Patents

Literature

365 results about "Gilding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gilding is any decorative technique for applying a very thin coating of gold to solid surfaces such as metal (most common), wood, porcelain, or stone. A gilded object is also described as "gilt". Where metal is gilded, it was traditionally silver in the West, to make silver-gilt (or vermeil) objects, but gilt-bronze is commonly used in China, and also called ormolu if it is Western. Methods of gilding include hand application and gluing, typically of gold leaf, chemical gilding, and electroplating, the last also called gold plating. Parcel-gilt (partial gilt) objects are only gilded over part of their surfaces. This may mean that all of the inside, and none of the outside, of a chalice or similar vessel is gilded, or that patterns or images are made up by using a combination of gilt and ungilted areas.

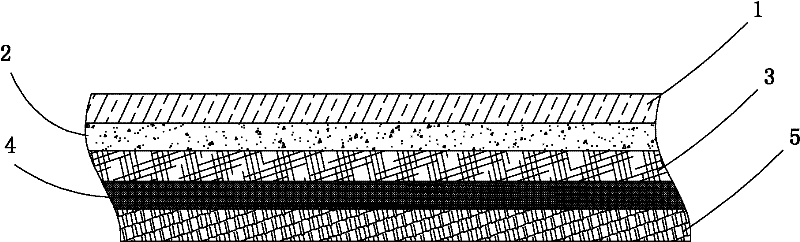

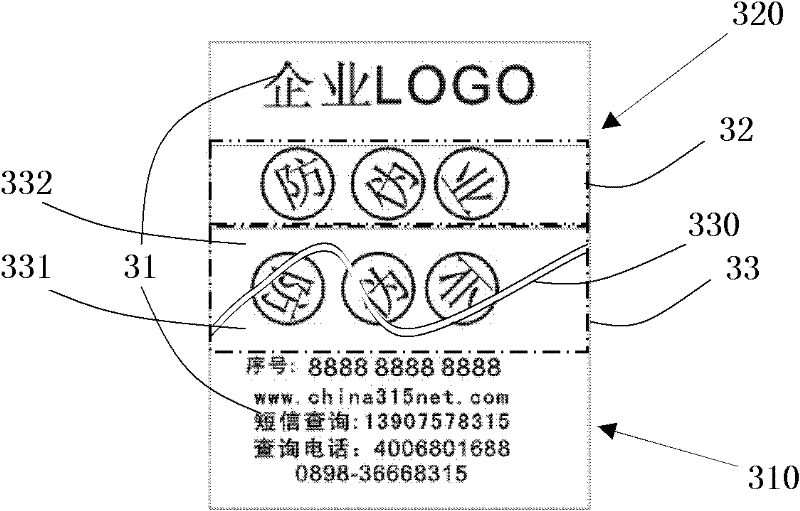

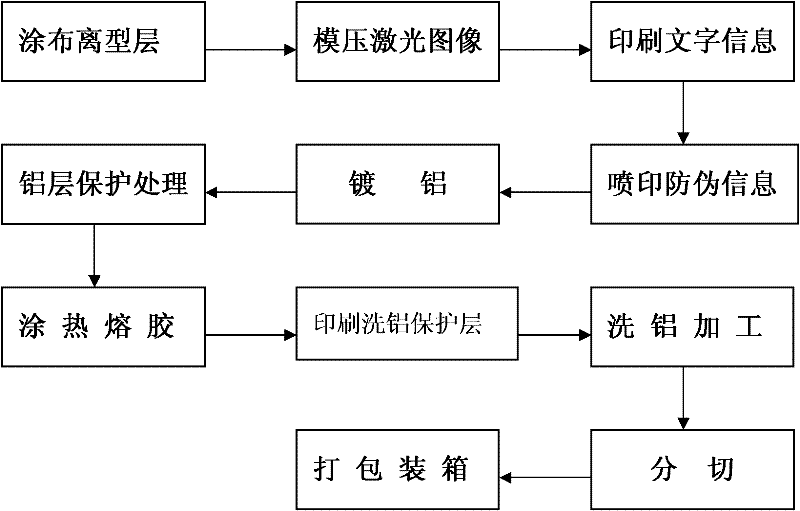

Character anti-counterfeiting gilding film and manufacture process thereof

ActiveCN102555573AGood anti-counterfeiting functionAnti-smugglingThermographyPolyesterInformation layer

The invention discloses a character anti-counterfeiting gilding film and manufacture process thereof. The gilding film sequentially comprises a transferring glue layer, an aluminum layer protective layer, an aluminum layer, a character information layer, a separation-type layer and a substrate medium layer, wherein the transferring glue layer is hot melt glue, the aluminum layer protective layer is a protective aluminum layer for preventing the aluminum layer form oxidation and dropping, the aluminum layer is a thin aluminum layer aluminized on a coating layer of the film, the character information layer comprises a printed essential information portion and a sprayed character anti-counterfeiting feature portion, and the separation-type layer comprises common transferring coating and laser mould pressing coating. The manufacture process comprises coating transferring materials on a polyester (PET) film and forming the separation-type layer; spraying anti-counterfeiting information on the separation-type layer of the film by using the spraying process; and finally coating the transferring glue layer. The character anti-counterfeiting gilding film and the manufacture process use advantages of the gilding film, combine with character anti-counterfeiting technology, give life force to each label, and achieve integration of the packing of products.

Owner:李峰

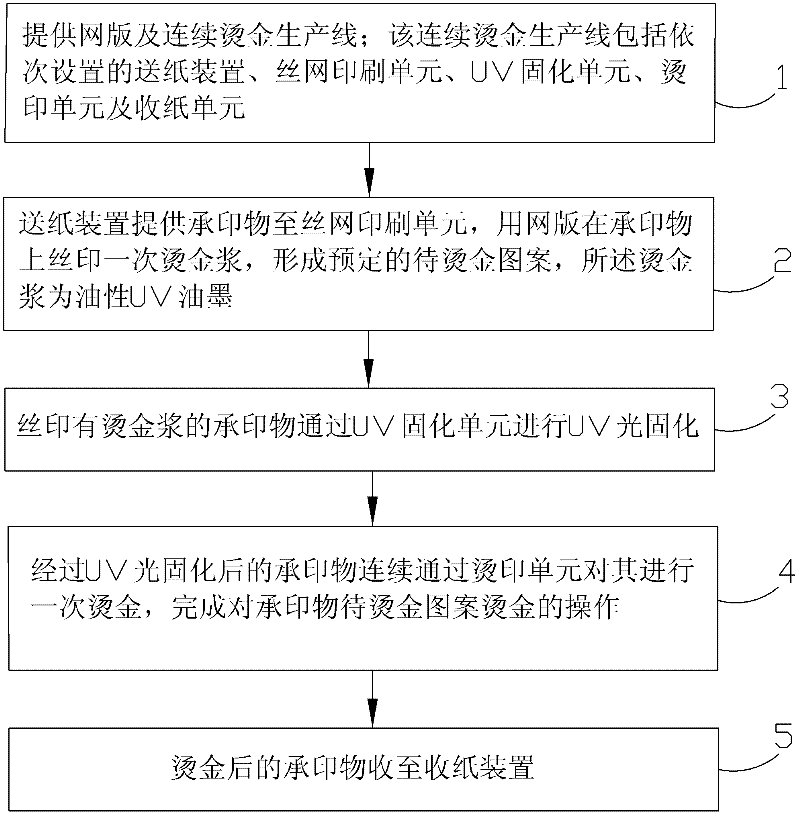

High-gloss three-dimensional gilding method

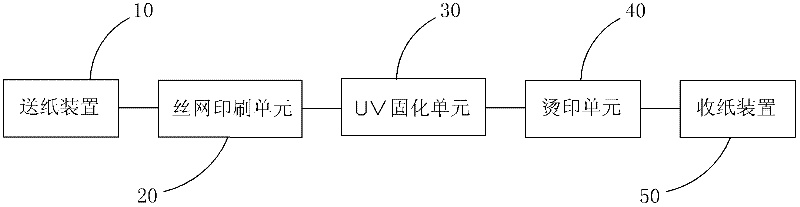

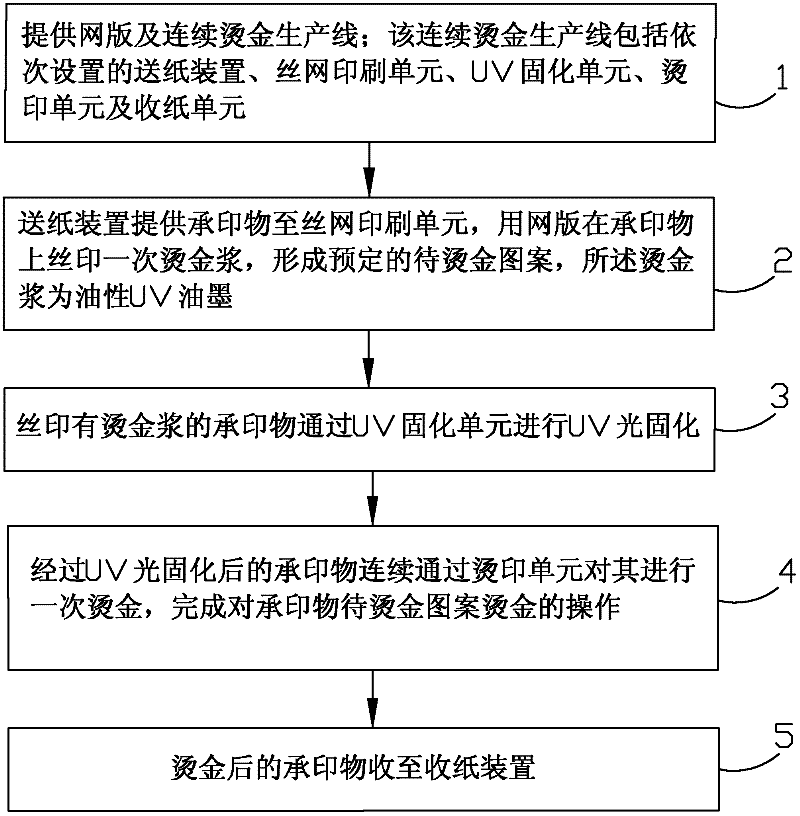

The invention relates to a high-gloss three-dimensional gilding method which comprises the following steps of; 1. providing a screen and silk-screen gilding continuous production line, wherein the silk-screen gilding continuous production line comprises a paper feeding device, a screen printing unit, a UV (ultraviolet rays) curing unit, a stamping unit and a paper delivery unit which are arranged successively; 2. the paper feeding device is used for providing a printing stock to the screen printing unit, the screen is used for performing primary gilding pulp screen-printing on the printing stock, so that a preset pattern to be gilded is formed, wherein the gilding pulp is oily UV printing ink; 3. the printing stock subjected to gilding pulp screen-printing is subjected to UV curing through the UV curing unit; 4. the printing stock subjected to UV curing continuously passes through the stamping unit to be subjected to primary gilding, so as to complete the gilding operation on the pattern to be gilded of the printing stock; and 5. the printing stock after gilding is delivered to the paper feeding device. In the gilding method, the oily UV printing ink is adopted as the gilding pulp, the high-gloss three-dimensional gilding effect can be realized on the surfaces of printed sheets composited with optical cement and dumb cement, various paper, plastic sheets and fiber slabs with different thicknesses, so that the demand on diversity in processing a base materials is met, and the on-line efficient and continuous gilding is realized.

Owner:SHENZHEN BAIXINGLONG CREATIVE PACKAGING

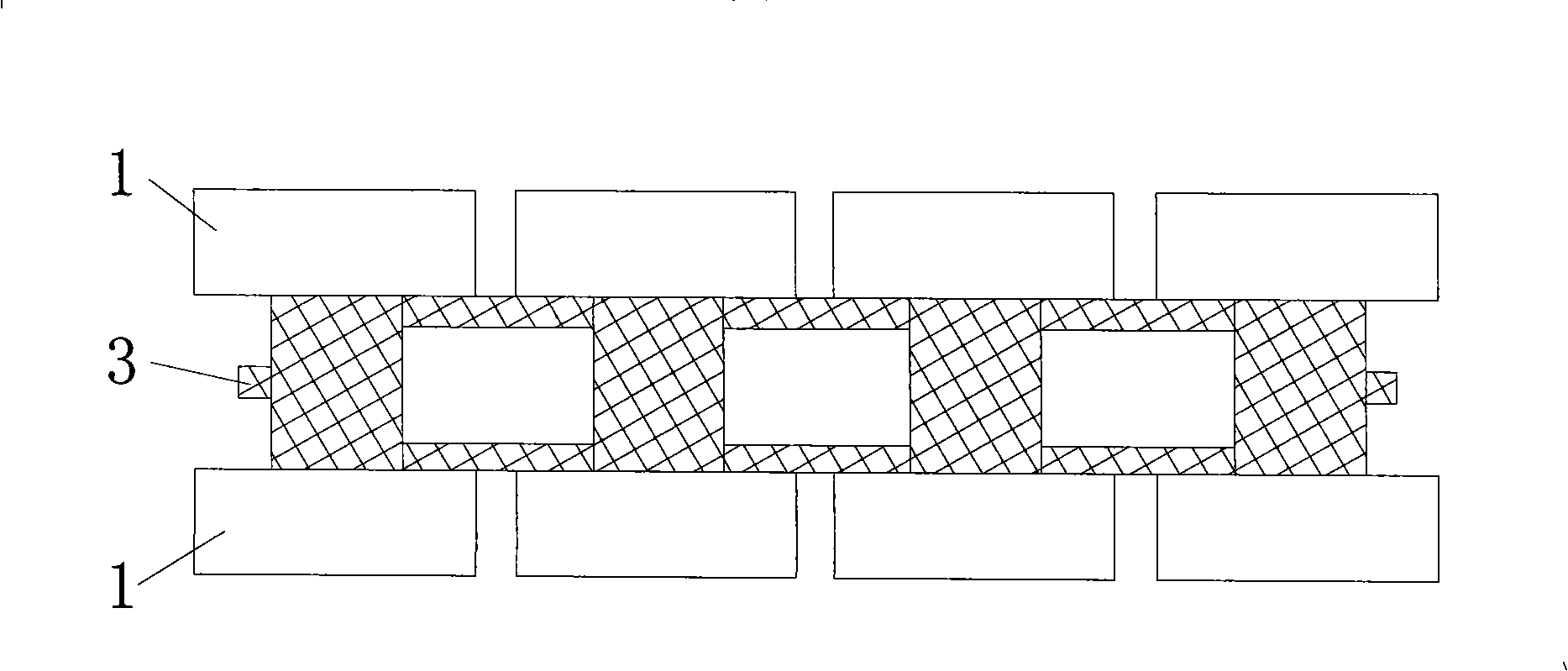

Method for preparing firm flexible printed board

InactiveCN101330805AAchieve protectionAvoid stickingMultilayer circuit manufacturePrinted element electric connection formationCopper platingEtching

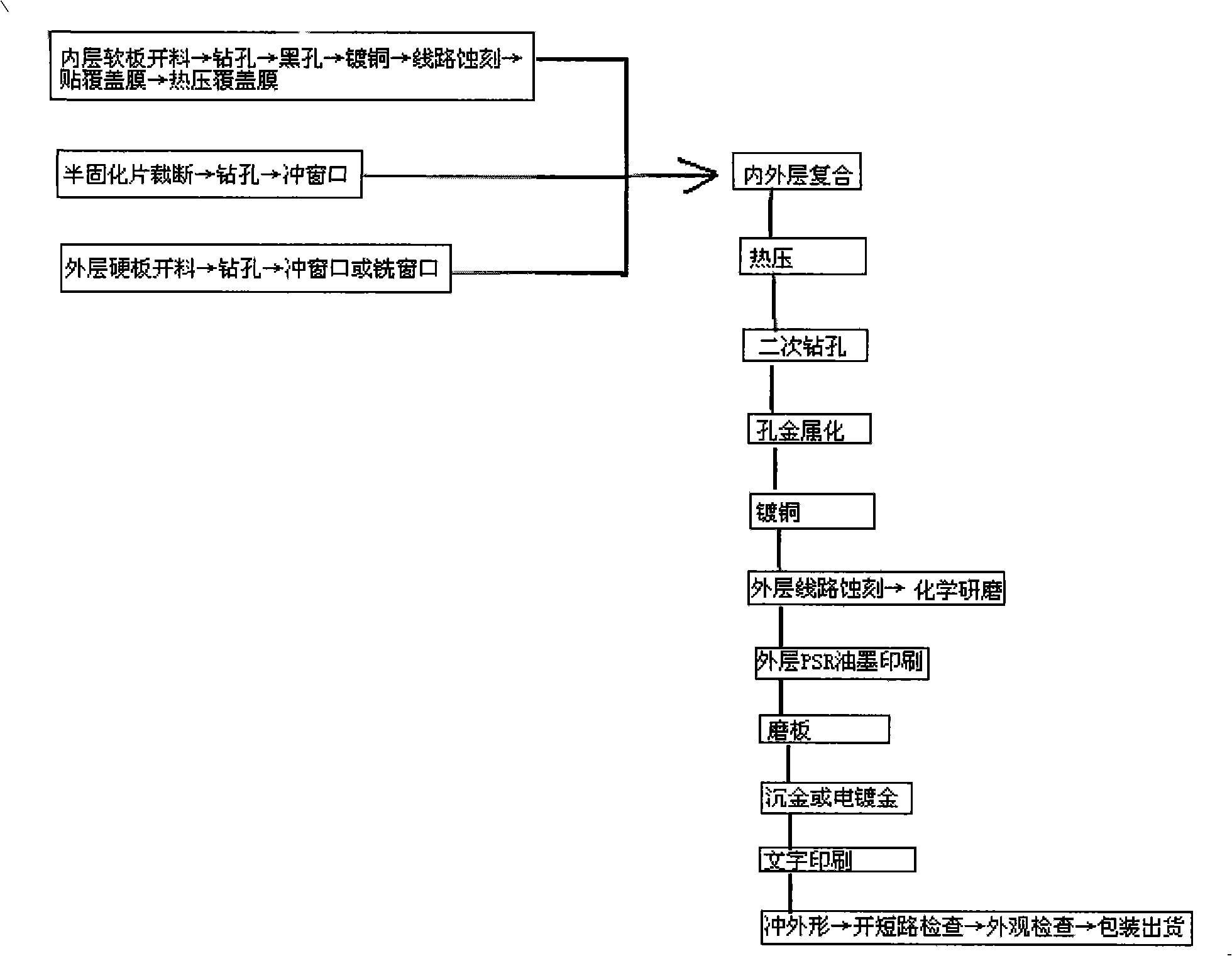

The invention discloses a method for producing rigid and flexible printed circuit boards, and comprises the following steps: a produced flexible circuit board and a produced rigid circuit board bond with each other by using bonding substrate; a second through-hole is drilled on a soft-hard combination area after the flexible circuit board and the rigid circuit board bond; peelable glue is printed and solidified on the exposed flexible circuit board, and then the second through-hole is blackened; the second through-hole and the outer surface of the substrate of the rigid circuit board is coated with copper, and then circuit etching is performed on the outer surface of the substrate of the rigid circuit board; the peelable glue is ripped off, so as to perform the subsequent grinding, welding resistance, gold immersion or electro-gilding technique. Based on the prior equipment in the FPC plant, before the second through-hole on the soft-hard combination area is blackened by the method for producing the rigid and the flexible printed circuit boards, the peelable glue is printed and solidified on the exposed flexible circuit board, thereby preventing carbon powder from being attached to a base film or a cover film of the fixable board in the blackening process, and realizing the protection for the exposed flexible circuit board.

