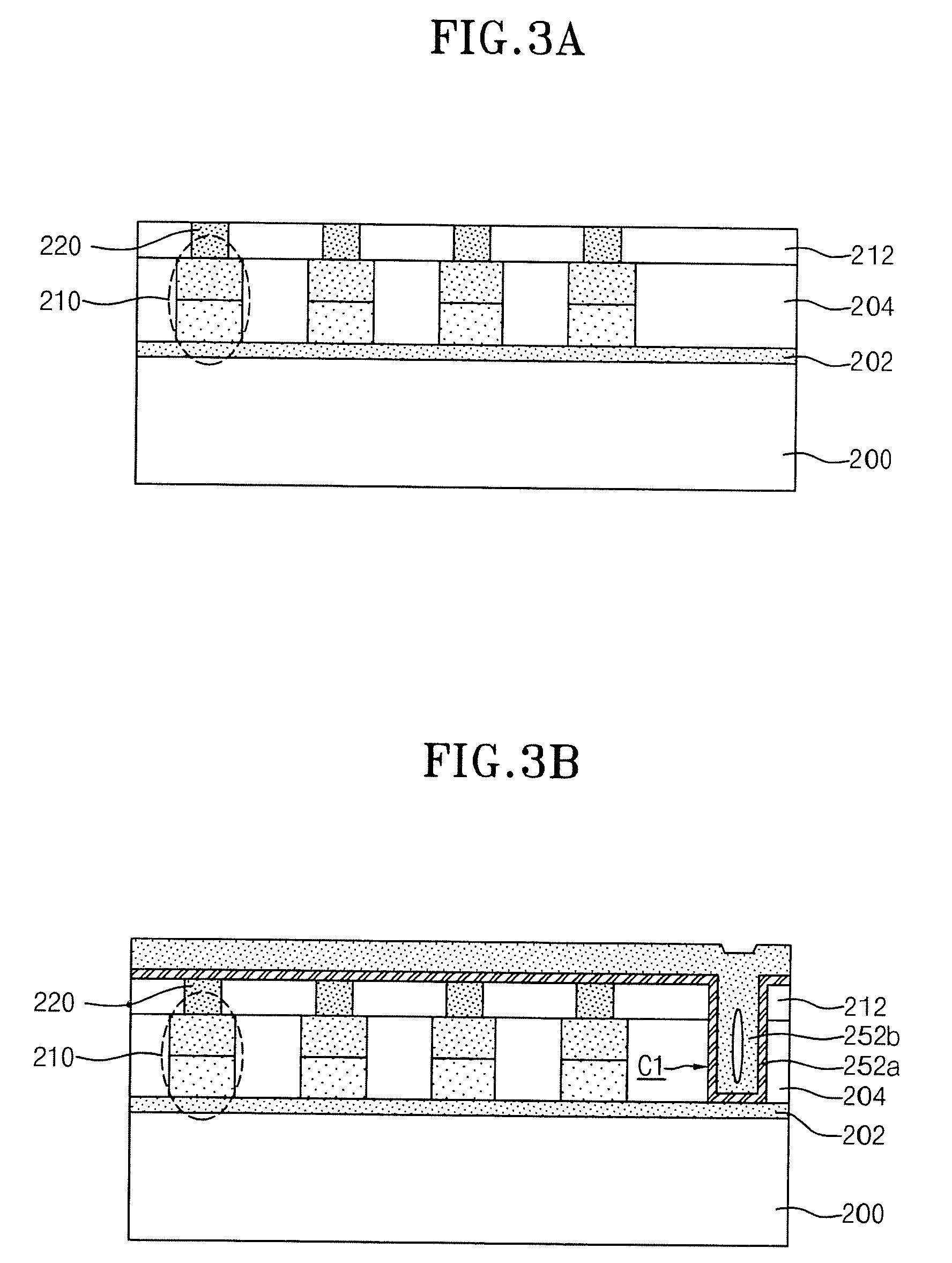

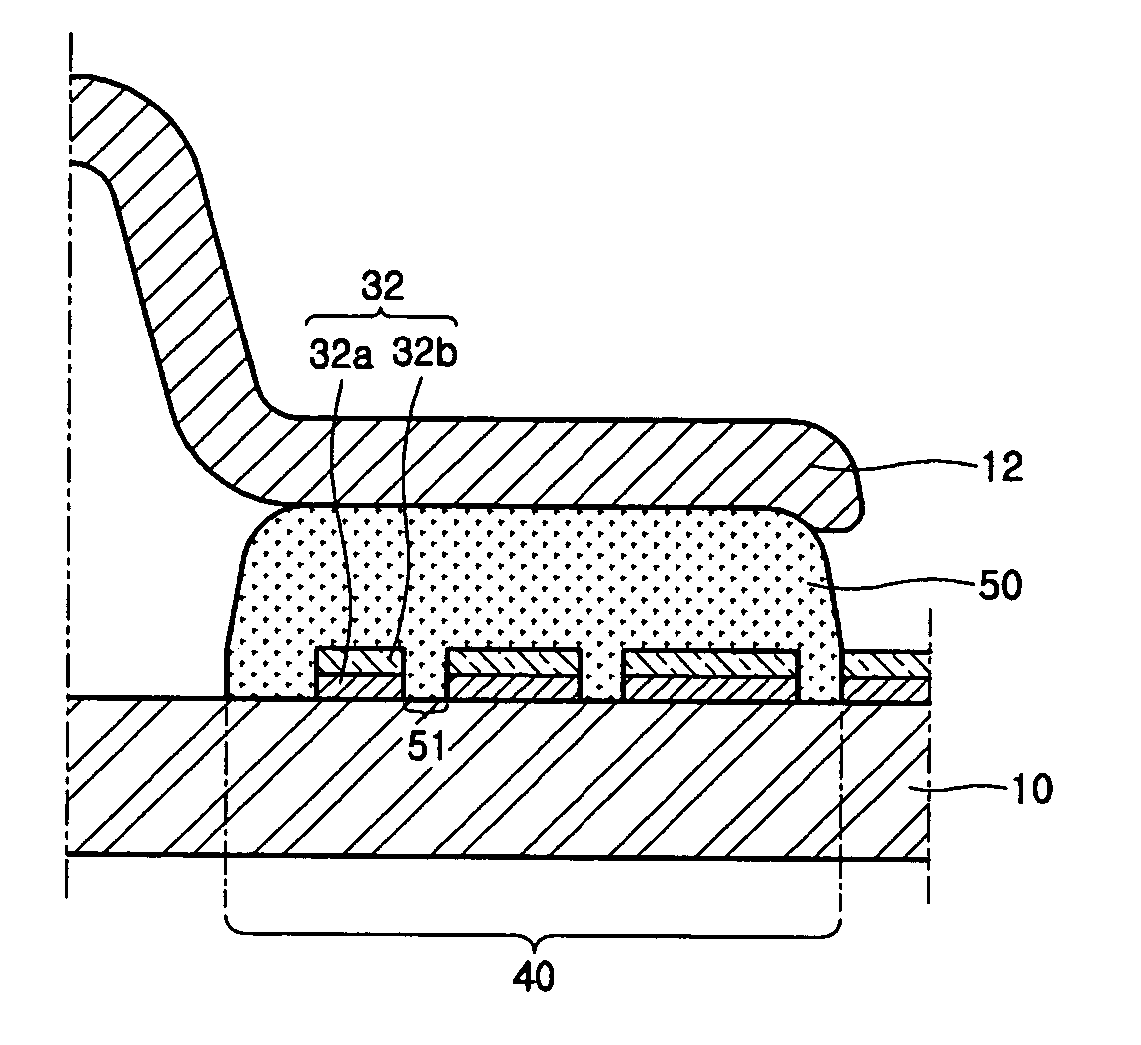

Organic light-emitting display device

InactiveUS6864638B2Variations in brightness due to the resistance of wiring connected to an electrodeVariation in brightnessDischarge tube luminescnet screensStatic indicating devicesDisplay deviceOrganic layer

A scanning line, signal line, first current supply line, and second current supply line are formed on a glass substrate. A first electrode is formed thereon; and, an organic layer, including a hole transport layer, light-emitting layer, electron transport layer, and electron injection layer is formed on the first electrode. A second electrode is formed as a cathode on the electron injection layer. The first electrode, serving as an anode, is connected to a plus terminal of a power source through driving devices and first current supply line, whereas the second electrode is connected to a minus terminal of the power source and is connected to the second current supply line in the display region of each pixel, with a contact hole serving as a feeding point, whereby the wiring resistance of the second electrode is reduced, and variations in the brightness of the panel is reduced.

Owner:SAMSUNG DISPLAY CO LTD +1

Electronic element

ActiveCN101458975AIncreased durabilityImprove performanceMaterial nanotechnologyNanomagnetismCarbon nanotubeOptoelectronics

Owner:TSINGHUA UNIV +1

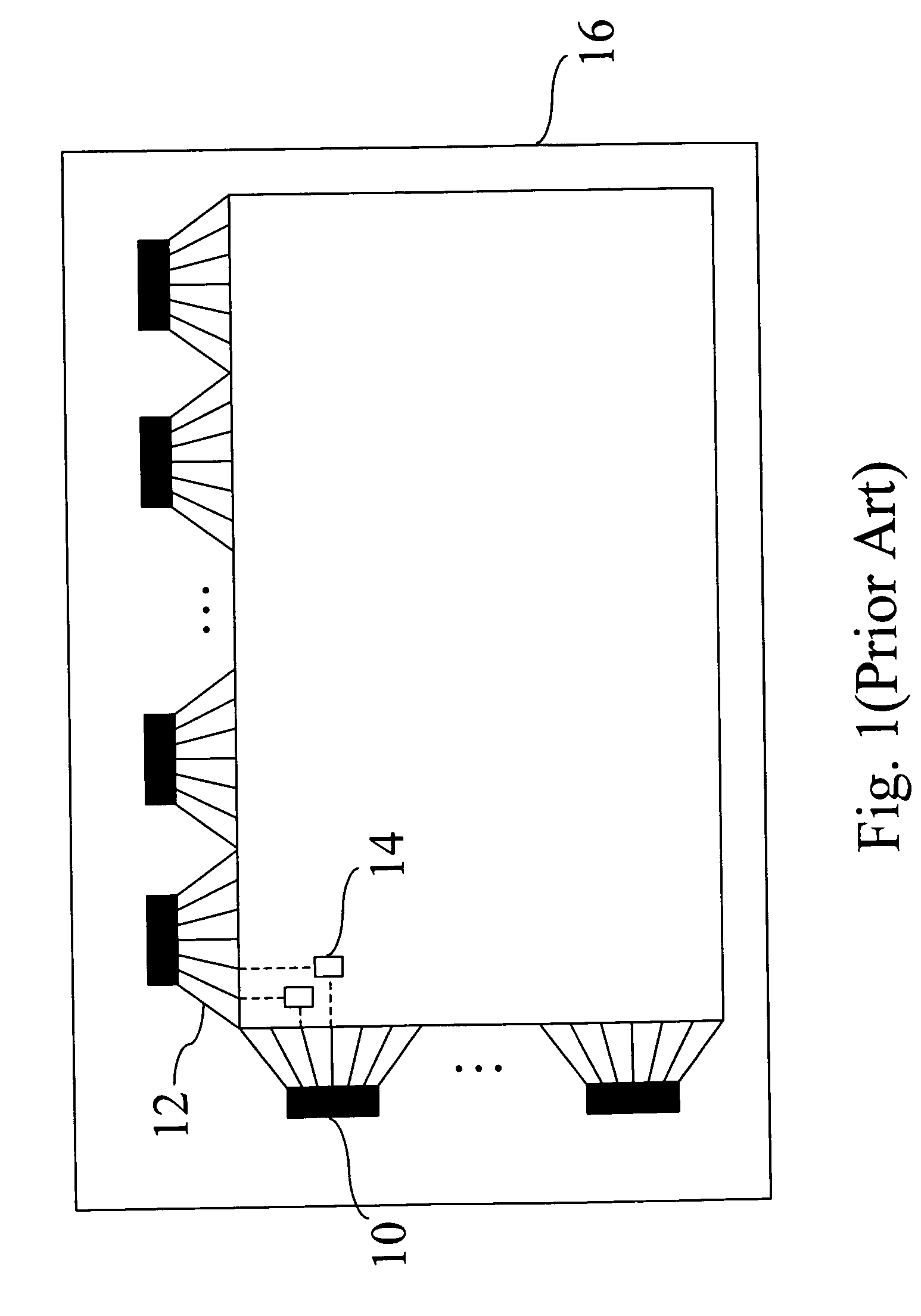

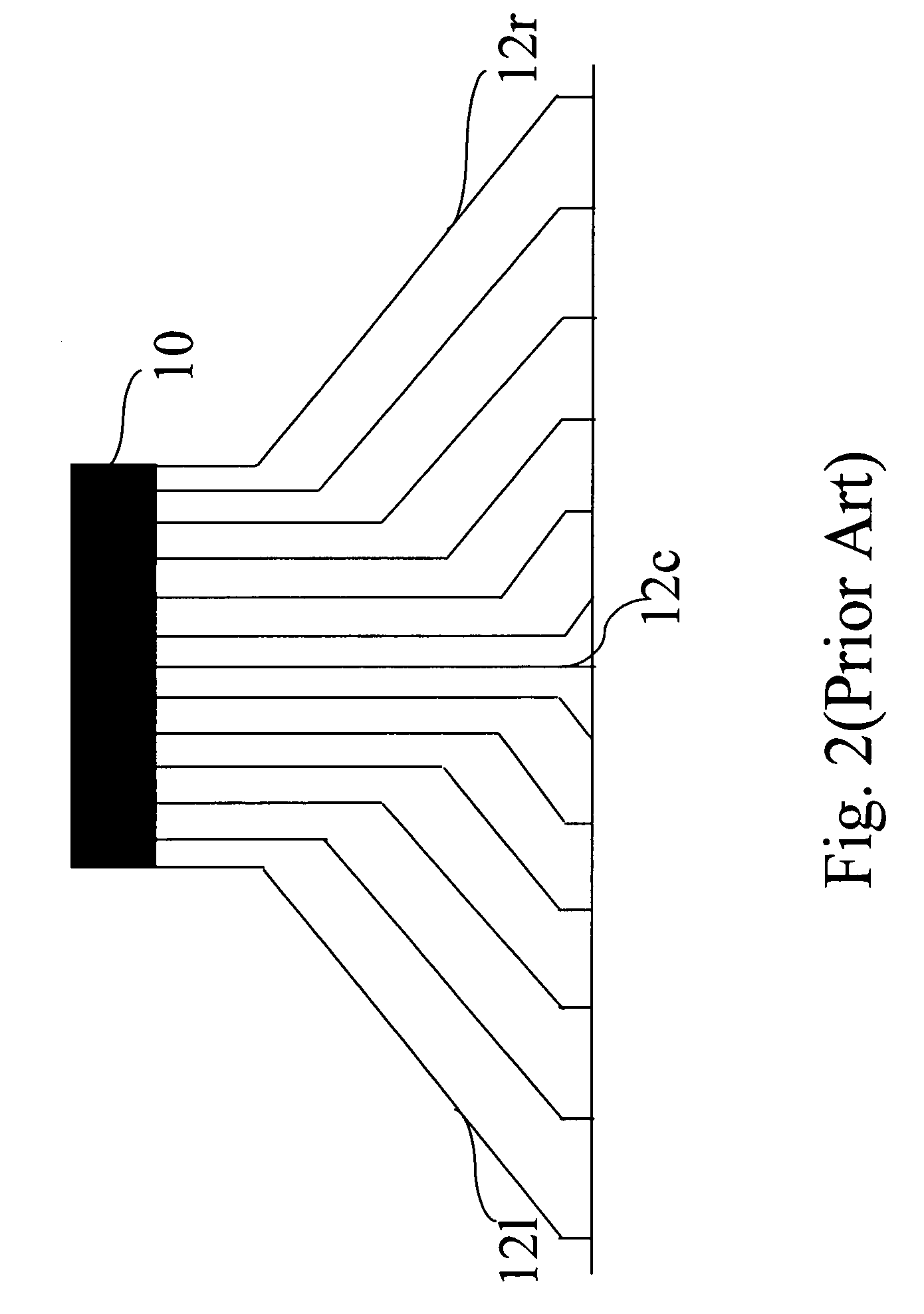

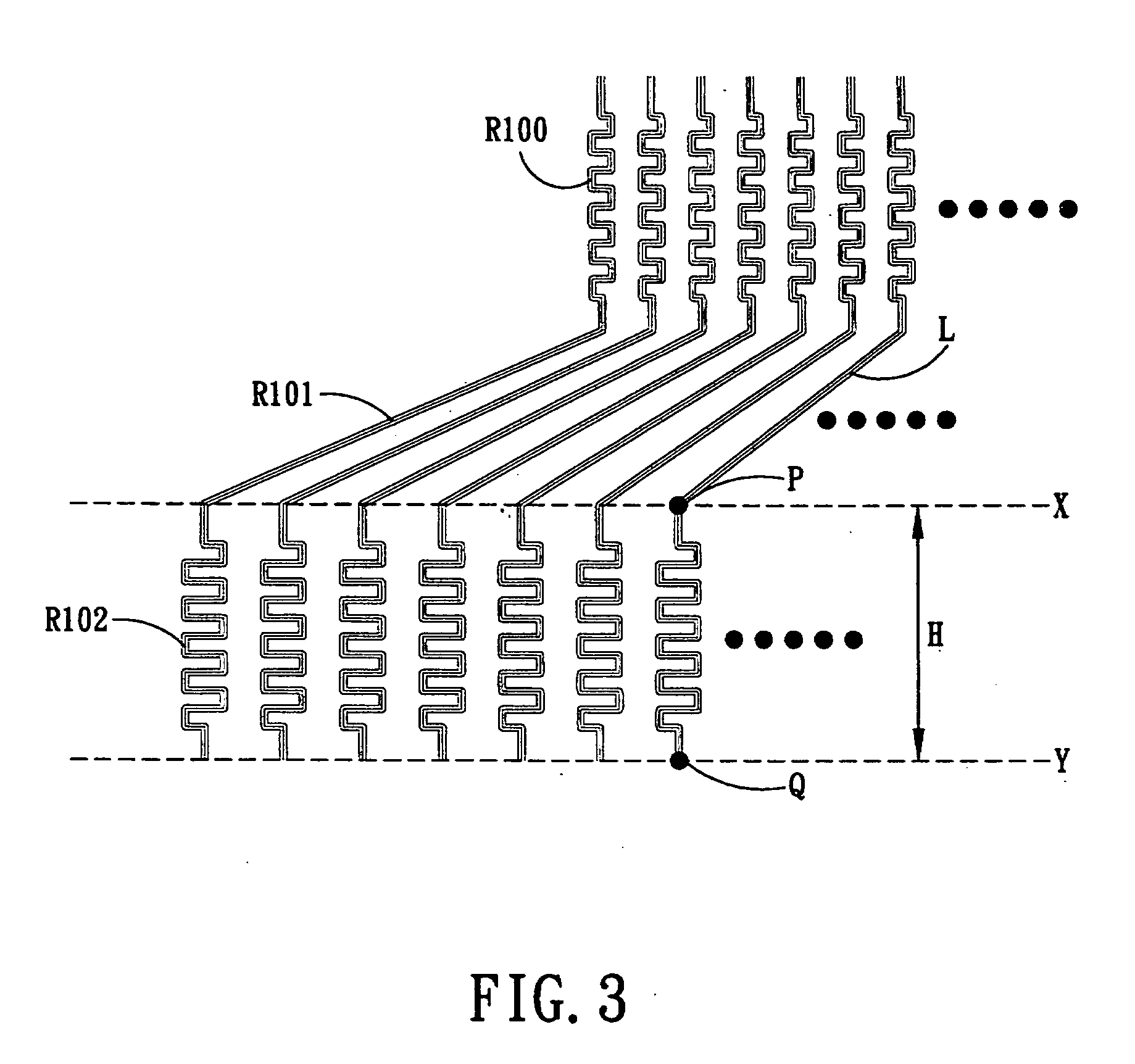

Uniform impedance conducting lines for a liquid crystal display

InactiveUS20070216845A1Capacitance of uniformUniform resistanceNon-linear opticsCapacitanceLiquid-crystal display

A liquid crystal display panel with a fanlike shaped conducting line design that provides uniform impedance is disclosed. The liquid crystal display panel comprises a plurality of transistors, a plurality of control ICs and a plurality of conducting lines. Each of the conducting lines comprises a respective width and a respective length. The width and length of the conducting lines increases towards the medial portion of the fanlike shape. The arrangement of the length and width makes the resistance and capacitance of the conducting lines uniform. As a result, the display panel achieves higher optical performance and improved quality.

Owner:HANNSTAR DISPLAY CORPORATION

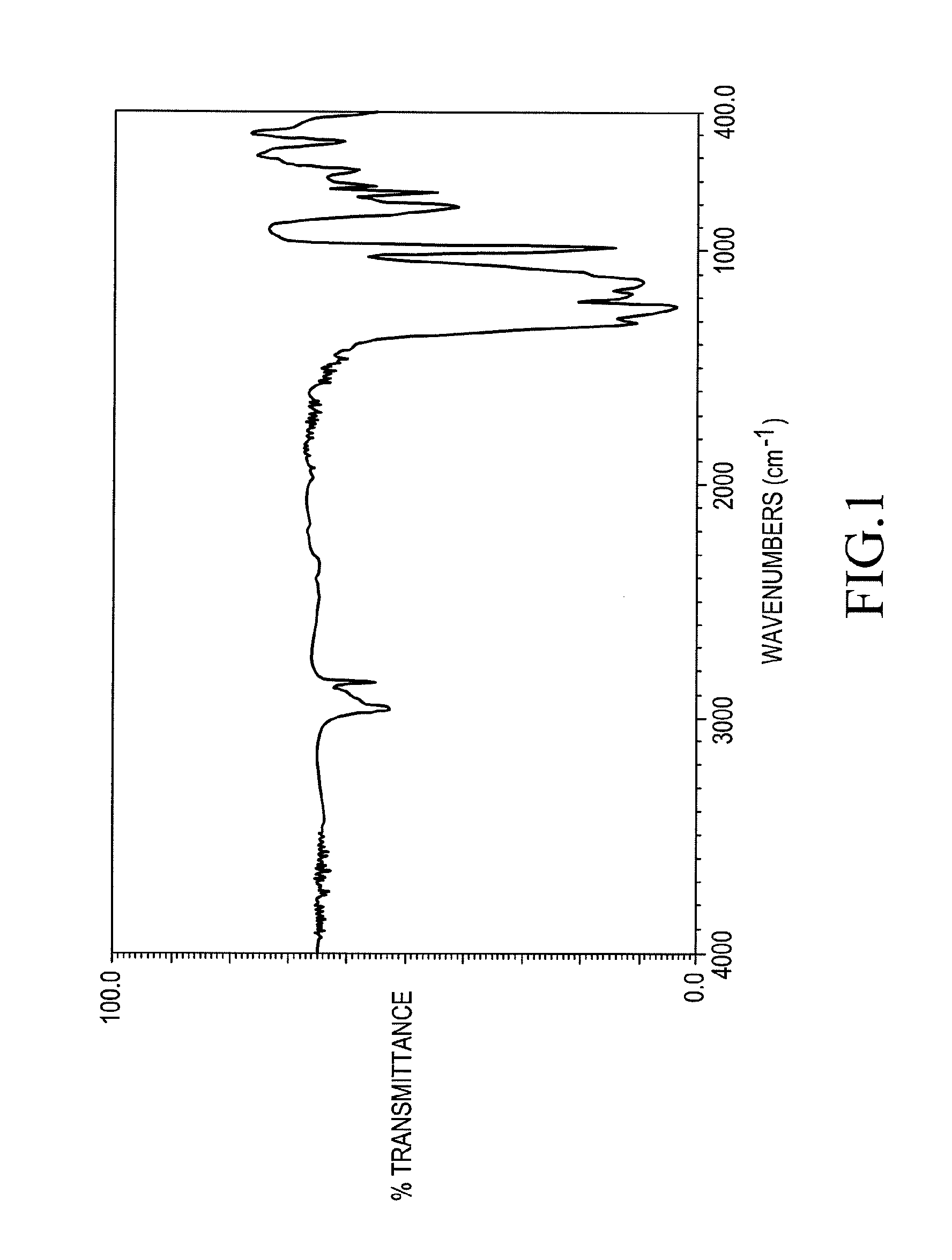

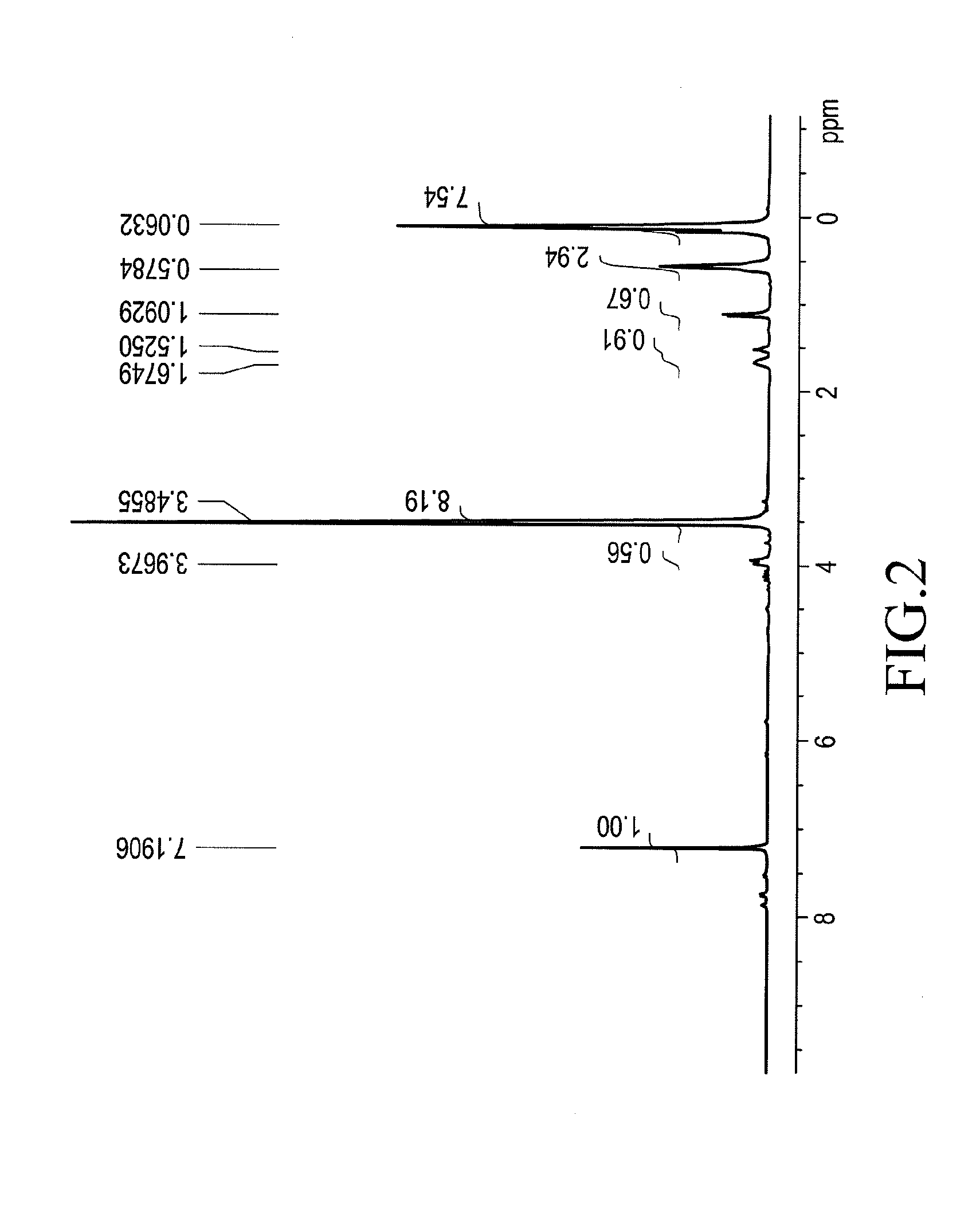

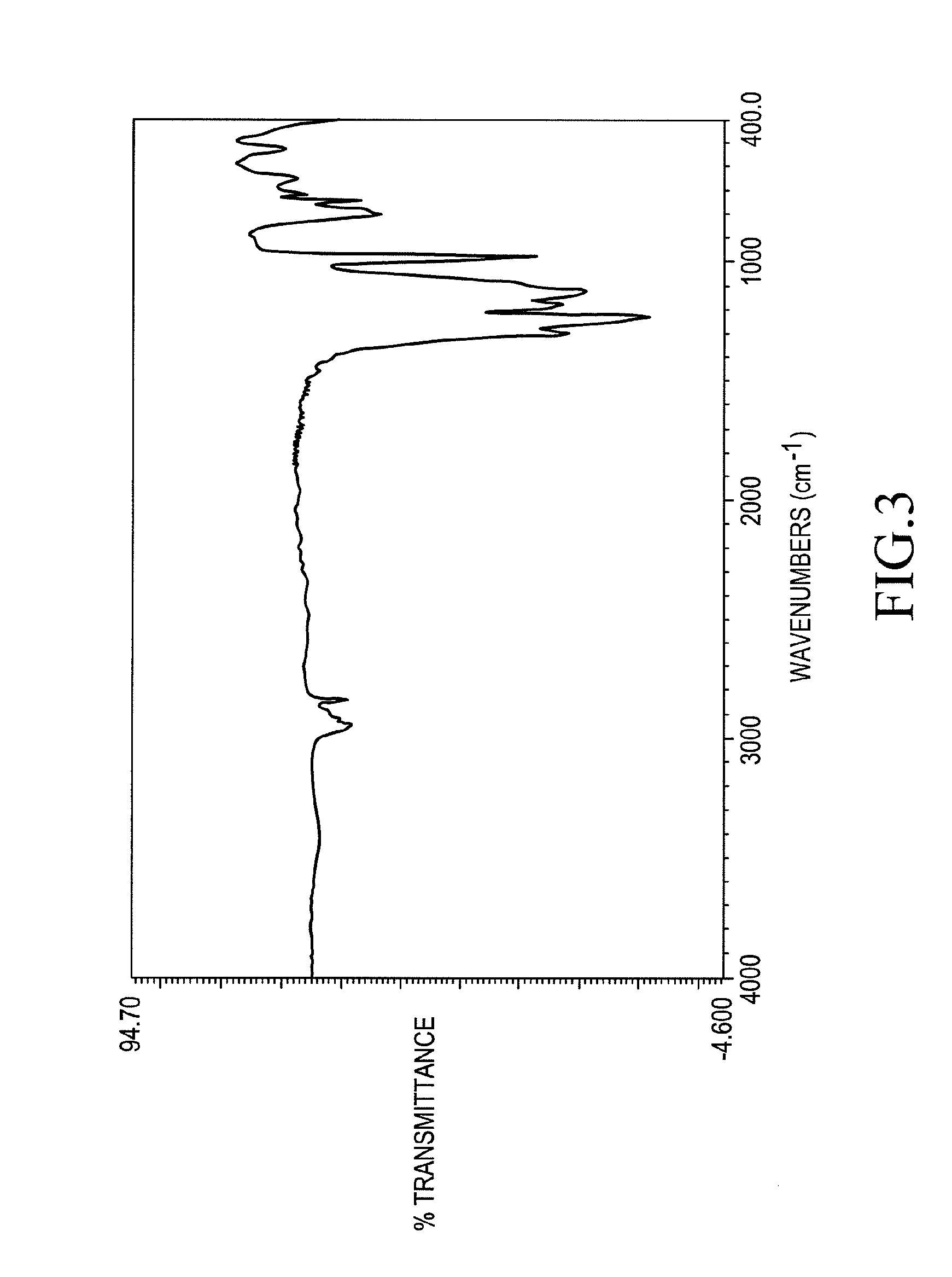

Fluorine-containing organopolysiloxane, a surface treatment composition comprising the same and an article treated with the composition

ActiveUS20070149746A1Increase resistanceHigh strengthSilicon organic compoundsLayered productsPolymer scienceHydrogen atom

An organopolysiloxane represented by the following general formula (A), (B) or (C) SinR12n+2On−1 (A) SinR12nOn (B) SinR12n+2R2kOn−k (C) wherein R1 may be the same with or different from each other and is a hydrogen atom or a monovalent organic group, R2 is an alkylene group having 2 to 6 carbon atoms, n is an integer of from 2 to 40 and k is an integer of 1 to 3, characterized in that at least two R1's are represented by the following formula (i): wherein X is a hydrolyzable group, R3 is an alkyl group having 1 to 4 carbon atoms or a phenyl group, y is an integer of from 1 to 5 and a is 2 or 3; and one SiR1 bond is represented by the following formula (ii) or one SiOSi bond is replaced with a bond represented by the following formula (iii): SiQRf1 (ii) SiQRf2QSi (iii) wherein Rf1 is a monovalent group containing a perfluoroether residue, Rf is a divalent group containing a perfluoroether residue, and Q is a divalent organic group.

