Patents

Literature

38 results about "Dental Base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

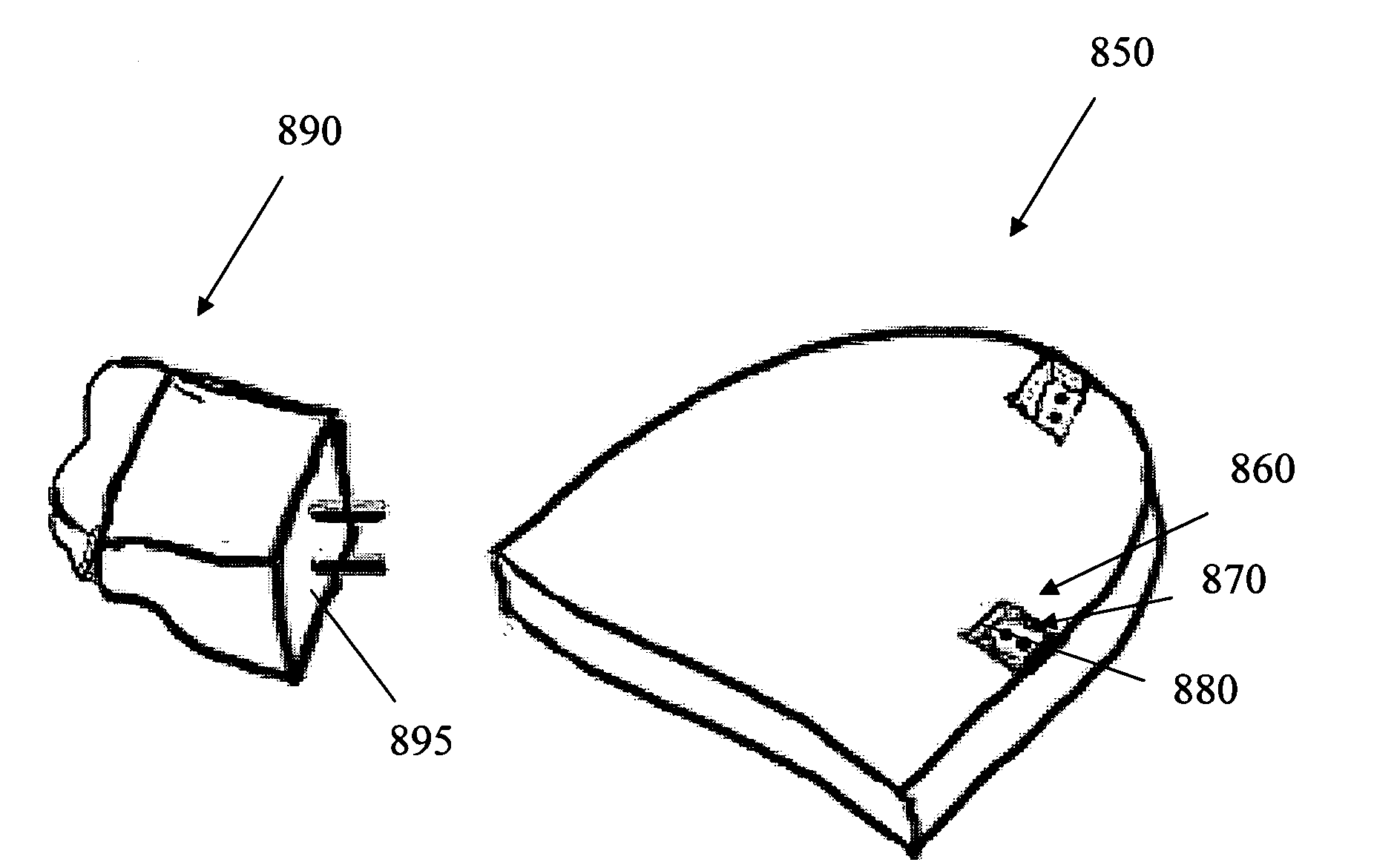

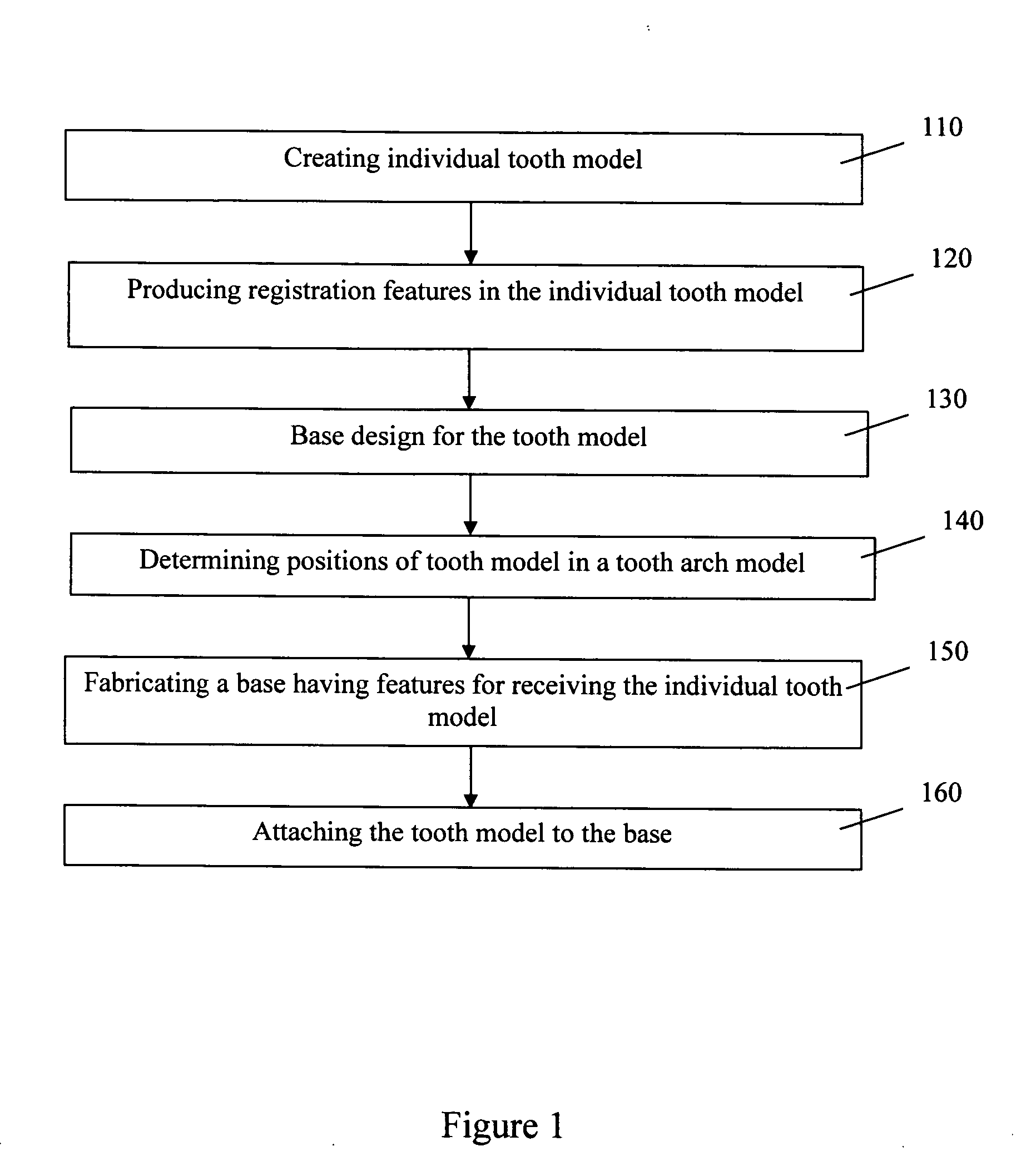

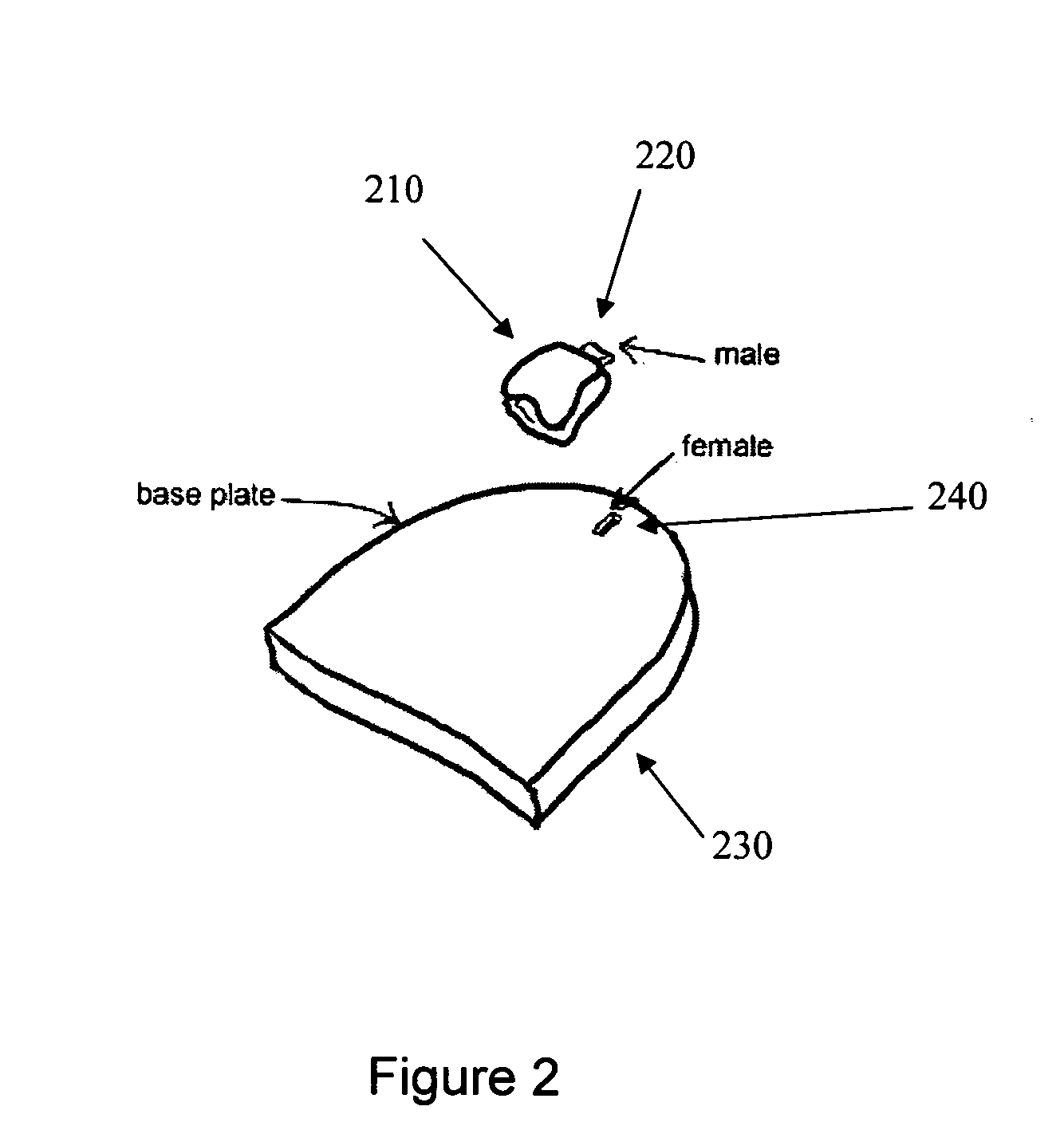

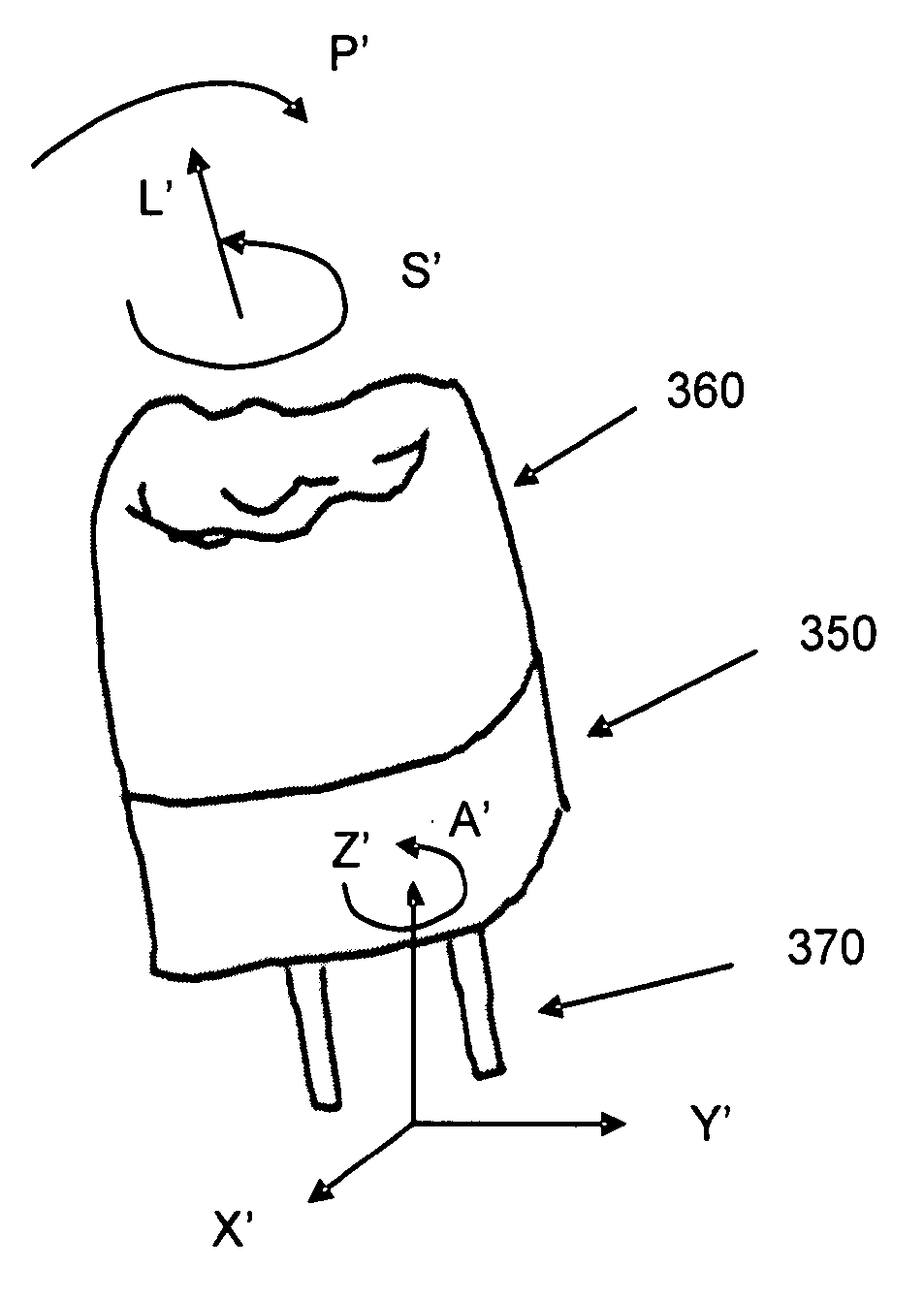

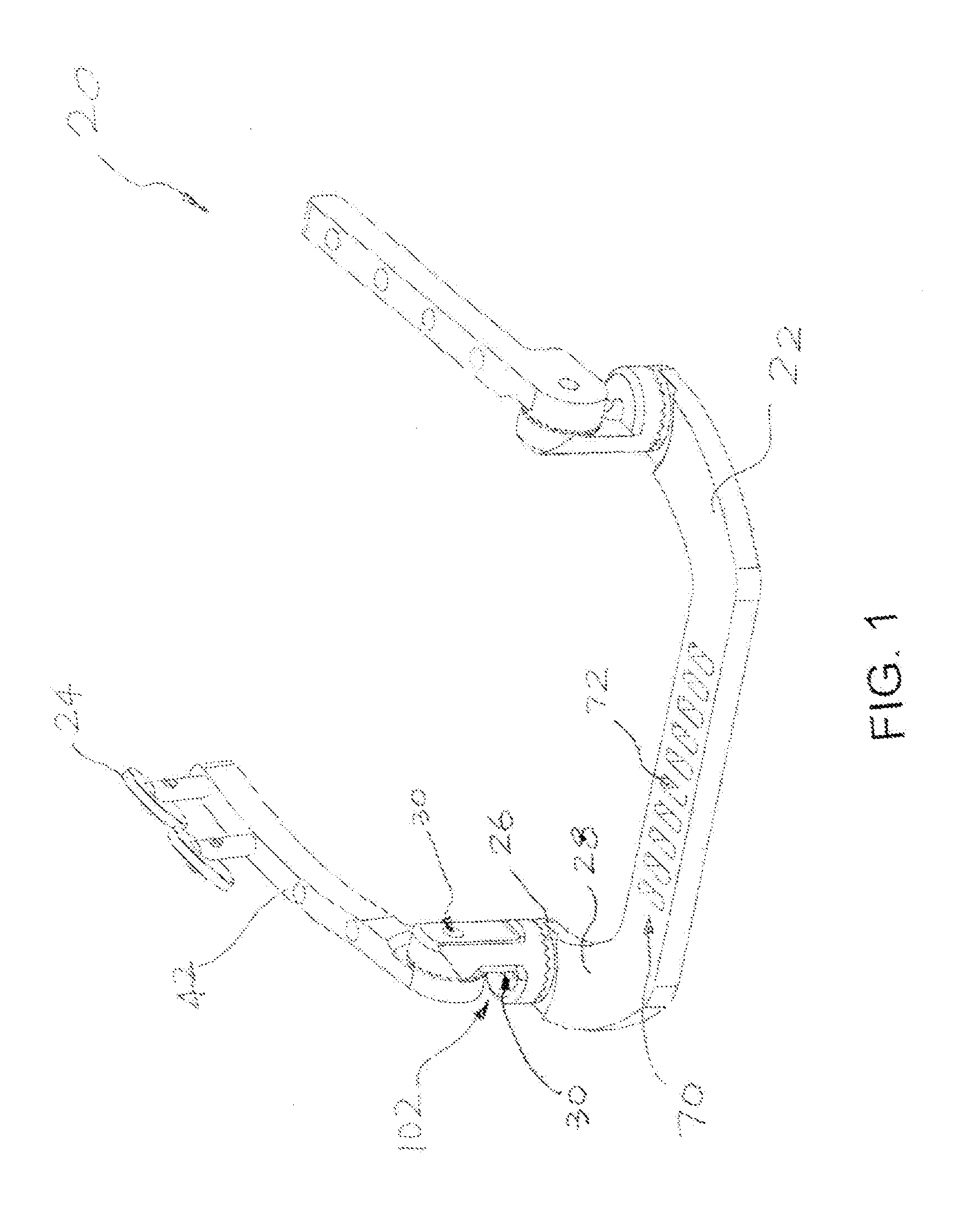

Accurately producing a base for physical dental arch model

InactiveUS20060127850A1Accurately and repeatedly producedLow costImpression capsDental articulatorsModel systemDental Base

Systems and methods are disclosed to produce a dental base having sockets for receiving physical tooth models. The method includes receiving positional information of the sockets on the base, determining a relative movement between a laser and a base plate; emitting a laser beam from the laser to the base plate, and producing a socket in the base plate by the emitted laser beam to form a dental base configured to receive the physical tooth models.