Owner:靖江市杰华网络技术有限公司

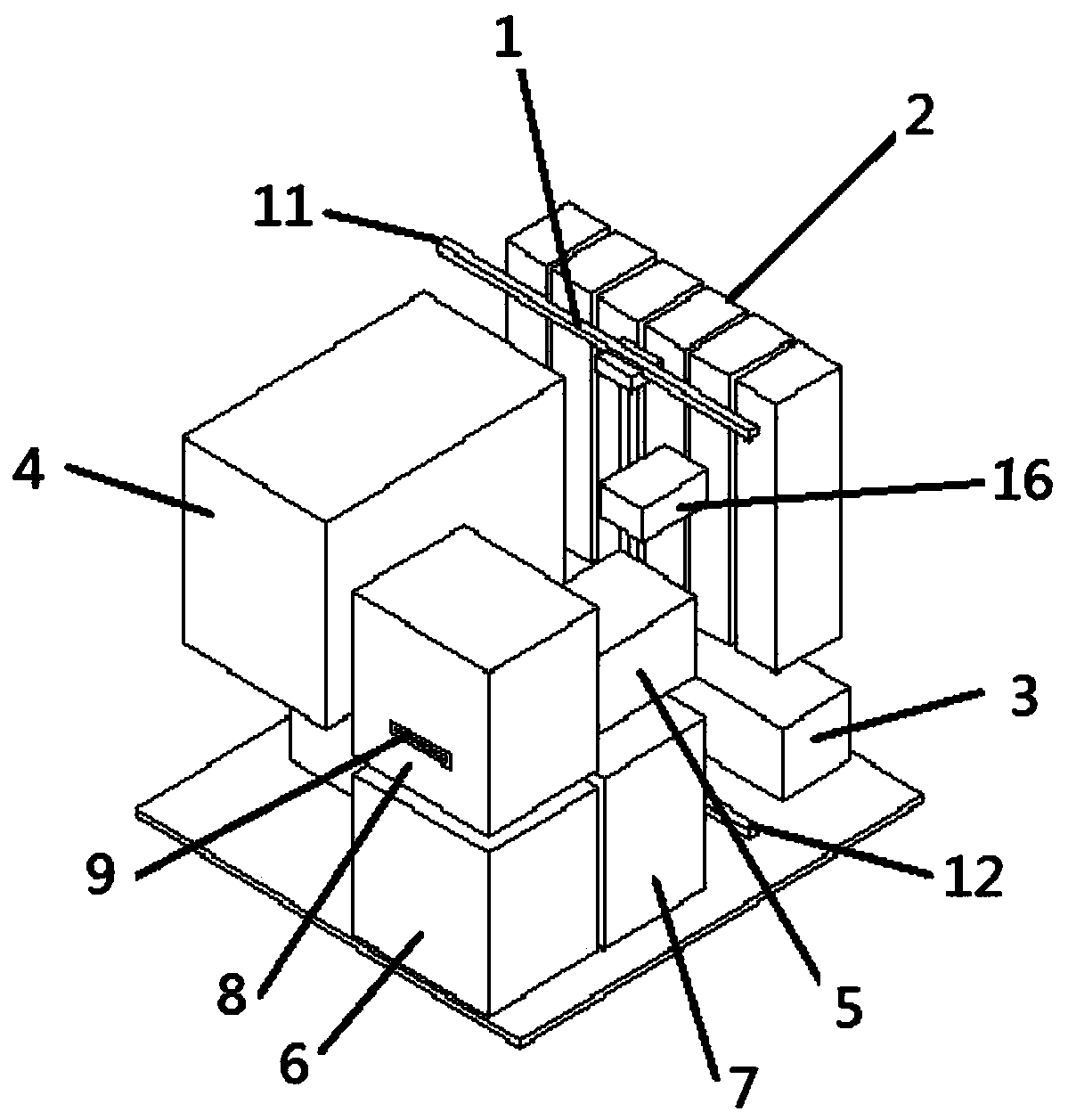

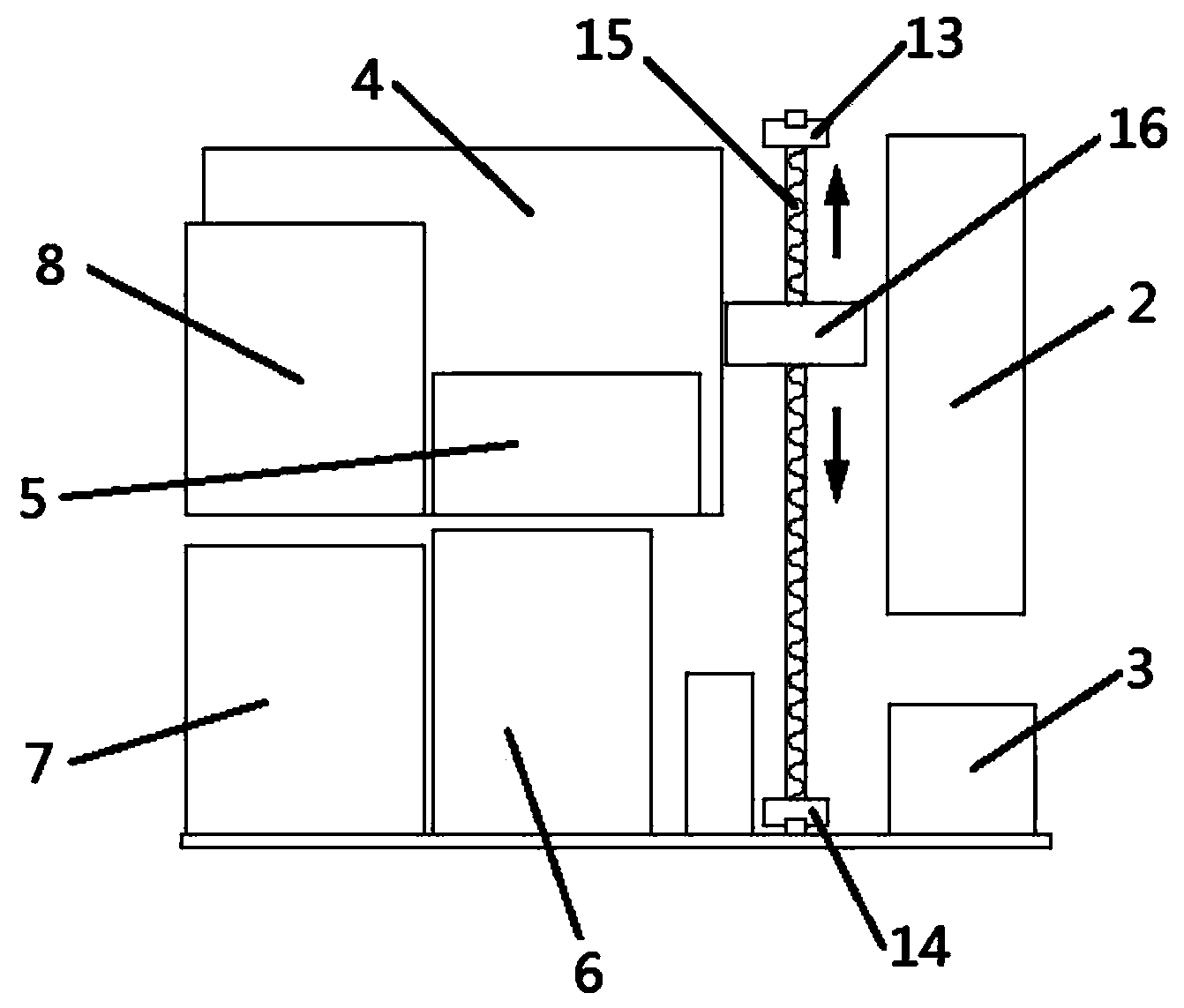

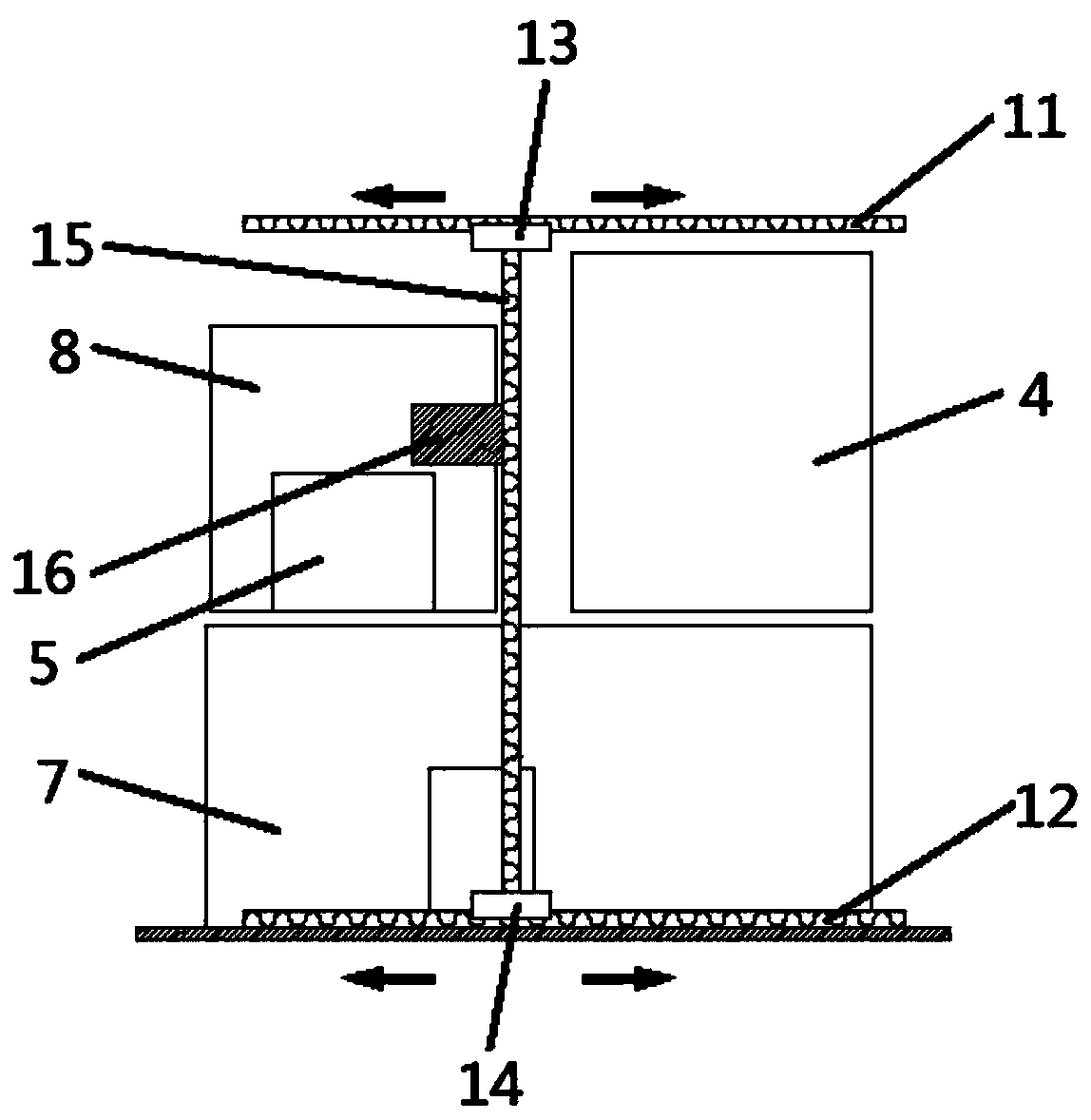

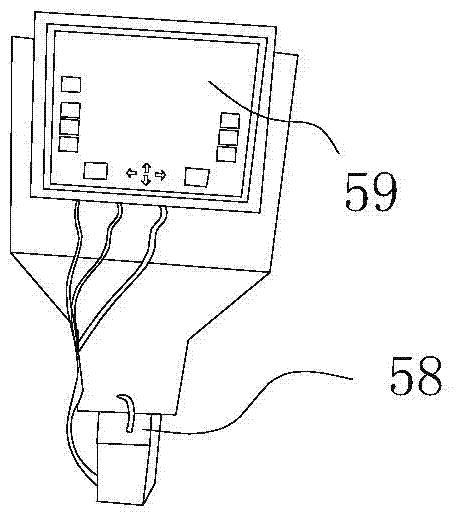

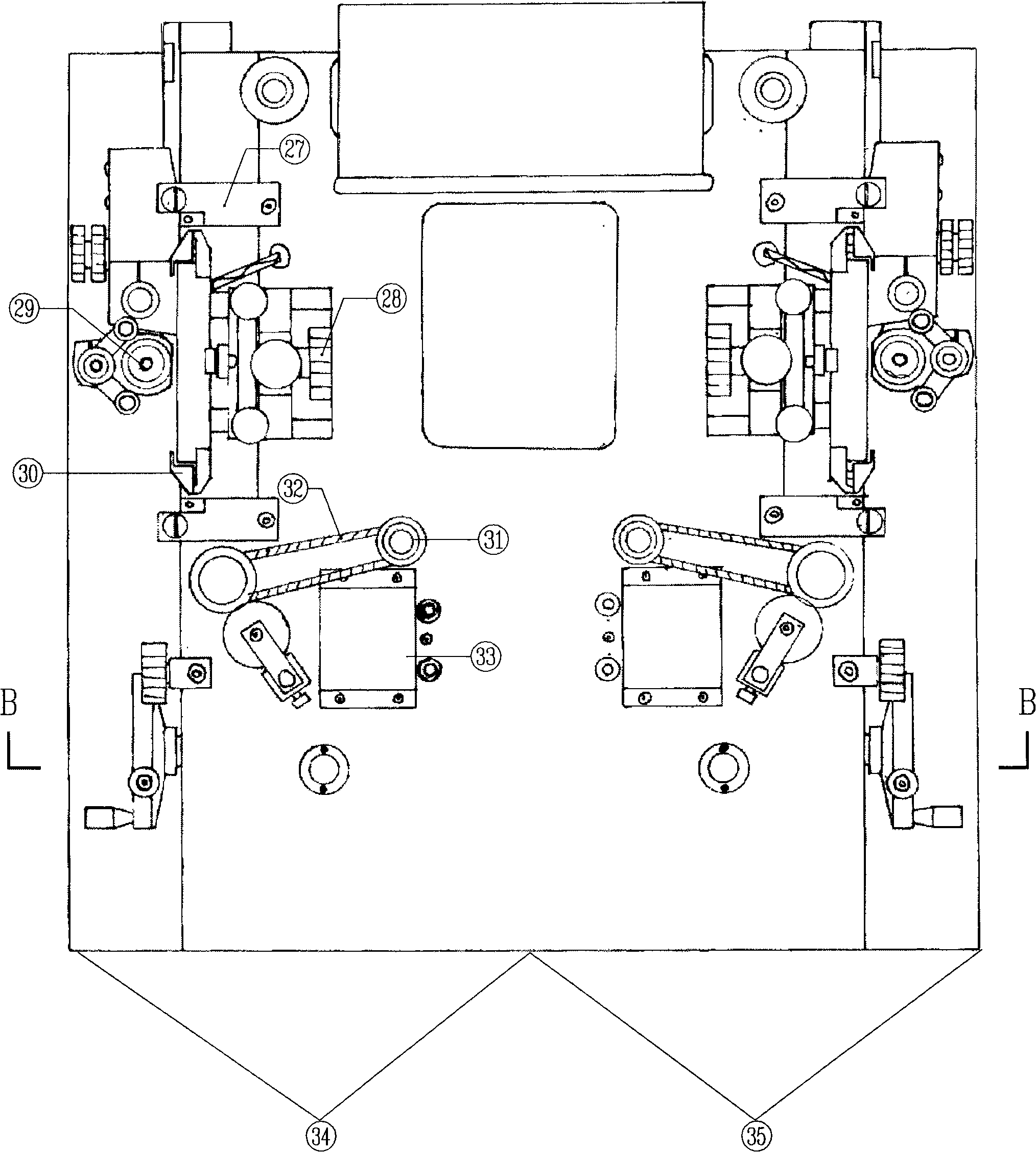

Immediate bank card sender

InactiveCN104318273ALess waitingLow costComplete banking machinesConveying record carriersEngineeringCard reader

The invention provides an immediate bank card sender. The immediate bank card sender comprises an upper computer, a case, a bank card conveying mechanism, a card inlet module, a waste card box, a printing module, a magnetism writing module, a gilding module, an embossment module, a silver plating module, a card in-out opening and a control module, wherein the bank card conveying mechanism, the card inlet module, the waste card box, the printing module, the magnetism writing module, the gilding module, the embossment module, the silver plating module, the card in-out opening and the control module are arranged in the case. According to the immediate bank card sender, the bank card conveying mechanism capable of performing the horizontal motion and the vertical motion is adopted, so that modules of the card sender can be arranged in a three-dimensional mode, and the size of the device with the same functions is reduced to one fifth to one fourth of the original size, and multiple cards can be loaded at a time; meanwhile, the immediate bank card sender can be arranged on a front counter of a bank for immediate card sending and can also be placed into a cabinet of a teller machine for self-help card sending, and waiting of clients and the cost for card posting of the bank are saved.