Owner:SHIN ETSU CHEM IND CO LTD

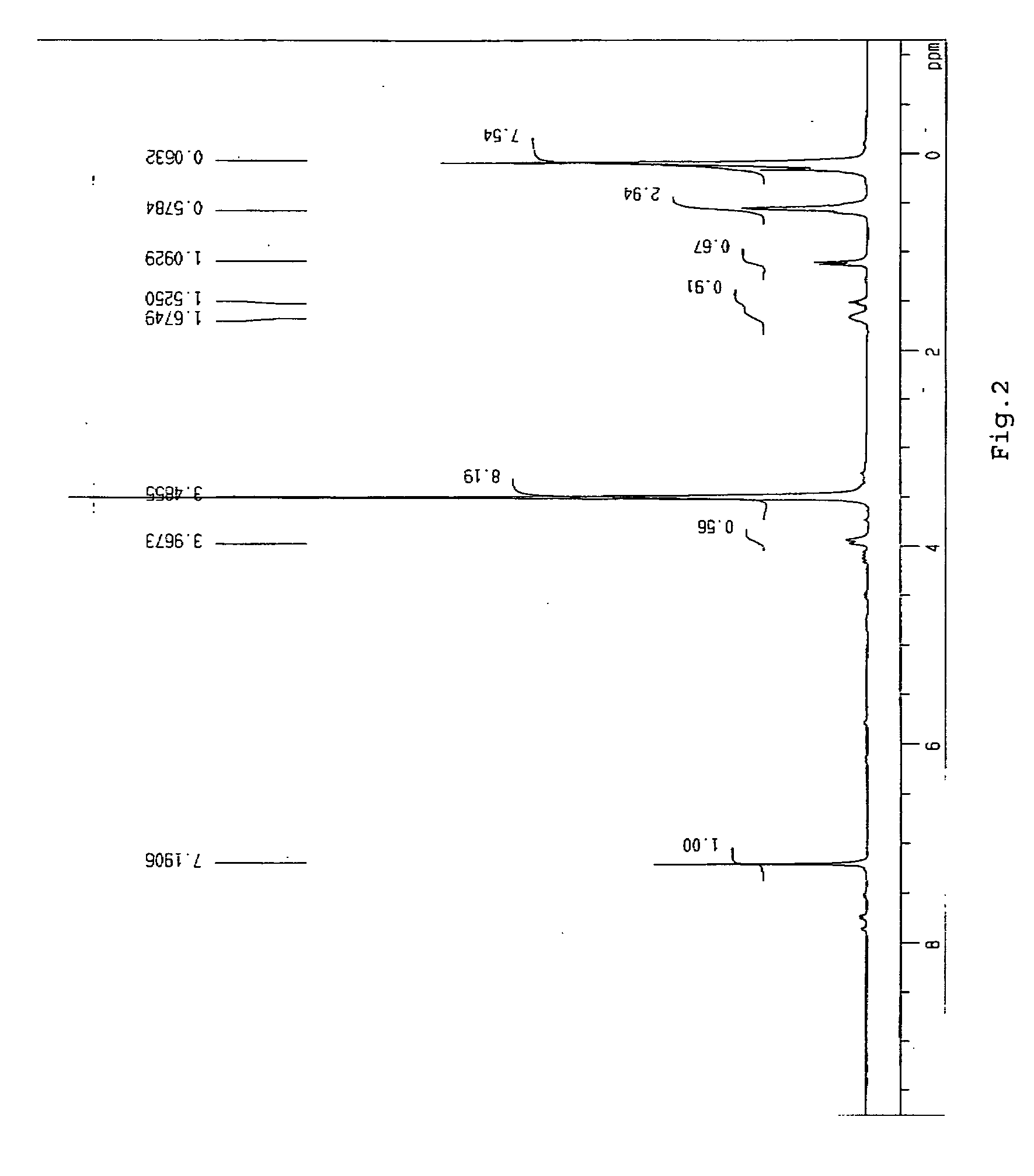

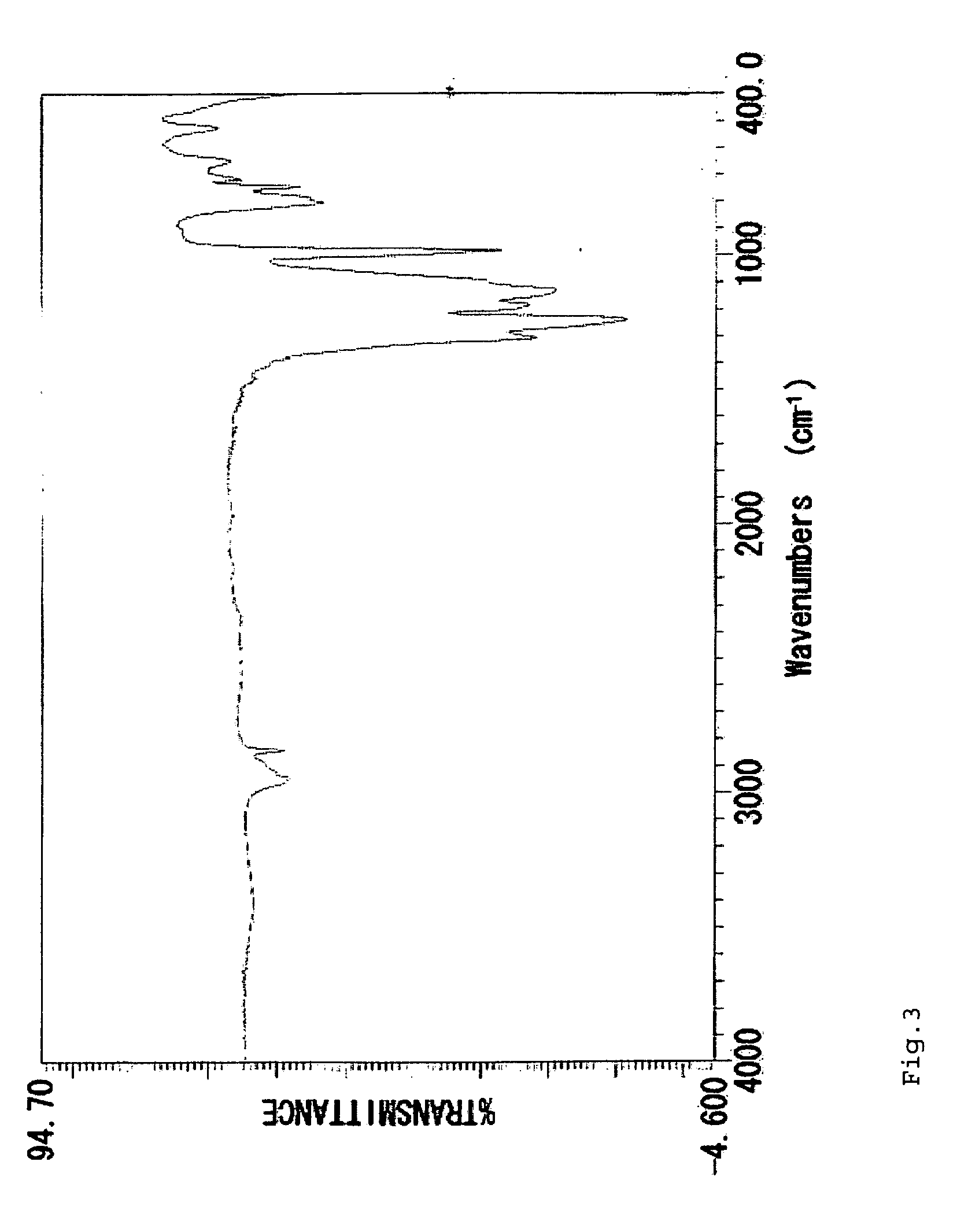

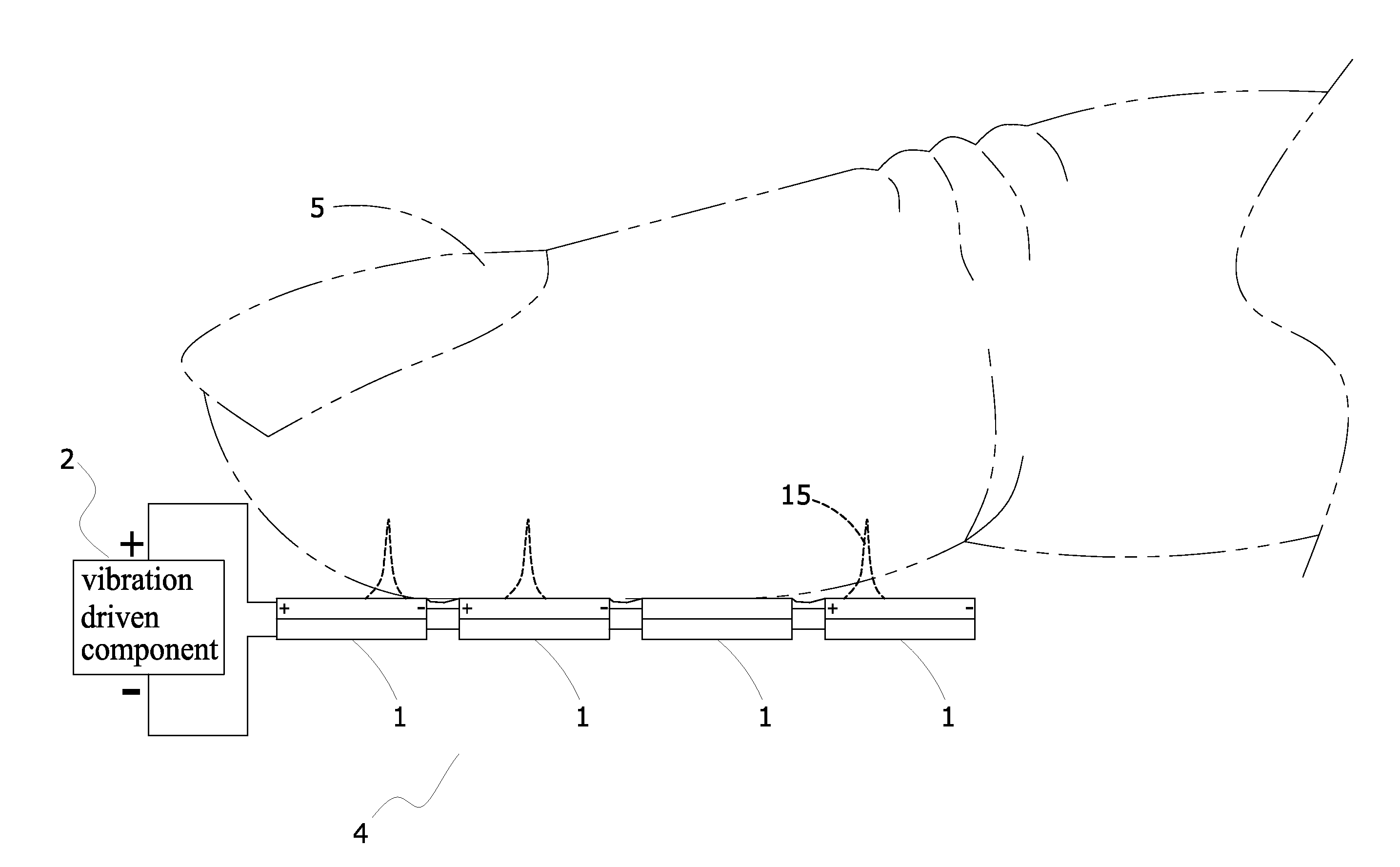

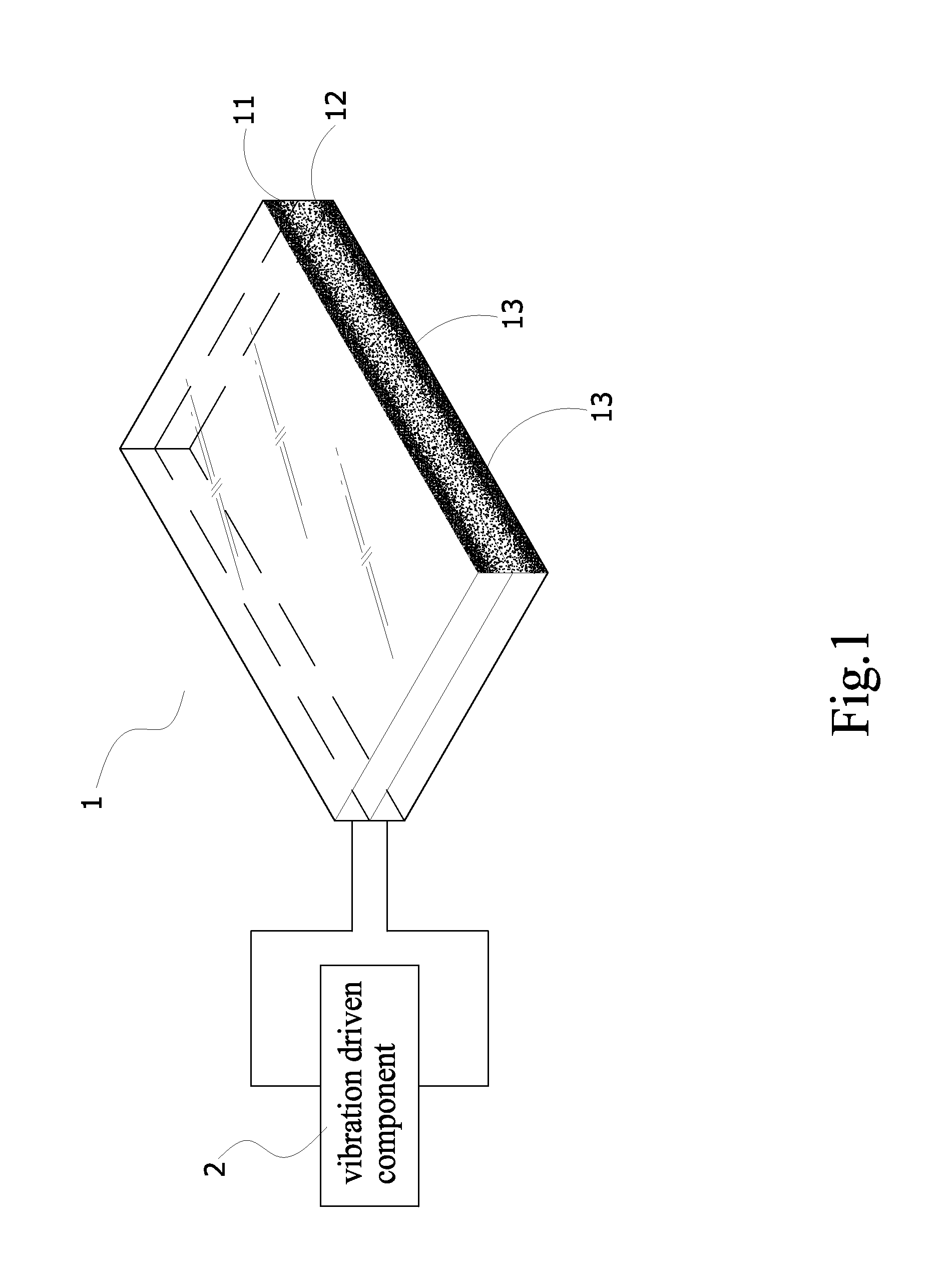

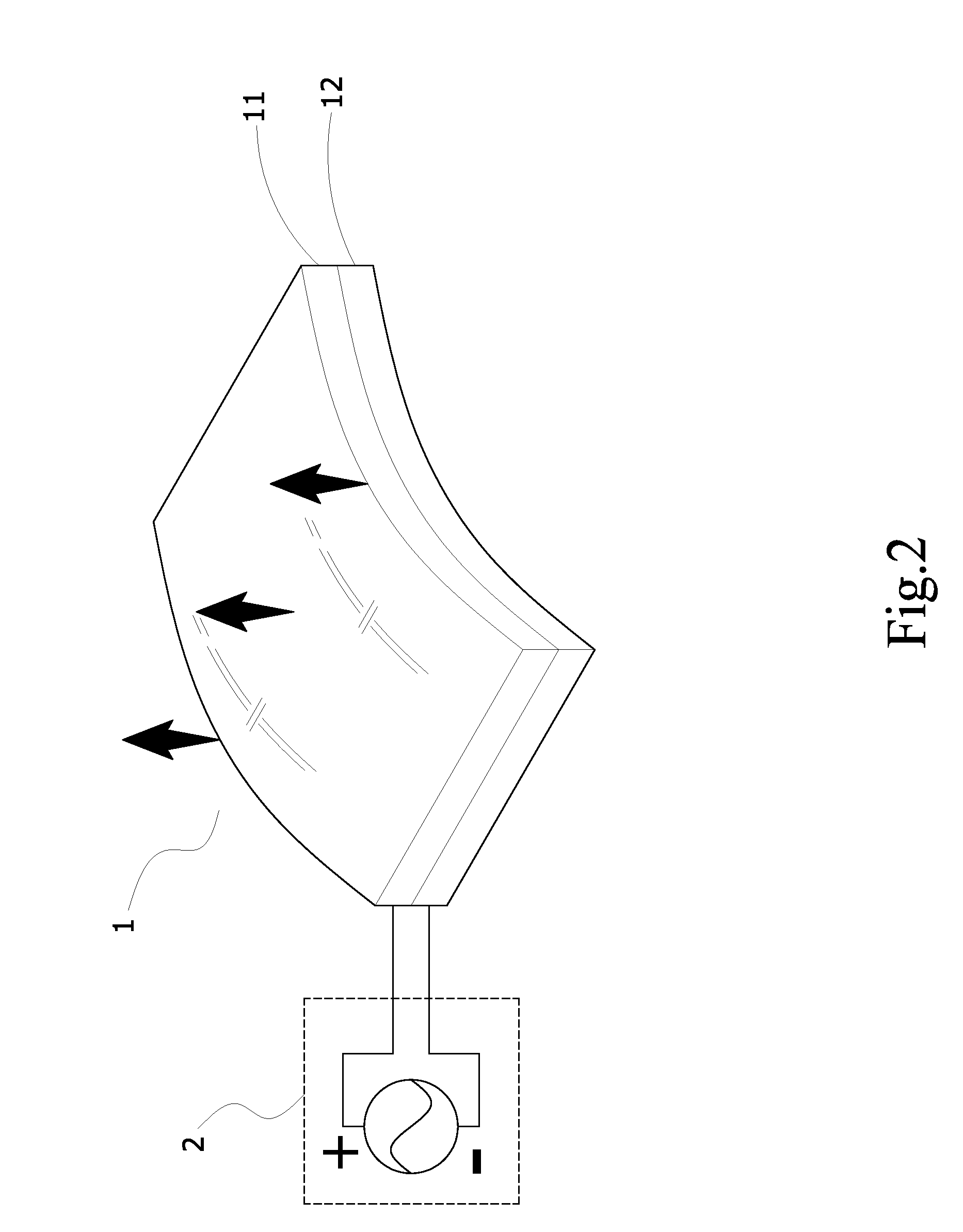

Light-transmitting vibration unit and module thereof

InactiveUS20110043077A1High voltageNo harmPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectricityElectrical resistance and conductance

In a light-transmitting vibration unit and the module thereof, which the vibration unit comprises a first and a second substrates stacked sequentially with each other, and made of a conductive polymer material, such that both first and second substrates have light transmittance and uniform resistance, and after a vibration driven component is electrically coupled to the first and second substrates, an electric field will be acted for converting electric energy into mechanical energy to produce vibrations. If the vibration unit is coupled directly to a touch-sensitive display unit, an image displayed by the touch-sensitive display unit will be able to pass through the vibration unit, and the vibrations produced by the vibration unit will be more directly transmitted to a touch object.

