Patents

Literature

991results about How to "Play a stabilizing role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

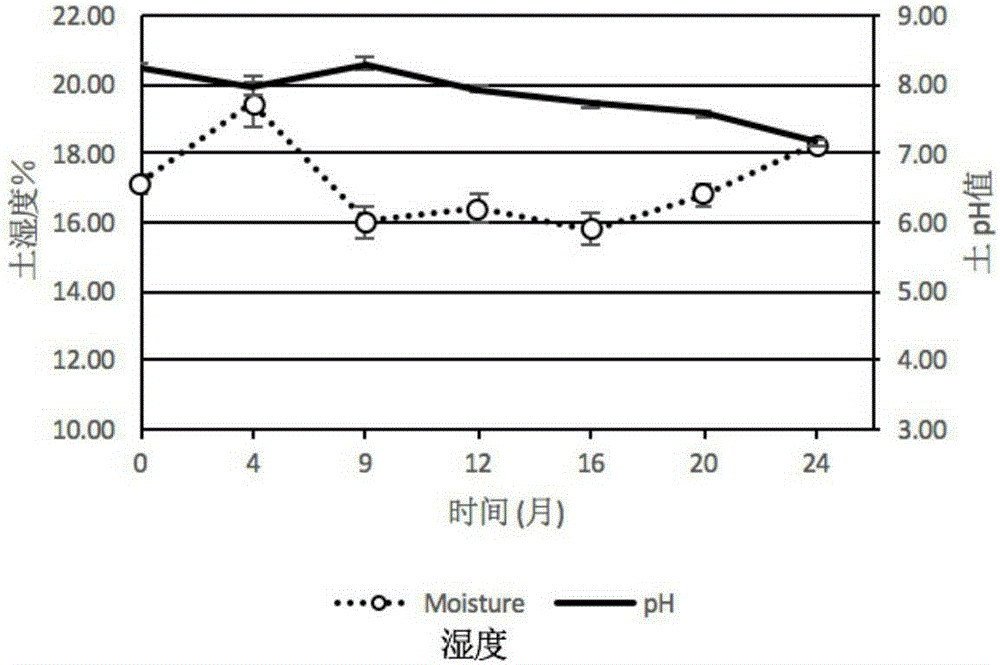

A method for the remediation of harmful organics and/or heavy metal contaminated matrix

ActiveCN105344709APlay a role in loosening and ventilatingRestoration concepts for green sustainabilityContaminated soil reclamationBiostimulationMicrobial agent

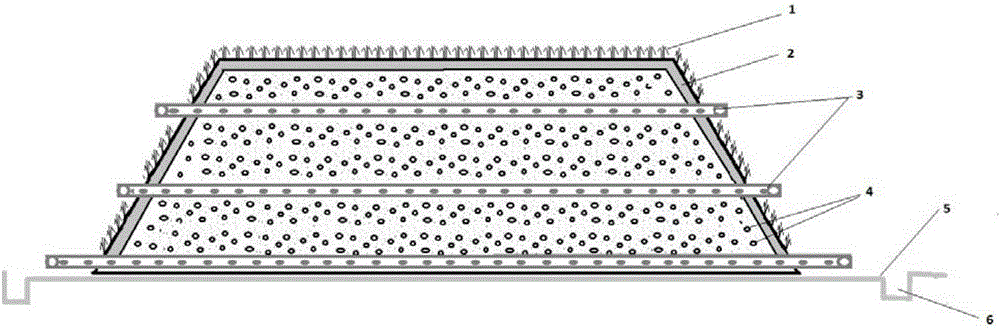

The present invention provides a method for the remediation of harmful organics and / or heavy metal contaminated matrix in order to remediate harmful organics and / or heavy metal contaminated soil, sediment and / or sludge. The method involves the processes of biostimulation, bioaugmentation, rhizoremediation, phytoremediation and a passive biopile. The method comprises steps of: a) designing a microbial agent comprising pollutant degrading bacteria, plant promoting bacteria and / or biosurfactant producing bacteria; b) preprocessing the matrix; c) constructing a passive biopile; and d) capping the biopile with plants for phytoremediation. The method achieves internationally-dominant green and persistent remediation while achieving bioremediation / phytoremediation degrading the organics and removing heavy metal.

Owner:山东迈科珍生物科技有限公司

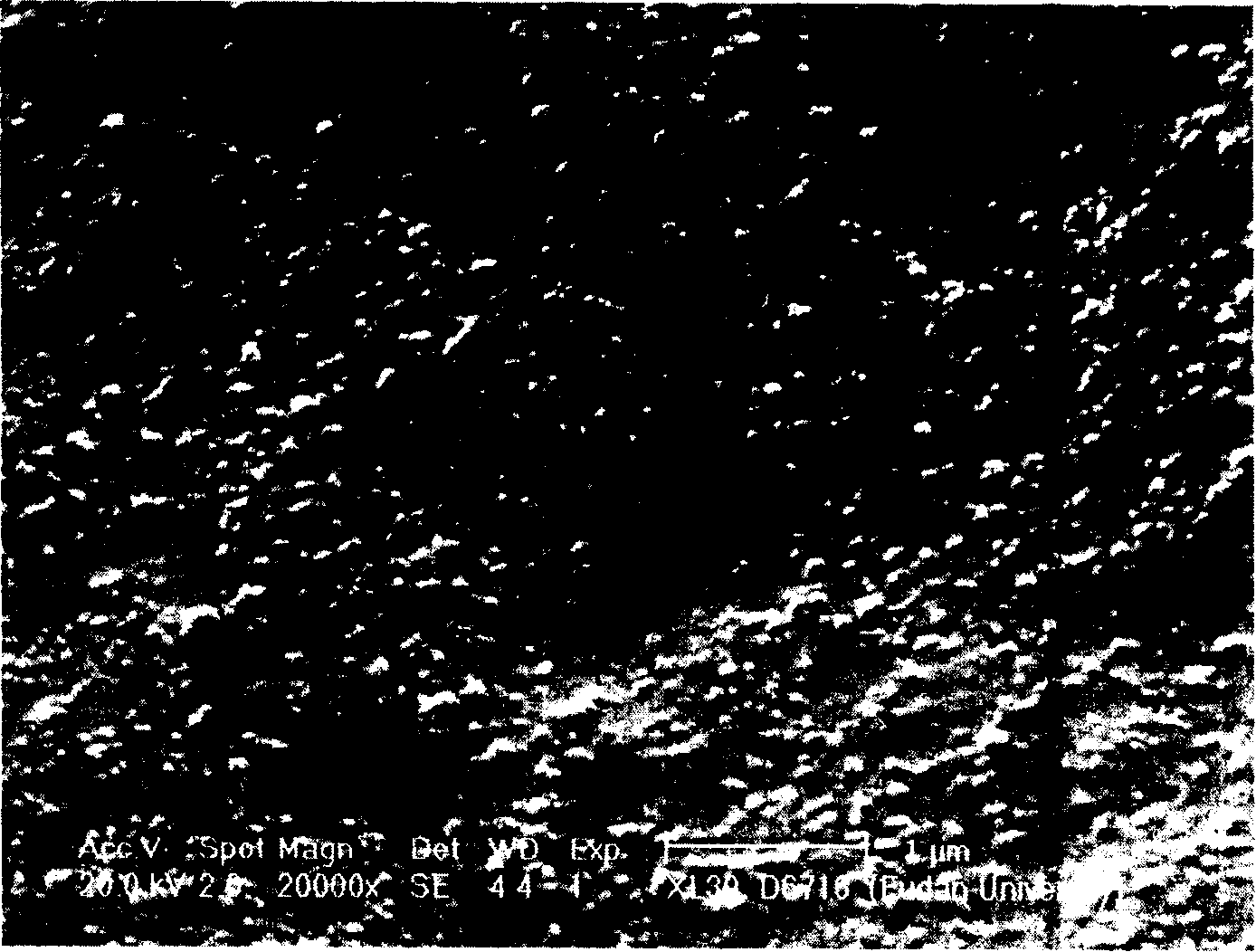

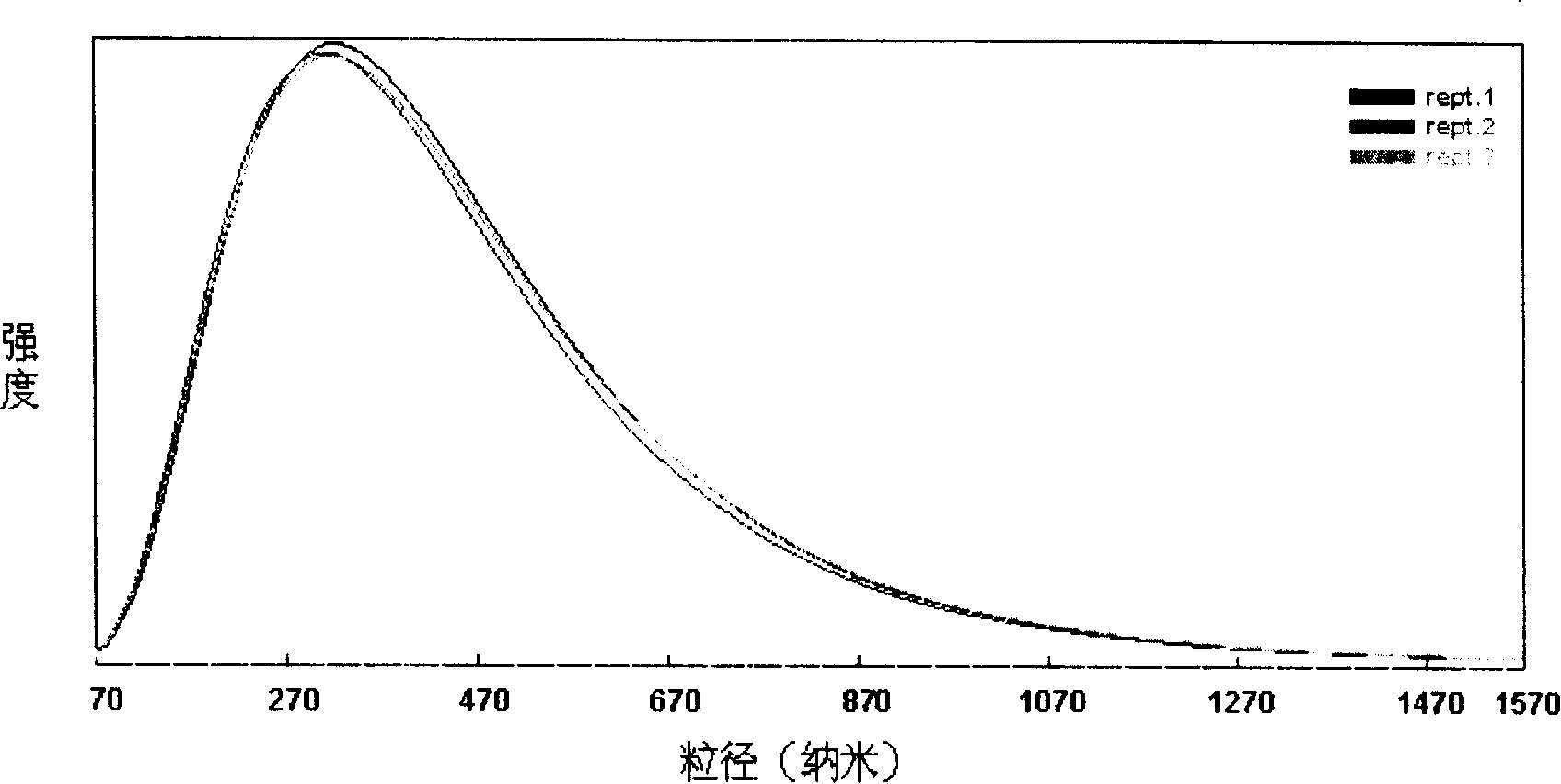

Aqueous siliconiting polymer emulsion as well as preparation method and use thereof

InactiveCN101230138AInhibition of self-crosslinkingPlay a stabilizing roleCosmetic preparationsOrganic detergent compounding agentsCross-linkElastomer

The invention relates to aqueous silanized polymer emulsion and the preparation method and the application thereof. The emulsion of the invention contains a silanized polymer, a hydrolysable silanized compound, water, non-essential emulsifier and non-essential nano-silicon dioxide. By adopting the preparation method of the invention, stable aqueous silanized polymer emulsion can be prepared, the prepared aqueous silanized polymer emulsion has the solid content of smaller than or equal to 85 weight percent, especially, prepared polyorganosiloxane emulsion has the solid content of smaller than or equal to 75 weight percent, and the particle diameter of smaller than 3 micrometers, and can be laid stably at the room temperature. An elastomer can be formed through cross linking after water in the emulsion is volatilized. During the operation, the emulsion can be directly diluted through the water, and can be used for preparing coating, adhesive, sealant, printing ink, release agent, skin food, cleansing agent and so on.

Owner:汉高股份两合公司

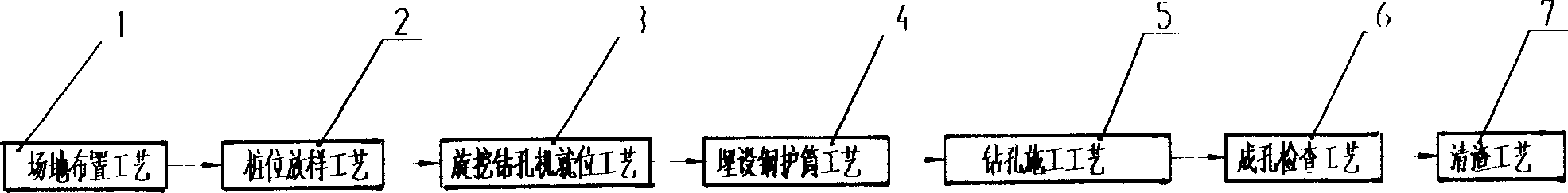

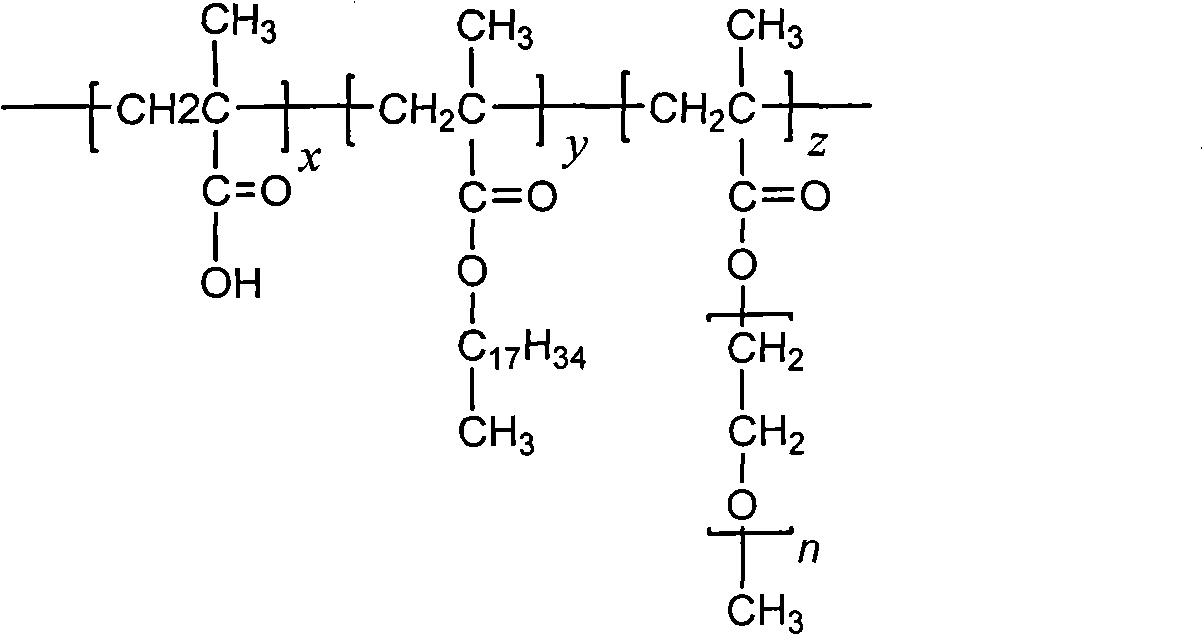

Construction technology of dry soil taking hole forming method of rotary digging drilling machine

InactiveCN1831250AReasonable construction technologySimple construction processSoil-shifting machines/dredgersBulkheads/pilesDry soilSlurry

The invention is a dry earth drawing-hole forming construction process of a helical digging driller, comprising in turn site layout process, pile position templating process, helical digging driller seating process, steel sleeve burying process, drilling construction process, geologic condition recording process, hole forming checking process, residues cleaning process, etc, and having the characters of replacing traditional manmade experience construction method, needing no slurry to protect walls in the hole forming course, reasonable and convenient to operate, low operating cost, etc.

Owner:徐州工程机械科技股份有限公司徐工研究院

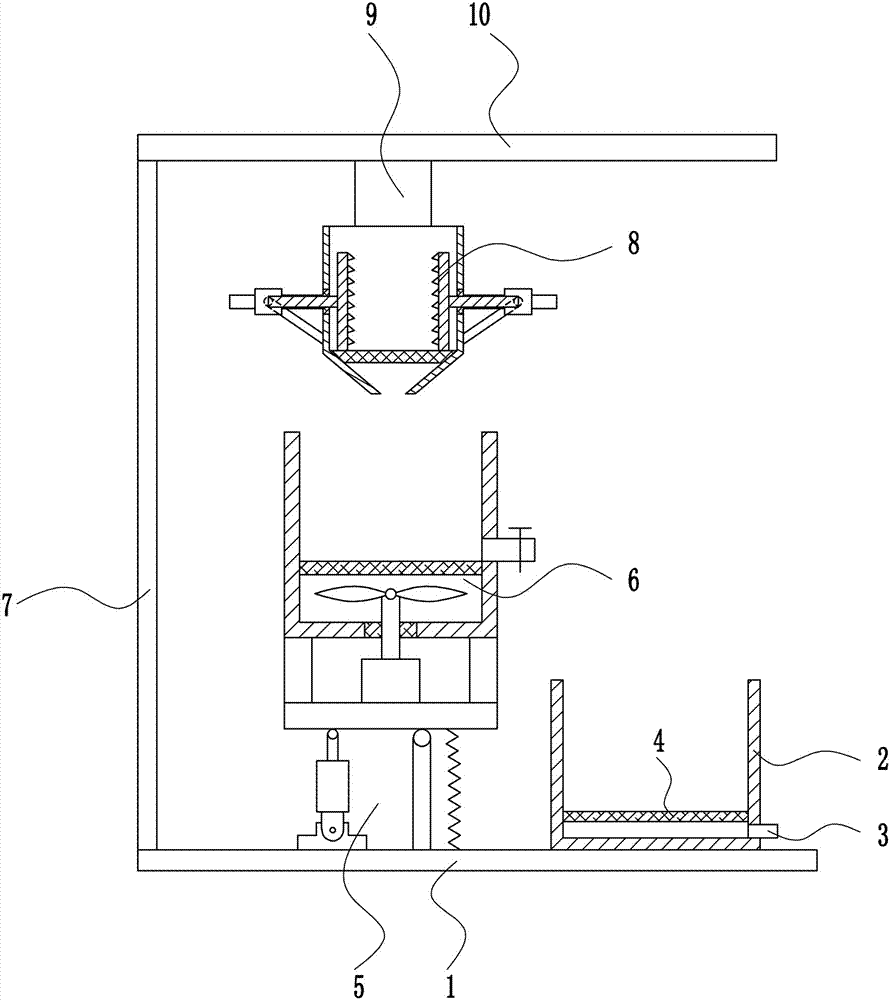

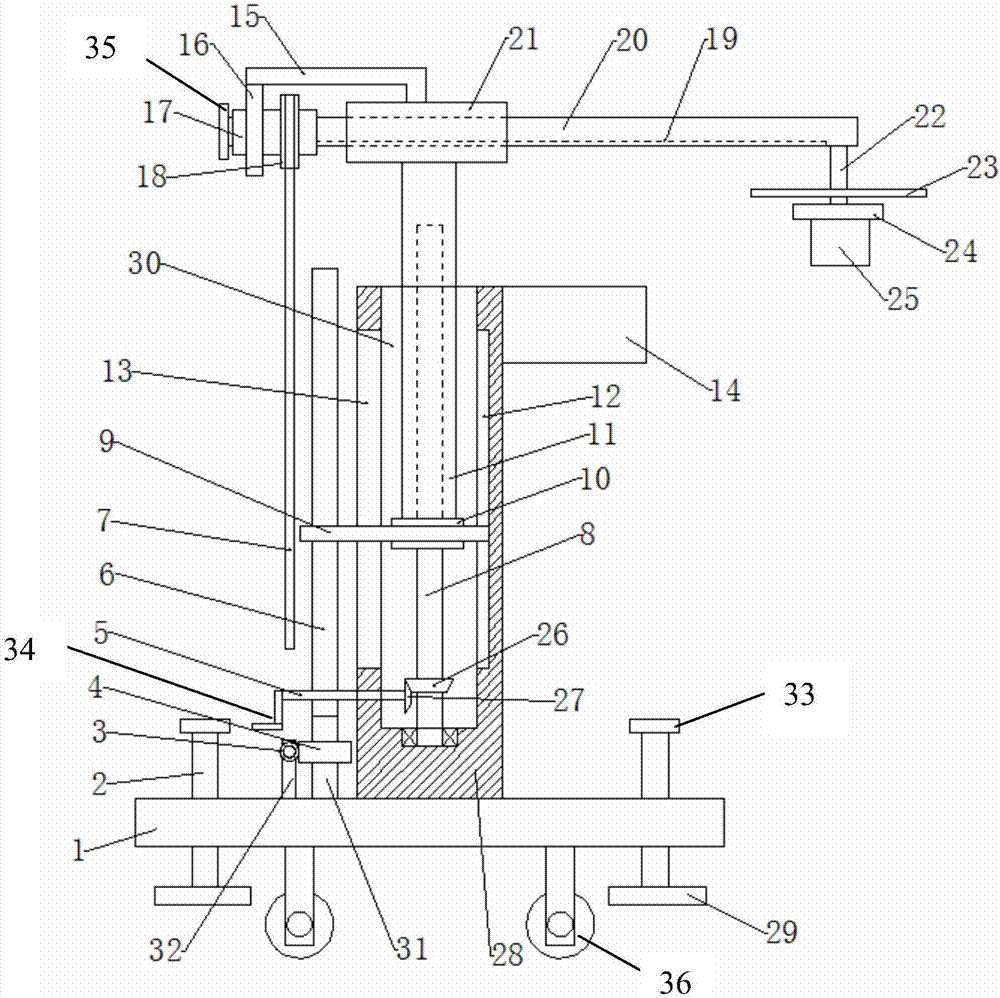

Crushing and cleaning integrated machine used for recycling waste plastics

PendingCN107097367APlay a stabilizing rolePlay a protective effectPlastic recyclingCleaning using liquidsPlastic recycling