Owner:江苏华桠融通智能科技有限公司 +1

Printing and gilding registration method in process of gilding before printing

The invention discloses a printing and gilding registration method in a process of gilding before printing, which comprises the following steps: 1, manufacturing a special positioning film for gilding positioning: manufacturing positioning documents and outputting at least two makeup films and a positioning film; 2, preparing a gilding plate into a conjoined plate: manufacturing the basic documents of the copper gilding plate, and preparing the gilding plate; 3, carrying out para-position on the positioning film by the gilding plate: calibrating the position of the gilding plate, and registering the gilding plate to the positioning film; and 4, printing a corrected plate. Compared with the traditional thermoprint process, the method disclosed by the invention has the advantages that: 1, before gilding, no offset printer is require for printing positioning paper for gilding the corrected plate, therefore, a good deal of offset print resources can be saved, and the production cost can be saved; and 2, in the process of printing a corrected plate after gilding, the phenomenon that the gilding registration is not accurate does not exist, and the modification on a printing plate caused by that the gilding registration is not accurate does not occur, thereby greatly improving the accuracy of registration, and saving plenty of time required by changing the position of the gilding plate for many times; and meanwhile, the rejection ratio of the production process is low.

Owner:HUCAIS PRINTING

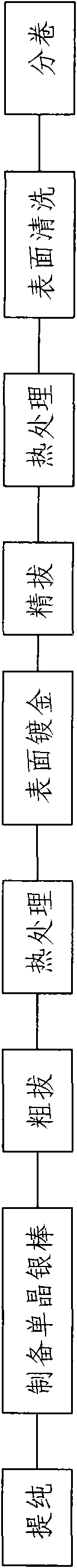

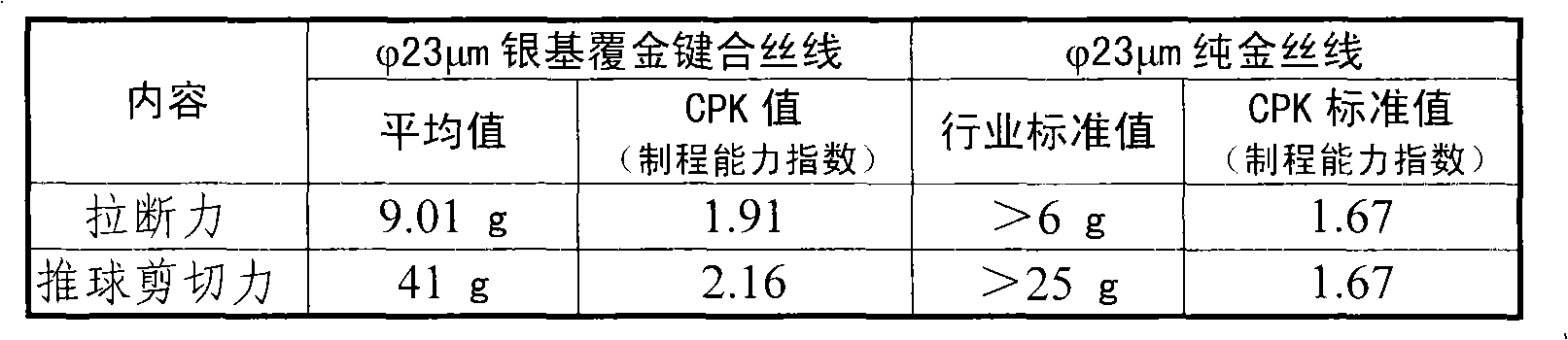

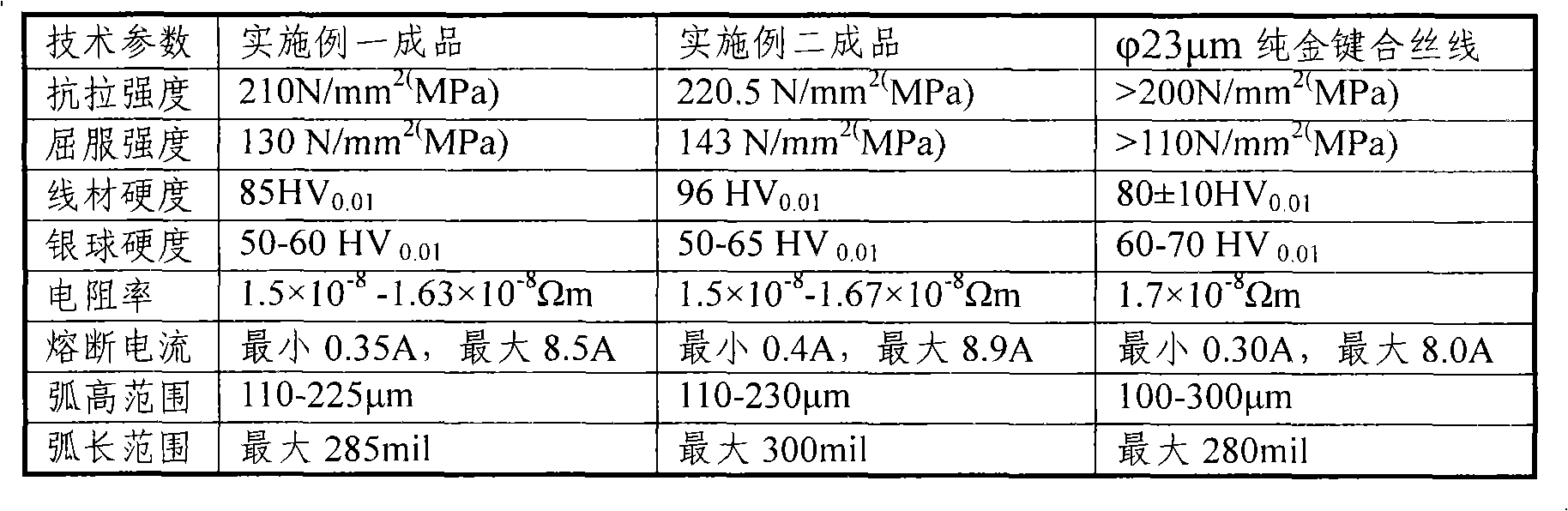

Gold-coated-sliver base bonding silk thread and manufacture method thereof

ActiveCN101667566AFlat surfaceImprove antioxidant capacitySemiconductor/solid-state device detailsSolid-state devicesSurface cleaningSingle crystal

The invention discloses a bonding silk thread product which takes sliver silk thread as a base material and is coated by a pure gold anti-oxidation protective layer on the surface thereof. The silversilk thread product comprises the following components in weight percent: 1.8%-10.0% of gold, and the balance silver. The manufacture method thereof comprises the following steps of purifying, preparing a monocrystal silver rod, coarse drawing, heat processing, surface gilding, fine drawing, heat processing, surface cleaning, decoiling and the like. The invention abandons the outmoded technique that the silk thread is directly used after being plated by a traditional thinking mode; and the silk thread is electroplated with a pure gold anti-oxidation protective layer with a certain thickness after being prepared into silver silk thread with diameter being smaller than 1mm, and then precisely drawn into the gold-coated-sliver base bonding silk thread products with different specifications bymultiple procedures. The plating layer of the product has compact and even material, greatly improved bonding strength with base materials and effectively prolonged product quality guarantee period;the manufactured silk thread has proper hardness and good soldering balling property; the cost of the silk thread is less than 1 / 3 of that of the pure gold boning silk thread; The technology in the invention can be widely used in preparing bonding silk thread products in composite structures.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

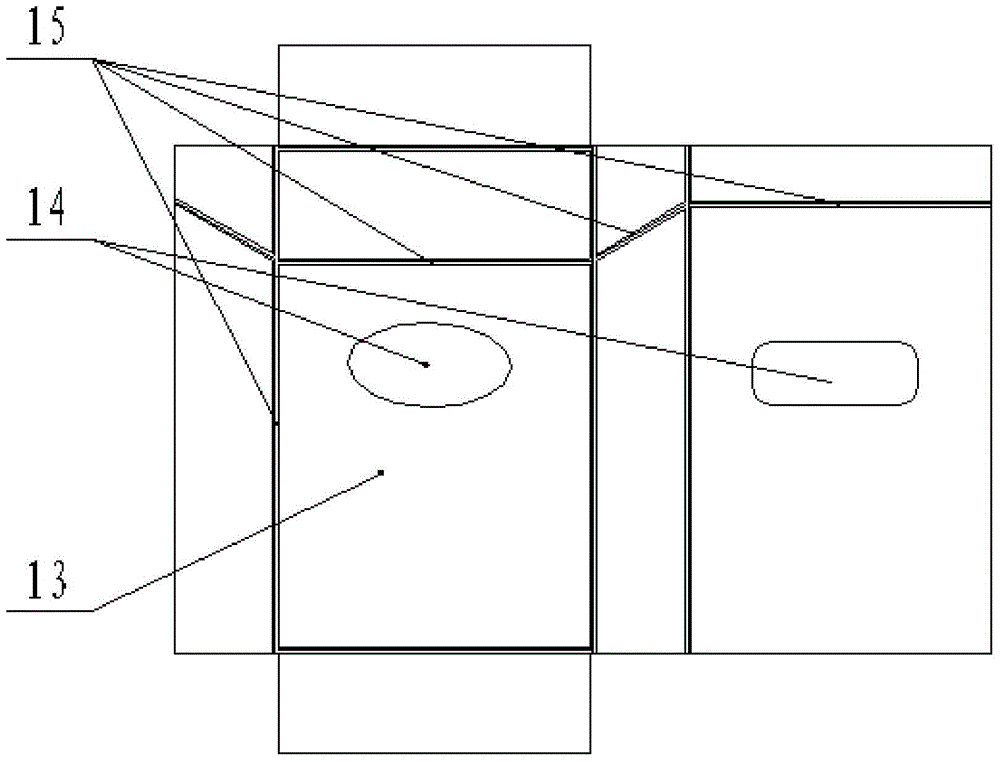

Digital holographic stamped anti-counterfeiting packing bag and production method thereof

ActiveCN103922018ARealize integrationHigh number of security featuresDuplicating/marking methodsBagsHot stampingInformation layer

The invention belongs to the technical field of anti-counterfeiting materials and particularly relates to a digital holographic stamped anti-counterfeiting packing bag and a production method thereof. The digital holographic stamped anti-counterfeiting packing bag comprises a packing bag body and anodized aluminum; the anodized aluminum is composed of a base layer, a transfer layer and a gum layer; the transfer layer is composed of a release layer, an information layer and an aluminized layer. The anodized aluminum is printed on the packaging bag body by hot stamping. The production method includes selecting materials, designing, making a plate and die-pressing, aluminizing, printing and partially aluminizing, coating with a printed layer, tagging, applying gum, gilding, and cutting and hot-sealing. The digital holographic stamped anti-counterfeiting packing bag and the production method thereof have the advantages that holographic anti-counterfeiting packing, print anti-counterfeiting packing and digital anti-counterfeiting packaging are integrated by means of the bidirectional-positioning hot stamping technique, various anti-counterfeiting features are applied to the packing bag according to needs of customers and features of the packing bag, the single anti-counterfeiting means of the original packing bag is broken, unachievable untransferability of anti-counterfeiting labels is achieved, and secondary use of anti-counterfeiting contents is avoided.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