Owner:ALIGN TECH

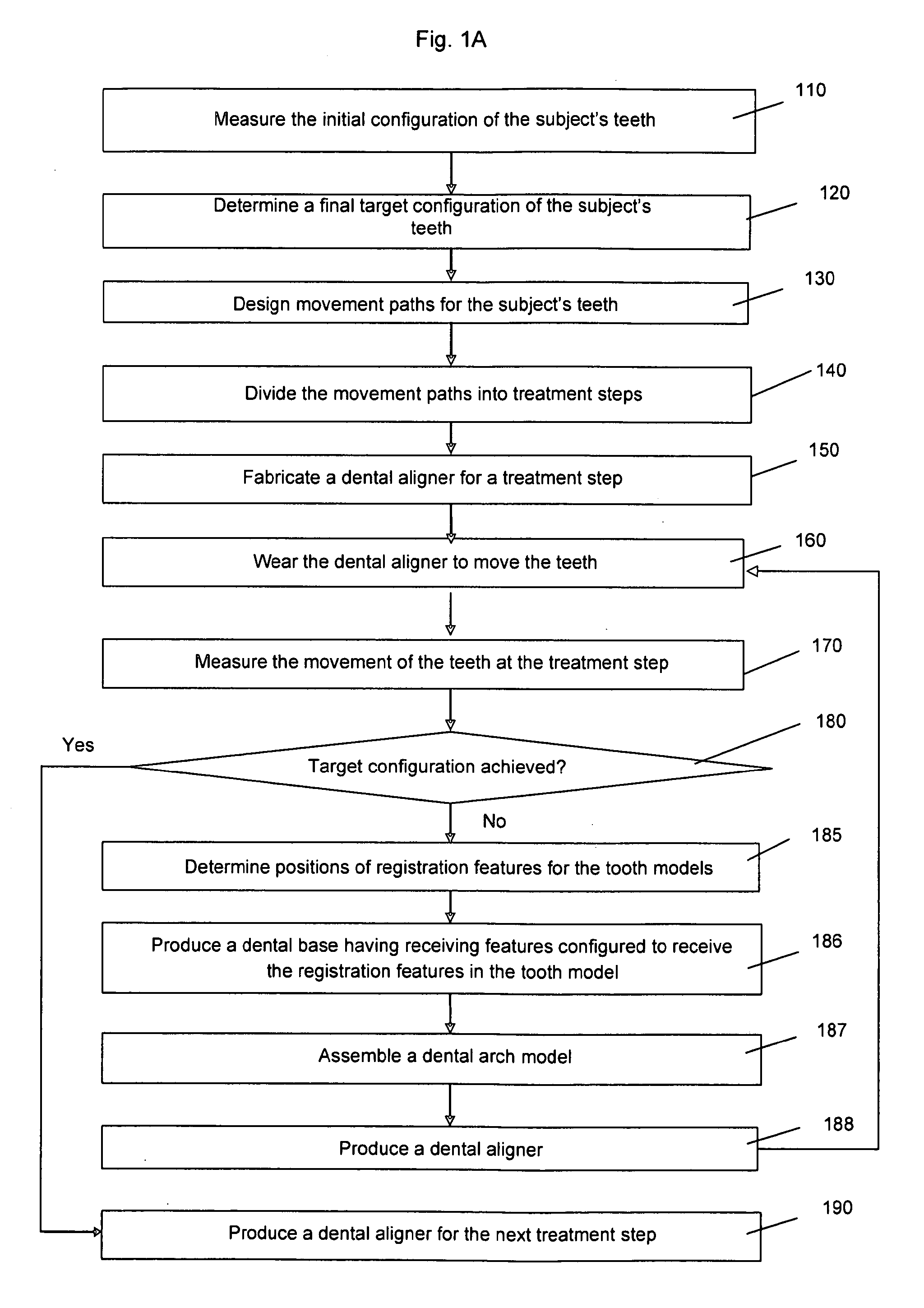

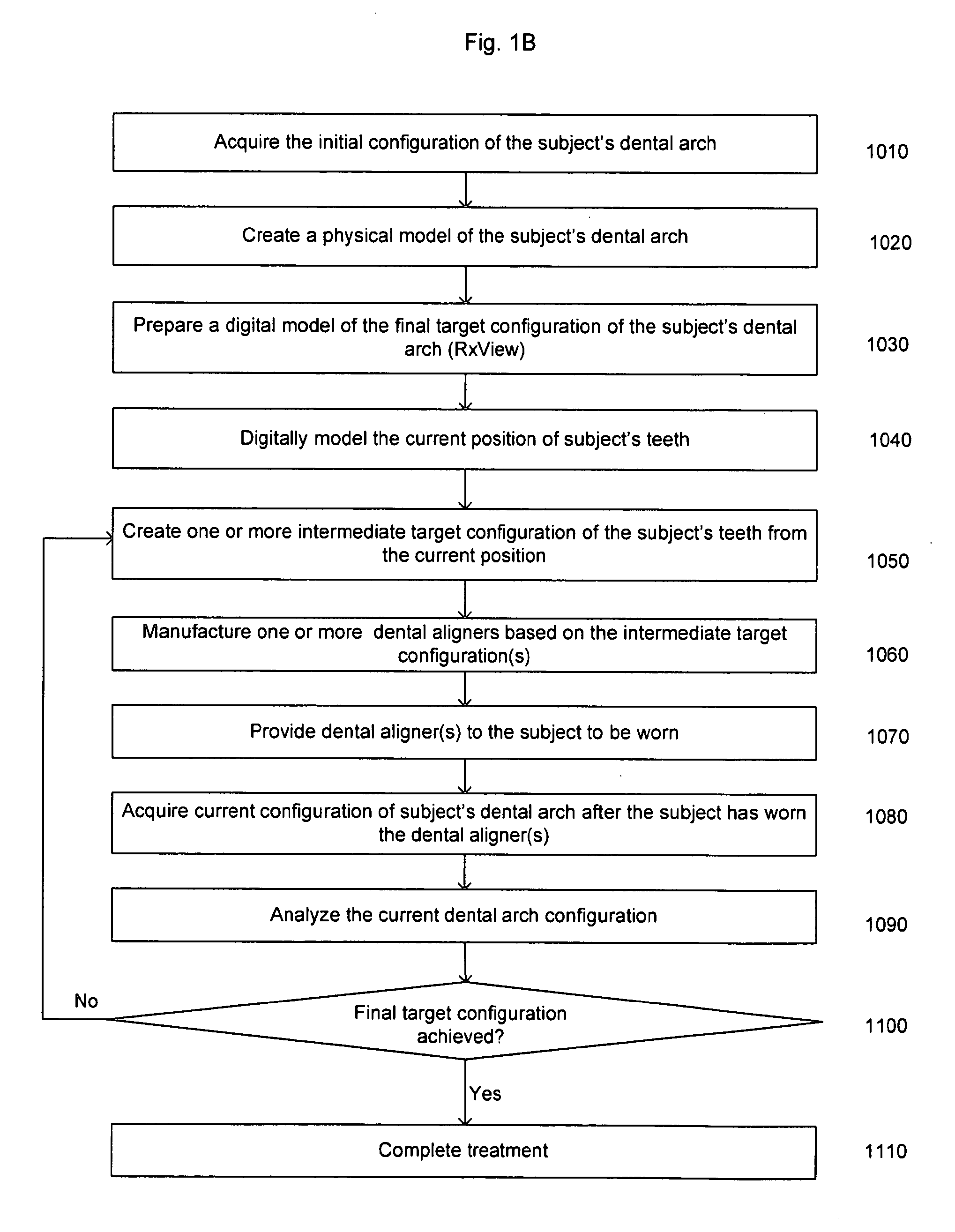

Treatment of teeth by aligners

ActiveUS20090286196A1Conveniently and inexpensively fabricatedImprove comfortImpression capsAdditive manufacturing apparatusDental BaseOrthodontics

A method for treating a subject's teeth. A target configuration for the subject's teeth is determined. Receiving features are produced on a dental base in response to the target configuration, the receiving features being configured to receive physical tooth models. The physical tooth models are assembled on the dental base to form a physical arch model. A dental aligner is produced using the physical arch model to move the subject's teeth to the target configuration.

Owner:ALIGN TECH

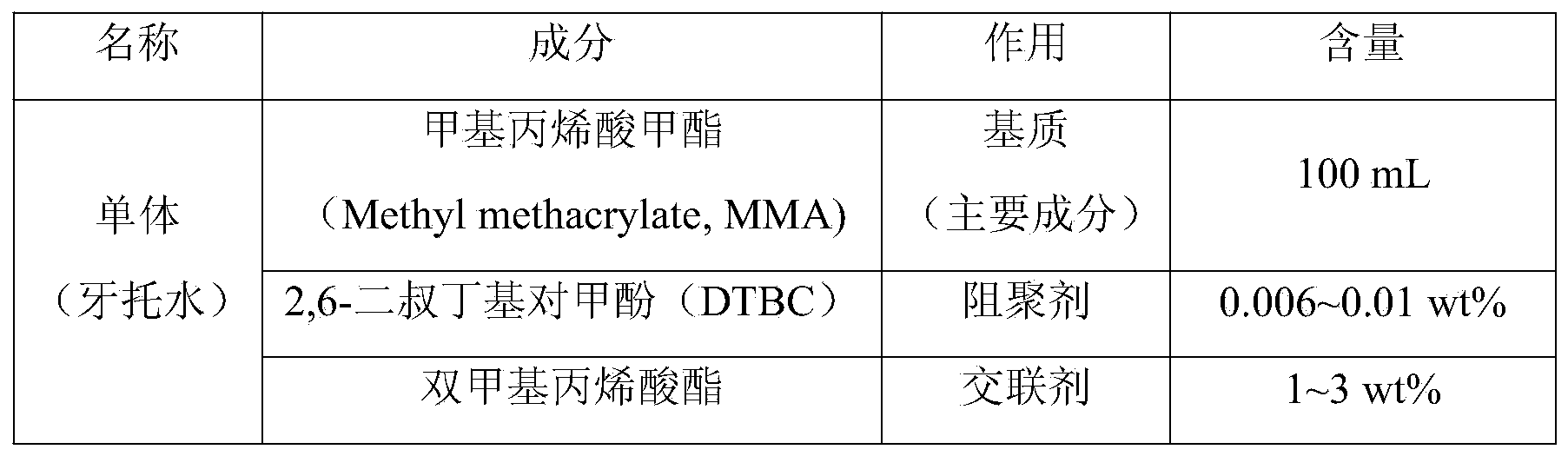

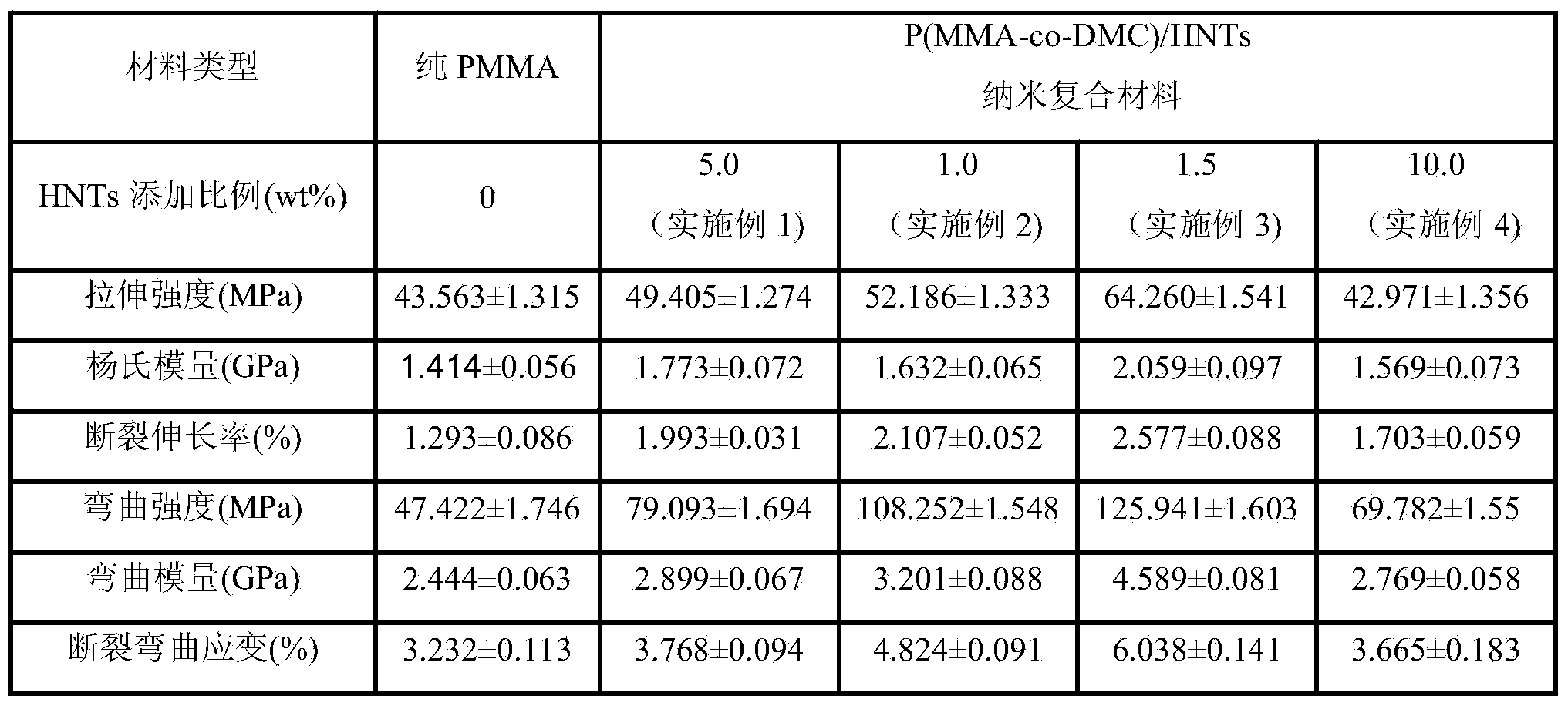

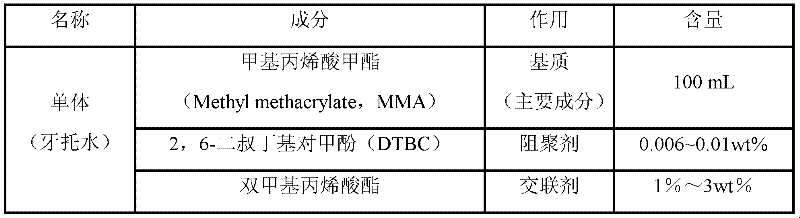

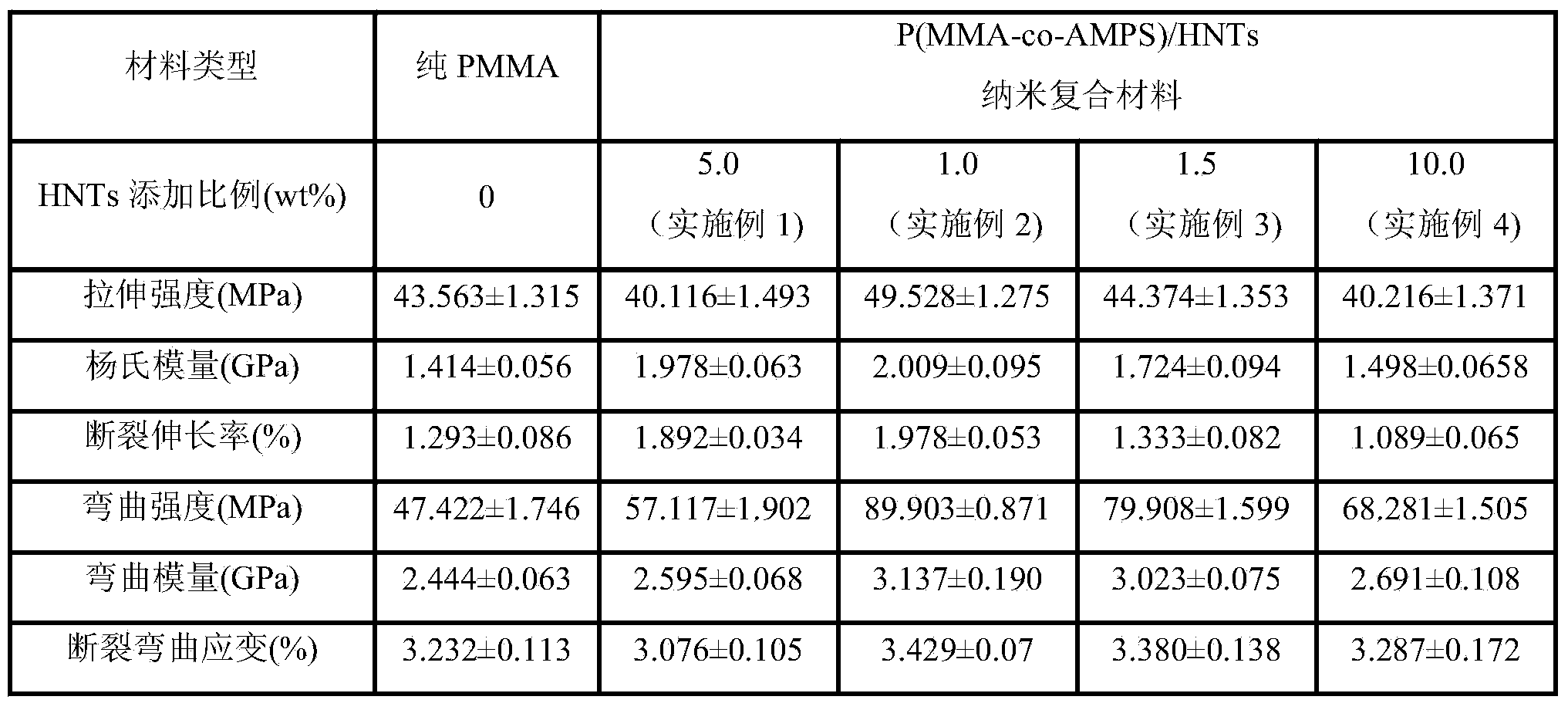

DMC-MMA (methyl methacrylate)-halloysite copolymerized denture base material and preparation method thereof

InactiveCN103622835AGood dispersionPlay a stabilizing roleImpression capsDentistry preparationsDispersityHalloysite

The invention discloses a DMC-MMA (methyl methacrylate)-halloysite copolymerized denture base material and a preparation method thereof. According to the invention, the charge environment of the polymeric substrate of the first monomer MMA is regulated and controlled through the second monomer DMC, and the two monomers are copolymerized through the suspension polymerization method, HNTs is added and compounded with the copolymerized product, and after the copolymerized product is mixed with thermosetting type dental base acrylic resin liquid, the mixture is heated and cured. According to the invention, the MMA is used as a base material, and the nanocomposite is prepared by adopting the in situ suspension polymerization method to regulate and control the charge environment of the substrate, and the halloysite nano filler is added for polymerization, so that the relatively pure PMMA resin is obtained, and the bending strength and the tensile strength of the denture base material are greatly improved to a great extent, the dispersity of halloysite in the substrate is successfully improved, and the problem about the mechanical strength, particularly the bending strength of the PMMA denture base material, is solved.

Owner:TIANJIN UNIV

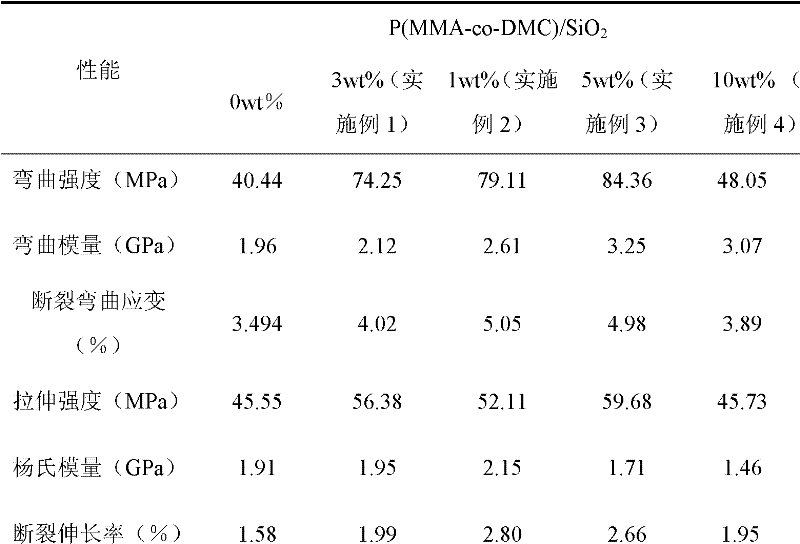

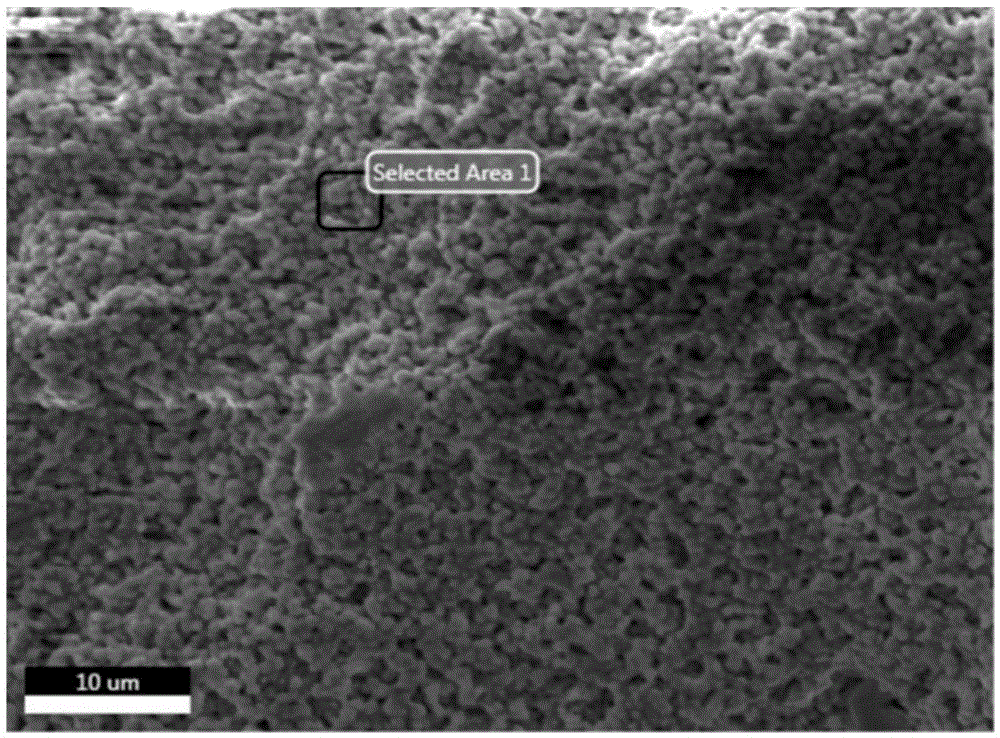

Poly methyl acrylyl oxygen ethyl trimethyl ammonium chloride-methyl methacrylate-silica denture base material and preparation method thereof

ActiveCN102525828AGood dispersionSolve problems with bending strengthImpression capsDentistry preparationsPolymethyl methacrylateDental Base

The invention discloses a poly methyl acrylyl oxygen ethyl trimethyl ammonium chloride-methyl methacrylate-silica compound denture base material and a preparation method and application thereof. A second monomer of methyl acrylyl oxygen ethyl trimethyl ammonium chloride is used for regulating the charge environment of polymer matrix of a first monomer of methyl methacrylate, two monomers are copolymerized in float copolymerization mode, nanometer silicon dioxide (SiO2) is added to be compounded with copolymerization products, and the copolymerization products are mixed with hot thermosetting dental base polymer liquid to be heated and cured. The methyl methacrylate is used as a base material, an in-situ float copolymerization method is utilized to prepare nanometer compound materials, regulation on the charge environment of polymer matrix is achieved, SiO2 nanometer fillers are added to copolymerize pure polymethyl methacrylate (PMMA) resin, bending strength and tensile strength are greatly improved, dispersibility of SiO2 in matrix is successfully improved, and the problem of the PMMA denture base material in mechanical strength especially bending strength is resolved.

