Gilding process for tobacco tipping paper

A cigarette tipping paper and technology of tipping paper, applied in the direction of temperature recording method, etc., can solve the problems of no luster, weak hot stamping, exposed bottom, etc., and achieve the effects of reducing impact, improving production efficiency, and ensuring the quality of hot stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

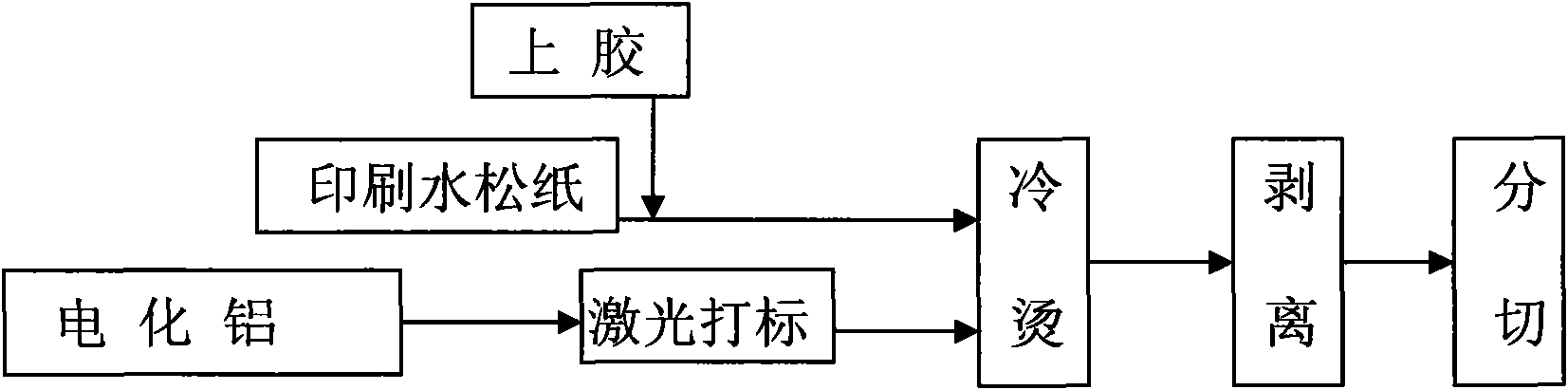

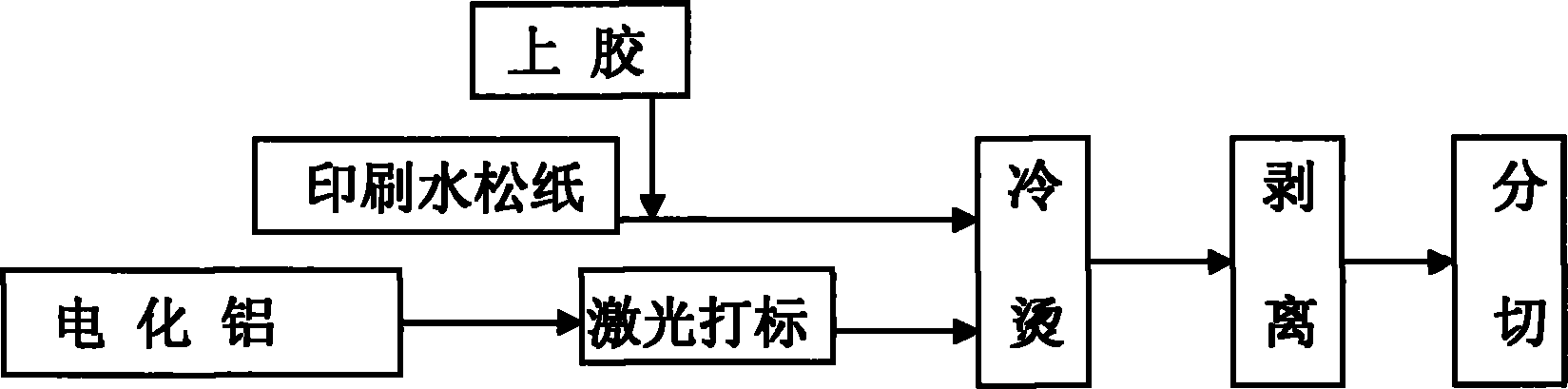

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0021] As shown in the accompanying drawings: a hot stamping process for cigarette tipping paper, comprising the following steps:

[0022] 1) Print on tipping paper base paper according to the printing requirements of tipping paper;

[0023] 2) After the tipping paper is printed and formed, a resin glue prepared by acrylic resin, fiber resin, ethylene acetic acid, vinyl resin, additives, etc. is printed according to the hot stamped text and pattern engraving roller;

[0024] 3) Input data according to the requirements of the hot stamping icon on the finished anodized aluminum, and the computer automatically adjusts the laser intensity, position, and adjusts the operation speed and positioning cycle to mark the anodized aluminum;

[0025] 4) After the marked anodized aluminum and the glued tipping paper are combined and peeled off by machine cold iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com