Patents

Literature

74results about How to "Same line speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

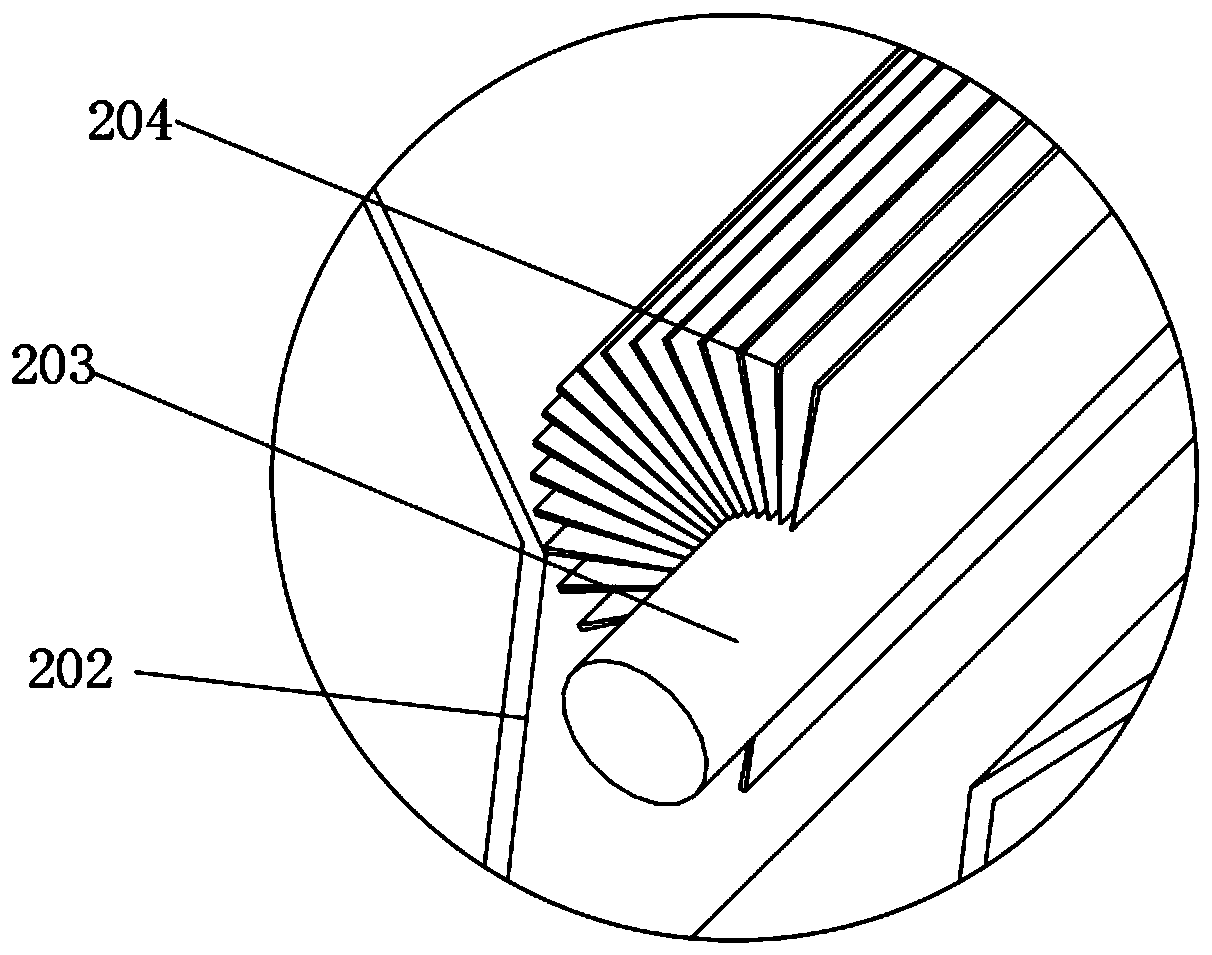

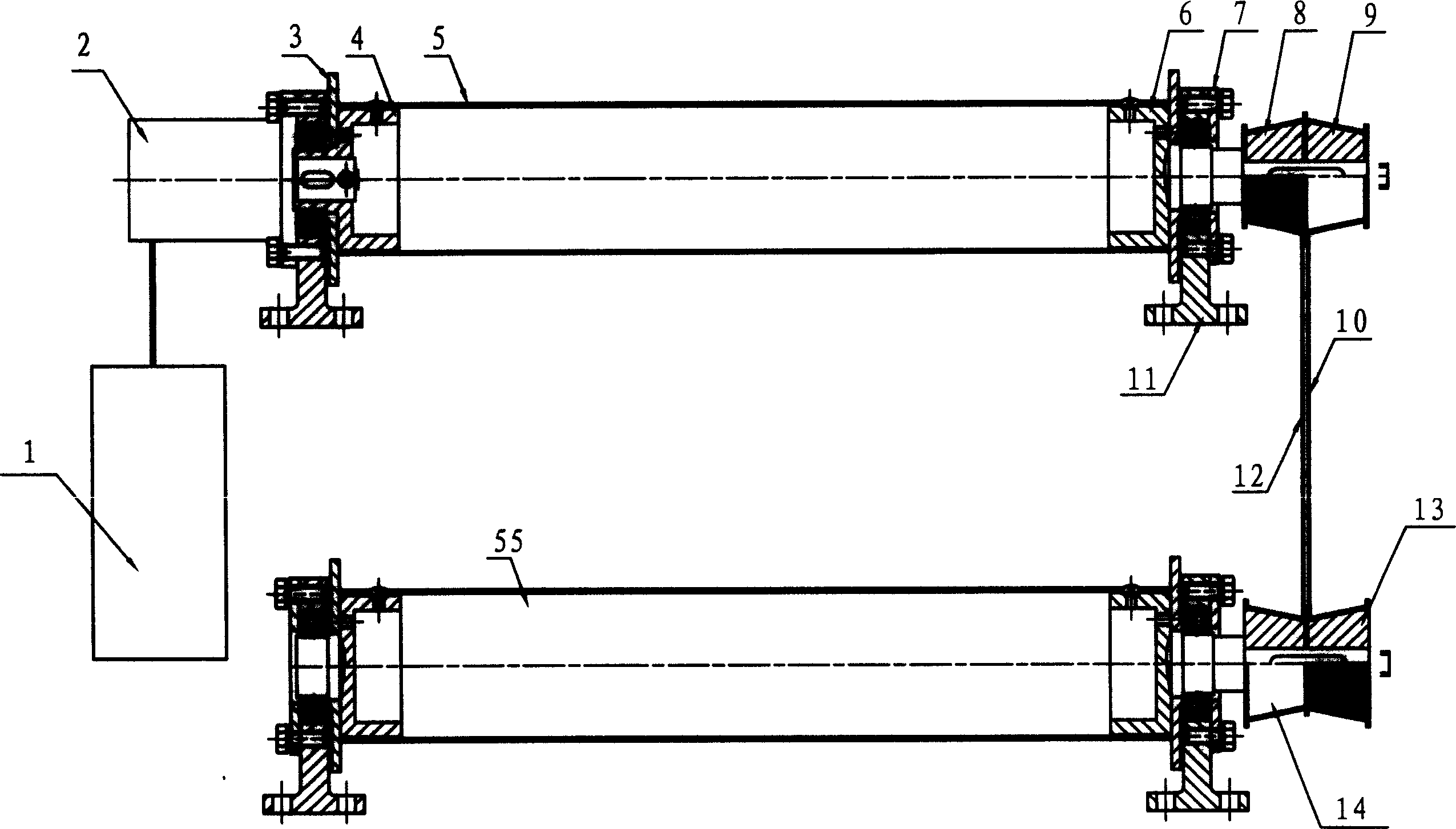

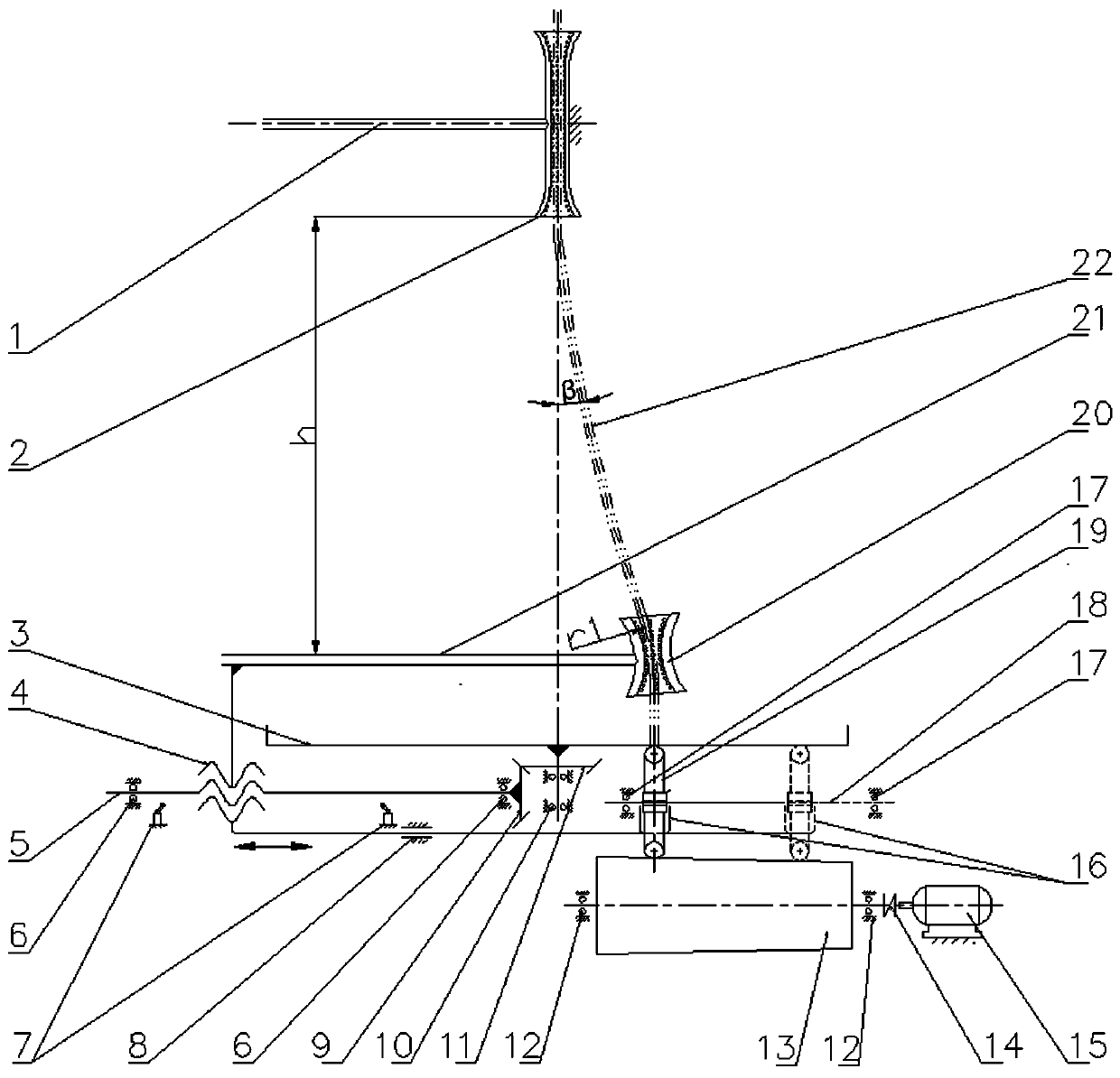

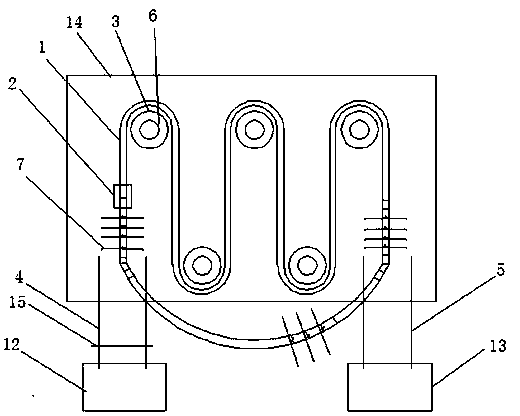

Device and method for tracing and checking shallow color code mark of drum type multicolor rotogravure press

ActiveCN102896892AIncrease brightnessMeet recognitionPrinting press partsEngineeringBrightness perception

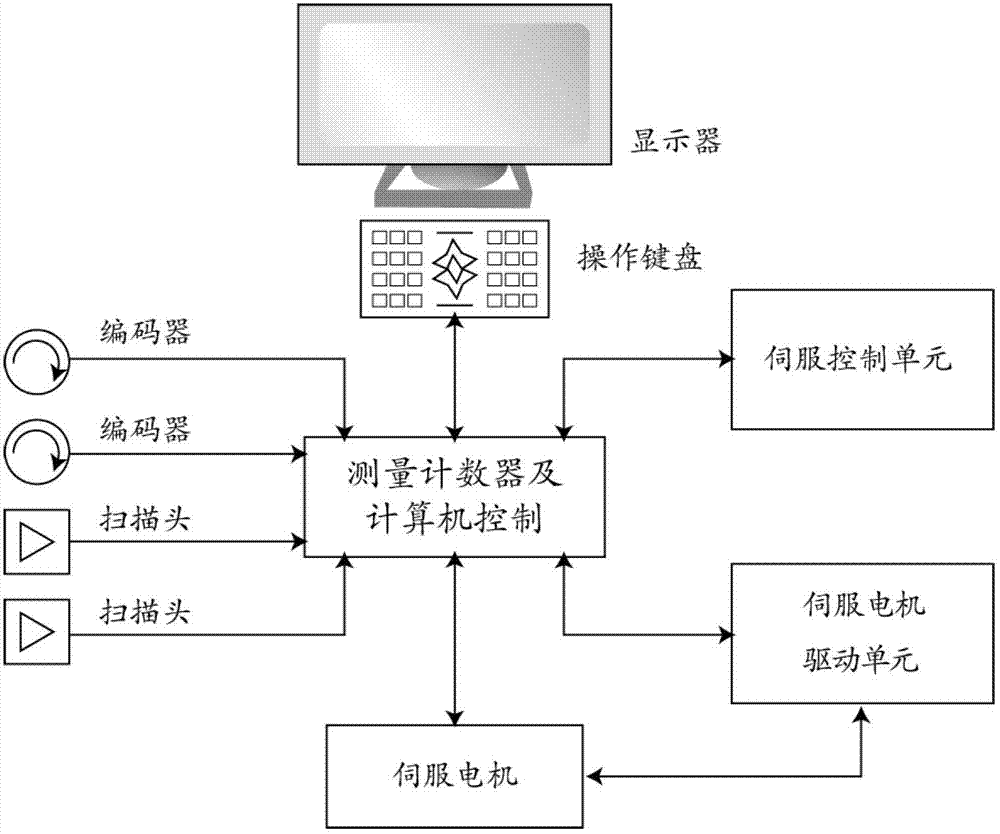

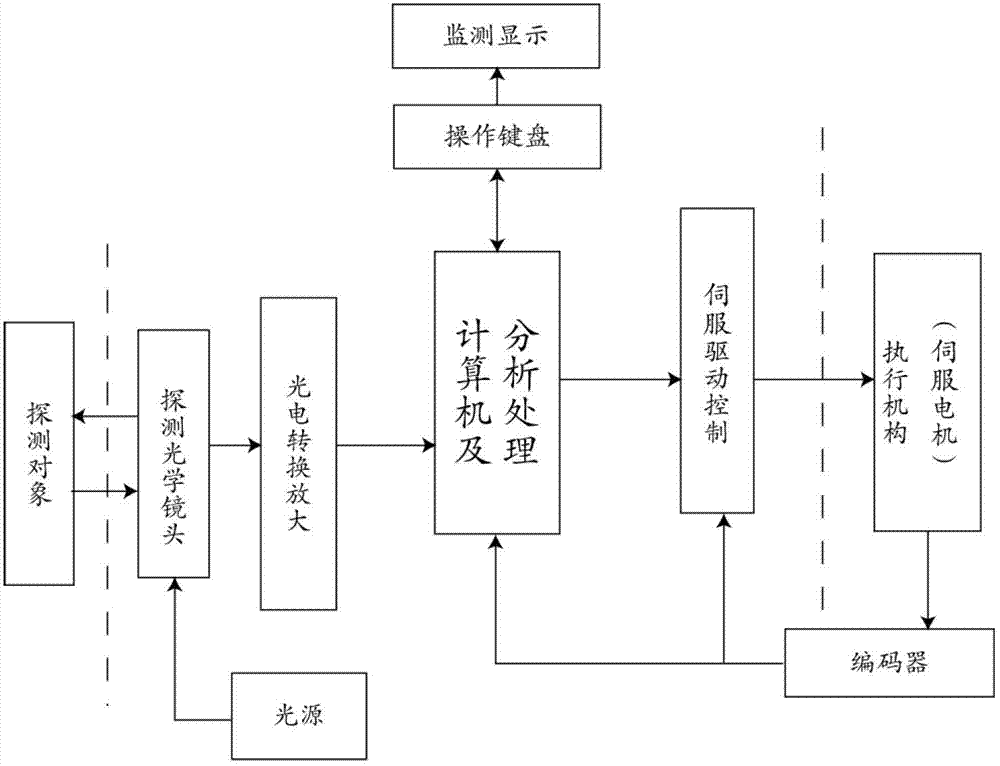

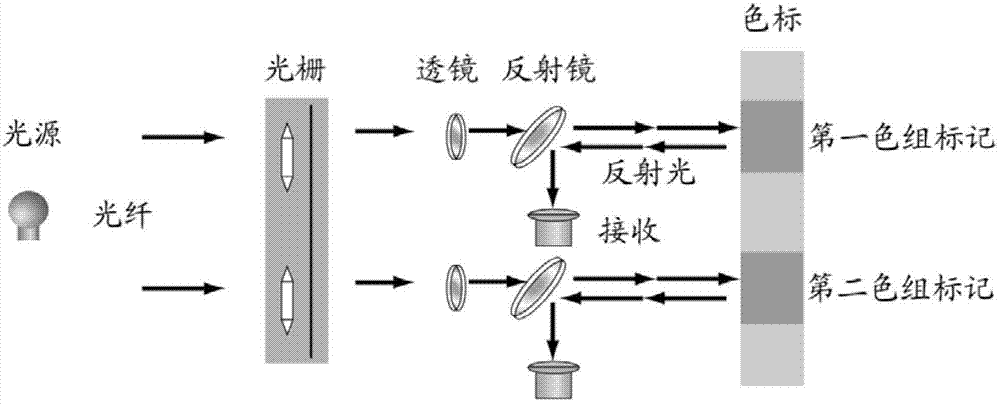

The invention relates to a device and a method for tracing and checking a shallow color code mark of a drum type multicolor rotogravure press. The device comprises an auxiliary roller (1), a scanning head (9), an imaging system (7) and a transmission optical fiber bundle (8), wherein the scanning head is arranged at a shallow color code mark to be checked (3) on a rotogravure press product; the auxiliary roller (1) and a printing plate roller (2) of a rotogravure press are same in diameter and are coaxially arranged on one side of the printing plate roller (2); the auxiliary roller (1) is provided with an auxiliary deep-color code mark (4) which is of consistent shape and size with the shallow color code mark to be checked (3); and the incident end of the transmission optical fiber bundle (8) is connected with a light source, and the emergent end of the transmission optical fiber bundle (8) is provided with a light-transmitting window which is of consistent shape and size with the shallow color code mark (3). According to the device disclosed by the invention, the scanning head (9) receives reflection lights of the shallow color code mark to be checked (3) with strengthened brightness so that requirements of the scanning head (9) during registration printing are met; and the device and method for tracing and checking the shallow color code mark of the drum type multicolor rotogravure press, disclosed by the invention, have the characteristics of simple technical scheme, low manufacturing cost, strong applicability and the like.