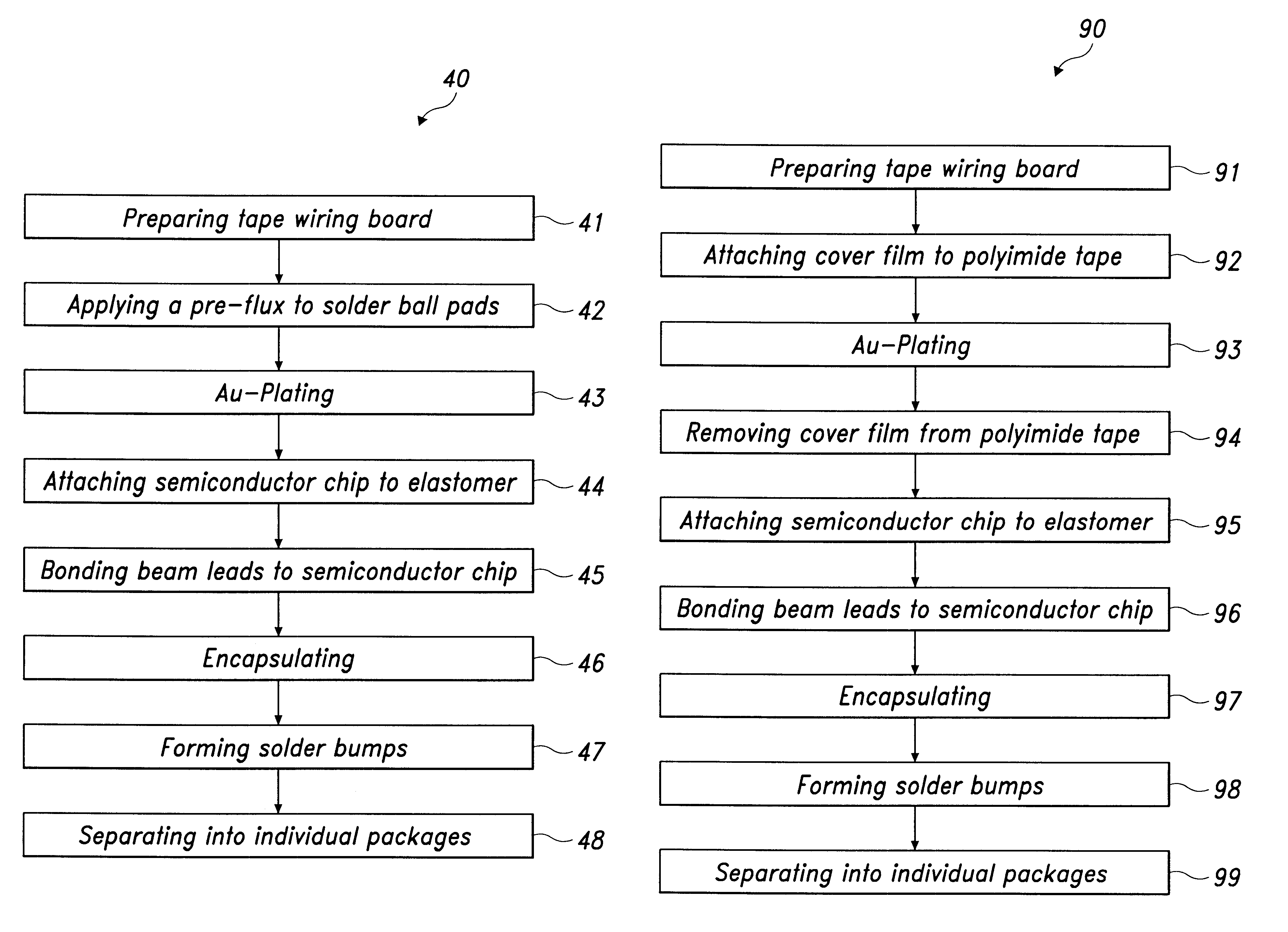

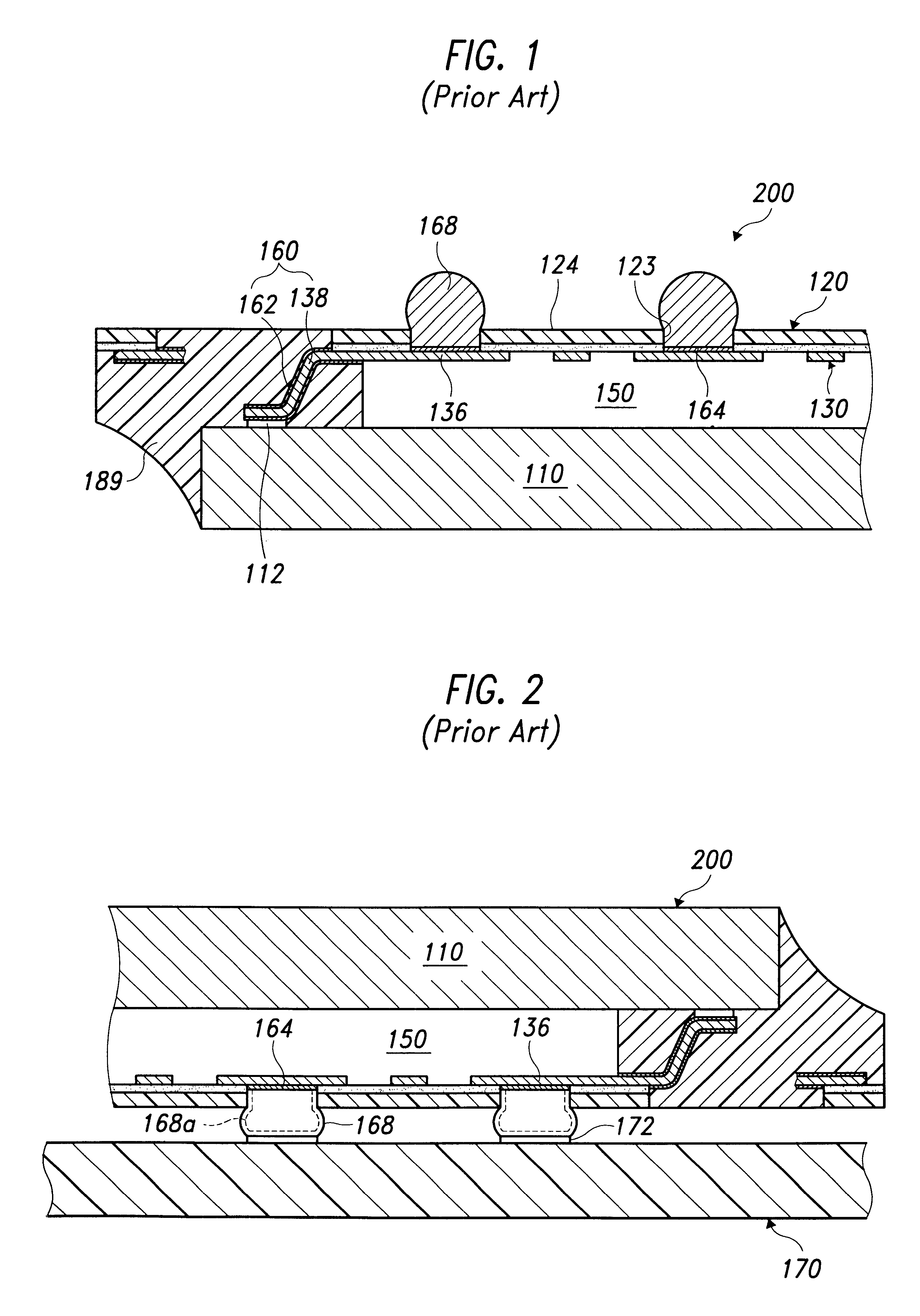

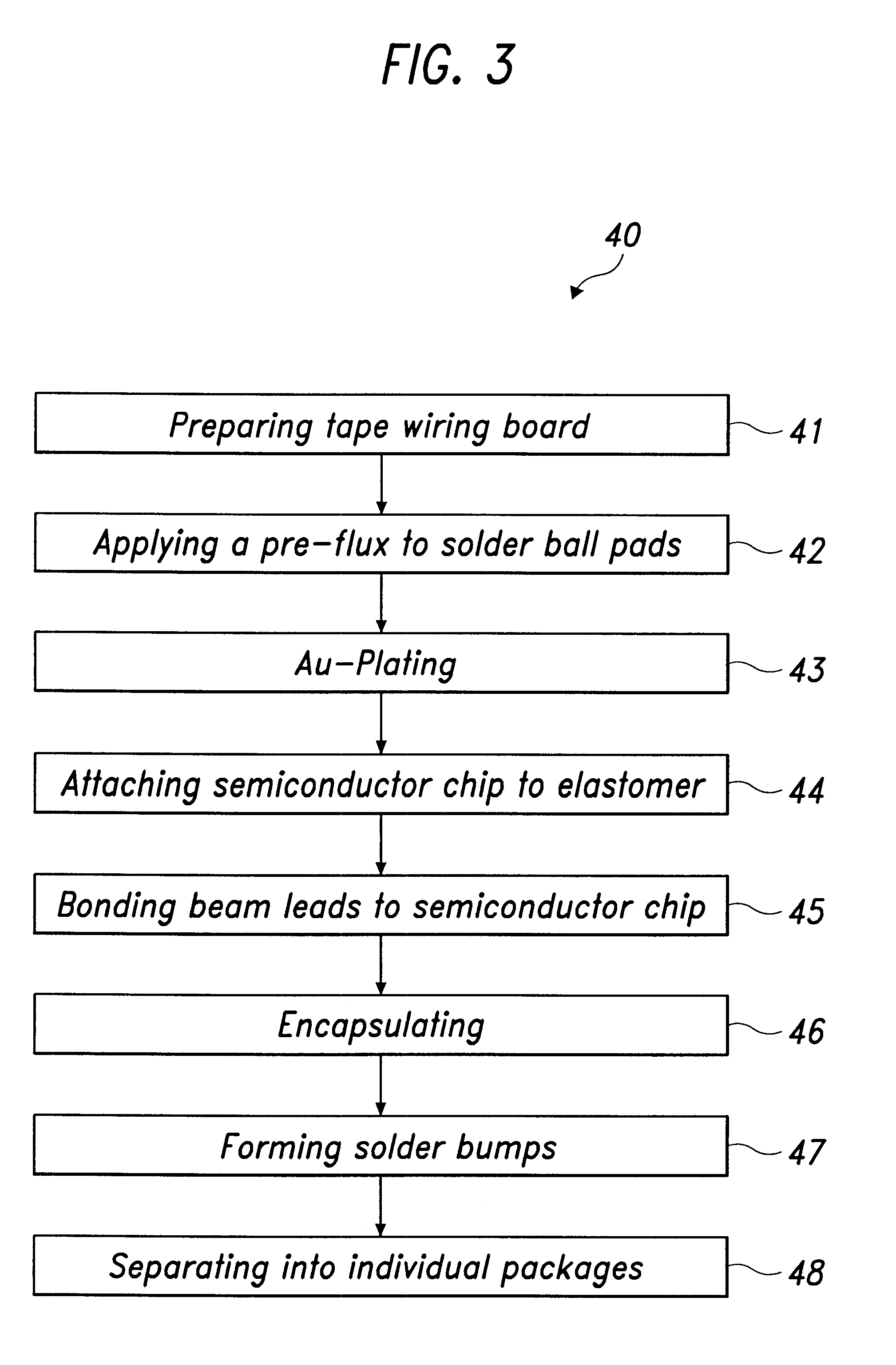

Method for manufacturing a chip scale package having copper traces selectively plated with gold

InactiveUS6319828B1Semiconductor/solid-state device detailsSolid-state devicesElastomerSemiconductor chip

A method for manufacturing a chip scale package comprises preparing a tape wiring board that includes a polyimide tape having top and bottom surfaces, Cu traces formed on the bottom surface of the tape, a window formed in the tape to enable the Cu traces to be connected to a semiconductor chip attached below the board, multiple connection holes formed in the tape to expose portions of the Cu traces therethrough and define solder ball mounting pads, and an elastomer chip carrier attached to the bottom surface of the tape. The method includes applying either a pre-flux or a cover sheet over the solder ball mounting pads. The pre-flux and the cover sheet each prevents the solder ball mounting pads being plated with gold. This, in turn, prevents the formation of intermetallic compounds in the solder balls so that the bond strength between the solder balls and a pad to which they attach is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Gilding press

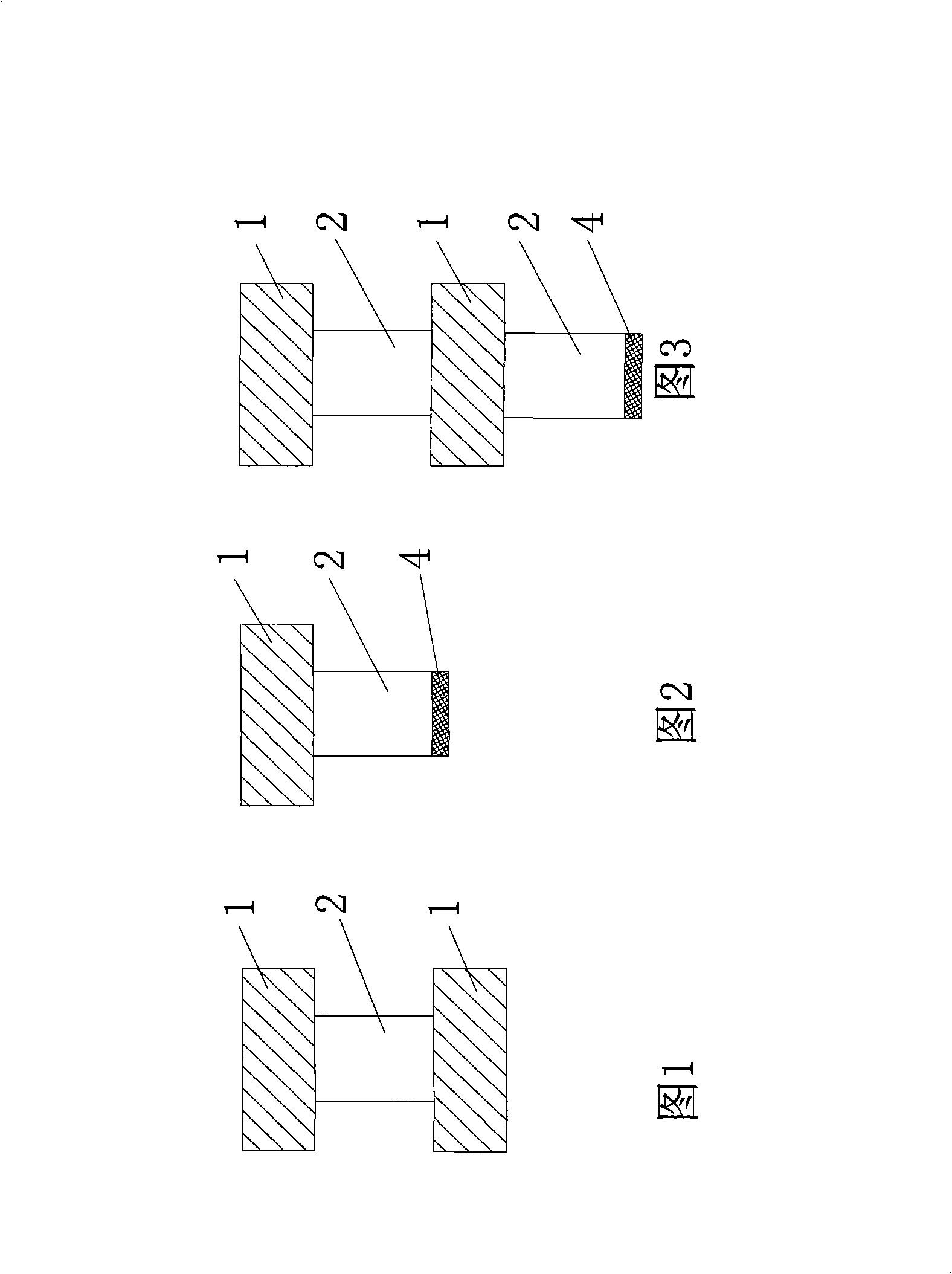

InactiveCN103660544ASimple structureEasy to operateRotary pressesBronze printingHot stampingPulp and paper industry

The invention provides a gilding press which comprises a paper transferring roller for transferring paper to be gilded, a film transferring roller for transferring hot stamping foils, a first gilding roller, a second gilding roller, a heating device for performing further treatment on paper and hot stamping foils which are pressed together, a motor for providing power for the rollers, wherein the first gilding roller and the second gilding roller are meshed with each other and used for pressing the paper and the hot stamping foils together. The gilding press has the advantages of being simple in structure, convenient to operate, high in working efficiency, good in gilded characters, patterns and the like and the like.

Owner:昆山亿达包装有限公司

Production technique of chromatic gold ornaments

The invention discloses a production process of color gold jewellery, comprising the following steps: cleaning the gold jewellery with ultrasonic to remove the grease on the surface; washing the detergent on the gold jewellery with water, and removing grease by electrochemical method; water washing; acid washing with sulphuric acid; plating germanium on the surface of the gold jewellery; water washing the plated gold jewellery to wash away plating solution; locally coating insulating paint on the gold jewellery according to the needed pattern; removing grease attached during the coating process by electrolysis; plating gold or gold-copper alloy on the gold jewellery by electrolysis; dropping off the insulating paint; and water washing and drying. By plating black nails, gold or gold-copper alloy outside the color gold jewellery, multicolor gold jewellery having black, yellow and red or white and the above three colors alternating pattern is formed, which changes the tradition that gold jewellery is only silvery white, in addition, since the plating layer is composed of nail or noble metal, the value of gold jewellery is remained.

Owner:SHENZHEN YUEHAO JEWELRY

Method for replacing gold stamping

InactiveCN1760043AQuality improvementHigh glossDecorative surface effectsDuplicating/marking methodsAdhesiveEngineering

A substitute method for gilding includes such steps as coating the parting paint on PET film, baking for solidifying, vacuum aluminizing, coating protecting paint with gilding pattern plate, baking for solidifying, immersing in alkali solution for removing aluminium, baking to obtain transfer film, coating adhesive, sticking onto substrate to obtain composite paper, stripping the film to obtain transfer paper, and printing with said transfer paper.

Owner:王尔健

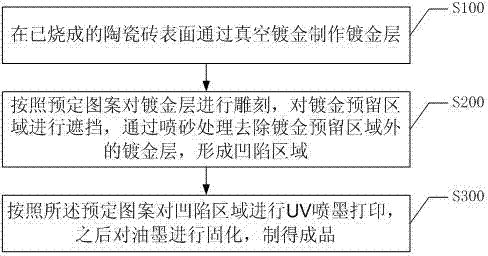

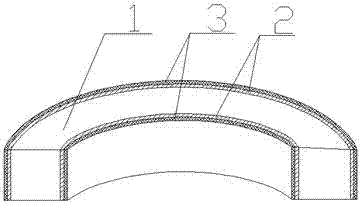

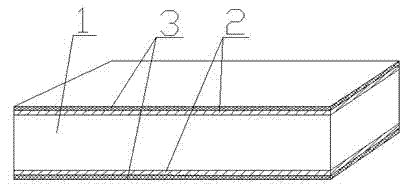

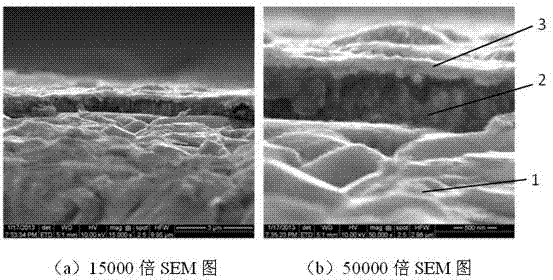

Gilded ceramic tile and manufacture method thereof

ActiveCN104844273AVariety of colorsStrong sense of three-dimensional presentationSurface patternBrick

The invention discloses a gilded ceramic tile and a manufacture method thereof. The method includes A, forming a gilding layer on the surface of a fired ceramic tile by vacuum metallizing; B, carving the gilding layer according to predetermined patterns, shielding the gilding preserved area, removing the gilding layer outside the gilding preserved area by sand blasting, and forming a concave area; C, performing UV inkjet printing on the concave area according to predetermined patterns, solidifying the ink, and obtaining a finished product. According to the method, the gilding, laser carving, inkjet printing are combined, and the effect of a gilded relief sheet paint is achieved; compared with the existing gilded ceramic tile, the gilded ceramic tile has the advantages that the ceramic tile surface pattern color is enriched, the three-dimensional rendering sense is enhanced, and the relief effect is more vivid.

Owner:FOSHAN JINYI GREEN ENERGY NEW MATERIAL TECH CO LTD +2

Preparation method of piezoelectric ceramic surface electrode

The invention discloses a preparation method of a piezoelectric ceramic surface electrode. The preparation method is characterized in that a layer of metallic nickel is plated on the surface of a piece of piezoelectric ceramic; gold is plated on the surface of a nickel plating layer by using a chemical plating method, so as to obtain a nickel-gold composite electrode, wherein a gold-plating liquid is a water solution which comprises the following components of 1.2-2.8g / L of Na3Au(SO3)2, 8-25g / L of Na2SO3, and 10-25g / L of KH2PO4; and the molar ratio of the concentration of C2H8N2 to the gold is kept to be (6-20):1. The preparation method is simple and easy to operate, and free from limit of shapes of workpieces; a cyanogen-free chemical plating technology is adopted for preparing the gold electrode, the use of highly-toxic cyanides is avoided, and the environment-friendly and safe performances can be realized; and the prepared gold electrode is uniform, stable in chemical property, low in resistivity, high in corrosion resistance, low in porosity, good in bonding force, and good in welding performance, can well meet the application requirements of the piezoelectric ceramic and improves the use performance of the piezoelectric ceramic.

Owner:UNIV OF JINAN

Process for producing case or accessories of precious metal wristwatch

ActiveCN104499008AHigh dimensional accuracyAchieve a smooth finishElectroforming processesChemical reactionBoiling point

The invention relates to a process for producing a case or accessories of a precious metal wristwatch. The method is characterized by comprising the following steps: firstly preparing a zinc alloy into a mold block in a die-casting manner, and finishing a die casting so as to ensure that the assembly size and surface roughness reach the requirements; sequentially carrying out electro-coppering and electro gilding, namely, electrochemical hardening gold, on the mold block; in order to enable parts to reach hard pure gold, removing the zinc alloy and copper inside the parts which comprises the following steps: drilling the parts subjected to electro-coppering and precious metal electroplating, by adding hydrochloric acid inside drilled blow-off holes and heating to a boiling point, carrying out chemical reaction and melting, dissolving the all zinc alloy in hydrochloric acid and flowing out, also dissolving a part of the copper in hydrochloric acid and flowing out; cleaning with clean water; by introducing sulfuric acid and heating to a boiling point, carrying out chemical reaction and melting, completely dissolving the copper electroplating layer in sulfuric acid and flowing out to obtain hard pure gold parts; and cleaning the parts with clean water to obtain hollow case or accessories of the precious metal wristwatch. The hollow parts prepared by the method, which is disclosed by the invention, has good size accuracy and appearance surface which can reach the desired degree of finish.

