Multi-beltsaw drive mechanism and working method thereof

A driving mechanism and a technology for band saws, applied in band saws, sawing equipment, manufacturing tools, etc., can solve the problems of high linear speed of band saw blades, affecting production progress, scrapping of band saw blades, etc., so as to improve economic benefits and reduce downtime for maintenance. frequency, the effect of ensuring the progress of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

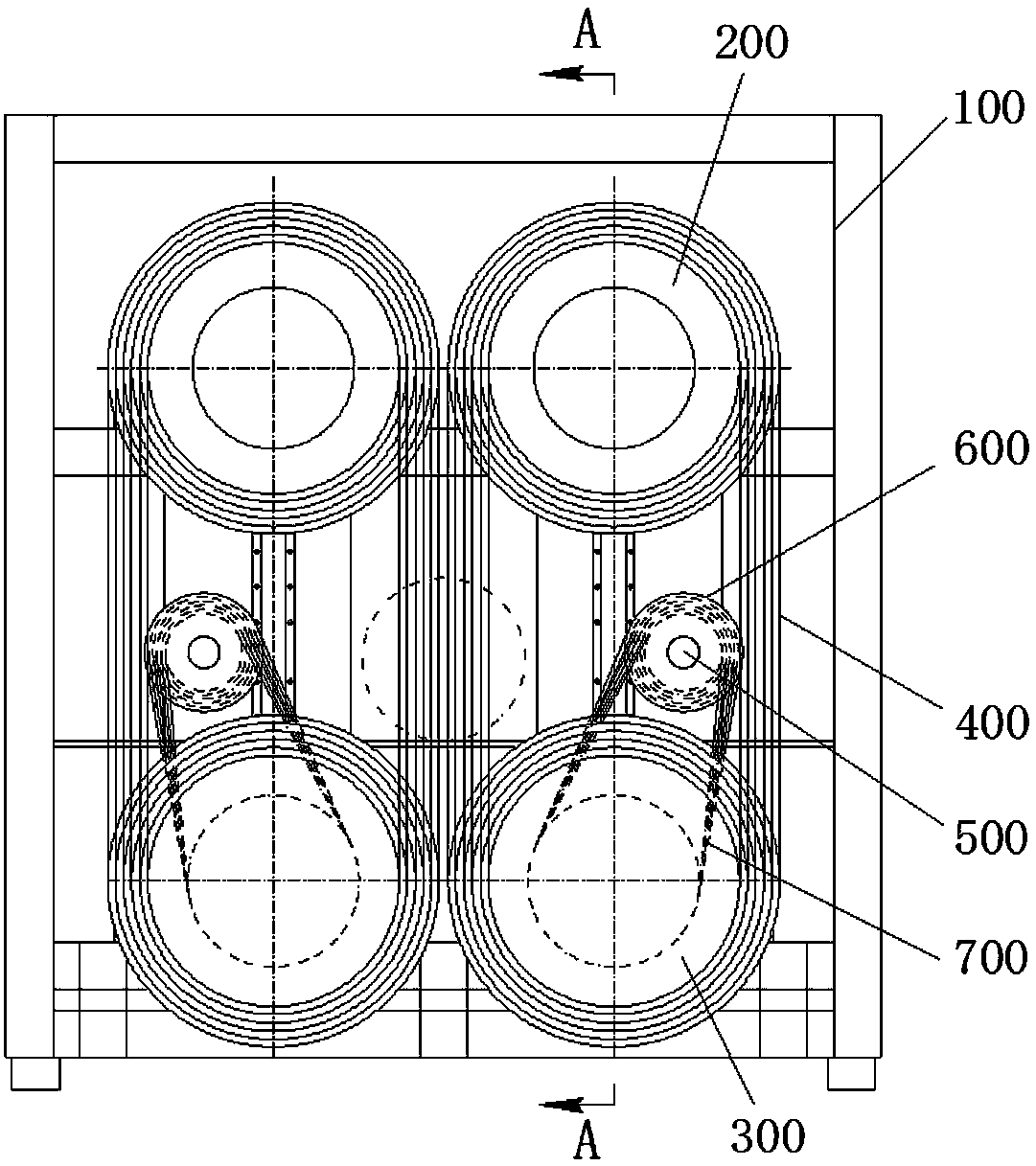

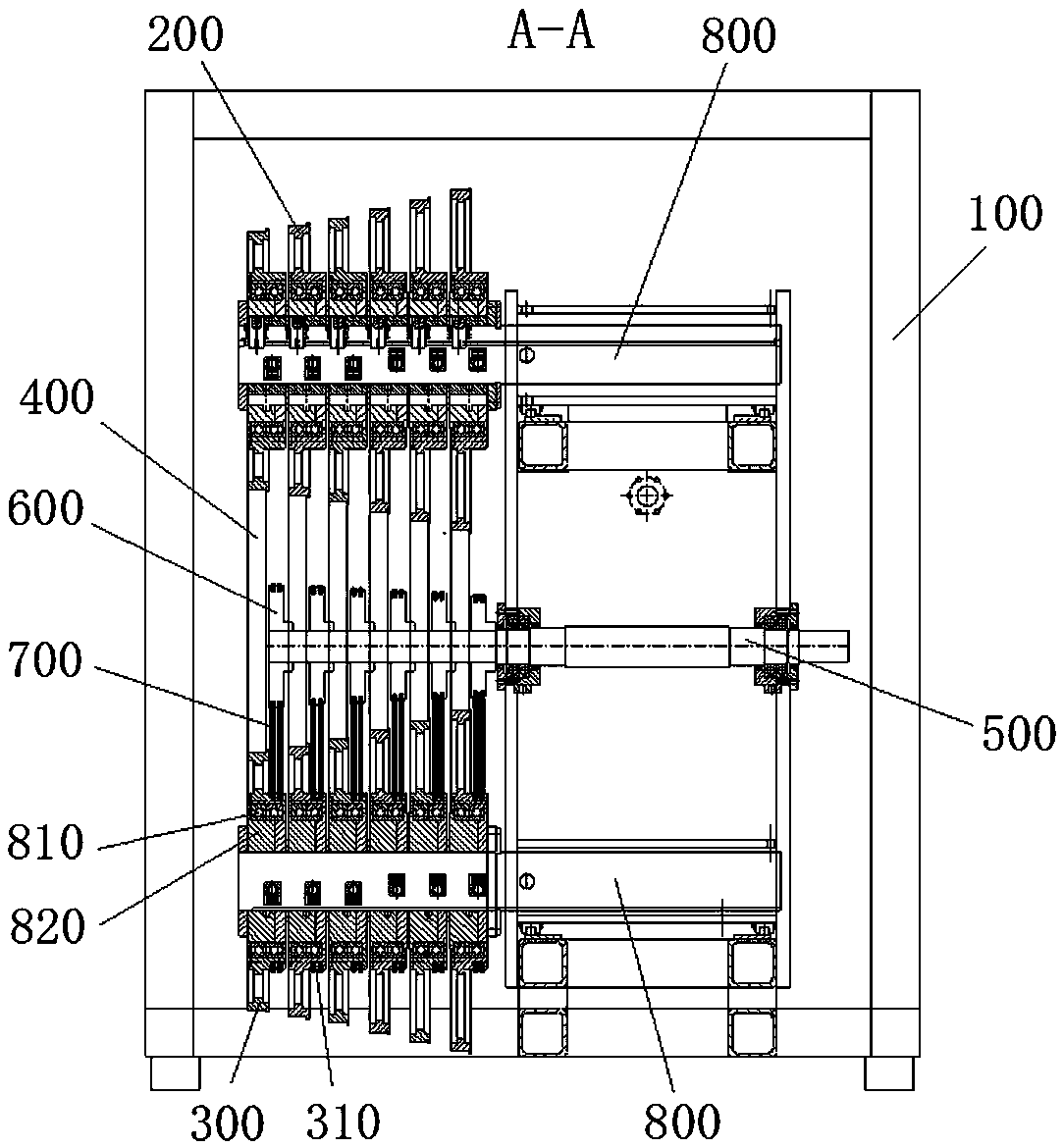

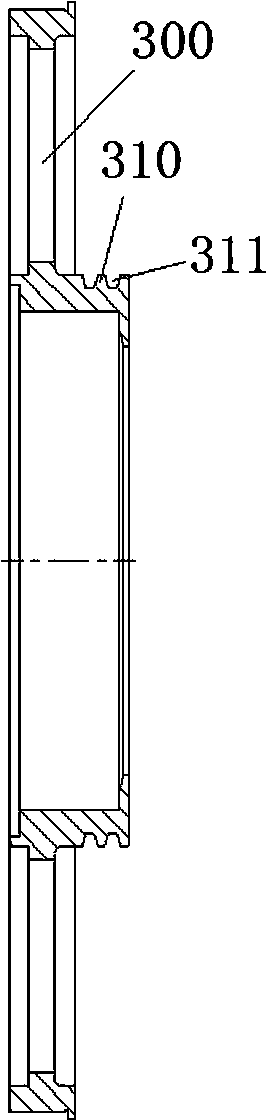

[0015] Embodiment one: if Figure 1~2 As shown, a multi-band saw driving mechanism includes a frame 100, and the frame 100 has a plurality of coaxially arranged upper pulleys 200 and lower pulleys 300 with increasing diameters, and the upper pulleys 200 and the lower pulleys A plurality of band saw blades 400 forming a multi-circle ring structure are set on the pulley 300, and a drive shaft 500 between the upper pulley and the lower pulley is installed on the frame 100, and a plurality of lower pulleys are set on the drive shaft 500. The pulleys are one-to-one corresponding to the pulley 600 with decreasing diameter. The direction of decreasing diameter of the pulley is consistent with the direction of decreasing diameter of the upper pulley or the lower pulley. The pulley 600 is connected with the corresponding lower pulley through the transmission belt 700. The pulley thus becomes the driving pulley to drive the band saw blade 400 to work; each upper pulley and lower pulley ...

Embodiment 2

[0021] Embodiment 2: Since the multi-band saw drive mechanism can use the lower pulley as the driving pulley, or the upper pulley as the driving pulley, the difference between this embodiment and Embodiment 1 is that the upper pulley is used as the driving pulley The drive shaft is set with a plurality of pulleys corresponding to one by one and with decreasing diameters, and the pulleys are connected to the corresponding upper pulleys through a transmission belt; The belt installation part of the belt has a belt groove on the belt installation part, and the diameter of the belt installation part of all the upper pulleys is the same.

[0022] A working method of the multi-band saw drive mechanism as described above, the drive shaft rotates and then drives each pulley on the drive shaft to rotate, the pulley drives the corresponding upper pulley or lower pulley to rotate through the transmission belt, and the pulley on the drive shaft The diameter decreases sequentially from fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com