Owner:大理九恒印务有限公司

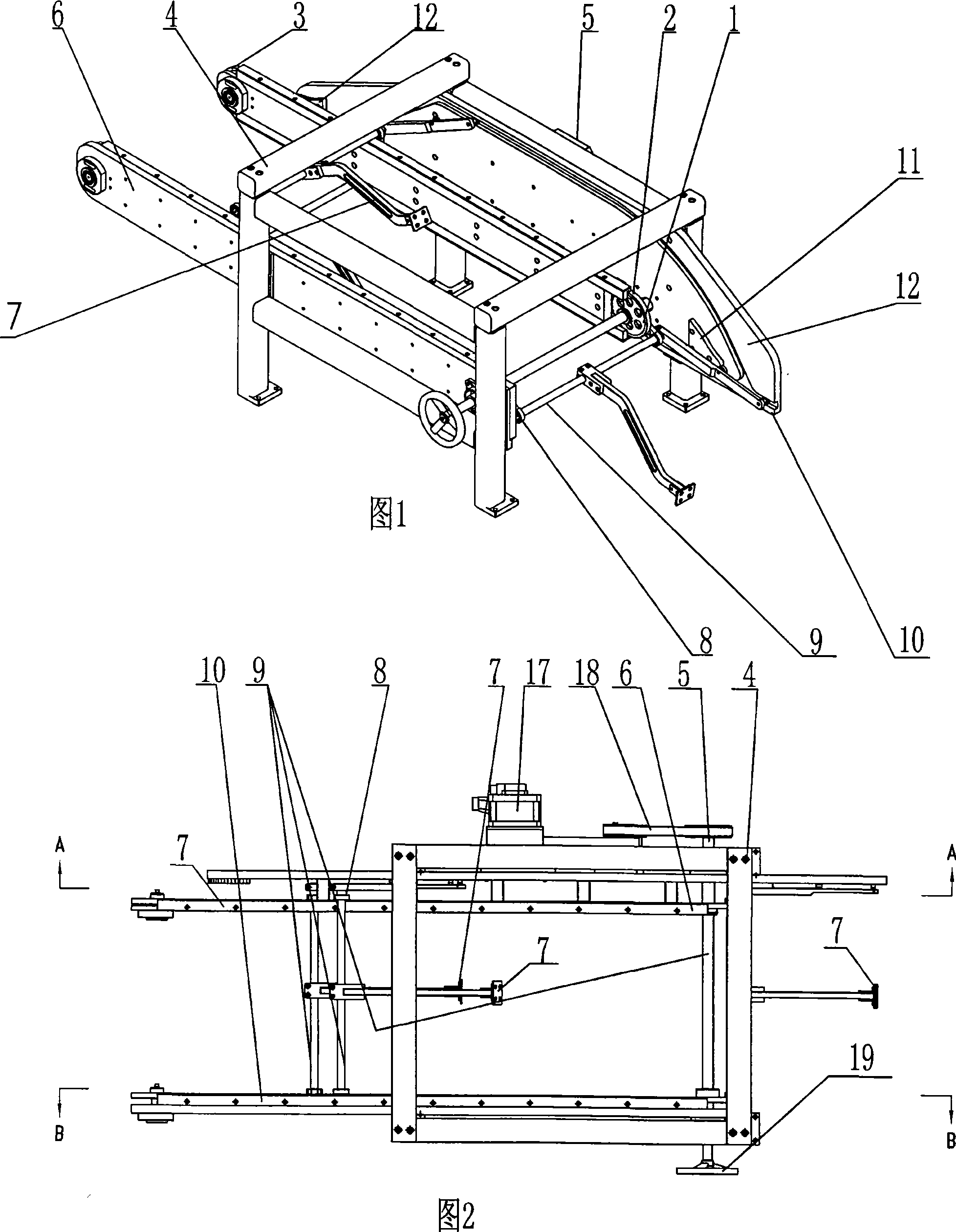

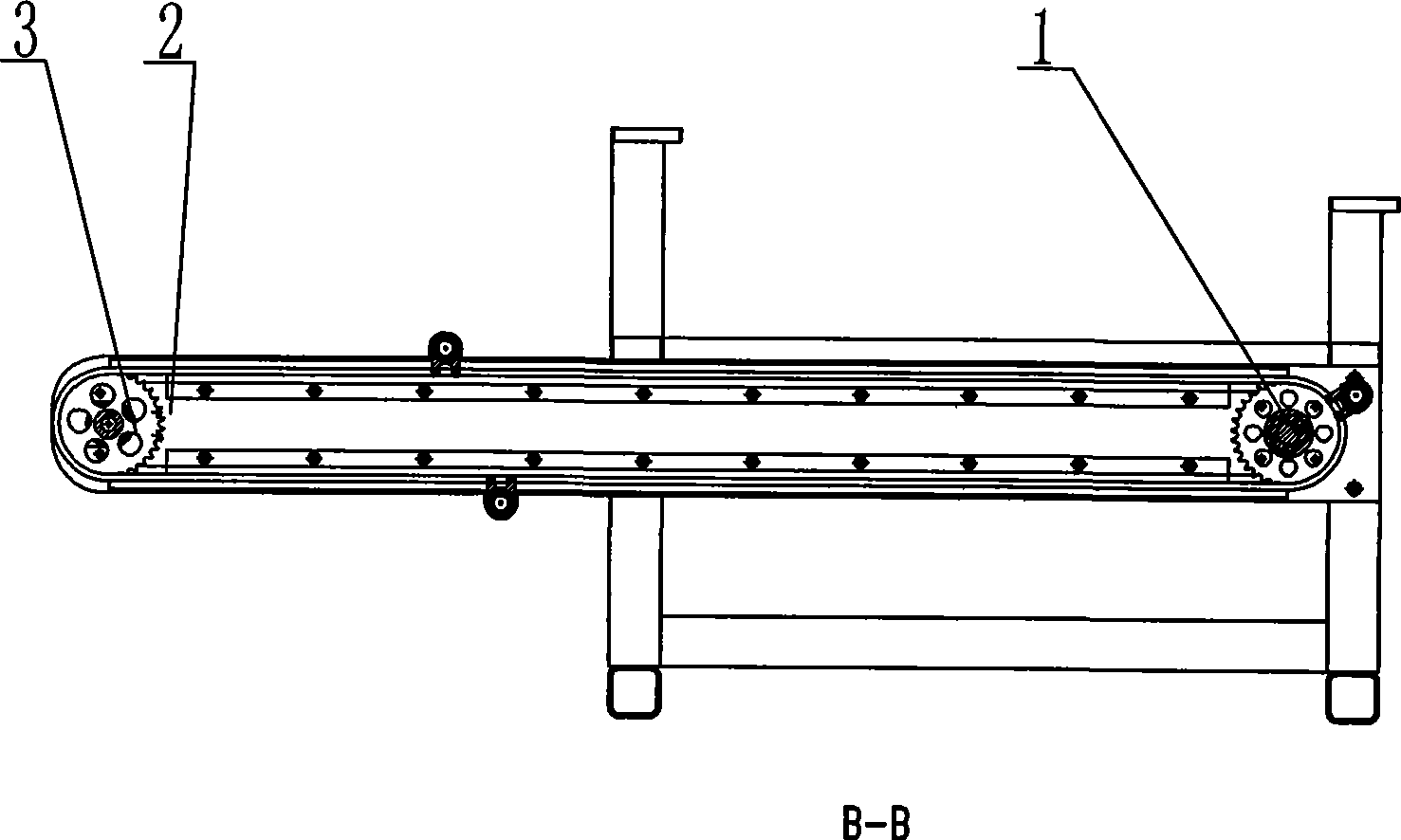

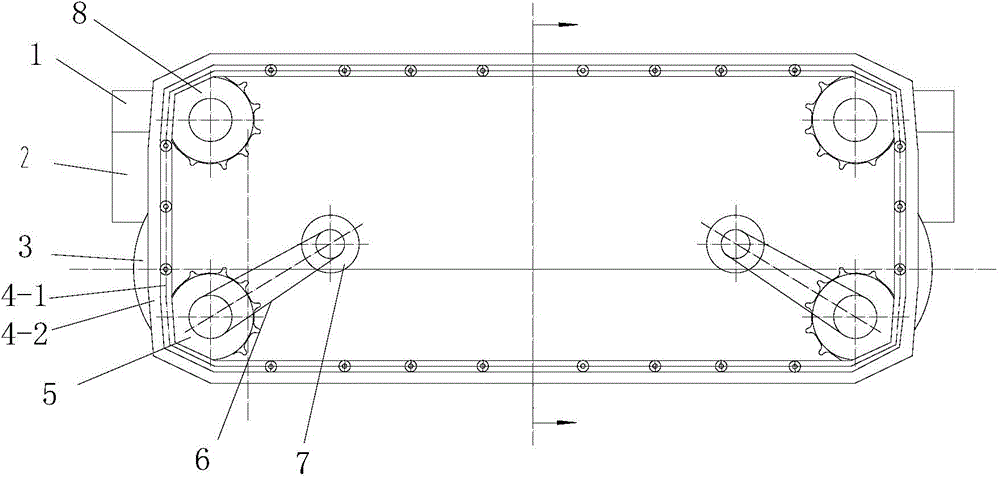

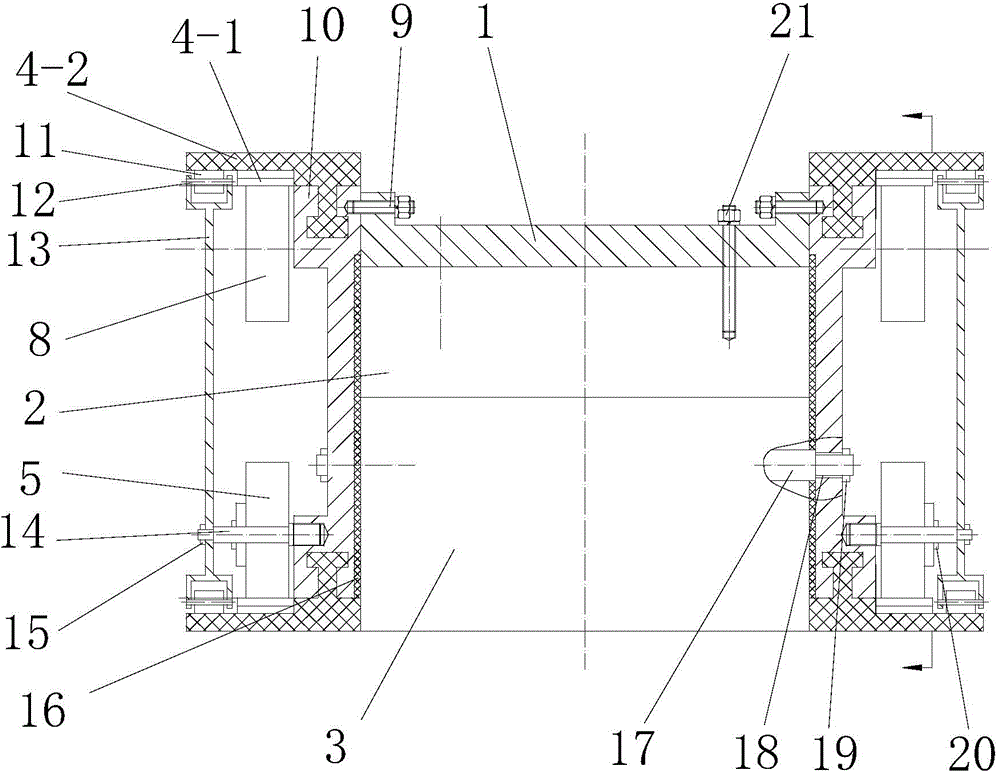

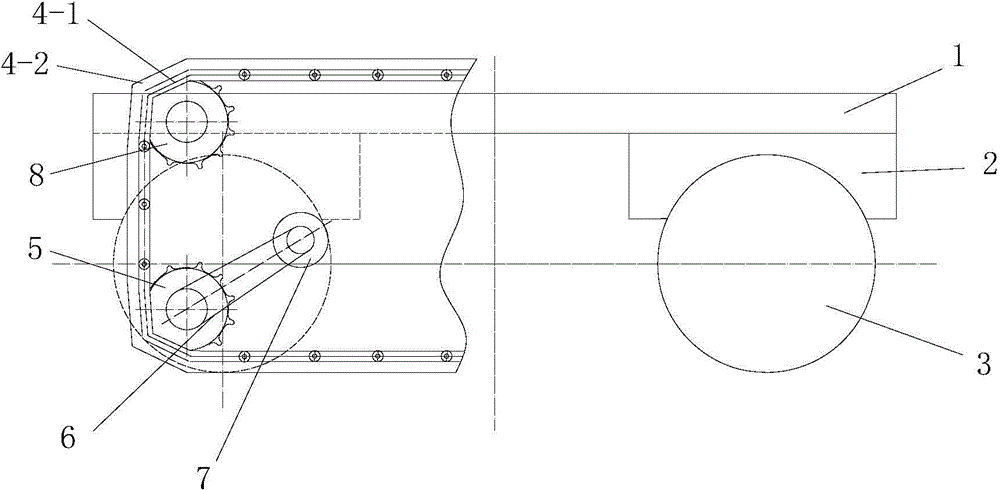

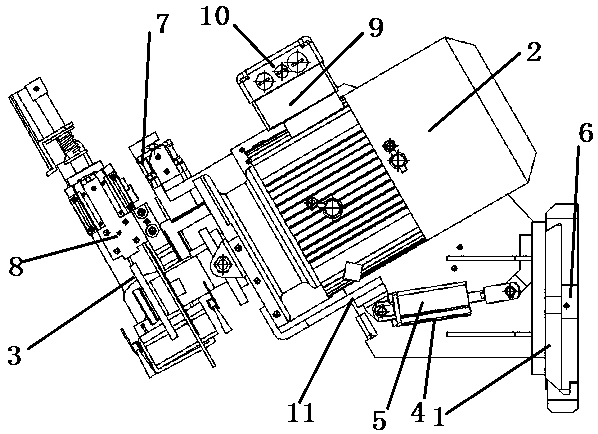

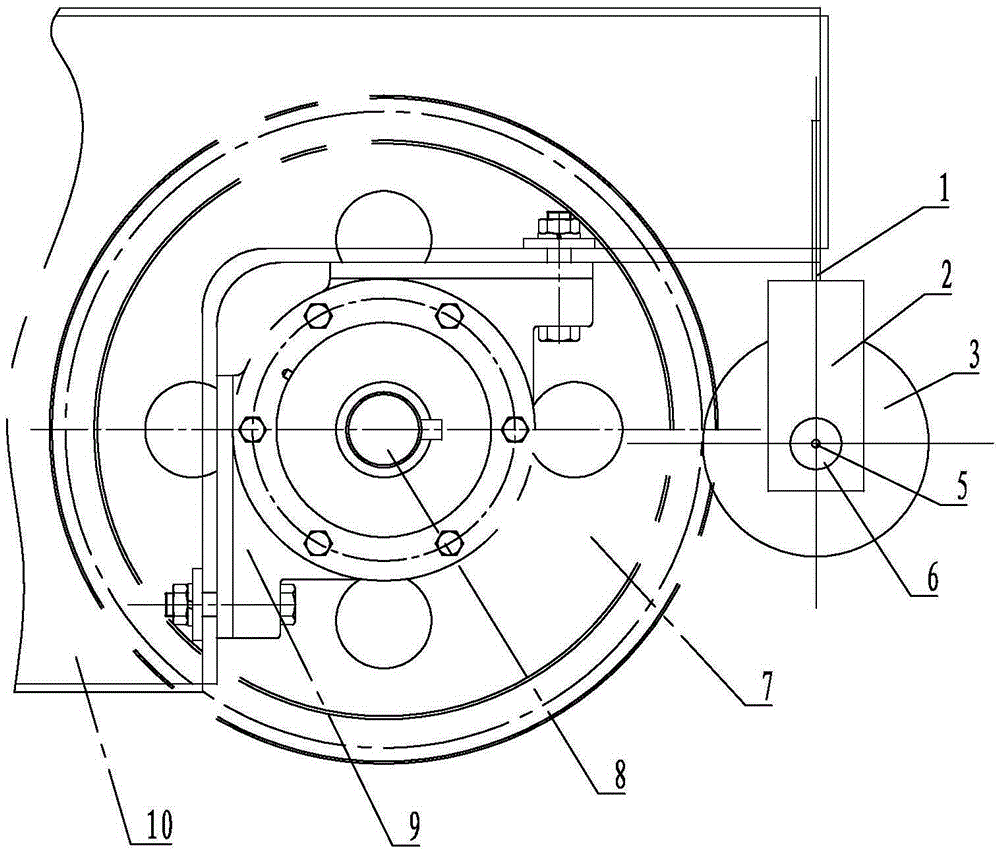

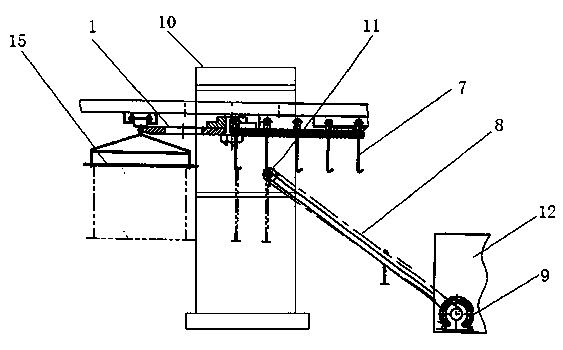

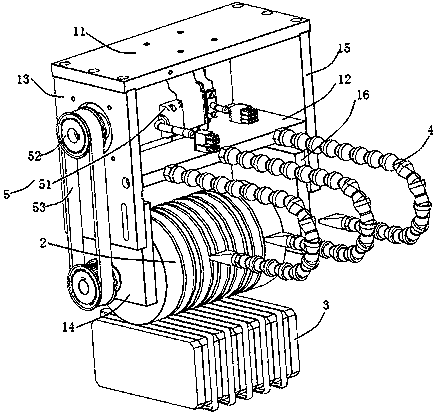

Pushing apparatus for packaging disposal sanitary article

InactiveCN101439770AAverage speed of rolloutSame line speedPaper article packagingElectric machineryManufacturing line

The invention relates to a packaging push handle device for one-off sanitary products on a production line of one-off sanitary articles, which solves the problems that the prior push handle device has low moving speed and cannot adapt to high-speed running of a machine. Two wheel shafts of the packaging push handle device run through the two ends of a left lateral plate and a right lateral plate respectively which are arranged on a machine frame; the inner lateral surfaces of the left lateral plate and the right lateral plate are provided with two chain transmission mechanisms respectively through the wheel shafts; two ends of three parallel push rod shafts are connected with two lateral chains of the chain transmission mechanism respectively; the middle parts of the three push rod shafts are provided with a push handle respectively; the outwards extending ends of the three push rod shafts are proved with a guide rod respectively; a track plate provided with a cycling track groove is arranged on the machine frame; and a pulley wheel on the end part of the guide rod is positioned in the cycling track groove. The guide rod performs track movement prescribed by the track groove together with a push handle assembly to substantially lighten the weight of a moving part; and under the condition that the motor power is unchanged, the moving speed and the moving frequency of the push handle are greatly improved to adapt to the high-speed running of the machine. The packaging push handle device has the advantages of simple and compact structure, reasonable design, and improved production capacity and production efficiency.

Owner:ANQING HENG CHANG MACHINERY

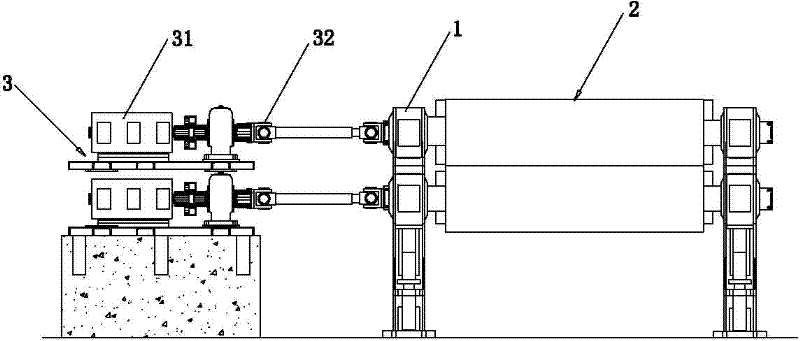

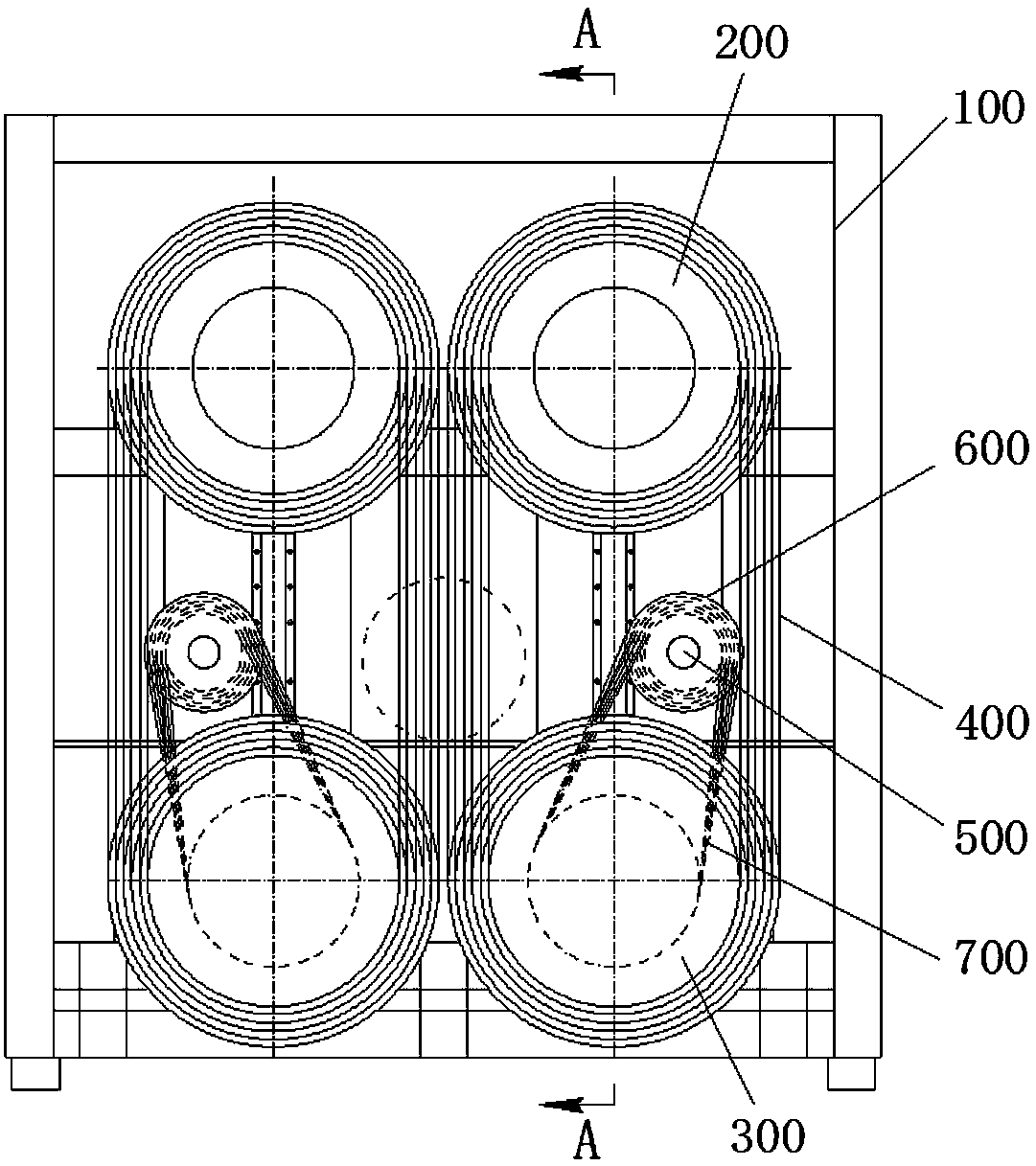

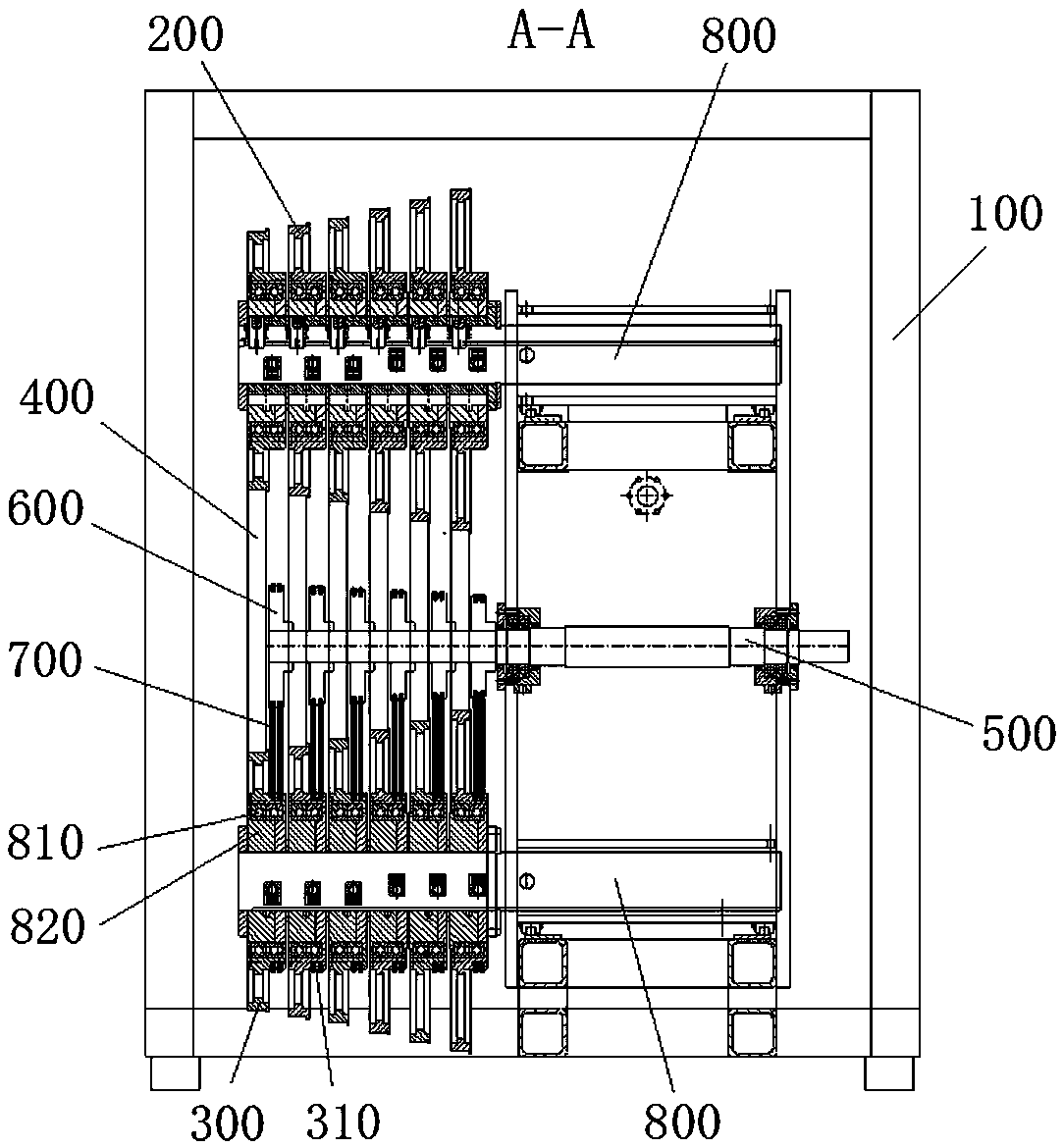

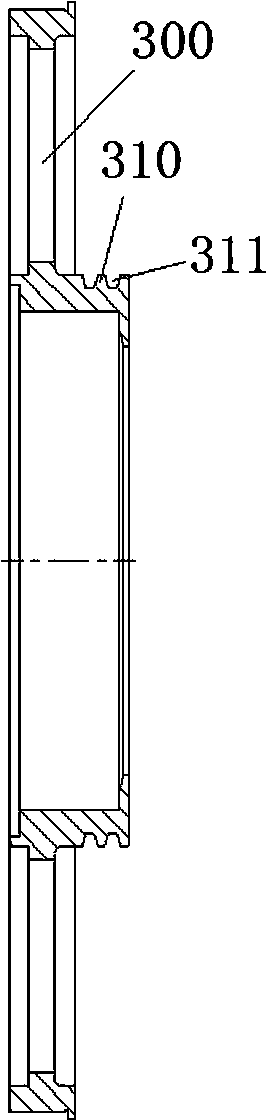

Plating press of improved structure

The invention relates to the technical field of plating presses, especially to a plating press of an improved structure. The plating press comprises a frame and a felt wrapped roll. The felt wrapped roll is connected to the frame. The felt wrapped roll comprises a top roller and a bottom roller. The plating press further comprises a roller gap adjusting system used for adjusting the gap between the top roller and the bottom roller, and a double motor apparatus. The felt wrapped roll is in driven connection with the double motor apparatus. The roller gap adjusting system comprises a PLC control system and a hydraulic pressure station. The hydraulic pressure station is connected with the felt wrapped roll. The PLC control system and the hydraulic pressure station are electrically connected. With the plating press of the improved structure of the invention, paper joints can automatically pass through the pressing zone of the felt wrapped roll, the artificial link of manual operation is decreased, the press polish effect of paper is effectively improved, and the labor intensity is reduced. The plating press of improved structure of the invention is characterized by a high automation degree and high production efficiency. The paper through the roll compacting of the plating press of the improved structure of the invention has a good quality, and the paper smoothness is much higher than the superior grade standard prescribed by national GB / T16797-2008.

