DMC-MMA (methyl methacrylate)-halloysite copolymerized denture base material and preparation method thereof

A technology of polymethacryloyloxyethyltrimethylammonium chloride and methacryloyloxyethyltrimethylammonium chloride, applied in dental preparations, pharmaceutical formulations, dental prostheses, etc., can solve basic Bracket fracture, mechanical properties can not fully meet the oral restoration, the upper denture is easy to longitudinal fracture and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

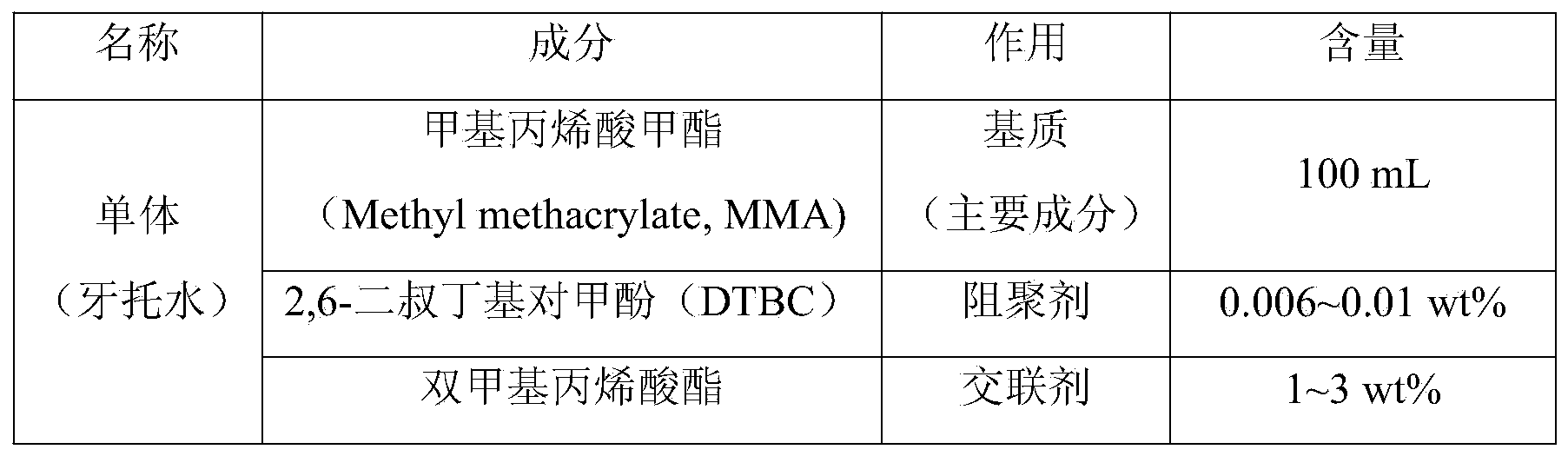

Method used

Image

Examples

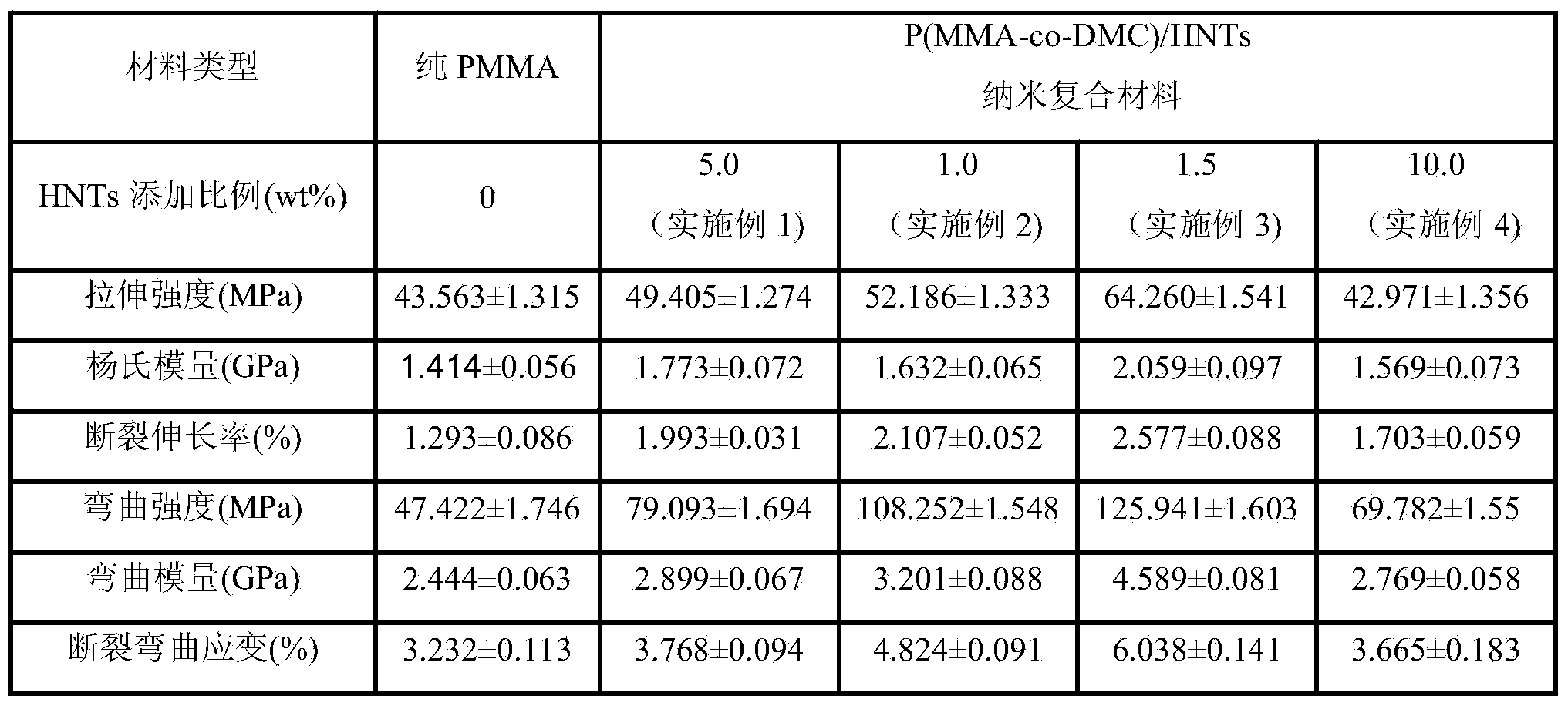

Embodiment 1

[0024] (1) Mix 1.8g of DMC and 58.2g of MMA monomer and add it to a three-necked flask (the total amount of monomer is 60mL), add 3g of HNTs, ultrasonically disperse the suspension, and add 1.5g of hydroxyethyl cellulose in 150mL of deionized water (HEC) and 0.075g sodium dodecylbenzene sulfonate (SDBS), pour it into a three-necked flask after preliminary stirring, and continue stirring at a low speed. Pass N 2 After 40 minutes of protection, the temperature was raised to 90° C., and the inert atmosphere was maintained continuously, and 0.4 g of initiator BPO was added to initiate polymerization. After reacting for 9 hours, the reaction system was cooled and filtered, the filtered product was repeatedly washed with deionized water, and vacuum-dried at 60°C to a constant weight to obtain a P(MMA-co-DMC) / HNTs nanocomposite;

[0025] (2) Mix the P(MMA-DMC) / HNTs copolymer product (powder) with the thermosetting tray water according to the mass ratio of 1:1, take it out after the ...

Embodiment 2