Owner:J TOUCH CORPORATION

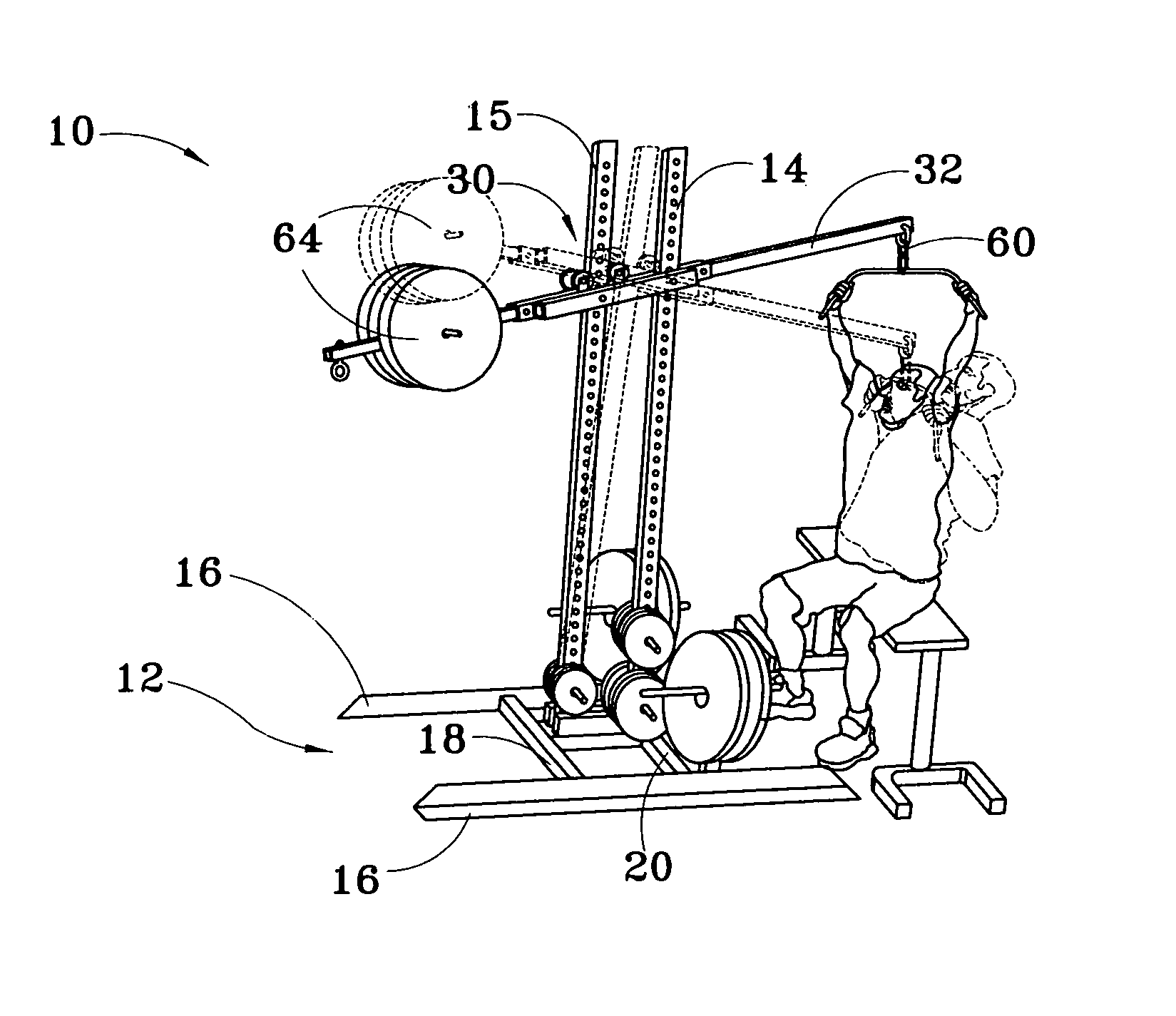

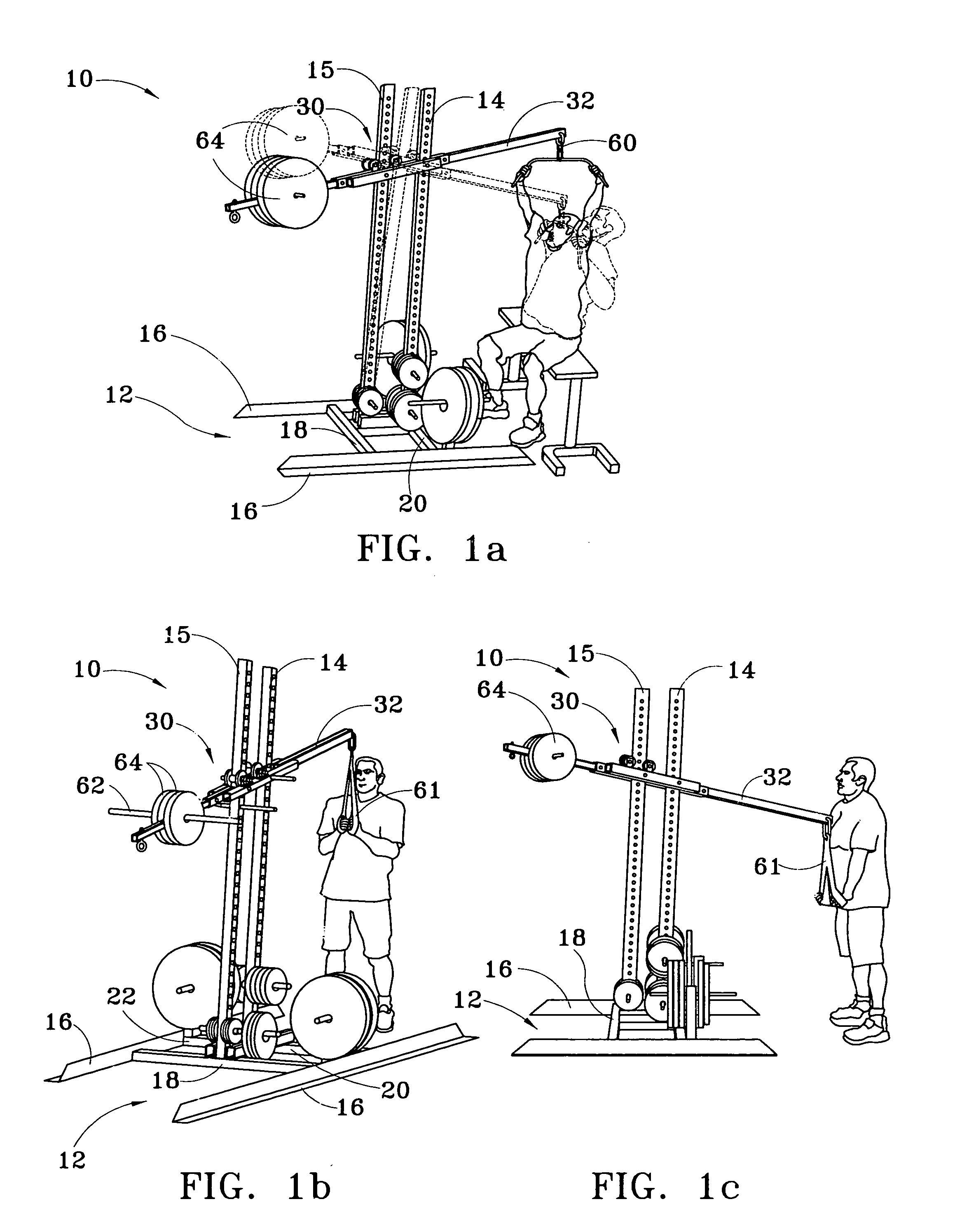

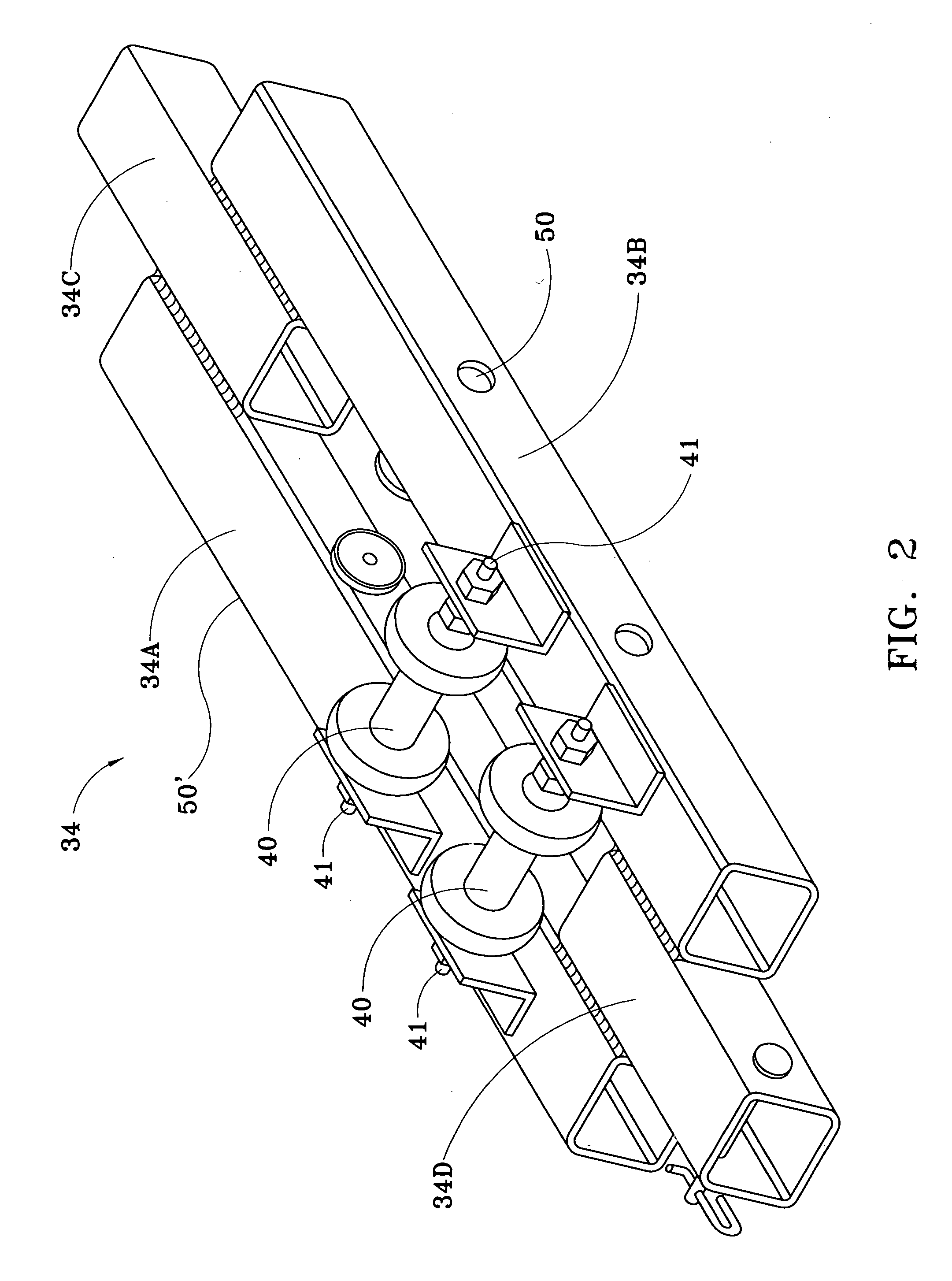

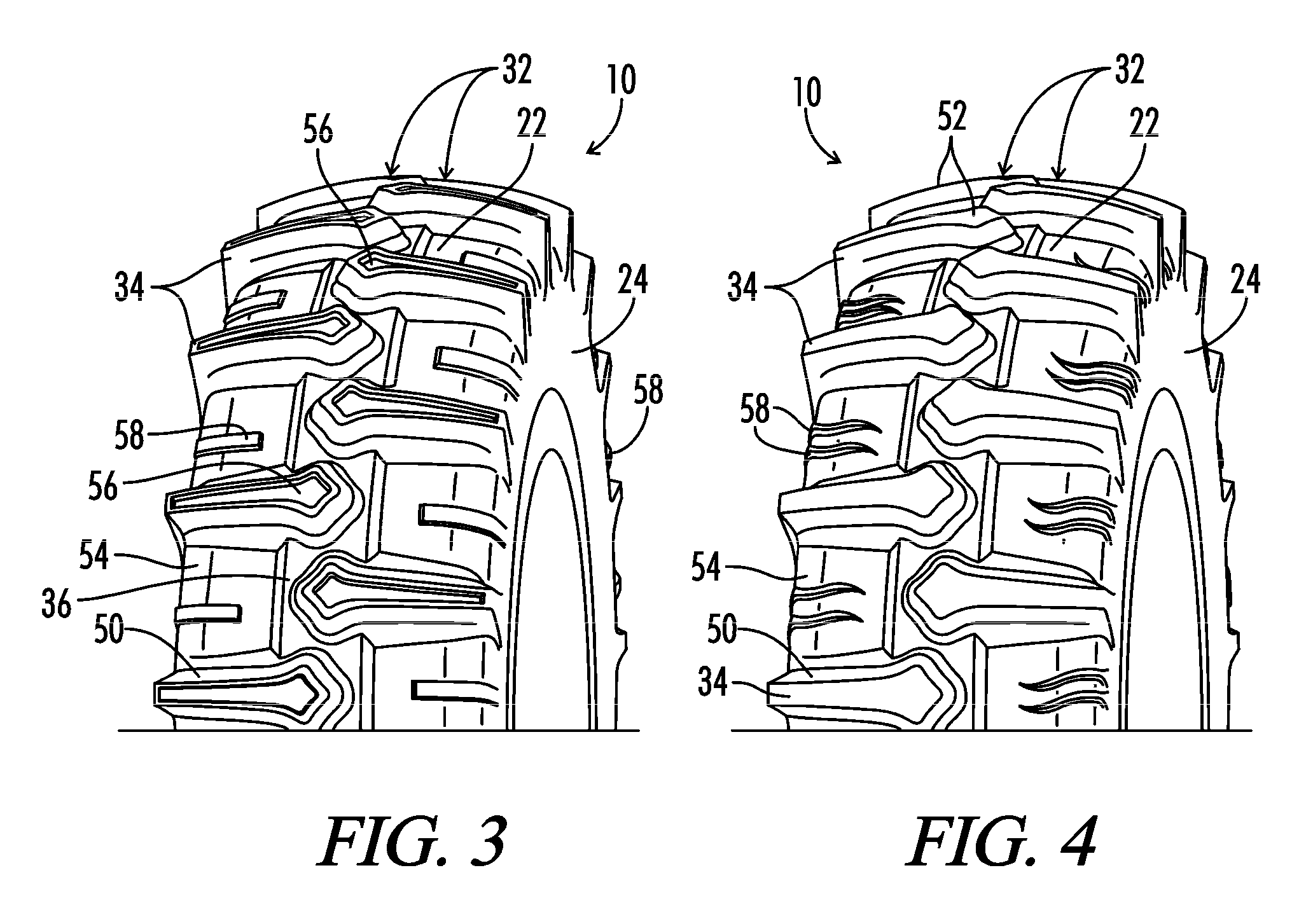

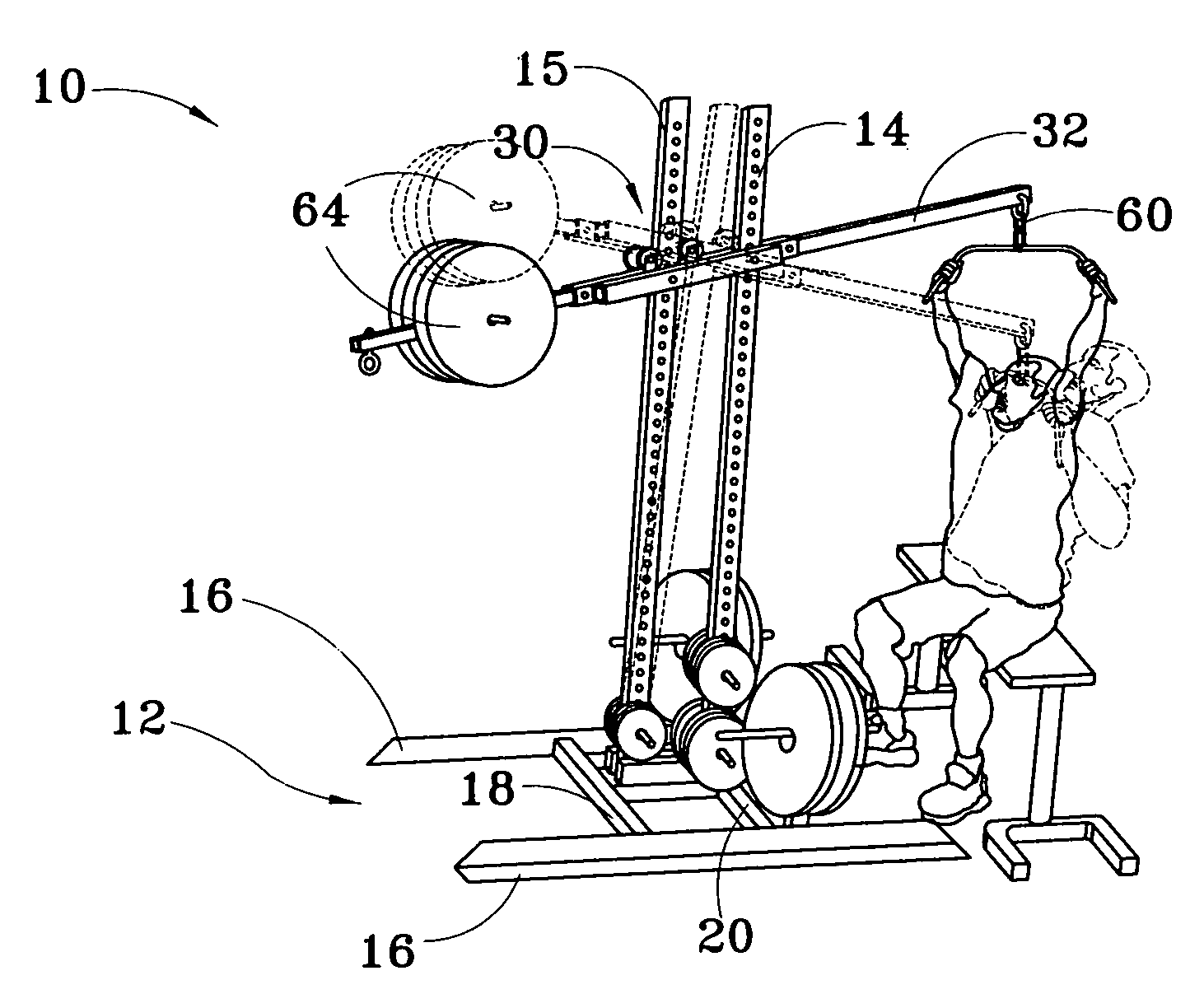

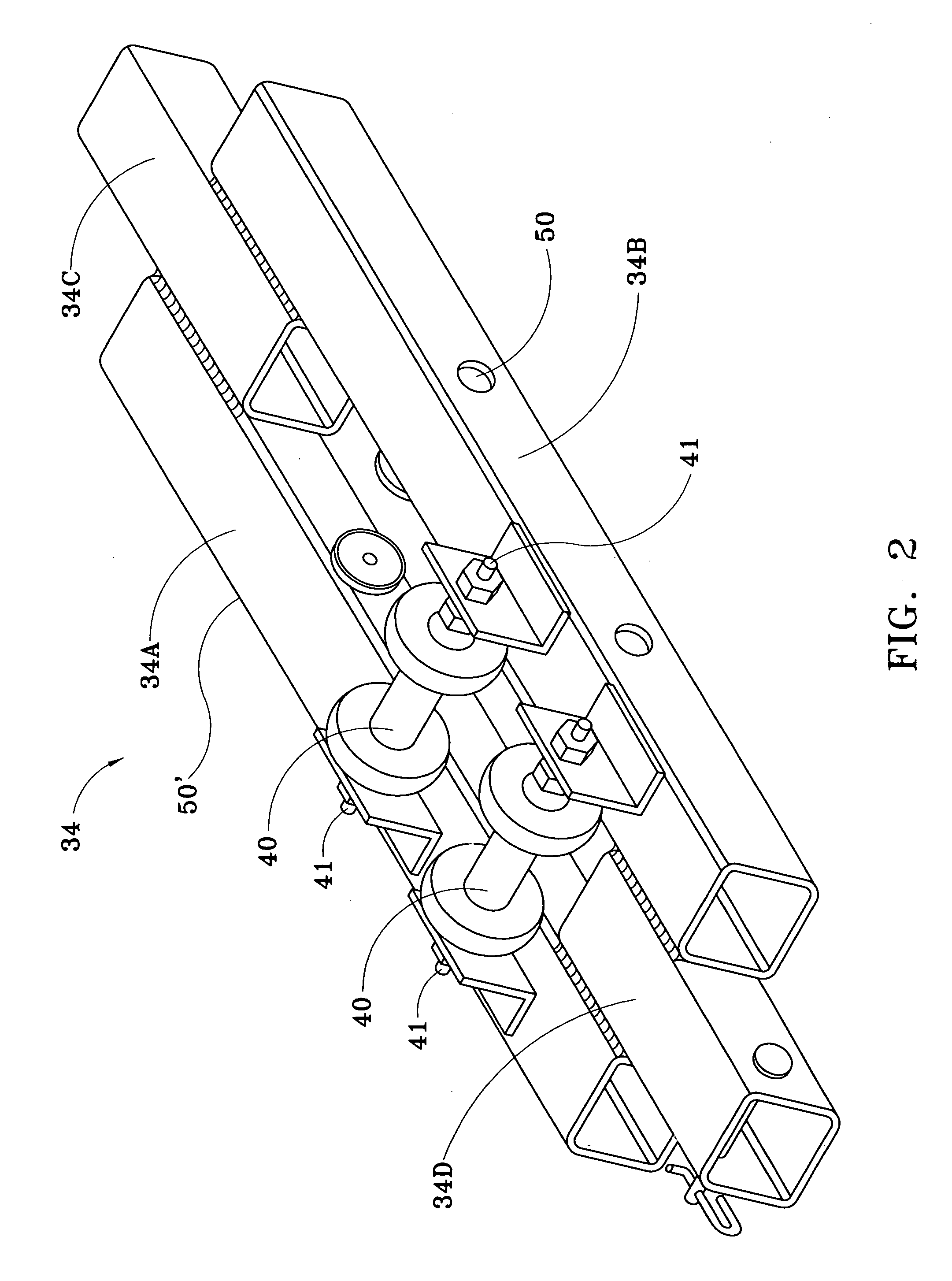

Weight exercise device

InactiveUS20050148445A1Uniform resistanceEasy to storeRefuse transferringStorage devicesVertical planeRange of motion

A weight training device for providing substantially uniform resistance throughout the range of motion of each of a variety of weight lifting exercises. Upstanding front and rear stanchions are attached to front and rear portions of a base, respectively. In a first embodiment, the front stanchion is rigidly attached to the base, the rear stanchion is pivotally attached to the base, and a lever arm assembly is pivotally attached to the front stanchion and includes a dolly cage attached to the rear stanchion that forces the rear stanchion to pivot toward and away from the front stanchion as the assembly is pivoted in a vertical plane by a weight trainee against the resistance of weight suspended from the assembly. In a second embodiment, the front stanchion is mounted for reciprocal, vertical motion on a rod attached to the base. A plurality of weight plates are disposed below the front stanchion in vertical, stacked relation, any or all of which can be suspended from the front stanchion by insertion of a stack pin through any one of the plates and into an aperture in a stack pin rod suspended from the front stanchion. A lever arm assembly has a front portion pivotally attached to the front stanchion and a rear portion pivotally attached to the rear, pivoting stanchion, such that when a trainee pivots the assembly in a vertical plane against the resistance of the weights, the rear stanchion pivots toward the front stanchion.

Owner:CARLE JOHN T

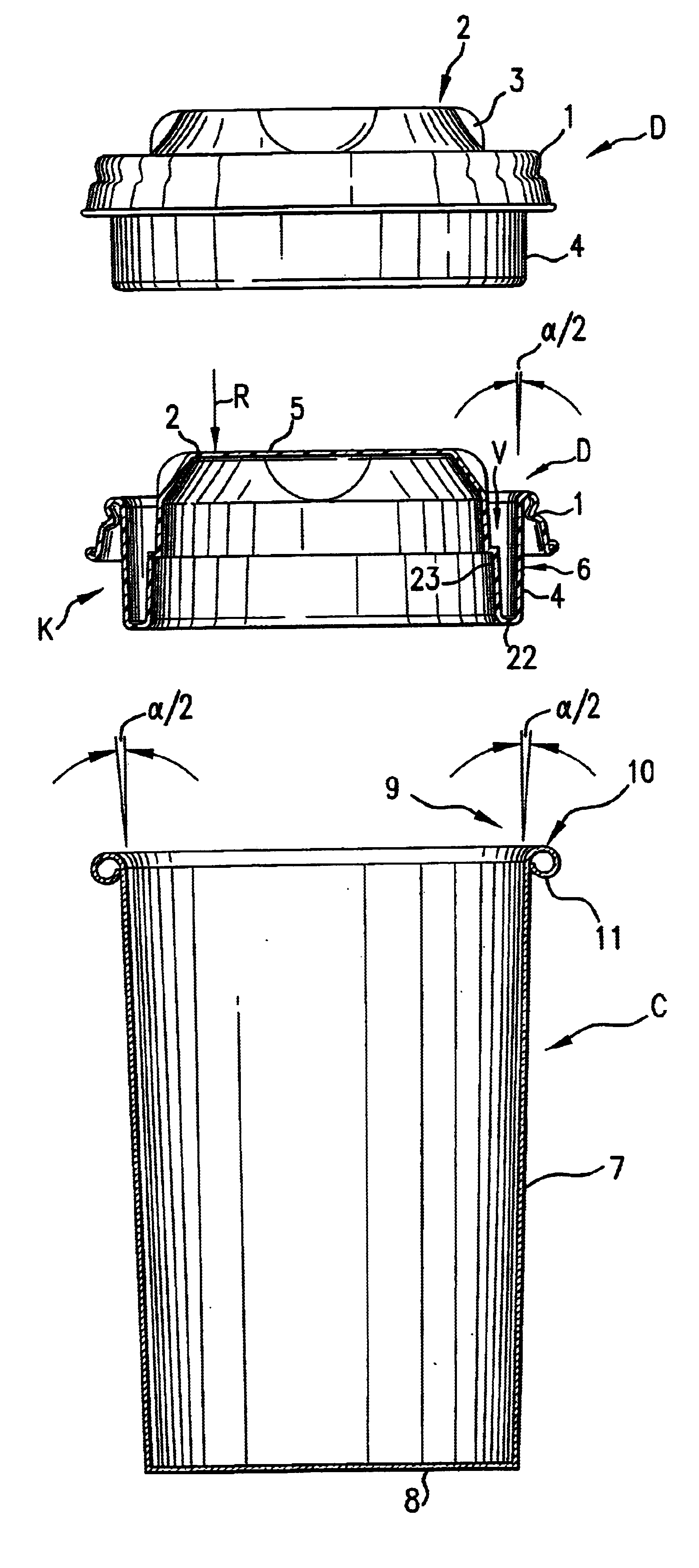

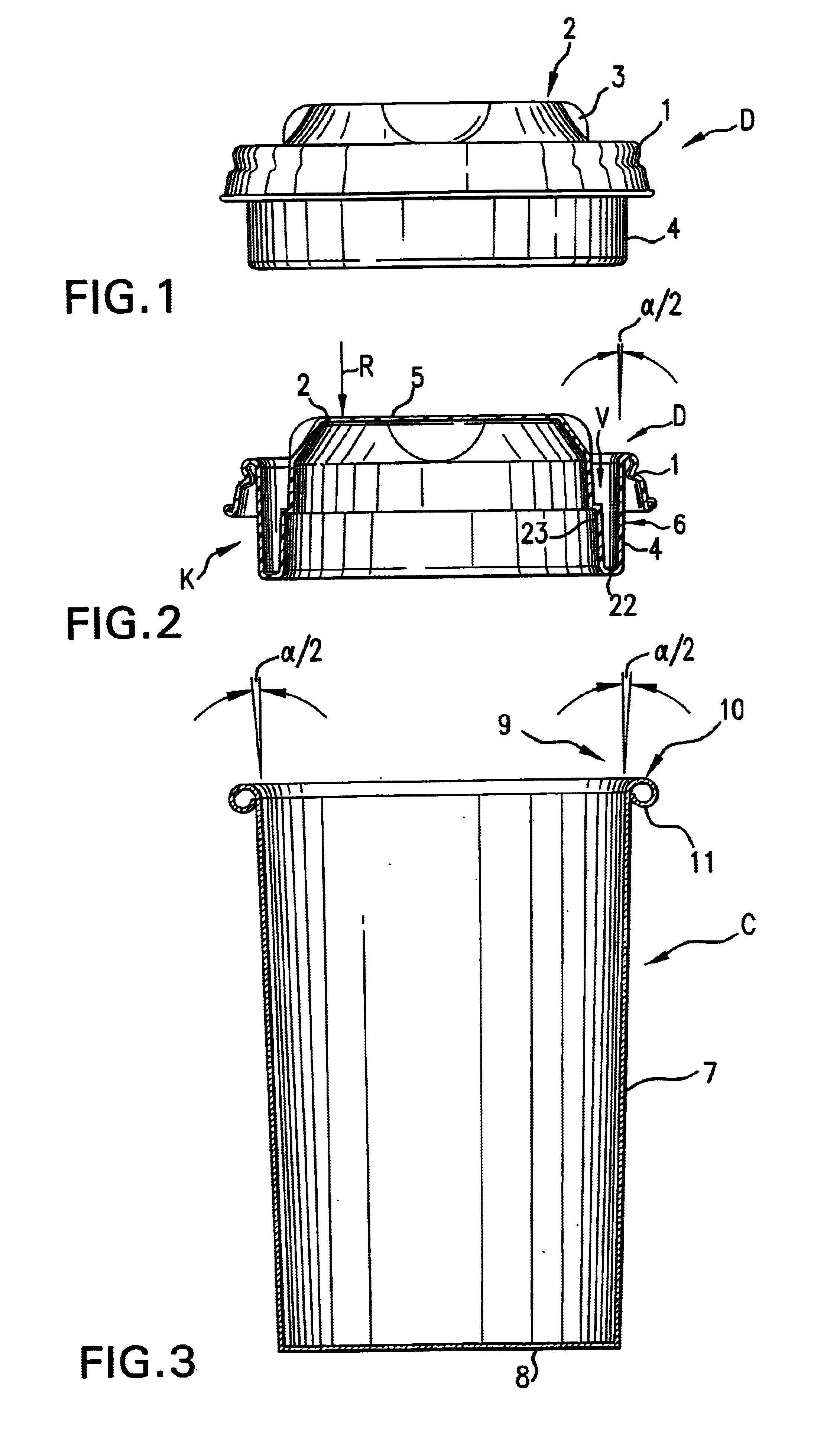

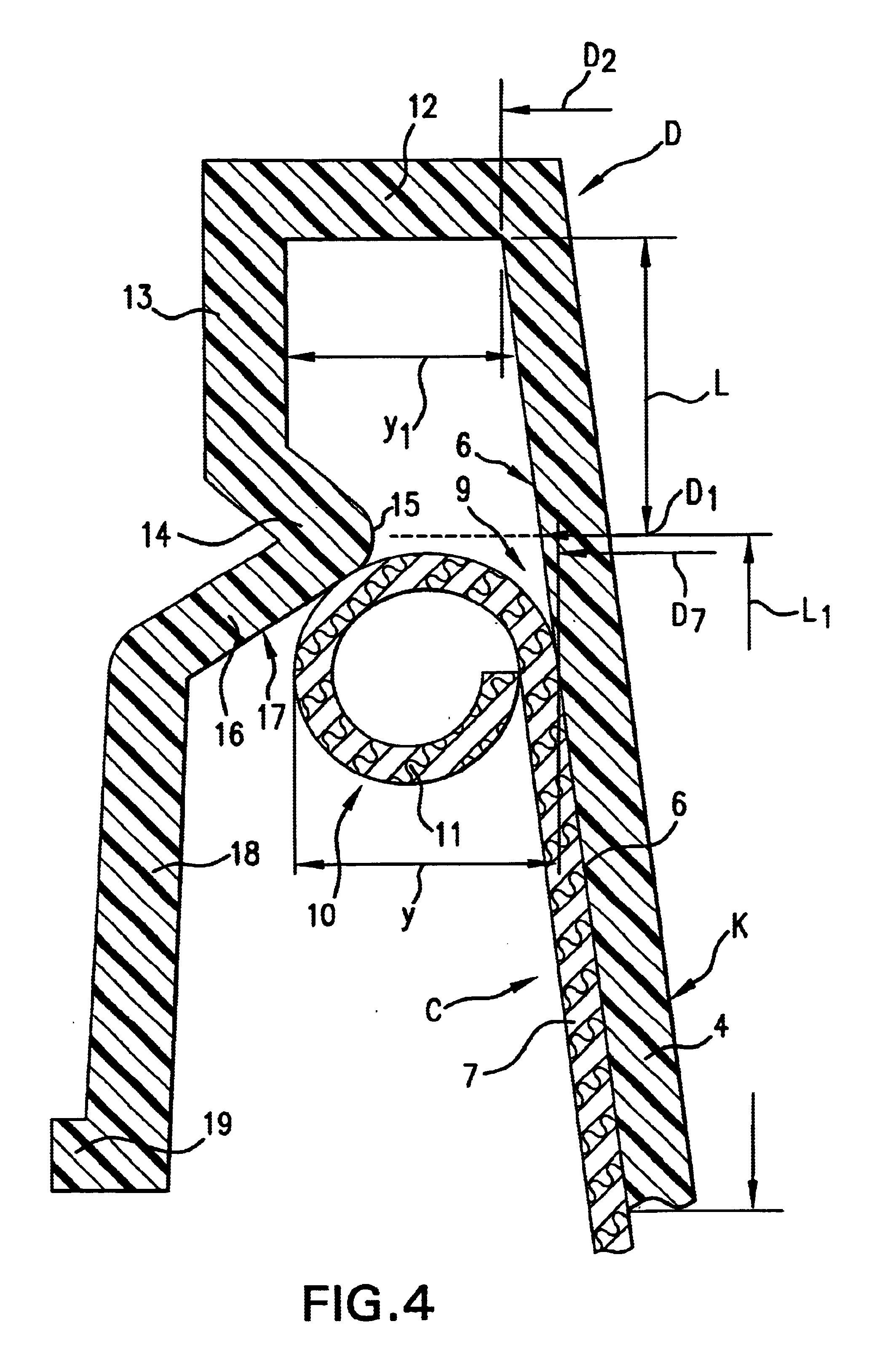

Cup-shaped receptacle and lid

InactiveUS6932234B2Intensified sealing effectImprove retentionContainer decorationsCapsBiomedical engineeringEngineering

A cup-shaped receptacle has an outer bead in its opening area for clipping on a plastic lid, which has a circumferentially continuous clamping groove for receiving the bead. The clamping groove is continued outwards by an elastically deformable constriction, and inwards by an outer wall of a circumferentially continuous, U-shaped lid recess, whose U-web of is situated below the height position of the constriction and whose inner leg wall forms a part of a dome wall of a dome which extends upwardly beyond the height position. The lid recess extends downwards beyond the height position and has an outer diameter at its outer surface which is adapted to the inner diameter of the receptacle wall such that the lid recess functions at least as a centring and guide projection for the lid-clip-on action, which projection slidingly co-operates with the receptacle wall already at least while the bead passes the constriction.

Owner:SEDA SPA

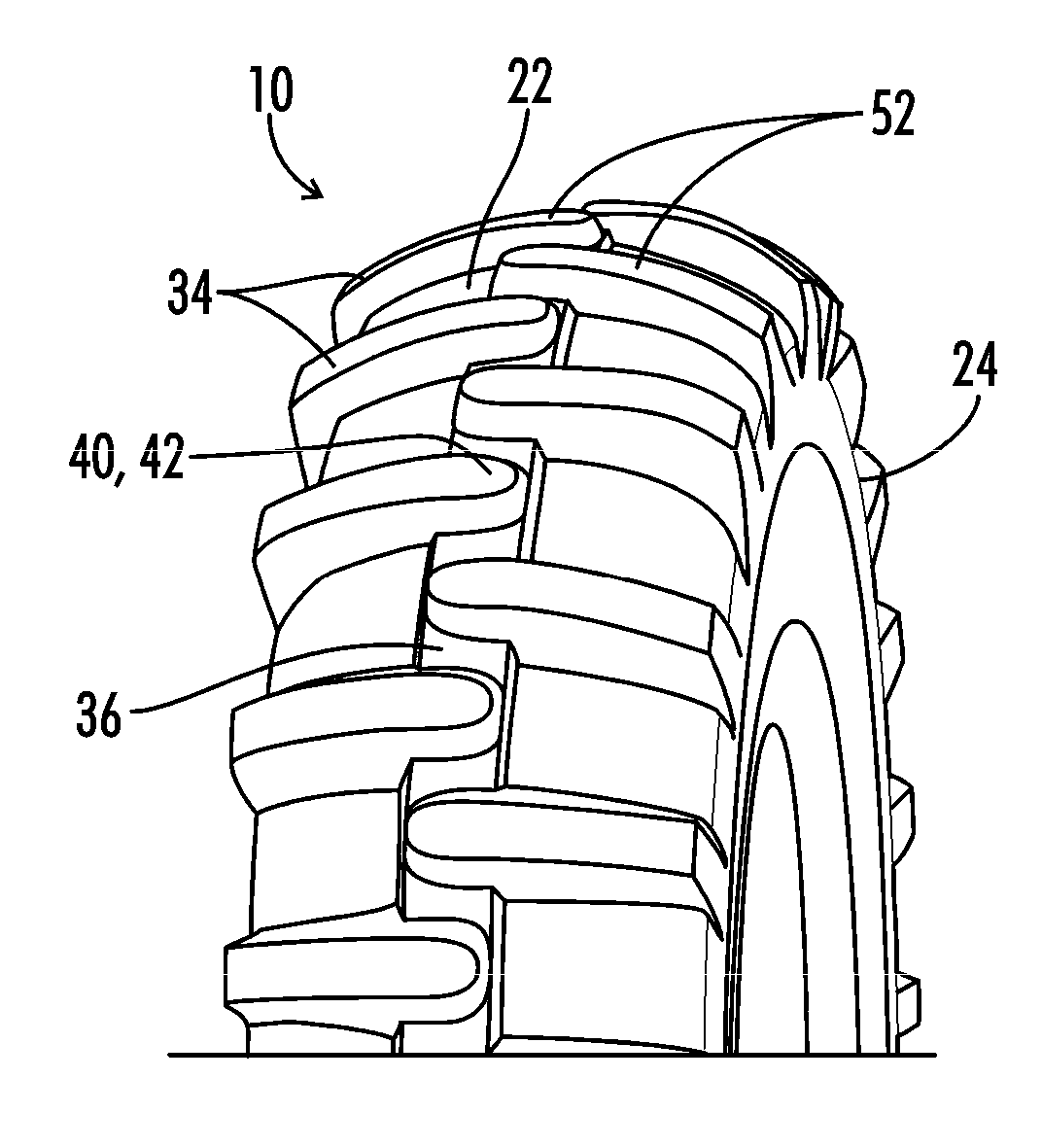

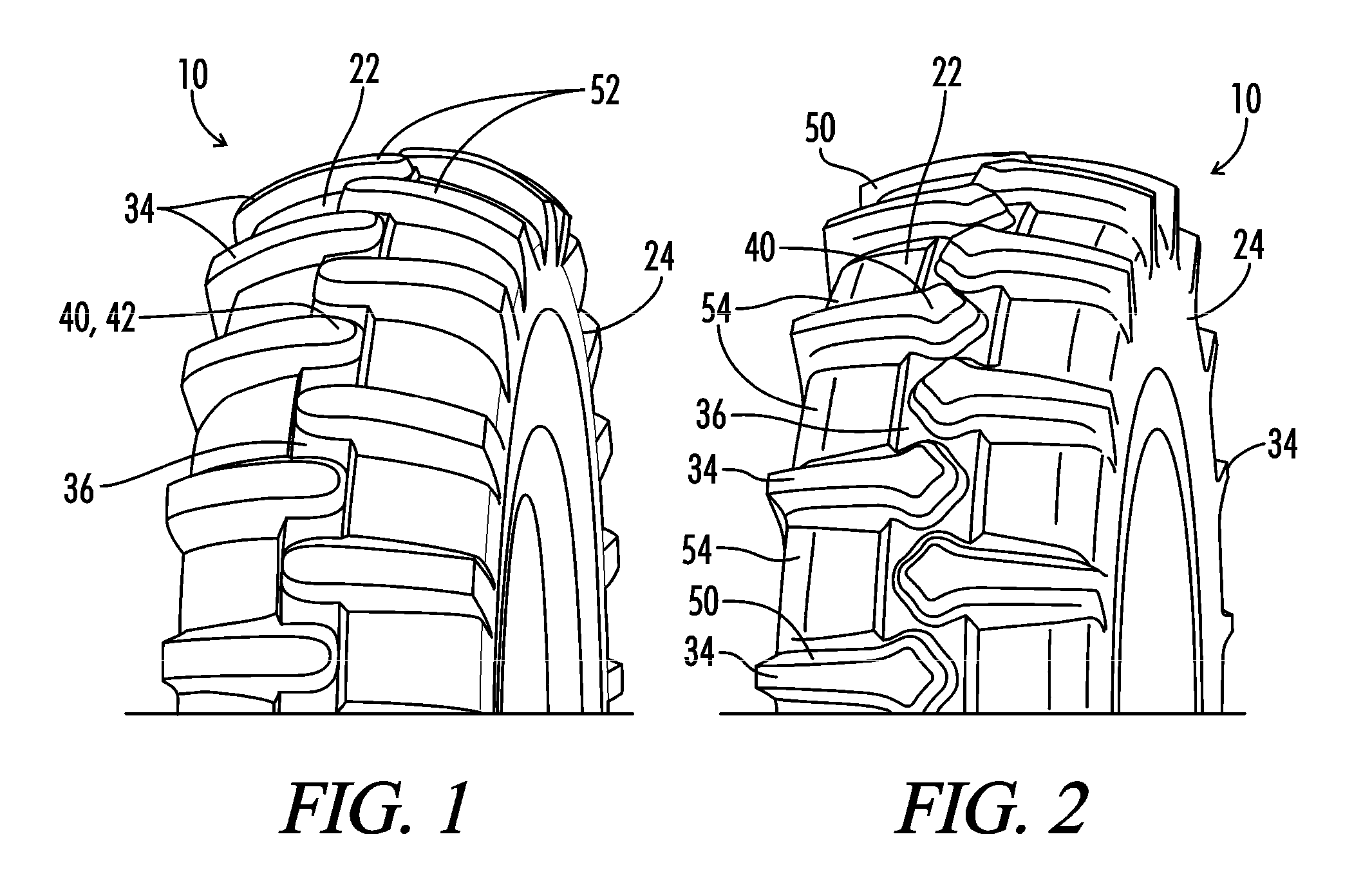

Irrigation tire

ActiveUS20090084478A1Uniform resistanceIncrease crown strengthAgricultural vehiclesAgricultural vehicle tyresRotational axisAgricultural irrigation