The invention belongs to the field of recycling of waste plastics, and particularly relates to a crushing and cleaning integrated machine used for recycling waste plastics. The technical problem needing to be solved by the invention is to provide the crushing and cleaning integrated machine used for recycling waste plastics, and the crushing and cleaning integrated machine used for recycling waste plastics can crush and clean simultaneously, and is simple in recycling process and high in efficiency. In order to solve the technical problem, the invention provides the crushing and cleaning integrated machine used for recycling waste plastics. The crushing and cleaning integrated machine used for recycling waste plastics comprises a base plate, a collecting frame, a liquid discharge pipe, a first screen plate, a turning mechanism and a cleaning mechanism; the collecting frame is arranged on the right side of the top of the base plate, the liquid discharge pipe is arranged at the bottom of the right wall of the collecting frame, the first screen plate is installed at the bottom of the interior of the collecting frame, the turning mechanism is installed in the middle of the top of the base plate, and the cleaning mechanism is connected onto the turning mechanism. The crushing and cleaning integrated machine used for recycling waste plastics achieves the effects that the crushing and cleaning integrated machine crushes and cleans simultaneously, is simple in recycling process, and is high in efficiency.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

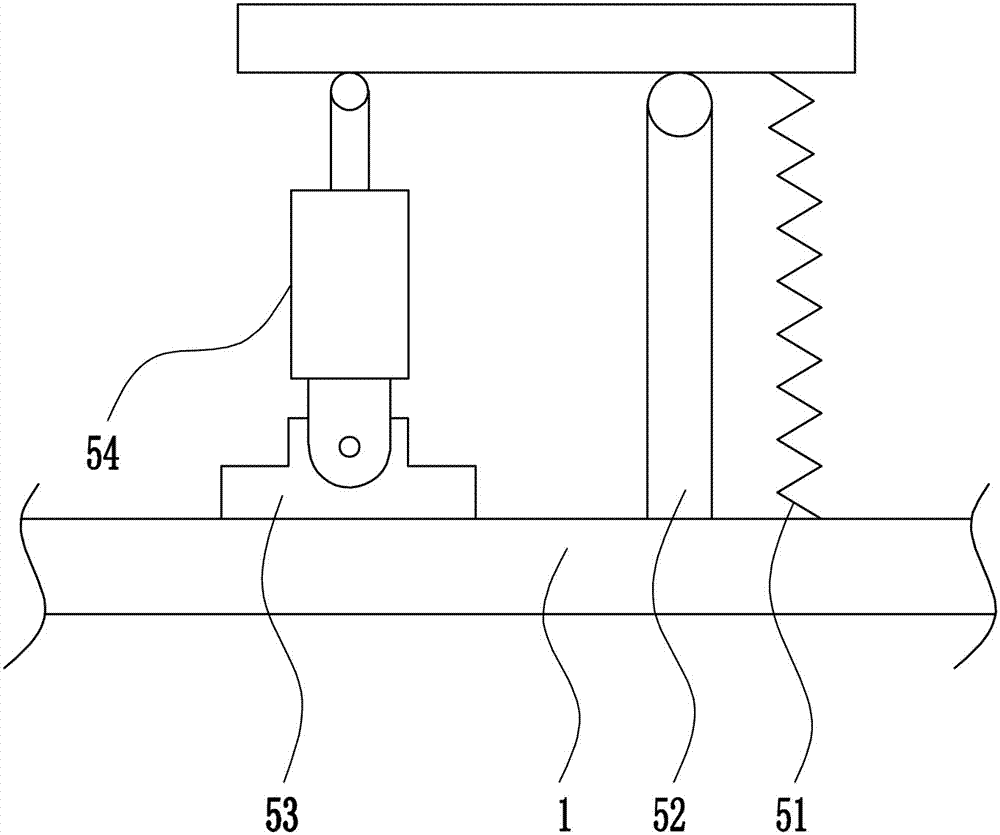

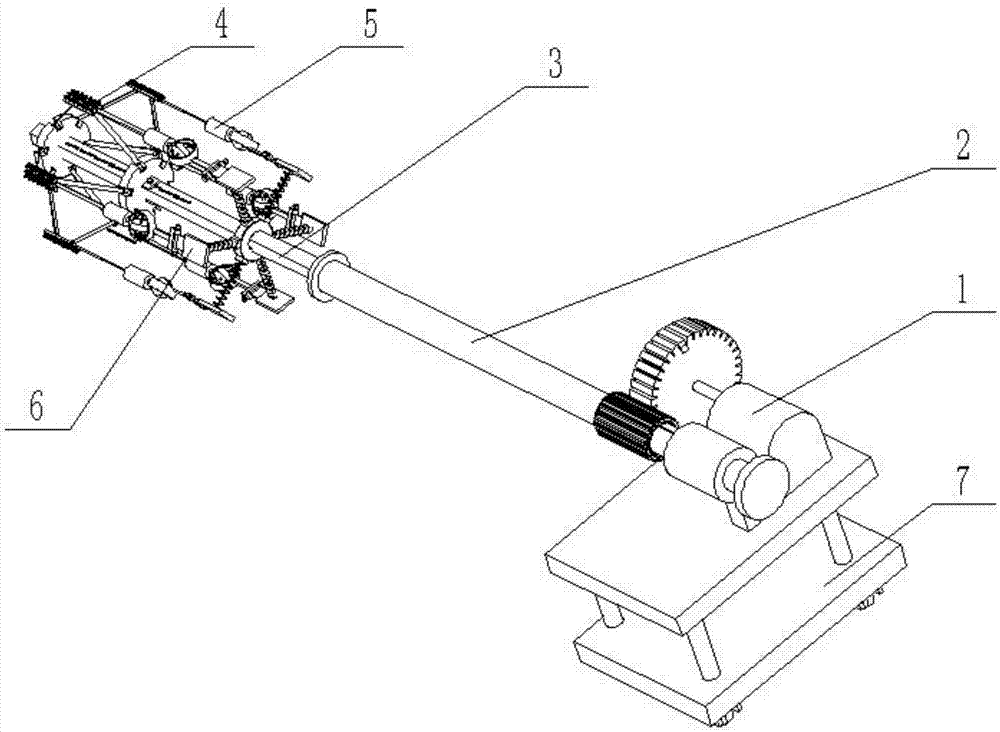

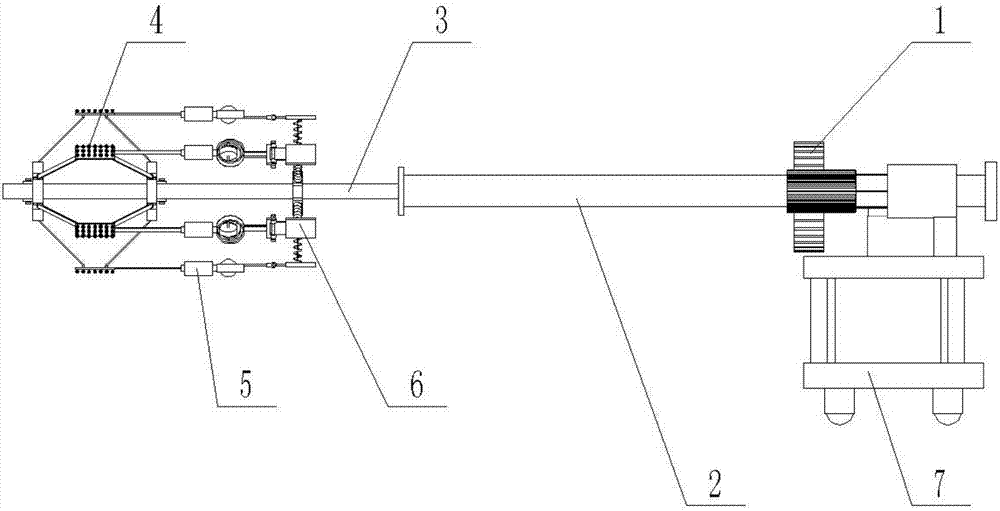

Petroleum pipeline cleaning device

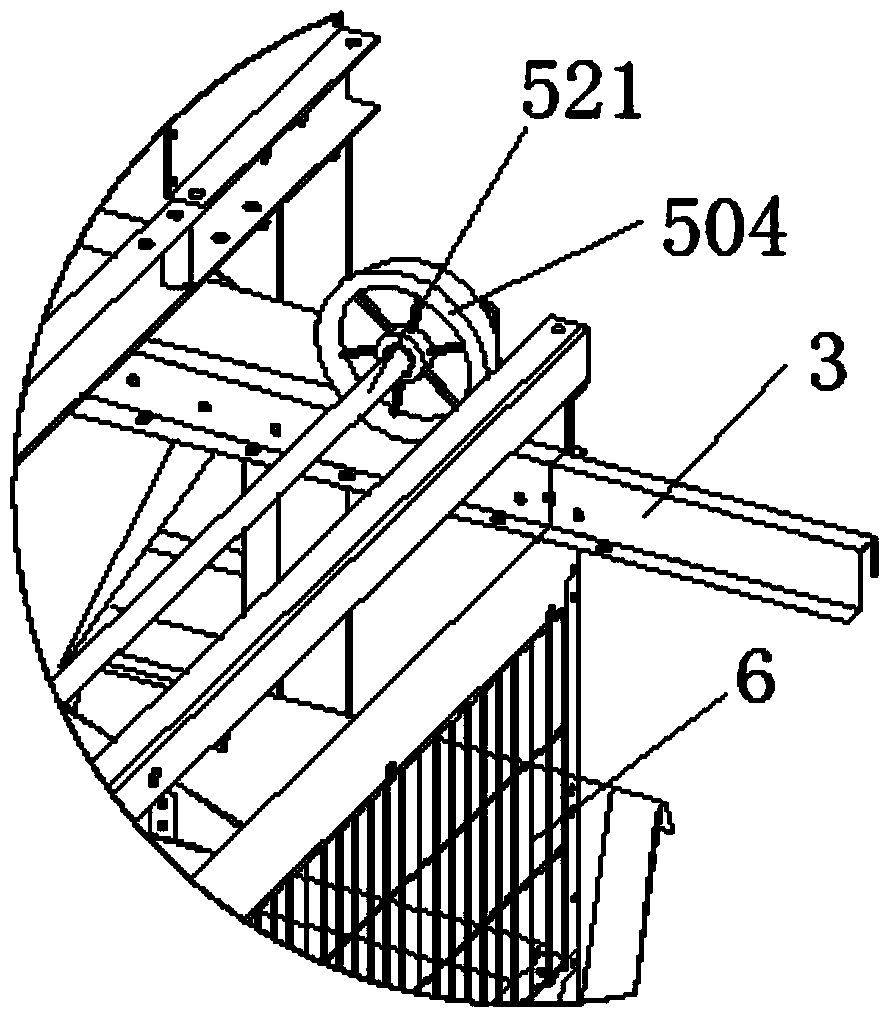

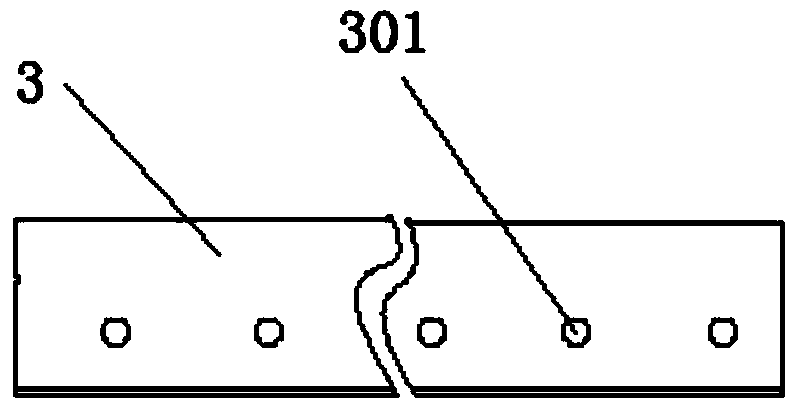

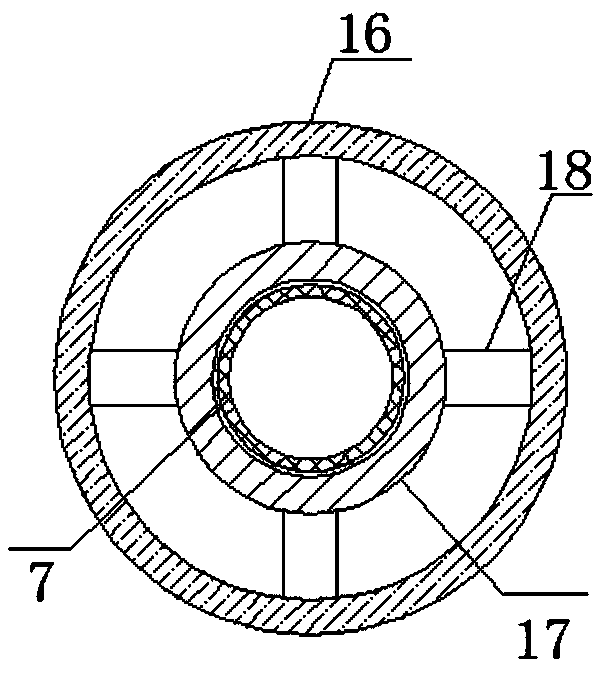

ActiveCN107262466AEasy to cleanAdjust the outer diameterHollow article cleaningGear wheelDrive shaft

The invention relates to a cleaning device, and particularly relates to a petroleum pipeline cleaning device. The petroleum pipeline cleaning device comprises a cleaning drive device, a telescoping transmission device, a rectangular installation pipe, a front variable-diameter brush head device, a cleaning steady wheel assembly, a rear auxiliary cleaning device and a movable support frame, wherein the cleaning drive device is composed of a drive motor, a drive shaft and a drive gear; the output end of the drive motor is connected with the drive shaft, and the drive gear is fixedly connected to the drive shaft; and the lower end of the drive motor is installed on the movable support frame through bolted connection. The petroleum pipeline cleaning device is capable of effectively solving the problems of low cleaning efficiency, poor cleaning effect and incapacity of cleaning pipe bodies with different apertures, of a pipeline cleaning device in the prior art, and provides a petroleum pipeline cleaning device capable of adjusting the dimensions of the brush head device according to the pipe diameters of actual pipelines and applicable to many pipelines with different apertures; and the petroleum pipeline cleaning device has the advantages of being high in cleaning efficiency, good in cleaning effect and the like.

Owner:温州市博纳电气有限公司

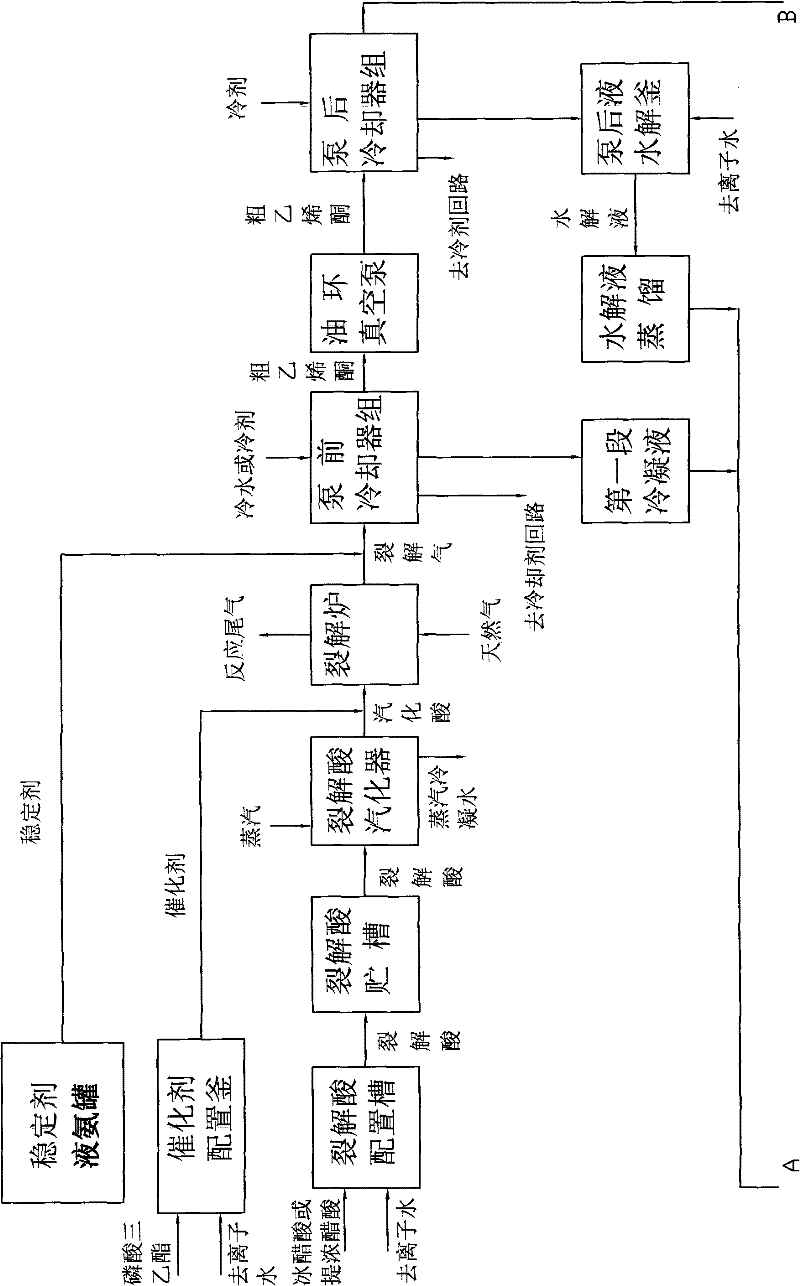

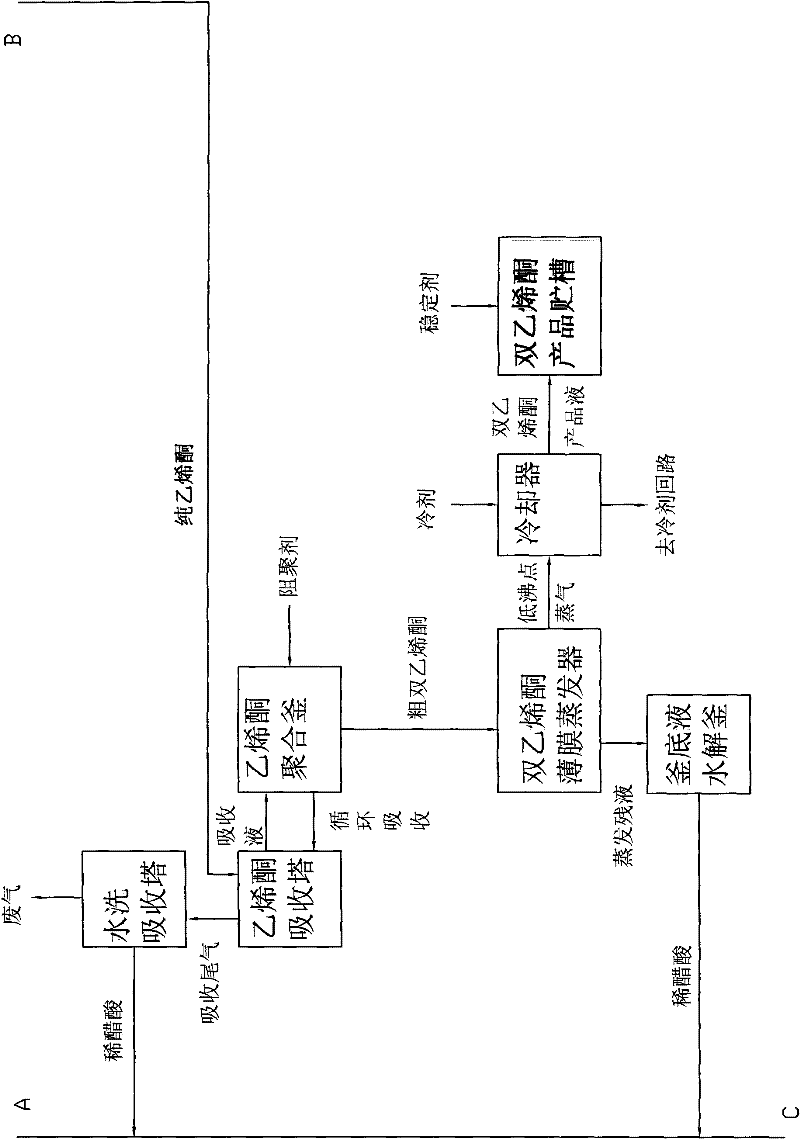

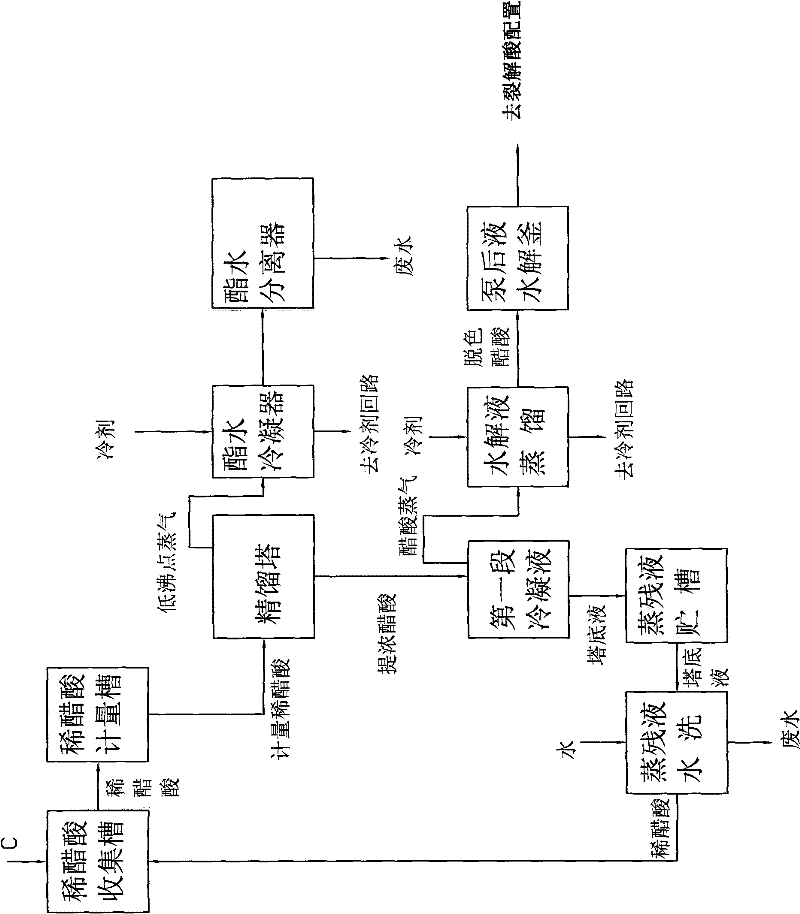

Process for preparing high-purity diketene

The invention relates to a process for preparing high-purity diketene, which overcomes the defects of low purity of ketene, low purity and poor safety of diketene products formed by absorbing and polymerizing ketene, as well as complex process, high cost and high acetic acid content of raffinate in the concentration recovery of dilute acetic acid. The process for preparing high-purity diketene is suitable for absorbing and polymerizing ketene dimer at low temperature on the basis of adopting stable acetic acid cracking conditions and deep refrigeration to remove impurities from cracking gas and generate pure ketene gas, adopting a film evaporator to further purify diketene products at low temperature under low pressure, and adding stabilizers after introducing polymerization inhibitor and diketene for refining during the absorption and polymerization of ketene in order to improve synthesis safety and the stability of products in storage tanks. Meanwhile, the dilute acetic acid produced in the process reasonably matches the temperature of each point of a stripping section through a sensitive plate technique, improves the water-carrying capability of butyl acetate, and greatly reduces the concentration of acetic acid in concentrated raffinate.

