Butyl acrylate-methyl methacrylate copolymer based denture base material as well as preparation method and application thereof

A technology of methyl methacrylate and butyl acrylate, applied in the field of prosthodontics, can solve problems such as unsatisfactory effect, and achieve the effect of improving residual monomer content, obvious effect and short operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

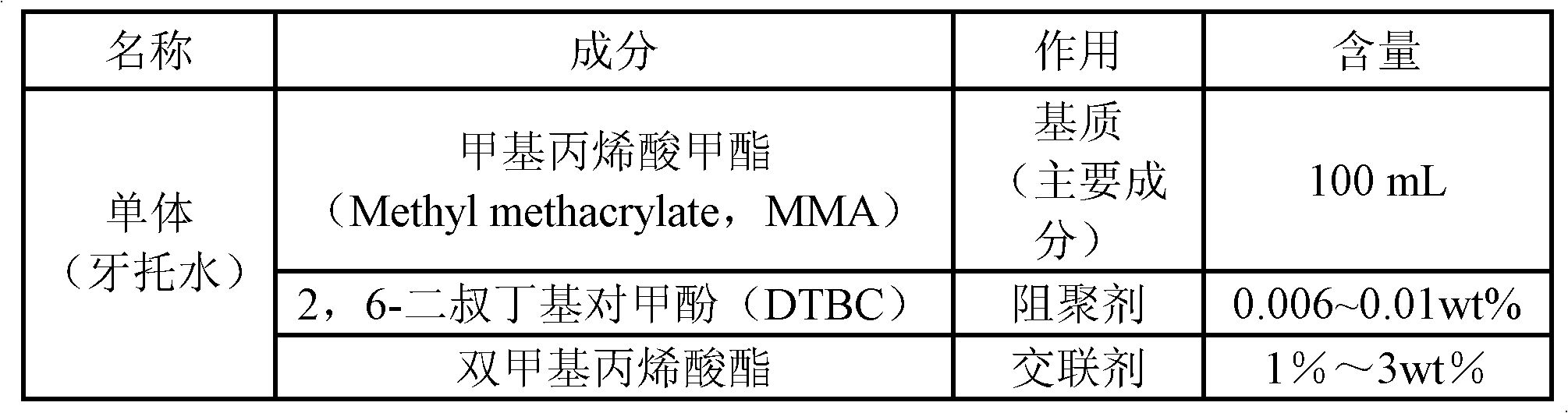

Method used

Image

Examples

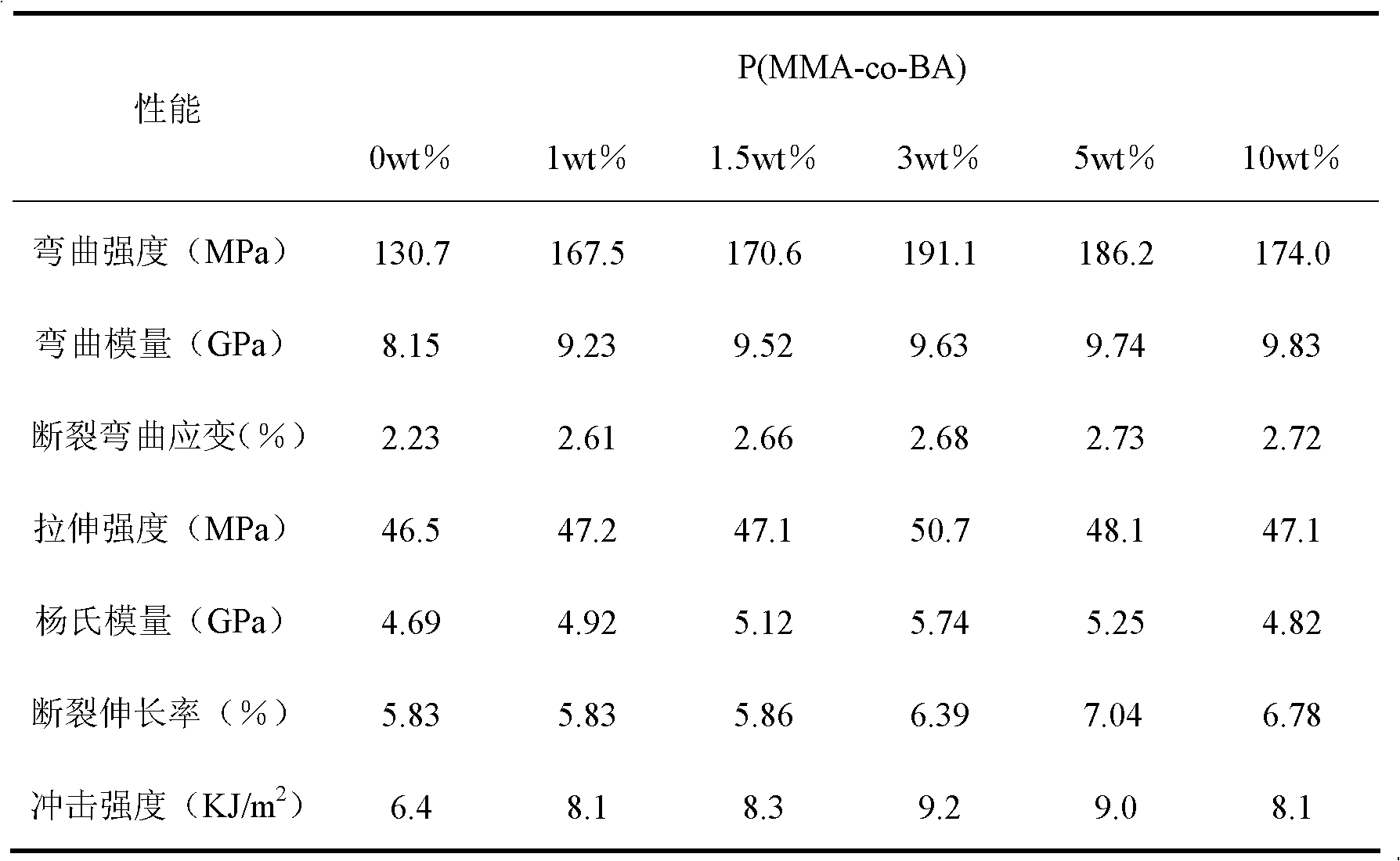

Embodiment 1

[0023] (1) After mixing 1wt% of BA and 99wt% of MMA monomer, add it to a three-necked flask (the total amount of monomer is 60mL), and add 1.8g hydroxyethyl cellulose (HEC) and 0.074g Sodium dodecylbenzenesulfonate (SDBS), pour it into a three-necked flask after preliminary stirring, and continue stirring at a low speed. Pass N 2 After 40 minutes of protection, the temperature was raised to 90° C., and the inert atmosphere was maintained continuously, and 0.4 g of initiator BPO was added to initiate polymerization. After reacting for 9 hours, the reaction system was cooled and filtered, and the filtered product was washed repeatedly. Vacuum drying to constant weight to obtain the corresponding copolymerized crude product, then dissolve the copolymerized crude product P(MMA-co-BA) in n-butanol at 50-80°C, cool to -20°C, and precipitate the PMMA homopolymer, Filter, wash, and add methanol dropwise to the filtrate under stirring until the methanol / total alcohol ratio is 0.5-2, ...

Embodiment 2

