Electronic element

An electronic component and electrode technology, applied in the field of electronic components containing a transparent conductive layer, can solve the problems of insufficient mechanical and chemical durability, uneven distribution of resistance resistance, poor performance of electronic components, etc. The effect of improving performance, good toughness and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

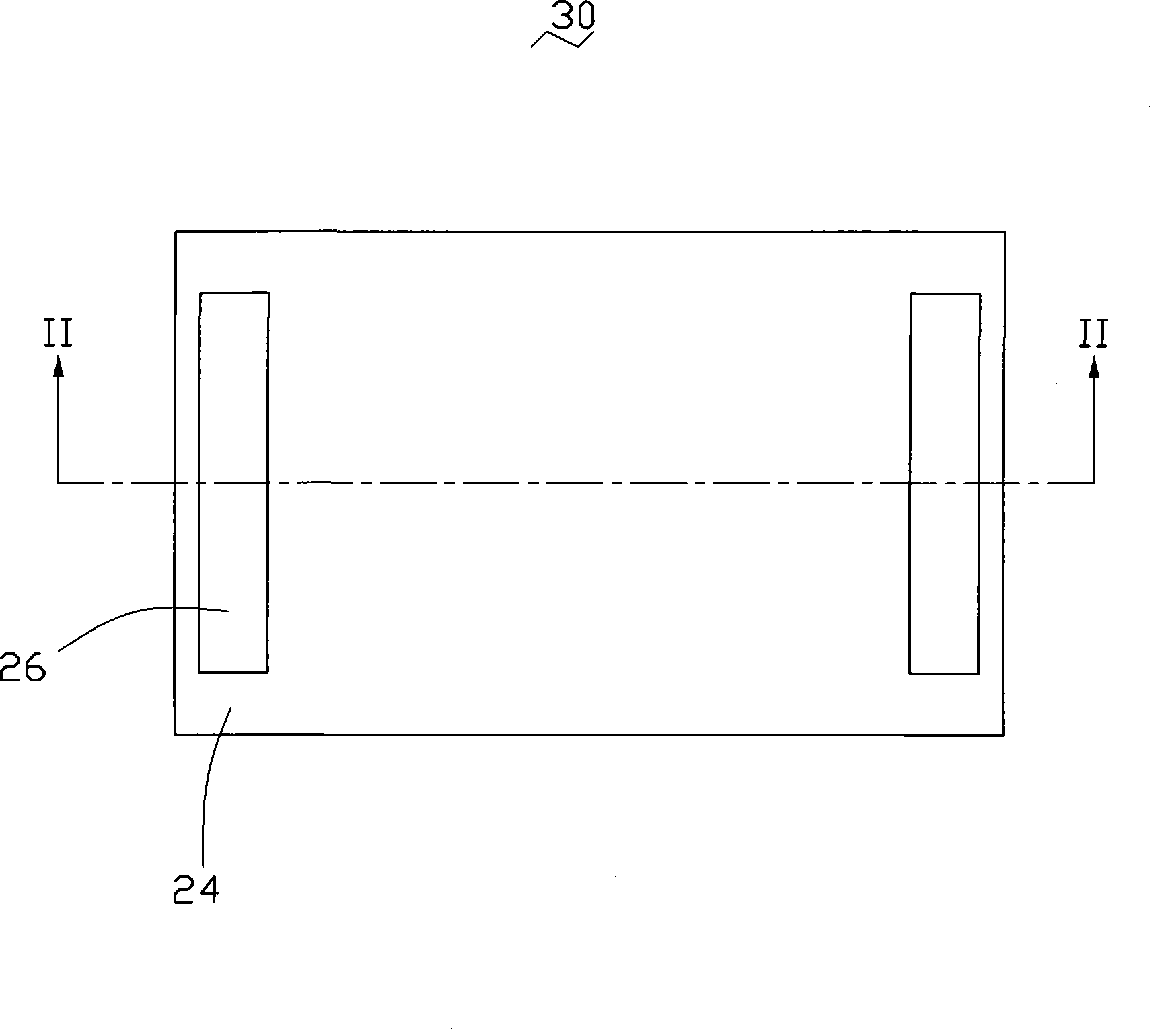

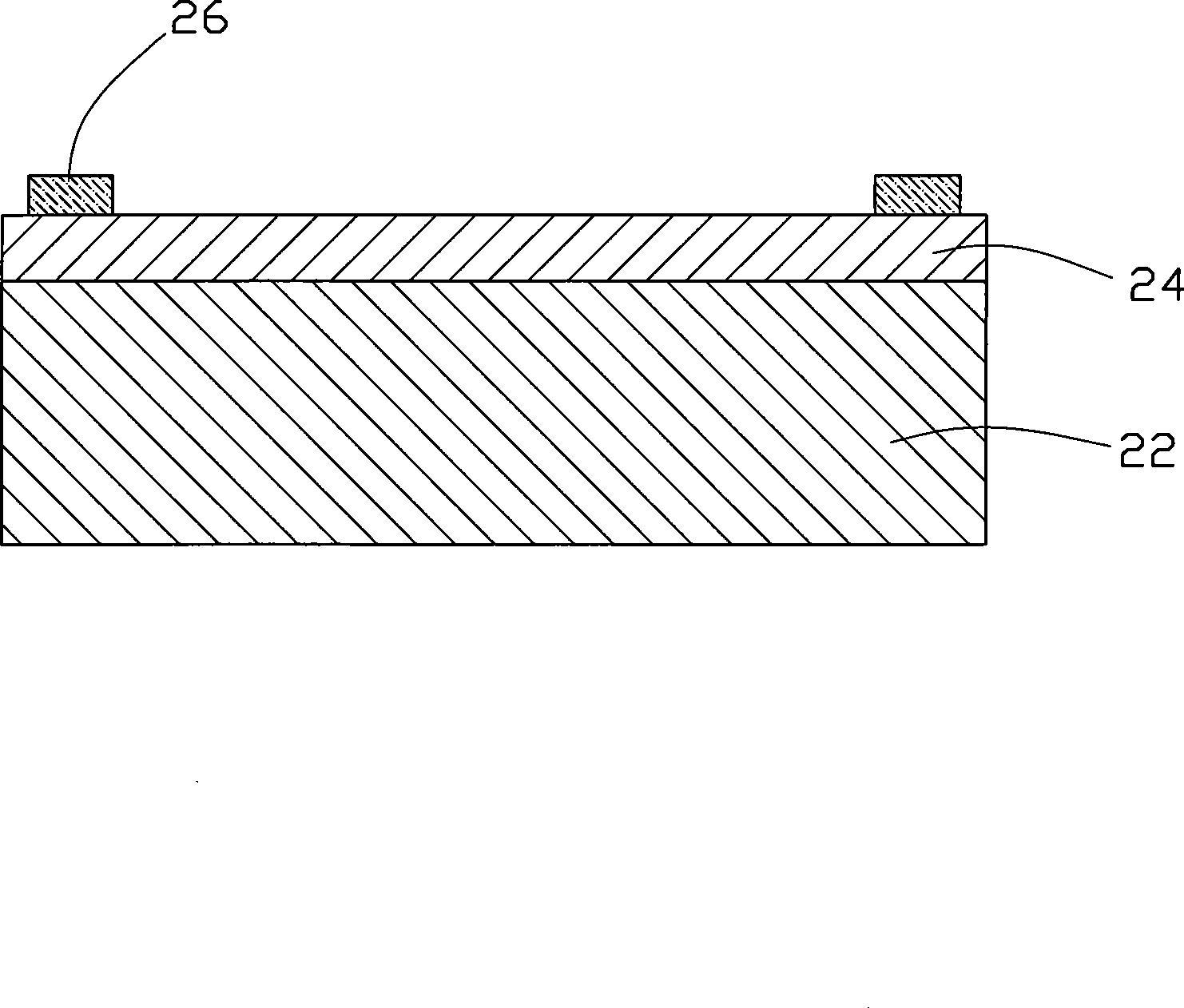

