Spinning method and device for symmetrically covering rigid fiber filament by short fiber bundles

A technology of rigid fibers and short fibers, which is applied in spinning machines, yarns, textiles and papermaking, etc. It can solve the problems of fiber bending and brittleness, resistance to bending and extrusion, etc., and achieve enhanced protection, quality assurance, and good tension and the effect of twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

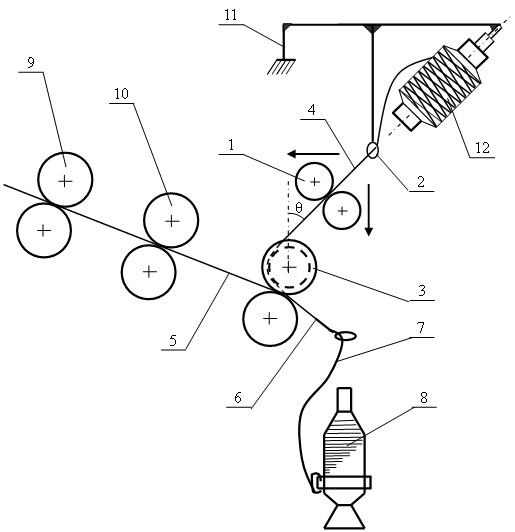

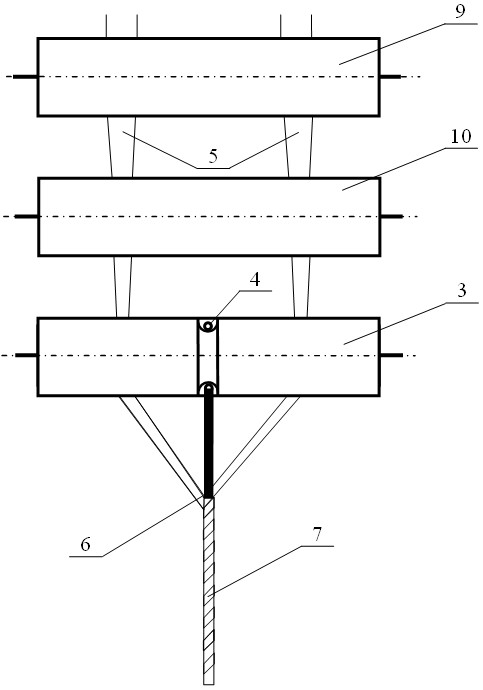

[0026] Such as figure 1 As shown, it is a side view of the spinning device in which short fiber bundles are coated with rigid fiber filaments. The spinning device includes a ring spinning frame and a fixed frame 11 fixed on the ring spinning frame. The fixed frame 11 is provided with There are filament drum 12 and yarn guide 2, and the position of yarn guide 2 on the fixed frame 11 can be adjusted, so that the clamping surface of unwinding roller 1 and yarn guide 2 are all arranged on the axis of filament drum 12 , the ring spinning frame has rear roller pairs 9, middle roller pairs 10 and front roller pairs 3, one roller of the front roller pair 3 is a slotted roller, and a back roller is provided between the slotted roller and the yarn guide 2. Around the roll 1.

[0027] The unwinding roller 1 can move in left and right and up and down directions. The unwinding roller 1 can be moved horizontally to the left to reduce or move vertically down to increase the enveloping ...

Embodiment 2

[0030] Adopt the spinning device described in embodiment 1, rigid fiber long filament 4 adopts carbon fiber long filament, short fiber bundle 5 adopts cotton short fiber bundle, under the drive of front roller pair 3, the rigid fiber long filament on the filament tube 12 4 is fed into the unwinding roller 1 through the yarn guide 2, and is pre-twisted while unwinding, and the pre-twisted rigid fiber filament 4 enters the groove of the slotting roller and is output along the groove, and passes through the back roller. 9 and the middle roller pair 10 feed the front roller pair 3 and the two symmetrical short fiber bundles 5 output by the front roller pair 3 converge at the convergence point 6, and at the same time, under the rotation of the spindle 8 of the ring spinning frame, the short The fiber bundle 5 and the rigid fiber filament 4 are turned and twisted at the converging point 6 to form a composite yarn 7 in which the short fiber bundle 5 covers the outside of the rigid fib...

Embodiment 3

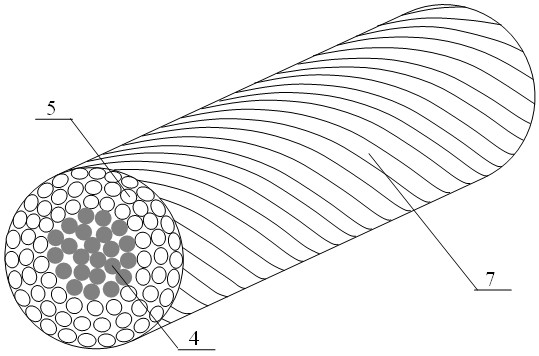

[0032]Adopt the spinning device described in embodiment 1, rigid fiber long filament 4 adopts glass long filament, short fiber bundle 5 adopts polyester short fiber bundle, under the drive of front roller pair 3, the rigid fiber long filament on the filament tube 12 4 is fed into the unwinding roller 1 through the yarn guide 2, and is pre-twisted while unwinding, and the pre-twisted rigid fiber filament 4 enters the slot of the slotting roller and is output along the slot. 9 and the middle roller pair 10 feed the front roller pair 3 and the two symmetrical short fiber bundles 5 output by the front roller pair 3 converge at the convergence point 6, and at the same time, under the rotation of the spindle 8 of the ring spinning frame, the short The fiber bundle 5 and the rigid fiber filament 4 are turned and twisted at the converging point 6 to form a composite yarn 7 in which the short fiber bundle 5 covers the outside of the rigid fiber filament 4 . Such as image 3 Shown is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com