Owner:GUANGDONG QIAOSHENG ANTI COUNTERFEITING MATERIALS CO LTD

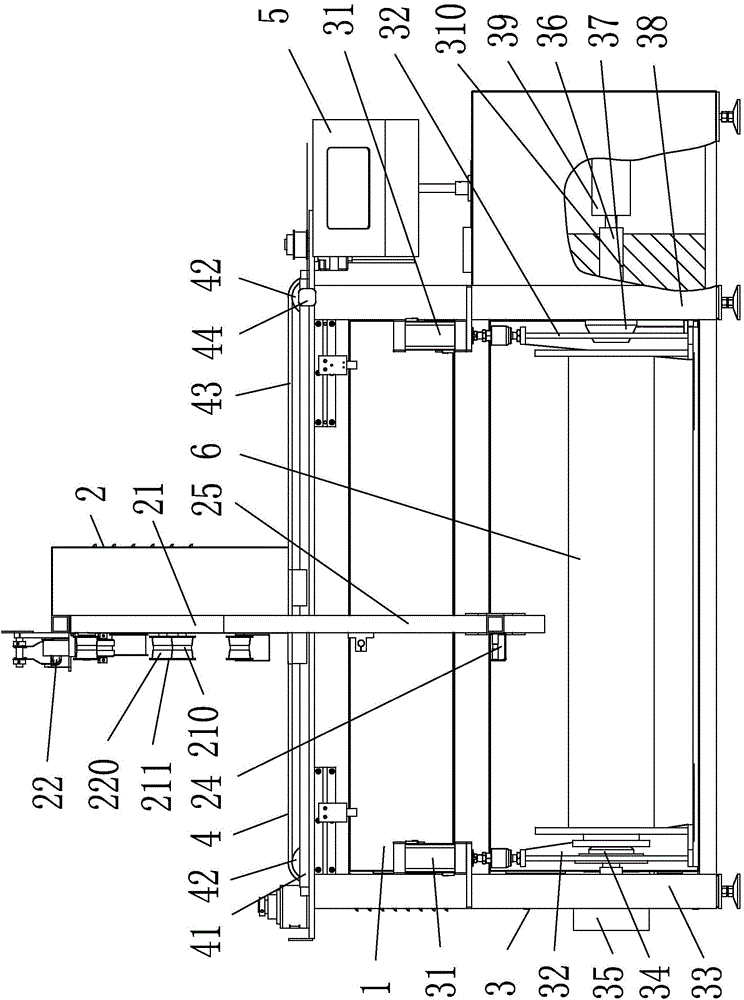

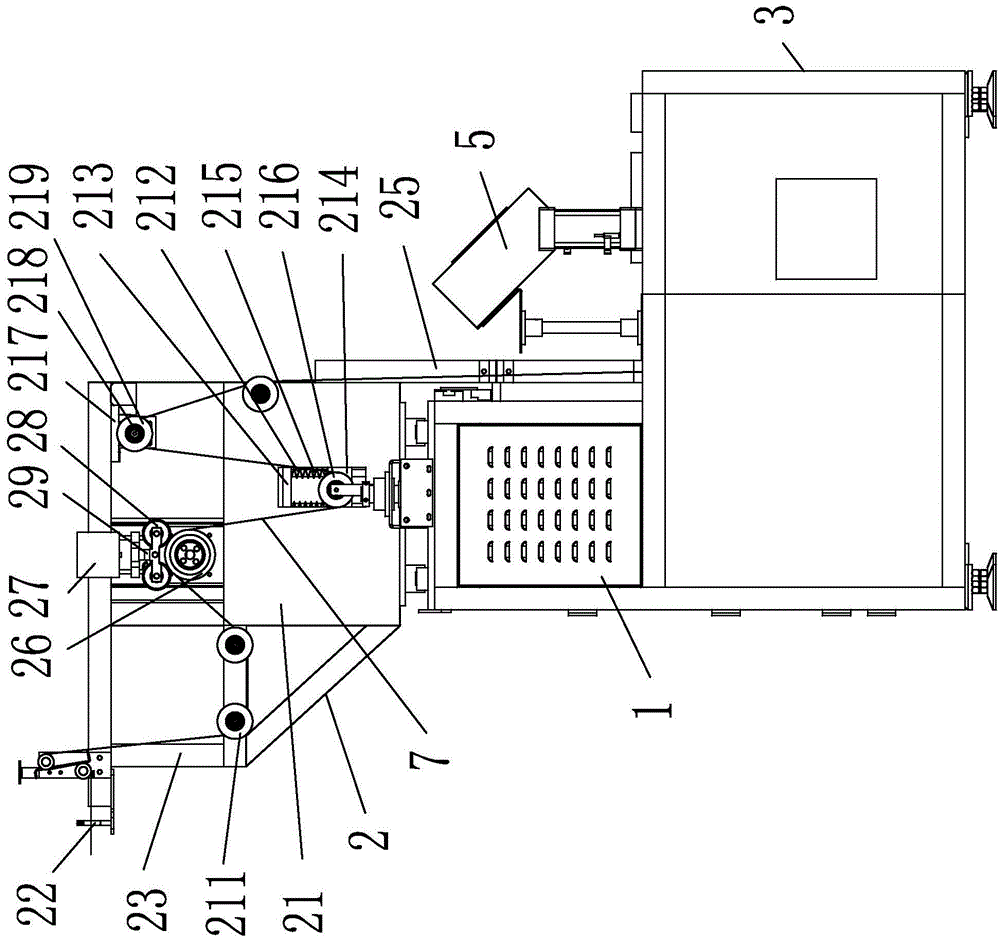

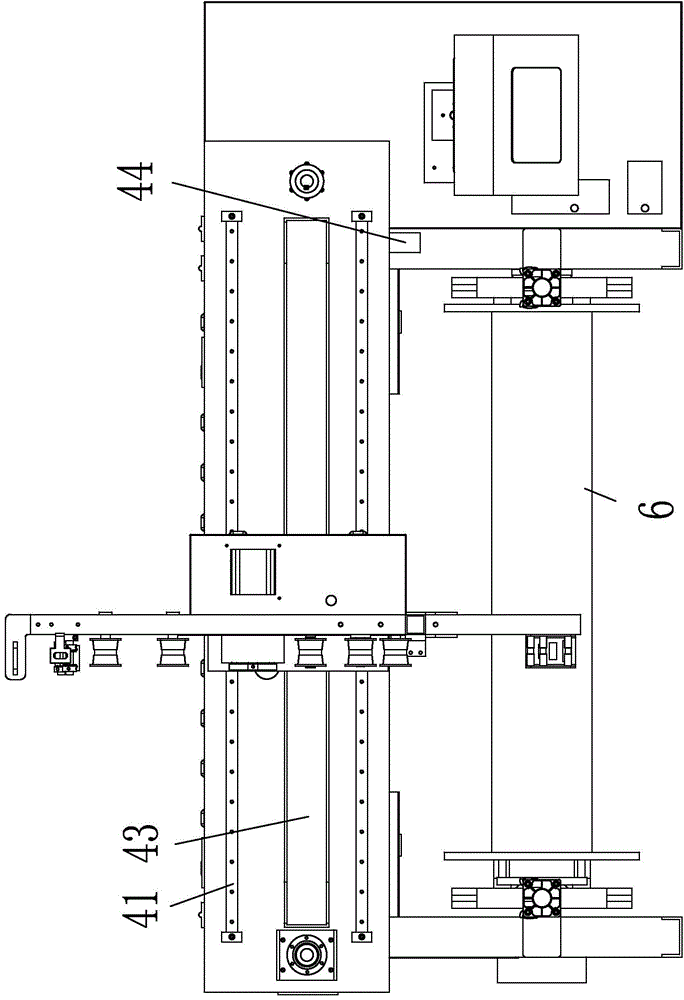

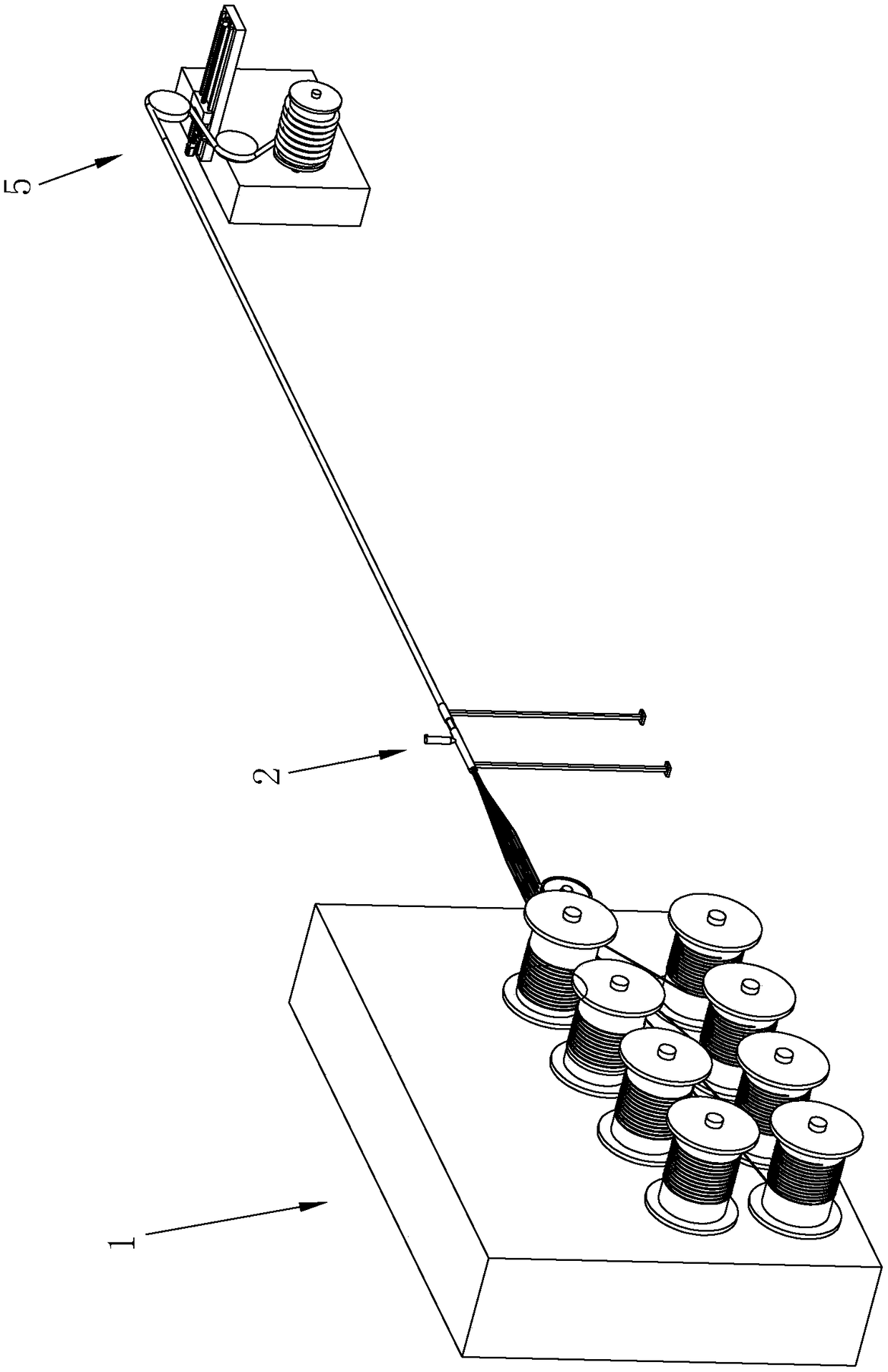

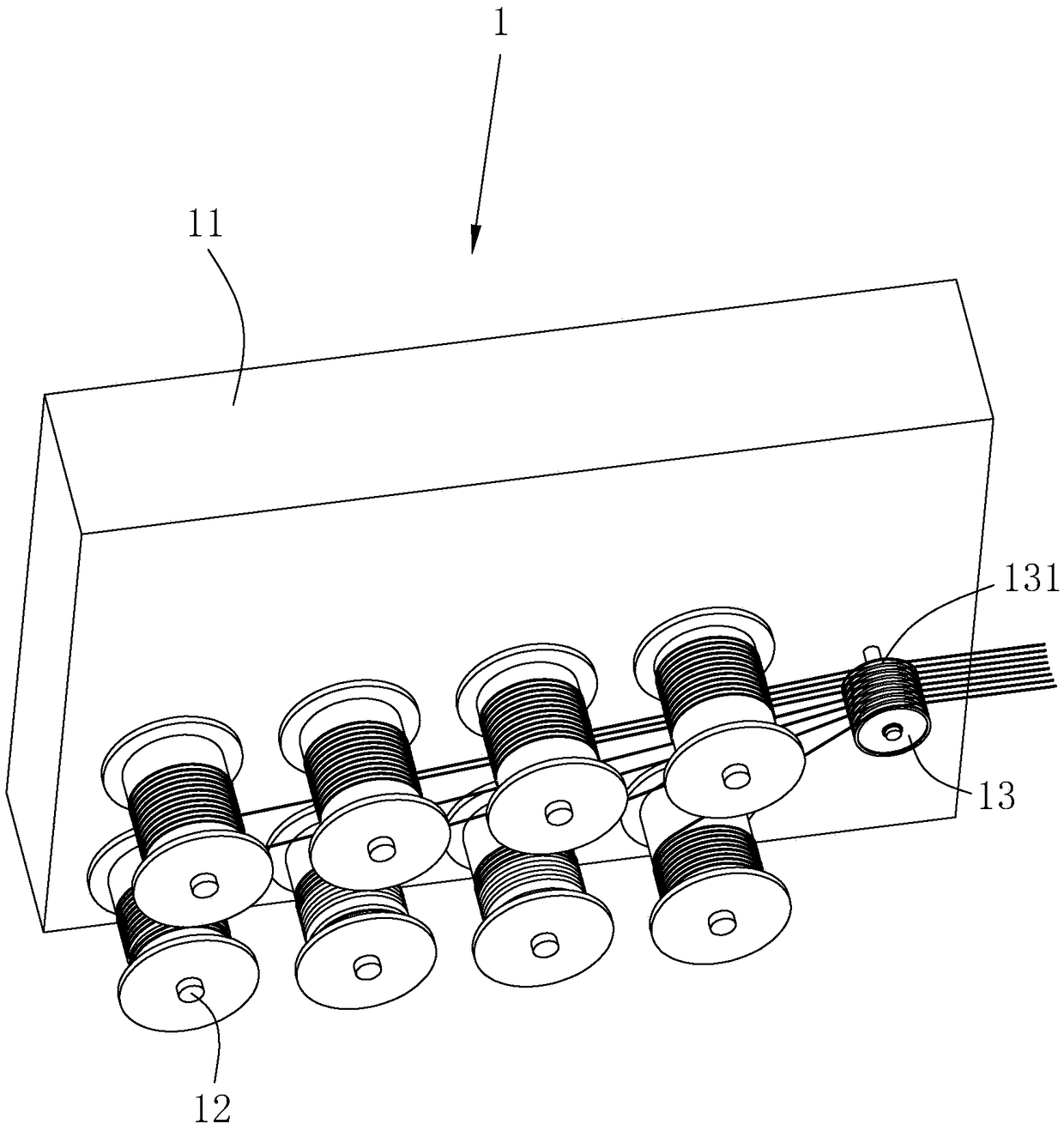

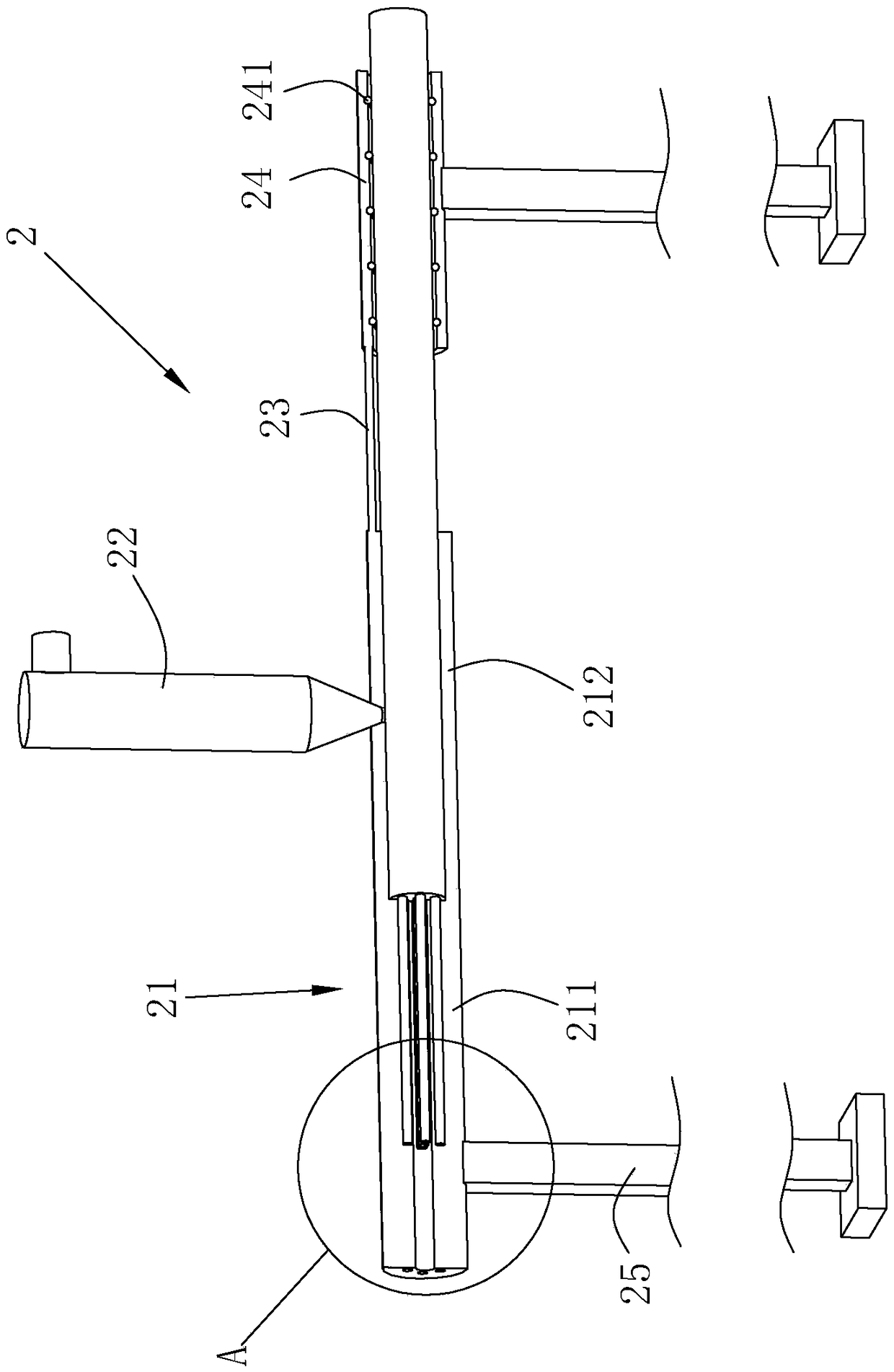

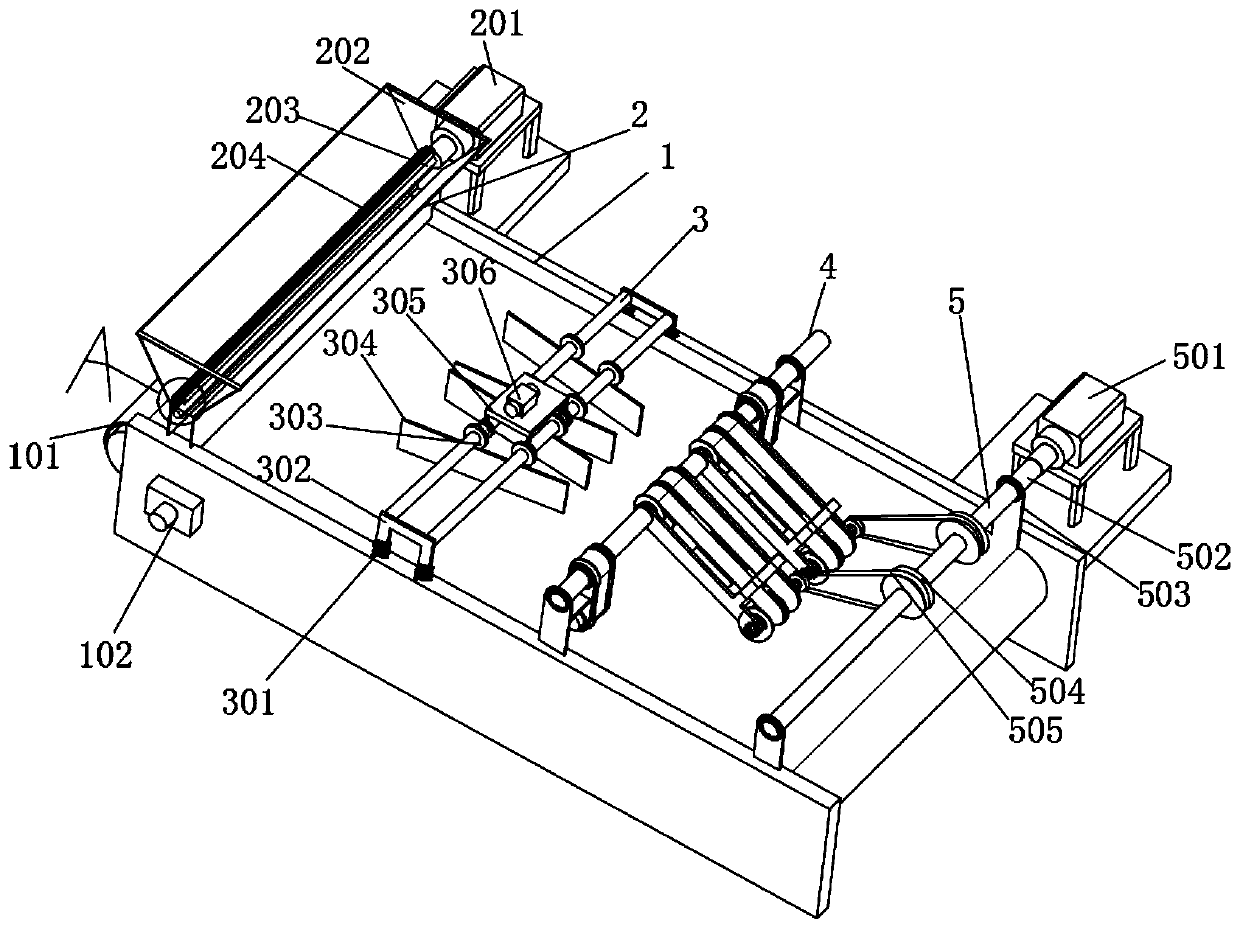

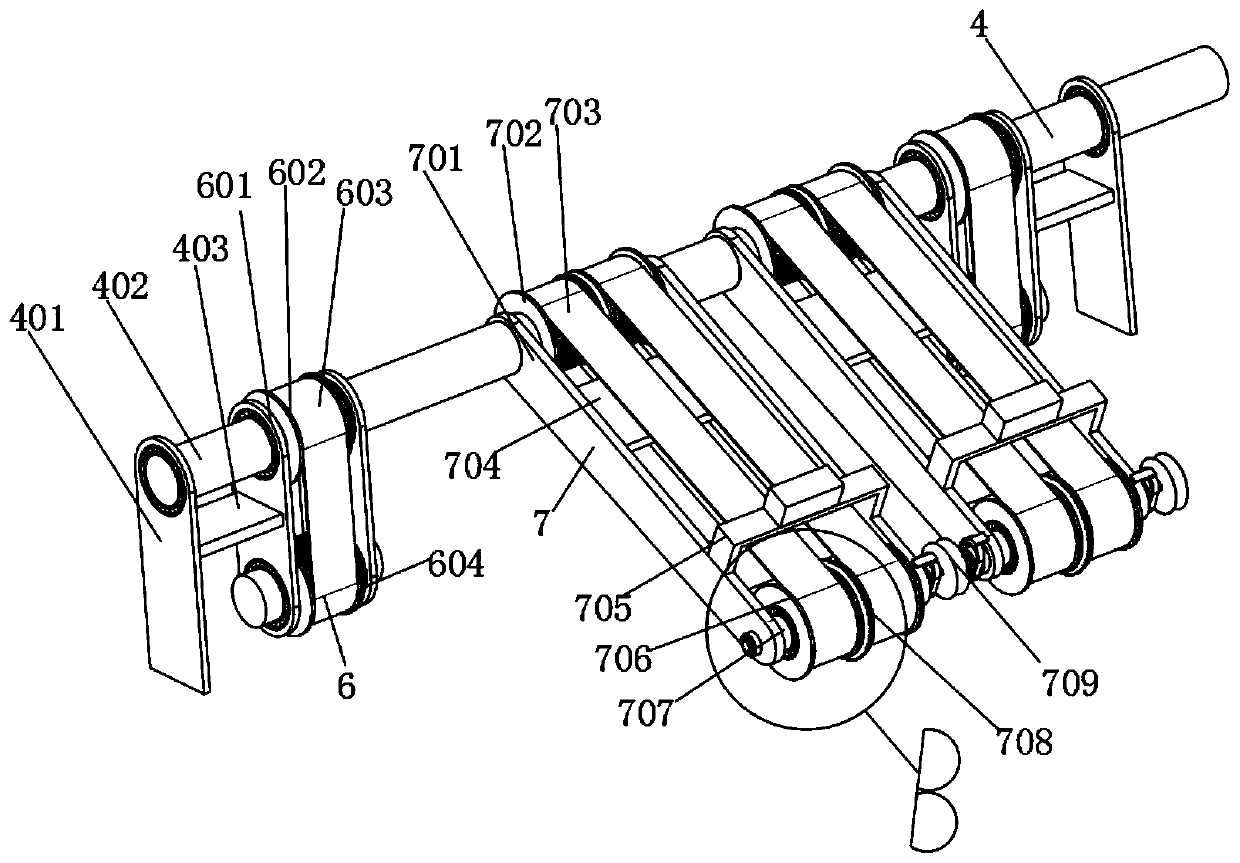

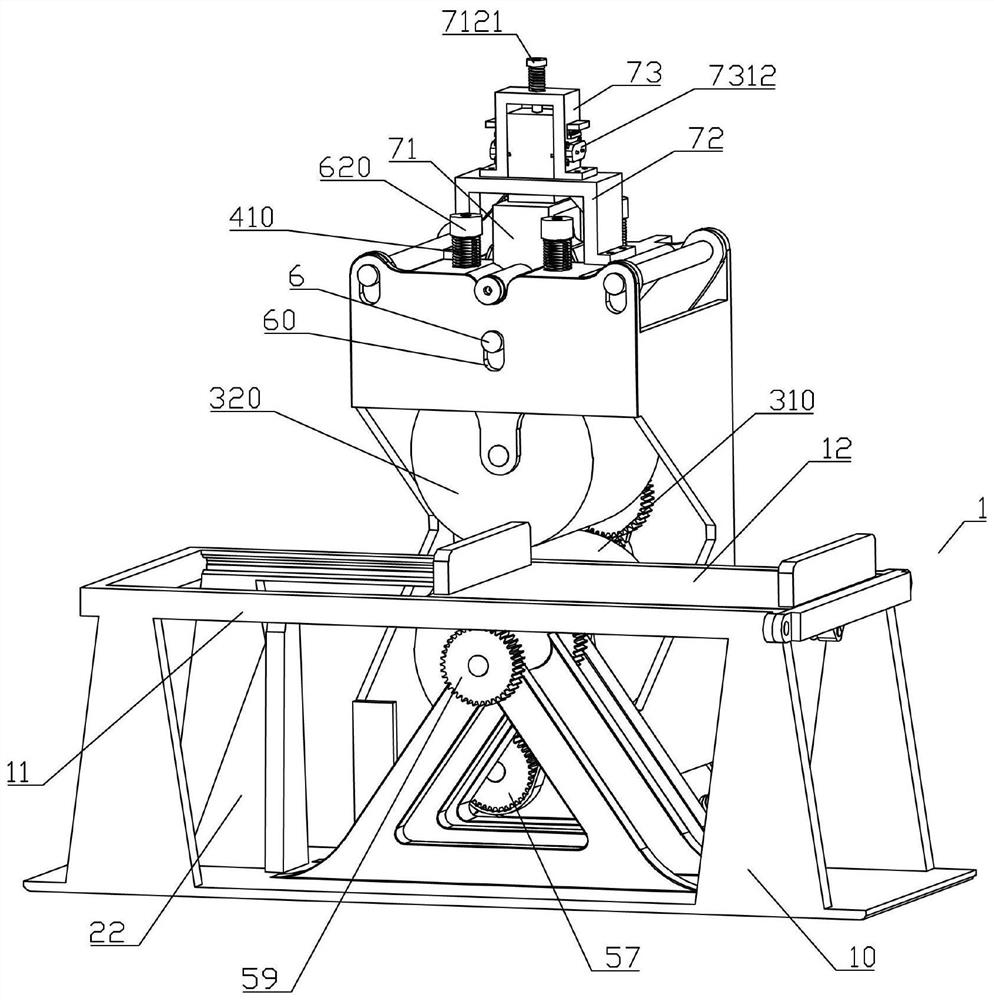

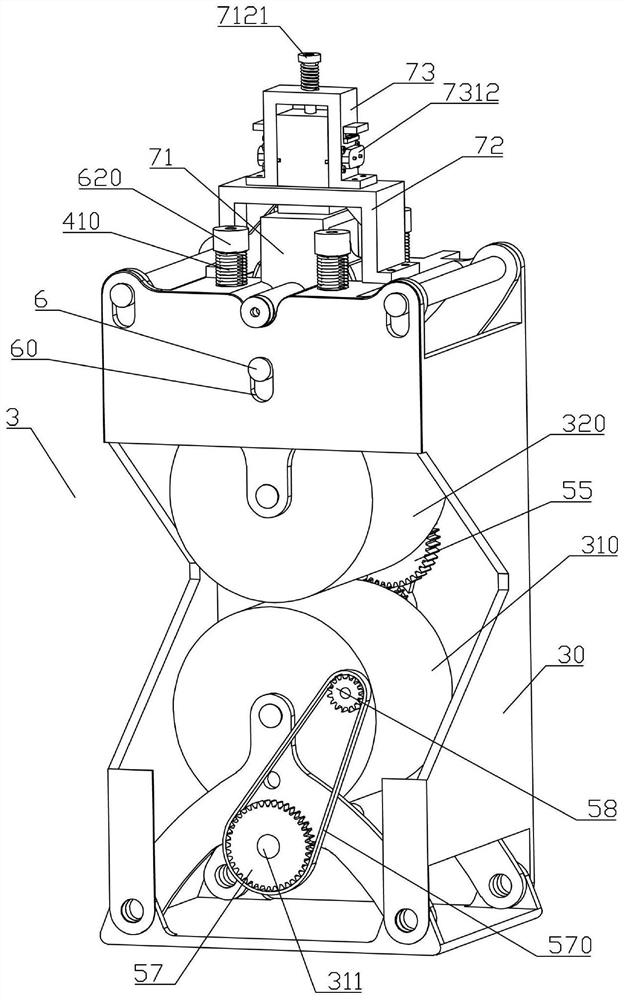

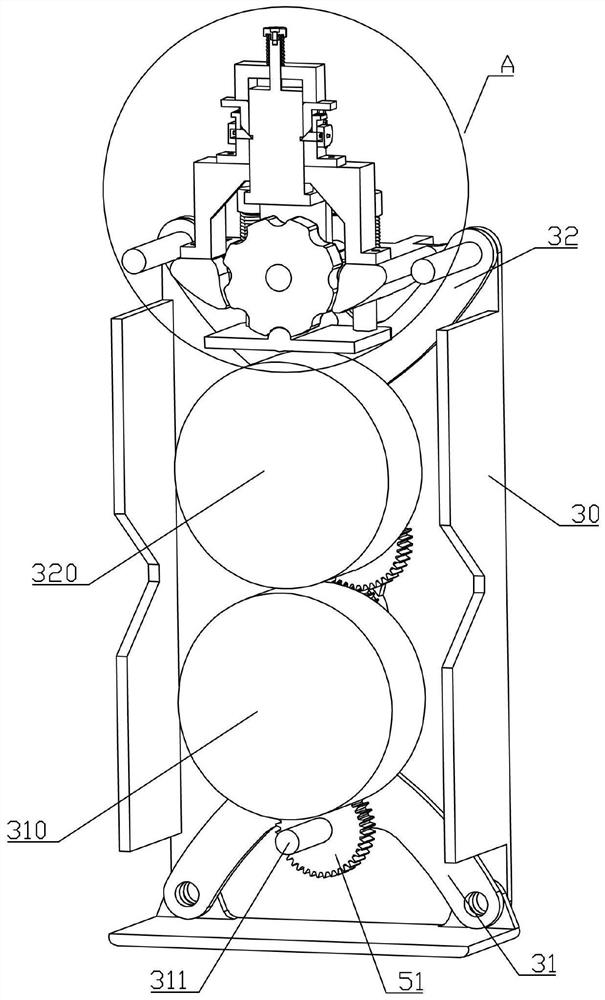

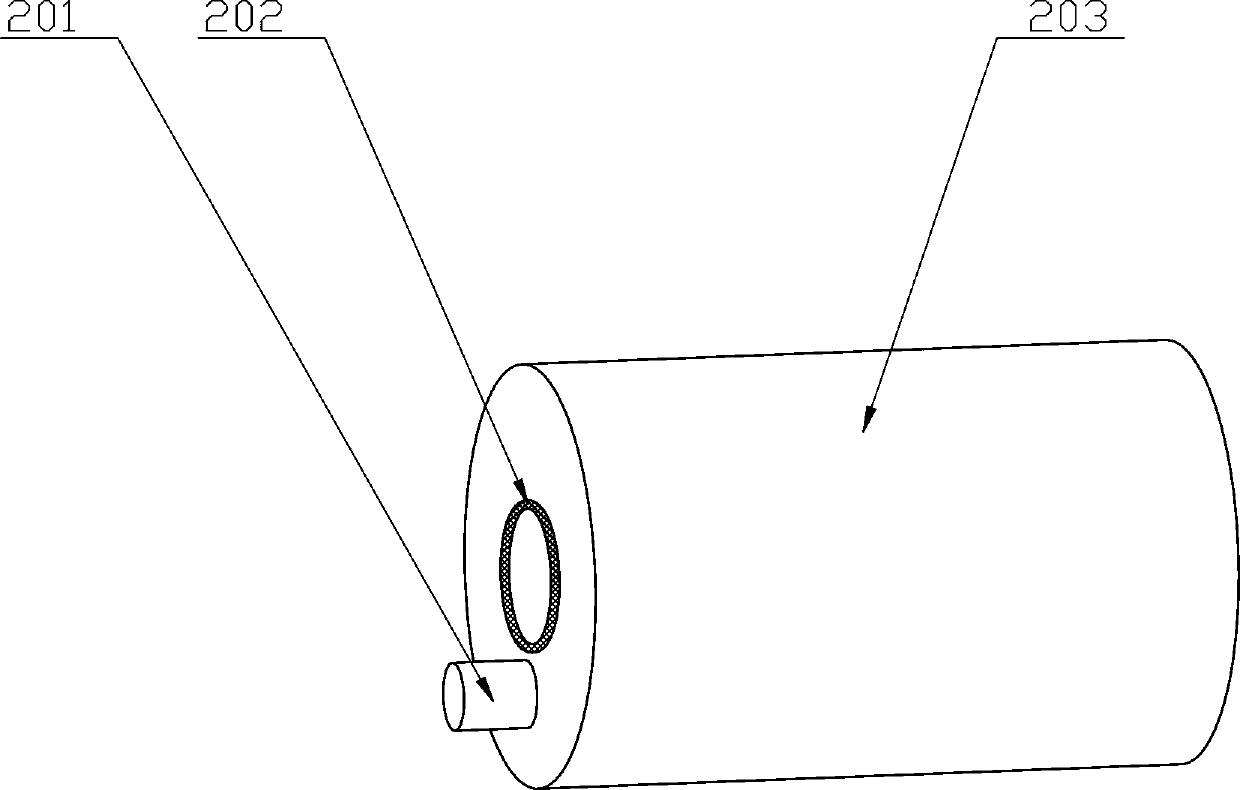

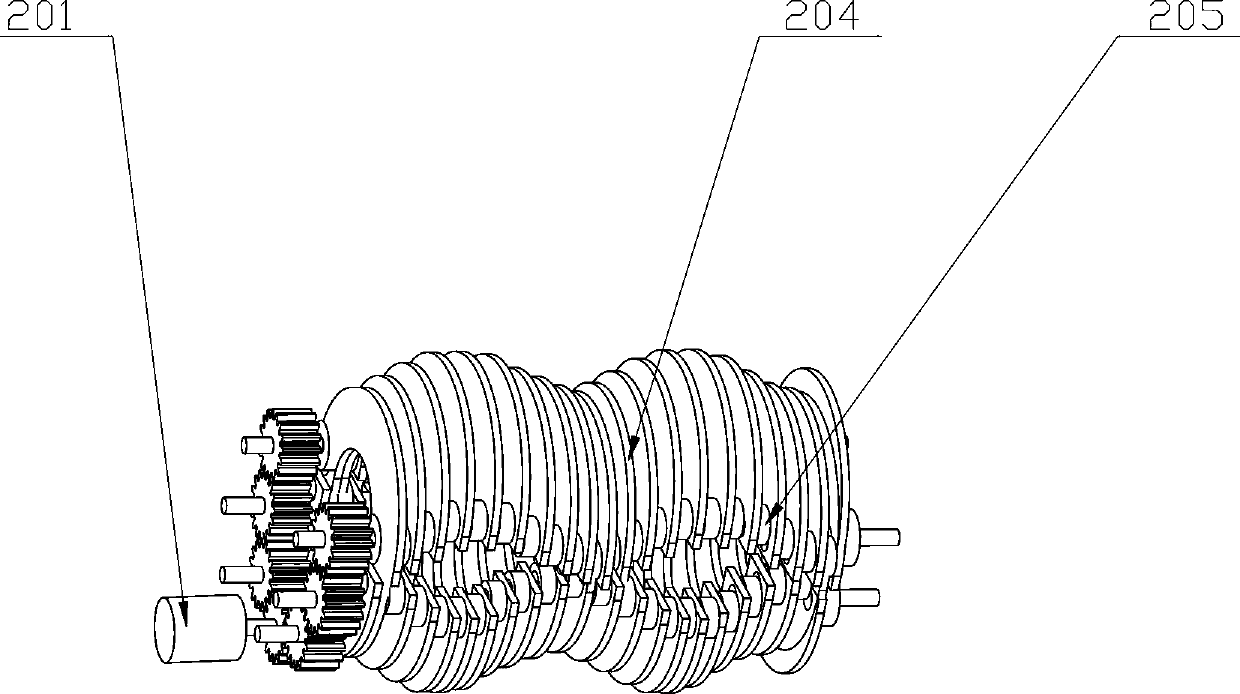

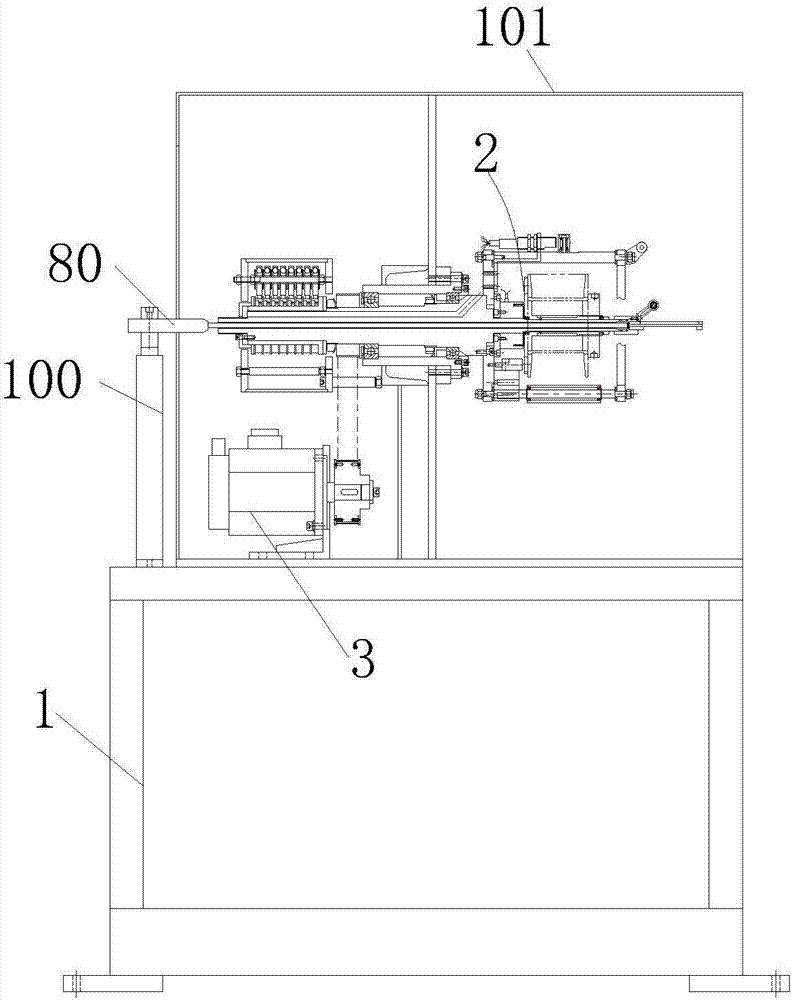

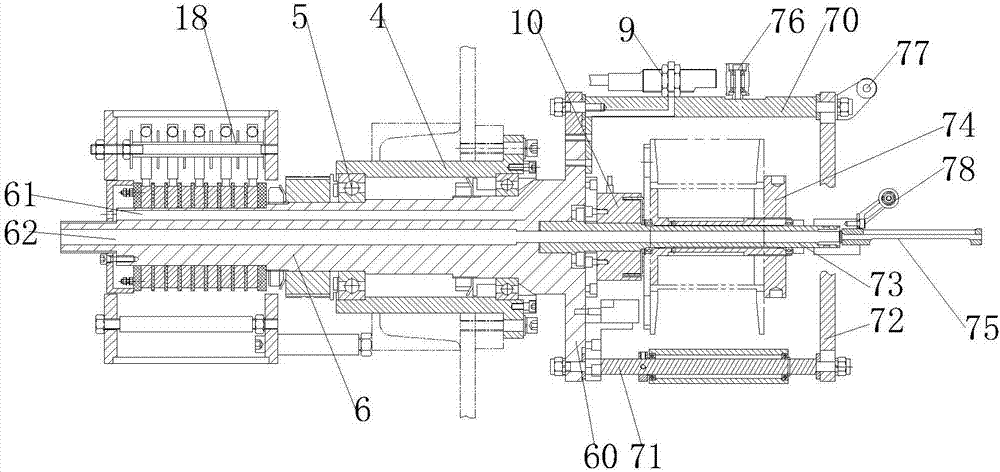

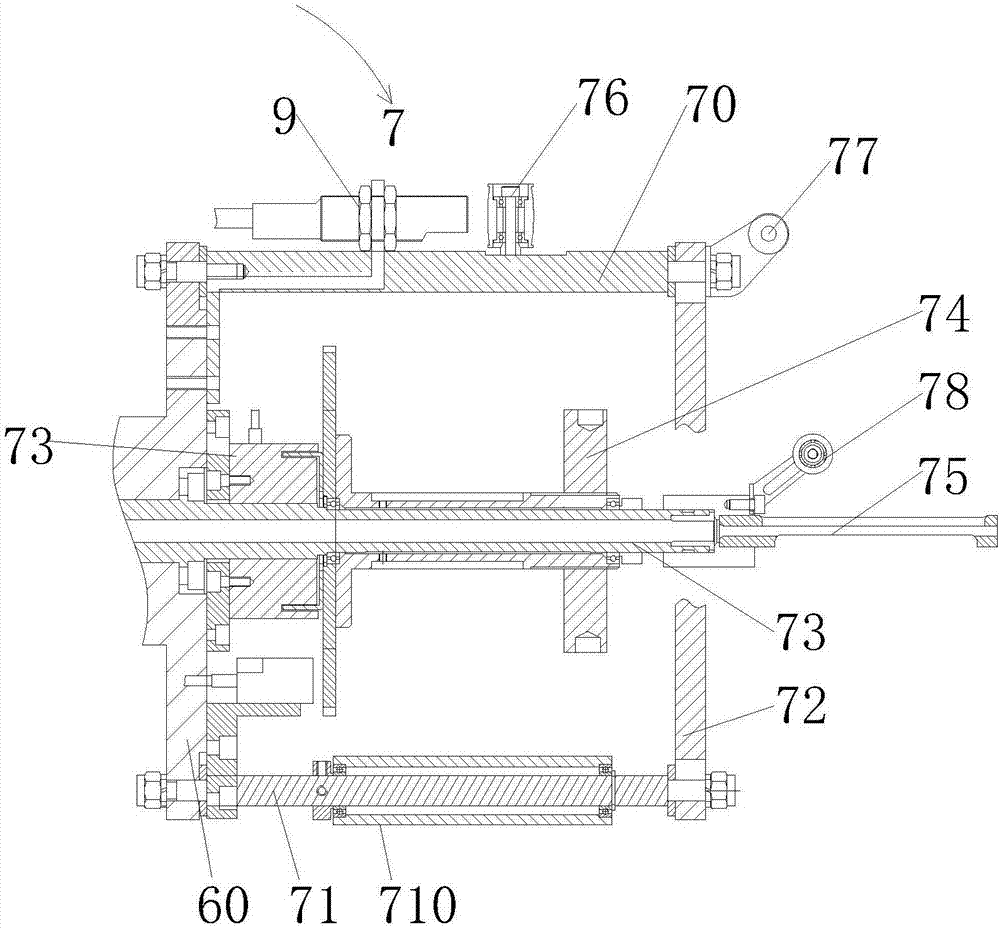

Zipper coiling machine and coiling method

InactiveCN104973448ASame line speedLine speed is simple and practicalFilament handlingColor ScaleEngineering

The invention relates to the field of zipper manufacturing, and aims to provide a zipper coiling machine and a coiling method. The zipper coiling machine comprises a machine base and a machine head, wherein the machine head is connected with the machine base. The zipper coiling machine is characterized in that the machine head comprises a speed measuring device. The zipper coiling machine further comprises a speed-adjusting coiling device and a controller. When the zipper coiling machine is used, the speed measuring device and the speed-adjusting coiling device are matched with each other, and therefore the linear speeds of zippers at the position of a coiling barrel can be kept consistent, the degrees of tightness of the interior and the exterior of a zipper coil formed through coiling can be consistent, and the color scale of the zippers can be uniform in the follow-up printing and dyeing process.

Owner:ZHEJIANG XINHONG ZIPPER CO LTD +2

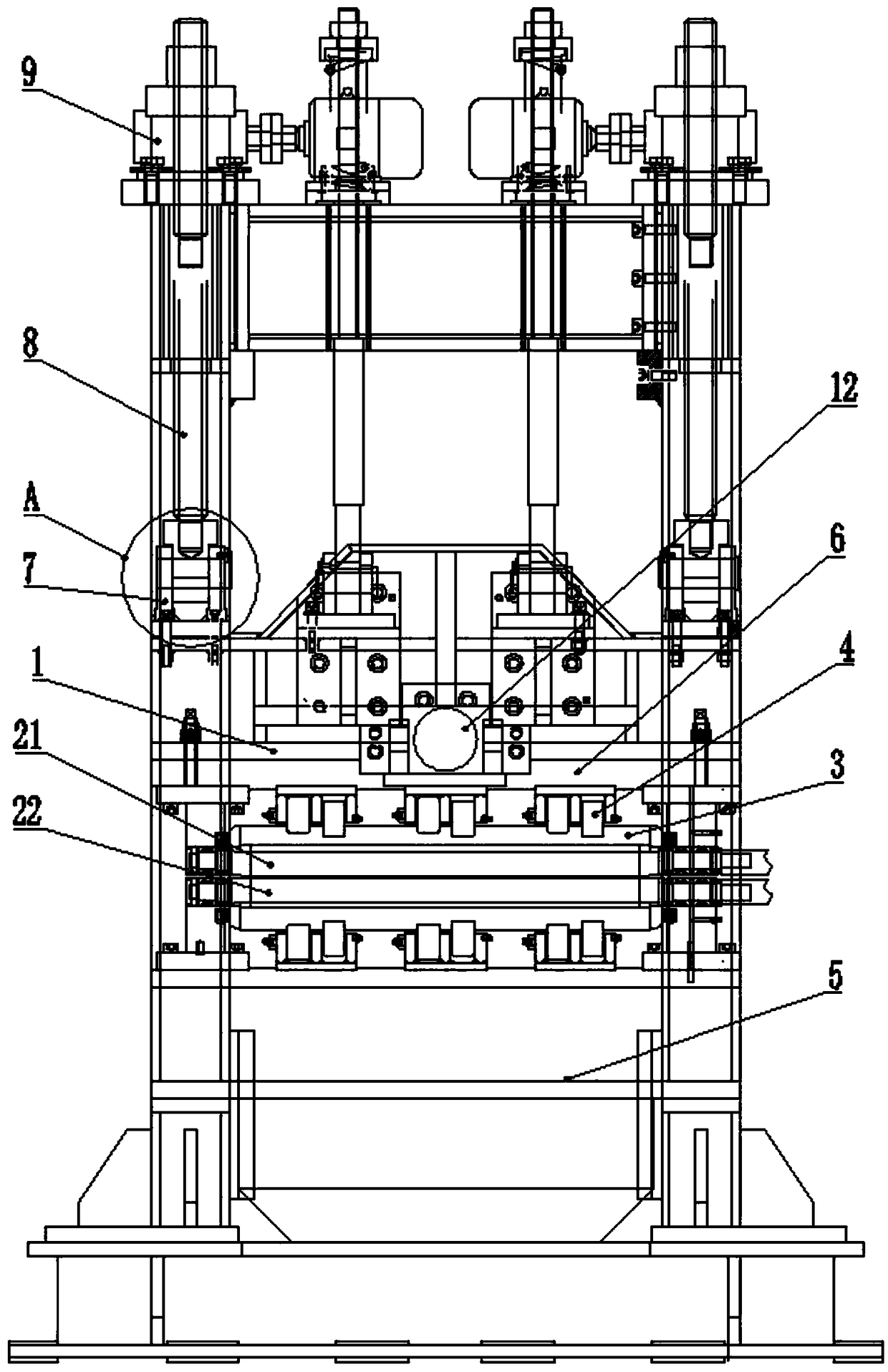

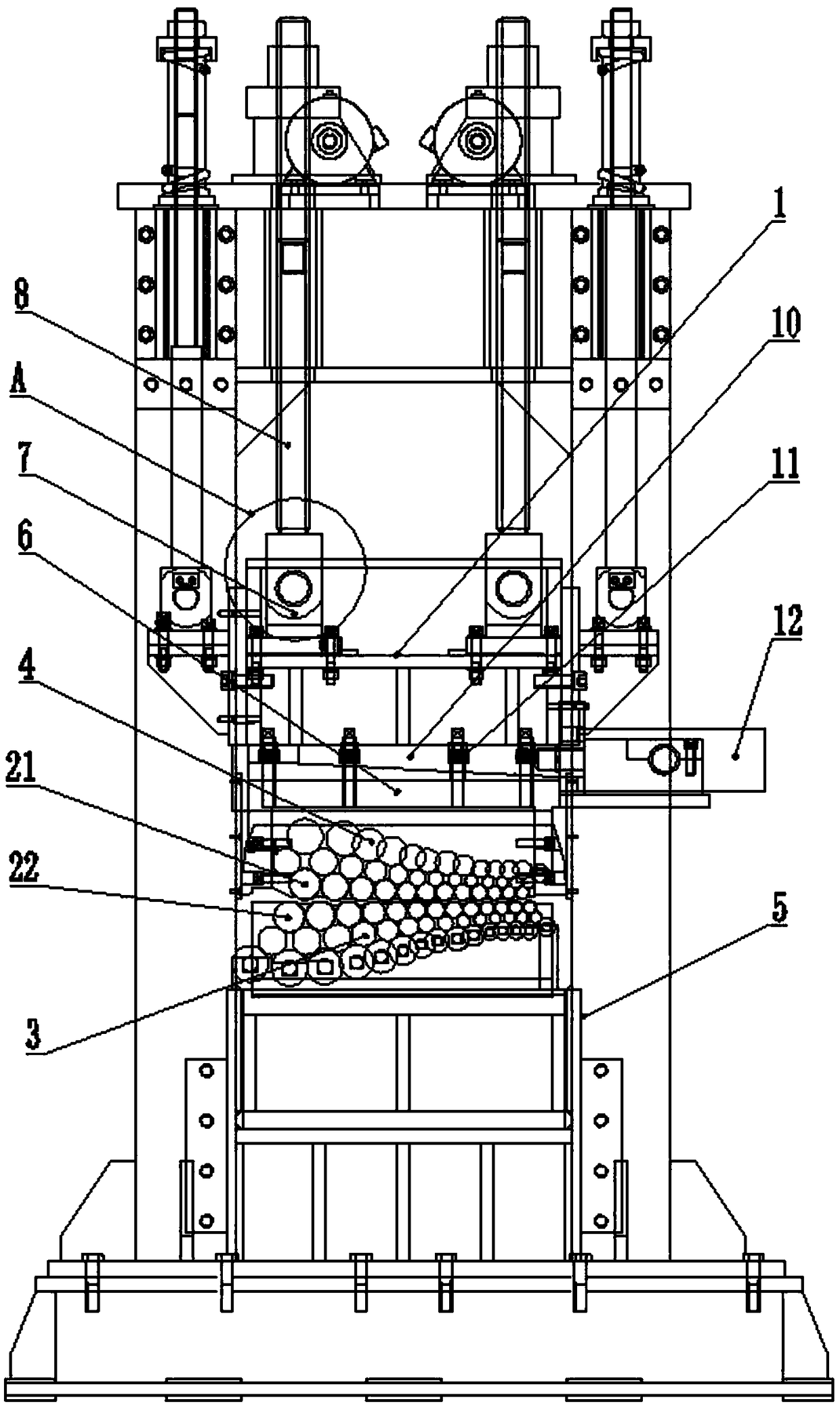

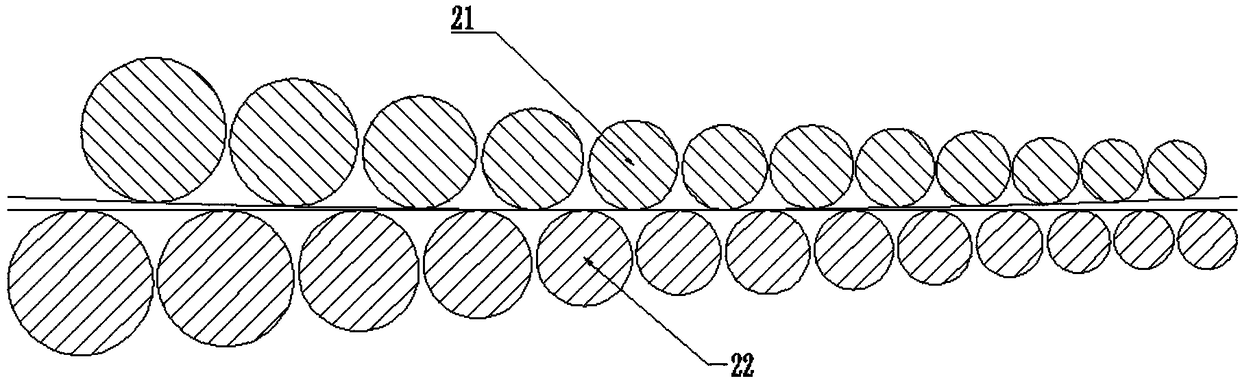

Straightening machine

ActiveCN109127782AGuaranteed Stepped GradientsImprove straightening effectProduction lineEngineering

The invention discloses a straightening machine used in the field of aluminum plate production. The straightening machine comprises an upper machine frame and a lower machine frame. An upper roller system is arranged on the upper machine frame. A lower roller system is arranged on the lower machine frame. The upper roller surface of the lower roller system is a plane. The upper roller system is arranged in a V shape in the vertical direction. The upper roller system and the