A non directional pneumatic tire is provided for an agricultural irrigation system. The tire includes first and second side walls and a radially outer wall defining an internal inflation chamber. A non directional tread pattern is defined on the tire and includes a plurality of longitudinal protrusions positioned substantially parallel to a rotational axis of the tire. The longitudinal protrusions are arranged in first and second rows extending from the first and second side walls toward and across the equatorial plane of the tire. The longitudinal protrusions of the first and second rows circumferentially alternate with each other and there is a circumferential spacing between adjacent longitudinal protrusions at the equatorial plane so that no portion of one longitudinal protrusion circumferentially coincides with or overlaps another.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Weight exercise device

InactiveUS7101322B2Uniform resistanceEasy to storeRefuse transferringLoading/unloadingVertical planeRange of motion

Owner:CARLE JOHN T

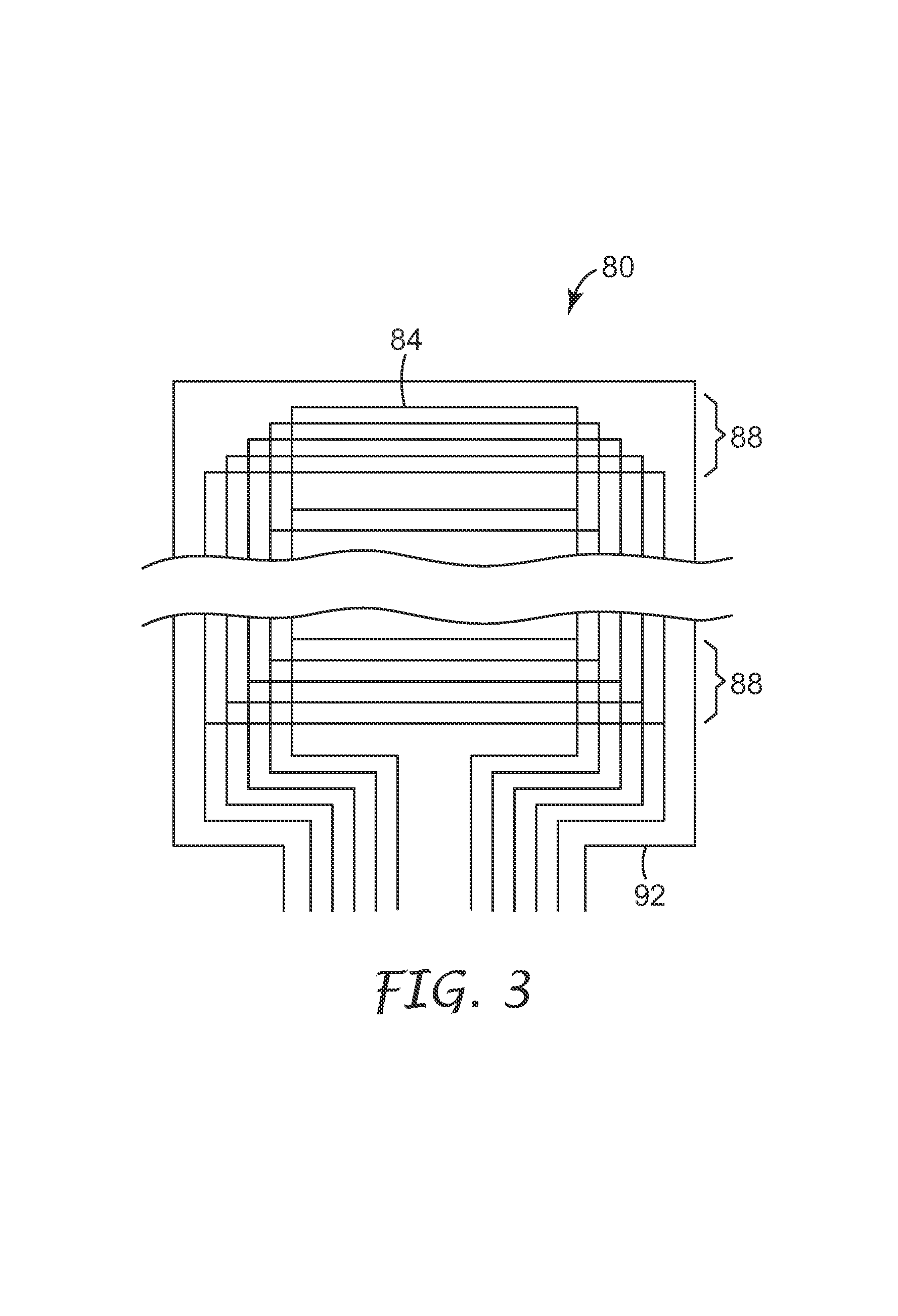

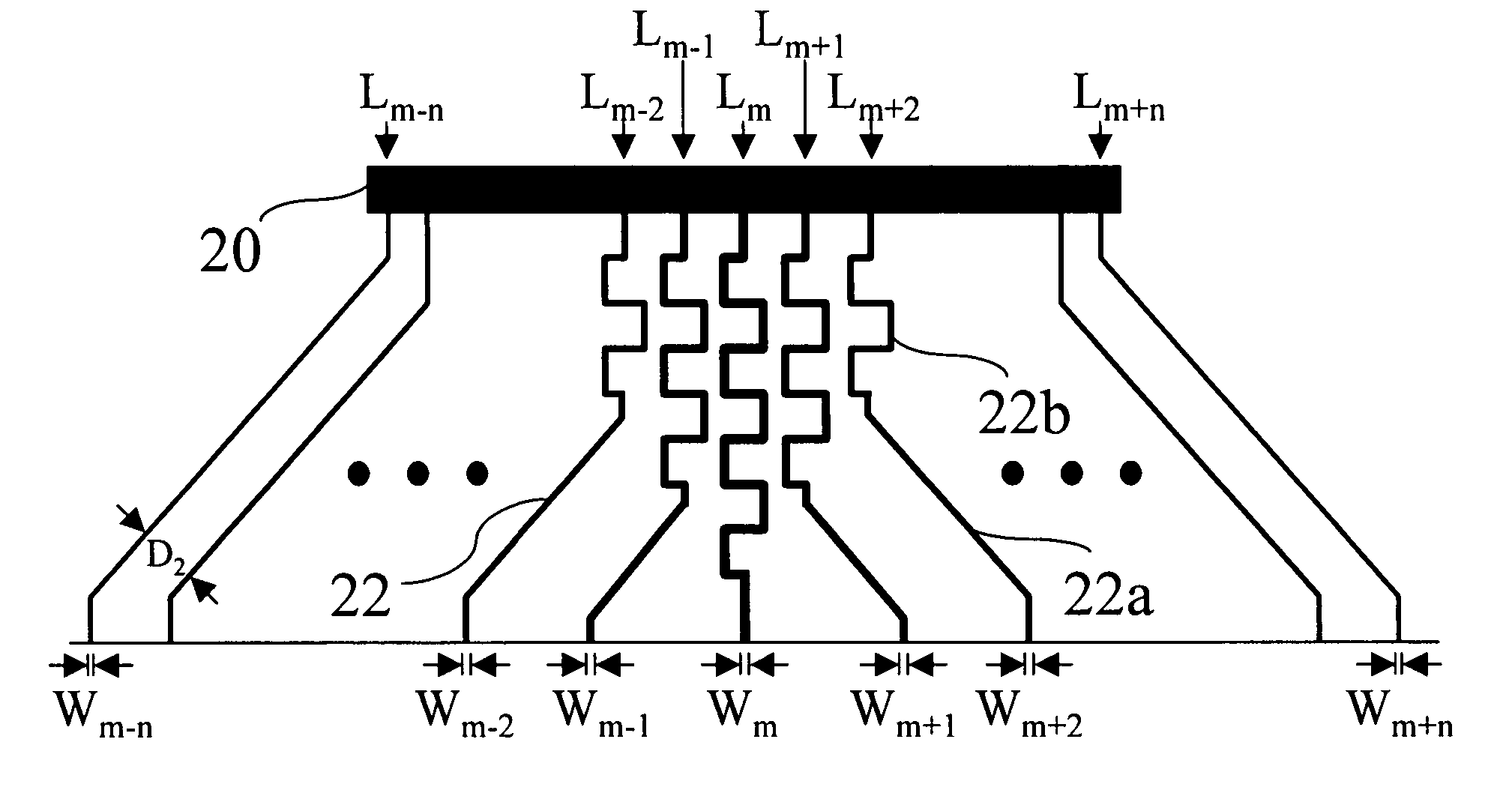

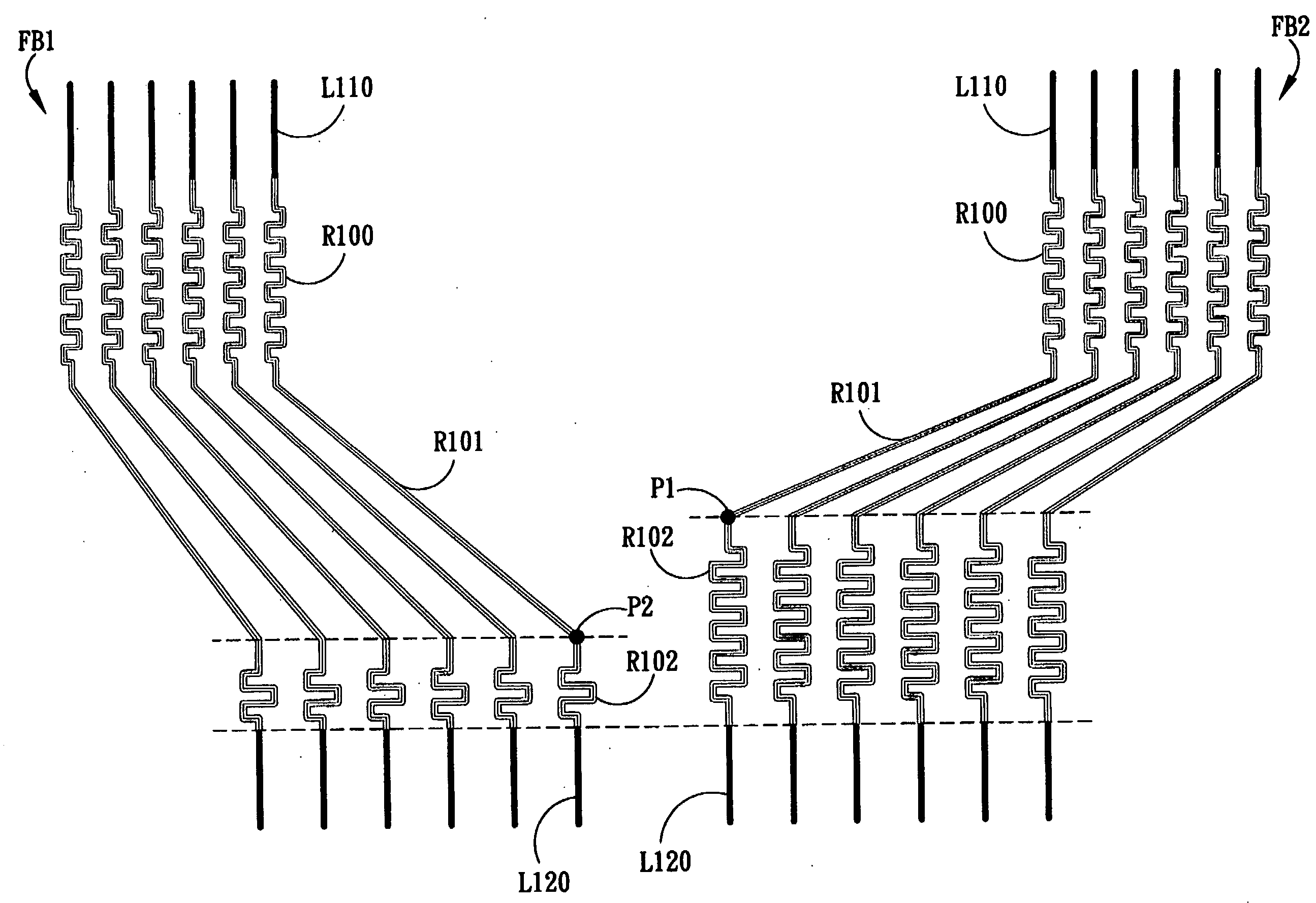

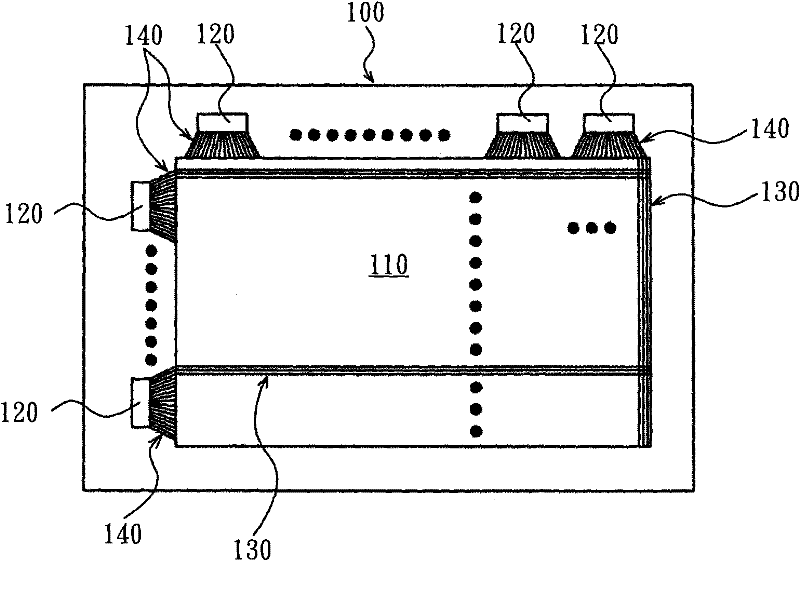

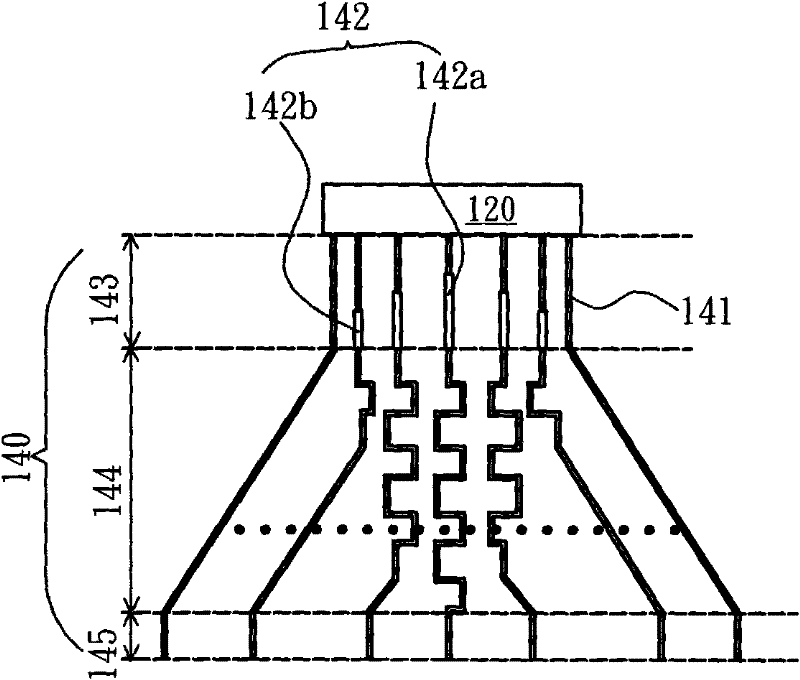

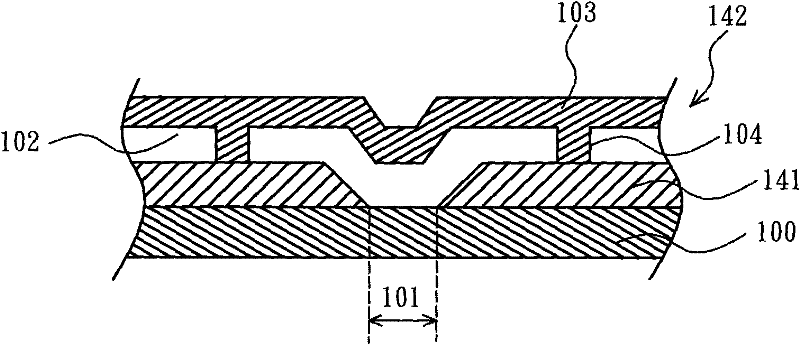

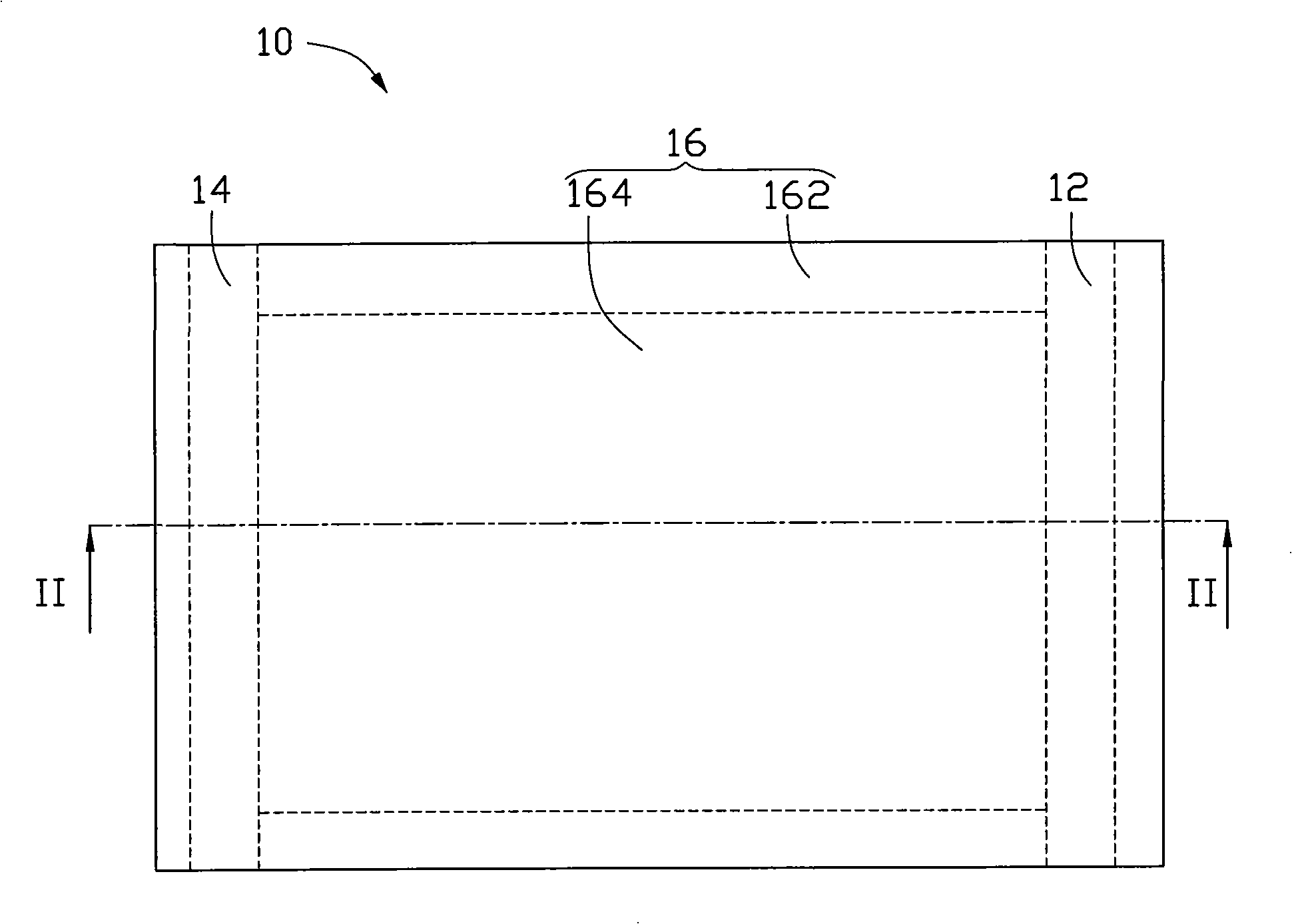

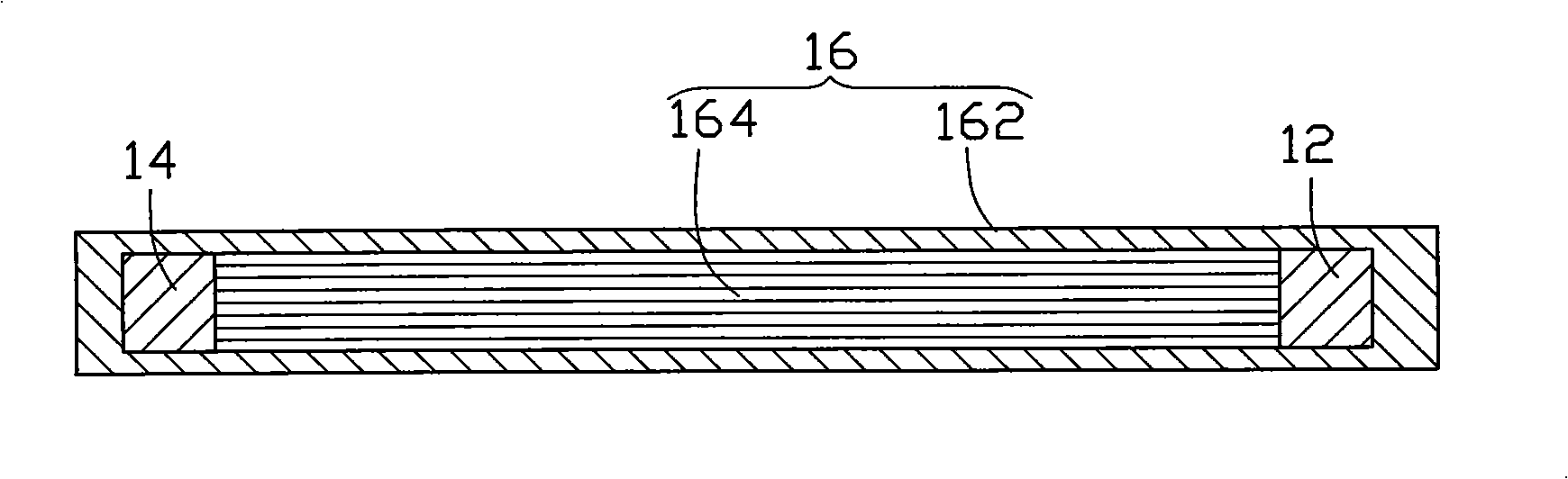

Electronic device with uniform-resistance fan-out blocks

ActiveUS20070195254A1Uniform resistanceNon-linear opticsElectrical resistance and conductanceEngineering

Owner:AU OPTRONICS CORP

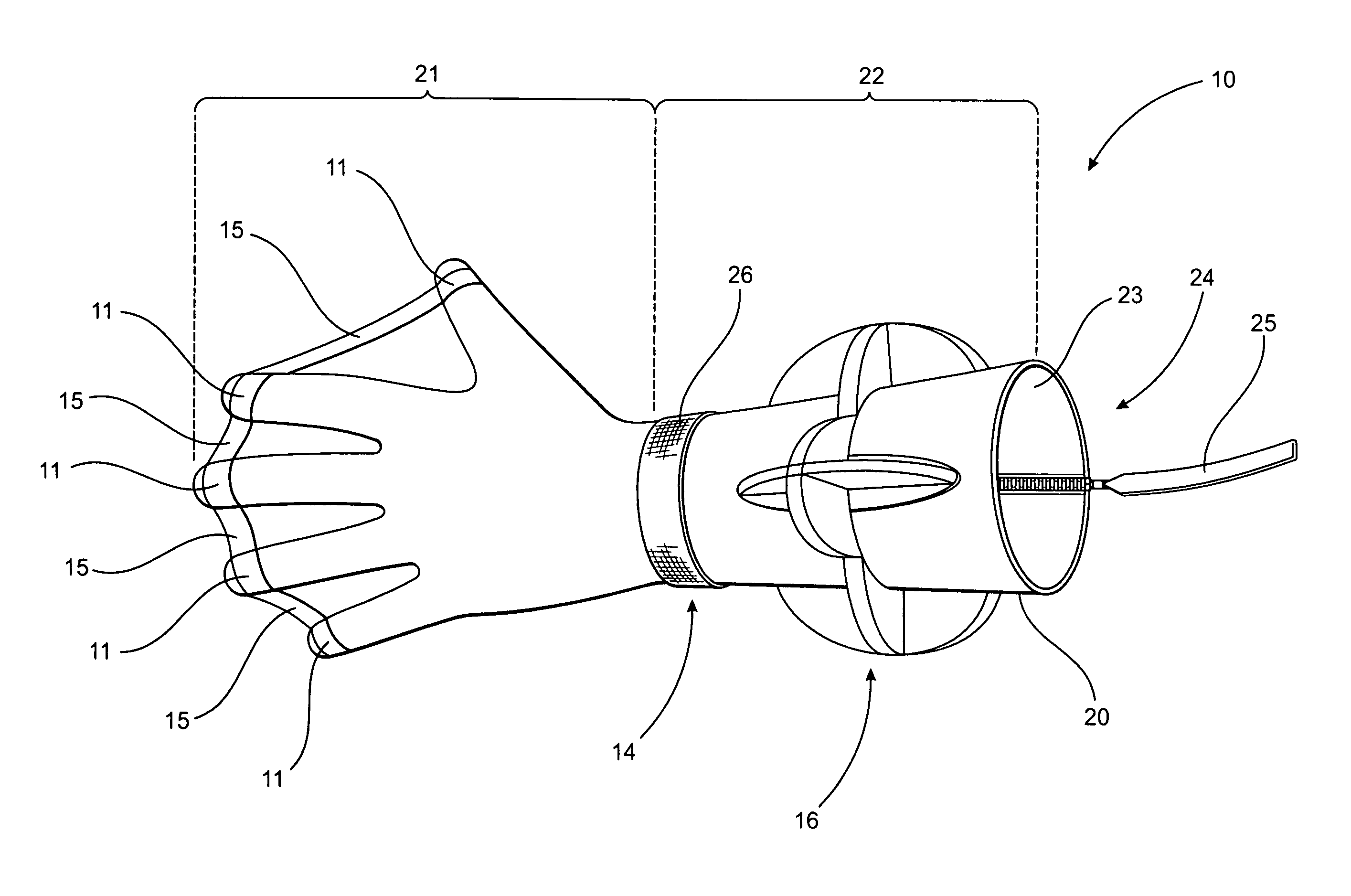

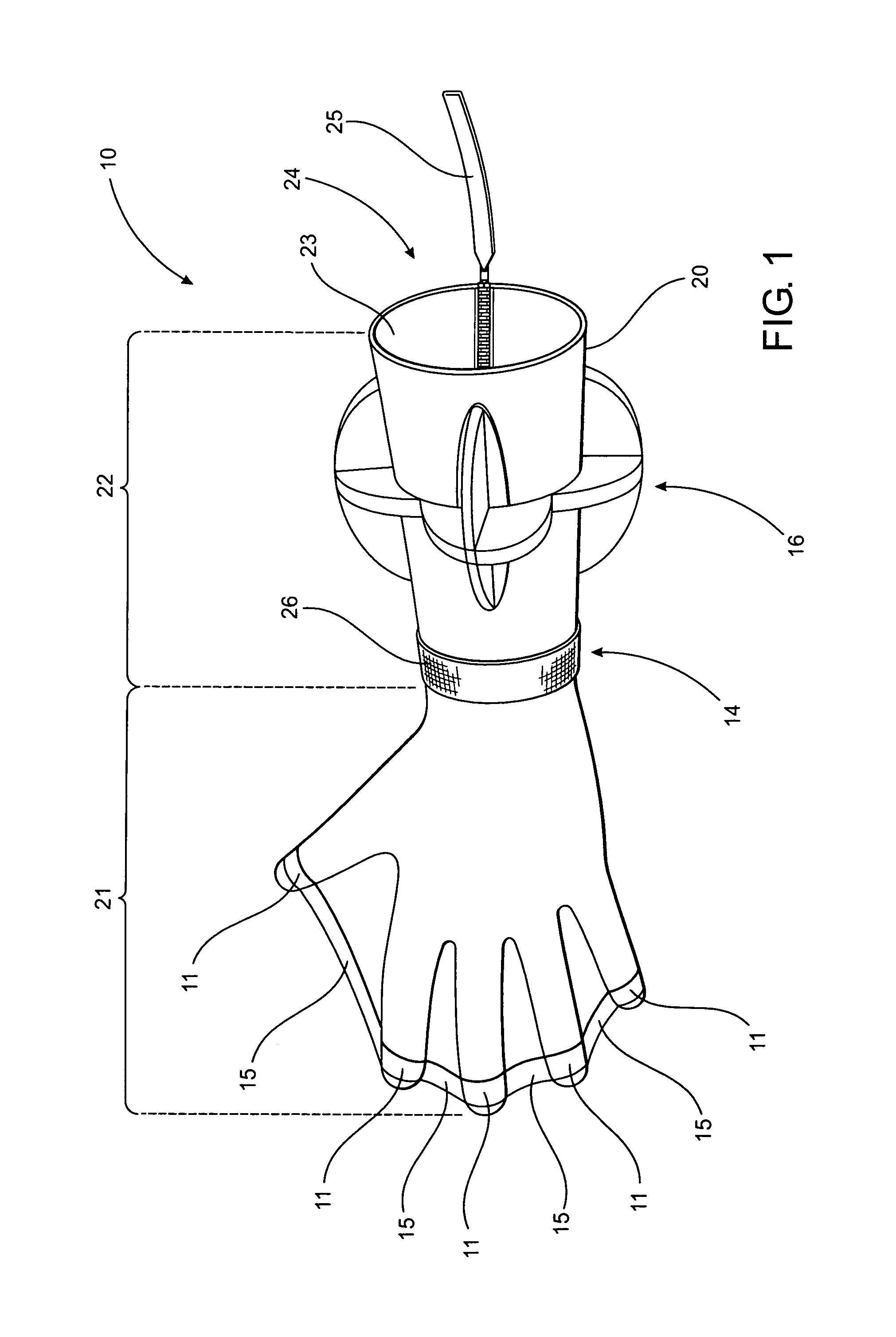

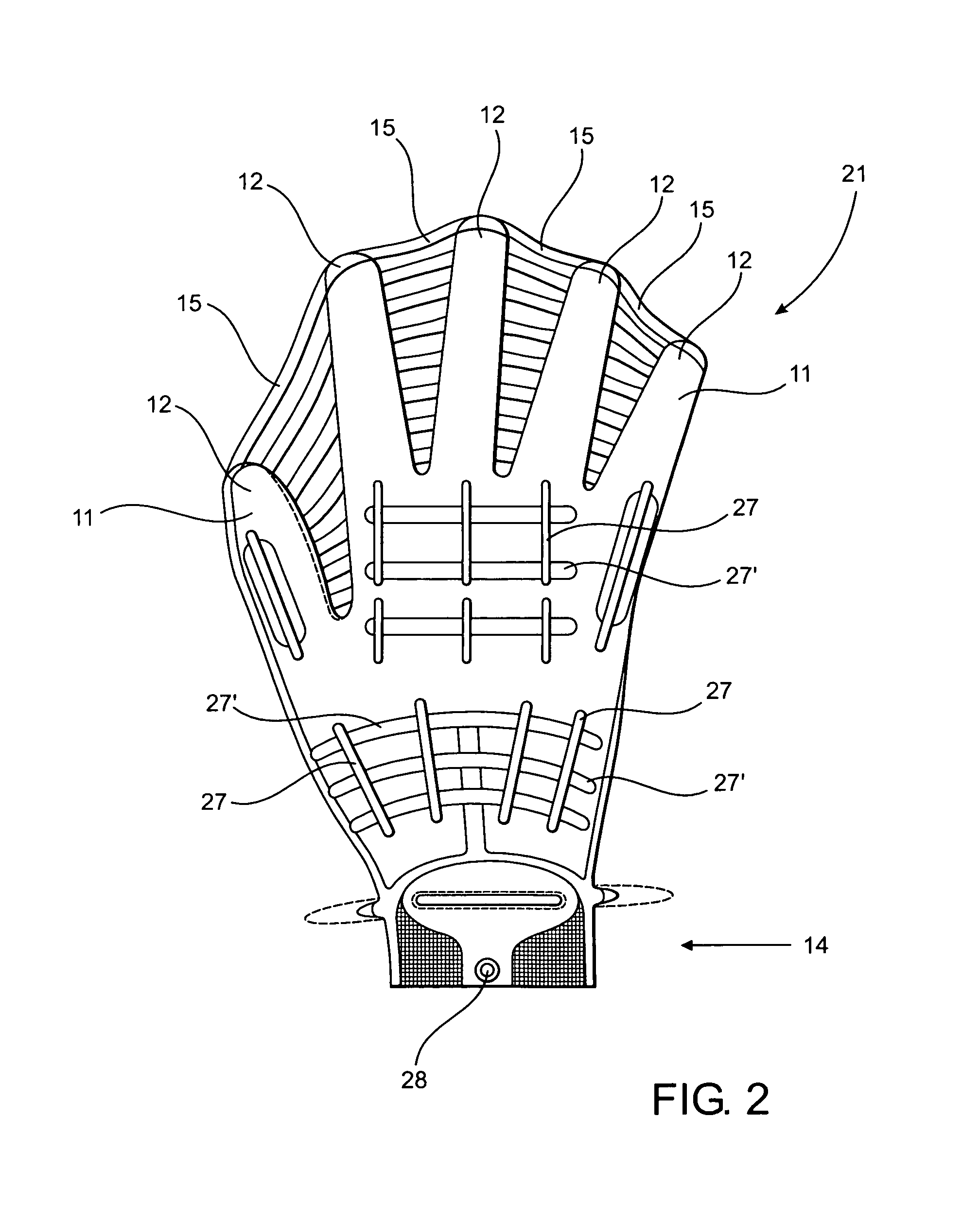

Aquatic exercise system and method

Aquatic exercise system and method for use in a body of water is presented. In particular, the system comprises a sleeve correspondingly disposable in covering relation to at least a portion of a user's appendage, such as an arm or leg, a securing assembly to secure the sleeve to a user, and at least one fin outwardly extending from the sleeve and structured to increase resistance to the user regardless of the particular directional or rotational movement. In some embodiments, the sleeve is further structured to cover an extremity of a user, such as a hand or foot. Further embodiments include a seat assembly connectable to an access pole of a pool or hot tub. The method includes applying an aquatic exercise system to an appendage of a user, submerging the appendage and system, and moving the appendage and system through water in at least one direction to create resistance.