Owner:NINGBO WANGLONG TECH

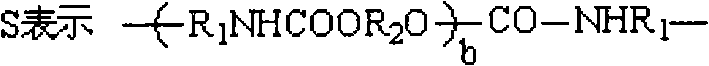

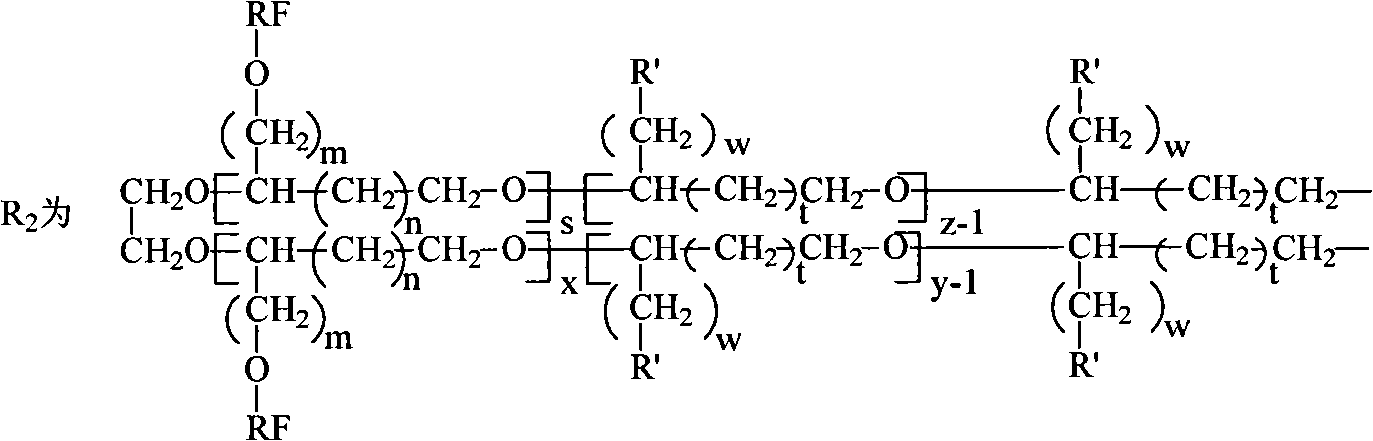

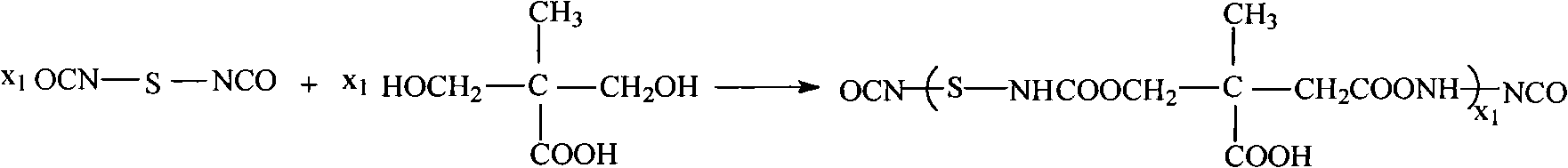

Room-temperature self-crosslinked aqueous polyurethane-polyacrylate containing fluoroalkyl groups in lateral chains and preparation method thereof

InactiveCN101792592AGood water resistanceAnti-pollution mechanical propertiesPolyurea/polyurethane coatingsPrepolymerChemistry

The invention discloses a room-temperature self-crosslinked aqueous polyurethane-polyacrylate containing fluoroalkyl groups in lateral chains and a preparation method thereof. The preparation method comprises following steps: vacuum-dehydrating polyether glycol containing fluorine, and reacting with polyisocyanate to obtain FPU prepolymer containing -NCO end groups; chain-extending with dimethylolpropionic acid to obtain FPU prepolymer containing carboxyl groups; neutralizing with triethylamine to obtain hydrophilic FPU prepolymer, adding water, stirring, and dispersing at high speed to obtain an emulsion; adding a water solution containing a chain extender ADH to obtain chain-extended FPU; orderly adding diacetone acrylamide and vinyl monomer, and initiating by stirring to obtain the PUA copolymerized emulsion; and finally, uniformly mixing the chain-extended FPU with the PUA copolymerized emulsion, coating the mixture on a teflon plate, and drying and crosslinking at room temperature to form the film. The invention can be widely used for surface protection for plastics, rubber, leather, fabrics, ceramics, glass, high-rise building external walls, solar batteries and other materials and devices.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Moving bracket for monitor

InactiveCN107956965APlay a protective effectAvoid damageTelevision system detailsColor television detailsEngineeringControl theory

Owner:STATE GRID TIANJIN ELECTRIC POWER +2

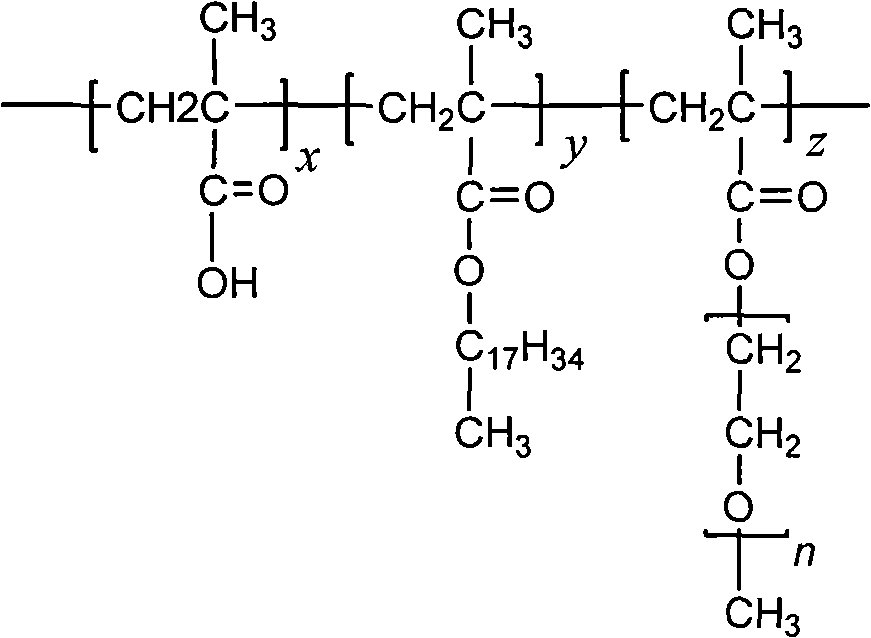

Acrylic ester polymer surfactant and preparation method thereof

InactiveCN102091564ASimple methodPlay a stabilizing roleTransportation and packagingMixingMethacrylatePolymer science

The invention discloses an acrylic ester polymer surfactant and a preparation method thereof. The acrylic ester polymer surfactant is characterized in that: solution polymerization is initiated by using free radicals; benzoyl peroxide is used as an initiator; anion hydrophilic methacrylic acid (MAA), lipophilic stearyl methacrylate (SMA) and nonionic hydrophilic poly(ethylene glycol) dimethacrylate (PEGMA) are used as polymerization monomers respectively; and thus, the amphipathic polymer surfactant is synthesized. In the invention, the drawback that the demanding reaction conditions during graft copolymerization and block copolymerization increases cost and limits yield is overcome, the method is simple and convenient to implement, ensures large monomer selection and component variation range, and contributes to promotion and use.

Owner:余林华

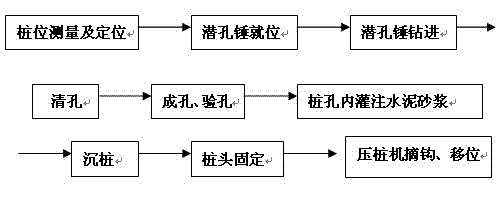

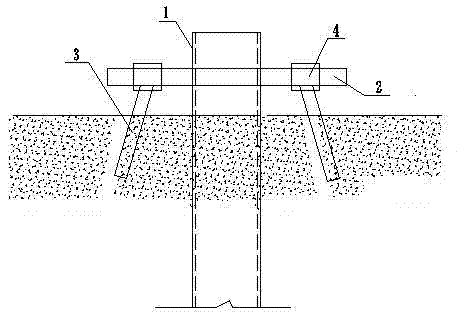

Prestressed pipe pile construction method under boulder group geological conditions

InactiveCN103290840AHigh selectivityPrevent buried drilling phenomenonBulkheads/pilesPre stressArchitectural engineering

The invention relates to a pipe pile construction method, in particular to a prestressed pipe pile construction method under boulder group geological conditions. According to the method, a down-the-hole hammer drilling process is adopted for guide hole construction; during pile sinking construction, first cement mortar is poured in a pile hole, and then a static pile driver is utilized to press a pipe pile into the pile hole; during pile head fixing construction, a #-shaped fixing frame formed by connecting fasteners is utilized to fix a pile head through a steel pipe at the position of an orifice of the pile hole, a splayed steel pipe is adopted to support two ends of the #-shaped fixing frame, the lower end of the steel pipe is embedded in a soil layer; and after the cement mortar is hardened and is integrated with surrounding rock stratums and the pipe pile, prestressed pipe pile construction is finished. According to the prestressed pipe pile construction method, a hole forming speed is quick, a construction period is short, and construction cost can be reduced by over 10%; by adopting a mode of pouring the cement mortar in the guide hole, pipe pile side pressure, end bearing capacity and the position of the pile side can be guaranteed, and side-direction stress safety of the pipe pile can be guaranteed; a pile head fixing head is simple, construction is convenient, verticality of the pipe pile is guaranteed, and bearing capacity of the prestressed pipe pile is also effectively improved.

Owner:二十二冶集团天津建设有限公司

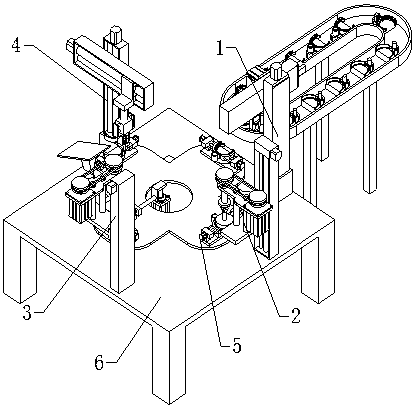

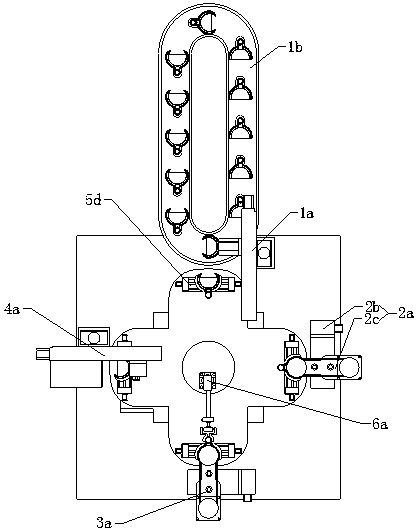

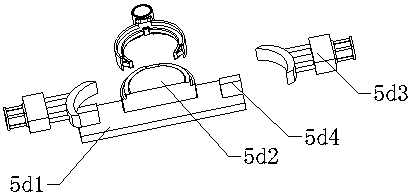

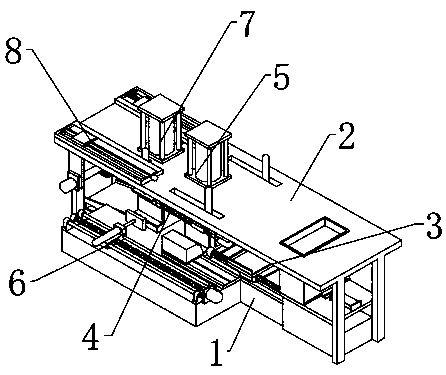

Automatic grinding machine for automobile shifting fork

ActiveCN108581771APlay a fixed rolePlay a stabilizing roleGrinding carriagesGrinding machinesWork statusMechanical engineering

The invention relates to the field of automobile part machining, in particular to an automatic grinding machine for an automobile shifting fork. The automatic grinding machine comprises a base and further comprises a feeding station, a first grinding station, a second grinding station, a discharging station and a rotating workbench; the rotating workbench comprises a fixture installing table, thefixture installing table is horizontally arranged on an index plate and provided with four workpiece fixtures used for containing and clamping workpieces, and the feeding station, the first grinding station, the second grinding station and the discharging station are clockwise and sequentially arranged along the periphery of the fixture installing table and correspond to the workpiece fixtures arranged on the fixture installing table one to one in a working state; the feeding station comprises a feeding mechanical arm used for putting the workpieces on the workpiece fixtures; the first grinding station comprises a first grinding mechanism used for grinding the workpieces; the second grinding station comprises a second grinding mechanism used for grinding the workpieces; and the dischargingstation comprises a discharging mechanical arm. Therefore, the problems that the human cost input is high, and the yield is low are solved.