Owner:吉林鼎辉电子科技有限公司

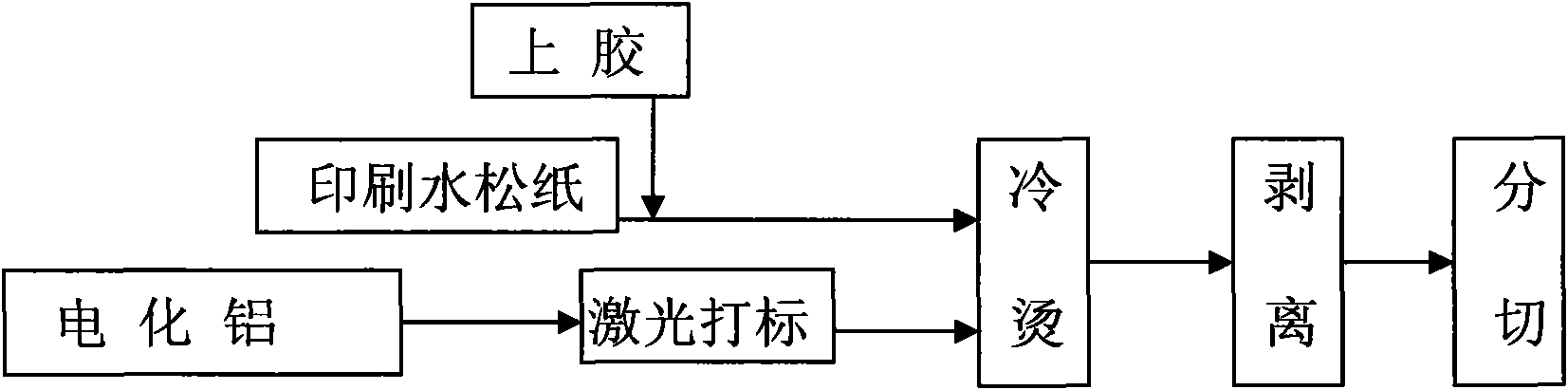

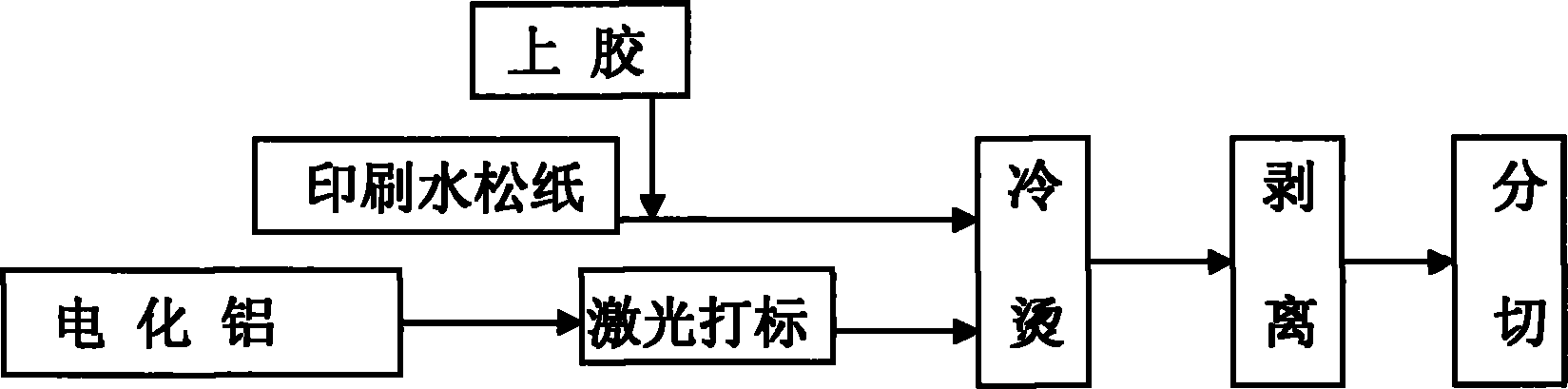

Gilding process for tobacco tipping paper

ActiveCN101870212AReduce the impact of foil stamping qualityBronzing Quality AssuranceThermographyHot stampingPulp and paper industry

The invention discloses a gilding process for tobacco tipping paper, which mainly comprises the following steps of: accurately positioning and marking texts needing gilding on a hot stamping foil with laser; and performing cold wave compounding on the marked hot stamping foil and sized tipping paper by using a machine and peeling to transfer the texts on the hot stamping foil to the tipping paper so as to realize hot stamping of the tipping paper. The process has the advantages of solving the problems that the conventional hot stamping for the tipping paper needs to continuously adjust temperature, speed and pressure to meet the requirement of the constantly changed hot stamping environment, reducing the influence of personal factors on the gilding quality, more effectively ensuring the hot stamping quality of the tipping paper and improving production efficiency.

Owner:江苏卫星新材料股份有限公司

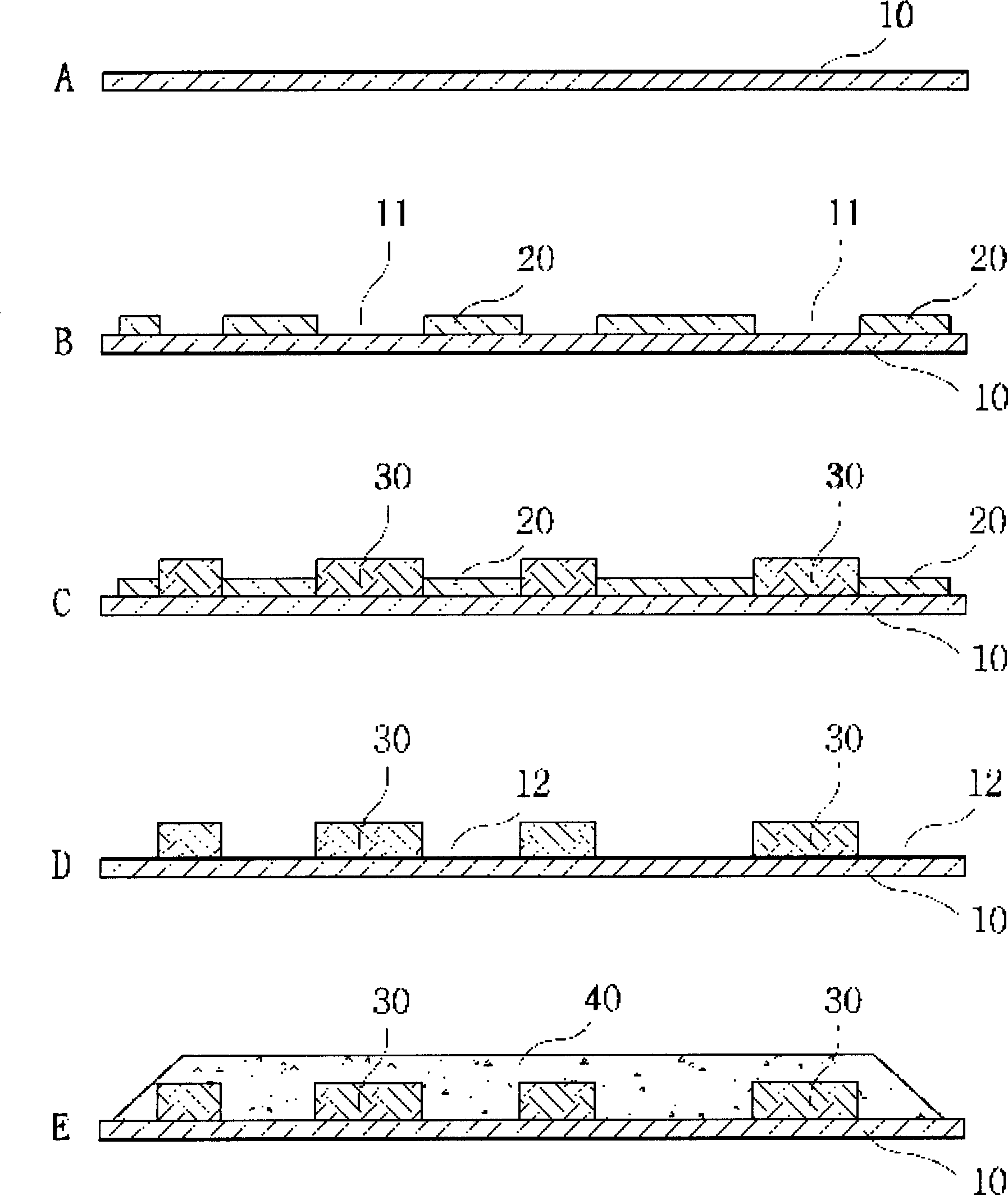

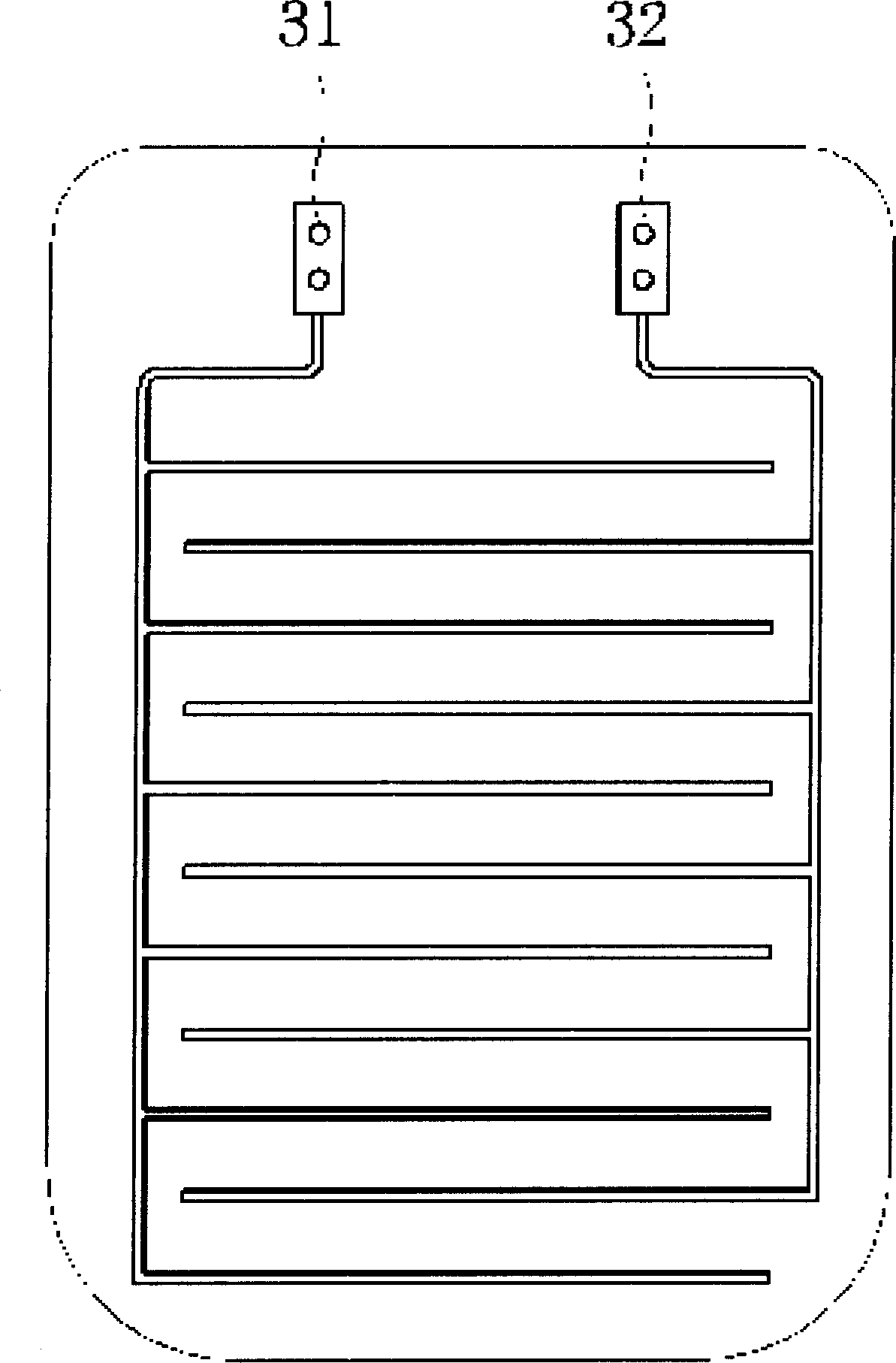

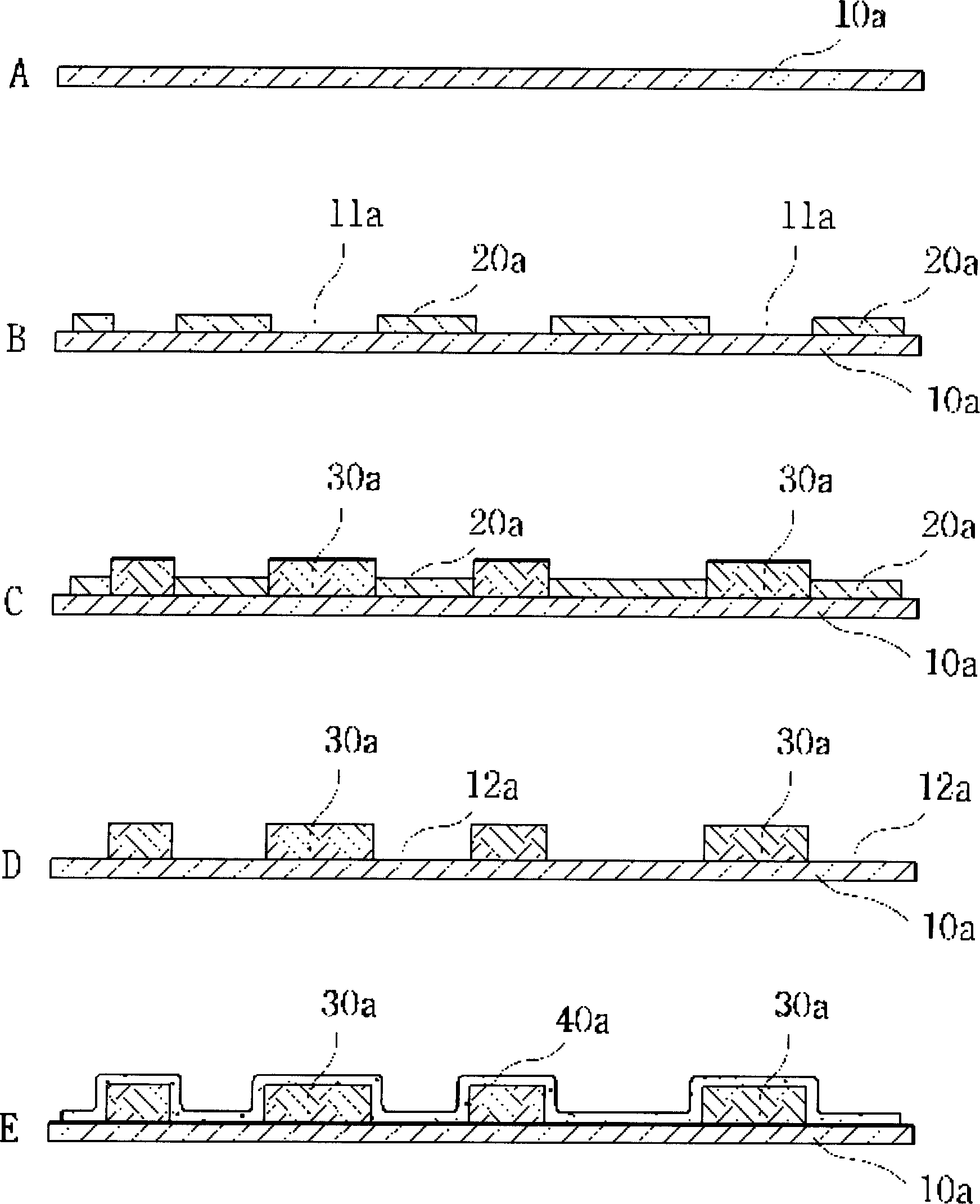

Heating film manufacturing method and its relational heater

InactiveCN1791308ASolve the problem of low durabilityNo damageTransparent/reflecting heating arrangementsPrinted circuit manufactureResistInsulation layer

The invention relates to a preparation method for heat film and opposite heater. Wherein, with the water-soluble Metallize Resist ink on insulation layer or assistant mold, gilding or vacuum coating for electrode line, using PTC ink to print the part not-formed electrode layer into special shape; or after coating film on not-formed electrode line upper, connecting the current input terminal parallel or in series. This invention is easy and low cost, saves erosion process, does not induce flare, and prolongs service time.