Owner:TIANJIN UNIV

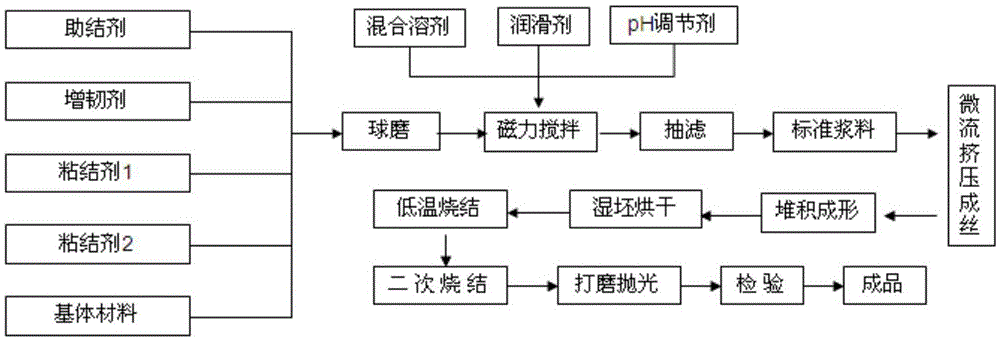

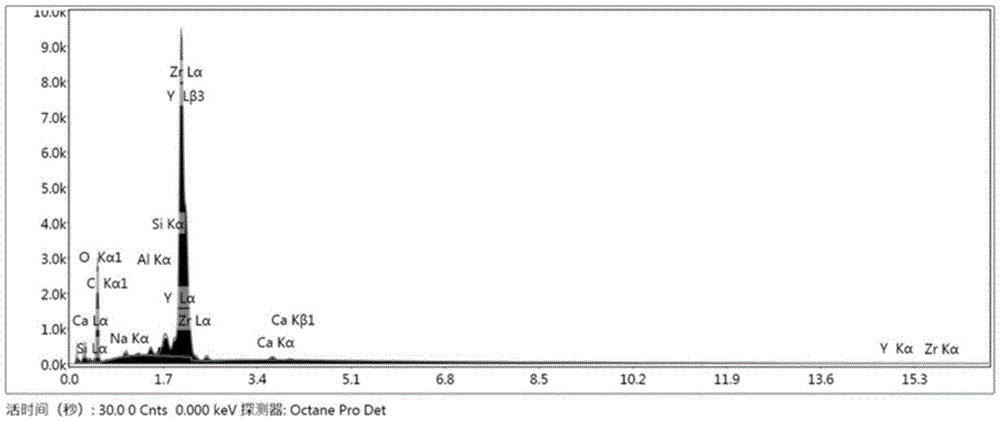

Zirconia ceramic slurry for manufacturing false tooth as well as preparation method and application thereof

The invention relates to zirconia ceramic slurry for manufacturing a false tooth as well as a preparation method and application thereof. The slurry consists of solid raw materials, mixed solvents, lubricating agents and pH regulators, wherein the solid raw materials consist of the following ingredients in percentage by mass: 2 to 5 percent of bonding aiding agents, 2 to 10 percent of tougheners, 4 to 20 percent of bonding agents and 70 to 90 percent of dental base body materials; the bonding aiding agents are magnesium oxide; the toughening agents are zinc oxides; the zinc oxides are ultra-fine zinc oxide powder with the particle diameter being smaller than 1 micrometers. The bonding agents are carrageenin or a mixture of silicon dioxide and the carrageenin. The hardness of a manufactured false tooth is between 1000 and 1300HV; the defects of high porosity and low hardness due to free accumulation of the current process are overcome.

Owner:HEBEI UNIV OF TECH

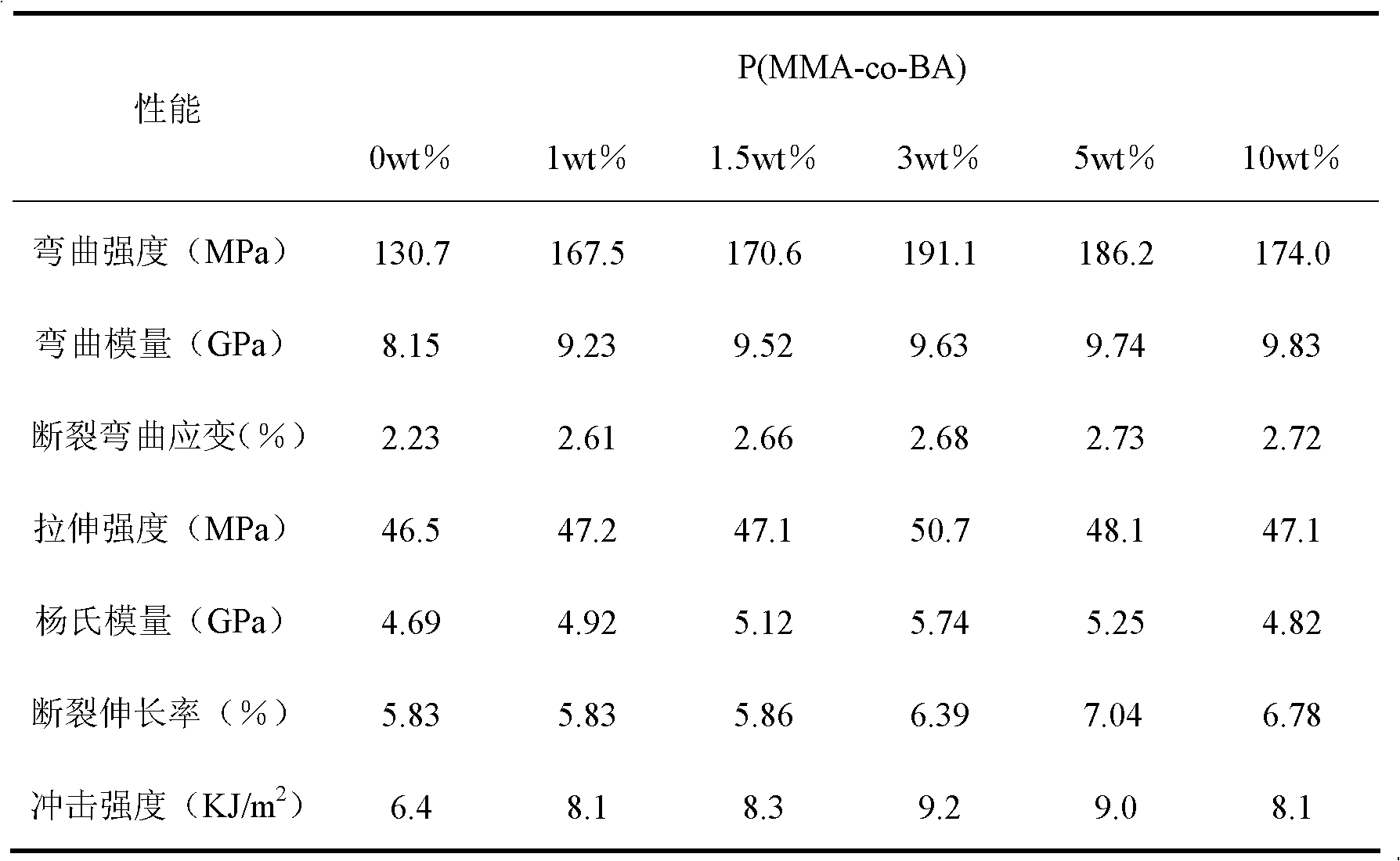

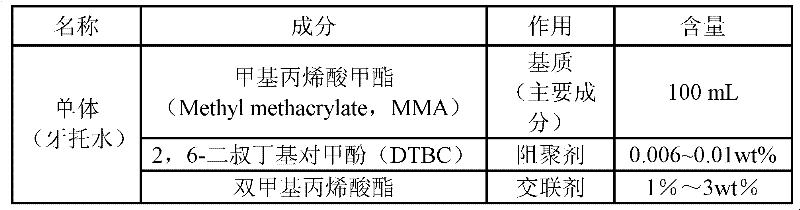

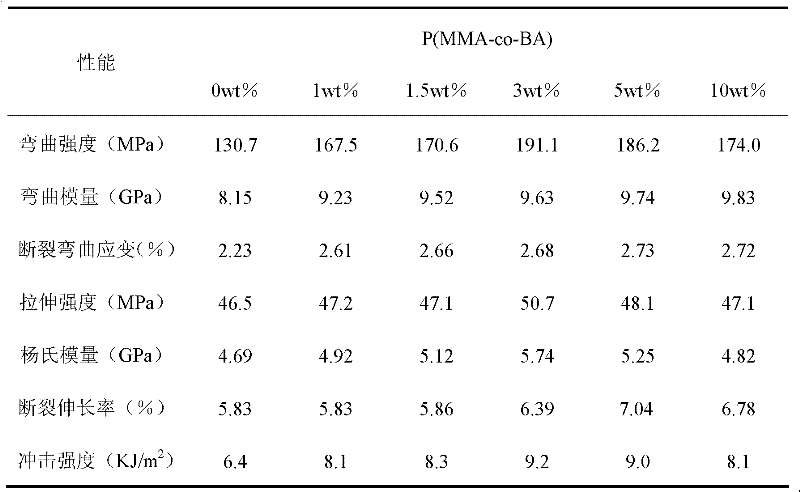

Butyl acrylate-methyl methacrylate copolymer based denture base material as well as preparation method and application thereof

InactiveCN102090983ASignificant saliva resistanceObvious water absorptionImpression capsDentistry preparationsPolymethyl methacrylateOil phase

The invention discloses a butyl acrylate-methyl methacrylate copolymer based denture base material as well as a preparation method and application thereof. Methyl methacrylate as a first monomer is toughened by using butyl acrylate as a second monomer, the two monomers are copolymerized by using a suspension polymerization manner, the two monomers of the butyl acrylate and the methyl methacrylate form an oil phase, the consumption of the butyl acrylate monomer accounts for 1-10 wt percent of the mass of the oil phase, the consumption of the methyl methacrylate monomer accounts for 90-99 wt percent of the mass of the oil phase, and a copolymerized product and thermally-coagulative dental base acrylic resin liquid are uniformly mixed and heated and cured. The P(MMA-co-BA) in the invention is applied to the field of denture base materials; compared with the pure PMMA (polymethyl methacrylate) material, the bending strength and the impact strength are greatly improved, and the tensile strength is slightly increased, and the problem of the PMMA denture base material in the aspect of the mechanical strength, especially impact strength, is successfully solved.

Owner:TIANJIN UNIV

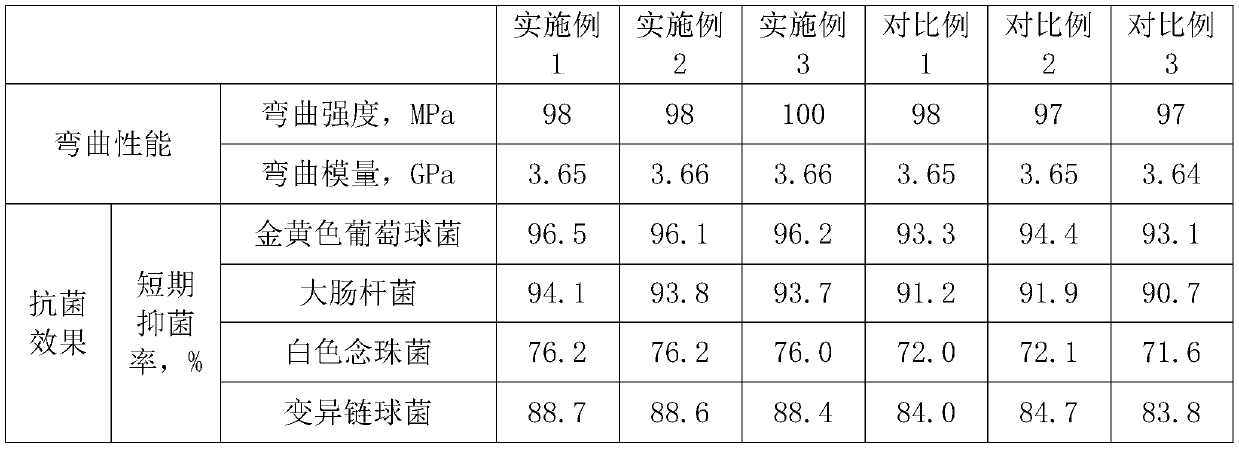

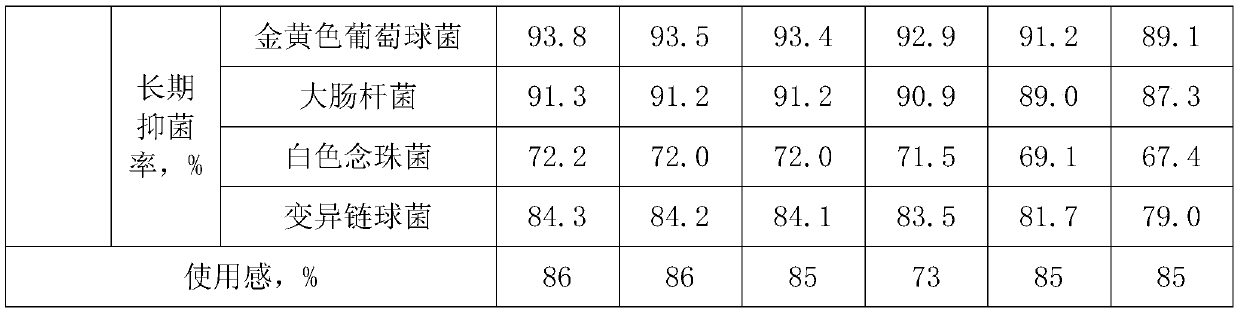

Anti-antibacterial complete denture and preparation method thereof

ActiveCN110384616AImprove antibacterial propertiesImprove toughnessImpression capsDentistry preparationsAcrylic resinDentures

The invention discloses an anti-antibacterial complete denture and a preparation method thereof. The anti-antibacterial complete denture comprises artificial teeth and a base plate, the base plate isprepared from the following components in parts by weight: 70-80 parts of dental base acrylic resin powder, 30-40 parts of dental base acrylic resin liquid, 2-3 parts of a silicon flexibilizer, 4-8 parts of silver-loaded silicon dioxide, 2-4 parts of a natural antibacterial agent, and 1-2 parts of nanometer titania. According to anti-antibacterial complete denture and the preparation method thereof, the silver-loaded silicon dioxide, the nanometer titania and the natural antibacterial agent are compound, thus the base plate has the excellent antibacterial performance, the base plate is compound with the silicon flexibilizer, thus the tenacity of the base plate is further improved, and the service life of the base plate is prolonged.