Owner:南理工泰兴智能制造研究院有限公司

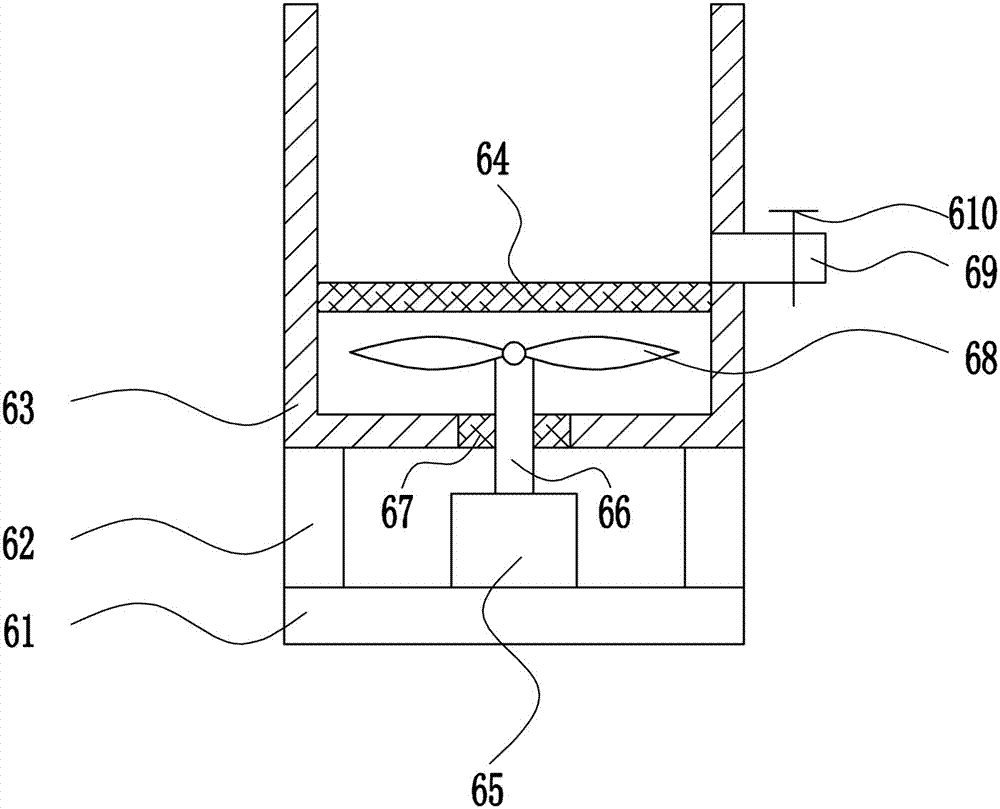

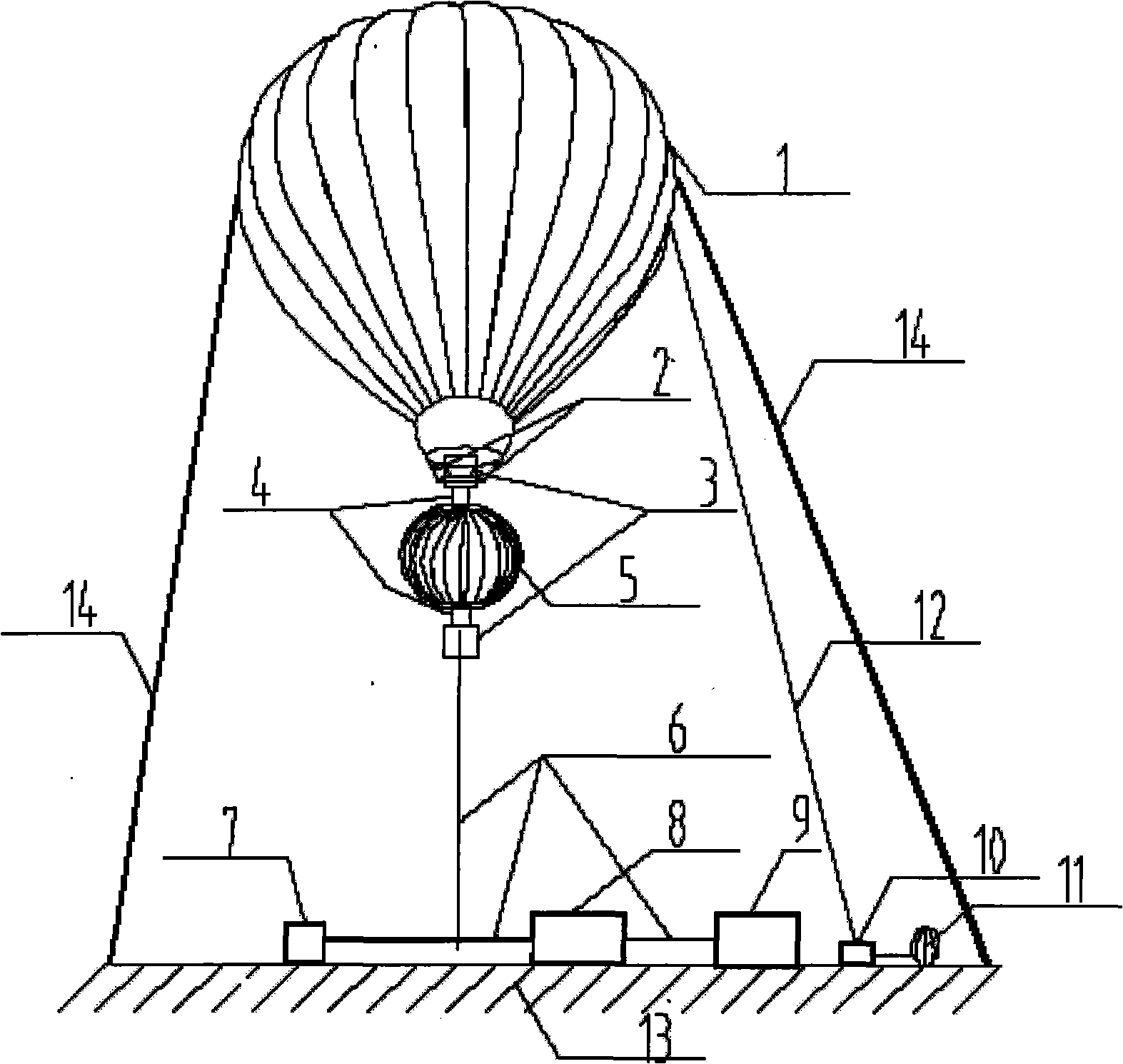

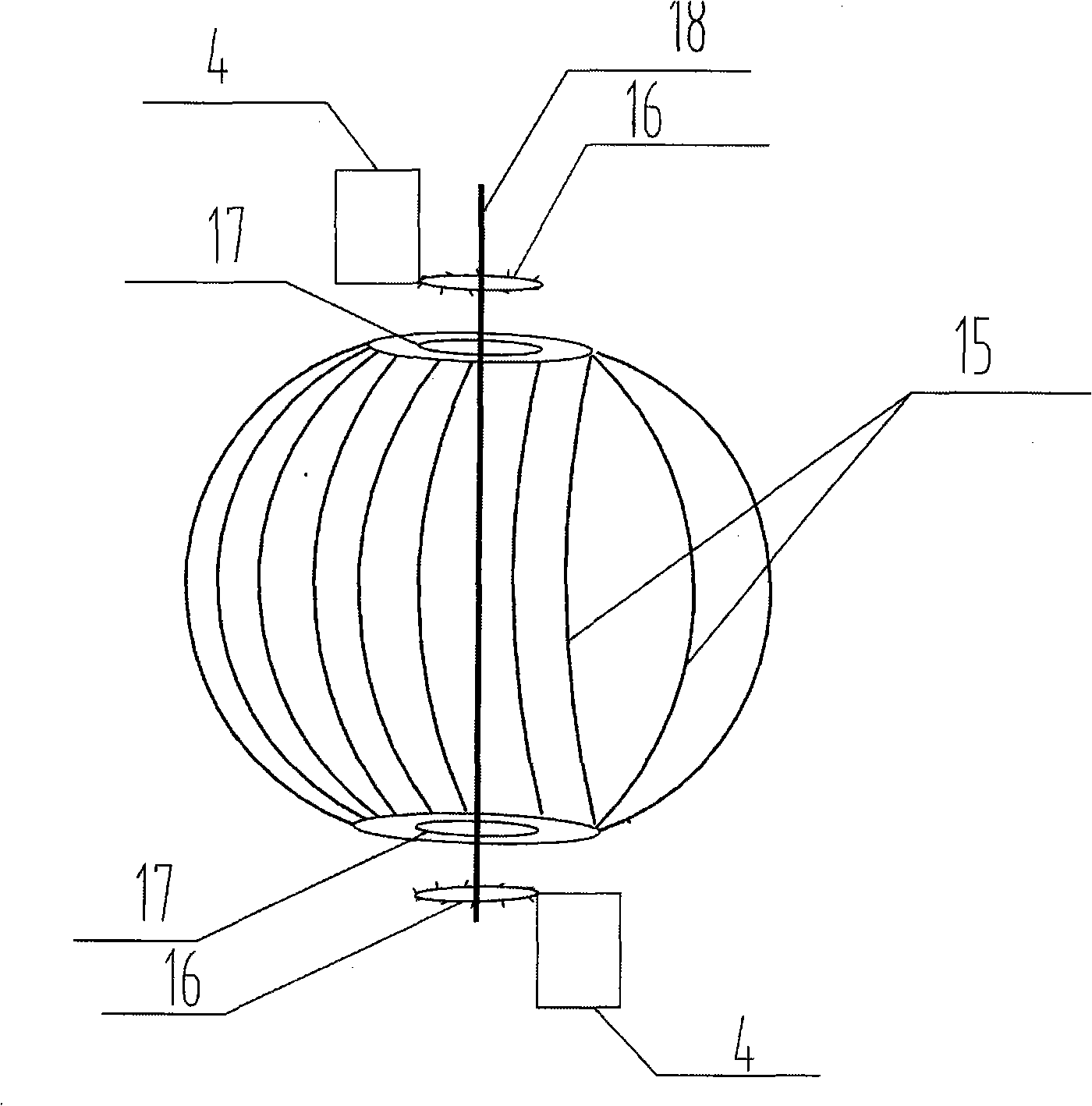

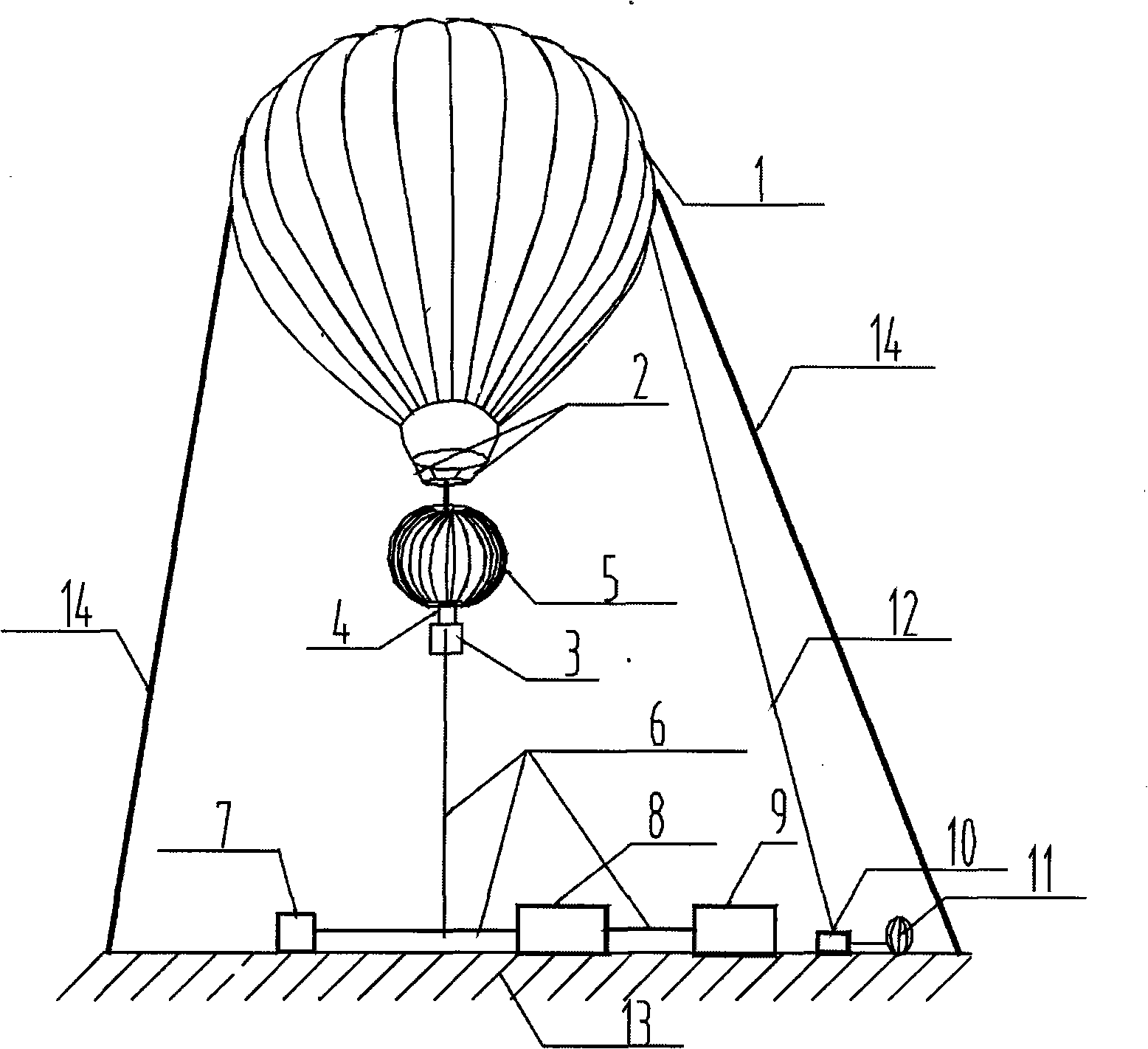

High altitude spherical hollow space turbine type wind power generator

InactiveCN101280764ALow costSolve many problems of wind power generationMachines/enginesWind motor combinationsWind drivenHigh-altitude wind power

Disclosed is an upper air spherical cavity turbo-type wind driven generator, which relates to the utilization of new energies. The upper air spherical cavity turbo-type wind driven generator comprises a helium balloon, a spherical turbo-type fan and a generator. The helium balloon lifts the wind driven generator composed of the spherical cavity turbo-type fan and the generator aloft and the wind driven generator utilizes the strong wind at the upper air and the advantages of low start-up wind speed, high safe wind speed, directional rotation, etc. of the spherical cavity turbo-type fan, makes full use of the wind power at the upper air to generate and transmits the power back to electrical equipment on the ground by cables. The wind driven generator overcomes the disadvantage that as the fan in the prior art is not so far away from the ground. the prior art cannot be used at areas with little strong wind at the shallow ground and solves the problems of high generating cost in the wind generation, difficulty in installing equipment, etc. of the prior art.

Owner:龚炳新

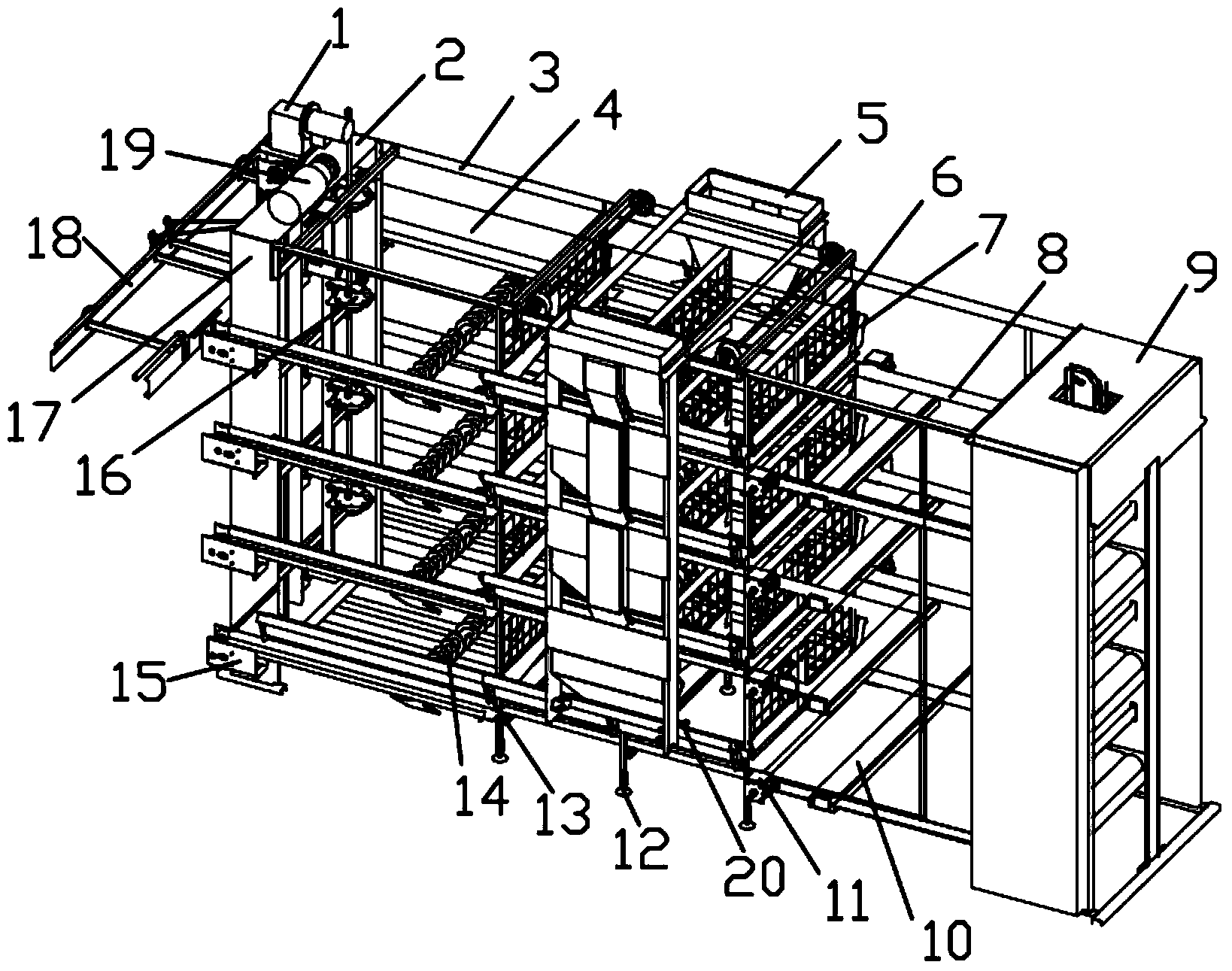

Laminated poultry raising equipment

The invention relates to the technical field of poultry raising equipment, in particular to laminated poultry raising equipment. The laminated poultry raising equipment provided by the invention comprises a machine frame adopting a framework structure, wherein a plurality of poultry cages adopting reticular structures are arranged in the middle part of the machine frame in a laminated way, a food tough support frame fixedly connected with the two sides of the machine frame is arranged in an outer lower position of the cage wall of each layer of poultry cage, a U-shaped food tough with an upward opening is fixedly arranged on the food tough support frame, walking guide rails in symmetrical arrangement are arranged on the top of the machine frame, a feeding machine doing reciprocating movement in the horizontal direction is arranged on the walking guide rails, an opening of each discharging hopper arranged at feeding machine is in corresponding arrangement to the opening of the U-shaped food tough, the feeding machine is provided with a material homogenizing device, an egg collecting device is fixedly arranged at the outer side of one end of the machine frame, water level pressure regulating devices with the same number as the layer number of the poultry cages are arranged at the inner side of one end of the machine frame, and the other end of the machine frame is provided with an excrement cleaning machine.

Owner:HENAN JINFENG POULTRY EQUIP

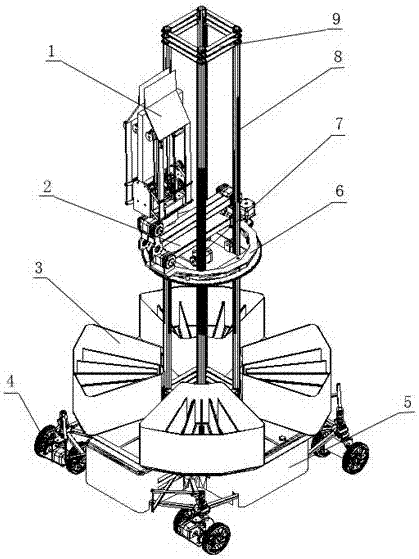

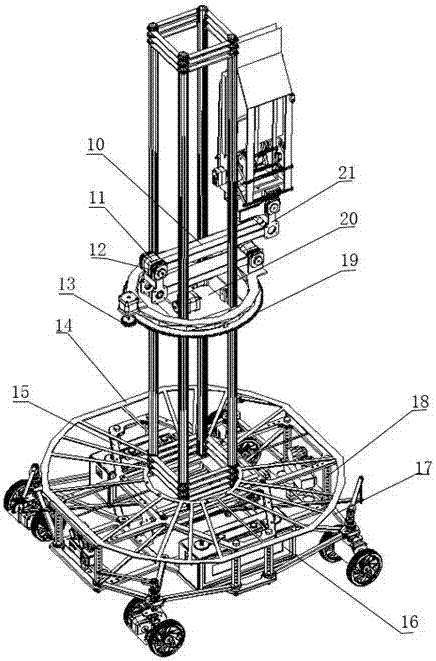

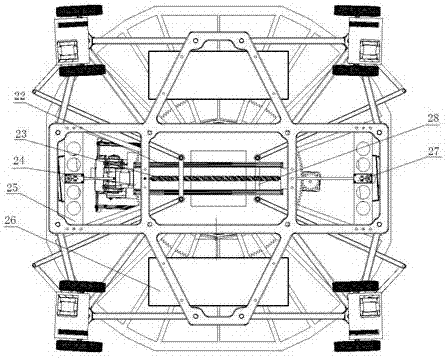

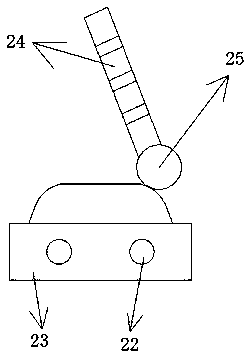

Intelligent book sorting robot

ActiveCN106903699ARealize all-round steeringReduce positioning errorsWaste collection and transferManipulatorDrive wheelControl engineering

The invention relates to an intelligent book sorting robot, and belongs to the technical field of robots. The intelligent book sorting robot comprises a hollow chassis, a chassis housing, a book storage box, independent drive wheels, a four-wheel rotation drive system, a lifting system, a mechanical arm, a clamping system and the like, wherein the four-wheel rotation drive system is mounted on the hollow chassis; the four independent drive wheels are separately connected with the four-wheel rotation drive system; the chassis housing is mounted on the hollow chassis; the book storage box is mounted on the chassis housing; the lifting system is mounted on the hollow-out chassis; the mechanical arm is mounted on a rotary disc of the lifting system; and the clamping system is mounted on the mechanical arm. The invention provides the intelligent book sorting robot which is economical and reasonable in price, is good in movement performance, is more in application scenarios and is high in precision; and the intelligent book sorting robot can be used for providing efficient and convenient book-storing book-getting service for a librarian and even a common reader as well as an intelligent booking sorting managing function.

Owner:KUNMING UNIV OF SCI & TECH

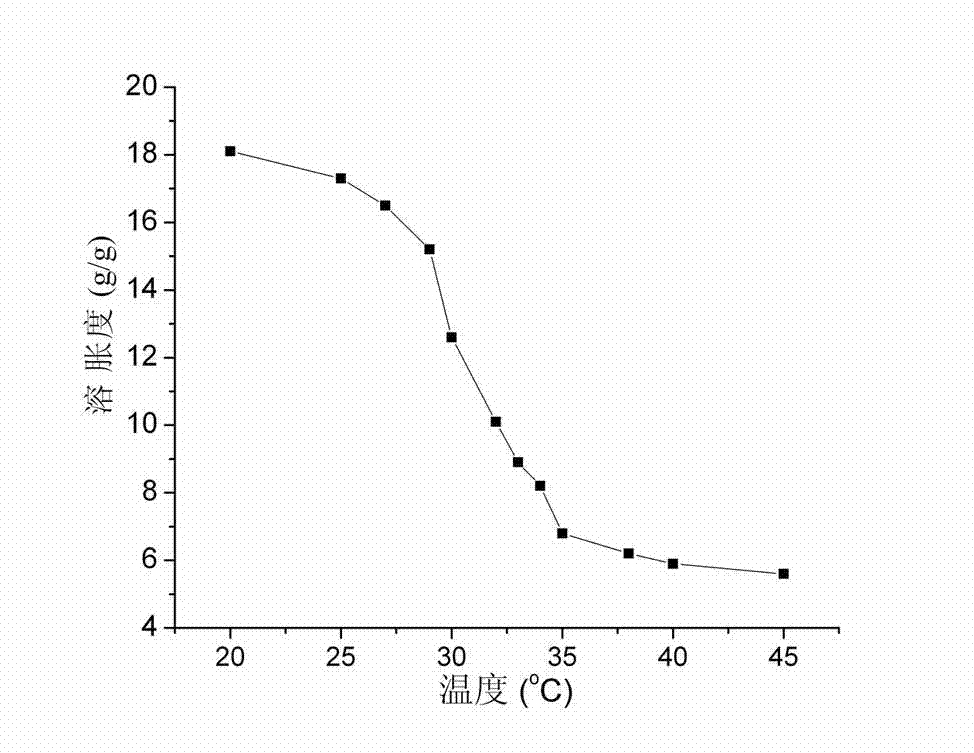

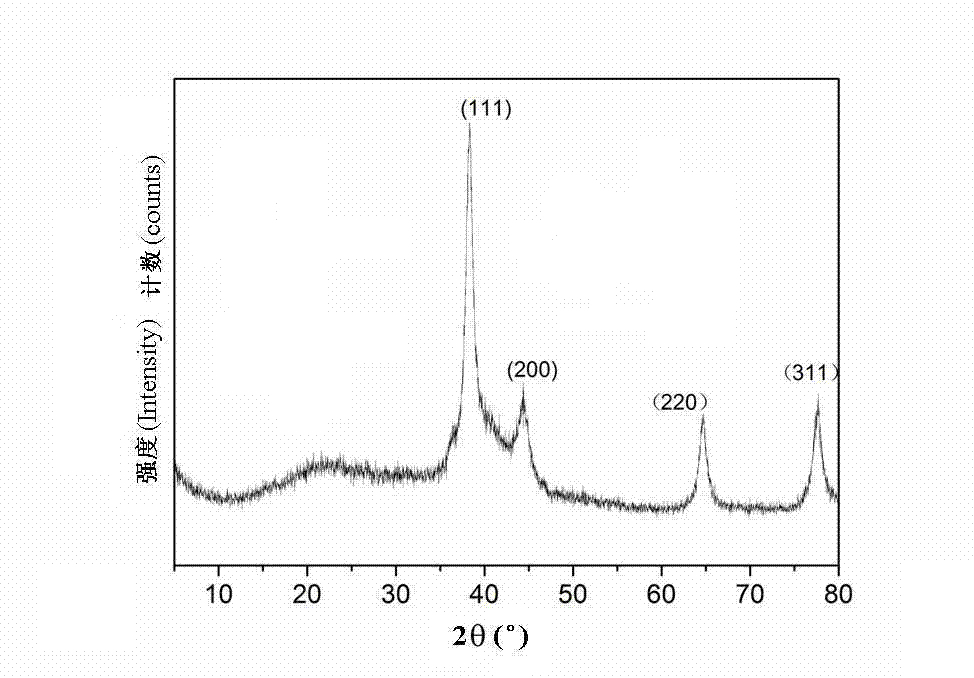

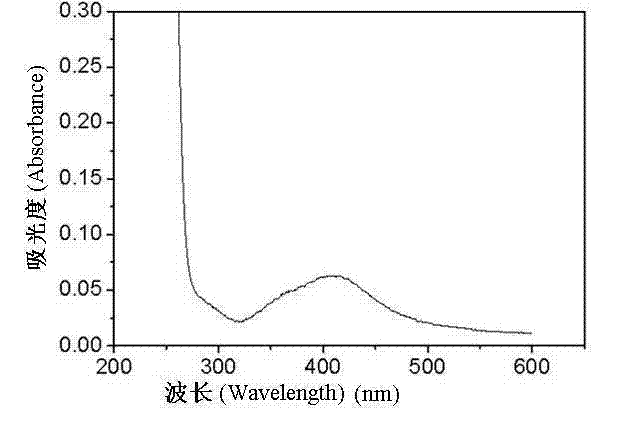

Preparation method for temperature-sensitive hydrogel/silver nanocomposite

InactiveCN103194030ASimple preparation processRaw materials are easy to getBiocideOrganic-compounds/hydrides/coordination-complexes catalystsAqueous solutionNanocomposite

The invention discloses a preparation method for a temperature-sensitive hydrogel / silver nanocomposite. The preparation method comprises the following concrete steps: (1) dissolving chitosan in an acetic acid solution to prepare a solution with a concentration of 1 to 10%, preparing an aqueous reactant solution from a temperature-sensitive monomer and a chemical cross-linking agent and adding the aqueous reactant solution into the above-mentioned solution; (2) adding an aqueous initiator solution into the aqueous reactant solution, introducing nitrogen for protection, heating to a temperature of 50 to 80 DEG C, carrying out a reaction for 6 to 12 h under the condition of uniform-speed stirring and carrying out washing and drying so as to obtain a temperature-sensitive chitosan hydrogel; and (3) subjecting the dried hydrogel to full swelling in distilled water for 1 to 3 d, adding a silver salt, adding a reducing agent for a reaction for 2 to 5 h and carrying out purifying and drying so as to obtain the hydrogel / silver nanocomposite. The preparation method provided by the invention has the advantages of simple process and mild reaction conditions. The hydrogel / silver nanocomposite prepared in the invention has stable physical and chemical performances and temperature sensitivity.