Owner:文登太成电子有限公司

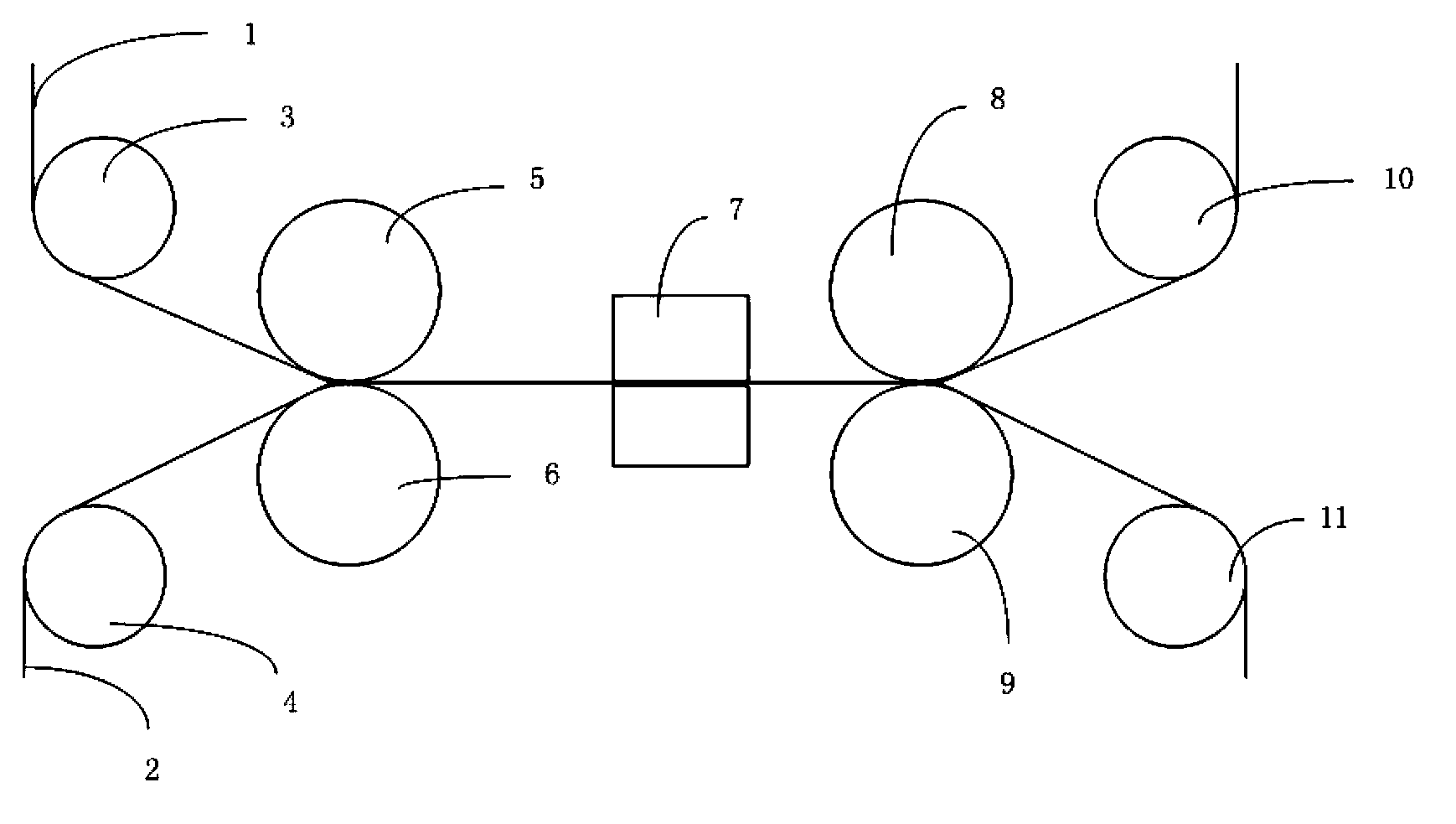

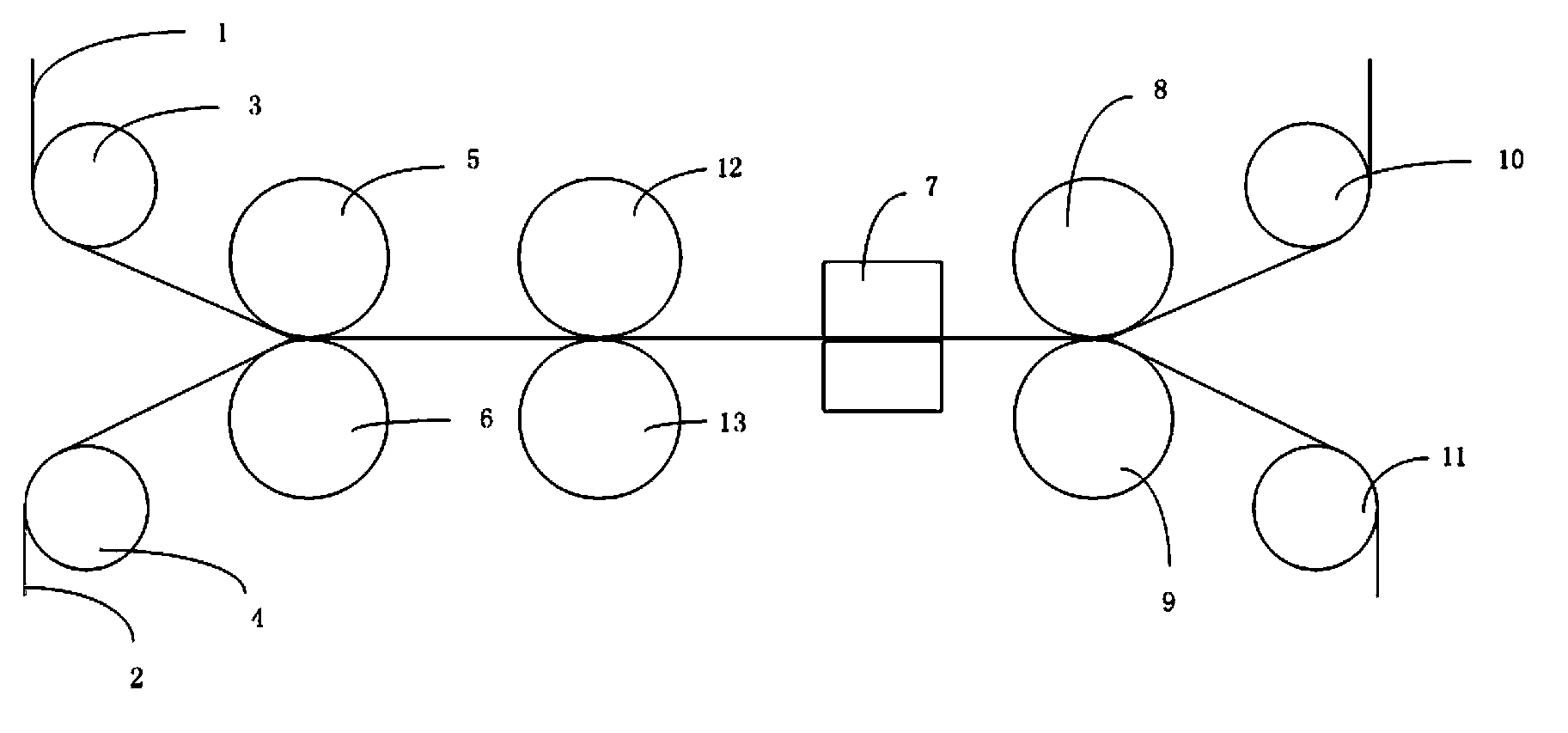

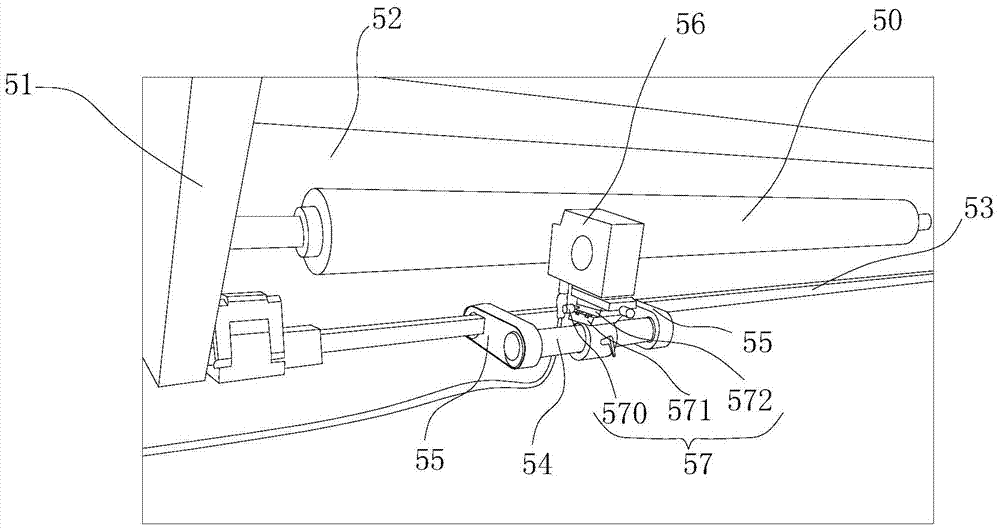

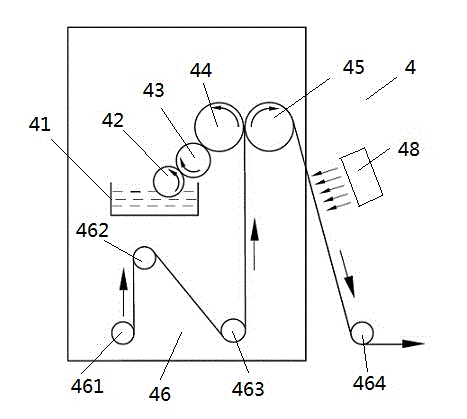

Slant drawing method for gilt alumite

InactiveCN103921580AIncrease profitImprove stabilityOther printing apparatusWebs handlingComputer scienceGilding

The invention discloses a slant drawing method for gilt alumite. The method comprises the steps of: computing an slant drawing angle of the gilt alumite theta according to spacing of gilding positions a, width of gilding position b, length of gilding position c, spacing of gilding traces on alumite d, and according to a formula that theta is equal to arctan (b+d) / a; gliding a pattern on the alumite by gilding press according to the angle. For the gliding precuts with small patterns, the slant drawing method can greatly increase the use ratio of the alumite, reduce the production cost, meanwhile, also can shorten the distance for drawing foil in a jumping manner on the alumite, effectively increase the stability of foil drawing on alumite and improve the production efficiency.

Owner:永发印务(东莞)有限公司

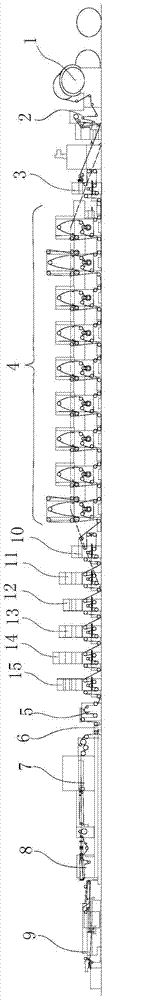

Multifunctional integrated intaglio printing press and machining process thereof

ActiveCN104708894AStable tensionSame line speedRotary intaglio printing pressHot stampingLaser holography

The invention provides a multifunctional integrated intaglio printing press which comprises an unreeling device, an introduction deviation rectifying device, a double-traction device, a printing unit, an edge cutting device, a belling device, a die cutting device, a soft pack cutting device and an automatic stacking paper collecting device. A first traction guide device, a gilding device, a holographic positioning ironing device, the belling device, an online detection device and a second traction guide device are sequentially arranged between the printing unit and the edge cutting device. The printing unit comprises at least nine gravure printing devices, and the multiple gravure printing devices are combined to form multi-color continuous gravure. The first traction guide device and the second traction guide device are provided with stepless speed regulating mechanisms to control the tension and the linear speed of paper passing the gilding device, the holographic positioning ironing device and the belling device at high accuracy, and accuracy control and position control over hot stamping, laser holography transfer printing and raised ironing of cigarette packs are achieved at the same time. The invention further provides a machining process of the multifunctional integrated intaglio printing press.

Owner:ZHUHAI S E Z CHENGCHENG PRINTING

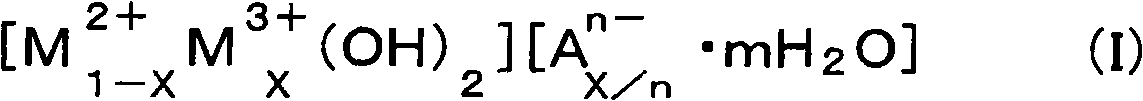

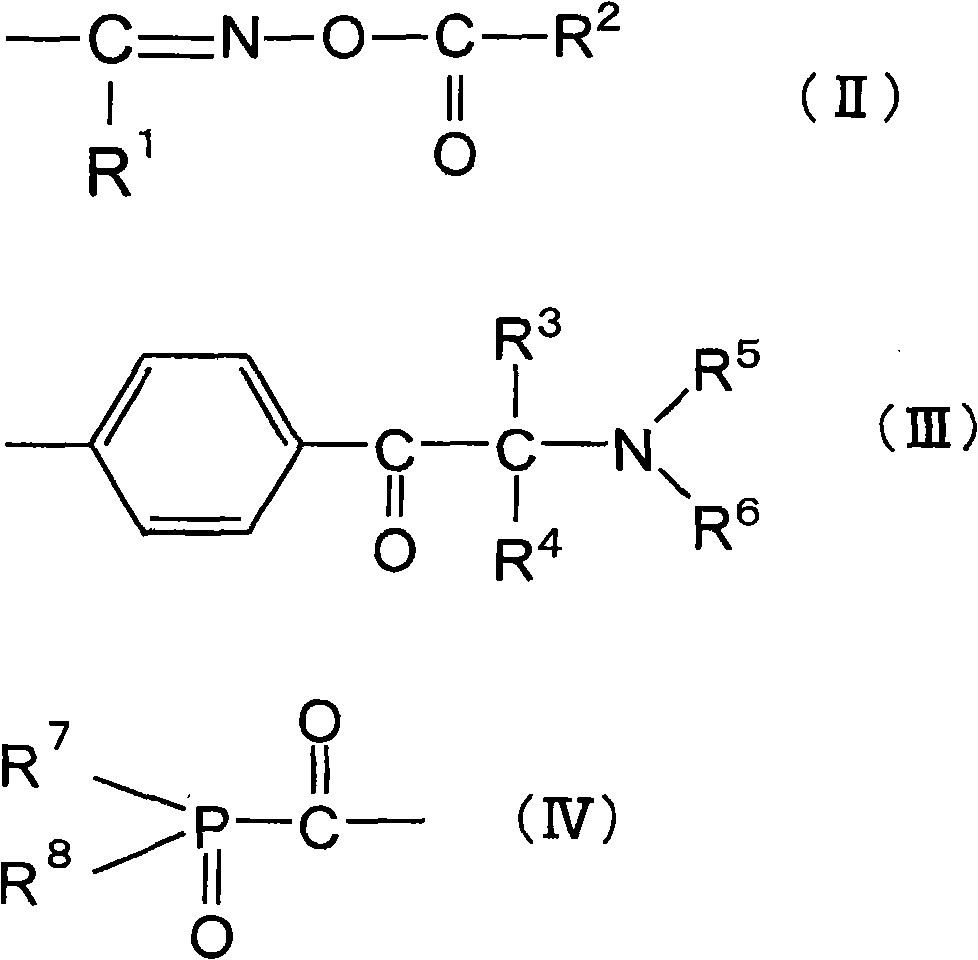

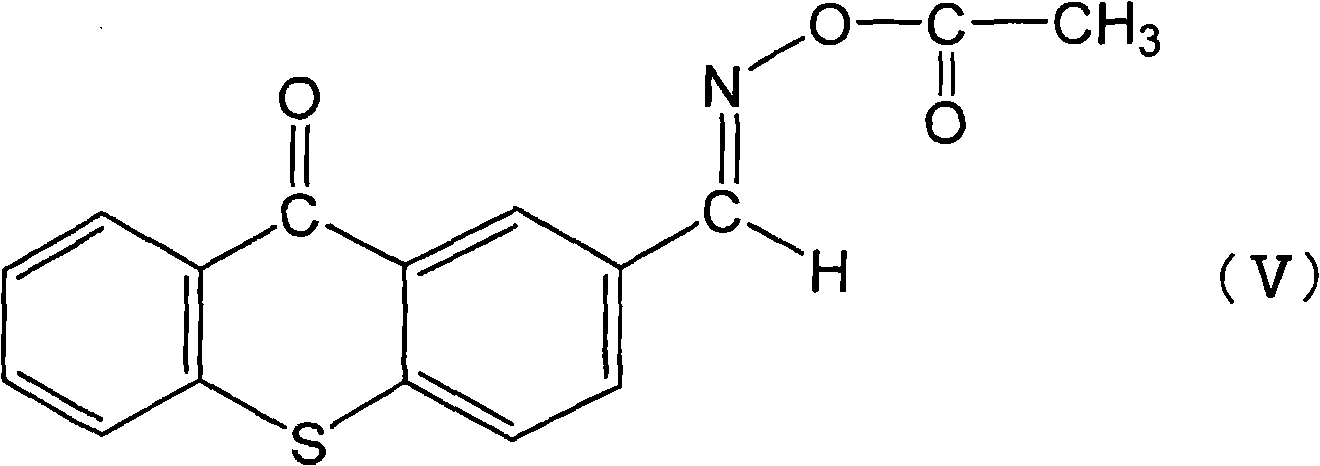

Photosensitive resin composition, and dry film and printed wiring board using the same

InactiveCN101852988AExcellent dryness to touchExcellent soldering heat resistancePhotosensitive materials for photomechanical apparatusNon-metallic protective coating applicationResistEngineering

The invention provids a photosensitive resin composition, and a dry film and a printed wiring board using the same, particularly the photosensitive resin composition, its dry film and the printed wiring board made of a cured film such as a solder resist manufatured by them, wherein the cured film such as the solder resist could prevent the ion migration in a fine space circuit. The dry film of the photosensitive resin composition has excellent finger contact drying property, scolder hear resistance, chemical gilding resistance and electrical insulation. The photosensitive resin composition with an alkaline developing property includes an carboxyl-contained resin (B), an photopolymerizable initiator (D), layer-shaped double hydroxides (A) preferably brucite, preferably a compound (C) with alkene unsaturated group; additionally adding a thermal cured component (E), a light cured and thermal cured resin composition is formed.

Owner:TAIYO INK MFG

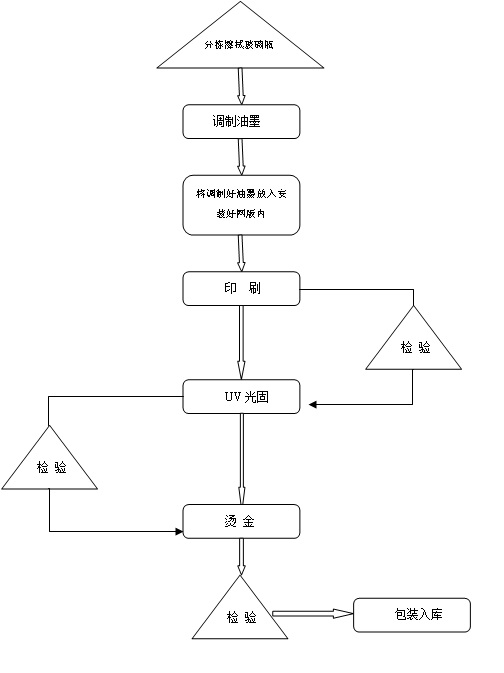

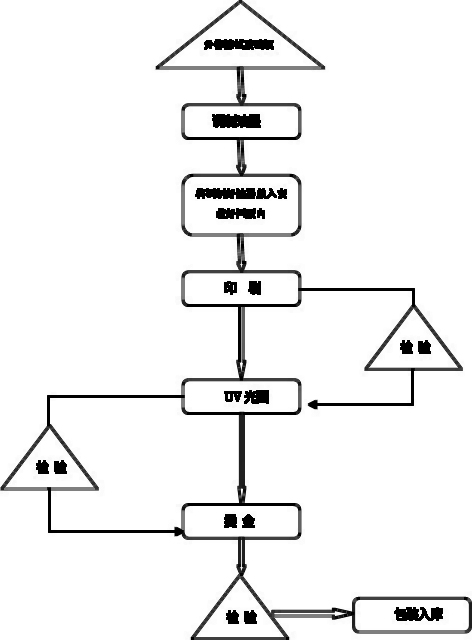

Embossing type fast stamping process for surface of glass bottle

InactiveCN102689533ANot corrosiveNo irritating smellDuplicating/marking methodsOther printing apparatusWater basedScreen printing

The invention discloses an embossing type fast stamping process for surface of a glass bottle. The embossing type fast stamping process is characterized by comprising the following steps: sorting and wiping glass bottles, modulating printing ink, putting well modulated printing ink into a well mounted screen printing plate, carrying out screen printing, UV optical solidifying, gilding, packaging and entering warehouse, and adopting BLA- printing ink as water-based printing ink which is incombustible, nonexplosible, nontoxic, noncorrosive, is free from pungent smell, is good in safety, and has no pollutions and damages to operators; and the products are free from any resolvent residue after printing, meet the requirements of environmental protection, due to the adoption of the UV optical solidifying, the printing ink solidification quality can be effectively improved, and immediate drying is achieved. The embossing type fast stamping process for the surface of the glass bottle has the characteristics of energy conservation, environment friendliness and high efficiency, a gilding layer made by adopting the technology has a strong stereoscopic sensation, brightness in color and fastness are achieved, and the probability of abrasion is low.

