High fire retardation type polyurethane thermal-insulation plate and preparation method thereof

A high flame-retardant, polyurethane rigid foam technology, applied in the field of external wall insulation, can solve problems such as cracking of the decorative layer, high energy consumption, and human hazards, and achieve the effects of enhanced mechanical properties, more procurement channels, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

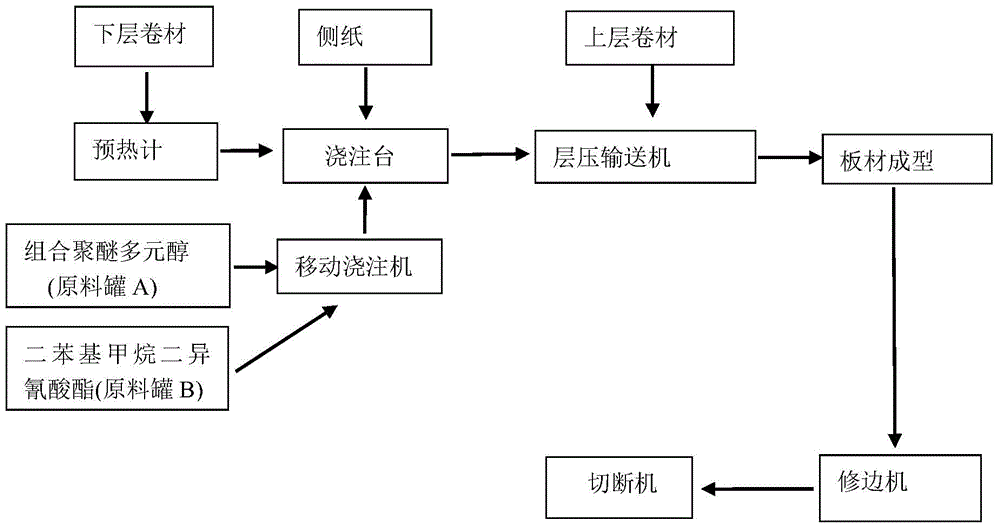

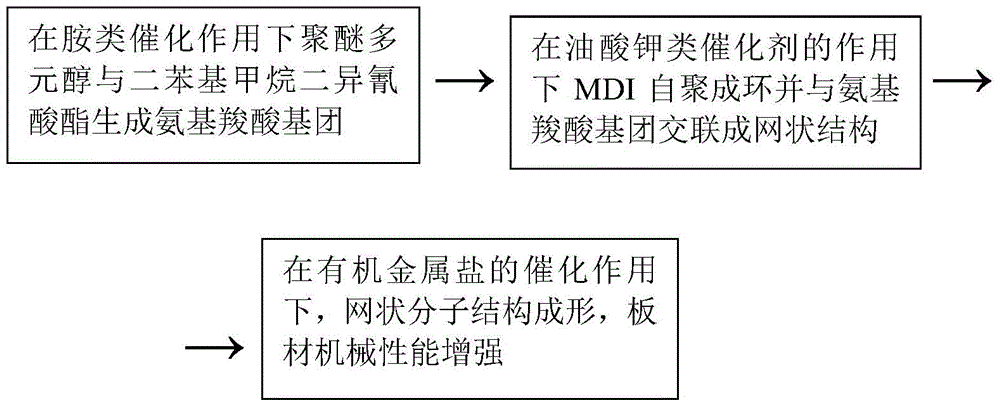

Method used

Image

Examples

Embodiment 1

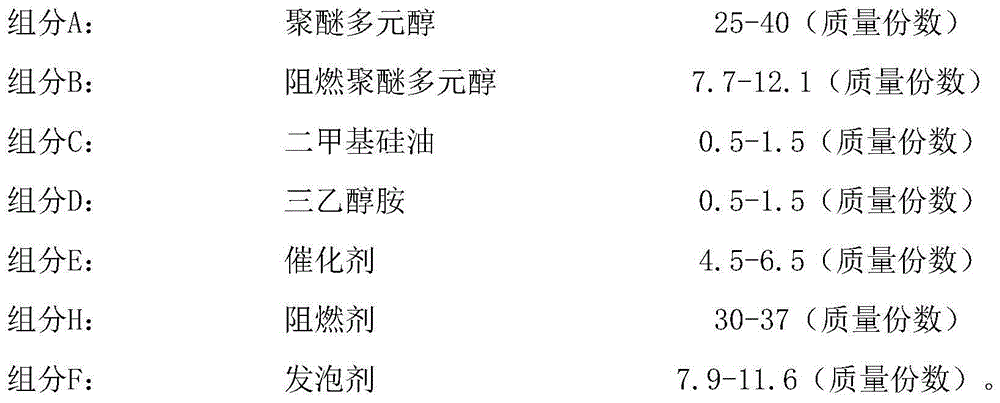

[0063] A high flame-retardant polyurethane rigid foam insulation material, the raw material formula of the polyurethane rigid foam insulation material is:

[0064] 1), diphenylmethane diisocyanate 1920kg;

[0065] 2), combination polyether polyol, the raw material formula of this combination polyether polyol is:

[0066] name

Feeding amount / kg

Polyether 4110

320

Flame Retardant Polyether Polyol

121

9

8.8

A33

6

PC-41

20

20

Blowing agent HFC141b

110

DMMP

350

[0067] Put the raw materials in the table into the reaction kettle one by one, stir at a constant temperature of 30°C for two hours, and then stand in the dark for 8 hours to obtain the combined polyether polyol.

[0068] A method for preparing a highly flame-retardant polyurethane thermal insulation board comprises the following steps: mixing and reacting...

Embodiment 2

[0077] A high flame-retardant polyurethane rigid foam insulation material, the raw material formula of the polyurethane rigid foam insulation material is:

[0078] 1), diphenylmethane diisocyanate 1920kg;

[0079] 2), combination polyether polyol, the raw material formula of this combination polyether polyol is:

[0080] name

Feeding amount / kg

Polyether 4110

320

Flame Retardant Polyether Polyol

121

9

8.8

A33

8

Potassium oleate

24

24

Blowing agent HFC141b

115

DMMP

300

TCPP

100

[0081] Put the raw materials in the table into the reaction kettle one by one, stir at a constant temperature of 30 degrees Celsius for two hours, and then stand in the dark for 8 hours to obtain the combined polyether polyol.

[0082] The preparation method of the high flame-retardant polyurethane insulation board is the sam...

Embodiment 3

[0084] A high flame-retardant polyurethane rigid foam insulation material, the raw material formula of the polyurethane rigid foam insulation material is:

[0085] 1), diphenylmethane diisocyanate 1920kg;

[0086] 2), combination polyether polyol, the raw material formula of this combination polyether polyol is:

[0087] name

Feeding amount / kg

Polyether 4110

320

Flame Retardant Polyether Polyol

121

9

8.8

A33

9

[0088] Potassium oleate

37.5

7.5

Blowing agent HFC245fa

115

DMMP

300

FR707

100

[0089] Put the raw materials in the table into the reaction kettle one by one, stir at a constant temperature of 30 degrees Celsius for two hours, and then stand in the dark for 8 hours to obtain the polyether polyol.

[0090] The preparation method of the high flame-retardant polyurethane insulation board...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com