[0028](1) Mix 3gDMC and 57gMMA monomers and add them into a three-necked flask (the total amount of monomers is 60mL), add 0.6gHNTs, and ultrasonically disperse the suspension, and add 1.8g hydroxyethyl cellulose to 150mL deionized water ( HEC) and 0.067g sodium dodecylbenzene sulfonate (SDBS), it is poured into the there-necked flask after initial stirring, and continues stirring at a low speed. Pass N 2 After 40 minutes of protection, the temperature was raised to 90° C., and the inert atmosphere was maintained continuously, and 0.4 g of initiator BPO was added to initiate polymerization. After reacting for 9 hours, the reaction system was cooled and filtered, the filtered product was repeatedly washed with deionized water, and vacuum-dried to a constant weight at 60°C to obtain a P(MMA-co-DMC) / HNTs nanocomposite;

[0029] (2) Mix the P(MMA-DMC) / HNTs copolymerization product (powder) with the thermosetting tray water according to the mass ratio of 1:1, take it out after the...

Embodiment 3

[0032] (1) Mix 6gDMC and 54gMMA monomers and add them into a three-neck flask (the total amount of monomers is 60mL), add 0.9gHNTs, and ultrasonically disperse the suspension, and add 1.6g hydroxyethyl cellulose to 150mL deionized water ( HEC) and 0.075g sodium dodecylbenzene sulfonate (SDBS), it is poured into the there-necked flask after preliminary stirring, and continues stirring at a low speed. Pass N 2 After 40 minutes of protection, the temperature was raised to 90° C., and the inert atmosphere was maintained continuously, and 0.6 g of initiator BPO was added to initiate polymerization. After reacting for 9 hours, the reaction system was cooled and filtered, the filtered product was repeatedly washed with deionized water, and vacuum-dried to a constant weight at 60°C to obtain a P(MMA-co-DMC) / HNTs nanocomposite;

[0033] (2) Mix the P(MMA-DMC) / HNTs copolymerization product (powder) with the thermosetting tray water according to the mass ratio of 1:1, take it out after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com