Owner:日照众兴包装有限公司

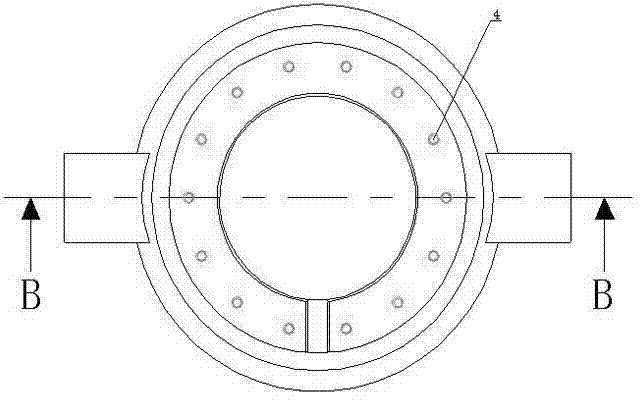

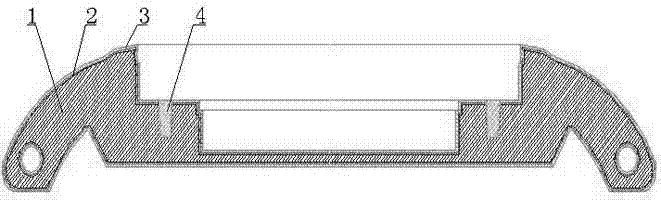

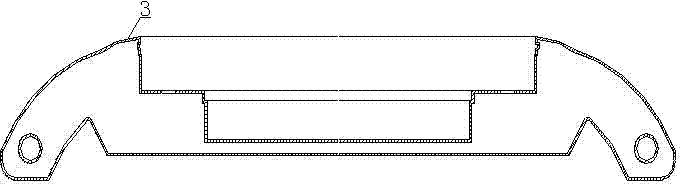

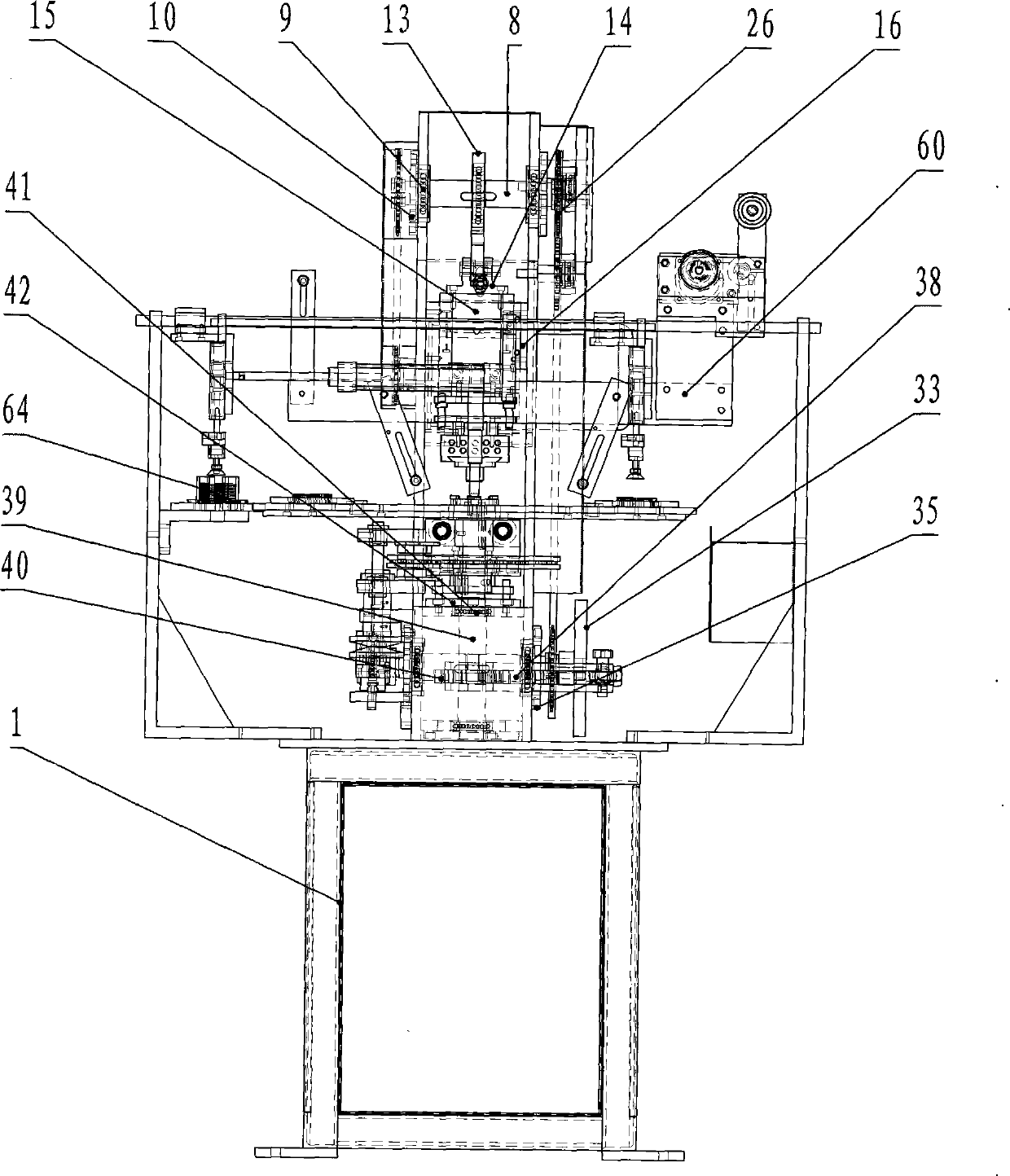

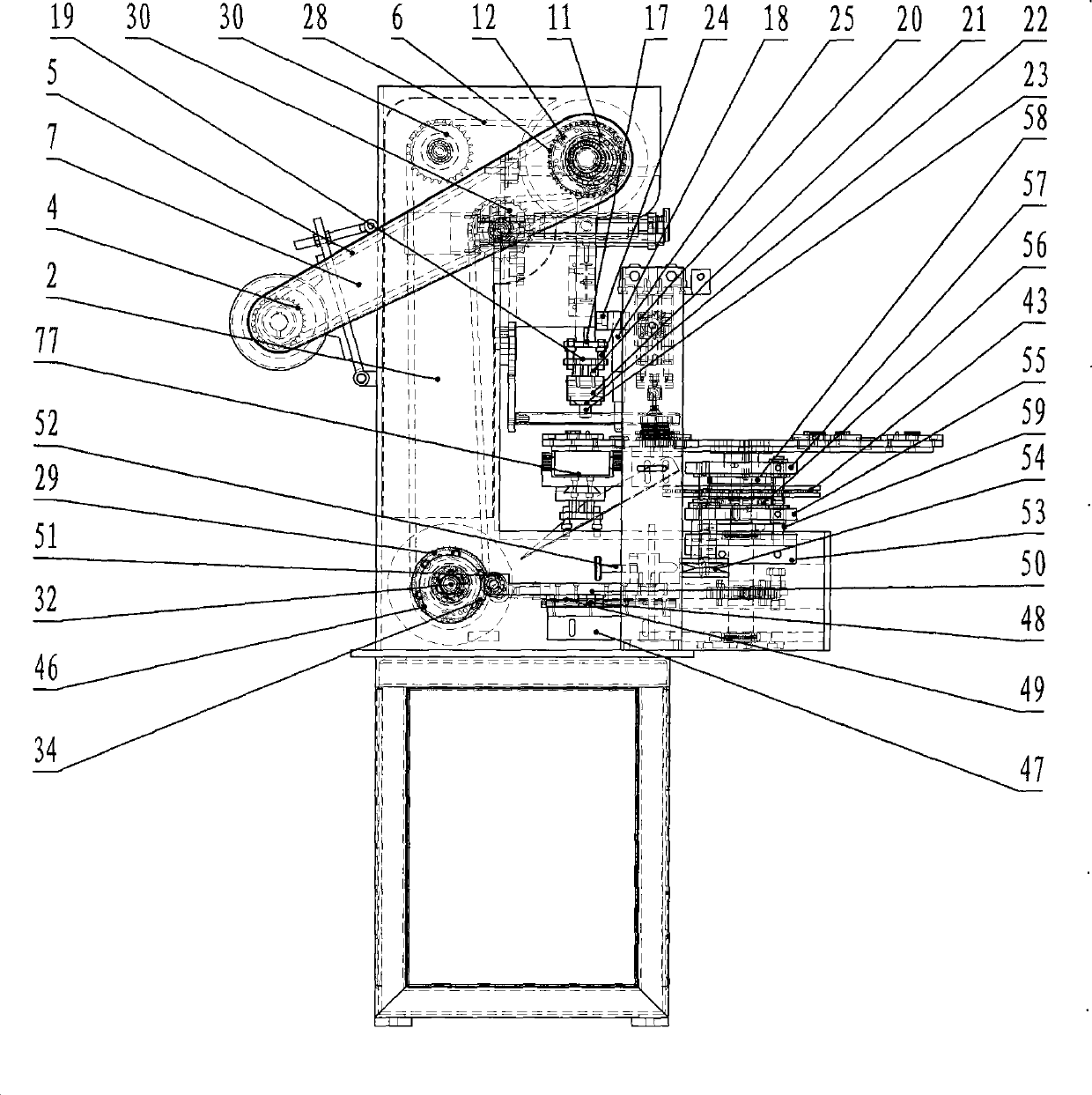

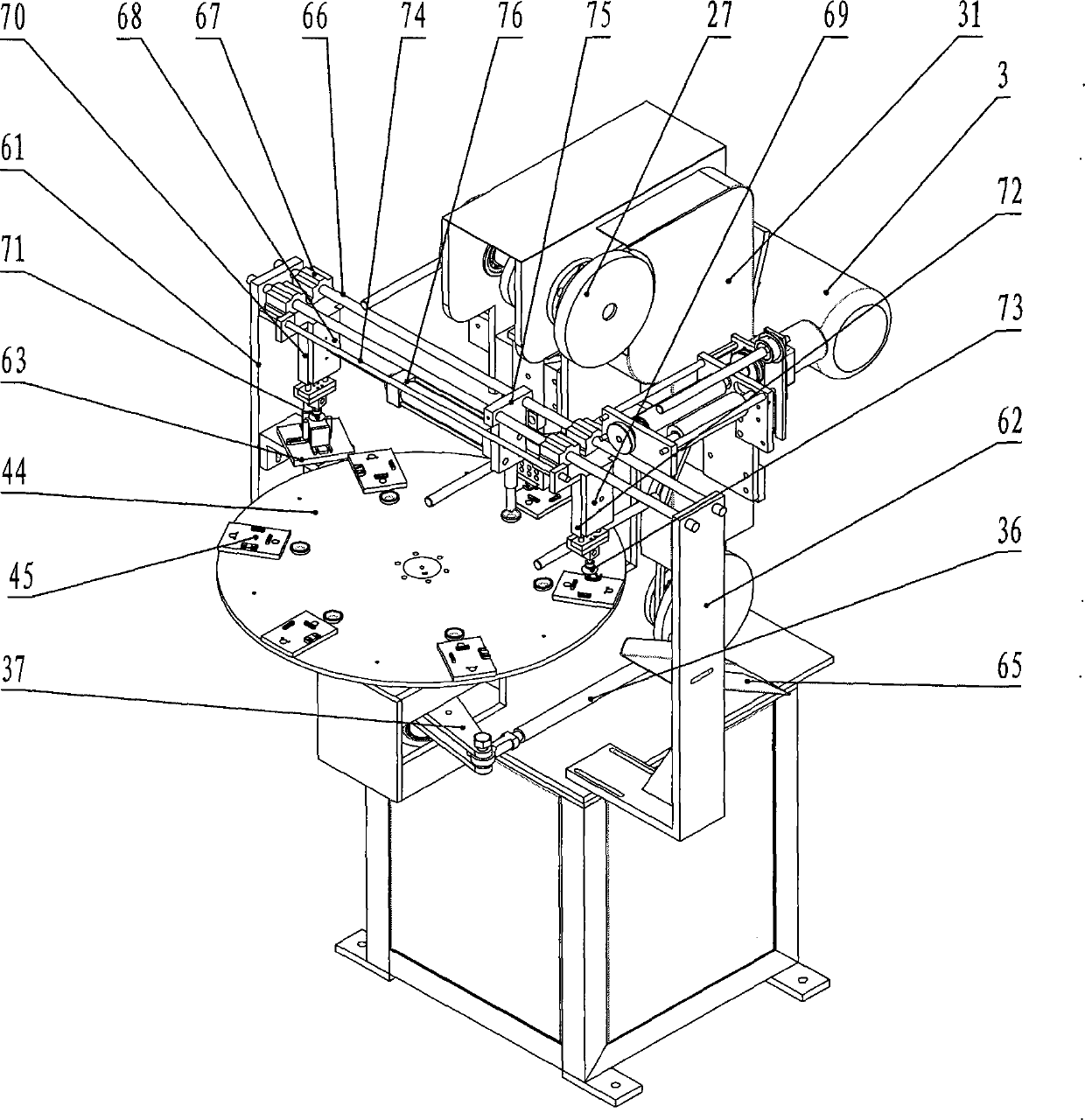

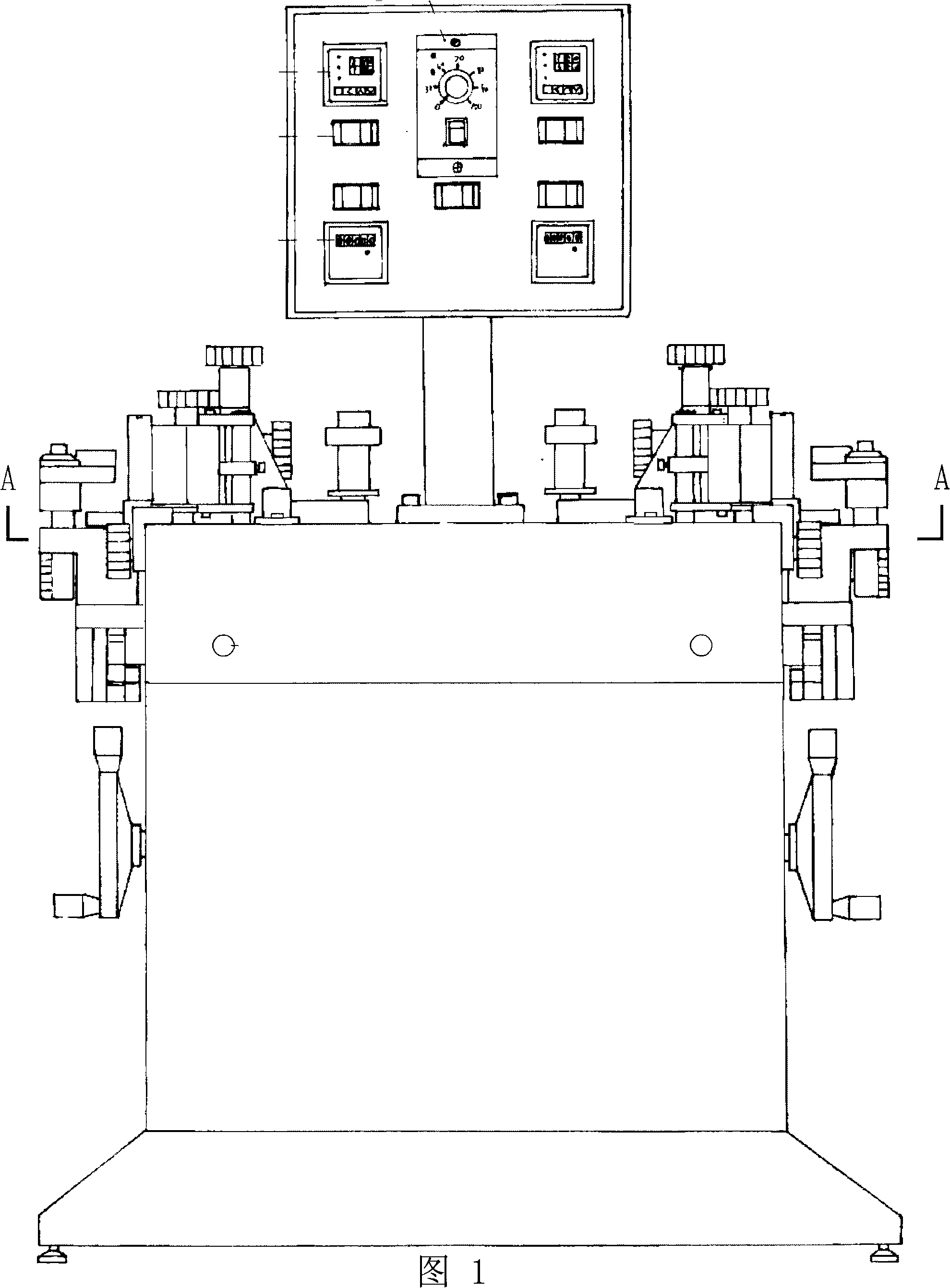

Mechanical-rotary-plate-type fully-automatic gilding press

InactiveCN103273738AEasy to operateImprove work efficiencyBronze printingRotary pressesHot stampingCam

A mechanical-rotary-plate-type fully-automatic gilding press comprises a base and a main unit, and is characterized in that the main unit is installed on the upper portion of the base, the upper portion of the back of the main unit is provided with an active power motor, an output shaft of the active power motor is provided with a driving chain wheel which is provided with an active power chain, a rotary plate shaft base is installed on the lower portion of a machine body, the upper portion of a rotary plate main shaft is provided with a brake plate, the upper portion of the brake plate is a six-working-station rotary plate which is provided with six decoration pad tools, the left end of a rotary plate power shaft is provided with a cam, the left front side of the machine body is provided with a brake mechanism, and the front of the base is provided with an automatic feeding device and an automatic discharging device. The gilding press solves the problems that in the prior hot stamping art of small workpieces such as crafts, decoration boxes and small plastic pieces, labor intensity is large, work efficiency is low and the safety coefficient is low, and is suitable for being used for the hot stamping of identifications and patterns on small articles such as the crafts, decoration pads and the small plastic pieces.