Owner:LUDONG UNIVERSITY

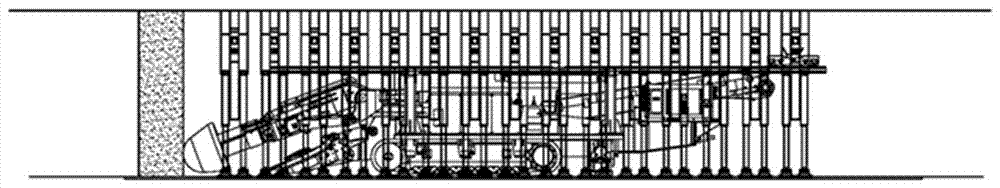

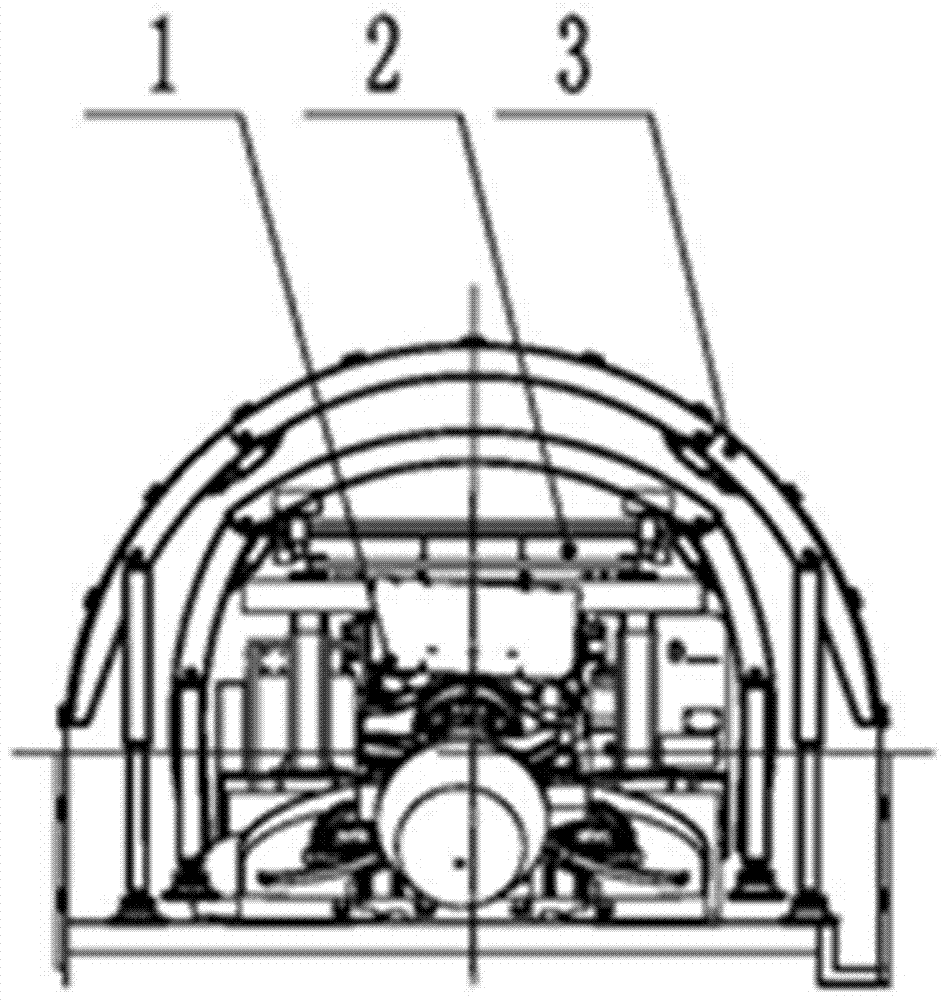

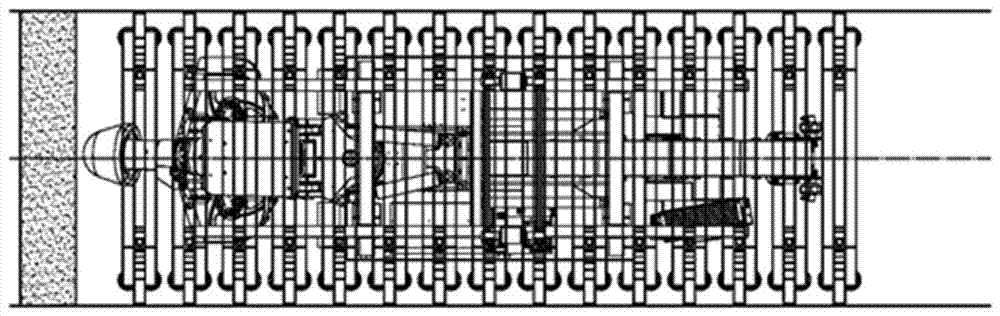

Arch tunnel drivage non-repeated-support self-moving complete equipment

PendingCN107965342AStrengthen security managementShorten the lengthUnderground chambersMine roof supportsEngineeringCoal

The invention belongs to the technical field of the underground coal mine fully-mechanized excavating face temporary support. In order to solve the above problem existing in the current underground coal mine temporary support, the invention provides arch tunnel drivage non-repeated-support self-moving complete equipment. The arch tunnel drivage non-repeated-support self-moving complete equipment comprises a heading machine, a support lifting platform and a plurality of external support devices. The external support devices use an arch support matched with an arch drivage tunnel. The external support devices are mutually parallel, and are installed across the heading machine to form the support to the arch drivage tunnel. The support lifting platform is installed at the top of the heading machine and can be freely ascended and descended to contact with the upper part of the external support devices. The external support devices can be forwards pushed to the front end of the heading machine along a travel line of tunneling along with the support lifting platform after contacting with the support lifting platform. The arch tunnel drivage non-repeated-support self-moving complete equipment is capable of creating reliable and flexible support conditions for the safe and high-efficient mining of a driving working face, realizing the non-repeated-support to a top board, and guaranteeing the integrity of the top board, and has the important significance of completing a mechanical mining technology of the tunneling face, and improving the tunneling speed and production efficiency.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

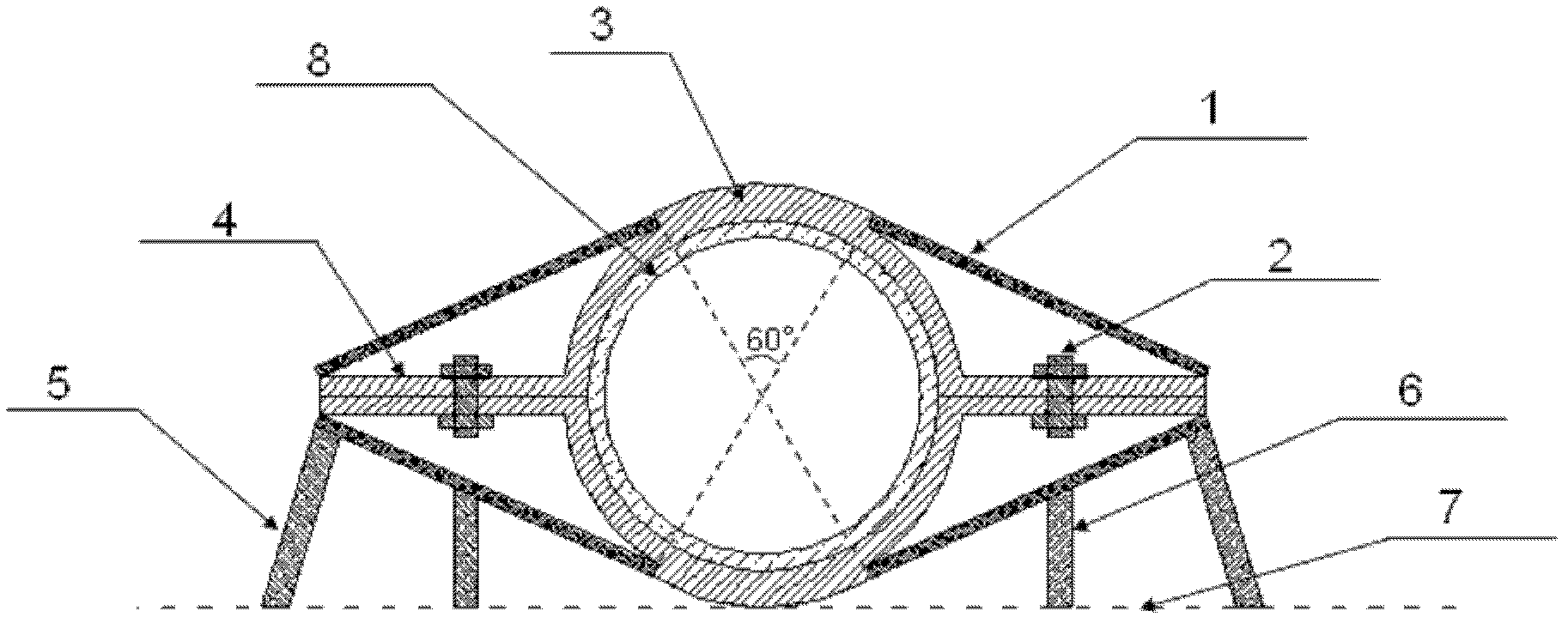

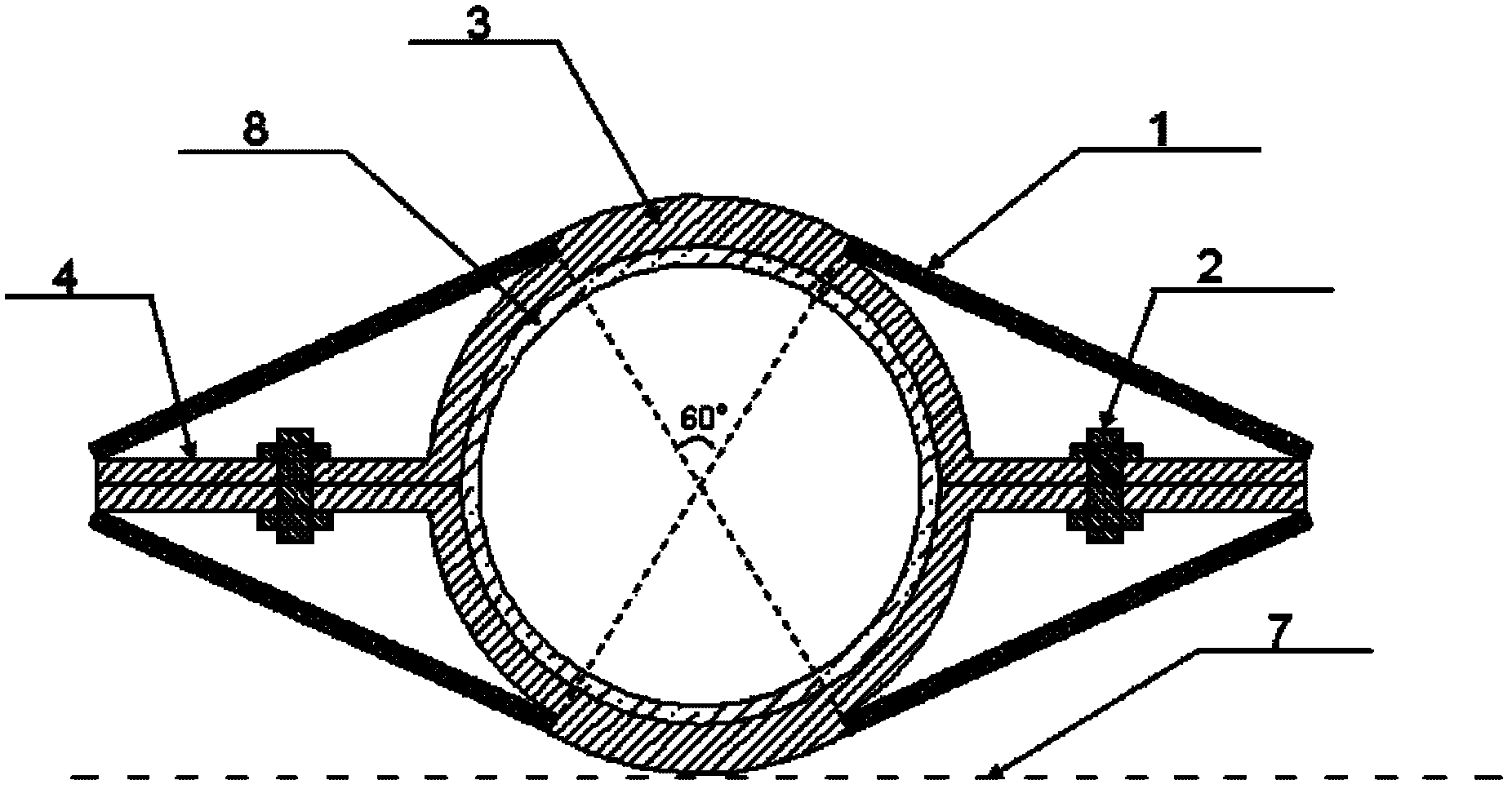

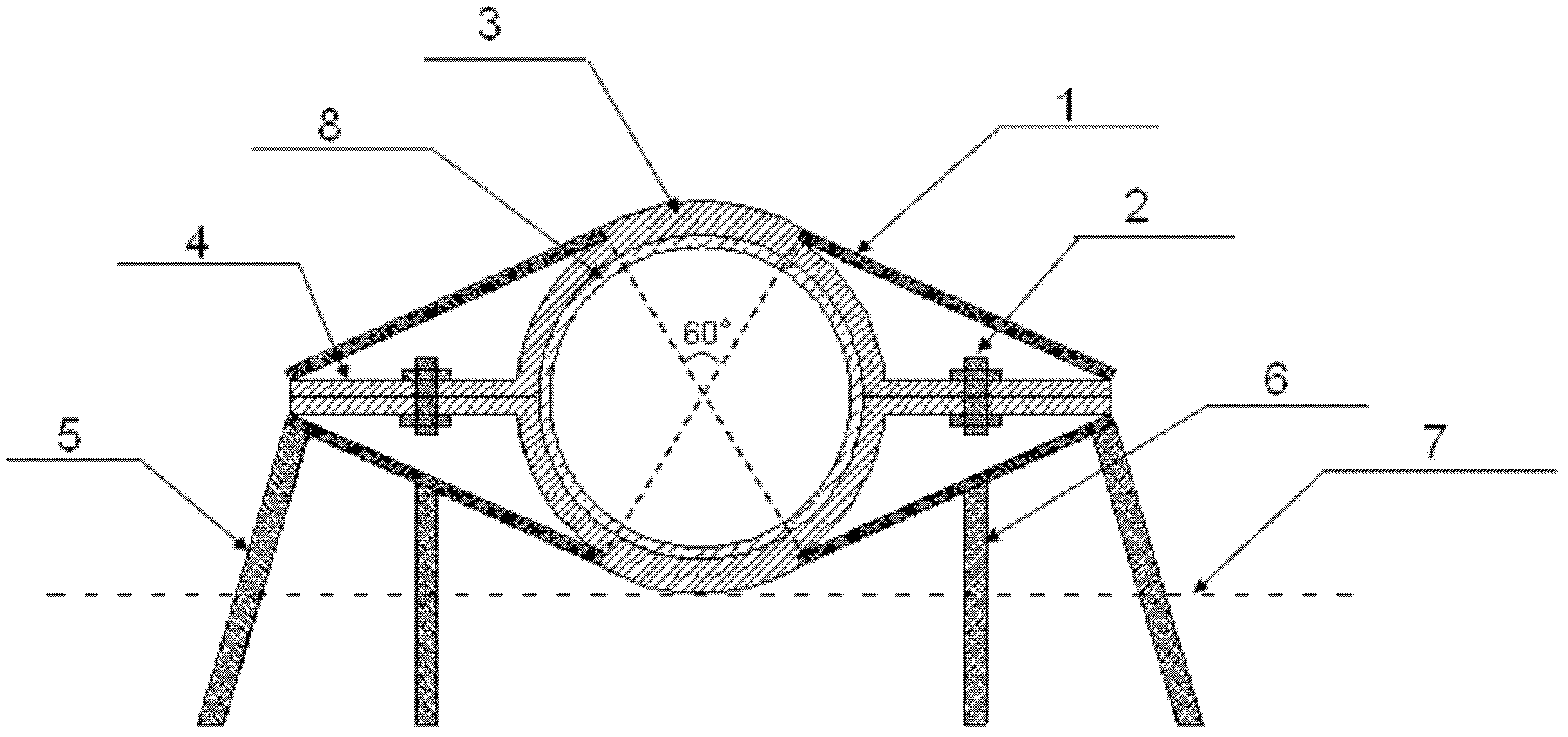

A bend arrester for submarine pipeline with deflector

ActiveCN102278530ARealize the anti-bending functionEfficient disseminationPipe laying and repairMarine engineeringSubmarine pipeline

The invention belongs to the technical field of laying of submarine pipeline facilities and relates to a submarine pipeline buckle arrestor with guide plates. The submarine pipeline buckle arrestor is used for fixing a submarine pipeline and comprises a pair of upper and lower valve shells, at least two groups of brackets and four guide plates, wherein the two groups of brackets are used for supporting the buckle arrestor and the submarine pipeline; the inner diameters of the two valve shells are the same with the outer diameter of the submarine pipeline; a lateral wing eye plate used for fixing the upper and lower valve shells at the outer part of the submarine pipeline is respectively arranged at two sides of each valve shell; the four guide plates are arranged at the outer side of the buckle arrestor; and one end of each guide plate is fixed on the upper valve shell or the lower valve shell, and the other end of each guide plate is fixed on the lateral wing eye plate. In the invention, two-in-one design is utilized, therefore, the construction process is simplified, the cost is lowered, buckle propagation and vortex induced vibration of the submarine pipeline are effectively controlled, and the integration purposes of economy and safety are achieved.

Owner:TIANJIN UNIV

Preparation method and application of silver-free powdery solid solution anti-bacterial agent

InactiveCN104206420APrevent crystallizationModerate melting propertiesBiocideAntifouling/underwater paintsSolid solutionAnti bacterial

The invention discloses a preparation method and application of a silver-free powdery solid solution anti-bacterial agent. The silver-free powdery solid solution anti-bacterial agent is prepared by adding a zinc salt or a copper salt and an oxide or a hydroxide to water, and performing a stirring process, a separating process, a cleaning process and a grinding process. The preparation method is simple and low in cost. The silver-free powdery solid solution anti-bacterial agent is wide in applications, is high-temperature-resistant, is safe and is good in anti-bacterial effect.

Owner:ANHUI WANXING IND LTD

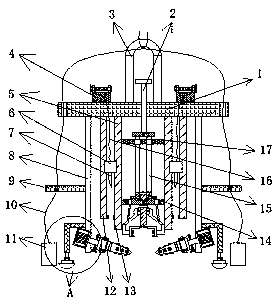

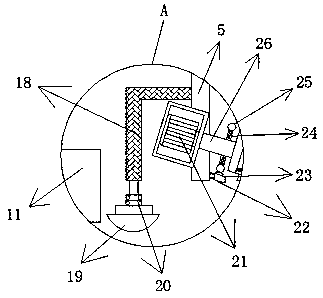

Submarine sediment sampling device for ocean engineering

ActiveCN109163925AImprove stabilityAvoid disturbing influencesWithdrawing sample devicesOcean bottomOcean sea

The invention belongs to the technical field of ocean engineering, and particularly relates to a submarine sediment sampling device for ocean engineering. in view of the problems that a device is relatively low in stability, and cannot perform massive sampling simultaneously, expel benthos or prevent re-dropping of a sampled sediment into ocean, the following scheme is provided: the sampling device comprises a buoyancy plate, wherein a fixed outer ring is arranged on the external wall on one side of the bottom of the buoyancy plate; a water-proof motor housing is arranged on the external wallof the bottom of one side of the fixed outer ring; motors are arranged in the water-proof motor housing; brackets are arranged on the external wall of the bottom of one side of the fixed outer ring; and the brackets are L-shaped. The stability of the sampling device is improved; infaunae are expelled by the vibrating action of the motors and the collision action of ball bodies and arc slide blocks, so that interference with a sampling process is avoided; the sampled sediment is separated from a submarine plane, so that the sampling is facilitated; and a pull plate is pulled upwards to allow clamping blocks to clamp the submarine sediment drilled out.

