A kind of anti-stripping castable at kiln mouth and using method thereof

An anti-spalling, castable technology, applied in the direction of manufacturing tools, supply devices, etc., can solve the problems of lack of effective elastic connection of anchors, poor thermal shock resistance of the kiln mouth lining, and increased compression and tension. Cracking and spalling, improved spalling resistance, improved thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

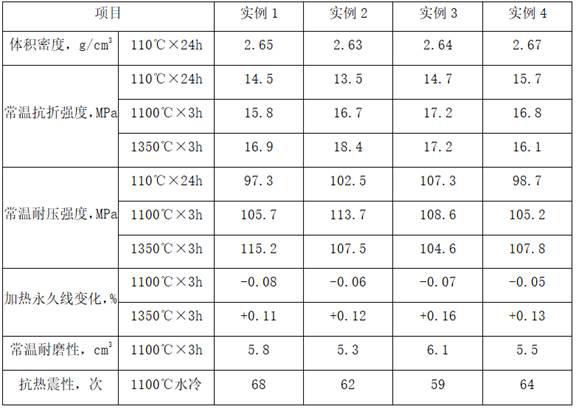

Embodiment 1

[0032] A kiln mouth anti-stripping castable is prepared from the following raw materials in parts by mass: 25 parts of aluminum titanate with a particle size of 8-5mm, 12 parts of aluminum titanate with a particle size of 5-3mm, and 12 parts of aluminum titanate with a particle size of 3- 1mm aluminum titanate, 23 parts aluminum titanate with a particle size of 1-0mm, 10 parts spodumene with a sieved particle size of less than or equal to 200 mesh, 10 parts dispersible alumina powder, 6 parts calcium ferric aluminate powder, 0.03 parts poly Propylene fiber, 0.01 part of dispersant and 6 parts of composite sol are mixed evenly to obtain the anti-stripping castable at the kiln mouth.

[0033] A method of using an anti-stripping castable at a kiln mouth:

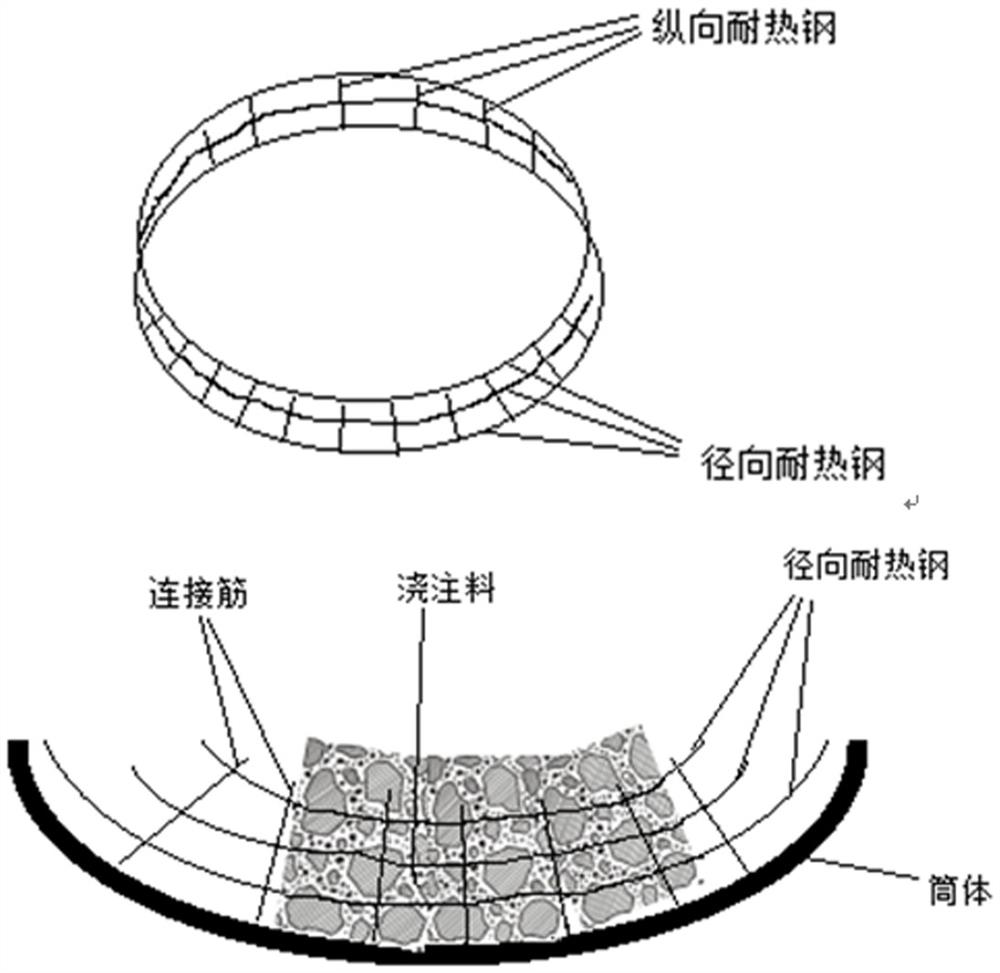

[0034] S1. Weld heat-resistant steel with a diameter of 10mm on the inner lining of the kiln mouth. The heat-resistant steel is arranged longitudinally and radially, with a spacing of 20cm and a height of 2 / 3 of the thickness o...

Embodiment 2

[0040] A kiln mouth anti-stripping castable is prepared from the following raw materials in parts by mass: 18 parts of aluminum titanate with a particle size of 8-5mm, 12 parts of aluminum titanate with a particle size of 5-3mm, and 8 parts of aluminum titanate with a particle size of 3- 1mm aluminum titanate, 18 parts aluminum titanate with a particle size of 1-0mm, 6 parts spodumene with a sieved particle size of less than or equal to 200 mesh, 15 parts dispersible alumina powder, 3 parts calcium ferric aluminate powder, 0.01 part polymer Propylene fiber, 0.03 part of dispersant and 4 parts of composite sol are mixed evenly to obtain the anti-stripping castable at the kiln mouth.

[0041] A method of using an anti-stripping castable at a kiln mouth:

[0042] S1. Weld heat-resistant steel with a diameter of 10mm on the inner lining of the kiln mouth. The heat-resistant steel is arranged longitudinally and radially, with a spacing of 15cm and a height of 2 / 3 of the thickness o...

Embodiment 3

[0048] A kiln mouth anti-stripping castable is prepared from the following raw materials in parts by mass: 20 parts of aluminum titanate with a particle size of 8-5mm, 15 parts of aluminum titanate with a particle size of 5-3mm, and 10 parts of aluminum titanate with a particle size of 3- 1mm aluminum titanate, 20 parts aluminum titanate with a particle size of 1-0mm, 8 parts spodumene with a sieved particle size of less than or equal to 200 mesh, 13 parts dispersible alumina powder, 5 parts calcium ferric aluminate powder, 0.02 part poly Propylene fiber, 0.02 part of dispersant and 5 parts of composite sol are mixed evenly to obtain the anti-stripping castable at the kiln mouth.

[0049] A method of using an anti-stripping castable at a kiln mouth:

[0050] S1. Weld heat-resistant steel with a diameter of 10mm on the inner lining of the kiln mouth. The heat-resistant steel is arranged longitudinally and radially, with a spacing of 20cm and a height of 2 / 3 of the thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com