Owner:DAVIS ADAM M

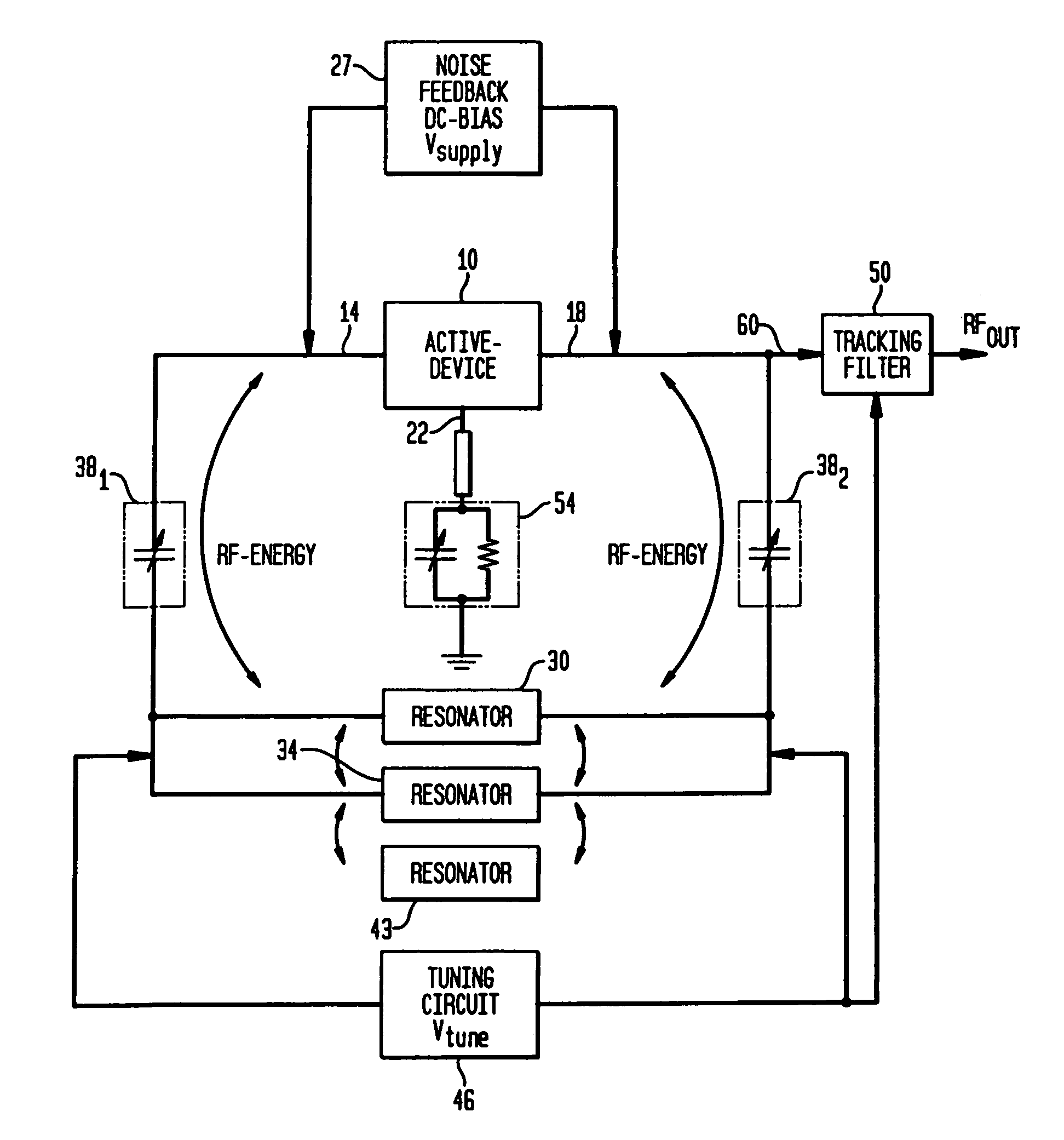

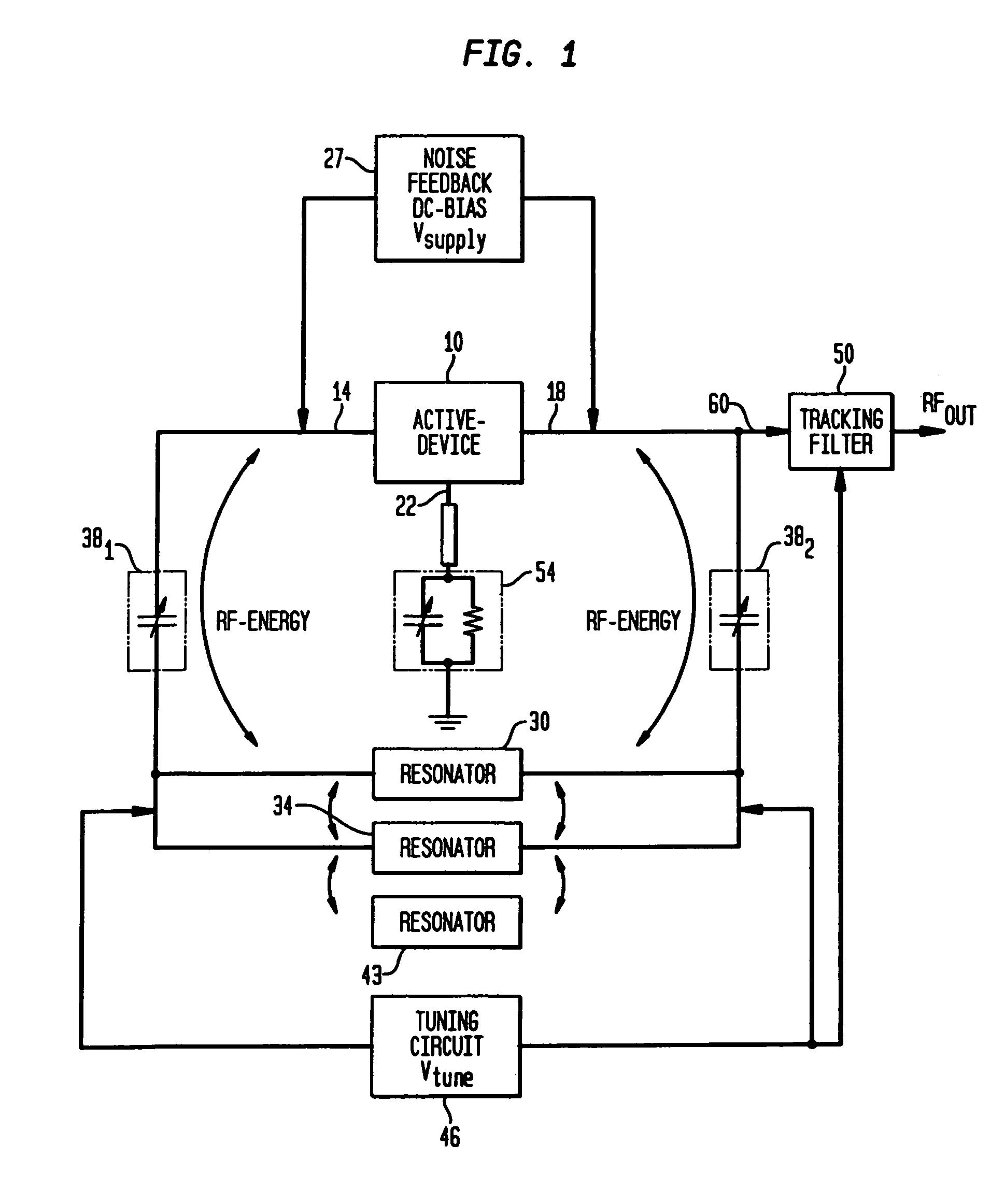

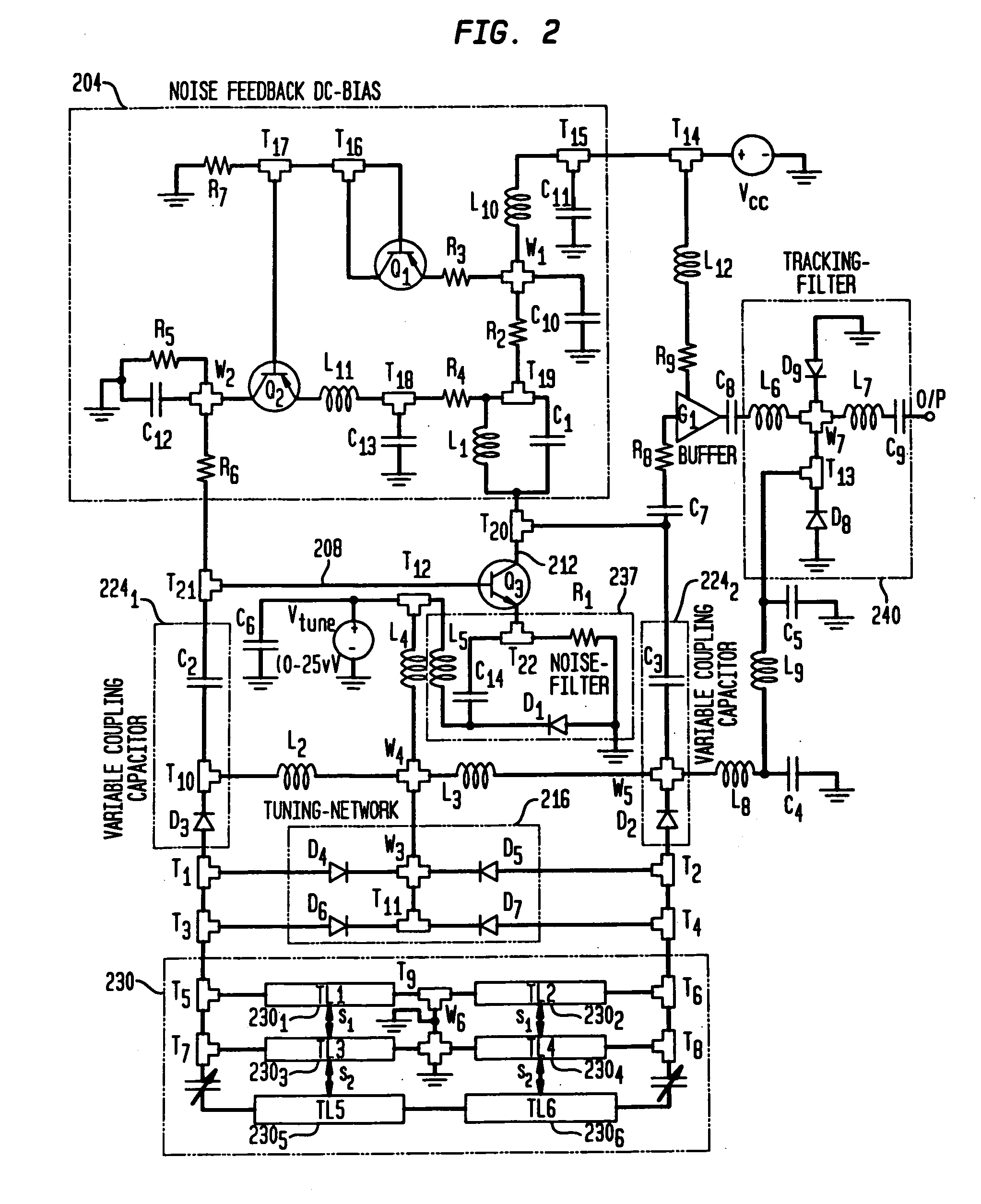

Wideband voltage controlled oscillator employing evanescent mode coupled-resonators

ActiveUS20050242896A1Increase working frequencyUniform resistanceOscillations generatorsEngineeringEvanescent mode

In one aspect, the present invention includes a voltage controlled oscillator comprising an active device having a plurality of resonators coupled across two terminals of the device and at least one resonator coupled across the plurality of resonators. The at least one resonator preferably operates as an evanescent mode buffer capable of storing a select amount of energy present in the oscillator.

Owner:SYNERGY MICROWAVE CORP

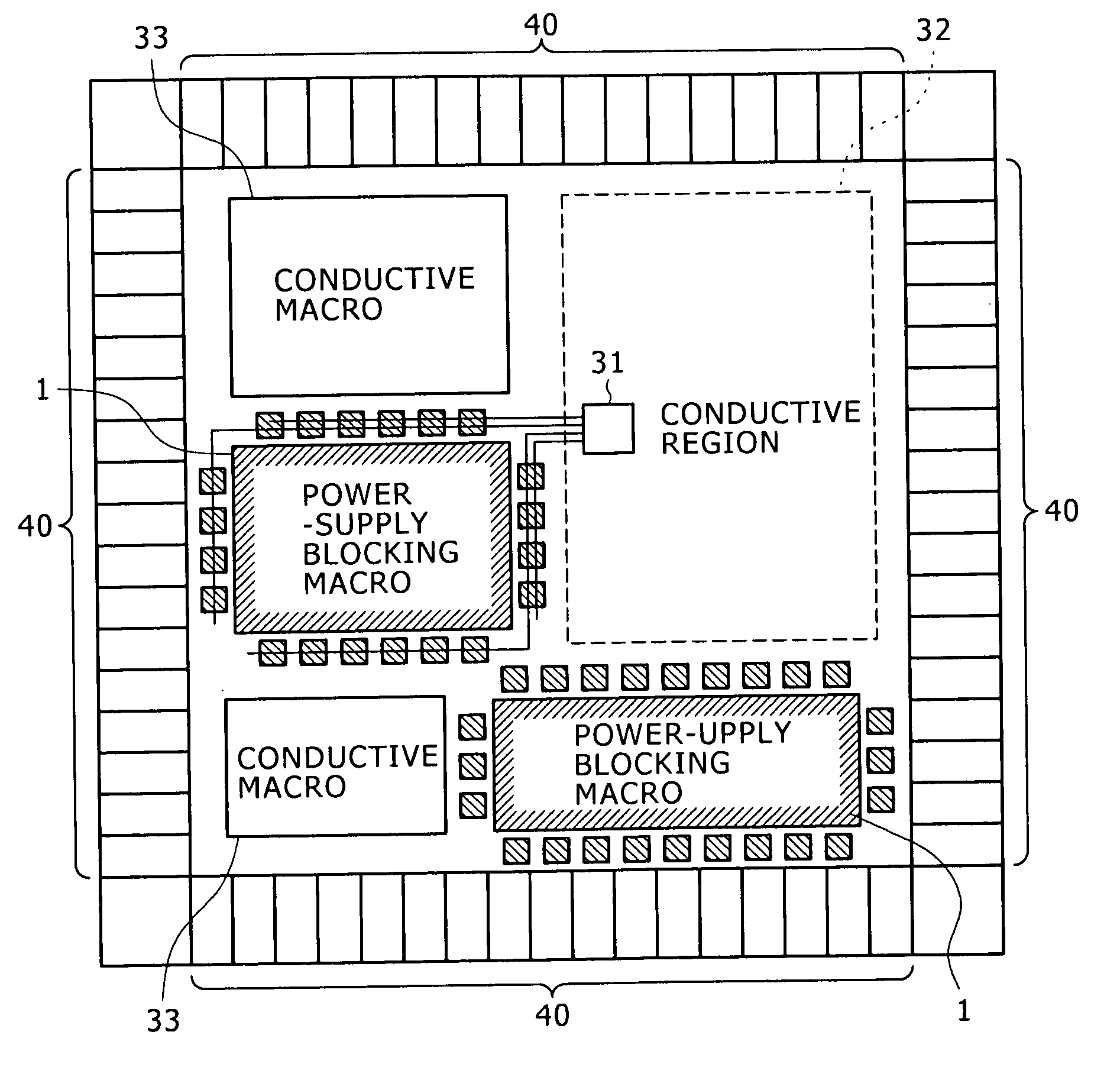

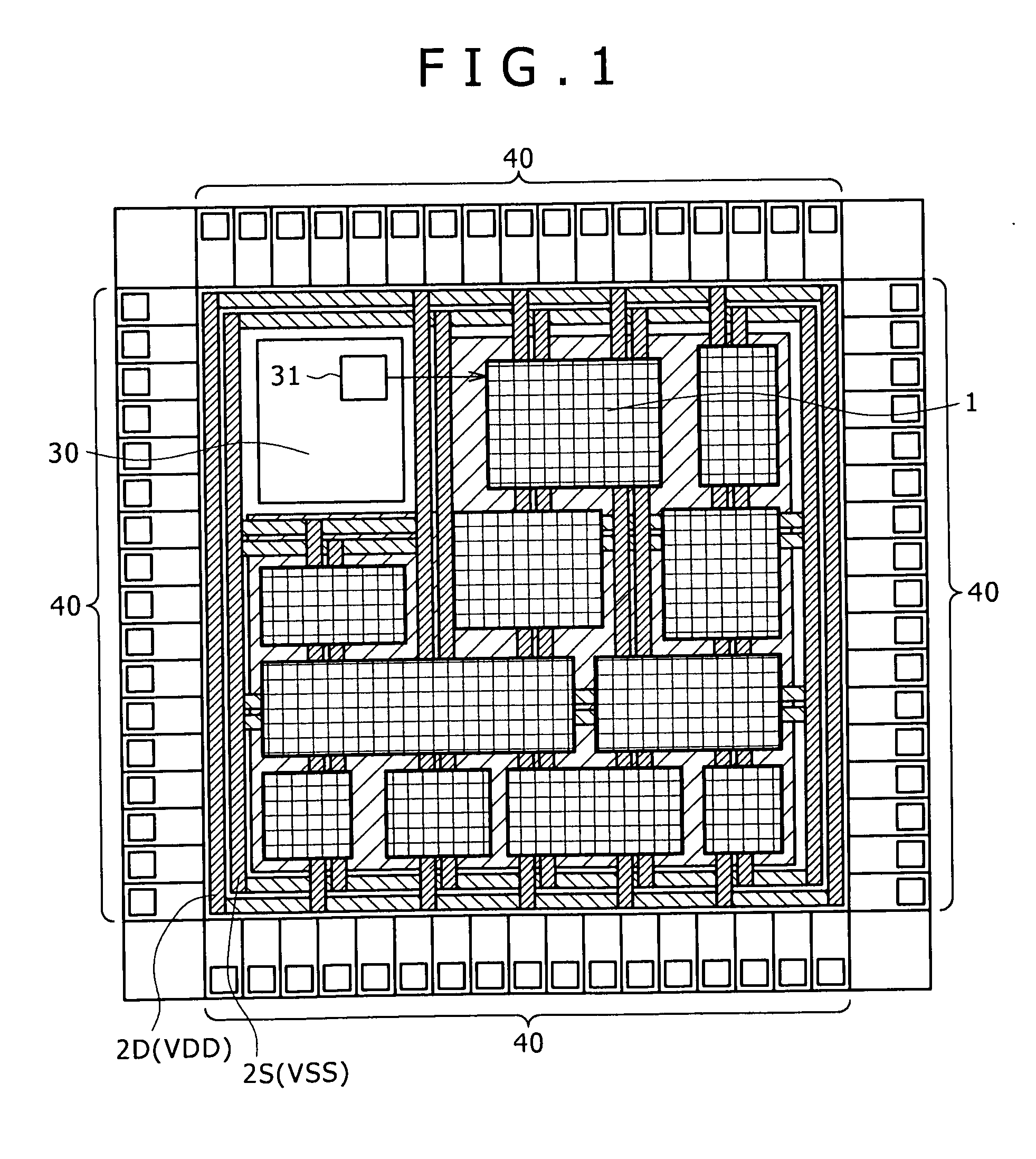

Semiconductor integrated circuit and power-supply control method

InactiveUS20090179688A1Shorten the time intervalShorten the length of timePower reduction by control/clock signalElectronic switchingElectrical resistance and conductanceEngineering

A semiconductor integrated circuit includes: a first voltage line on which a specific one of a power-supply voltage and a reference voltage appears; a second voltage line; a plurality of circuit cells each receiving power generated as a difference between a voltage appearing on the second voltage line and the other one of the power-supply voltage and the reference voltage; a plurality of switch transistors connected in parallel between the first and second voltage lines to serve as switch transistors including switch transistors each having different conducting-state resistances; and a switch conduction control section for controlling a transition of each of the switch transistors from a non-conducting state to a conducting state by turning on the switch transistors at separate points of time.

Owner:SONY CORP

Fan-out signal line structure and display panel

InactiveCN102243383AImprove the problem of resistance differenceUniform resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringLine structure

The invention provides a fan-out signal line structure and a display panel. The fan-out signal line structure comprises a plurality of fan-out signal lines and resistance compensating units, wherein the fan-out signal lines are in fan-shaped configuration; and the resistance compensating units are formed on the fan-out signal lines and used for compensating a resistance difference between the fan-out signal lines. The fan-out signal line structure can be applied to the display panel to ensure the quality of signal transmission.

Owner:HANNSTAR DISPLAY CORPORATION

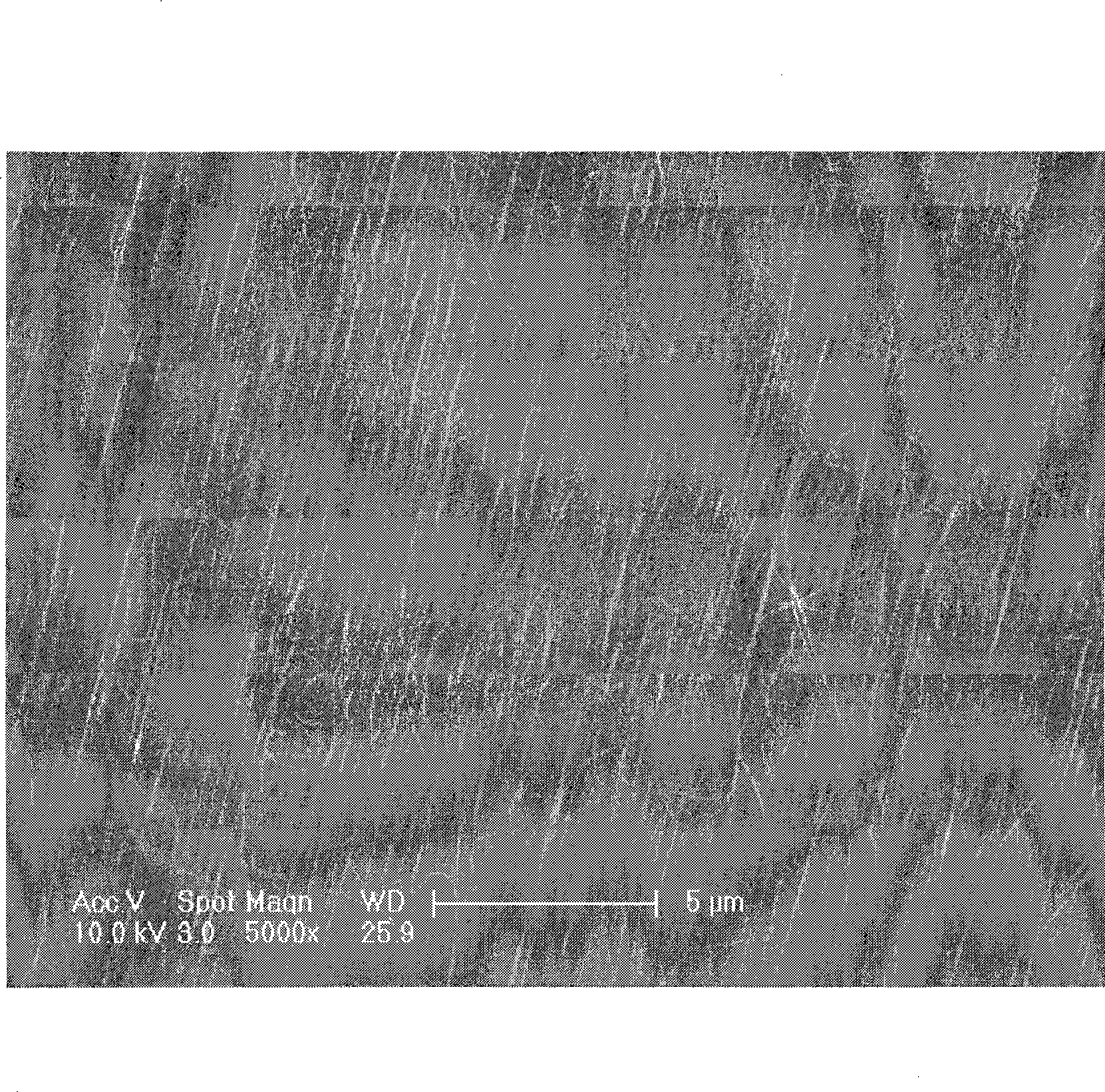

Plane heat source

ActiveCN101868066BHigh electrothermal conversion efficiencyHeating up fastIndividual molecule manipulationElectricityInfrared therapy

The invention relates to a plane heat source, comprising a heating element and at least two electrodes which are arranged at intervals and electrically connected with the heating element, wherein the heating element is composed of a substrate and an integrated self-supporting carbon nano tube structure formed by a plurality of carbon nano tubes. The plane heat source can be used for producing self-heating clothes, gloves or shoes, electric heaters, infrared therapy apparatuses, electric radiators and the like and has wide application range.