Owner:QINGDAO HAIGANG GILDING PRESS EQUIP

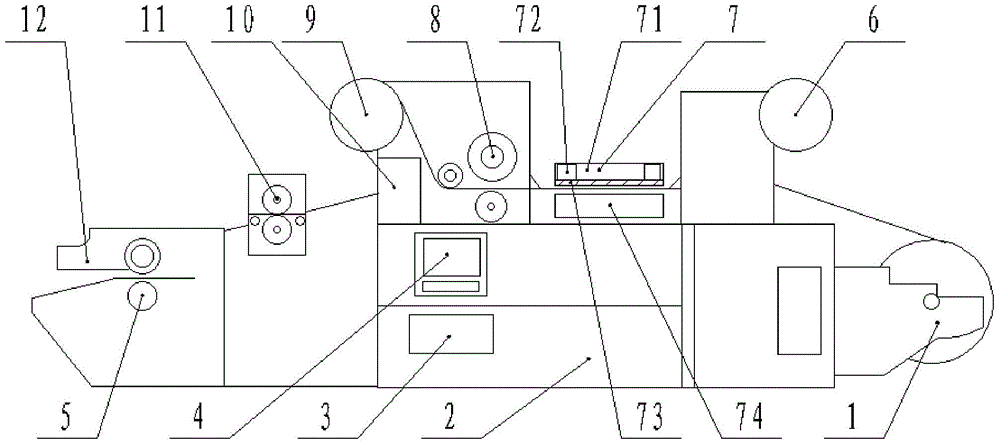

Processing method and integrated processing device for hard shell cigarette packaging box

InactiveCN104626738AIncrease productivityAvoid rubbingRotary pressesBronze printingCardboardEngineering

The invention belongs to the technical field of printing and packaging devices, and particularly relates to a processing method and integrated processing device for a hard shell cigarette packaging box. The processing method comprises the following steps that white cardboard rolls are uncoiled, gilded and printed to form semi-finished paperboards; the paperboard are dried; the pressing mark technology is carried out on the semi-finished paperboards to form a plurality of folding marks; die cutting is carried out on the semi-finished paperboards to form packaging paper; the packaging paper is folded and stuck to form the square and strips-shaped hard shell cigarette packaging box. The integrated processing device comprises a rack, an uncoiling mechanism, a gilding film paying-off device, a gilding mechanism, a printing mechanism, a waste film taking-up mechanism, a drying device, a pressing mark mechanism and a die cutting mechanism which are sequentially arranged on the rack. The gilding mechanism comprises an upper gilding and printing film and a gilding bearing base. A heating disc and a temperature sensor are arranged on the upper gilding and printing film. According to the processing method and device, the cigarette packaging and printing quality is better ensured, the production efficiency is high, and the production cost is saved.

Owner:CHUXIONG JIXING COLOR PRINTING

Printing process of UV flash three-dimensional pyrography

InactiveCN107443942AStrong concave-convex feelGood three-dimensional effectOther printing apparatusPrinting after-treatmentCartonPrinting ink

The invention discloses a printing process of UV flash three-dimensional pyrography, which is used for printing on cartons. The printing process comprises the following steps of (1) plating silver: partially plating silver on the cartons; (2) calibrating: determining that the gilding position and the printing position are kept consistent through the registration of a positioning film; (3) printing patterns: partially printing patterns on the cartons with printing ink, wherein the registration error of the printing patterns is less than or equal to 0.05 mm; (4) performing matte printing: performing matte printing on full pages of the cartons; and (5) glazing: registering gilding and printing contents, and glazing with UV varnish. The printing process of the UV flash three-dimensional pyrography has the following advantages that (1) the visual stereoscopic effect of the surfaces of the graphic cartons is good, and the display effect is good; (2) the UV flash three-dimensional pyrography has a strong concave-convex feeling.

Owner:昆山科望快速印务有限公司

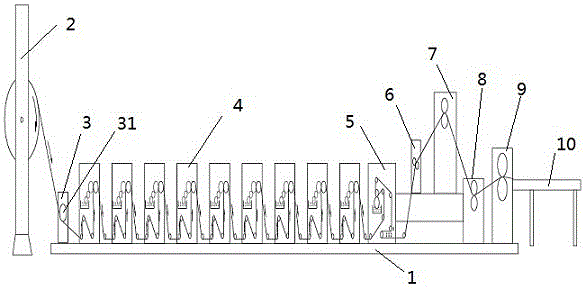

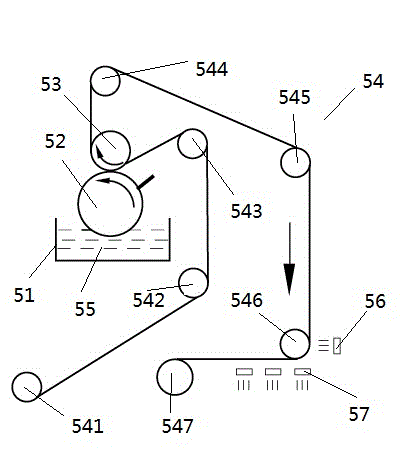

Freezing point printing and holographic gilding printing integrated printing equipment and application method thereof

ActiveCN104553292AGuaranteed uptimeGuaranteed compensation for overprint deviationScreen printersBronze printingTension controlPaper sheet

The invention discloses freezing point printing and holographic gilding printing integrated printing equipment and an application method thereof. The freezing point printing and holographic gilding printing integrated printing equipment comprises a base, a paper unwinding device, a paper guide mechanism, flexography units, a gravure freezing point unit, a tension control unit, a holographic gilding device, a concave-convex unit, a cutting unit and a finished paper collecting unit, wherein the paper guide mechanism is disposed on one side of the paper unwinding device, the plurality of flexography units are sequentially disposed on one side of the paper guide mechanism, and the gravure freezing point unit, the tension control unit, the holographic gilding device, the concave-convex unit, the cutting unit and the finished paper collecting unit are sequentially disposed on one side of the flexography units. The freezing point printing and holographic gilding printing integrated printing equipment has the advantages that printing combining multiple working procedures is achieved, freezing point printing and holographic gilding printing are integrated, the printing equipment is high in continuity, high in automation level, convenient to operate, stable in operation, good in printing effect, high in chromatography precision and high in yield, efficient and high-quality printing is achieved, production procedures are reduced, production time is saved, production efficiency is increased, and production cost is lowered.

Owner:KUNMING WEIJIAN KECHUANG PRINTING

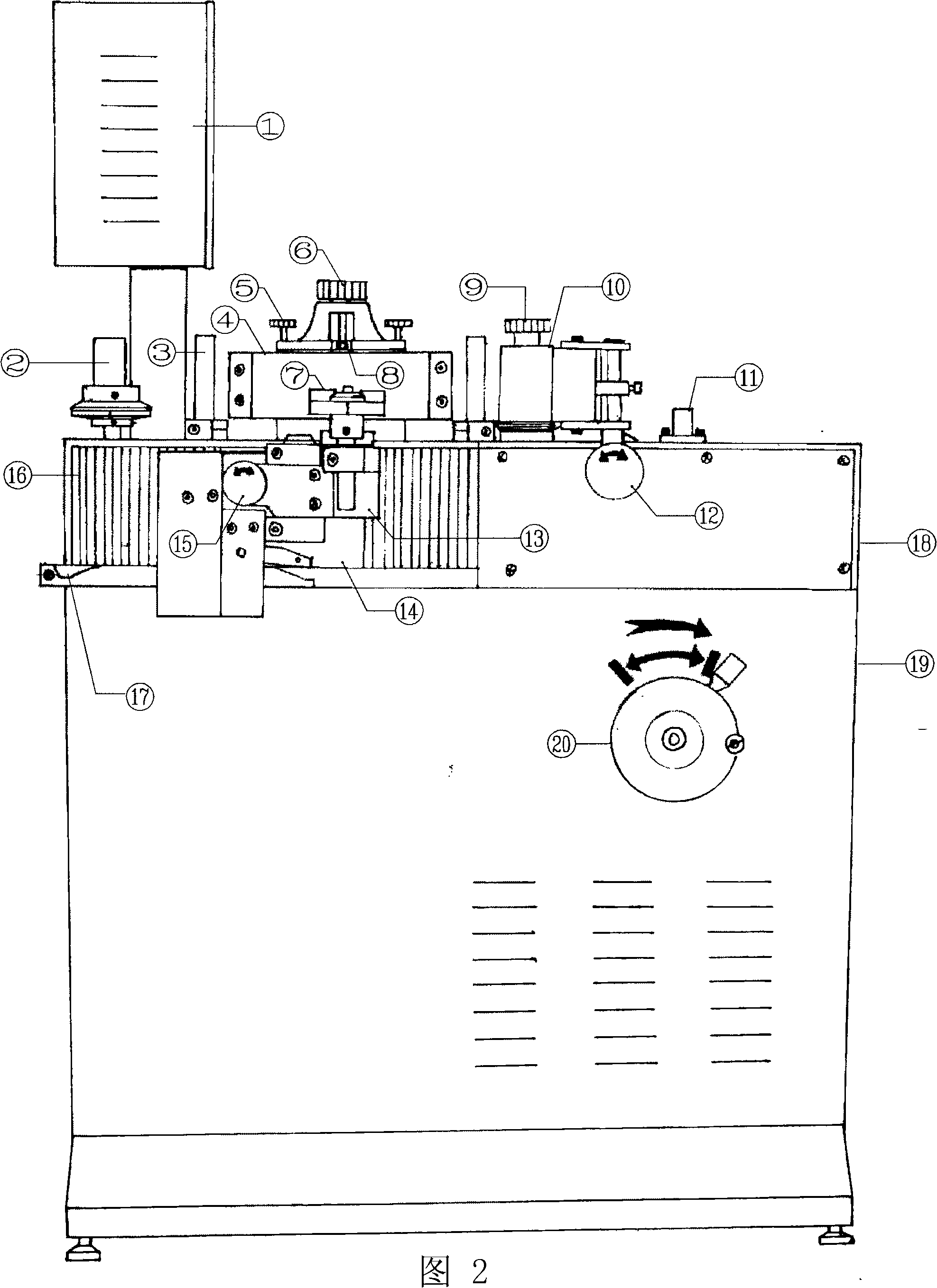

Electric combined gold stamping machine

The invention relates to an electric combined gilding press which includes a heating hot stamping device arranged on a frame, a hot stamping foil transmitting and adjusting device, a transmission device, a main motor, a control device and a counting device; the transmission device includes a slide body reciprocating along a lead rail; the transmission device also includes a main shaft matched with the main motor, a foil collection drive gear and a slide body drive wheel arranged on the main shaft as well as a clutch; the clutch includes a clutch slide sleeve, a power clutch manual debugging wheel, a fork plate and a clutch check ring; the inside of the foil collection drive gear is provided with a clutch gag lever post parallel to the main shaft by spring; the outer circle of the slide body drive wheel is in a step shape with two levels; an inward step circle is provided with a location slot; an outward step circle is provided with a gear which can be engaged with a debugging gear on the axle of the power clutch manual debugging wheel; a connection rod is articulated between the slide body drive wheel and the slide body. The electric combined gilding press of the invention has the advantages of being quiet, low loss, high output capacity and good stamping quality.

Owner:黄修宝

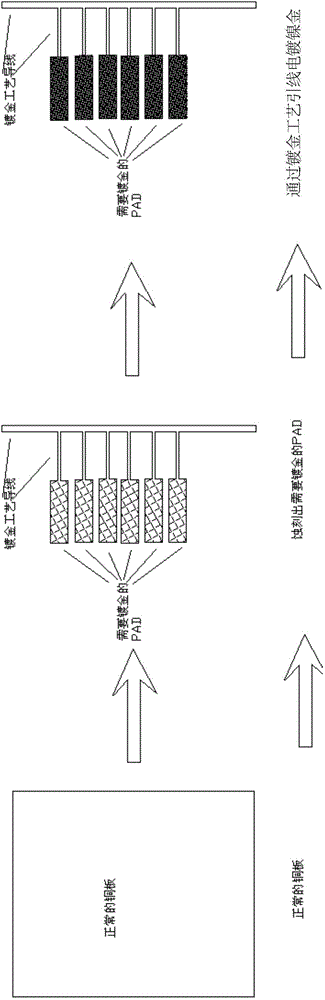

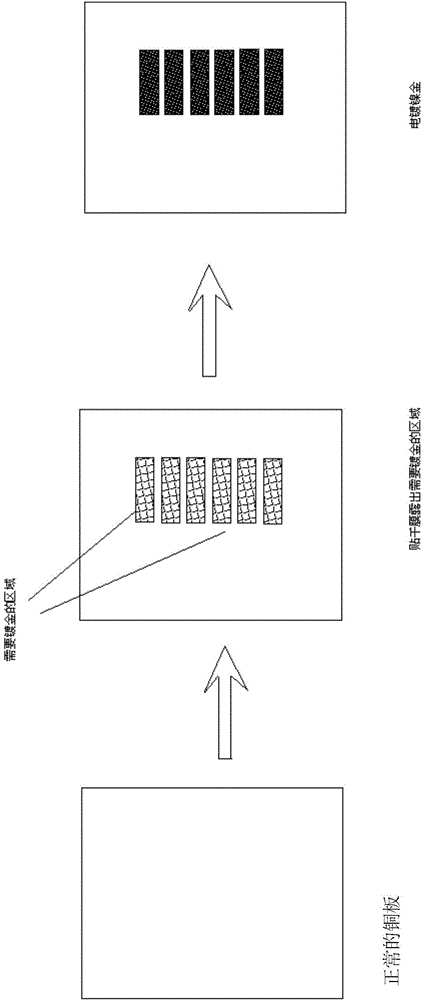

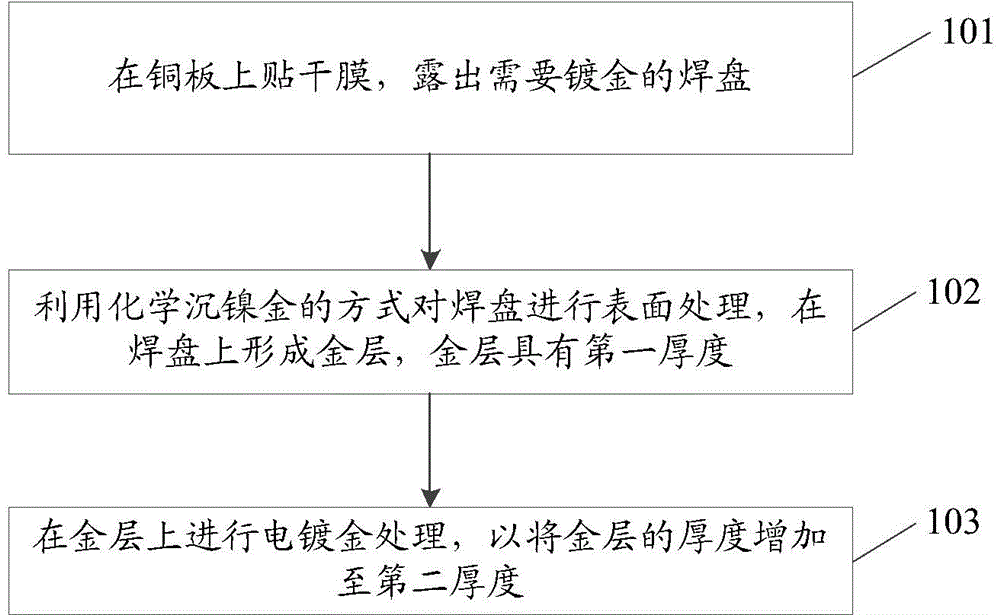

Circuit board and gilding method thereof

ActiveCN104582299AIncreasing the thicknessReduce the temperaturePrinted circuit aspectsConductive pattern reinforcementPower flowCopper

The invention discloses a circuit board and a gilding method thereof. The gilding method of the circuit board comprises the following steps: pasting a dry film on a copper plate to expose welding plate to be gilded; processing the surface of the welding plate through chemical nickel gold immersion to form a gold layer on the welding plate, wherein the gold layer has first thickness; electrogilding the gold layer so as to increase the thickness of the gold layer to second thickness, wherein the thickness current is 0.2-0.6A.

Owner:CHONGQING FOUNDER HI TECH ELECTRONICS +1

Chasing piece gilding and silvering process

InactiveCN1422758ASimple processLow priceDecorative surface effectsArtistic surface treatmentWaxLacquer

The gilding and silver-plating process of through-carved work includes the following steps: grinding the through-carved work and printing coat, bedding putty, spraying and brushing prime paint, using matched flow thick material to cover prime paint, after 5-10 hr., sticking pure golf foil or pure silver foil on the surface, pressurizing and planishing, spray-coating finish coat by using transparent lacquer, after 24 hr. applying polish wax and polishing. Said invention is simple in process, and its gilding and silver-plating effect is good, and its application is extensive.

Owner:曾剑

Tin enameling treatment method

The invention discloses a tin enameling treatment method, and belongs to the field of chemical treatment processes. The tin enameling treatment method is characterized by comprising the following steps: (1) the root of a lead is wrapped by a gauze; and (2) a gold plating lead coated with soldering flux is dipped for 2-3 s in a special tin pot for tin enameling; and the temperature is kept within 250-270 DEG C; and (3) the lead is dipped in a general tin pot again for secondary tin enameling; and the time and temperature are the same with that of the tin pot in the step (1). The static tin dipping is performed for a tin enameling circuit board by adopting double tin pots, and the tin enameling operation is finished more thoroughly through twice heat impact under the precondition of no mechanical damage, so that the consistency is good; and the tin enameling treatment method has the advantages of simple process and easy promotion.

Owner:XIAN SANWEI SECURITY TECH

Processing method for fine gilding and overprinting in large size

ActiveCN102887000AFine printing effectThe printing effect is beautifulOther printing apparatusGraphicsLarge size

The invention discloses a processing method for fine gilding and overprinting in large size. The processing method comprises the following steps of: color matching: adjusting the ground color for printing and the colors of printing patterns, wherein tones of the same color system are adopted, and alumite stamping foil adopts the tone the same with those of the ground color for printing and the colors of the printing patterns; graphic processing: carrying out virtual-edge adding or feathering treatment on the printing patterns by adopting software; shape adjusting: adjusting the gilding shape to be an irregular shape for a circular arc shape; line width and space adjusting: adjusting line width and space between the patterns of the patterns to be gilded; and making a gilding plate, during plate making, the gilding plate is compressed in proportions. With the adoption of the processing method for fine gilding and overprinting in large size, the printing effect is more fine and more attractive than that of the prior art, the requirements for high-grade product can be met, and the processing method can adapt to mass production, has lower cost than the traditional technology, and improved yield.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com