lower roller system are arranged in parallel. According to the straightening machine, the lower roller system is flat, the upper roller system is arranged in the V shape in the vertical direction, and thus, aluminum plates in a wider thickness range can be straightened. A straightening machine in the prior art can onlymachine aluminum plates in the thickness range of 0.3-1.5mm and in the thickness range of 1.5-4.5mm. The straightening machine provided by the invention can machine aluminum plates in the thickness range of 0.3-6mm. Enterprises do not need to introduce production lines for machining aluminum plates within different thickness ranges anymore, the production cost is reduced, and the problem that an existing straightening machine is narrow in straightening range and cannot be used for producing aluminum plates with different thickness requirements is solved.

Owner:CHONGQING DONG CHONG ALUMINUM CO LTD

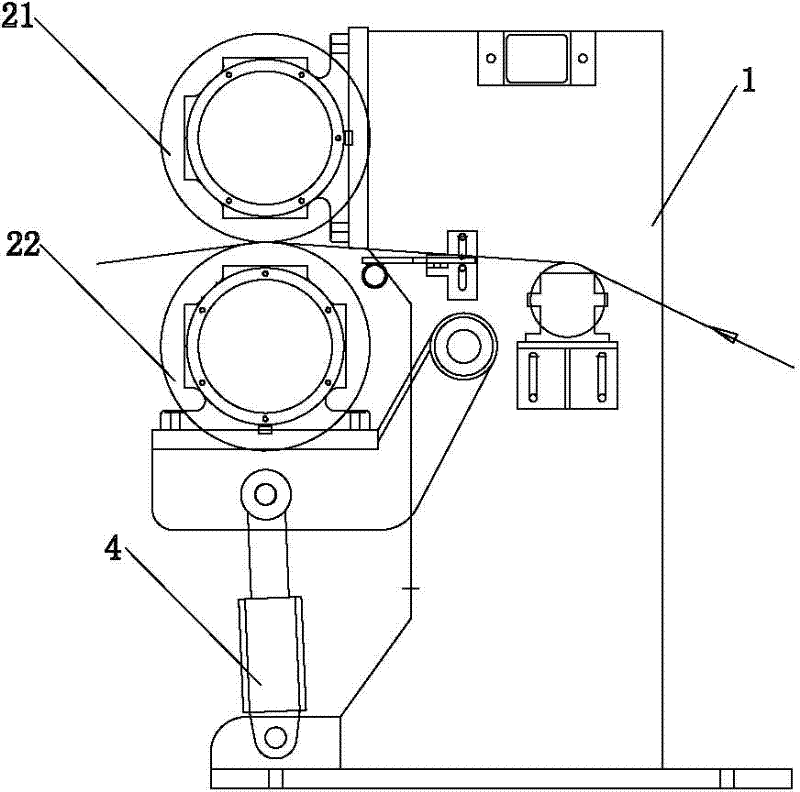

Gilding press used for special-shaped glass bottle

InactiveCN110103583APrecise positioningGuarantee hot stamping qualityRotary pressesDrive motorEngineering

The invention belongs to the technical field of gilding presses, in particular to a gilding press used for a special-shaped glass bottle. The gilding press comprises a box used for holding the gildingpress, a hot gold foil clamping structure used for clamping hot gold foil, and a tooling structure used for holding the special-shaped glass bottle, and a hot gold foil pressing structure for printing the contents of the hot gold foil on the surface of the special-shaped glass bottle, and further comprises a rotating structure comprising a driving motor and a rotating frame; the rotating frame and the box are rotationally connected in the horizontal plane, and the end, away from the box, of the rotating frame is connected with the tooling structure; one end of the rotating frame is provided with a gear plate; and the driving motor is mounted on the box, and the output end of the driving motor is provided with a driving gear engaged with the gear plate. According to the gilding press provided by the invention, the problems of filling-in, stretching, defects and the like of thermoprinted characters and / or patterns of the special-shaped glass bottle can be well avoided; and by means of asector approach, the situation that due to linear speed inconsistence of the special-shaped glass bottle in the thermoprinting process, the hot gold foil is insufficient in tension, and consequentially, the product quality is low is compensated.