Owner:TSINGHUA UNIV +1

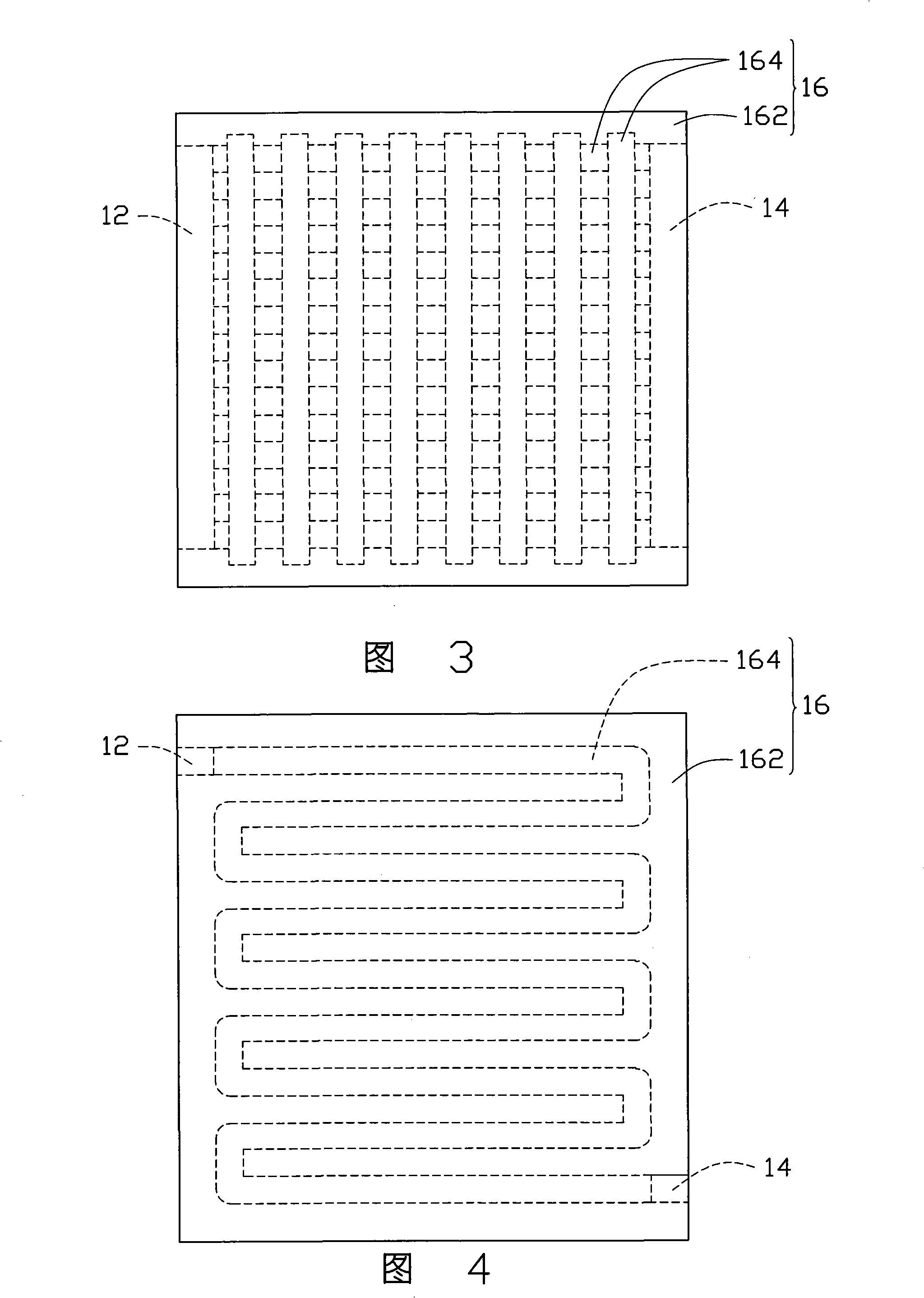

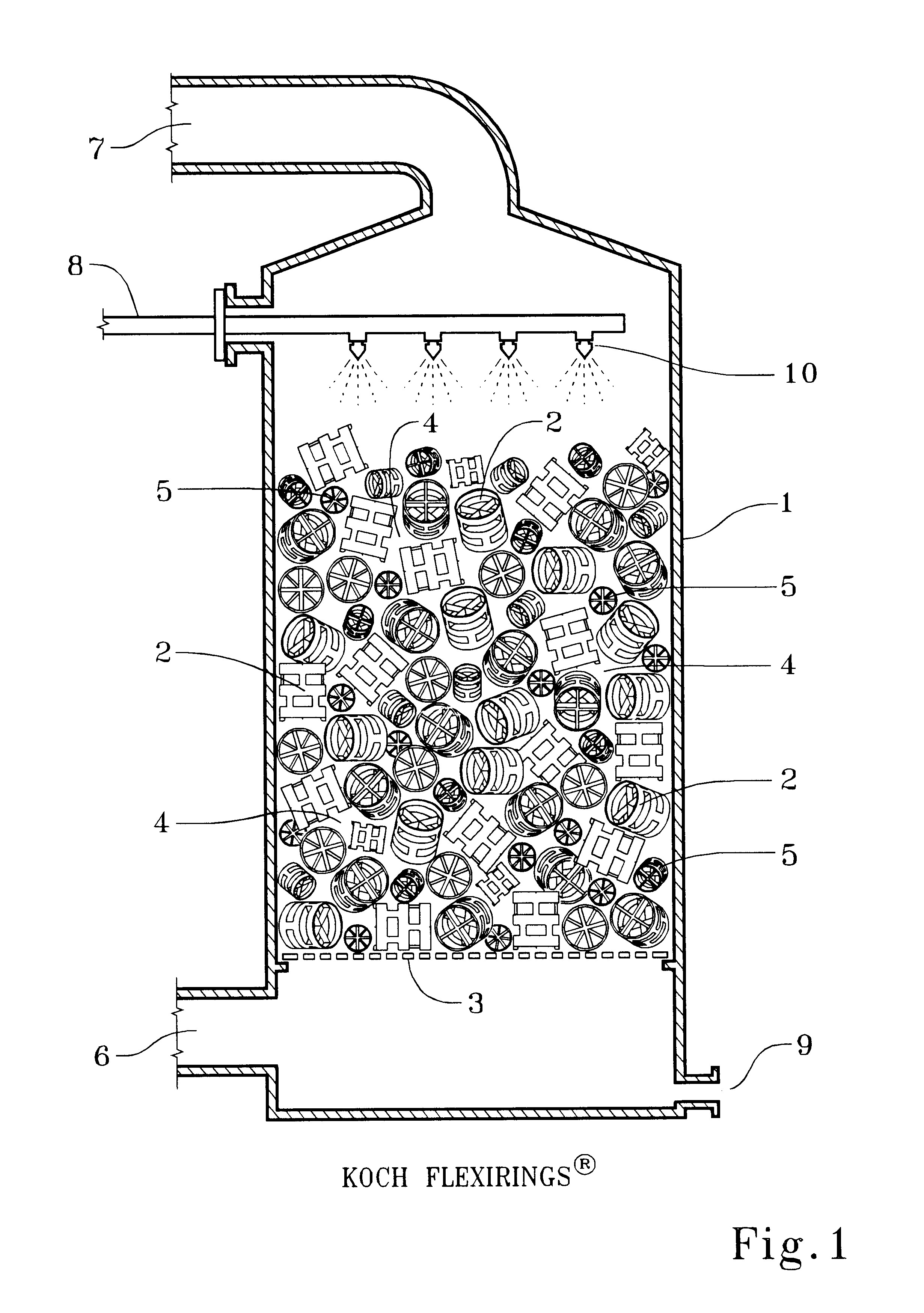

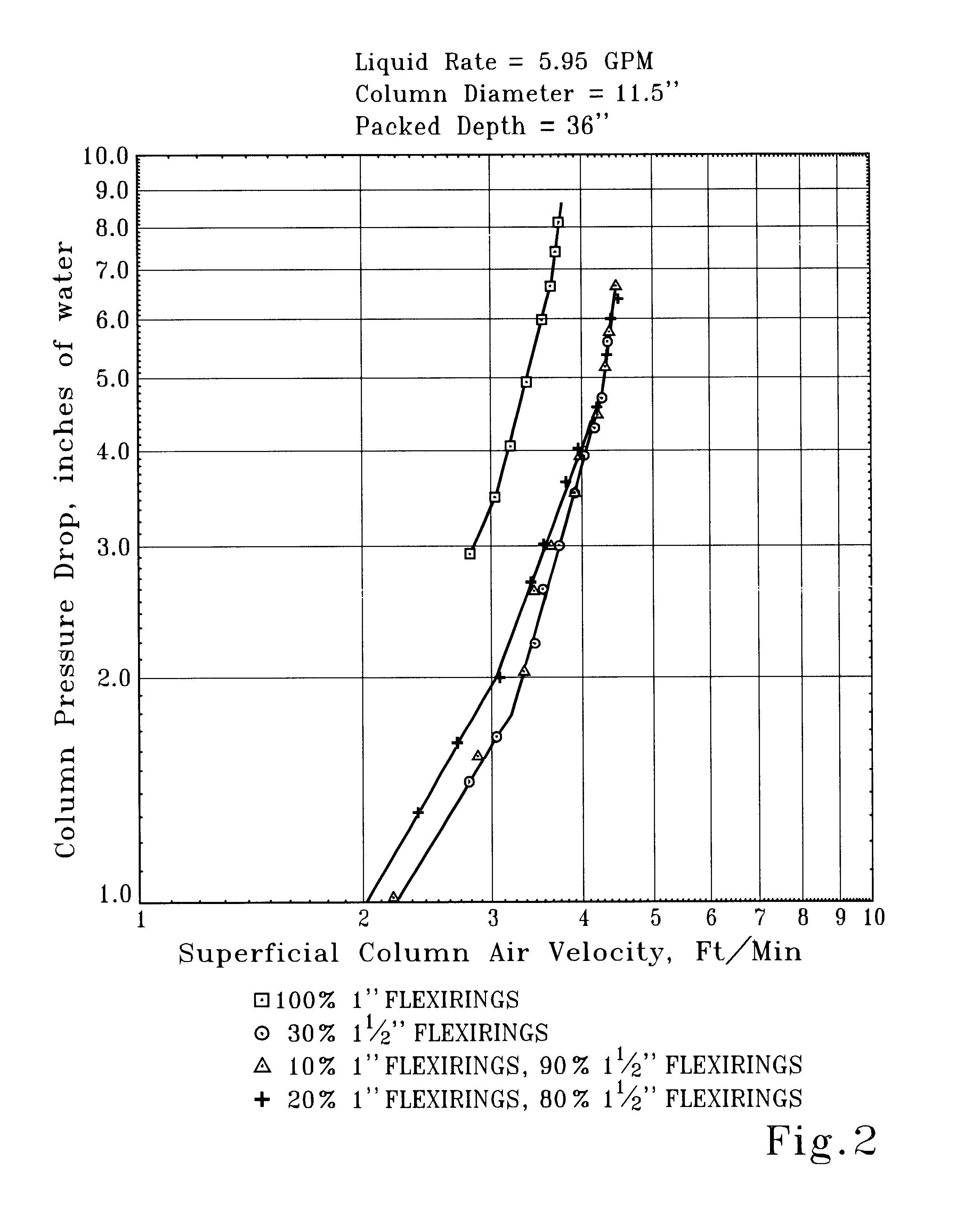

Mixed-size packed beds

InactiveUS6666436B1Improve mass transfer effectHigh limiting flow capacityUsing liquid separation agentMixing methodsMass transferEngineering

An improved random-dumped packed bed for effecting inter-phase heat and mass transfer. The packed bed is a plurality of a first packing size substantially uniformly mixed and co-mingled with a plurality of the suitable second larger packing size. The mixed bed so formed provides the additional surface area and mass transfer capacity of the plurality of the added first smaller packing size while maintaining the gas and liquid limiting flow capacity of a bed of the second larger packing size absent the smaller first packing size.

Owner:BECO ENG

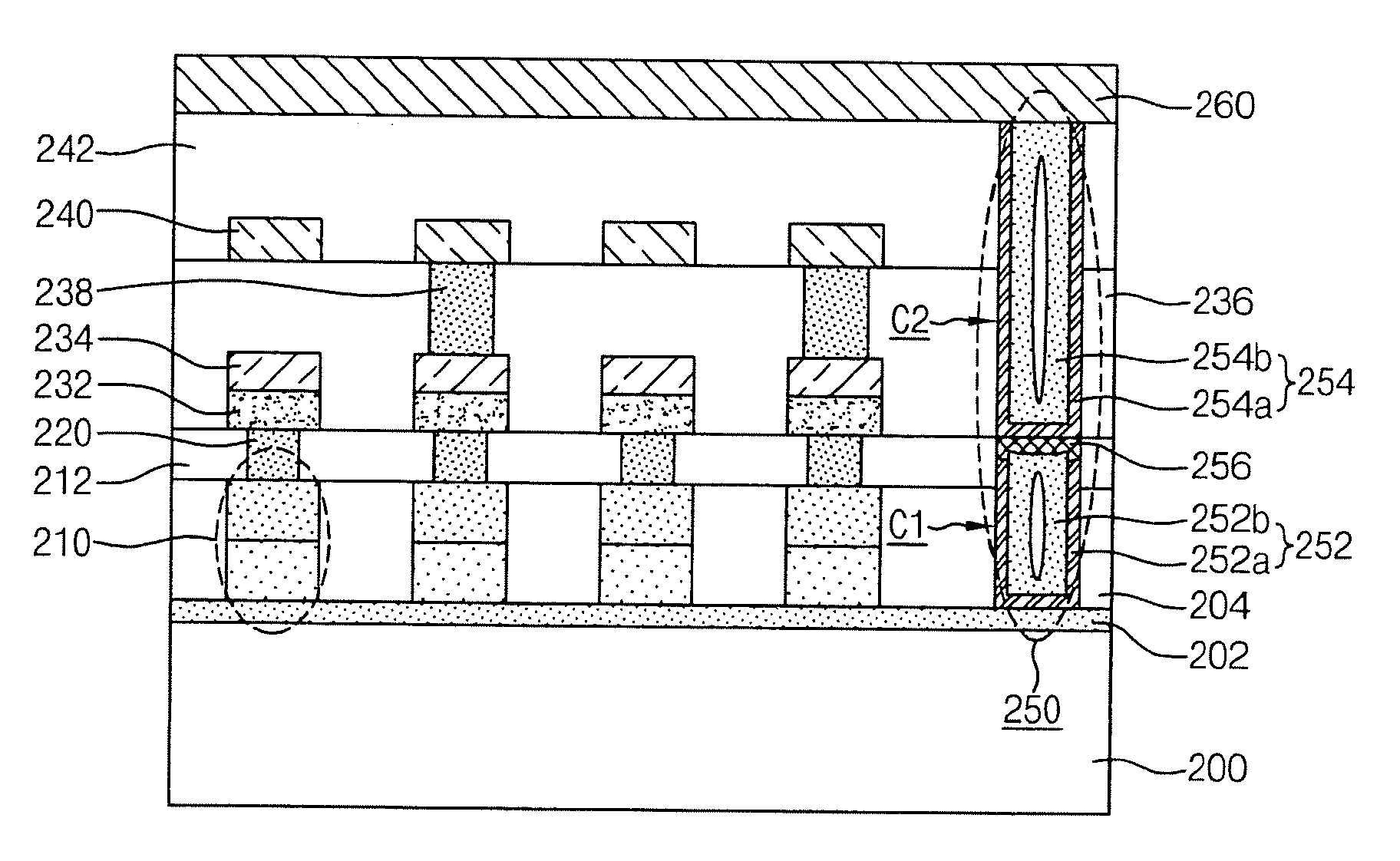

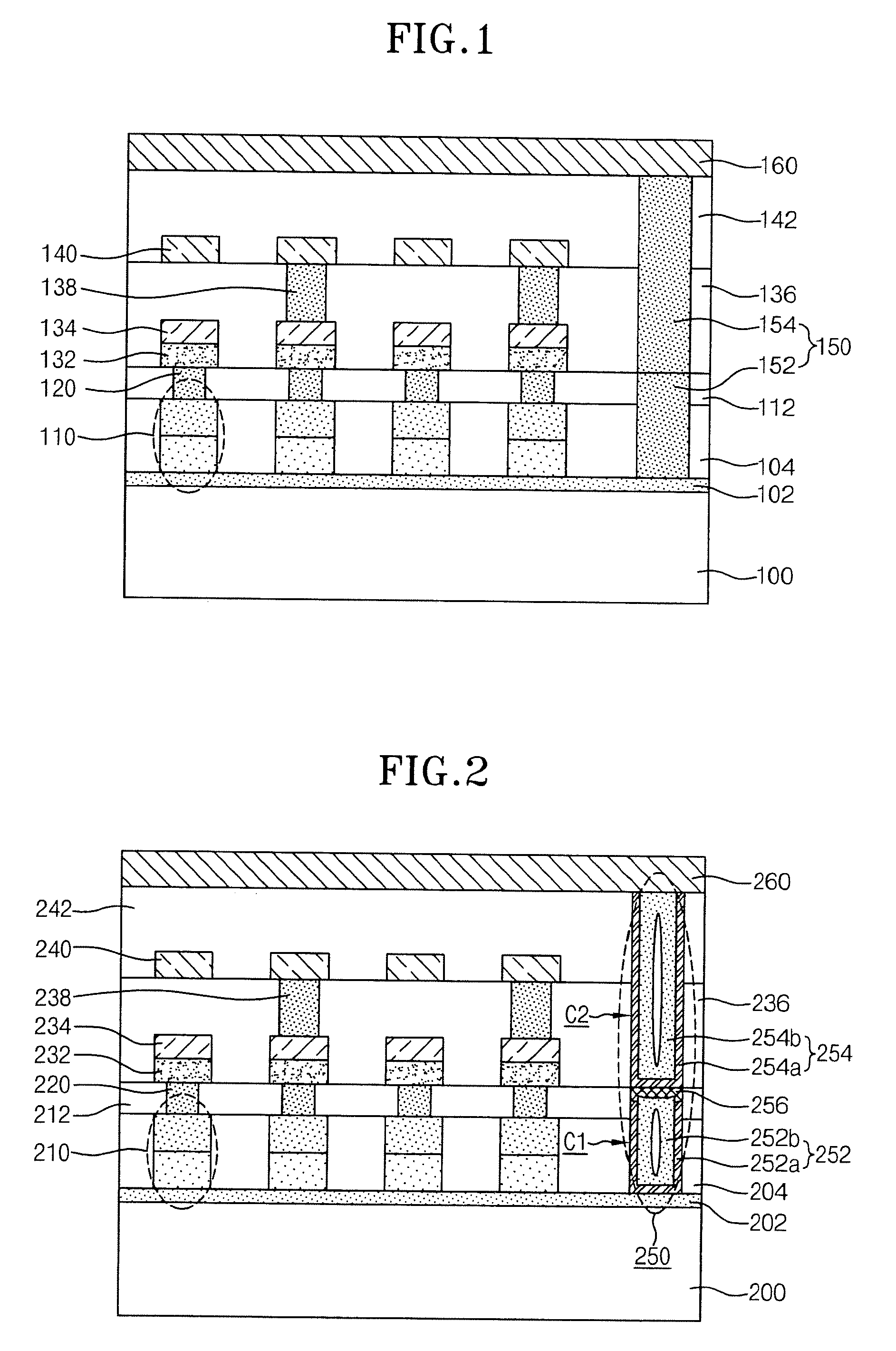

Phase change memory device having a word line contact and method for manufacturing the same

ActiveUS20090302299A1Stably formUniform resistanceSemiconductor/solid-state device detailsSolid-state devicesEtchingPhase-change memory

A phase change memory device having a word line contact includes an N+ base layer formed in a surface of a semiconductor substrate. A word line is formed over the N+ base layer. The word line contact is formed to connect the N+ base layer to the word line. The word line contact includes a first contact plug, a barrier layer formed on the first contact plug, and a second contact plug formed on the barrier layer coaxially with the first contact plug. The barrier layer prevents unwanted etching of the first contact plug when the second contact plug is being formed.