Owner:杭州拉瓦生物科技有限公司

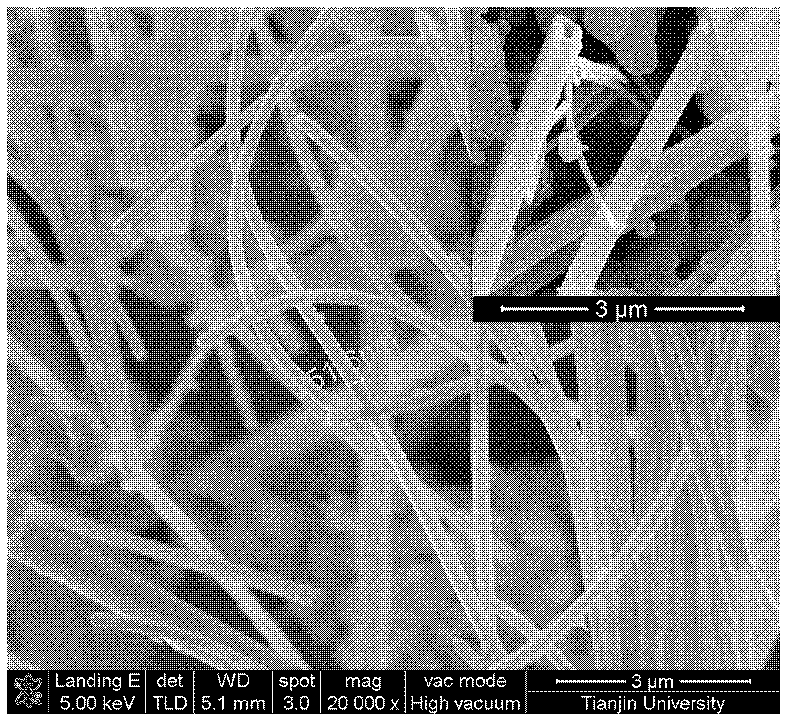

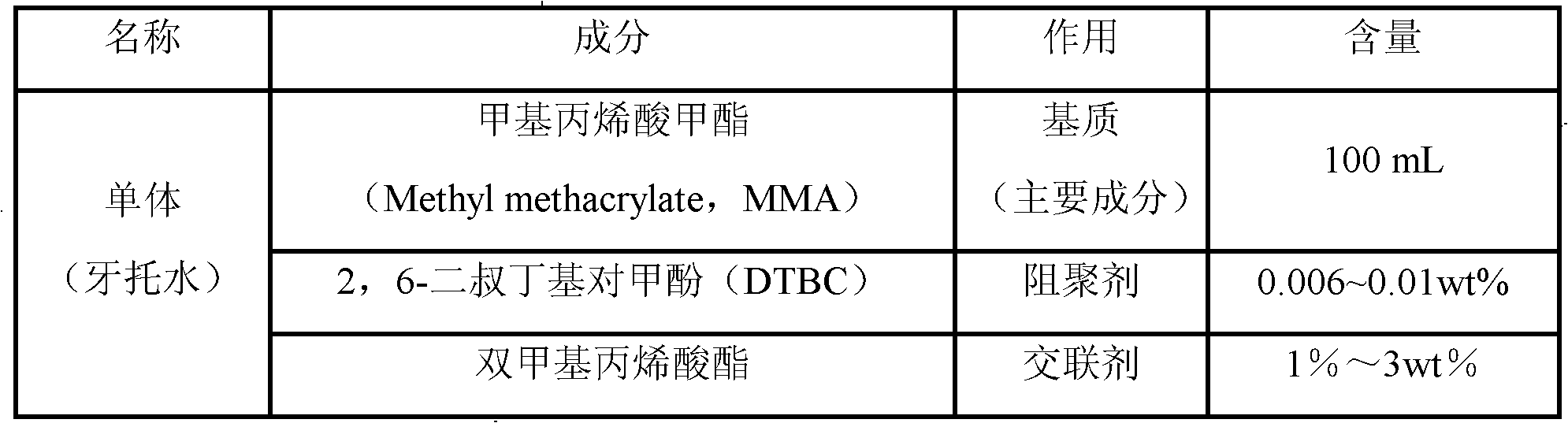

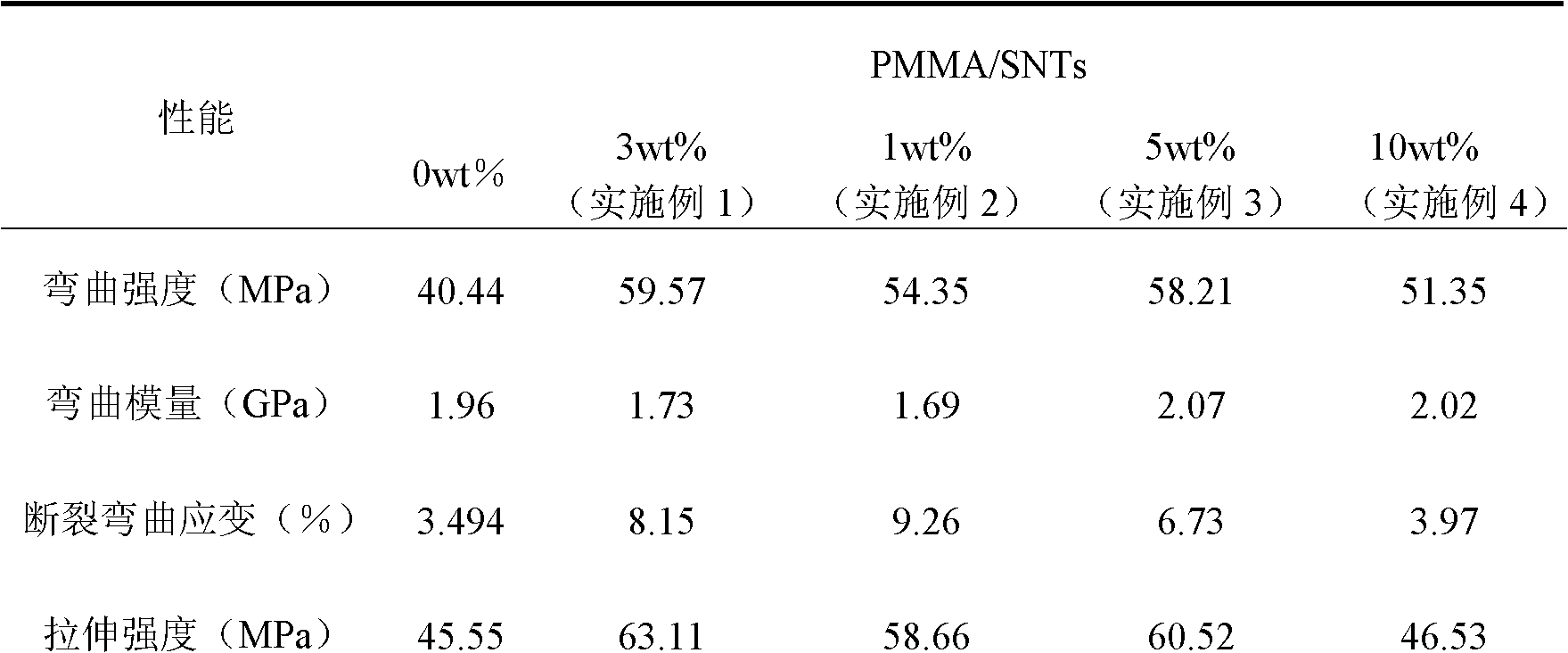

Polymethyl methacrylate (PMMA)-silicon nanotube (SNT) composite denture base material and preparation method and application thereof

InactiveCN102488623AImprove bending strengthHigh tensile strengthImpression capsDentistry preparationsFlexural strengthThermal coagulation

The invention discloses a polymethyl methacrylate (PMMA)-silicon nanotube (SNT) composite denture base material and a preparation method and an application thereof. The preparation method comprises the following steps of: suspending and polymerizing 100 parts by weight of methyl methacrylate monomers and 1-10 parts by weight of silicon nanotubes, uniformly mixing a product with a thermal coagulation dental base acrylic resin liquid; and heating and curing. In the invention, a PMMA / SNTs nano-composite material is prepared by adopting an in-situ suspension polymerization method, SNTs are taken as fillers, the performance of the PMMA is improved by performing SNTs in-situ filling, so that bending strength and tensile strength are improved greatly in comparison to pure PMMA resin, problems existing on the aspect of mechanical strength, in particular on the aspect of tensile strength of the PMMA denture base material are solved, and an oral rehabilitation material with excellent performance is obtained.

Owner:TIANJIN UNIV

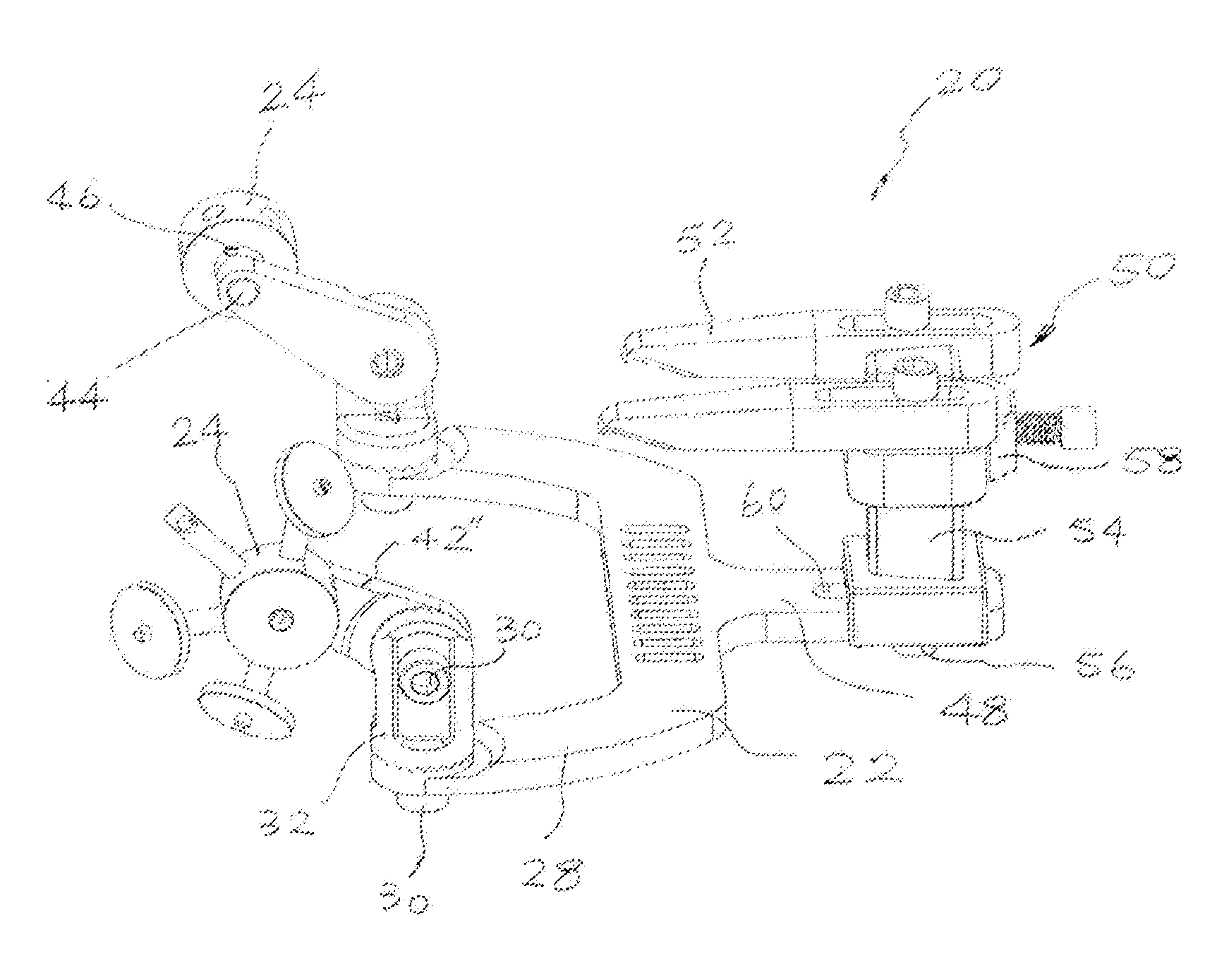

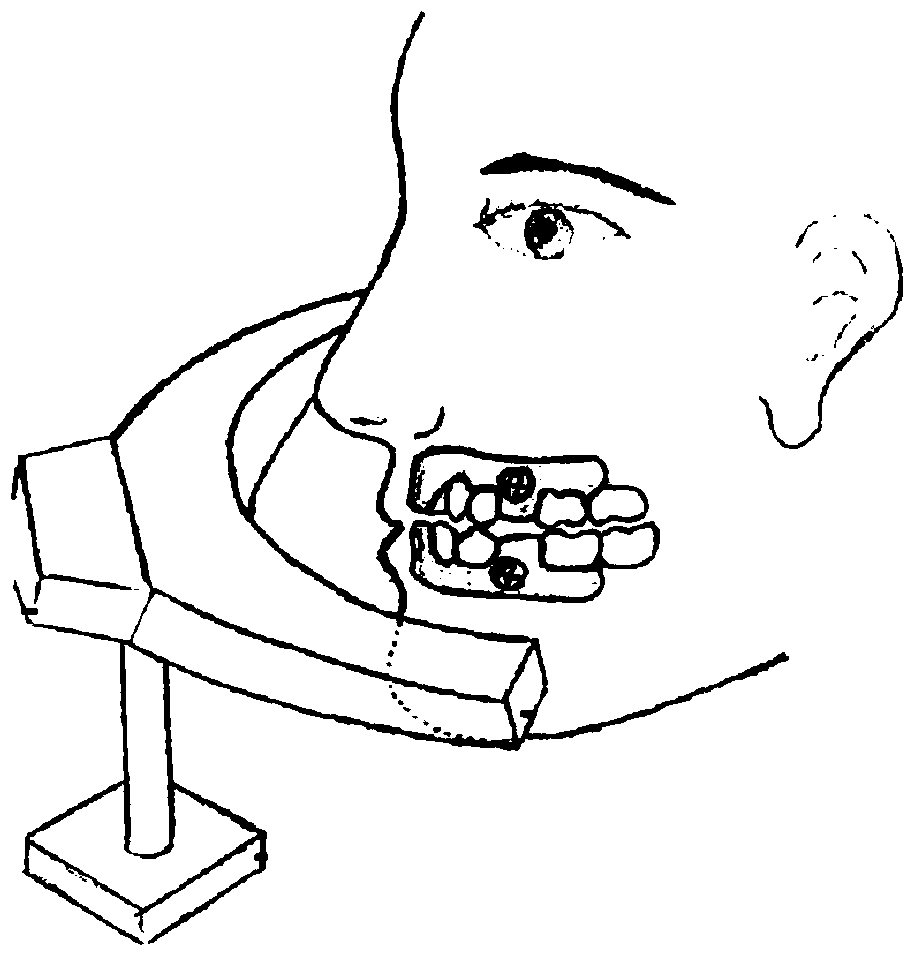

Non-invasive dental based fiducial array

InactiveUS20110092803A1Precise positioningDiagnostic markersDiagnostic recording/measuringDental BaseNon invasive

The invention relates generally to apparatus and devices for neuronavigation. A non-invasive dental based fiducial array is disclosed. The fiducial array has a base support member, one or more removable and repositionable marker bases supported by the base support member and a stopper spaced from and supported by the base support member that engages a part of the head of a patient or an animal and cooperates with the base support member to immobilize the fiducial array relative to a location of the head, such as maxillary teeth. An anchoring site is formed on the base support member to accept a custom made dental impression to precisely position the base support member relative to the location of the head.

Owner:HYBEX HLDG

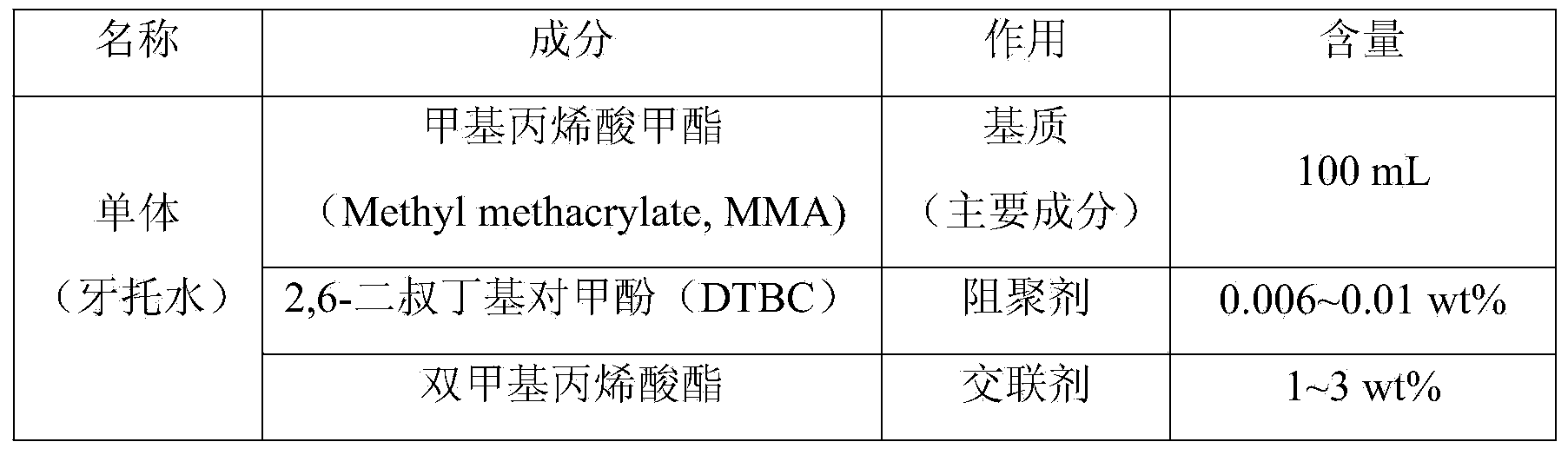

Homogeneous denture material and patternless manufacturing process

ActiveCN106074183AImprove mechanical propertiesImprove toughnessImpression capsDentistry preparationsPlasticizerAcrylic resin

The invention belongs to the technical field of denture preparation and particularly relates to a homogeneous denture material and a patternless manufacturing process. The material is mainly prepared from the following components in parts by weight: 100 to 120 parts of special water for a dental department, 95 to 105 parts of dental base acrylic resin powder, 0.8 to 2 parts of binding agent and 0.5 to 0.8 part of plasticizer. The patternless manufacturing process of the homogeneous denture material comprises the following steps: firstly, weighing all the components according to the weight parts; secondly, uniformly mixing all the components, then filling an injection pipe with a mixture, injecting the mixture into a plaster model with a denture female die cavity at a certain pressure by using a special injection molding machine; performing heat treatment under the condition that the temperature is 90 to 150DEG C and the pressure is 1 to 20MPa, and cooling to obtain a finished product. The denture material provided by the invention has the properties of high toughness and mechanical strength, good bacteria resistance, and the like.

Owner:珠海新茂义齿科技有限公司

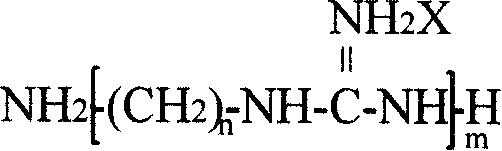

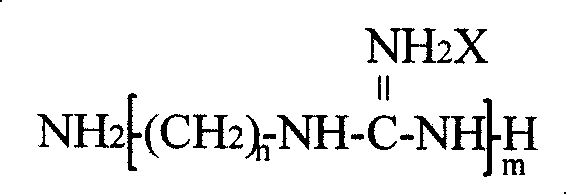

Antibiotic dental prosthetic materials and preparation method thereof

InactiveCN101209228AImprove antibacterial propertiesImpression capsDentistry preparationsEpoxyEscherichia coli

The invention discloses an antibacterial dental prosthetic material and a preparation method thereof. The antibacterial dental prosthetic material is obtained by injecting the raw materials in a specific mold for curing and forming after even mixing of 25 percent to 94 percent (by weight) of epoxy resin, 0.5 percent to 40 percent (by weight) of polyamine and guanidine oligomer, 5 percent to 65 percent (by weight) of curing agent, the amount which is equivalent to 10 to 50 percent of the total weight of the three matters of filler and the amount which is equivalent to 0 to 20 percent of the weight of the epoxy resin of epoxy thinner. The dental prosthetic material prepared by the ingredients and the method of the invention is safe for the human body, does not damage the oral bacteria group and has the long-term antibacterial property; the antibacterial rate of the invention on staphylococcus aureus is more than 98 percent, and the antibacterial rate on Escherichia coli is more than 98 percent. The invention can be used as dental base material, adhesive, filling material, closure agent and other dental materials.

Owner:EAST CHINA UNIV OF SCI & TECH

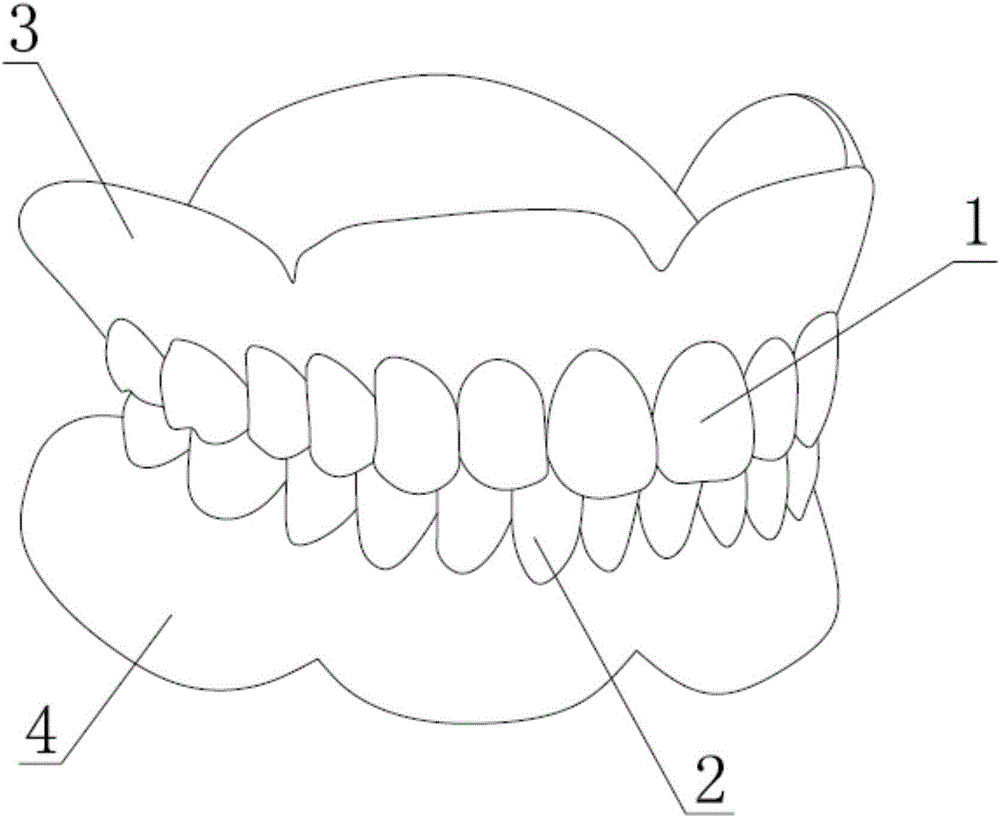

Detachable denture and preparation method thereof

InactiveCN106510875AImprove the level of rowing teethLow costDental implantsArtificial teethDenturesDental Base

The present invention relates to the field of a denture, and especially relates to a detachable denture and a preparation method thereof. The denture comprises a mounting unit, also includes an upper dental crown, a lower dental crown, an upper dental base and a lower dental base which are formed by 3D printing, the upper dental crown and the lower dental crown are filled with filling bodies, the mounting unit comprises an implant abutment and an abutment yoke body, the implant abutment is fixed in the upper dental crown and the lower dental crown, the abutment yoke body is fixed in the dental base and the lower dental base, the implant abutment and the abutment yoke body are in magnetic connection, and connection gaps between the upper dental crown and the upper dental base and between the lower dental crown and the lower dental base are filled with paste. The upper dental crown and the lower dental crown are overall structures comprising a plurality of dental crowns, the upper dental crown and the lower dental crown are printed directly by 3D printing technology after tooth-arrangement design by use of a computer, the integrity is good, the upper dental crown and the lower dental crown are not easy to deform and misplace, by the tooth-arrangement design by use of the computer, the tooth-arrangement level of a technician can be improved maximally, a lot of work steps are saved, and cost is saved for patients.