[0027] (1) Add 1.5wt% BA and 98.5wt% MMA monomer into the there-necked flask after mixing (monomer total amount is 50mL), add 1.8g hydroxyethyl cellulose (HEC) and 0.074g sodium dodecylbenzene sulfonate (SDBS), pour it into a three-necked flask after initial stirring, and continue stirring at a low speed. After argon protection for 40 minutes, the temperature was raised to 90° C., and the inert atmosphere was maintained continuously, and 0.4 g of initiator azobisisobutyronitrile was added to initiate polymerization. After reacting for 5 hours, the reaction system was cooled and filtered, and the filtered product was washed repeatedly. Vacuum drying to constant weight to obtain the corresponding copolymerized crude product, then dissolve the copolymerized crude product P(MMA-co-BA) in n-butanol at 50-80°C, cool to -20°C, and precipitate the PMMA homopolymer, Filter, wash, and add methanol dropwise to the filtrate under stirring until the methanol / total alcohol ratio is 0.5-2, ...

Embodiment 3

[0031] (1) After mixing 3wt% of BA and 97wt% of MMA monomer, add it to a three-necked flask (the total amount of monomer is 50mL), and add 1.8g of calcium hydroxyphosphate and 0.074g of dodecylsulfuric acid to 200ml of deionized water at the same time Sodium, pour it into the three-necked bottle after preliminary stirring, and continue stirring at a low speed. After protecting with helium for 40 minutes, the temperature was raised to 90° C., and the inert atmosphere was maintained continuously, and 0.4 g of initiator azobisisoheptanonitrile was added to initiate polymerization. After reacting for 3 hours, the reaction system was cooled and filtered, and the filtered product was washed repeatedly. Vacuum drying to constant weight to obtain the corresponding copolymerized crude product, then dissolve the copolymerized crude product P(MMA-co-BA) in n-butanol at 50-80°C, cool to -20°C, and precipitate the PMMA homopolymer, Filter, wash, and add methanol dropwise to the filtrate u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com