Owner:成都市德工智动科技有限公司

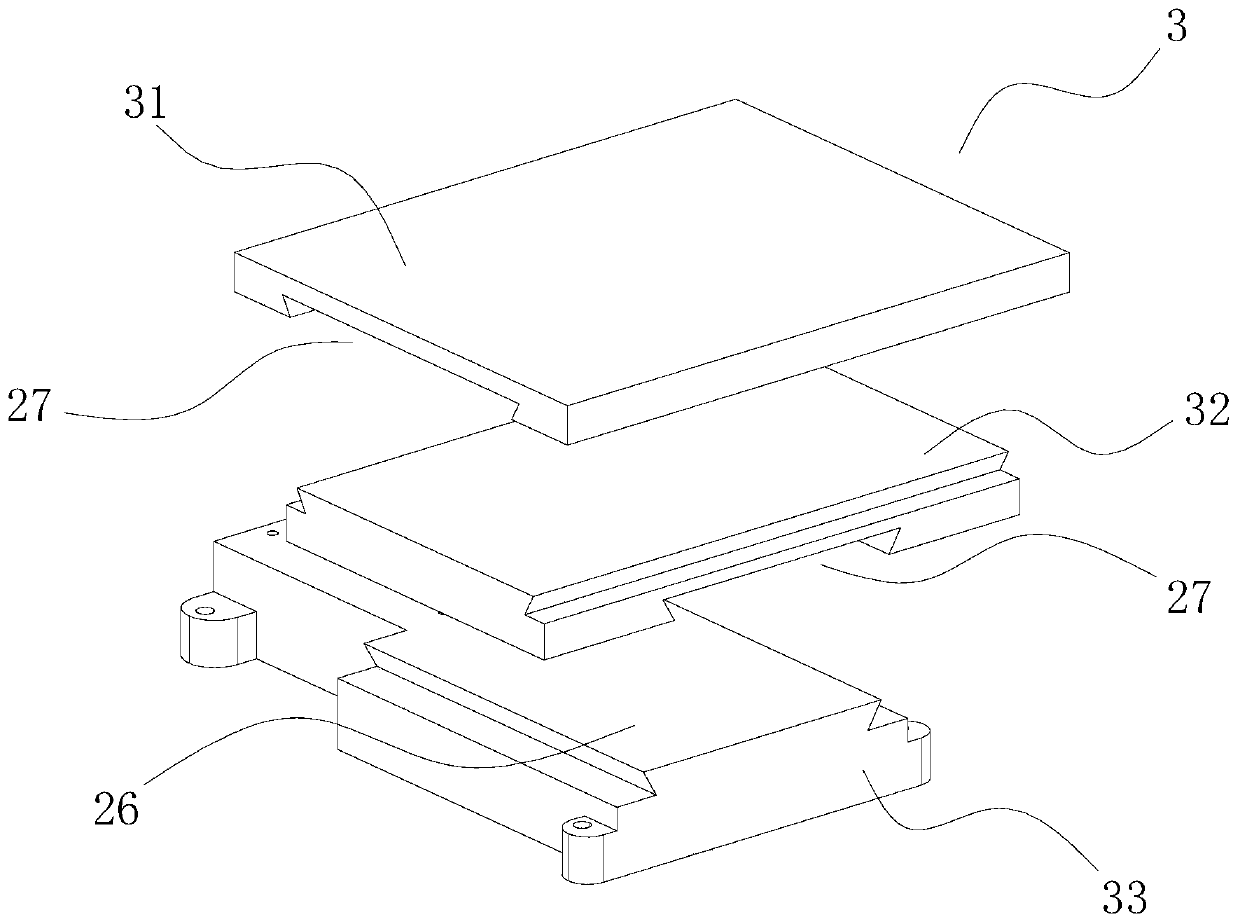

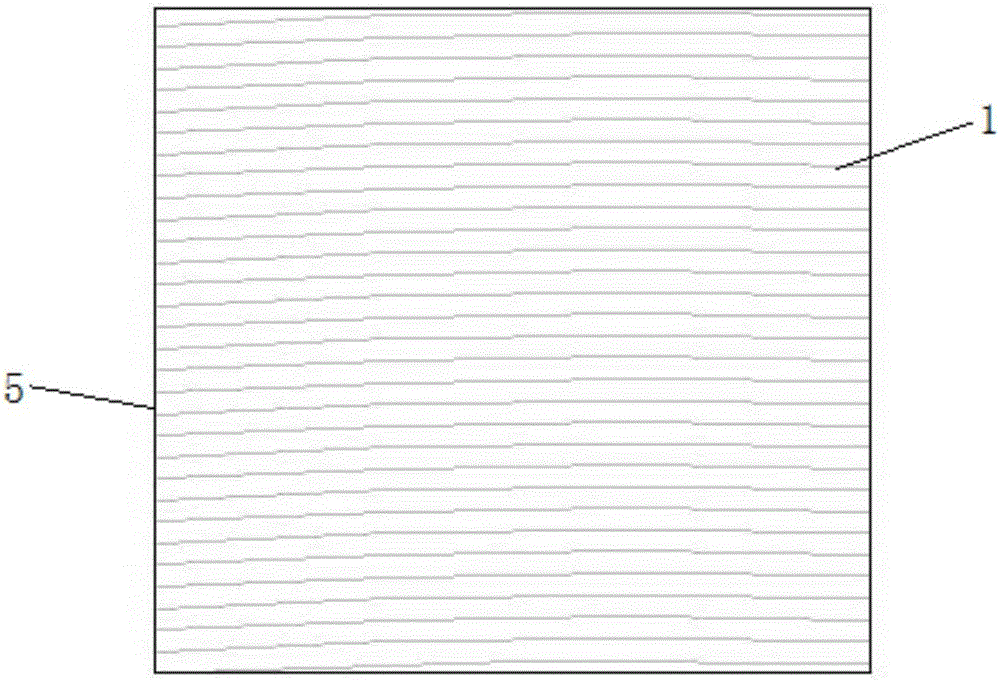

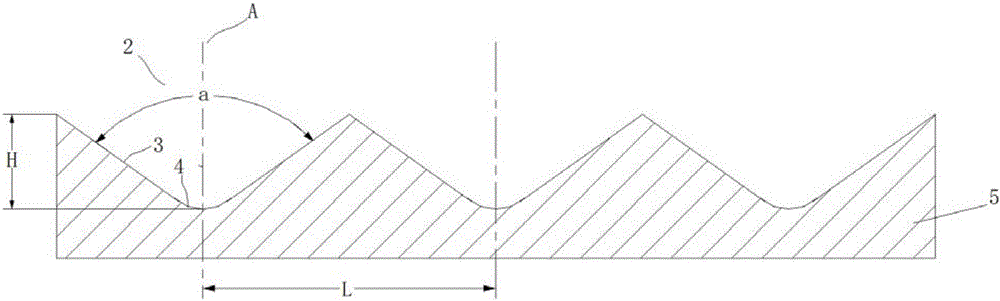

Metal piece, machining method for surface veins of metal piece and electronic equipment

The invention relates to the technical field of machining of metal pieces, in particular to a metal piece, a machining method for surface veins of the metal piece and electronic equipment. The surface veins of the metal piece include multiple spaced strip-shaped ripples; each strip-shaped ripple is overally arched; the multiple strip-shaped ripples are projected in the same direction; a groove of each strip-shaped ripple includes two first inclined surfaces, and a first arc surface for connecting the two first inclined surfaces; the two first inclined surfaces and the first arc surface are symmetrically arranged about a vertical center surface; the horizontal distance between the two first inclined surfaces is gradually increased from bottom to top; and the first arc surface is downwards projected. The veins are set to form a bright vertical line appearance effect on a metal surface; and along with change of an observing angle, bright vertical lines are changed, so that the surface fineness of the metal piece is improved. The machining method for the surface veins of the metal piece for machining the metal piece can machine out the veins on the surface of the metal piece. The electronic equipment comprises the metal piece.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

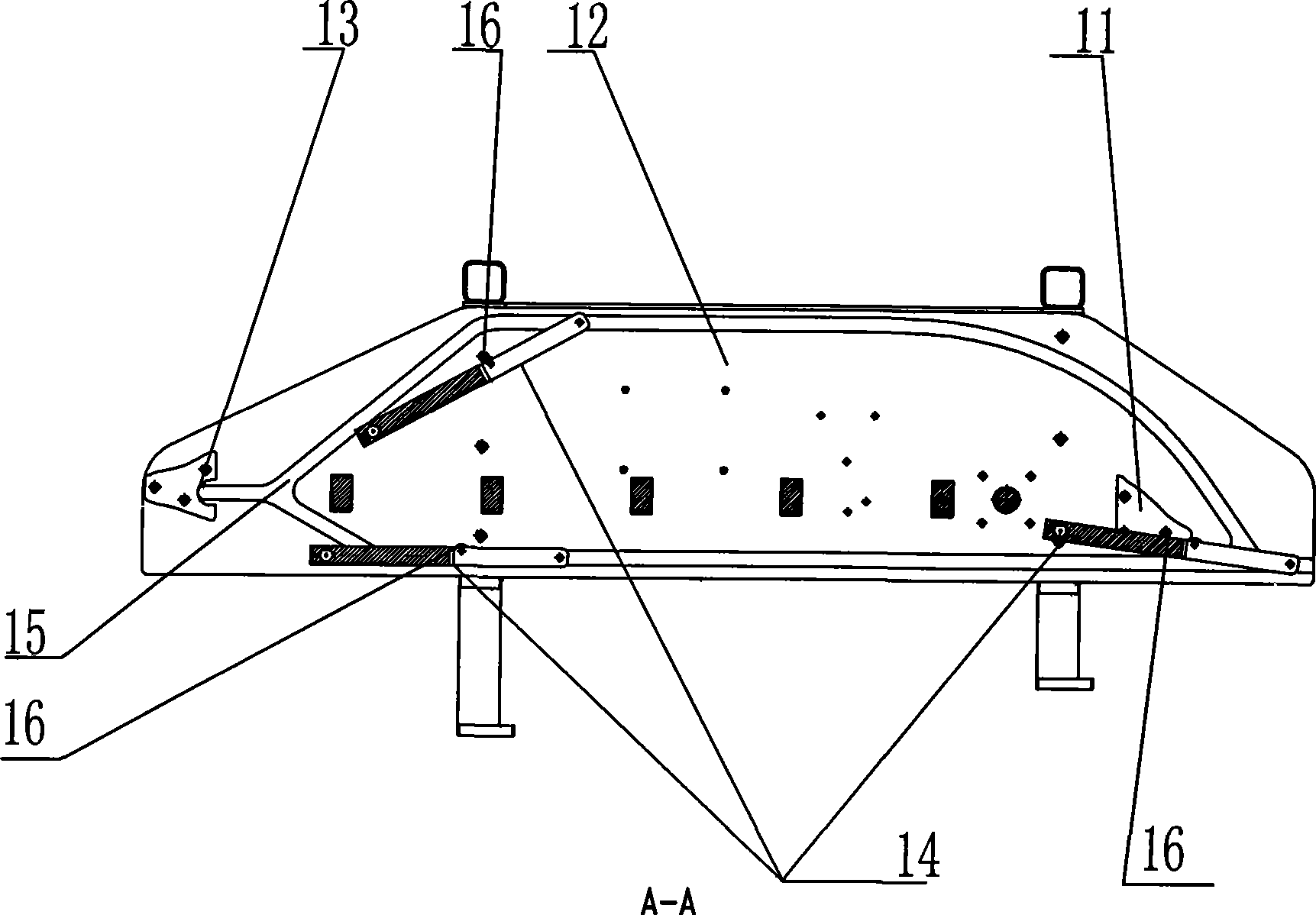

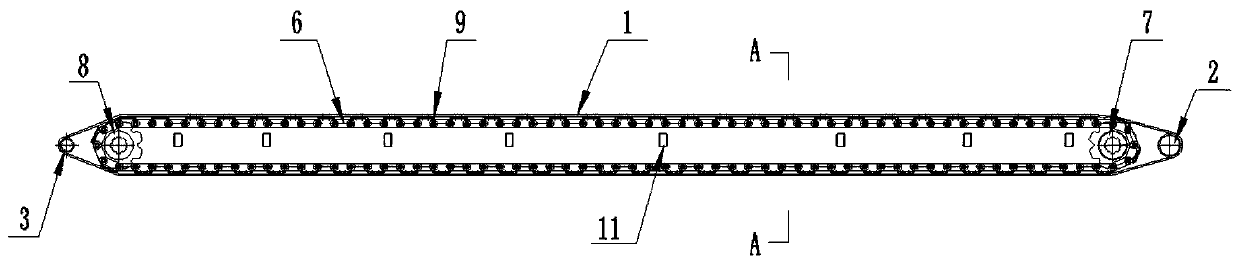

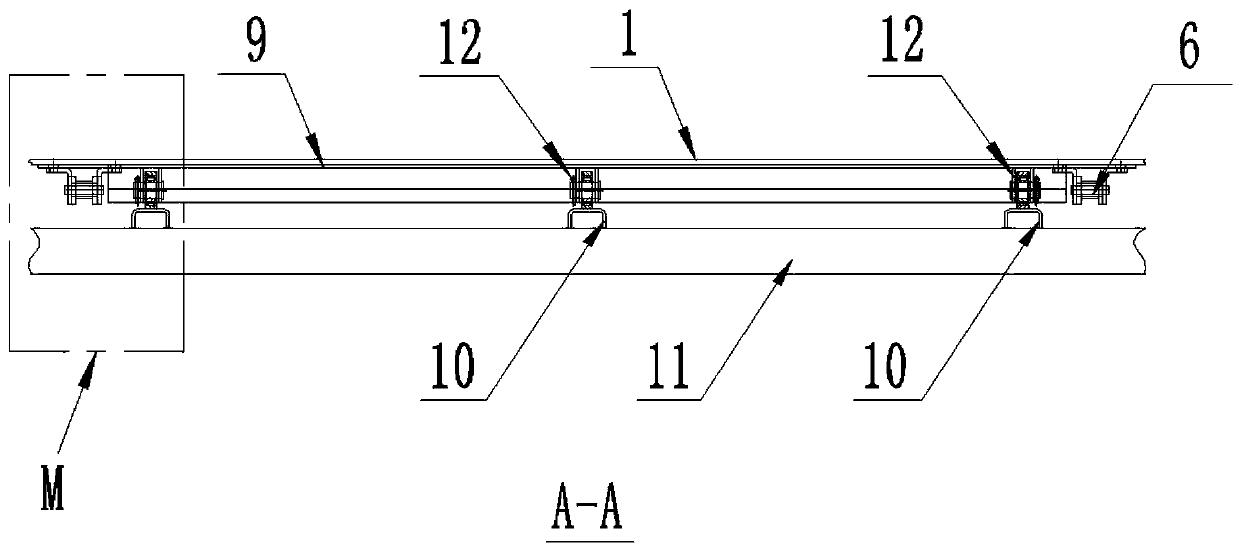

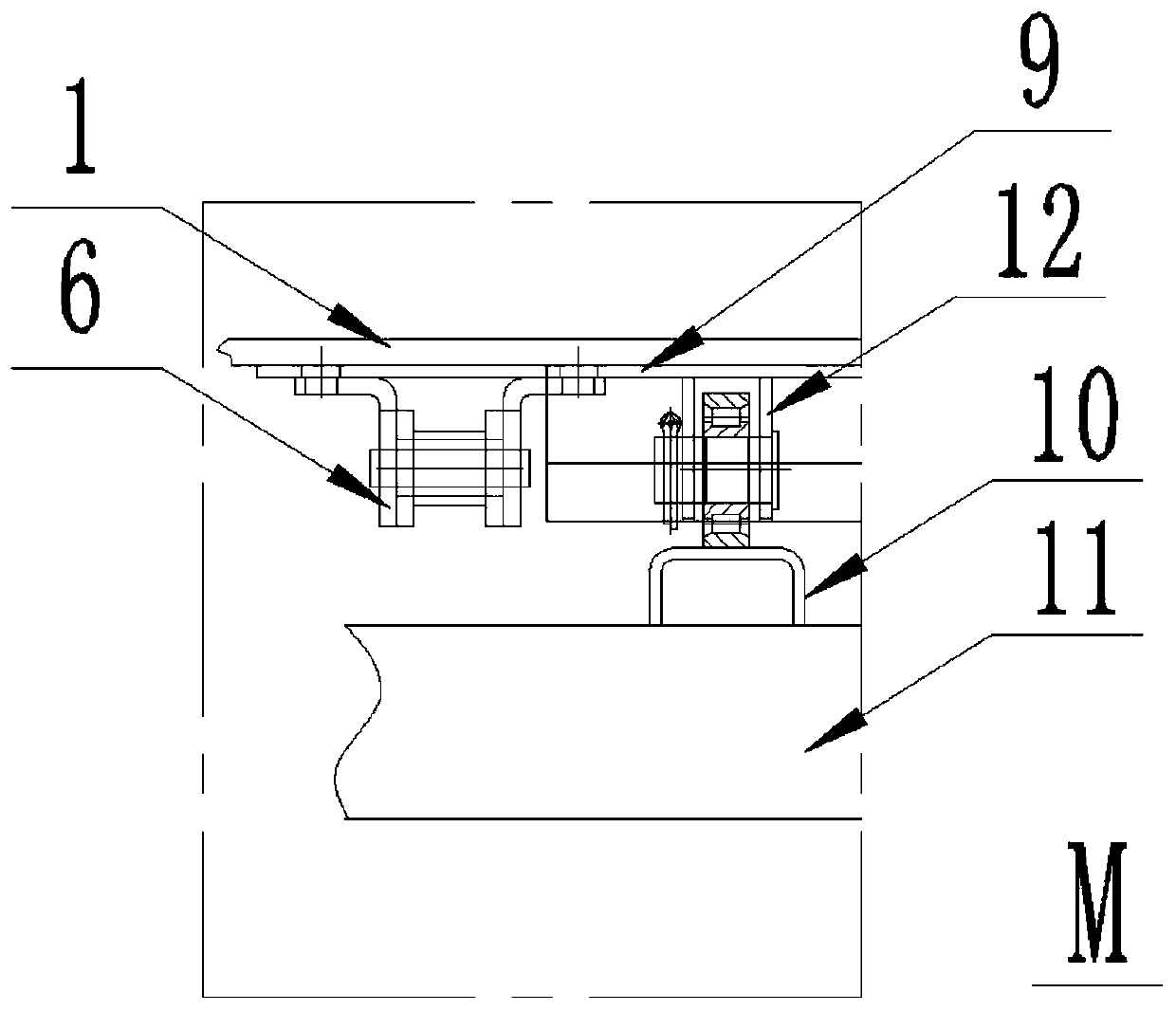

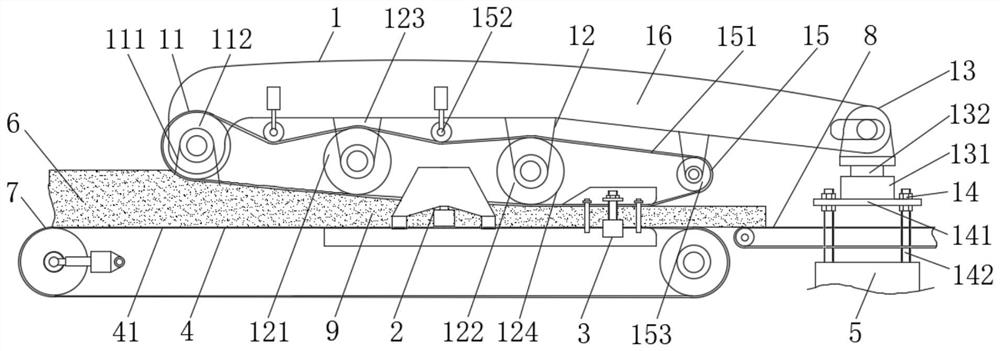

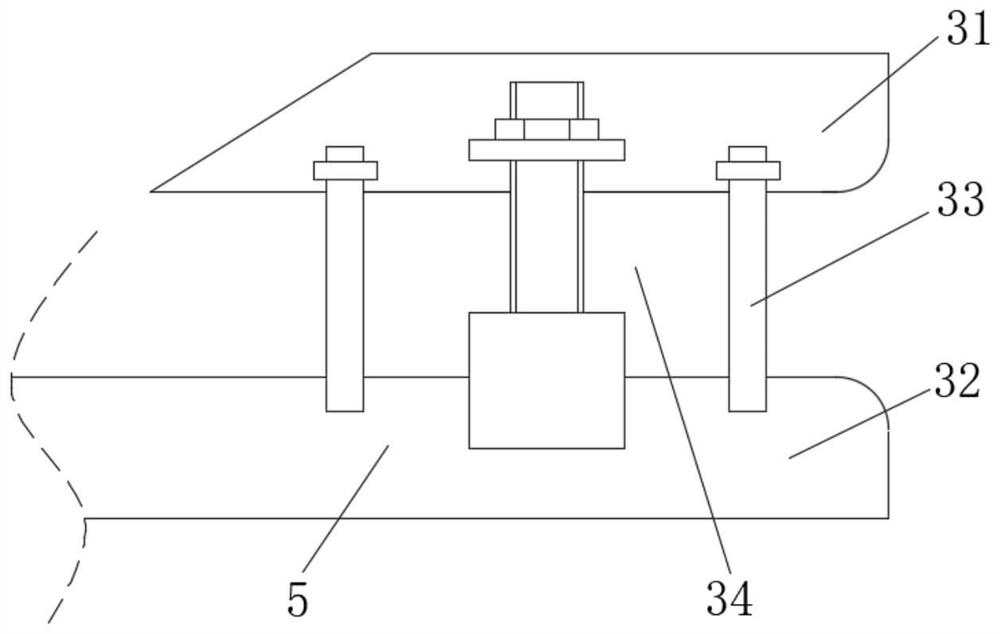

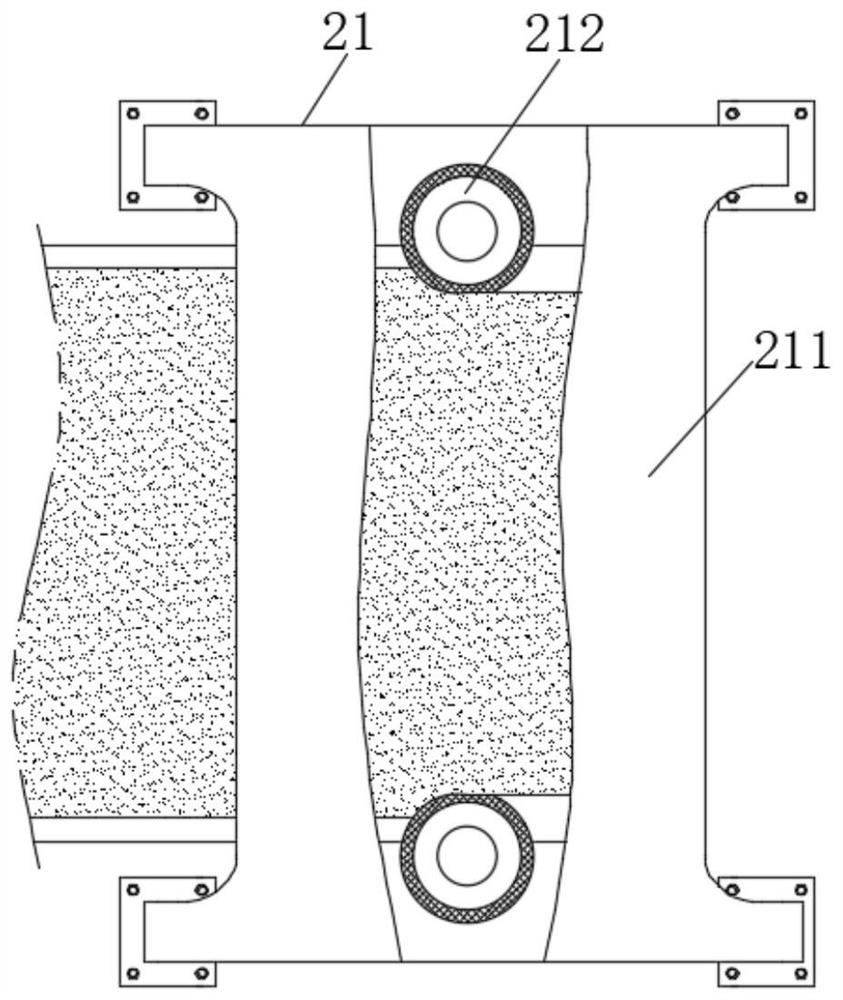

Vehicle-mounted conveying belt structure

PendingCN110877807ASolve wear and tearExtended service lifeConveyorsVehicle with endless chains/beltsIn vehicleChain link

Owner:湖北汇龙专用汽车有限公司

Optical cable production equipment and system

InactiveCN108761677AOutstanding tensile strengthHigh strengthFibre mechanical structuresOpto electronicInstability

The invention relates to the technical field of photoelectric machineries and in view of the problem of optical cable production quality instability, provides optical cable production equipment and system. The optical cable production equipment, in the technical scheme, comprises an unwinding device, an extruding device and a winding device arranged in sequence, wherein the extruding device comprises an extruding die and a protection material extruding part; the extruding die comprises a positioning pipe; the positioning pipe is provided with an optical fiber hole and a plurality of strength member holes distributed along the circumference of the optical fiber hole; the extruding die also comprises an injecting pipe; the axis of the injecting pipe is consistent with that of the positioningpipe; the optical fiber and the strength members pass through the injecting pipe and gaps are left with the inner wall of the injecting pipe; and the extruding head of the protection material extruding part is communicated with the injecting pipe. Through enabling the optical fiber to pass through the optical fiber hole and enabling the strength members to pass through the strength member holes so as to position the optical fiber and the strength members, the optical cable is wound through the winding device, the optical fiber and the strength members are in a tensioning state, and thus, accurate positioning is achieved when the optical fiber and the strength members pass through the injecting pipe.

Owner:上海富瑞电缆股份有限公司

Semiconductor processing device and method thereof

ActiveCN106803477AControl liquidityControl flow speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingChemical reactionEngineering

The invention discloses a semiconductor processing device and a method thereof, which relate to the technical field of semiconductors. The semiconductor processing device comprises a body and at least one semiconductor processing unit formed on the body, wherein each semiconductor processing unit comprises a recessed part formed on the upper end surface of the body, a first channel and a second channel, the bottom wall of the recessed part is provided with at least position, a fall trend is presented from the position to the edge of the bottom wall along a gravity direction or a rise trend is presented from the position to the edge of the bottom wall along a direction opposite to the gravity direction, the first channel is opened in each position of the bottom wall and communicated with the recessed part, the second channel is opened in the body at the edge of the bottom wall of the recessed part and communicated with the recessed part, and the first channel and the second channel can be used as outlets and / or inlets of fluid. Through controlling the flowing direction of the fluid on the surface of a substrate, the fluid is contacted with the surface of the substrate during a process of flowing the recessed part and a physical and / or chemical reaction happens, and process processing is carried out on the surface of the substrate.