Owner:东莞市永嘉义齿有限公司

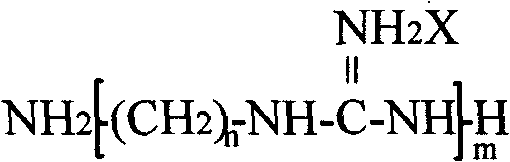

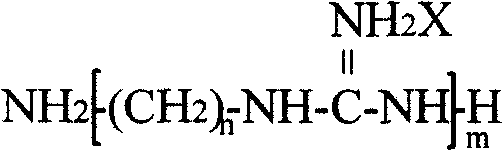

2-Acryloylamino-2-methyl-1-propanesulfonic acid (AMPS)-methyl methacrylate (MMA)-halloysite copolymerized denture base material and preparation method thereof

ActiveCN103622836AGood dispersionSolve problems with bending strengthImpression capsDentistry preparationsDispersityHalloysite

The invention discloses a 2-Acryloylamino-2-methyl-1-propanesulfonic acid (AMPS)-methyl methacrylate (MMA)-halloysite copolymerized denture base material and preparation method thereof. According to the invention, the charge environment of the polymer substrate of the first monomer MMA is regulated and controlled through the second monomer AMPS, the two monomers are copolymerized through the suspension polymerization method, HNTs is added and compounded with the copolymerization product, and after the copolymerization product is mixed with thermosetting type dental base acrylic resin liquid, the mixture is heated and cured. According to the invention, the MMA is used as a base material, and the in situ suspension polymerization method is adopted to prepare a nanocomposite to regulate and control the charge environment of the substrate, and the halloysite filler is added for polymerization, so that relatively pure PMMA resin is obtained, the bending strength and tensile strength are improved to a great extent, the dispersity of halloysite in the substrate is successfully improved, and the problem about the mechanical strength, particularly the bending strength of the PMMA denture base material, is solved.

Owner:TIANJIN UNIV

Antibiotic dental prosthetic materials and preparation method thereof

InactiveCN101209228BImprove antibacterial propertiesImpression capsDentistry preparationsEscherichia coliEpoxy

The invention discloses an antibacterial dental prosthetic material and a preparation method thereof. The antibacterial dental prosthetic material is obtained by injecting the raw materials in a specific mold for curing and forming after even mixing of 25 percent to 94 percent (by weight) of epoxy resin, 0.5 percent to 40 percent (by weight) of polyamine and guanidine oligomer, 5 percent to 65 percent (by weight) of curing agent, the amount which is equivalent to 10 to 50 percent of the total weight of the three matters of filler and the amount which is equivalent to 0 to 20 percent of the weight of the epoxy resin of epoxy thinner. The dental prosthetic material prepared by the ingredients and the method of the invention is safe for the human body, does not damage the oral bacteria groupand has the long-term antibacterial property; the antibacterial rate of the invention on staphylococcus aureus is more than 98 percent, and the antibacterial rate on Escherichia coli is more than 98 percent. The invention can be used as dental base material, adhesive, filling material, closure agent and other dental materials.

Owner:EAST CHINA UNIV OF SCI & TECH

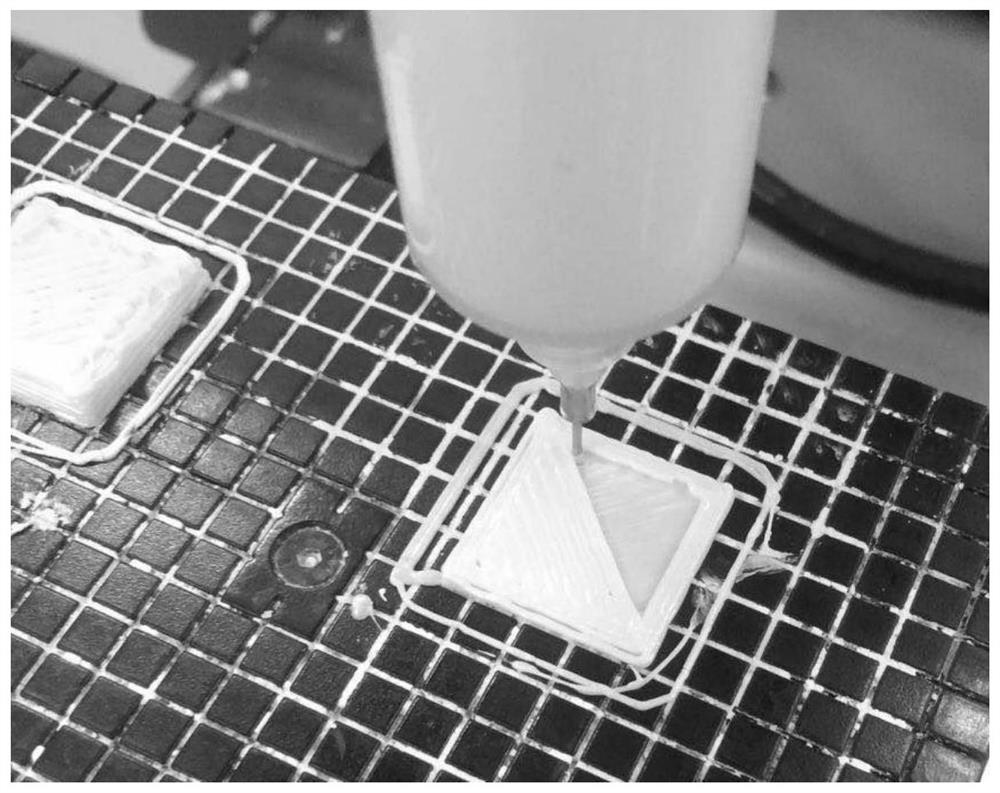

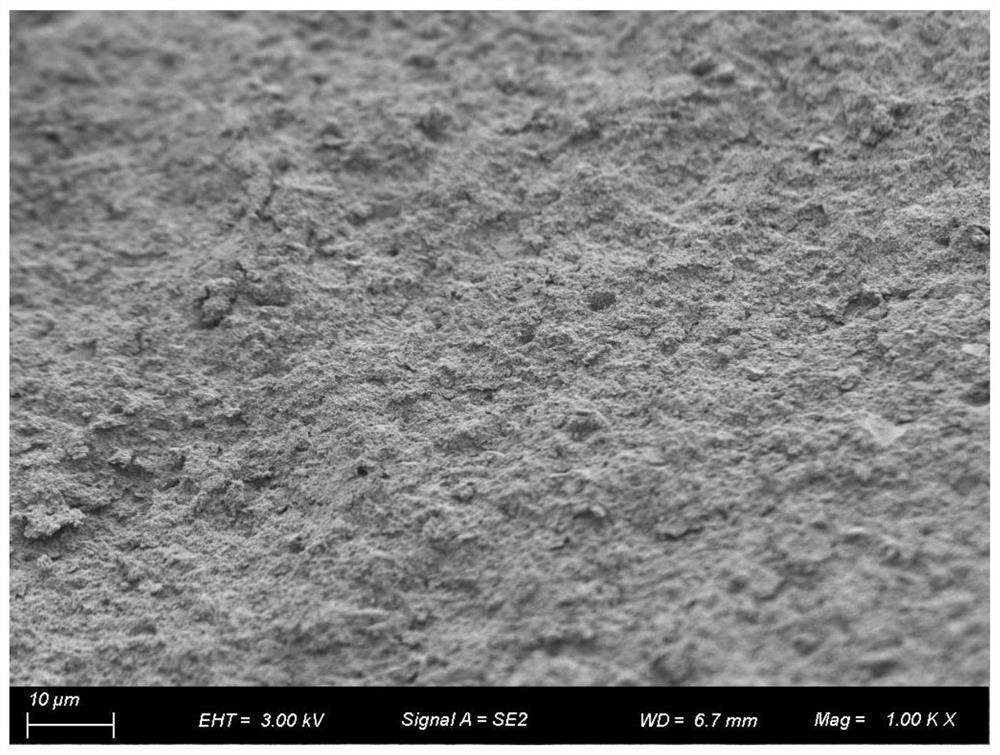

Zirconia ceramic slurry for micro-flow extrusion molding, and preparation method and application thereof

ActiveCN111018520AExtrude evenlyHigh strengthAdditive manufacturing apparatusImpression capsFluid phaseDental Base

The invention relates to a zirconia ceramic slurry for micro-flow extrusion molding, and a preparation method and an application thereof. The zirconia ceramic slurry comprises ceramic powder, a lubricant, a dispersant, a toughening agent and a pH regulator, wherein the ceramic powder comprises, by mass, 3-6% of alumina, 2-5% of titanium oxide and 90-95% of dental base material zirconia; the volumeratio of deionized water to glycerol in the lubricant is 9:1; the dispersant is sodium polyacrylate, and the mass of the dispersant is 4-10% of that of zirconia; and the mass ratio of the sum of theceramic powder, the dispersant and the toughening agent to the lubricant is 3:(7-17). The addition of the sodium polyacrylate organic matter improves the rheological properties of the slurry, and makes the high solid phase and the rheological property considered at the same time; and the strength and the toughness of the ceramic slurry are enhanced, so that the ceramic slurry is smoothly extrudedunder a micro-flow extrusion molding process, no liquid phase migration occurs or the generated liquid phase migration is low and can be ignored, and an extruded green body is not prone to collapsing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

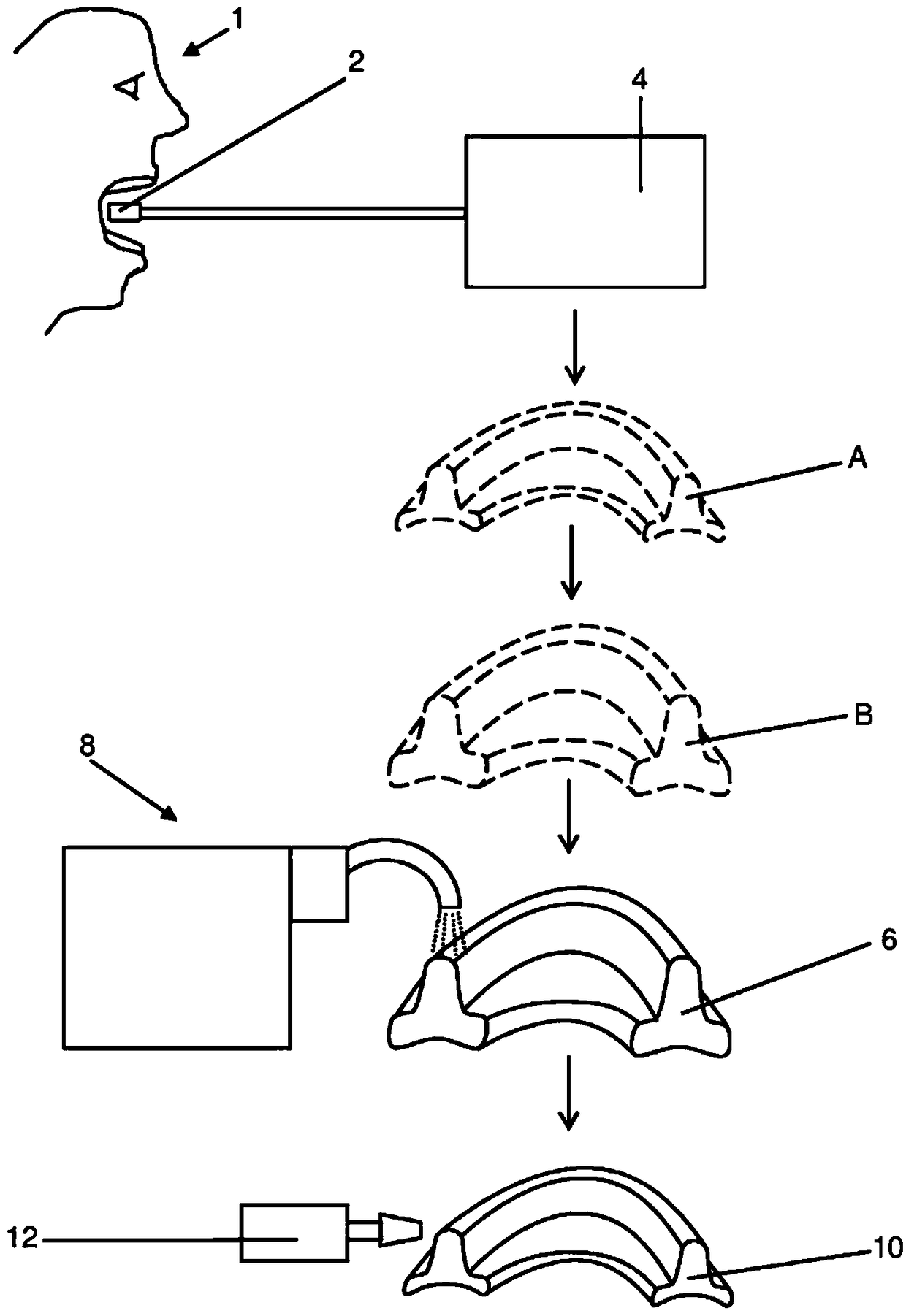

Method for making semi-finished dental base

The invention relates to a method for making a dental base semi-finished product (6), comprising the following steps: 1) collecting and digitizing the oral condition of a patient (1), generating a digital three-dimensional oral model of the patient (1), or providing the patient (1) 2) performing a first calculation in which a digital three-dimensional first model (A) of the denture base is calculated, wherein the oral model is based on the oral condition in the first calculation; 3) performing a second calculation in which a digital three-dimensional second model (B) of the base semi-finished product is calculated from the first model (A) of the denture base, wherein on the three-dimensional model (A) of the denture base at least Add volume locally; 4) make the dental base semi-finished product (6) by rapid prototyping method, wherein CAM method is used in the rapid prototyping method and the digital three-dimensional second model (B) of the base semi-finished product is based on the CAM method. The invention also relates to a device for carrying out this method and a base semi-finished product produced by this method.

Owner:HERAEUS KULZER GMBH

A technology for removing laser printing or copying writing on the surface of paper

ActiveCN104861764BEasy to purchaseEasy to removeChemical paints/ink removersHandwritingPolymer science

Owner:胡锴

Method for preparation of metallographic sample by cold processing

InactiveCN108168970AImprove permeabilitySolve the lack of hardnessPreparing sample for investigationHardnessSoft materials

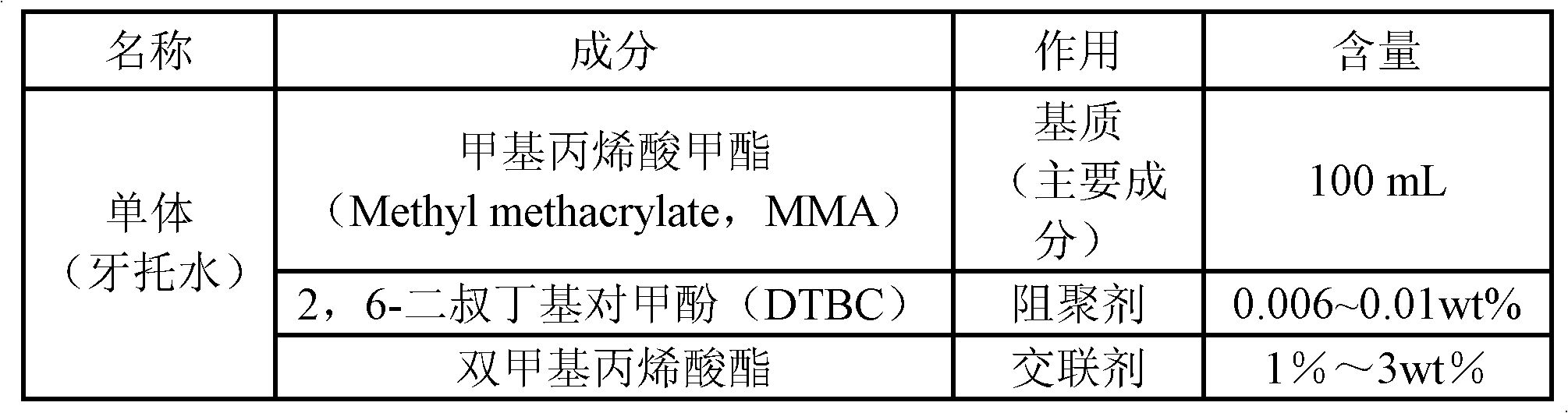

The invention discloses a method for preparation of a metallographic sample by cold processing. According to the shape and size of a sample to be prepared, a simple mold is made of a soft material, the sample to be prepared is placed in the center of the mold, and powdered dental base powder is poured into the mold to fully fill a mold cavity, dental base water is poured into the mold cavity, andnaturally solidified, and the processed metallographic sample is obtained after solidification. The method for preparation of the metallographic sample is not limited by the shape and size of the sample itself, has good permeability to the sample with racks and voids, and is simple in operation, and resampling is convenient. The method has low requirements on the sample, and is not limited by theshape and size of the sample, the dental base powder is solidified quickly and steadily, and has excellent permeation capacity for small holes and dents; the prepared sample has sufficient hardness and toughness, and has good acid and alkali resistance; the resampling is easy, and the original sample can be obtained by removing of the dental base powder with an acetone solution.