Owner:SK HYNIX INC

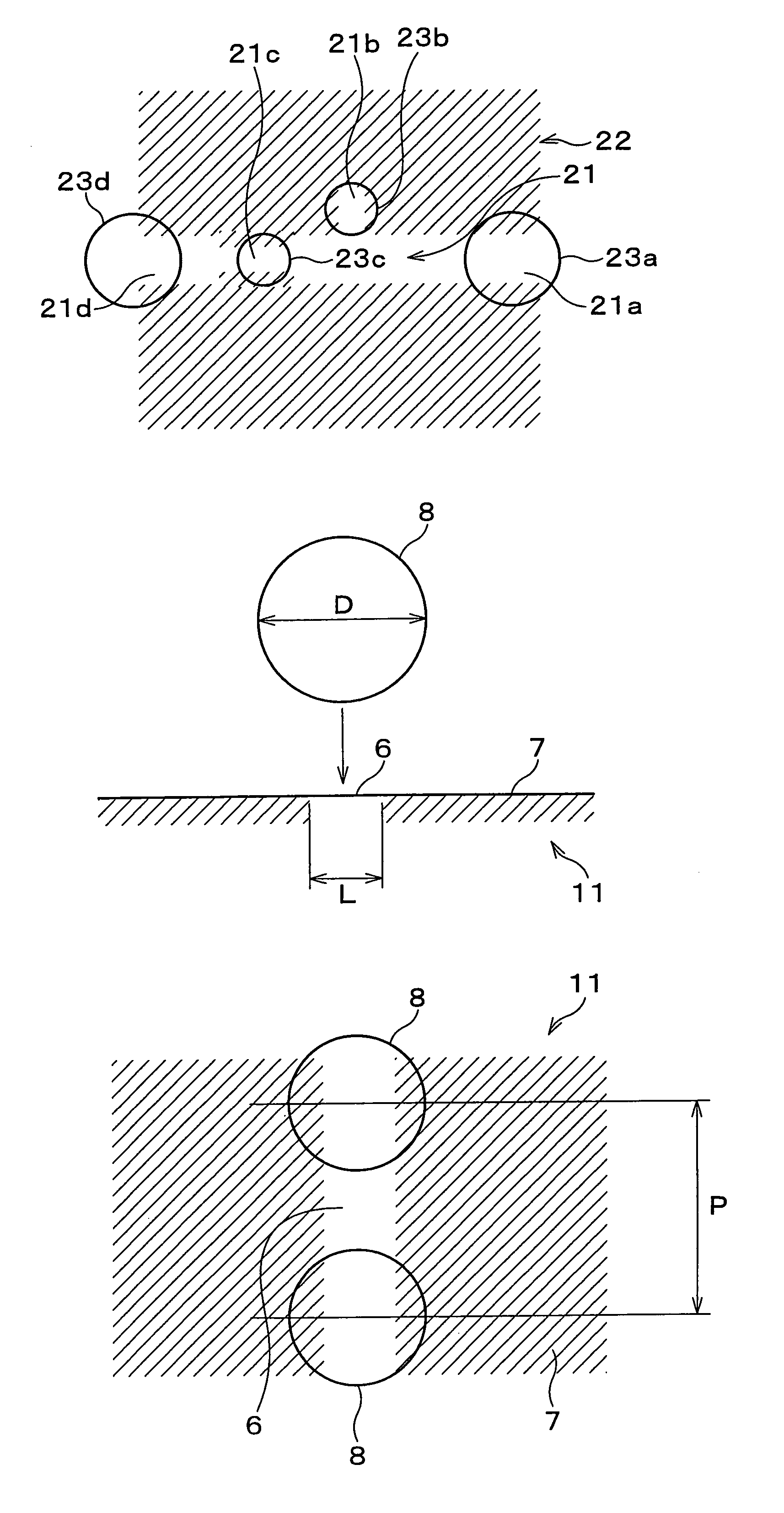

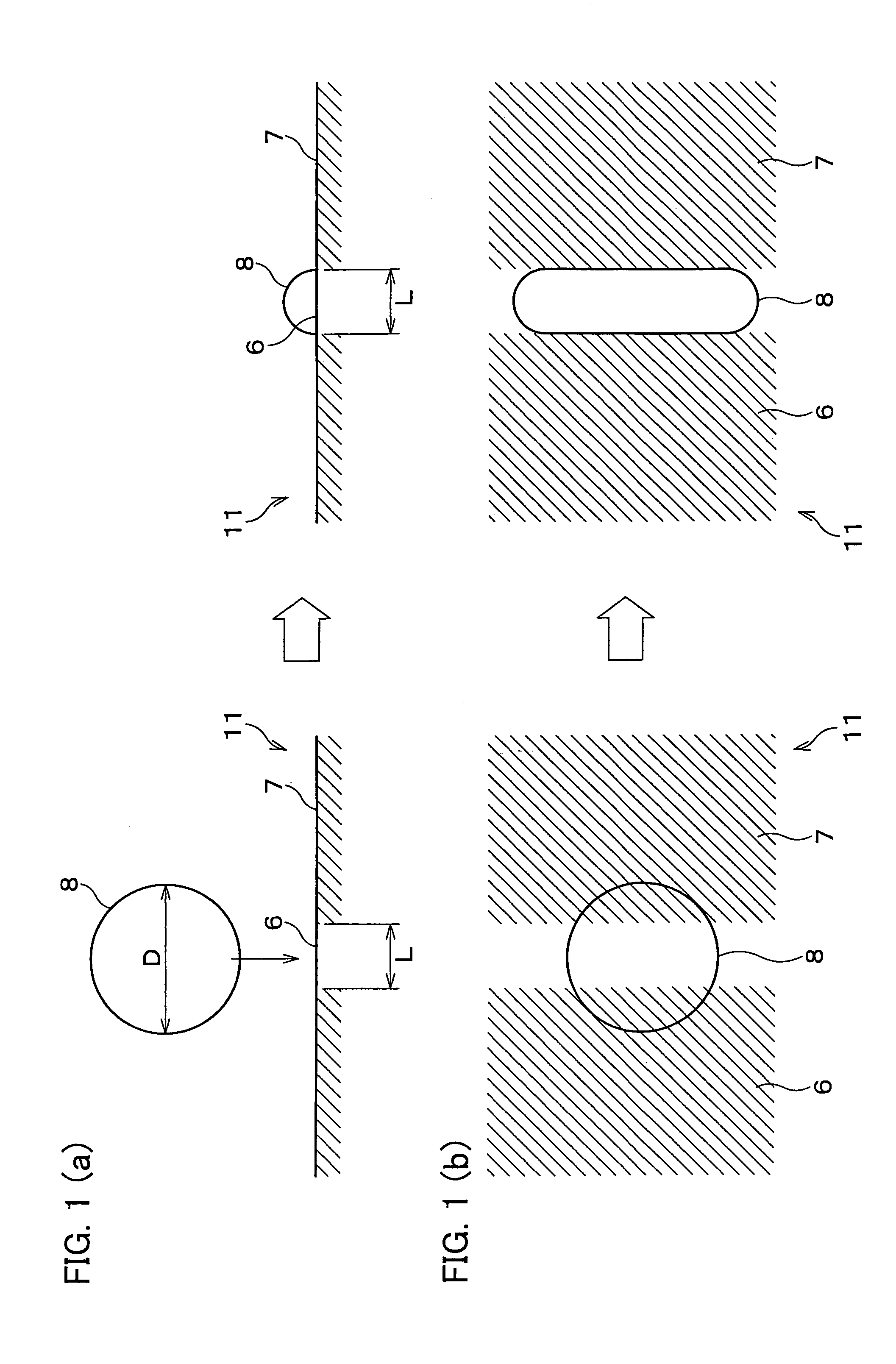

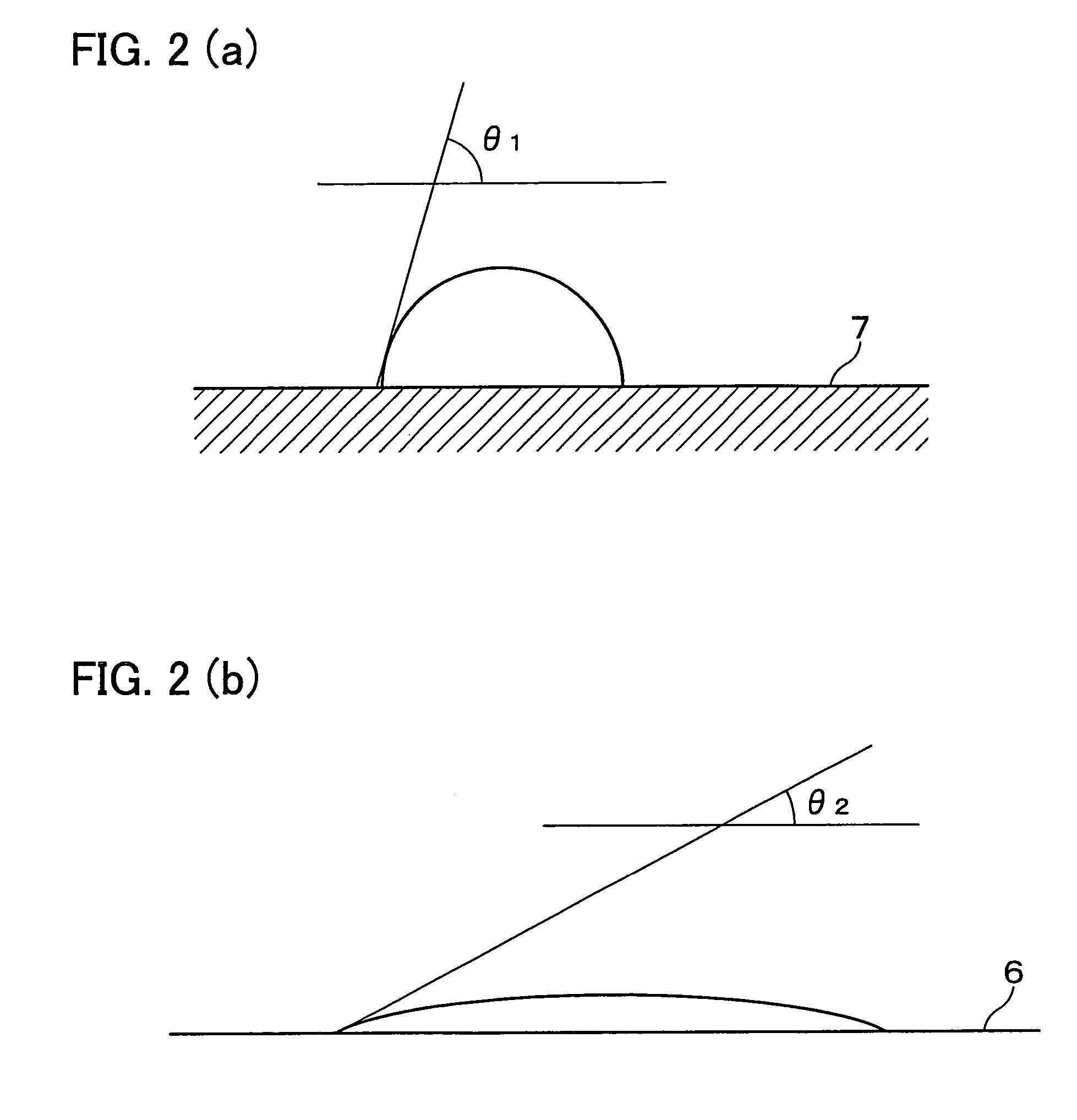

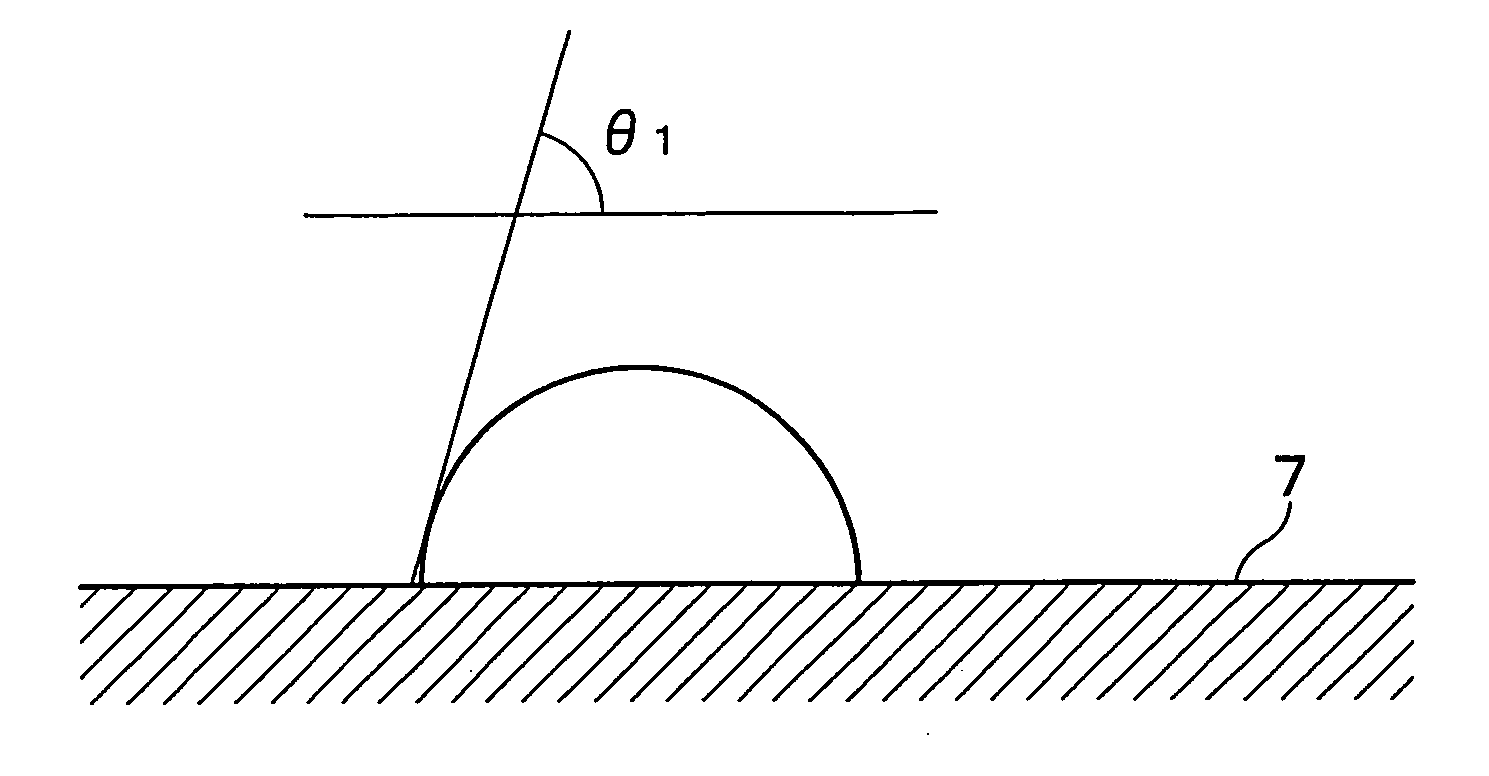

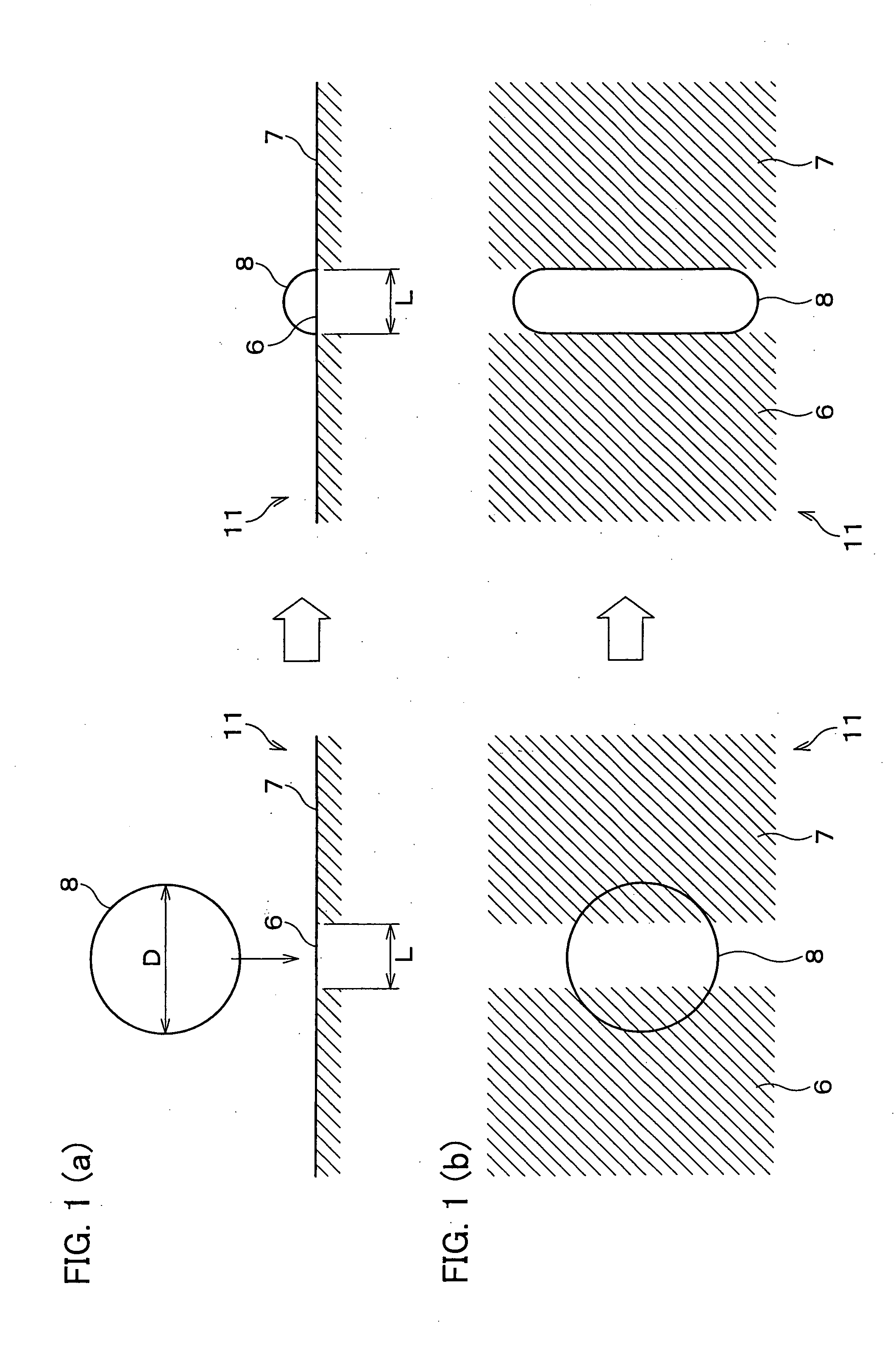

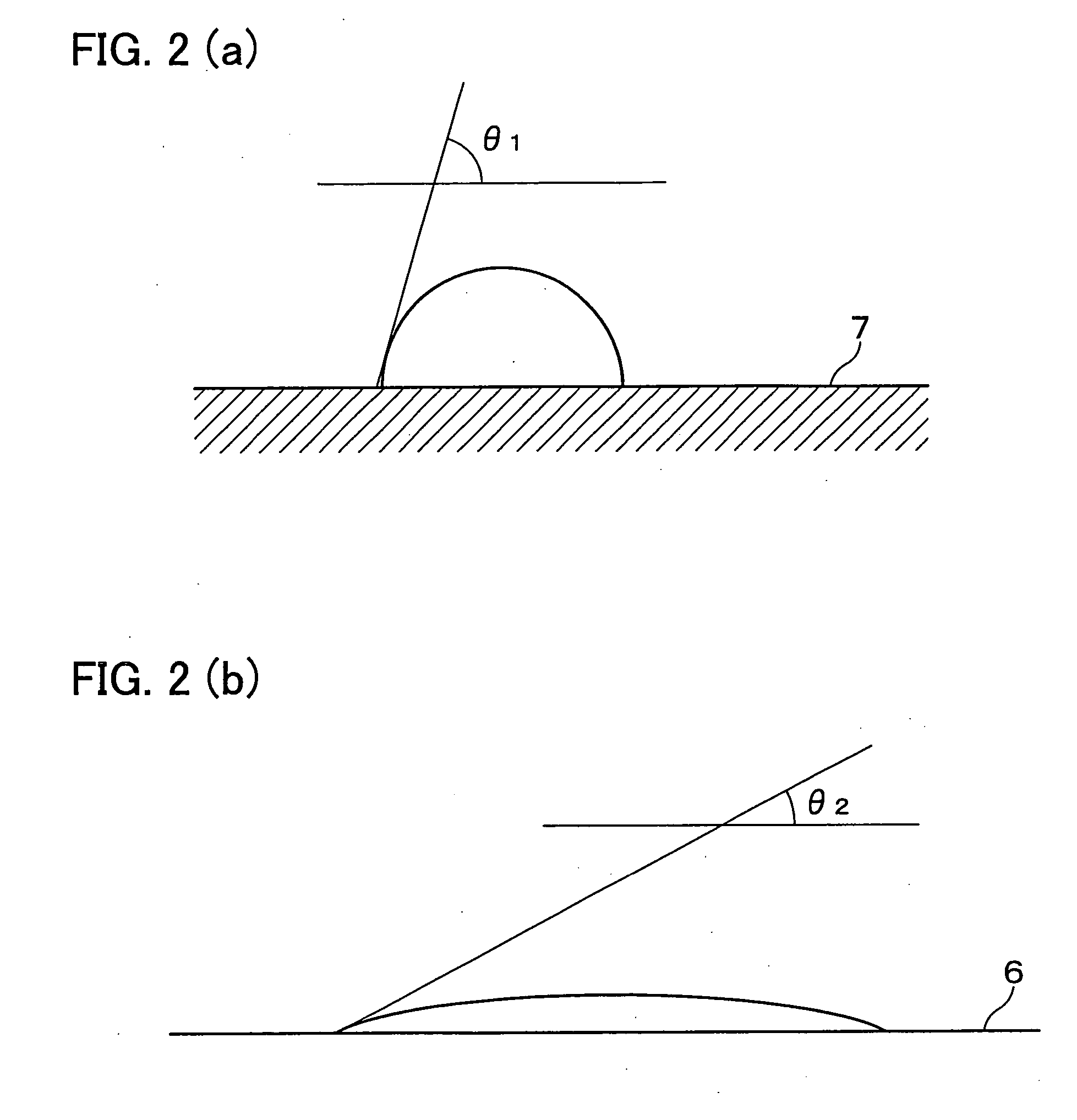

Basic material for patterning and patterning method

InactiveUS7119026B2Reduce in quantityUniform thicknessTransistorLiquid surface applicatorsTarget surfaceOperating life

A pattern forming method of the present invention includes the steps of forming, on a substrate before droplets are ejected onto the substrate, a water repelling area, in which a contact angle between the droplet and the target surface is a first contact angle, and a water attracting line, which is adjacent to the water repelling area and in which a second contact angle is smaller than the first contact angle and which is to be the pattern to be formed; and landing droplets onto the target surface such that part of the droplet landed is in a water repelling area and part of the droplet landed is in a water attracting line, the equation (1) is satisfied,D≦L×{1+2(cos θ2−cos θ1)} (1)where D is a droplet diameter, L is a pattern width, θ1 is a first contact angle, and θ2 is a second contact angle. By decreasing the number of discharged droplets, it is possible to prevent increase of a tact time and decrease of an inkjet operating life.

Owner:SHARP KK

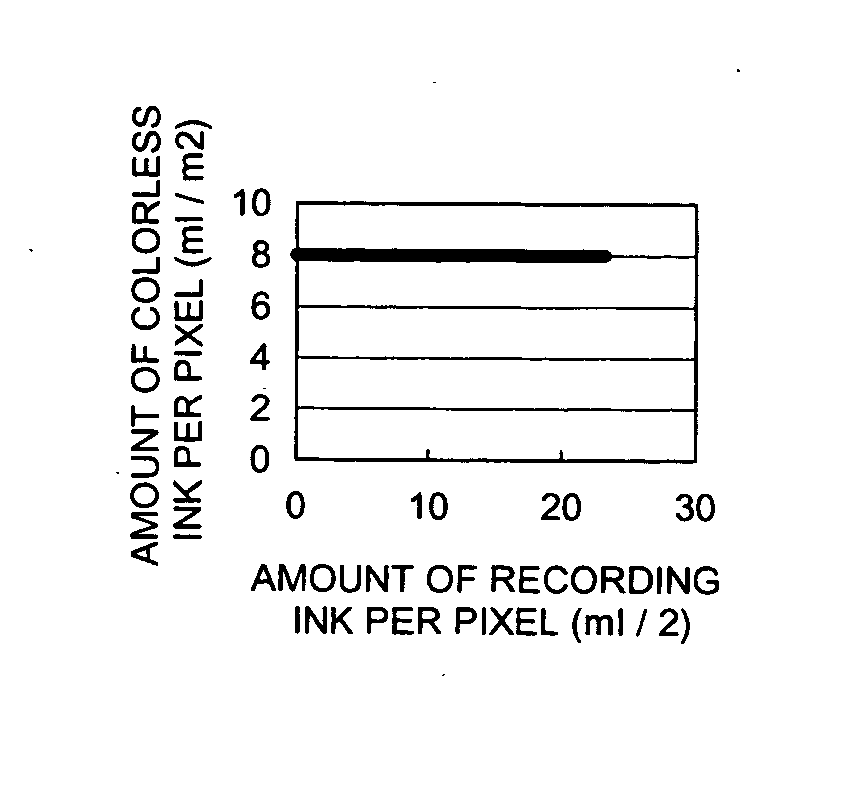

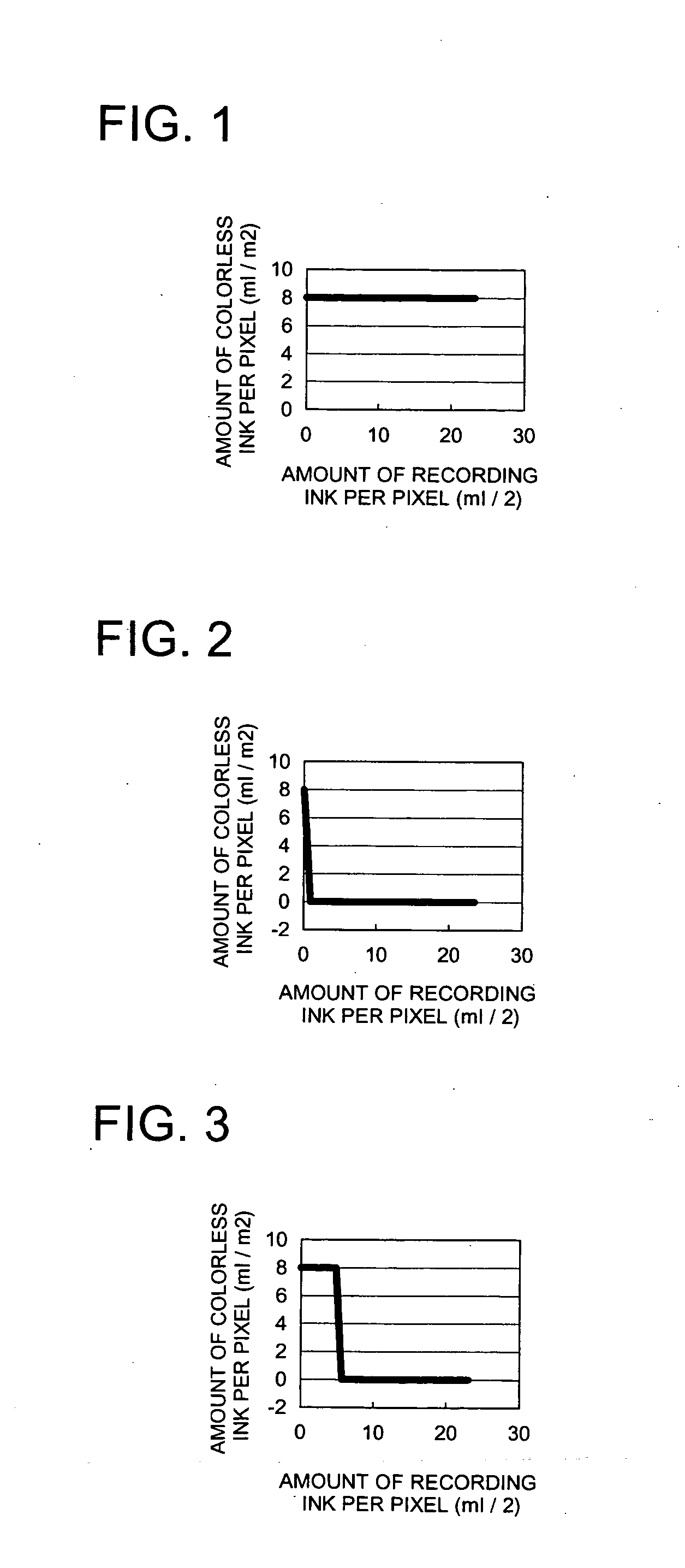

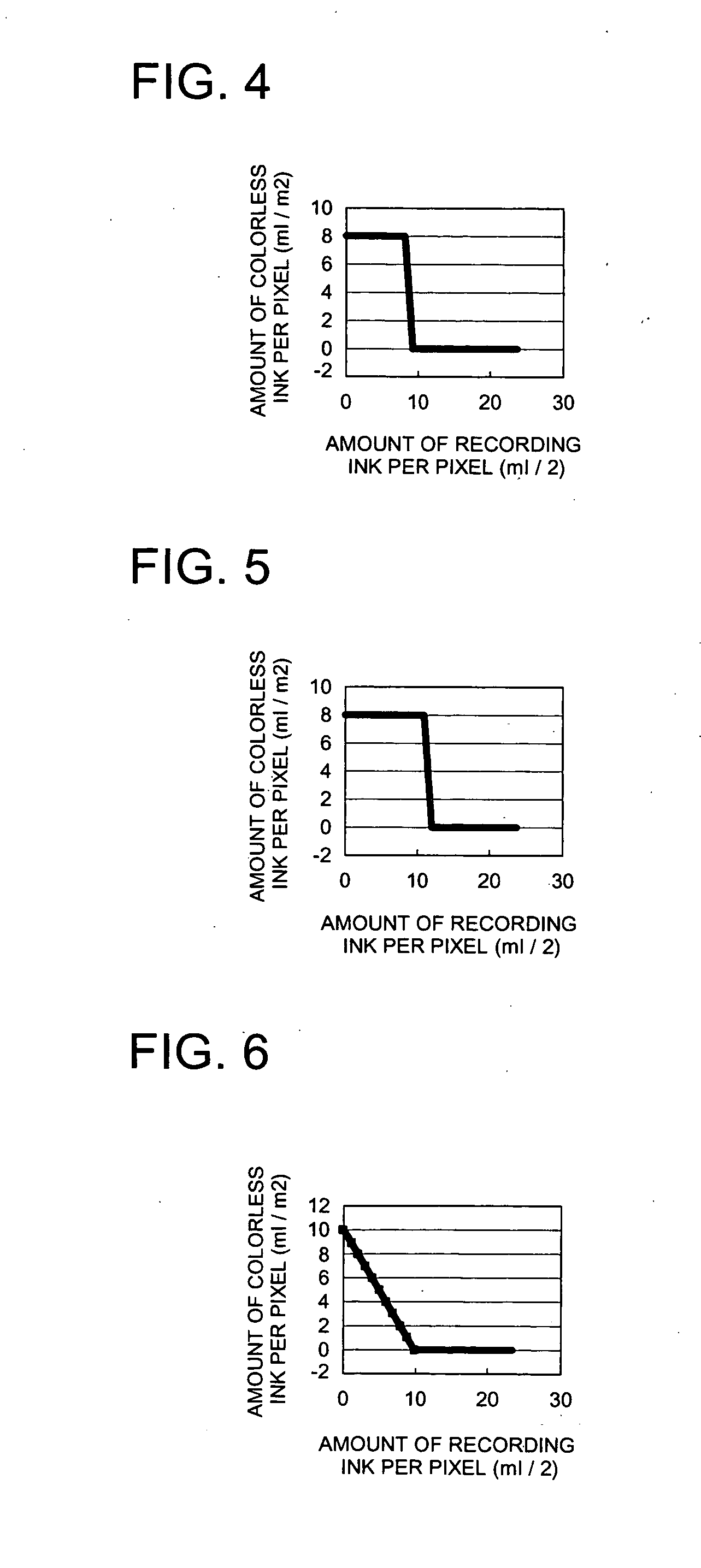

Ink-jet recoding method and recorded matter

InactiveUS20050062819A1Uniform glossinessUniform resistanceMeasurement apparatus componentsDuplicating/marking methodsWater solublePolymer chemistry

Owner:KONICA MINOLTA INC

Temperature sensor element, method for manufacturing same, and temperature sensor

ActiveUS20130020670A1Reduce the differenceInhibit the generation of cracksThermoelectric device manufacture/treatmentThermometers using electric/magnetic elementsElectrical resistance and conductanceBond interface

A temperature sensing element includes a thermistor composed of Si-base ceramics and a pair of metal electrodes bonded onto the surfaces of the thermistor. The metal electrodes contain Cr and a metal element α having a Si diffusion coefficient higher than that of Cr. A diffusion layer is formed in a bonding interface between the thermistor and each metal electrode, the diffusion layer including a silicide of the metal element α in a crystal grain boundary of the Si-base ceramics. A temperature sensor including the diffusion layers is provided. Owing to the diffusion layers, the temperature sensor ensures heat resistance and bonding reliability and enables temperature detection with high accuracy in a temperature range, in particular, of from −50° C. to 1050° C.

Owner:DENSO CORP

Basic meterial for patterning and patterning method

InactiveUS20050245079A1Less non-uniformityLower resistanceTransistorLiquid surface applicatorsTarget surfaceOperating life

A pattern forming method of the present invention includes the steps of forming, on a substrate before droplets are ejected onto the substrate, a water repelling area, in which a contact angle between the droplet and the target surface is a first contact angle, and a water attracting line, which is adjacent to the water repelling area and in which a second contact angle is smaller than the first contact angle and which is to be the pattern to be formed; and landing droplets onto the target surface such that part of the droplet landed is in a water repelling area and part of the droplet landed is in a water attracting line, the equation (1) is satisfied, D≦Lx{1+2(cos θ2−cos θ1)} (1) where D is a droplet diameter, L is a pattern width, θ1 is a first contact angle, and θ2 is a second contact angle. By decreasing the number of discharged droplets, it is possible to prevent increase of a tact time and decrease of an inkjet operating life.