Owner:SECOND INST OF OCEANOGRAPHY MNR

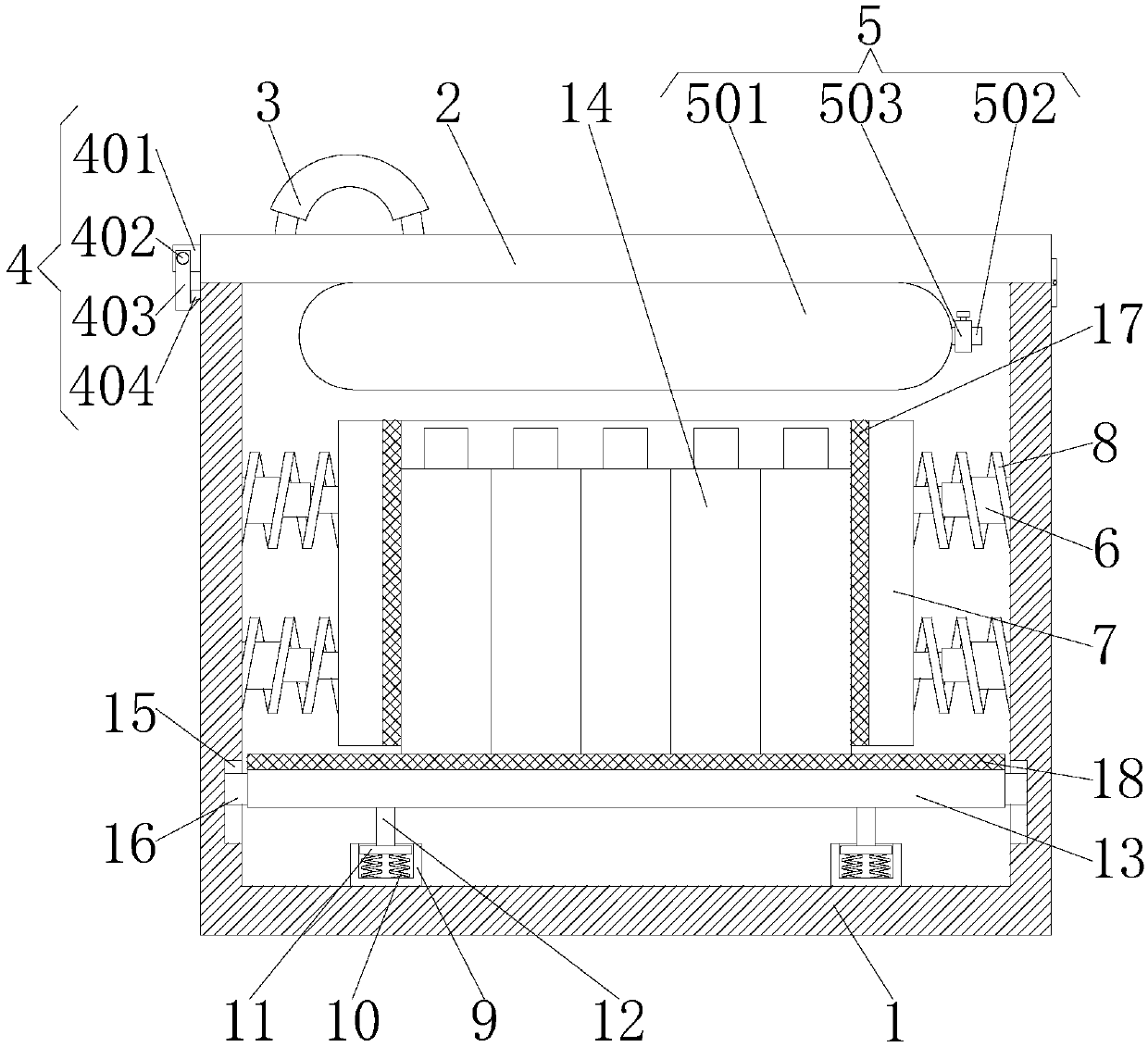

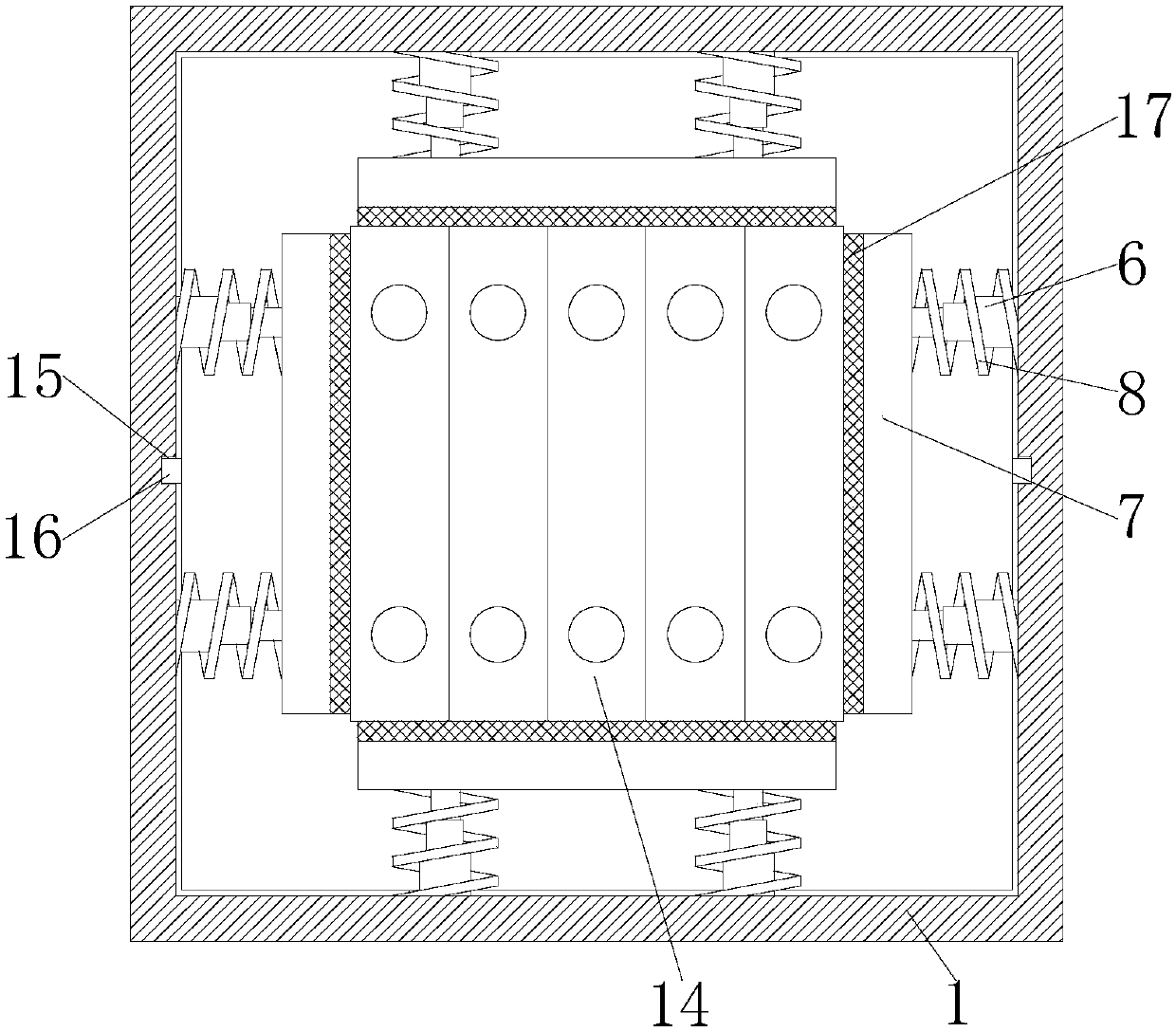

Protection device for storage battery

InactiveCN111146378AGood protectionExtended service lifeCell component detailsSecondary cells servicing/maintenanceTop capAirbag

The invention discloses a protection device for a storage battery. The protection device comprises a protection box, wherein a top cover is movably connected to the top of the protection box through ahinge, a handle is fixedly connected to the left side of the top of the top cover, a clamping device is fixedly connected to the left side of the top cover, an airbag buffer device is fixedly connected to the bottom of the top cover, and telescopic columns are fixedly connected to four corners of one side of the inner wall of the protection box. By cooperatively arranging the clamping device, thefixing block, the fixing shaft, the buckle, the clamping block, the airbag buffer device, the air inflation bag, the air inflation pipe, the valve, the telescopic columns, the first buffer plate, thefirst spring, the shell, the second spring, the movable plate, the fixing column, the second buffer plate, the sliding groove, the sliding block, the first buffer pad and the second buffer pad, the protection effect is good, and the storage battery can be prevented from colliding with the box body when used, so that the service life of the storage battery is prolonged so as to improve the practicability of the protection device for the storage battery.

Owner:江苏宇光电源科技有限公司

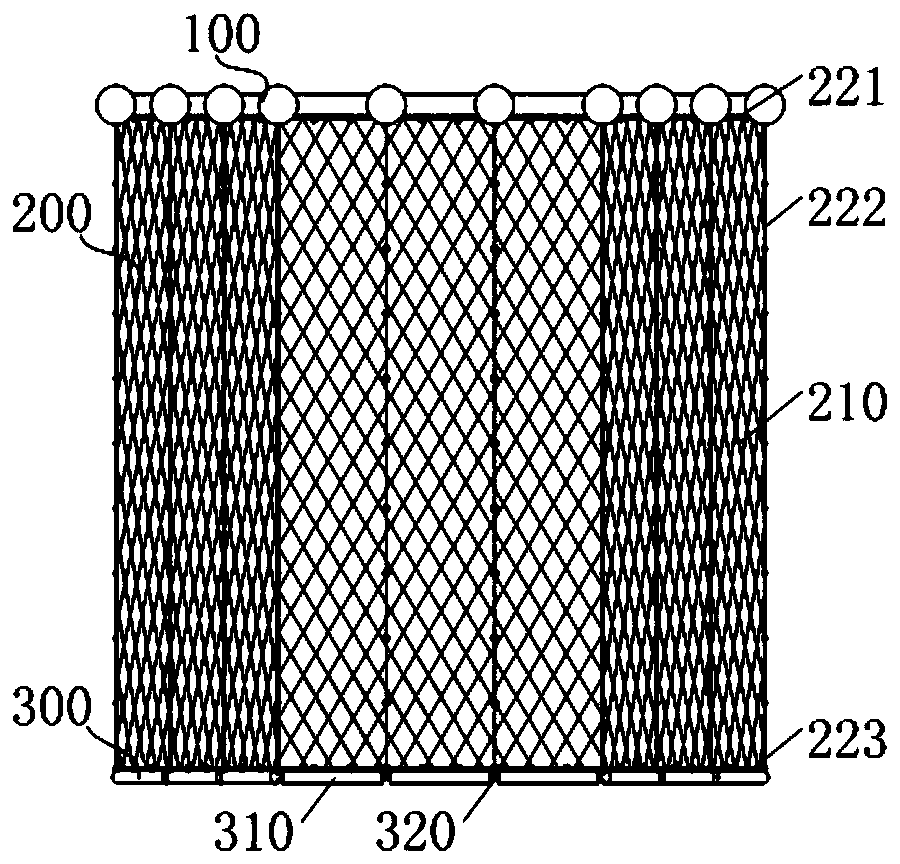

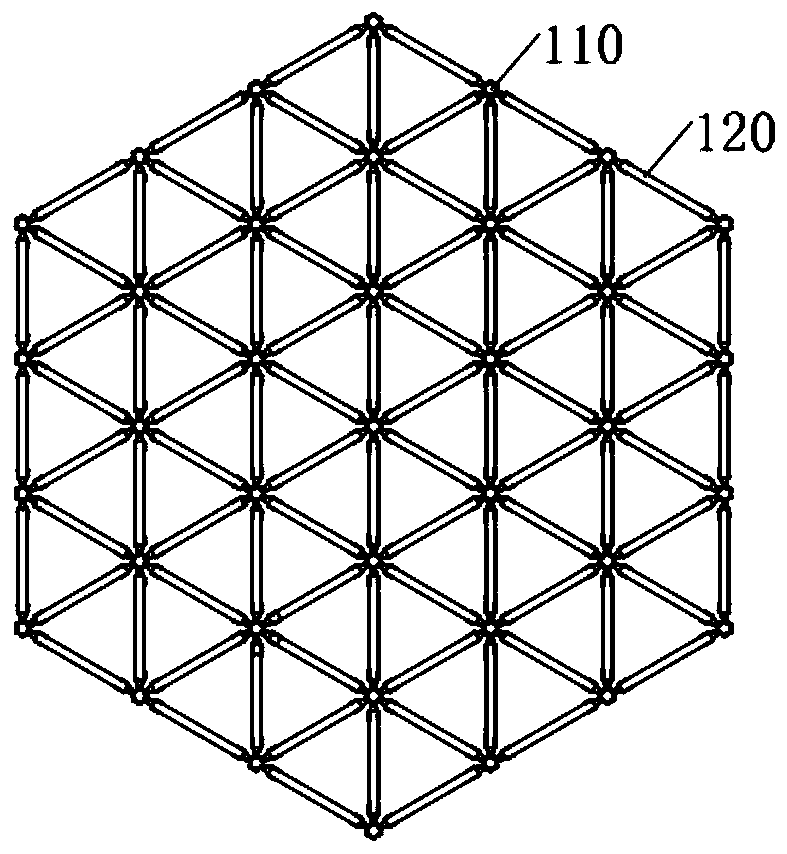

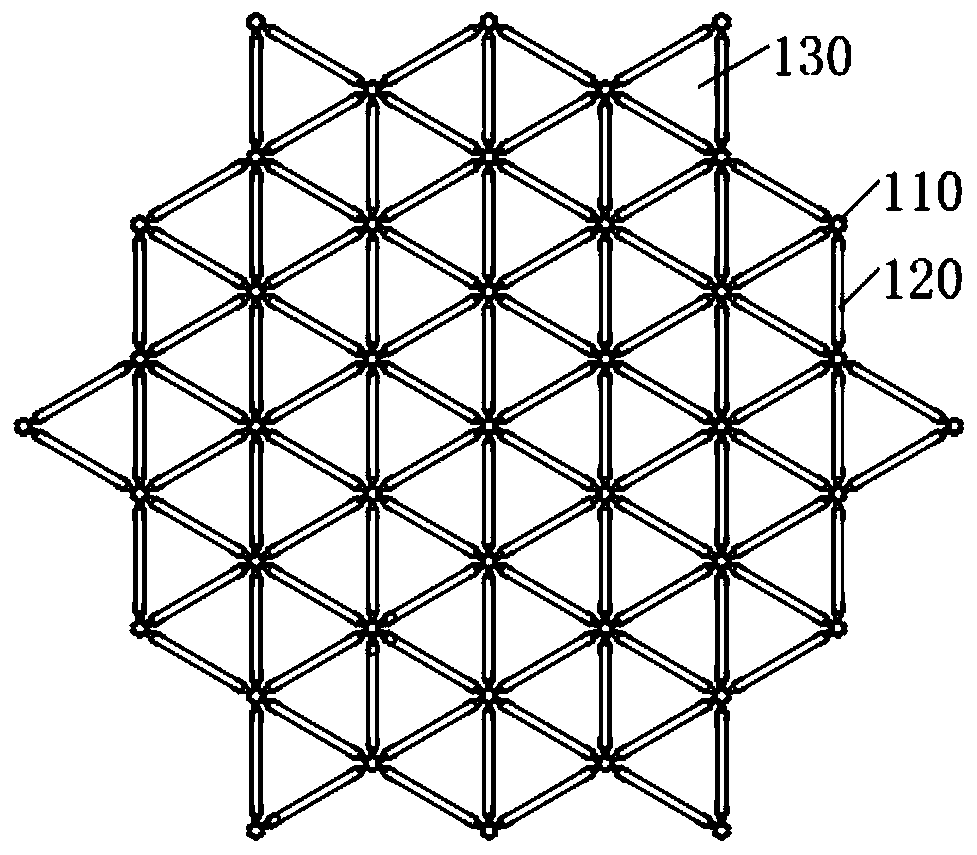

Breeding net cage

PendingCN109874716APlay a stabilizing roleImprove adaptabilityClimate change adaptationPisciculture and aquariaMaricultureSea waves

The invention provides a breeding net cage, and relates to the technical field of mariculture. The breeding net cage comprises a flexible floating frame device, a net device and drooping weight devices; the flexible floating frame device can float on the sea surface, and multiple sets of anchoring devices are connected with the surrounding portion of the flexible floating frame device; the top ofthe net device is connected with the flexible floating frame device, the net device is strutted under the sea surface to form a space used for breeding marine organisms, and multiple sets of droopingweight devices are connected to the bottom of the net device. The problems that an existing net cage is complex in structure and high in cost and can be easily damaged by sea wave impacting are effectively solved.

Owner:肖志东 +1

Supported phosphorus-vanadium-cesium-lanthanum catalyst and application thereof

InactiveCN102652922AImprove catalytic performanceReduce manufacturing costPhysical/chemical process catalystsOrganic compound preparationActive componentMethyl acetate

The invention relates to a supported phosphorus-vanadium-cesium-lanthanum catalyst and application thereof, particularly a catalyst for synthesizing methyl acrylate from formaldehyde and methyl acetate and application thereof.. The invention aims to provide a catalyst for preparing methyl acrylate from methyl acetate and formaldehyde, which has the advantages of high catalytic performance and long service life, and application thereof. According to the technical scheme, the active components of the catalyst are vanadium, phosphorus, cesium and lanthanum, the charge capacity of vanadium is 0.2-2 mmol / g, and the V:P:Cs:La mol ratio is 1:(0.5-1.5):(0.1-1.1):(0.01-0.05). The invention can be used for preparing methyl acrylate from methyl acetate and formaldehyde, and has the advantages of high catalytic performance and long service life.

Owner:TAIYUAN UNIV OF TECH

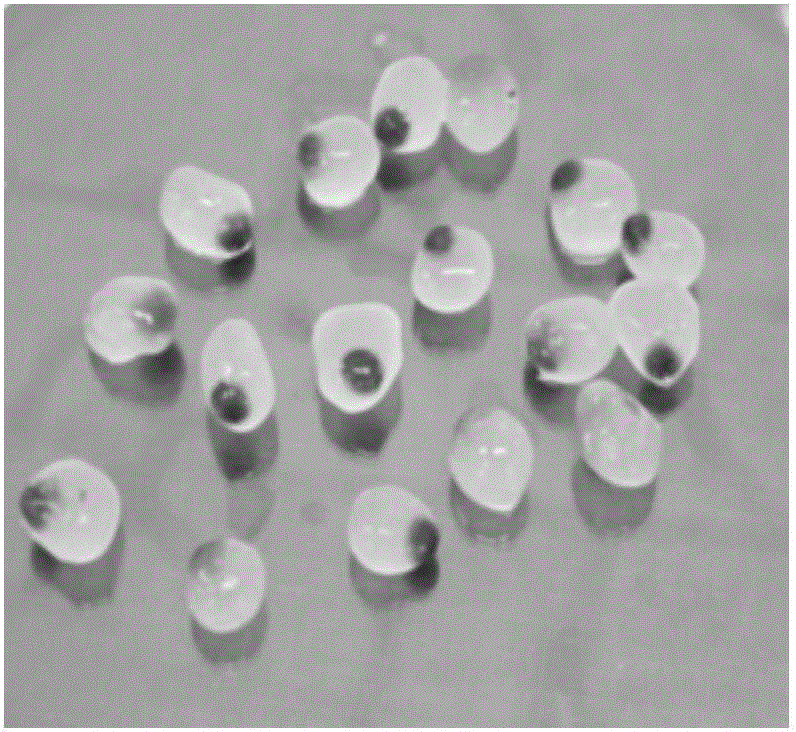

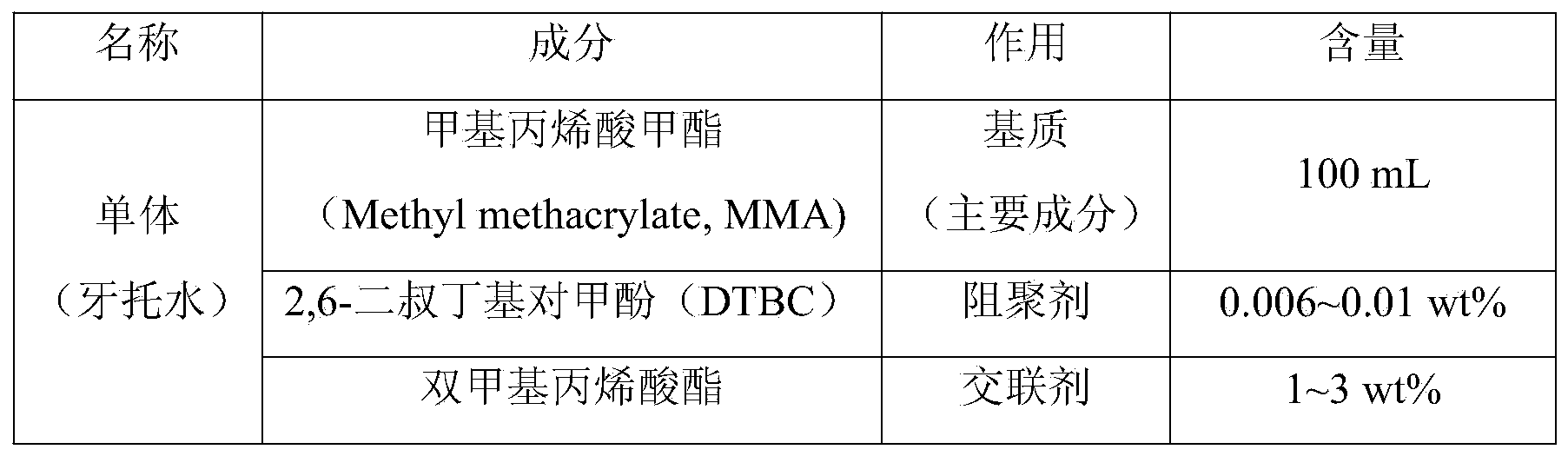

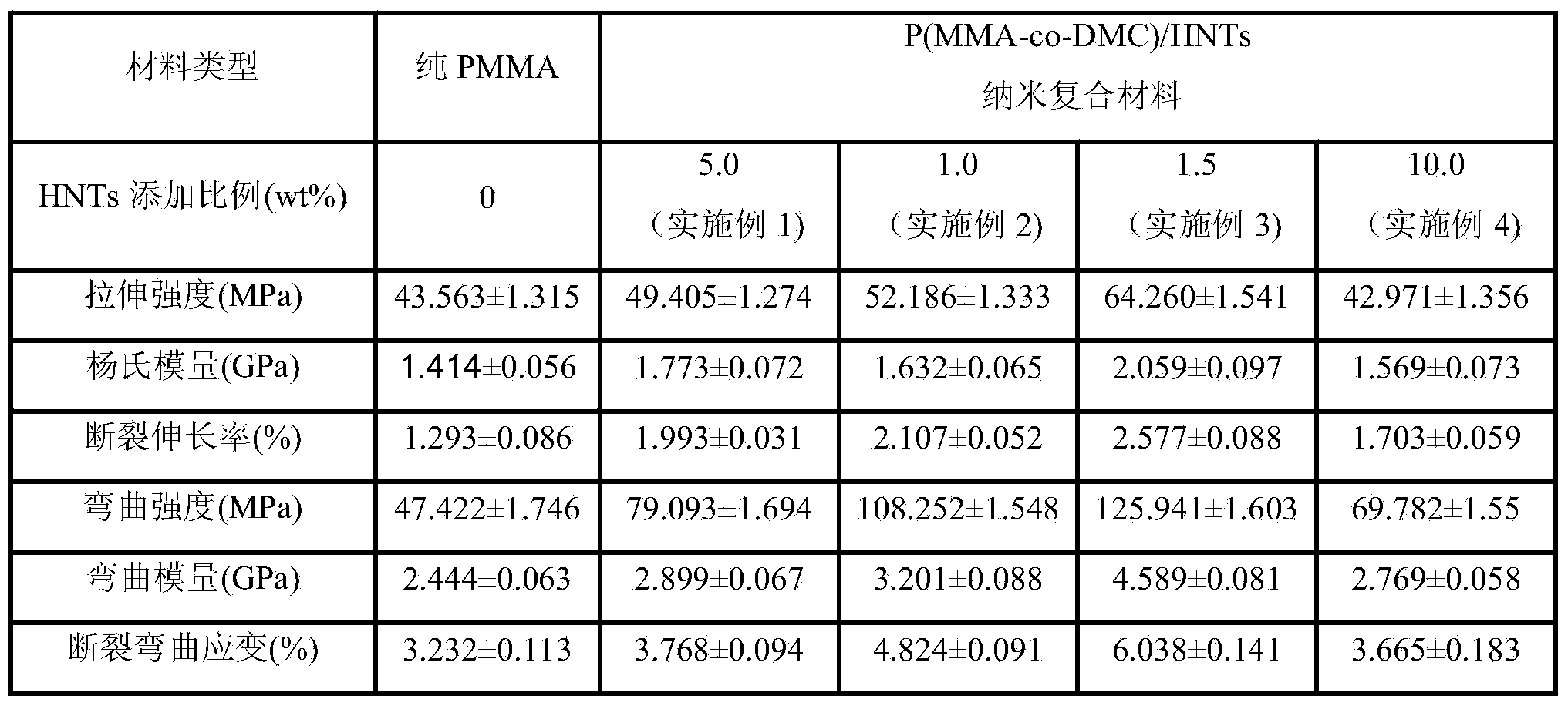

DMC-MMA (methyl methacrylate)-halloysite copolymerized denture base material and preparation method thereof

InactiveCN103622835AGood dispersionPlay a stabilizing roleImpression capsDentistry preparationsDispersityHalloysite

The invention discloses a DMC-MMA (methyl methacrylate)-halloysite copolymerized denture base material and a preparation method thereof. According to the invention, the charge environment of the polymeric substrate of the first monomer MMA is regulated and controlled through the second monomer DMC, and the two monomers are copolymerized through the suspension polymerization method, HNTs is added and compounded with the copolymerized product, and after the copolymerized product is mixed with thermosetting type dental base acrylic resin liquid, the mixture is heated and cured. According to the invention, the MMA is used as a base material, and the nanocomposite is prepared by adopting the in situ suspension polymerization method to regulate and control the charge environment of the substrate, and the halloysite nano filler is added for polymerization, so that the relatively pure PMMA resin is obtained, and the bending strength and the tensile strength of the denture base material are greatly improved to a great extent, the dispersity of halloysite in the substrate is successfully improved, and the problem about the mechanical strength, particularly the bending strength of the PMMA denture base material, is solved.