Owner:西安赛特思迈钛业有限公司

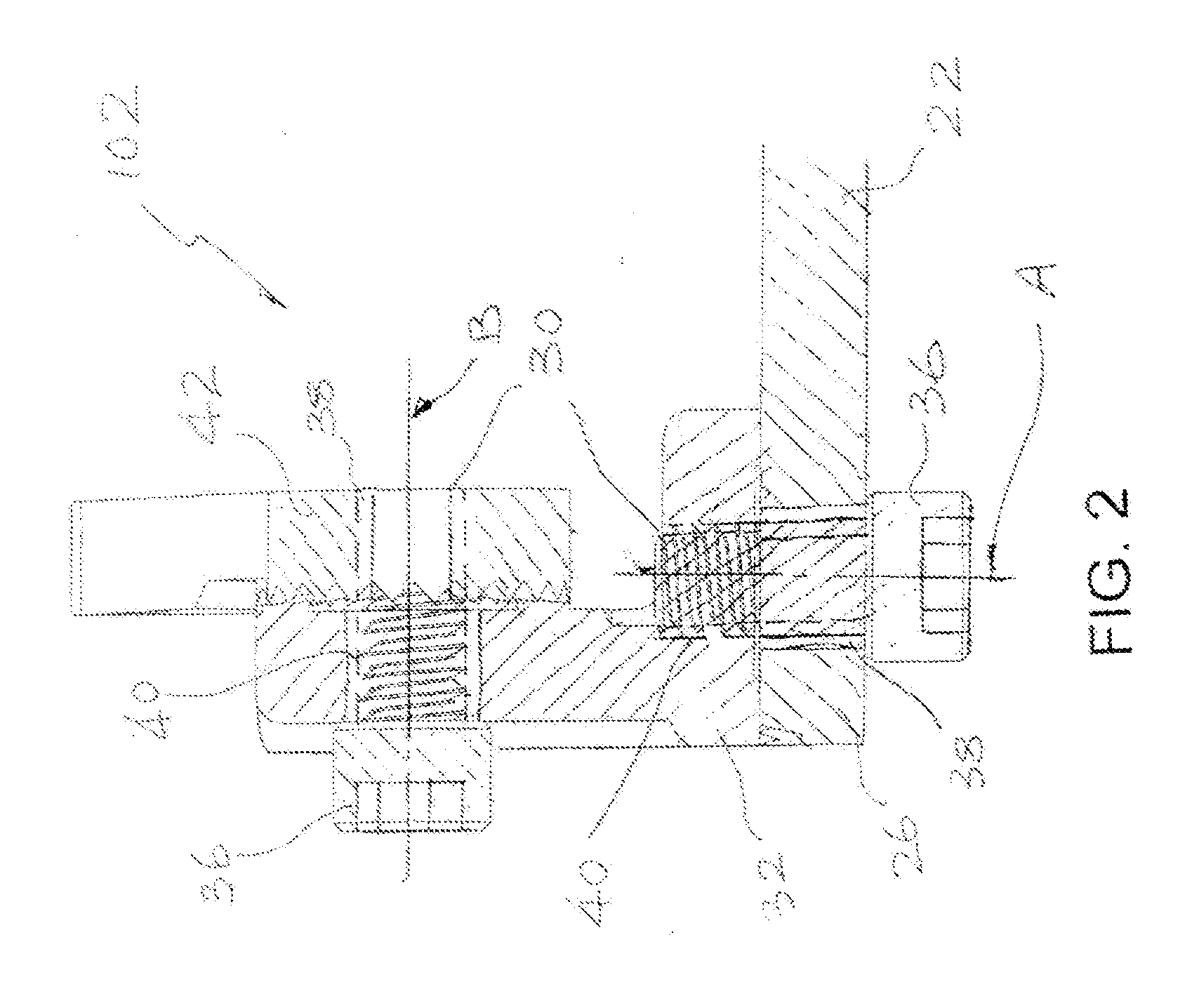

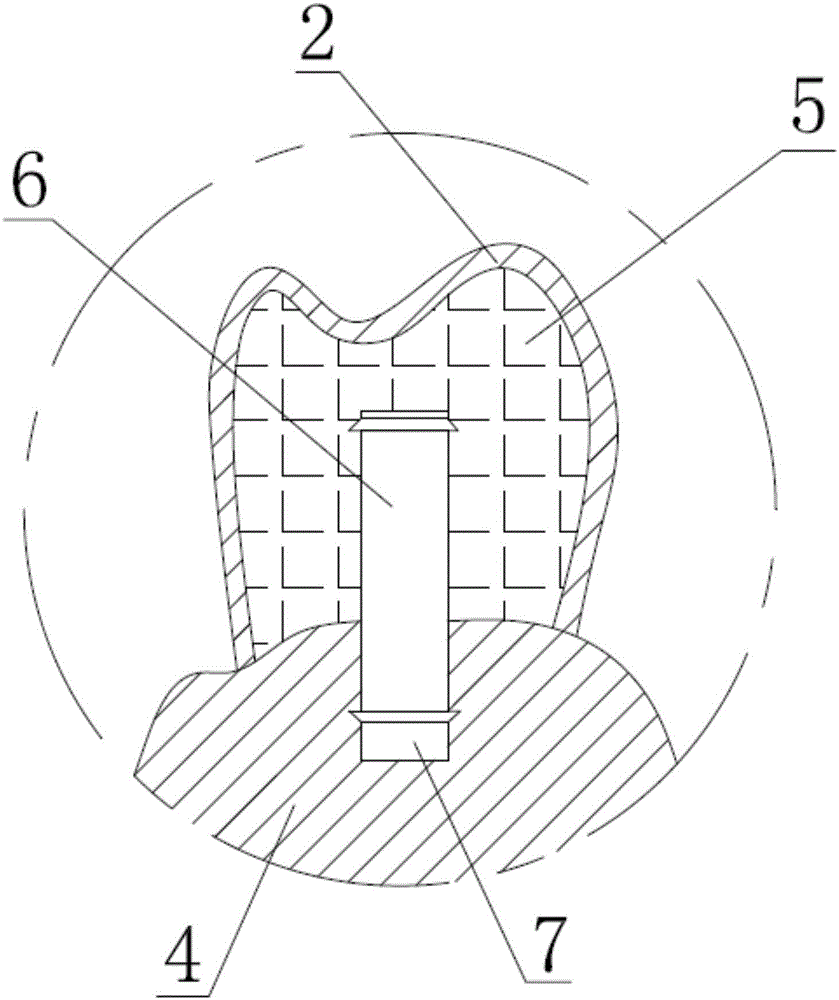

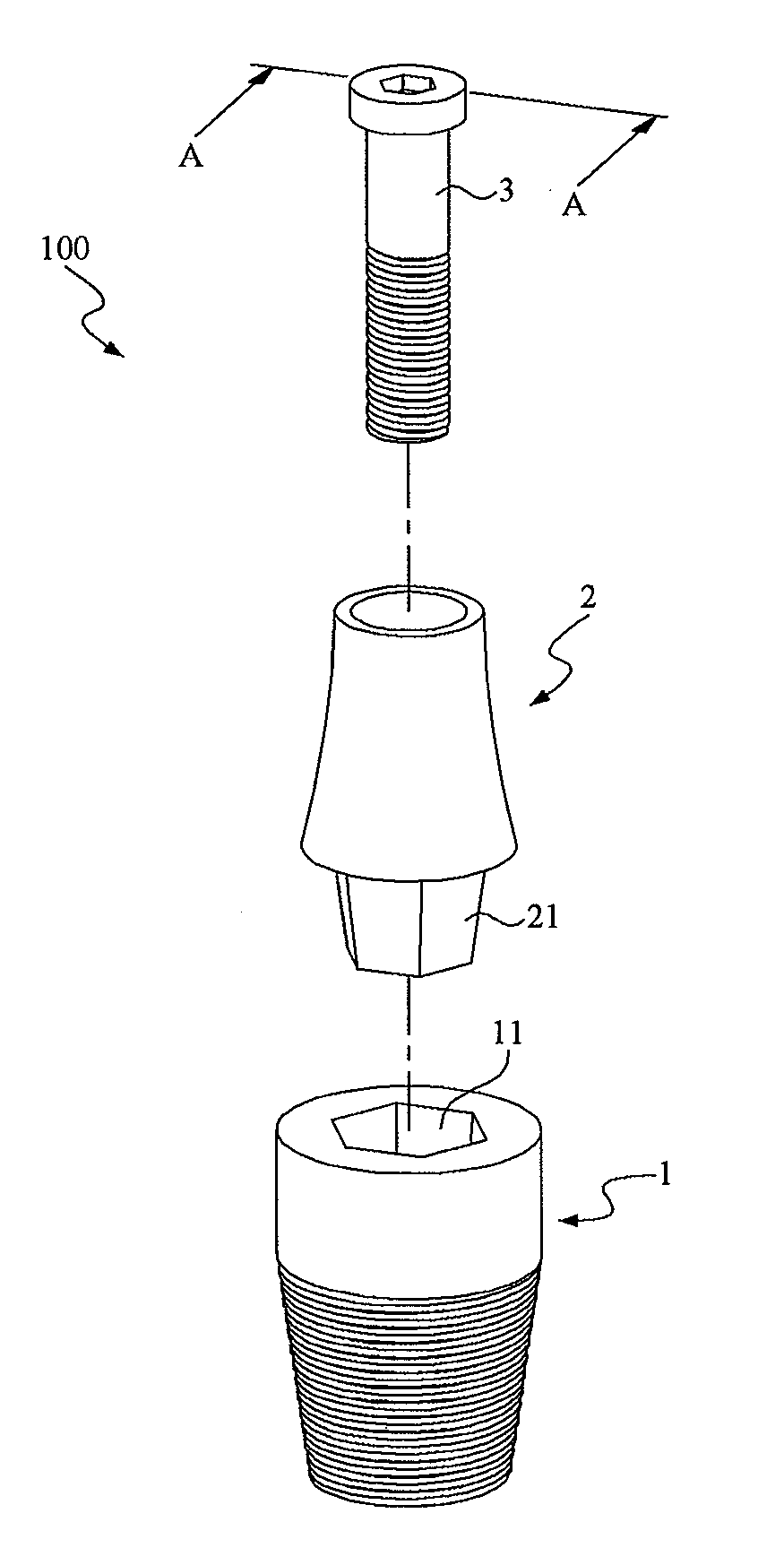

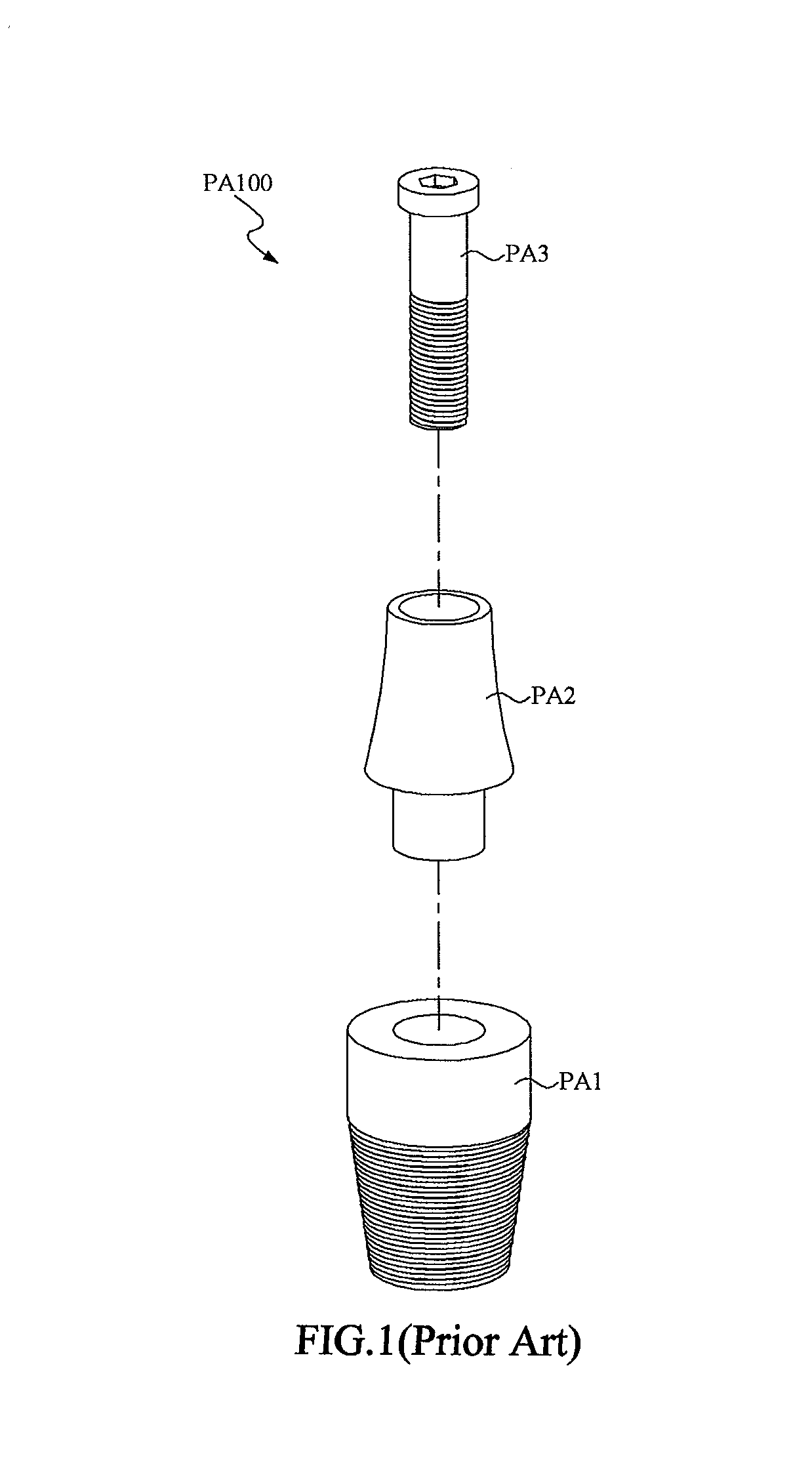

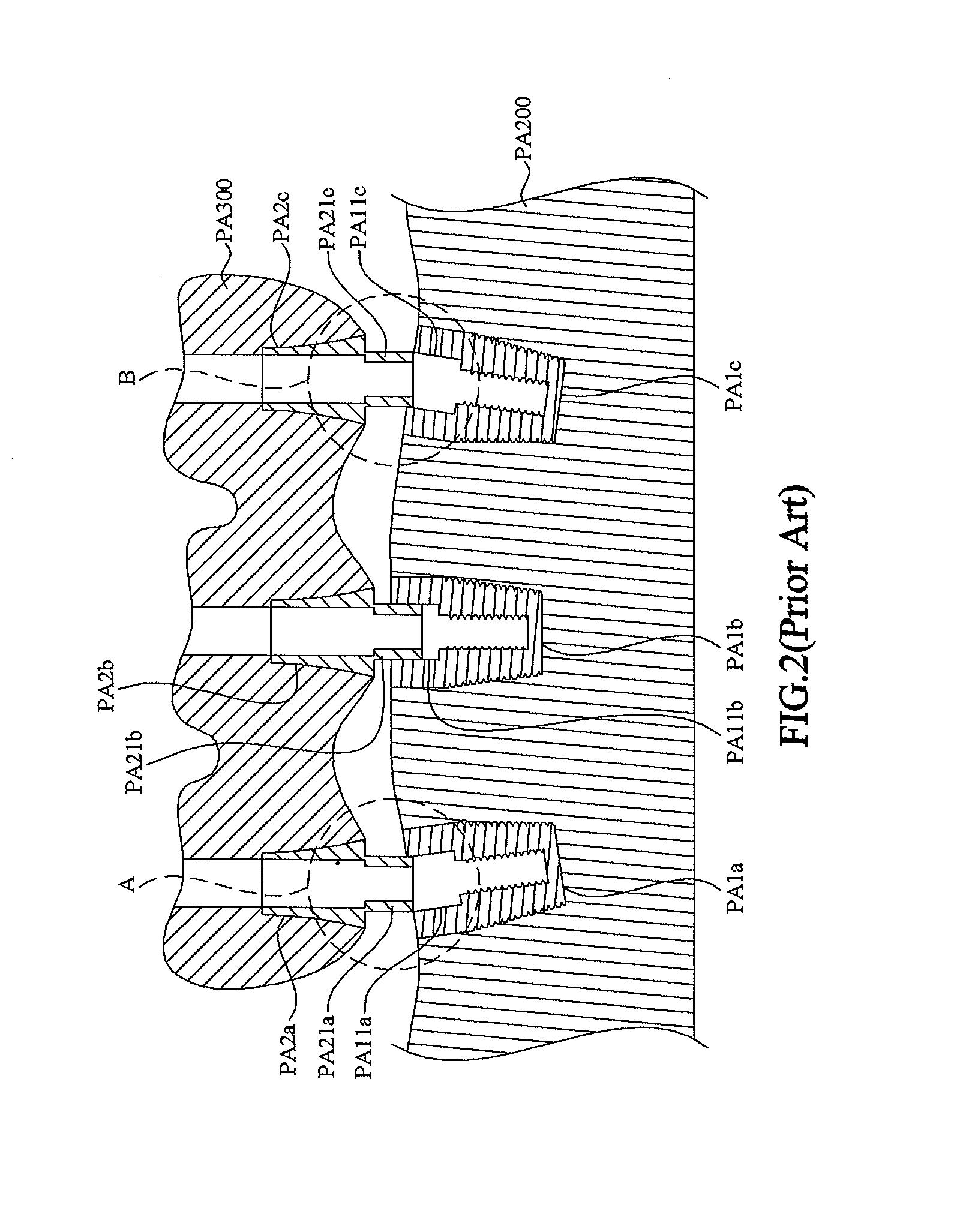

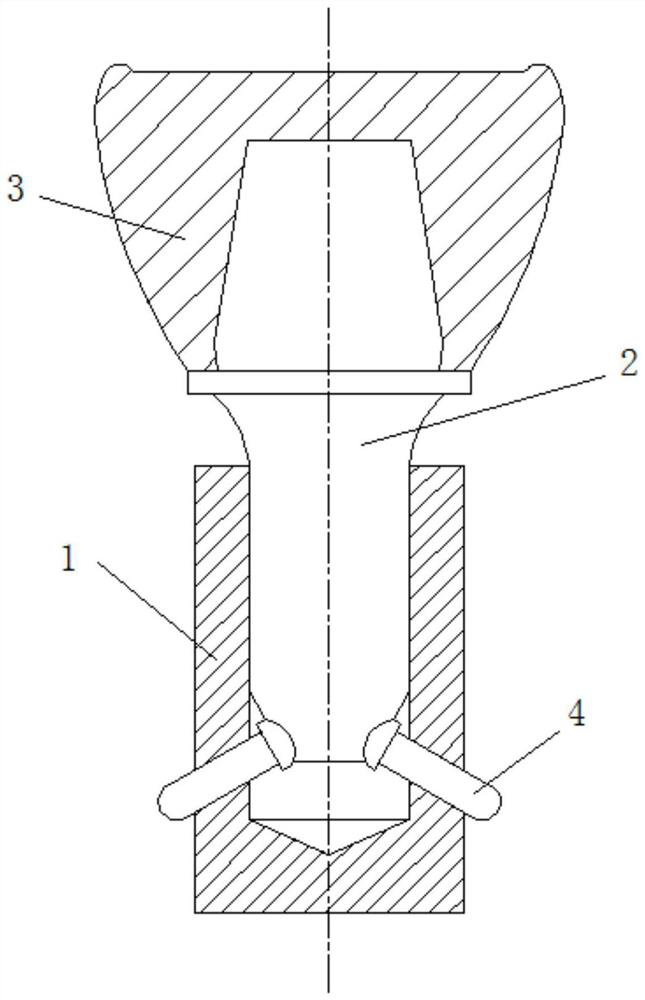

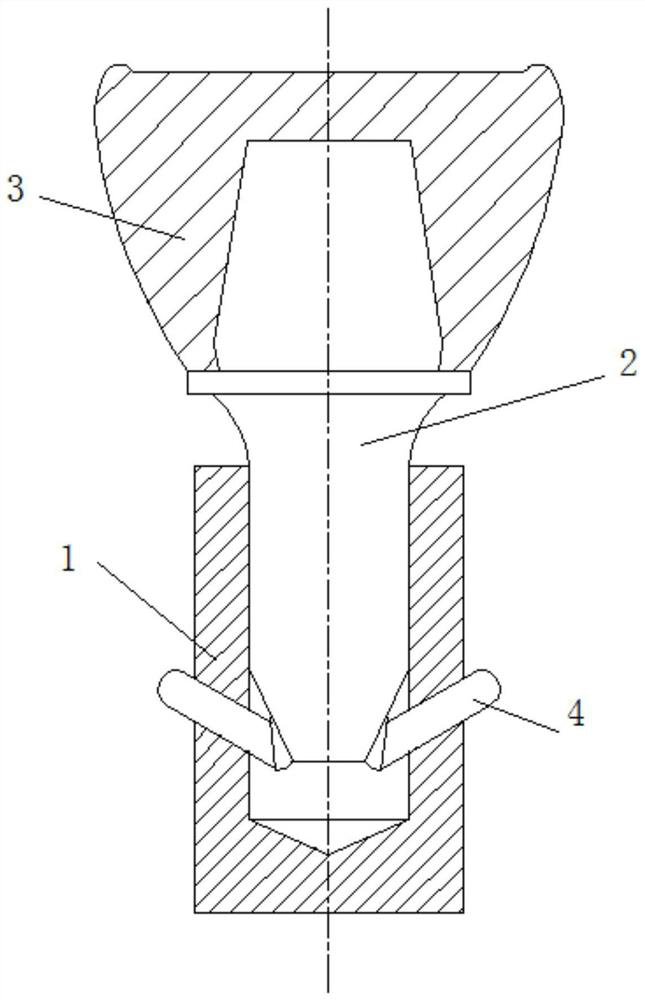

Dental implant member

A dental implant member includes an implant body for implanting into an alveolar bone, the implant body having an axial hole with a truncated cone-shaped section defined by a polygonal inner wall surface; a dental base including a low inset having a truncated cone-shaped section defined by a polygonal outer wall surface for inserting into the axial hole in such a manner that the polygonal inner and outer wall surfaces of the implant body and the dental base cooperatively define a fault-tolerance space therebetween; and a fastener unit for extending through the dental base so as to fasten the dental base securely on the implant body.