Owner:WUXI HUAYING MICROELECTRONICS TECH CO LTD

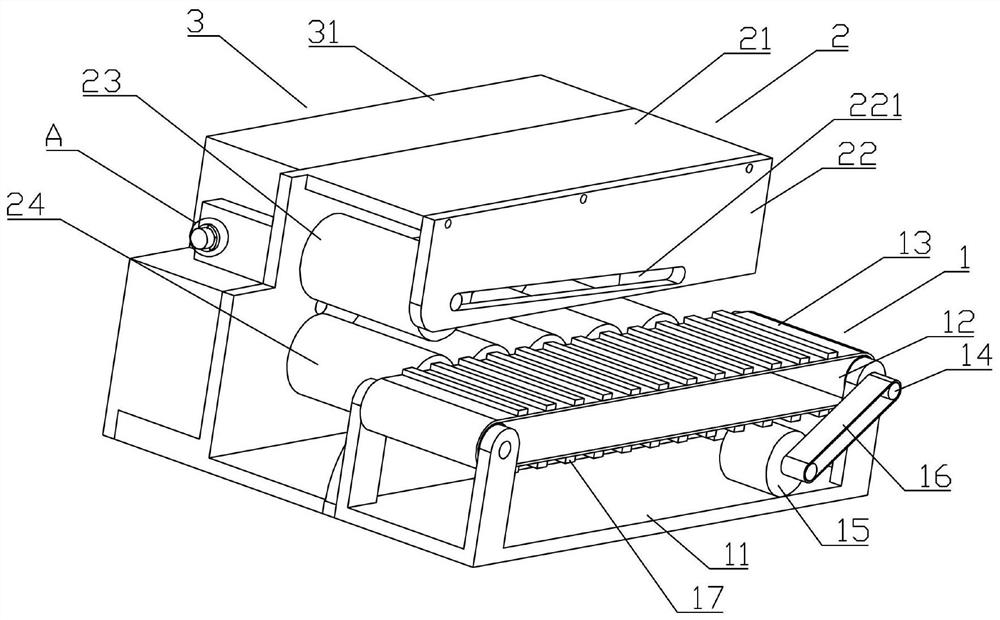

Chinese chestnut opening device

InactiveCN110959875AImprove adjustabilityGood flexibilityHuskingHullingStructural engineeringMechanical engineering

The invention relates to the technical field of chestnut processing and further discloses a Chinese chestnut opening device. The device includes two supporting plates. A main conveyor belt is arrangedbetween the two supporting plates, and a switch is fixed to one side of the supporting plate through bolts. The device further comprises a blanking device, a carding device, a cutting device and a power device. And the cutting device comprises a center shaft, a first connecting plate and two fixed plates. The two fixed plates are fixed to the tops of the two supporting plates through bolts correspondingly, and a first mounting opening is formed in one side of each fixed plate. A first bearing is clamped in each first mounting opening, and the first bearings are rotatably connected with the center shaft. According to the Chinese chestnut opening device, Chinese chestnuts can be clamped under the cooperation of the gravity of a balancing weight when passing through the Chinese chestnut opening device, which facilitates the subsequent opening work; and when Chinese chestnuts of different sizes pass through the Chinese chestnut opening device, a clamping frame can rotate around the centershaft to automatically adjust the position, so that each Chinese chestnut can be fully clamped, and the flexibility of the device is improved.

Owner:李旋

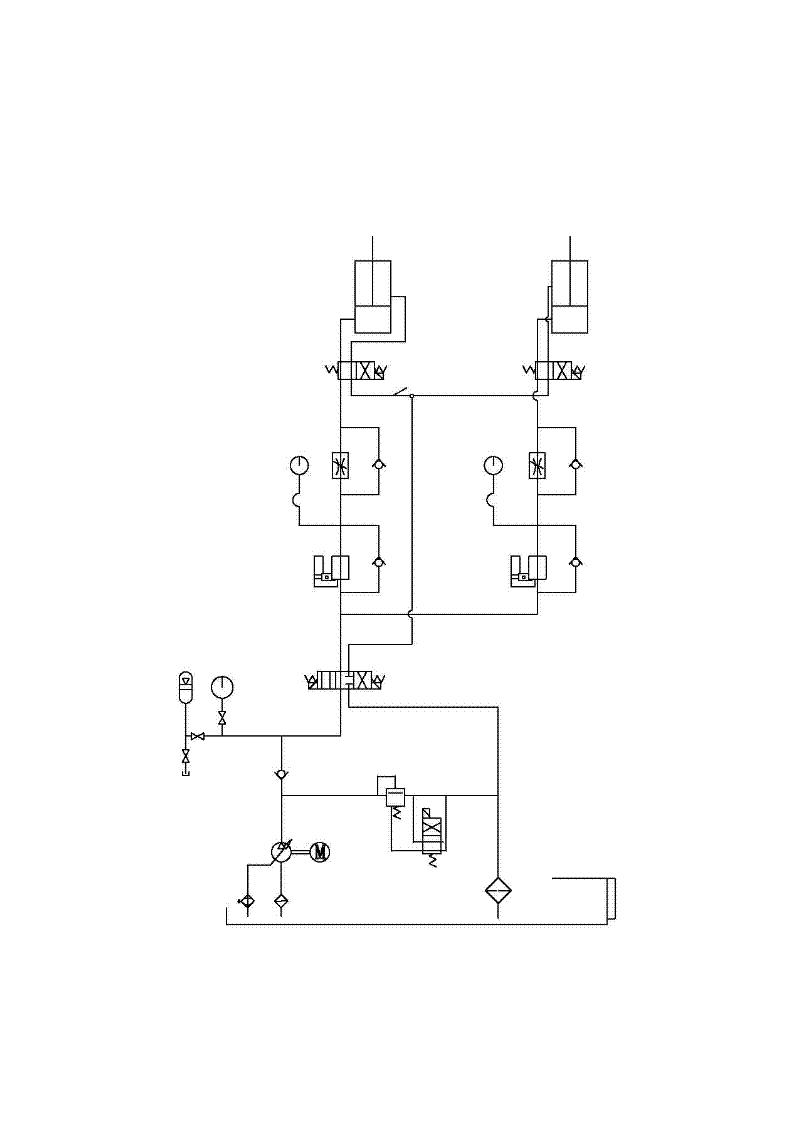

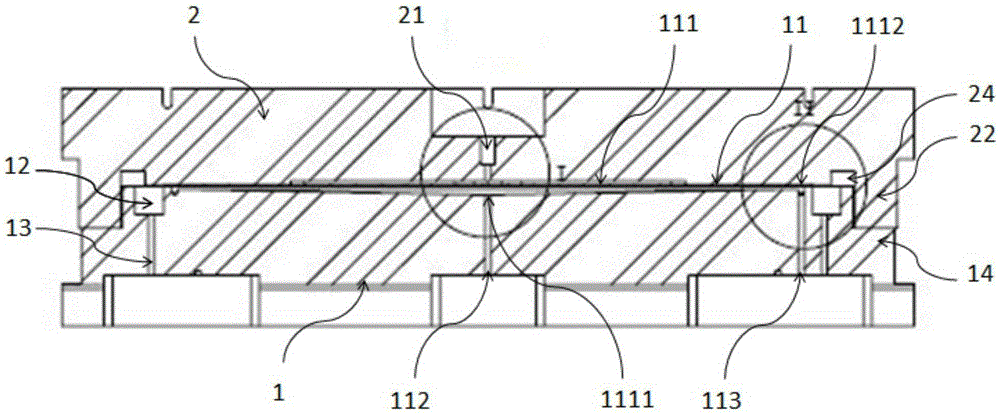

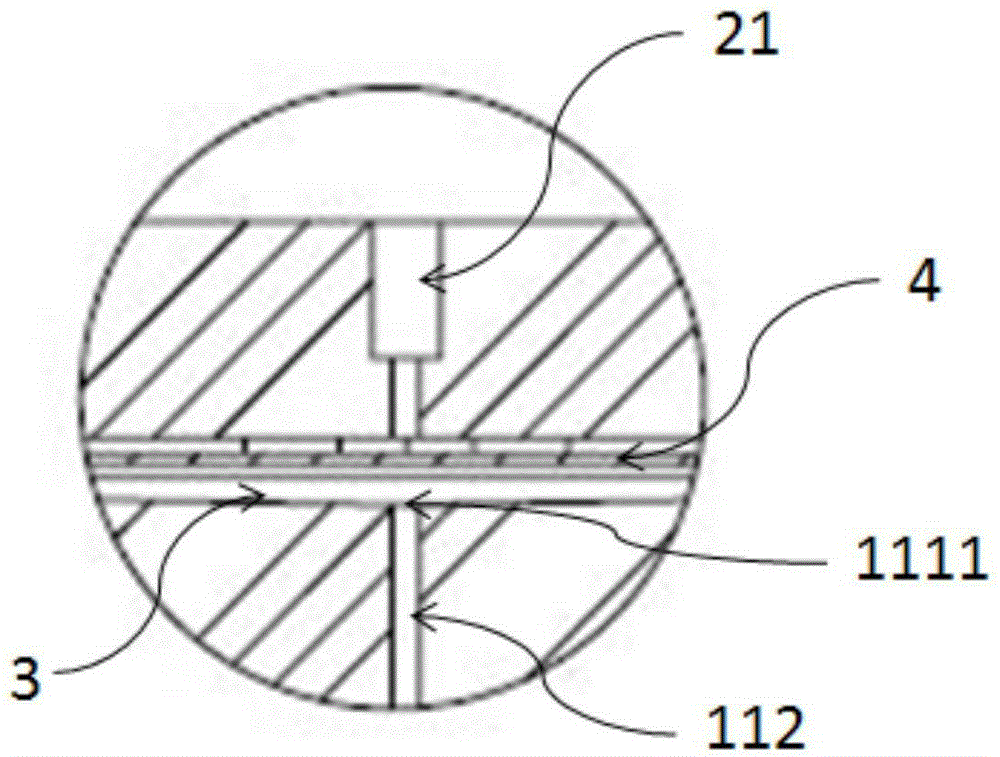

Sealing structure for vacuum compaction road roller

InactiveCN104527823AWon't breakReduce frictionEndless track vehiclesHydraulic motorHydraulic circuit

The invention discloses a sealing structure for a vacuum compaction road roller, and belongs to the technical field of engineering machinery. The sealing structure comprises an upper steel plate, a rubber plate, a steel wheel, a side steel plate, a rubber backing plate, a crawler device and a side supporting plate, a hydraulic motor drives a driving sprocket through a belt, the driving sprocket is matched with a crawler chain to drive a crawler rubber belt, an onboard hydraulic circuit supplies oil for the hydraulic motor, synchronization of the linear speed of the crawler rubber belt and the linear speed of the steel wheel is ensured through a control device, a guide sprocket can function in guiding, a dragging wheel supports the crawler rubber belt, and the lower portion of the dragging wheel and a road surface are compressed, so that tightness is kept. The crawler device is skillfully used, friction between rubber and the road surface is transformed into friction between the rubber and the steel plate, friction force is remarkably reduced, and the road surface cannot be damaged. The simple sealing structure meets vacuum degree requirements of vacuum compaction.

Owner:CHANGAN UNIV

Continuous forming equipment for ceramic plate production

PendingCN114434605AContinuous molding realizedIncrease productivityPress rollersAuxillary shaping apparatusProcess engineeringContinuous production

The invention discloses continuous forming equipment for ceramic plate production, the continuous forming equipment for ceramic plate production comprises a rack, a conveying device and a pressure applying device, the conveying device comprises a conveying piece, powder is placed on the conveying piece, and the pressure applying device is arranged on the conveying piece. The pressure applying device comprises a supporting frame, a front pressure applying mechanism, a rear pressure applying mechanism and a lever pressure applying mechanism, and when the conveying piece drives the powder to move, the front pressure applying mechanism and the rear pressure applying mechanism can press and form the powder; the movable end of the lever pressure applying mechanism can drive the supporting frame to swing up and down around the front pressure applying mechanism and drive the rear pressure applying mechanism to move up and down. By the adoption of the device, continuous production can be achieved, the production efficiency can be improved, large pressing force can be obtained through small driving force, pressure borne by the oil cylinder can be reduced, the service life can be prolonged, and the purpose of saving energy can be achieved.

Owner:FOSHAN HENGLITAI MACHINERY

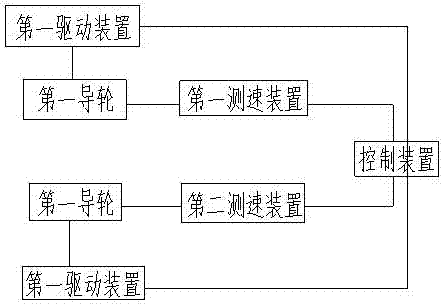

Linear speed adjusting system of copper wire drawing machine

InactiveCN107999550AAvoid slackReal-time adjustment of line speedMetal working apparatusWire speedCopper wire

The invention relates to a linear speed adjusting system of a copper wire drawing machine. The linear speed adjusting system comprises a first guide wheel, a second guide wheel, a first driving device, a second driving device, a first speed measurement device and a second speed measurement device, wherein the first driving device and the second driving device are used for driving the first guide wheel and the second guide wheel, and the first speed measurement device and the second speed measurement device are used for measuring the linear speed of the first guide wheel and the linear speed ofthe second guide wheel. The linear speed adjusting system further comprises a control device, the control device is used for adjusting the first driving device and the second driving device accordingto the measurement result of the first speed measurement device and the measurement result of the second speed measurement device so that the linear speed of the first guide wheel and the linear speed of the second guide wheel can keep consistent. According to the linear speed adjusting system of the copper wire drawing machine, the linear speed of the guide wheels can be adjusted in real time, thus, the linear speed of the guide wheels keep consistent, and the phenomenon that a copper wire is loosened or snapped is prevented.

Owner:SUZHOU JIN JU SONG MECHANICAL & ELECTRICAL CO LTD

Robot laser welding and grinding device

PendingCN108406801AOptimum grinding line speedSame line speedProgramme-controlled manipulatorSolenoid valveSurface roughness

The invention provides a robot laser welding and grinding device comprising a grinding execution part, a force regulating part and a fixed support base. The force regulating part is arranged on the fixed support base, and the grinding execution part is arranged at the front end of the force regulating part; the grinding execution part comprises a motor and a grinding disk installed at the front end of the motor, and the force regulating part comprises a cylinder and a solenoid valve; and the motor is arranged at one end of the cylinder of which the other end is connected to the fixed support base, and the solenoid valve is arranged on the cylinder. The advantages of mechanical and electronic integration are fully utilized, and the control over the mechanical execution part is achieved through programming of corresponding control procedures while different feedbacks are arranged rationally. If the control is proper, proper grinding of a weld joint can be ensured, and the ground surfaceroughness is no more than 1.6 [mu]m; and base metal is not damaged. One grinding disk can be used for grinding at least 300 finished vehicles, and the length of each weld joint is ensured to be 2.0 m.

Owner:芜湖鲍斯柯机器人股份有限公司

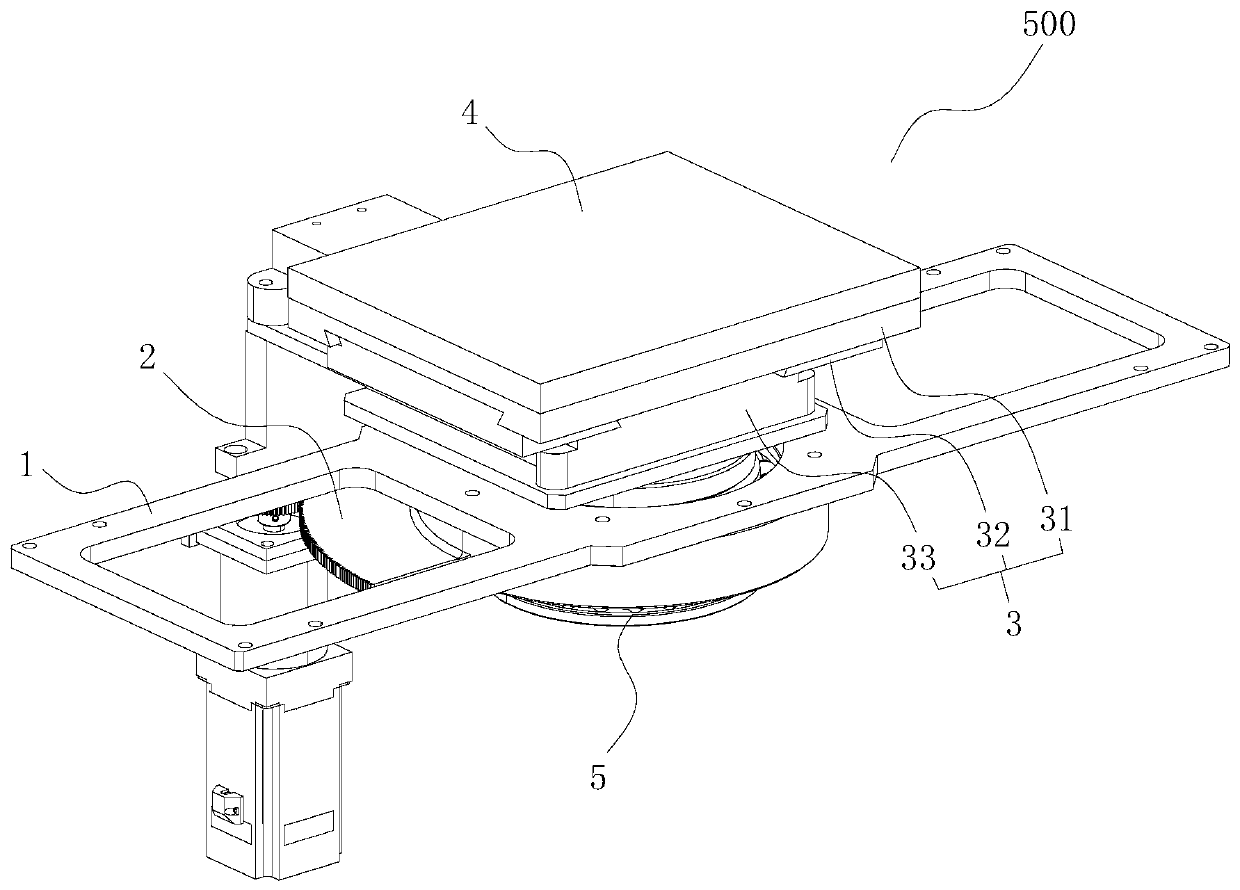

Rotary adjusting type cigarette paper ink explosion testing device

PendingCN111948138AImprove detection accuracySimple structureUsing mechanical meansArticle feedersStructural engineeringPaper sheet

The invention belongs to the technical field of detection equipment, and particularly relates to a rotary adjustment type cigarette paper ink explosion testing device, which comprises a conveying mechanism and an extrusion mechanism, wherein the conveying mechanism comprises a bottom support, two sliding rods, a moving plate, a rack, a ninth gear and a mounting shaft, and the two sliding rods aretransversely and fixedly mounted on the bottom support; a lifting rod is arranged in the third via hole in a penetrating mode, wherein the free end of the lifting rod is fixedly provided with a firststop block, and the lifting rod is sleeved with a first compression spring that is located between the first stop block and the mounting plate; the adjusting component comprises an adjusting disc, a through groove is formed in the mounting plate, and the adjusting disc is located in the through groove; multiple notches are formed in the outer wall of the adjusting disc, and are equal in radius anddifferent in depth; the clamping rods are located in the corresponding notches, and a rotating rod is fixedly installed on the adjusting disc and rotationally installed on the supporting frame. The problem that whether cigarette paper is qualified or not cannot be accurately judged due to an existing ink explosion detection mode is solved.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

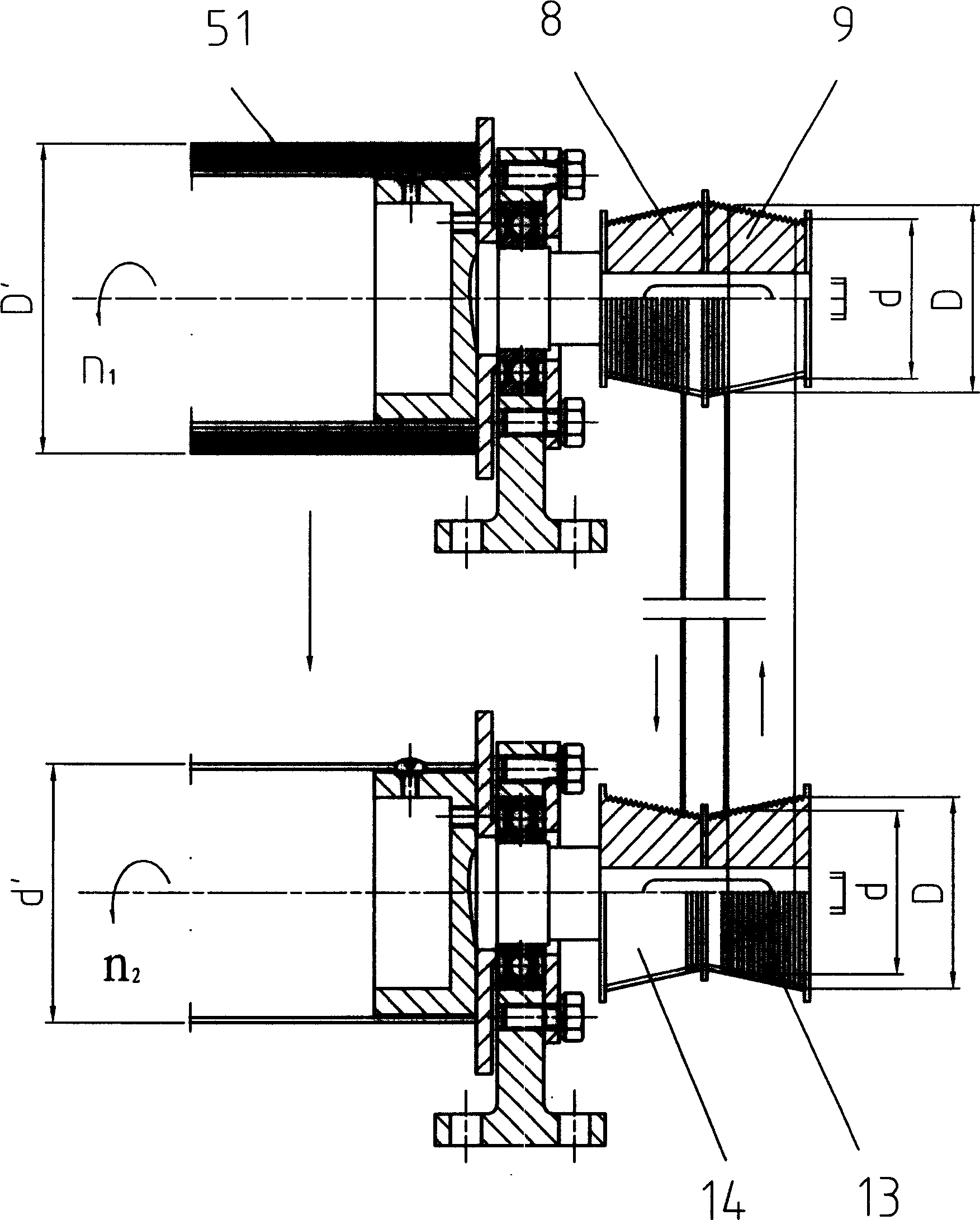

Multi-beltsaw drive mechanism and working method thereof

PendingCN109849110AConsistent service lifeGuaranteed progressBand sawsEconomic benefitsThrough transmission

The invention relates to a multi-beltsaw drive mechanism and a working method thereof. The multi-beltsaw drive mechanism comprises a rack. The rack is provided with multiple upper belt wheels and lower belt wheels, wherein the upper belt wheels and the lower belt wheels are arranged coaxially, the diameters of the upper belt wheels and the lower belt wheels are increased gradually. Multiple beltsaw blades for forming a multi-circle ring-shaped structure are installed on the upper belt wheels and the lower belt wheels in a sleeving manner. The rack is provided with a drive rotating shaft located between the upper belt wheels and the lower belt wheels. Multiple belt wheels are installed on the drive rotating shaft in a sleeving manner, wherein the belt wheels correspond to the upper belt wheels or the lower belt wheels one to one, and the diameters of the belt wheels are reduced gradually. The belt wheels and the corresponding upper belt wheels or lower belt wheels are connected in a transmission manner through transmission belts. According to the multi-beltsaw drive mechanism, linear speeds of all the lower belt wheels can be consistent basically, it is ensured that all the beltsawblades can keep the consistent linear speeds to work, it is ensured that the service life of all the beltsaw blades tends to be consistent, the situation that due to the too high linear speed, the beltsaw blades on the belt wheels with the large diameters are scraped in advance, the shutdown overhaul frequency is reduced, the schedule of workpieces is ensured, and the economic benefits are increased.

