Belted layer winding device and control method

A technology of a winding device and a control method, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of missed signal detection, poor reliability, and long signal detection delay when the speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

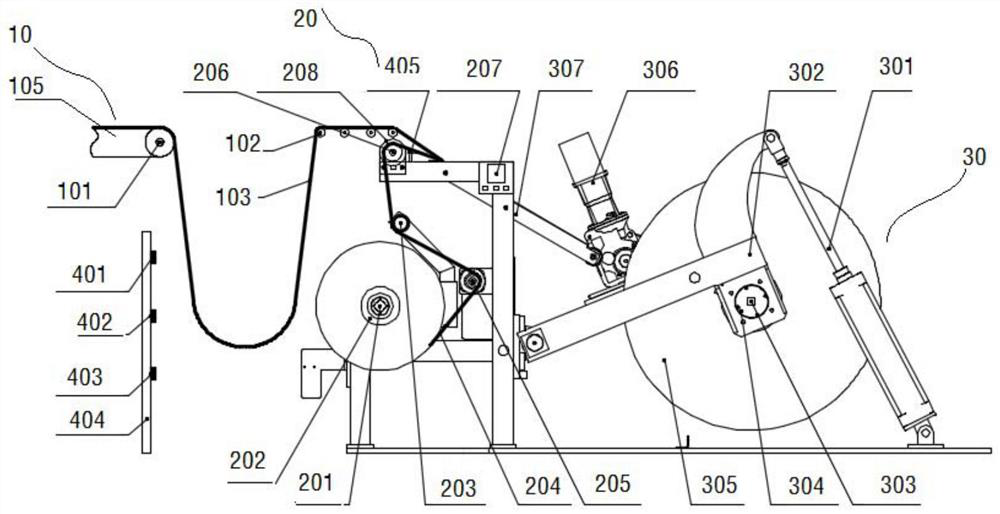

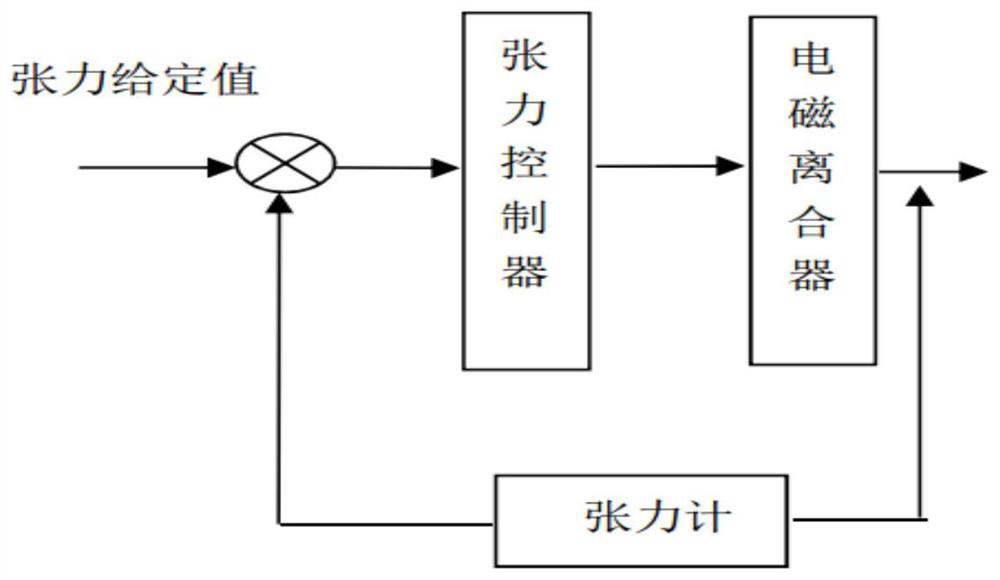

[0032] A kind of winding device of belt layer of present embodiment, see figure 1 As shown, it includes: a belt layer conveying unit 10; the plastic paper conveying unit 20 unwinds the plastic paper 204 through the rotation of the plastic paper reel 201 and imports it on the conveying plate 307 at the same rate as the belt layer 103; the tension sensor 208 senses The unwinding tension of the plastic paper is controlled by the tension controller 207 to adjust the electromagnetic clutch 202 on the plastic paper reel 201 to adjust the tension; to the tooling barrel 305.

[0033] Specifically, the belt layer conveying unit 10 includes a conveying device 101 and a plurality of unpowered rollers 102, the unpowered rollers 102 are arranged on the top of the plastic paper conveying unit 20 and are positioned on the same level as the conveying device 101, and the belt layer 103 During the conveying process, a material pocket is formed between the conveying device 101 and the non-movin...

Embodiment 2

[0037] The present invention also includes a control method of a belt winding device, comprising:

[0038] The belt layer conveying unit 10 conveys the belt layer 103 at a certain speed;

[0039] The plastic paper delivery unit 20 unwinds the plastic paper 204 at the same rate as the belt layer delivery unit 10;

[0040] The crimping unit 30 curls the bonded belt layer and plastic paper to the tooling cylinder at a certain speed; during the product winding process, the linear speed of the belt layer conveying unit 101 is consistent with the linear speed of the crimping unit 30 .

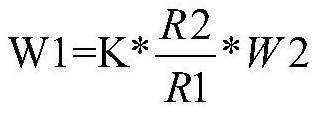

[0041] Specifically, a proximity switch 405 is provided on the reel frame near the leading end of the conveying plate 307 . As the number of winding meters increases, the rolling diameter of the product becomes larger, so it is necessary to control the angular velocity of the servo motor 306 to meet the rolling requirements. During the speed control process, the number of meters is calculated throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com