Owner:WEN SHIH CHENG

Method for measuring through hole rate of 3D printing titanium alloy bone trabecula structure oversleeve

ActiveCN110542632ASimple and effective method for detecting through-porosityGuaranteed reliabilityPermeability/surface area analysisBone TrabeculaeAcrylic resin

The invention provides a method for measuring the through hole rate of a 3D printing titanium alloy bone trabecula structure oversleeve. According to characteristics of the bone trabecula structure oversleeve, the bone trabecula structure oversleeve is divided into 12 areas; a bone trabecula structure oversleeve theoretical model formed by a crystal structure bone trabecula or a bone trabecula facilitating bone growth is created, and graphs of surface and internal bone trabecula structure forms of the bone trabecula structure oversleeve theoretical model are obtained; the dental base acrylic resin powder is poured into the 3D printing titanium alloy bone trabecula structure oversleeve to obtain morphological graphs of the 3D printing titanium alloy bone trabecula structure oversleeve on the surface and the internal bone trabecula structure; clear images of bone trabecula structure morphological graphs on the surface and inside the 3D printing titanium alloy bone trabecula structure oversleeve are collected by utilizing the digital correlation technology; the surface and internal through hole rate of the 3D printing titanium alloy bone trabecula structure oversleeve is determined byadopting the comparison method. The method is advantaged in that the purpose is to accurately detect the through hole rate of the titanium alloy bone trabecula structure oversleeve printed by a 3D printer.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

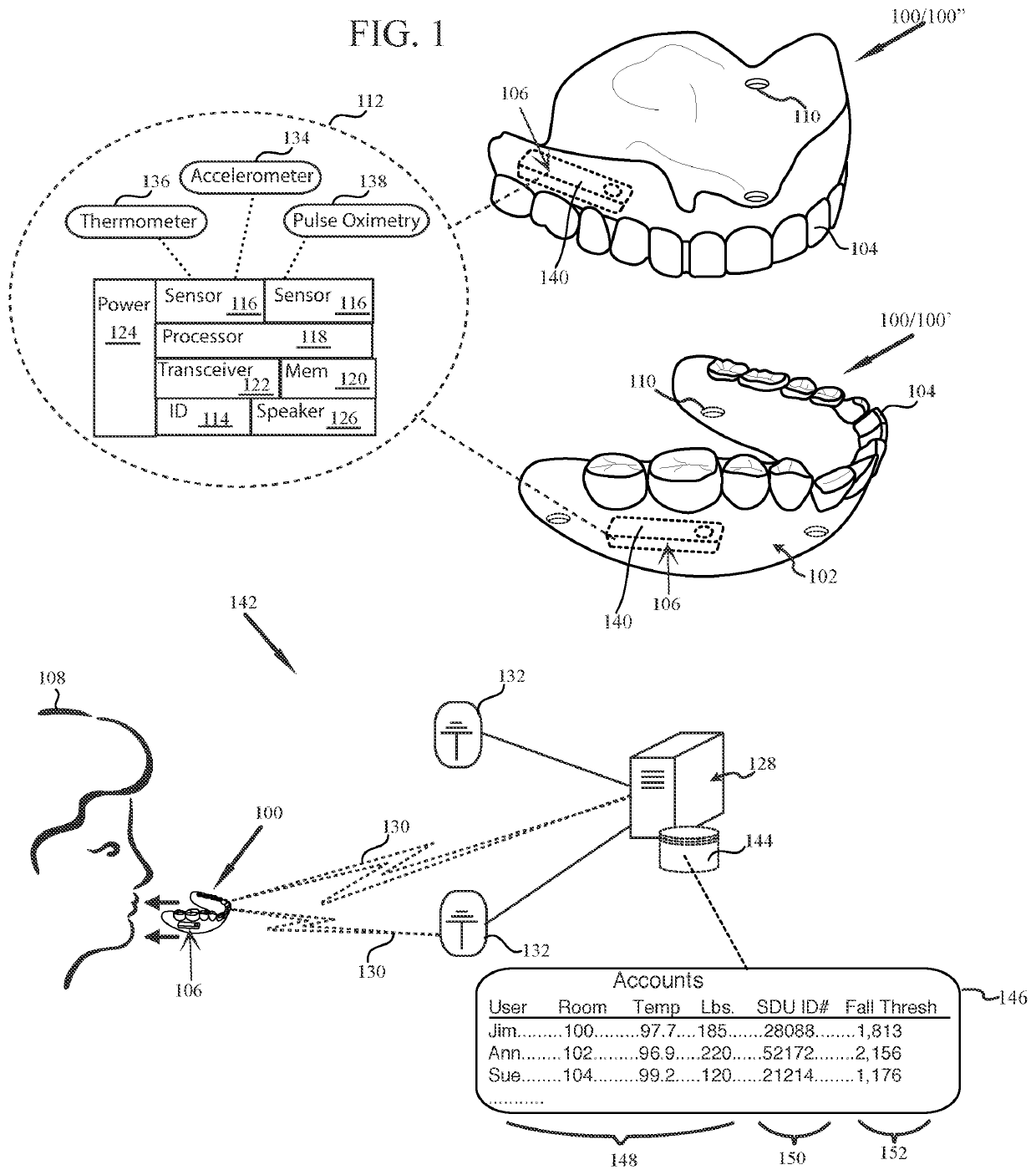

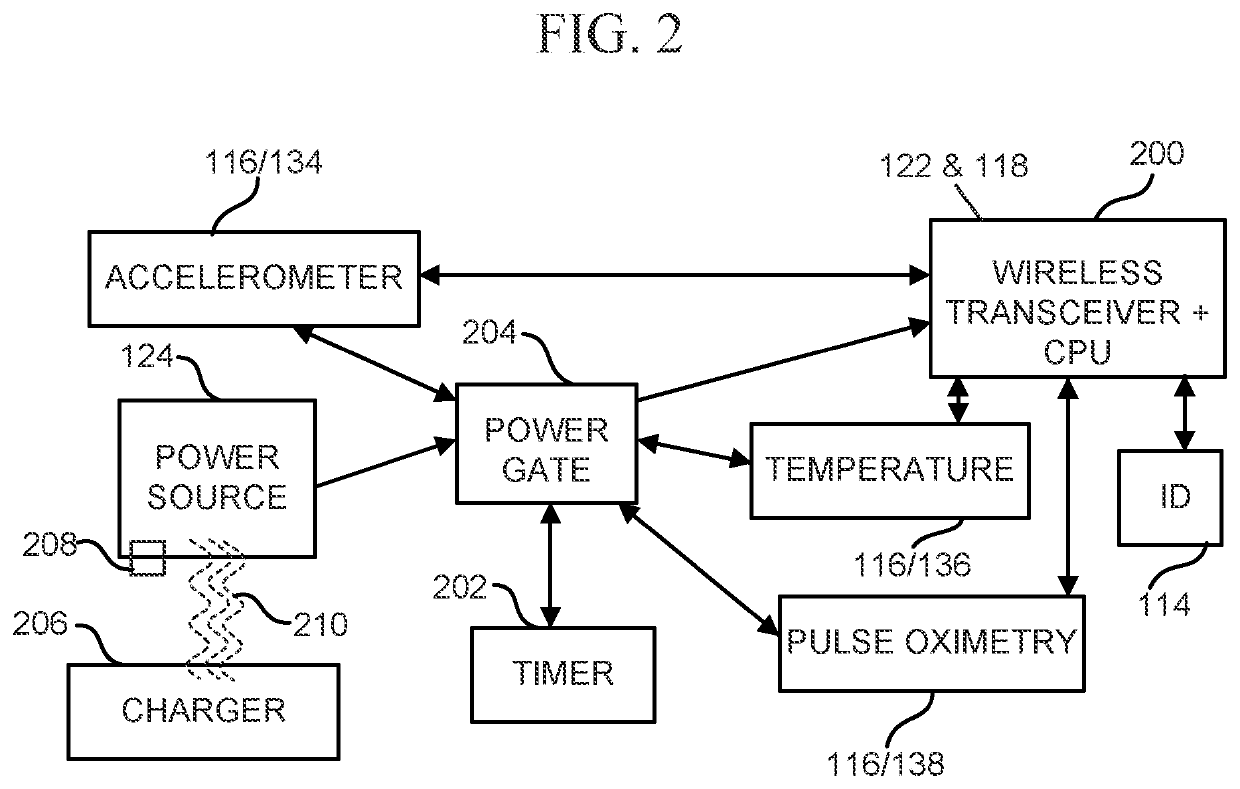

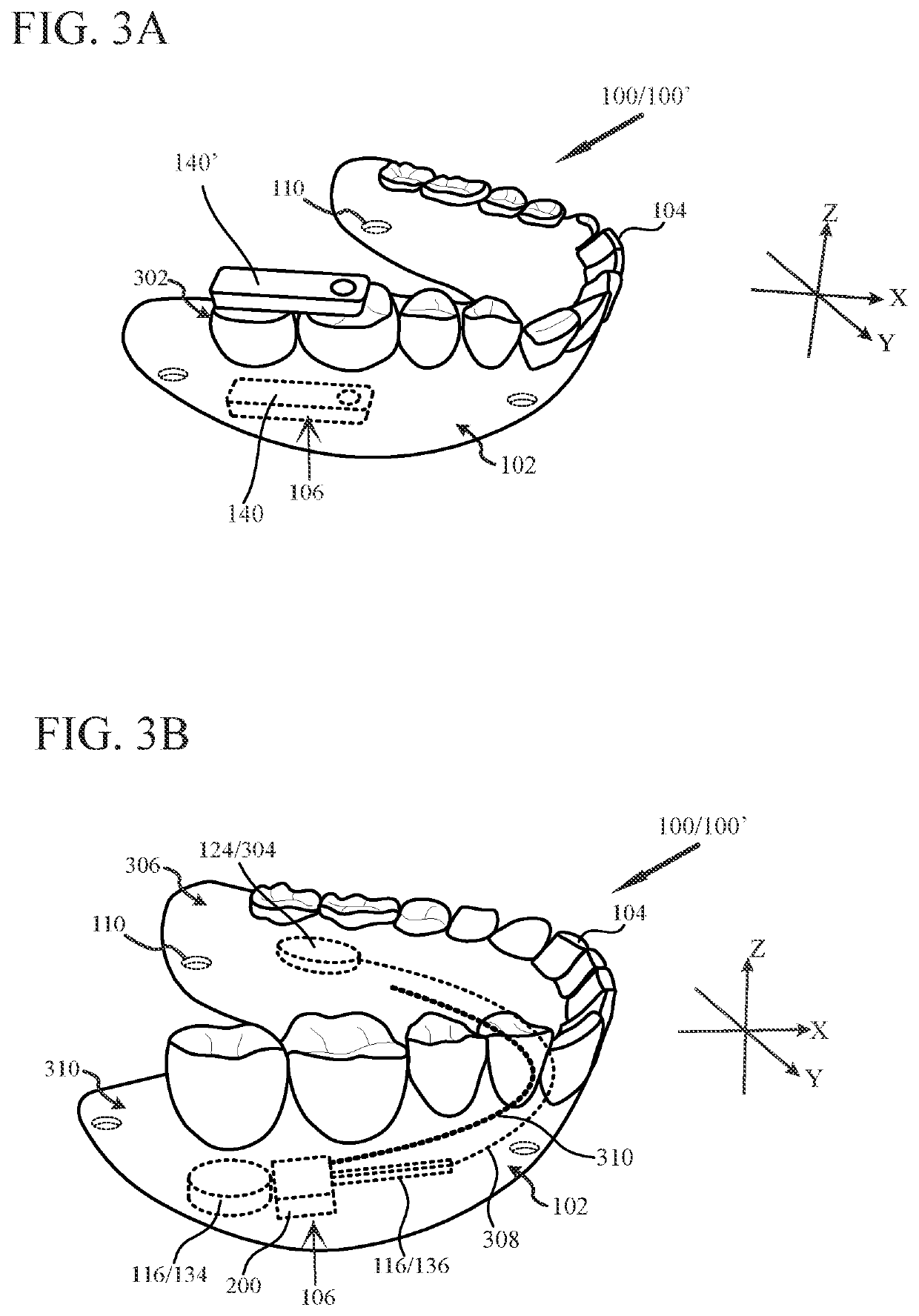

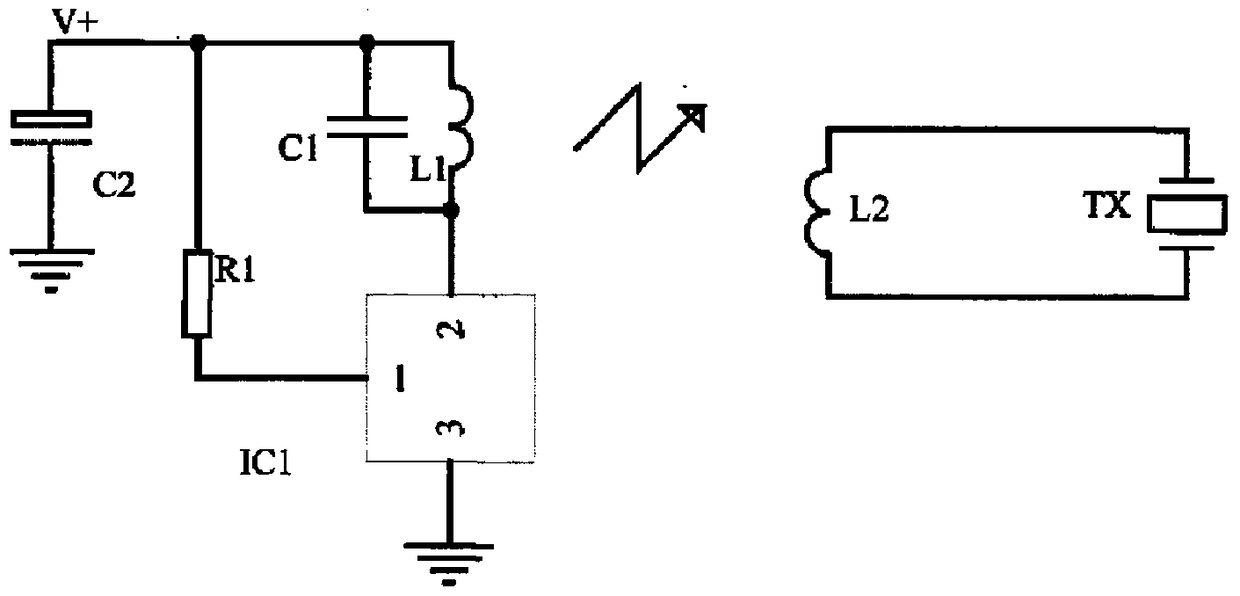

System and method for smart dental unit

Provided is a system and method for smart dental unit. The system provides smart dental unit restoring one or more teeth, including: a prosthetic base structured and arranged to engage with mouth tissue. The prosthetic base supports at least one tooth and at least one sensor system structured and arranged to detect at least one event. The sensor system further has a processor coupled to a wireless transceiver operable to communicate with at least one remote computing system. The smart dental unit also has a unique identifier. In response to a detected event the processor generates data communicated by the wireless transceiver to the remote computer. The unique identifier is also used by the remote computer to determine the location of the smart dental unit. An associated method for making a smart dental unit and a system for dental based patient care are also disclosed.

Owner:CYDENT LLC

Novel high-temperature-resistant cold mounting material

The invention relates to an ingredient designing and preparing method of a novel cold mounting material, in particular to a novel cold mounting material for metallographic specimen mounting. The coldmounting material is composed of, by mass, 5-8 parts of dental base acrylic resin liquid, 7-9 parts of dental base acrylic resin powder and 6-15 parts of aluminate cement. The preparation method includes: sufficiently mixing the dental base acrylic resin powder and the aluminate cement, and adding the dental base acrylic resin liquid. The cold mounting material prepared by the method is quick in curing, good in forming effect, high in hardness, wear resistance and deformation temperature and free of deformation after being formed below 200 DEG C.

Owner:HARBIN UNIV OF SCI & TECH

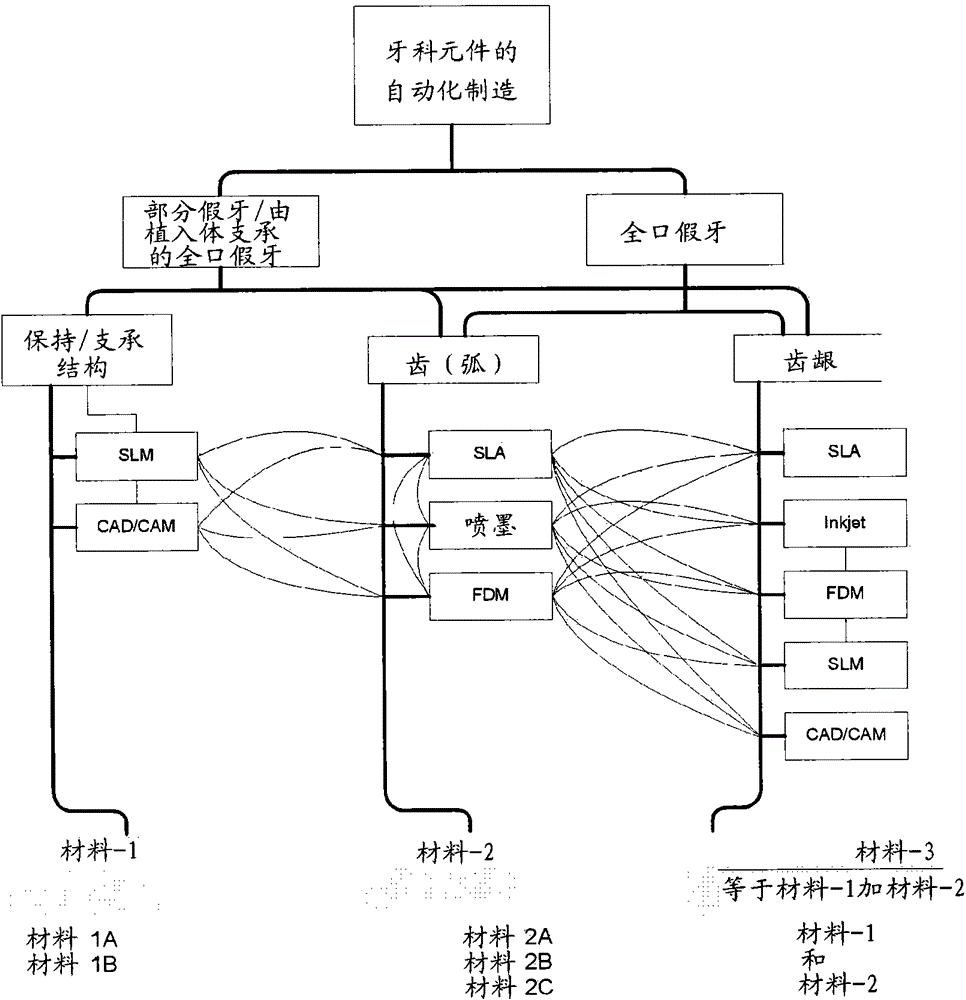

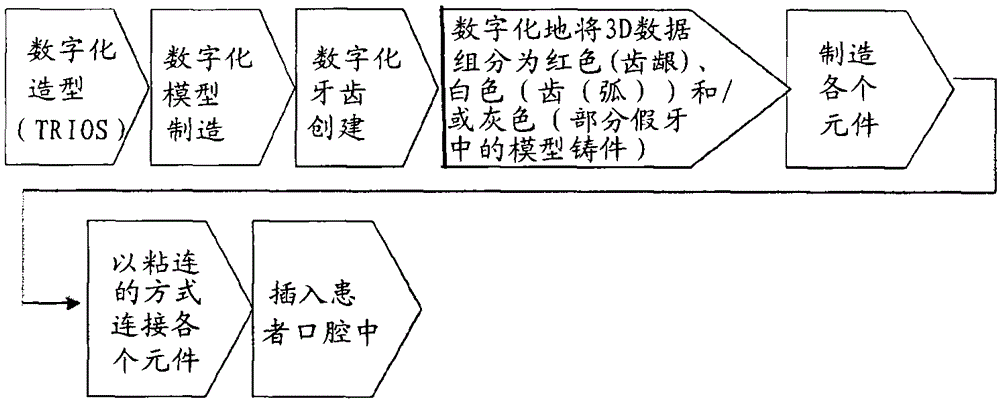

Manufacture of dentures from digital data of oral conditions via cad and rapid manufacturing

ActiveCN103637851BAdditive manufacturing apparatusMechanical/radiation/invasive therapiesDigital dataDentures

In the method for manufacturing full or partial dentures: A) providing 3D data of the oral cavity situation in the state without teeth or with partial teeth; B) digitally constructing the denture base for the lower and upper jaw respectively; C) digitizing accurately create virtual teeth with a matching occlusion and tooth shapes chosen according to esthetic criteria; in the case of complete dentures: D1) using an automated method from the group consisting of methods for building layers and methods for grinding materials and D2) using an automated method from the group consisting of a method of building layers and a method of grinding material to make a denture base; or in the case of a partial denture: D1) using a method consisting of a building layer and D2) using an automated method of the group consisting of a method of building layers and a method of grinding material to manufacture the support structural or fixed elements.

Owner:赫罗伊斯库尔泽有限公司

A uniform denture material and moldless manufacturing process

ActiveCN106074183BImprove mechanical propertiesImprove toughnessImpression capsDentistry preparationsPlaster CastsAcrylic resin

The invention belongs to the technical field of denture preparation and particularly relates to a homogeneous denture material and a patternless manufacturing process. The material is mainly prepared from the following components in parts by weight: 100 to 120 parts of special water for a dental department, 95 to 105 parts of dental base acrylic resin powder, 0.8 to 2 parts of binding agent and 0.5 to 0.8 part of plasticizer. The patternless manufacturing process of the homogeneous denture material comprises the following steps: firstly, weighing all the components according to the weight parts; secondly, uniformly mixing all the components, then filling an injection pipe with a mixture, injecting the mixture into a plaster model with a denture female die cavity at a certain pressure by using a special injection molding machine; performing heat treatment under the condition that the temperature is 90 to 150DEG C and the pressure is 1 to 20MPa, and cooling to obtain a finished product. The denture material provided by the invention has the properties of high toughness and mechanical strength, good bacteria resistance, and the like.

Owner:珠海新茂义齿科技有限公司

Butyl acrylate-methyl methacrylate copolymer based denture base material as well as preparation method and application thereof

InactiveCN102090983BApparent water absorption valueImprove thermal performanceImpression capsDentistry preparationsFlexural strengthPolymethyl methacrylate

The invention discloses a butyl acrylate-methyl methacrylate copolymer based denture base material as well as a preparation method and application thereof. Methyl methacrylate as a first monomer is toughened by using butyl acrylate as a second monomer, the two monomers are copolymerized by using a suspension polymerization manner, the two monomers of the butyl acrylate and the methyl methacrylateform an oil phase, the consumption of the butyl acrylate monomer accounts for 1-10 wt percent of the mass of the oil phase, the consumption of the methyl methacrylate monomer accounts for 90-99 wt percent of the mass of the oil phase, and a copolymerized product and thermally-coagulative dental base acrylic resin liquid are uniformly mixed and heated and cured. The P(MMA-co-BA) in the invention is applied to the field of denture base materials; compared with the pure PMMA (polymethyl methacrylate) material, the bending strength and the impact strength are greatly improved, and the tensile strength is slightly increased, and the problem of the PMMA denture base material in the aspect of the mechanical strength, especially impact strength, is successfully solved.