Owner:MINHOU MINTAI MACHINERY CO LTD

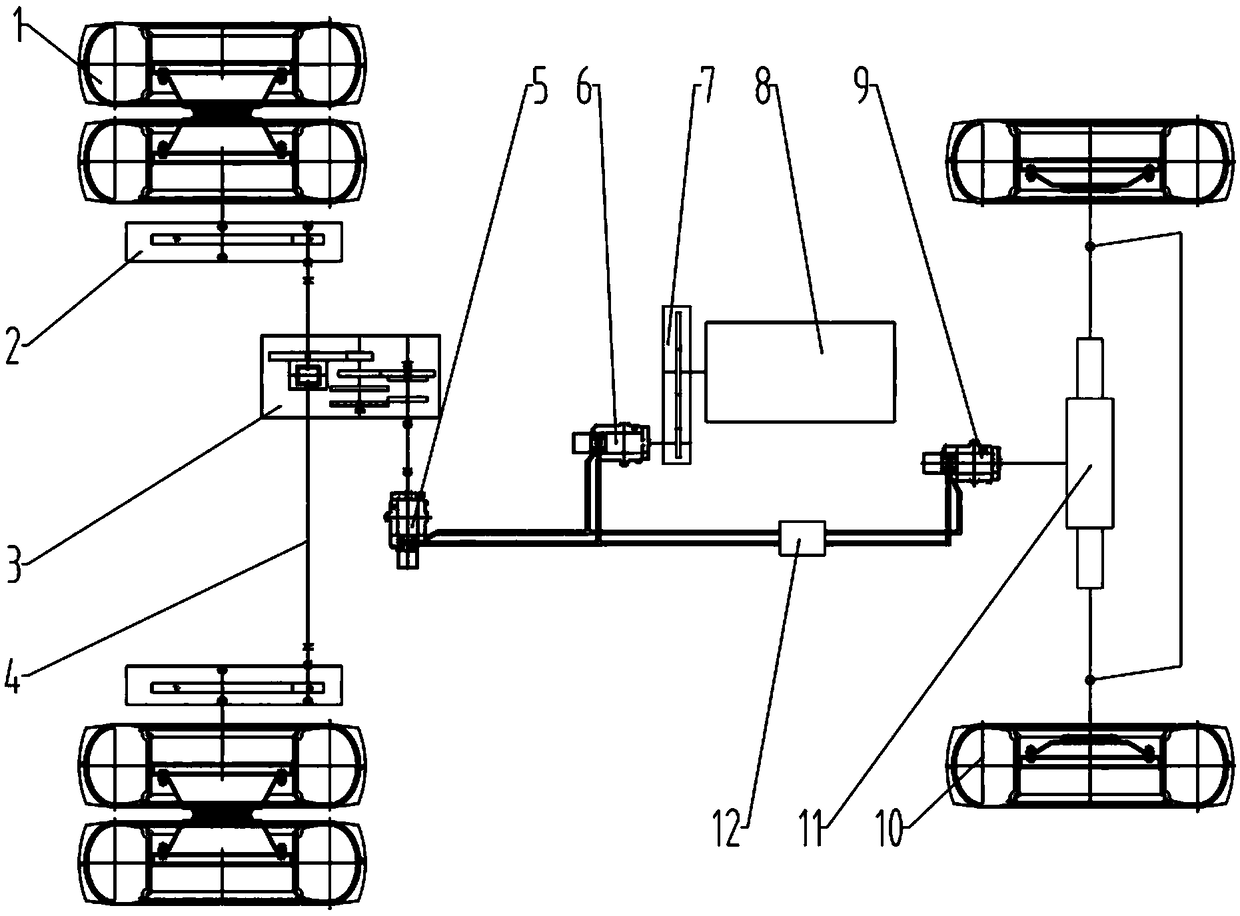

Wheeled agricultural machine and its hydraulic traveling system

The invention discloses a hydraulic traveling system of a wheeled agricultural machine, includes a hydraulic pump assembly and a power unit that drives the hydraulic pump assembly, and a driving axleand a steering axle respectively arranged at the front and rear ends of the agricultural wheeled machinery, also included are a first hydraulic motor assembly and a second hydraulic motor assembly, wherein an oil outlet of the hydraulic pump assembly is communicated with an oil inlet of the first hydraulic motor assembly, and an oil outlet of the hydraulic pump assembly is communicated with an oilinlet of the second hydraulic motor assembly through a control valve capable of controlling an on-off state of the hydraulic pump assembly and the second hydraulic motor assembly. A hydraulic systemcan be used to switch between two drives and four drives, which is easy to operate, can adapt to different working conditions, ensures the use of more reliable and safe components, and prolongs the life of the components. The invention also discloses a wheeled agricultural machine comprising the hydraulic traveling system.

Owner:RAILWAY CONSTR HEAVY IND XINJIANG CO LTD

Detection device for cigarette packaging box ink printed matter

InactiveCN113428441ASimple structureEasy to useUsing mechanical meansPackaging automatic controlStructural engineeringManufacturing engineering

The invention belongs to the technical field of detection equipment, and particularly relates to a detection device for a cigarette packaging box ink printed matter. The detection device comprises a conveying mechanism, an extrusion assembly, a power mechanism and an adjusting assembly, the extrusion assembly is installed on one side of the conveying mechanism, the power mechanism is installed on one side of the extrusion assembly, the adjusting assembly is installed on the power mechanism, the extrusion assembly comprises a supporting frame, a first connecting plate, a second connecting plate, an upper roller wheel and five lower roller wheels, the detection device is used for simulating the situation that when a packaging box is folded in a packaging machine, if the intervals of the folding parts formed by extrusion of the packaging machine are not right, coloring layer of the folded parts is prone to cracking, and therefore the situation that the ink coloring layer is cracked in the cigarette production process is avoided.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

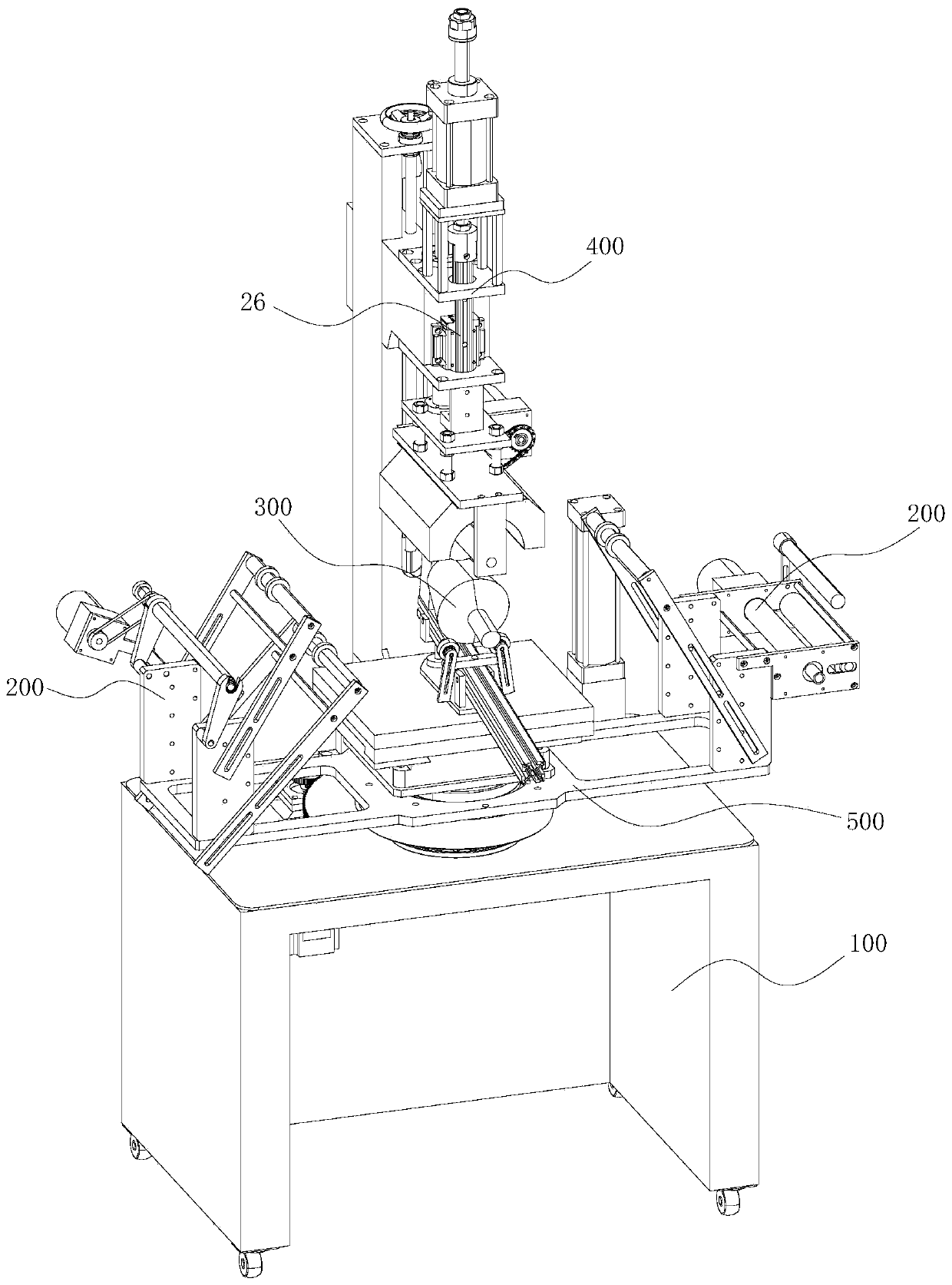

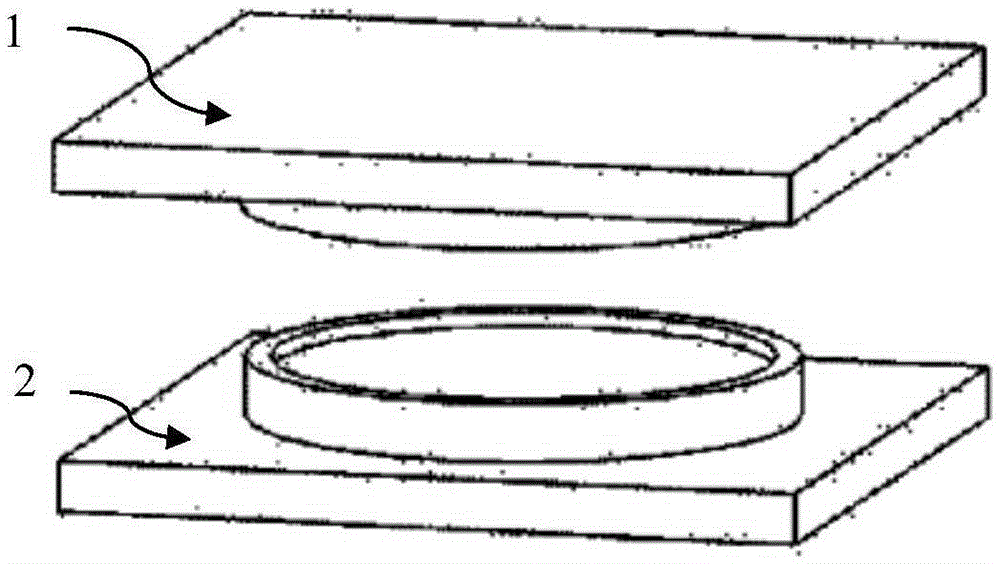

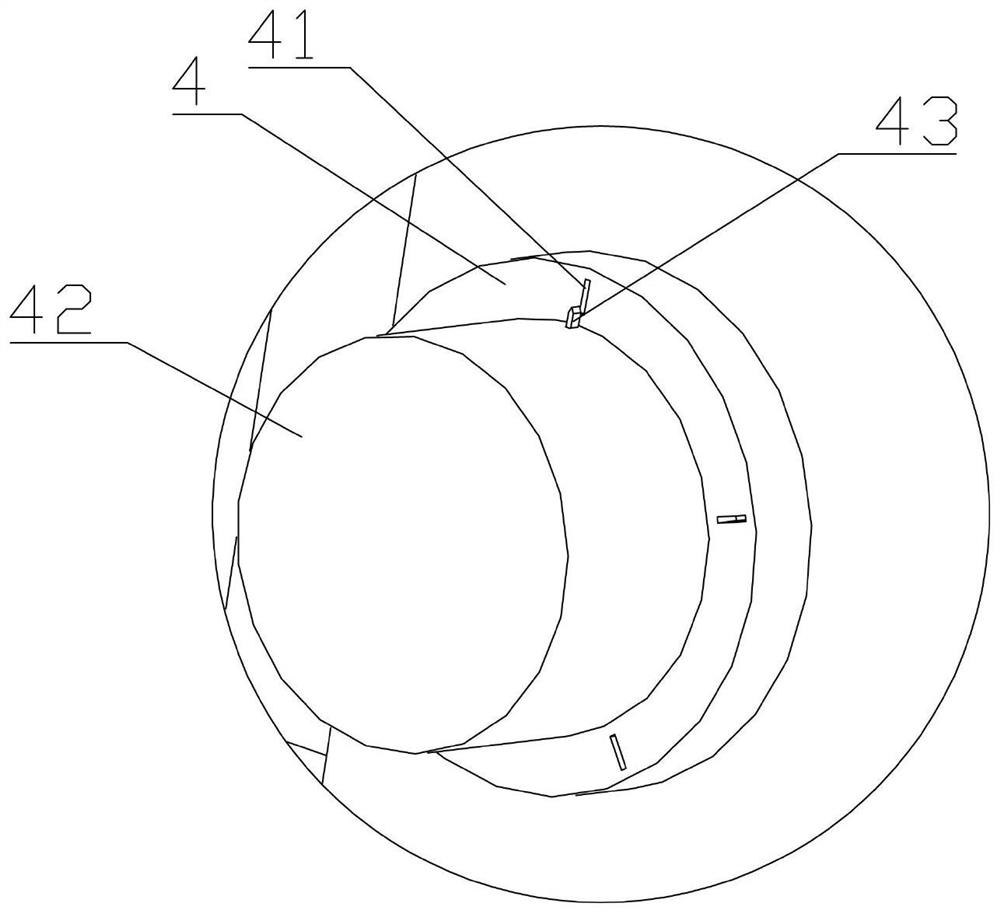

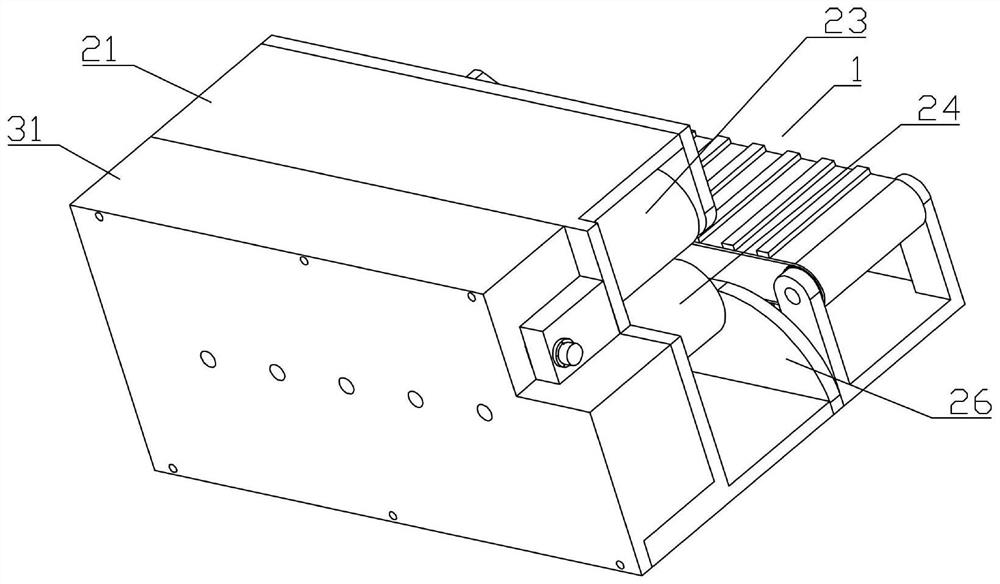

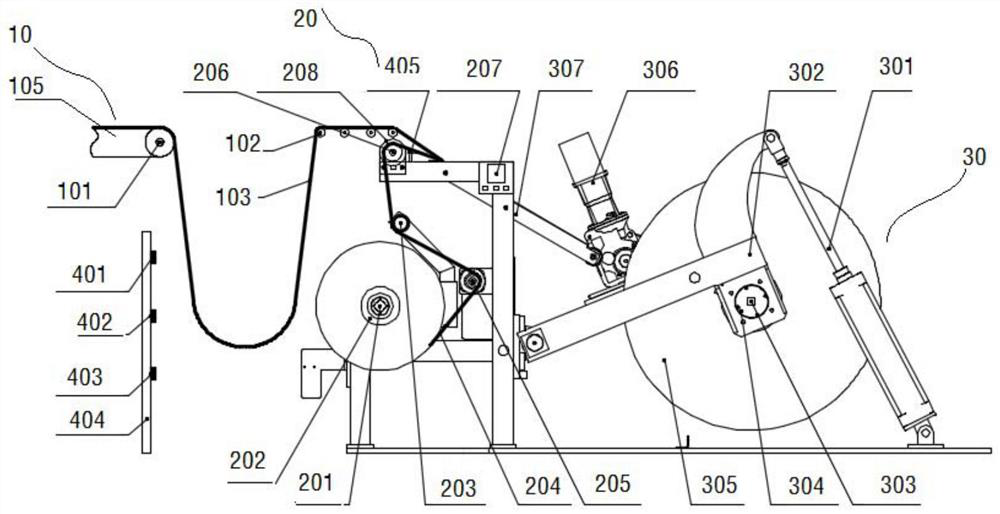

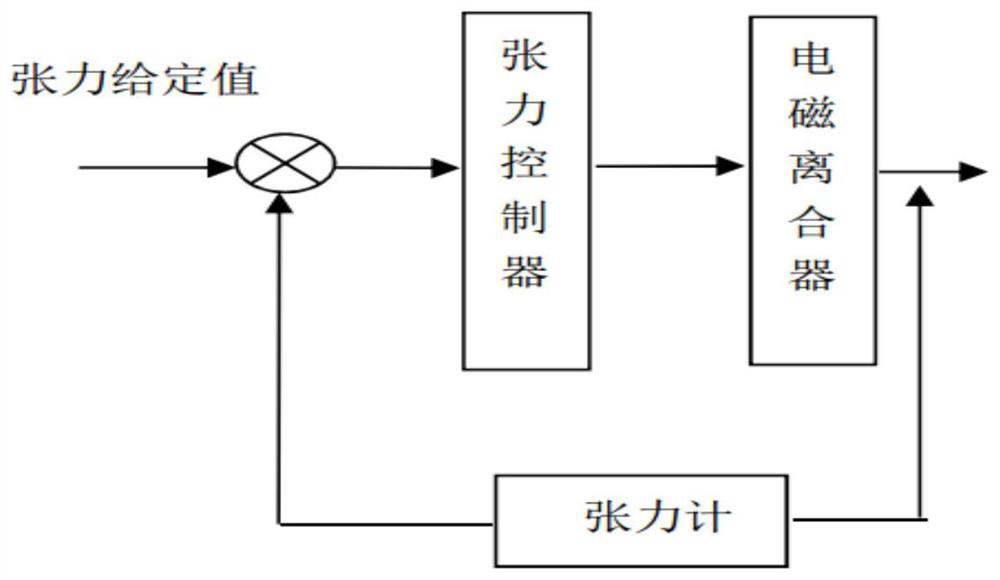

Belted layer winding device and control method

The invention discloses a belted layer winding device. The belted layer winding device comprises a belted layer conveying unit, a plastic paper conveying unit and a curling unit. The plastic paper conveying unit unwinds plastic paper through rotation of a plastic paper reel, and the plastic paper is guided to a conveying plate at the rate the same as that of a belted layer. A tension sensor inducts the unwinding tension of the plastic paper, and an electromagnetic clutch arranged on the plastic paper reel is controlled through a tension controller to adjust the tension. The belted layer and the plastic paper laminated on the conveying plate are guided into a tool barrel through the curling unit, the curling device winds the belted layer and the plastic paper into the tool barrel at the linear rate the same as that of a conveying belt after the belted layer and the plastic paper are laminated, and the problems of material bending, drooping, curling and deviating and the like caused by plastic paper tension changes and the inconformity of front and back conveying and curling rates are avoided; and meanwhile, the invention discloses a control method of the belted layer winding device.Signal detection is stable, the problem of possible missing detection is avoided, and the linear velocity of a conveying device is consistent with the linear velocity of the winding device.

Owner:HANGZHOU CHAOYANG RUBBER

Display equipment

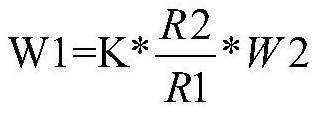

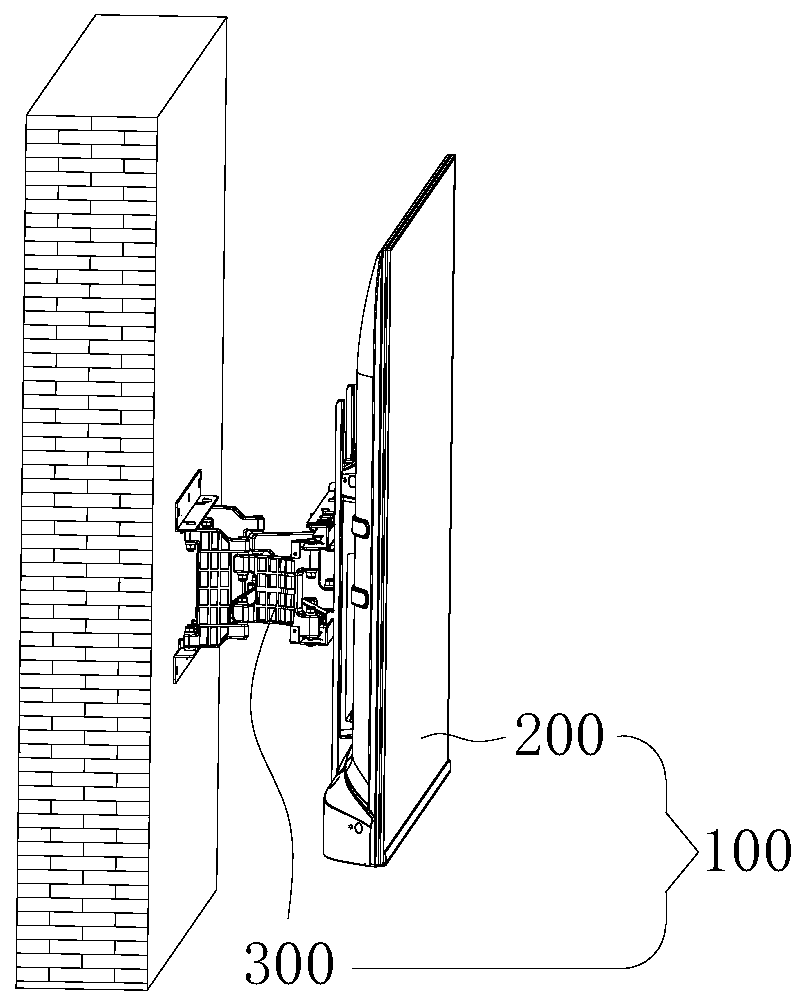

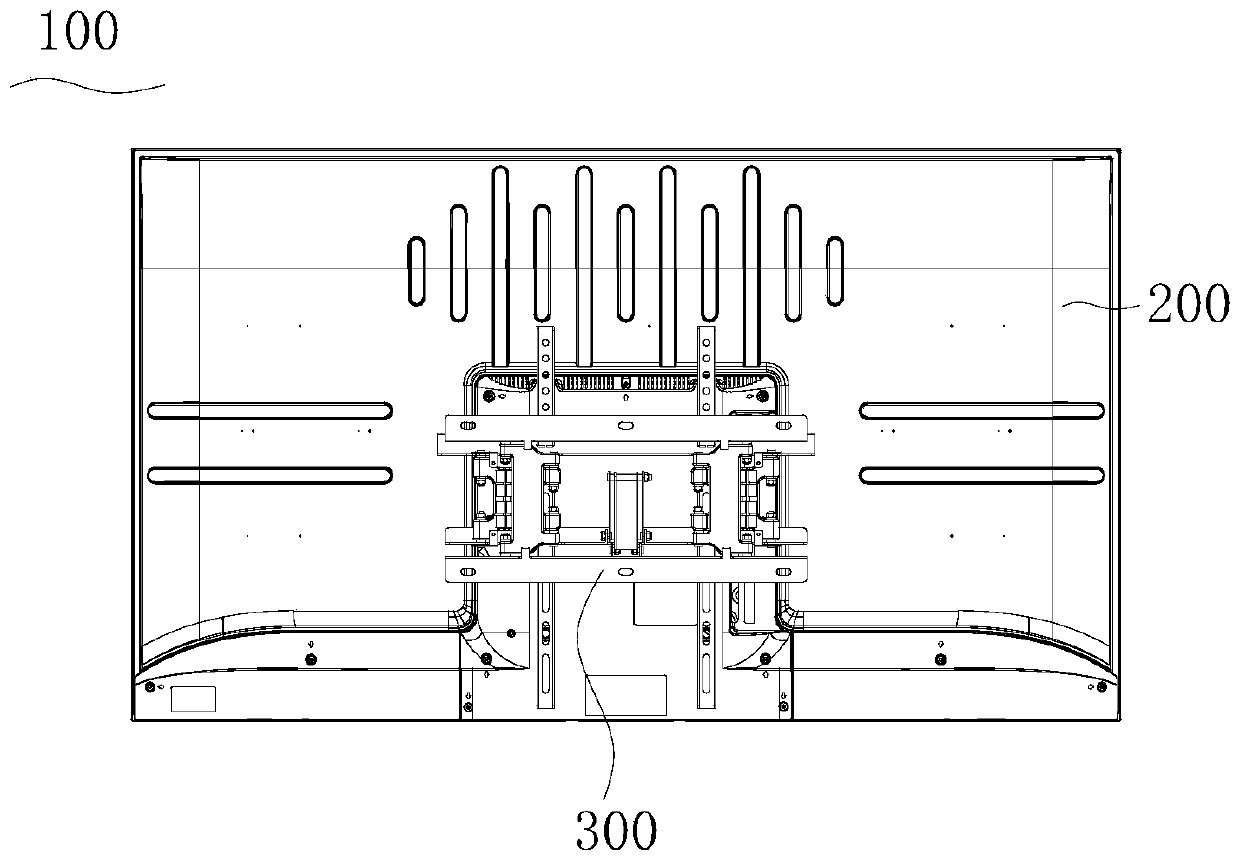

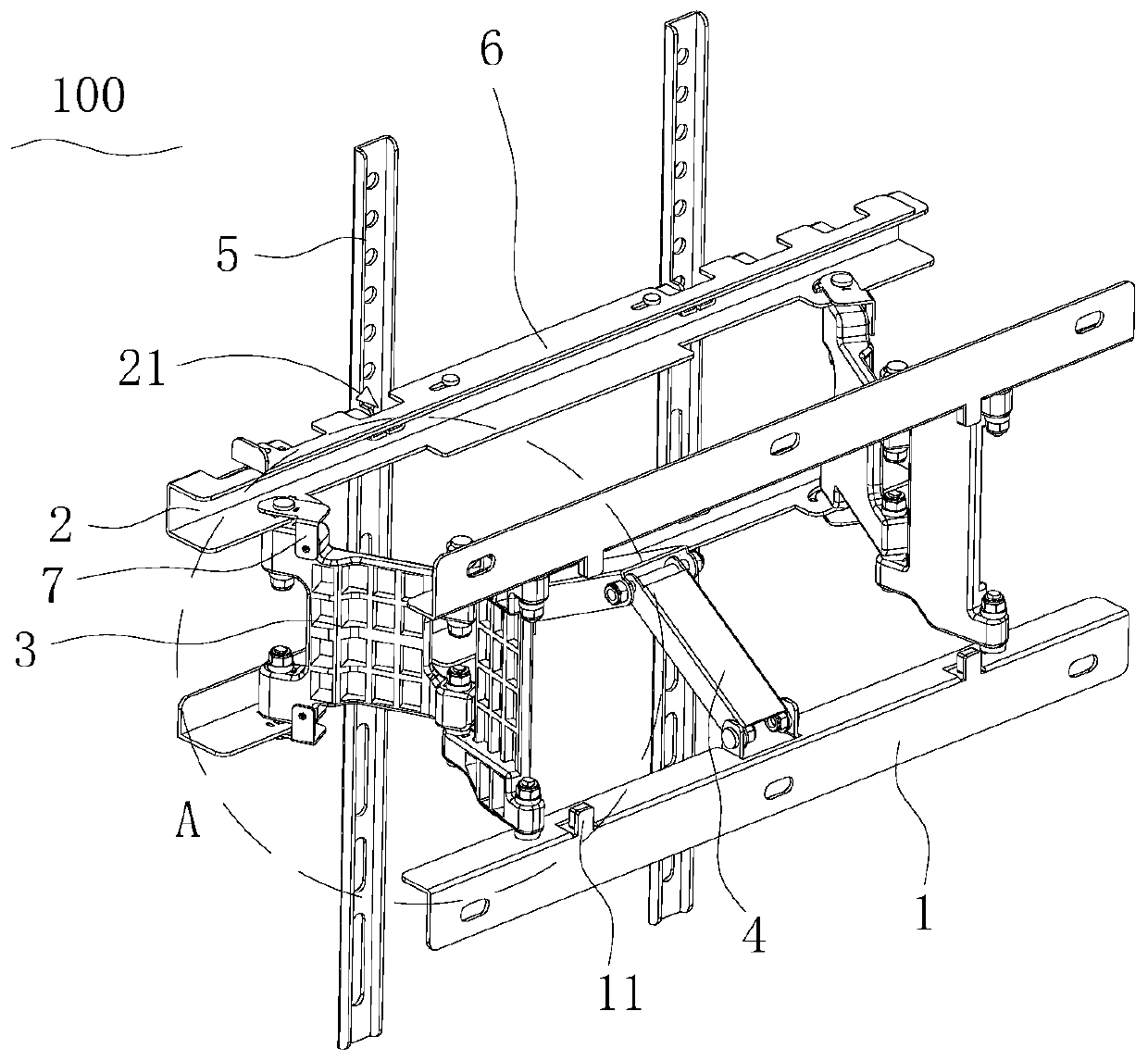

InactiveCN111457229AAvoid collisionSame line speedStands/trestlesControl theoryMechanical engineering

The invention provides display equipment. The display equipment comprises a display equipment main body and a hanging rack, wherein the hanging rack is connected to the display equipment main body, and drives the display equipment main body to move front and rear relative to a wall body; the hanging rack comprises a fixed beam, a movable beam, a swing mechanism and a directional mechanism; the fixed mechanism is fixedly arranged on the wall body; the movable beam is arranged at the front side of the fixed beam in a spaced mode; the swing mechanism comprises two swing arms which are mutually hinged, and can be oppositely opened and closed; ends of the two swing arms are separately hinged to the movable beam and the fixed beam; the directional mechanism comprises two directional arms which are mutually hinged to each other, and can be oppositely opened and closed; the two ends of the two directional arms are separately hinged to the movable beam and the fixed beam; a hinge axis between the two directional arms is mutually perpendicular to the hinge axis between the two swing arms, so that the directional arms limit a swing direction of the swing arms, and therefore, the movable beammoves front and back linearly relative to the fixed beam; and linear speed on each position on the display equipment is kept consistent, so that the display equipment is prevented from being in collision with the wall body in a shrinking process.