Owner:TIANJIN UNIV

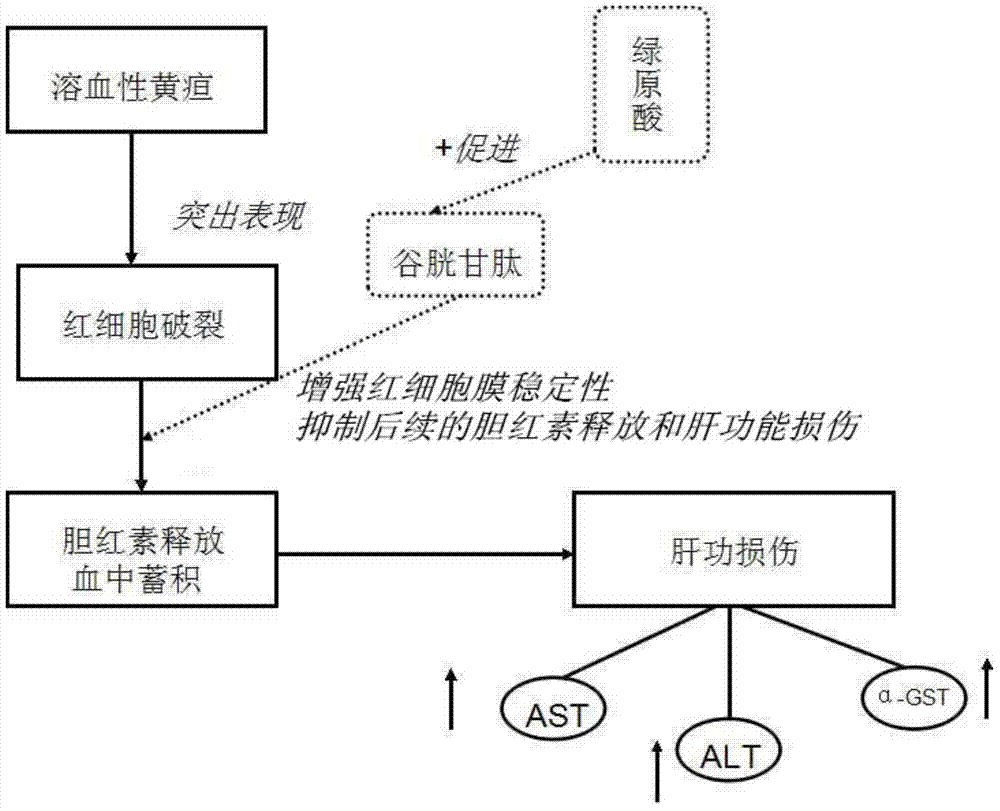

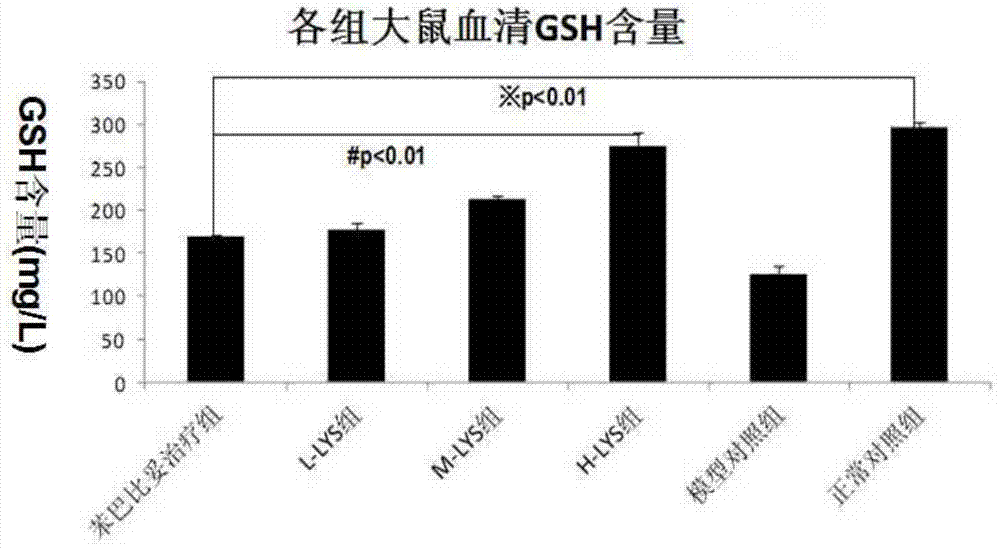

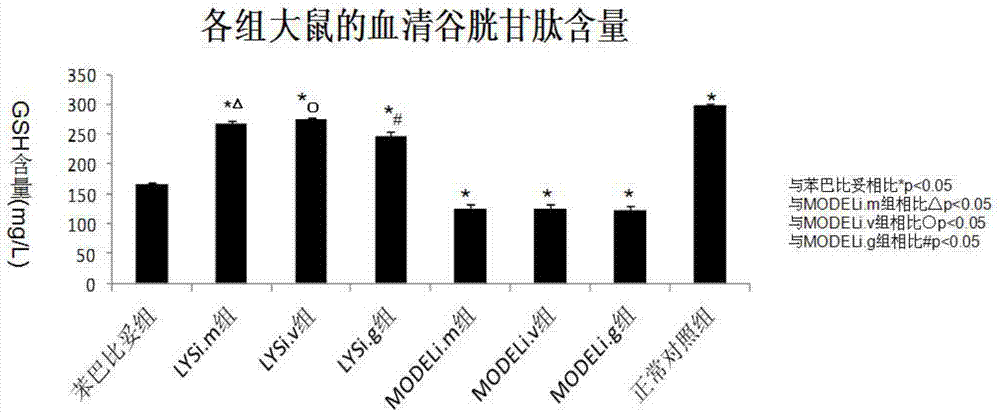

Application of chlorogenic acid in preparation of medicines for treating pathologic jaundice

InactiveCN104739818APromotes glutathione biosynthesisInhibition releaseOrganic active ingredientsDigestive systemIndirect bilirubinHemolytic jaundice

The invention discloses application of a chlorogenic acid in preparation of medicines for treating pathologic jaundice, and belongs to the field of biological medicines. The medicines prepared from the chlorogenic acid as an active component are capable of powerfully promoting biosynthesis of glutathione, so as to effectively play a role in stabilizing a red cell membrane and inhibit release of bilirubin (indirect bilirubin), and simultaneously are capable of recovering the injured liver function and effectively reducing the activity of alpha-glutathione-s-transferase (alpha-GST), alanine aminotransferase (ALT) and aspartic transaminase, so as to promote transformation of the indirect bilirubin into direct bilirubin and drainage through the liver and biliary tracts. Therefore, the content of total bilirubin and indirect bilirubin in the blood is effectively reduced; and new means and choice are provided for drug treatment of pathologic jaundice, especially hemolytic jaundice.

Owner:SICHUAN JIUZHANG BIO TECH CO LTD

Plate polishing machine for building materials

InactiveCN107309778ASolve the problem of prone to fallingDrop won't appearGrinding carriagesPolishing machinesCantilevered beamArchitectural engineering

The invention discloses a plate polishing machine for building materials, which comprises a workbench. A column is fixedly connected to the center of the rear side of the top of the workbench. The top of the column is fixedly connected to a cantilever beam. The front end of the bottom of the cantilever beam A first motor is fixedly connected, the output end of the first motor is fixedly connected with a polishing wheel, and the center of the top of the workbench is fixedly connected with a storage table. In the present invention, a chute, a bearing platform, a clamping device, a box body, a through groove, a second motor, a screw, a bearing seat, a screw sleeve, a connecting column, a fixing column, a clamping block, a sliding block, a protective pad and a controller are mutually arranged. The cooperation achieves the clamping effect, which solves the problem that the existing plate polishing machine has a poor clamping effect and causes the plate to fall easily, so that when the workers use the plate polishing machine to polish the plate, the plate will not fall off. It improves the practicability of the plate polishing machine and is suitable for popularization and use.

Owner:湖州华科建设工程质量检测有限公司

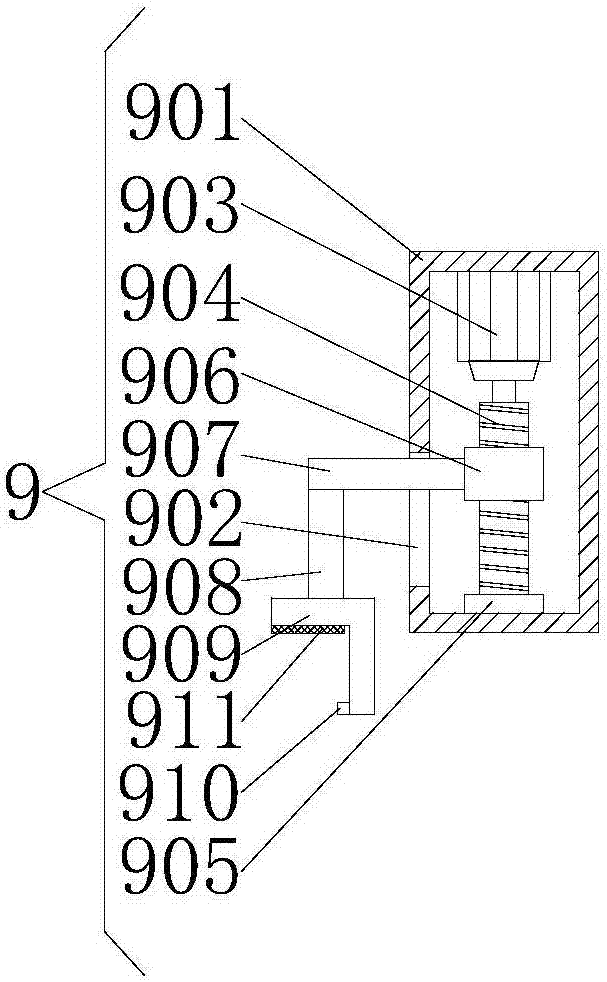

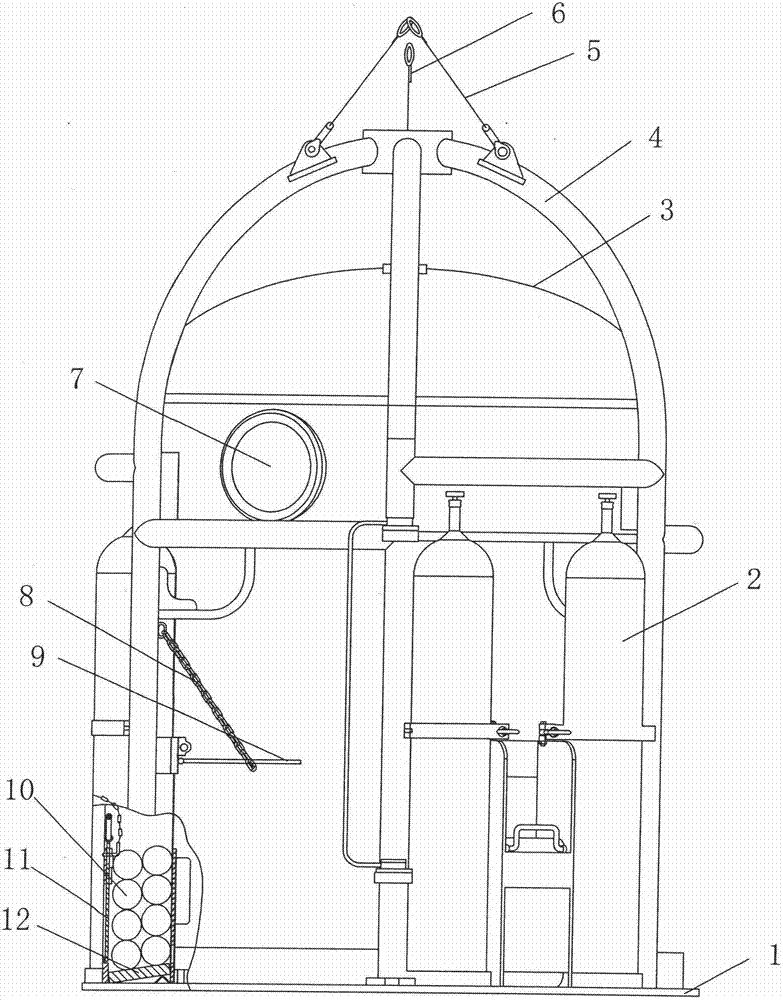

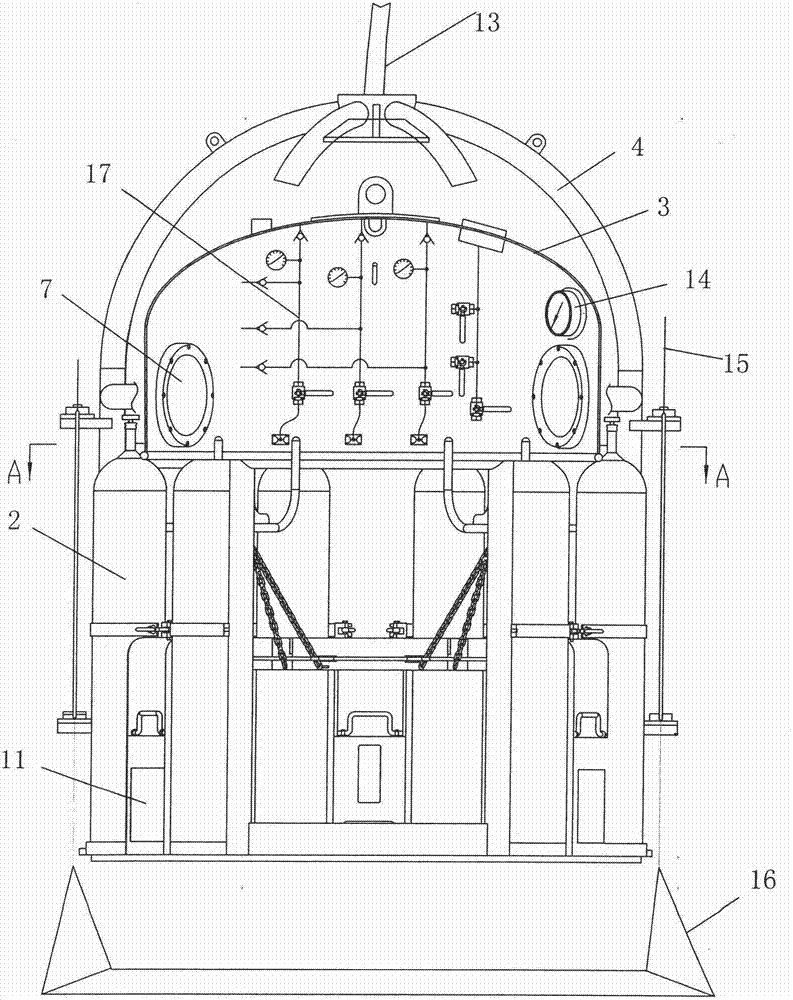

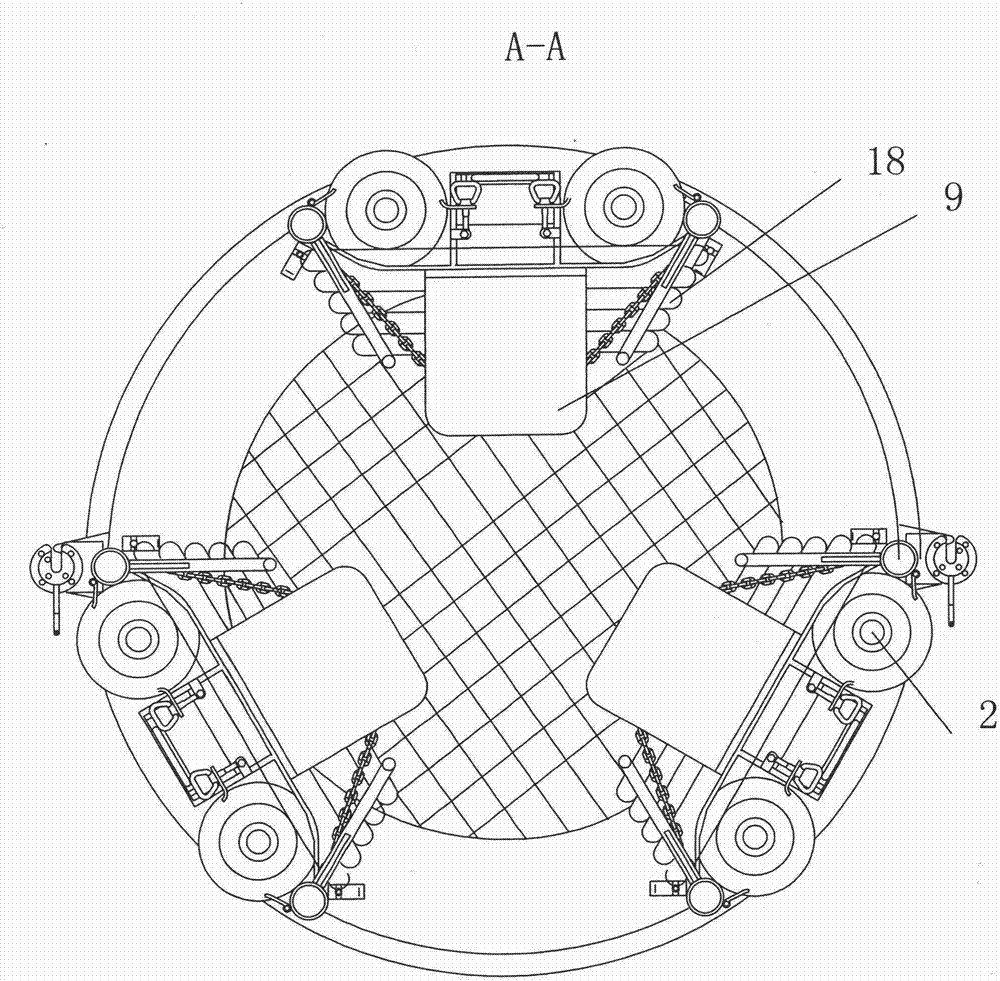

Deepwater open diving bell and self-rescuing method thereof

The invention discloses a deepwater open diving bell and a self-rescuing method thereof. The deepwater open diving bell comprises a platform and is characterized in that a bell jar is hung above the platform, a space between the top of the bell jar and the platform is adaptive to the height of a human body, a main belly belt is connected to the top of the bell jar, a basic surviving device is arranged in the bell jar, viewing windows capable of viewing situations outside the bell are formed in the side wall of the bell jar, and a guiding weight is arranged at the lower part of the platform. Due to the adoption of the technical scheme of the deepwater open diving bell and the self-rescuing method thereof, the 120 meters of diving depth of the diving bell is realized, the simultaneous diving of three users is satisfied, and the working efficiency of diving operation is improved.