Owner:SHARP KK

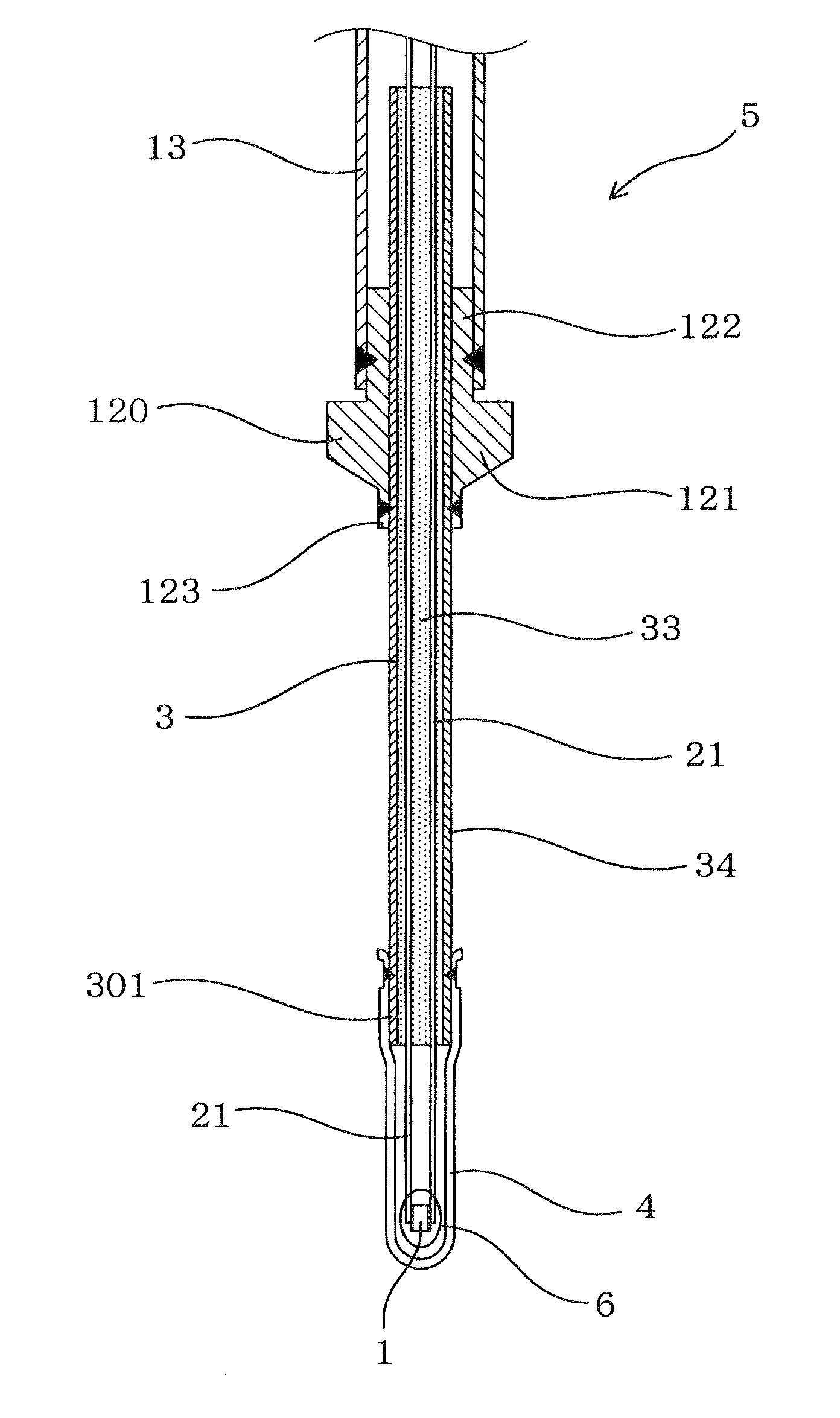

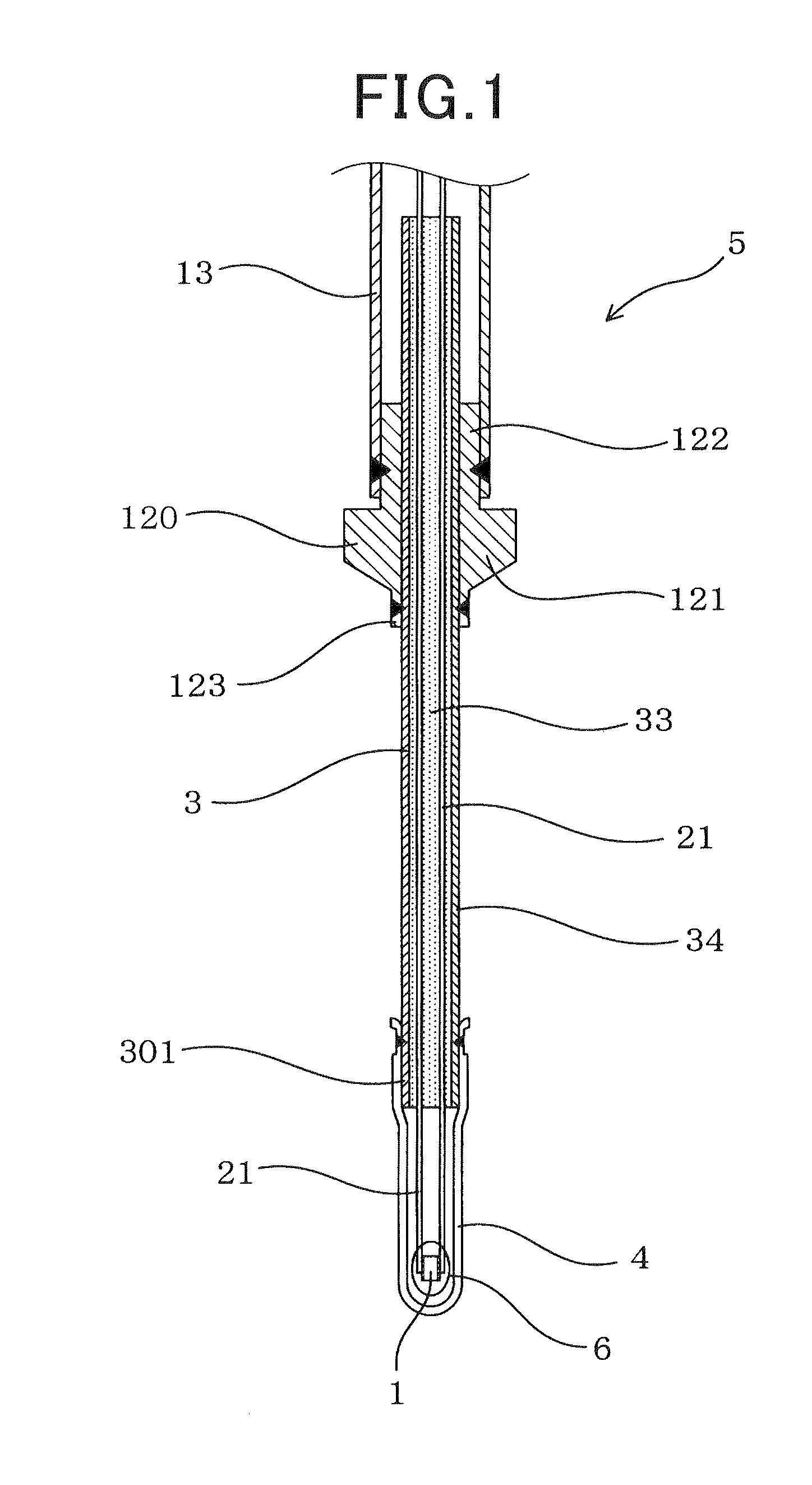

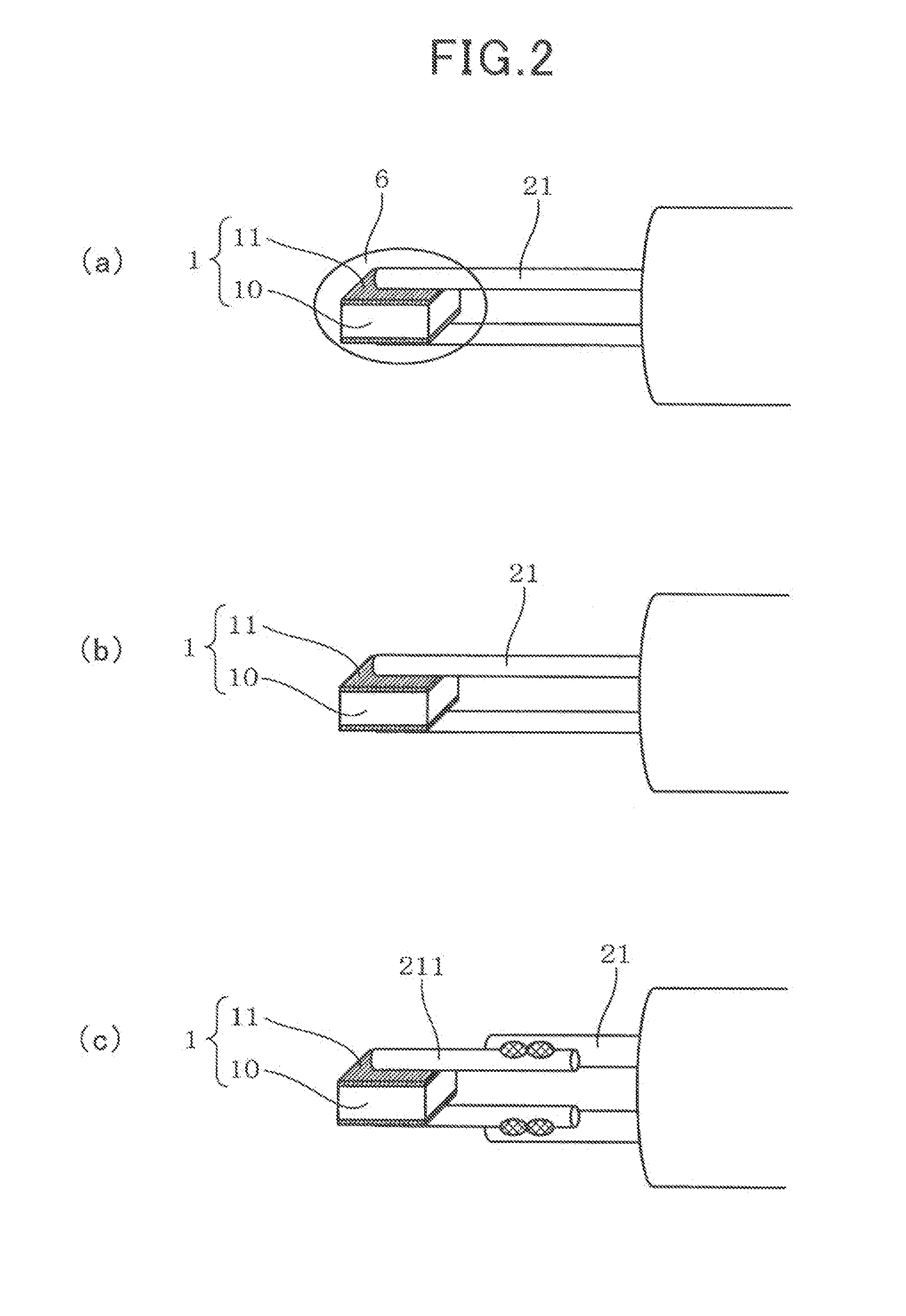

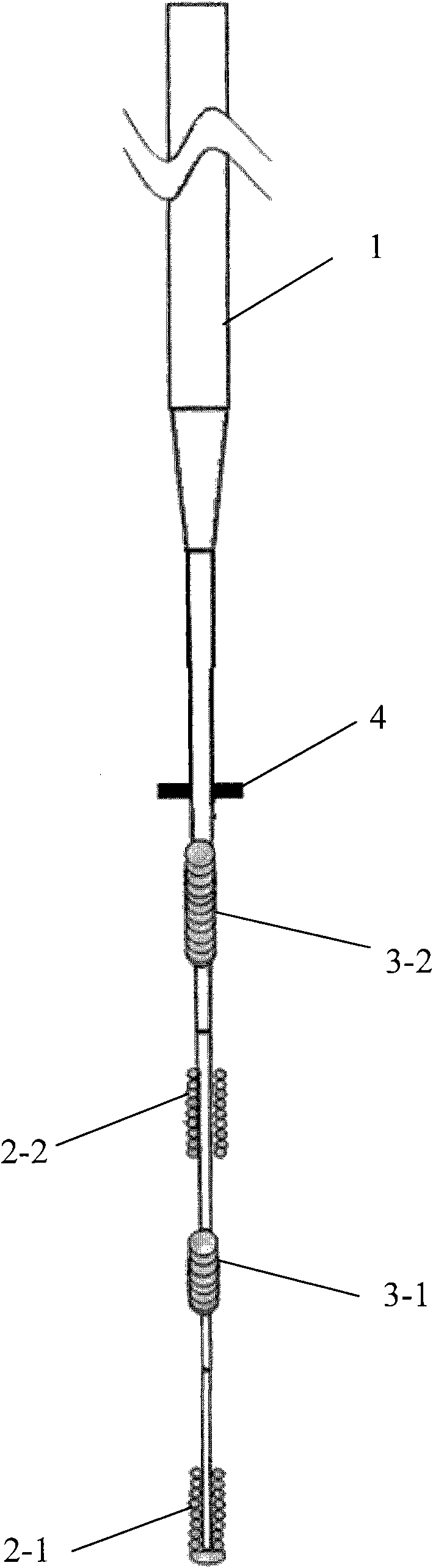

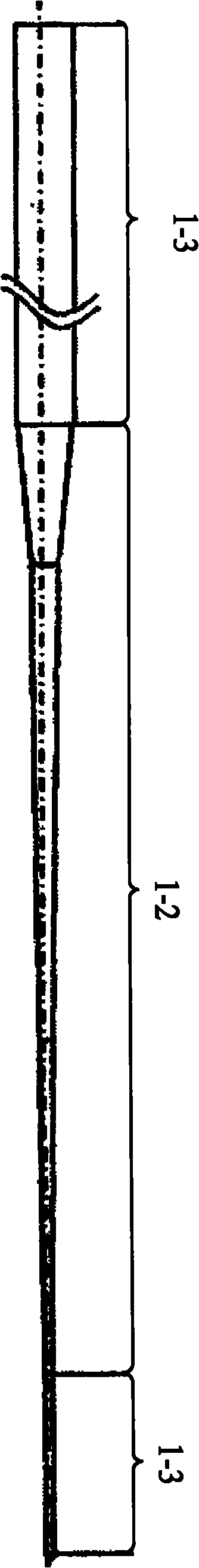

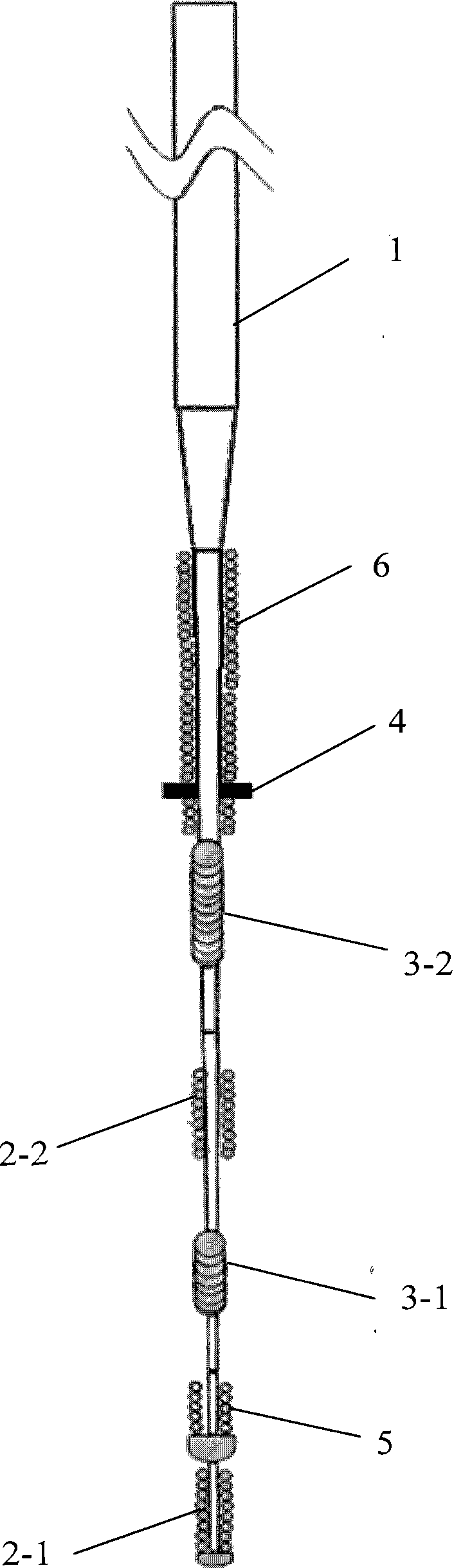

Medical guide wire

The application discloses a medical guide wire which is used for conveying implanted instruments and comprises a metal core, one or more spiral filaments, one or more conveying elements and a boss, wherein the metal core is of a diameter-altered structure which sequentially comprises a linear structure, a stepped structure and a linear structure from a near end to a far end; the spiral filaments are fixed on the linear structure and the stepped structure which are positioned at the far end of the metal core; the conveying elements are fixed on the stepped structure of the metal core; and the boss is fixed on the stepped structure of the metal core behind the conveying elements. The medical guide wire provided by the application has the following advantages: as the metal core is provided with multiple conveying elements, during the conveying process, the conveying elements are implanted into the inner wall of an instrument by virtue of friction and provide thrust section by section, sothat all sections of the implanted instrument are subjected to uniform resistance, thus the problems of wrinkles and deformation of the implanted instrument caused by overlarge resistance during the process of conveying the implanted instrument due to the bending of a medical conduit are solved, thereby integrally conveying the implanted instrument into a human vessel through the medical conduit.

Owner:MICROPORT NEUROTECH SHANGHAI

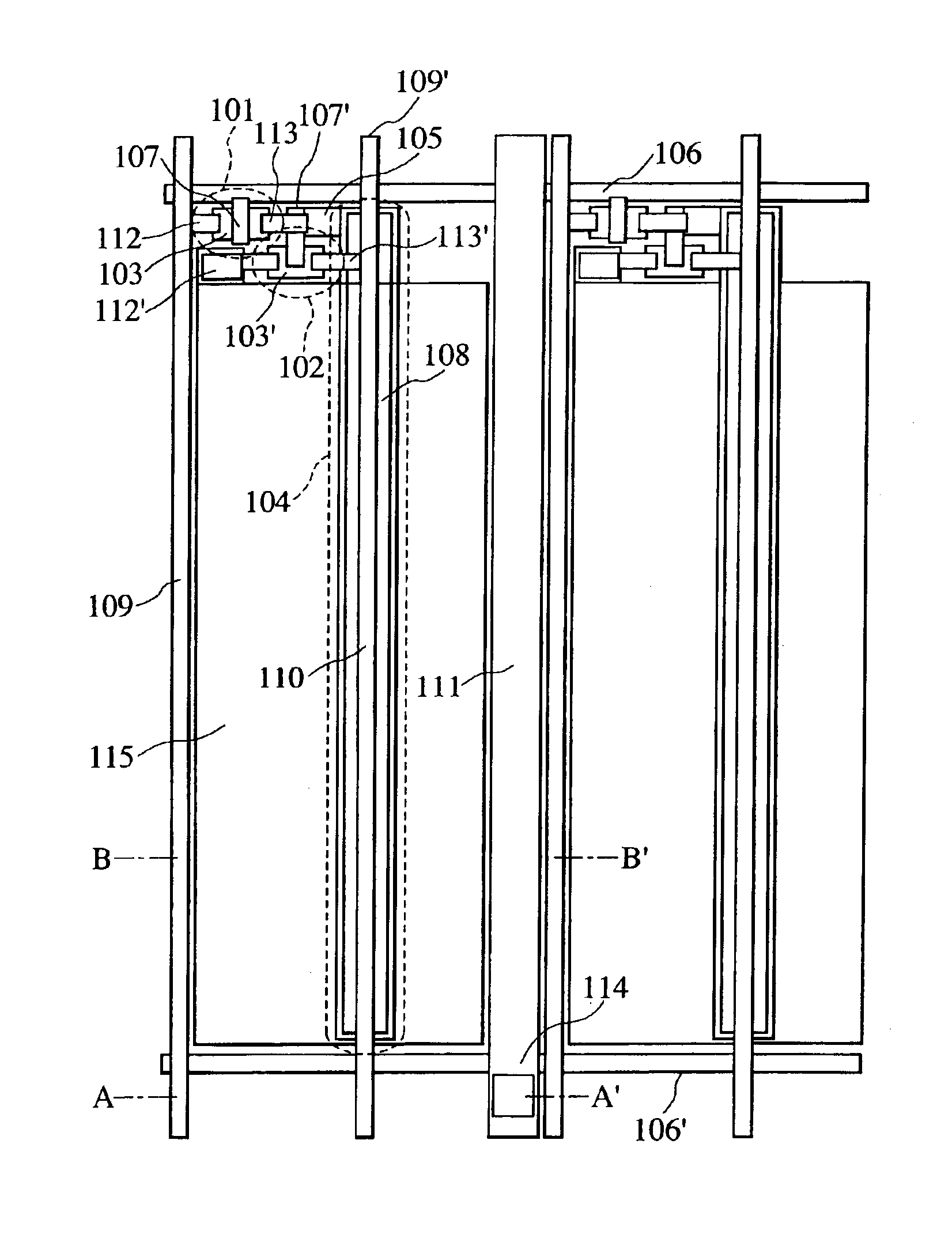

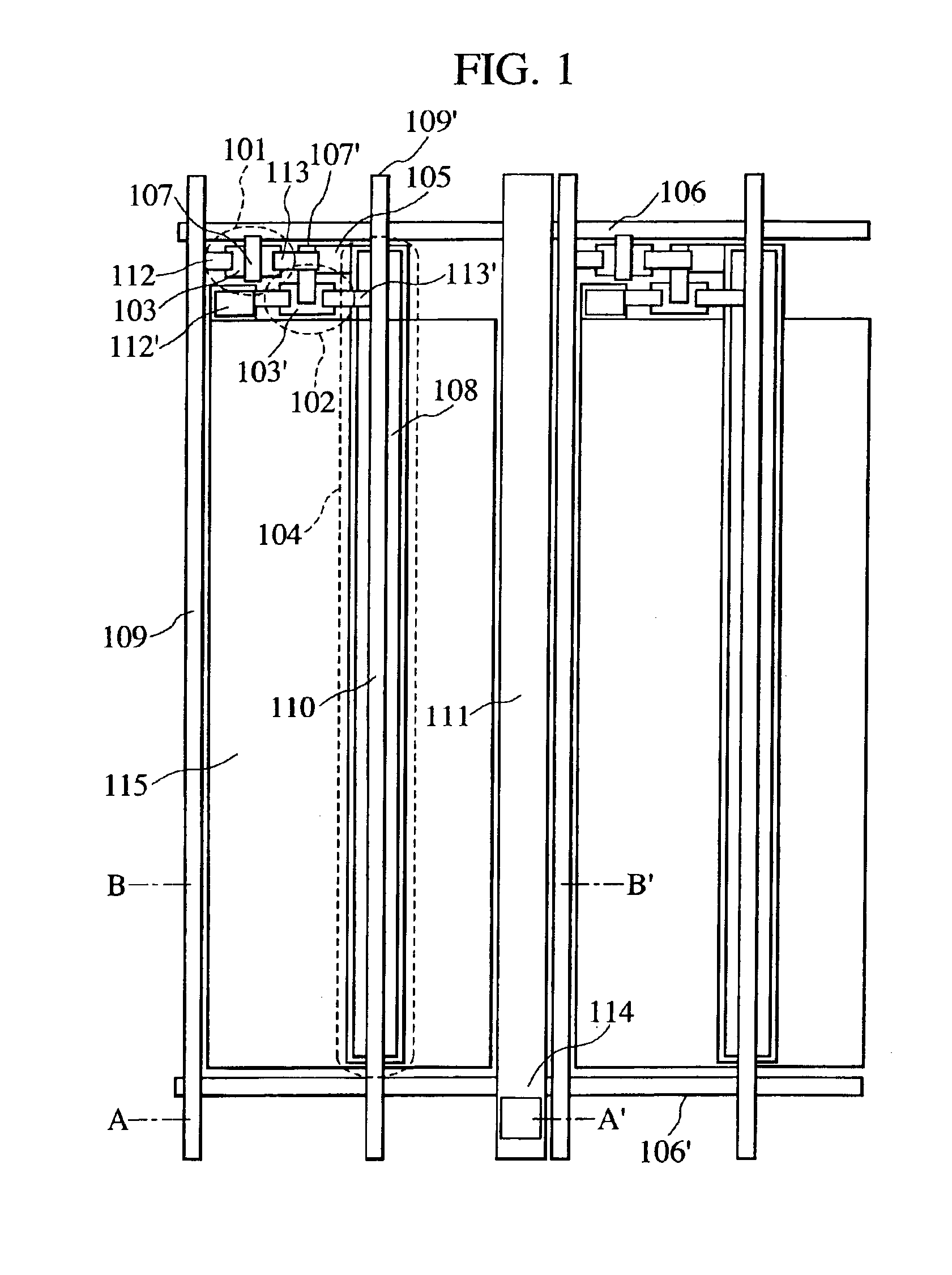

Organic light-emitting display device

InactiveUS20050127372A1Variation in brightnessDeterioration of image qualityElectroluminescent light sourcesSolid-state devicesOrganic layerDisplay device

A scanning line, a signal line, a first current supply line, and a second current supply line are formed on a glass substrate, a first electrode is formed on the wiring layer comprising the above members, an organic layer comprising a hole transport layer, a light-emitting layer, an electron transport layer, and an electron injection layer is formed on the first electrode, a second electrode is formed as cathode on the electron injection layer, the first electrode as anode is connected to a plus terminal of a power source through the driving devices and the first current supply line, whereas the second electrode as cathode is connected to a minus terminal of the power source, and is connected to the second current supply line in the display region of each pixel, with a contact hole serving as a feeding point, whereby wiring resistance due to the second electrode is reduced, and variations in the brightness of a panel is reduced.

Owner:SAMSUNG DISPLAY CO LTD +1

Fluorine-containing organopolysiloxane, a surface treatment composition comprising the same and an article treated with the composition

ActiveUS7794843B2Increase resistanceHigh strengthSilicon organic compoundsLayered productsHydrogen atomOrganic group

An organopolysiloxane represented by the following general formula (A), (B) or(C)SinR12n+2On−1 (A)SinR12nOn (B)SinR12n+2R2kOn−k (C)wherein R1 may be the same with or different from each other and is a hydrogen atom or a monovalent organic group, R2 is an alkylene group having 2 to 6 carbon atoms, n is an integer of from 2 to 40 and k is an integer of 1 to 3,characterized in that at least two R1's are represented by the following formula (i):wherein X is a hydrolyzable group, R3 is an alkyl group having 1 to 4 carbon atoms or a phenyl group, y is an integer of from 1 to 5 and a is 2 or 3; andone SiOSi bond is replaced with a bond represented by the following formula (iii):SiQRf2QSi (iii)wherein Rf1 is a monovalent group containing a perfluoroether residue, Rf2 is a divalent group containing a perfluoroether residue, and Q is a divalent organic group.

Owner:SHIN ETSU CHEM IND CO LTD

Electroluminescence device having lead line with low resistance

InactiveUS20050127830A1Uniform resistanceDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceLead lines

An organic electroluminescence device including a plurality of electrodes formed on a substrate, and a plurality of lead lines are coupled to the plurality of electrodes. At least two or more lead lines among the plurality of lead lines have different widths, and a width of a longer lead line among the plural lead lines is greater than a width of a shorter lead line.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

Semiconductor device

InactiveUS20100006848A1Wiring resistanceImprove protectionSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor

To improve the performance of a protection circuit including a diode formed using a semiconductor film. A protection circuit is inserted between two input / output terminals. The protection circuit includes a diode which is formed over an insulating surface and is formed using a semiconductor film. Contact holes for connecting an n-type impurity region and a p-type impurity region of the diode to a first conductive film in the protection circuit are distributed over the entire impurity regions. Further, contact holes for connecting the first conductive film and a second conductive film in the protection circuit are dispersively formed over the semiconductor film. By forming the contact holes in this manner wiring resistance between the diode and a terminal can be reduced and the entire semiconductor film of the diode can be effectively serve as a rectifier element.

Owner:SEMICON ENERGY LAB CO LTD

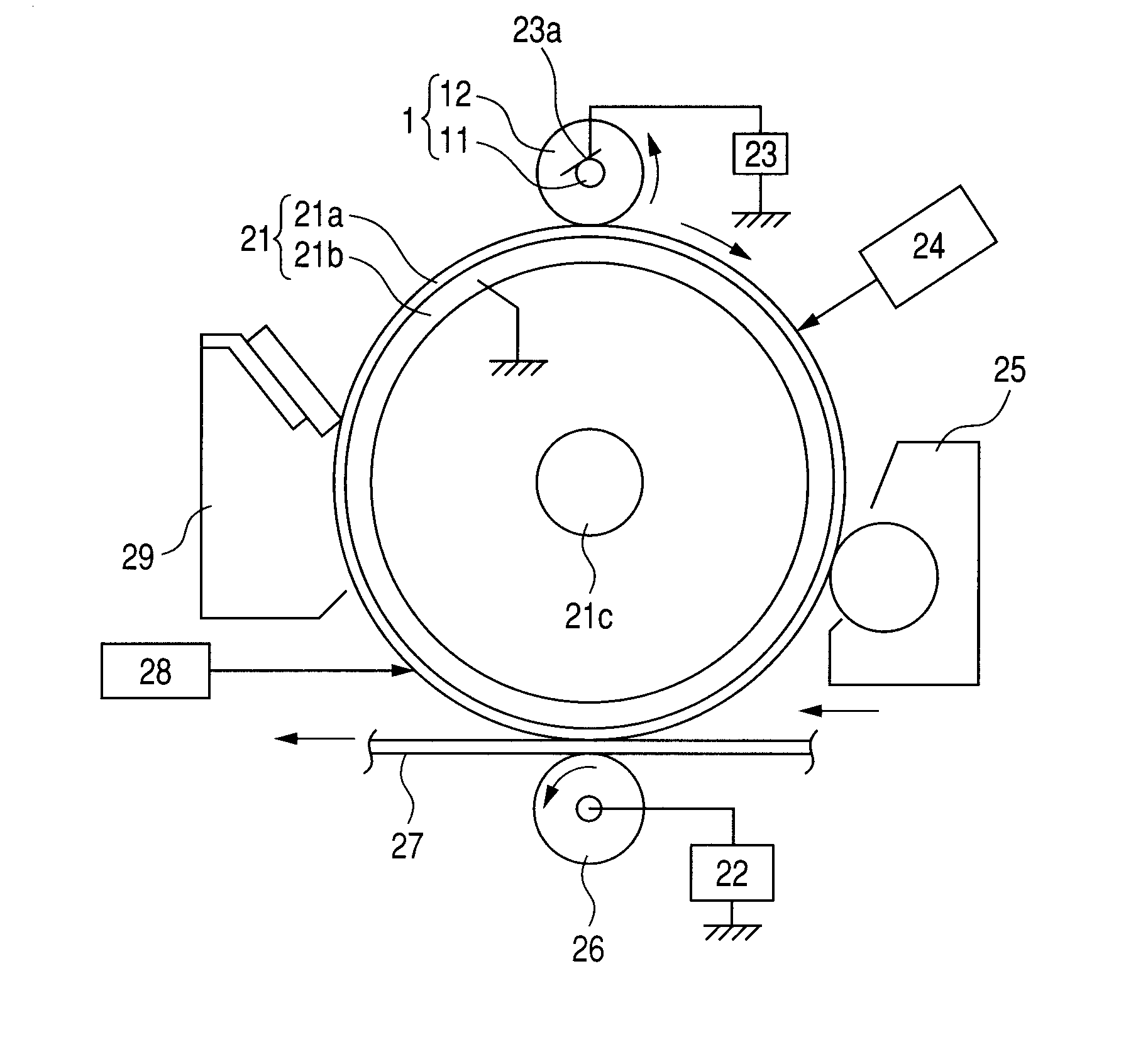

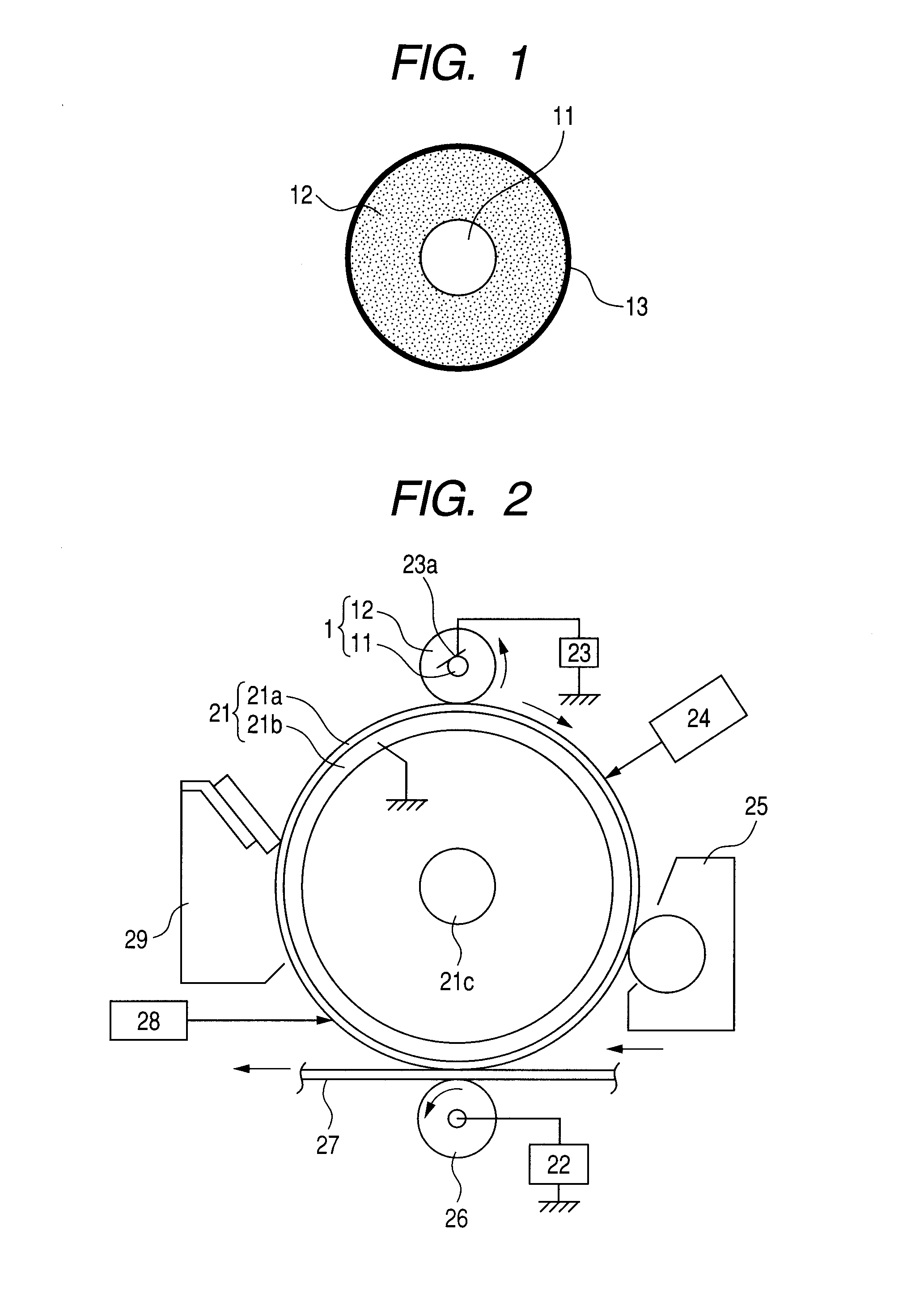

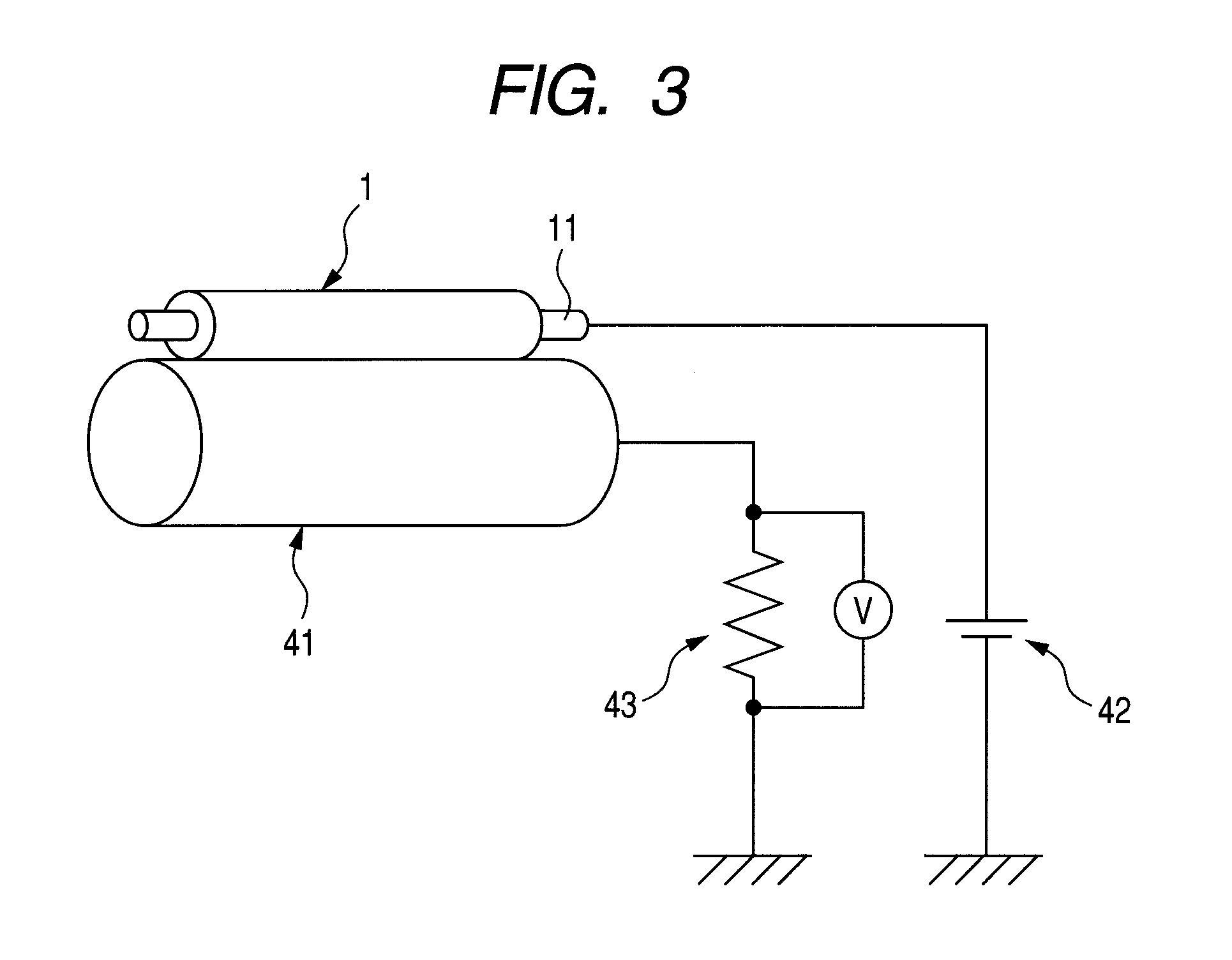

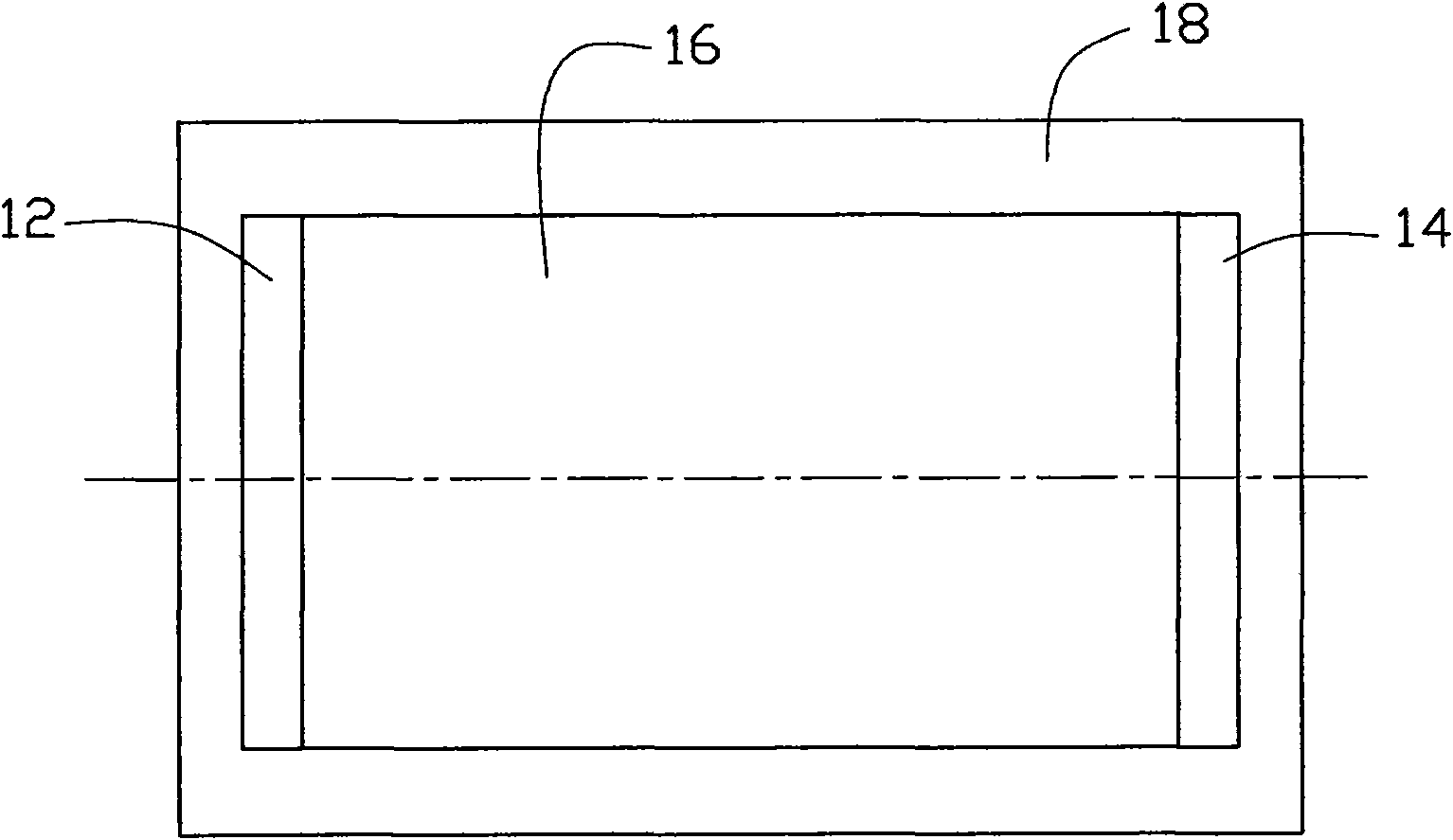

Charging member and electrophotographic apparatus

ActiveUS20110176833A1Uniform resistanceNot easy to changeElectrographic process apparatusCorona dischargeElectrical resistance and conductancePolymer science

To provide a charging member that can have a uniform electrical resistance, can not easily change in electrical resistance even by any long-term continuous electrification and, as a result thereof, may cause less change in its charging performance with time. A charging member having a conductive support and an elastic-material layer; the elastic-material layer comprising a vulcanized rubber; the vulcanized rubber being a vulcanized product of a composition which comprises i) a binder polymer comprising a polymer having a butadiene skeleton and ii) carbon black as electrically conductive particles; and the polymer having a butadiene skeleton has a molecular terminal modified with an atomic group having a specific structure.

Owner:CANON KK

Surface heat source

ActiveCN101605409AGood flexibilityNot easy to breakIndividual molecule manipulationHeating element materialsCarbon nanotubeElectricity

The invention relates to a surface heat source, which comprises a heating element including a carbon nanotube structure which comprises a plurality of evenly distributed carbon nanatubes; and at least two electrodes spacedly arranged and electrically connected with the heating element. The surface heat source can be used for manufacturing self-heating warming clothes, warming glove or warming shoes, electric heater, infrared therapeutic apparatus, electrical heater and the like.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com