Owner:TIANJIN UNIV

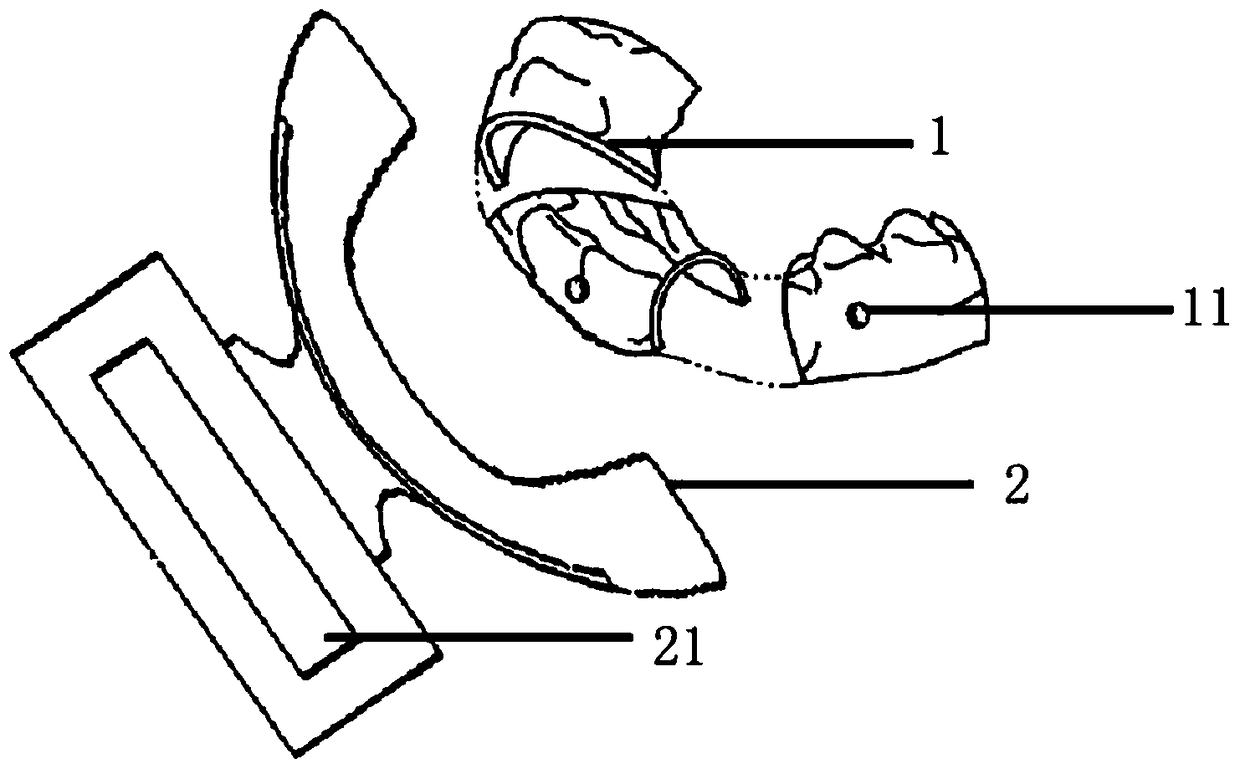

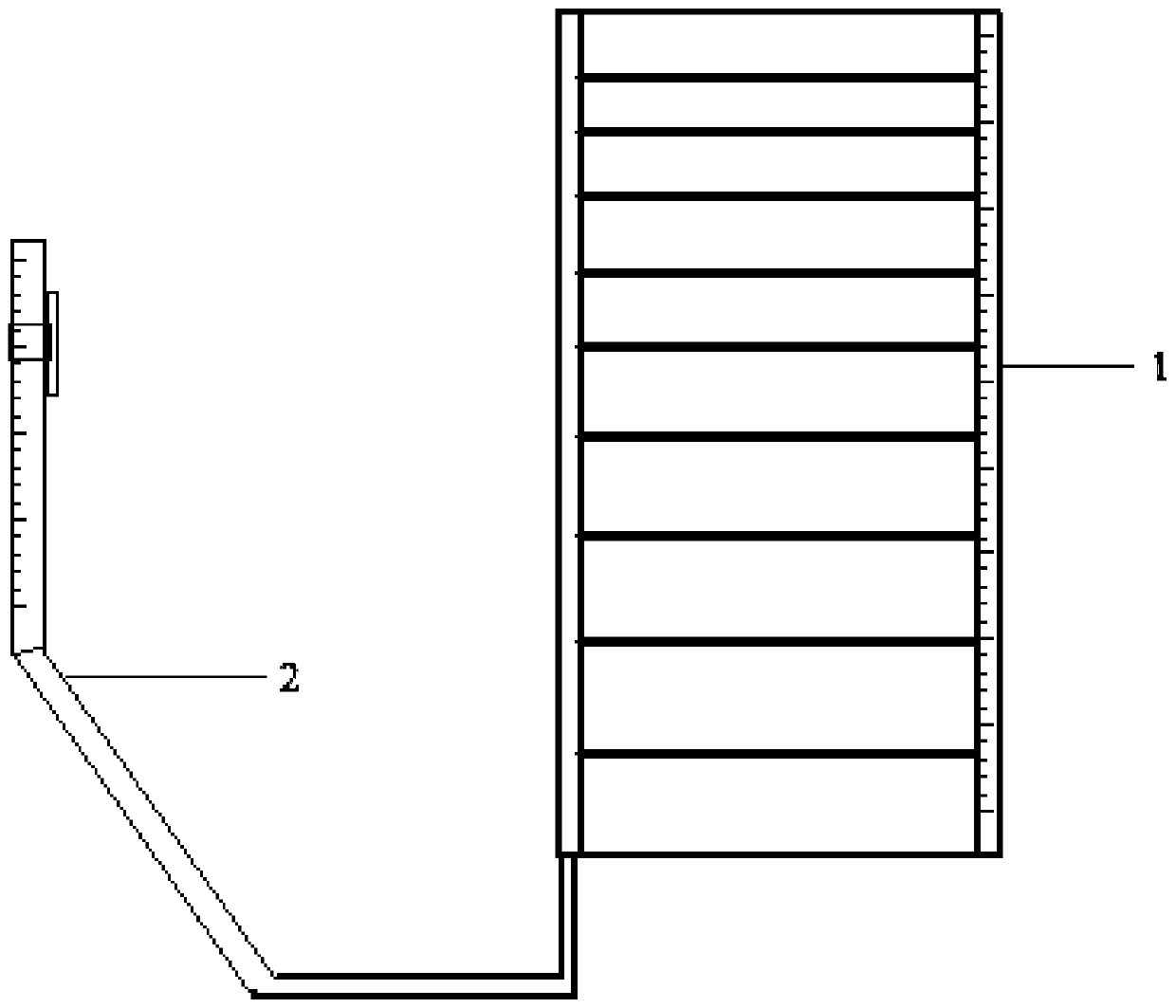

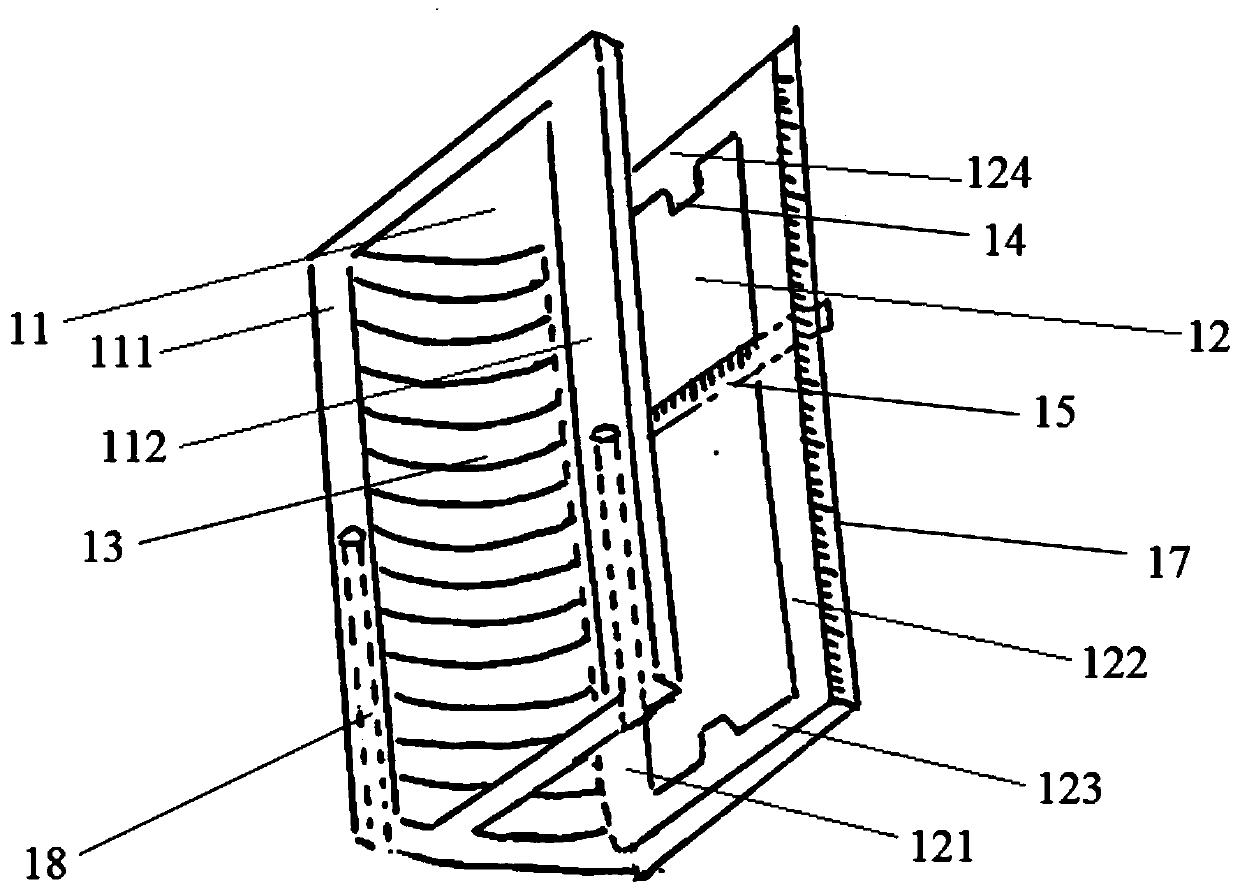

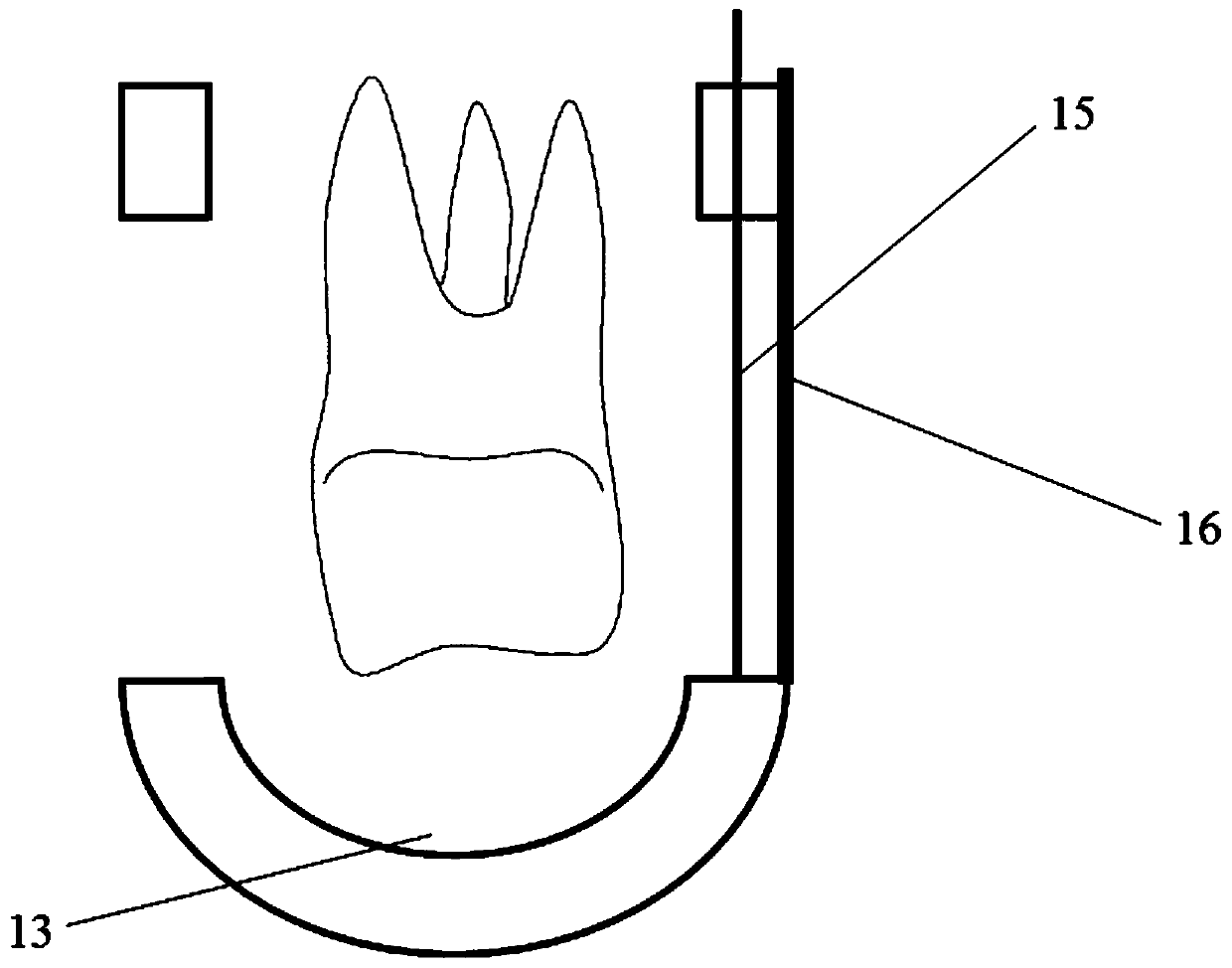

Partial tray combined dental film positioning and measuring device

ActiveCN108542418BReduce volumeSimple structureRadiation diagnostics for dentistryDental BaseBiomedical engineering

The invention discloses a device for taking dental pictures, positioning and measuring, wherein the device includes a dental tray assembly (1) and a ball tube positioning assembly (2). The dental tray assembly (1) is placed inside the oral cavity to fix the teeth. The position of the negative film (16); the tube positioning component (2) is placed outside the oral cavity to locate the photographing position. The dental film photographing positioning and measuring device of the present invention has a simple structure, is easy to operate, is low in cost, has strong versatility, and can accurately locate the photographing position and can be used with a scale to accurately measure.

Owner:GENERAL HOSPITAL OF PLA

Zirconia ceramic slurry for micro-flow extrusion molding and its preparation method and application

ActiveCN111018520BExtrude evenlyHigh strengthImpression capsAdditive manufacturing apparatusGlycerolDental Base

Owner:TIANJIN UNIV OF SCI & TECH

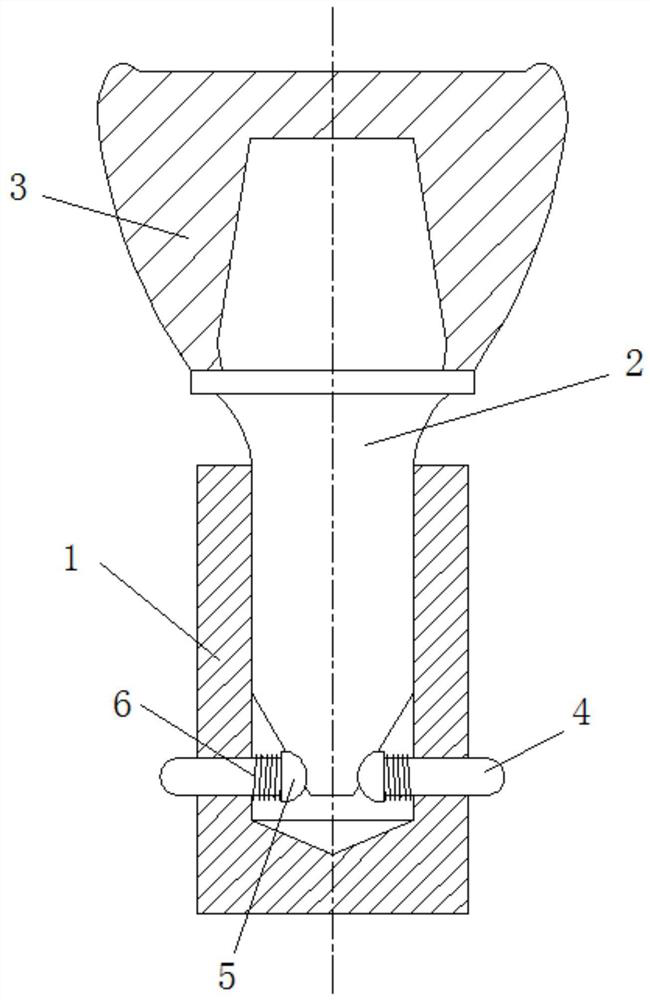

Dental implant system

The invention provides a dental implant system. The dental implant system comprises an implant, an abutment and a dental crown, wherein the implant is in a cylinder shape, the implant is provided witha longitudinal blind hole and a side through hole, the blind hole is provided with an internal thread, the side through hole is located at the lower half part of the blind hole, and a movable claw penetrates through the side through hole and can slide in the side through hole; and the abutment comprises an upper connecting part and a lower connecting part, the upper connecting part is inserted into the dental crown and fixedly connected with the dental crown, the lower connecting part is provided with an external thread matched with the internal thread of the blind hole, and the bottom of thelower connecting part abuts against the end, at the blind hole, of the movable claw, so that the other end of the movable claw protrudes out of the outer side face of the implant. According to the dental implant system, the side through hole is formed in the lower half part of the blind hole of the implant of the abutment, the movable claw is arranged in the side through hole, and the bottom endof the lower connecting part of the abutment abuts against one end of the movable claw, so that the other end of the movable claw protrudes out of the outer side surface of the implant to abut againstbone tissue of a dental base, the dental implant is combined with smooth tissue more firmly, and the service life is prolonged.

Owner:北京联袂义齿技术有限公司

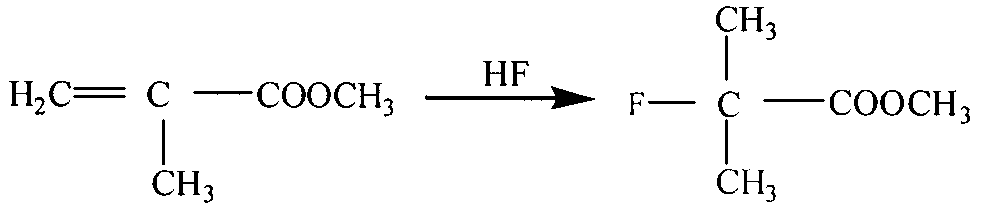

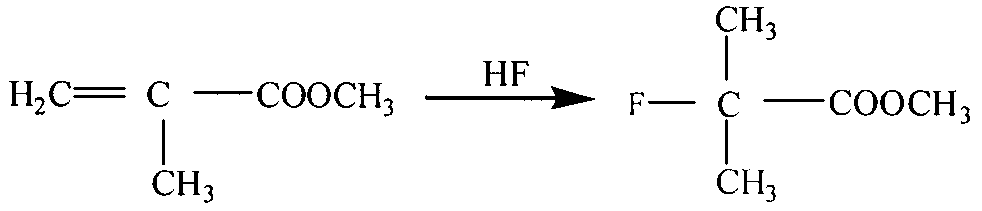

Technology for removing laser printed or copied writings on paper surface

ActiveCN104861764AEasy to purchaseEasy to removeChemical paints/ink removersHydrofluoric acidDistilled water

The invention discloses a technology for removing laser printed or copied writings on a paper surface, wherein the technology includes a removing solution and a removing method. The removing solution formula comprises hydrofluoric acid, a self-solidifying denture base polymer (also known as a dental base acrylic resin liquid) and water (tap water or distilled water) with the preparation ratio described in the description. The removing method comprises paper soaking. With utilization of the theory of 'similarity and intermiscibility', the laser printed or copied writings on the paper surface are dissolved by the prepared solution, so as to achieve the purpose of removal. Because the dissolution method almost has no damage to the paper, the paper having the writings removed can be recycled.

Owner:胡锴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com