Owner:上海打捞局芜湖潜水装备厂有限公司

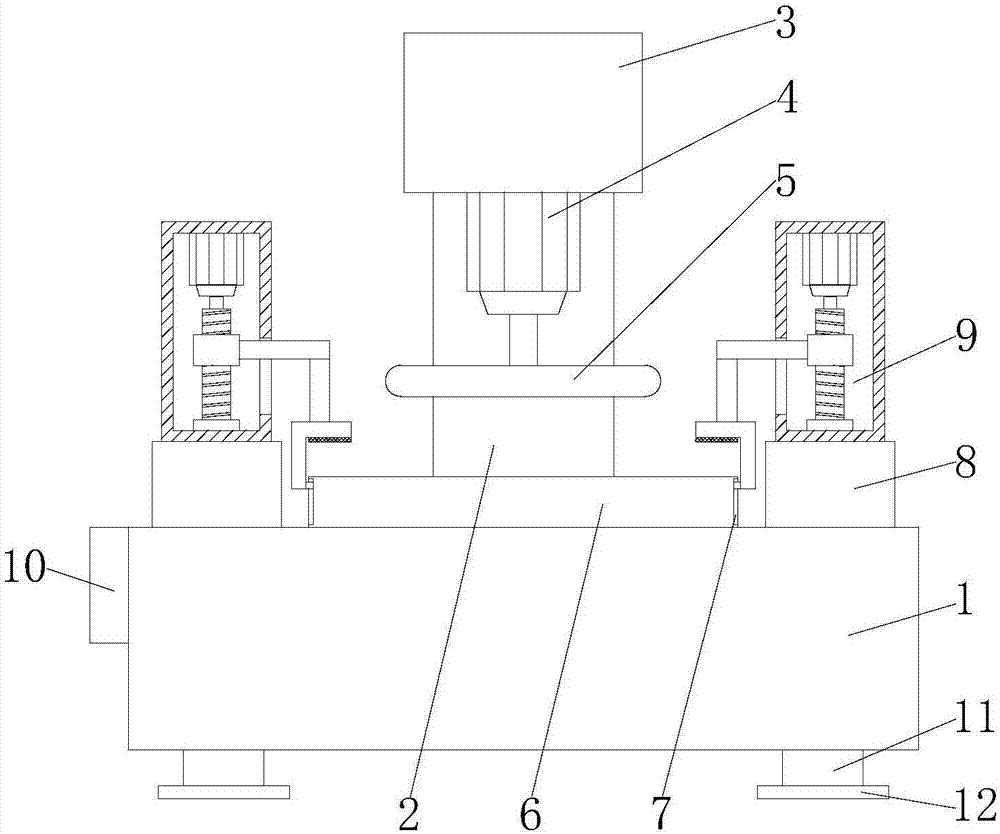

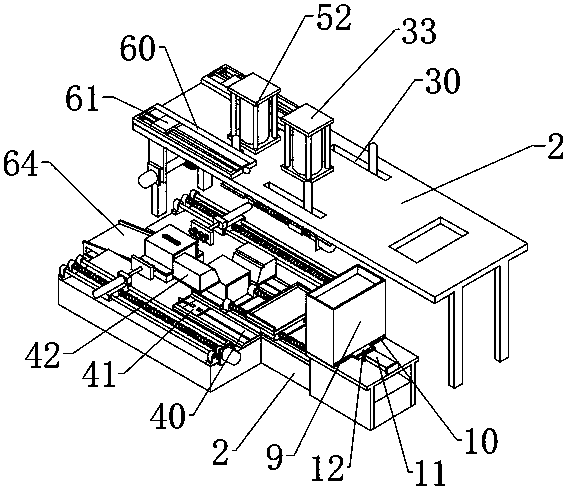

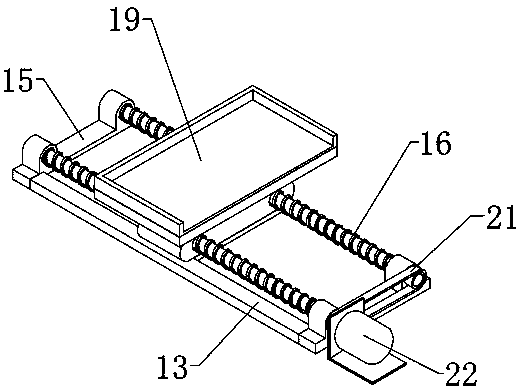

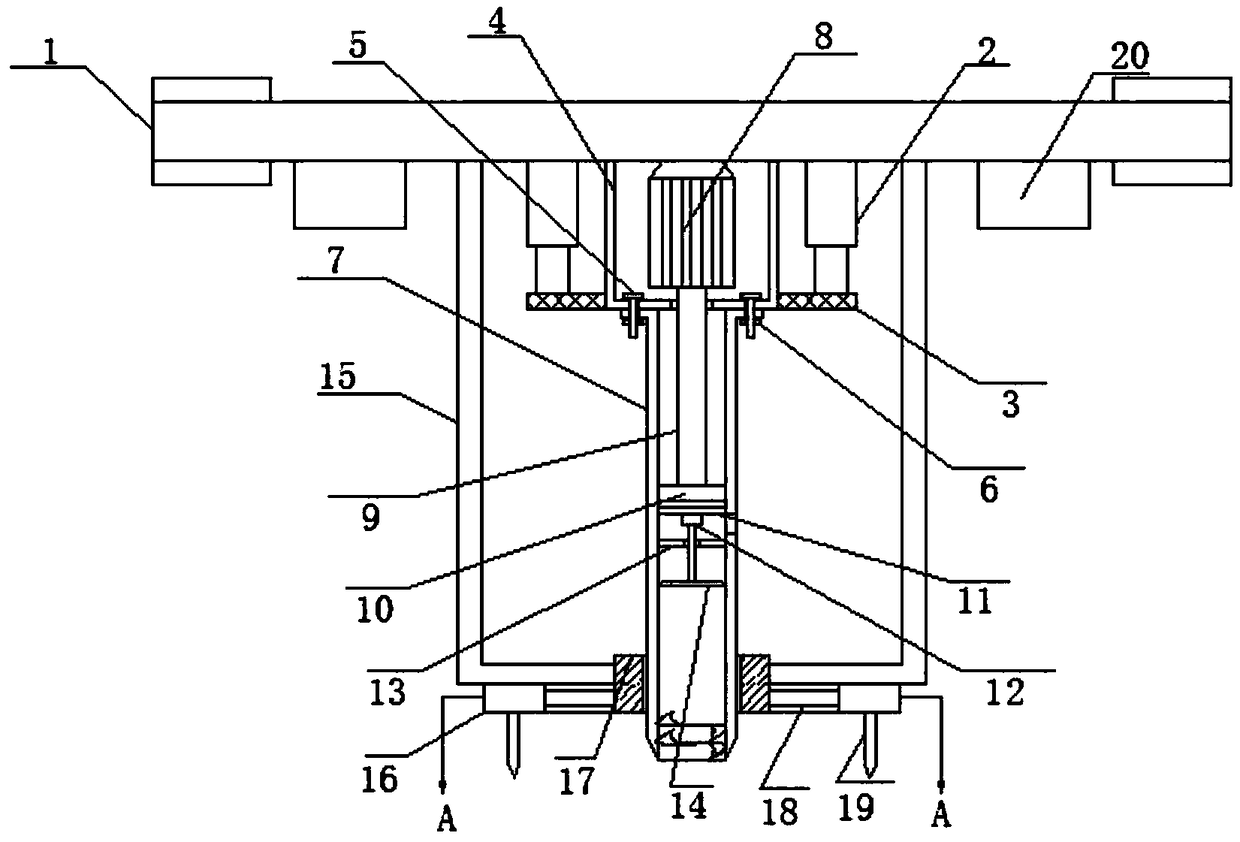

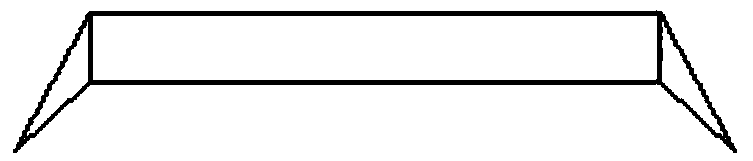

Stamping and punching integrated equipment of electrical installation rail

ActiveCN110773632APlay a stabilizing roleSolve problems that cannot be done simultaneouslyMetal-working feeding devicesCleaning using toolsStructural engineeringManufacturing engineering

The invention relates to the field of machining, in particular to stamping and punching integrated equipment of an electrical installation rail. The stamping and punching integrated equipment of the electrical installation rail comprises a workbench and further comprises a support, a conveying assembly, feeding assemblies, a stamping assembly, a material moving assembly, a punching assembly and acleaning assembly; the conveying assembly is arranged on one side of the top of the workbench; the feeding assemblies are arranged on the support and positioned above the conveying assembly; the punching assembly is arranged on one side of the conveying assembly; the stamping assembly is arranged between the punching assembly and the conveying assembly; the material moving assembly is arranged onthe side of the punching assembly; the cleaning assembly is arranged on the support; the cleaning assembly is arranged on the side, away from the stamping assembly, of the punching assembly; the conveying assembly comprises a storage box and a conveying mechanism; the storage box is arranged at one end of the workbench; and the conveying mechanism is arranged between the stamping assembly and thestorage box. The stamping and punching integrated equipment of the electrical installation rail solves the problem that the electric installation rail cannot be simultaneously stamped and punched, thecost is saved and the production efficiency is improved.

Owner:昆山共宇电子科技有限公司

Soil sampler for biological soil enzyme activity determination

InactiveCN109187080ALabor savingImprove sampling efficiencyWithdrawing sample devicesPush outEngineering

The invention discloses a soil sampler for biological soil enzyme activity determination. The soil sampler comprises a handheld rod and a limiting frame; the lower end of the handheld rod is fixedly connected with the limiting frame; a movable sleeve is fixedly connected to the middle of the limiting frame; the lower end of the handheld rod is symmetrically connected with one ends of two telescopic rods; when a motor rotates, a rotating shaft can be driven to rotate, so that a sampling cylinder is driven to move downwards; the sampling cylinder can move downwards better due to the existence ofa spiral blade, so that the sampling can be performed better, the manual sampling is facilitated, and the labor force is reduced; the lower end of the spiral blade and the lower end of the sampling cylinder adopt conical structures, and in the sampling process, the sampling cylinder can enter the soil more easily, so that the sampling efficiency is improved; after the sampling is finished, in theprocess that a scraping plate moves downwards, a soil sample is pushed downwards, so that the soil sample is pushed out; and meanwhile, the inner side wall of the sampling cylinder is scraped by thescraping plate so as to ensure that the next sampling can be very smooth.

Owner:HEFEI HUAGAI BIOTECH CO LTD

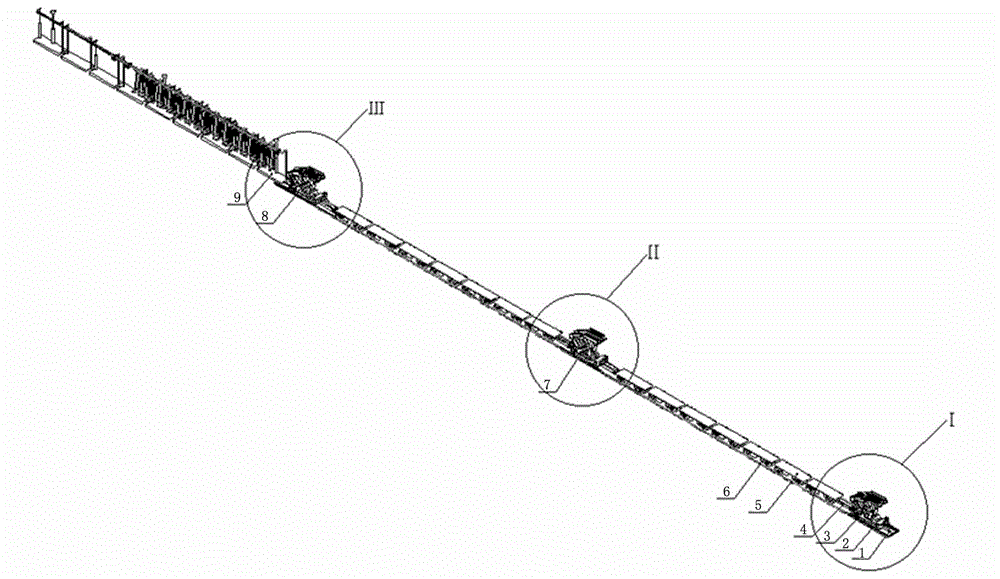

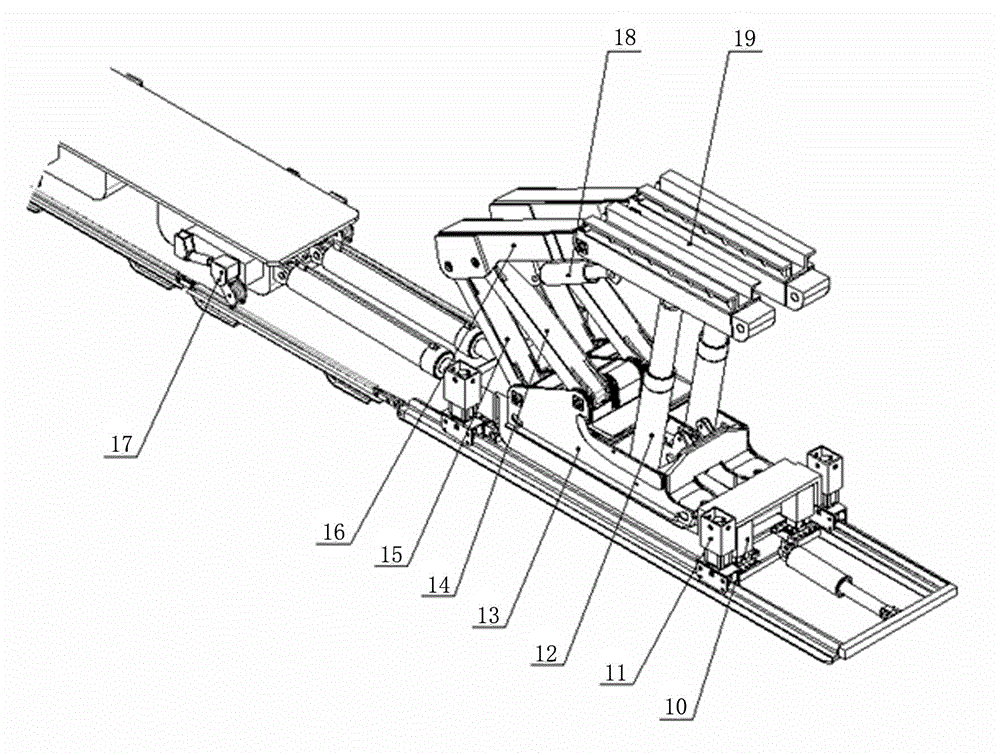

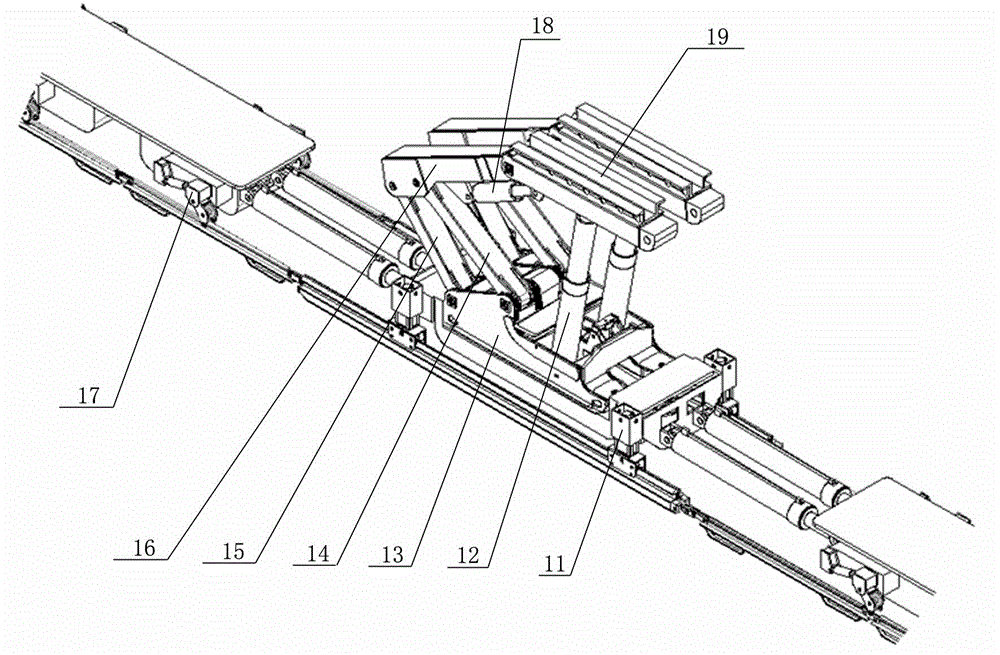

Big-gradient crossheading step-forward self-moving equipment train

ActiveCN104791003AIncrease frictionFully mechanized mining work is fastEarth drilling and miningUnderground transportManufacturing technologyEngineering

The invention belongs to the technical field of design and manufacturing of coal mine underground auxiliary transportation equipment in order to solve the transportation problem of a coal mine underground big-gradient crossheading roadway, and provides a big-gradient crossheading step-forward self-moving equipment train. The equipment train comprises a front anchoring, pulling and moving device, a middle anchoring, pulling and moving device, a rear anchoring, pulling and moving device, platform trolleys, advancing jacks and a pipe cable telescopic bearing system, wherein a front advancing jack is arranged at the front end of the front anchoring, pulling and moving device, the rear end of the front anchoring, pulling and moving device is connected with the platform trolleys through rear advancing jacks, the two ends of the middle anchoring, pulling and moving device are connected with the platform trolleys through the corresponding advancing jacks, the front end of the rear anchoring, pulling and moving device is connected with the platform trolleys through the corresponding advancing jacks, and the rear end of the rear anchoring, pulling and moving device is connected with the pipe cable telescopic bearing system through connecting rods. The train self-moving function, the walking deviation adjusting function, the pipe cable self-moving function and the like are highly integrated for the equipment train, and therefore the equipment train can step forward to move by itself when the gradient of the crossheading roadway is + / -25-degrees, slippage of equipment is effectively prevented, and it is guaranteed that the equipment train safely works in the big-gradient roadway.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

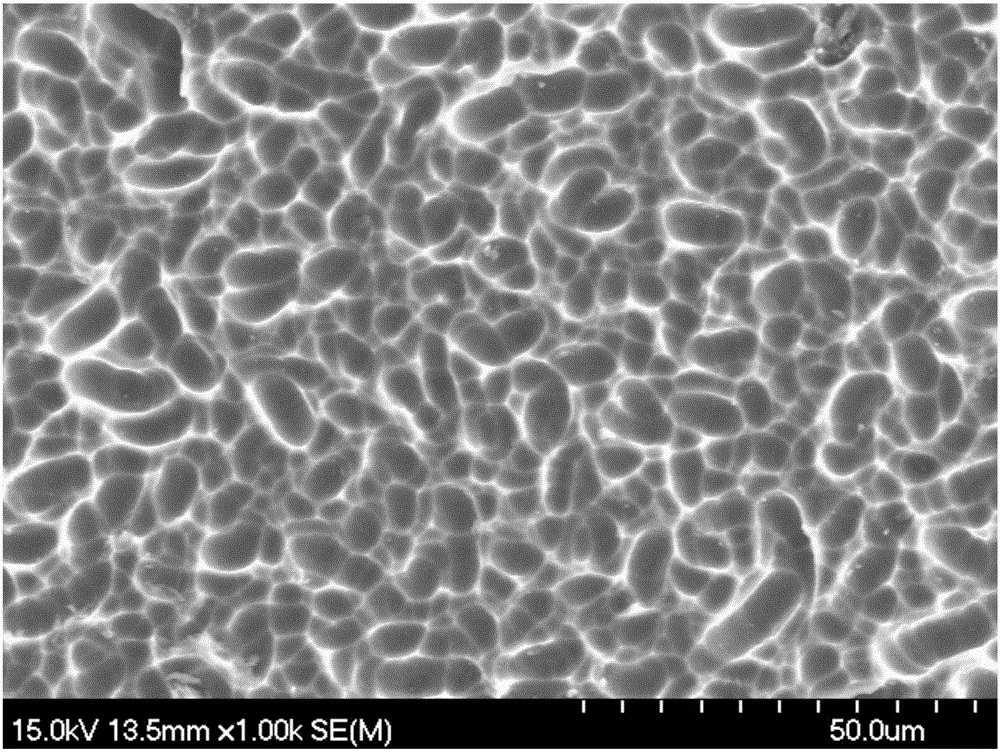

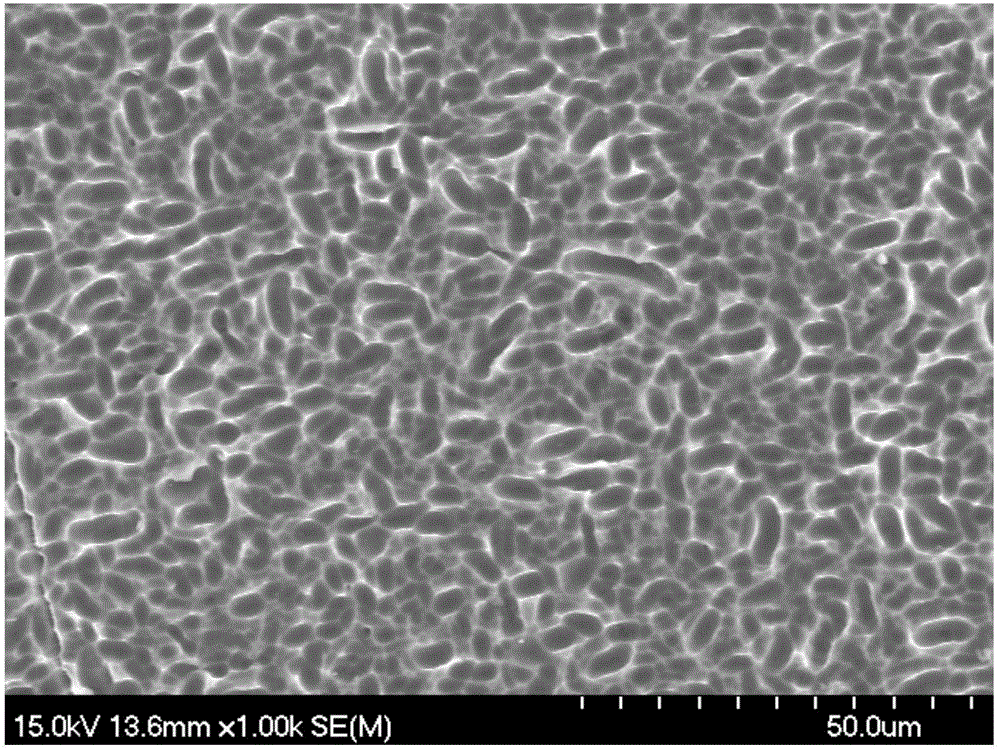

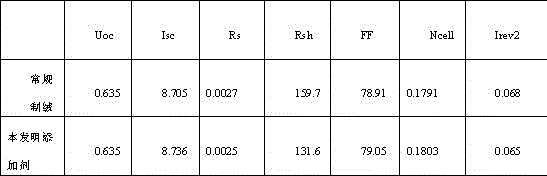

Additive for polycrystalline silicon wafer texturization and application method thereof

InactiveCN106222755AReduce reflectivitySteady increase in conversion efficiencyPolycrystalline material growthAfter-treatment detailsCarboxylic acidContamination

The invention provides an additive for polycrystalline silicon wafer texturization and a method of applying the additive to perform texturization. The additive is prepared from polymer carboxylic acid, micromolecular organic acid, non-ionic surfactant and water, wherein the weight ratio of the polymer carboxylic acid to the water is 0.5-5 to 100, the weight ratio of the micromolecular organic acid to the water ratio is 1-10 to 100, and the weight ratio of the non-ionic surfactant to the water is 0.01-1 to 100. The texturization is performed by using the additive, the uniformity of suede can be improved, further polycrystalline silicon wafer reflectivity is reduced, and the side effects such as silicon wafer surface contamination and suede inside porous silicon are not produced.

Owner:杭州飞鹿新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com