Owner:HISENSE VISUAL TECH CO LTD

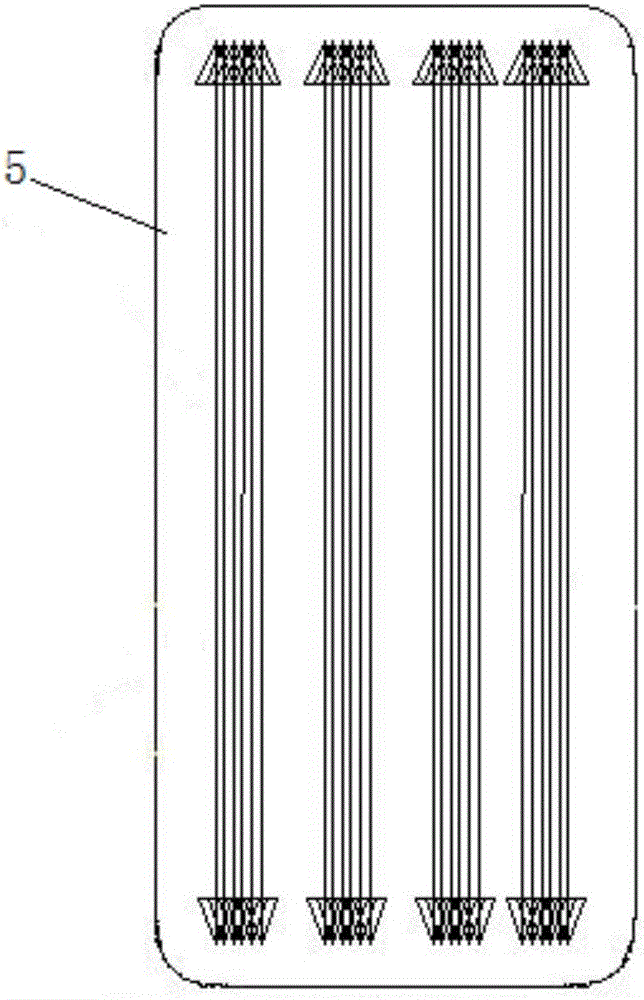

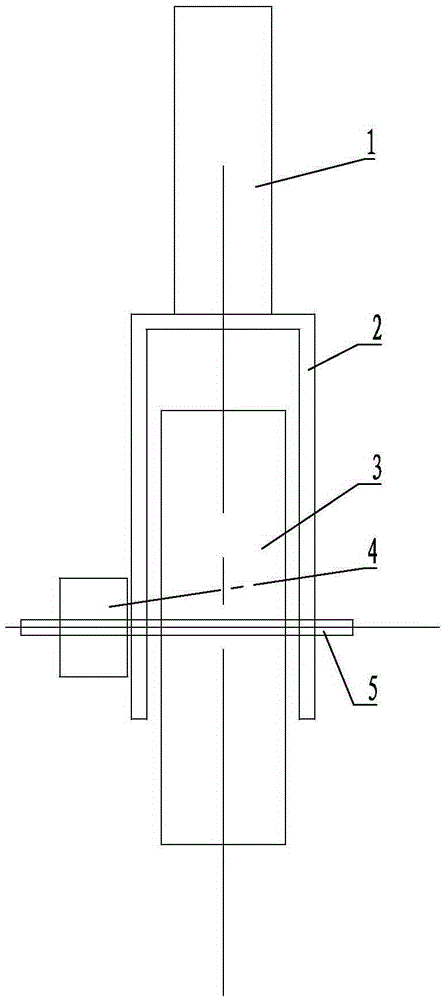

Polytetrafluoroethylene-made blank pipe plane collecting device and method

ActiveCN110562802AOffset the difference in line speedSame line speedFilament handlingEngineeringRisk stroke

The invention discloses a polytetrafluoroethylene-made blank pipe plane collecting device. The device comprises a vertically-arranged central air floating type guide pipe module, wherein the lower part of the central air floating type guide pipe module is provided with an air floating type pipe arranging guide pipe module with the same structure as the central air floating type guide pipe module,a round and horizontally-arranged pipe collecting disc is arranged at the lower part of the air floating type pipe arranging guide pipe module, the pipe collecting disc rotates through a pipe collecting disc supporting bearing, a screw rod is arranged on the lower part of the pipe collecting disc, a nut sliding block is arranged on the screw rod, a stroke switch for controlling the stroke of the nut sliding block is arranged on each of the opposite positions of the left side and the right side of the lower part of the screw rod, and the nut sliding block and all the structures fixedly connected on the nut sliding block move left and right through rotation of the screw rod. The device and the method have the beneficial effects that under the condition that a polytetrafluoroethylene-made blank pipe is produced at constant speed, the ordered pipe collecting can be effectively ensured, and uniform gaps are arranged between the arranged adjacent polytetrafluoroethylene-made blank pipes.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

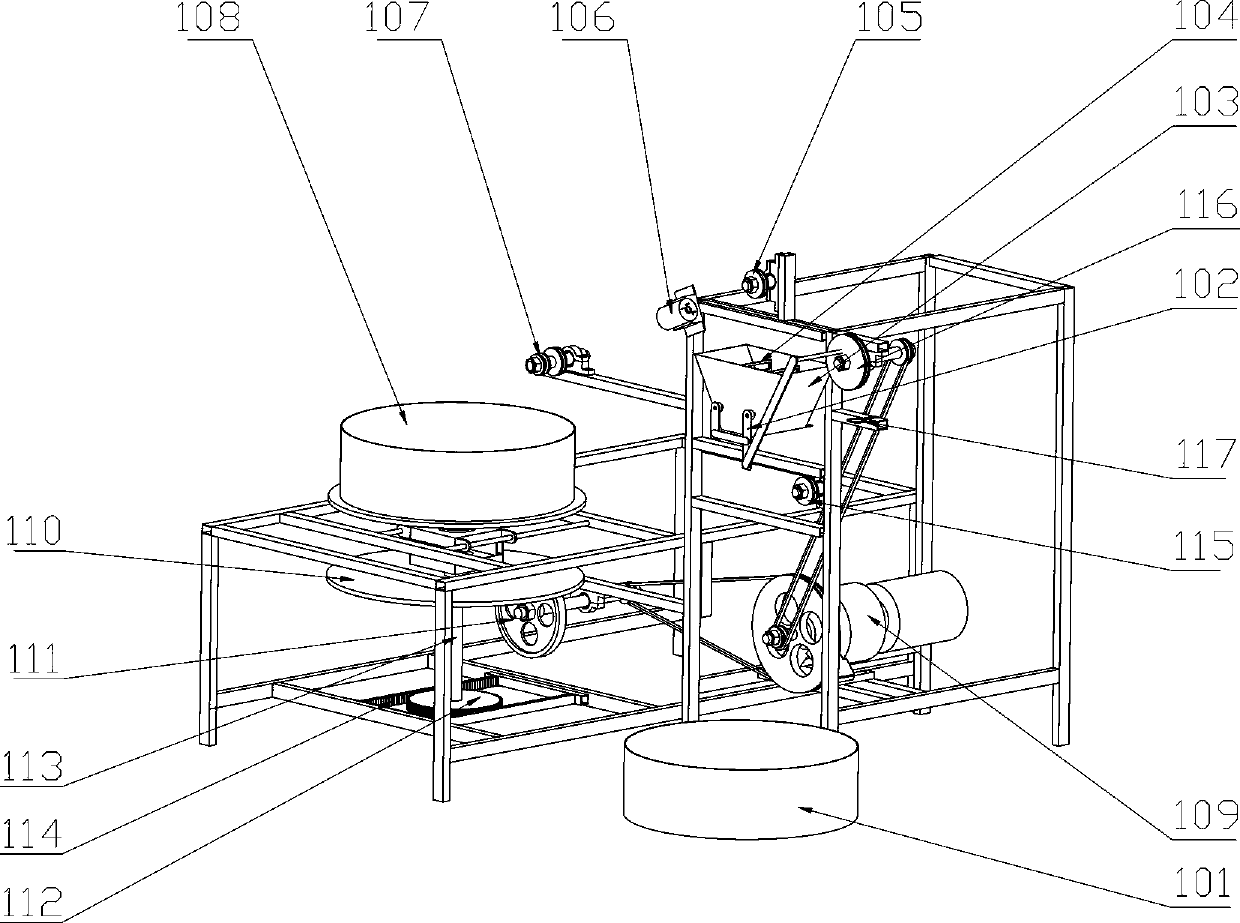

Royal noodle drawing and coiling machine

PendingCN110583732ASolve bending discountSame line speedDough extruding machinesDough processingEngineeringMechanical engineering

The invention discloses a royal noodle drawing and coiling machine. The royal noodle drawing and coiling machine comprises a tray, a delivery system, a noodle drawing system and a noodle coiling system. Noodles in the tray are delivered into the noodle drawing system through the delivery system, and are drawn and thinned by twisting through the noodle drawing system and are delivered into the noodle coiling system. According to the royal noodle drawing and coiling machine, the problems that the noodle drawing efficiency is relatively low, a thin layer of flour should be added manually, and royal noodles are bent and broken in a coiling process in existing royal noodle mechanical production can be solved by adding or improving a feed hopper, a connecting rod assembly, a noodle drawing machine, an active friction wheel, a passive friction wheel, a gear and a rack.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

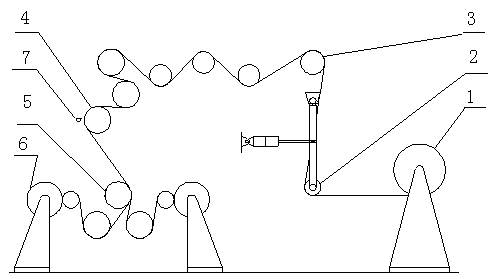

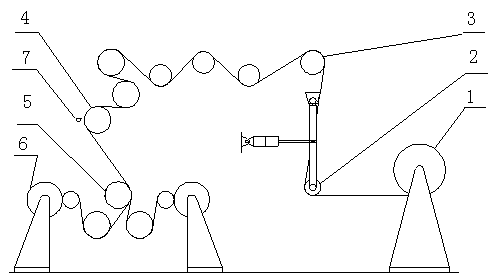

Low-tension high-synchronization ultrathin film slitting machine

InactiveCN111086902AReduce frictionPrevent re-scratchArticle deliveryWebs handlingIndustrial EthernetElectric machinery

The invention discloses a low-tension high-synchronization ultrathin film slitting machine, and solves the problems that the physical deformation of a film is caused by the excessive tension in the accelerating and decelerating processes of an existing film splitting machine, and the physical characteristics of the film and the consistency of the film quality are further influenced. The low-tension high-synchronization ultrathin film slitting machine is characterized that each roller of a swing roller (2), transmission rollers (3), a knife groove roller (4) and driving rollers (5) is providedwith an independent servo driving device and an independent motor, and all the servo driving devices are controlled by an industrial Ethernet arranged on a rack so that the linear speed of each rollercan be the same. By means of the low-tension high-synchronization ultrathin film slitting machine, the slitting quality is obviously improved, the number of the common phenomena during the slitting of the ultrathin film that many wrinkles appear, end faces are irregular and the film is prone to being broken is obviously reduced, and the electrical property consistency of the ultrathin film is also synchronously improved.

Owner:胡振喜

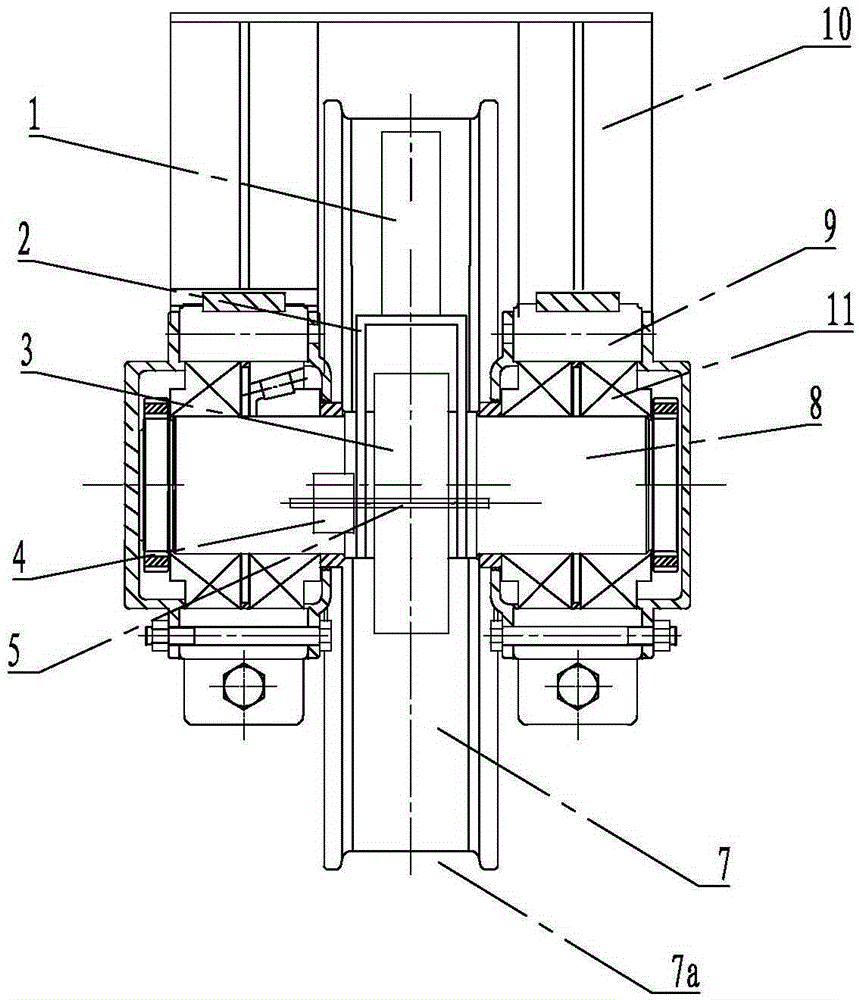

Crane encoder mounting structure

InactiveCN105236266AModerate intensityReduce wearTravelling gearData acquisitionMechanical engineering

The invention discloses a crane encoder mounting structure which comprises a wheel axle and a crane wheel and further comprises a U-shaped mounting frame, wherein the wheel axle is fixedly sleeved with the crane wheel; two ends of the wheel axle are fixedly sleeved with first bearings; each first bearing is mounted in one corresponding bearing housing; the U-shaped mounting frame is oppositely fixed with the bearing housing; a rotating shaft is arranged between two side plates of the mounting frame in a penetrating manner, and is fixedly sleeved with a friction wheel; the friction wheel is coaxial with the rotating shaft; the circumferential side wall of the friction wheel is in contact and matched with that of the crane wheel; an encoder is fixedly connected with one end of the rotating shaft; an input shaft of the encoder is coaxially arranged with the rotating shaft. Through adoption of the crane encoder mounting structure, no mounting hole needs to be formed in the wheel axle and the friction wheel is in direct contact with the crane wheel, so that the accuracy of data acquisition is remarkably improved; besides, the encoder is convenient to mount and operate, and particularly under the circumstance that no mounting hole is formed in a delivered wheel axle, additional arrangement of the encoder can be convenient. Therefore, the crane encoder mounting structure has the characteristics of ingenious concept, simple structure, easiness in transformation and the like.

Owner:CHONGQING KESHUO HOISTING EQUIP

Noodle drying and conveying device

InactiveCN103416446ASame line speedSimple structureDough processingProcess engineeringIndustrial engineering

The invention relates to noodle production equipment, and particularly relates to a noodle drying and conveying device in a noodle production line. The noodle drying and conveying device comprises a drying and conveying chain and a transmission system, and also comprises a noodle rod turning mechanism, a noodle rod racking mechanism and a noodle rod disassembly mechanism. The noodle rod turning mechanism drives the drying and conveying chain to turn 180 degrees through a composite worm-gear speed reducer. The noodle drying and conveying device has a simple structure. After coming out from a noodle cutting main machine, the wet noodles can be automatically conveyed to a noodle cut-to-length machine through a chain so as to achieve automatic transmission of the noodles and ensure more reliable operation and higher efficiency of the noodle production line. The drying and conveying chain can turn 180 degrees through the noodle rod turning mechanism, and noodle rods hanging the noodles can move back and forth in a drying room, and therefore sufficient time is guaranteed for drying the noodles in a conveying process, and the noodle drying effect is better.

Owner:中江县三鑫粮油有限公司

Automatic feedback control tension taping machine

The invention discloses an automatic feedback control tension taping machine. The machine comprises a frame, a taping mechanism arranged on the frame, and a driving mechanism for driving the taping device to operate; the taping device includes a bearing base arranged at the top end of the frame, multiple bearings arranged in the bearing base, a rotating shaft for penetrating through the multiple bearings in sequence, and a taping mechanism arranged at one end of the rotating shaft; a wire passing hole for penetrating through two ends of the rotating shaft is formed in the rotating shaft; and the taping mechanism is provided with a detecting mechanism for detecting the diameter of a taping disc arranged on the taping mechanism, and an adjusting mechanism for adjusting the resistance of the taping disc. During taping, the detecting mechanism detects the diameter of the taping disc arranged on the taping mechanism to adjust the resistance of the adjusting mechanism to the taping disc, so that the taping disc is not influenced by inertia in the taping process; and when wrapping tapes are ruptured, the diameter of the taping disc is invariable, so that the rupture of the wrapping tapes can be detected.

Owner:DONGGUAN QINGFENG ELECTRIC MACHINERY

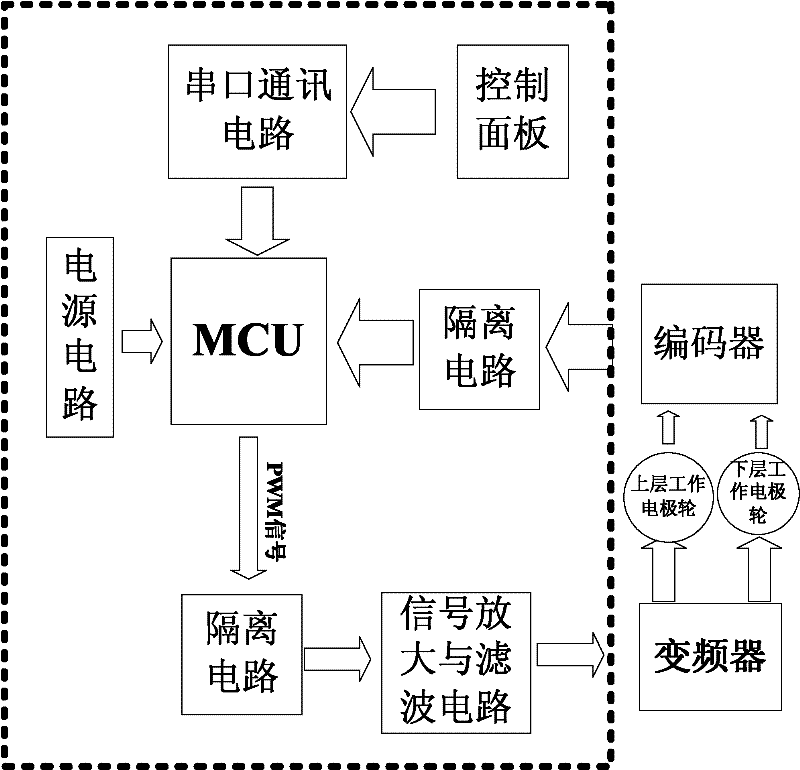

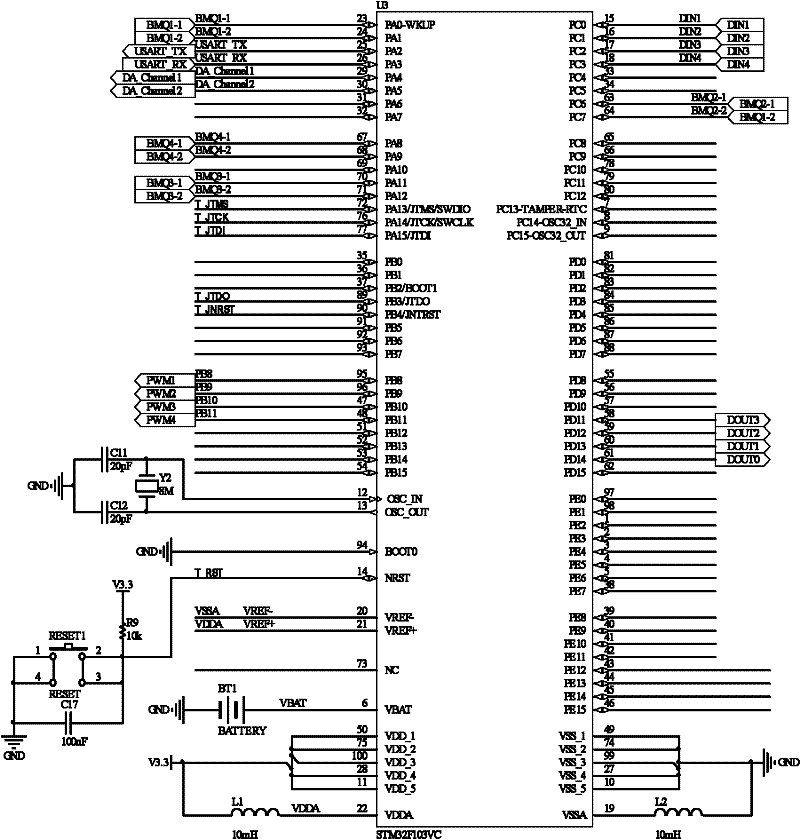

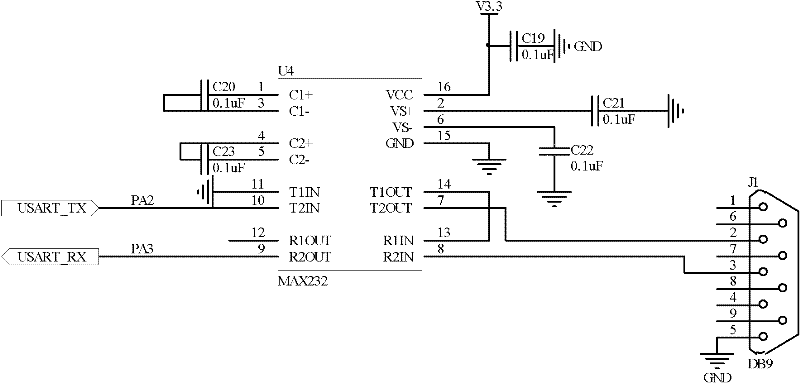

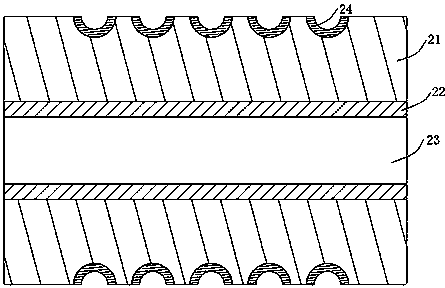

Seam welder electrode wheel synchronous control system and method

InactiveCN102310257ASame line speedPrecision weldingWelding with roller electrodesSynchronous controlPwm signals

The invention relates to a seam welder electrode wheel synchronous control system and method for solving the problem that the linear speed of rotation is inconsistent because the diameters of a motor head of a seam welder are inconsistent due to abrasion, and relates to the control field of seam welder electrode wheel rotation. The invention is used for controlling the synchronous rotation of two electrode wheels. A coder is used for acquiring the speed signal of the working electrode wheel and feeding back the signal to an MCU (Microprogrammed Control Unit) controller, and a PWM (Pulse-Width Modulation) signal with certain frequency and duty ratio is generated through the analysis calculation of the MCU. The signal is used for controlling the rotation speed of the next layer of electrode wheel through isolation and filter amplification, and the electrode wheel is kept to have the same linear speed with the former layer of electrode wheel.

Owner:BEIJING UNIV OF TECH

Novel grinding part and automatic grinding device

PendingCN110434719APolished evenlyAutomate operationGrinding machinesGrinding/polishing safety devicesEngineeringScrap

The invention provides a novel grinding part. The grinding part is of a cylindrical structure, a abrasive particle layer, a flexible base material layer and a hollow shaft structure are sequentially arranged from outside to inside, the abrasive particle layer is arranged on the flexible base material layer, the hollow shaft structure is wrapped by the flexible base material layer, and the grindingpart is arranged on the corresponding grinding device through the hollow shaft structure. According to the grinding part, the cylindrical side surface serves as a grinding contact surface, so that the linear speed of abrasive grains during grinding is relatively consistent, and the abrasive grain layer is in matched contact with the curved surface of a product to be machined through the flexiblebase material layer, so that uniform grinding is realized, and the grinding effect is ideal. The invention further provides the automatic grinding device. The grinding device comprises a machine frame, a power part and the grinding part, wherein the power part and the grinding part are installed on the machine frame, the power part is in driving connection with the grinding part so that the grinding part can rotate at the set rotating speed, cleaning cooling water can be applied to one side of the grinding part, the surface temperature of a ground workpiece is effectively reduced, and scraps are removed in time.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com