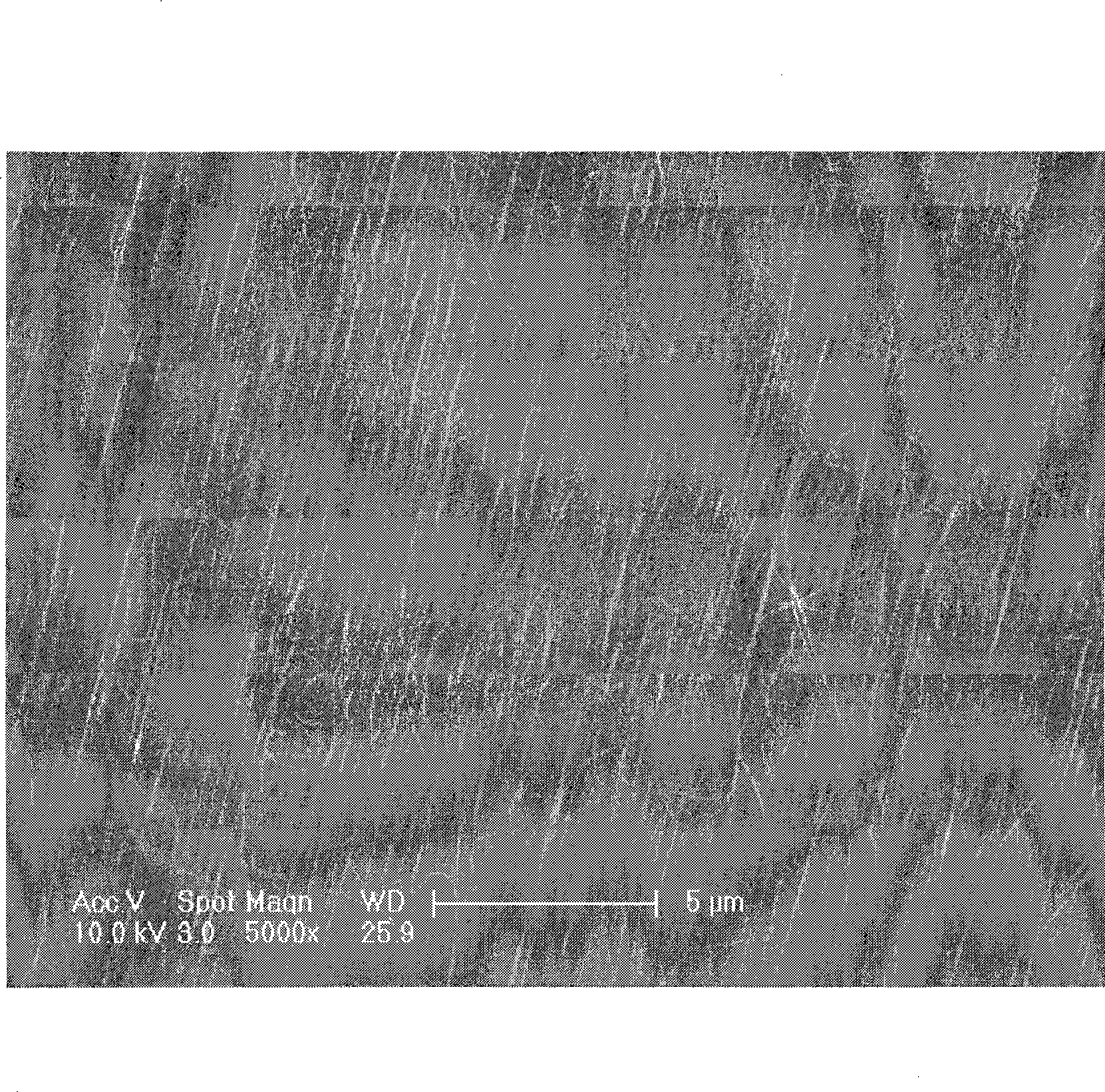

[0017] The transparent conductive layer 24 of the embodiment of the technical solution includes at least two overlapping carbon nanotube layers, each carbon nanotube layer includes a plurality of aligned carbon nanotubes, and the carbon in two adjacent carbon nanotube layers The nanotubes are aligned in different directions or aligned in the same direction. The preparation method of the above-mentioned transparent conductive layer 24 mainly includes the following steps:

[0018] Step 1: providing a carbon nanotube array, preferably, the array is a super-aligned carbon nanotube array.

[0019] The carbon nanotube array provided in the embodiment of the technical solution is a single-walled carbon nanotube array or a multi-walled carbon nanotube array. In this embodiment, the preparation method of the super-parallel carbon nanotube array adopts the chemical vapor deposition method, and its specific steps include: (a) providing a flat substrate, which can be a P-type or N-type s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com